Page 1

01-00

U.S. Navy Electric Fryers

*8195184*

Installation, Operation, Service and Parts Manual

FPH17, H14/H17/H22, H14 Sub Series

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

819-5184

Page 2

FRYMASTER ELECTRIC FRYERS ARE MANUFACTURED FOR USE WITH THE TYPE

VOLTAGE SPECIFIED ON THE FRYER RATING PLATE LOCATED ON THE FRYER

DOOR. FOR PROPER INSTALLATION PROCEDURES IN THE UNITED STATES,

REFER TO THE LATEST EDITION OF THE NATIONAL ELECTRIC CODE

ANSI/N.F.P.A. NO. 70; IN CANADA, CANADIAN ELECTRICAL CODE PART 1, CSA-22.1.

INFORMATION ON THE CONSTRUCTION AND INSTALLATION OF VENTILATING

HOODS MAY BE OBTAINED FROM THE LATEST EDITION OF THE "STANDARD FOR

THE INSTALLATION OF EQUIPMENT FOR THE REMOVAL OF SMOKE AND

GREASE LADEN VAPORS FROM COMMERCIAL COOKING EQUIPMENT, "N.F.P.A.

NO. 96. COPIES OF THESE ELECTRICAL STANDARDS ARE AVAILABLE FOR THE

NATIONAL FIRE PROTECTION ASSOCIATION, BATTERY MARCH PARK, QUINCY,

MASS. 02269

WARNING

In the event of a power failure, the fryer(s) will automatically shut down. Should this occur, turn

the power switch off. Do not attempt to start the fryer(s) until power is restored.

WARNING!

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result from

contact with hot oil, slips or falls.

WARNING!

The crumb tray must be emptied into a fireproof container at the end of each day. Some food

particles can spontaneously combust if left in certain shortening.

THE FRYER(S) MUST BE INSTALLED WITH A SIX-INCH (15 cm) CLEARANCE AT BOTH

SIDES AND ADJACENT TO COMBUSTIBLE CONSTRUCTION. A MINIMUM OF 24INCHES (60 cm) SHOULD BE PROVIDED AT THE FRONT OF THE FRYER(S) DOOR.

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

THIS MANUAL SHOULD BE KEPT IN A CONVENIENT LOCATION AND REFERRED TO

WHEN ANY PROBLEM OCCURS AND FOR FUTURE REFERENCE.

Page 3

TABLE OF CONTENTS

Page #

1. PARTS ORDERING/SERVICE INFORMATION 1-1

2. IMPORTANT INFORMATION 2-1

3. INSTALLATION INSTRUCTIONS 3-1

4. ELECTRICAL SERVICE CONNECTIONS 4-1

5. POWER REQUIREMENTS 5-1

6. OPERATING INSTRUCTIONS 6-1

7. DRAINING AND MANUAL FILTERING INSTRUCTIONS 7-1

8. ANALOG CONTROLLERS 8-1

9. TROUBLESHOOTING GUIDE 9-1

10. SERVICE PROCEDURES 10-1

11. PREVENTIVE MAINTENANCE 11-1

12. *FILTRATION (BUILTIN) 12-1

13. *CARE AND CLEANING FILTER SYSTEM 13-1

14. *BUILT-IN FILTRATION TROUBLESHOOTING GUIDE 14-1

15. WIRING DIAGRAMS 15-1

16. PARTS LISTS 16-1

*For FPH17 only

Page 4

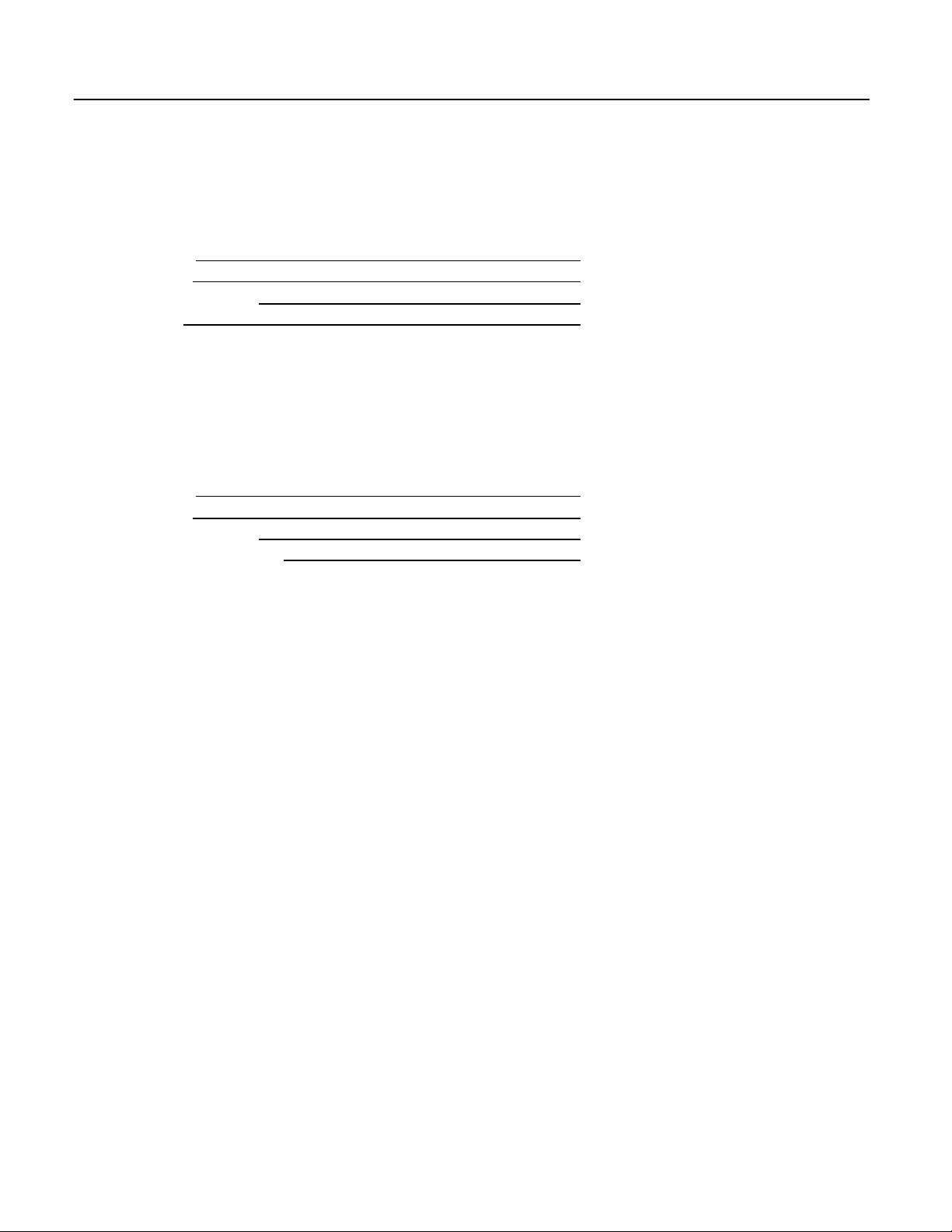

CHAPTER 1: PARTS AND SERVICE INFORMATION

Parts orders must be placed directly with your local Frymaster Parts Distributor. A list of Frymaster Parts

Distributors was included with the fryers when shipped from the factory. If you do not have access to this

list, please contact the Frymaster Technical Services Department at 1-800-551-8633 or 1-318-865-1711.

To help speed your order, the following information is required:

Model Number:

Serial Number:

Type of Gas or Voltage:

Part Number:

Service information may be obtained by calling your local Factory Authorized Service Center. A list of

these agencies was packed with your fryer.

Service information may also be obtained by calling the Frymaster Technical Services Department.

When calling, please have the following information available:

Model Number:

Serial Number:

Type of Gas or Voltage:

Nature of Service Problem:

And other information that may be helpful in solving your service problem.

Note: Retain and store this manual in a safe place for future use. Additional copies may be obtained

from the Frymaster Technical Services Department.

1

Page 5

CHAPTER 2: IMPORTANT INFORMATION

2.1. Introduction

The H14, H17, H22 Series are deep-well, single open-pot fryers. FPH14, FPH17, FPH22 filter models

come in single, double, triple, and four-fryer configurations. The H14 for use in submarines is a single

only. Read the instructions in this manual thoroughly before attempting to install, operate or service

this equipment.

2.2. Operating, Installation, and Service Personnel

Operating information for FRYMASTER equipment has been prepared for use by qualified and/or

authorized operating personnel only.

All installation and service on FRYMASTER equipment must be performed by qualified, certified,

licensed, and/or authorized installation or service personnel.

