Page 1

LOV Fryer Technical Information Manual

Description Page

1.1 ATO (Automatic Top-Off) Service Procedures……………………….2

1.1.1 ATO (Automatic Top-Off) Troubleshooting………………………….. 2

1.1.2 ATO (Automatic Top-Off) Board #1 Pin Positions/Harnesses……... 4

1.1.3 ATO (Automatic Top-Off) Board #2 Pin Positions/Harnesses……... 5

1.1.4 Replacing the ATO (Automatic Top-Off) Board/Transformer……... 6

1.1.5 Replacing the ATO Pump/Solenoid………………………………….. 6

1.2 MIB (Manual Interface Board) Service Procedures………………… 6

1.2.1 Manually Draining……………………………………………………… 8

1.2.2 MIB (Manual Interface Board) Troubleshooting…………………….. 8

1.2.3 MIB (Manual Interface Board) Pin Positions/Harnesses…………. ...10

1.2.4 MIB (Manual Interface Board) Display Diagnostics………………….12

1.2.5 MIB (Manual Interface Board) Auto Filtration Failure Scenarios…...14

1.2.6 Replacing an MIB Board………………………………………………. 14

1.3 AIF (Automatic Intermittent Filtration) Service Procedures………… 15

1.3.1 AIF (Automatic Intermittent Filtration) Troubleshooting…………….. 15

1.3.2 AIF (Automatic Intermittent Filtration) Board #1 Pin Positions......…16

1.3.3 AIF (Automatic Intermittent Filtration) Board #2Pin Positions………17

1.3.4 Replacing an AIF (Automatic Intermittent Filtration) Board…………18

1.3.5 Replacing an Actuator………………………………………………….. 18

1.4 M2007 Computer Filtration Service Procedures…………………….. 19

1.4.1 M2007 Computer Troubleshooting…………………………………….19

1.4.2 M2007 Useful Codes…………………………………………………… 22

1.4.3 Get Mgr Flowchart……………………………………………………… 22

1.4.4 M2007 Menu Summary Tree..………………………………………… 24

1.4.5 M2007 Pin Positions/Harnesses………………………………………. 26

1.5 Loading and Updating Software………………………………………. 27

1.5.1 Loading Software from SD card to MIB and AIF Boards…………… 27

1.5.2 Loading Software from SD card to M2007 Computer………………. 29

1.6 Tech Mode………………………………………………………………. 31

1.7 Fryer Setup Mode………………………………………………………. 32

1.8 RTI Service Issues……………………………………………………… 34

1.8.1 RTI MIB Tests…………………………………………………………… 34

1.8.2 RTI LOV Wiring…………………………………………………………. 35

1.8.3 RTI LOV Test Quick Reference……………………………………….. 36

1.9 Wiring Diagrams………………………………………………………… 37

1.9.1 LOV Electric Wiring Diagram with Thermal Sensor ……………….. 37

1.9.2 LOV Electric Wiring Diagram with RTD………………………………. 38

1.9.3 LOV Gas Wiring Diagram with Thermal Sensor…………………….. 39

1.9.4 LOV Gas Wiring Diagram with RTD………………………………….. 40

rev. 12.7.2007

DECEMBER 2007

819xxxx

Page 2

1.1 ATO (Automatic Top-off) Service Procedures

2

The automatic top-off system is activated when the oil level falls below a sensor in the rear of the

frypot. The signal is sent to the ATO board to engage the solenoid to the frypot and turn on the

ATO pump. The pump draws oil from the JIB (Jug In Box) to a port in the rear of the frypot.

Once the oil level has satisfied the sensor, the pump and solenoid turn off.

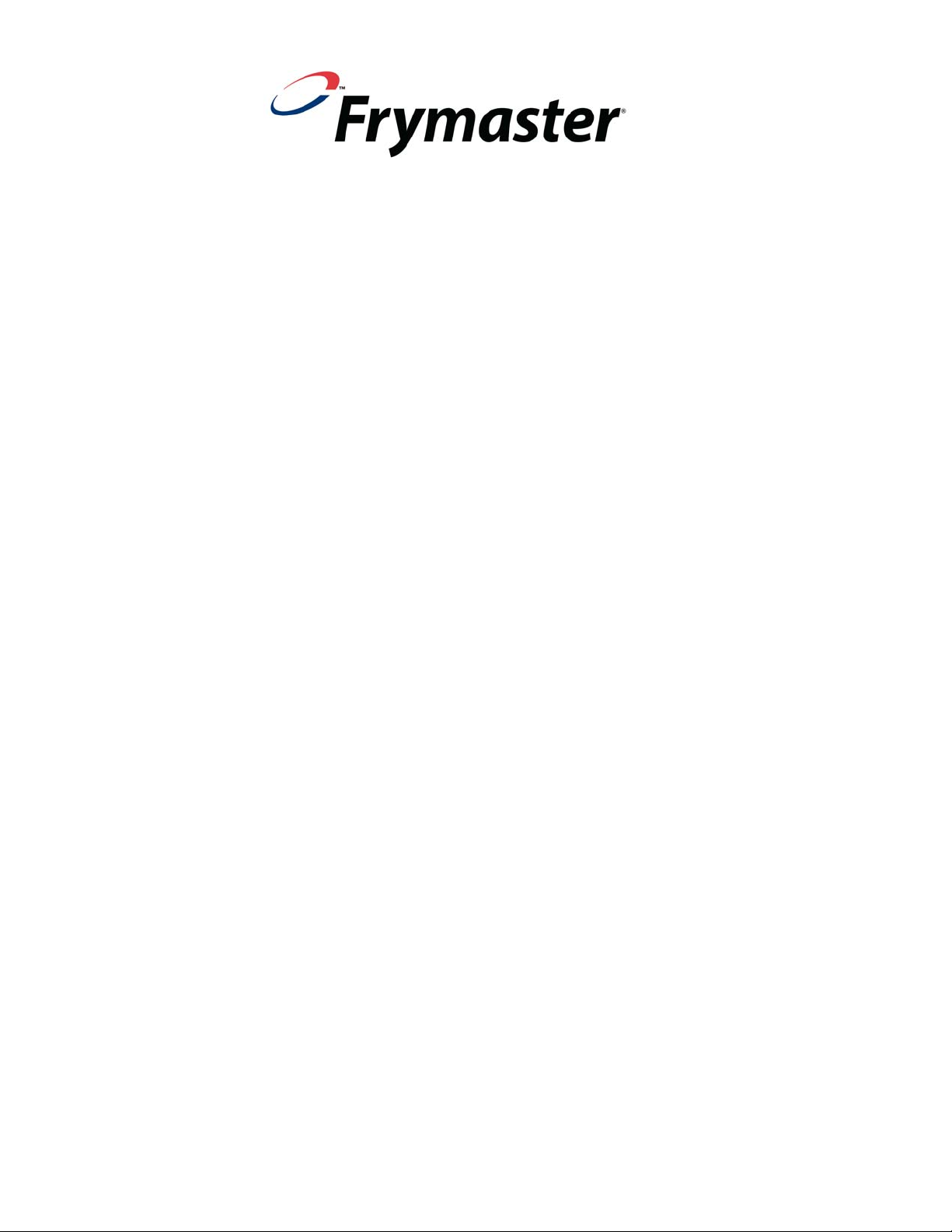

The ATO board is located inside the box, behind the

JIB (see Figure 1). The power for the ATO board in

electric fryers is supplied from the right hand

component box. On gas fryers the power is supplied

from the transformer box in the rear of the fryer. The

power passes through the transformer inside the ATO

box to the board. On the left side of the ATO box is

a power switch, which controls the flow of power

between the component/transformer box and the

ATO board.

Figure 1 Close up of

switch located

on the left side

of the JIB auto

top off box.

1.1.1 ATO (Automatic Top-off) Troubleshooting

Problem Probable Causes Corrective Action

A. Verify that the auto top off

power switch is switched on.

The yellow JIB low

light won’t

illuminate.

One vat tops off but

other vats fail to top

off.

Incorrect vat tops

off.

A. Auto top off power switch is off.

B. Power in the component box is

not present.

C. Failed transformer.

D. Loose wire connection

A. Failed solenoid

B. Loose wire connection.

A. Wired incorrectly.

B. Flexlines connected to wrong vat.

The switch is located behind the

JIB on the left side of the auto

top off control box.

B. Ensure power is present in the

component box.

C. If power is present in

component box, check the

transformer for correct voltage.

D. Ensure the yellow LED is

securely attached to plug J6 on

the ATO board.

A. Check power to the pump. If

the pump is hot, the solenoid

has probably failed.

B. Ensure all wiring harnesses are

securely connected to ATO

board and solenoids.

A. Ensure wires are wired

correctly.

B. Switch flexlines to correct vat.

Page 3

3

Problem Probable Causes Corrective Action

A. Verify that the auto top off

power switch is switched on.

The switch is located behind the

JIB on the left side of the auto

top off control box.

B. Check to see that fryer is

heating. Fryer temperature

must be at least 300°F (149°C).

Check probe resistance. If

probe is bad, replace the probe.

C. Ensure oil viscosity is thin

enough to pump.

D. Power to the ATO board has

been cut off. Restore power to

the board and cycle all

computers off and on to

readdress system.

E. Check solenoid to see if

functioning properly.

F. If the solenoid is working,

ensure that the screws on the

bottom of the pump are not too

tight. Loosen the screws. If

loosening the screws doesn’t fix

the problem, replace the pump.

G. Ensure transformer in ATO box

is functioning properly. Check

power from transformer to ATO

board. Ensure all harnesses are

plugged securely into place.

H. Check for proper voltages using

the pin position chart found on

page 4. If ATO found

defective, replace ATO board.

Frypots won’t top

A. Auto top off power switch is off.

B. Probe temperature lower than

setpoint.

C. Oil viscosity too thick

D. ATO board power loss

E. Failed solenoid.

off.

F. ATO pump failed or over

tightened.

