Page 1

Service, Parts Manual for 4, 2-Slot and Narrow Models

UHC-P /HCP

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

*8196044*

24-Hour Service Hotline

1-800-551-8633

Price: $6.00

819-6044

APRIL 09

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY

FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS, AND/OR THE

PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL

BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY

CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART

AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

THE CABINET IS NOT SUITABLE FOR OUTDOOR USE. WHEN OPERATING TH IS UNIT, IT

MUST BE PLACED ON A HORIZONTAL SURFACE.

THE CABINET IS NOT SUITABLE FOR INSTALLATION IN AN AREA WHERE A WATER JET

CAN BE USED. THIS APPLIANCE MUST NOT BE CLEANED WITH A WATER JET.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

DO NOT OPERATE OR SERVICE THE CABINET WITHOUT FIRST READING THIS MANUAL.

DO NOT OPERATE THE CABINET UNLESS IT HAS BEEN PROPERLY INSTAL LED AND

CHECKED.

DO NOT OPERATE THE CABINET UNLESS ALL SERVICE AND ACCESS PANELS ARE IN

PLACE AND PROPERLY SECURED.

DO NOT ATTEMPT TO REPAIR OR REPLACE ANY COMPONENT OF THE CABINET UNLESS

ALL POWER TO THE UNIT HAS BEEN DISCONNECTED.

USE CAUTION WHEN SETTING UP, OPERATING, OR CLEANING THE CABINET TO AVOID

CONTACT WITH HEATED SURFACES.

