Page 1

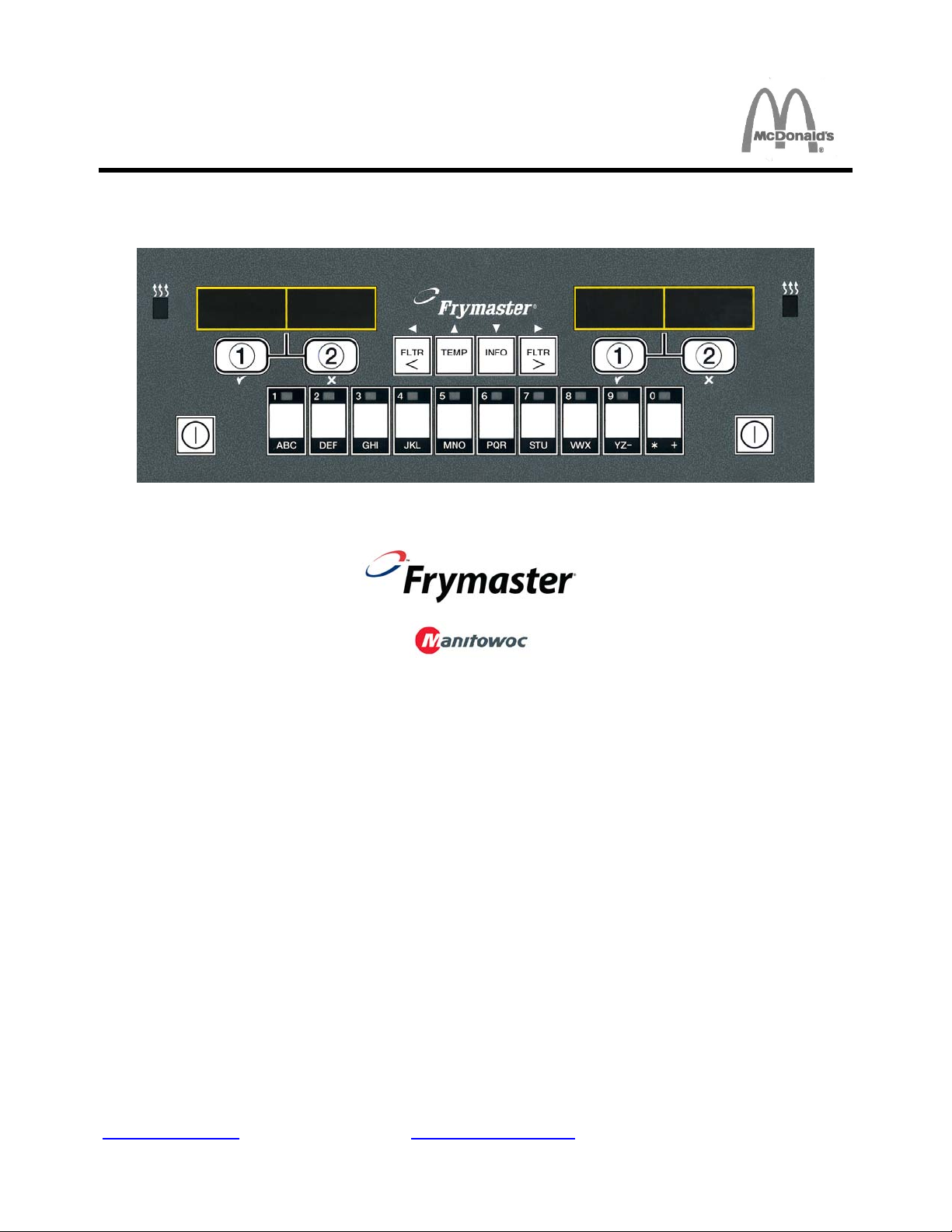

FRYMASTER MANUAL LOV™ M3000 CONTROLLER

This equipment chapter is to be

installed in the Fryer Section of the

Equipment Manual.

OPERATION MANUAL

INSTALLATION INSTRUCTIONS ....................................................................................... Page 1-1

MANUAL LOV™ M3000 OPERATING INSTRUCTIONS ..................................................... Page 2-1

OPERATOR TROUBLESHOOTING ..................................................................................... Page 3-1

PRINTED IN THE UNITED STATES SERVICE HOTLINE 1-800-24-FRYER JULY 2012

www.frymaster.com Email: service@frymaster.com

SHREVEPORT, LOUISIANA 71106

Frymaster L.L.C., 8700 Line Avenue, Shreveport, LA 71106

PHONE 318-865-1711 FAX 318-219-7135

MANUFACTURED

BY

8700 Line Ave.

PHONE: 1-318-865-1711

TOLL FREE: 1-800-551-8633

1-800-24 FRYER

FAX: 1-318-219-7135

TABLE OF CONTENTS

*8196964*

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS

MANITOWOC FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR

RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS

FACTORY AUTHORIZED SERVICERS, AND/OR THE PART BEING USED IS MODIFIED FROM

ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER

DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR

EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN

WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART

RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster Dean Factory Authorized Servicer (FAS) or other qualified

professional should perform installation, maintenance, and repairs. Installation,

maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local

codes of the country and/or region in which the appliance is installed.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning

and technical procedures and may not conform to onsite management operational

procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: 1) This device may not cause harmful interference, and 2) This device must

accept any interference received, including interference that may cause undesired

operation. While this device is a verified Class A device, it has been shown to meet the

Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as

set out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de

classe A et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations

du Canada.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating,

and service instructions thoroughly before installing or servicing this equipment.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are

for an RTI system. These instructions may not be applicable to other bulk oil systems.

Page 3

MANUAL LOV™ M3000 CONTROLLER

CHAPTER 1: INSTALLATION INSTRUCTIONS

1.1 Installation

Before attempting to operate your unit, read the instructions in this manual thoroughly before

installation. Installation of the Manual LOV™ (Low Oil Volume) M3000 controller requires some

extra steps prior to use. This controller uses network cables for communication between controllers.

The controllers also require locator connectors which identify the position of the controllers in the

bank of fryers. Finally the network must be terminated on the far left controller and the far right

controller of the network.

1.2 Controller Information for the M3000 Controllers

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been

shown to meet the Class B limits. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

the equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at their own expense.

The user is cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission

helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available

from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.3 Shipping Damage Claim Procedure

What to do if your equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before

leaving the factory. The freight company assumes full responsibility for safe delivery upon

acceptance of the equipment.

1. File Claim for Damages Immediately - regardless of extent of damage.

2. Inspect For and Record All Visible Loss or Damage, and ensure that this information is noted

on the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed Loss or Damage- If damage is unnoticed until equipment is unpacked, notify the

freight company or carrier immediately upon discovery and file a concealed damage claim.

1-1

Page 4

This must be submitted within 15 days of date of delivery. Be sure to retain container for

inspection.

Frymaster

DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1.4 Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster

Authorized Servicer (FAS). In order to assist you quickly, the Frymaster Authorized Servicer (FAS)

or Service Department representative requires certain information about your equipment. Most of

this information is printed on a data plate affixed to the inside of the fryer door. Part numbers are

found in the Service and Parts Manual. Parts orders may be placed directly with your local FAS or

distributor. A list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster

website at www.frymaster.com

. If you do not have access to this list, contact the Frymaster Service

Department at 1-800-551-8633 or 1-318-865-1711 or by email at service@frymaster.com.

The following information will be needed in order to assist you efficiently:

Model Number _________________________

Serial Number __________________________

Voltage _______________________________

Gas Type _____________________________

Nature of the Problem ____________________

_____________________________________

_____________________________________

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-2

Page 5

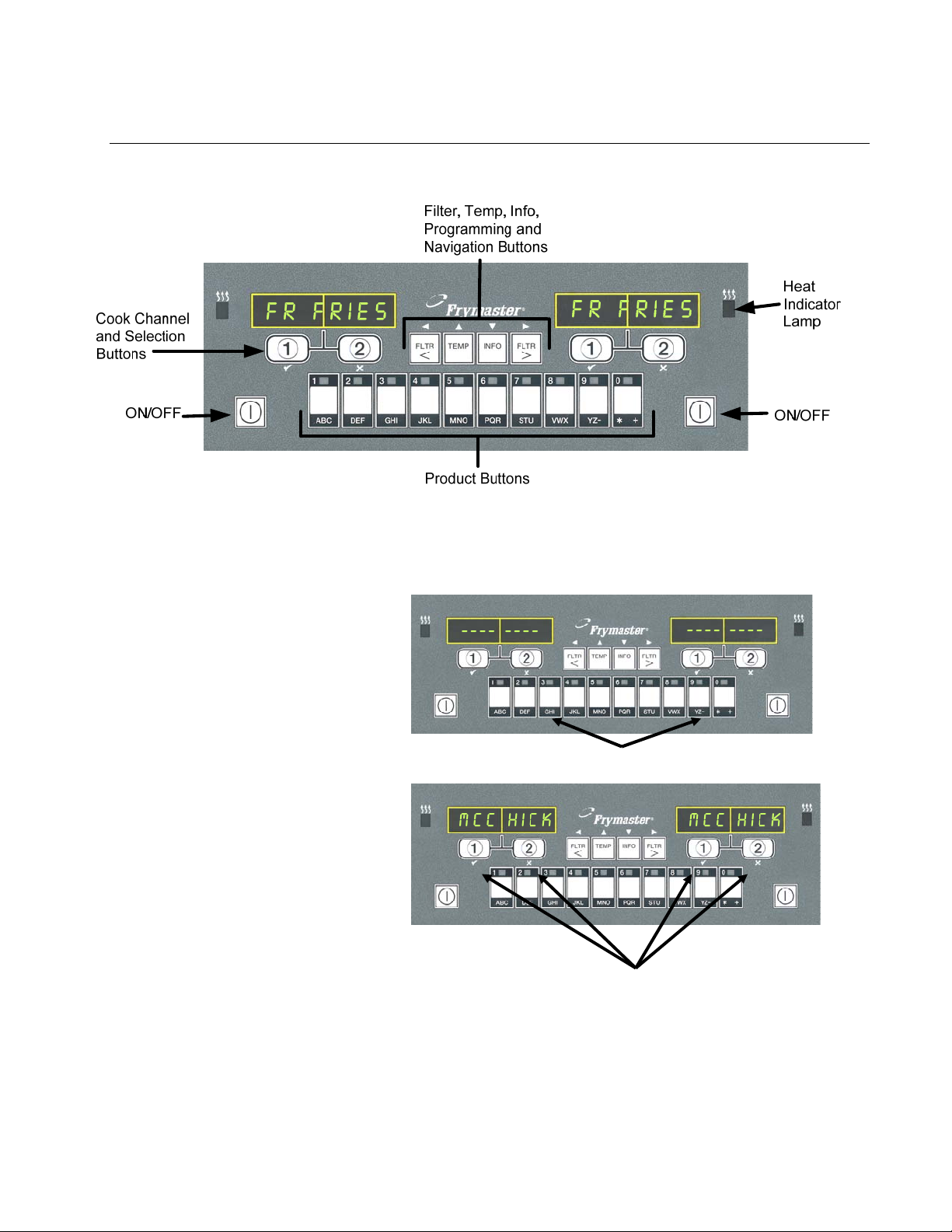

CHAPTER 2: MANUAL LOV™ M3000 CONTROLLER

OPERATION INSTRUCTIONS

2.1 M3000 General Information

Welcome to the Manual LOV™ M3000, a controller that retains the one-button ease of the M2000

and 100B and the utility of 40-product menu capability. The controller is easy to use. One button

push starts a cook cycle for an item cooked in a dedicated vat. The same flexible controller on a

multi-product vat requires only two

button pushes to launch a cook

cycle. Just choose a menu item on a

product button and press, and then

press a cook channel button under

the display showing the desired

item. The controller can move

seamlessly from McNuggets to

Crispy Chicken to any added menu

item.