G. Failed transformer/harness.

H. Failed ATO board.

Page 4

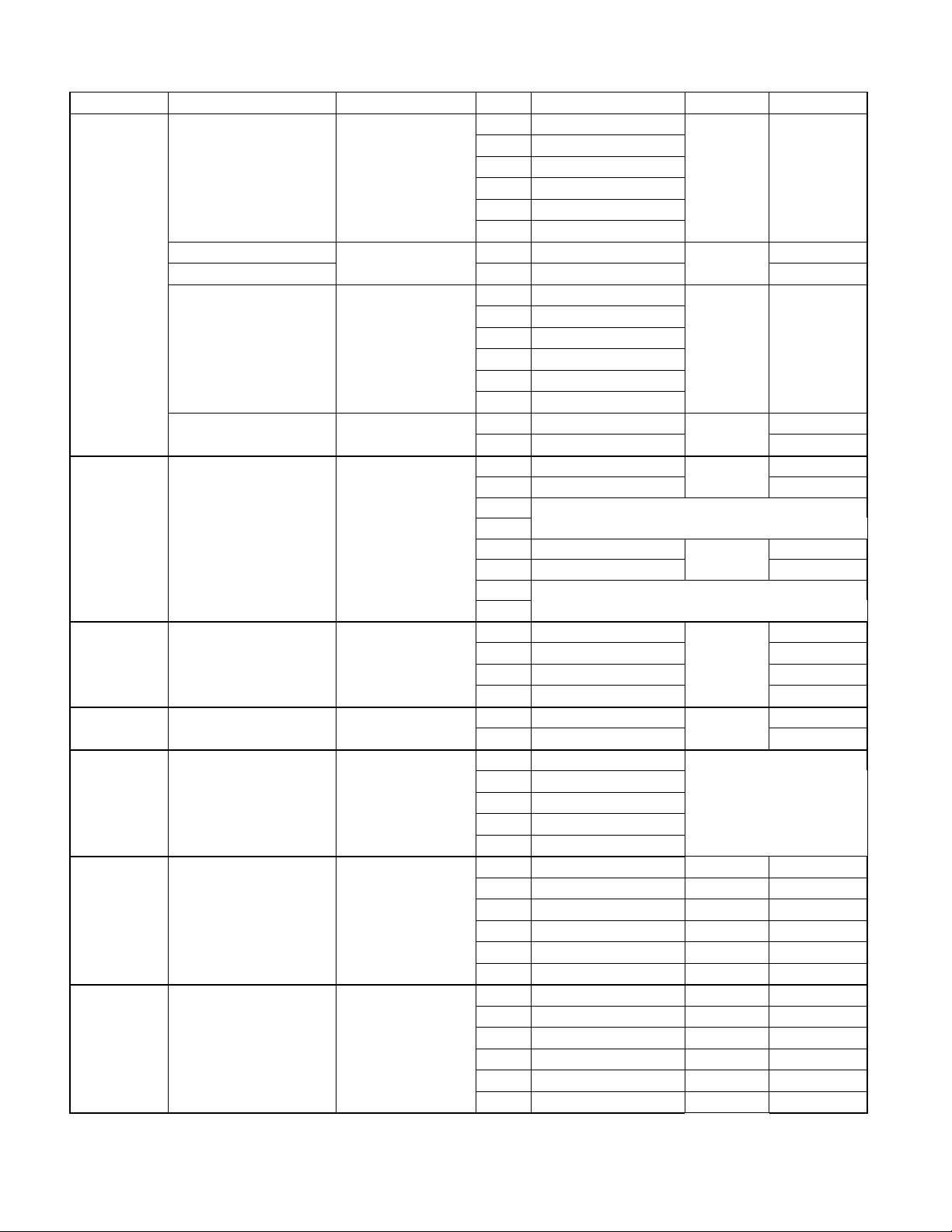

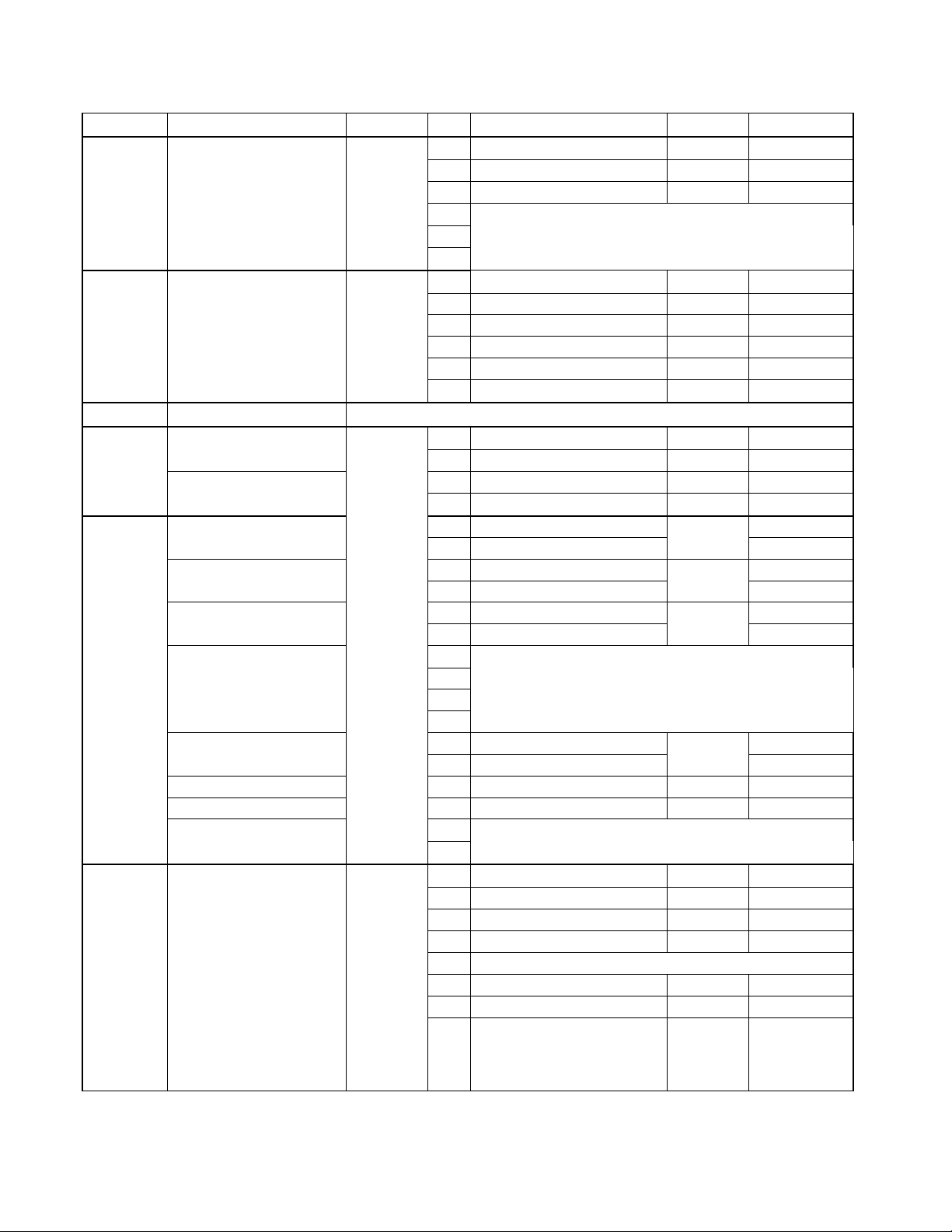

1.1.2 ATO (Automatic Top-Off) Board #1 Pin Positions (Current Prod with Thermal Sensors)

4

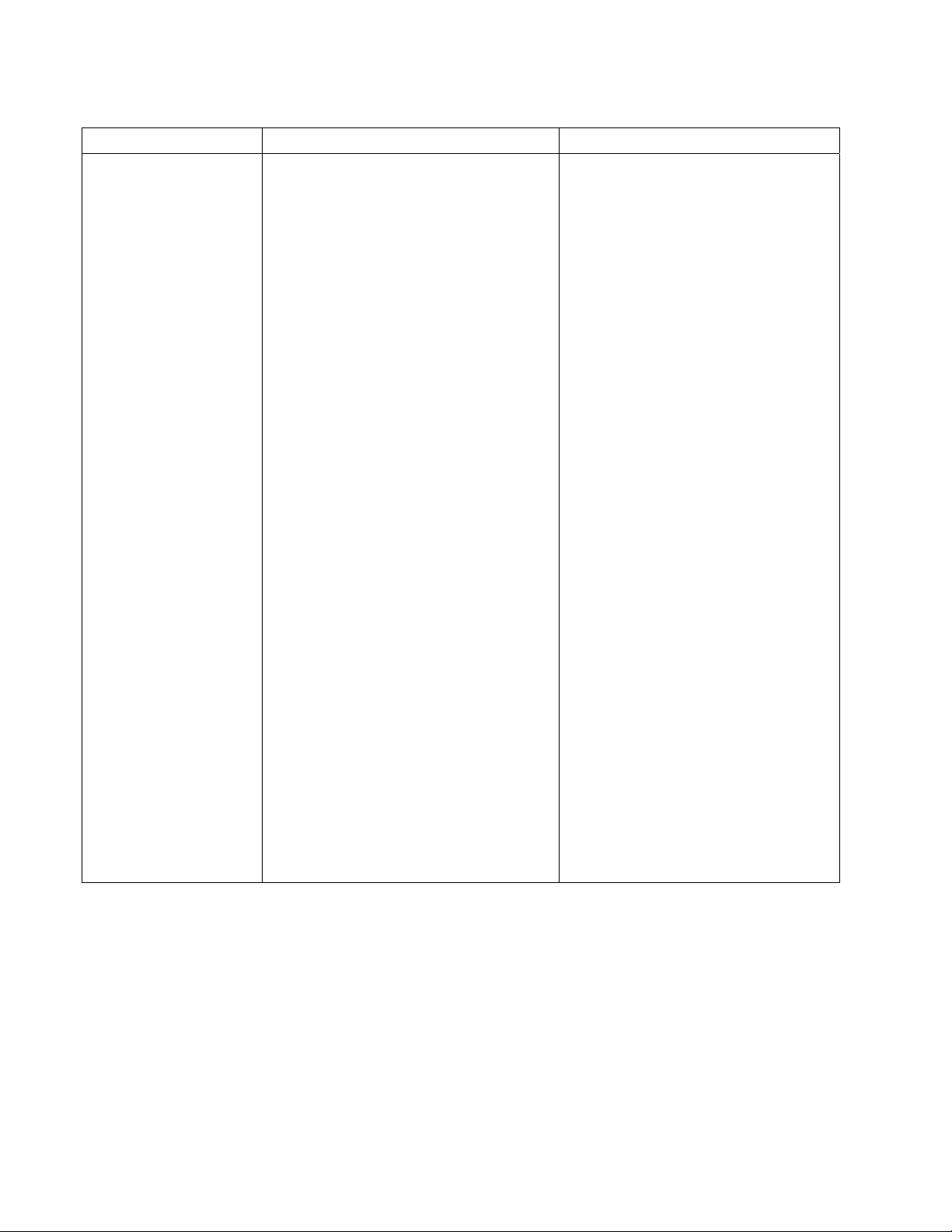

Connector From/To Harness # Pin # Function Voltage Wire Color

1 Output DV - Vat #1

2 Output FV - Vat #1

Solenoids

Top Off Pump

J1

J3 Transformer 8074553

J4 - Vat #3

J5 - Vat #2

J6 - Vat #1

J7 Orange LED 8074555

J8

J9

J10 AIF J5 8074546

JIB Reset Switch

Solenoids

Top Off Pump & JIB

Reset Switch

O/Flow Sensor & Fill

Sensor

Network Resistor

(pins 2 & 3)

or to next ATO Board

(4 & 5 vat units)

8074572 x1 (FV)

8074572 x2 (DV)

8074627

8074572 x1 (FV)

8074572 x2 (DV)

