Page 1

LOV

FRYER Generation II

TECHNICAL REFERENCE MANUAL

Introducing the LOV™ Fryer 1

FRYER Generation II

™

LOV

FEB 2010

Edition

The LOV

M3000 12

RTI-equipped Systems 31

Board Replacement 38

Wiring Diagrams 41

Pin Positions 44

Frymaster and Dean Technical Service

TECHNICAL REFERENCE MANUAL

8700 Line Ave, Shreveport, LA 71106

Service Hotline: 800-551-8633

Website: www.frymaster.com

™

Systems 2

*8196506*

Page 2

LOV™ Generation II Technical Reference

M3000 Computer

Replace JIB Light

Diagnostic

LED Screen

Filter Light

JIB

(behind right door)

The LOV™ fryer.

Introducing the Low Oil Volume Fryer

The Low Oil Volume (LOV™) fryer is a McDonald’s-only, feature-laden version of the electric RE

™

fryer or gas H55 fryer. The enhancements found on the LOV

• Low volume frypot — 30 pounds (15 liters) rather than 50 pounds (25 liters) of oil.

• Automatic top-off — the fryer automatically maintains an optimal oil level with a reservoir in the cabinet.

• M3000 computer — a sophisticated controller with multiple levels of programming.

• Automatic fi ltration — the fryer performs hands-free fi ltering at prescribed cook cycle counts or at

prescribed times.

fryer include:

• Oil savings — The combination of a low-volume fry vat and oil automatically kept at a optimal level,

reducing oil usage.

1

Page 3

LOV™ Generation II Technical Reference

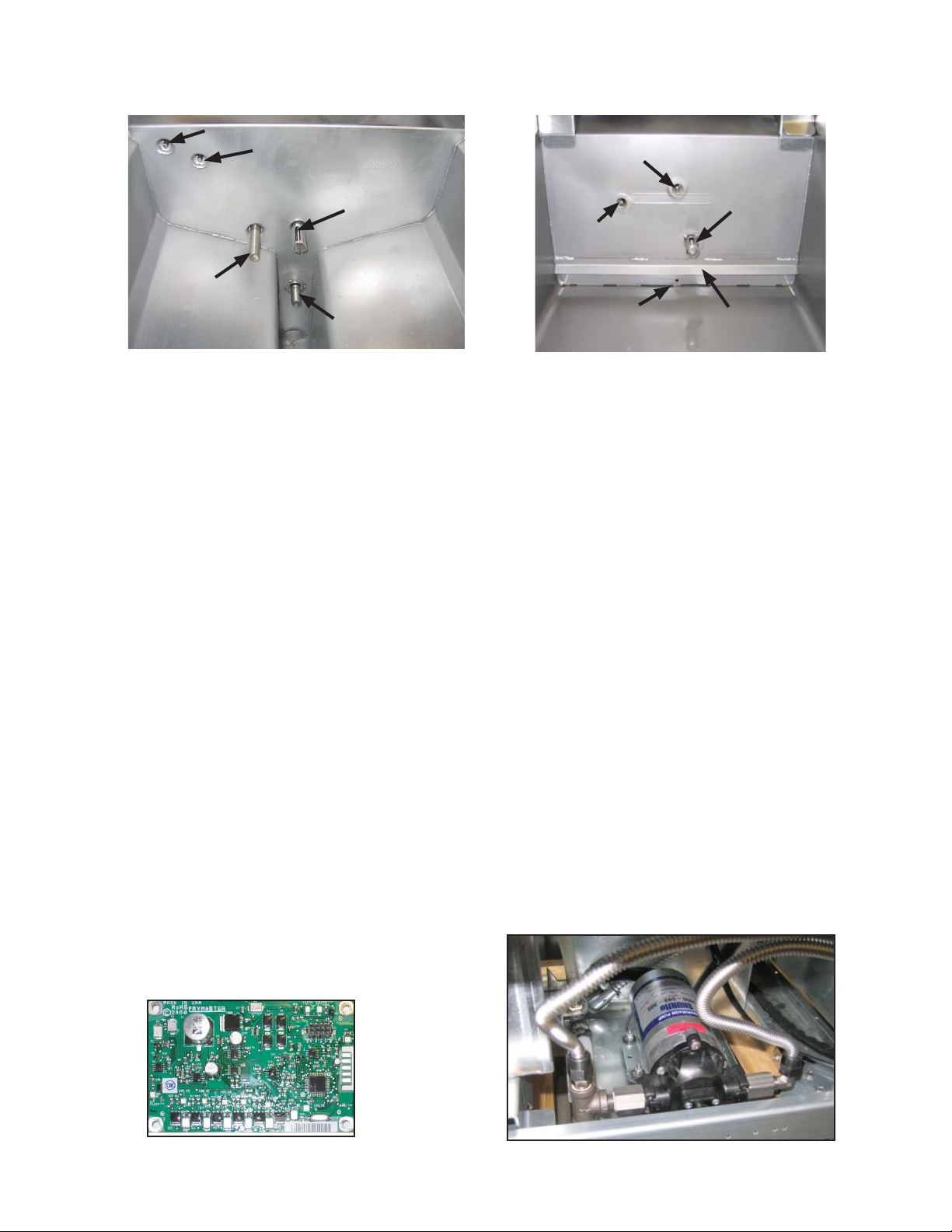

ATO Sensor

AIF Sensor

Temperature

RTD

Oil Return

Sensor

Ports and sensors inside a gas frypot. Oil return/

top off is at bottom rear of cool zone.

High limit

The LOV™ Systems

Auto Top Off

The core of the system is the automatic top-off

board, which senses when the oil level is low and

fi lls the pot to the top line.

The oil level is monitored by an R TD (Resistance

Temperature Detector) sensor in the frypot at the

upper oil level. The oil is moved to the pot from a

reservoir, called a JIB (Jug In Box), to the frypot

with a pump.

A circuit board, the AT O (Automatic Top Off), is

located inside a box behind the JIB. It monitors the

oil-level R TD and activates the pump when it senses

an oil temperature drop of 60°F (33°C) below setpoint, indicating the oil has moved away from the

sensor. The AT O sends a signal to the MIB (Manual

Interface Board), which then sends a signal to the

AIF to open the actuator on the return valve of the

frypot to be topped off.

Once the actuator has opened the return valve, oil is

pumped into the vat for a specifi ed amount of time

(approximately 60 seconds). When the ATO RTD

detects a temperature within 55°F (30°C) of setpoint, it is satisfi ed and the actuator closes the valve.

ATO Sensor

High limit

AIF Sensor

Oil Return/Top

Off Slots

Ports and sensors inside an electric frypot.

T op of f will continue on the next vat if needed.

The system is not suited to fi lling the frypot when it

is empty and there are safeguards to prevent it from

activating when the fryer is cold and the oil is resting at the lower position.

The system is not active until the oil in the frypot

reaches setpoint. That temperature is monitored by

the temperature probe. The activation of the system

is handled by the fryer’s computer , the M3000. The

automatic top off system is also inactive during

fi lter dispose cycles.

The system works the same in McDonald’s gas and

electric LOV

The level of the reservoir, or JIB, is monitored by

the ATO and the M3000 computer. If a low oil

condition is not rectifi ed with two top off attempts

or within 6 minutes, the low JIB light is illuminated

on the front of the fryer. It will stay illuminated until

the JIB is replaced and the orange button has been

pressed and held to reset the light (see page 34).

™

systems.

Oil Defl ector

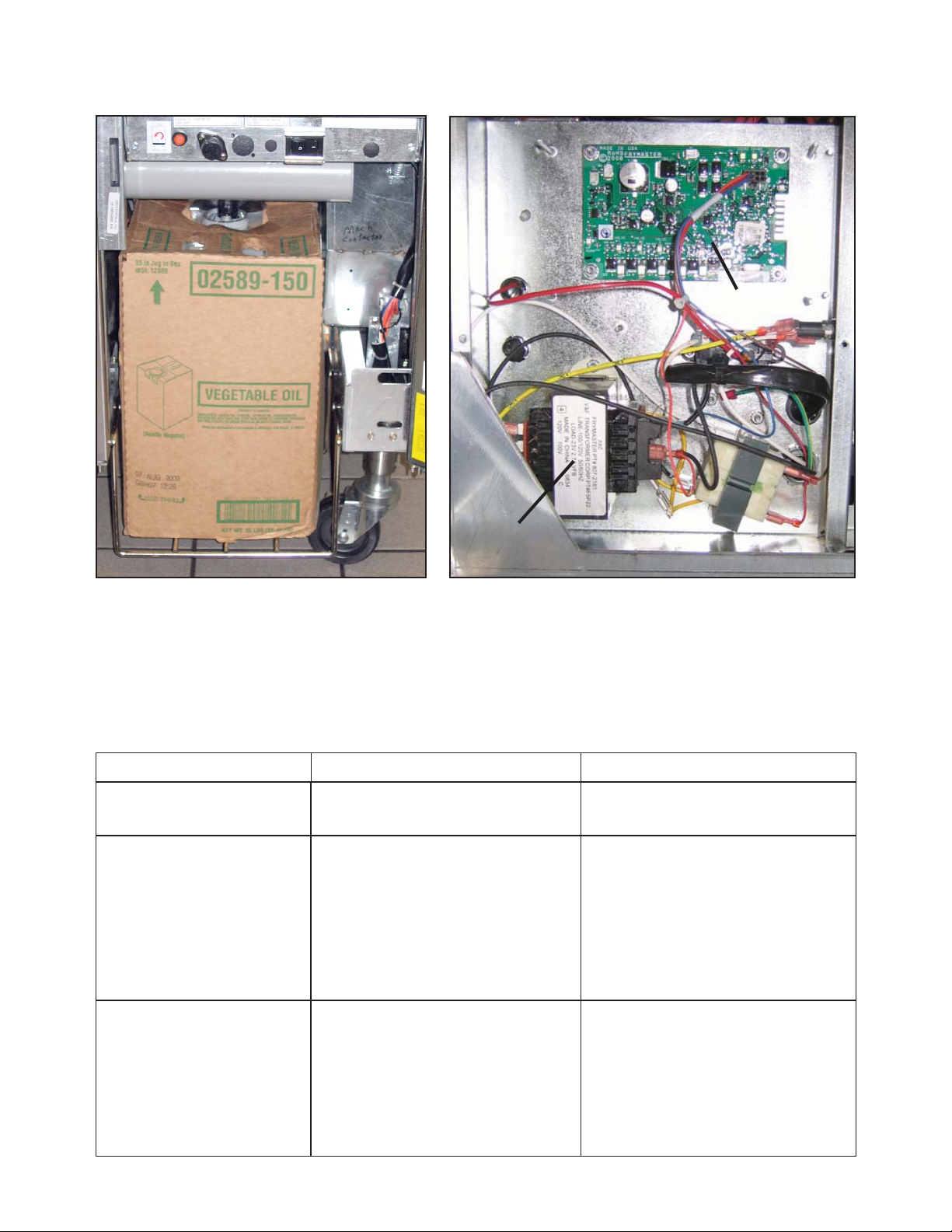

The ATO board positioned underneath the LON

gateway controls the top off of the fry pots.

The pump that moves oil from the reservoir to the frypots is visible above.

2

Page 4

LOV™ Generation II Technical Reference

ATO Board

The reservoir, or JIB, rests behind the right

door of the fryer. A light on the front of the fryer

illuminates when the jug is empty.

The ATO board is positioned under the LON gateway in a

box with a transformer that provides power to the board.

The LON gateway must be removed to access the ATO

board.

Troubleshooting the Top Off System

Problem Probable Causes Corrective Action

Frypot tops off cold. Incorrect setpoint. Ensure setpoint is correct.

A. J5 connection unplugged.

No power to ATO board.

B. Fuse blown.

C. Transformer malfunction.

Transformer

A. Check to ensure J5 on front of

ATO board is fully locked into

connector.

B. Ensure fuse below right control

box is not blown.

C. Check that proper voltage is

present at transformer. See

charts on pages 43-47.

The yellow JIB low light

won’t illuminate.

A. Loose wire connection.

B. Power in the component box is not

present.

