Frymaster M2000 Owner’s Manual

FRYERS

Frymaster

Fryer

Electric and Gas models using an M2000 Computer

Computer model M2000

Daily maintenance tasks

FR 2 D1 Cleaning fryer

FR 2 D2 Maintenance filter

Weekly maintenance task

FR 2 W1 Clean area behind

fryers

Bi-weekly maintenance task

FR 2 B1 Calibrate fryer

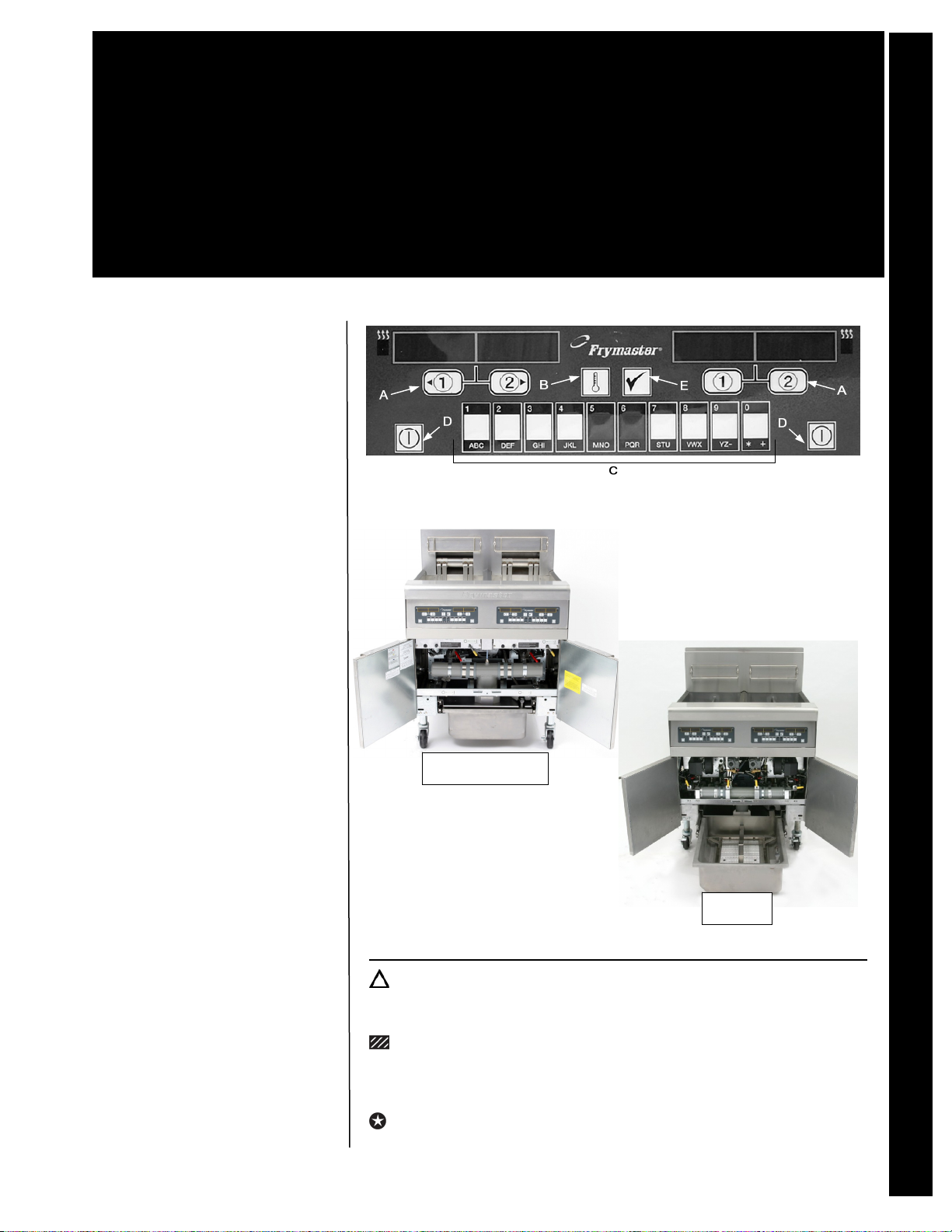

A. Cook cycle buttons, B. Temp button, C. Product Buttons, D. ON/OFF, E. Programming button

FR 2

Frymaster Fryer All models using an M2000 Computer FR 2

Monthly maintenance task

FR 2 M1 Calibrate fryer

recovery time

Quarterly maintenance tasks

FR 2 Q1 Boil out fry vats

(electric fryers

only)

FR 2 Q2 Verify high-limit

controls

FR 2 Q3 Replace filter O-

rings

Semi-annual maintenance task

FR 2 S1 Boil out fry vats

(gas fryers only)

Annual maintenance task

FR 2 A1-T Service inspection

(Gas fryers only)

FR 2 A2-T Service inspection

(Electric fryers only)