8074627

8074569 - Vat #1

8074567 - Vat #2

8074548 - Vat #3

8074570 - Vat #1

8074568 - Vat #2

8074549 - Vat #3

8074552

3 Output DV - Vat #2

4 Output FV - Vat #2

5 Output DV - Vat #3

6 Output FV - Vat #3

7 Top Off Pump Black

8 JIB Low Reset

9 24VAC DV - Vat #1

10 24VAC FV - Vat #1

11 24VAC DV - Vat #2

12 24VAC FV - Vat #2

13 24VAC DV - Vat #3

14 24VAC FV - Vat #3

15 Ground Red

16 Ground

1 24VAC Ret Orange

2 24VAC

3

4

5 12VAC Ret Red

6 12VAC

7

8

1 FV – SW Out Black

2 FV – Sw In White

3 DV – Sw Out Red

4 DV – Sw In

1 16VDC Black

2 16VDC Ret

1

2

3 Ground

4 RB7/DATA

5 RB6/CLOCK

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

Ground Orange

16VDC

24VAC Orange

16VDC

24VAC

12VAC

16VDC

16VDC

Black

Red

Blue

Brown

Green

Red

Page 5

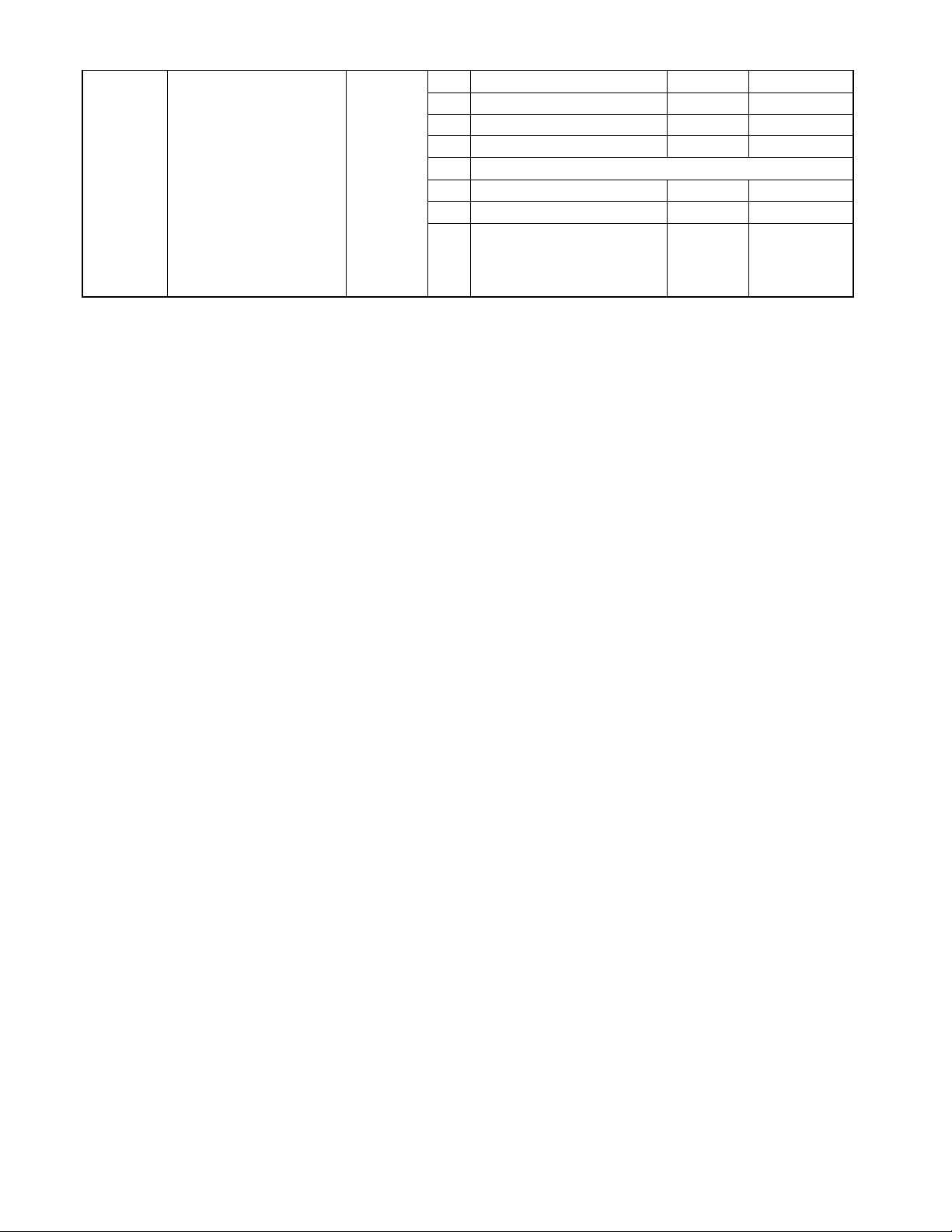

1.1.3 ATO (Automatic Top-Off) Board #2 Pin Positions (Current Production with RTD)

5

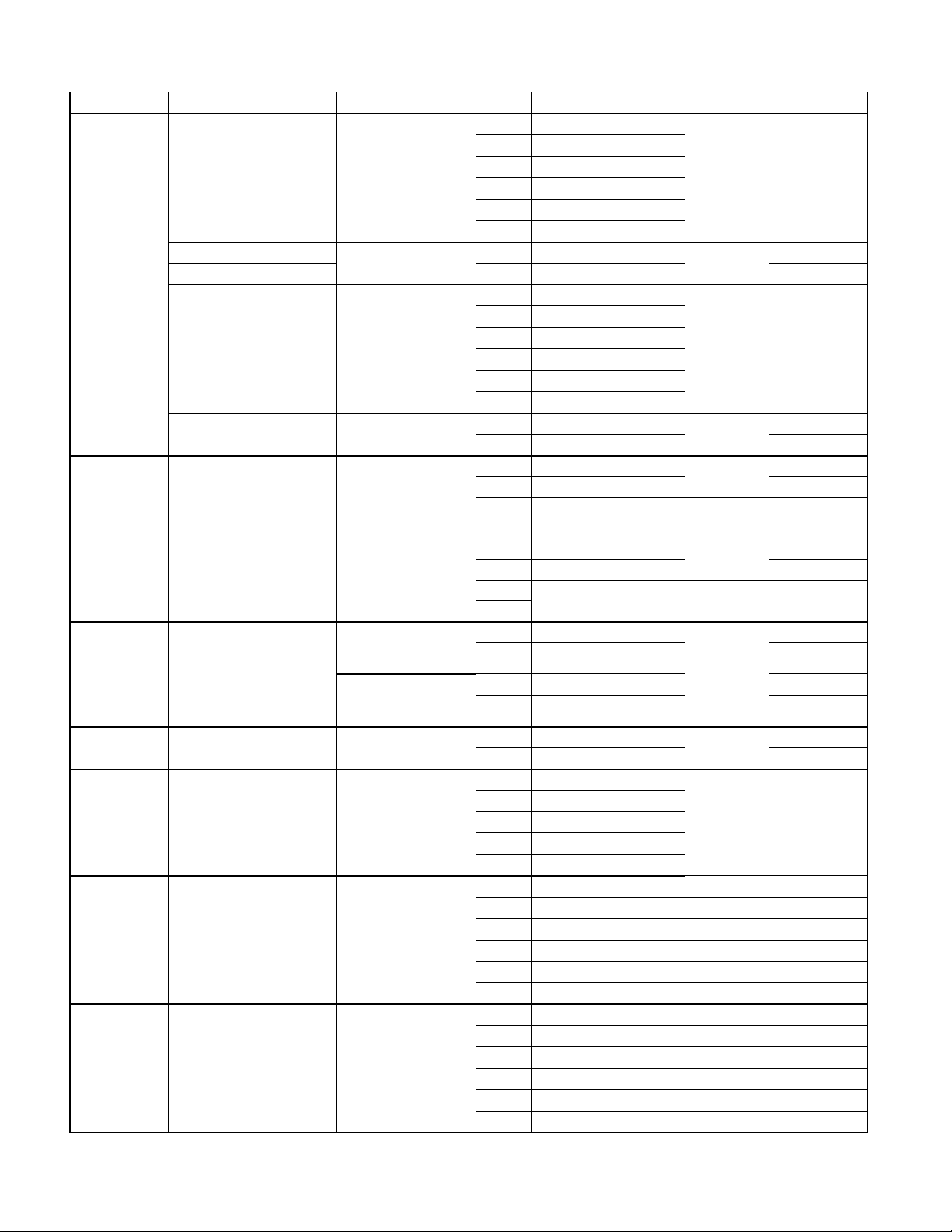

Connector From/To Harness # Pin # Function Voltage Wire Color

1 Output DV - Vat #1

2 Output FV - Vat #1

Solenoids

Top Off Pump

J8

J4 (Rear) /

J5 (Front)

J3 - Vat #3

J2 - Vat #2

J1 - Vat #1

J6 Orange LED 8074555

J7

J10

J9 AIF J5 8074546

JIB Reset Switch

Solenoids

Top Off Pump & JIB

Low Reset Switch

Transformer 8074553

ATO RTD

Network Resistor

(pins 2 & 3)

or to next ATO Board

(4 & 5 vat units)

8074572 x1 (FV)

8074572 x2 (DV)

8074627

8074572 x1 (FV)

8074572 x2 (DV)