Page 3

Table of Contents

Theory of Operation 1-1

Service Procedures 2-1

Re-addressing Cabinet 3-1

Troubleshooting 4-1

Illustrated Parts List 5-1

Wiring Diagram s 6-1

Page 4

Cabinet Service Procedures

1 Functional Description

Power switch

IR port

Menu key

Temperature

Key

Timer key

Timer keys

Figure 1: UHC-P cabinet

1.2 Theory of Operation

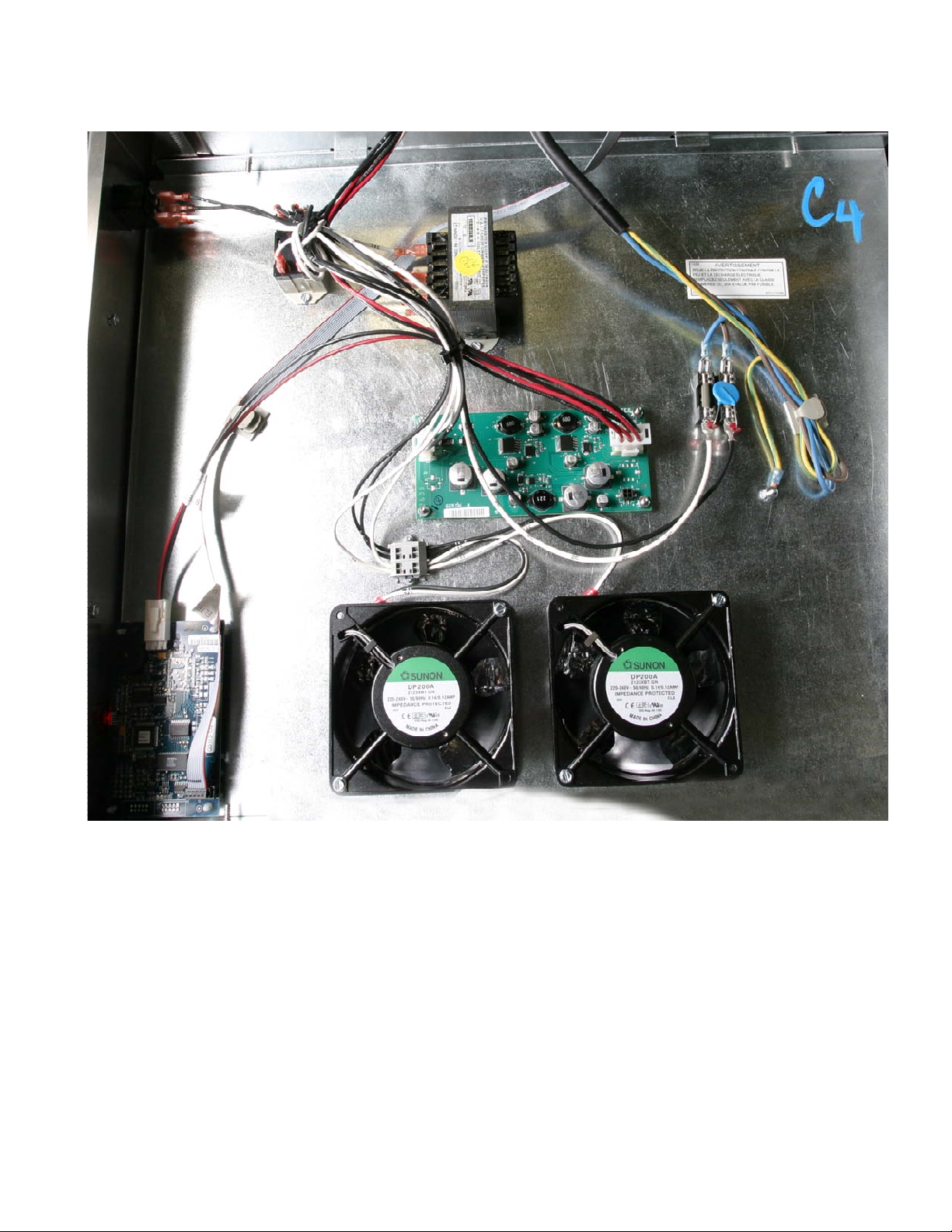

The CABINET operates on 208-250VAC 50 or 60 cycle single-phase power. The main switch

activates a relay, which supplies line voltage to two distribution boards, two cooling fans and a 12volt transformer, which supplies a power supply. The power supply provides 5VDC to the

communication board and the distribution boards.

A ribbon cable connects the communication board to both distribution boards, connecting at J9.

Ribbon cables, which carry 5V DC, also connect the distribution boards to the displays. The

resistance of RTDs attached to the heater plates is monitored by the distribution boards. The board

switches power through solid-state relays to the heater plates when the resistance, which is used as

an indicator of temperature, falls out of the range for the product held in the cabinet.

The switch, transformer, communication board, cooling fans and power supply are mounted under

the top of the unit. There is a small dark lens portal on the upper right side of the cabinet, which

allows infrared communication between the cabinet and a Palm Pilot. The distribution boards are

mounted on the left side (as viewed from the front).

The parameters for holding temperatures are transferred to the cabinet’s communication board via a

Palm Pilot with special CABINET software. All programming of the cabinet is done on the Palm.

NOTE: This manual covers the UHC-P, the original

PDA-programmed cabinet for McDonald’s and the HCP

or Holdmaster, a similar cabinet made for the general

market. UHC-P parts are compatible with the HCP,

except for the heater plates and bezel.

Note: The illustrations

for these service

procedures are of the 4slot full size UHC-P. The

procedures are similar

for the 2-slot and the

narrow models.

1-1

Page 5

Cabinet Service Procedures

1.3 Start Up Indicators and Test Points

Upon startup, the communication board beeps. On the

distribution boards, an LED flashes rapidly for a few

seconds and then slows to one flash every two seconds.

The displays will show the version number of the

cabinet’s firmware and then the slot’s status.

LED

1-2

Page 6

2 Service Procedures

DANGER: Failure to disconnect the power supply before servicing could result in serious

injury or death. The cabinet power switch DOES NOT disconnect all incoming power to the

cabinet.

The top is held

in place by

screws behind

the side panel.

The side panels are

secured with two

screws at the base.

Cabinet Service Procedures

Tab and screw

securing top

Figure 2: Four sheet metal tabs hold the top in place.

Remove these screws at each corner and lift off the

top.

Remove the

bottom screw

and loosen

the top one to

tilt out the

front panel.

Figure 1: The side panels must be removed to

access the component shelf.

2.1 Accessing the Electronic Components

1. The component shelf is accessed by removing two

screws on each side of the unit. See figure 1.

2. Lift and remove the sides, which exposes screws

that hold the top in place. See figure 2.

3. The front panel, which holds the switch and the IR

lens, can be rotated forward by removing a screw on

either side and loosening two others. See figure 3.

With the removal of four more screws, the

component shelf will slid forward if necessary.

Figure 3: Remove the screws which secure the

component shelf, allowing the shelf to be pulled

forward.

2-1

Page 7

Under the top

y

Figure 4

Com board

Cabinet Service Procedures

Transformer

Rela

Power

supply

Fuses

Fans

2-2

Page 8

Cabinet Service Procedures

All the components are readily removed. There are no replaceable components on the circuit boards.

The replacement of a display, distribution or communication board will require re-addressing the

cabinet, covered in Section 3.

2.2 Tests

2.2.1 Transformer

1. Disconnect power to cabinet. Remove side and top panels, unless stacked. See the service

procedures for access instructions, Section 2.1

2. Check for 208VAC at the primary, 12VAC at the secondary terminals.

2.2.2 Power Supply

1. Disconnect power and check all terminals and

connections for loose or disconnected wires.

2. Apply power and check for +5VDC at the J5 terminal

on the communications board, using the center pin for

the positive lead and either adjacent for the negative

lead.

