Page 1

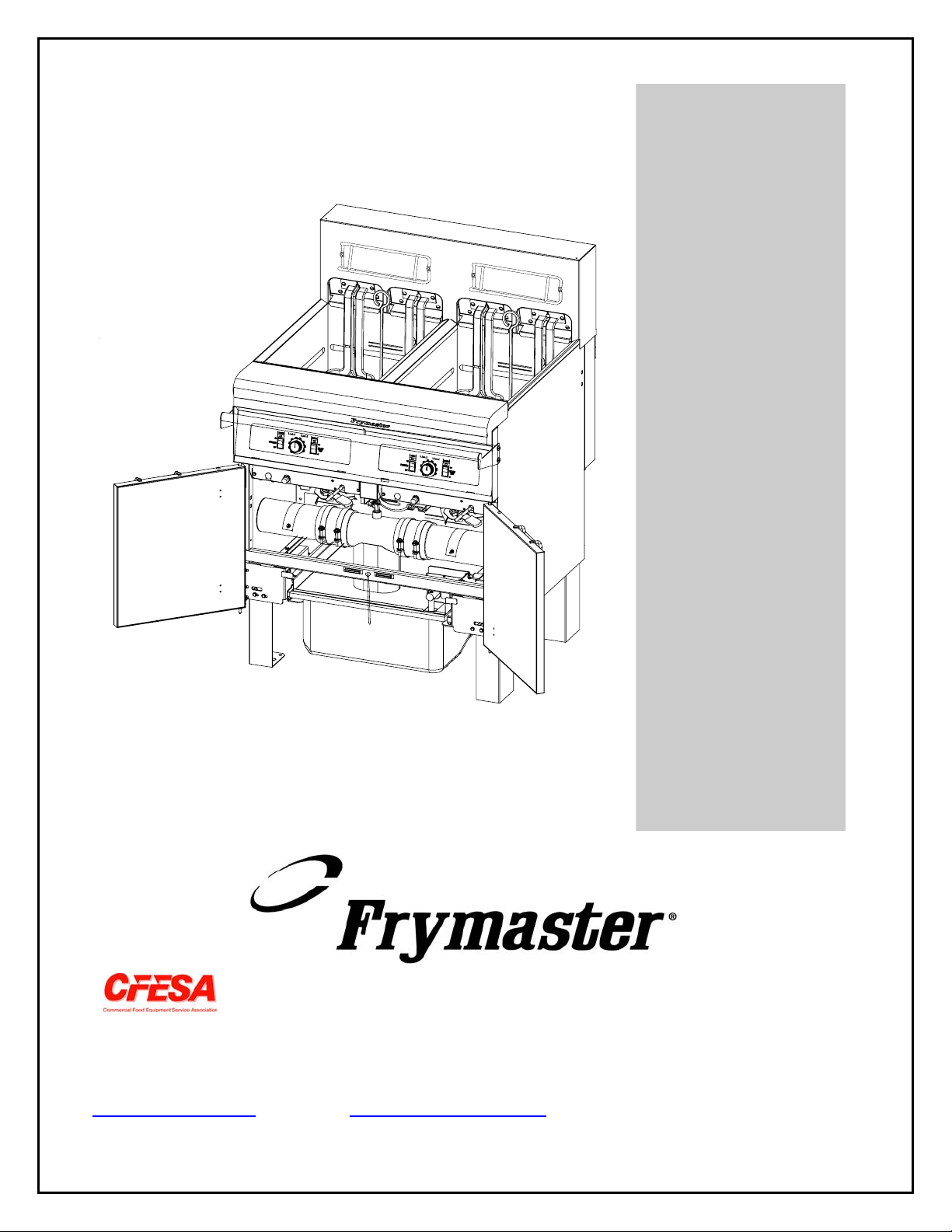

H14SC/H17SC/H22SC Single Fryers, FPPH17SC and FPH17SC Series Filtration System

Installation, Operation, Service, and Parts Manual

NAVY SURFACE SHIP ELECTRIC

FRYERS

Fryers

This manual is applicable to fryers manufactured beginning

numbers beginning with 0308. For serial numbers prior to 0308, refer to manual

819-5184.

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

www.frymaster.com

24-Hour Service Hotline 1-800-551-8633

E-mail: service@frymaster.com

August 2003 with serial

AUGUST 2005

*8196004*

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVIC E CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIAT ES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

DANGER

Copper wire suitable for at least 167°F (75°C) must be used for power connections.

DANGER

The electrical power supply for this appliance must be the same as indicated on the rating and

serial number plate located on the inside of the fryer door.

DANGER

This appliance must be connected to the voltage and phase as specified on the rating and serial

number plate located on the inside of the fryer door.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagrams

furnished with the equipment. Wiring diagrams are located on the inside of the fryer door.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures. They may differ slightly in appearance or placement between fryers but

functionality should remain the same. They may not conform to onsite management operational

procedures.

WARNING

Frymaster fryers equipped with legs are for permanent installations. Fryers fitted with legs

must be lifted during movement to avoid damage and possible bodily injury. For a moveable or

portable installation, Frymaster optional equipment casters must be used.

Questions? Call 1-800-551-8633 or email Service @Frymaster.com

DANGER

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagrams

furnished with the equipment. Wiring diagrams are located on the inside of the fryer door.

WARNING

This equipment is intended for indoor use only. Do not install or operate this equipment in

outdoor areas.

Page 3

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster/DEAN Factory Authorized Service Center (FASC) or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the U.S. Food and Drug Administration.

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating,

and service instructions thoroughly before installing or servicing this equipment.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container

at the end of frying operations each day. Some food particles can spontaneously combust if left

soaking in certain shortening material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the frypots. Banging fry baskets on the strip to dislodge shortening will

distort the strip, adversely affecting its fit. It is designed for a tight fit and should only be

removed for cleaning.

WARNING

Never spray the fryer with water or use water jets to clean the fryer.

Page 4

Navy Surface Ship Electric Fryers

Installation, Operation, Service, and Parts Manual

TABLE OF CONTENTS

Page

Chapter 1: Introduction

Chapter 2: Installation Instructions

Chapter 3: Operating Instructions 3-1

Chapter 4: Filtration Instructions 4-1

Chapter 5: Preventive Maintenance 5-1

Chapter 6: Operator Troubleshooting 6-1

Chapter 7: Service Procedures 7-1

Chapter 8: Parts List 8-1

1-1

2-1

i

Page 5

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 1: INTRODUCTION

1.1 General

Read the instructions in this manual thoroughly before attempting to operate this equipment. This

manual covers all configurations of Navy Surface Ship Electric Fryer models specifically configured

for use aboard surface ships of the U.S. Navy, including H14SC/H17SC/H22SC kW and FPH17SC

kW filtration system models. The fryers in this model family have most parts in common, and when

discussed as a group, will be referred to as “Navy Surface Ship Electric” fryers.

Although similar in appearance to the Footprint III family of Navy Electric fryers, the Navy Surface

Ship Electric fryers feature a significantly different built-in filtration system. Other features,

including the deep cold-zones and open frypots with tilt-up elements remain essentially unchanged.

All Navy fryers are equipped with solid-state analog controllers. Fryers in this series can be single

units or grouped in batteries of two or more fryers.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

one below.

DANGER

Hot cooking oil causes severe burns. Never attempt to move a fryer containing hot

cooking oil or to transfer hot cooking oil from one container to another.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

DANGER boxes contain information about actions or conditions that may cause or result in

injury to personnel, and which may cause damage to your system and/or cause your system to

malfunction.

Fryers in this series are equipped with the following automatic safety features:

1. Two high-temperature detection features shut off power to the elements should the temperature

controls fail.

2. A safety switch built into the drain valve prevents the elements from heating with the drain valve

even partially open.

1-1

Page 6

1.3 Controller Information

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been

shown to meet the Class B limits. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications.

The user may find the following booklet prepared by the Federal Communications Commission

helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available

from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.4 Shipping Damage Claim Procedure

What to do if this equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before

leaving the factory. The freight company assumes full responsibility for safe delivery upon

acceptance of the equipment.

1. File Claim for Damages Immediately—Regardless of extent of damage.

2. Visible Loss or Damage—Be sure this is noted on the freight bill or express receipt and is signed

by the person making the delivery.

3. Concealed Loss or Damage—If damage is unnoticed until equipment is unpacked, notify the

freight company or carrier immediately and file a concealed damage claim. This should be done

within 15 days of date of delivery. Be sure to retain container for inspection.

1.5 Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster

Authorized Service Center (FASC). Service information may also be obtained by calling the

Frymaster Technical Services Department (1-800-551-8633) or via e-mail at service

@frymaster.com. The following information will be needed in order to assist you efficiently:

Model Number:

Serial Number:

Voltage:

Also be prepared to describe the specific problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-2

Page 7

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 Introduction

The instructions in this chapter cover all configurations of Navy Surface Ship Electric Fryer models

specifically configured for use aboard surface ships of the U.S. Navy, including

H14SC/H17SC/H22SC kW and FPH17SC kW filtration system models. The instructions do not

cover and may not be used for installations aboard submarines or ashore.

Proper installation is essential for the safe, efficient, trouble-free operation of this appliance.

Any unauthorized alteration of this equipment will void the Frymaster warranty.

NOTICE

If this equipment is wired directly into the electrical power supply, a means for

disconnection from the supply having a contact separation of at least 3-mm in all

poles must be incorporated in the fixed wiring.

NOTICE

This equipment must be positioned so that the plug is accessible unless other

means for disconnection from the power supply (e.g., a circuit breaker) is provided.

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by

means of copper wires having a temperature rating of not less than 167°F (75°C).

NOTICE

If the electrical power supply cord is damaged, it must be replaced by a Frymaster

Dean Factory Authorized Service Center technician or a similarly qualified person in

order to avoid a hazard.

DANGER

This appliance must be connected to a power supply having the same voltage and

phase as specified on the rating plate located on the inside of the appliance door.

DANGER

All wiring connections for this appliance must be made in accordance with the

wiring diagram(s) furnished with the appliance. Refer to the wiring diagram(s)

affixed to the inside of the appliance door when installing or servicing this

equipment.

DANGER

The appliance area must be kept free and clear of combustible material at all times.

WARNING

Do not block the area around the base or under the fryers.

2-1

Page 8

All installation and service on FRYMASTER equipment must be performed by qualified, certified,

licensed, and/or authorized installation or service personnel.

Service may be obtained by contacting a local Frymaster DEAN Factory Authorized Service Center.

In the event of a power failure, the fryer(s) will automatically shut down. If this occurs, turn the

power switch OFF. Do not attempt to start the fryer(s) until power is restored.

A clearance of 6 inches (15cm) must be provided at both sides and back adjacent to combustible

construction. A minimum of 24 inches (61cm) should be provided at the front of the equipment for

servicing and proper operation.

Connections should be made by means of an approved, flexible-metallic or rubber-covered electrical

cable and quick-disconnect plug. The fryers may be installed with “hard-wired” connections, but

use of quick-disconnect plugs will facilitate service if required. Connections are made to the fryer

power input terminal block located in the contactor box(es) in the bottom of the fryer(s).

DANGER

Observe the following precautions when connecting the fryer to an emergency cutoff

system:

● Be sure that each fryer is connected to a dedicated set of contacts in the

emergency cutoff system.

● Do not connect the contacts in series.

● Do not connect more than one fryer to each set of contacts.

● The contacts MUST be normally closed contacts that open in an emergency.

● The contacts CANNOT have an external voltage applied.