8074627

8074655 - Vat #1

8074654 - Vat #2

8074621 - Vat #3

8074552

3 Output DV - Vat #2

4 Output FV - Vat #2

5 Output DV - Vat #3

6 Output FV - Vat #3

7 Top Off Pump Black

8 JIB Low Reset

9 24VAC DV - Vat #1

10 24VAC FV - Vat #1

11 24VAC DV - Vat #2

12 24VAC FV - Vat #2

13 24VAC DV - Vat #3

14 24VAC FV - Vat #3

15 Ground Red

16 Ground

1 24VAC Ret Orange

2 24VAC

3

4

5 12VAC Ret Red

6 12VAC

7

8

1 DV - Probe Ground White

2 DV - Probe Red

3 FV - Probe Ground White

4 FV - Probe

1 16VDC Black

2 16VDC Ret

1

2

3 Ground

4 RB7/DATA

5 RB6/CLOCK

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

Ground Orange

16VDC

24VAC Orange

16VDC

24VAC

12VAC

Ohm

16VDC

Black

Red

Blue

Brown

Red

Red

Page 6

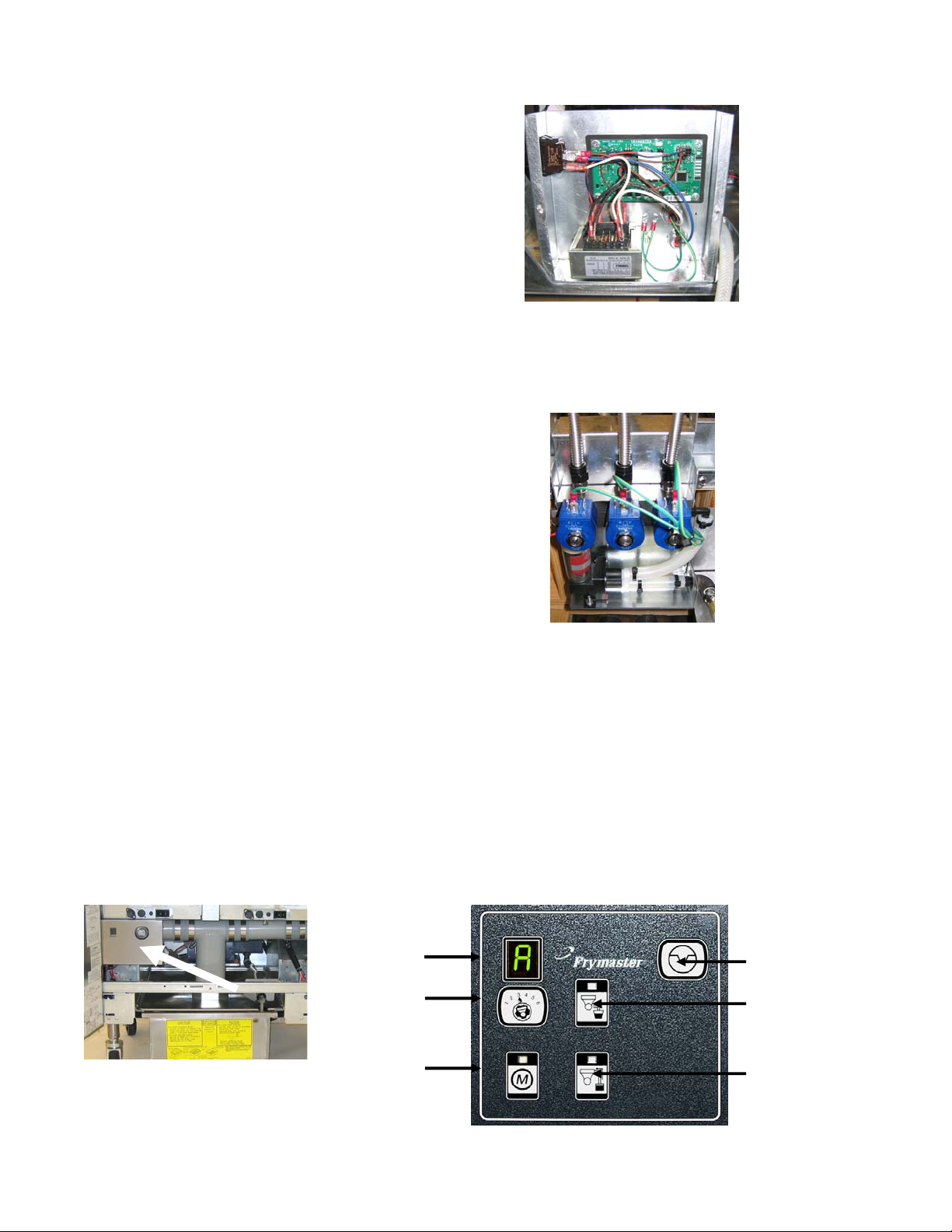

1.1.4 Replacing the ATO board or Transformer

6

Disconnect the fryer from the electrical power

supply. Locate the ATO box (see Figure 1 on

page 12), behind the JIB (Jug In Box).

Remove the cover to expose the transformer

and ATO board (see Figure 2). Mark and

unplug any wires or harnesses. Replace the

defective component and reattach all wires or

harnesses. Replace the cover. Once replaced,

reconnect the power. Power cycle all

computers after power has been restored to the

Figure 2

ATO board.

1.1.5 Replacing the ATO Pump or Solenoid

Disconnect the fryer from the electrical power

supply. Locate the ATO pump and solenoid

tree (see Figure 3), behind the ATO box. Mark

and unplug any wires or harnesses. Replace

the defective component and reattach all wires

or harnesses. Once replaced, reconnect the

power.

Figure 3

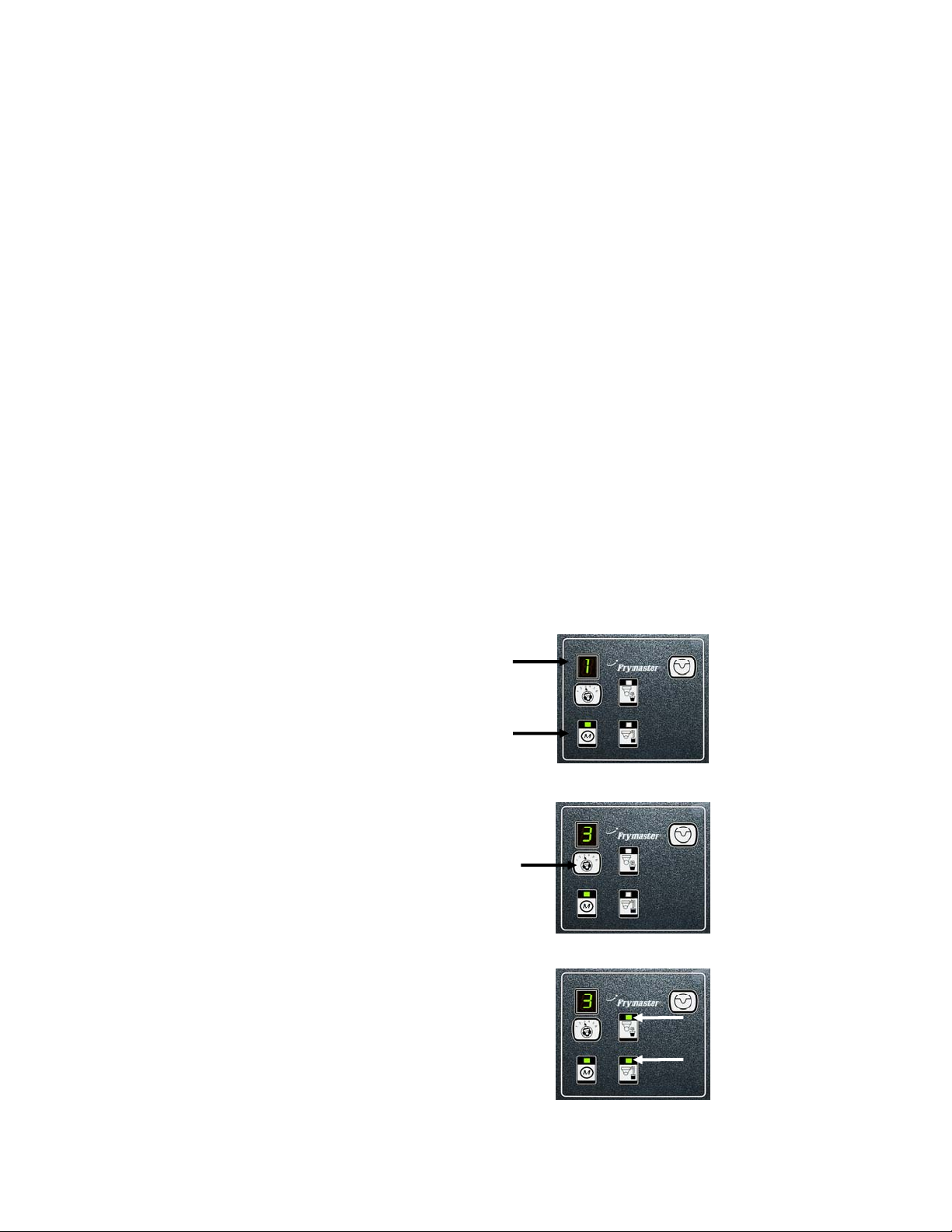

1.2 MIB (Manual Interface Board) Service Procedures

The MIB (Manual Interface Board) oversees and controls filtration. It receives and sends data

over the CAN (Controller Area Network) to and from various sensors and computers. It

activates the filtration cycle; controlling when actuators should open and close.

The MIB controller is located inside the left cabinet (see Figure 4). In normal operation a cover

hides the MIB controls and the LED display is visible. The cover is held in place with three torx

screws. In normal operation, an “A” is displayed for automatic mode. The MIB control board is

useful for diagnostic purposes. It allows manual operation of both the actuators and filter pump

without using the M2007 computer.

Mode Display

Reset Switch

Drain Switch

Return Switch

Figure 4: MIB controller cover.

Vat Selector

Switch

Manual /Auto

Switch

Figure 5

Page 7

Buttons and LED’s

7

Manual – This button is used to toggle between auto and manual filtration mode. A

corresponding LED is lit when in Manual mode. When pressed, a message will be sent to all

vats, indicating the mode has changed.

The following buttons are inoperable in auto mode:

Select - This button is used to scroll through available vats, choosing one to be manually filtered.

Drain – This button is used to open and close the drain on the vat indicated on the display.

When the button is pressed and the manual board is waiting for a response from the AIF board,

the corresponding LED will blink slowly. Once a response is received the LED will be

illuminated if the drain is open or extinguished if the drain is closed. If a message was not

received from the AIF board, it times out and the LED will blink rapidly.

Return – This button is used to open and close the return valve on the vat indicated on the

display. It also turns on and off the pump. When the button is pressed and the manual board is

waiting for a response from the AIF board, the corresponding LED will blink slowly. Once a

response is received, the LED will be illuminated if the return is open or extinguished if the

return is closed. If a message is not received from the AIF board, it times out and the LED will

blink rapidly. The pump is turned off first before closing the return valve or the valve will open

first before turning on the pump.

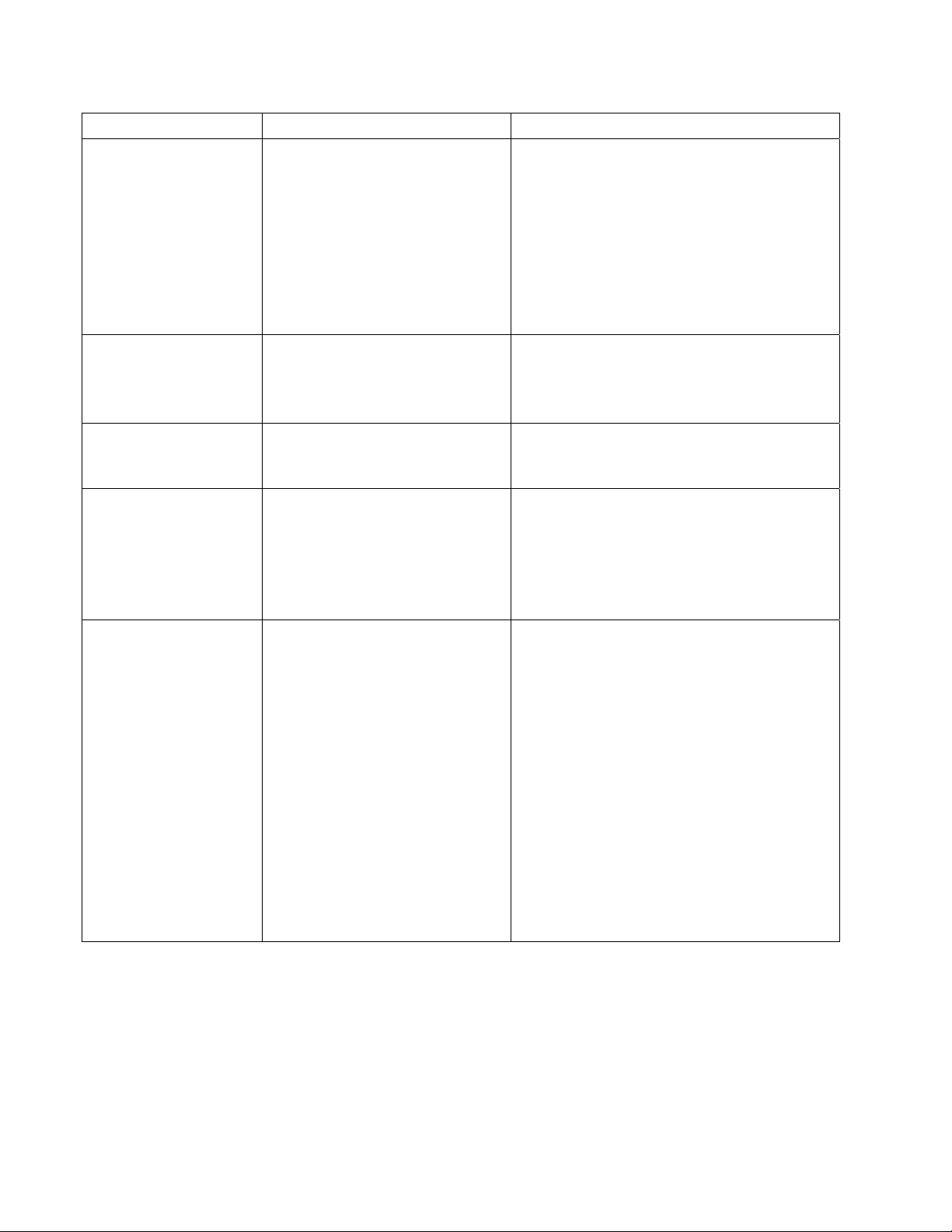

1.2.1 Manually Draining, Refilling or Filtering using the MIB board

Press the manual/auto switch to set to manual.