APR 2013

*8196566*

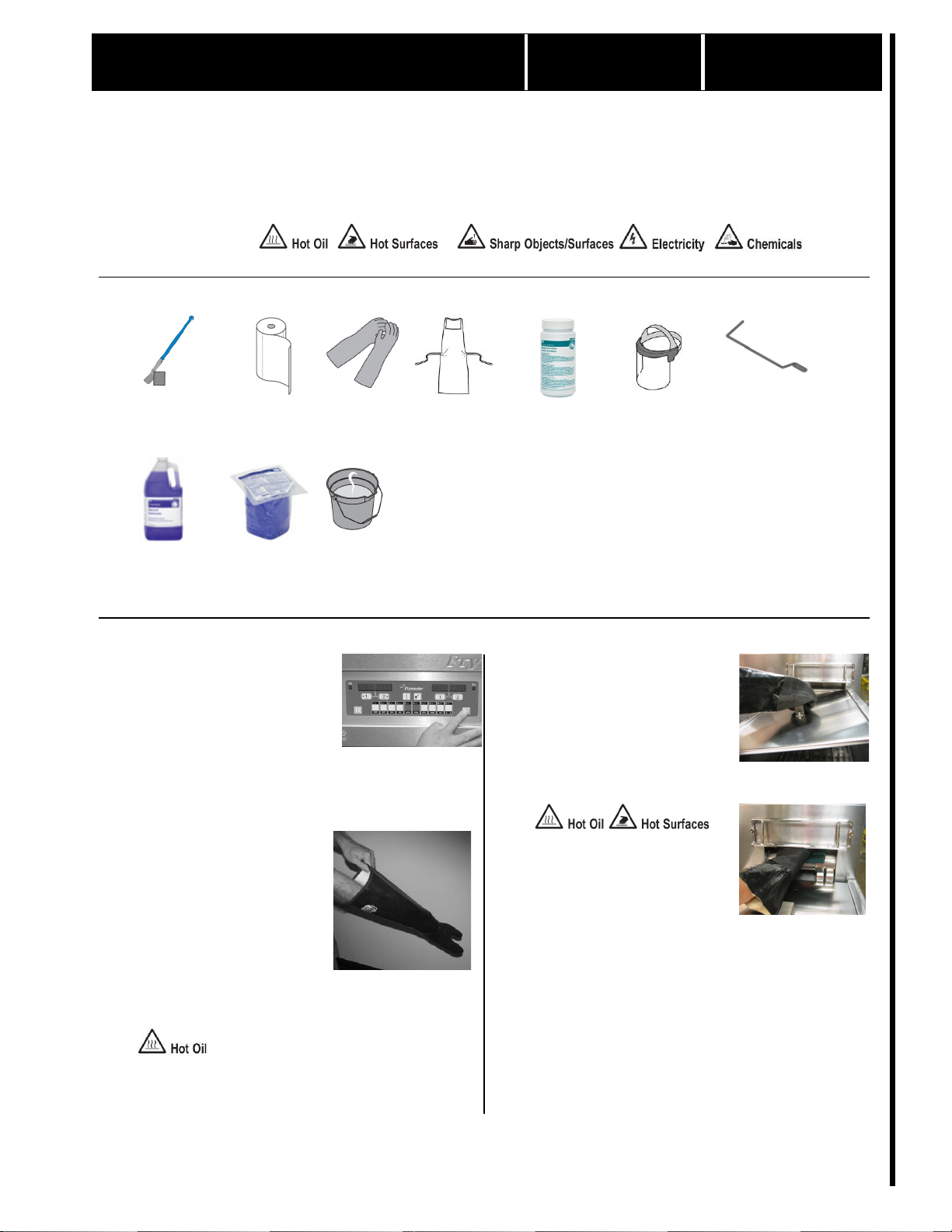

ELECTRIC

GAS

Hazards

These icons alert you to a possible risk of personal injury.

Equipment alerts

Look for this icon to find information about how to avoid damaging the

equipment while doing a procedure.

Tips

Look for this icon to find helpful tips about how to do a procedure.

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013

Daily Cleaning of Fryers Daily FR 2 D1

`

Why

Removes caramelized oil from fryer and cleans element hub.