Pressing product buttons 3 or 9 displays McChick.

In a typical store setting, the

M3000s on the three-vat fry station

display FR FRIES (shown above)

and will launch a cook cycle with

one push of a cook channel button.

On the chicken/filet station, the

LED display shows dashed lines.

To launch a cook cycle, press a

product button and then press the

Pressing either cook cycle button under the McChick

displays launches a cook cycle.

cook channel button that

corresponds with the location of the

dropped basket. By pressing the product button for McChicken, McChick will appear in the display.

Just press the cook channel button corresponding to the location of the appropriate dropped basket.

The M3000 will operate with electric and gas fryers, both full- and split-vat.

2-1

Page 6

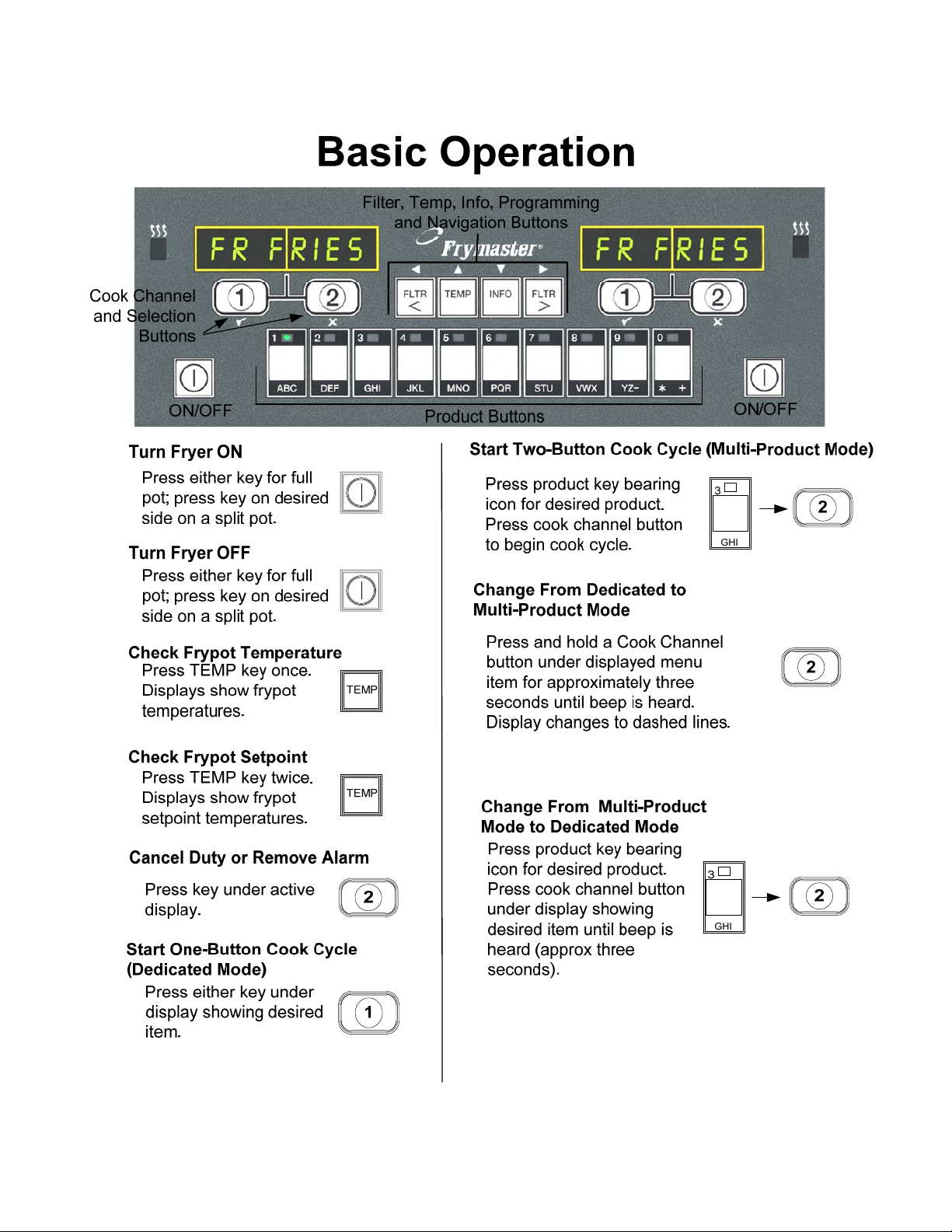

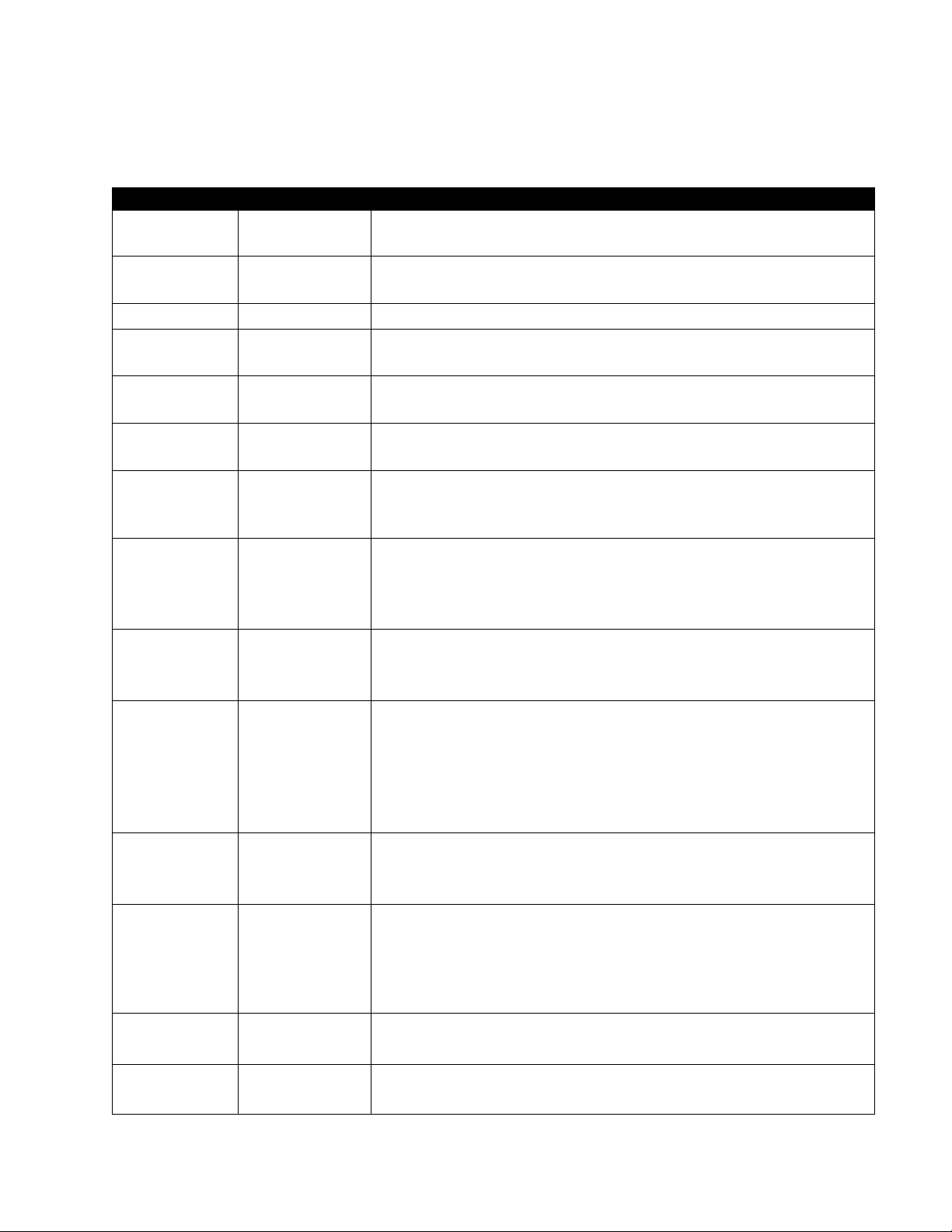

2.2 Basic Operation

2-2

Page 7

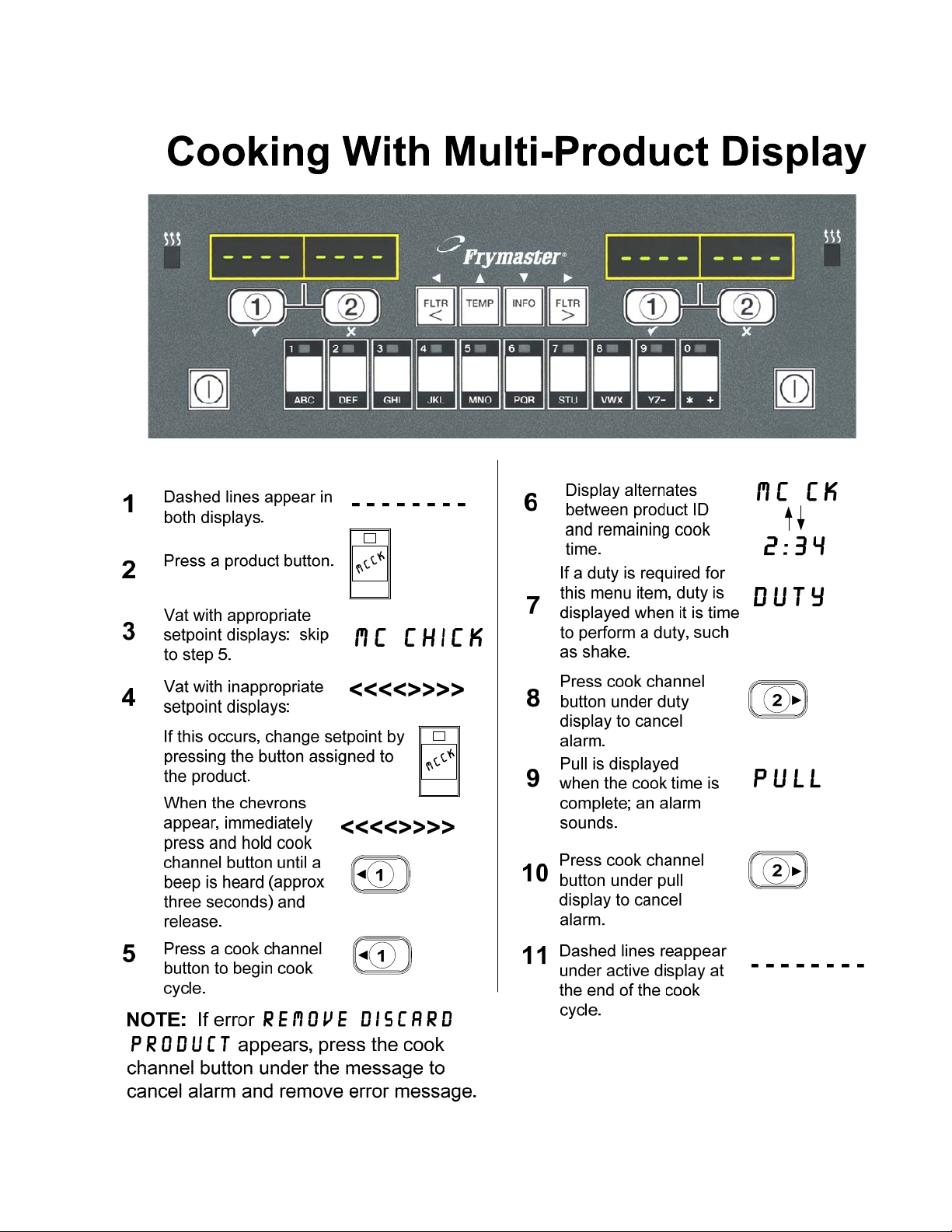

2.3 Cooking with Multi-Product Display

2-3

Page 8

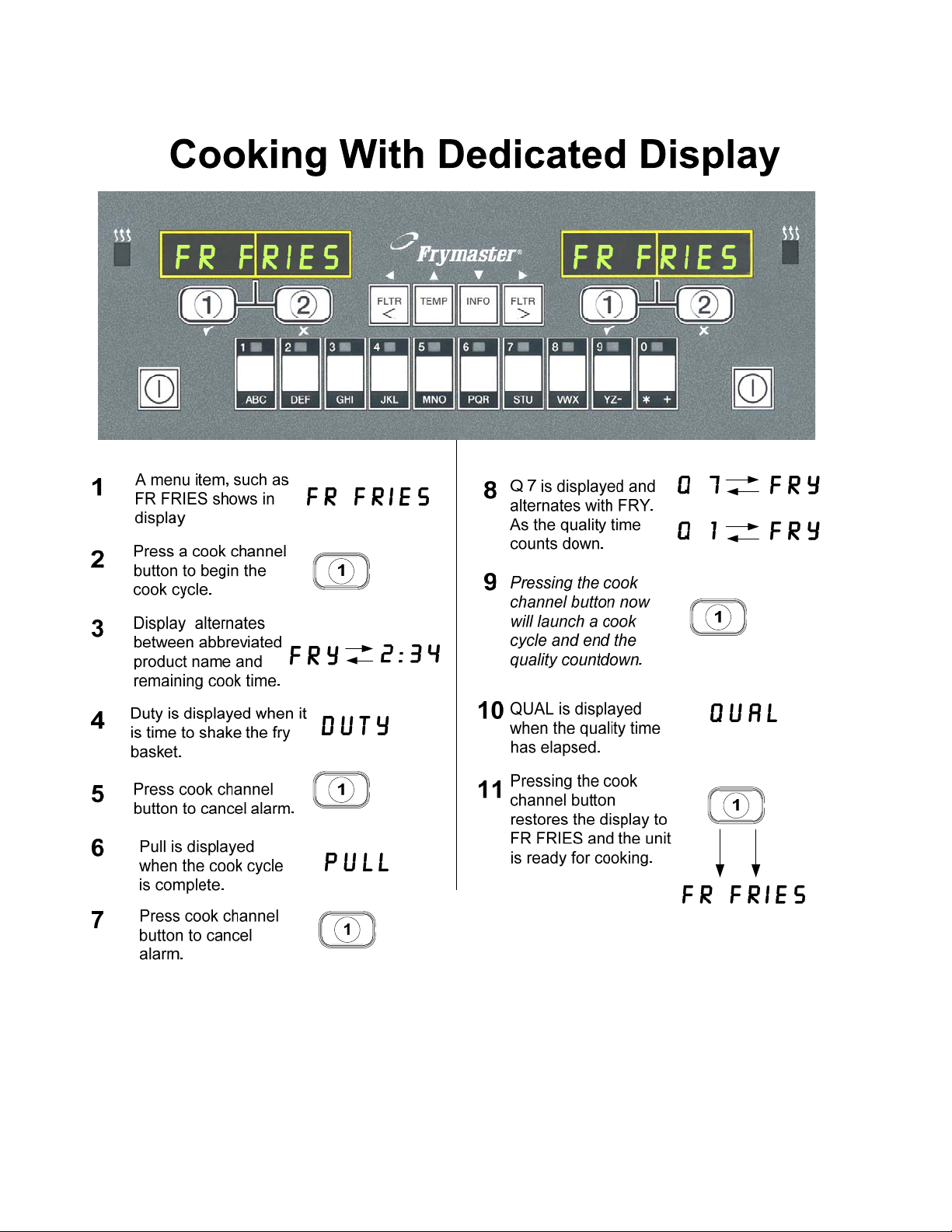

2.4 Cooking with Dedicated Display

2-4

Page 9

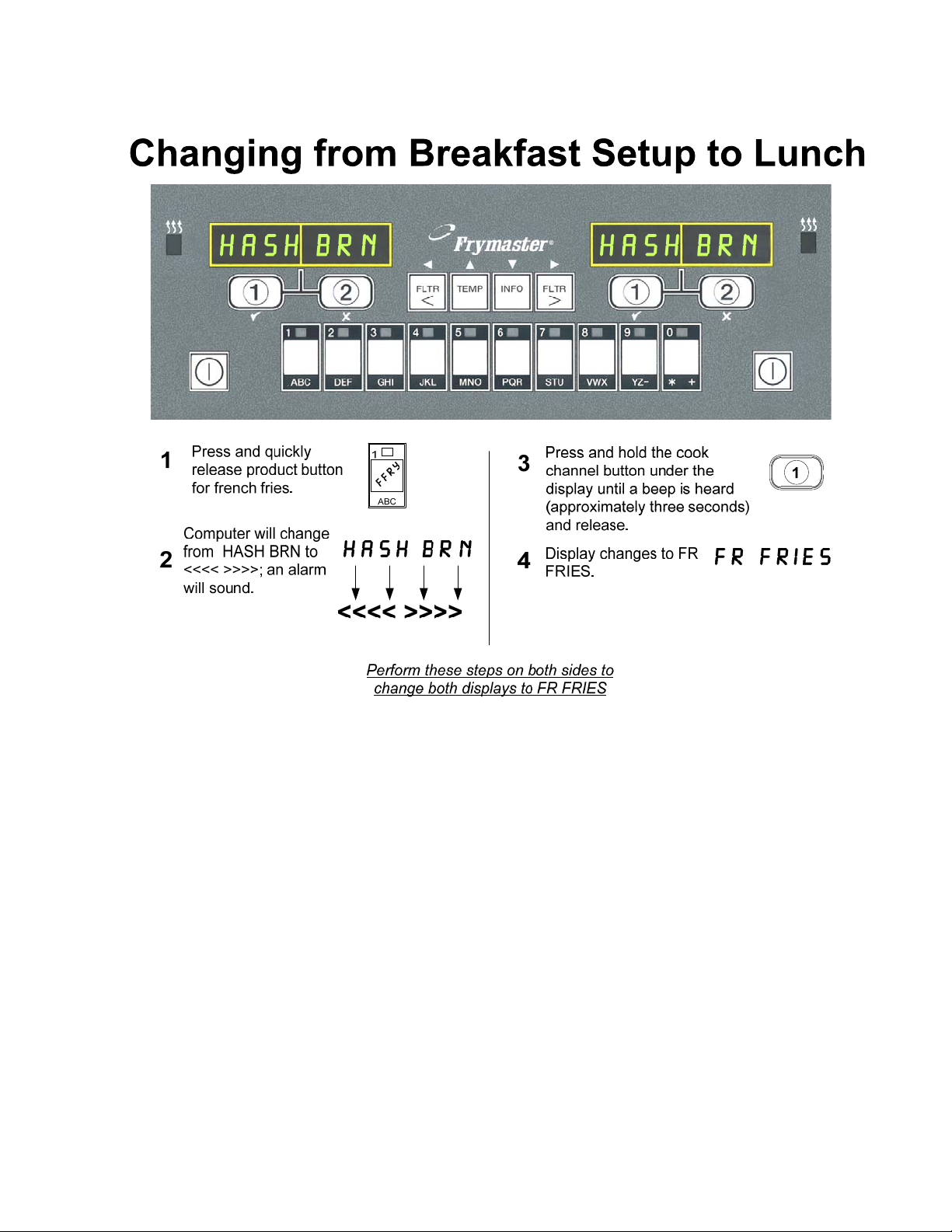

2.5 Changing from Breakfast Setup to Lunch

2-5

Page 10

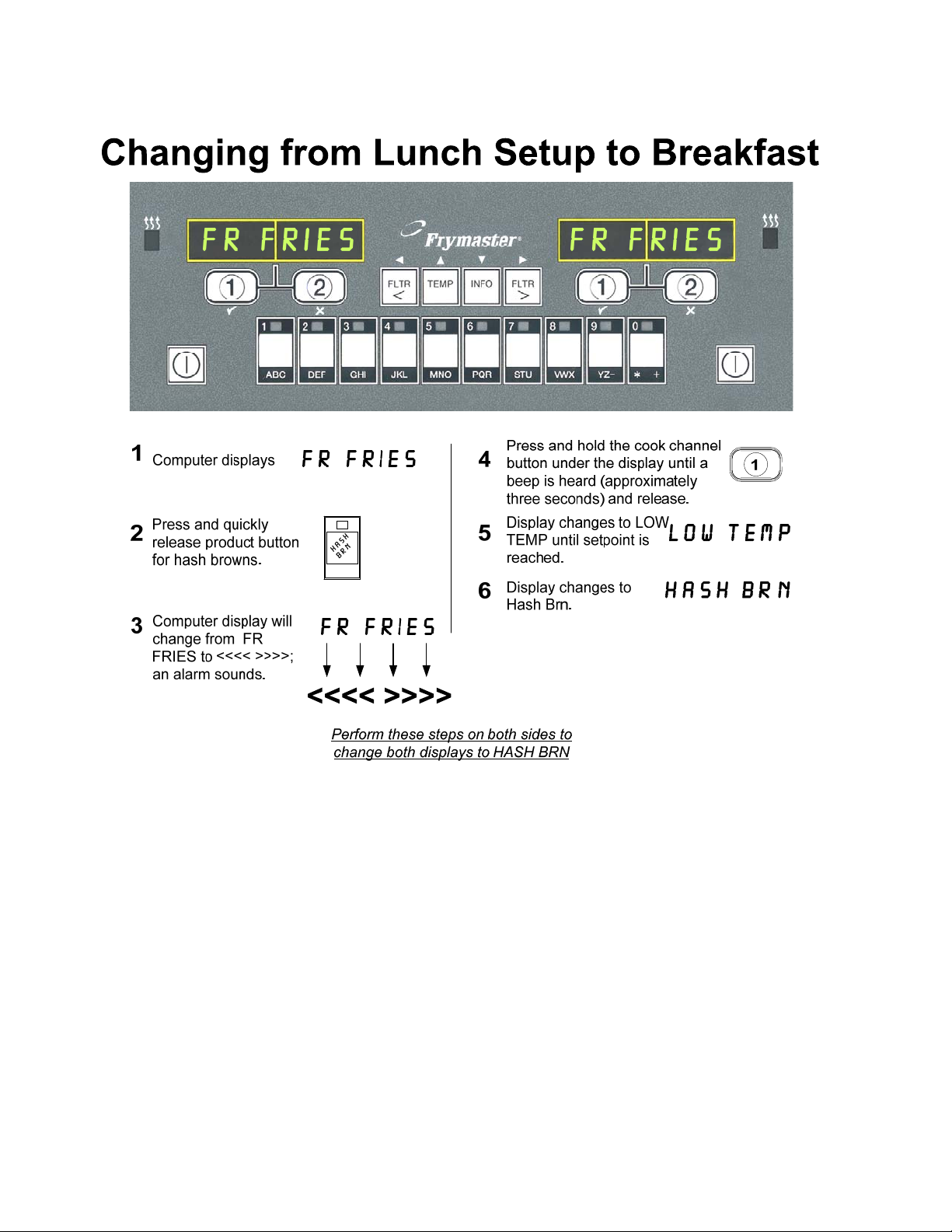

2.6 Changing from Lunch Setup to Breakfast

2-6

Page 11

2.7 M3000 Button Description and Functions

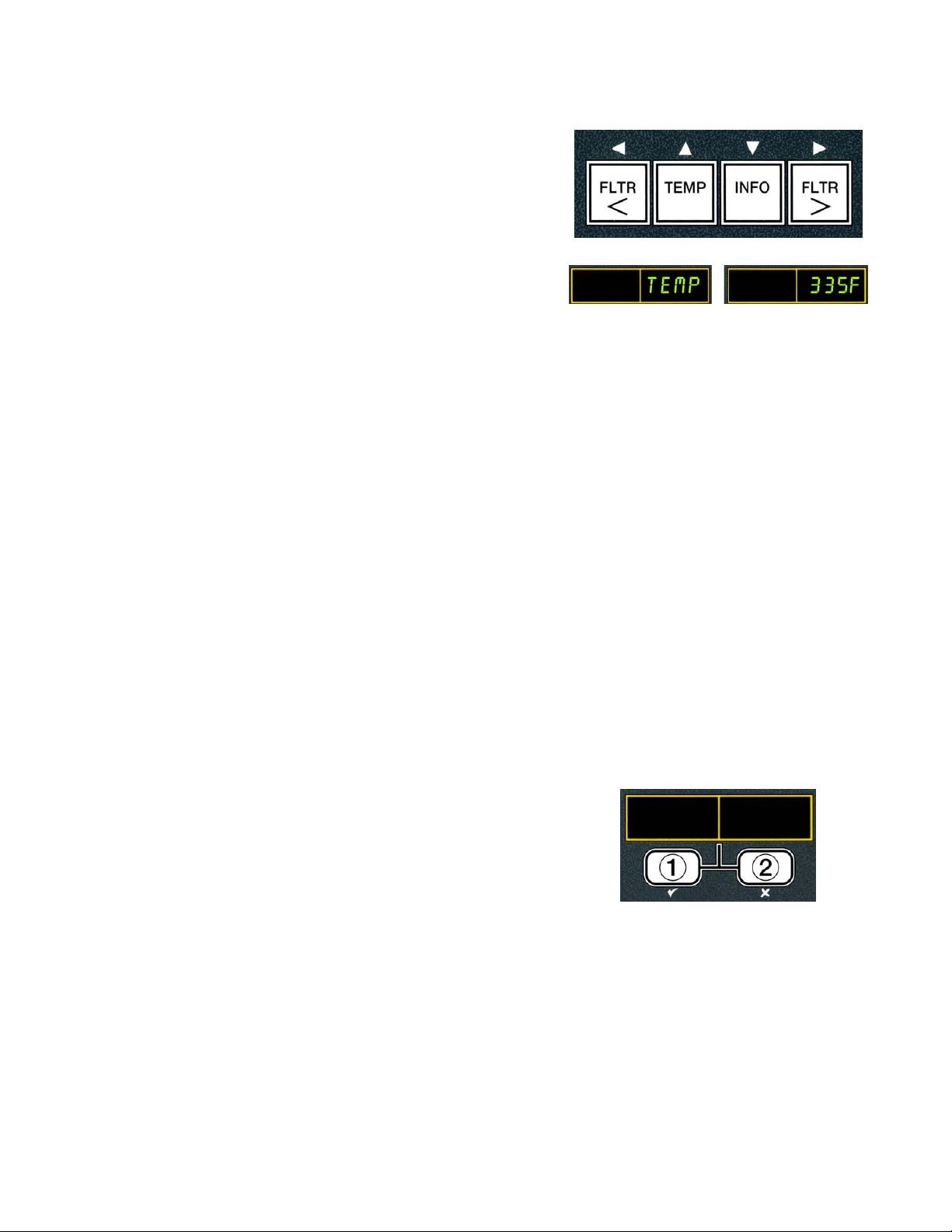

2.7.1 Navigation Buttons

The menu on the M3000 uses 34and tu buttons to

navigate the various menus and submenus.

When programming, the left screen shows a menu or

submenu item. The right screen is for data entry. Data is

entered with alpha-numeric characters, scrolling through

lists or by toggling between choices.

During programming if a button is not pushed within one minute, the controller returns to operation

mode.

Left Display Right Display

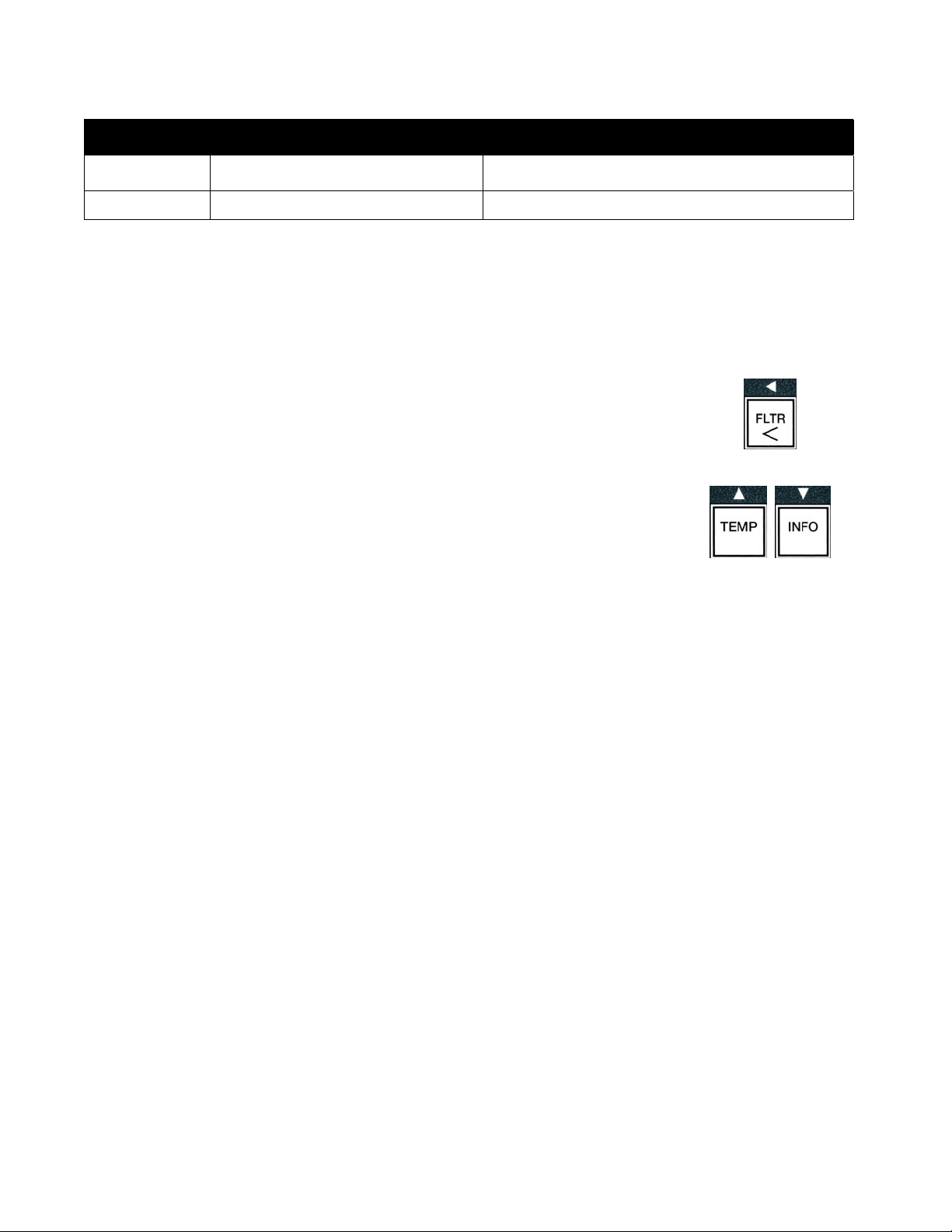

2.7.2 Filter, Temperature and Info Buttons