Service may be obtained by contacting your local Factory Authorized Service Center.

2.3. Definitions

Qualified and/or Authorized Operating Personnel

Qualified or authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions or have had previous

experience with the operation of equipment covered in this manual.

Qualified Installation Personnel

Qualified installation personnel are: individuals, a firm, corporation, or a company which either in

person or through a representative are engaged in, and are responsible for the installation of electrical

wiring from the electric meter, main control box, or service outlet to the electrical appliance. Qualified

installation personnel must be experienced in such work, be familiar with all electrical precautions

required, and have complied with all requirements of applicable national, European Community and

local codes.

Qualified Service Personnel

Qualified service personnel are those familiar with FRYMASTER equipment and have been

authorized by THE FRYMASTER CORPORATION. All authorized service personnel are required to

be equipped with a complete set of service parts manuals and stock a minimum amount of parts for

FRYMASTER equipment.

A list of Frymaster Factory Authorized Service Centers is included with the fryer when shipped from

the factory. If you do not have access to this list, please contact the Frymaster Customer Service

Department, using the number listed on the front of this manual. Failure to use qualified service

personnel will void the Frymaster warranty.

2-1

Page 6

CHAPTER 2: IMPORTANT INFORMATION

2.4. Shipping Damage Claim Procedure

Please note that the FRYMASTER equipment was carefully inspected and packed by skilled personnel

before leaving the factory. The transportation company assumes full responsibility for safe delivery

upon acceptance of the equipment.

What to do if equipment arrives damaged:

1. File claim for damages immediately---regardless of extent of damage.

2. Visible loss or damage---be sure this is noted on the freight bill or express receipt and is signed

by the person making the delivery.

3. Concealed loss or damage---if damage is unnoticed until equipment is unpacked, notify freight

company or carrier immediately and file a concealed damage claim. This should be done within

15 days of date of delivery. Be sure to retain container for inspection.

FRYMASTER DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT

2-2

Page 7

CHAPTER 3: INSTALLATION INSTRUCTIONS

CAUTION

CAUTION

PROPER INSTALLATION IS ESSENTIAL TO EFFICIENT TROUBLE-FREE OPERATION.

ANY ALTERATION OF THE EQUIPMENT VOIDS THE FRYMASTER WARRANTY.

Before installing the newly arrived equipment, inspect it carefully for visible and concealed damage.

See Shipping Damage Claim Procedure, Section 2.4.

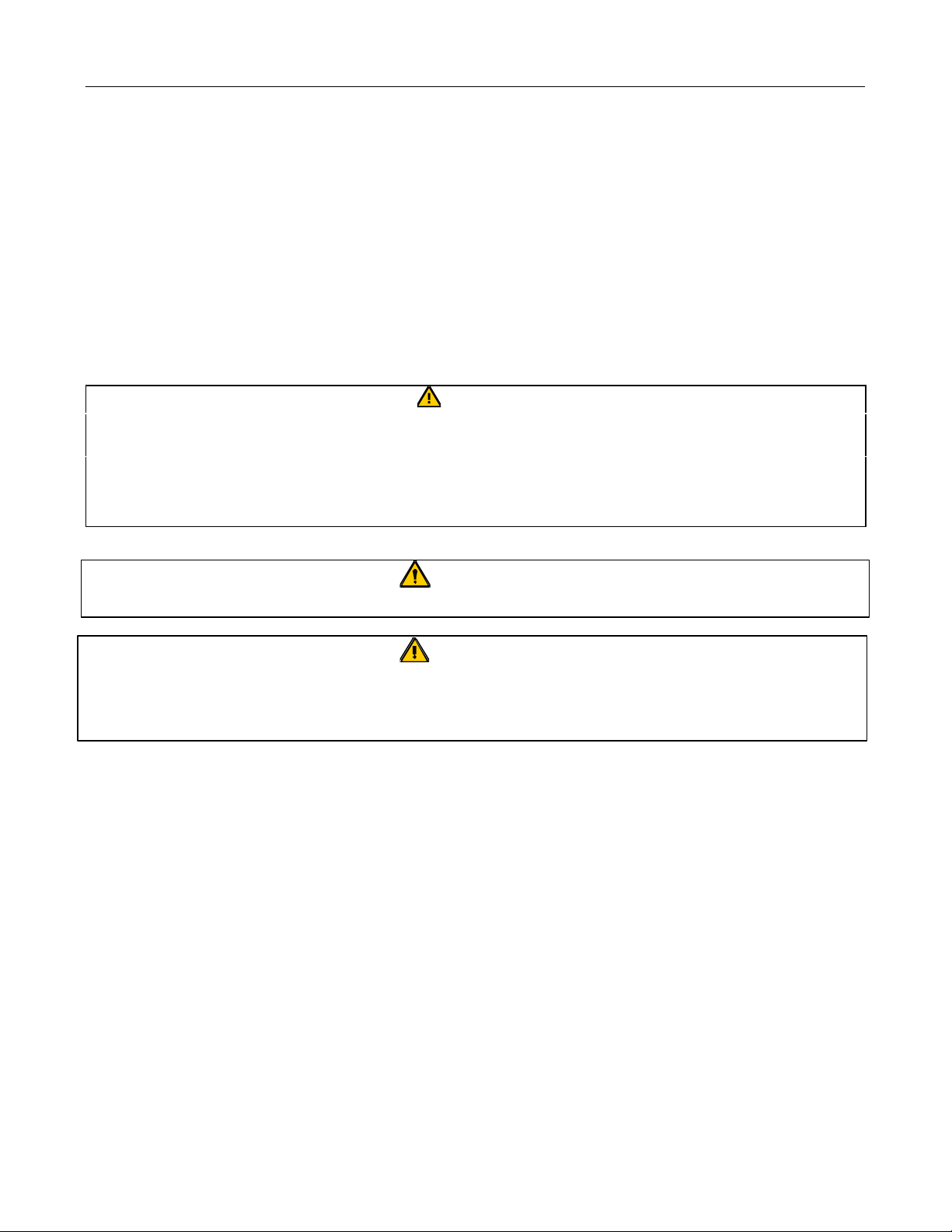

3.1 Fryer Leg Information

The following drawings give the leg patterns for the FPH17 in two, three and four- vat configurations, which are

commonly placed on ships and the single-vat fryer, which is used on submarines. (See Page 3-3, Sub Fryer

base).

CAUTION

If you need to relocate a fryer installed with legs, remove all the weight from each leg before moving.

If a leg becomes damaged, contact your service agent for immediate repair or replacement.

Any flashing on or around the cap covering the top of the heating elements must be removable.

Prior to installation, make sure the foundation is adequate to secure the fryer front and rear. Depending on

existing conditions, most foundations can be modified to suit the fryer’s base plate.