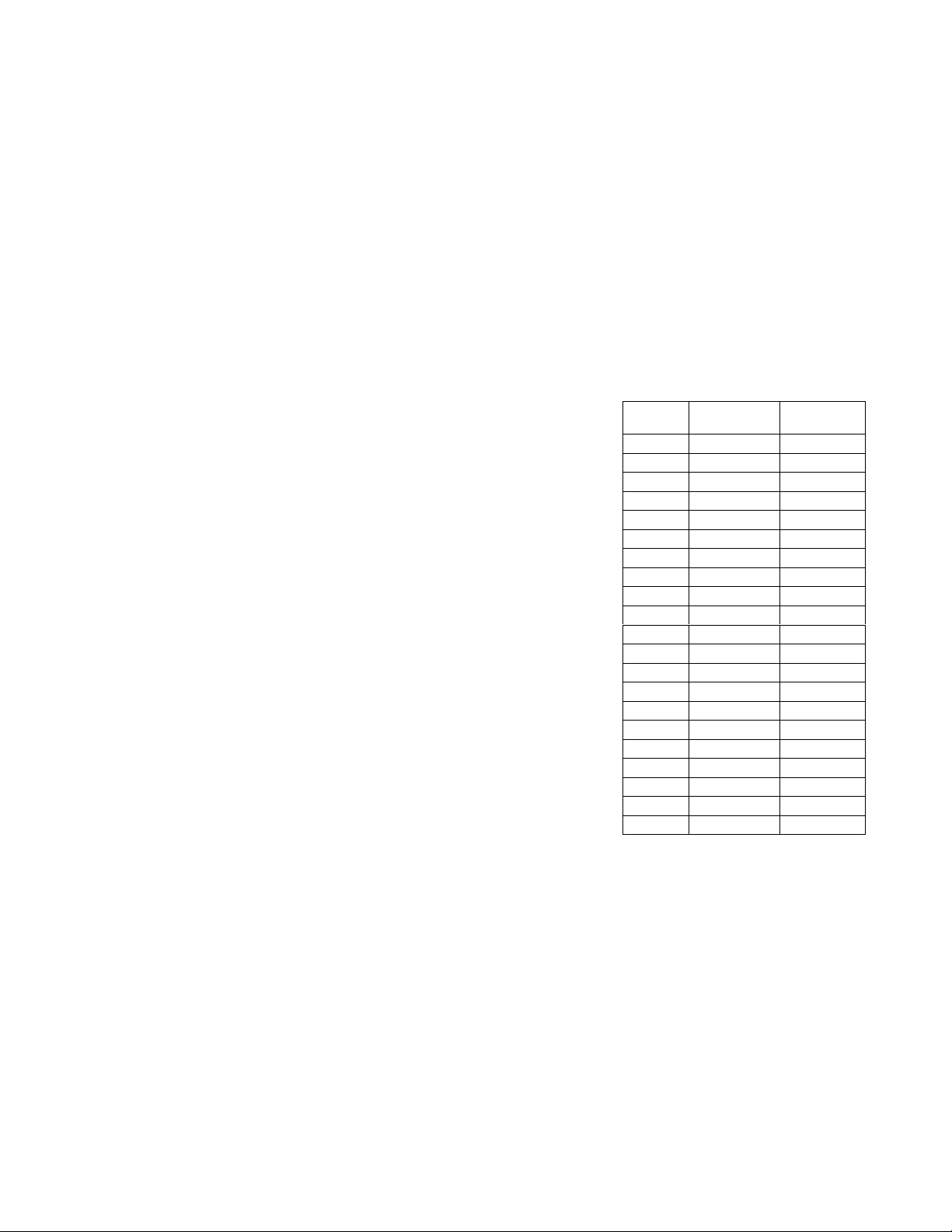

2.2.3 RTD

1. Remove the leads from the suspect RTD and test for

resistance. selected temperatures and resistances are

show in Figure 7, a chart at right.

NOTE: After testing, reconnect all leads to their

original positions.

Sensor

(°F)

60 106.065 15.55

70 108.224 21.11

80 110.380 26.66

90 112.532 32.22

100 114.680 37.77

110 116.825 43.33

120 118.966 48.88

130 121.104 54.44

140 123.239 60.00

150 125.369 65.55

160 127.496 71.11

170 129.620 76.66

180 131.740 82.22

190 133.856 87.77

200 135.969 93.33

210 138.078 98.88

220 140.184 104.44

230 142.286 110.00

240 144.385 115.55

250 146.480 121.11

260 148.570 126.66

Figure 7: RTD resistance chart

Resistance

Sensor

(°C)

2-3

Page 9

Cabinet Service Procedures

2.2.4 Distribution Boards

1. Check for line voltage

between the heater

plate terminal on the

board and the terminal

block for the suspect

heater. Note: Line

voltage is only seen

when the slot is calling

for heat.

2. Check for line voltage

between the power

input terminal and the

terminal block.

3. Check for +5VDC at

the Power In terminal

between the positive

center pin and either

adjacent pin.

NOTE: After testing,

reconnect all

connections to their

original positions.

Figure 8: Testing distribution board.

2.2.5 Display

1. Connect the ribbon cable from a faulty display to the connector of a properly working display to

isolate the problem to the display or the distribution board.