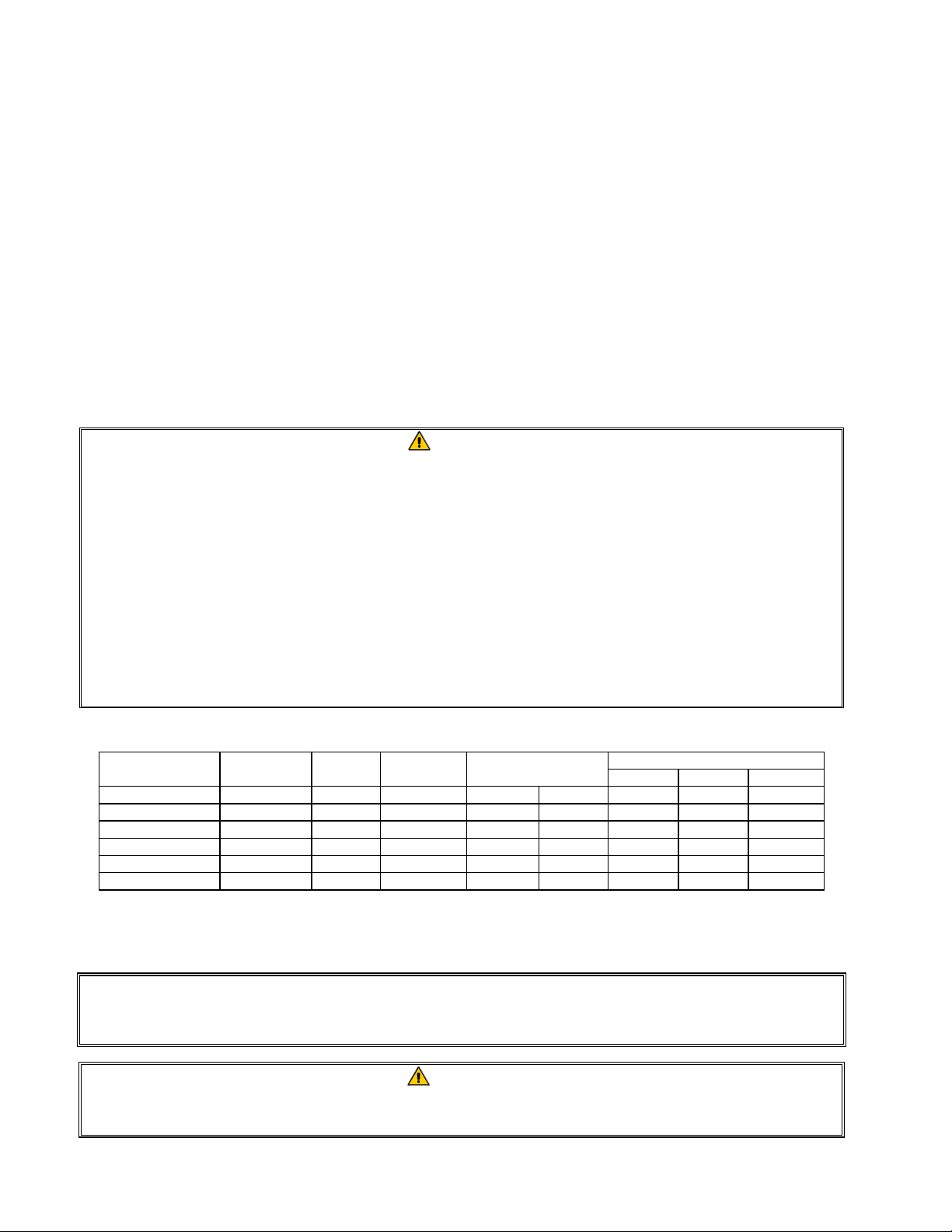

2.2 Power Requirements

WIRE

MODEL VOLTAGE PHASE

H14SC 440 3 3 8 (10) 19 19 19

H14SC 480 3 3 8 (10) 17 17 17

H17SC/FPH17SC 440 3 3 6 (16) 23 23 23

H17SC/FPH17SC 480 3 3 6 (16) 21 21 21

H22SC 440 3 3 6 (16) 29 29 29

H22SC 480 3 3 6 (16) 27 27 27

SERVICE

MIN.

SIZE

AWG

(mm

2

)

AMPS PER LEG

L1 L2 L3

The FPH17SC Navy Surface Ship electric fryers are equipped with a filter system that requires a

separate 120VAC, single-phase, 3-wire, 20 amp service (refer to wiring diagrams in paragraphs 7.10

and 7.11).

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by

means of copper wires having a temperature rating of not less than 167°F (75°C).

DANGER

This appliance must be connected to a power supply having the same voltage and

phase as specified on the rating plate located on the inside of the appliance door.

2-2

Page 9

DANGER

All wiring connections for this appliance must be made in accordance with the

wiring diagram(s) furnished with the appliance. Refer to the wiring diagram(s)

affixed to the inside of the appliance door when installing or servicing this

equipment.

2.3 Installation

1. This equipment must be securely bolted to the deck.

2. Install deck studs for the specific fryer configuration in accordance with the diagrams at the end

of this chapter.

3. Position the fryer on the deck studs and secure with appropriate nuts and lock washers.

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster Dean Service

Hotline at 1-800-551-8633.

2.4 After Fryers Are Anchored At the Frying Station

DANGER

Hot oil can cause severe burns. Avoid contact. Under all circumstances, oil must be

removed from the fryer before attempting to move it to avoid oil spills, falls and

severe burns. This fryer may tip and cause personal injury if not secured in a

stationary position.

1. Close frypot drain-valve(s) and fill frypot(s) with water to the bottom oil level line.

2. Boil out frypot(s) in accordance with the instructions in Section 5.1.3 of this manual.

3. Drain, clean, and fill frypot(s) with cooking oil. (See Equipment Setup and Shutdown

Procedures in Chapter 3.)

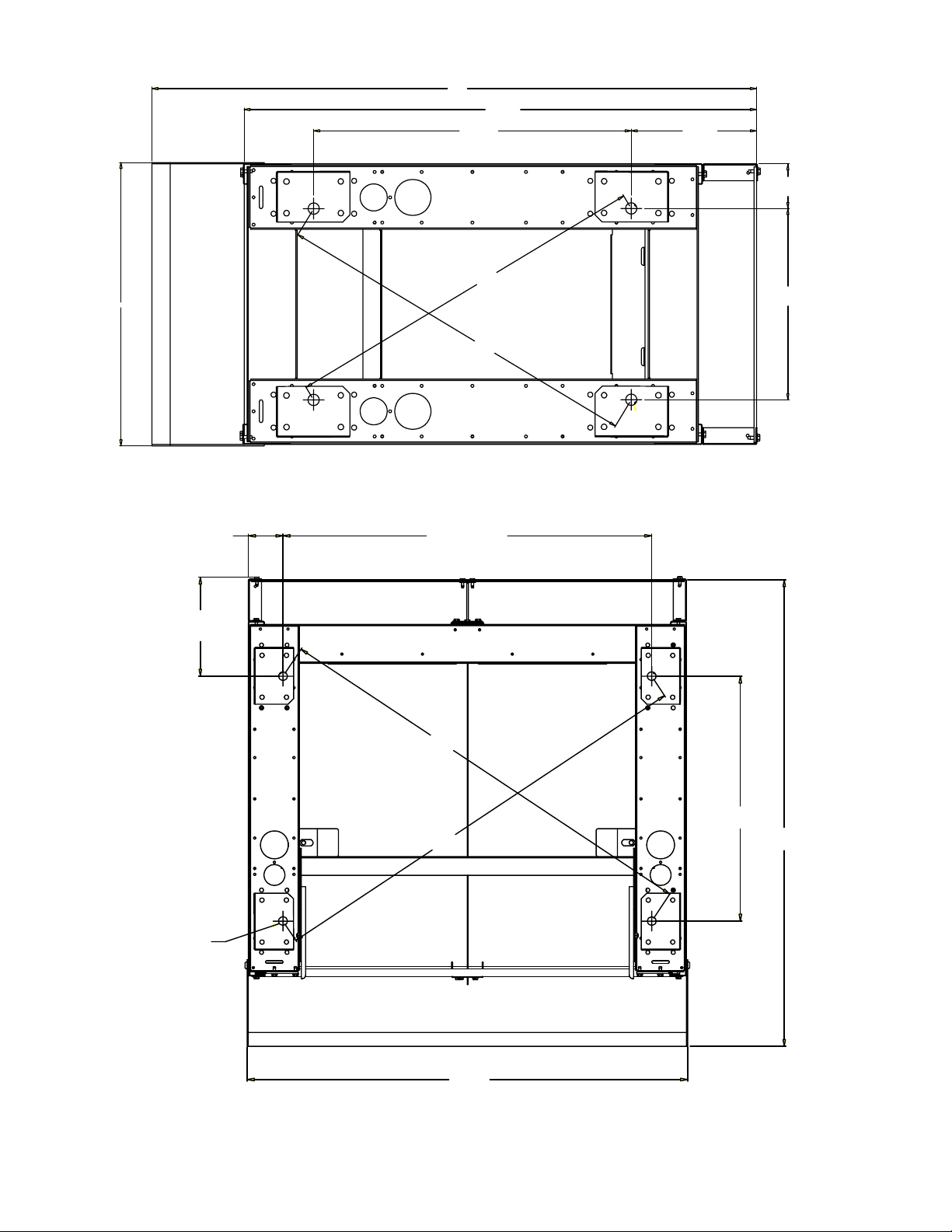

2.5 Dimensions and Weights

Single Fryer: LWH (inches) 33.38 X 15.67 X 45.5 – 190 lbs. empty.

2-Fryer Battery: LWH (inches) 33.39 X 31.45 X 45.5 – 490 lbs. empty.

3-Fryer Battery: LWH (inches) 33.24 X 47.10 X 45.5 – 570 lbs. empty.

4-Fryer Battery: LWH (inches) 33.45 X 62.55 X 45.5 – 780 lbs. empty.

2-3

Page 10

15.67

FRONT HANDLE

2.470

TYPICAL

33.38

17.534 6.913

20.48

20.48

Single Fryer

26.316

BACK OF FRYER UNIT

28.29

2.465

10.580

BACK

OF

FRYER UNIT

MOUNTING HOLES

Ø .625

4 PLACES

7.098

TYPICAL

31.62

31.62

FRONT HANDLE

2-Fryer Battery

31.45

17.515

33.39

2-4

Page 11

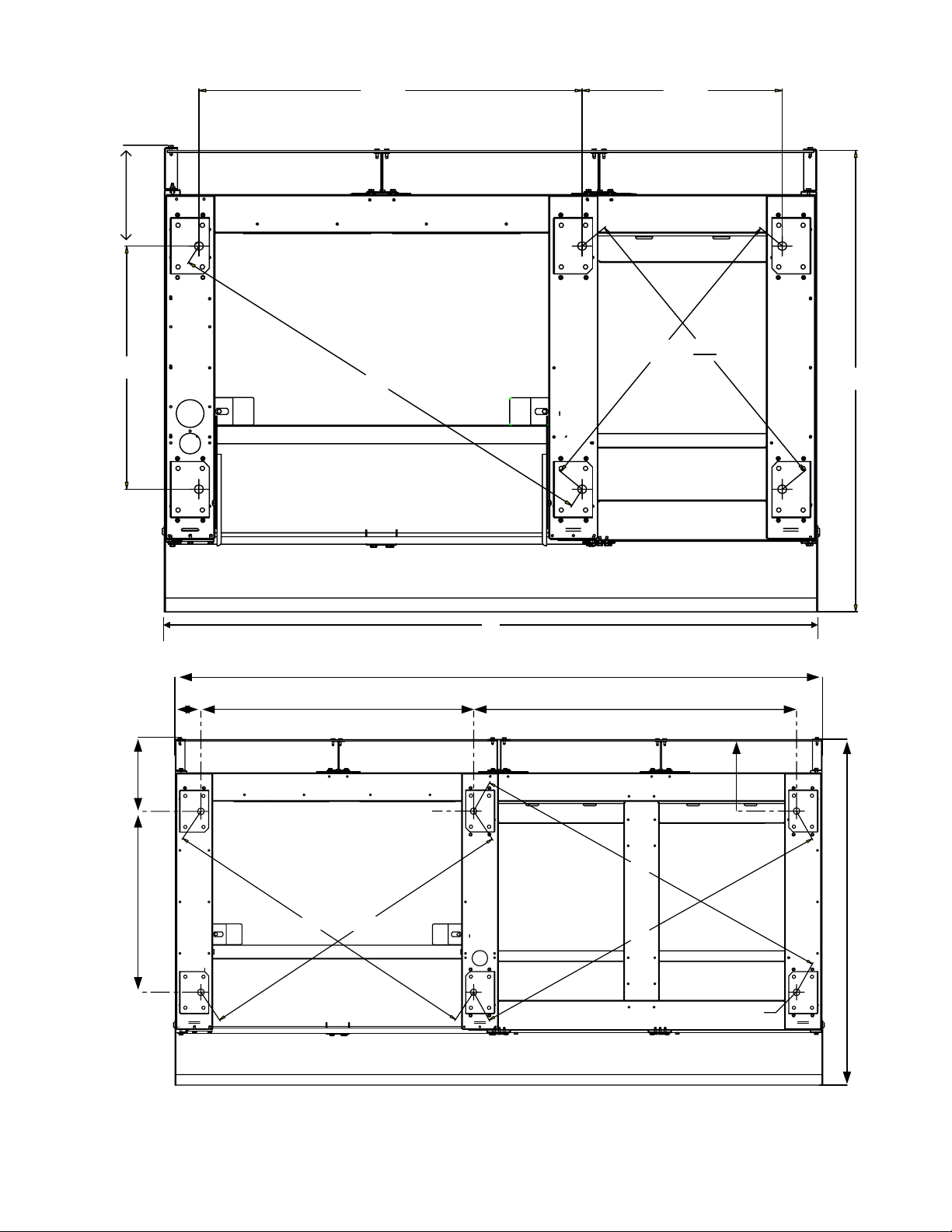

17.516

7.229

27.570 14.400

BACK OF FRYER UNIT

22.68

32.66

22.68

33.24

2.470

7.119

17.490

3-Fryer Battery

FRONT HANDLE

47.1

62.55

26.320 31.180

BACK OF FRYER UNIT

31.61 31.61

35.76

35.76

7.119

Mounting Holes

.625

Six Places

33.45

4-Fryer Battery

FRONT HANDLE

2-5

Page 12

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.1 Equipment Setup and Shutdown Procedures

Setup

DANGER

Never operate the appliance with an empty frypot. The frypot must be filled with

water or cooking oil before energizing the elements. Failure to do so will result in

irreparable damage to the elements and may cause a fire.