3-1

Page 8

CHAPTER 3: INSTALLATION INSTRUCTIONS

62.55

2.470

7.119

17.490

26.320 31.180

BACK OF FRYER UNIT

31.61 31.61

FPH417

FRONT HANDLE

35.76

35.76

7.119

Mounting Holes

.625

Six Places

33.45

17.516

7.229

27.570 14.400

BACK OF FRYER UNIT

22.68

32.66

22.68

33.24

FPH317

FRONT HANDLE

3-2

Page 9

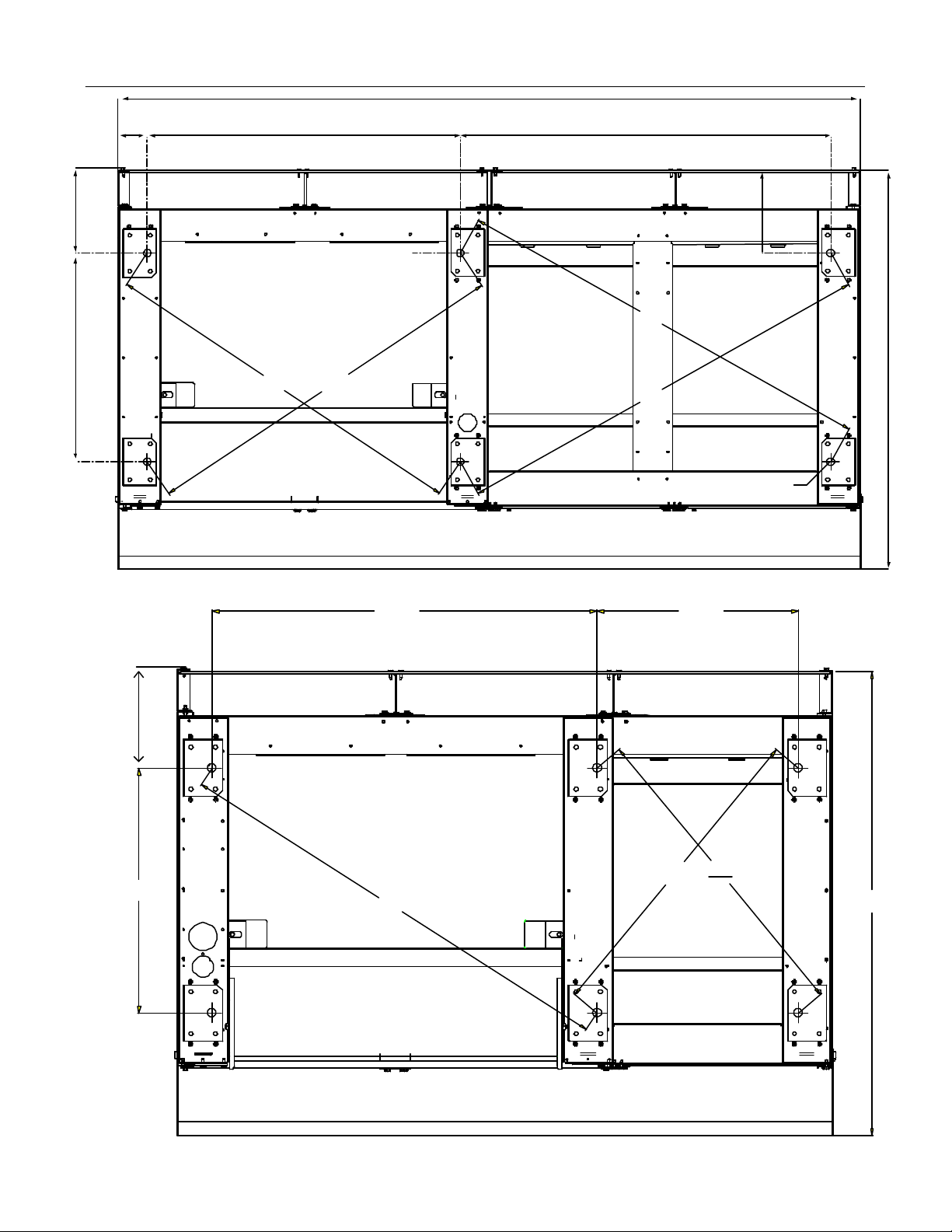

CHAPTER 3: INSTALLATION INSTRUCTIONS

MOUNTING HOLES

Ø .625

4 PLACES

TYPICAL

7.098

TYPICAL

2.470

26.316

BACK OF FRYER UNIT

31.62

31.62

17.515

33.39

15.67

FRONT HANDLE

FPH217

31.45

33.38

28.29

17.534 6.913

2.465

20.48

10.580

20.48

FRONT HANDLE

BACK

OF

FRYER UNIT

H14/17 Single for Surface Ship

3-3

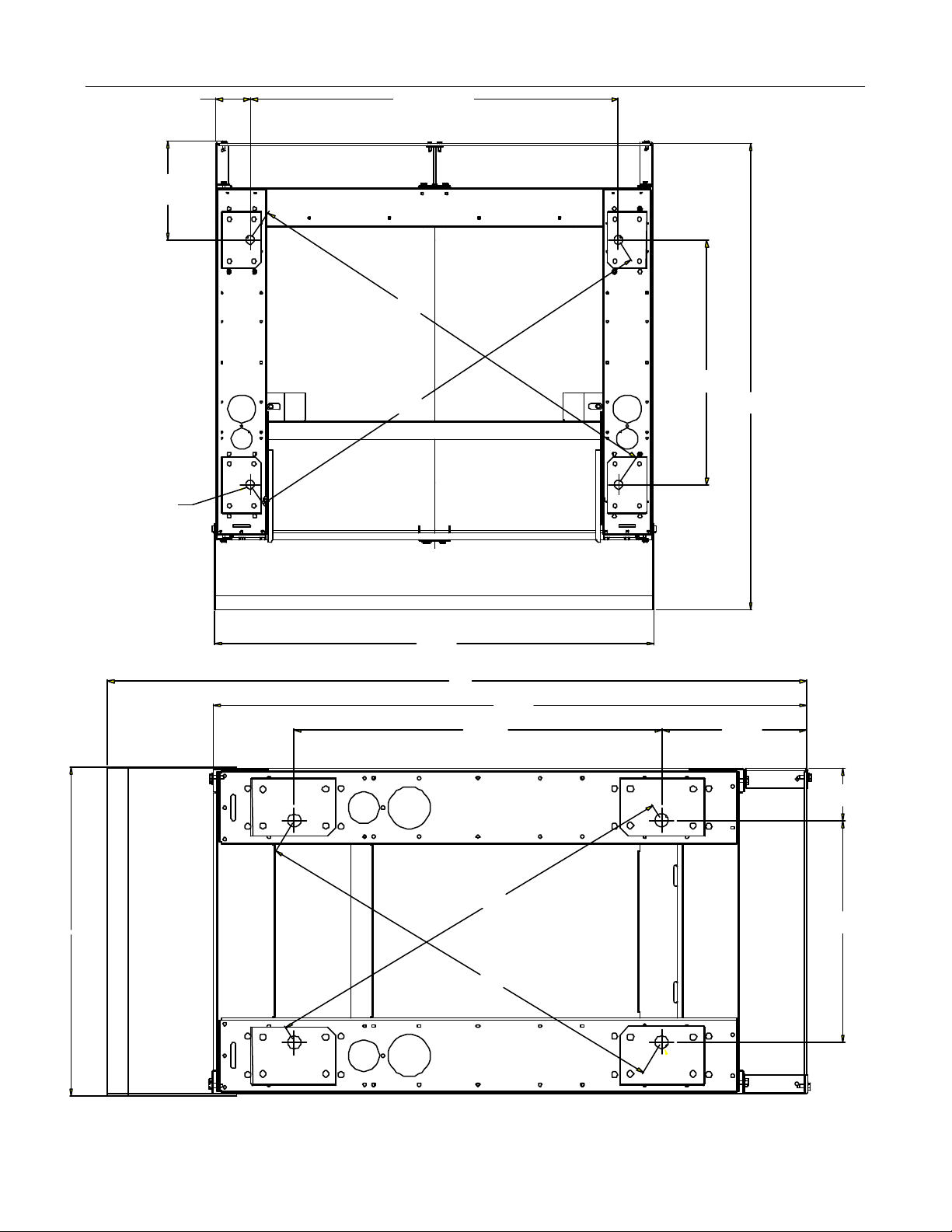

Page 10

Note:

In most

Note:

If nut cannot be secured to bolt

FRONT

CHAPTER 3: INSTALLATION INSTRUCTIONS

25.00

22.00 1.37

1.50

cases, the

contactor box

in a Sub Fryer

25.06

12.00

25.06

will have to be

removed to

secure

15.00

baseplate to

existing

foundation.

MOUNTING HOLES

Navy Sub Fryer

Ø.375

4 PLACES

from deck, the hole will have to be

drilled and tapped.

If it is necessary to install legs, use the instructions provided in the accessories package shipped with

the fryer.

3-4

Page 11

CHAPTER 4: ELECTRICAL SERVICE CONNECTIONS

Connections should be made by means of an approved, flexible-metallic or rubber-covered electrical

cable and quick-disconnect plug. The fryers may be installed with “hard-wired” connections, but use

of quick-disconnect plugs will facilitate service if required. This connection should be made to the

fryer power input terminal block. The terminal block is located in the contactor box in the bottom of

the fryer. CONNECTIONS MUST BE MADE BY QUALIFIED PERSONNEL ONLY AND MEET

NATIONAL AND LOCAL CODES

CAUTION

The fryer(s) MUST be connected to the voltage and phase as specified on the rating and serial number

plate located on the fryer door. To determine the proper wire size and amperage service per fryer, use

the chart on the next page.

CAUTION

A ground wire MUST be connected to the GROUND terminal near the input power terminal block.

CAUTION

Note the following before connecting the fryer to an emergency cutoff system:

• Be sure that each fryer is connected to a dedicated set of contacts in the emergency cutoff system.

• Do not attempt to connect the contacts in series.

• Do not connect more than one fryer to each set of contacts.

• The contacts MUST BE normally closed contacts that open during the emergency.

• The contacts CANNOT have an external voltage applied.

4-1

Page 12

CHAPTER 5: POWER REQUIREMENTS

WARNING

For power supply connection, use copper wire only, suitable for at least 167°F(75°C).