2.2.6 Shorted Triac

1. Turn the suspect slot off and measure voltage between the suspect heater lead on the distribution

board and the terminal block With the slot off, there should be no line voltage. If the triac is

shorted, you will measure AC line voltage. If the triac is half waving, you will get DC voltage of

approximately one-half the line AC voltage.

2.2.7 Calibration

Calibrate the top and bottom plates in all four UHC slots by performing the following procedure

with the slots clean, empty and at operating temperature for at least 30 minutes.

1. Press the temperature key to ensure the slot is at setpoint.

2. Slide the Atkins sensor into a slot with the sensor facing up to measure the top heater plate or

down to measure the bottom heater plate. Move the sensor to the center of the plate. To get an

accurate reading, the sensor must be within ±1 inch (25mm) of the center of the plate.

Line voltage between

slot leads and

common on terminal

block with slot calling

for heat.

Line Voltage between

power input and

common on terminal

block.

+ 5VDC between

positive center pin

and either

adjacent pin.

2-4

Page 10

Cabinet Service Procedures

play

3. Allow three minutes for the sensor to stabilize.

4. Read the temperature on the Atkins meter and compare to the reading from the cabinet, which is

displayed by pressing the temperature key once for the top plate temperature and twice for the

bottom plate. The displayed temperature should be within ±5°F (±3°C) of the meter. If the

reading is out of tolerance, perform the following procedure.

Launch the UHC-P software on the Palm and follow these steps:

Step 1: Tap the left corner

of the display in Setup or

Menu mode. A menu bar is

dis

ed.

Step 4: The Cabinet

Configuration Offset menu

is displayed. The offset

entry fields for the slots are

arranged left to right and

top to bottom

Figure 2: Tap View in the

menu bar and tap Cabinet

in the pull-down menu.

Step 3: The Cabinet

Configuration menu is

displayed. Tap the

Offsets button in the left

corner.

Offset Entry

Examples

Display Meter Correction

150°F 155°F 5

150°F 145°F -5

Step 5: Tap on the number

line by the plate being offset

and then the number in the

bottom right of the Palm

display. Use the backspace

key to erase number in the

field and use the keypad to

enter the desired offset.

See examples in Table 1 (at

right). Tap Done.

66°C 69°C 3

66°C 63°C -3

Table 1

2-5

Page 11

Cabinet Service Procedures

Step 6: The entered offset is

visible on the menu. In this

case we offset the top slot’s

top heater plate –5°F. Adjust

other slots as necessary.

2.2.7 Heater Plate

1. Disconnect power to the cabinet. On stand-alone units, remove side and top panels. On stacked

units, see Service Procedures for instructions on accessing the top panel.

Step 7: With the Palm horizontal and

approximately one foot from the

receiving lens on the cabinet, tap the

Transmit button. The Transfer menu will

be displayed. A message will be

displayed when the transfer starts and

when the transfer is complete.

2. Disconnect the black heater lead and the two RTD leads (brown and red) of the suspect plate

from distribution board. Measure resistance of the heater from the black lead to any terminal on

the white terminal block. Resistance should be 140-150 ohms.

3. Measure resistance across the brown and red RTD leads. Resistance must be within a range of

104-148 ohms. Resistance at room temperature is approximately 107 ohms. See chart on Page

2-3 for resistance at different temperatures. If either resistance is incorrect, replace the heater

plate.

2.2.8 Display Meanings

1. SLOT TEMP HIGH OR SLOT TEMP LOW and no audible alarm. This is normal when

the slot is changing temperature in association with a menu change.

2. LLLL means the RTD indicates a temperature below 50°F (10°C). Unit will automatically heat

at 20 percent until temperature is above 50°F (10°C), then operate normally.

3. HHHH means RTD indicates the temperature is above 255°F (124°C), but below "Open" circuit

resistance, which causes SENS ALARM.

UHC VERSION _ _ _ (version number will vary) appears for five seconds when the

unit is turned on.