DANGER

Remove all drops of water from the frypot before filling with cooking oil. Failure to

do so will cause spattering of hot liquid when the oil is heated to cooking

temperature.

1. Fill the frypot with cooking oil to the bottom OIL LEVEL line located on the rear of the frypot.

This will allow for oil expansion as heat is applied. Do not fill cold oil any higher than the

bottom line; overflow may occur as heat expands the oil.

NOTE: If solid shortening is used, first raise the elements, then pack the shortening into the

bottom of the frypot. Lower the elements, and then pack the shortening around and over the

elements. It may be necessary to add shortening to bring the level up to the proper mark after the

packed shortening has melted.

DANGER

Never set a complete block of solid shortening on top of the heating elements.

When using solid shortening, always pre-melt the shortening before adding it to the

frypot. If the shortening is not pre-melted, it must be packed down into the bottom of

the frypot and between the elements, and the fryer must be started in the melt-cycle

mode.

Never cancel the melt-cycle mode when using solid shortening. Doing so will result

in damage to the elements and increase the potential for a flash fire.

2. If the fryer(s) is/are not hard-wired into the power supply, ensure that the power cord(s) is/are

plugged into the appropriate receptacle(s). Verify that the face of the plug(s) is/are flush with the

outlet plate, with no portion of the prongs visible.

3. Ensure that the oil level is at the top OIL LEVEL line when the oil is at its cooking temperature.

It may be necessary to add oil to bring the level up to the proper mark, after it has reached

cooking temperature.

3–1

Page 13

Shutdown

1. Turn the fryer off.

2. Filter the cooking oil and clean the fryers (See Chapters 4 and 5).

3. Place the frypot covers on the frypots.

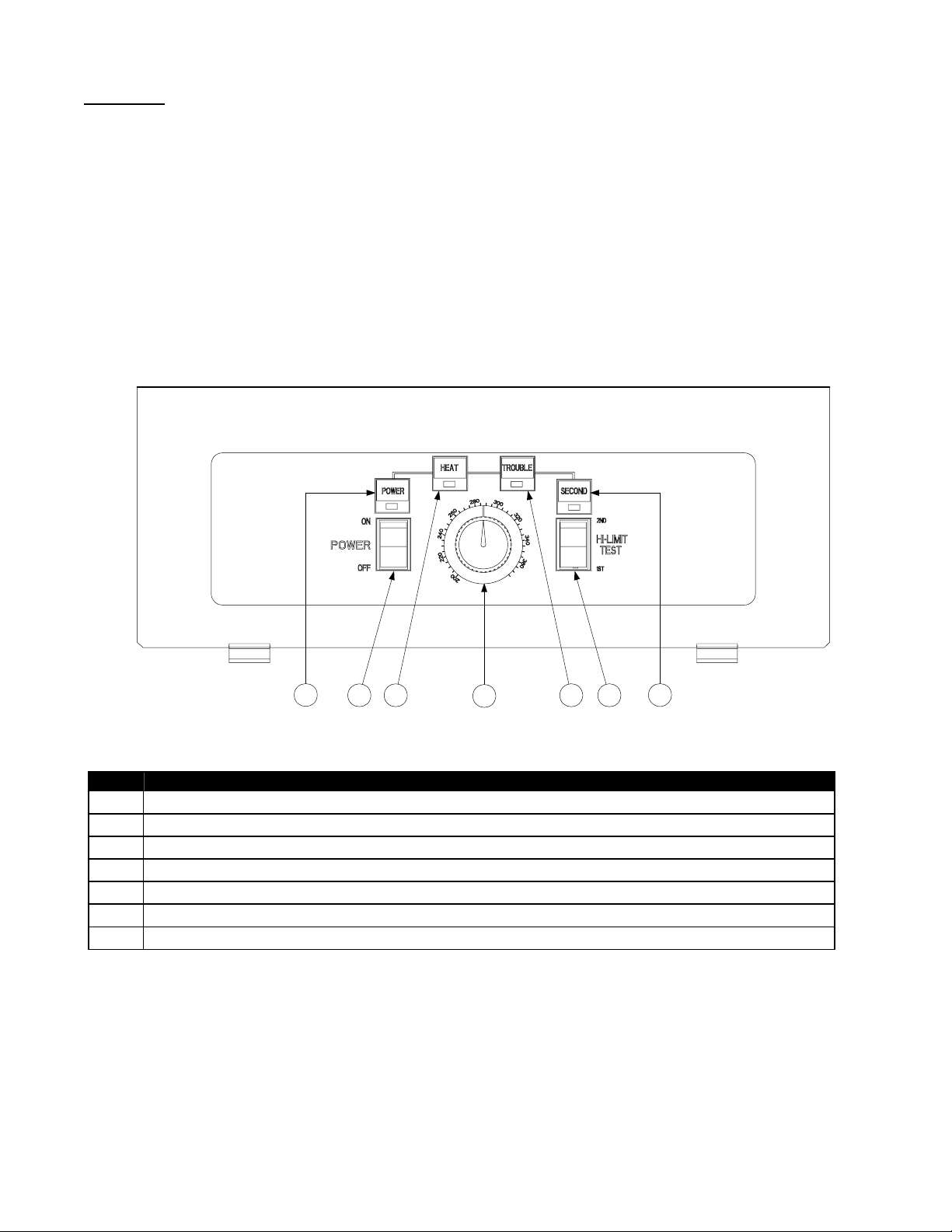

3.2 Operation of the Solid-State Analog Controller

NOTE: Refer to Chapter 4 of this manual for operating instructions for the built-in filtration system.

Fryers configured for the U.S. Navy are equipped with solid-state analog controllers.

2 7

1 3 4

U.S. Navy Solid-State Analog Controller

5

6

ITEM DESCRIPTION

1 Power Switch – Controls electrical power to fryer.

2 Power-On Light – Indicates when electrical power to fryer is ON.

3 Heating Mode Light – Indicates when heating element is ON.

4 Trouble Light – Indicates over high-limit or problem in heat control circuitry.

5 Thermostat Control Knob – Sets desired frying temperature.

6 Hi-Limit Test Switch – Tests high-limit thermostat.

7 Second Hi-Limit Test Light – Indicates fryer is in second high-limit test mode.

The analog controller, illustrated above, is used to adjust and maintain oil at the temperature

indicated by the thermostat knob.

The fryer has two built-in high-limit protection features. If the temperature in the frypot reaches

approximately 410°F, the controller opens the heat relay circuit, turning the elements off. If the

temperature in the frypot reaches 450°F, a mechanical high-limit shuts off electrical power to the

elements. The operator should periodically test each of the high-limit protection features, using

the procedure at the end of this chapter, to verify that they are operating correctly.

3–2

Page 14

The analog controller has no timing features. The operator must monitor shake and pull times.

WARNING

Before pressing the power switch to the ON position, ensure that the frypot is

properly filled with oil. See Section 3.1.

CONTROLLER OPERATING PROCEDURE

1. Verify that the thermostat knob is set to the desired cooking temperature.

2. Press the power switch to the ON position. The POWER light will illuminate.

3. If the frypot temperature is below 180°F, the controller will automatically enter a warm-up cycle

(often called a melt cycle). The heating elements will cycle on and off repeatedly, allowing the

oil to heat gradually, without scorching. During the warm-up cycle, the heating mode light will

alternately illuminate and go off as the elements cycle on and off. Within about 45 minutes, the

controller will exit the warm-up cycle and the heating mode light will remain continuously

illuminated.

4. When the oil temperature reaches the thermostat knob setpoint, the elements will cycle OFF and

the HEAT light will go off, indicating that the fryer is ready for the cooking process to begin.

HIGH-LIMIT TEST PROCEDURE

Tools Required: One 0-600°F pyrometer with sensing probe or an equivalent high-temperature

thermometer.

NOTE: Conduct this test when the fryer will not be needed for about one hour and when the

cooking oil is due to be changed (the test will ruin the cooking oil). Start the test with the controller

turned ON and with the cooking oil at normal frying temperature. Stir the oil thoroughly to ensure

even distribution and temperature.

DANGER

If the expected results (indicated by italics) for Steps 3 and 4 below do not occur,

turn off the fryer at the main circuit breaker panel and do not use the fryer until it has

been repaired by an authorized technician.

1. Verify that cooking oil is at the bottom OIL-LEVEL line. Add oil if necessary.

2. Turn the power switch ON and set the control knob to the normal frying temperature.

3. Insert the pyrometer probe into the frypot so that its tip is near the temperature probe on the

element (i.e., approximately 5-inches into the oil, near the center of the frypot). Press and hold

the high-limit test switch in the “1st” test position until the TROUBLE light illuminates. Release

the test switch.

The trouble light should have come on when the temperature was approximately 410°F (± 10°F)

and the heating elements should have de-energized (indicated by the HEAT light going out).

3–3

Page 15

4. Press and hold the high-limit test switch in the “2nd” test position until the 2nd High-Limit light

illuminates. Release the switch.

The 2nd High-Limit light should have come on when the temperature was between 430°F and

460°F.

For fryers connected to an external shunt power supply, all fryers should have been shut off

completely and all control panel lights should have been extinguished. For fryers not connected

to an external shunt power supply, only the fryer being tested should have been shut off.

5. Place the controller power switch in the OFF position.

6. Allow the cooking oil to cool to below normal frying temperature. When the power switch is

again placed in the ON position, the elements should re-energize and the operating thermostat

should resume control of the temperature. If the TROUBLE light remains on instead, allow the

oil additional time to cool.

3–4

Page 16

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 4: FILTRATION INSTRUCTIONS

4.1 Introduction

The FootPrint Pro filtration system allows the cooking oil or shortening in one frypot to be safely

and efficiently filtered while the other frypots in a battery remain in operation. Section 4.2 covers

preparation of the filter system for use. Operation of the system is covered in section 4.3.

WARNING

The work center supervisor is responsible for ensuring that operators are made

aware of the inherent hazards of operating a hot oil filtering system, particularly the

aspects of oil filtration, draining and cleaning procedures.