The LED on the manual key will illuminate

and a vat number is displayed (see Figure 6).

Press the vat selector switch to change vats

(see Figure 7).

Pressing the drain or return switch illuminates

and activates the drain or return valve for the

vat indicated. Pressing both allows filtration

(see Figure 8).

Pressing the manual/auto switch will return to

automatic mode.

Figure 6

Figure 7

Figure 8

Page 8

1.2.2 MIB (Manual Interface Board) Troubleshooting

b

8

Problem Probable Causes Corrective Action

A. Ensure MIB board is in “A”

automatic mode. Press the reset

button.

B. Re move and replace cover and see if

filtration will start.

C. Replace filter relay with part number

8074482 24VDC relay.

See MIB display diagnostics on page 12

for explanation.

Check the left transformer in left

component box. Should read 24VDC. If

not replace transformer.

Press the reset switch on the top right

corner of the MIB board. This will

reinitialize the CAN system. This reset

takes about 20 seconds per vat. It could

exceed one minute before returning to

“A”.

A. Ensure the CAN bus system is

terminated at BOTH ENDS (on the

M2007 connector J6 and on the ATO

board connector J9) with a resistor

equipped 6-pin connector. The resistor

can be shorted. If so, remove the

shrink wrap and ensure that the resistor

leads are not touching.

B. Unplug and reseat all wiring harnesses

in CAN system. Check resistance

etween pins 2 and 3 on the CAN

network connectors. If checking with

resistor at the end reading should be

120 ohms.

Auto filtration won’t

start.

MIB display shows

something other

than an “A” or vat

number.

No power present at

the MIB board

MIB error will not

clear.

MIB indicates more

or less vats than

fryer has.

A. Check that MIB board is not

in manual mode.

B. Check to see that the MIB

cover is not damaged and

depressing the buttons.

C. Filter relay has failed.

An error has occurred.

Transformer has failed in left

component box.

Power surge or other electrical

problem.

A. Network is not terminated

correctly.

B. Wiring harnesses are loose

or damaged.

Page 9

Problem Probable Causes Corrective Action

9

A. Ensure the CAN bus system is

terminated at BOTH ENDS (on the

M2007 connector J6 and on the ATO

board connector J10) with a resistor

equipped 6-pin connector. The resistor

can be shorted. If so, remove the

shrink wrap and ensure that the resistor

leads are not touching.

B. Ensure all 6-pin CAN connectors are

tight between the M2007 (J6 and J7),

MIB (J1 and J2), AIF (J4 and J5) and

ATO (J10) boards.

MIB board

alternating “N” and

“r”.

Network error on the CAN bus

communication.

C. Check continuity between each color

wire on the CAN connectors into J7 on

the far right computer and J10 on back

of the ATO board (black to black,

white to white, and red to red), and

ensure there is no continuity between

different color wires (black to red, red

to white, and white to black).

D. Ensure black computer locator wires

are connected from ground to correct

pin position (see drawing 8051656

page 34 and 35).

E. Ensure all boards have the corner

ground wire attached and tightened.

Page 10

1.2.3 MIB (Manual Interface Board) Pin Positions and Harnesses

10

Connector From/To Harness # Pin # Function Voltage Wire Color

1 Ground Black

2 CAN Lo Red

J1 M2007 J7 8074546

J2 AIF J4 8074547

J3 SD Card

RTI - JIB Fill Switch

J4

Reset Switch

Transformer

Filter Relay

Blue LED

8074649

J5

J6

Pan Switch

RTI - Pump &

Solenoids

3 CAN Hi White

4

5

6

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Momentary Switch - Out 5VDC Red

2 Momentary Switch - In 5VDC Black

3 Ground Red

4 Reset Green

1 24VAC Black

2 24VAC Ret

3 Pump Motor Red

4 Pump Motor

5 Blue LED + Black

6 Blue LED 7

8

9

10

11 Pan Sw + Black

12 Pan Sw 13 Ground

14 Ground

15

16

1 From RTI transformer 24VAC Black

2 Common White

3 To RTI "Add Pump" Relay 24VAC Green

4 To Waste Solenoid - 3 Way 24VAC Brown

5

6 To Fill Solenoid - 3 Way

7 Ground - Fill Solenoid

From RTI "Waste Tank Full

8

Sensor" Test Pins 1 to 8

24VAC

24VDC

24VDC

24VDC

24VAC

0VDC –

5VDC –

Not Full

Full

White

Green

White

Red

Black

Black

Red

Page 11

J7 From RTI Box

11

1 From RTI transformer 24VAC Black

2 Common White

3

4 To Waste Solenoid - 3 Way 24VAC Brown

5

6 RTI JIB Valve Fill Solenoid

7 Ground - Fill Solenoid

24VAC

Green

0VDC –

From RTI "Waste Tank Full

Sensor" Test Pins 1 to 8

8

Full

5VDC –

Not Full Red

Page 12

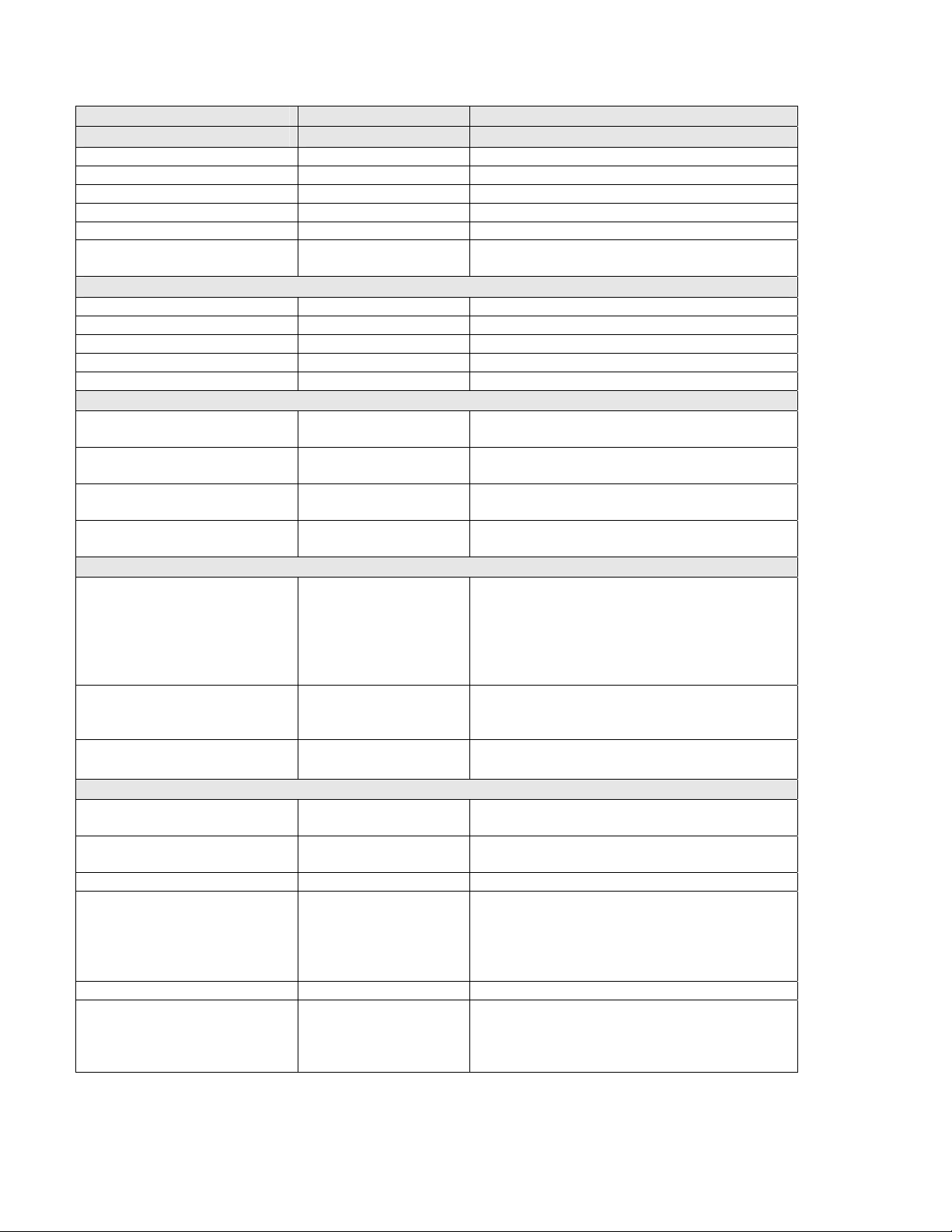

1.2.4 MIB (Manual Interface Board) Display Diagnostics

12

DISPLAY LEDS EXPLANATION

Drain

Vat # Drain led on Drain valve on vat # is open

Vat # Drain led off Drain valve on vat # is closed

Vat # Drain led slow blink Drain valve on vat # is opening or closing

Vat # alternating with O Drain led fast blink Problem opening drain valve on vat#

Vat # alternating with C Drain led fast blink Problem closing drain valve on vat#

Vat # alternating with d Drain led fast blink Problem with drain on vat#. (i.e. possible plugged

drain)

Return

Vat # Return led on Return valve on vat # is open

Vat # Return led off Return valve on vat # is closed

Vat # Return led slow blink Return valve on vat # is opening or closing

Vat # alternating with O Return led fast blink Problem opening return valve on vat#

Vat # alternating with C Return led fast blink Problem closing return valve on vat#

Network

Vat # alternating with n Drain led fast blink Network timeout waiting for response. Could be

on drain opening or on drain closing.