C. Failed transformer.

3

A. Ensure the yellow LED is

securely attached to plug J6 on

the ATO board.

B. Ensure power is present in the

component box.

C. If power is present in component

box, check the transformer for

correct voltage.

Page 5

LOV™ Generation II Technical Reference

change filter pad YES/

NO

Problem Probable Causes Corrective Action

A. Check to see that fryer is heating.

Fryer temperature must be at

setpoint. Check ATO probe

resistance. If probe is bad, replace

the probe.

B. Ensure that the oil in the JIB is

above 70°F (21°C).

C. With the computer OFF, press

TEMP button and ensure the

ATO version appears. If not,

the connection between the AIF

and the ATO board may be bad.

Ensure the 6-pin CAN connectors

are tight between AIF (J4 and J5)

and ATO (J10) boards.

D. Power to the ATO board has been

cut off. Restore power to the board

and clear any service required

errors.

E. Ensure transformer in ATO box is

functioning properly. Check power

from transformer to ATO board.

Ensure all harnesses are plugged

securely into place.

F. Ensure pump is operational.

Check voltage to pump. Replace

the pump if defective.

G. Check for proper voltages using the

pin position charts found on pages

43-47. If ATO found defective,

replace ATO board and clear any

errors.

Frypots won’t top off.

A. Probe temperature lower than

setpoint.

B. Oil is too cold.

C. Bad Connection.

D. ATO board power loss.

E. Failed transformer/harness.

F. ATO pump failed.

G. Failed ATO board.

One vat tops off but other

vats fail to top off.

Incorrect vat tops off.

One vat doesn’t top off.

A. Loose wire connection.

B. Actuator issue.

A. Wired incorrectly.

B. Flexlines connected to wrong vat.

A. Filter error exists.

B. Actuator, pump, loose connection,

RTD or ATO issue.

4

A. Ensure all wiring harnesses are

securely connected to ATO board

and solenoids.

B. Check return actuator to ensure

actuator is functional.

A. Check wiring.

B. Switch fl exlines to correct vat.

A. Clear fi lter error properly. When

change filter pad YES/

NO is displayed, do NOT press

any button until the pan has been

removed for at least thirty seconds.

After thirty seconds have elapsed,

the computer returns to OFF or last

display.

B. Check actuator, ATO pump, wire

connections, RTD and ATO board.

Page 6

LOV™ Generation II Technical Reference

Auto Filtration (MIB and AIF)

The auto fi ltration system is controlled by the

M3000 computer, the AIF (Automatic Intermittent

Filtration) board and the MIB (Manual Interface

Board). The fi ltration is made hands-off by

actuators operating the drain and return valves.

The computer is programmable, and it allows fi lter

cycles to be launched after a set number of cook

cycles and a prescribed elapsed time.

The system can be set to lock out automatic

fi ltration during busy times, such as the lunch rush.

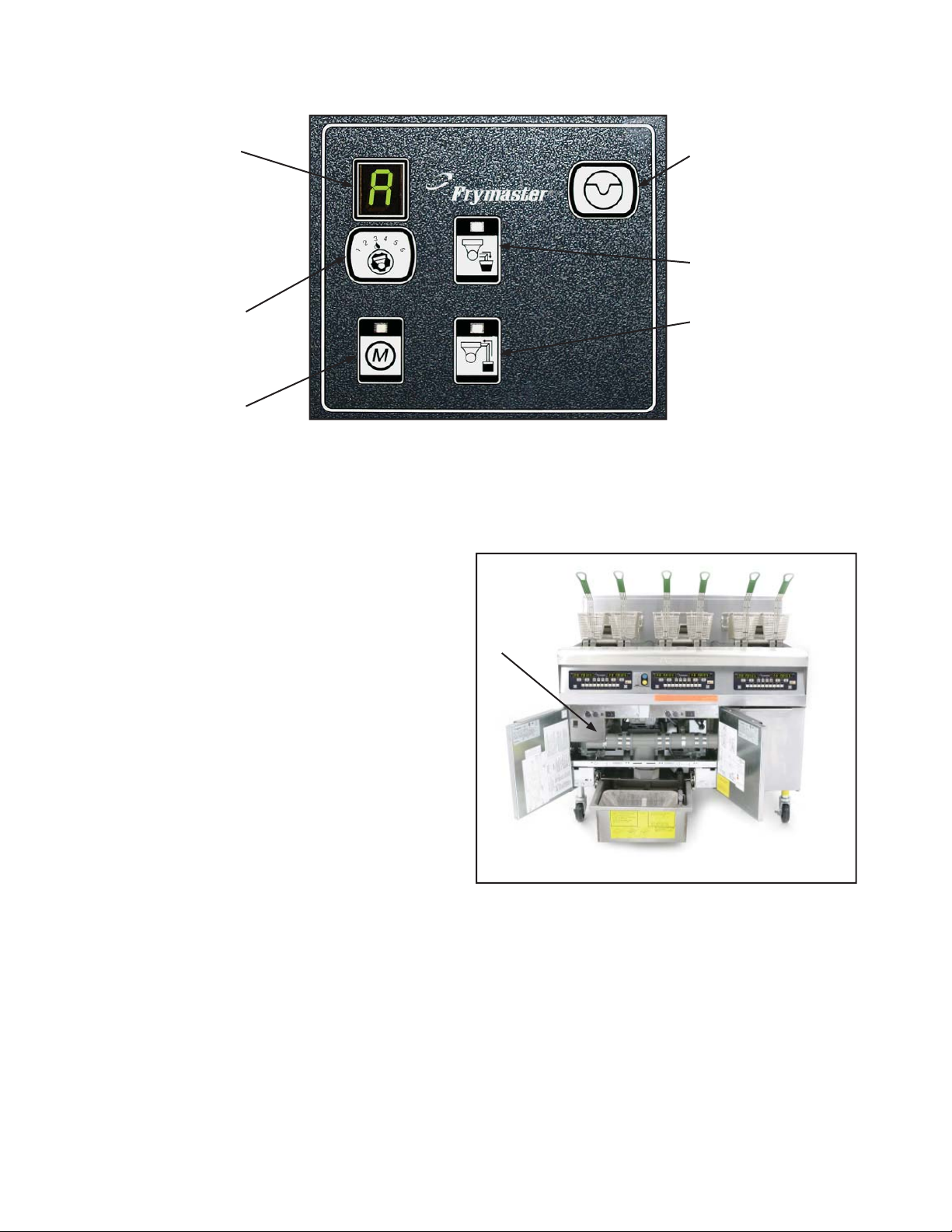

The fryer prompts for fi ltration by illuminating a

blue LED on the front and a text prompt on the

computer. The operator can say no; cooking can

continue.

An AIF board is mounted under each fry vat.

Responding “yes” leads to communication between the MIB and the AIF boards. The MIB controls

and oversees the fi ltration; the AIF board operates the actuators, which open and close the valves.

The MIB is in the fryer cabinet. It is partially covered by a sheet metal cover and the LED display is

visible. Buttons behind the cover allow limited manual operation of the system and its valves. The

cover should be reinstalled after service.

The LED displays codes that can be used to diagnose failures (see chart on page 45).

(1) Responding to the Blue LED fi lter

prompt with “yes” starts a fi lter cycle

that lasts about as long as a cook cycle

(approx. 4 minutes). Communication

between the M3000 computer, the

manual interface (MIB board), and

the automatic intermittent fi ltration

(AIF board) handle the process.

(2) Actuators open and close the

drain valve and return valve, (3)

emptying and refi lling the frypot.

1

2

3

5

Page 7

LOV™ Generation II Technical Reference

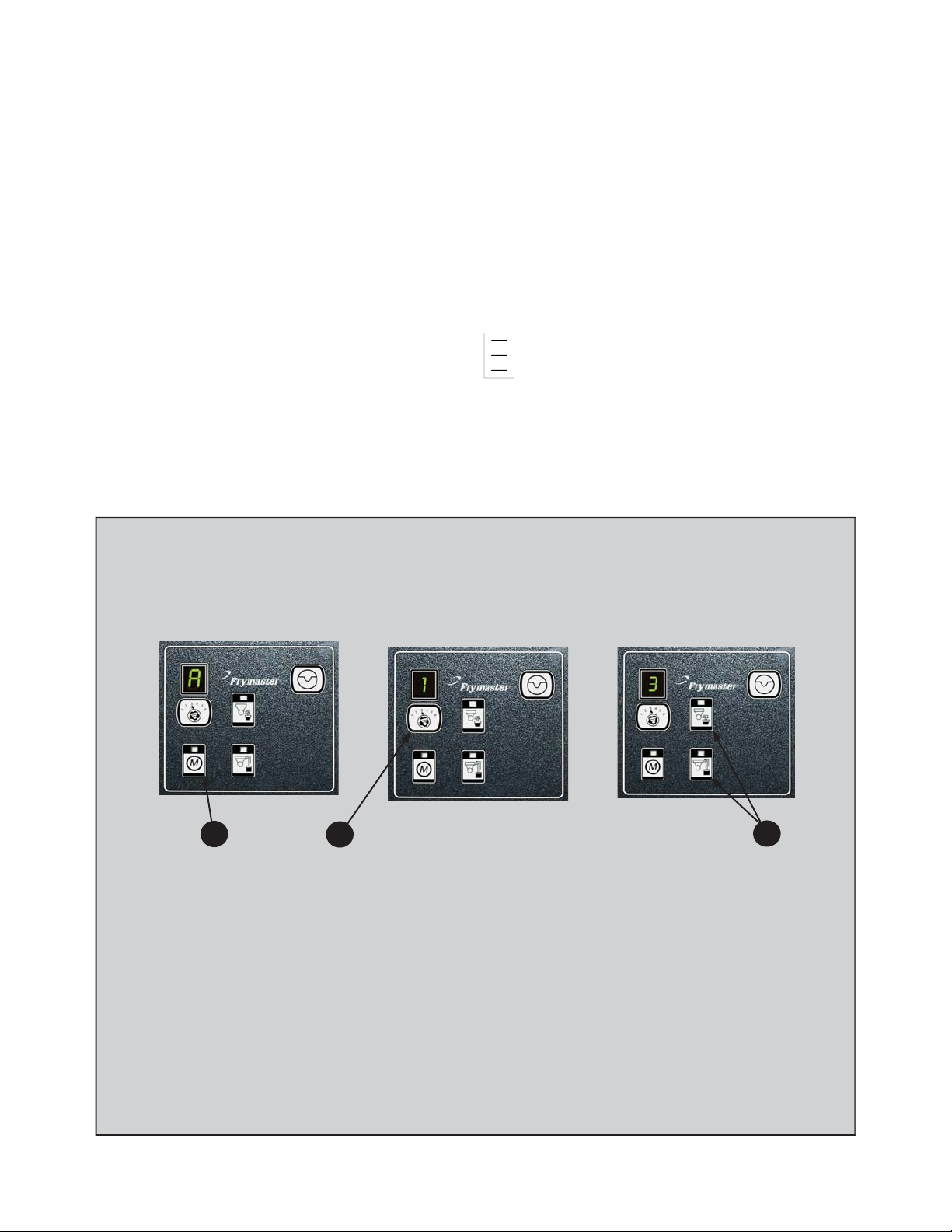

Mode Display

Shows status

(auto or manual)

vat number (when

operating valves

manuals) and displays error codes.

Vat Selection

Selects vat for

manual operation of

valves.

Manual/Auto

Switches fryer from

auto to manual

operation.

The MIB board.

Reset

Resets system,

ensures all valves

are closed.

Drain

Opens and closes

drain valves in

manual mode.

Return

Opens and closes

return valves and

turns on fi lter

pump in manual

mode.

Manual — Used to toggle between automatic

and manual fi ltration mode. The unit must be

in manual mode for the other MIB buttons

to operate.

Select — Used to scroll through the vats,

which are shown numerically in the LED.

Drain — Used to open and close the drain

valve of the vat indicated on the display.

When pressed an LED on the button indicates

activity: slow blink, awaiting response from

AIF; LED illuminated constantly, drain open;

no illumination, drain closed.