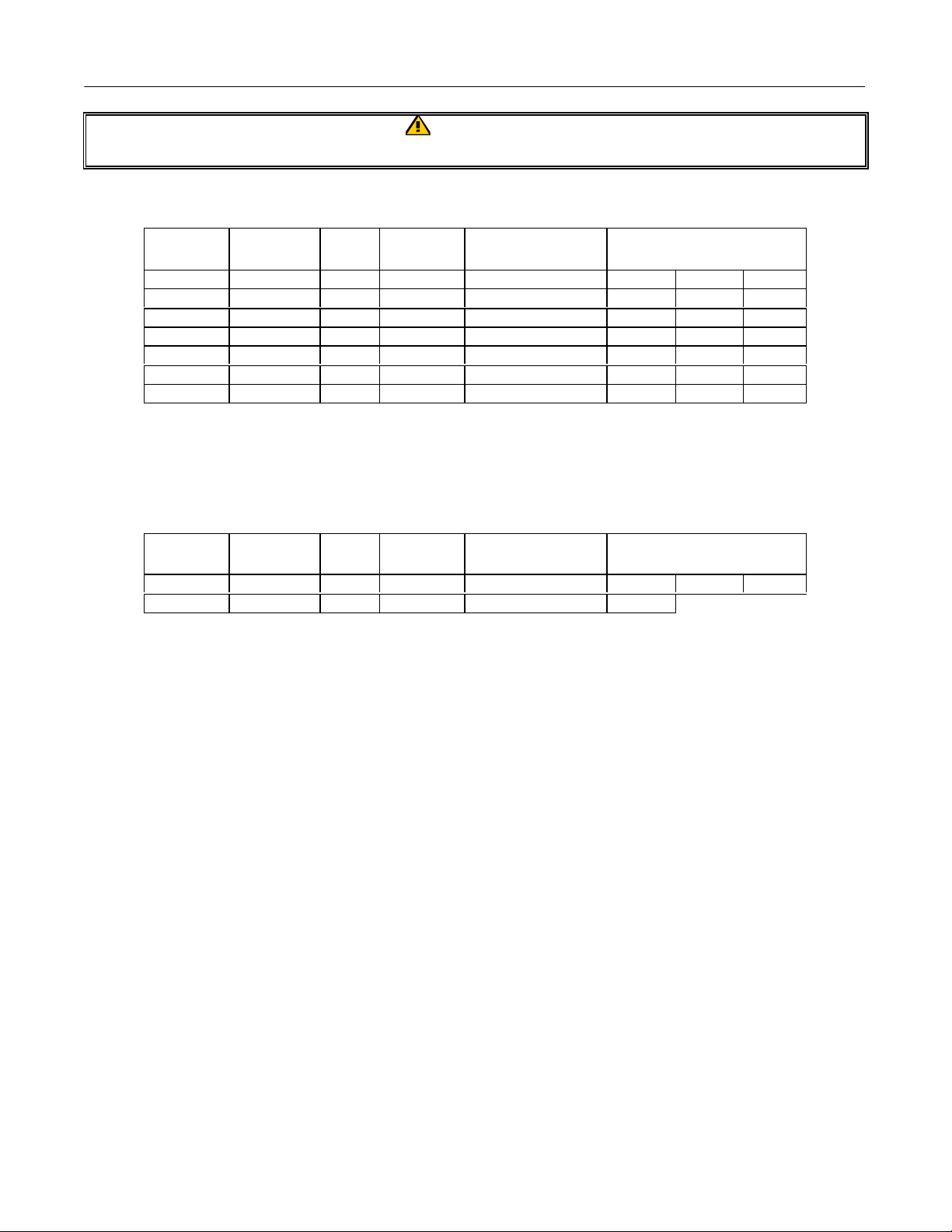

MODEL VOLTAGE PHASE

H14 440 3 3 8 (10) 19 19 19

H14 (Sub) 440 3 3 8 (10) 19 19 19

H14 480 3 3 8 (10) 17 17 17

H17 440 3 3 6 (16) 23 23 23

H17 480 3 3 6 (16) 21 21 21

H22 440 3 3 6 (16) 29 29 29

H22 480 3 3 6 (16) 27 27 27

WIRE

SERVICE

MIN.

SIZE

AWG

(mm2)

AMPS PER LEG

L1 L2 L3

The FPH17 fryer is equipped with a filter system, which requires 120VAC, 20 amp service. The filterequipped fryer also has these power requirements per vat:

MODEL VOLTAGE PHASE

FPH*17 480 3 3 6 (16) 21 21 21

Filter 120 1 3 Standard cord 20

WIRE

SERVICE

MIN.

SIZE

AWG

(mm2)

AMPS PER LEG

L1 L2 L3

* Denotes number of vats. For example, an FPH317 has three vats.

The electrical power supply for the fryers MUST be the same as the voltage

indicated on the rating and serial number plate located on the fryer door.

5-1

Page 13

CHAPTER 6: OPERATING INSTRUCTIONS

6.1. After Fryer(S) Have Been Installed At Frying Station:

NOTE: If you need to relocate a fryer installed with legs, remove all the weight from each leg before

moving. If a leg becomes damaged, contact your service agent for immediate repair or

replacement.

1. Close fryer drain valve(s) and fill frypot with water to the bottom oil level line on the rear wall of

vessel.

2. Boil out frypot(s). See Boil Out instructions on this page.

3. Drain, clean, and fill frypot(s) with cooking oil. See Section 6.3, Filling With Shortening.

4. Check thermostat calibration on fryers with solid-state controller.

6.2 Boiling Out The Frypot:

WARNING

Never run water through built-in filtration system

Clean frypot(s) as follows before filling with cooking oil for the first time and

at least once a month thereafter:

1. Before switching the fryer(s) ON, close the frypot drain valve(s), fill empty frypot with mixture of

cold water and Frymaster Fryer 'N' Griddle Cleaner. Other heavy-duty low sudsing degreaser

compounds may also be used. Follow instructions on bottle when mixing.

2. Press fryer ON/OFF switch to the ON position.

3. Set thermostat knob to 200°F (93°C).

4. Allow the solution to simmer for 45 minutes to one hour. Do not permit the water level to drop

below the bottom oil-level line in frypot during boil-out operation.

5. Carefully monitor the fryer during this time to prevent solution from boiling over.

CAUTION

Do not leave fryer unattended. The boil out solution may foam and overflow if fryer is left unattended.

Press ON/OFF switch to the OFF position to control this condition.

6. Turn the fryer ON/OFF switch(es) to the OFF position.

6-1

Page 14

CHAPTER 6: OPERATING INSTRUCTIONS

7. Add sufficient cold water to lower temperature to a safe level. Drain out the solution and clean the

frypot(s) thoroughly.

8. Refill the frypot(s) with clean water. Rinse the frypot(s) twice, drain and dry inside of pot

thoroughly to remove all residual water.

CAUTION

All drops of water must be removed from frypot before filling with cooking oil.

6.3 Filling With Cooking Oil

Note: Cooking oil/shortening capacity of H14, H17, and H22 Series fryers is 50 lbs. (25 liters) at

70°F (21°C). The capacity of the H14 Submarine fryer is 47 pounds.

Before filling the frypot(s) with cooking oil/shortening:

1. Close the frypot drain valve.

2. Place the power switch(es) to the OFF position.

3. Remove the basket support rack..

4. Fill the empty frypot(s) to the bottom oil-level line.

5. Replace the basket support rack on top of the heating element.

6. Place the ON/OFF switch to the ON position.

7. Set the controller for normal cooking temperature.

6-2

Page 15

CHAPTER 6: OPERATING INSTRUCTIONS

6.4 Before Relocating Fryer for Service

WARNING

Moving a fryer filled with hot cooking oil may cause splattering. Extreme care must be

exercised. It is recommended that the operator or servicer follow the draining instructions of

this manual before attempting to relocate the fryer for service.

If you need to relocate a fryer installed with legs, remove all the weight from each leg before moving.

If a leg becomes damaged during movement, contact your service agent for immediate

repair/replacement.

1. Turn off fryer controller. Disconnect the electrical power from the source.

2. Relocate the fryer for service accessibility.

3. After servicing is complete, return the fryer to the operating position. Reconnect all electrical

power into source. Secure fryers into position. Refill fryer and resume use.