The < FLTR and FLTR > buttons (see Figure 1) are used to filter the left and right vats of a split

vat or a full vat fryer on demand. The FLTR buttons, if pressed once displays the number of cook

cycles remaining until a filtration prompt. When the FLTR button is pressed twice, the date and

time of the last filter is displayed. The TEMP button, if pressed once while the fryer is on,

displays current vat temperature on both sides. If the TEMP button is pressed twice while the fryer

is on, it shows the setpoint temperatures of the vats. If the fryer is off, the display shows the current

versions of software. The INFO button (see Figure 1), if pressed once when the fryer is on, shows

the recovery time for each vat from the last test. Recovery is the time required for the fryer to raise

the temperature of the oil 50°F (28°C) between 250°F (121°C) and 300°F (149°C). Maximum

recovery time should not exceed 1:40 for electric or 2:25 for gas. If the INFO button is pressed and

held for three seconds it shows information such as usage, filter statistics and last cook cycles (see

page 2-31 for more details on the INFO button).

2.7.3 Cook Channel and Selection Buttons

buttons are dual-function buttons shared with

The

the number 1 and 2 buttons. They are located directly

below the LED displays. Use these buttons to select or

cancel functions. The button is used to back out of and

exit submenus.

2-7

Page 12

2.8 Manual LOV™ M3000 Menu Summary Tree

Reflected below are the major programming sections in the M3000 and the order in which submenu headings will be

found under the sections in the controller operation chapter.

Adding New Product Menu Items (Product Selection) See section 2.10.2

Storing Product Menu Items in Product Buttons See section 2.10.3

Draining, Refilling, and Disposing of Oil See section 2.10.4

Filter Menu

[Press and hold ◄ FLTR or FLTR ►]

Programming

………………………………………………………………………………………………………….. 2.11