Frymaster Fryer All Models using an M2000 Computer

Time required

Time of day

Hazard icons

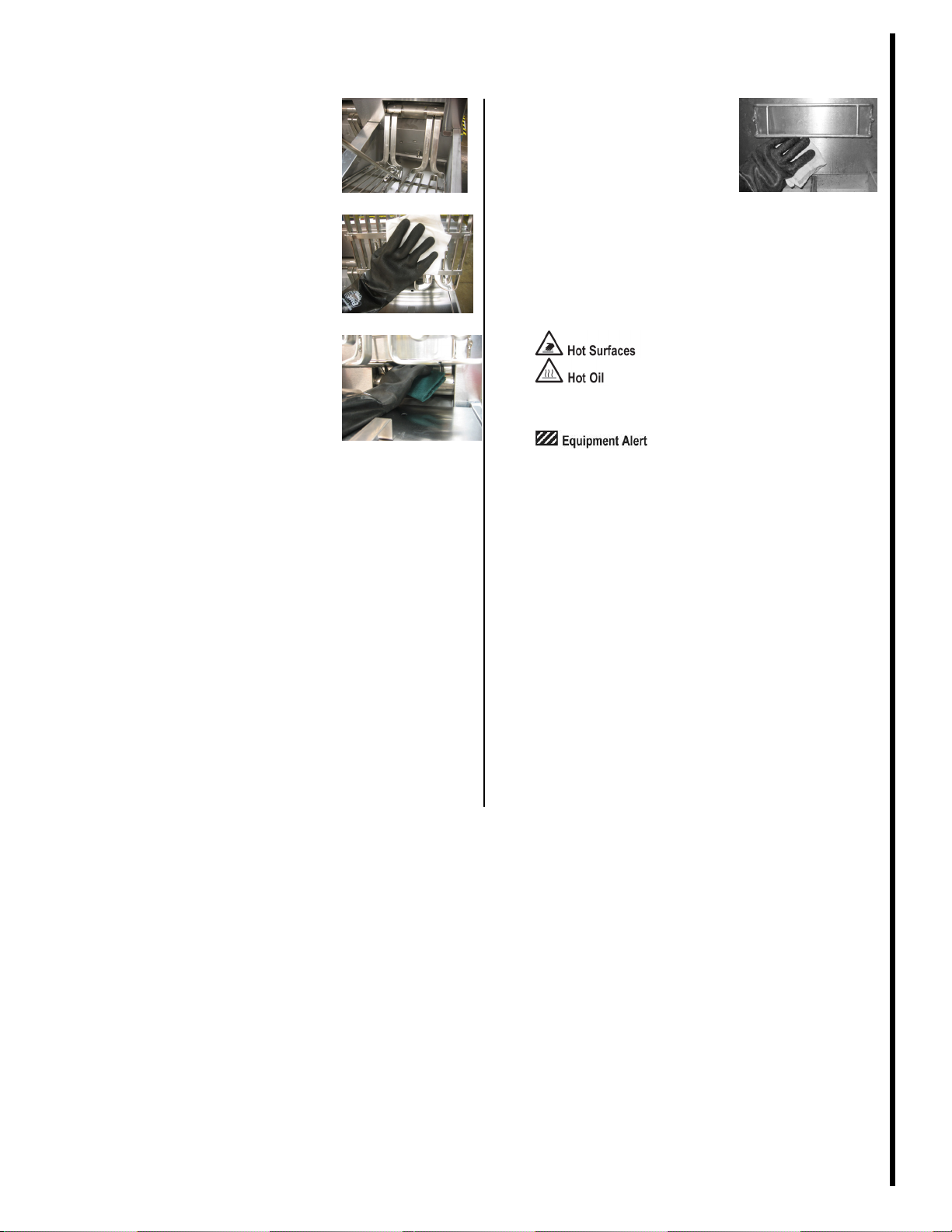

Tools and supplies

Ecolab Hi-Temp Pad Holder

and Pad

KAY® QSR Heavy Duty

Degreaser

5 minutes to prepare 15 minutes to complete (5 minutes per pot)

Low-volume periods For 24-hour restaurants: overnight or during low-

volume periods

Paper towel

KAY® SolidSense

All Purpose Super

Concentrate (APSC)

Neoprene Filtering

Gloves

Bucket with

Sanitizer Soaked

Towels

Apron, heat-resistant KAY® QSR

Fryer Cleanser

Face shield

Fryer’s Friend

Procedure

Turn fryers off.

1

Turn all fryer power

switches to the off

position.

Put on protective gear.

2

Use all McDonald’s approved safety equipment,

including heat-resistance

apron, face shield and neoprene gloves.

This procedure should be

done for only one vat at a

time.

Hot oil can cause severe

burns

Clean front and topside area

3

of heating element hub

(electric only).

Wearing heat resistant

gloves, place covers on

frypots ensuring they are

square with the frypot.

Use a small amount of QSR

Fryer Cleanser on a Hi-Temp

pad (electric only).

Use Hi-Temp pad to clean

around the element hub and

surrounding housing area.

Once area has been cleaned,

wipe off excess with a sanitizer soaked towel. Ensure

the towel is not dripping

with solution around hot oil.

Daily FR2 D1

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 1 of 2

Daily Cleaning of Fryers (continued)

Remove frypot cover and

remove basket rack using a

fryer’s friend, set aside. Lift

elements using fryer’s friend.

Replace frypot covers and

wipe excess oil from the elements with paper towel.

Clean underside area of heat-

4

ing element hub (electric

only).

Use a small amount of QSR

Fryer Cleanser on a

Hi-Temp pad.

Use Hi-Temp pad to clean

the underside of the element

hub and surrounding housing

area.

Once area has been cleaned

wipe off excess with a sanitizer soaked towel. Ensure

the towel is not dripping

with solution around hot oil.

Remove frypot cover. Using

a fryer’s friend, lower the

elements and replace the basket rack.

Wipe down surfaces.

5

Spray a clean, sanitizersoaked towel with Heavy

Duty Degreaser solution to

thoroughly wipe down all

surfaces of the fryer to remove grease and soil buildup. Ensure the towel is not

dripping with solution around

hot oil. Allow surface to air

dry.

Oil in fryer may be very hot.

When wiping down equipment, always be careful not

to drip water into electrical

components.

Repeat for remaining frypots.