2-6

Page 12

Cabinet Service Procedures

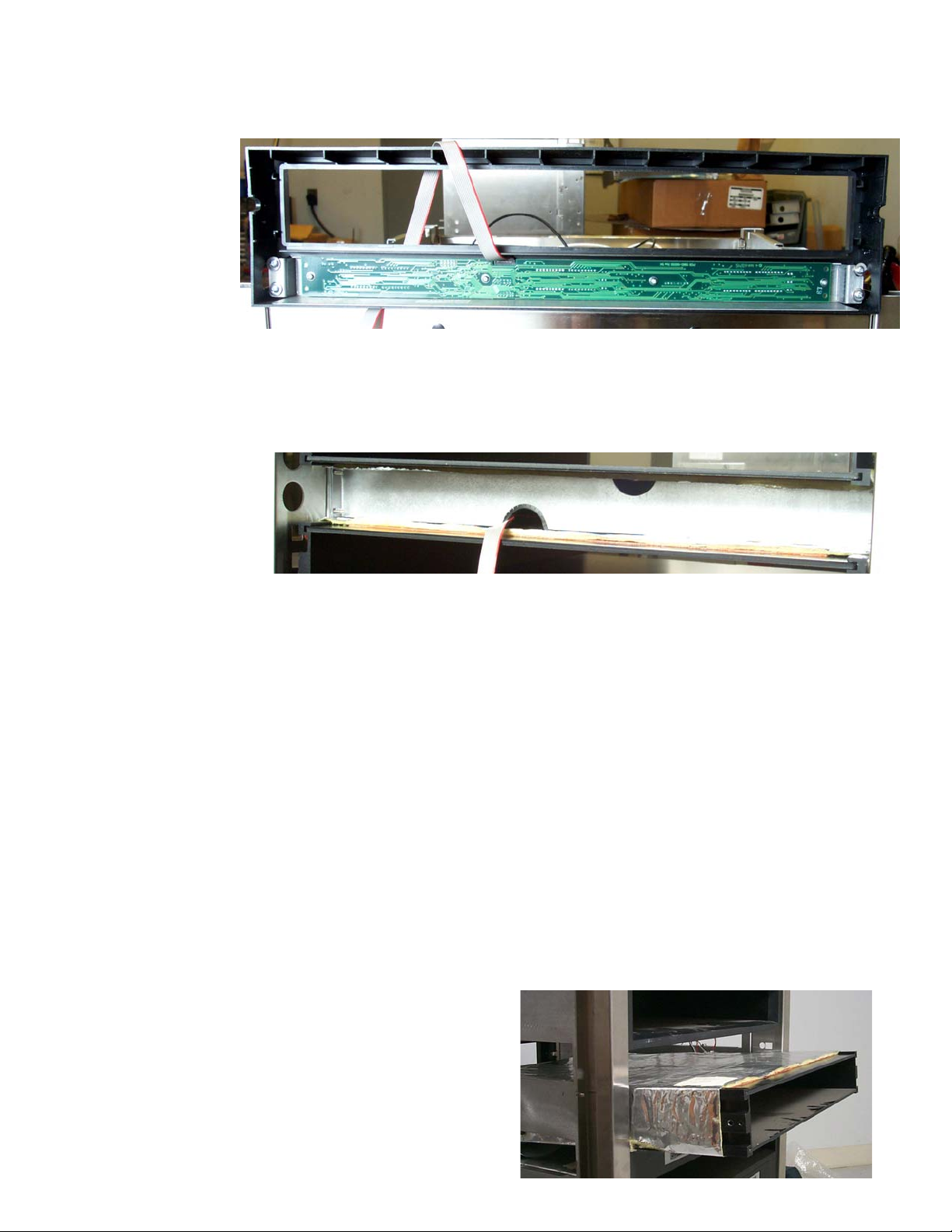

2.3 Removing/Replacing Components

1.

The bezel

holding

the

controller

display is

secured

in the

cabinet

by two

allen and two hex-head screws. The bezel is shown removed (Figure 9). Four screws secure the

display in the bezel. The ribbon cable attaches to the distribution board on the side of the unit.

2. A baffle

(Figure 10) is

behind the

display and it

must be

removed to

feed the

ribbon cable

from a new display through the cabinet framework to the distribution board.

3. After replacing a display, the cabinet must be re-addressed. See Section 3.

2.3. 1 Removing/Replacing a Distribution Board or Communication Board

1. Remove and mark the wires on the faulty component.

2. Remove the board by lifting it from its standoffs.

3. Rewire the board.

4. After replacement of a communication, display or distribution board, the cabinet must be re-

addressed, which is covered in Section 3.

2.3.2 Removing a Slot

Figure 9: The bezel holding the display is shown removed.

Figure 10: A baffle is secured behind the bezel.

2-7

Figure 11: A faulty slot is slipped from the cabinet.

Page 13

Cabinet Service Procedures

1. Perform steps in Section 2-1. Disconnect the faulty slot from the distribution board, and terminal

block.

2. Loosen, but do not remove, the screws from each corner of the slot to be removed.

3. Remove wire wraps from wiring harness holding heater and control wires for affected slot.

4. Lifting slightly, carefully slide the malfunctioning slot out of the cabinet. Do not allow the slot to

contact or damage the controls of the unit

below (Fig 11).

2.3.3 Replace Heater Plate/RTD

1. Perform Sections 2-1, 2.3.2

2. Run your fingers around the outside surface of

the slot assembly. There are four raised areas.

These are the setscrews, which hold the heater

plate to the spacer. Punch 4 holes in the

insulation, directly above the location of the

setscrews (Fig. 12).

3. Use an allen wrench to loosen the four

spacer-setscrews along the edges of the plate

(Fig. 12).

Figure 12: Find the set screws under the foil

insulation and push through with an allen wrench.

4. Slide the malfunctioning plate out of the

spacer (Fig. 13).

