Page 1

Ultimate Electric Series Fryers

Service & Parts Manual

Frymaster/Dean, a member of the Commercial Food Equipment Service Association,

recommends usi ng CFE S A Ce r tifie d T ec hnic ia ns.

24-Hour Service Hotline 1-800-551-8633

Price: $28.00

819-5981

JUNE 2003

Page 2

Please read all sections of this manual and retain for future reference.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster/Dean Factory Authorized Service Center (FASC) or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of

this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed.

NOTICE TO U.S. CUSTOMERS

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COM PUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communications du Canada.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating and

service instructions thoroughly before installing or servicing this equipment.

Page 3

DANGER

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container

at the end of frying operations each day. Some food particles can spontaneously combust if left

soaking in certain shortening material. Additional information can be obtained in the filtration

manual included with the system.

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster/Dean Service Hotline at 1-800-551-8633.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the frypot. Banging fry baskets on the strip to dislodge shortening will distort

the strip, adversely affecting its fit. It is designed for a tight fit and should only be removed for

cleaning.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODI S

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER/DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER/DEAN AND ITS AFFILIATES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

Page 4

Ultimate Electric Series Fryers

Service & Parts Manual

TABLE OF CONTENTS

Page #

1. SERVICE PROCEDURES 1-1

1.1 General 1-1

1.2 Replace Computer/Controller 1-1

1.3 Replace Interface Board 1-2

1.4 Replace Transformer 1-3

1.5 Replace Temperature Probe 1-3

1.6 Replace Heating Element 1-6

1.7 Replace High-Limit 1-9

1.8 Replace Frypot 1-10

1.9 Replace Contactor (Latching or Heating) 1-11

1.10 Built-in Filter System Service Procedures 1-11

1.11 Basket Lift Service Procedures 1-13

1.12 Electric Interface Board Diagnostic Chart 1-17

1.13 Probe Resistance Chart 1-18

1.14 Element Wattage/Amperage Calculation Charts 1-18

1.15 Wiring Diagrams, Main 1-19

1.15.1 480V 18UE and EH1721 1-19

1.15.2 208V 18UE and EH1721 1-20

1.15.3 KSCFH218E 1-21

1.15.4 BIH1721 1-22

1.16 Wiring Diagrams, Basket Lifts 1-23

1.16.1 Modular Basket Lifts 1-23

1.16.2 Bell Crank Style Basket Lifts 1-23

1.17 Wiring Diagrams, Built-in Filtration 1-24

1.17.1 480V Systems 1-25

1.17.2 208V Systems 1-26

1.17.3 115/230V KFC Systems 1-27

Page 5

Ultimate Electric Series Fryers

Service & Parts Manual

TABLE OF CONTENTS (CONT.)

Page #

2. PARTS LIST 2-1

2.1 Accessories 2-1

2.2 Basket Lift Assembly (Modular) and Related Components 2-2

2.3 Cabinetry and Related Components 2-5

2.3.1 EH1721 & 18UE Electric 2-5

2.3.2 KFC18E Electric 2-8

2.3.3 Door Components – Spring-Loaded Door Pins 2-10

2.3.4 Top Caps and Tilt Housing Components 2-11

2.4 Computer and Related Components 2-12

2.5 Contactor/Wireway Box and Related Components 2-14

2.6 Filter Pan and Related Components 2-16

2.6.1 Under Fryer Filter (UFF) – UFF 80 (100 Lb Capacity) 2-16

2.6.2 Under Fryer Filter (UFF) – KFC18E Only 2-17

2.6.3 Under Fryer Filter (UFF) – Filter-Leaf/Suction Tube Assembly 2-19

2.6.4 Single Under Fryer Filter (SUFF) – BIH1721 & 18UE 2-20

2.7 Frypot and Drain Valve Components 2-21

2.8 Oil Drain Flush Components 2-22

2.9 Oil Drain Manifold Components 2-23

2.10 Oil Return Manifold, Motor and Pump Components 2-24

2.11 Oil Return Line Assemblies 2-27

2.12 Probes, High-Limits, Elements and Related Components 2-29

2.13 Tilt Safety Switch Components 2-32

Page 6

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Frymaster/Dean Ultimate Electric fryer, you must

disconnect the electrical power supply.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to

facilitate reassembly.

DANGER

Hot cooking oil or shortening will cause severe burns. Never attempt to move this appliance

when filled with hot cooking oil or shortening, or to transfer hot cooking oil or shortening

from one container to another.

DANGER

This equipment should be unplugged when servicing, except when electrical circuit tests are

required. Use extreme care when performing such tests.

This appliance may have more than one electrical power supply connection point.

Disconnect all power cords before servicing.

Inspection, testing and repair of electrical components should be performed by an

authorized service agent only.

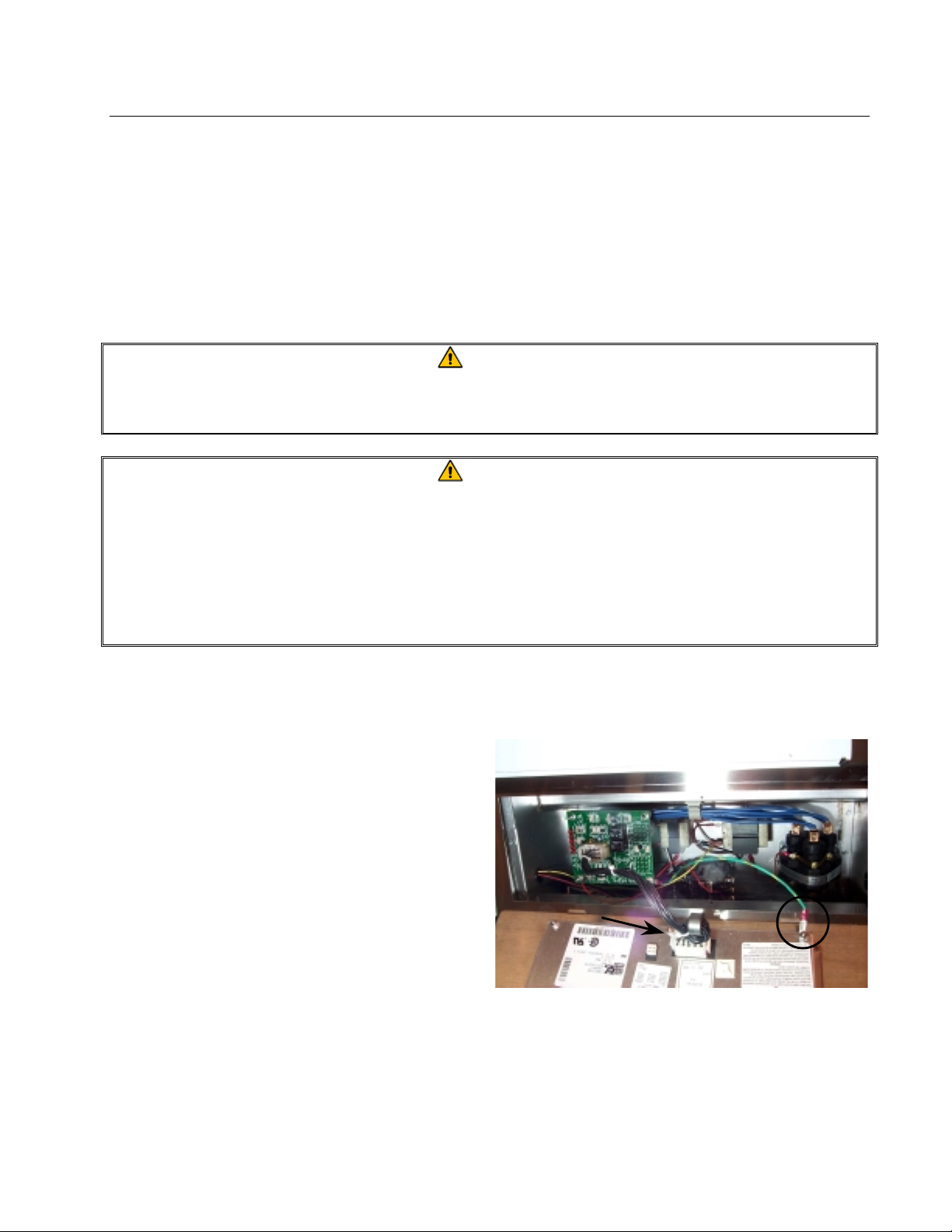

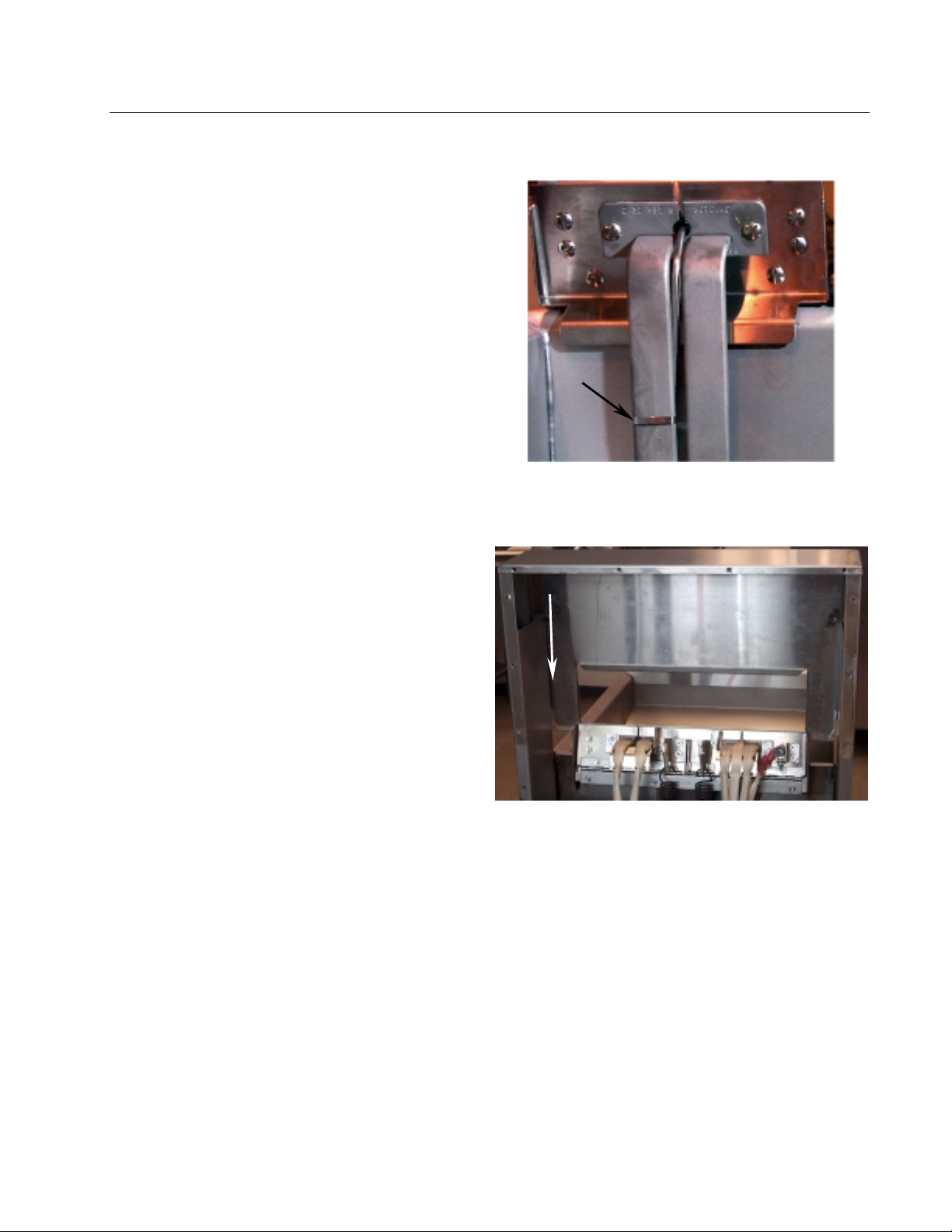

1.2 Replace Computer/Controller

1. Unscrew and remove two control panel

screws on control panel front. Swing the

panel open from the top.

2. Unplug wiring harness at plug on back of

controller (arrow). Unplug controller ground

wire from controller (circle).

3. Remove the control panel/controller by lifting

the assembly from the hinged slots in the

control-panel frame.

4. Reverse procedures to install new controller.

Wire harness/connector and ground wire on controller

back.