6.5 Shutting Fryer(S) Off

1. Press fryer controller ON/OFF switch(es) to OFF position.

2. Put frypot cover(s) in place over frypot(s).

6-3

Page 16

CHAPTER 6: OPERATING INSTRUCTIONS

6.6 Testing Dual Hi-Limit Controls

Note: Perform this test before replacing old shortening. This high temperature test will greatly

reduce life of new shortening. Start test with the fryer turned ON and with the oil at normal

frying temperature. Stir the oil thoroughly to ensure even distribution and temperature and

place a pyrometer sensing probe in center of frypot about one-inch deep. When verifying oil

temperature, use a pyrometer indicating 0-6000F and a pryometer sensor probe. A high

temperature thermometer may be used instead of a pyrometer.

CAUTION

If the result listed for each step does not occur, turn off fryer at the main circuit breaker panel and do

not use the fryer. Call service agency.

To test the high limit thermostats, proceed as follows:

STEP 1: Press the hi-limit test switch to the 1st hi-limit switch and hold in that position until the

trouble light comes on. The trouble light should come in between 4100F + or - 30F, and

the heating elements must shut off. The HEAT light goes out and the TROUBLE light

comes on. Release the test switch.

STEP 2: Press the hi-limit test switch to the 2nd hi-limit position and hold in that position until the

2nd hi-limit light comes on. It should illuminate between 430°F and 460°F, and the heating

elements must shut off. Release the test switch. All fryers connected to the external shunt

power supply will be shut off completely and all control panel lights will be extinguished.

For fryers not connected to an external shunt power supply, the 2nd hi-limit light will come

on and the fryer will shut off.

STEP 3: Turn power switch to the OFF position.

STEP 3: Allow the cooking oil to cool to below normal frying temperature. When the power switch

is again turned ON, the heaters will turn on and the operating thermostat will resume

control of the temperature. If the red trouble light remains on instead, allow the oil

additional time to cool.

6-4

Page 17

CHAPTER 7: DRAINING AND MANUAL FILTERING

WARNING

Use care when draining and filtering cooking oil/shortening to avoid serious burns.

7.1 Filtering

If you are using a filter other than a FRYMASTER built-in filter system, consult the filter unit

manufacturer’s operating instructions for the recommended procedures. Instructions for using the

FRYMASTER Footprint systems are included in Chapter 16 of this manual.

7.1.a Manual Filtering

The following procedure is recommended to drain and filter your cooking oil/shortening when a filter

machine is not available:

1. Turn the fryer controller power switch to the OFF position. Screw the drain extension pipe

(provided with the fryer) tightly into the drain valve. Make sure the curved end of the tube is

pointing down.

2. Position a metal container with sealable cover under the drain pipe. The metal container must be

able to withstand the hot cooking oil and other hot liquids and be of sufficient capacity to hold

the contents of the frypot. Frymaster recommends that a Frymaster filter cone holder and filter

cone be used when a filter machine is not available. If you are using the Frymaster filter cone

holder and cone, be sure the filter holder rests firmly on the metal container.

3. Open the drain valve slowly to avoid splattering. If splattering occurs, exercise extreme caution.

4. If the drain valve becomes clogged with food particles, use the Fryer’s Friend (poker-like tool).

Use this tool from inside of the frypot ONLY. Grip the tool on the handle as far as possible

from the hot shortening in the frypot. DO NOT HAMMER ON THE DRAIN VALVE, as this

will damage the drain valve ball.

WARNING

Never run water through built-in filtration system.

DANGER

Do not insert the tool into the front of the drain valve to unclog the valve. Hot oil will rush out,

creating an extreme burn hazard!

CAUTION

Allow the shortening to cool to 100°F (38°) or lower before transporting the container and removing

the drain pipe. Exposure to oil at temperatures above 140°F (60°C) can result in severe burns.

5. After draining the oil/shortening, clean all food particles and residual oil/shortening from the

frypot before refilling.

6. Close the drain valve and refill the frypot with clean (or filtered) oil/shortening.

7-1

Page 18

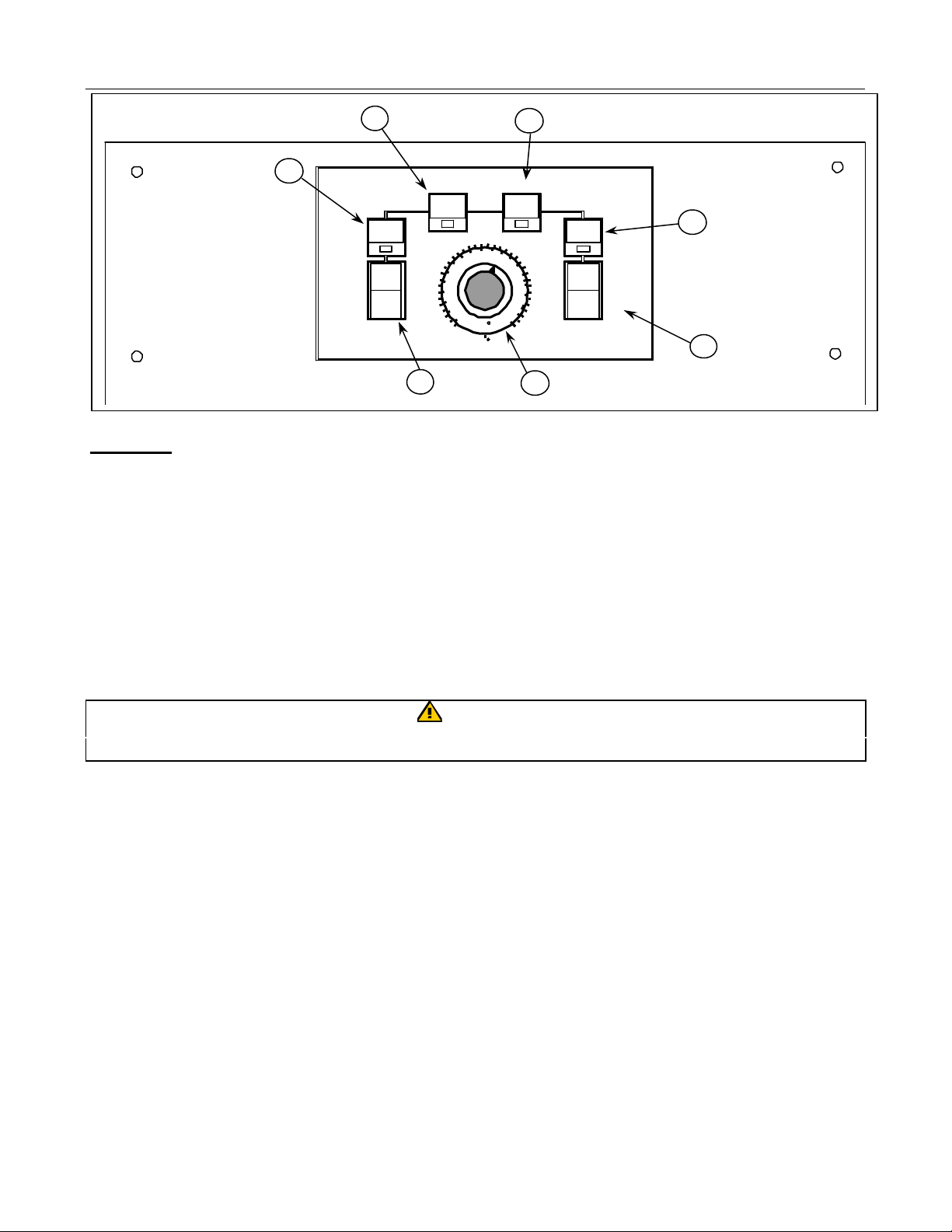

CHAPTER 8: NAVY SHIPBOARD CONTROLLER

Fig. 8-1

4

5

2

TROUBLEHEAT

POWER

ON

POWER

OFF

260

240

220

1

ITEM NO.

1. Power Supply Switch - controls power supply.

2. Power On Light - indicates when electrical power is on.

3. Temperature Control Knob - sets desired frying temperature.

4. Heating Light - indicates element is on.

300

280

130

120

110

100

200

320

140

150

160

340

170

180

360

190

C

F

3

SECOND

2

ND

HI LIMIT

TEST

1

ST

6

7

5. Trouble Light - indicates malfunction of fryer control circuit or overheat condition. Reset by

turning the ON/OFF switch OFF for 30 seconds, then ON.

6. Second High-Limit Light – indicates fryer has overheated and the high limit has shut fryer off.

7. High-Limit Test Switch – Tests high-limit thermostats.

CAUTION

Fryer must be filled with oil, shortening, or water before turning on controller.

8.1 Temperature Calibration

1. Insert a good grade thermometer or pyrometer probe into the cooking oil/shortening near the fryer

temperature-sensing probe.

2. Turn thermostat knob to frying temperature.

3. Let elements cycle on and off automatically three times to allow the cooking oil temperature to be

uniform.