Return — Used to open and close the return

valve on the vat indicated on the display. It also

controls the pump. When pressed an LED on the

button indicates activity:

blink: awaiting response from AIF,

•

LED illuminated constantly: drain open,

•

no illumination: drain closed.

•

The MIB is mounted behind the left door. See arrow.

The pump operates with a momentary switch.

Pressing and holding the return button after

the valve is open activates the fi lter pump.

Releasing the button deactivates the pump.

The mode display on the face of the MIB board

displays a range of letters, which indicate

activity or an error. These codes are listed on

the next page.

6

Page 8

2

1

3

Error Codes

LOV™ Generation II Technical Reference

1L, 1r - 5L, 5r — Numbers correspond to

vats: “L” indicates the left side of a split vat. “r”

indicates a full vat or the right side of a split vat.

A — Auto mode: auto fi ltration enabled.

E — Drain or return valve not in desired

state: display alternates between E and vat

number. (Ensure actuator is plugged in and in the

home position.)

n — Network Error: An “n” displays for 10

seconds if no communication is received from the

cooking computer within ten seconds after a power

on.

Manual Draining, Filling, Filtering with MIB

P — Pan switch: fi lter pan is not in place or not

sensed. Auto Filtration disabled.

r — Reset: r alternating with a vat number

indicates that the MIB board is resetting. If r is

displayed without alternating with a vat number,

a problem may exist with the MIB board itself.

Three horizontal lines — temperature

sensor: sensor did not detect that the vat

was full during auto fi ltration.

1

Press the M button, which switches the board to manual. The display becomes

1.

the number of the vat to be controlled manually.

Press the vat selector button until the desired vat number is displayed.

2.

Press the drain button to drain the oil or the press and hold the return button to

3.

return oil to the vat displayed. Opening the drain and pressing and holding the

return button after valve is open allows fi ltration.

Pressing the M button again returns the board to automatic mode.

4.

2

7

3

Page 9

LOV™ Generation II Technical Reference

Troubleshooting the Manual Interface Board (MIB)

Problem Probable Cause Corrective Action

Filter pan out of position.

Auto fi ltration

won’t start.

1.

Oil Level is too low.

2.

Ensure MIB board is not in

3.

manual mode.

Ensure MIB cover is not

4.

damaged and pressing

against buttons.

Filter relay has failed.

5.

AIF disable is set to YES,

6.

blue light doesn’t light.

Filter motor thermal switch

7.

is tripped.

AIF clock enabled.

8.

Ensure fi lter pan is fully inserted into fryer.

1.

Ensure oil level is above the oil level sen-

2.

sor.

Ensure MIB board is in “A” automatic

3.

mode.

Remove and replace cover and see if fi ltra-

4.

tion will start.

Replace fi lter relay with part number 807-

5.

4482 24VDC relay.

Set AIF disable in Level 1 to NO.

6.

Press fi lter motor thermal switch.

7.

Ensure AIF clock is set to disabled.

8.

MIB display shows

something other

than an “A” or vat

number.

No power present

at the MIB board

MIB will not clear

error.

MIB indicates incorrect number of

vats.

An error has occurred and

displayed character indicates

error.

Transformer has failed in left

component box.

Error remains in non-volatile

memory.

See MIB display diagnostics on page 46 for

explanation.

Check output on the left transformer in left

component box; should read 24VAC. If not

replace transformer.

Press and hold reset button in top right corner for fi ve seconds. The drain, return and

manual/auto LEDS will illuminate and the MIB

will reset and clear any remaining errors from

memory. Allow 60 seconds to reset. If an error

still exists, then another issue exists.

Ensure the CAN bus system is terminated at

BOTH ENDS (on the M3000 connector J6 and

on the ATO board connector J9) with a resistor

equipped 6-pin connector.

Unplug and reseat all wiring harnesses in

•

CAN system. Resistance between pins

2 and 3 on the CAN network connectors

should be 120 ohms.

Check software version numbers on all

•

M3000 computers and ensure all display

an AIF version. If an AIF version is missing, the AIF board may be missing power.

Check pins 5 and on J4 and J5 of the affected AIF board for proper voltage.

The locator pin in J2 of the AIF board is

•

either loose or in the incorrect position.

See the chart on pages 47 of this manual

for proper pin position.

8

Page 10

LOV™ Generation II Technical Reference

Problem Probable Cause Corrective Action

Ensure the CAN bus system is terminated

A.

at BOTH ENDS (on the M3000 connector

J6 and on the ATO board connector J10)

with a resistor equipped 6-pin connector.

With the computer OFF, press TEMP but-

B.

ton and ensure the AIF version appears.

If not, the 24V to the AIF boards may be

missing. Ensure all 6-pin CAN connectors

are tight between the M3000 (J6 and J7),

MIB (J1 and J2), AIF (J4 and J5) and ATO

(J10) boards.

With the computer OFF, press TEMP but-

C.

ton and ensure the ATO version appears. If

not, check the CAN wire harness between

the AIF board J4 or J5 and the ATO board

J9 or J10. The ATO fuse on the right side

of the ATO box may be loose or blown;

the 110V to the ATO transformer may be

missing or bad. The J4/J5 connector may

be loose.

Check to see if MIB has 24V on pins 5 and

D.

MIB board alternating “E” and “vat

number and side.”

Network error on the CAN bus

communication.

6 of J2. Check to see if 24V is present on

pins 5 and 6 of wire harness plugging into

J4 or J5 of the fi rst AIF board. If 24V miss-

ing, check the pins. Replace the harness if

necessary.

Check continuity between each color wire

E.

on the CAN connectors into J7 on the far

right computer and J10 on back of the ATO

board (black to black, white to white, and

red to red) and ensure there is no continuity between different color wires (black to

red, red to white, and white to black).

Ensure black computer locator wires are

F.

connected from ground to correct pin position (see pages 43-47).

Ensure all boards have the corner ground

G.

wire attached and tightened.

Check for loose locator pin or incorrect

H.

positioning in J2 of the AIF board. See the

charts on pages 43-47 of this manual for

proper pin position.

Bad MIB and/or AIF board.

I.

Broken resistor lead. Unwrap the resistor

J.

leads and check ends.

9

Page 11

LOV™ Generation II Technical Reference

Troubleshooting the AIF System (AIF)

Problem Probable Cause Fix

Ensure the actuator is plugged into the correct

1.

connection (J1 for FV return, J3 for DV return;

J6 for FV drain, J7 for DV drain).

Ensure the locator pin is in the proper position

2.

in plug J2. (See charts on pages 43-47 of this

manual for proper pin position.)

Check pins 5 and 6 of J2 at the MIB board.

1.

Should read 24VDC. Check voltage on pins

5 and 6 at the other end of the harness and

ensure 24VDC is present. Check pins 5 and 6

for 24VDC on plugs J4 and J5 on AIF boards.

Ensure actuator leads are plugged into AIF

2.

board (J1 for FV return, J3 for DV return; J6

for FV drain, J7 for DV drain).

Check the power on the connector of the

3.

problem actuator while manually opening

or closing the actuator. Pins 1 (black) and 4

(white) should produce +24VDC when the

actuator is opening; -24VDC should be read

from Pins 2 (red) and 4 (white) when the

actuator is closing. If either voltage is missing,

the AIF board is likely bad. Test the actuator

by plugging into another connector to open

or close. If the actuator operates, replace the

board.

Check resistance of the potentiometer

4.

between pin 2 (purple wire) and pin 4 (gray/

white wire). Closed should read 0-560Ω. Open

should read 3.8KΩ - 6.6KΩ.

If proper voltages are seen at the connector

5.

and the actuator doesn’t operate, replace the

actuator.

Wrong vat

opens.

Actuator doesn’t

function.

Actuator is plugged into wrong

1.

connector.

Locator pin is in wrong position.

2.

No power to AIF board.

1.

Actuator unplugged.

2.

AIF board failure.

3.

Actuator readings are out of

4.

tolerance.

Actuator is bad.

5.

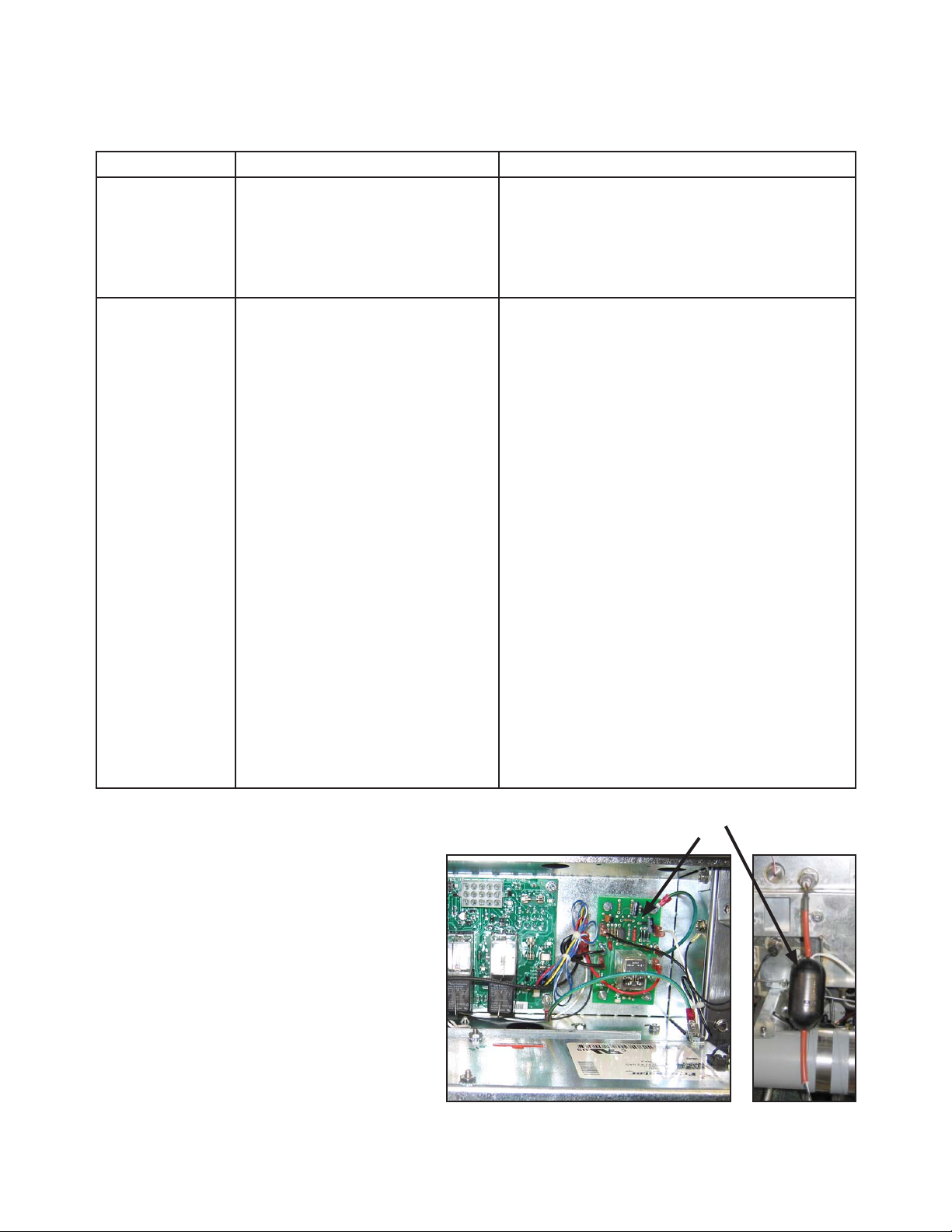

Oil Return Sensor Troubleshooting (Gas LOV™ Fryers)

The oil return sensor is a device that is used

to prevent dry fi ring of the burners. The

sensor looks similar to a high limit. The

sensors are energized when the computer

is powered on with a soft on. The sensor

heats up and detects the oil around it.

During fi ltration when the oil is drained, it

senses the difference between the oil and

air. It is controlled with a board located

next to the interface board (right) and a

separate egg shaped plastic device (far

right) that contains additional electronics.

Use care when working with the sensor as

temperatures may reach as high as 500°F

(260°C).

The oil return sensor is controlled by a small green board

and the electronics inside the plastic, egg-shaped device

shown above to prevent dry fi ring.