4.2 Preparing the Filter for Use

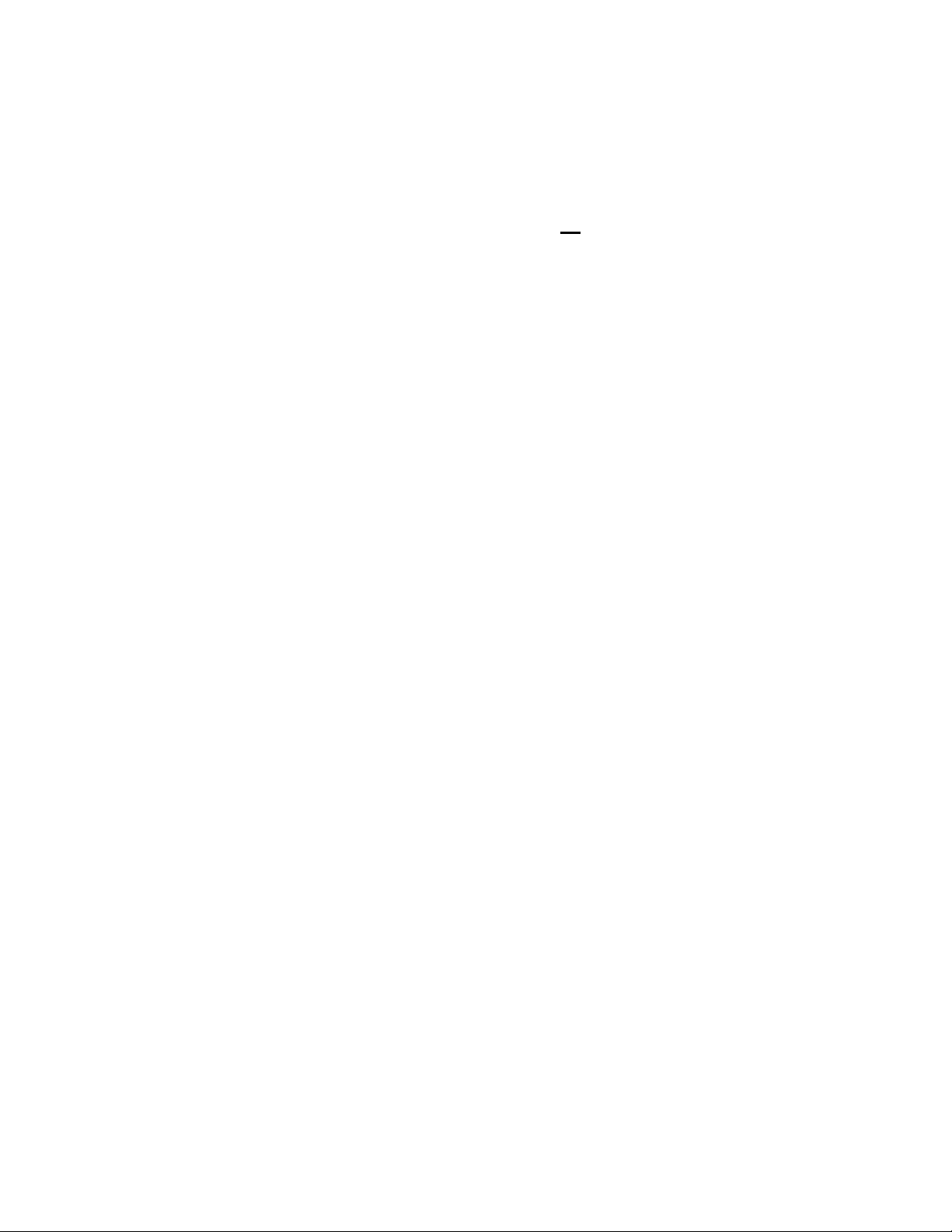

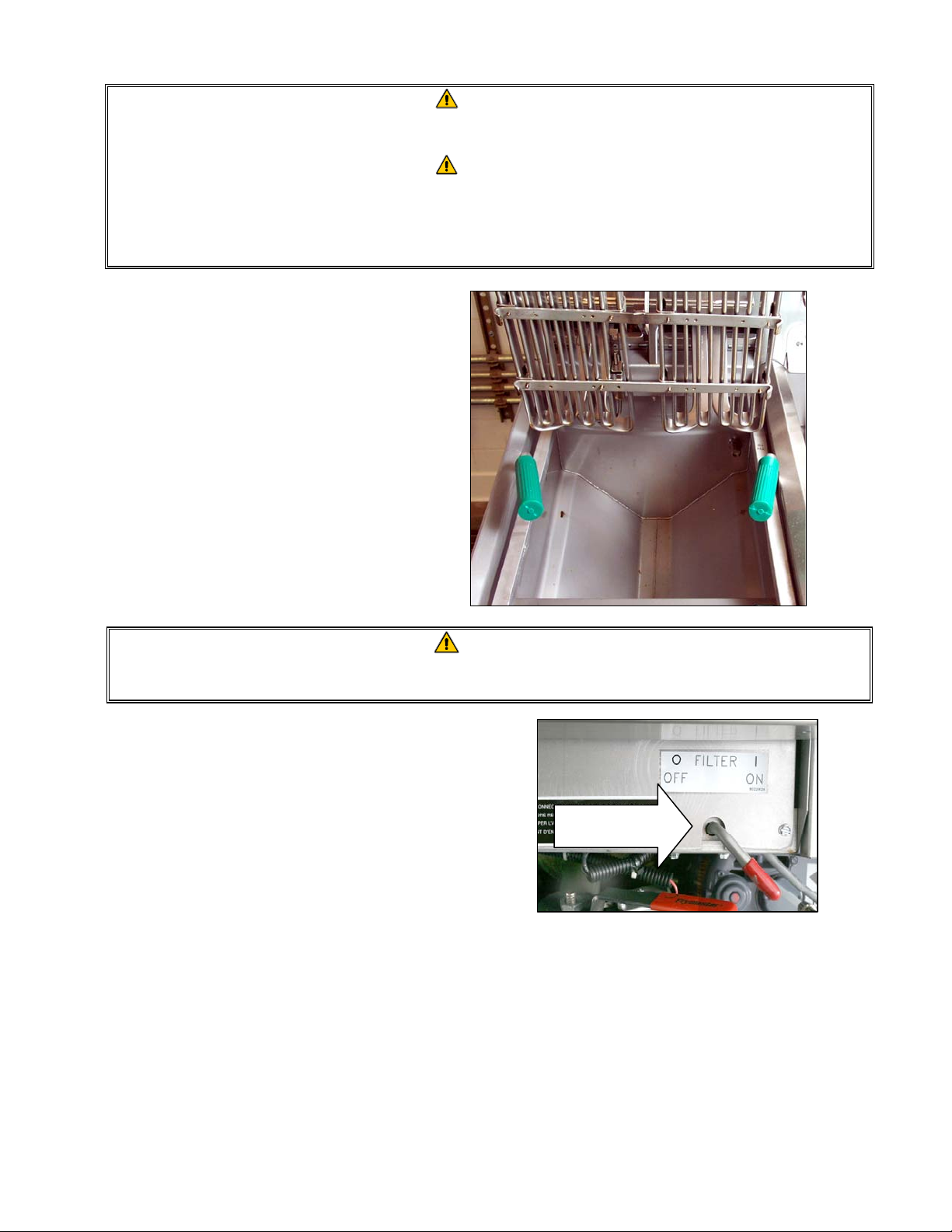

1. Rotate the pan-locking rod to either side

until it clears the filter pan, then pull the

pan out from the cabinet. Remove the

crumb tray, hold-down ring and filter

screen. Clean all components with a

solution of detergent and hot water, then

dry thoroughly.

The filter pan is equipped with rollers in

rails, much like a kitchen drawer. The

pan may be removed for cleaning or to

gain access to interior components by

lifting the front of the pan to disengage

the front rollers, then pulling it forward

until the rear rollers clear the rails. The

pan cover must not be removed except

for cleaning, interior access, or to allow

a shortening disposal unit (SDU) to be

positioned under the drain.

2. Inspect the filter pan connection fitting

to ensure that both o-rings are in good

condition. On the FPH117 fryers the orings are located on the tube spout

behind the filter pan at the rear of the

fryer. O-rings on fryers having more

than one battery are located on the tube

disconnect inside the fryer as shown to

the right.

Rotate the locking rod

to either side to allow

the pan to be pulled

out from the fryer.

Inspect O-Rings

4-1

Page 17

t

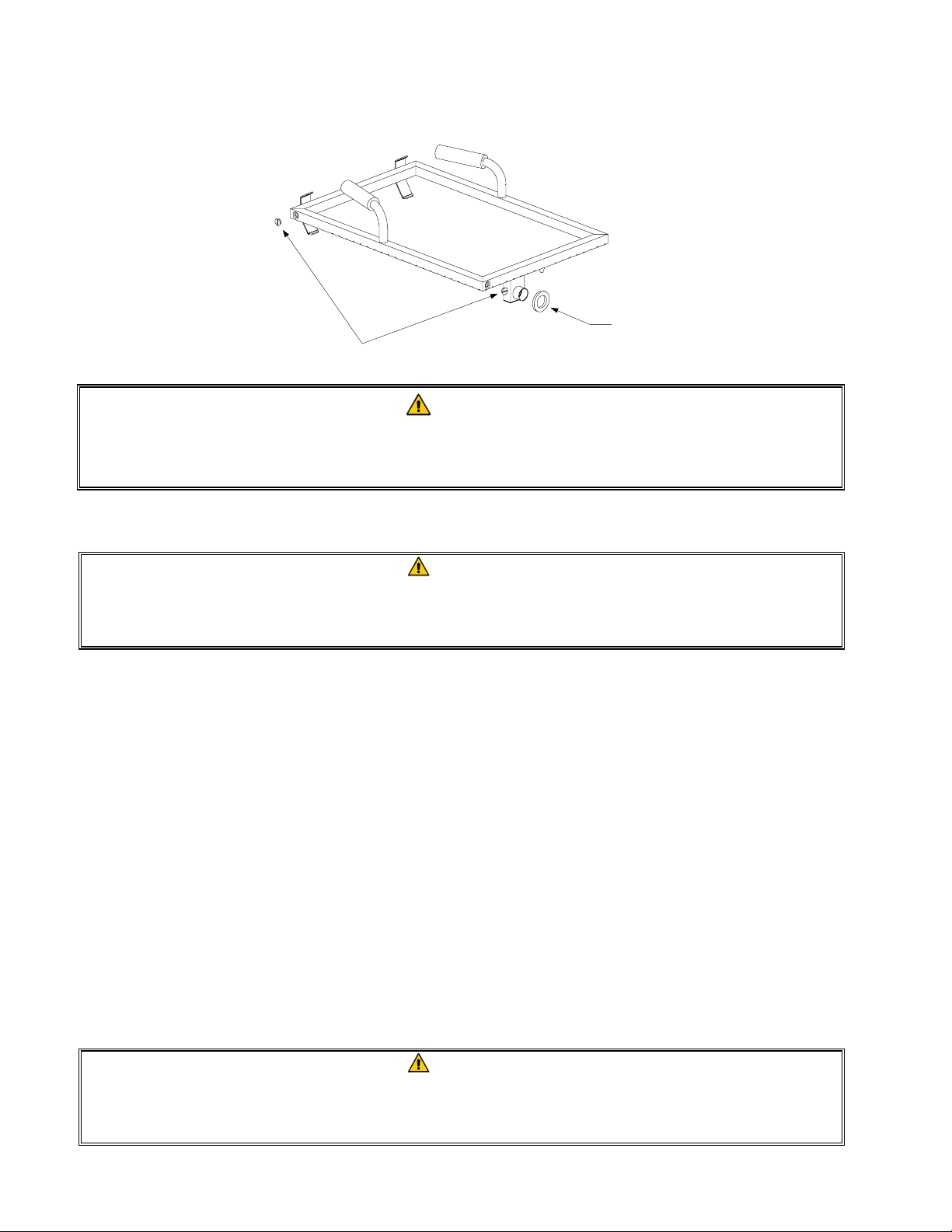

3. Place the metal filter screen in the center

of the bottom of the pan, then lay a shee

Filter Paper

Screen

of filter paper on top of the screen, overlapping on all sides.

4. Position the hold-down ring over the

filter paper and lower the ring into the

pan, allowing the paper to fold up

around the ring as it is lowered to the

bottom of the pan.

5. When the hold-down ring is in position, sprinkle one cup of filter powder evenly over the paper.

6. Replace the crumb tray in the filter pan, then push the filter pan back into the fryer, positioning it

all the way to the back of the cabinet.

4.3 Operation of the Filter

DANGER

Draining and filtering of cooking oil must be accomplished with care to avoid the

possibility of a serious burn caused by careless handling. The oil to be filtered is at

or near 350°F. Ensure drain handles are in their proper position before operating

any switches or valves. Wear all appropriate safety equipment when draining and

filtering cooking oil or shortening.

DANGER

NEVER attempt to drain cooking oil from the fryer with the elements energized!

Doing so will cause irreparable damage to the elements and may cause a flash fire.

Doing so will also void the Frymaster warranty.