4. When the elements start for the fourth time, the pyrometer reading should be within 5°F (2°C) of

the thermostat knob setting. If it is not, calibrate as follows:

a. Loosen set screw in thermostat control knob until outer shell of knob will rotate on insert inside

knob.

b. Rotate outer shell of knob until index line on knob aligns with marking that corresponds to

thermometer or pyrometer reading.

c. Hold knob and tighten set screw.

8-1

Page 19

CHAPTER 8: NAVY SHIPBOARD CONTROLLER

Press and hold rocker switch down

d. Recheck the thermometer or pyrometer reading and the thermostat knob setting the next time

the elements come on.

e. Repeat Steps 4.a. through 4.d. until thermometer or pyrometer reading and knob setting agree

within 5°F (2°C).

f. If calibration cannot be obtained for any reason, call a Factory Authorized Service Center.

5. Remove thermometer or pyrometer probe.

8.2 Hi-Limit tests

Hi-limit 1 checks the ability of the fryer’s controller to shut down

the fryer.

The test is conducted with the oil at or near operating temperature.

Hold the Hi-limit rocker switch in the 1st position.

The oil will heat to 4100F +- 30F degrees before the controller stops

calling for heat. The trouble light will illuminate just at the heat

light goes out.

Reset the fryer by turning the unit off and back on at the control

panel.

Hi-Limit 2 checks the ability of the fryer’s mechanical hi-limit

probe to shut down the fryer. To run the test, hold the rocker

switch in the 2nd position. With the rocker depressed, the oil will

heat to 430-4500F degrees before the mechanical hi-limit probe

opens, which shuts off power to the fryer.

Fig. 8-2

for Hi-Limit 1 test. Hold the switch

up for the second hi-limit test.

8-2

Page 20

CHAPTER 9: TROUBLESHOOTING GUIDE

Directions for Troubleshooting Flow Chart

1. Always start at the first condition and follow each step in sequence.

2. Perform the test set-up at the beginning of each condition.

3. Normal Operation (“yes” after each decision block) flows down the page in sequence.

4. Abnormal Operation (a “no” answer) branches to the right side of the page where you will find the steps

for problem resolution.

Warning:

Inspection, testing and repair of electrical equipment should be performed by qualified service

personnel. Unplug the unit before servicing, except when electrical test are required.

DANGER

USE EXTREME CARE DURING ELECTRICAL CIRCUIT TESTS. LIVE CIRCUITS WILL BE

EXPOSED.

Note: Access to the interface board is required to

perform troubleshooting. See Figures 10-6 and 10-7.

Fryer is Off

Using interface board

lights to diagnose fryer.

Press the ON/OFF

Switch to OFF

Is

CMP light

Interface board on?

Is

24V Light

Interface board on?

All other lights

on

YES

on

YES

off?

NO

NO

NO

1. No power applied to fryer from power supply.

2. Defective 12 volt transformer.

3. Defective interface board ( 12 VAC circuit).

4. Broken or improper wire connection.

5. Blown fuse.

1. Defective 24 volt transformer.

2. Defective interface borard (24 volt circuit).

3. Broken or improper wire connection.

4. Blown fuse.

1. Defective controller.

2. Improper wire connection.

YES

Condition is

normal

9-1

Page 21

CHAPTER 9: TROUBLESHOOTING GUIDE

Turning Fryer On

Fryer fails to heat

the oil.

Fryer is on and the

thermostat is set at least 45

degrees above the

temperature of the cool oil.

Yes

Are the power and heat

lights on the controller on?

Yes

NO

1. Trouble light ON indicates

a. Oil temperature is above the accepted range.

b. Problem in temperature measuring circuit (including probe).

2. Heat light and trouble light on indicates a latching circuit problem.

3. Defective controller.

4. Broken or improper wire connection.

Is 24 Volt light on interface

board lit?

Yes

Right HI light on

interface board on?

Yes

24 volts supplied to

latching contactor coil;

contactor activates?

Yes

NO

NO

1. Problem in 24-volt circuit.

1. Open high limit.

2. Open drain valve microswitch.

3. Broken or defective wiring connection.

1. Defective latching relay.

2. Broken or improper wire connection.

3. Defective interface board.

NO

4. Defective latching contactor.

As controller heat light

illuminates, interface HT light

comes on?

(Continued on Page 9-3)

1. Defective heat relay.

NO

2. Broken or improper wire connection.

3. Defective interface board.

4. Defective control.

9-2

Page 22

CHAPTER 9: TROUBLESHOOTING GUIDE

Fryer Fails to Heat

Yes

24 volts supplied to heat

contactor and heating

contactor closes?

Yes

Do the elements heat

and draw proper amps?

Yes

Do elements continue to

heat and maintain proper

temperature?

( Continued from Page 9-2 )

1. Defective heating contactor.

No

2. Broken or defective wiring connection.

3. Defective interface board.

No

No

1. Defective heating contactor.

2. Defective heating element.

3. Broken or defective wire connection.

4. Improper wire connection.

Unit stops heating with heat light on.

Defective or improperly installed high-limit.

Defective heating or latching contractor.

Unit heats until high limit trips without heat light on.

Defective (shorted or grounded) heating element.

Defective (sticking) temperature probe.

Defective controller.

Bad harness, wire connections.

Yes

Fryer operating

normally.

9-3

Page 23

CHAPTER 10: SERVICE PROCEDURES

Fig: 10-2

Fig: 10-3

10.1 Replace Controller

10.11 Shipboard fryer

1. Disconnect the fryer from electrical power.

2. Turn controller off.

3. Remove the two screws securing the controller.

4. The controller is hinged at the bottom, and will swing

open from the top.

5. Unplug the wiring harness from the back of the

controller. Fig: 10-1

6. Remove the ground wire by unscrewing the securing

nut or disconnecting the ground connector.

7. Remove the controller from the control panel.

8. Reverse the procedure to install a new controller.

10. 12 Submarine Fryers

1. Disconnect the fryer from electrical power.

2. Turn the controller off.

3. Remove the two screws securing the

controller bezel to the front of the fryer. Fig

10-2.

4. Pull the controller forward and under the grab bar.

5. Remove the two screws that secure the lower

section of the bezel.

6. Unplug the controller from the 15-pin plug.

Fig: 10-1

Unplug wiring harness from back of controller.

Two screws secure

the controler bezel

to the fryer’s front

Two screws hold

the bezel inside the

cabinet.

7. Push the controller forward and under the

grab bar. Fig 10-3

8. Remove the heat shield from at the rear of

the controller. Fig: 10-4

9. Remove controller from bezel.

10. Reverse procedure to install new controller.

Fig: 10-4

A shield, which must be removed, protects

the controller from heat.

10-1

Page 24

CHAPTER 10:

SERVICE PROCEDURES

Fig: 10-5

Control box screws.

Drain

box lid.

box behind the controller.

Screw that

10.2 Replace Interface Board

10.2.1 Surface Ship Fryers

1. Disconnect the fryer from electrical power.

2. For surface ship fryers perform Section 10.1, Steps 1-

6, Replace Controller.

3. Unplug the wire harness from the interface board. Fig

10-1. Remove all wiring from the interface board,

carefully marking wires for correct reattachment.

NOTE: If fryer is part of a battery of two or more fryers, the control panel and top cap are one piece,

and must be removed as one piece.

4. Remove the screws securing the control panel.

5. Remove the screws securing the top cap, and set the top

cap and screws aside.

6. Remove the screws securing the component box. Let the

top of the box swing forward enough so that the wire

harness can be unplugged from the back of the interface

board. Fig: 10-6

7. Remove the nuts from each corner of the interface board

and slide the board from the studs.

Control panel mounting screws.

Fig: 10-6

The interface board on the surface

ship fryer is located in the controller

8. Install the new interface board by reversing the above procedures. Ensure the spacers are on the

studs before installing the interface board. Make sure the wiring is reconnected to the proper

terminals and the harnesses to the correct connectors.

10.2.2 Submarine Fryers

1. Disconnect the fryer

from electrical power.

2. Open the front door of

the fryer, and remove

the screw holding the

contactor box lid in

place. Fig: 10-8

Fig: 10-8

Hold-down

screw for

contactor

3. Slide lid from cabinet.

4. Unplug the wire

harnesses from the front

and back of the interface

board.

Fig: 10-7

The interface board is in the

contactor box in the sub fryer.