10

Page 12

LOV™ Generation II Technical Reference

IS VAT FULL?

IS DRAIN CLEAR?

If oil is surrounding the heater, the oil will prevent the heater from ever reaching its setpoint. Once

oil is removed during fi ltration, the heater reaches setpoint and cycles a thermostat every four

seconds. Since the cycle is only four seconds long, the seven second delay is not made and the gas

valve won’t open.

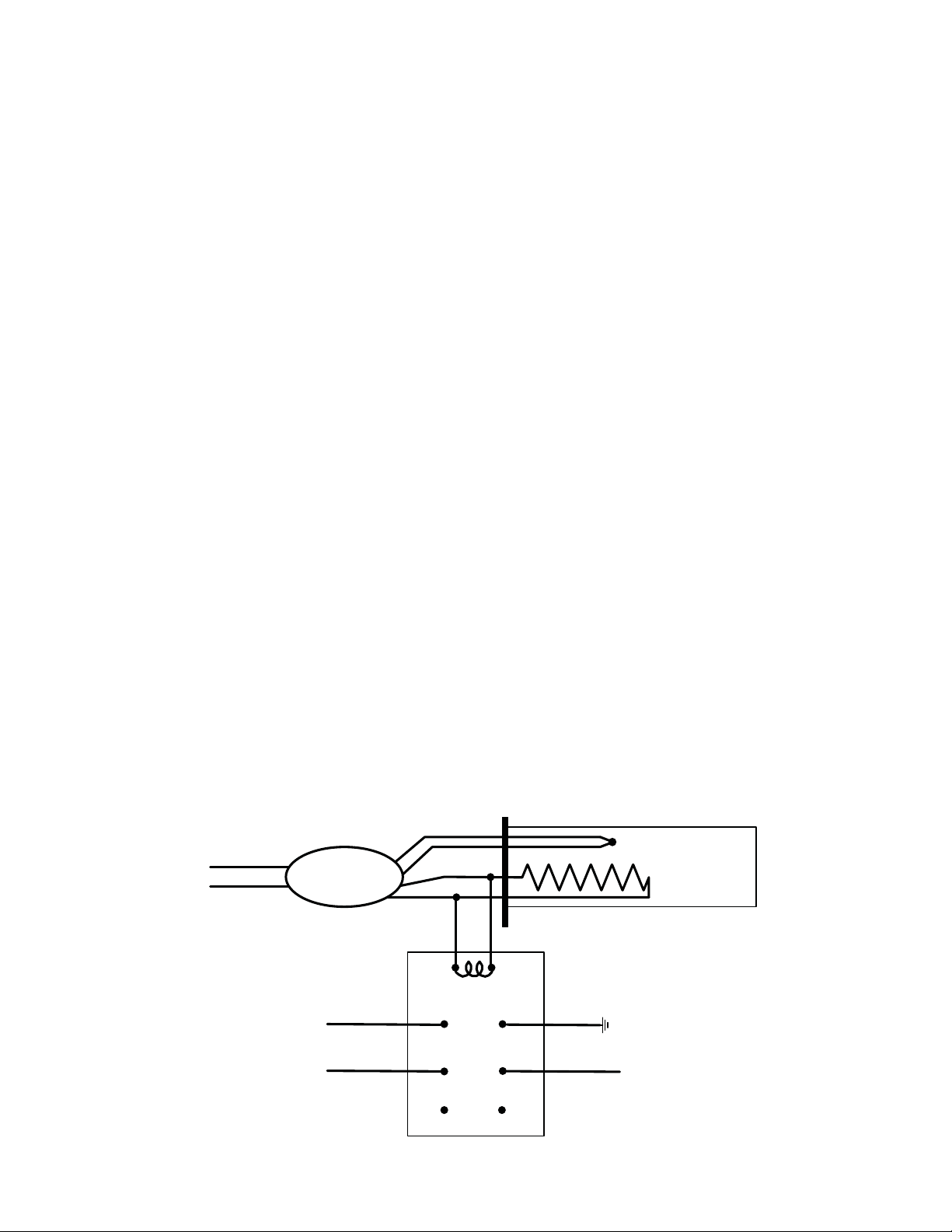

The 120VAC is on T2 in the control box traveling in on pin 11 of J3 and out pin 7 on J1 (DV) or pin

7 on J3 (FV).

Typical sensor-related failures:

•

Low temp but no call for heat (heat light),

•

Stuck in melt cycle with no call for heat,

•

Filter error (

If the computer doesn’t exit melt cycle or continues to display low temp and does not heat,

ensure that the gas supply, gas valve, and other components are working properly. If no heat lamp

illuminates because no call for heat is initiated, check the following (see diagram below):

Power to oil sensor (from previous basket lift relay on interface board K1(DV) or K4 (FV)). Check

•

pin 7 on J1 (DV) or pin 7 on J3 (FV) for 120VAC.

Power to heater/relay coil on relay board. Check voltage to the coil on pins 8 and 1 to ensure that

•

120VAC is present with oil in the vat. If the vat is empty, the power will cycle 4 seconds on, 4

seconds off.

Check between pin 3 and 2; 5VDC for air and 0VDC for oil. A common message for a shorted

•

harness or issue is

Check ground on pin 2 on relay board to stud for a secure ground.

•

Check AIF communication harness. Interrupted communication will prevent the fryer from

•

heating.

If the oil level sensor is cycling 4 sec. on/off and oil is surrounding the sensor , the sensor may have

•

a carbon build up that is self insulating the sensor. Use a no scratch pad to remove carbon build up.

IS VAT FULL?) with oil in the fi lter pan (no oil in the vat).

IS DRAIN CLEAR? with oil in the fi lter pan.

Black

(To J1 Pin 7 (DV)

or J3 Pin 7 (FV))

120V

White

(To T2 Terminal Block

Line Voltage In From

Oil Level Sensor

(Basket Lift) Relay on

Interface Board

24VAC from Interface Board

through High Limit (Ign. Module

Call for Heat)

To (optional Drain

Switch) and Gas

Valve

Fixed Setpoint

Temp. Control

120V

120V (US) 230V (Intl) 40W

Heater w/ Thermocouple

WhiteBlack

C

NO

NC

1

2

3

Green

Red

8

7

Black

6

Black

5 4

Time Delay Relay Board

DPDT 7sec. Delay on Make

11

Thermocouple

Heater

(350 ohms US)

(1325 ohms Intl)

To AIF Board J2 Pin 9 DV

or 10 FV (AIF Oil Signal)