1-1

Page 7

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

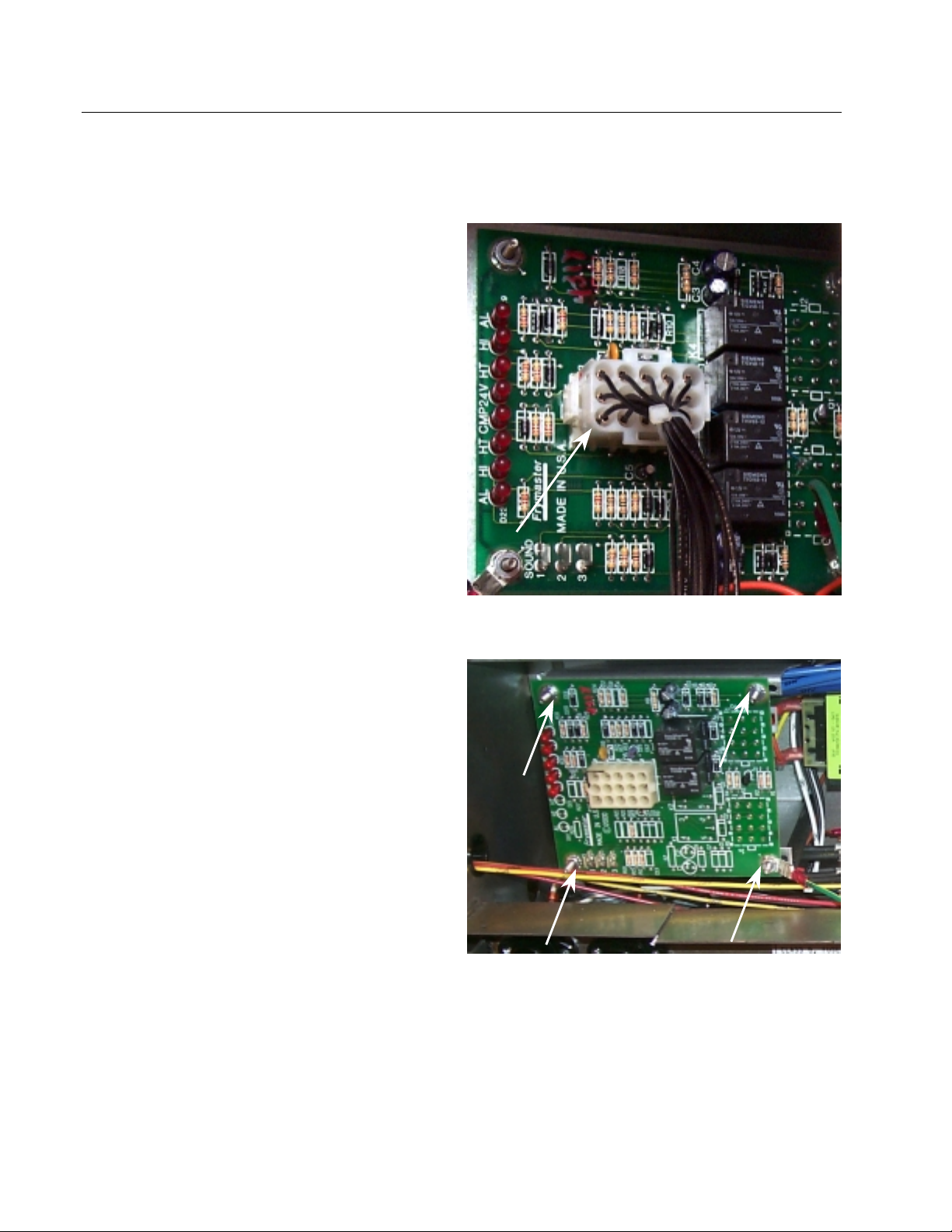

1.3 Replace Interface Board

1. Unplug all power cords. Perform Procedure 1.2, Steps 1-4, Replace Computer/Controller.

2. Unplug wire harness from the interface board

(arrow). Remove all wiring from the

terminals of the interface board, ensuring that

each wire is marked for reattachment.

3. Remove the nuts from each corner of the

interface board and slide the board from the

studs. Unplug connectors J1 and J2, mark

and unplug all other wiring on rear of the

interface board. Ensure that standoffs remain

in place on studs, prior to installing new

interface board. Install the new interface

board by reversing the previous procedures.

Ensure that wire harnesses are connected to

back of interface board prior to securing

interface board. Also, ensure that wiring and

wire harnesses are connected to the proper

terminals.

Wire harness/connector.

Nuts securing interface board (arrows).

1-2

Page 8

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

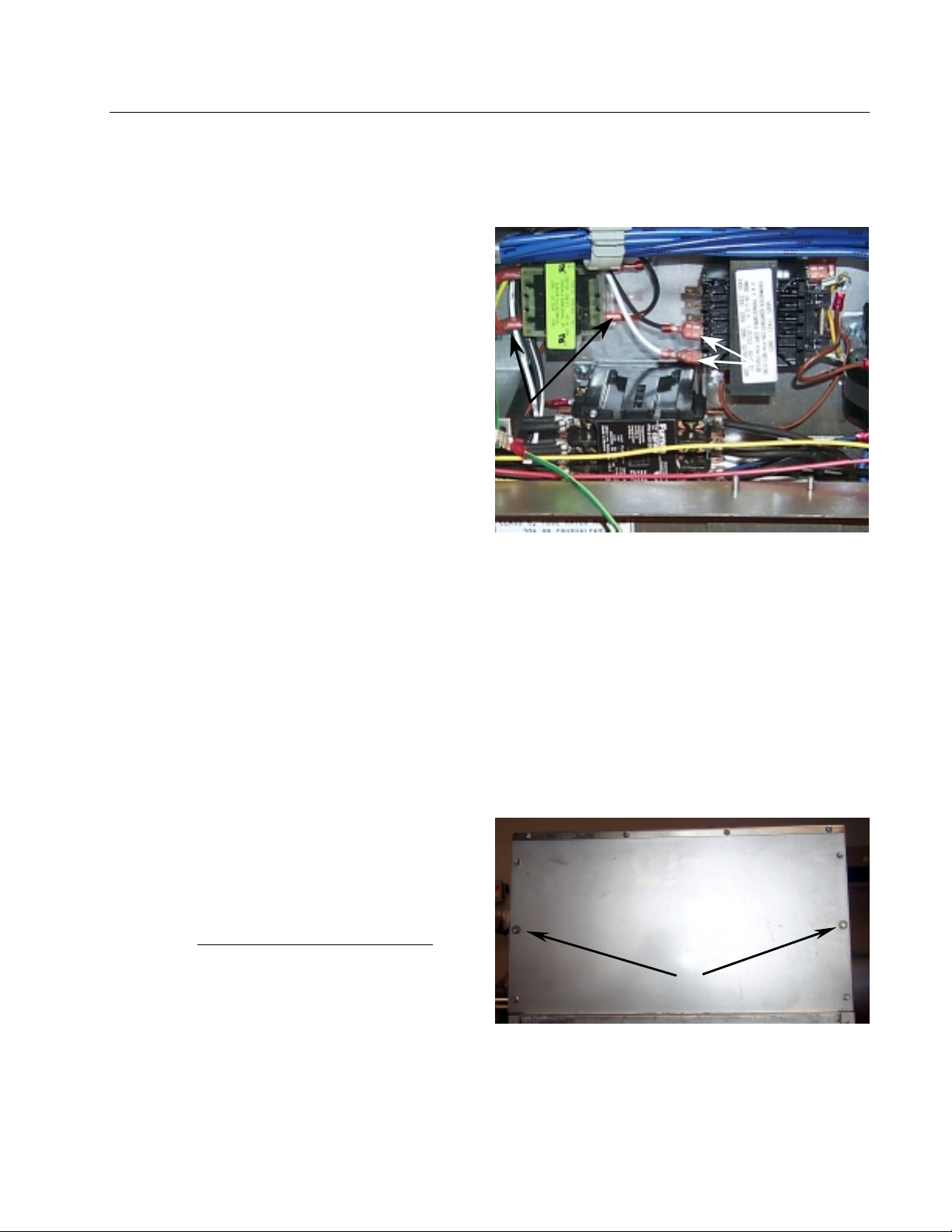

1.4 Replace Transformer

1. Unplug all power cords. Perform Procedure 1.2, Steps 1-4, Replace Computer/Controller.

2. Remove all wiring from the terminals of the

transformer to be replaced (arrows).

3. Remove the screws that secure the

transformer to the component box.

4. Install the new transformer by reversing the

preceding procedures. Make sure you

reconnect the wiring to the proper terminals

and the harnesses to the correct connectors.

Mark and disconnect wiring from the transformer

being replaced.

1.5 Replace Temperature Probe

1. Unplug fryer from the electrical source.

2. Drain the cooking oil from the frypot.

3. Remove the fryer from the exhaust hood to gain access to the rear of the fryer.

4. Remove the screws from the back cover(s).

Set the cover(s) and screws aside.

5. After removing back(s), remove two

remaining screws securing the tilt housing

cover (arrows). Remove the tilt housing.

Note: Early production model shown.

Current production units have a one-piece

back panel (remove all screws securing back

panel). Older units have a three-piece back

panel.

Screws securing back cover and tilt housing.

Remove two tilt-housing screws (arrows) after

removing all other screws and back panel(s).