6

Frymaster Fryer All Models using an M2000 Computer Daily

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 2 of 2

FR 2 D1

Maintenance Filter Daily FR 02 D2

Why

Cleans the vat of crumbs and filters the oil thoroughly to prolong the life of the oil

Frymaster Fryer Models Using Model M2000 Computer

Time required

Time of day

Hazard icons

Tools and supplies

Gloves, filtering Face shield

Procedure

Put on protective gear

1

Use all McDonald’s approved

safety equipment, including

heat-resistance apron, face

shield and neoprene gloves.

CAUTION: This procedure

should be done for only one

vat at a time.

Hot oil can cause severe

burns

Check filter pan

2

Make sure filter drain pan and

pan cover are properly in

place.

Turn fryers off.

3

Turn all fryer power switches

to the off position.

5 minutes to prepare 10 minutes per vat to complete

During low volume hours.

Apron, heatresistant

Ecolab Hi-Temp

Pad Holder & Pad

McFiltering Kit for

built-in filtering

system

4

5

Ecolab Hi-Temp

Detail Brush

KAY® QSR

Fryer Cleanser

Skim the vat

Using the skimmer skim large

particles from oil before

draining.

Open the drain valve

Carefully open the drain valve

and let the oil drain into the

filter pan. Push any pieces of

fried food or other sediment

into the drain valve using the

fryer’s friend.

CAUTION: Do not drain more

than one fryer at a time. To

do so will cause overfilling of

the filter pan.

KAY® SolidSense All

Purpose Super

Concentrate (APSC)

Fryer’s Friend

Daily FR 02 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 1 of 3

Maintenance Filter (continued)

Lift elements (electric only)

6

Once oil has drained, raise the

hinged elements.

Use protective gloves when

lifting elements or burns

could result.

Be careful not to damage the

probe in center of elements.

Open the return valve

7

Once oil has drained, open the

return valve to begin the filter

process.

Scrub inside vat

8

Use the Hi-Temp Pad Holder,

pad, and a small amount of

KAY QSR Fryer Cleanser to

scrub the walls, corners and

bottom of the inside of the

vat. Use the Hi-Temp Detail

Brush to remove debris build

up from elements (electric

only), corners of vats and

other hard-to-reach areas.

Be careful not to damage the

probes.

Close drain valve

10

Close the drain valve and

allow the vat to fill.

Close the return valve

11

Once the vat is full and

bubbles appear in the oil,

allow bubbling to continue

15-20 seconds to ensure the

oil return lines are clear of

residual oil then close the

return valve.

Add oil

12

Some oil may be lost in the

filtering process. Fill to the

top oil level line.

Turn on fryer

3

Press the power button to turn

the controller on and return

the fryer to normal operation.

The oil may drop below

operating temperature during

the filtering process.

If so, the fryer will display

LOW TEMP while heating the

oil to operating temperature.

Frymaster Fryer Models Using Model M2000 Computer

Filter additional fryers

4

Repeat steps 1 through 13 for

each remaining fryer.

Pull-out filter pan

Filter the oil

9

Once the vat is clean, lower

the elements (electric only)

and allow the oil to circulate

through the pot for five (5)

minutes. This process is

called polishing the

oil. Polishing cleans the oil

and washes small particles

from the vat.