Page 13

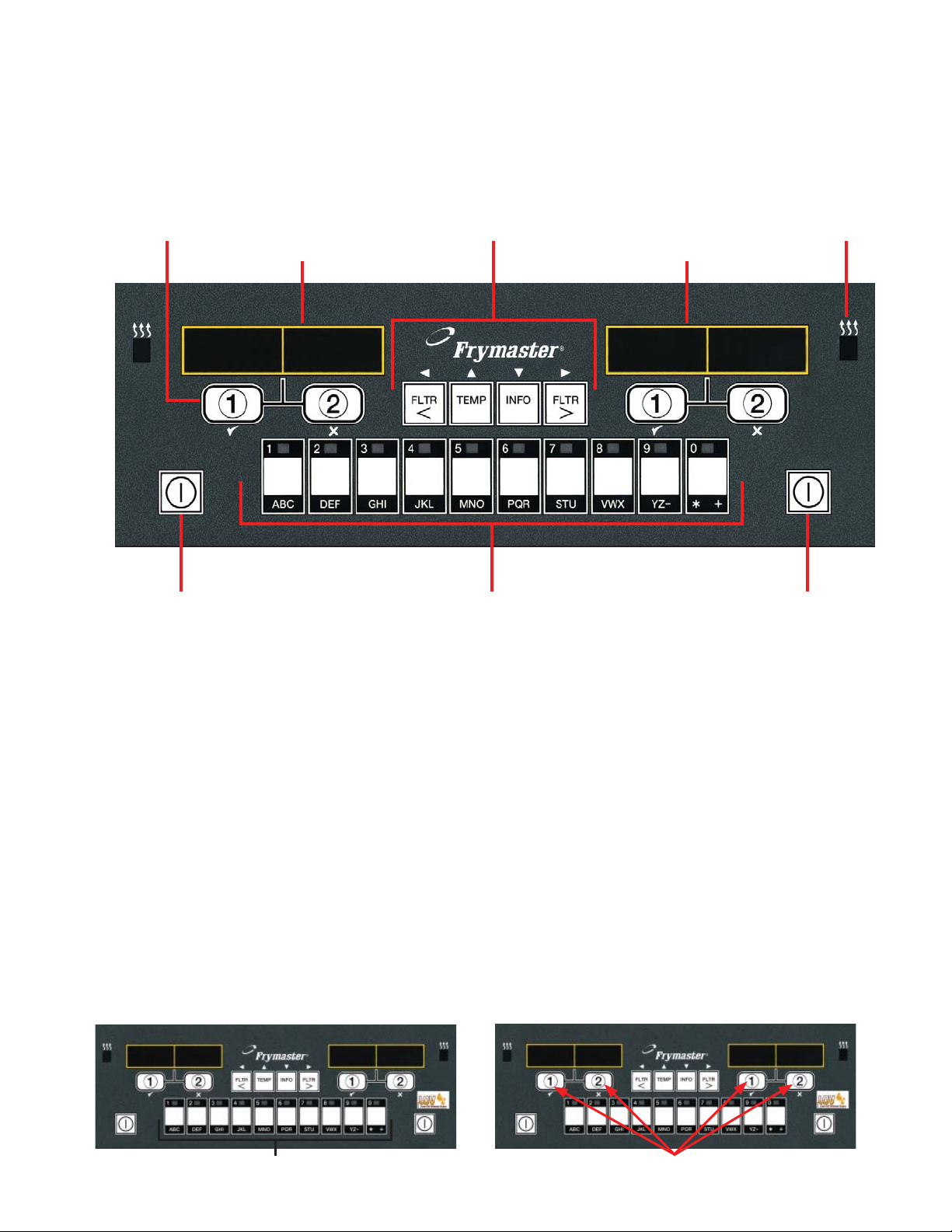

LOV™ Generation II Technical Reference

FR FRIES

----

mcchick

mcchick

M3000 Computer

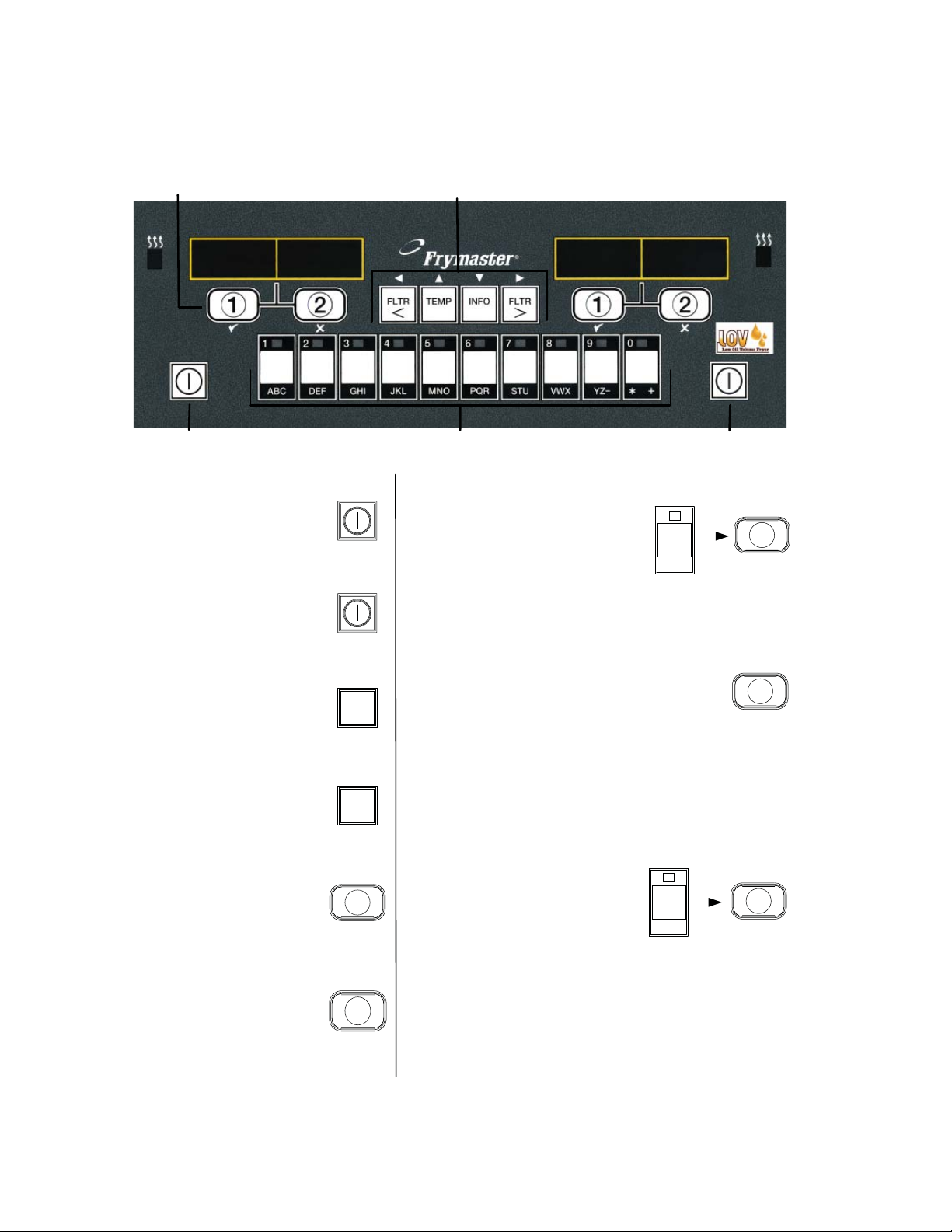

Overview

Cook Cycle and

Selection Buttons

ON/OFF ON/OFFProduct Buttons

LED Display

Filter, Temp, Info, Programming

and Navigation Buttons

Heat Indicator

Lamp

LED Display

The M3000 computer retains the one-button ease of the M2000 and M100B, combining it with the

utility of 40-product menu capability. It will operate with electric and gas fryers, both full- and splitvat.

On single product vats, press any of the cook cycle buttons to begin cooking. On multi-product vats,

press a product button, and then a cook cycle button under the display showing the desired product

name.

For example, a typical M3000 computer on a 3-vat fry station will display

FR FRIES. Pressing

one of the cook cycle buttons will begin a cook cycle for French fries.

The chicken/fi llet station will usually display dashed lines [

assigned to McChicken, for example, will cause

cycle button beneath the word

---- ----

mcchick to start a cook cycle for McChicken.

---- ----

mcchick to be displayed. Then, press a cook

----]. Pressing the product button

MCC HICK MCC HICK

Product Buttons Cook Cycle Buttons

12

Page 14

LOV™ Generation II Technical Reference

RECOVERY FAULT

RECOVERY FAULT CALL SERVICE

Navigation

The M3000 uses and buttons to navigate the various menus and submenus.

When programming, the left screen shows the menu or submenu item. The right screen is for data

entry. Data is entered with alpha-numeric characters, scrolling through lists or by toggling between

choices (see diagrams on previous page).

During programming, if a button is not pushed within one minute, the computer returns to operation

mode.

Cook Cycle and Selection Buttons

The 9 and 8 buttons are dual-function buttons shared with the number 1 and 2 buttons. They are

located directly below the LED displays (see diagrams on previous page). Use these buttons to select

or cancel functions. The 8 button is used to back out of and quit submenus.

Filter, Temperature, and Info Buttons

The < FLTR and FLTR > buttons (see diagram) are used to fi lter the left and right vats of a split vat

fryer on demand, while the right FLTR > button is used to fi lter a full vat on demand. If pressed once,

the FLTR buttons will display the number of cook cycles remaining until a fi ltration prompt. When a

FLTR button is pressed twice, the date and time of the last fi lter will be displayed.

Temp Button

The TEMP button, if pressed once while the fryer is on, displays current vat temperature on both

sides. If the TEMP button is pressed twice while the fryer is on, it shows the setpoint temperatures of

the vats. If the fryer is off, the display shows the current versions of software.

Info Button

The INFO button, if pressed once when the fryer is on, shows the recovery time for each vat from the

last test. Recovery displays the time required for the fryer to raise the temperature of the oil 50°F

(28°C) between 250°F (121°C) and 300°F (149°C). Maximum recovery time should not exceed 1:40

for electric or 2:25 for gas.

If recovery time exceeds these times, the computer will display

can be cleared and alarm silenced by pressing the 9 button. The second consecutive time it will

display

cleared by pressing the 9 button. However, each time the fryer is started up and the test performed,

the error will continue to appear until code 0042 is entered in tech mode (see page 27).

RECOVERY FAULT CALL SERVICE. The error can be silenced and temporarily

RECOVERY FAULT. The error

If the INFO button is pressed and held for three seconds it shows information such as usage, fi lter

statistics and last cook cycles.

13

Page 15

LOV™ Generation II Technical Reference

Cook Channel

and Selection Buttons

Basic Operation

Filter, Temp, Info,

Programming and Navigation Buttons

ON/OFF

Turn Fryer ON

Press right key for full

pot; press key on desired

side on a split pot.

Turn Fryer OFF

Press right key for full

pot; press key on desired

side on a split pot.

Check Frypot Temperature

Press Temp key once.

Displays show frypot

temperatures.

Check Frypot Setpoint

Press Temp key twice.

Displays show frypot

setpoint temperatures.

Cancel Duty or Remove

Press key under active

display.

Start One-Button Cook Cycle

(Dedicated Mode)

Press key under

display showing

desired item.

Alarm

TEMP

TEMP

2

1

Product Buttons

Start Two-Button Cook Cycle (Multi-Product Mode)

Press product key

bearing icon for desired

product. Press cook

channel button to begin

cook cycle

Change From Dedicated

Press and hold Cook

Channel button under

displayed menu item for

approximately 3 seconds

until beep is heard.

Display changes to dashed

lines.

Change From Multi-Product

Press product key bearing

icon for desired product.

Press cook channel button

under display showing

desired item until beep is

heard (approx 3 seconds).

.

to Multi-Product Mode

Mode to Dedicated Mode

ON/OFF

2

2

2

14

Page 16

LOV™ Generation II Technical Reference

y

K

4

Cooking With Multi-Product Display

Dashed lines appear

1

in both displays.

Press a product

2

button.

Vat with appropriate

3

setpoint displays:

MC CHICK. Skip

to step 5.

Vat with inappropriate

4

setpoint displays:

If this occurs, change

setpoint by pressing the

button assigned to the

product. When the

chevrons appear,

immediately press and

hold the cook button

until a beep is heard

(approximately three

seconds) and then

release it.

Press a cook channel

5

button to begin cook

cycle.

- - - - - - - -

McCK

Mc chick

<<<<>>>>

McCK

<<<<>>>>

1

1

Display alternates

6

between MCCK and

remaining cook time

If a duty is required for

7

this menu item

displayed when it is time

to perform a duty, such

as shake.

Press cook

8

channel button

under duty display

to cancel alarm.

Pull is displayed

9

when the cook time

is complete; an

alarm sounds.

Press cook

10

channel button

under pull display

to cancel alarm.

Dashed lines reappear

11

under active display at

the end of the cook

cycle.

.

, duty is

Mc c

2:3

dut

2

pull

2

- - - - - - -

NOTE:

If error Remove Discard Product

appears, press the cook channel button

under the message to cancel alarm and

remove error message.

15

Page 17

LOV™ Generation II Technical Reference

s

4

y

Cooking With Dedicated Display

A menu item, such as

1

FR FRIES shows in

display

Press a cook channel

2

button to begin the

cook cycle.

Display alternates

3

between abbreviated

product name and

remaining cook time.

Duty is displayed

4

when itis time to shake

the fry basket.

Press cook channel

5

button to cancel alarm

Pull is displayed

6

when the cook cycle

is complete.

fr

FRY

.

fries

1

2:3

dut

1

pull

Fr fries

Q7 is displayed and

8

alternates with

FRY. As the quality

time counts down.

Pressing the cook

9

channel button now

will launch a cook

cycle and end the

quality countdown.

QUAL is displayed

0

1

when the quality

time has elapsed.

Pressing the cook

1

1

channel button

restores the display

to FR FRIES

unit is ready for

cooking

.

Q7 Fry

Q1 Fry

1

Qual

1

and the

FR FRie

Press cook channel

7

button to cancel

alarm.

1

16

Page 18

LOV™ Generation II Technical Reference

s

Changing from Breakfast Setup to Lunch

Hash brn Hash brn

Press and quickly

1

release product

button for french fries.

Computer will change

2

from Hash Brn to

<<<<<>>>>>; an

alarm will sound.

Perform these steps on both sides to change both displays to FR FRIES.

FFRY

hash brn

<<<<<>>>>>

Press and hold the cook

3

channel button under the

display until a beep is

heard (approximately three

seconds) and release.

Display changes to FR

4

Fries..

1

fr frie

17

Page 19

LOV™ Generation II Technical Reference

r

s

Changing from Lunch Setup to Breakfast

Fr

Computer displays

1

FR FRIES.

Press and quickly

2

release product

button for hash

browns.

Computer display

3

will change from

FR Fries to

<<<<<>>>>>; an

alarm sounds.

fries

FRFRie

f

<<<<<>>>>>

Hash

brn

fries

Fr

Press and hold the cook

4

channel button under the

display until a beep is

heard (approximately

three seconds) and release.

Display changes to

5

Low Temp until

setpoint is reached.

Display changes to

6

Hash Brn.

fries

1

LOW temp

hash brn

Perform these steps on both sides to change both displays to FR FRIES.

18

Page 20

LOV™ Generation II Technical Reference

A

r

The following chart maps the menu options available in the M3000 computer and indicates the

location of more information on each menu item within the LOV™ Fryer Installation and Operation

Manual. For more information, consult the indicated section.

M3000 Menu Items

Location in IO manual

Adding New Menu Items See section 4.10.2

Storing Menu Items in Product Buttons See section 4.10.3

Draining, Refi lling, and Disposing of Oil See section 4.10.4

Filter Menu

Programming

………………………………………………………………………………………………………….. 4.11

[Press and hold ◄ FLTR or FLTR ►]

Auto Filter

Maint Filter

Dispose

Drain to Pan

Fill Vat from Drain Pan

Fill Vat from Bulk (Bulk Only)

Pan to Waste (Bulk Only)

Level 1 Program

[Press and hold TEMP and INFO buttons, 2 beeps, displays Level 1, enter 1234]

Product Selection

…….……………….....………………………………………………………….. 4.12

..…….....………………………………………………………….. 4.10.2

Name

Cook Time

Te mp

Cook ID

Duty Time 1

Duty Time 2

Qual Tmr

AIF Disable

Assign Btn

IF Clock

..………………………………………………………………………………… 4.12.1

Disabled

Enabled

Deep Clean Mode

High-Limit Test

Fryer Setup

……..……………………...…………………………………….. 4.12.2

…………….…………………….…………………………………….. 4.12.3

…………………….……………………………………………………………….. 4.9

Level 2 Program (Manager Level)

[Press and hold TEMP and INFO buttons, 3 beeps, displays Level 2, enter 1234]

Prod Comp

E-Log

Password Setup

Sensitivity for product

Log of last 10 error codes

Change passwords

Setup [enter 1234]

Usage [enter 4321]

Level 1 [enter 1234]

Level 2 [enter 1234]

Alert Tone Volume and Tone

Volume 1-9

Ton e 1 - 3

Filter Afte

Filter Time

Tech Mode

[Press and hold ◄ and ► for 10 seconds, 3 beeps, displays TECH MODE, enter

1650]

Sets number of cooks before filter prompt

Sets amount of time between filter cycles

Clear Passwords

Filter Pad Time

Info Mode

………………...………………………...………………………………………..……………………….. 4.14

[Press and hold INFO for 3 seconds, displays Info Mode]

Full/Split Vat Configuration

Filter Stats

Review Usage

Last Load

..……………….……………………………………………………………….. 4.14.1

………….……………………………………………………………….. 4.14.2

………………….……………………………………………………………….. 4.14.3

……………………………………………….. 4.13

…………………………………….. 4.13.1

…………………………….. 4.13.2

……………………………… 4.13.3

...………………………………………….. 4.13.4

………….. 4.13.5

………….. 4.13.6

19

Page 21

LOV™ Generation II Technical Reference

OFF

UPGRADE IN PROGRESS

WAIT

CC UPDATING

BOOT

UPGRADE IN PROGRESS

WAIT

COOK HEX

mib HEX

aif HEX

aTO HEX

REMOVED SD CARD

100

CYCLE POWER

M3000 CAN TX FULL

SERVICE REQUIRED

BOOT

OFF

YES

SYSTEM ERROR FIXED?