1-3

Page 9

p

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

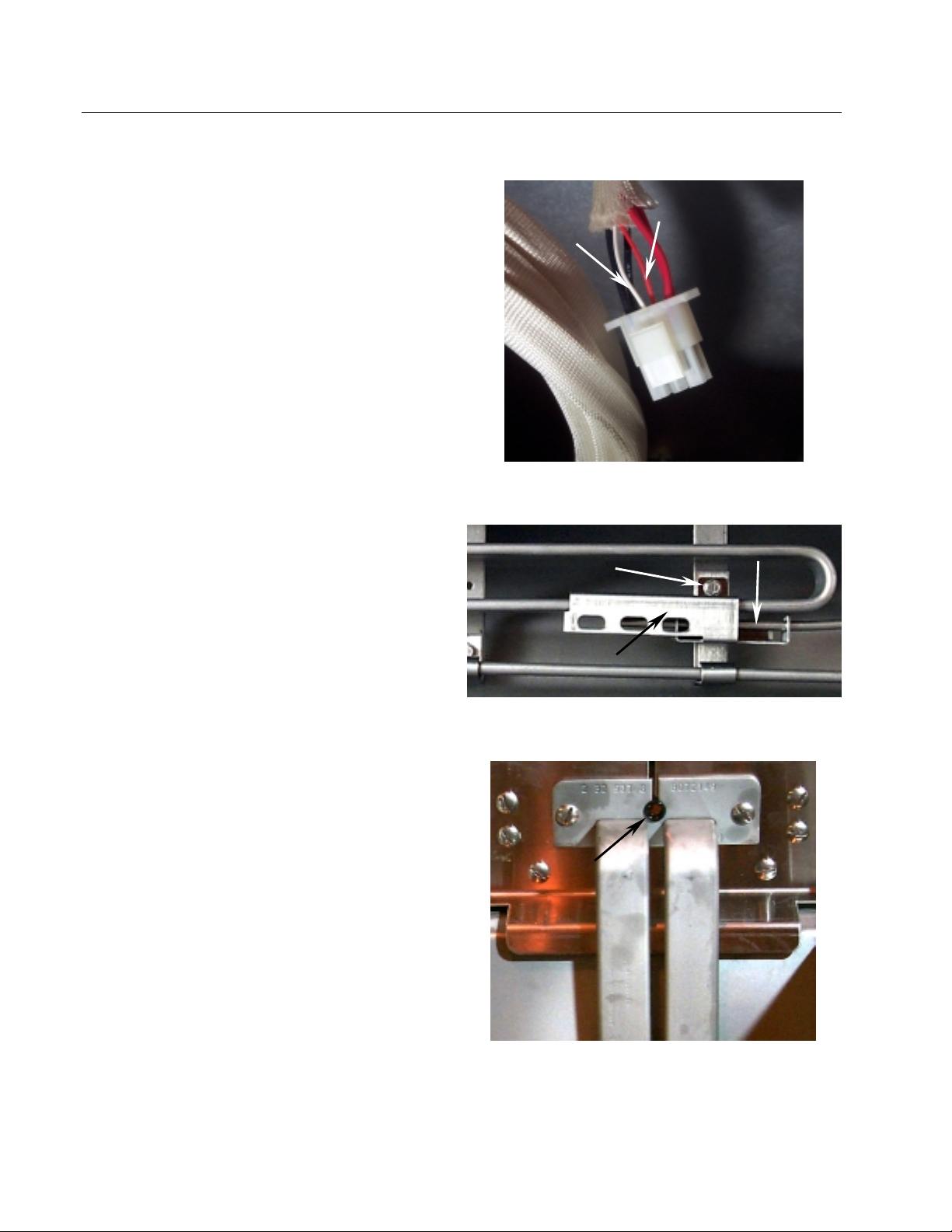

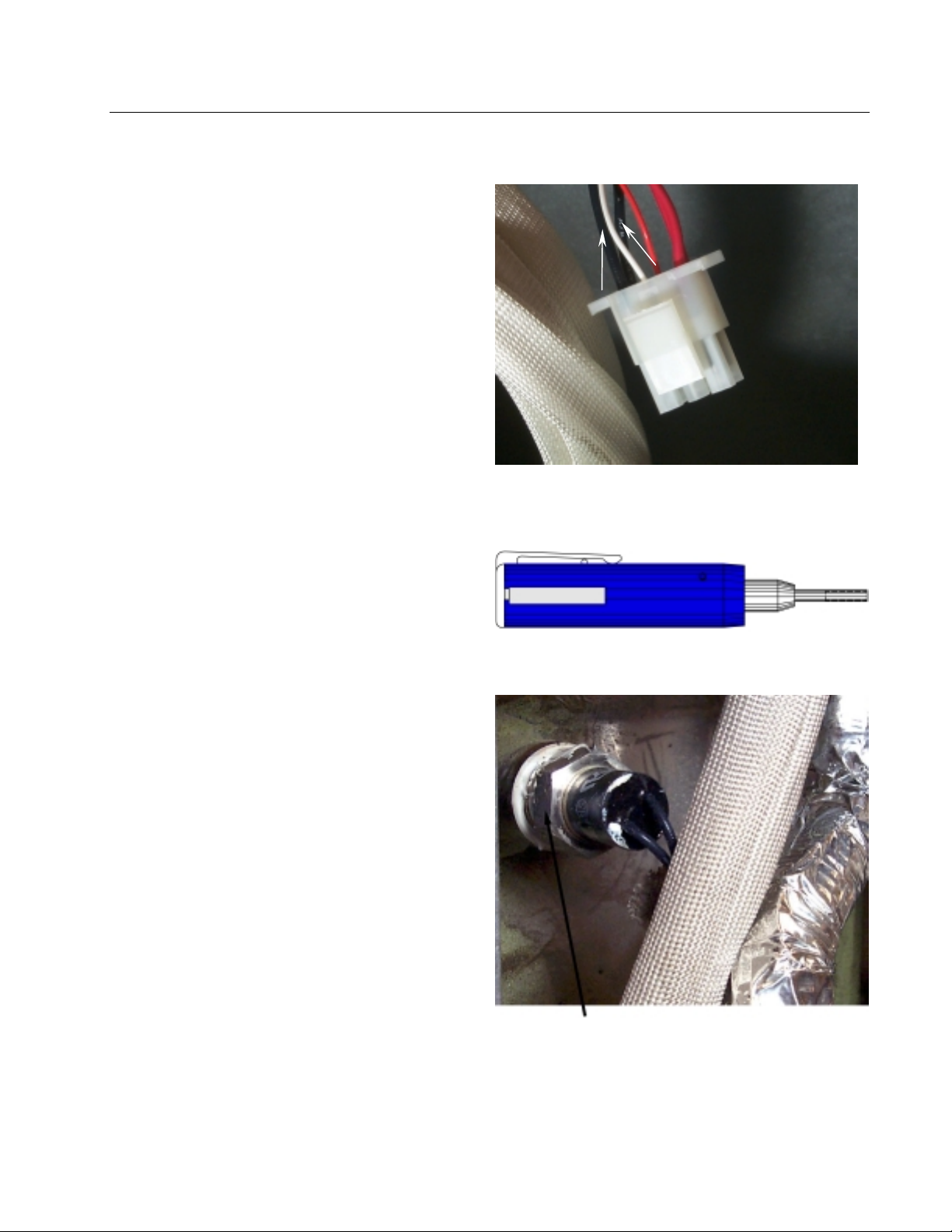

1.5 Replace Temperature Probe (cont.)

6. Disconnect the wire harness containing the

probe wiring (arrows). It may be necessary

to remove the wire ties.

7. Use a pin-pusher (P/N 806-4855 or P/N 8070928—see Section 1.7) to remove the red and

white probe wires from the connector. Note

probe pin location in plug. Pull the probe

wires out of the insulation.

8. Remove the screw(s) securing the probe

bracket to the element. Remove the metal

wraps securing the probe to the element.

9. Remove the probe bracket and the securing

components from the probe bulb and element.

Thread the probe wire through the hole

(arrow) in the tilt plate assembly and remove

the probe.

Use a pin-pusher to remove probe wires from

connector (arrows).

Remove probe bracket screw and bracket to remove

robe.

Probe Bulb

Bracket Screw

Probe Bracket

Pull old probe wire through grommet to remove

probe.

1-4

Page 10

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.5 Replace Temperature Probe (cont.)

10. Thread the new probe wire through the hole

in tilt plate. Place the new temperature probe

assembly onto the element and secure with

the bracket and screws removed earlier. Clip

the probe onto the rear of the element (arrow)

in two places. The temperature probe

assembly should be oriented in the same

manner as the probe being replaced.

11. Thread the probe wires into the harness

insulation. Note the pin positions and insert

pins in the connector. Reconnect the harness

and secure with a wire-tie.

12. Lower the element into the frypot with the lift

handle.

13. Place the tilt housing cover over the tilt

housing assembly and secure with screws.

Slightly raising the elements will facilitate

tilt-housing installation.

14. Install back cover(s) and secure with screws

Secure probe bulb to the element back in two places

with metal wire wrap (arrow).

Install tilt housing and cabinet backs after probe

installation is complete.

1-5

Page 11

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.6 Replace Heating Element

1. Perform Procedure 1.5, Replace Temperature Probe, Steps 1-7.

2. Unplug the element connectors for the

element being removed (right element- 6-pin

harness connector; left element- 9-pin harness

connector). Remove the element wires from

the connector. Press down on either side of

the connector while pulling up on the top

portion. The connector will open from the

top. Note wiring configuration in connector

before removing element wire pins. Pull all

wires from the connector.

3. Remove the screws securing the temperature

probe bracket from the element. Remove the

probe clamp (metal wire-wrap). Set the

temperature probe and probe-securing

components aside.

NOTE: Temperature probe removal is not

required if the left element is being replaced.

4. Disconnect the element springs from the tilt

brackets.

Push in on tabs to release

Remove metal wire wrap (arrow), and screws

securing probe bracket to element (inset, arrow).

Harness

Connector

Closed

top portion

Harness

Connector

Open

Top Portion

Disconnect element springs here.

1-6

Page 12

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.6 Replace Heating Element (cont.)

5. Remove the element clamps and hardware

before removing mounting-screws and nuts

on the defective element. Remove all wireties securing element wiring, and then

remove element from frypot.

6. Install the replacement element in the frypot

and secure with the mounting hardware

removed in Step 5.

7. Reinstall the temperature probe and probe-

bracket components onto the replacement

element.

8. Route the element leads (terminals) to the

rear of the fryer. Ensure the element-harness

insulation is in place prior to installing

connectors.

9. Secure element wiring with wire-ties.

Element mounting screws on tilt-plate front. (Inset:

element mounting plate on tilt-plate back.)

Ensure element wire insulation is installed and that

the wires are properly routed to prevent wire chaf ing.

Use wire-ties (arrows) to secure ele ment wiring.

1-7

Page 13

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.6 Replace Heating Element (cont.)

10. When replacing the left element (as viewed

from the rear of the fryer), use the 9-pin

connector, inserting the leads from the

replacement element. Ensure the pin

numbers match the numbers of the defective

element wires. When all pin terminals have

been fully inserted, close the connector by

sliding the halves together until the tabs snap

back into place (reverse procedure in this

section, Step 2). Check wire numbers to

ensure correct wiring of the replacement

element.

When replacing the right element (as viewed

from the rear of the fryer), follow the above

procedure, inserting pin terminals into the

corresponding holes in the 6-pin connector.

11. Connect the connectors, ensuring the latches

lock in place (arrow).

12. Install the temperature probe wires (marked

for re-assembly) in the corresponding pin

locations.

13. Reconnect the element springs. Older models

have turnbuckles (arrow) to allow adjustment

of the spring tension.

14. Place the tilt housing cover over the tilt

housing assembly and secure with screws.

15. Install back covers and secure with screws.

16. Position fryer under exhaust hood.

Left Element—

9-Pin Connector

Right Element—

Connector

6-Pin

Ensure the connection is complete and the latches

(arrow) are locked in place.

Older units have turnbuckles to adjust spring tension.

Current production models are not adjustable.

1-8

Page 14

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7 Replace High-Limit

1. Perform Procedure 1.5, Replace Temperature

Probe, Steps 1-4.

2. Disconnect the wire harness containing the

high-limit wires.

3. Use a pin-pusher (P/N 806-4855 or P/N 807-

0928) to remove the two high-limit wires

from the wire harness connector (arrows).

Note pin location in connector before

removing wires.

4. Remove the high-limit from the frypot using

an open-end wrench or other suitable tool.

5. Apply Loc-Tite PST 567 sealant to the

replacement high-limit threads.

6. Screw the replacement high-limit into the

frypot and tighten to 170-180 inch-pounds

torque. DO NOT OVERTIGHTEN.

7. Insert the replacement high-limit wires into

the connector, ensuring each wire is in the

correct hole..

8. Reconnect the high-limit wire-harness

connector.

9. Install and secure the back cover(s).

10. Return fryer to operation.

Using a pin-pusher, remove two high-limit wires

(arrows) from connector.

Pin Pusher— P/N 807-0928

Place wrench here when rem oving and ins ta ll ing

high-limit.

1-9

Page 15

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8 Replace Frypot

1. Perform Procedure 1.5, Replace Temperature Probe, Steps 1-7.

2. Perform Procedure 1.2, Replace Computer/Controller, Steps 1-3.

3. Perform Procedure 1.7, Replace High-Limit, Steps 1-4.

4. Disconnect the element wire harnesses.

5. Remove the screws securing the capping piece from the fryer. Remove the capping piece and set

aside.

6. If the fryer has a built-in filtration system, remove all the plumbing from the frypot, including

oil-return and drain plumbing.

7. Remove the screws securing the frypot to the front frame of the fryer.

8. Carefully lift the frypot from the cabinet.

9. Remove the drain valve from the old frypot and install on the new frypot.

10. Apply Loc-Tite Sealant PST 567 to the high-limit threads. Install high-limit into the new frypot.

11. Disconnect the tilt plate springs from the old frypot.

12. Remove the securing screws from the tilt plate. Lift the tilt plate/heating element assembly from

the old frypot and install on the new frypot.

13. Follow the preceding steps in reverse to install the new frypot into the fryer.

14. NOTE: Apply Loc-Tite Sealant PST 567 to all pipefittings prior to installation.

1-10

Page 16

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

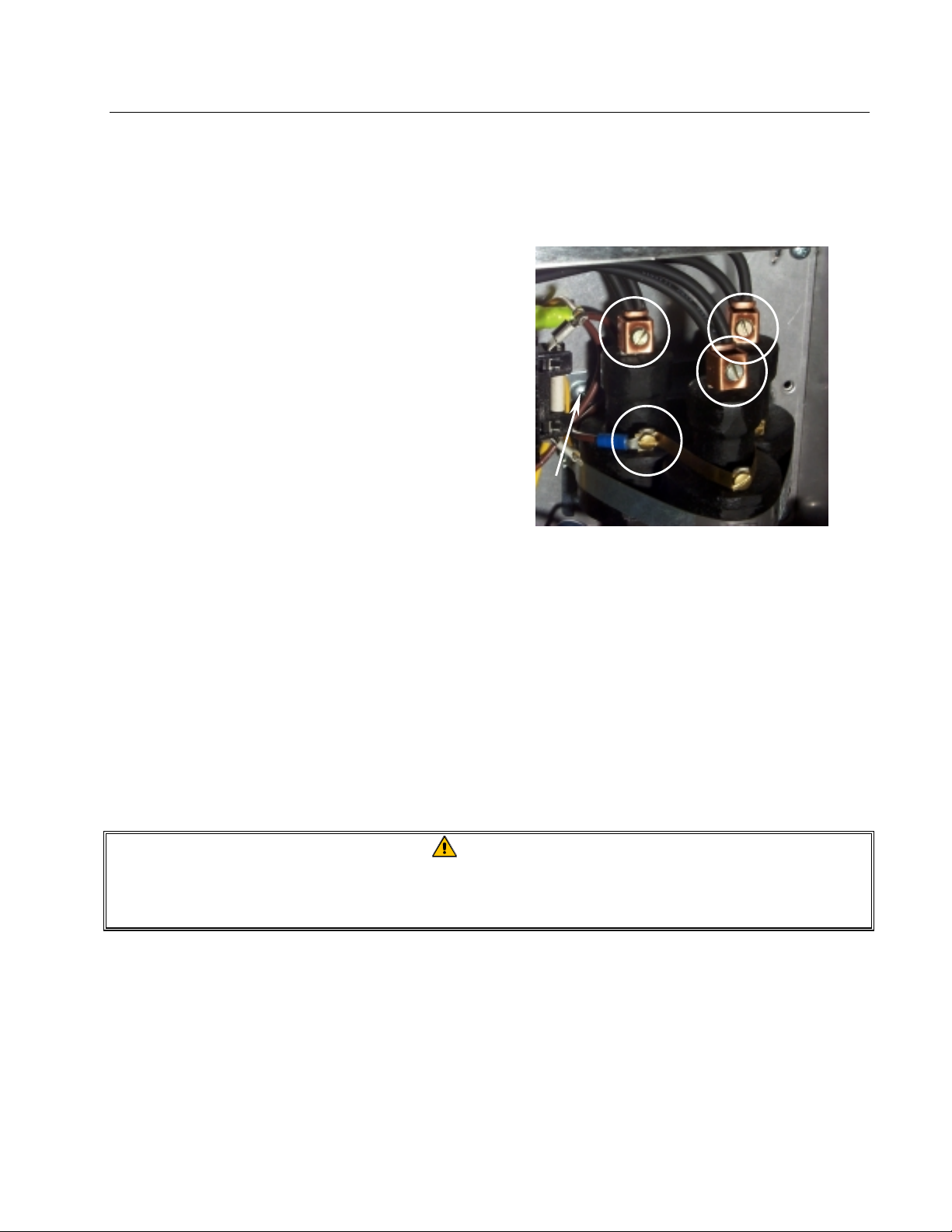

1.9 Replace Contactor (Latching or Heating)

1. Perform Procedure 1.2, Replace Computer/Controller, Steps 1-3.

2. Identify faulty contactor. Remove all wiring

connected to the contactor terminals (circles)

inside the component box. Tape wire-pairs

together and mark each wire-set or wire for

reassembly.

3. Remove contactor-mounting screws (arrow)

and remove the contactor.

4. Install the new contactor and connect the

wiring removed in Step 2.

Remove contactor-mounting screws after removing

all wiring from the contactor (circles).