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 2 of 3

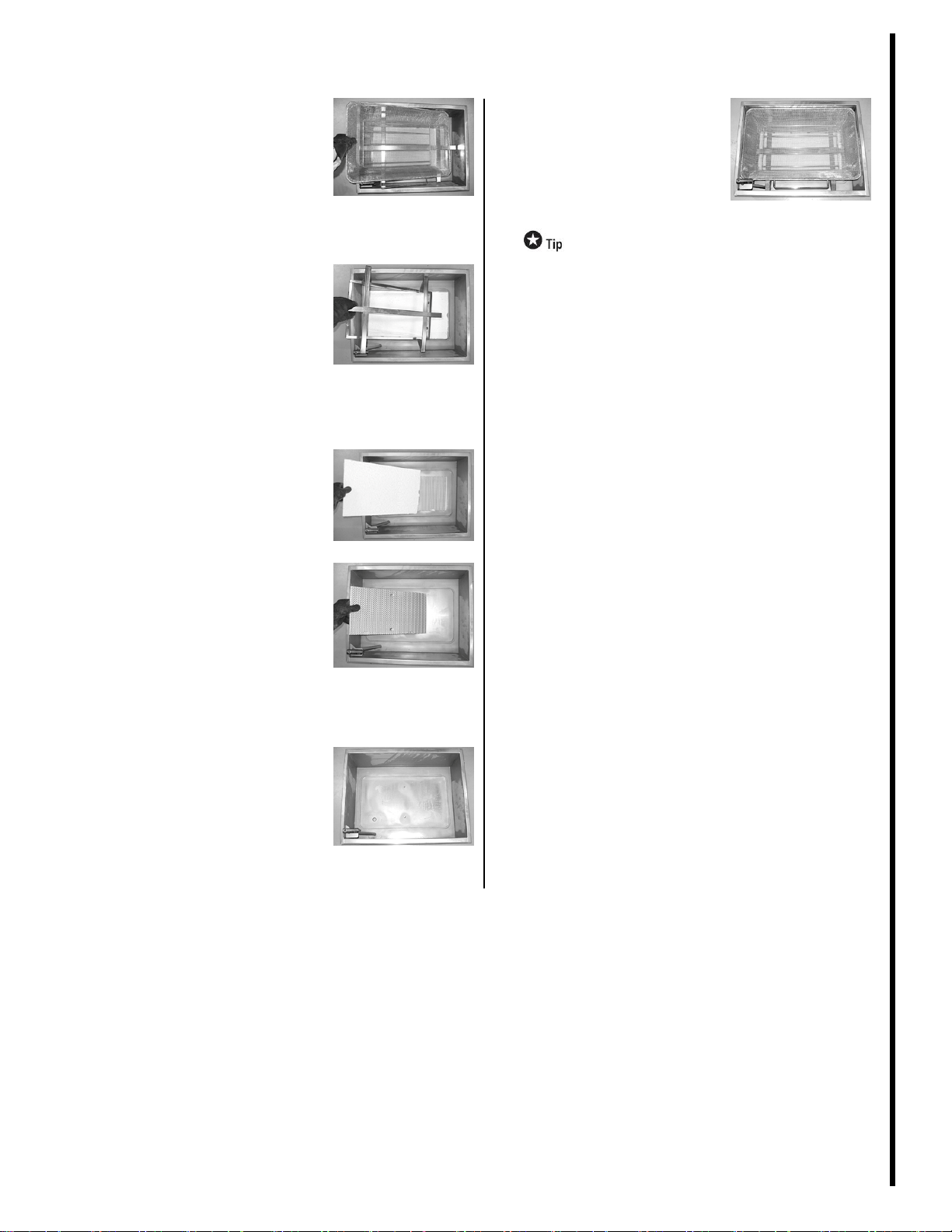

5

Open the door and pull the

filter pan assembly out.

The filter pan may be hot!

Use protective gloves, or

severe burns may result.

Daily FR 02 D2

Maintenance Filter (continued)

Remove crumb basket

6

Lift the crumb basket from

the filter pan. Wipe the oil

and crumbs from the crumb

basket. Clean the crumb

basket with soap and water,

and thoroughly rinse with hot

water.

Remove filter pad hold down

ring

Remove the filter pad hold

down ring and clean with hot

SolidSense All Purpose Super

Concentrate (APSC) solution

at the compartment sink.

Rinse thoroughly with hot

water.

Remove filter pad from pan

7

Pull the filter pad from the

pan and discard pad.

Reassemble

0

Reassemble in reverse order,

placing the bottom screen into

the filter pan first, followed

by the filter pad with rough

side facing up, hold down

ring and the crumb basket.

Ensure the filter pan, bottom

screen, crumb basket, and the

hold down ring are

thoroughly dry before placing

filter pad into pan as water

will dissolve the filter pad.

Frymaster Fryer Models Using Model M2000 Computer

Remove bottom inner screen

8

Pull the bottom inner screen

from pan and clean

thoroughly with hot

SolidSense All Purpose Super

Concentrate (APSC) solution

at the compartment sink.

Rinse thoroughly with hot

water.

Clean filter drain pan

9

Wipe the oil and crumbs from

the filter pan.

Daily FR 02 D2

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 3 of 3

Clean area behind fryers Weekly FR 2 W1

Why

To ensure high-quality fried products and reduce the possibility of a fire near the fryer