OFF

Loading and Updating Software Procedures

Updating the software takes approximately 20 minutes. To update the software, follow these steps:

1. Switch all computers to

version.

2. Remove the two screws on the left side cover plate of the M3000 board.

3. With the computer folded down, insert the SD card into the slot on the left side of the M3000. The

contacts on the card should face down and the notch should appear on the bottom right (see pictures

below).

4. Once inserted,

5. The display then changes to

right. The display counts up to 100 on the right, changing to a fl ashing

THE CARD UNTIL THE DISPLAY PROMPTS TO DO SO IN STEP 8.

6. Then,

7. The display then changes to

8. Remove the SD card using the fi ngernail slot on the top of the SD card.

9. Once the SD card is removed the display changes to

UPGRADE IN PROGRESS is displayed on the left display and

followed by

the percentage complete on the right.

UPGRADE IN PROGRESS appears on the left display and

COOK HEX,

OFF. Press the TEMP button to check current M3000/MIB/AIF/ATO software

WAIT on the right.

CC UPDATING on the left and the percentage completed appears on the

BOOT. DO NOT REMOVE

WAIT on the right again,

mib HEX,

REMOVED SD CARD on the left and

aif HEX ending with

CYCLE POWER.

aTO HEX displayed on the left and

100 on the right.

10. Cycle the control power using the hidden reset switch behind the right control box (see page 38). HOLD

THE SWITCH FOR 10 SECONDS ENSURING THE MIB BOARD HAS POWERED FULLY

DOWN.

11.

M3000 CAN TX FULL (a

rebooting. Press YES at the prompt to cancel alarm. A fl ashing

computers while the program is transferred.

12. When the update is complete, the M3000 displays

software is loading, changing to show the vat numbers. Once the LEDs stop blinking, press

SYSTEM ERROR FIXED? Enter 1111. The MIB board will display A.

13. Cycle the control power using the hidden reset switch behind the right control box again. ENSURE

THE SWITCH IS HELD FOR 10 SECONDS. WAIT ANOTHER 20 SECONDS UNTIL THE MIB

BOARD HAS FULLY RESET BEFORE CONTINUING.

14. With the computer displaying

updated M3000/MIB/AIF/ATO version on each computer. IF ANY BOARDS DID NOT UPDATE,

REPEAT THE PROCESS STARTING WITH STEP 3.

Insert the SD card

with contacts fac-

ing down.

SERVICE REQUIRED error) may appear while computers are

BOOT is displayed on the remaining

OFF. The MIB display will remain blank while

YES to

OFF, VERIFY software update by pressing the TEMP button to check

Remove the SD card

using the fi ngernail

slot on the top of the

card.

20

Page 22

LOV™ Generation II Technical Reference

filter busy

.

FILL VAT FROM DRAIN

PAN

M3000 Troubleshooting

Problem Probable Causes Corrective Action

No display on computer.

A. Computer not turned on.

B. No power to the fryer.

C. Power switch turned off.

D. Loose fuse holder.

E. Computer has failed.

F. Damaged computer wiring

harness.

G. Power supply component or

interface board has failed.

A. Press the ON/OFF switch to turn

the computer on.

B. This fryer may have two cords: a

computer power cord and a main

power cord. If the computer cord

is not plugged in, the computer will

not activate. Verify computer power

cord is plugged in and that circuit

breaker is not tripped.

C. Some fryers have a rocker power

switch inside the cabinet below the

computer. Ensure the switch is

turned on.

D. Ensure fuse holder is screwed in

properly.

E. Swap the computer with a computer

known to be good. If computer

functions, replace the computer.

F. Swap with a harness known to

be good. If computer functions,

replace the harness.

G. If any component in the power

supply system (including the

transformer and interface board)

fail, power will not be supplied to

the computer and it will not function.

Computer locks up. Computer error.

A. Another fi ltration cycle is still in

process.

M3000 display shows

filter busy

B. Computer error.

C. Computer error.

Remove and restore power to the

computer.

A. Wait until the previous fi ltration

cycle ends to start another fi ltration

cycle.

B. A computer has an error. Using

the fi lter menu, try to perform

a

FILL VAT FROM DRAIN

PAN on each vat (see Chapter 4

of the BIELA14 IO manual). Only

computers with errors can perform

this function with a fi lter busy error.

Computer should clear and return

to normal operation once complete.

C. If fi lter busy is still displayed with

no activity, ensure the fi lter pan is

empty and remove and restore ALL

power to the fryer.

21

Page 23

LOV™ Generation II Technical Reference

RECOVERY FAULT

CALL SERVICE.

ENERGY

MISCONFIGURED

EXCEPTION ERROR

SERVICE

REQUIRED

SYSTEM

ERROR FIXED? YES/NO.

ENTER

CODE

CHANGE

FILTER PAD

CHANGE FILTER

PAD

INSERT pan

INSERT

pan

hot-hi-1

HI-

LIMIT

.

Problem Probable Causes Corrective Action

M3000 display shows

RECOVERY FAULT

CALL SERVICE.

M3000 display

shows

MISCONFIGURED

M3000 display shows

EXCEPTION ERROR

with the description on the

M3000 displays

REQUIRED followed by

ENERGY

SERVICE

the error.

right.

Recovery time exceeded maximum

time limit for two or more cycles.

Wrong energy type selected in

setup.

An error has occurred.

An error has occurred.

Silence the alarm by pressing the 9

button. Clear the error using the code

on page 25. Maximum recovery for

electric is 1:40.

Press 1234 to enter setup and set

energy type for electric.

Press 1234 to enter setup and

reconfi gure the computer.

Press YES to silence alarm. The

error is displayed three times. See

list of issues on page 26. Fix issue.

The computer displays

ERROR FIXED? YES/NO. Press

YES. Computer displays

CODE.. Enter 1111 to clear error

code. Pressing NO will allow the fryer

to cook, but error will be redisplayed

every 15 minutes.

SYSTEM

ENTER

M3000 display is in

wrong temperature scale

(Fahrenheit or Celsius).

M3000 displays

M3000 display shows

M3000 display shows

CHANGE

FILTER PAD.

INSERT pan.

hot-hi-1.

Incorrect display option

programmed.

Filter error has occurred, fi lter pad

clogged, 24 hour fi lter pad change

prompt has occurred, or change

fi lter pad was ignored on a prior

prompt.

A. Filter pan is not fully inserted into

fryer.

B. Missing fi lter pan magnet.

C. Defective fi lter pan switch.

Frypot temperature is more than

410ºF (210ºC) or, in CE countries,

395ºF (202ºC).

See page 28 to change temperature

scale.

Change the fi lter pad and ensure the

fi lter pan has been removed from the

fryer for a minimum of 30 seconds.

Do NOT ignore

PAD prompts.

A. Pull fi lter pan out and fully reinsert

into fryer.

B. Ensure the fi lter pan magnet is in

place and replace if missing.

C. If the fi lter pan magnet is fully

against the switch and computer

continues to display

pan, switch is possibly defective.

This in an indication of a malfunction

in the temperature control circuitry,

including a failure of the high-limit

thermostat.

CHANGE FILTER

INSERT

M3000 display shows

LIMIT

HI-

Computer in high-limit test mode.

This is displayed only during a test of

the high-limit circuit and indicates that

the high-limit has opened properly.

22

Page 24

LOV™ Generation II Technical Reference

low temp

with MLT-CYCL

EXIT

MELT

YES

ERROR RM SDCRD

TEMP PROBE

FAILURE.

MAINT FILTER

MAINT FILTER.

REMOVE DISCARD

HEATING FAILURE

.

HI

2 BAD.

HELP HI-2

HIGH

LIMIT FAILURE

Problem Probable Causes Corrective Action

M3000 display shows

low temp alternating

with MLT-CYCL.

Frypot temperature is between

180°F (82°C) and 315°F (157°C).

This display is normal when the fryer

is fi rst turned on while in the melt cycle

mode. To bypass the melt cycle press

and hold either #1 or #2 product button

under the LCD display until a chirp is

heard. The computer displays

MELT alternating with

Press the #1 YES button to exit melt.

If the display continues, the fryer is not

heating.

YES and NONO.

EXIT

M3000 display shows

ERROR RM SDCRD

M3000 display shows

TEMP PROBE

FAILURE.

MAINT FILTER (Manual

Filter) won’t start.

M3000 display shows

REMOVE DISCARD.

M3000 display shows

HEATING FAILURE

Defective SD card. Replace card with another card.

A. This indicates a problem within the

A. Problem with the temperature

measuring circuitry including the

probe.

B. Damaged computer wiring

harness or connector.

Temperature too low.

In non-dedicated mode, a product is

dropped that has a different setpoint

that the current vat temperature.

Failed computer, failed interface

board, open high-limit thermostat.

temperature measuring circuitry.

Check resistance of probe, if faulty

replace probe.

B. Swap the computer wiring harness

with one known to be good. If

problem is corrected, replace the

harness.

Ensure fryer is at setpoint before starting

MAINT FILTER.

Remove and discard product. Press a

cook button under the display with the

error to remove the error. Reset the

setpoint of the vat before trying to cook

product.

Turn off the vat with the problem. This

error is displayed if the fryer loses its

ability to heat oil. It is also displayed

when the oil temperature is above

450°F (232°C) and the high-limit

thermostat has opened, halting the

heating of the oil.

Computer will not go into

program mode or some

buttons do not actuate.

M3000 display shows

M3000 display shows

HELP HI-2 or

LIMIT FAILURE.

HI

2 BAD.

HIGH

Failed computer. Replace computer

This is displayed during a test of the

Computer in high-limit test mode.

Failed high-limit.

high-limit circuit to indicate if the highlimit has failed.

This is displayed to indicate the highlimit has failed.

23

Page 25

LOV™ Generation II Technical Reference

low temp

IS

VAT FULL? YES NO.

Problem Probable Causes Corrective Action

M3000 display shows

software for only M3000

or MIB but not all boards.

Loose or damaged harness.

Check that all harnesses between

M3000’s, MIB, AIF and ATO are

secure. Ensure 24VDC is present on

pins 5 & 6 of J2 on MIB board and on

J4 or J5 of AIF board. Check for loose

or broken pins/wires. If the problem

persists, swap out computer from one

bank to another and cycle power on

the fryer.

M3000 display shows

low temp,

indicator cycles on and

off normally but fryer

M3000 display shows

VAT FULL? YES NO.

Fryer fi lters after each

heating

does not heat.

IS

cook cycle.

A. Three phase power cord

unplugged or circuit breaker is

tripped.

B. Failed computer.

C. Damaged computer wiring

harness.

D. Open connection in high-limit

circuit.

A fi lter error has occurred due to

dirty or clogged fi lter pad or paper,

clogged fi lter pump, fi lter pump

thermal overload, improperly

installed fi lter pan components, worn

or missing O-rings, cold oil or an

actuator problem.

Filter after setting incorrect or

software update issue.

A. Ensure all cords are fully seated in

the receptacles, locked into place

and that circuit breakers are not

tripped.

B. Replace computer.

C. Replace computer wiring harness.

D. Check high limit circuit starting at

the control box connector working

to the high-limit.

Follow the steps in the fl owchart on

page 30.

Overwrite the fi lter after setting by re-

entering the fi lter after value in level two.