Vat # alternating with n Return led fast blink Network timeout waiting for response. Could be

on return opening or on return closing.

An “r” alternating with an “n” Network timeout waiting for a response on a reset

command.

An “F” alternating with an “n” Network timeout waiting for a success or failure

message during auto filtering.

Initial State, Configuring the system, and resetting

U The state of the battery is unknown. The manual

board is waiting for an INIT_CONFIG message

from a cooking computer. Once the message is

received the manual board will start the process

of determining which fryers have split or full

vats.

L An L will be displayed while the manual board is

contacting the cooking computers for the initial

configuration of the system.

An “r” An “r” is displayed to indicate that the system is

in the process of resetting a vat.

Miscellaneous

Vat # alternating with an “E” The actuator circuit has an issue. Check th at the

actuator is plugged in.

Vat # alternating with an “R” The vat is trying to close the corresponding drain

and return valves.

A Manual LED off The system is in auto filtration mode.

Vat # LED fast blinking

There will also be a fast

blinking LED

corresponding to the

problem valve.

Vat # Manual LED on The system is in manual mode.

P This will only be displayed in auto filtration

The system can not go into auto filtration mode

because there is a problem closing a valve on one

of the vats.

mode. It indicates that the pan is not in the

system. Any auto filtration messages received at

this time are ignored.

Page 13

13

MIB (Manual Interface Board) Display Characters

A – Auto Mode – Auto Filtration enabled.

C – Closed Valve - The display will alternate between C and the corresponding vat number and

the corresponding valve led is blinking.

d – Drain Issue- The display will alternate between d and the corresponding vat number. This

indicates the drain valve has a problem. i.e. The drain is clogged.

E – Actuator circuit is not sensing the actuator. The display will alternate between E and the

corresponding vat number. Ensure the actuator is plugged in.

F – An “F” alternating with an “n” appears when the MIB doesn’t receive a complete filtration

response from the AIF board.

L – Loading - Loading the vat configuration from the cooking computers. The MIB has been in

an unknown state (i.e. Initial startup) and is reloading information. This is not displayed often.

n – Network Error - An “n” displayed alternating with another character indicates a network

error. An “r” alternating with an “n” indicates a network timeout on a reset. An “F” alternating

with an “n” appears if the manual board never receives a complete filtration response from the

AIF board. If a vat number is alternating with an “n”, either the drain or the return led is also

blinking, indicating a timeout error opening or closing the drain.

O – Open Valve - The display will alternate between O and the corresponding vat number and

the corresponding valve led is blinking.

P – Pan Switch – Filter Pan is out of the battery. Filtration is suspended.

r – Reset Switch - Reset the vat closes all of the valves on the vat. If displayed for some time,

there is probably a problem with the board.

U – The battery is not configured. The manual board must receive a message from a cooking

computer telling it to initialize the battery.

1 – 8 – These are the numbers that correspond to the vats. These numbers are displayed in

Manual mode.

Page 14

1.2.5 MIB (Manual Interface Board) Auto Filtration Failure Scenarios

14

Failure Display Solution

Cannot open drain valve. Vat # alternating with O, fast

Check drain valve.

blinking drain LED.

No message from the cooking

computer, indicating that the oil

has drained out.

Vat # alternating with d, fast

blinking drain LED.

Close drain valve.

Cannot open return valve

Vat # alternating with O, fast

blinking return LED.

Close drain valve.

Cannot close drain valve

Vat # alternating with C, fast

blinking drain LED.

Turn off pump. Close Return

Valve. Open Drain valve in

case something is stuck.

Actuator is not plugged in. Vat # alternating with E. Plug in actuator.

Cannot close return valve

Vat # alternating with C, fast

blinking return LED.

Check return valve.

Manual board never gets a

response back from AIF board

“N” is displayed. Check network cable from

MIB plug J2 to AIF plug J4.

indicating success or failure in

filtering.

1.2.6 Replacing the MIB Board

Disconnect the fryer from the electrical power supply. Remove the torx screws from the MIB

cover, exposing the MIB board (see Figure 9). Removing the four nuts in the corners

disconnects the MIB board. Carefully remove the plugs on the rear of the board (see Figure 10).

Replace with a new MIB board and reverse steps to reassemble. Once replaced, reconnect the

power.

The board will need to be readdressed to the system. Readdress the fryer by pressing and

holding

3and 4 simultaneously for TEN seconds until a third chirp is heard and code

appears. Enter 2007. The MIB display will display L for several seconds followed by the vat

number alternating with “r” until the readdress is complete. When the readdress is finished, the

MIB board will display A. This step must be done when a MIB board is replaced. The

readdress procedure can be done from any one M2007 computers in the bank.

Figure 9

Figure 10

Page 15

1.3 AIF (Automatic Intermittent) Filtration Service Procedures

15

The AIF (Automatic Intermittent Filtration)

board controls the actuators that open and

close the drain and return valve. The AIF

boards are located inside a protective housing,

under each frypot (see Figure 11).

Figure 11

1.3.1 AIF Troubleshooting

Problem Probable Causes Corrective Action

A. Ensure the actuator is plugged

into the proper connection.

B. Check power on the connector

of the problem actuator while

trying to manually open or close

an actuator. Pins 1 (Black) and

4 (White) should read +24VDC

when trying to open an actuator.

Pins 2 (Red) and 4 (White)

should measure -24VDC when

trying to close an actuator). If

either one of these voltages are

missing, the AIF board may be

bad. Test the actuator by

plugging into another connector

to open or close the actuator. If

the actuator operates, the board

is bad. Replace the board.

C. If proper voltages are present at

the connector and actuator

doesn’t operate, actuator may be

bad. Replace the actuator.

A. Ensure the actuator is plugged

into correct connection.

B. Ensure the locator pin is in

proper position in plug J2. See

table B on page 37-40.

Actuator doesn’t

function.

Actuator functions

on wrong vat.

A. Actuator is unplugged.

B. AIF board failure.

C. Actuator is bad.

A. Actuator plugged into wrong

connector.

B. Locator pin is in wrong position.

Page 16

1.3.2 AIF (Auto Intermittent Filtration) Actuator Board Pin Positions with

16

Thermal Sensors

Pin

Connector From/To Harness PN

J1

FV Return

Actuator

N/A

FV AIF RTD

DV AIF RTD

O/Flow Sensor

& Fill Sensor

8074551 (FV)

J2

Pressure Switch

(Gas)

8074550 (DV)

Locator Pin

Locator

J3

DV Return

Actuator

N/A

8074547

J4

MIB J2 or

AIF J5

AIF Board

Communication

and Power

8074547

J5

AIF J4 or

ATO J10

AIF Board

Communication

and Power

J6 FV Drain N/A

J7 DV Drain N/A

#

Function Voltage

1 Ret + (Open) 24VDC Black

2 Ret – (Closed) 24VDC Red

3 Ret Position Purple

4 Ground White

1 Ground White

2 FV - Temp Red

3 Ground White

4 DV - Temp Red

5 FV - Top In 16VDC Black

6 FV- Top Out 16VDC Red

7 DV-Top In 16VDC White

8 DV- Top Out Green

DV – Press Sw (Gas)

9

FV – Press Sw (Gas)

10

11 Locator Vat #5

12 Locator Vat #4

13 Locator Vat #3

14 Locator Vat #2

15 Locator Vat #1

16 Locator Signal Black

1 Ret + (Open) 24VDC Black

2 Ret – (Closed) 24VDC Red

3 Ret Position Purple

4 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Drain + (Open) 24VDC Black

2 Drain – (Closed) 24VDC Red

3 Drain Position Purple

4 Ground White

1 Drain + (Open) 24VDC Black

2 Drain – (Closed) 24VDC Red

3 Drain Position Purple

4 Ground White

Wire

Color

Black

Page 17

17

1.3.3 AIF (Auto Intermittent Filtration) Actuator Board Pin Positions with RTD

Sensor

Connector From/To Harness PN

J1 FV Return N/A

FV AIF RTD

DV AIF RTD

8074551 (FV)

J2

Pressure Switch

(Gas)

Locator Pin

Locator

J3 DV Return N/A

J4

J5

MIB J2 or

AIF J5

AIF J4 or

ATO J10

J6 FV Drain N/A

J7 DV Drain N/A

8074550 (DV)

8074547

AIF Board

Communication

and Power

8074547

AIF Board

Communication

and Power

Pin

#

Function Voltage

1 Ret + (Open) 24VDC Black

2 Ret – (Closed) 24VDC Red

3 Ret Position Purple

4 Ground White

1 Ground White

2 FV - Temp Red

3 Ground White

4 DV - Temp Red

5

6

7

8

DV – Press Sw (Gas)

9

FV – Press Sw (Gas)

10

11 Locator Vat #5

12 Locator Vat #4

13 Locator Vat #3

14 Locator Vat #2

15 Locator Vat #1

16 Locator Signal Black

1 Ret + (Open) 24VDC Black

2 Ret – (Closed) 24VDC Red

3 Ret Position Purple

4 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Drain + (Open) 24VDC Black

2 Drain – (Closed) 24VDC Red

3 Drain Position Purple

4 Ground White

1 Drain + (Open) 24VDC Black

2 Drain – (Closed) 24VDC Red

3 Drain Position Purple

4 Ground White

Wire

Color

Black

Page 18

1.3.4 Replacing an AIF (Automatic Intermittent Filtration) board

18

Disconnect the fryer from the electrical power supply. Locate the AIF board to be replaced

under a frypot. Mark and unplug the harnesses. The AIF board assembly is held in place with

one screw in the front of the assembly (see Figure 12). Remove the screw and the front of the

assembly drops down (see Figure 13) and the back tab slides out of the bracket attached to the

frypot (see Figure 14). Reverse steps to reassemble, ensuring that the new AIF assembly slides

into the slot in the rear of the bracket.

Figure 12 Figure 13 Figure 14

1.3.5 Replacing an Actuator

Disconnect the fryer from the electrical power supply. Locate the actuator to be replaced under a

frypot and mark and unplug the actuator. The actuators are held in place by two clevis pins that

are held in by cotter ring pins (see Figure 15). Remove both clevis pins and remove the actuator.

Attach the new actuator with the rear clevis pin and cotter ring pin first (see Figure 16). With the

actuator attached with the rear clevis pin only, adjust the new actuator by rotating the shaft until

the holes of the actuator and valve plate are aligned. Rotating the shaft clockwise, adjusts it

outward. While rotating it counterclockwise adjusts the shaft inward. Insert the clevis pin and

the cotter ring pin to secure. If a return valve was replaced, filter a different vat of oil. If bubbles

appear in the vat where the actuator was replaced, further adjustment is necessary. Take out the

pins and adjust the valve until no bubbles are present in the vat. Reinsert the pins to secure the

actuator.

Figure 15 Figure 16

Page 19

1.4 M2007 Computer Filtration Service Procedures

b

19

1.4.1 M2007 Computer Troubleshooting

Problem Probable Causes Corrective Action

A. Press the ON/OFF switch to turn

the computer on.

B. This fryer has two cords: a

computer power cord and a main

power cord. If the computer

cord is not plugged in, the

computer will not activate.