1.10 Built-in Filter System Service Procedures

Troubleshooting Built-In Filtration Systems

One of the most common errors is placing the filter paper on the bottom of the filter pan rather than

over the filter screen.

CAUTION

Ensure that the paper support screen is in place prior to filter paper placement and

filter pump operation. Improper screen placement is the major cause of filter system

malfunction.

Whenever the complaint is "the pump is running, but no oil is being filtered", check the installation

of the filter paper, and ensure that the correct size is being used. While you are checking the filter

paper, verify that the O-rings on the supply line connection are present and in good condition.

Missing or worn O-rings allow the pump to take in air, decreasing its efficiency. In addition, oil

leaks into the fryer and on the floor each time a frypot is filtered.

1-11

Page 17

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10 Built-in Filter System Service Procedures (cont.)

If the pump motor overheats, a circuit breaker will trip and the motor will not start until the breaker

is reset. If the pump motor does not start, press the white reset button located under the component

box, inside the cabinet.

If the pump starts after resetting the breaker, then something is causing the motor to overheat. A

major cause of overheating is when several frypots are filtered sequentially, thus overheating the

pump and motor. Allow the pump motor to cool at least 30 minutes before resuming operation, and

allow time for the motor to cool between sequential frypot filtering.

Pump overheating can be caused by:

• Solidified shortening in the pan or filter lines,

or

• Attempting to filter unheated oil or shortening.

Cold oil and shortening are more viscous, causing the pump motor to load up and overheat. Always

filter with the oil or shortening at operating temperature [~350°F (177°C)].

If the motor runs but the pump does not, there is a blockage in the pump. Incorrectly sized or

installed paper/pads will allow food particles and sediment to pass through the filter pan and into the

pump. When sediment enters the pump, the gears bind, causing the motor to overload, again

tripping the thermal overload. Shortening that has solidified in the pump will also cause it to seize,

with the same result.

A pump seized by debris or hard shortening must be disassembled, cleaned, and then reassembled

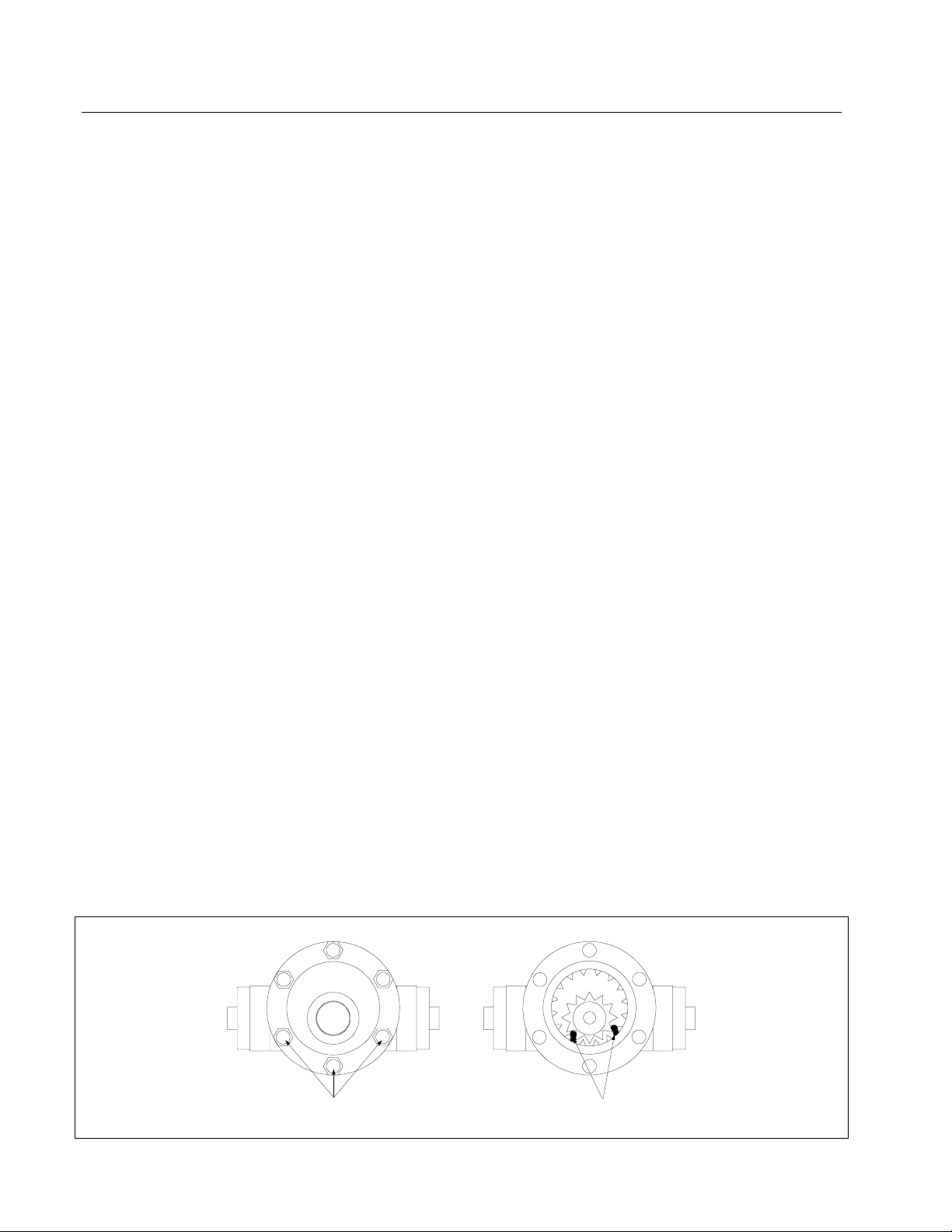

before continuing use. Use the following procedure:

1. Disconnect power to the filter system.

2. Remove the front cover of the pump to access the gears inside (see illustration below- 8-GPM

pump shown), if the pump is accessible while still inside the cabinet.

Remove bolts to remove

pump cover.

1-12

Remove debris or harden ed

shortening to free gears.

Page 18

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10 Built-in Filter System Service Procedures (cont.)

3. If the front cover is not accessible, the pump must be removed from the pump motor (remove

input/output plumbing from the pump prior to removing pump). Remove three setscrews from

the pump-shaft housing to disengage the pump from the motor. Remove the gears and

thoroughly clean all internal components. Ensure the inside of the pump housing is free of any

debris or hardened shortening before reassembling. Failure to completely clean the inside

housing and ring gear will cause gear binding after reassembly.

Filter paper/pads that are the wrong size or installed incorrectly will also allow food particles and

sediment to pass through and clog the suction tube in the bottom of the filter pan. Particles large

enough to block the suction tube may indicate that the crumb tray is not being used.

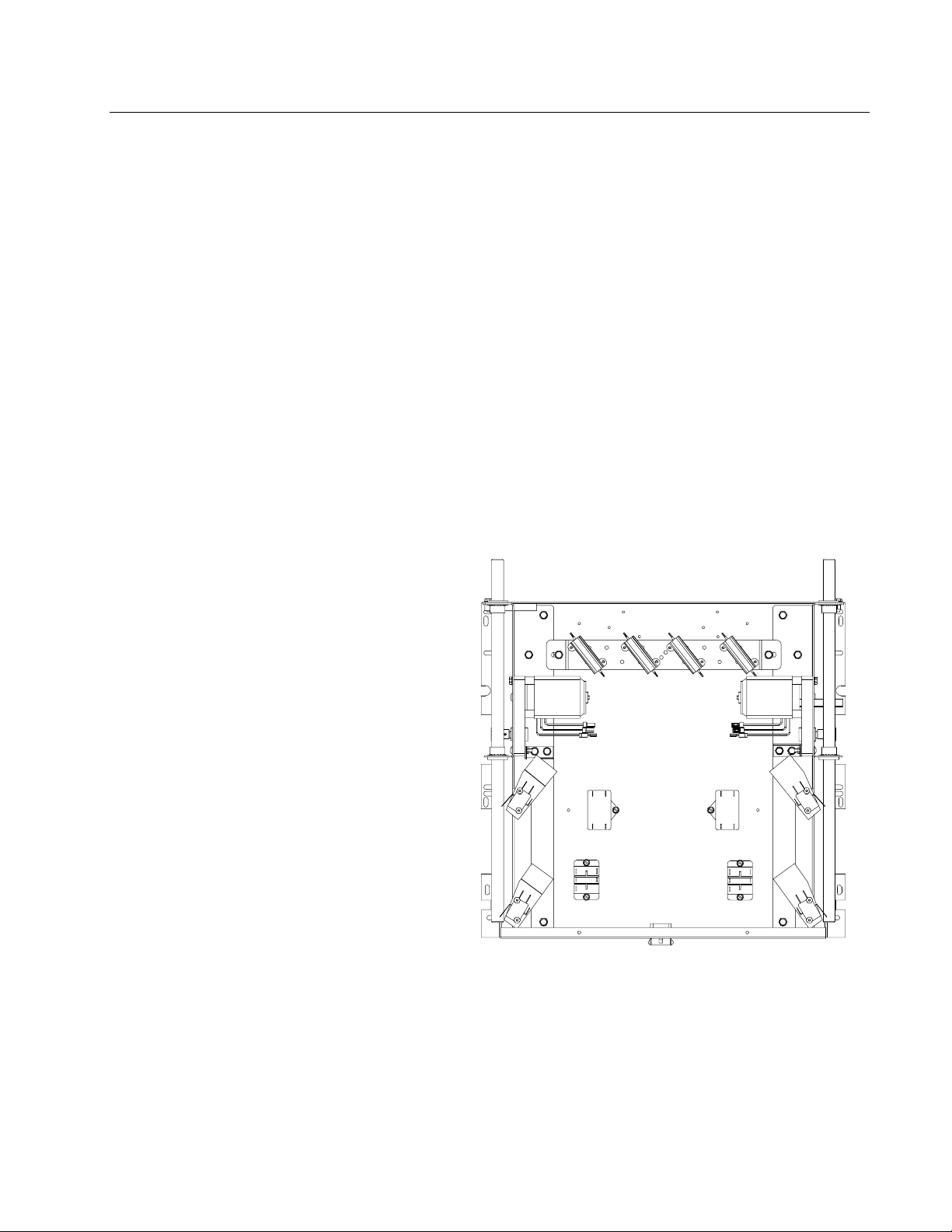

1.11 Basket Lift Service Procedures

Ultimate Electric Series fryers may optionally be equipped with automatic basket lifts to ensure

uniform cooking times. Electric fryers can be equipped with "modular" or "bell-crank" basket lifts.

A modular basket lift (illustrated) consists

of a toothed rod to which the basket lift arm

is attached, a reversible-drive gear motor

and a pair of roller-activated microswitches.

The gear motor engages the teeth in the rod,

moving it up or down, depending upon the

direction of rotation of the motor.

Microswitches at the upper and lower limits

of movement stop the motor when the

basket is in the full up or full down position.

Timing circuitry in the controller initiates

and stops basket lift operation depending

upon the variables programmed by the

operator. When the product button is

pressed, or the manual control is activated,

the timing circuitry activates a coil in the

basket lift relay to supply power to the lower

microswitch. The microswitches stop the

motor at the lift’s upper and lower travel

limits and reverse the direction of current

flow thus reversing the motor direction.

Modular Basket Lift Assembly (Typical).

1-13

Page 19

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.11 Basket Lift Service Procedures (cont.)

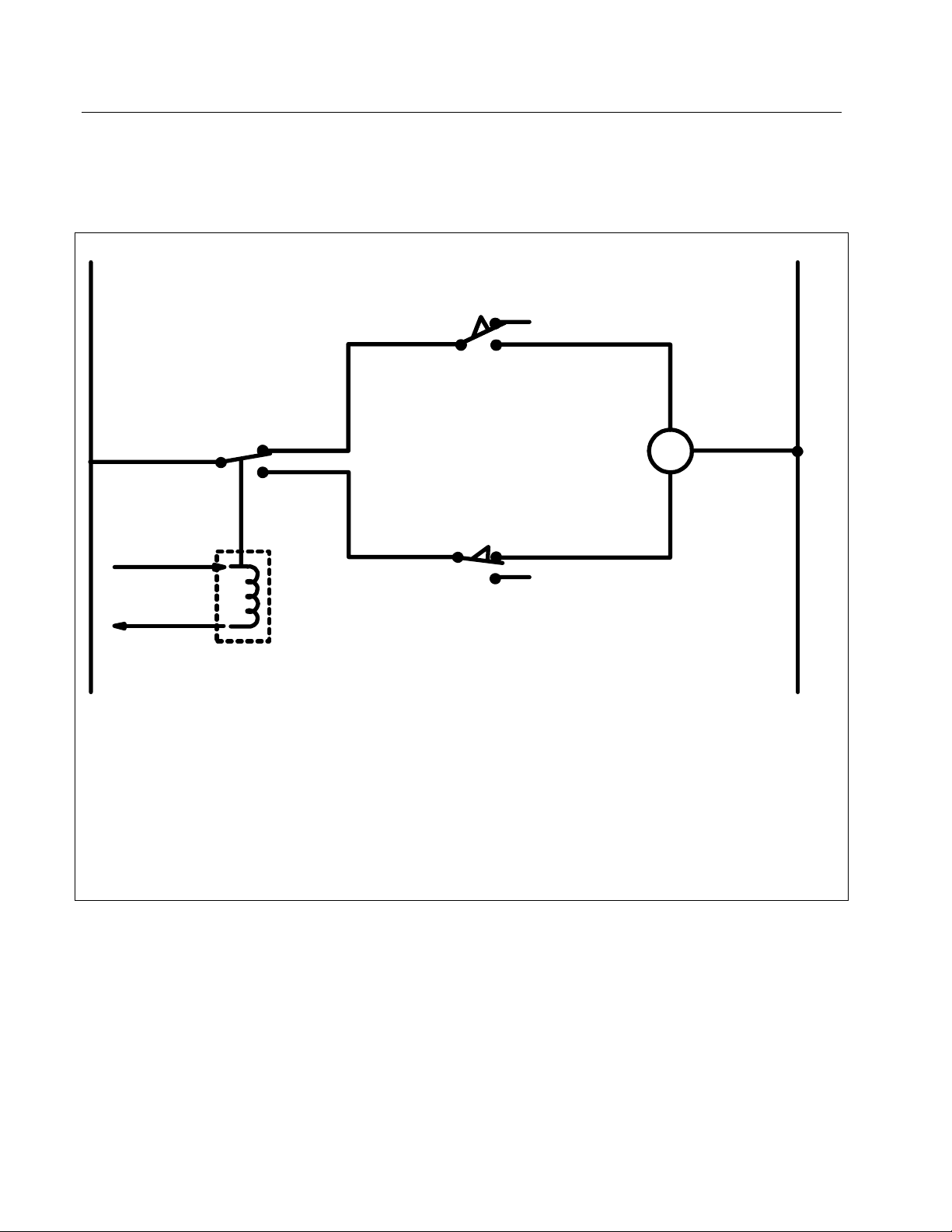

Simplified Schematic

H

5

1 or 4

3

To computer/controller via

interface board

Basket Lif t

Relay

Normally Open Upper-limi t

Microswitch

M

Normally Closed Lower-lim it

Microswitch

N

6

When the product button is pushed on the computer/controller, current flows through a coil in the