10-2

15-pin plug for controller.

secures

contactor

box in

cabinet.

elbow

Page 25

CHAPTER 10:

SERVICE PROCEDURES

5. Remove the nuts from each corner of the interface board and slide the board from the studs. Fig:

Fig: 10-10

10-7

6. Install the new interface board by reversing the above procedures. Ensure the spacers are on the

studs before installing the interface board. Make sure the wiring is reconnected to the proper

terminals and the harnesses to the correct connectors.

10.3 Replace Transformer

10.3.1 Surface Ship Fryers

1. Disconnect the fryer from electrical power.

2. Perform Section 10.1, Steps 1-6, Replace Controller.

3. Remove all wiring from the terminals of the transformer to be

replaced, carefully noting where the wires are attached. Fig: 10-9

4. Remove the transformer mounting nuts.

5. Install the new transformer by reversing the procedure. Make sure

the wires are correctly connected to the proper terminals.

10.3.2 Submarine Fryers

On the surface ship fryer, the

transformer is in the controller box.

Fig: 10-9

1. Drain frypot and close drain valve

2. Disconnect the fryer from electrical power.

3. Remove elbow from drain.

4. Open the front door of the fryer, and remove screw

holding contactor box in place. Fig: 10-8

5. Remove door magnet to ensure space to pull contactor box

forward.

6. Push contactor box toward the rear of the fryer and lift to

release it from clips in the rear.

7. Lift the front of the contactor over the mounting hardware

and pull forward out of the cabinet the distance the wiring

harness will allow. Fig: 10-10

8. Remove screw holding the lid on the contactor box.

9. Remove all wiring from the terminals of the transformer to

be replaced, carefully noting where the wires are

attached.

10. Install the new transformer and attach wires.

Contactor box partially removed from the

11. Reverse steps to complete installation.

10-3

Page 26

CHAPTER 10:

SERVICE PROCEDURES

10.4 Replacing Temperature Probe

Tilt-plate

Fig: 10-12

1. Disconnect electrical power to the fryer.

2. Drain the cooking oil from the frypot.

3. Remove cap over elements.

4. Disconnect the wiring harness, which is visible inside the cabinet, containing the red and white

probe wiring. It may be necessary to remove the wire ties.

Red & white

probe wires

Black high-limit

wires.

Fig: 10-11

hole

Probe clip

Temp

probe and

bracket

Fig: 10-13

Hardware on fixed elements

in sub fryer.

5. Use a pin pusher (Frymaster Part Number 806-4855) to remove the probe wires from the

connector. Mark each wire for re-assembly. Fig: 10-11

6. Remove the screw(s) securing the probe bracket to the element. Fig: 10-12

7. Thread the wires through the hole in the tilt plate assembly on the surface ship fryers and through

the access hole near the fixed elements on the sub fryer. Fig: 10-13. Remove the probe and the

securing components from the element.

8. Remove the probe from the probe bracket, and place the new probe into the bracket.

9. Place the new temperature probe assembly onto the element and secure with the screws. Clip the

probe onto the rear of the element. The temperature probe assembly should be oriented in the

same manner as the probe being replaced.

10. Thread the probe wires into the harness connector as removed in Steps 6 & 7.

11. Lower the element into the frypot. (surface ship only).

12. Place the housing cover over the element housing assembly and secure with screws.

10-4

Page 27

CHAPTER 10:

SERVICE PROCEDURES

10.5 Replace Heating Element

Fig: 10-15

10.51 Surface Ship

1. Remove temperature probe per Section 10.4, Steps 1-5, and step 8.

2. Unplug element wire plugs from rear of contactor box. It may be necessary to pull the contactor

box forward to reach the connectors.

3. Remove the heating element wires from the connector. Press down on either side of the connector

while pulling up on the top portion. The connector will open from the top, releasing the wires.

Pull all wires from the connector, noting wire locations in the connector for re-assembly.

4. Remove the temperature probe clamp. Set temperature probe and bracket components aside.

5. Disconnect the element springs. Fig: 10-14

Fig: 10-14

Element springs on surface ship fryer.

Element mounting screws on surface ship fryer.

6. Remove the element mounting screws and pull the element out of the frypot. Fig: 10-15

7. If present, remove the lift handle from the old element and install it on the new one.

8. Install the temperature probe and probe-securing components onto the replacement element.

9. Install the replacement element in the frypot and secure with mounting screws removed in Step 6.

10. Route the element leads (terminals) to the rear of the frypot.

11. When replacing the left element (as viewed from the front of the fryer) insert pin terminals into

the correct holes in the 6-pin connector. When all pins are fully inserted, close the connector by

sliding the halves together until the tabs snap back into place.

12. When replacing the right element (as viewed from the front of the fryer), use the 9-pin connector.

Follow the steps outlined in Step 11.

13. Insert the connector(s) into the receptacle(s) in the rear of the contactor box. Be sure the latches

lock the connectors in place.

14. Install the temperature probe wires into the corresponding pin locations.

15. Reconnect the element spring.

16. Install the tilt housing assembly.

10-5

Page 28

CHAPTER 10:

SERVICE PROCEDURES

17. 10.5.2 Submarine

Left element

Temp, hi-limit

1. Disconnect electrical power to the fryer.

2. Drain the cooking oil from the frypot.

3. Remove drain system elbow.

4. Remove screw holding contactor box in place. Fig: 10-8

5. Lift contactor box at rear and push backward slightly to

disengage tabs which secure the rear of the box.

Fig: 10-16

6. Lift front of contactor box and pull it forward to create

Mounting hardware on fixed-element sub fryer.

working room at the rear of the box to remove element

connectors.

7. Unplug two lower plugs. Fig: 10-17

8. Remove temperature probe per Section 10.4, Steps 1-5, and step 8.

9. Remove mounting hardware on heating elements and lift from unit. Fig: 10-16

10. Remove the heating element wires from the connector. Press down on either side of the connector

while pulling up on the top portion. The connector will open from the top, releasing the wires. Pull

all wires from the connector, noting wire locations in the connector for re-assembly.

11. Install the temperature probe and probe-securing components onto the replacement element.

12. Install the replacement element in the frypot and secure with mounting screws removed in Step 9.

13. Route the element leads (terminals) to the rear of the frypot.

14. When replacing the left element (as viewed from the front of the fryer) insert pin terminals into the

correct holes in the 6-pin connector. When all pins are fully inserted, close the connector by

sliding the halves together until the tabs snap back into place.

15. When replacing the right element (as viewed from the front of

the fryer), use the 9-pin connector. Follow the steps outlined

in Step 11.

16. Insert the connector(s) into the receptacle(s) in the rear of the

contactor box. Be sure the latches lock the connectors in

place.

17. Install the temperature probe wires into the corresponding pin

locations.

18. Feed wires down back of fryer and plug into receptacles on

rear of contactor box.

Right element

connector

Fig: 10-17

connector

connector

19. Restore contactor box to its original position, replace element

cap and replace drain elbow.

20. Fill with oil and return fryer to operation.

10-6

Page 29

CHAPTER 10:

SERVICE PROCEDURES

10.6 Replace High-Limit Thermostat

lifted from the cabinet.

Fig: 10-18

1. Drain frypot.

2. Remove drain elbow from drain assembly.

3. Remove screw securing contactor box in place. Lift the contactor box

and push back slightly to release tabs holding the box in the rear of

the cabinet. Lift and pull the box forward to allow access to the plugs

at rear of unit. Fig: 10-8

4. Unplug 15-pin plug from front of contactor box (sub fryer only).

5. Unplug the three plugs on the rear of the contactor box.

6. Remove the element cap.

7. Remove two screws securing controller bezel to fryer’s

frame and pull controller forward to access lower screws.

8. Remove lower bezel screws.

9. Remove controller.

10. Remove screw at front of fryer that holds frypot in place.

Fig: 10-19.

11. Lift frypot from cabinet.

12. Disconnect the wiring harness containing the high-limit

wires.

13. Use a pin pusher (Frymaster Part Number 806-4855) to remove the two high-limit wires from wire

harness connector C6. For split pot fryers, remove only the wires for the high-limit to be replaced.

Mark each wire for re-assembly. Fig: 10-11

14. Use a 7/8” wrench to remove the high-limit thermostat from the frypot.

15. Apply LocTite PST 567 sealant (enclosed with replacement high -limit) to the threads of the new

high-limit thermostat.

The removal of one screw behind

the controller allows the frypot to be

Hi-limit probe

Fig: 10-19

16. Screw the new high-limit into the frypot and tighten securely. DO NOT OVERTIGHTEN!

17. Rest frypot on cabinet sideways, allowing wires to hang near the back of unit.

18. Insert the replacement high-limit wires into the holes in the connector, making certain to insert the

pins into the same two holes from which the old high -limit wires were removed.