Verify computer power cord is

plugged in and that circuit

breaker is not tripped.

C. Swap the computer with a

computer known to be good. If

computer functions, replace the

computer.

D. Swap with a harness known to

e good. If computer functions,

replace the harness.

E. If any component in the power

supply system (including the

transformer and interface board)

fail, power will not be supplied

to the computer and it will not

function.

Power cycle the computer using the

master switch on the component

box next to the fuse.

A. Wait until the previous

filtration cycle ends or an error

is cleared to start another

filtration cycle.

B. Press reset button and wait at

least 60 seconds. Computer

should clear and return to

normal operation once

complete.

Remove and discard product.

Press and hold the cook butto n for

three seconds under the display

with the error to remove the error.

Reset the setpoint of the vat before

trying to cook product.

No Display on

Computer.

Computer locks up.

M2007 display

shows filter

busy.

M2007 display

shows REMOVE

DISCARD.

A. Computer not turned on.

B. No power to the fryer.

C. Computer has failed.

D. Damaged computer wiring

harness.

E. Power supply component or

interface board has failed.

Computer error.

Another filtration cycle is still in

process.

In non-dedicated mode a product is

dropped that has a different setpoint

than the current vat temperature.

Page 20

Problem Probable Causes Corrective Action

20

A. Pull filter pan out and fully

reinsert into fryer.

B. Ensure the filter pan magnet is

in place and if missing replace.

C. If the filter pan magnet is fully

against the switch and

computer continues to display

chk pan, switch is

possibly defective.

M2007 computers may be

programmed to display in either

Fahrenheit or Celsius. Press and

hold 3and 4simultaneously until

code appears. Enter 1658.

The computer displays OFF. This

toggles the temperature from F° to

C° or vice versa. Turn the

computer on to check temperature

and see the temperature scale. If

the desired scale is not displayed,

repeat.

This in an indication of a

malfunction in the temperature

control circuitry, including a

failure of the high-limit thermostat.

This is displayed only during a test

of the high-limit circuit and

indicates that the high-limit has

opened properly.

This display is normal when the

fryer is first turned on while in the

melt cycle mode. To bypass the

melt cycle press and hold a #2

product button under the LCD

display until a chirp is heard. The

alarm will chirp and the computer

displays EXIT MELT alternating

with YES NO. Press the #1 YES

button to exit melt. It may appear

for a short while if a large batch of

frozen product is added to the

frypot. If the display never goes

out, the fryer is not heating.

M2007 display

shows chk pan.

M2007 display is in

wrong temperature

scale (Fahrenheit or

Celsius).

M2007 display

shows hot-hi-1.

M2007 display

shows HI-LIMIT.

M2007 display

shows low temp.

A. Filter pan is not fully set into fryer.

B. Missing filter pan magnet.

C. Defective filter pan switch.

Incorrect display option programmed.

Frypot temperature is more than

410ºF (210ºC) or, in CE countries,

395ºF (202ºC).

Computer in high-limit test mode.

Frypot temperature is between 180°F

(82°C) and 315°F (157°C).

Page 21

Problem Probable Causes Corrective Action

21

M2007 display

shows

PROBE

FAILURE.

M2007 display

shows PROBE

FAILURE

with

alarm sounding.

M2007 display

shows IGNITION

FAILURE.

Computer will not

go into program

mode or some

buttons do not

actuate.

M2007 display

shows HI 2 BAD.

Heat indicator off

upon initial startup.

Display shows hi or

hot with alarm

sounding.

M2007 display

shows ignition

FAILURE with

alarm sounding.

Heating indicator is

on, but fryer is not

heating.

M2007 display

shows IGNITION

FAILURE and

alarm sounds, but

fryer operates

normally (false

alarm).

Problem with the temperature

measuring circuitry including the

probe.

Damaged computer wiring harness or

connector.

Open drain valve, failed computer,

failed interface board, open highlimit thermostat.

Failed computer. Replace computer

Computer in high-limit test mode.

Failed computer.

Drain valve not fully closed.

Failed computer.

This indicates a problem within the

temperature measuring circuitry

that is beyond the scope of

operator troubleshooting.

Swap the computer wiring harness

with one known to be good. If

problem is connected replace

harness.

This indicates that the fryer is not

heating. It is displayed if the fryer

loses its ability to heat oil. It is

also displayed when the oil

temperature is above 450°F

(232°C) and the high-limit

thermostat has opened, halting the

heating of the oil. Verify that the

drain valves are fully closed.

This is displayed only during a test

of the high-limit circuit and

indicates that the high-limit has

failed.

Replace computer.

Press the reset switch on the MIB

board. All drain valves should

close. Using the ON/OFF switch,

turn the computer OFF and then ON

again.

Replace computer.

Page 22

Problem Probable Causes Corrective Action

E

C

R

22

M2007 display

shows low temp,

heating indicator

cycles on and off

normally but fryer

does not heat.

M2007 display

shows GET MGR

followed by ENTER

MGR CODE.

M2007 display

shows software for

only M2007 or MIB

but not all boards.

M2007 display

shows ERROR RM

SDCRD

1.4.2 M2007 Useful Codes

To enter any of the following codes: Press and hold 3and 4simultaneously for TEN seconds

and a third chirp sounds. Release the buttons and code appears.

Reset Factory Menu - Enter 3322. The computer display flashes and quickly counts from

1-40 and switches to off. (NOTE: This will delete any hand-entered menu items).

Reset CALL TECH Message - Enter 1000. Computer display switches to off.

Change from F° to C° - Enter 1658. The computer displays off. Turn the computer on

and check temperature to see the temperature scale. If the desired scale is not displayed, repeat.

Enter Tech Mode – Enter 1650.

Readdress LOV configuration after changing an MIB board – Enter 2007.

PASSWORDS

To enter level one, level two passwords: Press and hold the TEMP and INFO buttons

simultaneously until level 1 or level 2 is displayed. Release the buttons and ENTER Code

appears.

Fryer Setup, Level One, Level Two and Get Manager Password – Enter 1234.

Usage Password – Enter 4321.

A. Failed computer.

B. Damaged computer wiring

harness.

A filter error has occurred due to dirty

or clogged filter pad or paper, clogged

filter pumps, filter pump thermal

overload, or an actuator problem.

Loose or damaged harness

Defective SD Card

A. Replace computer.

B. Replace computer wiring

harness.

nter the MGR CODE (1234)

and follow the steps on the

flowchart on the next page.

heck that all harnesses between

M2007’s, MIB, AIF and ATO are

secure.

eplace card with another card.

Page 23

1.4.3 Get Mgr Flowchart

23

Page 24

1.4.4 M2007 Menu Summary Tree

24

Reflected below are the major programming sections in the M2007 and the order in which submenu headings will be

found under the sections in the Installation and Operation Manual.

Adding New Product Menu Items See pg. 4-12

Storing Product Menu Items in Product Buttons See pg. 4-15

Draining, Refilling, and Disposing of Oil and Boil-out See pg. 4-16

Filter Menu See pg. 4-20

1. Auto Filter See pg. 5-2

2. Maint Filter See pg. 5-8

3. Dispose See pg. 4-16 thru 4-20

4. Drain to Pan See pg. 4-21

5. Fill Pot from Drain Pan See pg. 4-22

6. Fill Pot from Bulk See pg. 4-22

Programming

Level 1 Program See pg. 4-24

1. Product Selection See pg. 4-24

a. Name

b. Cook Time

c. Temp

d. Cook ID

e. Qual Tmr

f. Duty Time 1

g. Duty Time 2

h. AIF Disable

i. Assign Btn

2. AIF Clock See pg. 4-25

a. Disabled

b. Enabled

3. Deep Clean Mode (Boil Out) See pg. 4-27

4. High-Limit Test See pg. 4-30

a. Hi-Limit Test 1

b. Hi-Limit Test 2

5. Fryer Setup See pg. 4-9

Level 2 Program (Manager Level) See pg. 4-31

1. Prod Comp Sensitivity for product See pg. 4-32

2. E-Log Log of last 10 error codes See pg. 4-33

3. Passwords

a. Setup

b. Usage

c. Level 1

d. Level 2

e. Get Mgr

4. Alert Tone Volume and Tone See pg. 4-34

a. Volume 1-9

b. Tone 1-3

5. Filter After Sets number of cooks before filter prompt See pg. 4-35

6. Filter Time Sets amount of time between filter cycles See pg. 4-36

Info Mode Menu See pg. 4-37

Full/Split Vat Configuration

1. Filter Stats See pg. 4-37

2. Review Usage See pg. 4-38

3. Last Load See pg. 4-40

Change passwords See pg. 4-33

Page 25

1.4.5 M2007 Pin Positions and Harnesses

25

Pin

Connector From/To Harness PN

Interface

J2

J6

J7

J9 ONLY USED ON NON-AIF UNITS

J10

J11 SD Card

Board to

Computer

Next M2007

J7 or Network

Resistor

MIB J1 or

previous

M2007 J6

Interface

Board Ground

to Computer

8074199

SMT Computer to

Interface Board

Harness

8074546

Computer

Communication

Harness

8074546

Computer

Communication

Harness

8074573

Computer Locator

Harness

# Function Voltage Wire Color

1 12VAC In 12VAC

2 Ground

3 12VAC In 12VAC

4 FV Heat Demand

5 V Relay 12VDC

6 DV Heat Demand

7 R/H B/L 12VDC

8 Analog Ground

9 L/H B/L 12VDC

10 ALARM

11 Sound Device 5VDC

12 ALARM

13 FV Probe

14 Common Probes

15 DV Probe

16

17

18

19

20

1 Ground Black

2 CAN Lo Red

3CAN Hi White

4

5

6

1 Ground Black

2 CAN Lo Red

3CAN Hi White

4

5

6

1 Vat #1

2 Vat #2

3 Vat #3

4 Vat #4

5 Vat #5

6

Black

Black

Page 26

1.5 Loading and Updating Software Procedures

26

1.5.1 Loading Software from an SD card to MIB and AIF boards

To update MIB or AIF software in the field follow these steps:

1. Switch all computers to OFF. With the computer displaying OFF, press the TEMP

button to check current M2007/MIB/AIF software version.

2. Remove the two screws on the right side cover plate of the MIB board.

3. With the MIB displaying “A” insert the SD card with the new software, with the card

contacts facing out and the notch on the bottom left, into the slot on the right side of

the MIB board (see Figure 17 and 18).

4. Once inserted, watch for a period in the display to appear on the bottom right of the

MIB display, indicating the software is being downloaded. If a period does not

appear, the software on the card and on the computer may be the same version, or the

boot loader software missing or corrupt. It will not update. If this happens, contact

Frymaster.

5. The period blinks several times while loading. Wait for a minimum of two minutes

and the period in the display stays off.

6. Remove the SD card from the MIB.

7. If only updating the MIB or AIF boards remove power from the MIB by carefully

removing the16-pin harness behind the MIB board or the five-pin control power cord

on the rear of the unit. If updating all the software update the MIB and then the

M2007 and then remove all power from the fryer using the five-pin control power

cord on the rear of the unit.