basket lift relay, causing the lower circuit to be activated. The basket lift lowers, closing the

normally open upper-microswitch. When the lower normally closed microswitch is opened by the

downward moving lift rod, power to the motor ceases to flow. When the computer/controller timesout, the current to the relay coil is interrupted, allowing the upper circuit to be activated. The basket

lift then raises and closes the lower microswitch. When the basket lift rod clears the upper

microswitch, the microswitch opens, and power to the circuit is interrupted, stopping the motor.

Pushing the product button or activating the manual control (if equipped) restarts the cycle.

Problems with the modular basket lift design can be grouped into three categories:

● Binding/jamming problems

● Motor and gear problems

● Electronics problems

1-14

Page 20

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.11 Basket Lift Service Procedures (cont.)

BINDING/JAMMING PROBLEMS

Noisy, jerky or erratic movement of the lifts is usually due to lack of lubrication of the rods and their

bushings. Apply a light coat of Lubriplate

bushings to correct the problem.

With the modular basket lift, another possible cause of binding is improper positioning of the motor,

which prevents the gear from correctly engaging the teeth in the rod. To correct the problem, loosen

the screws that hold the motor in place and move it forward or backward until the rod has just

enough slack to be rotated slightly.

or similar lightweight white grease to the rod and

MOTOR AND GEAR PROBLEMS

With the modular basket lift, the most likely problem to be encountered in this category is erratic

motion of the lift due to a worn drive gear. Failure to keep the lift rod and bushings properly

lubricated will cause unnecessary wear of the gear. The problem is corrected by replacing the worn

gear.

If the lift cycles correctly but fails to remain in the up position (i.e., goes up, but then slowly settles

back down into the frypot), the problem is a failed motor brake. The motor must be replaced.

If power is reaching the motor but the motor fails to run, the motor is burned out and must be

replaced.

ELECTRONICS PROBLEMS

Within this category are problems associated with the relays, microswitches, capacitors, resistors,

interface board, wiring, and controls. The most common problem in this category is a lift that

continuously travels up and down. This is usually caused by a microswitch that is out of adjustment.

Troubleshooting the electronics of a modular-type basket lift is simply a process of verifying current

flow through the individual components up to and including the motor. Using a multimeter set to the

250 VAC range, check the connections on both sides of the component for the presence of the

applied line voltage. The accompanying simplified wiring diagrams identify the components and

wiring connection points.

1-15

Page 21

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.11 Basket Lift Service Procedures (cont.)

Ultimate Electric Series fryers, used to cook large

amounts of bone-in chicken in a single drop, are

equipped with bell-crank style basket lifts.

Two components, a cam and bell crank, are

connected to the basket lift arm by a flat metal

link. The cam is attached to a drive motor. The

motor rotates the cam, thus raising or lowering

the lift arm linked to the bell crank. A rolleractivated microswitch is used to limit travel.

When the roller in the microswitch is in contact

with the cam, the motor is energized. As the cam

rotates, the roller loses contact with the cam and

the motor power circuit is broken, de-energizing

the motor.

Bell-crank style basket lift.

Timing circuitry in the controller initiates and stops basket lift operation. When the product button is

pressed, the timing circuitry activates a coil in the basket lift relay to supply power to the motor. The

microswitch stops the motor at the lift’s lower travel limit and the switch contacts are reversed. At

the end of the programmed cooking time, the timing circuit activates the coil once more and the lift

rises until the microswitch again loses contact with the cam, opening the motor power circuit and

stopping the motor. A typical bell-crank wiring diagram is shown below.

REFERENCES TO LEFT & RIGHT ARE FROM REAR OF

FRYER

M

LH SIDE

ALL RELAYS

12VDC COIL

N.O.

N.C.

RED

BLU

132

NC

5 4

2 1

B.L.COM 2

COM

NO

6 5 4

WHT

COM

3

1

2 1

NC

NO

5

4

FUSE

5AMP

LINE LOAD

LINE COM

B.L. LH

WHT

RH SIDE

COM

3

2

NO

NC

5

4

3 2 1

GRD

B.L. COM

M

BLK

COM

3

1

2

NC

NO

5

4

B.L. RH

PUR

ORG

N.O.

N.C.

1-16

Page 22

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.12 Electric Interface Board Diagnostic Chart

The following diagram and charts provide ten quick system checks that can be performed using

only a multimeter.

1

23

6

5

4

8

7

9

12

11

10

13

15

14

K1

K2

K3 K4

Note: The sealed relays

are not replaceable. If a

relay fails, the interface

board must be replaced.

Diagnostic LED Legend

CMP indicates power from 12V transforme r

24 indicates power from 24V transformer

HI (RH) indicates output (closed) from right latch

relay

HI (LH) not applicable to Ultimate Electric fryers

HT (RH) indicates output from right heat relay

HT (LH) not applicable to Ultimate Electric fryers

AL (RH) indicates output (open) from right latch

relay

AL (LH) not applicable to Ultimate Electric fryers

4

7

10

11

12

1

5

8

2

6

9

3

4

1

7

10

5

2

8

11

6

3

9

12

Meter Setting Test Pin Pin Results

12 VAC Power 50 VAC Scale 1 of J2 3 of J2 12-16 VAC

24 VAC Power 50 VAC Scale 2 of J2 Chassis 24-30 VAC

*Probe Resistance R X 1000 OHMS 11 of J2 12 of J2 See Chart

Hi-Limit Continuity R X 1 OHMS 7 of J2 4 of J2 0 - OHMS

Latch Contactor Coil R X 1 OHMS 8 of J2 Chassis 3-10 OHMS

Heat Contactor Coil R X 1 OHMS 9 of J2 Chassis 18-25 OHMS

*Disconnect 15-Pin harness from the computer/controller before testing the probe circuit.

1-17

Page 23

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.13 Probe Resistance Chart

Use the chart below when testing temperature probes and probe circuits for proper operation.

Probe Resistance Chart

F OHMS C F OHMS C F OHMS C F OHMS C F OHMS C

60 1059 16 130 1204 54 200 1350 93 270 1493 132 340 1634 171

65 1070 18 135 1216 57 205 1361 96 275 1503 135 345 1644 174

70 1080 21 140 1226 60 210 1371 99 280 1514 138 350 1654 177

75 1091 24 145 1237 63 215 1381 102 285 1524 141 355 1664 179

80 1101 27 150 1247 66 220 1391 104 290 1534 143 360 1674 182

85 1112 29 155 1258 68 225 1402 107 295 1544 146 365 1684 185

90 1122 32 160 1268 71 230 1412 110 300 1554 149 370 1694 188

95 1133 35 165 1278 74 235 1422 113 305 1564 152 375 1704 191

100 1143 38 170 1289 77 240 1432 116 310 1574 154 380 1714 193

105 1154 41 175 1299 79 245 1442 118 315 1584 157 385 1724 196

110 1164 43 180 1309 82 250 1453 121 320 1594 160 390 1734 199

115 1174 46 185 1320 85 255 1463 124 325 1604 163 395 1744 202

120 1185 49 190 1330 88 260 1473 127 330 1614 166 400 1754 204

125 1195 52 195 1340 91 265 1483 129 335 1624 168 405 1764 207

1.14 Element Wattage/Amperage Calculation Charts

Use the charts below when changing voltages or determining amperage for a given element

configuration.

L1

L1

Three Phase

Amperage

L2

L3

To determine Three Phase Amperage, solve for

Single Phase first:

Wattage

Voltage

Then divide the Single Phase Amperage by 1.73 to

determine Three Phase Amperage.

Example:

17,000W

= 40.944 Amps per Phase

= Single Phase Amps

70.833 Amps

240V

=

1.73

Three Phase

Wattage

L2

L3

To compute the New Wattage Rati ng of an el ement if a

different voltage is applied, use the following formula:

208V

240V

2

2

kW Listed

X

X

17,000 Watts

New Voltage

[]

Old Voltage

= New Wattage Rating

Example:

If 208V supply is applied to a 17 kW element

rated for 240V, the calculation is as follows:

[]

= 12.77 kW

1-18

Page 24

L

1

480V ELEMENTS

5 632 4

1.15 Wiring Diagrams, Main

1.15.1 Wiring Diagram, Main- 480V: 18UE and EH1721

9R76 854312

1-19

WHT 70C

T1

T2

TILT SWITCH

PROBE

BLK 2C

BLK 71C

C

WHT 3C

BLK 6C

HIGH LIMIT

THERMOSTAT

NC

BLU 60C

BLU 61C

RED

WHT

WHT 4C

BLK 5C

FUSE

WHT 1C

BLU 28C

WHT

FUSE

BLK

RED

To Basket Lift

BLU 29C

C6

1 1

2

3

4

5

6

2

3

4

5

6

RED 34CBLK

WHT 33C

BLU 37C

RED 35C

RED 32C

BLU 36C

LATCH

CONTACTOR

21436 5

BRN 40C

K1

3 51

120V

24V

GRN/YEL 74C

BRN 40C

YEL 12C

RED 73C

PUR 75C

YEL 72C

120V

12V

ORG 14C

ORG 15C

WHT 42C

9

12

J2

12

6 7345

67345

11 1298 10

9

1298 10

11

COMPUTER INTE RF ACE

BOARD (NO. 8067965)

GND

321

4

TO FRY BM 3.5 COMPUTER

131110 1287 965

14

CONTACTOR

K2

624

BLK 48C

J1

HEAT

BRN 40C

BLK 5H

BLK 3H

BLK 1H

120V

480V

RED 30C

RED 31C

DRAIN

SWITCH

FRY CM 3.5 COMPUTER

(NO. 8067158)

TO INTERFACE BOARD

BLU 6H

BLU 6H

BLU 2H

RED 38C*

RED 39C*

* Non Basket

Lift Position

GROUND

TERMINAL

3 WIRE

3 PHASE

6

L3

3,6

3

4

L2

4,5

5

L1

1,2

2

1

TERMINAL

BLOCK

15141310 11 12985 6 7341 215

8051401D

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

Page 25

208V ELEMENTS

L

1

1.15.2 Wiring Diagram, Main- 208V- 18UE and EH1721

5 632 4

9R76 854312

1-20

WHT 70C

T1

T2

TILT SWITCH

PROBE

BLK 2C

BLK 71C

C

WHT 3C

BLK 6C

HIGH L IMI T

THERMOSTAT

NC

BLU 60C

BLU 61C

RED

WHT

WHT 4C

BLK 5C

FUSE

WHT 1C

BLU 28C

WHT

BLK

RED

FUSE

1 1

2

3

4

5

6

To Basket Lift

BLU 29C

C6

RED 34CBLK

WHT 33C

2

BLU 37C

3

RED 35C

4

RED 32C

5

BLU 36C

6

LATCH

CONTACTOR

21436 5

208V

24V

BLU 28C

RED 73C

PUR 75C

BRN 40C

YEL 12C

GRN/YEL 74C

YEL 72C

208V

12V

ORG 15C

ORG 14C

12

J2

12

COMPUTER INTERFACE

BOARD (NO. 8067965)

GND

321

4

TO FRY BM 3.5 COMPUTER

BRN 40C

6 7345

67345

K1

3 51

WHT 42C

9

11 1298 10

11

9

1298 10

131110 1287 965

14

CONTACTOR

K2

624

J1

HEAT

BRN 40C

BLK 48C

FRY CM 3.5 COMPUTER

BLK 5H

BLK 3H

BLK 1H

DRAIN

SWITCH

(NO. 8067158)

TO INTERFACE BOARD

BLU 6H

BLU 6H

BLU 2H

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

GROUND

TERMINAL

4 WIRE

3 PHASE

5

L41,3,5

3

1

L3

6

6

L24

4

2L1

2

TERMINAL

BLOCK

3 WIRE

3 PHASE

6

L3

3,6

3

4

L2

4,5

5

L1

1,2

2

15141310 11 12985 6 7341 215

1

TERMINAL

BLOCK

8051412A

Page 26

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.15.3 Wiring Diagram, Main- KSCFH218E

HEATING

ELEMENT

6C

L3

6C

4C

L2

4C

CYCLING

2C

CONTACTOR

L1

2C

6

54321

9

6

3

2

8

5

1

7

4

77C

27C

26C

25C

76C

L2

L1 L3

LATCH CONTACTOR

6C

6C

4C

4C

2C

2C

CYCLING

CONTACTOR

60A FUSE EACH

FUSE BLOCKS

24C

23C

22C

21C

L3

19C

L2

L1

20C

18C

L2

L3

16C

L1

GROUND

L3L2

17C

L1

BLOCK

TERMINAL

LATCH

CONTACTOR

DELTA

3 PHASE, 3 WIRE

LATCH CONTACTOR

1C ARE ELIMINATED

WIRE 7C GOES FROM

HOLDER AND WIRE

NOTE: RIGHT FUSE

TO T2.