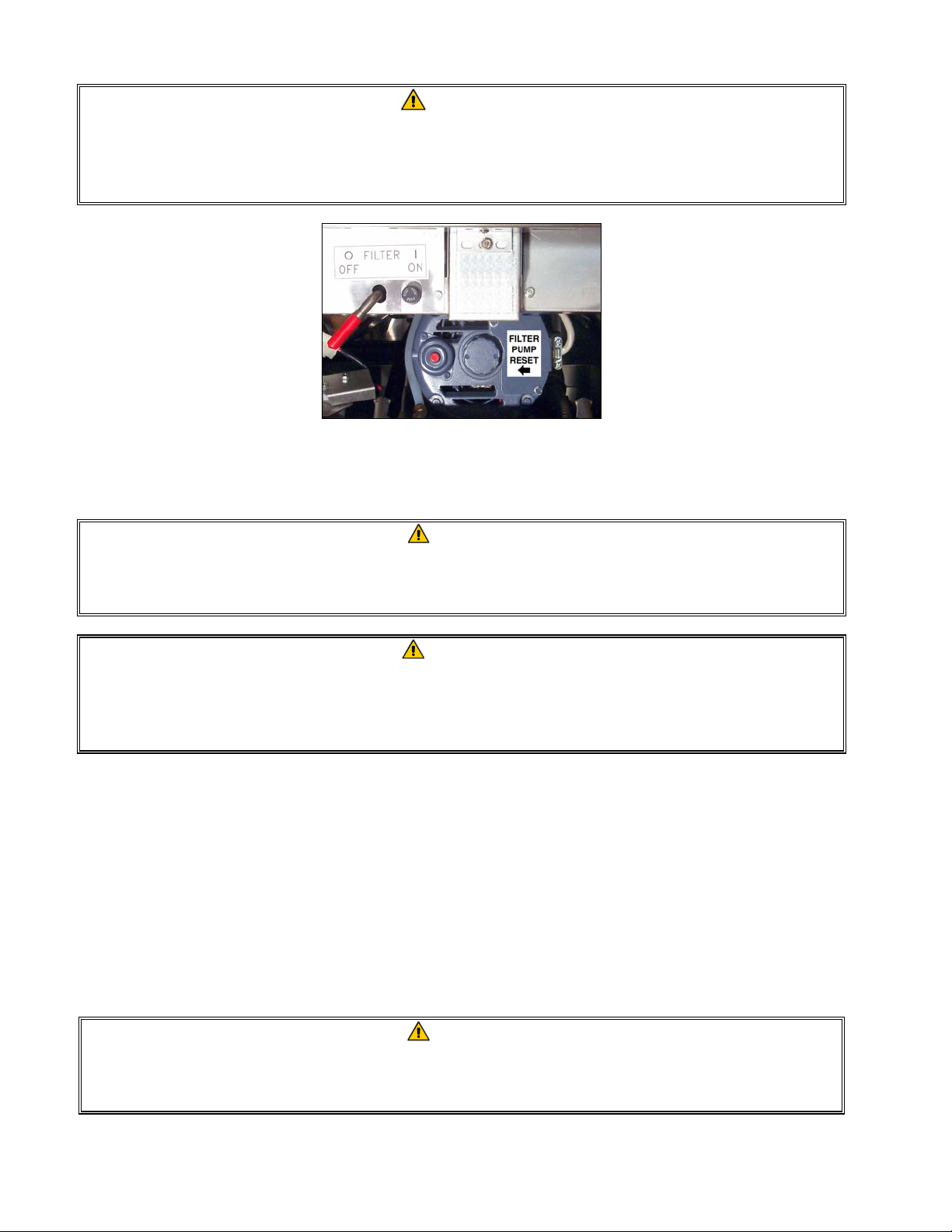

1. Turn the fryer power OFF. Drain the

frypot into the filter pan. If necessary,

use the Fryer's Friend clean-out rod to

clear the drain from inside the frypot.

Open valve by

moving handle to

the right.

4-2

Page 18

DANGER

Do not drain more than one frypot at a time into the built-in filtration unit to avoid

overflow and spillage of hot oil.

DANGER

NEVER attempt to clear a clogged drain valve from the front of the valve! Hot oil will

rush out creating the potential for severe burns. DO NOT hammer on the drain valve

with the cleanout rod or other objects. Damage to the ball inside will result in leaks

and will void the Frymaster warranty.

2. Remove the basket support rack from the

frypot, raise the element assembly to the

up position, and snap the Power Shower

into position.

DANGER

DO NOT operate the filter without the Power Shower in place. Hot oil will spray out of

the fryer and cause injury.

3. After the cooking oil has drained from

the frypot, turn the filter handle to the

ON position to start the pump and begin

Turn filter handle

to the ON position.

the filtering process. There may be a

slight delay before the pump activates.

4. The filter pump draws the cooking oil through the filter medium and circulates it back up to and

through the frypot during a 5-minute process called polishing. Polishing cleans the oil by

trapping solid particles in the filter medium.

5. After the oil is filtered (about 5 minutes), close the drain valve and allow the fryer to refill. Let

the filter pump run 10 to 12 seconds after the oil begins to sputter from the Power Shower

openings. Turn the filter off, remove the Power Shower and let it drain.

4-3

Page 19

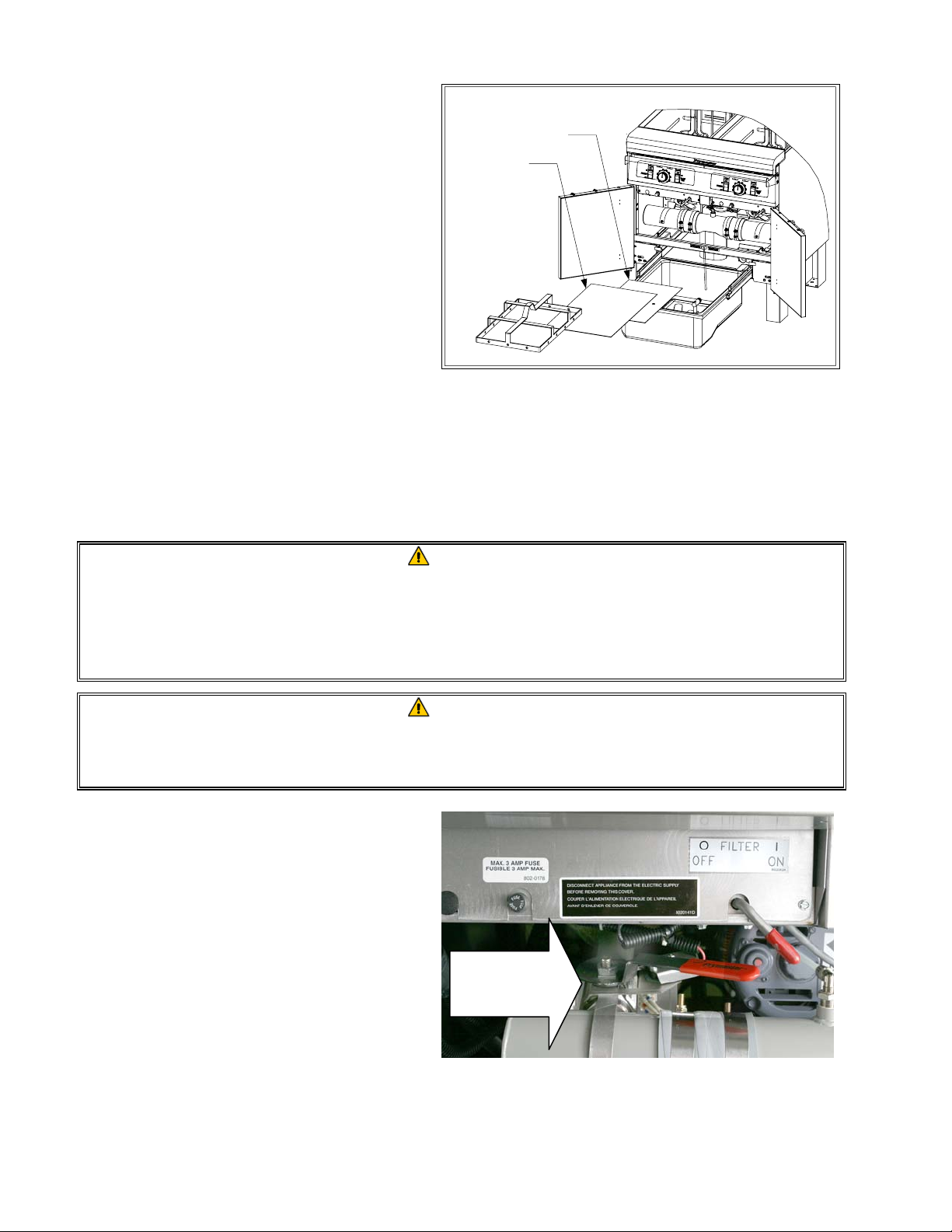

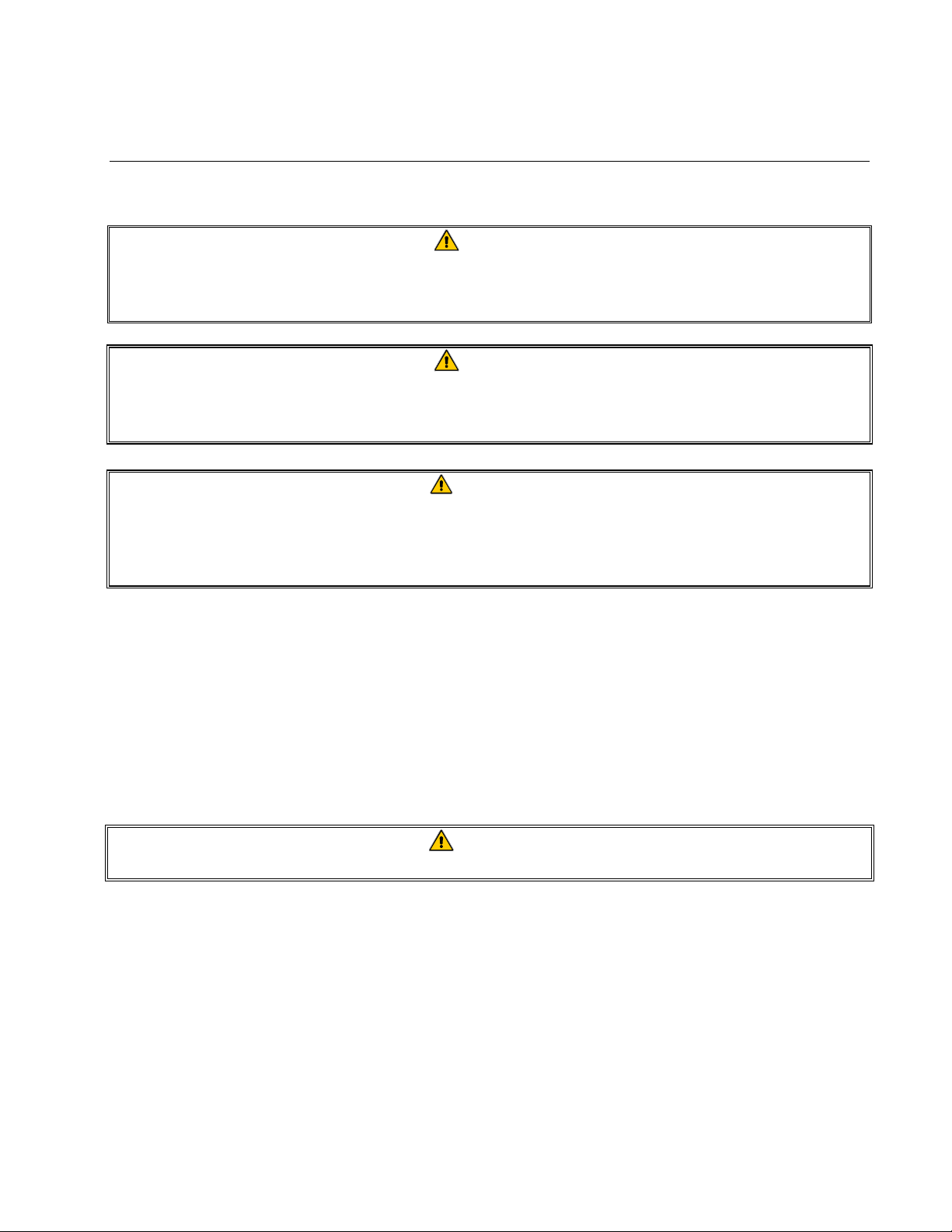

WARNING

The filter pump is equipped with a manual reset switch (see photo below) in case the

filter motor overheats or an electrical fault occurs. If this switch trips, turn off power

to the filter system and allow the pump motor to cool 20 minutes before attempting

to reset the switch.

6. Lower the elements into the frypot and reinstall the basket support rack. Ensure the drain valve

is fully closed. (If the drain valve is not fully closed, the fryer will not operate.) Turn the fryer

ON and allow the cooking oil to reach setpoint.

DANGER

The crumb tray must be emptied into a fireproof container at the end of frying

operations each day. Some food particles can spontaneously combust if left soaking

in certain shortening material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is

present to seal the joint between the fry vessels. Banging fry baskets on the strip to

dislodge shortening will distort the strip, adversely affecting its fit. It is designed for

a tight fit and should only be removed for cleaning.

4.4 Draining and Disposing of Waste Oil

When your cooking oil has reached the end of its usable life, drain the oil into an appropriate

container for transport to the disposal container. Frymaster recommends the use of the Frymaster

Shortening Disposal Unit (SDU). Refer to the documentation furnished with the disposal unit for

specific operating instructions. If a shortening disposal unit is not available, allow the oil to cool to

100°F, then drain the oil into a metal stockpot or similar metal container. When draining is finished,

close the fryer drain valve securely.

NOTE: The filter pan cover must be removed from the fryer in order to position the SDU beneath

the drain.