5. Slide the replacement plate into position.

Make sure the plate is inserted squarely.

CAUTION

Ensure the heater plate setscrews are tightened securely to the spacer.

Tightening the setscrews will ensure the plate is properly grounded.

Figure 13: The heater plate slides from the

insulation.

2-8

Page 14

Cabinet Service Procedures

3.1 Re-addressing the Cabinet

If any board or display is changed on the CABINET, the unit must be re-addressed. This essentially

tells each board which position it occupies. The cabinet must also be re-programmed with the Palm.

Changing the power supply doesn’t require re-addressing or programming. (Note: Re-addressing a

Narrow unit is slightly different and a separate button-push sequence is provided below.)

The process of re-addressing begins with the Palm. The security level has to be changed to admin in

the Palm software to access the re-address feature. The cabinet must be ON. Follow these steps to readdress the cabinet with the Palm.

Step 1: Tap the key icon

ix

at the top of the screen

(see arrow) to access the

security manager.

Step 5: The Cabinet

Configuration screen is

displayed. Make sure that

the proper slot size is

displayed. ie ( 2 slots, 4

slots, narrow). (NOTE: The

button-push sequence for

the Narrow unit is different

and covered in Steps 7N14N on the adjoining page.)

With the Palm horizontal and

near the lens on the UHC-P

cabinet, tap the ReAddr

button in the bottom center

of the screen.

Step 2: Use the

Palm's keyboard

feature (see arrow)

to type admin in the

security manager

dialog box. Tap OK.

Step 6: The addresses of

the cabinet's boards will be

beamed to the cabinet. A

success message will

display when the process is

complete. Press 1 Button

will be displayed on each

slot.

*NOTE: Failure to

press the button in

less than 30 seconds

will cause the cabinet

to react slowly to

button pushes.

Repeat readdress

sequence to eliminate

delay.

Step 3: A dialog box

appears, saying the

security level has

been changed. Tap

OK.

Step 4: Tap the Setup bar in

the top left to reveal the menu

bar. Tap View and in the dropdown menu highlight Cabinet

by tapping it.

Button-Push Sequence for 4, 2-slot Units

Step 7: Press and release the right timer key

on the top slot on front of the unit. Wait until

the Push 1 ButN display dims.

Step 8: Repeat for second, third and fourth

(if present) slots, moving to the next slot only

after the display dims.

Step 9: Move to the back of the unit and

press the left top slot timer key. Wait until

Push 1 Butn display dims.

Step 10: Repeat for second, third and fourth

slots, moving to the next slot only after the

display dims.

Step 11: *Press the back bottom left timer

button a second time within 30 seconds of

the previous button push.

Step 12: Press temperature key on top front

slot. Verify temperature display and repeat

steps for remaining slots.

Step 13: Repeat step 12 on back displays if

present.

Step 14: Repeat readdress sequence if

temperature displays fail.

3-1

Page 15

Cabinet Service Procedures

Button-Push Sequence for

Narrow Unit

Step 7N: Press and release

the top front timer key. Wait

until the Push 1 BUTN

display dims.

Step 8N: Repeat for second,

third and fourth slots, moving

to the next slot only after the

display dims.

Step 9N: Move to the back of

the unit and press the top

temperature key. Wait until the

Push 1 BUTN display dims.

Step 10N: Repeat for second,

third and fourth slots, moving

to the next slot only after the

display dims.

Step 11N: *Press the back

bottom timer key within 30

seconds of the previous

temperature key push.

Step 12N: Press temperature

key on top front slot. Verify

temperature display and repeat

steps for remaining slots.

Step 13N: Repeat step 12 on

back displays if present.

Step 14N: Repeat readdress

sequence if temperature

displays fail.

*NOTE: Failure to press the button in

less than 30 seconds will cause the

cabinet to react slowly to button pushes.

Repeat readdress sequence to eliminate

delay.

Step 15: Beam over the cabinet

configurations with a Palm,

which holds the restaurant’s

desired cabinet configurations

by opening the UHC-P software

to the setup window.

Step 16: Ensure the dark receiving

lens on the front of the cabinet is

clean. Hold the Palm Pilot parallel

with the floor and aim it at the lens

from no more than one foot away.

Tap the Transfer button.

Tap the TxirDa button.

The cabinet will beep and the Palm

Pilot will display a message,

indicating a successful transfer. All

five menus established on the

Palm are now accessible with the

menu key on the cabinet. Note:

Text on buttons can vary between

software versions.

3-2

Page 16

Cabinet Troubleshooting

Symptom Possible Causes Tests

Unit fails to

power up; fans

don’t run.

Unit powers up

and fans run; a

display fails to

light.

Unit powers up

and fans run; all

displays fail to

light.

Slots heat

improperly or

not at all.

• No power to cord.

• Blown 20 amp fuse.

• Broken or improperly

seated ribbon cable.

• Defective display.

• Failed transformer.

• Failed power supply.

