Page 1

™

8700 Line Avenue 71106

P. O. Box 51000 71135-1000

Shreveport, LA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0499 9/07

H55 and H55-2 High Efficiency Gas Fryers

H55 and H55-2 High

Efficiency Gas Fryers

Specifications

Specifically designed for high production frying

The Energy Star® rated high efficiency H55 fryer is designed

for high-volume frying with maximum fuel efficiency. The

solid-state controller assures pinpoint accuracy of

shortening temperature, extending shortening life and

producing a uniformly-cooked product. The sensor is

mounted in the center to permit quick sensing of any

temperature drop caused by cold food placed in either side

of the cooking area. The infrared power burner directs its

heat on a large heat transfer area to fry more product with

less fuel consumption. The open-pot design allows easy

access so every inch of the frypot can be cleaned and wiped

down by hand.

The deep cold zone catches crumbs and sediment from the

frying area. These particles are trapped in the cold zone,

where they do not carbonize, contaminate shortening or

cling to fried foods.

Computer MagicTMcomputers and basket lifts are available.

FootPrint PRO® filtration is available with up to six (6) fryers

batteried together into a single system, or with a single H55

fryer and a spreader cabinet. The spreader cabinet can

include an optional heat lamp and dump station. The heat

lamp can be a choice of rod style or bulb type. The dump

stations can use either cafeteria-style pan or scoop-type pan.

The heat lamp and pans are integrated into the cabinet,

making a complete warming station. The solid-state controls,

electronic ignition and melt cycle are standard.

Boil-out mode is activated by setting the temperature to

200°F.

The H55 has a maximum 50-lbs. (25 liters*) shortening

capacity. The frying area is 14 x 15 in. (356 x 381 mm) and

has 80,000 BTUs (20,151kcal) (23.4 kW).

Each side of the H55-2 -- split pot fryer operates on 40,000

BTU/hr. (10,076 kcal/hr.) (11.7 kW), has a maximum

shortening capacity of 25 lbs. (12 liters*), and has a frying

area of 6-1/2 x 15 inches (165 x 381 mm). This fryer has all of

the features and options of the H55 and gives the operator

the discretion of using only half the fryer.

*Liter conversions are for solid shortening @70°F.

H55 H55-2

Models

Standard Features

• Open-pot design (split or full),

easy-to-clean

• Solid state controller -- automatic

melt cycle

• High efficiency turbo jet infrared

burners

• Electronic ignition

• Deep cold zone

• Boil-out mode

• Durable centerline temperature

sensor, under 10-second response

to loads

Options & Accessories

Computer MagicTMcooking

computer

Automatic basket lifters

Digital solid state controller

Electronic timer controller

Casters

Frypot cover

Flexible metal connector with

quick-connect coupler

Stainless steel apron drain with

basket (interchangeable right or

left side)

Sediment tray

Screen type basket support

Spreader cabinet

Power Shower®

FootPrint PRO filtration system

Project

Item

Quantity

CSI Section 11400

Approval

Date

Shown with optional computer and casters

H55-2

H55

Unique frypot

design with deep

cold zone and

turbocharged,

infrared burners.