Quick Filter

Maint Filter

Dispose

Drain to Pan

Fill Vat from Drain Pan

Level 1 Program

[Press and hold TEMP and INFO buttons, 2 beeps, displays Level 1, enter 1234]

Product Selection

…….……………….....………………………………………………………….. 2.12

..…….....………………………………………………………….. 2.10.2

Name

Cook Time

Temp

Cook ID

Duty Time 1

Duty Time 2

Qual Tmr

AIF Disable

Assign Btn

AIF Clock (Suppress Filter Prompt)

…………………………………… 2.12.1

Disabled

Enabled

Deep Clean Mode

High-Limit Test

Fryer Setup

……..……………………...…………………………………….. 2.12.2

…………….…………………….…………………………………….. 2.12.3

…………………….……………………………………………………………….. 2.9

Level 2 Program (Manager Level)

[Press and hold TEMP and INFO buttons, 3 beeps, displays Level 2, enter 1234]

Prod Comp

E-Log

Password Setup

Sensitivity for product

Log of last 10 error codes

Change passwords

Setup [enter 1234]

Usage [enter 4321]

Level 1 [enter 1234]

Level 2 [enter 1234]

Alert Tone Volume and Tone

Volume 1-9

Tone 1-3

Top Off After

Filter After

Filter Time

Info Mode

………………...………………………...………………………………………..……………………….. 2.14

[Press and hold INFO for 3 seconds, displays Info Mode]

Sets number of cooks before top off prompt

Sets number of cooks before filter prompt

Sets amount of time between filter cycles

Full/Split Vat Configuration

Filter Stats

Review Usage

Last Load

..……………….……………………………………………………………….. 2.14.1

………….……………………………………………………………….. 2.14.2

………………….……………………………………………………………….. 2.14.3

……………………………………………….. 2.13

…………………………………….. 2.13.1

….……...…………………………….. 2.13.2

..……………………………… 2.13.3

...………………………………………….. 2.13.4

…….. 2.13.5

………….. 2.13.6

………….. 2.13.7

2-8

Page 13

2.9 Fryer Setup Mode Programming

Ensure the fryer is OFF and follow the steps below to navigate the options. The setup mode sets the

time, date, date format, language, fryer type, vat type, oil system type and the temperature scale.

These settings should only be changed by a technician.