• Improper wiring on

distribution board.

• Defective distribution

board.

• Defective heater.

• Defective sensor.

• Check for line voltage at the

switch and the transformer.

• Switch ribbon cable from

functioning display to failed

component to isolate problem.

• Check for 12VAC at

transformer.

• Check for 5VDC at

communication board and

distribution boards.

• Ensure heater leads and power

inputs on the distribution boards

are properly seated.

• Test for 208VAC input on

distribution board and 208VAC

output from heater leads to

heater plate when the unit is

calling for heat.

• Switch power leads from

properly operating slot to faulty

slot to isolate problem.

• Check resistance of RTD lead

against temperature chart. See

Page 2-3.

• Switch RTD lead from properly

operating slot to faulty slot to

isolate problem.

• Test continuity of heater plate.

Cabinet beeps

continuously.

• Stuck display button.

• Defective display.

• Shorted capacitor on

one or more display.

• Bad communication

board.

4-1

• With power applied, unplug

each display, one at a time, to

isolate beeping. Replace

beeping display.

• Beeping continues? Replace

communications board.

Page 17

Cabinet Troubleshooting

Unit locks up;

buttons won’t

respond.

Display shows

Off or Clean

Mode only.

After brief

operation, all

displays dim

except

countdown.

• Cabinet not

readdressed.

• Cabinet not

reprogrammed

after

readdressing.

• Failed

transformer.

• Readdress cabinet.

• Reprogram cabinet.

• Check for 12VAC at

transformer.

4-2

Page 18

Cabinet Parts

NOTE: This manual covers the UHC-P, the original PDA-programmed cabinet for McDonald’s and the HCP or

Holdmaster, a similar cabinet made for the general market. UHC-P parts are compatible with the HCP, except for the

heater plates and bezel.