24C

23C

8C

22C

27C

26C

25C

7C TO T2

GROUND

L3

L2

L1

N

BLOCK

TERMINAL

KSCFH218

4 WIRE WYE

CONNECTION

65432

TILT

SWITCH

58C

WHT

RED

3

614

5

2

1

4

5C

3C

5C

3C

1C

1C

12

7

4

8

5

9

1C

3C

1C

3C

5C

4

5

6

6

5

4

2C

6

3

4C

6C

5C

2C

4C

1

2

3

3

2

1

CABLE TO REAR

24V

TRANSF

240

220

230

208

COM

6C

3C

5C

12C

HEATING

ELEMENT

COM

208V

12V

TRANSF

1

8C BLK

TO

FILTER

75C

RED

BLK

SPEAKER

44C

DRAIN SWITCH

43C

7

9

8

6C

T1T2

4C

240V

15C

14C

4563

1

2

COMPUTER (BACK)

13C

33C

36C

32C

59C

5

2

3

6

OIL

SENSOR

ON ELEMENT

TEMPERATURE

34C

35C

33C

32C

36C

37C

CABLE TO REAR

34C

6

3

1210 11

2

5

897

1

4

35C

654

11 1210

1 2 3

7 89

15 PIN CABLE

37C

BOARD

INTERFACE

110C

2C BLK

8C BLK

41C

1C WHT

7C WHT

FUSE

HOLDER

FUSE

HOLDER

AMP

PINS

FEMALE

8051429B

HIGH LIMIT

BLK

FLOAT

SWITCH

BLK

AMP

PINS

MALE

1-21

Page 27

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.15.4 Wiring Diagram, Main- BIH1721

R

6 7 8 9

6H BLU

CONTACTOR

HEAT

132 54

6

208V OR 240V ELEMENTS

1 3254

L

K2

K1

LATCH

CONTACTOR

37C BLU

4H BLU

41C BRN

40C BRN

2H BLU

5H BLU

64231 5

3H BLU

1H BLU

42C WHT

15C ORG

14C ORG

BLOCK

240V ONLY

4 WIRE

1514

1311 126 7891034512

TERMINAL

N

L2

L1

L3

L4

3 PHASE

331

5

2,4,6

4

2

6

1

5

BLOCK

TERMINAL

GROUND

3 WIRE, 3 PHASE

FUSES USED ONLY FOR

NC

COM

SWITCH

DRAIN

L3

3 WIRE, 3 PHASE

3,6

6

3

1C WHT

20A

FUSE

NO

48C BLK

12

119107856

3421

TERMINAL

L1

L2

1,2

4,5

1

5

2

4

12

119107856

3421

BOARD (NO. 806-7965)

COMPUTER INTERFACE

J2

GND

32C RED

36C BLU

34C RED

35C RED

33C WHT

37C BLU

2

145

3

BLK

BLK 10C

BLK 20C

66

2

1

4

5

3

RED

WHT

61C BLU

RED

60C BLU

BLK

SWITCH

BY-PASS

BLK 23C

BLK 26C

WHT 46C

WHT

PROBE

TILT SWITCH

POSITION

MICRO SWITCH83C

OIL RETURN

SHOWN IN OFF

WHT 22C

NC

NO

COM

NC

NO

RELAY

BLK 11C

YEL

24V

COM

WHT 45C

T8

RED 80C

RED 25C

LOW VOLTAGE SHOWN

24V

T5

CB

HIGH VOLTAGE SHOWN

BREAKER

CIRCUIT

WHT

ON THE MOTOR

MOTOR

FOR CHANGE OF ROTATION

INTERCHANGE LEADS T5 AND T8

T2T4T3P2T5

T4

T8

2 AMP FUSE

HEAT TAPE - 25 WATT

P1

WHT

RED

TAIL

BOMB

P2

T2

T3

P1

100C WHT

101C RED

BLK

104C WHT

105C BLK

BOMB TAIL

12V

240V

28C BLK

29C WHT

240V

6C BLK

3C WHT

20A FUSE

BLK

WHT

T1

T2

C6

YEL

YEL

24V

NC

C

HIGH LIMI T

THERMOSTAT

2C BLK

29C WHT

8051445B

1-22

Page 28

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.16 Wiring Diagrams, Basket Lifts

1.16.1 Modular Basket Lifts

LEFT

SIDE

RESISTORS**

RIGHT

SIDE

MM

NO

NC

UPPER

SWITCH

NO

NC

LOWER

SWITCH

COM

COM

**120V UNITS: TWO 13 OHM

**208-220V UNITS: FOUR 50 OHM

COM

3

2

1

NONC

45

4 3 26 5

1

COM

3

2

1

NO

NC

45

12.5 µF12.5 µF

NO

COM

UPPER

SWITCH

NO

COM

NC

NC

LOWER

GND

LIN COM

B.L. LH

B.L. COM

B.L. RH

SWITCH

LINE LOAD

240V Basket Lifts OnlyThree Sets of Resistors

LEFT SIDE RIGHT SIDE

MM

25 Ohm 25 Ohm

50 Ohm

1-23

Page 29

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.16.2 Bell-Crank Style Basket Lifts

REFERENCES TO LEFT & RIGHT ARE FROM REAR OF FRYER

M

LH SIDE

WHT

RH SIDE

M

BLK

ALL RELAYS

12VDC COIL

COM

N.O.

N.C.

132

NC

5 4

NO

RED

WHT

1

NC

5

COM

3

2 1

NO

4

COM

3

2

NC

NO

5

4

BLU

FUSE

5AMP

2 1

6 5 4

3 2 1

COM

3

1

2

NC

NO

5

4

N.O.

N.C.

PUR

ORG

LINE LOAD

B.L.COM 2

LINE COM

B.L. LH

GRD

B.L. COM

B.L. RH

1-24

Page 30

SCF OIL RETURN

TRANSFORMER/RELAY ASSY

1.17 Wiring Diagrams: Built-in Filtration

1.17.1 Wiring Diagram, 480V Systems With Built-in Filtration

1-25

BLK #2

INPUT

115V

CIRCUIT

BLK 11C

CIRCUIT BREAKER

WHT#1

BLK

WHT#2

WHT 45C

WHT 46C

CB

7 AMP-120V

5 AMP-480V

HIGH VOLTAGE SHOWN

BLK 20C

ULTIMATE ELECTRIC SERIES FRYERS

BLK 23C

BLK 26C

NC

120V

24V

LOW VOLTAGE SHOWN

T5

T4

T8

T3

T2

P2

P1

J BOX

FUSE

2 AMP

GRN

JUCTION BOX

COVER PLATE

FUSE

FUSE HOLDER

T8

T4

T2

T5

T3

P2

P1

FOR CHANGE OF ROTATION INTERCHANGE

HEAT TAPE - 25 WATT

MOTOR

LEADS T5 AND T8 ON THE MOTOR

RELAY

RED 25C

NO

COM

24V

RED 80C

YEL 83C

COM COM

OIL RETURN

LH FRYER

NC

YEL 84C

RED 81C

NC

NONO

OIL RETURN

CENTER FRYER

MICROSWITCH

SHOWN IN

OFF POSITION

YEL 85C

RED 82C

NC

COM

NO

OIL RETURN

RH FRYER

(TRIPLE)(DOUBLE)

8051403F

CHAPTER 1: SERVICE PROCEDURES

Page 31

SCF OIL RETURN

TRANSFORMER/RELAY ASSY

1.17.2 Wiring Diagram, 208V Systems With Built-in Filtration

1-26

INPUT

208V

CIRCUIT

BLK 11C

WHT#1

BLK

WHT 45C

WHT 46C

CB

LOW VOLTAGE SHOWN

BLK 20C

BLK 23C

BLK 26C

NC

208V

24V

T5

T4

T8

T3

T2

P2

P1

HIGH VOLTAGE SHOWN

T5

T4

T2

T8

T3

P2

P1

FOR CHANGE OF ROTATIO N I NTE RCHA NGE

MOTOR

LEADS T5 AND T8 ON THE MOTOR

RELAY

PN 1932

RED 25C

NO

COM

24V

RED 80C

YEL 83C

COM COM

OIL RETURN

LH FRYER

NC

BLK 10C

BY-PASS SWITCH

WHT 22C

YEL 84C

RED 81C

OIL RETURN

CENTER FRYER

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

YEL 85C

RED 82C

NC

NONO

NC

COM

NO

OIL RETURN

RH FRYER

(TRIPLE)(DOUBLE)

MICRO SWITCH SHOWN IN

OFF POSITION

8051413A

Page 32

1.17.3 Wiring Diagram, 115/230V KFC Systems With Built-in Filtration

1-27

11

2 2

NC

COM

NO

OIL RETURN

MICRO SWITCH

RH FRYERLH FRYER

PUR

NC

RED

NO

YEL #1

COM

24V

YEL

PUR

ORG

WHT

YEL

1

2

PUR

ORG

WHT

YEL

1

2

RH FRYER TRANFORMER

115 VAC OR 230 V AC

TO 24 VAC

NC

NO

COM

24V

YEL #1

BLK

ORG

115V

230V

BLK

BLU

ULTIMATE ELECTRIC SERIES FRYERS

24V

YEL

YEL

24V OUT

YEL

YEL

CHAPTER 1: SERVICE PROCEDURES

TO RH FRYER

CIRCUIT

ORG

MANUAL

BY PASS

SWITCH

CIRCUIT

BREAKER

115 V - 7 AMP

230 V - 5 AMP

CB

BLK

BLK

BLK

WHT

INPUT

115V/230V

FILTER CIRCUIT

1

2

WHT#1

BLK

T5

T4

T8

MOTOR

T3

T2

T1

FOR CHANGE OF ROTATI ON I NTERCH A NGE

LEADS T5 AND T8 ON THE MOTOR

1

2

RED

NC

COM

NO

OIL RETURN

MICROSWITCH

KSCFH18E FILTER CIRCUIT

8051366B

Page 33

ULTIMATE ELECTRIC SERIES FRYERS

2.1 Accessories

CHAPTER 2: PARTS LIST

1

2

5

3

4

6

7

Item Part Number Description

1 810-2092 Basket Hanger

* 106-1968 Cover, Vat- All Ultimate Electrics

2 809-0171 Thumbscrew, Basket Hanger

3 210-1288 Joiner Strip

4 803-0209 Brush, Frypot

* 810-2120 Grid, Frypot W/Standoff

* 803-0149 Grid, Frypot- FPH1721 Systems

5 803-0306 Fry Basket, Twin Basket

* 803-0017 Fry Basket, Full Basket

6 826-1117 Caster, 5"- W/O Brake (Mounting Hardware Included)

7 826-1118 Caster, 5"- With Brake (Mounting Hardware Included)

* 803-0197 Fryer’s Friend (Clean-out Rod)

* Not Illustrated

2-1

Page 34

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.2 Basket Lift Assembly (Modular) and Related Components

120V Basket Lifts Only

18

8

1

208-230V Basket

Lifts Only

20

9

3

1415

5

13

22

16

21

2

19

7

11

17

6

12

Item Part Number Description

* Not Illustrated

10

4

1 200-2564 Mount, Basket Lift Assembly

2 806-5964 Motor Assembly- All EH172 1 Bask et Lif ts

3 106-2770SP Resistor Assembly, 200/208/220V

* 106-2771SP Resistor Assembly, 230/240/250V

806-8530SP Resistor Assembly, 120V (Used On 480V Fryers)

* 807-2661 Resistor, 13 Ohm-120V (For 480V Fryers)

* 807-3893

Resistor, 50 Ohm- 200V/250V (For 208/220V and

230/250 Fryers)

* 807-2511 Resistor, 25 Ohm- 230V/250V (For 230/250V Fryers)

2-2

Page 35

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.2 Basket Lift Assembly (Modular) and Related Components (cont.)