Frymaster Fryer Models Using Model M2000 Computer

Time required

Time of day

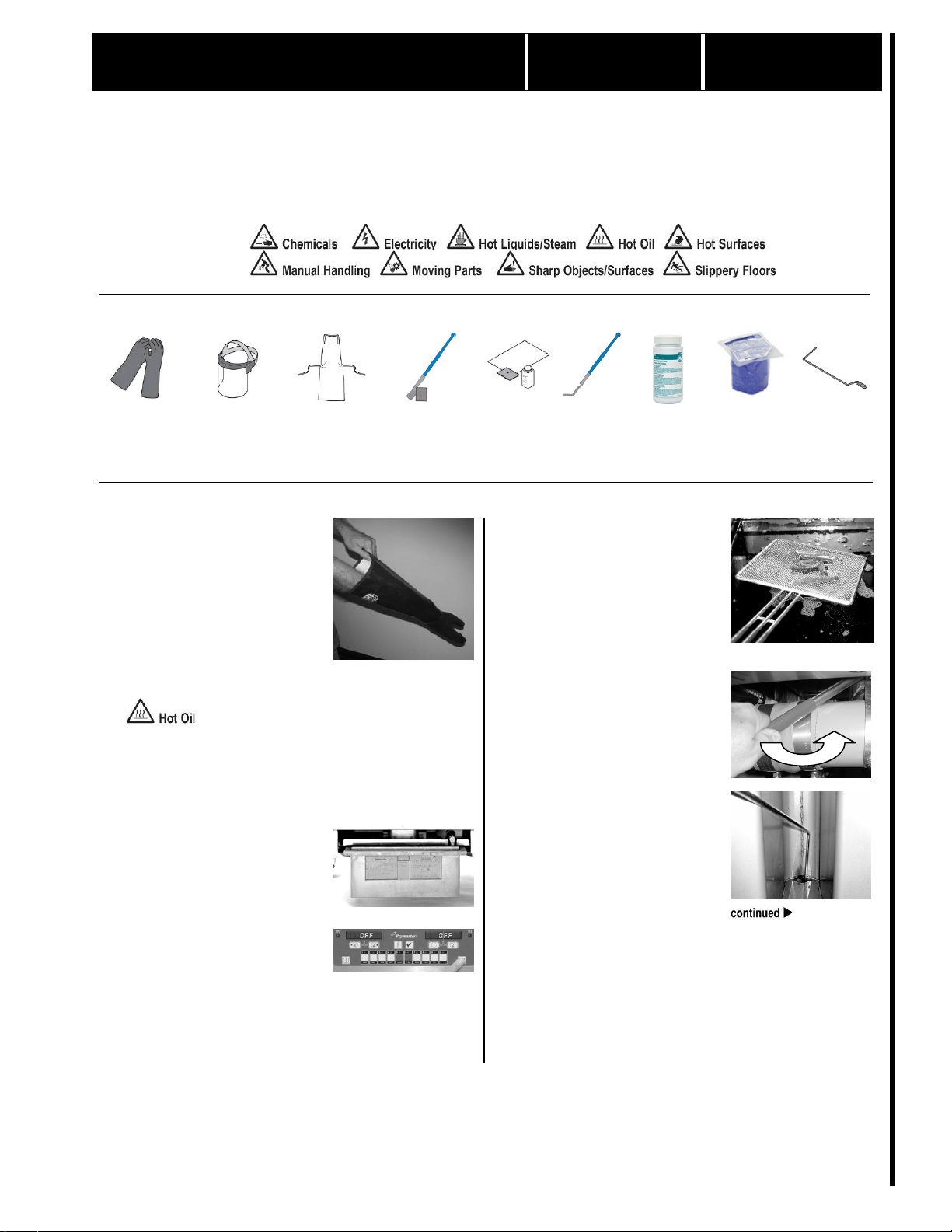

Hazard icons

5 minutes to prepare 45 minutes to complete

After close

For 24-hour restaurants: overnight or during lowvolume periods

Tools and supplies

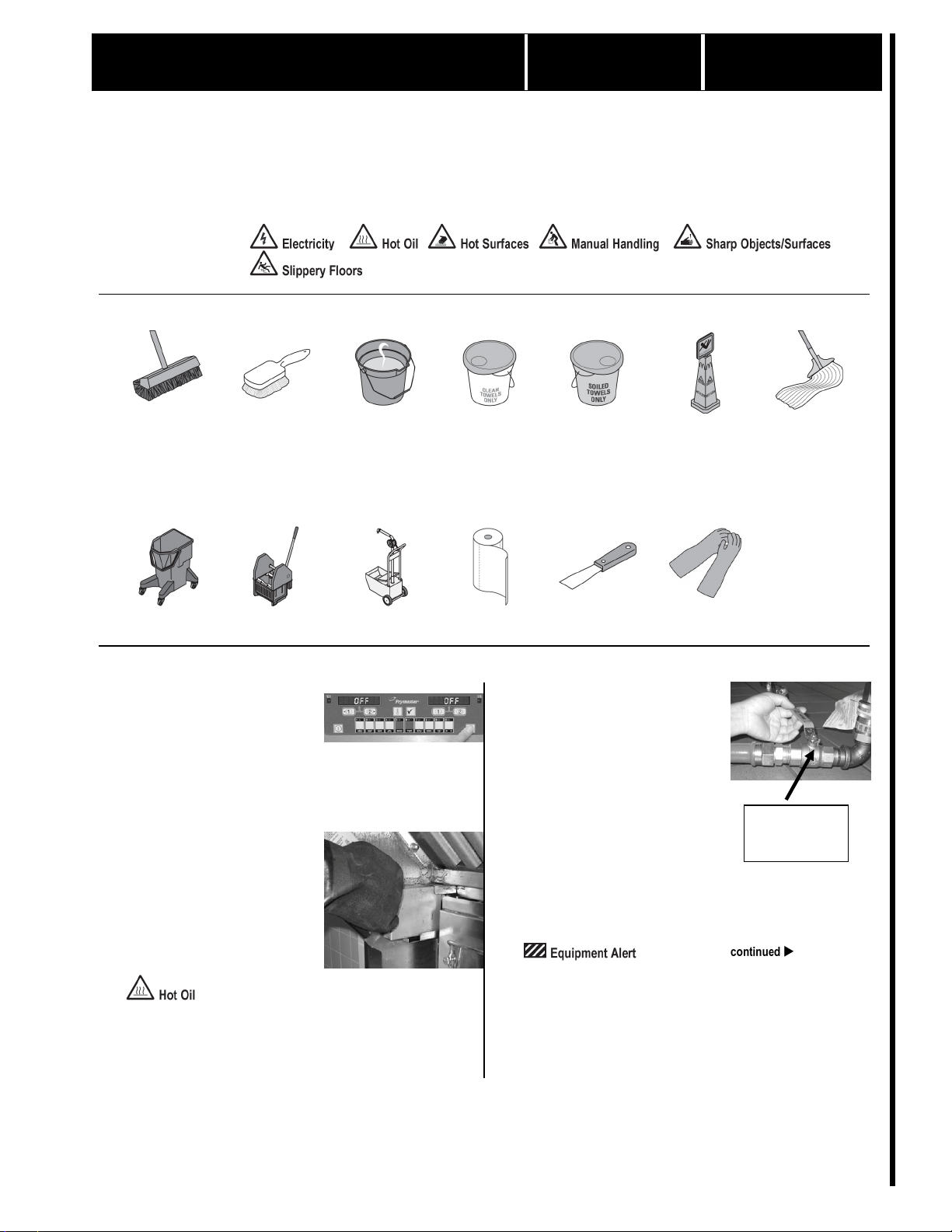

Brush, hi-lo deck

Brush, pot, nylon

Bucket with

KAY®

SolidSense™

All Purpose

Super Concentrate

(APSC)