DANGER

Allow oil to cool to 100°F before draining into an appropriate container for disposal.

When draining oil into a disposal unit, do not fill above the maximum fill line located

on the container.

4-4

Page 20

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 5: PREVENTIVE MAINTENANCE

5.1 Cleaning the Fryer

The crumb tray in fryers equipped with a filter system must be emptied into a

fireproof container at the end of frying operations each day. Some food particles

can spontaneously combust if left soaking in certain shortening material.

Never attempt to clean the fryer during the frying process or when the frypot is filled

with hot oil. If water comes in contact with oil heated to frying temperature, it will

cause spattering of the oil, which can result in severe burns to nearby personnel.

Use a commercial-grade cleaner formulated to effectively clean and sanitize

food-contact surfaces. Read the directions for use and precautionary statements

before use. Particular attention must be paid to the concentration of cleaner and the

length of time the cleaner remains on the food-contact surfaces.

5.1.1 Clean Inside and Outside of the Fryer Cabinet – Daily

Clean inside the fryer cabinet with a dry, clean cloth. Wipe all accessible metal surfaces and

components to remove accumulated oil/shortening and dust.

Clean outside the fryer cabinet, with a clean, damp cloth soaked with dishwashing detergent. Wipe

with a clean, damp cloth.

5.1.2 Clean the Built-in Filtration System – Daily

DANGER

DANGER

WARNING

WARNING

Never drain water into the filter pan. Water will damage the filter pump.

There are no periodic preventive maintenance checks and services required for the FootPrint Pro

Filtration System other than daily cleaning of the filter pan and associated components with a

solution of hot water and detergent.

Immediately after each use, drain the Power Shower completely. If oil is leaking at the point where

the Power Shower plugs into the frypot, verify the gasket on the connection fitting is present and in

good condition. If you suspect blockage, unscrew the clean-out plugs at each corner of the frame.

Place the frame in a pan of hot water for several minutes to melt any solidified oil or shortening.

Use a long, narrow bottlebrush, hot water and detergent to clean inside the frame. If necessary,

insert a straightened paper clip or similarly sized wire into the holes in the frame to remove any

5–1

Page 21

solidified shortening or other blockages. Rinse with hot water, dry thoroughly, and reinstall the

plugs before using.

Gasket

Clean-out Plugs

DANGER

Failure to reinstall the clean-out plugs in the Power Shower will cause hot oil to

spray out of the frypot during the filtering process, creating an extreme burn hazard

to personnel.

5.1.3 Clean the Frypot and Heating Elements – Weekly

DANGER

Never operate the appliance with an empty frypot. The frypot must be filled with

water or cooking oil before energizing the elements. Failure to do so will result in

irreparable damage to the elements and may cause a fire.

Boiling-Out the Frypot

Before the fryer is first used, it should be boiled out to ensure that residue from the manufacturing

process has been eliminated. Also, after the fryer has been in use for a period of time, a hard film of

caramelized vegetable oil will form on the inside of the frypot. This film should be periodically

removed by following the boil-out procedure that follows.

1. Before switching the fryer(s) ON, close the frypot drain valve(s), then fill the empty frypot with

a mixture of cold water and dishwashing detergent. Follow instructions on detergent container

when mixing.

2. Press the fryer ON/OFF switch to the ON position.

3. Set the temperature control knob to the lowest setting.

4. Simmer the solution for 45 minutes to one hour. Do not allow the water level to drop below the

bottom oil-level line in the frypot during the boil-out operation.

DANGER

Never leave the fryer unattended during the boil-out process. If the boil-out solution

boils over, turn the fryer off immediately and let the solution cool for a few minutes

before resuming the process.

5–2

Page 22

5. Turn the fryer ON/OFF switch(s) to the OFF position.

6. Add two gallons of water. Drain out the solution and clean the frypot(s) thoroughly.

WARNING

Do not drain boil-out solution into a shortening disposal unit, a built-in filtration unit,

or a portable filter unit. These units are not intended for this purpose, and will be

damaged by the solution.

7. Refill the frypot(s) with clean water. Rinse the frypot(s) twice, drain and dry with a clean towel.

Thoroughly remove all water from the frypot and elements before refilling the frypot with

cooking oil.

DANGER

Remove all drops of water from the frypot before filling with cooking oil. Failure to

do so will cause spattering of hot liquid when the oil is heated to cooking

temperature.

5.1.4 Clean Detachable Parts and Accessories – Weekly

Wipe all detachable parts and accessories with a clean, dry cloth. Use a clean cloth saturated with

detergent to remove accumulated carbonized oil on detachable parts and accessories. Rinse the parts

and accessories thoroughly with clean water and wipe dry before reinstalling.

5.2 Check Calibration of Temperature Control Knob – Monthly

1. After the cooking oil reaches operating temperature, let the heating elements cycle at least four

times (indicated by the HEAT light going out and coming back on).

2. Insert a thermometer or pyrometer probe near the temperature-sensing probe approximately five

inches deep into the cooking oil. When the heating elements cycle on for the fourth time, the

thermometer should read within ±5°F of the temperature control knob setting.

3. If the knob requires adjustment:

a. Loosen the setscrew in the control knob until the outer shell of the knob will rotate on the

insert inside the knob.

b. Rotate the outer shell of the knob until the index line on the knob aligns with the mark that

corresponds to the thermometer or pyrometer reading.

c. Hold the knob and tighten the setscrew.

d. Recheck the thermometer or pyrometer reading and the temperature control knob setting the

next time the HEAT light illuminates.

e. Repeat steps a through d until the thermometer or pyrometer reading and the knob setting

agree within 5°F.

5-3

Page 23

5.3 Annual/Periodic System Inspection

This appliance should be inspected and adjusted periodically by qualified service personnel as

part of the galley material maintenance management (3M) program.

Frymaster recommends that a Factory Authorized Service Technician inspect this appliance at

least annually as follows:

Fryer

• Inspect the cabinet inside and out, front and rear for excessive oil build-up and/or oil migration.

• Verify that the heating element wires are in good condition and that leads have no visible fraying

or insulation damage and that they are free of oil migration build-up.

• Verify that heating elements are in good condition with no carbon/caramelized oil build-up.

Inspect the elements for signs of extensive dry-firing.

• Verify that the tilt mechanism is working properly when lifting and lowering elements, and that

the element wires are not binding and/or chafing.

• Verify the heating-element amp-draw is within the allowed range as indicated on the appliance’s

rating plate.

• Verify that the temperature and high-limit probes are properly connected, tightened and

functioning properly, and that mounting hardware and probe guards are present and properly

installed.

• Verify that component box and contactor box components (i.e. controller, relays, interface

boards, transformers, contactors, etc.) are in good condition and free from oil migration build-up

and other debris.

• Verify that component box and contactor box wiring connections are tight and that wiring is in

good condition.

• Verify that all safety features (i.e. contactor shields, drain safety switches, reset switches, etc.)

are present and functioning properly.

• Verify that the frypot is in good condition and free of leaks and that the frypot insulation is in

serviceable condition.

• Verify that all wiring harnesses and wiring connections are tight and in good condition.

Built-In Filtration System

• Inspect all oil-return and drain lines for leaks and verify that all connections are tight.

• Inspect the filter pan for leaks and cleanliness. If there is a large accumulation of crumbs in the

crumb basket, instruct the work center supervisor/watch supervisor that the crumb basket must

be emptied into a fireproof container and cleaned daily.

5–4

Page 24

• Verify that all O-rings and seals (including those on the Power Shower and on quick-disconnect

fittings) are present and in good condition. Replace o-rings and seals if worn or damaged.

• Check filtration system integrity as follows:

− Verify that filter pan cover is present and properly installed.

− With the filter pan empty, place each oil return handle, one at a time, in the ON position. Verify

that the pump activates and that bubbles appear in the cooking oil (or that gurgling is heard from

the Power Shower port) of the associated frypot.

− Close all oil return valves (i.e., place all oil return handles in the OFF position). Verify proper

functioning of each oil return valve by activating the filter pump using the lever on one of the oil

return handle microswitches. No air bubbles should be visible in any frypot (or no gurgling

should be heard from the Power Shower ports).

− Verify that the filter pan is properly prepared for filtering, then drain a frypot of oil heated to

350°F into the filter pan and close the frypot drain valve. Place the oil return handle in the ON

position. Allow all cooking oil to return to the frypot (indicated by bubbles in the cooking oil or,

on units with Power Showers, cessation of oil flow from the Power Shower). Return the oil

return handle to the OFF position. The frypot should have refilled in no more than 2 minutes and

30 seconds.

5-5

Page 25

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 6: OPERATOR TROUBLESHOOTING

6.1 Introduction

This section provides an easy reference guide to some of the common problems that may occur

during the operation of this equipment. The troubleshooting guides that follow are intended to help

correct, or at least accurately diagnose, problems with this equipment. Although the chapter covers

the most common problems reported, you may encounter problems that are not covered. In such

instances, the Frymaster Technical Services staff will make every effort to help you identify and

resolve the problem.

When troubleshooting a problem, always use a process of elimination starting with the simplest

solution and working through to the most complex. Never overlook the obvious – anyone can forget

to plug in a cord or fail to close a valve completely. Most importantly, always try to establish a clear

idea of why a problem has occurred. Part of any corrective action involves taking steps to ensure

that it doesn’t happen again. If a controller malfunctions because of a poor connection, check all

other connections, too. If a fuse continues to blow, find out why. Always keep in mind that failure

of a small component may often be indicative of potential failure or incorrect functioning of a more

important component or system.

Before calling a service agent or the Frymaster HOTLINE (1-800-551-8633) or

contacting via e-mail at service@frymaster.com:

• Verify that power is connected and that circuit breakers are on.

• Verify that frypot drain valves are fully closed.

DANGER

Hot cooking oil will cause severe burns. Never attempt to move this appliance when

filled with hot cooking oil or to transfer hot cooking oil from one container to

another.

DANGER

This equipment should be disconnected from the electrical power supply when

servicing, except when electrical circuit tests are required. Use extreme care when

performing such tests.

This appliance may have more than one electrical power supply connection point.

Disconnect all power supplies before servicing.

Inspection, testing, and repair of electrical components should be performed by

authorized personnel only.

6-1

Page 26

6.2 Troubleshooting

6.2.1 Control and Heating Problems

Problem Probable Causes Corrective Action

A. Power cord is not plugged in or

circuit breaker is tripped.

B. Controller has failed.

Controller won't

activate.

C. Power supply component or

interface board has failed.

A. Drain valve is open.

B. Controller has failed.

Fryer does not heat.

C. One or more other components

have failed.

A. Plug power cord in and verify

that circuit breaker is not

tripped.

B. If available, substitute a

controller known to be working

for the suspect controller. If the

substitute controller functions

correctly, order a new controller.

C. If any of the components in the

power supply system (including

the transformer and interface

board) fail, power will not be

supplied to the controller and it

will not function. Determining

which component has failed is

beyond the scope of operator

troubleshooting. Call FASC.

A. This fryer is equipped with a

drain safety switch that prevents

the heating element from being

energized if the drain valve is

not fully closed. Verify that the

drain valve is fully closed.

B. If available, substitute a

controller known to be working

for the suspect controller. If the

substitute controller functions

correctly, order a new controller.

C. If the circuitry in the fryer

control system cannot determine

the frypot temperature, the

system will not allow the

element to be energized or will

de-energize the element if it is

already energized. If the

contactor, element, or associated

wiring fails, the element will not

energize. Determining which

specific component is

malfunctioning is beyond the

scope of operator

troubleshooting. Call FASC.

6-2

Page 27

Problem Probable Causes Corrective Action

This is normal. The standard

operational mode for the controller

is for the elements to cycle on and

Fryer repeatedly

cycles on and off

when first started.

Fryer does not heat

after filtering.

Fryer heats until

high limit trips with

heat indicator ON.

Fryer heats until

high limit trips

without heat

indicator ON.

Fryer stops heating

with heat indicator

ON.

Fryer is in melt-cycle mode.

Drain valve is open.

Temperature probe or controller has

failed.

Contactor or controller has failed.

The high limit thermostat or

contactor has failed.

off until the temperature in the

frypot reaches 180ºF (82ºC). The

purpose of the melt-cycle is to

allow controlled melting of solid

shortening to prevent scorching

and flash fires or damage to the

element.

This fryer is equipped with a drain

safety switch that prevents the

heating element from being

energized if the drain valve is not

fully closed. Verify that the drain

valve is fully closed.

If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly,

order a new controller. If

substitution of the controller does

not resolve the problem, the most

likely cause is a failed temperature

probe.

If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly,

order a new controller. If

substitution of the controller does

not resolve the problem, the most

likely cause is a contactor failed in

the closed position.