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons simultaneously for THREE

seconds until LEVEL 1 is displayed.

ENTER

CODE

Blank

LEVEL 1 PROGRAM

Product

Selection

FRYER

SETUP

ENTER

CODE

Blank

Blank

Blank

Enter 1234.

None required.

Press the t button once to scroll to FRYER SETUP.

Press the (1) button.

Enter 1234.

Use the 3and 4buttons to scroll through the language menu.

LANGUAGE ENGLISH

With the desired language selection displayed, press the u

button.

Press the 3and 4buttons to toggle between F and C

TEMP

Format

F

temperature scales.

NOTE: F is used for Fahrenheit, C is used for Celsius.

With the desired format displayed, press the u button.

TIME

FORMAT

12 HR

Press the 3and 4 buttons to toggle between 12hr and

24hR.

With the desired format displayed, press the u button.

ENTER

TIME

hh:MM Enter time in hours and minutes using the number buttons 0-9.

Example:

7:30 AM is entered 0730 if using the 12 hour format. 2:30 is

entered 1430 if using 24 hour format. To change AM and PM

use the tu buttons.

With the correct time displayed, press the u button.

DATE

FORMAT

US

Press the 3and 4 buttons to toggle between US and

interntl.

With the desired format displayed, press the u button.

enter

date

MM-DD-YY or

DD-MM-YY

Enter the date using the number buttons 0-9.

Example:

US Format – Dec. 5, 2010 is entered as 120510.

International Format – 5 Dec. 2010 is entered as 051210

With the correct date displayed, press the u button.

fryer

type

VAT type SPLIT

Elec

Press the 3and 4buttons to toggle between elec and gas.

With the fryer type displayed, press the u button.

Press the 3and 4buttons to toggle between split and

full. With the vat type displayed, press the u button.

2-9

Page 14

Fryer Setup Mode Programming cont.

Left Display Right Display Action

OIl

NONE

Press the u button.

SYSTEM

DISPOSE

NONE

Press the u button.

SYSTEM

LANGUAGE ENGLISH

Press the tu buttons to scroll and edit any additional fields.

Press the (2) button to exit.

setup complete

OFF OFF

None required.

None required.

2.10 M3000 Common Tasks

Covered in this section are common tasks used in stores:

1. Escaping out of a menu or sub-menu.

2. Adding new product items.

3. Storing menu items in product buttons.

4. Draining, disposing and refilling the vats.

2.10.1 Escape Menu Items

To escape or back out of MENUS and SUB-MENUS, press the (2)

button.

2.10.2 Adding New Product Items to the Menu (PRODUCT SELECTION)

This function is used to add additional products to the controller menu. To add a new product to the

menu turn the fryer off and follow the steps below:

Left Display Right Display Action

OFF OFF

ENTER

CODE

Blank

LEVEL 1 PROGRAM

Product

Selection

SELECT

PRODUCT

Blank

FR FRIES

Press the TEMP and INFO buttons simultaneously until

LEVEL 1 is displayed.

Enter 1234.

None required.

Press the (1) button.

Press the tu buttons to advance through menu items until the

menu item to be modified or a numbered spot is displayed (ex.

PROD 13).

With the desired product displayed, press the (1) button.

MODIFY?

YES NO

Blank Press the (1) button.

2-10

Page 15

Adding New Product Items to the Menu (PRODUCT SELECTION) cont.

Left Display Right Display Action

Use the number keys to enter the first letter of the new product.

Each key has three letters. Press until derived character is

displayed.

The full product name is limited to eight characters including

spaces (ex. FR FRIES).

Press the 4 button to advance the cursor to the next display

Name PROD 13

cook time :00

TEMP 32F

cook ID P 13

duty

time1

qual tmr :00

AIF

Disable

:00

NO

space. Use the #0 key to insert a space. The 3button can be

used to move the cursor back.

For example, to enter “WINGS”, press the #8 key two times

until W appears in the display. Then use the 4 button to

advance the cursor to the next display space. Press the #3 key

until I appears. Continue on until WINGS is spelled out on the

display.

With the desired name displayed, press the u (INFO) button.

Use the number keys to enter the product cook time in minutes

and seconds (ex. 3:10 as 310).

With the desired cook time displayed, press the u (INFO)

button.

Use the number keys to enter the cook temperature for the

product (ex. 335° as 335).With the cook temperature entered,

press the u (INFO) button.

Use the instructions above for entering a product name to enter

a four-letter name for the menu item. This is the shortened

name that alternates with the cook time during a cook cycle.

With the cook ID entered, press the u (INFO) button.

Use the number keys to enter the time in minutes and seconds

for the first duty (shake time) to be preformed (ex. shake the

product after 30 seconds is entered as 30).

With the shake time entered, press the u (INFO) button to

scroll to duty time 2. If a product calls for a second duty to be

preformed, it can be entered here. Use the instructions above to

enter duty time two, otherwise press the u (INFO) button

Use the number keys to enter the quality timer time in minutes

and seconds for the product hold time (ex. 7:00 minutes as 700).

This is used to set the hold time before the food is to be

discarded.

With the QUAL TMR (hold time) entered, press the u

(INFO) button.

Use the 3and4 buttons to toggle between YES and NO.

This feature, if set to yes, disables the filter prompts for the

programmed product. This is used to prevent co-mingling of

product-specific oils.

With the filter option displayed, press the u (INFO) button.

2-11

Page 16

Adding New Product Items to the Menu (PRODUCT SELECTION) cont.

Left Display Right Display Action

ASSIGN

BTN

Product name

With the chosen product displayed on the right and ASSIGN

BTN on the left, press a button between 1-0 to assign the

product. The LED in the chosen product button will illuminate.

To unassign a product from a button, press the button assigned

to that product. The LED no longer illuminates.

With the assigned button illuminated, press the u (INFO)

button.

If additional programming, to add other products, is desired

Name

Product name

press the (2) button once and then the u button and return to

MODIFY? YES NO step above. If no further programming is

desired, press the (2) button three (3) times.

OFF OFF None required.

2.10.3 Storing Menu Items in Product Buttons

This function is used to store individual menu items to product buttons for one or two button

cooking. To store menu items to a specific button follow the steps below:

Left Display Right Display Action

OFF OFF

ENTER

CODE

Blank

LEVEL 1 PROGRAM

Product

Selection

SELECT

PRODUCT

MODIFY?

YES NO

Blank

FR FRIES

Blank

Name PROD 13

ASSIGN

Product name

BTN

Name

Product name

OFF OFF

Press the TEMP and INFO buttons simultaneously until

LEVEL 1 is displayed.

Enter 1234.

None required.

Press the (1) button.

Press the tu buttons to advance through menu items until the

menu item to be modified or a numbered spot is displayed (ex.

PROD 13). With the desired product displayed, press the

(1) button.

Press the (1) button.

Press the t button to scroll to the ASSIGN BTN option used

to assign a menu item to a specific product button.

With the chosen product displayed on the right and ASSIGN

BTN on the left, press a button between 1-0 to assign the

product. The LED in the chosen product button will illuminate.

To unassign a product from a button, press the button assigned to

that product. The LED no longer illuminates. With the assigned

button illuminated, press the u (INFO) button.

If additional programming, to add other products, is desired press

the (2) button once and then the u button and return to

MODIFY? YES NO step above. If no further programming is

desired, press the (2) button three (3) times.

None required.

2-12

Page 17

2.10.4 Draining and Refilling Vats, and Disposing of Oil

When cooking oil is exhausted, drain the oil into an appropriate container for transport to the

disposal container. Frymaster recommends a McDonald’s Shortening Disposal Unit (MSDU). Do

not drain deep clean (boil-out) solution into an MSDU. NOTE: If using an MSDU built

before January 2004 the filter pan cover must be removed to allow the unit to be positioned beneath

the drain. To remove the cover, lift up on the front edge slightly and slip the oil guard up and pull it

straight out of the cabinet. Refer to the documentation furnished with your disposal unit for specific

operating instructions. If a shortening disposal unit is not available, allow the oil to cool to 100°F

(38°C), then drain the oil into a METAL container.

2.10.4.1 Oil Disposal

This option is used to dispose of old oil into either an MSDU or a METAL pot. To dispose of oil

turn the fryer off and follow the steps below:

Remove the filter pan and position the MSDU or METAL container under the fryer to drain the oil.

Left Display Right Display Action

OFF OFF

FILTER MENU

Blank

Blank

Blank

MAINT FILTER

DISPOSE

DISPOSE? alternating with

YES NO

NEVER drain deep clean (boil-out) solution into an MSDU. Deep Clean (boil-out)

solution can cause damage to an MSDU.

When draining oil into a disposal unit, do not fill above the maximum fill line

located on the container.

Allow oil to cool to 100°F (38°C) before draining into an appropriate METAL

container for disposal.

DISPOSAL UNIT IN

Blank

PLACE alternating with

CONFIRM

Blank

Blank

Blank

OPEN DRAIN VALVE

DISPOSING

Vat empty? confirm

Press and hold the FLTR button of the

corresponding vat until FILTER

MENU/MAINT FILTER is displayed.

Press the u (INFO) button to scroll to

dispose.

Press the (1) button.

Press the (1 yes) button to continue.

WARNING

DANGER

DANGER

Remove the filter pan and insert the disposal

unit or a METAL container. Press the (1)

button.

Open the drain valve.

None required.

Press the (1) button once the vat is empty.

2-13

Page 18

Oil Disposal cont.

Left Display Right Display Action

Blank

OFF

CLOSE DRAIN VALVE

OFF None required.

Close the drain valve.

2.11 Filter Menu

The filter menu selections are used for filtering, draining, filling and disposing.

2.11.1 Accessing the Filter Menu

1. With the controller on, press and hold the filter button for the selected vat for

three seconds.

The controller displays filter menu for three seconds, changing to QUICK Filter.

2. Press the t and u buttons to scroll between:

a. QUICK filter See pg. 2-15

b. maint filter (Manual or Maintenance Daily Filter) See pg. 2-16

c. dispose See pg. 2-13

d. drain to pan See pg. 2-18

e. fill VAT from DRAIN pan See pg. 2-18

2-14

Page 19

2.11.2 Quick Filter

Prepare the filter for use using the instructions that accompanied the fryer.

Quick Filtration is a feature that, after a number of cook cycles, will automatically prompt to filter a

frypot. Alternatively pressing and holding the filter button with the fryer on and at setpoint will also

prompt a demand filtration.

WARNING

Do not drain more than one frypot at a time into the built-in filtration unit to avoid overflow and

spillage of hot oil that may cause severe burns, slipping and falling.

The filter pad or paper MUST be replaced daily.

DANGER

Left Display Right Display Action

Blank

FILTER NOW? alternating

with

YES NO

After a preset number of cook cycles or time

the controller displays FIltEr now?

alternating with YES NO. Press the (1

yes) button.

Blank

SKIM VAT alternating with

Confirm

Blank

Blank

OPEN DRAIN VALVE

DRAINING

OPEN RETURN VALVE

Blank

Blank

Blank

Blank

alternating with CONFIRM

WASHING

CLOSE DRAIN VALVE

FILLING

CLOSE RETURN VALVE

Blank

when vat full

alternating with CONFIRM

OFF OFF

Skim the vat and press the (1) button to

start filtration

Open the drain valve.

None required.

Open the return valve and press the (1)

button.

None required.

Close the drain valve.

None required.

Close the return valve when the vat is full and

bubbles appear in the oil and press the (1)

button.

2-15

Page 20

2.11.3 Filter Busy

If FILTER BUSY is displayed, another controller has not completed a process, or is waiting on

another vat to be filtered. Wait 15 minutes to see if problem is corre cted. If not, call your local

FAS.