Bucket, clean and

sanitized towels

Bucket, soiled towels

Caution Wet Floor

Sign

Mop bucket

Mop wringer

Oil removal cart

Paper towels

Putty knife

Neoprene Gloves

Mop

Procedure

Turn fryers off.

1

Turn all fryer power switches

to the off position.

Remove and empty grease

2

trough and cup.

Remove the grease trough

from the exhaust hood. Remove the grease cup from the

hood. The trough and cup are

located beneath the hood filters. Pour any oil in the

trough and cup into the oil

removal cart.

Oil in trough and cup may be

hot. Use gloves.

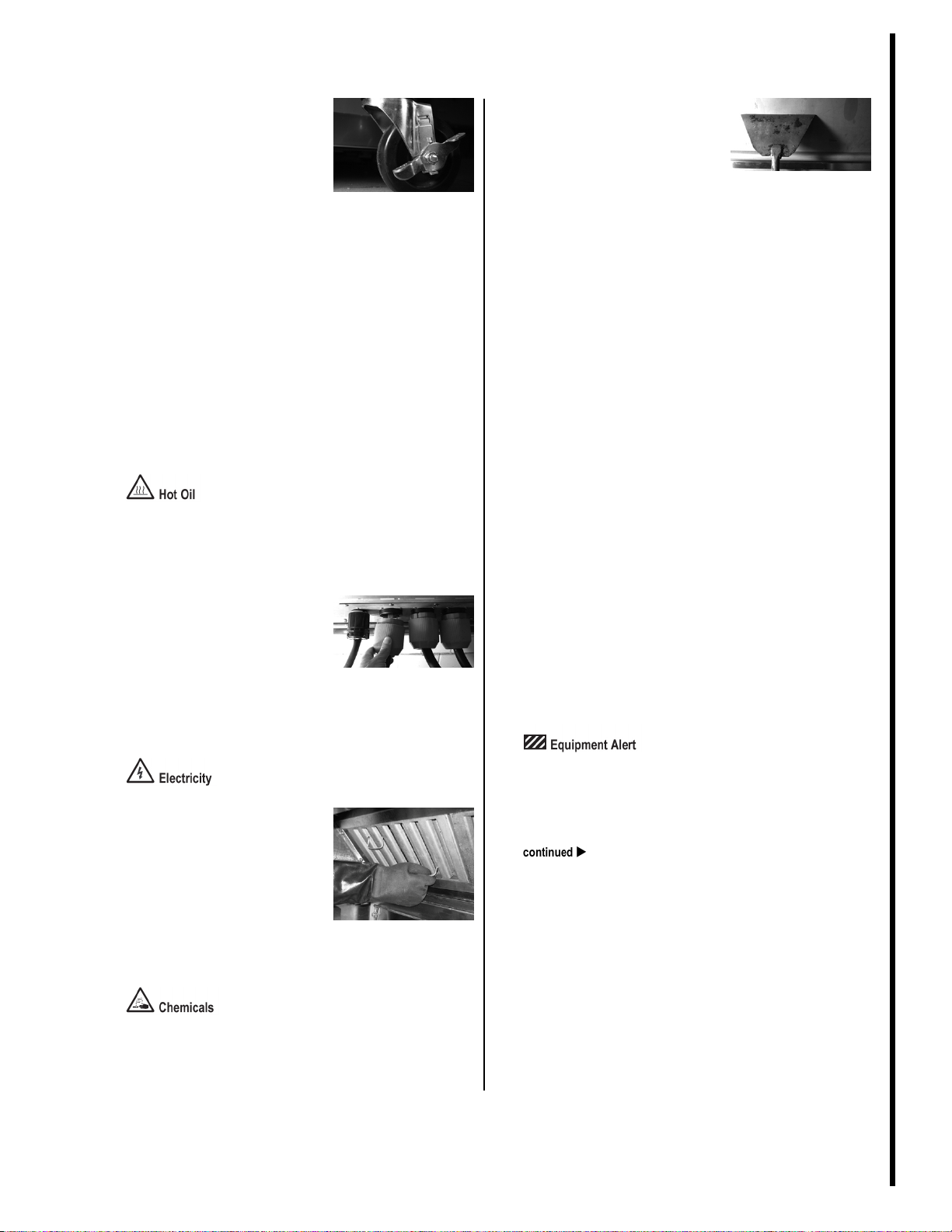

Shut off and disconnect gas.

3

If the fryer is not a gas fryer,

skip this step.

If the fryer is a gas fryer, use

the manual gas shut-off valve

to shut off the gas supply. The

manual gas shut-off valve is

located on the supply line

before the quick disconnects.