The fact that the heat indicator is

ON indicates that the controller is

functioning properly and is calling

for heat. The high limit thermostat

functions as a normally closed

switch. If the thermostat fails, the

"switch" opens and power to the

elements is shut off. If the

contactor fails to close, no power is

supplied to the elements.

Determining which component has

failed is beyond the scope of

operator troubleshooting. Call

FASC.

6-3

Page 28

6.2.2 Error Messages and Display Problems

Problem Probable Causes Corrective Action

This in an indication of a

malfunction in the temperature

Controller trouble

light ON.

Controller trouble

light ON and heating

mode light ON.

6.2.3 Filtration Problems

Oil temperature above acceptable

range or a problem with the

temperature measuring circuitry.

Open drain valve or problem with

latching circuits

measuring or control circuitry,

including a failure of the high limit

thermostat. Determining the

specific problem is beyond the

scope of operator troubleshooting.

Shut the fryer down immediately.

Verify that the drain valve is fully

closed. The fryer will not function

if the drain valve is not fully

closed. If the drain valve is fully

closed, the problem is within the

latching circuitry and is beyond the

scope of operator troubleshooting.

Problem Probable Causes Corrective Action

A. Verify that the power cord is

Filter pump won't

start.

A. Power cord is not plugged in or

circuit breaker is tripped.

B. Pump motor has overheated

causing the thermal overload

switch to trip.

C. Blockage in filter pump.

Test: Close the drain valve and

pull the filter pan out from the

fryer. Activate the pump. If the

pump motor hums for a short time

then stops, the probable cause is

blockage of the pump itself.

(continued on following page)

fully plugged in. If so, verify

that circuit breaker is not

tripped.

B. If the motor is too hot to touch

for more than a few seconds, the

thermal overload switch has

probably tripped. Allow the

motor to cool at least 20

minutes then press the Pump

Reset Switch.

C. Pump blockages are usually

caused by sediment buildup in

the pump due to improperly

sized or installed filter paper

and failure to use the crumb

screen.

6-4

Page 29

Problem Probable Causes Corrective Action

Filter pump runs

but oil does not

return to frypot and

there is no bubbling

oil or air coming

from the Power

Shower.

Filter pump runs,

but oil return is very

slow and bubbling

oil comes out of the

Power Shower.

Power Shower not

spraying properly.

Blockage in filter pan suction tube.

Test: Close the drain valve and pull

the filter pan out from the fryer.

Activate the pump. If the air or

bubbling oil comes out of the Power

Shower, there is a blockage in the

filter pan suction tube.

A. Improperly installed filter pan

components.

B. Attempting to filter with oil or

shortening that is not hot enough.

A. Missing or worn Power Shower

gasket.

B. Clogged openings in Power

Shower frame.

The blockage may be caused by

sediment buildup or, if solid

shortening is used, solidified

shortening in the tube. Use a thin,

flexible wire to remove the

blockage.

A. Verify that filter screen is in

bottom of pan with paper top of

screen.

Verify that o-rings are present

and in good condition on filter

pan connection fitting.

B. In order to properly filter, the

oil or shortening should be at

or near 350ºF (177ºC). At

temperatures lower than this,

the oil becomes too thick to

pass through the filter medium

easily, resulting in much slower

oil return and eventual

overheating of the filter pump

motor. Make sure oil is at or

near frying temperature before

draining oil into filter pan.

A. Verify that the gasket is present

and in good condition.

B. If the Power Shower is not

cleaned on a routine basis,

sediment will eventually block

the small holes around the

edges of the frame. Also, when

using solid shortening, if the

Power Shower is not allowed to

drain completely, the

shortening will solidify in the

holes and may fill the frame.

Completely drain the Power

Shower after each filtering and

clean regularly in accordance

with the instructions in Chapter

5 of this manual.

6-5

Page 30

6.3 Replacing the Controller or Controller Wiring Harness

1. Disconnect the fryer from the electrical supply. For fryers that have 90º-angle topcaps, remove

the two screws in the upper corners of the control panel and swing the panel open from the top,

allowing it to rest on its hinge tabs. The bezel on fryers with rounded topcaps is held in place by

tabs at the top and bottom. Slide the bezel up to disengage the lower tabs. Then slide the bezel

down to disengage the upper tabs. Remove the top two screws holding the controller to the

control panel frame. The controller will hinge down to access the 15-pin connector on the back.

2. Disconnect the wiring harness from the back of the controller. If replacing the harness,

disconnect it from the interface board. If replacing the controller, disconnect the ground wire

and remove the controller by lifting it from the hinge slots in the control panel frame.

3. Reverse the procedure to install a new controller or wiring harness.

15-Pin Connector

Ground Wire Terminal

6-6

Page 31

NAVY SURFACE SHIP ELECTRIC FRYERS

CHAPTER 7: SERVICE PROCEDURES

7.1 General

Before performing any maintenance on this equipment, disconnect the fryer from the electrical

power supply.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to

facilitate re-assembly.

7.2 Replacing a Controller

1. Remove the two screws from the upper corners of the control panel on fryers that have 90º angle

topcaps. The controller bezel on fryers that have rounded topcaps is held in place by tabs at the

top and bottom. Slide the bezel up to disengage the lower tabs. Then slide the bezel down to

disengage the upper tabs. If applicable, remove the top two screws holding the controller to the

control panel frame. The control panel is hinged at the bottom and will swing open from the top.

Remove screws in upper

corners of cont ro l panel

and swing panel down.

2. Unplug the wiring harness from the connector on the back of the controller and disconnect the

grounding wire from terminal adjacent to the connector. Remove the control panel assembly by

lifting it from the hinged slots in the control panel frame.

15-Pin Connector

Ground Wire Terminal

3. Remove the controller from the control panel assembly and install the replacement controller.

Reinstall the control panel assembly by reversing steps 1 and 2.

7-1

Page 32

7.3 Replacing Component Box Components

1. Remove the control panel (see steps 1 and 2 of section 7.2 on preceding page).

2. Unplug the wiring harness from the 15-pin connector on the interface board and disconnect the

grounding wire from terminal adjacent to the 15-pin connector on the back of the controller.

Remove the control panel assembly by lifting it from the hinge slots in the control panel frame.

3. Disconnect the wiring from the component to be replaced, being sure to make a note of where

each wire was connected.

NOTE: If replacing the interface board, connectors J1 and J2 must also be disconnected from

the 12-pin connectors on the rear of the component box, directly behind the interface board.

4. Dismount the component to be replaced and install the new component, being sure that any

required spacers, insulation, washers, etc. are in place.

NOTE: If more room to work is required, the control panel frame and top cap assembly may be

removed by removing the hex head screws that secure it to the fryer cabinet (see illustration

below). If this option is chosen, all control panel assemblies must be removed per steps 1 and 2

above. The cover plate on the lower front of the component box may also be removed if desired.

Removing the component box itself from the fryer is not recommended due to the difficulty

involved in disconnecting and reconnecting the oil-return valve rods, which pass through

openings in the component box.

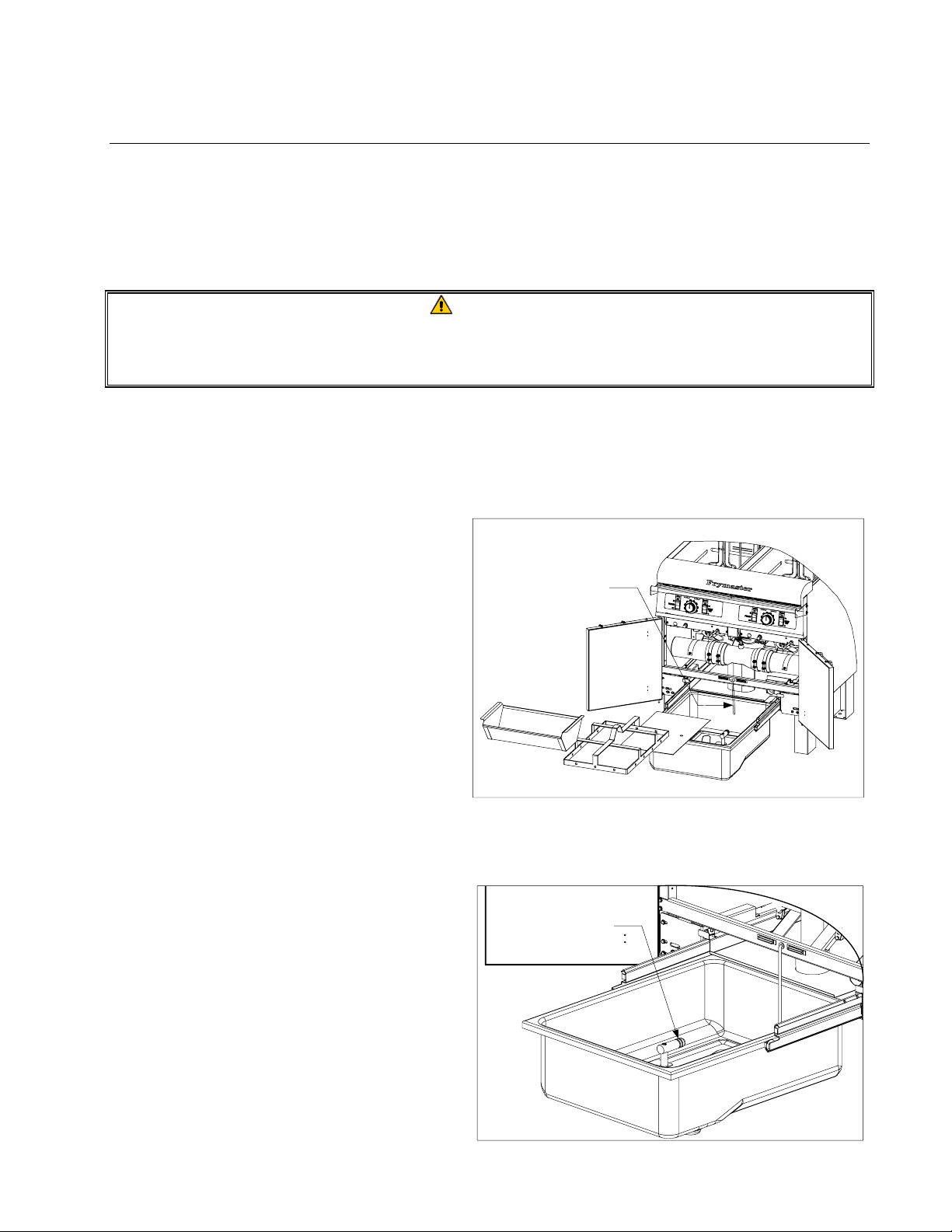

Remove these three

screws at each end.

Remove these two screws

from the center supports.

Removing the Control Panel Frame and Top Cap Assembly

5. Reconnect the wiring disconnected in step 3, referring to your notes and the wiring diagrams on

the fryer door to ensure that the connections are properly made. Also, verify that no other wiring

was disconnected accidentally during the replacement process.

6. Reverse steps 1 and 2 to complete the replacement and return the fryer to service.

7-2

Page 33

7.4 Replacing a Temperature Probe or High-Limit Thermostat

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit

(SDU) or other appropriate container.

DANGER

DO NOT drain more than one full frypot into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear

of the fryer.

3. Remove the tilt housing and back panels from the fryer. The tilt housing must be removed first in

order to remove the upper back panel. To remove the tilt housing, raise the elements and allow

them to rest on the basket support racks as shown in the photo below.

Next, remove the hex head screws from the rear edge of the housing. The housing can then be

lifted straight up and off the fryer. Lift up on the upper back panel to disengage the tabs on its

upper corners from the cutouts in the fryer frame.

4. Disconnect the wire harness at connector C6 and, using a pin pusher, disconnect the probe leads

or high-limit leads from the connector.

5. If replacing a temperature probe, remove the screw securing the probe bracket to the element

and slide the bracket off the element and probe. Pull the probe out of the tilt housing assembly,

install the replacement probe, and reattach the element bracket. Secure the upper portion of the

probe with a replacement metal wire tie.

Probe Leads

Probe Bracket

Metal Wire Ti e

If replacing a high-limit thermostat, unscrew the thermostat to be replaced. Apply Loctite

™

PST

567 or equivalent sealant to the threads of the replacement and screw it securely into the frypot.

7-3

Page 34

6. If a temperature probe was replaced, insert the probe leads into the connector (see left

illustration below). For full-vat units or the left half (as viewed from the rear of the fryer) of a

dual-vat unit, the red lead goes into position 6 and the white into position 7. For the right half of

a dual-vat unit (as viewed from the rear of the fryer), the red lead goes into position 12 and the

white into position 13.