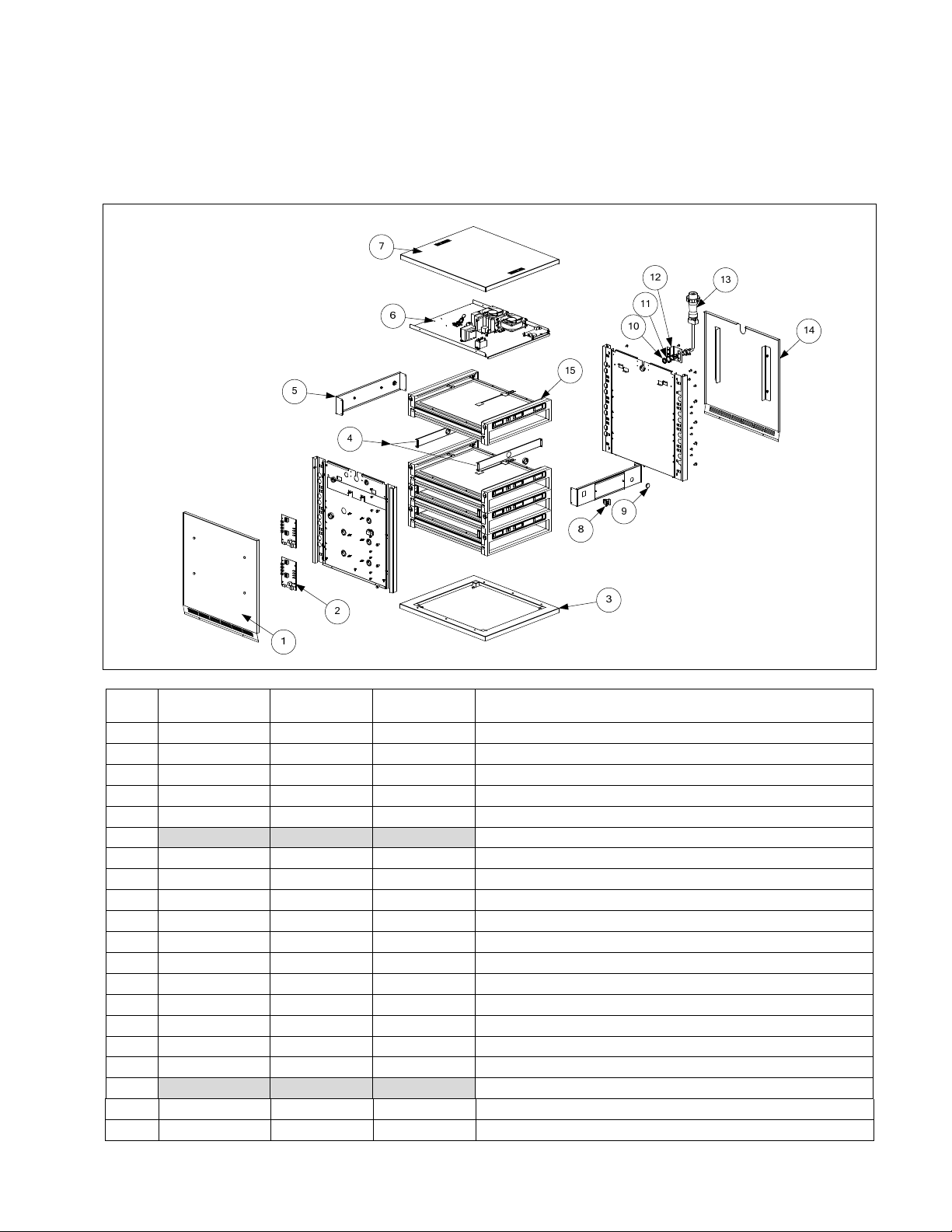

5 Parts Lists, Exploded Views

5.1 Cabinet Components

Item

10 809-0581 809- 0581 809-0581 Nut, ½ N.P.T. Locking

11 809-0582 809- 0582 809-0582 Washer, ½ N.P.T. Star-Lock

12 200-3639 200-3639 200-3639 UHC Cordset Bracket

13 807-2473 807-2473 807-2473 Pin & Sleeve Cordset with Strain Relief 8073238 and washer.

14 910-4876 910- 9452 910-4876 Right Side Cabinet Assembly

15 Slot assemblies, see page 5- 3

4- Slot Part # 2-Slot Narrow Description

1 210-3659 210-3710 210-3659 Left Side Cabinet

2 826-2644 826-2644 826-2644 Distribution board

3 806-7904SP 806-7904SP 106-4549 Base

4 106-4571 106-4571 N/A Bracket Assembly, UHCII Insulator

5 106-4225 106-4225 106-4547

6 Component shelf, See page 5 - 2

* 809-0256 809-0256 809-0256 Button Hanger Nut

7 806-7906SP 806-7906SP 106-4544SP Top Cap Assembly

8 807-4036 807-4036 807-4036 ON/OFF Switch

9 816-0634 816-063 4 816-0634 Communications port cover

* 807-2474 807-2474 807-2474

* 807-4409 807-4409 807- 4409 UHC-P Cordset, includes strain relief (China)

* 807-2766 807-2766 807-2766 Power Line Filter, CE only

* 826-2632 826-2632 826-2632 Palm Tungsten with UHC-P software

Rear Fascia Assembly without Menu.

Cordset, Twist Lock Power Cord (HC-P)

5-1

Page 19

Cabinet Parts

Item

4- Slot Part # 2-Slot Narrow Description

* 826-2633 826-2633 826-2633 Palm Tungsten with UHC-P software and Int’l power adapters

* 108-0902 108-0902 108-0902 Palm Tungsten with HCP software

* 826-2635 826-2635 826-2635 Palm Tungsten with HCP software and Int’l power adapters

5.2 UHC-P/HCP Component Shelf

6

5

8

4

3

7

9

2

1

Item 4-slot Part # 2-Slot Narrow Description

1 826-2590 826-2590 826-2590 Board, UHC-P/HCP Communications Board

2 807-3490 807-3490 807-3490 Relay, Omron Power

3 807-4024 807-4024 807-4024 Transformer, 208-240/12V 60VA

4 807-2820 807-2820 807-2820 Block, Fuse Omni-Blok

5 807-2819 807-2819 807-2819 Fuse, 3AB-314 20 amp

6 812-1306 812-1306 812-1306 Metal Oxide Varistor

7 807-2665 807-2665 807-2665 Blower, Exhaust

8 106-9516 106-9516 106-9516 Power Supply

9 810-1164 810-1164 810-1164 Block, I Plc Screwless Terminal

* 807-3918 807-4071 807-3918 Ribbon Cable, Communications for UCH-P/HCP

*Not Illustrated

5-2

Page 20

5.3 Slot Assembly

Cabinet Parts

Item

1 816-0584 Bezel

* 816-0714 Bezel, HCP

2 812-1814 Heater plate

* 106-6577 Heater plate, HCP

3 810-1286

4 826-2588 Display

5 816-0572 Bezel, Spod

6 816-0649 Bezel, narrow

7 810-1286 Spacer, extruded

8 807-4065 Heater plate, narrow

9 807-4681 Display, narrow

* 803-0370

* 816-0727

* 816-0726

Part Number Description

Spacer, extruded

Wire Rack for 816-0726 (HCP Non-McDonald’s Only)

High-side tray, (HCP Non-McDonald’s Only)

Low-side tray, (HCP Non-McDonald’s Only)

5-3

Page 21

Cabinet Wiring Diagrams

6 Wiring Diagram, UHC-P

UHC-P 4 Slot Wiring Diagram

6.1 Simplified Wiring Diagram

6-1

Page 22

Cabinet Wiring Diagrams

UHC-P 2-slot wiring diagram

UHC-P N Wiring

6-2

Page 23

Cabinet Wiring Diagrams

HCP wiring diagram

6-3

Page 24

Frymaster, L.L.C., 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

Price: $6.00

819-6044

APRIL 09

Loading...

Loading...