WARNING

The filter pump is equipped with a manual reset switch in case the filter motor overheats or an

electrical fault occurs. If this switch trips, turn off power to the filter system and allow the pump

motor to cool 20 minutes before attempting to reset the switch (see photo below).

WARNING

Use caution and wear appropriate safety equipment when resetting the filter pump reset switch.

Resetting the switch must be accomplished with care to avoid the possibility of a serious burn from

careless maneuvering around the drain tube and frypot.

Filter Pump

Reset Switch

2.11.4 Maintenance (Manual) Filtration

NOTICE

The filter pad or paper must be replaced daily.

DANGER

Do not drain more than one frypot at a time into the built-in filtration unit to avoid overflow and

spillage of hot oil that may cause severe burns, slipping and falling.

Ensure the filter pad or paper is replaced daily to keep the system operating correctly. The fryer

MUST

be at setpoint temperature. Turn the fryer off and follow the steps below:

Left Display Right Display Action

OFF OFF

Press and hold the FLTR button of the

corresponding vat until FILTER

MENU/MAINT FILTER is

displayed.

FILTER MENU/

Blank

changing to MAINT FILTER

Blank Maint filter?

alternating with YES NO

Blank

Blank

OPEN DRAIN VALVE

DRAINING

Blank SCRUB VAT COMPLETE?

alternating with CONFIRM

Press the (1) button.

Press the (1 yes) button.

Open the drain valve.

None required.

Scrub the vat with the no scratch pad

and press the (1) button when

complete.

2-16

Page 21

Maintenance (Manual) Filtration cont.

Left Display Right Display Action

Blank WASH VAT?

alternating with CONFIRM

Blank OPEN RETURN VALVE

alternating with CONFIRM

WASHING

Blank Close drain valve

Blank Rinsing

Blank Close return valve

when vat full

alternating with CONFIRM

Blank

Blank Rinse again?

Blank

Blank OPEN RETURN VALVE

Blank FILL vat?

Blank Close drain valve

Blank filling

Blank CLOSE RETURN VALVE

OFF OFF

OPEN DRAIN VALVE

alternating with YES NO

POLISH? alternating with

CONFIRM

alternating with CONFIRM

POLISHING alternating with 5

minute countdown timer.

alternating with CONFIRM

WHEN VAT FULL alternating with

CONFIRM

Press the (1) button.

Open the return valve and press the

(1) button.

None required.

Close the drain valve.

None required.

Close the return valve and press the

(1) button.

Open the drain valve.

If the pot is clear of debris, press the (2

NO) button to continue. If another rinse

is desired, press the (1 yes) button

and return to CLOSE DRAIN

VALVE step above.

Press the (1) button to continue.

Open the return valve and press the

(1) button.

The polish begins and a alternates with a

five minute countdown timer.

Press the (1) button to continue.

Close the drain valve.

None required.

Close the drain valve and press the

(1) button.

2-17

Page 22

The DRAIN TO PAN and FILL VAT FROM DRAIN PAN functions are used primarily for

diagnostic purposes. They are used to drain oil to the filter pan or returned to the frypot.

2.11.5 Drain to Pan

The drain to pan function drains the oil from the frypot to the filter pan. Turn the fryer off and follow

the steps below:

Left Display Right Display Action

OFF OFF

Press and hold the FLTR button of the

corresponding vat until FILTER

MENU/MAINT FILTER is displayed.

Blank

Blank

FILTER MENU/

changing to MAINT FILTER

DRAIN TO PAN

Press the u (INFO) button to scroll to

Drain to pan

Press the (1) button.

DRAIN TO PAN?

Blank

Blank

Blank

alternating with YES NO

OPEN DRAIN VALVE

DRAINING

Press the (1 yes) button.

Open the drain valve.

None required.

Blank VAT EMPTY?

alternating with CONFIRM

Blank Close drain valve

OFF OFF

Press the (1) button.

Close the drain valve.

2.11.6 Fill Vat from Drain Pan

Fill vat from drain pan function is used to refill the frypot from the filter pan.

Ensure the fryer is off and follow the steps below:

Left Display Right Display Action

OFF OFF

Press and hold the FLTR button of the

corresponding vat until FILTER

MENU/MAINT FILTER is displayed.

Blank

FILTER MENU/ changing to

MAINT FILTER

Press the u (INFO) button to scroll to

FILL VAT FROM Drain pan.

Blank

FILL VAT FROM DRAIN PAN

FILL VAT FROM DRAIN

Blank

PAN? alternating with

YES NO

Blank OPEN RETURN VALVE

alternating with CONFIRM

Blank filling

Blank Close return valve

when vat full alternating with

CONFIRM

OFF OFF

2-18

Press the (1) button.

Press the (1 yes) button.

Open the return valve and press the (1)

button.

None required.

Close the return valve when the vat is full

and bubbles appear in the oil and press the

(1) button.

Page 23

2.12 Programming Level One

Level one programming is used to enter new products, control when AIF (filter prompt clock) is

disabled and perform deep clean (boil-out) and high-limit test. Ensure the fryer is off and follow the

steps below:

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons

simultaneously for THREE seconds until

LEVEL 1 is displayed.

ENTER

CODE

Blank

LEVEL 1 PROGRAM

Enter 1234.

None required.

Press the tu buttons to scroll between:

a. Product selection See pg. 2-10

b. aif clock (Suppress Filter Prompt) See

pg. 2-20

Product

Selection

Blank

c. DEEP CLEAN MODE See pg. 2-21

d. hi limit test See pg. 2-23

e. Fryer setup See pg. 2-9

With the selection displayed, press the (1)

button to select chosen menu item.

2-19

Page 24

2.12.1 AIF CLOCK

The AIF Clock (suppress filter prompt) mode allows programming of times to lock out the filter

prompt. This is useful for busy times of the day, like the noon rush. Ensure the fryer is off and

follow the steps below:

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons

simultaneously for THREE seconds until

LEVEL 1 is displayed.

ENTER

CODE

Blank

LEVEL 1 PROGRAM

Product

Selection

Blank

Enter 1234.

None required.

Press the u (INFO) button to scroll to aif

clock (Filter Prompt).

Press the (1) button.

Use the 3and

4buttons to toggle between

disabled or enabled

Default setting is disabled. Set this function

AIF CLOCK DISABLED

to enabled if there are times in which the AIF

(filter prompt) feature is disabled (ex. noon rush).

If ENABLED is chosen proceed to the next step.

If DISABLED is chosen press the (2 NO)

button to quit and return to OFF.

If enabled is chosen press the u (INFO) button to

Blank

ENABLED

scroll between M-F 1 thru Sun 4. These are

the different time periods which filter prompts will

be suspended.

Enter the starting time, using the number keys,

which no filter prompts are desired. (ex. On

Monday – Friday no filtering is desired during a

M-F 1 12:00am

lunch rush from 11:30 AM until 1:30 PM.) Press

t and u buttons to toggle from AM to PM.

the

Once the starting time is entered, press the u

(INFO) button.

This is the amount of time the filter prompt is to

remain suspended. Use the number keys to enter a

time between 0 and 999 minutes (ex. 1½ hours is

entered as 90 minutes). Enter 90 for this example.

The controller displays 090 DUR. Four

M-F 1 0 DUR

different time periods to suspend filtration are

available for each day or set of days. (M-F 1-4, Sat

1-4 and Sun 1-4)

Press the u (INFO) button to accept time and

move to the next time period. When finished, press

the (2) button two times to return to OFF.

OFF OFF

None required.

2-20

Page 25

2.12.2 DEEP CLEAN MODE (BOIL-OUT)

The deep clean mode is used to remove carbonized oil from the frypot.

NOTE: Refer to the MRC Deep Clean (boil out) instructions to clean the fryer.

DANGER

When draining oil into a disposal unit, do not fill above the maximum fill line located on

the container.

DANGER

Allow oil to cool to 100°F (38°C) before draining into an appropriate METAL container

for disposal.

Left Display Right Display Action

OFF OFF Ensure an MSDU or suitable metal container is in

place under the drain. Open the drain valve to the

corresponding vat and drain the oil.

Once the oil is completely drained close the drain

valve.

Press the TEMP and INFO buttons simultaneously

for THREE seconds until LEVEL 1 is displayed.

ENTER CODE

LEVEL 1 PROGRAM

Product

Selection

DEEP CLEAN?

alternating with

yes no

DEEP CLEAN

alternating with

L and R

IS OIL REMOVED?

Blank

alternating with yes no

Blank DISPOSAL UNIT IN

PLACE alternating with

Blank OPEN DRAIN

Blank

DISPOSING alternating

with countdown timer.

Blank VAT EMPTY?

Blank

CLOSE DRAIN

Blank

Blank

Blank

CONFIRM

VALVE

alternating with

CONFIRM

VALVE

Enter 1234.

None required.

Press the u (INFO) button to scroll to DEEP

CLEAN (Boil-Out). Press the (1) button.

Press the (1 yes) button.

On split vat units press either L to start a deep clean on

the left vat or R to start a deep clean on the right vat.

Press the (1 yes) button if the oil is removed and

skip to SOLUTION ADDED? at the top of the next

page. If not press the (2) button and continue.

Remove the filter pan and insert a disposal unit or

METAL pan. Once in place press the (1) button.

Open the drain valve.

None required.

Press the (1) button.

Close the drain valve.

2-21

Page 26

Left Display Right Display Action

Fill frypot to be cleaned with water and cleaning

Blank

SOLUTION ADDED?

alternating with

CONFIRM

solution mix. Referring to maintenance requirement

card and Kay Chemical provided instructions “Fryer

Deep Clean Procedure” for McDonald’s deep clean

(boil-out) procedure and press the (1 ) button.

None required. The vat heats to 195° F (91° C) for one

hour. To cancel DEEP CLEAN, press and hold the

(2) button for three seconds and proceed to IS

SOLUTION REMOVED? below.

Blank

DEEP CLEAN

alternating with 60:00

minute timer

CLEAN DONE

Blank

alternating with

CONFIRM

Press the (1 ) button.

DANGER

Allow deep-clean (boil-out) solution to cool to 100°F (38°C) before disposal,

otherwise hot liquid can cause injury.

WARNING

Do not drain boil-out solution into a McDonald’s shortening disposal unit (MSDU), a

built-in filtration unit, or a portable filter unit. These units are not intended for this

purpose, and will be damaged by the solution.

Blank

IS SOLUTION

REMOVED? alternating

with yes

Open drain valve to remove the small amount of

solution left in the drain. When finished press the

(1 yes) button.

Scrub vat

Blank

complete?

alternating with

Once the vat is scrubbed and rinsed press the (1)

button.

CONFIRM

OPEN DRAIN

Blank

Blank

VALVE

DRAINING

Open the drain valve.

None required.

Blank RINSE COMPLETE?

alternating with

CONFIRM

Rinse the vat several times and press the (1) button

when complete.

Blank Close drain

valve

Close the drain valve.

Blank Remove pan

alternating with

Remove the filter pan.

CONFIRM

2-22

Page 27

Left Display Right Display Action

Blank Vat and pan

dry? alternating with

CONFIRM

Dry the vat and filter pan thoroughly and press the

(1) button when complete.

DANGER

Ensure that the frypot and filter pan are completely dry and free of water before

filling with oil. Failure to do so will cause splattering of hot liquid when the oil is

heated to cooking temperature.

Blank INSERT PAN

alternating with

CONFIRM

Insert the filter pan and press the (1) button

Blank MANUAL FILL

VAT alternating with

CONFIRM

OFF OFF

Carefully pour oil into the pot until it reaches the low fill

line in the fryer.

None required.

2.12.3 HIGH-LIMIT TEST MODE

The high-limit test mode is used to test the high limit circuit. The high-limit test will destroy the oil.