8. Restore power to the MIB to reboot the system.

9. A successful upgrade is confirmed by a “cLc” display on the MIB board upon restart

followed by “r, 1, r, 1, r, 2, r, etc ending with A”. If this does not happen, try

reloading the software.

10. Verify software upgrade by pressing the TEMP button with the computer OFF to

check the updated MIB/AIF version.

Figure 17 Figure 18

Page 27

27

Page 28

1.5.2 Loading Software from an SD card to an M2007 Computer

28

To update M2007 and ATO software in the field, follow these steps:

1. Switch all computers to OFF. With the computer displaying OFF, press the TEMP

button to check current M2007/MIB/AIF software version.

2. With the computer displaying OFF, remove the two screws on the left side cover plate of

the M2007 board.

3. With the computer folded down and the MIB displaying A, insert the SD card, with the

contacts facing down and the notch on the bottom right (see Figure 19 and 20), into the slot

on the left side of the M2007.

4. Once inserted, FWUPD appears on the left display and SCCRCOK appears on the right.

Numbers count up on the right display.

5. The display then changes to FWLOAD on the left; numbers count up on the right.

6. The computer displays OBFCRC. If updating ATO software the computer will display

FWU ATO on the left and will count down from 2500 on the right.

7. When the update is complete the M2007 displays DONE on the left and RM SDCRD on

the right.

8. Remove the SD card using the fingernail slot on the top of the SD card.

9. If updating the M2007 or ATO board, remove power to the M2007 by removing the 20-pin

J2 plug on the rear of the computer, or remove power to the fryer to reboot the computer. If

updating all the software update the MIB and then the M2007 and then remove all power

from the fryer using the five-pin control power cord on the rear of the unit.

10. Restore power to the M2007 – There is short delay prior to the computer powering up and

displaying OFF.

11. Repeat steps 1-10 for all computers.

12. With the computer displaying OFF, verify software update by pressing the TEMP button

to check updated M2007/MIB/AIF version.

13. If the software is adding fields that require passwords, enter Level 2 mode and change

passwords.

Figure 19 Figure 20

Page 29

29

Page 30

1.6 Tech Mode

30

Tech mode allows technicians to reset passwords set in levels one and two. It also resets the

time and date. It also allows the technician to access the fryer main setup mode.

1. Press and hold 3and 4 simultaneously for TEN seconds until a third chirp is heard and

CODE is displayed.

2. Enter 1650.

3. The computer displays TECH MODE and changes to CLEAR PASSWORDS.

4. Press the 9 (1) button to accept selection and clear the passwords.

5. The computer displays CLEAR PASSWORDS on the left and COMPLETE on the

right. This clears any passwords set up under levels one and two.

6. Press the ubutton to toggle to CLEAR SIGNATURE.

7. Press the 9 (1) button to accept the change.

8. The computer displays CLEAR SIGNATURE on the left and COMPLETE on the

right. This resets the date and time.

9. Press the ubutton to toggle to FILTER PAD TIME on the left and 25 on the right.

(25 hours is the default time to change the pad)

10. Press the 8 (2) button to accept changes and exit.

11. The computer displays OFF. Proceed to the next page to enter the setup mode.

Page 31

1.7 Fryer Setup Mode

31

Setup mode allows technicians to set the time, date, temperature format, language, fryer type,

vat type and oil system.

1. With the computer displaying OFF, press and hold the TEMP and INFO buttons until

LEVEL 1 is displayed.

2. Press the TEMP key once to FRYER SETUP.

3. The computer displays FRYER SETUP and then changes to ENTER CODE.

4. Enter 1234.

5. Press the 9 (1) button to accept selection.

6. The computer displays TIME FORMAT on the left and 12 HR on the right.

7. Press the 4button to toggle between 12 HR and 24 HR time formats.

8. Press the 9 (1) button to accept selection.

9. The computer displays ENTER TIME on the left and HH:MM on the right.

10. Enter the time in hours and minutes using the 0-9 keys.

11. Press the 9 (1) button to accept selection.

12. The computer displays ENTER TIME on the left and am on the right.

13. Press the 4button to toggle between AM and PM if 12 HR time format was chosen.

14. Press the 9 (1) button to accept selection.

15. The computer displays DATE FORMAT on the left and US on the right.

16. Press the

4button to toggle between US and INTERNTL time formats.

17. Press the 9 (1) button to accept selection.

18. The computer displays enter date on the left and MM-DD-YY or DD-MM-YY

on the right.

19. Enter the date using the 0-9 keys.

20. Press the 9 (1) button to accept selection.

21. The computer displays language on the left and English on the right.

Page 32

32

22. Press the 4button to toggle between ENGLISH, FRENCH, FRENCH CANADIAN,

SPANISH, PORTUGUESE, GERMAN and SWEDISH languages.

23. Press the 9 (1) button to accept selection.

24. The computer displays FRYER TYPE on the left and eLEC on the right.

25. Press the 4button to toggle between ELECTRIC and GAS fryers.

26. Press the 9 (1) button to accept selection.

27. The computer displays VAT TYPE on the left and SPLIT on the right.

28. Press the 4button to toggle between SPLIT and FULL vats.

29. Press the 9 (1) button to accept selection.

30. The computer displays oil system on the left and jib on the right.

31. Press the 4button to toggle between JIB and BULK oil systems.

32. Press the 9 (1) button to accept selection.

33. The computer displays temperature on the left and f on the right.

34. Press the 4button to toggle between F° and C° temperature scales.

35. Press the 9 (1) button to accept selection.

36. The computer displays FRYER Setup for three seconds and the computer displays

off on both sides.

Page 33

1.8 RTI Service Issues

33

1.8.1 RTI MIB Tests

Normal measurements, measured on MIB J6 8 pin connector with

everything connected.

AC voltage measurements:

Pin 1 to Pin 2 - 24 VAC.

Pin 2 to Pin 3 - 24 VAC when RTI add pump is on, 0 VAC when it is off.

Pin 4 to Pin 5 - 24 VAC when RTI waste valve is on, 0 VAC when it is off.

Pin 6 to Pin 7 - 24 VAC when RTI JIB valve is on, 0 VAC when it is off.

DC voltage measurements:

Pin 1 to Pin 8 - 0 VDC when waste tank is full, 5 VDC when it is not full.

Troubleshooting.

The valves and pump should be off while MIB is resetting, 5 seconds or so after a power on or after

pressing the reset button; if any are on during reset then the MIB board is bad or wires are shorted.

If JIB valve is not opening:

Measure when JIB valve should be opened:

1. Voltage at MIB board from Pin 1 to Pin 2, should be 24 VAC; if not then check connections from RTI

24VAC transformer and check transformer.

2. Voltage at MIB board from Pin 6 to Pin 7, should be 24 VAC; if not then MIB board is bad or wires to

JIB valve are shorted or both.

3. Voltage at JIB valve, should be 24 VAC; if not then check wiring from MIB board.

If Waste valve is not opening:

Measure when Waste valve should be opened:

1. Voltage at MIB board from Pin 1 to Pin 2, should be 24 VAC; if not then check connections from RTI

24VAC transformer and check transformer.

2. Voltage at MIB board from Pin 4 to Pin 5, should be 24 VAC; if not then MIB board is bad or wires to

Waste valve are shorted or both.

3. Voltage at Waste valve, should be 24 VAC; if not then check wiring from MIB board.

If Add pump is not operating:

Measure when Add pump should be on:

1. Voltage at MIB board from Pin 1 to Pin 2, should be 24 VAC; if not then check connections from RTI

24VAC transformer and check transformer.

2. Voltage at MIB board from Pin 2 to Pin 3, should be 24 VAC; if not then MIB board is bad or wires to

pump relay are shorted or both.

3. Voltage at Add pump relay, should be 24 VAC; if not check wiring from MIB board.

Waste full signal:

Pin 1 to Pin 8 should be 0 VDC when full, 5 VDC when not full; if no level change, then bad

connection from RTI switch or MIB board is bad.

Page 34

1.8.2 RTI LOV Wiring with RTI Switchbox

34

Page 35

1.8.3 RTI LOV TEST QUICK REFERENCE

35

DISPOSE TO WASTE, REFILL POT FROM BULK:

1. Hold down “filter” button until computer beeps twice.

2. Scroll down to “dispose” using “Info" button then press “√” button to select.

3. Select “Yes” by pressing “√” to dispose of oil in pot (this is a timed function).

4. “Vat Empty” is displayed

5. Select “Yes” (by pressing “√”) if it is empty or “No” (by pressing “X”) if vat still has oil.

6. “Clean Vat Complete” is displayed

7. Press “√” if vat is clean (oil disposes automatically for 60 seconds, if this is selected) and “X”

if it is not clean and needs to be.

8. “Engage Dispose” is displayed. Switch the RTI switch to dispose.

9. Press the “√” to start disposal. “Pan to Waste” displayed.

10. “Pan Empty” is displayed

11. Press “√” if oil in filter pan is empty. Select “X” if pan still has oil in it.

12. “Disengage Dispose” is displayed. Switch off the RTI dispose switch.

13. Press “√” when RTI dispose switch is off.

14. “Fill Pot From Bulk” is displayed.

15. Press “√” if you wish to fill pot.

16. Hold down “√” to fill pot to desired level.

17. Press “X” to Exit program.

DISPOSE TO WASTE:

1. Hold down “filter” button until computer beeps twice.

2. Scroll down to “dispose” using “Info” button and press “√” button to select

3. Select “Yes” by pressing “√” to dispose of oil in pot (this is a timed function).

4. “Vat Empty” is displayed

5. Select “Yes” (by pressing “√”) if it is empty or “No” (by pressing “X”) if vat still has oil.

6. “Clean Vat” is displayed

7. Press “√” if vat is clean (oil disposes automatically for 60 seconds, if this is selected) and “X”

if it is not clean and needs to be.

8. “Engage Dispose” is displayed. Switch the RTI switch to dispose.

9. Press the “√” to start disposal. “Pan to Waste” displayed.

10. “Pan Empty” is displayed

11. Press “√” if oil in filter pan is empty. Select “X” if pan still has oil in it.

12. “Disengage Dispose” is displayed. Switch off the RTI dispose switch.

13. “Fill Pot From Bulk” is displayed.

14. Press “X” if you wish to leave pot empty and exit program.

FILL POT FROM BULK:

1. Hold down “filter” button until computer beeps twice.

2. Scroll down to “Fill Pot From Bulk”

3. Press “√” if you wish to fill pot.

4. Hold down “√” to fill pot to desired level.

5. Press “X” to Exit program.

FILL JUG FROM BULK:

1. When “Orange” indicator light is on, the pot top-off jug is empty.

2. To refill jug press ADD button on the RTI box located on back side of door that accesses jug.

3. Hold down button until oil is to desired level in jug.

Page 36

1.9 Wiring Diagrams

36

1.9.1 LOV Electric Wiring Diagram with Thermal Sensor

RESET

SWITCH

Page 37

1.9.2 LOV Electric Wiring Diagram with RTD

37

RTI SWITCHBOX

J3 J2 J1

J5

Page 38

1.9.3 LOV Gas Wiring Diagram with Thermal Sensor

38

Page 39

1.9.4 LOV Gas Wiring Diagram with RTD

39

Loading...

Loading...