Item Part Number Description

4 807-0159 Connector, 12-Pin

5 807-2133 Capacitor, 120V Basket Lifts

* 807-2513 Capacitor, 208V Basket Lifts

6 807-2572 Microswitch

7 809-0082 Ring, Truarc

8 809-0111 Screw, 8-32

9 809-0186 Washer, Lock #6

10 809-0237 Nut, 4-40

11 809-0247 Nut, 8-32, Hex Keps

12 809-0354 Screw, 4-40 x ¾"

* 809-0358 Screw, 4-40 x ¼" (Use with 208V Basket Lifts)

13 809-0361 Screw, (Drill #8)

14 809-0412 Screw #10-1/2 Hex

15 809-0503 Screw, Hex 8-32 x ½"

16 810-1012 Basket Lift Rod

17 812-0442 Insulation, Switch Box

18 813-0035 Bushing, Bronze .620 ID

19 900-5529 Gusset

20 901-8499 Chassis, Left

21 902-8499 Chassis, Right

22 807-1683 Relay, 12VDC

* 200-2565 Enclosure, Basket Lift Assembly

* 200-3232 Mount, Conduit- Basket Lift Wire Harness Cover

* 200-3224 Cover, Basket Lift Wire Harness

* Not Illustrated

2-3

Page 36

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.2 Basket Lift Assembly (Modular) and Related Components (cont.)

1

7

6

5

4

2

Item Part Number Description

1 106-1594SP Roller Assembly, Bracket

2 809-0508 Bolt, ¼-20 x 1-¼" Hex Head S/S

3 809-0190 Washer, Flat- ¼" S/S

3

8 9

4 810-0374 Spacer, Tubular Basket Lift Roller

5 810-0194 Roller, Basket Lift

6 809-0047 Nut, Cap- ¼-20 S/S

7 809-0132 Screw, ¼-20 x ¾" Round Slotted S/S

8 823-3992 Basket Lift Arm- Left

9 823-3993 Basket Lift Arm- Right

2-4

Page 37

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.3 Cabinetry and Related Components

2.3.1 EH1721 & 18UE

1

5

2

24

39

38

19

20

16

17

22

6

31

26

9

18

25

30

12

27

10

23

29

11

3

14

154

13

7

28

21

8

33

34

37

32

36

35

2-5

Page 38

ULTIMATE ELECTRIC SERIES FRYERS

2.3.1 EH1721 & 18UE (cont.)

Item Part Number Description

1 106-1724SP Cover Assembly, Dump Station Front

2 200-1254 Guard, Rear Wire- Top

3 200-1255 Guard, Rear Right Center Wire, Side

4 200-1263 Channel, Bus Electric

5 200-1284 Channel, Vessel- Outer Back Panel

6 200-1285 Channel, Vessel- Outer Back Panel

7 200-1331 Shield, Burner- Heat

8 200-1675 Bracket, Lower Hinge

9 200-2308 Post, Door

10 200-2493

* 200-2534 Channel, Front & Rear- 3-Battery With Dump Station

CHAPTER 2: PARTS LIST

Channel, Front & Rear- Single and 2-Battery With

Dump Station

11 200-2526 Channel, Base

12 200-3215 Frame, Base- 1721 Systems

* 200-3491 Frame, Base- BIH1721

13 200-3264 Base, Cabinet Lower Frame- 1721 Systems

* 200-3494 Base, Cabinet Lower Frame- BIH1721

14 200-3242 Guard, Center Rear Wire

15 200-2842 Cover, Structural Back- Lower

16 201-3216 Panel, Inner-Left Side

17 201-2533 Side, Cabinet- Left (With Hole)

18 201-2552 Gusset, Side Panel- Lef t

19 202-3216 Panel, Inner- Right Sid e

20 202-2533 Side, Cabinet- Right (With Hole)

21 202-2552 Gusset, Side Panel- Rig ht

22 210-2756 Duct, Door Access

23 210-2848 Bracket, Cabinet Batter

24 211-2532 Side, Cabinet- Left Side

25 212-2532 Side, Cabinet- Right Side

26 823-3248 Support, Leg

27 823-3458 Wireway, Control Panel

* Not Illustrated

2-6

Page 39

ULTIMATE ELECTRIC SERIES FRYERS

2.3.1 EH1721 & 18UE (cont.)

Item Part Number Description

28 823-3468 Channel, Leg Support

29 823-3559 Slide, Filter Pan Su pport

30 200-3240 Bottom, Bus Channel

31 823-3688 Cover, Bus Channel (With Bracket)

32 106-0855SP

33 200-1185 Panel, Door- Inner

34 200-1301 Door Pin

35 210-1271 Panel, Door- Outer

36 810-0180 Handle, Door

CHAPTER 2: PARTS LIST

Door Assembly (Door Pin Not Included) See Section

2.3.3 For Additional Door Components

* Not Illustrated

* 809-0918 Screw, 10-24 x ½" Slotted Head (Use With 810-2105)

* 809-0191 Washer, ¼ Spring-Lock (Use With 810-2105)

37 810-0066 Magnet, Door

38 200-1252 Back, Upper Cabinet

39 200-1283 Cover, Vent- Cabinet Back

2-7

Page 40

2.3.2 KFC18E Electric

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

32

30

31

29

35

34

24

25

28

18

1

19

3

26

22

21

20

33

14

27

2

23

17

16

15

8

6 7

5

4

9 10

11

12 13

2-8

Page 41

ULTIMATE ELECTRIC SERIES FRYERS

2.3.2 KFC18E Electric (cont.)

Item Part # Description

1 201-1299 Side Panel, Painted, LH

2 202-1299 Side Panel, Painted, RH

3 810-0378 Caster, Stationary- 5" Rigid

4 806-5043 Leg

0 823-3180 Support, Channel- Leg/Caster

6 201-1182 Gussets, L/H

7 202-1182 Gussets, R/H

8 200-1675 Lower Hinge Bracket (Door)

9 200-1185 Door Panel, Inner

10 210-1271SP Door Panel, Outer

* 106-0855SP

11 810-1105 Magnetic Door Catch

12 810-0180 Handle, Door

* 809-0918 Screw, 10-24 x ½" Slotted Head (Use With 810-2105)

* 809-0191 Washer, ¼ Spring-Lock (Use With 810-2105)

13 200-1301 Door Pin

14 210-1262 Top Cap

15 210-1806 Slide, UFF Filter Pan- Front (Long)

16 210-2128 Slide, UFF Filter Pan- Rear (Short)

17 200-1331 Shield, Heat

18 200-1297 Base, Lower Frame

19 200-1198 Channel, Base

20 200-2134 Plate, Mounting (UFF)

21 200-1611 Base, Upper

22 200-1263 Channel, Bus

23 200-1471 Cover, Access Duct

24 202-1245 Panel, Inner- Right Sid e

25 201-1245 Panel, Inner- Left Side

26 200-2308 Post, Door

27 210-1278 Guard, Wire- Center

28 200-1254 Guard, Wire- Top

29 200-1255 Guard, Wire- Right Side Center

30 200-1252 Back, Cabinet

* 200-3362 Closure, Lower Structural Back (Single Fryers)

* Not Illustrated

CHAPTER 2: PARTS LIST

Door Assembly (Door Pin Not Included) See Section

2.3.3 For Additional Door Components

2-9

Page 42

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.3.2 KFC18E Electric (cont.)

Item Part # Description

31 200-1283 Cover, Back Vent

* 809-0360 Screw, Hex Slotted Head – With Washer- #8 x 3/8"

32 823-3551 Housing, Tilt

33 210-1288 Joiner Strip

34 810-2092 Hanger, Basket

35 809-0171 Thumbscrew, ¼ x 1-3/8" Nickel-Plated

* Not Illustrated

2.3.3 Door Components – Spring-Loaded Door Pins

Item Part # Description

* Not Illustrated

4

5

6

2

1

3

1 824-1146 Panel, Door- Outer (Current Production UE Only)

2 200-4610 Liner, Door (Current Production UE Only)

3 810-0180

4 810-1105 Magnet, Door (Offset)

5 106-0554SP Pin, Door Slotted (With Keeper)

6 810-0275 Spring, Door Hinge

Handle, Door (See Section 2.3.1 and 2.3.2 for

connecting hardware)

2-10

Page 43

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.3.4 Top Cap and Tilt Housing Components

1

4

7

2 3

5

8

9

6

10

Item Part Number Description

* Not Illustrated

1 106-1722SP

2 106-1723SP Tilt Housing - EH1721 W/Dump Station

3 823-3551 Tilt Housing, 2-Batter y EH1 721

4 824-0946 Tilt Housing, 3-Batter y EH1 721 W/Dump Station

5 823-3855 Tilt Housing, BIH/EH1721- Single

6 824-0944 Top Cap, 4-Battery EH1721

7 824-0945 Top Cap, 3-Battery EH1721

8 823-3436 Dump Station, EH1721

* 823-2335 Strainer (Screen), Dump Station Drain

9 803-0310 Grid, Dump Station

10 106-1724SP Cover Assy, Dump Station- Front

Tilt Housing (With Nutsert), 2-Battery EH1721 W/Dump

Station

2-11

Page 44

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.4 Computers, Controllers and Related Components

1 2

12345 678

4

1

9

0

CM4-S

3

5

6

7

8

2-12

Page 45

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.4 Computers, Controllers and Related Components (cont.)

Item Part Number Description

1 106-1827 Computer, CM-III Full-Vat

2 106-1503 Controller, Digital- Full-Vat

* 106-2510 Controller, Digital- Full-Vat- CE

3 106-0063 Computer, KFC-1 Electric (Non-CE)

* 106-0064 Computer, KFC-1 Electric (CE)

4 106-3028 Computer, CM4-S (Segmented Programming)

5 806-7422 Controller, Analog- Solid State (3 On, 12 Off)

6 210-1256 Control Panel- All Ultimate Electrics

All Computers/Controllers Come With Bezels

Except Item #5

7 823-3433 Bezel, Computer- All Except KFC18E

* 823-2882 Bezel, Computer- KFC18E Only

8

210-1985 Faceplate, Potentiometer Assembly- 18UE

802-2052 Label, Faceplate- Electronic Thermostat Controller

106-0801SP Pot Assy, Electronic Thermostat Controller- 18UE

816-0534

* Not Illustrated

Electronic Thermostat Controller

Kno b, Pot As s y- Electron ic Thermostat Controller 18UE

2-13

Page 46

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.5 Contactor/Wireway Box and Related Components

2

15

3

1

8

10

7

PUMP

OFF

12

911

14

4

5

6

13

2-14

Page 47

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.5 Contactor/Wireway Box and Related Components (cont.)

Item Part Number Description

1 806-6336

2 807-3722

3 807-0855 Transformer, 120V, 50/60 Hz –12V 20VA (480V Units)

* 807-0979 Transformer, 208-240V, 50/60Hz –12V 20VA

4 807-0800 Transformer, 120V 50/60 Hz –24V 50VA (480V Units)

* 807-0680 Transformer, 208-240V, 50/60Hz –24V 20VA

5 807-3611 Relay, 24VAC

6 807-1071 Contactor, Mercury- 240VAC 30-Amp (17 kW Units)

* 807-0884 Contactor, Mercury- 240VAC 50-Amp (21 kW Units)

Interface Board- (All Except Electronic Thermostat

Controller)

Interface Board- (Electronic Thermostat Controllers

Only)

* Not Illustrated

7 810-1202 Contactor, Latching- 40-Amp, 3-Pole

8 807-0922 Fuse Holder, Buss Fuse

* 807-2278 Fuse, 20-Amp

9 806-3660 Sound Device- All Except KFC18E

10 806-3660 Speaker, Sound- KFC18E Only

11 807-3538 Breaker, Circuit- 5 Amp (230V Filter Circuit)

* 807-3577 Breaker, Circuit- 7 Amp (120V Filter Circuit)

12 807-3539 Switch, Toggle- Filter Bypass- ON-OFF

13 807-0501 Fuse Block, Buss #2968, 3-Pole

14 807-2465

* 807-3610

15 823-3458 Wireway Control Panel (Box)- All Ultimate Electrics

* 816-0570 Cover, Wireway Control Box (Clear Lexan)

* 807-0331 Transformer, 480V-250VA (With Basket Lift)

* 807-0064 Transformer, 480V-150VA (Without Basket Lift)

* 807-0800

* 807-0680

* 824-0955 Cover, 480V Transformer- Left Side

* 200-1291

* 18-0350-1

Power Block– 3-Phase- WYE Only

Power Block– 3-Phase- DELTA Only

Transformer, 120V 50/60 Hz -24V 50VA (UFF 100

Pump Motor Relay)

Transformer, 208V, 50/60Hz –24V 20VA (UFF 100

Pump Motor Relay)

Cover, Terminal Block- All Except Electronic

Thermostat Controller

Cover, Terminal Block- Electronic Thermostat

Controller Only

2-15

Page 48

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.6 Filter Pan and Related Components- Built-in Filtration

2.6.1 Under Fryer Filter (UFF) – UFF 80 (100 Lb Capacity)

6

7

5

4

3

2

10

1

11

8 12

9

Item Part Number Description

1 106-1584SP Filter Pan, UFF 80 (100 Pound Capacity)

2 823-3365 Support Grid (Bottom Pan Screen)

3 803-0303 Filter Paper, 26 x 34" (100 Sheets)

4 823-3439 Hold-down Ring, Weighted

5 823-3443 Crumb Basket

6 106-1587SP Filter Pan Cover, Front

7 106-1588SP Filter Pan Cover, Back

8 809-0822 Bolt, ¼-20 x ½" Steel

9 210-2291 Insert, Caster

10 809-0820 Nut, Oval Locking- ¼-20

11 809-0805 Screw, ¼-20 x ½"

12 810-0006 Caster, 2"

2-16

Page 49

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.6.2 Under Fryer Filter (UFF) – KFC18E Only

6

5

7

4

24

23

13

22

14

3

21

2

1

8

9

18

19

20

19

15

16

17

18

11

12

10

2-17

Page 50

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.6.2 Under Fryer Filter (UFF) – KFC18E Only (cont.)