Ensure that the down arrow is pressed

after entering the value to save the

setting (see Chapter 4 in the BIELA14

IO Manual for more information).

24

Page 26

LOV™ Generation II Technical Reference

TECH MODE

0042

RECOVERY FAULT CALL SERVICE

1658

off

3322

COMPLETE

off

1650

1212

COMPLETE

off

0469

Filter Stat Data

1000

CALL TECH

1000

off

9988

BADCRC

9988

off

1111

SERVICE REQUIRED

1234

SETUP MODE

level 1

level 2

ENTER

Code

1234

4321

M3000 Useful Codes

To enter any of the following codes: Press and hold and simultaneously for TEN seconds; three

chirps sounds. The computer displays

•

0042 – Reset

•

1658 – Change from F° to C°. The computer displays

temperature to see the temperature scale. If the desired scale is not displayed, repeat.

•

3322 – Reset Factory Menu. The computer displays

This will delete any hand-entered menu items.)

•

1650 – Enter Tech Mode. See page 1-36 to reset passwords and change fi lter pad time.

•

1212 – Switch Between Domestic and International Menu. The computer displays

COMPLETE, and then

•

0469 – Reset

RECOVERY FAULT CALL SERVICE.

off. (NOTE: This will delete any hand-entered menu items.)

Filter Stat Data.

TECH MODE. Enter the codes below to perform this function.

off. Turn the computer on and check

COMPLETE, and then

off. (NOTE:

The following codes require the removal and reinsertion of the J3 locator plug on the rear of the computer

before entering the code.

•

1000 – Reset

Enter

1000. Computer display switches to

using the 20-pin plug.

•

9988 – Reset

9988. Computer display switches to

the 20-pin plug. Replace the computer.

The following codes are entered when prompted to do so or from an energy misconfi gured exception error.

•

1111 – Reset

are prompted to enter.

•

1234 – Enter

ally can be done without pressing the fi lter buttons if an error is displayed.)

CALL TECH Message. Disconnect board locator plug (J10). Reinsert plug.

off. Remove and then restore power to the computer

BADCRC Message. Disconnect board locator plug (J10). Reinsert plug. Enter

off. Remove and then restore power to the computer using

SERVICE REQUIRED Message. Enter this when the issue is fi xed and you

SETUP MODE from energy misconfi gured exception error. (This usu-

Passwords

To enter level one, level two passwords – Press and hold the TEMP and INFO buttons simultane-

ously until

level 1 or

level 2 is displayed. Release the buttons and

ENTER

Code appears.

•

1234 – Fryer Setup, Level One, and Level Two.

•

4321 – Usage Password.

25

Page 27

LOV™ Generation II Technical Reference

SERVICE REQUIRED

YES

YES

SYSTEM ERROR FIXED?

YES/NO

yes

1111

SERVICE RE-

QUIRED

Service Required Errors

A

SERVICE REQUIRED error alternating with

pressed the alarm is silenced. The computer displays an error message from the list below three

times with the location of the error. Then, the computer displays

YES/NO. If

yes is chosen, enter code

1111. If NONO is chosen, the system returns to cook

mode for 15 minutes then redisplays error until issue is fi xed.

YES displays on the computer. After

SYSTEM ERROR FIXED?

YES is

Pressing the MIB reset button during any fi lter function will generate a

QUIRED error.

SERVICE RE-

This is a list of the service required errors and cause.

ERROR MESSAGE EXPLANATION

Oil not returning to vat quickly. Possible problems: dirty pad, bad

PUMP NOT FILLING

DRAIN VALVE NOT OPEN Drain valve failed to open; the valve’s position is unknown.

DRAIN VALVE NOT CLOSED Drain valve failed to close; the valve’s position is unknown.

RETURN VALVE NOT OPEN Return valve failed to open; the valve’s position is unknown.

RETURN VALVE NOT CLOSED Return valve failed to close; the valve’s position is unknown.

MIB BOARD

AIF BOARD MIB detects AIF missing; AIF board failure.

ATO BOARD MIB detects ATO board connection lost; ATO board failure.

HIGH LIMIT FAILURE High limit circuit has an issue.

AIF PROBE AIF RTD reading out of range.

ATO PROBE ATO RTD reading out of range.

TEMP PROBE FAILURE TEMP Probe reading out of range.

MIB SOFTWARE Internal MIB software error.

INVALID CODE LOCATION SD card removed during update.

MISCONFIGURED ENERGY

TYPE

RTC INVALID DATE

or missing O-rings, tripped or defective fi lter pump, actuators or

linkage.

Problem with CAN communications; check for loose CAN connections. MIB board failure.

Energy type in fryer setup is incorrect; set proper energy type gas

or electric. Press 1234 to enter setup to properly confi gure fryer.

The date is invalid. Press 1234 to enter setup to properly confi g-

ure fryer and set proper date.

26

Page 28

LOV™ Generation II Technical Reference

CODE ERROR MESSAGE EXPLANATION

A product cook is started on the right side of a split vat

E01 REMOVE DISCARD (Right)

E02 REMOVE DISCARD (Left)

E03 ERROR TEMP PROBE FAILURE TEMP Probe reading out of range.

E04 HI 2 BAD High limit reading is out of range.

E05 HOT HI 1

E06 HEATING FAILURE

E07 ERROR MIB SOFTWARE Internal MIB software error.

E08 ERROR ATO BOARD

E09 ERROR PUMP NOT FILLING

E10 ERROR DRAIN VALVE NOT OPEN

E11 ERROR DRAIN VALVE NOT CLOSED

E12 ERROR RETURN VALVE NOT OPEN

E13 ERROR RETURN VALVE NOT CLOSED

E14 ERROR AIF BOARD MIB detects AIF missing; AIF board failure.

E15 ERROR MIB BOARD

E16 ERROR AIF PROBE AIF RTD reading out of range.

E17 ERROR ATO PROBE ATO RTD reading out of range.

E18 Not Used

E19 M3000 CAN TX FULL Connection between computers lost.

E20 INVALID CODE LOCATION SD card removed during update.

E21

E22 OIL IN PAN ERROR The MIB has detected oil may be in the pan.

E23 CLOGGED DRAIN (Gas) Vat did not empty during fi ltration.

E24

E25 RECOVERY FAULT Recovery time exceeded maximum time limit.

E26 RECOVERY FAULT CALL SERVICE

E27 LOW TEMP ALARM

FILTER PAD PROCEDURE ERROR

(Change Filter Pad)

OIL RETURN (level) SENSOR FAILED

(Gas)

or in a full vat that has a different setpoint other than the

current vat temperature.

A product cook is started on the right side of a split vat

or in a full vat that has a different setpoint other than the

current vat temperature.

High limit temperature is past more than 410°F (210°C),

or in CE countries, 395°F (202°C).

A component has failed in the high limit circuit such as

computer, interface board, contactor or open-high limit.

MIB detects ATO board connection lost; ATO board

failure.

Oil not returning to vat quickly. Possible problems: dirty

pad, bad or missing O-rings, tripped or defective fi lter

pump, actuators or linkage.

Drain valve failed to open; the valve’s position is

unknown.

Drain valve failed to close; the valve’s position is

unknown.

Return valve failed to open; the valve’s position is

unknown.

Return valve failed to close; the valve’s position is

unknown.

Cooking computer detects MIB connections lost;

check software version on each computer. If versions

are missing, check CAN connections between each

computer; MIB board failure.

25 hour timer has expired or dirty fi lter logic has

activated.

Oil return sensor may have failed.

Recovery time exceeded maximum time limit for two or

more cycles.

Oil temperature has dropped lower than 15°F (8°C) in

idle mode or 45°F (25°C) in cook mode.

27

Page 29

LOV™ Generation II Technical Reference

TEN

CODE

1650

TECH MODE

CLEAR PASS-

WORDS

CLEAR PASSWORDS

COM-

PLETE

FILTER PAD TIME

OFF

OFF

LEVEL 1

ENTER

CODE

1234

level 1 program

Product selection

FRYER SETUP

Tech Mode

Tech mode allows technicians to reset all passwords set in Levels One and Two and change the time

at which the fryer calls for a fi lter pad change. The default is 25 hours.

1. Press and hold and simultaneously for

heard and

2. Enter

3. The computer displays

WORDS.

4. Press the 9 (1) button to accept selection and clear the passwords.

5. The computer displays

PLETE on the right. This clears any passwords set up under levels one and

two.

6. Press the button to toggle to

the right. (25 hours is the default time to change the pad.)

7. Press the 8 (2) button to accept changes and exit.

8. The computer displays

CODE is displayed.

1650.

TECH MODE and changes to

CLEAR PASSWORDS on the left and

FILTER PAD TIME on the left and 2525 on

OFF. Continue below to enter the setup mode.

TEN seconds until a third chirp is

CLEAR PASS-

COM-

Fryer Setup Mode

Fryer Setup Mode is used to setup the time, date, date format, language, fryer

type, vat type, oil system type, and temperature scale in the fryer’s computer.

These settings are needed for the fryer to function properly and should only be

changed by a technician upon initial power up after installing a new computer or

after accessing from Level 1.

With the computer displaying

1. Enter Level 1 programming mode by pressing the TEMP and INFO buttons

simultaneously until

CODE.

2. Enter

The computer displays

Product selection .

3. Press the a button once to scroll to

1234.

LEVEL 1 is displayed. The computer displays

OFF:

ENTER

level 1 program for three seconds changing to

FRYER SETUP.

28

Page 30

LOV™ Generation II Technical Reference

yes

ENTER CODE

1234

Language

english

yes

temp format

yes

time format

12 hr

12 hr

24 hr

yes

enter time

hh:MM

yes

DATE FORMAT

interntl

yes

enter date

MM-DD-YY

DD-MM-YY

4. Press the 9 (1

The computer displays

5. Enter

1234.

The computer displays

yes) button.

ENTER CODE.

Language on the left and

english on the

right.

6. Use the _ and ` buttons to scroll through the language menu.

7. With the desired language selection displayed, press the 9 (1

The computer displays

temp format on the left and f on the right.

yes) button.

8. Use the _ and ` buttons to toggle between f and c temperature scales.

NOTE: F is used for Fahrenheit, C is used for Celsius.

9. With the desired selection displayed, press the 9 (1

computer displays

time format on the left and

yes) button. The

12 hr on the right.

10. Use the _ and ` buttons to toggle between

12 hr and

11. With the desired selection displayed, press the 9 (1

The computer displays

right in

hh:MM format. AMAM or PMPM is displayed if 12 hour system is chosen.

enter time on the left and current time on the

24 hr.

yes) button .

For example:

12 Hour Format – 7:30 AM is entered as 0730.

24 Hour Format – 2:30 is entered as 1430.

Change AMAM and PMPM – use the cd buttons.

12. Enter time in hours and minutes using the number buttons 0-9.

13. With the desired selection displayed, press the 9 (1

The computer displays

DATE FORMAT on the left and USUS on the right.

14. Use the _ and ` buttons to toggle between USUS and

15. With the desired selection displayed, press the 9 (1

yes) button.

interntl.

yes) button.

The computer displays

DD-MM-YY on the right changing to the current date. For example:

US Format – Dec. 5, 2008 is entered as 120508.

International Format – 5 Dec. 2008 is entered as 051208.

enter date on the left and

MM-DD-YY or

29

Page 31

LOV™ Generation II Technical Reference

yes

fryer type

Elec

elec

gas

yes

VAT

type

SPLIT

SPLIT

FULL

yes

OIl SYSTEM

JIB

JIB

BULK

JIB

BULK

yes

LANGUAGE

ENGLISH

SETUP COMPLETE

off

16. Enter the date using the number buttons 0-9.

17. With the desired selection displayed, press the 9 (1

The computer displays

18. Use the _ and ` buttons to toggle between

19. With the desired selection displayed, press the 9 (1

The computer displays

20. Use the _ and ` buttons to toggle between

21. With the desired selection displayed, press the 9 (1

The computer displays

22. Use the _ and ` buttons to toggle between

NOTE: A JIB system uses a disposable

system has large storage oil tanks that are connected to the fryer that

fi lls a reservoir.

fryer type on the left and

elec and

VAT

OIl SYSTEM on the left and

type on the left and

SPLIT and

JIB and

JIB (Jug in a Box). A

SPLIT on the right.

yes) button.