Then disconnect the gas line

from the fryer via the quick

disconnect.

Manual

off

shut-

Weekly FR 2 W1

Use only the manual shut-off

valve to shut off the gas. Do

not use the quick disconnects.

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 1 of 4

Clean area behind fryers (continued)

Prepare fryer for cleaning.

4

Release the locks on the fryer

wheels.

If the fryer has a capping

piece, lift the front of the capping piece far enough to let

the backsplash clear the filter

shelf. Roll the fryer carefully

away from the firewall, just

until the capping piece clears

the filter shelf.

Secure the capping piece, if

there is one. Place vat covers

on all vats.

Roll the fryer farther away

from the firewall, far enough

to clean behind the fryer.

Oil in fryer may be very hot.

Roll the fryer slowly to avoid

splashing the oil. Use gloves

Disconnect fryer from

5

electricity.

Unplug the fryer’s electrical

cord from the outlet by pulling on the electrical plug’s

body. You may need to twist

the plug to remove from the

outlet.

Clean fryer filters.

6

Remove the fryer filters from

the exhaust hood. Take the

filters to the threecompartment-sink and soak

them in KAY® SolidSense™

All Purpose Super Concentrate (APSC).

Scrape area behind fryer.

7

Use a putty knife to scrape off

all soft grease and hard carbon from the area behind the

fryer. Clean the following

areas in this order: the parts of

the stack you can reach; the

back of the exhaust hood; the

sides of the exhaust hood; and

the fryer filter recess area.

On an electric fryer, next use

the putty knife to scrape all

soft grease and hard carbon

from all sheet metal around

the fryer, the standoff piece,

and the fryer stand. Skip to

step 8 after these areas are

cleaned.

On a gas fryer, next use the

putty knife to scrape all soft

grease and hard carbon from

these areas in this order: the

flue restrictor, all sheet metal

around fryer, the removable

gravity blade, the seal angle,

the stand-off piece, and the

fryer stand.

On a gas fryer, be careful not

to drop any soft grease or

hard carbon into the fryer flue

passage while cleaning.

Do not break the fire protection fusible link in the lower

area of the stack. Breaking the

link will activate the fire extinguishing system.

Frymaster Fryer All models using an M2000 Computer Weekly

KAY® SolidSense™ All

Purpose Super Concentrate

(APSC)

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 2 of 4

FR 2 W1

Clean area behind fryers (continued)

Clean area behind fryer.

8

Use a nylon pot brush, a hi-lo

deck brush, and a bucket of

hot KAY® SolidSense™ All

Purpose Super Concentrate

(APSC) solution to scrub all

of the areas you scraped in

step 7. Clean the areas in the

same order that you scraped

them in step 7. Then use the

hi-lo deck brush to scrub the

floor around the fryer.

Wipe all areas with paper

towels until they are clean

and dry.

The floor may be wet where

you have scrubbed it.

Ask manager to inspect.

9

Ask a manager to inspect

your work and approve the

cleaning. Repeat any cleaning

as your manager directs.

Wash fryer legs and casters.

10

Use a nylon pot brush and a

bucket of hot KAY®

SolidSense™ All Purpose

Super Concentrate (APSC)

solution to wash the legs and

casters of the fryer. Wipe dry

with paper towels.

Mop floor around fryer.

11

Use a mop and a bucket of

hot KAY® SolidSense™ All

Purpose Super Concentrate

(APSC) solution to mop the

entire floor around the fryer.

Floor may be wet from mopping.

Allow surfaces to dry.

12

Allow all fryer, wall, and

floor surfaces to air dry.

Reconnect fryer to electricity.

13

Roll the fryer slowly toward

the electrical outlet until it is

close enough to connect the

plug. Plug the fryer into the

outlet.

Oil in fryer may be very hot.

Roll the fryer slowly to avoid

splashing the oil.

Prepare fryer for use.

14

Roll the fryer forward carefully until it is close to the filter

shelf. Remove the vat covers

from all vats. Lift the front of

the capping piece until the

backsplash clears the filter

shelf, and roll the fryer carefully into its normal position.

Reconnect fryer to gas supply.

15

If the fryer is an electric fryer,

skip this step.

Check both ends of the quick

disconnect for grease. Wipe

the quick disconnect clean if

necessary. Reconnect the gas

line coupling.

Be sure the gas quick disconnect is fully engaged and

interlocked before turning on

the gas supply.

Frymaster Fryer All models using an M2000 Computer Weekly

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 3 of 4

FR 2 W1

Clean area behind fryers (continued)

Reinstall fryer filters and

16

grease trough.

Lock wheels into place. Reinstall the fryer filters and the

grease trough in the exhaust

hood.

Turn on gas supply.

17

If the fryer is an electric fryer,

skip this step.

Turn the manual gas shut-off

valve to the on position. Turn

the computer on to verify

burners will re-light. Once the

burners have been re-lit you

can turn the computer off.

Clean area behind other fryers.

18

Repeat steps 1 through 17 for

all remaining fryers.

Frymaster Fryer All models using an M2000 Computer Weekly

©McDonald’s Corporation · Planned Maintenance Manual · Revised April 2013 Page 4 of 4

FR 2 W1

Loading...

Loading...