Rib marks Position 1

13

7

6

12

Probe Lead Positions High-Limit Lead Positions

10

4

11

5

If a high-limit thermostat was replaced, insert the leads into the connector (see right illustration

above). For full-vat units or the left half of a dual-vat unit (as viewed from the rear of the fryer),

the leads go into positions 4 and 5 of the connector. For the right half of a dual-vat unit (as

viewed from the rear of the fryer), the leads go into positions 10 and 11. In either case, polarity

does not matter.

7. Reinstall the back panels and tilt housing to complete the installation, then reverse steps 1 and 2

to return the fryer to service.

7.5 Replacing a Heating Element

1. Perform steps 1-3 of section 7.4, Replacing a Temperature Probe.

2. On dual-vat fryers, and on full-vat fryers where the temperature probe is attached to the element

being replaced, disconnect the wire harness containing the probe wiring (connector C6). Using a

pin pusher, disconnect the probe wires from the connector.

3. On the front of the contactor box, disconnect the 6-pin connector for the left element (as viewed

from the front of the fryer) or the 9-pin connector for the right element and pull the harness out

through the rear of the fryer. Press in on the tabs on each side of the connector while pulling

outward on the free end to extend the connector and release the element leads (see photo below).

Pull the leads out of the connector and out of the plastic wire loom.

4. Raise the element to the full up position and disconnect the element springs.

7-4

Page 35

5. Remove the nuts and machine screws that secure the element to the tilt plate assembly and pull

the element out of the frypot. NOTE: Full-vat elements consist of two dual-vat elements

clamped together. For full-vat units, remove the element clamps before removing the nuts and

machine screws that secure the element to the tilt plate assembly.

6. If applicable, recover the probe bracket and probe from the element being replaced and install

them on the replacement element, then install the replacement element in the frypot, securing it

with the nuts and screws removed in Step 5.

7. Route the element leads through the wire loom to prevent chafing and press the pins into the

connector in accordance with the diagram below, then close the connector to lock the leads in

place. NOTE: It is critical that the wires be routed through the loom to prevent chafing.

Pip marks Position 1

1

2

3

1

2

3

5

6

5L 4L6L 1L2L3L

6

4

5R 4R6R 1R2R3R

4

5

789

8. Insert the element connector into the receptacle on the front of the contactor box, ensuring that

the latches lock.

9. If disconnected in step 2, insert the temperature probe leads into the wiring harness connector

(see illustration below). For full-vat units or the right half of a dual-vat unit, the red lead goes

into position 6 and the white into position 7. For the left half of a dual-vat unit, the red lead goes

into position 12 and the white into position 13. NOTE: Right and left refer to the fryer as

viewed from the rear.

13

7

Rib marks Position 1

6

12

10. If disconnected in step 2, reconnect connector C6 of the wiring harness.

11. Reconnect the element springs and lower the element back down onto the basket rack.

12. Reinstall the tilt housing and back panels, reposition the fryer under the exhaust hood, and

reconnect it to the electrical power supply.

7-5

Page 36

7.6 Replacing Contactor Box Components

1. If replacing a contactor box above the built-in filter system, remove the filter pan and lid from

the unit. Drain the frypots into a Shortening Disposal Unit (SDU) or other appropriate container.

If replacing a contactor box in a non-filter unit, drain the frypot above the box into a Shortening

Disposal Unit (SDU) or other appropriate container.

DANGER

DO NOT drain more than one full frypot into the SDU at one time.

2. Disconnect the fryer from the electrical power supply.

3. Unplug the wiring harnesses from the contactor box to be serviced.

4. Remove the two screws that secure the box in place.

Remove these screws t o di s mount the left c on tactor box.

The right contacto r box is s e c u red i n a si milar manner.

5. Carefully lower the box to the floor and pull it out the front of the fryer. Remove the top cover

to access contactors and other components.

6. After performing necessary service, reverse steps 1-5 to return the fryer to operation.

7.7 Replacing a Frypot

1. Drain the frypot into the filter pan or, if replacing a frypot over the filter system, into a

Shortening Disposal Unit (SDU) or other appropriate container. If replacing a frypot over the

filter system, remove the filter pan and lid from the unit.

DANGER

DO NOT drain more than one full frypot into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to both the

front and rear.

3. Remove the two screws from the upper corners of the control panels and allow them to swing

down (see illustration and photo on page 7-1).

4. Unplug the wiring harnesses and ground wires from the backs of the controllers. Remove the

controllers by lifting them from the hinge slots in the control panel frame.

7-6

Page 37

5. Remove the tilt housing and back panels from the fryer. The tilt housing must be removed first in

order to remove the upper back panel. To remove the tilt housing, raise the elements and allow

them to rest on the basket support racks (see photo on page 7-3).

Next, remove the hex head screws from the rear edge of the housing. The housing can then be

lifted straight up and off the fryer. Lift up on the upper back panel to disengage the tabs on its

upper corners from the cutouts in the fryer frame.

6. Dismount the top cap by removing the hex head screws at each end that secure it to the control

panel frame.

7. Remove the hex head screw that secures the front of the frypot to the cabinet cross brace.

8. Remove the top-connecting strip that covers the joint with the adjacent frypot.

9. Open the drain tube cleanout covers, unscrew the retainer nuts from the drain valve nipples, and

remove the tube assembly from the fryer. (If replacing a frypot over the built-in filtration

system, unscrew the vacuum-breaker tube fitting from the drain tube assembly also.)

10. Remove the covers from the drain safety switch(es) and disconnect the switch wiring at the

switch(es).

11. At the rear of the fryer, unplug the C6 connector and, using a pin pusher, disconnect the high-

limit thermostat leads.

12. Disconnect the oil return flexline(s) at the frypot end(s).

13. Raise the elements to the full up position and disconnect the element springs.

14. Remove the machine screws and nuts that secure the tilt plate and element assembly to the

frypot. Carefully lift the tilt plate and element assembly from the frypot and secure it to the cross

brace on the rear of the fryer with wire ties or tape.

15. Carefully lift the frypot from the fryer and place it upside down on a stable work surface.

16. Recover the drain valve(s), oil return flexline connection fitting(s), and high-limit thermostat(s)

from the frypot. Apply Loctite™ PST 567 or equivalent sealant to the threads of the recovered

parts and install them in the replacement frypot.

17. Carefully lower the replacement frypot into the fryer. Reinstall the hex head screw removed in

step 7 to attach the frypot to the fryer.

18. Position the tilt housing and element assembly in the frypot and reinstall the machine screws and

nuts removed in step 14.

19. Reconnect the oil return flexlines to the frypot, and replace aluminum tape, if necessary, to

secure heater strips to the flexlines.

20. Insert the high-limit thermostat leads disconnected in step 11 (see illustration on page 7-4 for pin

positions).

7-7

Page 38

21. Reconnect the drain safety switch wiring to the switch(es) in accordance with the diagram below

then reinstall the switch covers.

RIGHT

58C BLK

57C RED

55C BLK

56C RED

DRAIN SAFETY SWITCH

LEFT

DRAIN SAFETY SWITCH

(DUAL-VAT ONLY)

22. Reinstall the drain tube assembly.

23. Reinstall the tilt housing and back panels, top cap, and top connecting strip.

24. Reinstall controllers in the control panel frame and reconnect the wiring harnesses and ground

wires.

25. Reposition the fryer under the exhaust hood and reconnect it to the electrical power supply.

7.8 Built-in Filtration System Service Procedures

7.8.1 Filtration System Problem Resolution

One of the most common causes of filtration problems is placing the filter paper on the bottom of the

filter pan rather than over the filter screen.

CAUTION

Ensure that filter screen is in place prior to filter paper placement and filter pump

operation. Improper screen placement is the primary cause of filtration system

malfunction.

Whenever the complaint is “the pump is running, but no oil is being filtered,” check the installation

of the filter paper, and ensure that the correct size is being used. While you are checking the filter

paper, verify that the O-ring on the bottom of the filter pan is present and in good condition. A

missing or worn O-ring allows the pump to take in air and decreases its efficiency. Also, oil leaks

on the floor each time a vat is drained.

If the pump motor overheats, the thermal overload will trip and the motor will not start until it is

reset. If the pump motor does not start, press the red reset switch (button) located on the rear of the

motor.

If the pump starts after resetting the thermal overload switch, then something is causing the motor to

overheat. A major cause of overheating is when several frypots are filtered sequentially, thus

overheating the pump and motor. Allow the pump motor to cool at least 30 minutes before resuming

operation. Pump overheating can be caused by:

7-8

Page 39

• Solidified shortening in the pan or filter lines, or

• Attempting to filter unheated oil or shortening (cold oil and shortening are more viscous,

overloading the pump motor and causing it to overheat).

If the motor runs but the pump does not,

Sediment Particle

there is a blockage in the pump. Incorrectly

sized or installed paper/pads will allow food

particles and sediment to pass through the

filter pan and into the pump. When sediment

Oil Flow

enters the pump, the gears bind, causing the

motor to overload, again tripping the thermal

overload. Shortening that has solidified in

the pump will also cause it to seize, with the

same result.

A pump seized by debris or hard shortening

can usually be freed by manually moving the

Sediment Particle

Up for reverse

gears with a screwdriver or other instrument.

Disconnect power to the filter system,

remove the input plumbing from the pump,

and use a screwdriver to manually turn the

Down for forward

gears.

● Turning the pump gears in reverse will

release a hard particle.

● Turning the pump gears forward will push softer objects and solid shortening through the

pump and allow free movement of the gears.

Incorrectly sized or installed paper/pads will also allow food particles and sediment to pass through

and clog the suction tube on the bottom of the filter pan. Particles large enough to block the suction

tube may indicate that the crumb tray is not being used. Pan blockage can also occur if shortening is

left in the pan and allowed to solidify. Blockage removal can be accomplished by forcing the item

out with an auger or drain snake. Compressed air or other pressurized gases should not be used to

force out the blockage.

7.8.2 Replacing the Filter Motor, Filter Pump, and Related Components

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit

(SDU) or other appropriate container.

DANGER

DO NOT drain more than one full frypot into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to both the

front and rear.

3. Remove the two lower back panels, unplug the wiring harnesses from the contactor boxes, and

remove the two screws that secure one of the boxes in place (it doesn’t matter which one; see

7-9

Page 40

illustration on page 7-6). NOTE: If you remove the screws from both boxes at the same time,

the boxes will jam against each other and neither can be removed.

4. Carefully lower the box to the floor and pull it out the front of the fryer. Remove the remaining

box following the same procedure.

5. Disconnect the two flexlines running to the oil-return manifold at the rear of the fryer. Remove

the nut and bolt that secures the bridge to the oil-return manifold.

Disconnect Vacuum-Breaker

Disconnect Pump

Solenoid flexline here.

Solenoid flexline here.

6. Disconnect the pump suction flexline at the filter pan connection end.

Disconnect Pump

Suction flexline here.

7. Remove the cover plate from the front of the motor and disconnect the motor wires.

7-10

Page 41

8. Unplug the 15-pin connector from the rear of the left component box and, using a pin pusher,

disconnect the solenoid valve wires (pins 4, 6, 10 and 12). NOTE: If the vacuum-breaker

solenoid valve is connected to the manifold rather than the pump, its wires (pins 4 and 6) do not

need to be disconnected.

9. Remove the two nuts and bolts that secure the front of the bridge to the cross brace and carefully

slide the bridge rearward off the cross brace until its front end can be lowered to the floor. Be

careful not to let the rear of the bridge slip off the manifold at this point. NOTE: In some early

production units, the bridge will not slide far enough to the rear to clear the front brace. In such

cases, the front brace must be removed. It is held in place by two hex head screws on each end

and a nut and bolt inside the brace near each end.

10. Get a good grip on the bridge, carefully pull it forward off the oil-return manifold, and lower the

entire assembly to the floor. Once on the floor, pull the assembly out the front of the fryer.

11. When required service has been completed, reverse steps 6-12 to reinstall the bridge. NOTE:

The black motor wires go on the top terminal, the white on the bottom. The pump solenoid valve

wires go in positions 10 and 12 of the 15-pin connector; the vacuum-breaker solenoid valve

wires go in positions 4 and 6. In both cases, polarity does not matter.

12. Once the bridge is back in place, reverse steps 4 and 5 to reinstall the contactor boxes.

13. Reconnect the unit to the electrical power supply, and verify that the pump is functioning

correctly (i.e., when a filter handle is placed in the ON position, the motor should start and there

should be strong suction at the intake fitting and outflow at the power shower or rear flush port).

14. When proper operation has been verified, reinstall the back panels and the filter pan and lid, and

return the fryer to service.

7.8.3 Replacing the Filter Transformer or Filter Relay