Elec on the right.

gas.

yes) button.

FULL.

yes) button.

JIB on the right.

BULK.

BULK

23. With the desired selection displayed, press the 9 (1

The computer displays

Use the cd buttons to scroll and edit any additional fi elds.

24. Press the 8 (2) button to exit.

The computer displays

LANGUAGE on the left and

SETUP COMPLETE changing to

yes) button.

ENGLISH on the right.

off.

30

Page 32

LOV™ Generation II Technical Reference

Filter Error

SERVICE

REQUIRED

SYSTEM ERROR FIXED? YES

NO

YES

SYSTEM ERROR FIXED? YES NO

Filter Error Flow Chart

NORMAL

OPERATION

RESUMES

MESSAGE

DISPLAYED

Call an Authorized

Repair Technician

SIXTH

CONSECUTIVE

FILTER ERROR

Change filter pad and

Fryer returns to

cook mode for 4

minutes or 15

minutes if pad

change expired.

ensure filter pan is

This chart follows the process of clearing a

following occur:

TECH

ENTERS

CODE

pulled out for a

minimum of 30

seconds.

Fryer returns to

cook mode for 15

minutes.

If the computer displays

REQUIRED, the fryer can be used in most

SERVICE

cases by answering NONO when the prompt

for

SYSTEM ERROR FIXED? YES

NO is displayed. The message repeats every

15 minutes until the issue is repaired and

error cleared by a technician. To clear the

error, enter 1111 after answering

SYSTEM ERROR FIXED? YES NO

YES when

is displayed.

Filter Error prompt. The prompt is displayed when any of the

1. a clogged fi lter pad,

2. a tripped or defective fi lter pump,

3. a leaky O-ring on the pick up tube,

4. a clogged pressure switch (gas fryer),

5. a failed drain valve/actuator, or

6. a failed return valve/actuator.

It is cleared by following the prompts.

31

Page 33

LOV™ Generation II Technical Reference

RTI-equipped Systems

Some stores may be equipped with RTI oil storage systems. If so, some of the settings, wiring, and

troubleshooting may differ from normal LOV™ fryer systems. (See next page for bulk oil wiring.)

The LOV™ fryer will ONLY operate with RTI systems that have the new RTI updated threepole fl oat switch. If the fl oat switch is the older two-pole switch, call RTI. These fl oat switches are

polarity specifi c and may short to ground and damage an MIB board.

Normal AC Voltage Measurements (MIB J6 8 pin connector with everything connected)

Pin 1 to Pin 2 - 24 VAC.

•

Pin 2 to Pin 8 - 24 VAC when waste tank is full, 0 VAC when it is not full.

•

Pin 2 to Pin 3 - 24 VAC when RTI fi ll pump is on, 0 VAC when it is off.

•

Troubleshooting

The valves and pump should be off while MIB is resetting. If any of the valves or pumps are on during reset then the MIB board is bad or wires are shorted.

If JIB valve is not opening, measure when JIB valve supposed to be open:

Voltage at MIB board from Pin 1 to Pin 2 should be 24 VAC; if not, check connections from

•

RTI 24VAC transformer and check transformer.

JIB solenoid is not opening:

Take these readings when the JIB valve is in the open position:

Reset the power; wait 60 seconds and see if the valve opens.

1.

Check voltage at ATO board on J8. Pin 9 to Pin 16 should be 24 VAC.

2.

RTI pump is not operating or JIB is not fi lling:

1. Voltage at MIB board from Pin 1 to Pin 2 should be 24 VAC; if not, check connections from

RTI 24VAC transformer and check transformer at RTI.

2. Voltage at MIB board from Pin 2 to Pin 3 should be 24 VAC; if not, check MIB board is bad

or wires to pump relay are shorted or both.

3. Voltage at Add pump relay should be 24 VAC; if not, check wiring from MIB board. Relay

located on top of RTI system.

Waste full signal: Pin 2 to Pin 8 should be 24 VAC when full, 0 VAC when not full; if no voltage

level change, then the connection from RTI switch or MIB board is bad.

32

Page 34

LOV™ Generation II Technical Reference

Bulk Oil LOV™ Wiring

DROP PLUG

BEHIND FR YER

GRAY 5-

CO NDUCT O R

123

RED

CA B L E

4

WHITE

BLACK

GREEN

5

12

4

3

3

4

12

5

TESTIN G BETW EEN PIN S 1 & 4 RTI

DROP PLUG SHOULD READ:

24VAC W HEN RTI TANK IS FULL

0 VAC WH EN R TI TANK IS EMPTY

BLAC K 24VAC IN FRO M R TI (HO T)

MIB J6

HIRS CHM ANN

REAR OF FRYER

CONNECTION ON

GREEN 24VAC OUT RTI PUMP

WHITE 24VAC IN FROM RTI(COM)

RED RTI DISPOSE TANK FULL

TESTING BETWEEN PINS 2 & 8 J6 MIB

SHOULD READ:

24VAC W HEN RTI TANK IS F ULL

0VACWHENRTITANKISNOTFULL

ADD

PUMP

LIN E

CONTROL

WASTE FULL

LINE

SENSE

33

Page 35

LOV™ Generation II Technical Reference

Oil Disposal and Fill with RTI-equipped Systems

Bulk oil systems have large oil storage tanks, typically located in the rear of the restaurant, that are

connected to the rear manifold on the fryer. Waste oil is pumped from the fryer, through the fi tting

located on the left, and into the disposal tanks. Fresh oil is pumped from the tanks, through the fi tting

located on the right, and into the fryer (as shown below).

™

LOV

used for fi lling the jug and topping off the frypot.

An orange momentary switch located adjacent to the JIB allows the operator to fi ll the JIB from the

bulk oil storage tank. To fi ll the JIB, press and hold the orange button until the JIB is full then release.

Using the fi lter menu scroll to DISPOSE and select to dispose using the RTI system. When prompt-

ed, open the dispose valve by pulling the handle forward. To close push the handle towards the rear

of the fryer until it stops. A key lock allows the store manager to control when oil is disposed.

fryers equipped for use with bulk oil systems have an onboard fresh oil jug. The same fi tting is

Warning: Do not add

HOT or USED oil to the

JIB.

The RTI JIB with fi tting.

Fresh Oil

Connection

Waste Oil

Connection

RTI Wiring

Connection

behind plate.

Fittings, LOV™ Fryer.

Orange JIB reset and momentary fi ll button.

Opening the RTI dispose valve.

34

Closing the RTI dispose

valve.

Page 36

LOV™ Generation II Technical Reference

Frymaster LOV™ Fryer and RTI Bulk Oil System Plumbing Schematic

Valves

Drain Ball

Fryer

Filter

Pump

Built-in Filter BoxBuilt-in Filter Box

Fry Pots

Valve

Bypass Check

Pump

Top-off

Return

Valves

Jug

Top-off

Jug Valve

New Oil PumpNew Oil Pump

Valve

Dispose Manual

New Oil

Tank

Tank

Waste Oil

35

Page 37

LOV™ Generation II Technical Reference

RTI LOV™ Test Quick Reference

DISPOSE TO WASTE, REFILL VAT FROM BULK:

1. Hold down “Filter” button until computer beeps twice.

2. Scroll down to “Dispose” using “Info” button then press “9” button.

3. “Dispose? Yes/No” is displayed.*

4. Press “9” to dispose of oil in pot.

5. “Draining” is displayed.

6. “Vat Empty? Yes” is displayed.

7. Press “9”.

8. “Cln Vat Complete? Yes” is displayed.

9. Press “9”.

10. “Open Dispose Valve” is displayed. Open dispose valve.

11. “Disposing” is displayed for fi ve minutes.

12. “Remove Pan” is displayed. Remove pan.

13. “Is Pan Empty? Yes No” is displayed.

14. Press “9” if fi lter pan is empty. Select “8” if pan still has oil in it.

15. “Close Dispose Valve” is displayed. Close dispose valve.

16. “Insert Pan” is displayed. Insert pan.

17. “Fill Vat From Bulk? Yes/No” is displayed.

18. Press “9”.

19. “Press and Hold Yes to Fill” alternating with “Yes” is displayed.

20. Hold down “9” to fi ll pot to desired level.

21. “Filling” is displayed while button is depressed.

22. “Continue Filling Yes/No” is displayed

23. Press “9” to continue fi lling or “8” to Exit program.

*NOTE: If the waste tank is full, the computer displays “RTI Tank Full.” Call RTI.

DISPOSE TO WASTE:

1. Hold down “Filter” button until computer beeps twice.

2. Scroll down to “dispose” using “Info” button and press “9” button.

3. “Dispose? Yes/No is displayed.

4. Press “9”.

5. “Draining” is displayed.

6. “Vat Empty? Yes is displayed.

7. Press “9”

8. “Cln Vat Complete? Yes” is displayed.

9. Press “9”.

10. “Open Dispose Valve” is displayed.

11. Open dispose valve by pulling completely forward to start disposal.

12. “Disposing” is displayed for four minutes.

13. “Remove Pan” is displayed.

14. Slide the fi lter pan slightly out of the fryer.

15. “Is Pan Empty? Yes/No” is displayed.

16. Press “9” if the fi lter pan is empty. Select “8” if pan still has oil in it.

17. “Close Dispose Valve” is displayed.

18. Close the dispose valve ensuring the handle is pushed completely towards the fryer.

19. “Insert Pan” is displayed.

20. “Fill Vat From Bulk? Yes/No” is displayed.

21. Press “8” if you wish to leave pot empty and exit.

36

Page 38

LOV™ Generation II Technical Reference

FILTER NOW? YES/NO

CONFIRM YES/NO

SKIM VAT

FILTER NOW? YES/NO

CONFIRM YES/NO

SKIM VAT

FILL VAT FROM BULK:

1. Hold down “fi lter” button until computer beeps twice.

2. Scroll down to “Fill Vat from Bulk” using the Info button.

3. Press “9”.

4. “Fill Vat from Bulk? Yes/No” is displayed.

5. Press “9”.

6. “Press and Hold Yes to Fill / Yes” is displayed.

7. Press and hold down “9” to fi ll pot to desired level.

8. “Filling” is displayed during fi ll.

9. Release button to stop fi lling.

10. “Continue Filling? Yes/No” is displayed.

11. Press “8” to exit.

FILL JUG FROM BULK:*

1. When “Orange” indicator light is on, the top-off jug is empty.

2. To refi ll jug press and hold the orange reset button above the jug until the jug is full.

3. Release the button to stop fi lling.

*NOTE: The jug may not fi ll if any of the following are in progress:

If

FILTER NOW? YES/NO,

CONFIRM YES/NO, or

SKIM VAT is displayed, the fi ll jug

button is disabled until either a fi lter is complete or until no is chosen.

The system also checks these conditions. The following must be met before jug fi ll is allowed:

Solenoid closed –

• Orange fi ll button pressed longer than 3 seconds.

• Waste valve closed.

•

FILTER NOW? YES/NO,

CONFIRM YES/NO, or

SKIM VAT cannot be

displayed.

• System power cycle (all boards – computers, MIB, AIF and ATO) after changing setup from

JIB to Bulk (use momentary reset).

• No fi ltration or other fi lter menu selection can be in process.

Other factors that may not allow fi ll jug from bulk –

• Defective solenoid.

• Defective switch.

• RTI pump issue.

• RTI relay stuck.

If using two fryer systems that are both attached to the RTI system, they may not be able to fi ll

both units at the same time if they have an RTI unit with a single head. Some RTI units have dual

heads which can fi ll simultaneously.

37

Page 39

LOV™ Generation II Technical Reference

Board and Computer Replacement

Readdress All Boards

It is necessary to readdress any replaced boards by resetting all power to the

entire fryer battery system.

The control power reset switch is a momentary rocker switch located behind

the control box above the JIB that resets all power to all the computers and

boards in the fryer. Press and hold the switch for at least 10 seconds when

resetting the control power to ensure power has suffi ciently drained from

boards. After releasing the momentary control power reset switch, wait at