Item Part Number Description

1 823-3240 Pan, Filter- KFC18E

2 810-2119 Grid, Filter- KFC18E

3 803-0170 Paper, Filter- 16-½ x 25-¾" (100 Sheets)

4 823-3201 Ring, Hold-Down (No Handles)- KFC18E

* 823-3202 Handle, Hold-Down Ring- KFC18E

5 823-3204 Crumb Basket- KFC18E

6 106-0903SP Lid, Filter Pan- Front

7 106-0905SP Lid, Filter Pan- Back

8 809-0866 Screw, SS- ¼-10 x ½" Phillips Head

9 210-1293 Insert, Mounting Plate- Caster

10 810-0006 Caster, 2"

11 809-0823 Nut, Nylock- ¼-20

12 809-0822 Bolt, ¼-20 x ½" Hex Head

13 813-0679 Plug, SS- 1/8 Squ are Head

14 810-2100 Motor, Filter Pump- 120/230V 1/3 HP

15 810-2098 Pump, Filter- 8GPM

16

813-0022 Nipple, ½" NPT x Close BM

813-0003 Tee, ½" NPT BM

813-0156 Plug, ½" NPT BM

17 813-0674 Nipple, ½ NPT x 7-¼"

18 813-0062 Elbow, ½" x 90°

19 813-0247 Nipple, ½ NPT x 3-½"

20 813-0173 Union, ½" NPT BM

21 823-3282 Tube, Suction Assembly

22 813-0608 Coupling, Full

Fitting, Oil Suction Start

23 810-0697 Disconnect, Male

* 826-1392 O-Ring, Disconnect (Qty: 5)

24 106-0820SP Drip Cup Assembly

* Not Illustrated

2-18

Page 51

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.6.3 Under Fryer Filter (UFF) – Filter-Leaf /Suction Tube Assembly

7

8

4

3

1

5

2

12

9

11

6

10

13

Item Part Number Description

1 823-4184

2 810-2350 Filter Leaf

3 810-2583 Fitting, Bottom- Filter Leaf

Filter Pan, UFF 80- Filter-Leaf Equipped

4 810-2582 Fitting, Upper- Filter Leaf

5 823-4112 Suction Tube Assembly- Filter Leaf

* 813-0679 Plug, 1/8 Square S/S (Suction Port)

6 823-3443 Crumb Basket

7 106-2953SP Filter Pan Cover, Front

8 106-2952SP Filter Pan Cover, Back

9 809-0822 Bolt, ¼-20 x ½" Steel

10 210-2291 Insert, Caster

11 809-0820 Nut, Oval Locking- ¼-20

12 809-0805 Screw, ¼-20 x ½"

13 810-0006 Caster, 2"

* Not Illustrated

2-19

Page 52

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.6.4 Single Under Fryer Filter (SUFF) – BIH1721 and 18UE

10

6

9

7

5

4

1

3

2

8

Item Part Number Description

1 106-2225SP Filter Pan, SUFF 60 BIH1721 and 18UE

2 810-2141 Caster, 2"-Swivel

3 809-0823 Nut, Nylock ¼-20

4 813-0679 Plug, 1/8" SS Square Head

* Not Illustrated

* 813-0684 Plug, Hex Socket, 3/8" NPT

5 823-3769 Support Grid (Bottom Pan Screen)- SUFF 60 BIH1721

6 803-0289 Paper, Filter- 22 x 34"

7 823-3768 Hold-Down Ring, Weighted- SUFF 60 BIH1721

8 823-3736 Crumb Basket

9 823-3766 Filter Pan Cover, Front

10 823-3767 Filter Pan Cover, Bac k

2-20

Page 53

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.7 Frypot and Drain Valve Components

1

High-Limit Location

3

4

5

6

7

Included with Drain Valve

2

Included with Drain Valve

8

Item Part Number Description

1 823-3235 Frypot- EH1721, 18UE & 18E

* 823-4290 Frypot- EH1721 With 3 Oil-Level Lines

2 823-4233

* 823-4187

Handle, Drain Valve- Filter Units Only

Handle, Drain Valve- Single Fryers Only

* Not Illustrated

* 816-0547 Cap, Drain Valve Handle- Red

3 200-1257 Retainer, Drain Valve Nut

4 816-0220 Insulation, Microswitch

5 807-2104 Microswitch (Domestic and CE)

6 210-1269 Guard, Drain Valve Microswitch

7 809-0237 Nut, 4-40 Keps Hex- With External Teeth

8 823-3236 Drain Valve- 1-½" Full Port W/ Microswitch Bracket

2-21

Page 54

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.8 Oil Drain Flush Components

10

11

8

23

4

6

1

7

9

5

Item Part Number Description

1 813-0686 Bell Reducer, 1-½ x ½"

2 813-0165 Elbow, Street- ½ x ½" 90°

3 810-1668 Adapter, Male- 5/8 O.D. x ½"

4 810-1069 Flexline, 5/8 x 29-½"

5 813-0051 Coupling, Full- ½" NPT BM

6 900-1958 Bracket, Flush Line Support

7 813-0022 Nipple, ½" x Close NPT BM

8 813-0460 Nipple, ½ x 3" NPT BM

9 813-0062 Elbow, ½" 90° NPT BM

10 810-1057 Flexline, 5/8 x 13"

11 810-0278 Valve, Ball- ½"

* 823-3481 Handle, Oil Flush Valve

* 816-0549 Cap, Oil Flush Valve Handle- Blue

* 807-1419 Heater Strip- 240V/45W 36" L

* Not Illustrated

2-22

Page 55

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.9 Oil Drain Manifold Components

To Dump Station

11

10

7

To Drain

9

Valve

5

To Drain

Valve

1

2

4

6

8

3

Item Part Number Description

1 823-3221 Elbow, with Bracket (Drain Valve Handle)

2 823-3558 Drain Pipe, Left Side

3 210-2311 Clamp, Center- Drain Pipe

4 823-3441 Drain Pipe, Right Side

5 813-0722 Tee, 1-½" NPT Male x 5-½" Long

* Not Illustrated

6 200-1840 Drain Manifold Tube

7 813-0659 Pipe Cap, 1-½" NPT BM

8 809-0884 Nut, Slip Joint- 1-½"

* 816-0544 O-ring (Slip-Joint Nut)

9 813-0818 Coupling, Full 1-½"-SS

10 813-0723 Nipple, 1-½" x 8" NPT BM

11 813-0667 Elbow, 1-½" x 90° SS

2-23

Page 56

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.10 Oil Return Manifold, Motor and Pump Components

PUMP

MOTOR

PUMP

1 2

VESSEL

OUTLET

(REF)

46

47

DETAIL A

5 6

4

3

SEE DETAIL B SEE DETAIL C

VESSEL

ASSEMBLY

(REF)

4445

BRIDGE

SEE DETAIL A

10

9

8

7

11

12

(REF)

VESSEL

OUTLET

(REF)

VESSEL

ASSEMBLY

(REF)

43

42

17

16

14

18

15

13

31

VESSEL

OUTLET

(REF)

VESSEL

ASSEMBLY

(REF)

PUMP

MOTOR

(REF)

40

BRIDGE

41

19

32

(REF)

DETAIL C

20

21

DETAIL B

23

22

26

25

24

27

28

29

20

30

33

34

35

36

38

39

37

2-24

Page 57

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.10 Oil Return Manifold, Motor and Pump Components (cont.)

Item Part Number Description

NOTE: Oil Return Components Will Vary From

1 823-4234 Handle, 3-Way Valve- Wand/Dispose

2 809-0056 Nut, 5/16-18 Hex

* 809-0681 Washer, Nylon- .340 ID, .740 OD

* 809-0194 Washer, Flat- 5/16" SAE

3 900-2110 Cover, Microswitch

* 809-0256 Nut, Microswitch Cover

4 807-2104 Microswitch, Roller

System To System- The Most Common

Components Are Included Below

Rinse Hose/Disposal Plumbing Components

5 812-0442 Insulation, Microswitch Switchbox

6 900-2112 Support, Microswitch Mount

7 810-0487 Coupling Disconnect- Male

8 813-0165 Elbow, Street- ½" 90° NPT BM

9 813-0265 Nipple, ½ x 2-½" NPT BM

10 810-1003 Valve, Ball- Three-Way 180°

11 823-4196 Nipple Weld Assembly- Three-Way Valve

12 200-4996 Bracket, Mounting Base

* 809-0131 Screw, ¼-20 x ¾" Hex Head

* 809-0070 Nut, ¼-20 Hex S/S

13 810-1669 Adapter, Female- 5/8 OD x ½"

14 810-1369 Flexline, 5/8 x 17-½ "

15 810-1069 Flexline, 5/8 x 29-½ "

16 810-1668 Adapter, Male- 5/8 OD x ½"

17 813-0331 Elbow, Side Outlet- ½" NPT

18 813-0247 Nipple, ½ x 3-½" NPT BM

19 813-0062 Elbow, ½" 90° NPT BM

20 810-0278 Valve, Ball- ½"

21 813-0342 Elbow, ½" 45° NPT BM

22 810-2626 Tubing, Flare- Oil Return- 3-Battery Church’s

* Not Illustrated

Drain Flush Components- 3-Battery & Larger Units

2-25

Page 58

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.10 Oil Return Manifold, Motor and Pump Components (cont.)

Item Part Number Description

23 823-4220 Handle, Drain Flush Valve

* 816-0549 Handle, Vinyl- Blue (Drain Flush/R ins e/D ispos e Va l ve )

24 807-2104 Microswitch (Same as Item #4)

25 810-2144 Spacer, Microswitch

26 200-5056 Bracket, Microswitch- Drain Flush

27 210-5057 Bracket, Main Mount- Microswitch Drain Flush

28 200-1341 Bracket, Microswitch Rod

29 813-0022 Nipple, ½" x Close NPT BM

30 813-0087 Nipple, ½ x 1-½" NPT BM

31 809-0885 Washer, 3/8 x 1 x .083"

* 809-0843 Pin, Cotter (For Retaining Washer/Rod to Arm)

32 901-0883 Arm, Oil Return Valve

33 823-3238 Handle Assembly, Oil Return

34 202-1233 Bracket, Oil Return Microswitch

35 809-0846 Screw, 4-40 x 1" Slotted

36 809-0237 Nut, Keps- 4-40 (With External Teeth)

37 816-0548 Handle, Vinyl- Yellow (Oil Return)

38 810-2100 Motor, Filter Pump- 120V/230V 1/3 HP

39 810-2098 Pump, Filter- 8GPM

40 810-1159 Flexline, 5/8 x 5"

41 813-0429 Nipple, ½ x 13" NPT BM

42

►►► See Oil Return Line Assemblies, Section 2.11

Oil Return Valve/Handle Components

43 813-0381 Nipple, ½ x 18-½" NPT BM

44 813-0673 Nipple, ½ x 8-½" NPT BM

45 813-0003 Tee, ½" NPT BM

46 810-1680 Flexline, 5/8 x 6-½"

47 813-0156 Plug, ½" NPT BM Hex Head

* Not Illustrated

2-26

Page 59

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.11 Oil Return Line Assemblies

1

2

3

9 10

6

8

4

5

17

16

Item Part Number Description

15

1 813-0165 Elbow, Street- ½" 90°

14

6

Oil Return Line Assemblies Will Vary From System

To System- Use The Above Illustration To Identify

Components

7

11

12

13

2 810-1668 Adapter, Male- 5/8 x ½"

3 810-1159 Flexline, 5/8 x 5"

4 810-1669 Adapter, Female- 5/8 x ½"

5 813-0429 Nipple, ½ x 13" NPT BM

6 813-0062 Elbow, ½" 90° NPT BM

7 813-0609 Nipple- ½ NPT x 1"

8 813-0156 Plug, ½" NPT Hex Head

9 813-0003 Tee, ½" NPT BM

* Not Illustrated

2-27

Page 60

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.11 Oil Return Line Assemblies (cont.)

Item Part Number Description

10 813-0281 Nipple- ½ NPT x 5" NPT BM

11 813-0091 Nipple- ½ NPT x 2-½" NPT BM

12 813-0173 Union- ½" NPT BM

13 813-0381 Nipple- ½ NPT x 18-½" BM

14 823-3562 Tube, Suction

15 813-0608 Coupling- ½" NPT- Full

16 810-0697 Disconnect, Male

17 826-1392 O-ring, Suction Tube- 2 Required (Qty:5)

* 806-5932 Heater Strip- 240V/45W 36" L

* Not Illustrated

2-28

Page 61

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.12 Probes, High-Limits, Elements and Related Components

4

5

3

2

1

6

18

7

4

9

11

17

16

10

8

13

12

14

15

19

2-29

Page 62

ULTIMATE ELECTRIC SERIES FRYERS

CHAPTER 2: PARTS LIST

2.12 Probes, High-Limits, Elements and Related Components (cont.)

Item Part Number Description

1 807-3652 Element- 208V 8.5 kW

807-3675 Element- 480V 10.25 kW

807-3655 Element- 240V 8.5 kW

807-3657 Element- 208V 9.0 kW

807-3658 Element- 240V 9.0 kW

807-2557 Element- 208V 10.25 kW

807-3655

807-3660 Element- 220V 8.5 kW

807-3661 Element- 220V 10.25 kW

807-3662 Element- 230V 7 kW

807-3663 Element- 230V 8.5 kW