It should only be performed with old oil. Shut the fryer off and call for service immediately if the

temperature reaches 460°F (238°C) without the second high-limit tripping and the controller

displays high LIMIT FAILURE alternating with DISCONNECT POWER with an alert

tone during testing.

The test is cancelled at any time by turning the fryer off. When the fryer is turned back on, it returns

to the operating mode and displays the product.

Left Display Right Display Action

OFF OFF

ENTER CODE

Blank

LEVEL 1 PROGRAM

Product

Selection

Blank

HI-LIMIT?

alternating with

Blank

yes no

press and

h0ld check

335F

(current

vat temp)

(current vat

Blank

335F

temp)

Press the TEMP and INFO buttons simultaneously for

THREE seconds until LEVEL 1 is displayed.

Enter 1234.

None required.

Press the u (INFO) button to scroll to HIGH LIMIT

TEST.

Press the (1) button.

Press the (1 yes) button or on a split vat on the sides that

corresponds to the vat.

Press and hold the (1 yes) button to initiate the high-limit

test.

None required. The vat begins to heat. The controller

displays the actual vat temperature during the test. When the

temperature reaches 410°F ± 10° F (210°C ± 12°C)*, the

controller displays hot hi-1 alternating with the actual

temperature (ex. 410F) and continues heating.

2-23

Page 28

Left Display Right Display Action

When the temperature reaches 410°F ± 10° F (210°C ±

12°C)*, the controller displays hot hi-1 alternating with

the actual temperature (ex. 410F) and continues heating.

NOTE: In controllers used in the European Union (those

Blank

hot hi-1

alternating with the

actual temperature

with the CE mark), the temperature is 395°F (202°C).

The fryer continues heating until the second (physical) high

limit opens. Generally this happens once the temperature

reaches 423°F to 447°F (217°C to 231°C) for non-CE high

limits and 405°F to 426°F (207°C to 219°C) for CE high

Blank

HELP HI-2

alternating with the

actual temperature

limits.

Release the (1 yes) button.

If the high-limit fails, the controller displays HIGH LIMIT

FAILURE alternating with DISCONNECT POWER.

If this happens, disconnect power to the fryer and call for

service immediately.

Press the soft power button on the controller to cancel the

alarm.

Vat

temperature

Vat

temperature

The vat stops heating and the controller displays the current

temperature setting alternating with the actual temperature

(ex. 430F) until the temperature cools below 400°F

(204°C). Once the temperature cools below 400°F (204°C)

press the (2) button twice to exit to OFF.

OFF OFF

Follow the procedures on page 2-13 to dispose of the oil.

2.13 Programming Level Two

Level two programming is used to adjust compensation (sensitivity), view the error log, change

passwords, adjust alarms and adjust filter prompts. Ensure the fryer is off and follow the steps

below:

Left Display Right Display Action

OFF OFF

ENTER

CODE

Blank

LEVEL 2 PROGRAM

Prod COMP

Blank

Press the TEMP and INFO buttons simultaneously for TEN

seconds until LEVEL 2 is displayed.

Enter 1234.

None required.

Press the tu buttons to scroll between:

a. Prod comp See pg. 2-25

b. e-log See pg. 2-25

c. password SETUP See pg. 2-27

d. alert tone See pg. 2-27

e. TOPOFF After See pg. 2-28

f. filter After See pg. 2-28

g. filter time See pg. 2-29

With the selection displayed, press the (1) button to select

chosen menu item.

2-24

Page 29

2.13.1 PRODUCT COMP MODE

The product comp mode allows the product compensation (sensitivity) to be changed. Some menu

items may need an adjustment, depending on their cooking characteristics. Use caution when

changing the product compensation, as it could have an adverse affect on the products cooking

cycles. The default setting for product compensation is set to (4) four.

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

ENTER CODE

LEVEL 2 PROGRAM

Prod COMP

Blank

Enter 1234.

None required.

Blank Press the (1) button.

PRODUCT

SELECTION

Select

product

Blank None required.

FR FRIES

Use the t and

With a product selected, press the (1 ) button to select

u to scroll through the product list.

a product.

modify?

alternating with

Product name

Press the (1 yes) button.

yes no

This is the sensitivity setting recommended for this

product.

NOTE: It is highly recommended to NOT adjust

this setting, as it could have an adverse effect

LOAD COMP 4

on the product.

If changing this setting, enter a number between 0-9.

Press the (2) button two times to accept selection and

exit to OFF.

OFF OFF

None required.

2.13.2 E-LOG MODE

The E-LOG mode is used to view the ten most recent error codes encountered on the fryer. These

codes are displayed from 1-10 with the most recent displayed first. The time, date and error code are

displayed.

Left Display Right Display Action

OFF OFF

ENTER CODE

Blank

LEVEL 2 PROGRAM

Prod COMP

Blank

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

Enter 1234.

None required.

Press the u (INFO) button to scroll to E-LOG.

Press the (1) button.

2-25

Page 30

Left Display Right Display Action

d

r

E-LOG

Blank Press the (1) button.

Press the u (INFO) and u (TEMP) buttons to scroll

through the ten most recent error codes starting with “A”

through “J”. If no errors exist, the controller displays

NO ERRORS. Errors are displayed by position A

through J, the side of the error, if a split vat error code

and time alternating with the date. An error code

displaying and “L” indicates left side of a split vat an

NOW

Current date alternating

with the time

“R” indicates right side of a split vat where the erro

occurred (example –A R E06 06:34AM 06/04/10).

Error codes are listed below.

Press the (2) button two times to exit.

OFF OFF

None required.

E-LOG Error Codes

Code ERROR MESSAGE

E03 ERROR TEMP PROBE FAILURE Temp probe reading out of range.

E04 HI 2 BAD High limit reading is out of range.

E05 HOT HI 1

E06 HEATING FAILURE A component has failed in the high limit circuit such

E20 INVALID CODE LOCATION SD card removed during update.

E21 FILTER PAD PROCEDURE ERROR

(Change Filter Pad)

E22 OIL IN PAN ERROR

E25 RECOVERY FAULT Recovery time exceeded maximum time limit.

E27 LOW TEMP ALARM Oil temperature has dropped lower than 15°F (8°C)

High limit temperature is past more than 410°F

(210°C), or in CE countries, 395°F (202°C).

as controller, interface board, contactor or openhigh limit.

25 hour timer has expired or dirty filter logic has

activated.

The controller detects oil may be in the filter pan.

in idle mode or 45°F (25°C) in cook mode.

EXPLANATION

2-26

Page 31

2.13.3 PASSWORD SETUP MODE

The password mode allows a restaurant manager to change passwords for various modes and levels.

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

ENTER CODE

LEVEL 2 PROGRAM

Prod COMP

Blank

Blank

Enter 1234.

None required.

Press the u (INFO) button to scroll to password

SETUP.

password

SETUP

Blank

Press the (1) button.

Press the t and u buttons to scroll between:

a. FRYER Setup – Established password to enter

FRYER Setup mode. (Default is 1234)

b. usage – Established password to enter usage

fryer setup

Current date and time

mode to reset usage statistics. (Default is 4321)

c. level 1 – Establishes password to enter level

1 mode. (Default is 1234)

d. level 2 – Establishes password to enter level

2 mode. (Default is 1234)

Press the (1) button once selection is displayed.

modify?

alternating with

Blank

Press the (1 yes) button.

yes no

NEW PASSWORD

FRYER SETUP

flashes for three seconds

then1234 or the

Using the 0-9 keys enter a new password or reenter the

existing password and press the (1 ) button.

current password is

displayed on the right

CONFIRM

PASSWORD

SETUP

OFF OFF

1234 or the new

password

Blank

Press the (1 yes) button.

Repeat process to change other passwords or press the

(2) button to exit.

None required.

2.13.4 ALERT TONE MODE

The alert tone volume is adjustable to nine levels and the tone is adjustable to three frequencies. Use

different frequencies to distinguish protein or French fry stations.

Left Display Right Display Action

OFF OFF

ENTER CODE

Blank

LEVEL 2 PROGRAM

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

Enter 1234.

None required.

2-27

Page 32

Left Display Right Display Action

Prod COMP

alert tone

Blank

Blank Press the (1) button.

Press the u (INFO) button to scroll to alert

tone.

Use the number keys to set volume level. Select from

volume 1-9 9

nine levels of volume with 1 being the softest and 9 the

loudest. Press the u (INFO) button.

tone 1-3 1

volume 1-9 9

OFF OFF

Use the number keys, to set the tone frequency from 1

to 3. Press the u (INFO) button.

Press the (2) button two times to exit.

None required.

2.13.5 TOP OFF AFTER

The prompt for topoff is initiated after a number of cycles have elapsed. The default is 40 and can be

adjusted. After the number of cycles have elapsed, the controller displays “CHECK OIL LEVEL”

and “CONFIRM”. Check oil level and add oil if necessary. Ensure oil is at the top oil level line and

press the (1) button.

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

ENTER CODE

LEVEL 2 PROGRAM

Prod COMP

Blank

Blank

Enter 1234.

None required.

Press the u (INFO) button to scroll to TOPOFF

AFTER. Press the (1) button.

Use the 3and 4buttons to toggle between

TOPOFF

AFTER

DISABLED

disabled or enabled

Default setting is disabled. Set this function to

enabled to prompt for top off. Press the u (INFO)

button

Use the number keys from 0 to 9 to enter the number of

TOPOFF

AFTER

40

cook cycles before prompting to top off. (ex. after

every 40 cycles enter as 40). The default is 40. Press

the (2) button two times to exit.

OFF OFF

None required.

2.13.6 FILTER AFTER

The FILTER AFTER option is used to set the number of cooking cycles which occur before the

filtration prompt is displayed.

Left Display Right Display Action

OFF OFF

ENTER CODE

Blank

LEVEL 2 PROGRAM

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

Enter 1234.

None required.

2-28

Page 33

Left Display Right Display Action

Prod COMP

Blank

Press the u (INFO) button to scroll to FILTER

AFTER. Press the (1) button.

Use the 3and

4buttons to toggle between disabled

or enabled.

FILTER AFTER DISABLED

Default setting is disabled. Set this function to

enabled if filter prompts are desired. Press the u

(INFO) button.

Use the number keys from 0 to 9 to enter the number of

filter after

6 DV

or 12 FV

cook cycles before prompting to filter (ex. after every 6

cycles enter as 6). The default is 6 for DV or 12 for FV.

Press the (2) button two times to exit.

OFF OFF

None required.

2.13.7 FILTER TIME

The FILTER time option is used to set default times for a filtration prompt. Two programmable

quick filter time prompts can be programmed. If this option is enabled, the controller will prompt to

filter at 10:00AM and 2:00PM each day.

Left Display Right Display Action

OFF OFF

Press the TEMP and INFO buttons simultaneously for

TEN seconds until LEVEL 2 is displayed.

ENTER CODE

LEVEL 2 PROGRAM

Prod COMP

FILTER TIME

Blank

Blank

Blank

Enter 1234.

None required.

Press the u (INFO) button to scroll to FILTER TIME.

Press the (1) button.

Use the 3and 4buttons to toggle between disabled

1 QUICK

FILTER

DISABLED

or enabled.

Default setting is disabled. Set this function to

enabled if a time filter prompt is desired. Press the u

(INFO) button.

Use the number keys from 0 to 9 to change the time of the

1 QUICK

FILTER

10:00AM

first timed quick filter prompt. The default is 10:00AM.

Press the u (INFO) button or press the (2) button two

times to exit.

4buttons to toggle between disabled

2 QUICK

FILTER

DISABLED

Use the 3and

or enabled.

Default setting is disabled. Set this function to

enabled if a second time filter prompt is desired. Press

the u (INFO) button.