Frymaster

®

Page 2

Model#___________

CSI Section 11400

H55 and H55-2 High Efficiency Gas Fryers

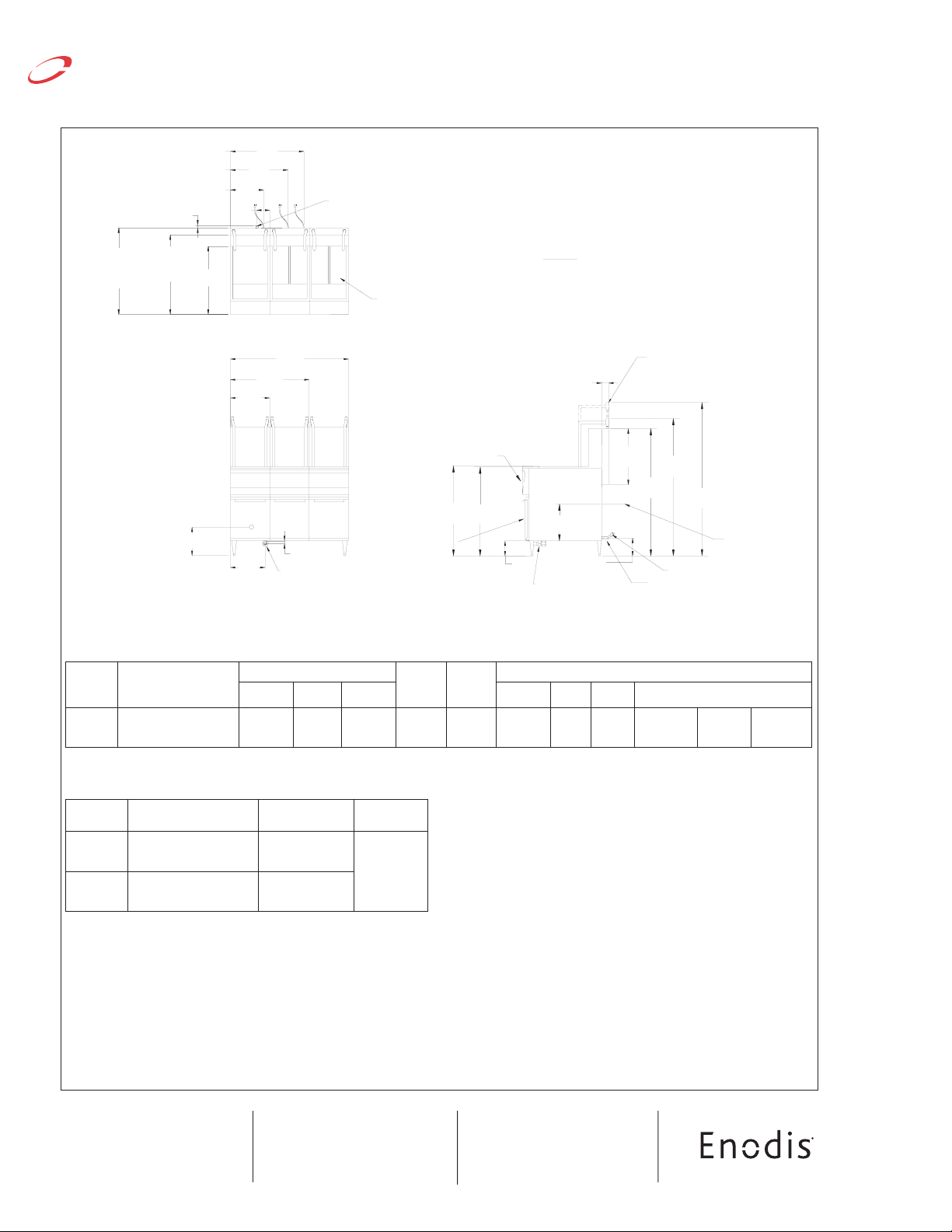

TOP VIEW

INCHES

36.00

13.75

45.60

47.10

55.75

SIDE VIEW

OPTIONAL BASKET LIFT

IN RAISED POSITION

FRONT VIEW

CONTROL PANEL

(MM)

(1416)

(1196)

(1158)

(914)

(349)

ELECTRICAL PLUG

ELECTRICAL SUPPLY

FOR BASKET LIFTER

MODEL

8.50

(216)

27

(675)

31.50

(799)

W/O BASKET

LIFTER

34.25

(869)

W/BASKET

LIFTER

2.25

(57)

REAR GAS CONNECTION

ON FRYERS

FRYPOT ASSEMBLY

CAN BE SPLIT POT

OR FULL POT OR IN

ANY COMBINATION

NOTE: BASKET LIFTS ARE OPTIONAL

10.26

2

11.63

(261)

(275)

(50)

FRONT GAS CONNECTION

W/QUICK CONNECT

DRAIN

HEIGHT

15.63

31.25

46.88

(397)

(794)

(1191)

DOOR ASSEMBLY

9.35

(237)

STANDARD GAS

CONNECTION & CORD SET FOR

NON-BASKET LIFTER MODEL

(SEE TOP VIEW)

2.75

(70)

QUICK CONNECT

COUPLER FOR FLEXIBLE

METAL CONNECTOR

(OPTIONAL)

GAS CONNECTION ON FRYERS:

FOR 2 OR MORE - 1" NPT

FOR SINGLE FRYERS - 1/2" NPT

17.50

(445)

36.50

(927)

14.35

(365)

22.00

(559)

26.70

(678)

6.38

(162)

ELECTRICAL SUPPLY FOR (3) BATTERY

ELECTRICAL SUPPLY FOR (2) BATTERY

ELECTRICAL SUPPLY FOR (4) BATTERY

We reserve the right to change specifications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

8700 Line Avenue 71106

P. O. Box 51000 71135-1000

Shreveport, LA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 818-0499 9/07

Litho in U.S.A. ©Frymaster, L. L. C.

MODEL

NO.

SHORTENING

CAPACITY

OVERALL SIZE DRAIN

HEIGHT

NET

WEIGHT

SHIPPING INFO

HEIGHT WIDTH LENGTH WEIGHT CLASS CUBE DIMENSIONS

H55

H55-2

50 lbs. (25 liters)

25 lbs. (12 liters) ea. side

45.6”

(1158 mm)

15.63”

(397 mm)

31.50”*

(799 mm)

10.26”

(261 mm)

160 lbs.

(73 kg)

202 lbs.

(92 kg)

85 21.32 H

46.50”

(1181 mm)

W

22”

(559 mm)

L

36”

(914 mm)

HOW TO SPECIFY -- EXAMPLE:

H55 Control panel, solid state controller,

electronic ignition, melt cycle, sealed

ON/OFF switch

H55-2 Split pot with same features as full pot plus

dual controls to operate each pot

independently

SD Stainless steel frypot and door -- enamel

cabinet

SC Stainless steel frypot, door and cabinet

NOTES:

Supply Voltage 120V 60Hz

120 VAC 5 ft. (1.5 m) grounded cord set provided.

Recommended minimum store supply pressure to be 6" W.C. for NAT Gas,

and 11" W.C. for L.P. Check plumbing codes for proper supply line sizing

to attain burner manifold pressure of 3.0" W.C. natural or 8.25" W.C. L.P.

Incoming supply line should be 1-1/2". Should flexible gas line be used, it

must be AGA approved, commercial type and sized per the gas line size

in above drawing.

CLEARANCE INFORMATION

A minimum of 24" (610 mm) should be provided at the front of the unit

for servicing and proper operation, and 6" (152 mm) between the sides

and rear of the fryer to any combustible material.

DIMENSIONS -- INCHES (mm)

POWER REQUIREMENTS:

MODEL NO. NATURAL OR LP GAS

INPUT RATING

ELECTRICAL EXPORT

H55 80,000 BTU/hr. input

(20,151 kcal) (23.4 kW)

Non-basket lift

120V (1.0 AMP)

220V (0.5 AMP)

200V - 250V

50/60 Hz.

3.5 AMP

H55-2 40,000 BTU/hr. input

each side (10,075 kcal)

(11.7 kW)

Basket Lift

120V (7.0 AMP)

220V (3.5 AMP)

*without basket lifts

™

Frymaster

®

Loading...

Loading...