2 QUICK

FILTER

2:00PM

OFF OFF

Use the number keys from 0 to 9 to change the time of the

second timed quick filter prompt. The default is 2:00PM.

Press the (2) button two times to exit.

None required.

2-29

Page 34

2.14 INFO Mode

The INFO button is used to display information and navigate menus. Pressed once, it shows each

vat’s recovery time. Press for three seconds and it displays usage, filter statistics and last cook

cycles.

Left Display Right Display Action

OFF OFF

info mode

filter stats

Blank

Blank

OFF OFF

2.14.1 FILTER STATS MODE

The filter stats mode displays vat filtration counts and skipped filters by day and the average number

of cook cycles per filter.

Left Display Right Display Action

OFF OFF

info mode

filter stats

Current Day

(ex. TUE)

fIltErEd

flt bpsd

flt avg

fIltErEd

(ex. 06/04/10)

Blank

Blank

Current date

(ex. 4 FRI)

(ex. 0 FRI)

(ex. 12 FRI)

(ex. 4 FRI)

OFF OFF

Press and hold the INFO button for THREE seconds

until info MODE is displayed.

None required.

Press the t and ubuttons to scroll between:

FULL VAT CONFIGURATION

a. filter stats See pg. 2-30

b. review usage See pg. 2-31

c. last load (split vat L or R)See pg. 2-31

None required.

Press and hold the INFO button for THREE seconds

until info MODE is displayed.

None required.

Press the (1) button.

Use the 3and

4 buttons to scroll from the current day

and going back one week. When the day is selected

press the u (INFO) button.

NOTE: Split vats have an L or R in front of the left

display indicating statistics for either the left or right

side of the vat.

Press the u (INFO) button. Number of times vat

filtered and day.

Press the u (INFO) button. Number of times filter was

bypassed and day.

Press the u (INFO) button. Average number of cook

cycles per filter and day.

Use the 3and

4 buttons to scroll to another day or

press the (2) button two times to exit.

None required.

2-30

Page 35

2.14.2 REVIEW USAGE MODE

The review usage displays total cook cycles per vat, number of cook cycles per vat, number of cook

cycles exited prior to completion, the number of hours the vat(s) have been on and the date of last

usage reset.

Left Display Right Display Action

OFF OFF

Press and hold the INFO button for THREE seconds

until info MODE is displayed.

info mode

filter stats

review usage

USAGE SINCE

Date Time

total cooks

quit cook

Blank

Blank

None required.

Press the u (INFO) button to scroll to review

usage.

Blank Press the (1) button.

Blank None required.

Press the u (INFO) button. Usage since date and time

of last reset.

26

3

Press the u (INFO) button. Number of cook cycles for

all products since last reset.

Press the u (INFO) button. Number of cook cycles

exited within first 30 seconds since last reset.

Press the u (INFO) button. Number of hours the vat

on hrs

54:56

has been on since last reset. Split vats will have an L or

R before on hrs to indicate left or right vat.

reset usage

alternating with

Blank

yes no

ENTER CODE

Blank

Reset usage COMPLETE

review usage

Blank

OFF OFF

Press the (1 YES) button to reset usage, otherwise

press (2 NO) button. Resets usage counters

Enter 4321.

None required.

Press the (2) button to exit.

None required.

2.14.3 LAST LOAD MODE

The last load mode displays data for the last cook cycle.

Left Display Right Display Action

OFF OFF

Press and hold the INFO button for THREE seconds

until info MODE is displayed.

info mode

Blank

None required.

Press the u (INFO) button to scroll to last LOAD

filter stats

Blank

for full vats or load l or Load r for split vat

configurations.

Last load

Blank

Press the (1) button.

NOTE – Below numbers are examples. They do not reflect actual conditions.

PRODUCT

STARTED 02:34PM

Product (ex. FRY)

Press the u (INFO) button. Last product cooked.

Press the u (INFO) button. Time last cook cycle

started.

2-31

Page 36

Left Display Right Display Action

Actual TIME 3:15

Press the u (INFO) button. Actual cooking time

including stretch time.

progtime 3:10

Max temp

Min temp

avg temp

heat on 70

ready yes

OFF OFF

337°

310°

335°

Press the u (INFO) button. Programmed cook time.

Press the u (INFO) button. Maximum oil temperature

recorded during the cook cycle.

Press the u (INFO) button. Minimum oil temperature

recorded during the cook cycle.

Press the u (INFO) button. Average oil temperature

recorded during the cook cycle.

Press the u (INFO) button. Percentage of the cook

time the heat source was on.

Press the (2) button two times to exit. Displays if the

fryer was back to proper temperature before the cook

cycle was started.

None required.

2-32

Page 37

MANUAL LOV™ M3000 CONTROLLER

CHAPTER 3: OPERATOR TROUBLESHOOTING

3.1 Introduction

This section provides an easy reference guide to some of the common problems that may occur

during the operation of this equipment. The troubleshooting guides that follow are intended to help

correct, or at least accurately diagnose, problems with this equipment. Although the chapter covers

the most common problems reported, you may encounter problems that are not covered. In such

instances, the Frymaster Technical Services staff will make every effort to help you identify and

resolve the problem.

When troubleshooting a problem, always use a process of elimination starting with the simplest

solution and working through to the most complex. Never overlook the obvious – anyone can forget

to plug in a cord or fail to close a valve completely. Most importantly, always try to establish a clear

idea of why a problem has occurred. Part of any corrective action involves taking steps to ensure

that it doesn’t happen again. If a controller malfunctions because of a poor connection, check all

other connections, too. If a fuse continues to blow, find out why. Always keep in mind that failure

of a small component may often be indicative of potential failure or incorrect functioning of a more

important component or system.

Before calling a service agent or the Frymaster HOTLINE (1-800-24-FRYER):

• Verify that electrical cords are plugged in and that circuit breakers are on.

• Verify that frypot drain valves are fully closed.

• Have your fryer’s model and serial numbers ready to give to the technician assisting

you.

DANGER

Hot oil will cause severe burns. Never attempt to move this appliance when filled

with hot oil or to transfer hot oil from one container to another.

DANGER

This equipment should be unplugged when servicing, except when electrical circuit

tests are required. Use extreme care when performing such tests.

This appliance may have more than one electrical power supply connection point.

Disconnect all power cords before servicing.

Inspection, testing, and repair of electrical components should be performed by an

authorized service agent only.

3-1

Page 38

3.2 Troubleshooting

3.2.1 Controller and Heating Problems

Problem Probable Causes Corrective Action

A. Press the ON/OFF switch to turn

the controller on.

B. Verify controller power cord is

plugged in and that circuit breaker

is not tripped.

D. Call your FAS for assistance.

No Display on

Controller.

A. Controller not turned on.

B. No power to the fryer.

C. Controller has failed. C. Call your FAS for assistance.

D. Damaged controller wiring

harness.

M3000 displays

CHANGE FILTER

PAD?

E. Power supply component or

interface board has failed.

25 hour filter pad change prompt has

occurred or change filter pad was

ignored on a prior prompt.

E. Call your FAS for assistance.

Change the filter pad. Do NOT

ignore CHANGE FILTER PAD

prompts.

A. Verify that both the main power

cord and 120V is fully seated in its

receptacle, locked into place and

that circuit breaker is not tripped

C. Call your FAS for assistance.

Call your FAS for assistance.

Fryer does not heat.

Fryer heats until high-

limit trips with heat

indicator ON.

Fryer heats until high-

limit trips without

heat indicator ON.

A. Main power cord not plugged in.

B. Controller has failed. B. Call your FAS for assistance.

C. One or more other components have

failed.

Temperature probe or controller has

failed.

Contactor or controller has failed Call your FAS for assistance.

3.2.2 Error Messages and Display Problems

Problem Probable Causes Corrective Action

Toggle between F° to C° by pressing

M3000 display is in

wrong temperature

scale (Fahrenheit or

Celsius).

M3000 display shows

hot-hi-1.

M3000 display shows

hELP HI-2 or

High limit

failure.

Incorrect display option programmed.

Frypot temperature is more than 410ºF

(210ºC) or, in CE countries, 395ºF

(202ºC).

Failed high limit

and holding 3and4simultaneously

until TECH MODE appears. Enter

1658. The controller displays OFF.

Turn the controller on to check

temperature. If the desired scale is not

displayed, repeat.

Shut the fryer down immediately and

call your FAS for assistance.

Shut the fryer down immediately and

call your FAS for assistance.

3-2

Page 39

Problem Probable Causes Corrective Action

M3000 display shows

TEMP PROBE

FAILURE.

M3000 display shows

HEATING

FAILURE.

Heating indicator is

on, but fryer is not

heating.

M3000 display shows

RECOVERY

FAULT and alarm

sounds.

M3000 display shows

REMOVE

DISCARD.

Controller locks up.

M3000 displays

SERVICE

REQUIRED followed

by an error message.

DRAIN OPEN

alternating with

CONFIRM

IS VAT FULL?

alternating with

CONFIRM

IS PAN EMPTY?

alternating with

CONFIRM

Problem with the temperature

measuring circuitry including the probe

or damaged controller wiring harness or

connector.

Failed controller, failed interface board,

open high-limit thermostat.

Three phase power cord unplugged or

circuit breaker is tripped.

Recovery time exceeded maximum time

limit.

A product cook is started that has a

different setpoint than the current vat

temperature.

Controller error. Call your FAS for assistance.

An error has occurred which requires a

service technician.

Drain valve is open.

A drain has been opened.

A drain has been opened.

Shut the fryer down and call your FAS

for assistance.

Call your FAS for assistance.

Verify that both the main power cord and

120V is fully seated in its receptacle,

locked into place and that circuit breaker

is not tripped If the problem continues

call your FAS for assistance.

Clear error and silence the alarm by

pressing the 9 button. Maximum

recovery time for electric is 1:40 and 2:25

for gas. If this error continues call your

FAS for assistance.

Remove and discard product. Press the

cook button under the display with the

error to remove the error. Reset the

setpoint of the vat before trying to cook

product.

Press 8 (2 NO) to continue cooking and

call your FAS for assistance. In some

cases, cooking may not be available.

Press either button under CONFIRM and

follow prompts.

Press either button under CONFIRM and

follow prompts.

Press either button under CONFIRM and

follow prompts.

3-3

Page 40

3.2.3 Filtration Problems

Problem Probable Causes Corrective Action

Change or overwrite the filter after

Fryer filters after each

cook cycle.

MAINT FILTER

(Manual Filter) won’t

start.

Filter pump won't

start or pump stops

during filtering.

Filter after setting incorrect.

Temperature too low.

A. Power cord is not plugged in or

circuit breaker is tripped.

B. Pump motor has overheated causing

the thermal overload switch to trip.

C. Blockage in filter pump.

setting by re-entering the filter after

value in level two. See section 2.13.6

on page 2-28.

Ensure fryer is at setpoint before

starting MAINT FILTER.

A. Verify that the power cord is fully

plugged in and the circuit breaker

is not tripped.

B. If the motor is too hot to touch for

more than a few seconds, the

thermal overload switch has

probably tripped. Allow the motor

to cool at least 45 minutes then

press the Pump Reset Switch. (See

page 2-16)

C. Call your FAS for assistance.

Filtration won’t start.

M3000 display shows

filter busy.

A. AIF disable is set to yes.

B. Filter relay has failed.

C. Oil temperature too low.

Another function or filter pad change is

still in process.

A. Set AIF disable in Level 1 to no.

B. Call your FAS for assistance.

C. Ensure oil temperature is at 300°F

(149°C) or above.

Wait until the previous function ends

to start another function. Change filter

pad if prompted.

3-4

Page 41

THIS PAGE INTENTIONALLY LEFT BLANK

Page 42

Frymaster, L.L.C., 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-688-2200 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-6964

JULY 2012

Loading...

Loading...