19. Position frypot in cabinet

20. Reconnect element wire harnesses to contactor box.

21. Restore contactor box to original location.

22. Replace drain elbow.

23. Replace controller and plug into 15-pin socket on front of contactor box.

24. Install the rear flue covers.

25. Return to service

10-7

Page 30

CHAPTER 10:

SERVICE PROCEDURES

10.7 Replace Frypot

1. If the fryer has a built-in oil filtration system, remove all the plumbing from the frypot. This

includes both oil return and drain fittings.

2. Perform Section 10.6 steps 1-11

3. Remove elements.

4. Remove hi-limit.

5. Apply LocTite PST 567 sealant to the threads of the

existing or new high-limit thermostat.

6. Screw the high-limit into the frypot and tighten

securely. DO NOT OVERTIGHTEN!

7. Install elements.

8. Rest frypot on cabinet sideways, allowing wires to hang

near the back of unit.

9. Insert the high-limit wires into the holes in the connector, making certain to insert the pins into the

same two holes from which the old high -limit wires were removed.

10. Position frypot in cabinet

11. Reconnect the wire harnesses to contactor box.

Fig: 10-20

Fig: 10-21

12. Restore contactor box to original location.

13. NOTE: Apply LocTite PST 567 sealant to all pipe connections prior to assembly.

14. Replace drain elbow.

15. Replace oil return lines on units with built-in filtration.

16. Replace controller and plug into 15-pin socket on front of contactor box.

17. Install the rear element cover.

18. Boil out new frypot as described on page 6.1

19. Return to service

10-8

Page 31

CHAPTER 10:

SERVICE PROCEDURES

10.8 Replace Heating or Latching Contactor

1. Disconnect electrical power to the fryer.

2. Drain the cooking oil from the frypot.

3. Remove cap over elements.

4. If present, remove the wire harness connector covers on the front of the contactor box.

5. Disconnect the 15-pin controller plug from the front of the contactor box, Remove screw securing

contactor box in place. Lift the contactor box (Fig: 10-8) and push back slightly to release tabs

holding the box in the rear of the cabinet. Lift and pull the box forward to allow access to the plugs

at rear of unit.

6. Remove the screws securing the contactor. (See drawing on page 16-3)

7. Remove wiring connected to the contactor terminals. Mark wires for re-assembly

8. Remove the contactor mounting screws and contactor.

9. Install new contactor and attach wiring.

10. Reverse Steps 1-7 to complete job.

10-9

Page 32

CHAPTER 11: PREVENTIVE MAINTENANCE

11.1 Clean Inside And Outside Of Fryer Cabinet - Daily

Clean inside the fryer cabinet with a dry, clean cloth. Wipe all accessible metal surfaces and

components to remove accumulated cooking oil and dust.

Clean outside the fryer cabinet, with a clean, damp cloth soaked with dishwashing detergent. Wipe

with a clean, damp cloth.

11.2 Once A Week - Clean Frypot And Heating Elements

WARNING

NEVER operate the fryer(s) with an empty frypot.

BOILING OUT THE FRYPOT: Clean frypot as follows before filling with cooking oil:

1. Before switching the fryer(s) ON, close the frypot drain valve(s), fill empty frypot to the normal

level with a mixture of water and Frymaster Fryer 'N' Griddle Cleaner or other low sudsing

degreasing compound. Follow instructions on bottle when mixing.

2. Press fryer ON/OFF switch to the ON position.

3. Set thermostat knob to 200°F (93°C).

4. Allow the solution to simmer for 45 minutes to one hour. Do not allow water level to drop below the

bottom oil-level line in frypot during boil-out operation.

CAUTION

Do not leave fryer unattended. The boil-out solution may foam and overflow if fryer is left

unattended. Turn controller OFF to control this condition.

5. Turn the fryer controller power switch to the OFF position.

6. Add enough cool water to permit draining without danger of burning. Drain out the solution and

clean the frypot(s) thoroughly.

WARNING

Do not run water/boil-out solution through filtration system.

7. Refill the frypot with clean water. Rinse the frypot twice, drain and wipe down with a clean, dish

towel. Thoroughly remove all water from the frypot and elements before filling the frypot with

cooking oil.

11.3 Once A Week - Clean Detachable Parts And Accessories

Wipe all detachable parts and accessories with a clean, dry cloth. Use a clean cloth saturated with

Frymaster Fryer 'N' Griddle Cleaner to remove accumulated carbonized oil on detachable parts and

accessories. Rinse the parts and accessories thoroughly with clean water and wipe dry before

reinstalling.

11-1

Page 33

CHAPTER 11: PREVENTIVE MAINTENANCE

11.4 Once A Month -

Check Calibration Of Controller

1. After the cooking oil has reached operating temperature, let the heating elements cycle at least 4

times.

2. Insert a good thermometer or pyrometer near the temperature-sensing probe approximately 3 inches

(7.5mm) deep into the cooking oil. When the heating elements just cycle on after the fourth time,

the thermometer should within ±5°F (±2°C) of the thermostat knob setting.

3. See the controller calibration section of the service manual.

11-2

Page 34

CHAPTER 12: OIL FILTRATION (Surface Ship Only)

Fig: 12-1

Removing filter pan prior to cleaning.

Fig: 12-2

Fig: 12-3

DANGER

Exercise extreme care when working with hot cooking oil. Allow the filter pan to completely cool

before attempting to change the filter paper.

WARNING

Never run water through built-in filtration system

12.1 Preparing The Filter Unit For Use

1.Turn the vat off you intend to filter.

2. Open cabinet and remove filter pan. It must be cleaned prior to

filtering. Fig: 12-1

3. The filter pan holds a crumb screen, hold-down ring and filter

paper or a filter pad. All must be removed and cleaned.

4. The crumb screen comes out first. This catches the large food

particles in the filtering process. Fig: 12-2

5. Remove hold-down ring, which holds the filter paper or filter pad

in place. Fig: 12-3

6. Remove filter paper or pad and discard.

Removing crumb basket.

Removing hold-down ring.

12-1

Page 35

CHAPTER 12: OIL FILTRATION (Surface Ship Only)

Fig: 12-5

Fig: 12-4

Remove screen from filter pan.

7. Remove screen from filter pan. Fig: 12-4

8. Clean filter pan. Fig: 12-5

9. Replace screen.

10. Replace filter pad or paper.

11. Replace hold-down ring.

12. Replace crumb screen. Fig: 12-8

Clean pan.

Fig: 12-6

Replace screen. It’s imperative the screen goes

in the pan first. It goes under the filter paper or

pad. The filter paper or pad must go on top.

Fig: 12-7

The filter paper goes on top of the screen.

Add 8-ounces of filter powder to the top of

the filter paper. Do not use filter powder

Fig: 12-8

The hold-down ring is placed on the filter

paper and the crumb screen is put in place.

12-2

Page 36

CHAPTER 12: OIL FILTRATION (Surface Ship Only)

Fig 12-14

Drain

Filter

With the oil above 300 degrees, move

13. Return filter pan to cabinet.

14. Skim large particles from the vat to be

filtered.

14. With the oil at operating temperature and

the fryer off, open valve of vat to be drained.

Caution: the oil is at or near operating

temperature during filtering. Fig: 12-14, 16

16. Snap the power shower into the frypot

connection. Fig: 12-15

17. For fryers with rear flush option, engage

the control lever to select rear flush. This

will wash sediment from the bottom of the

frypot.

18. Turn the filter pump on. Fig: 12-17

19. The oil is pumped back into the frypot. If

polishing of the oil is desired, allow pump to

run with the drain valve open for no more than

Handles used during filtering:

valves

five minutes.

20. At the end of the filter process, close the

drain and allow the pump to run as the oil fills

up the frypot.

21. When the filter pan empties, air will be pumped into the frypot, causing the oil in the frypot to bubble.

Allow bubbling to continue 15 to 20 seconds before shutting off

filter pump. This action ensures the oil-return lines are clear of

oil.

22. Remove Power Shower. Fig: 12-15

pump

handles

Fig: 12:15

A Power Shower is shown being

placed in a frypot. Filtered oil returning

to the frypot flows through the device

and down the sides of the vessel,

cleaning the pot walls.

Fig: 12-16

the handle to the right to empty the

frypot into the filter pan.

Fig: 12-17

The filter pump

moves oil from

the drain pan to

the frypot.

12-3

Page 37

CHAPTER 12: OIL FILTRATION (Surface Ship Only)

DANGER

Never attempt to remove a filter pan containing hot cooking oil/shortening. Hot oil/shortening will flow

through the outlet in the bottom of the pan and cause severe burns to feet and legs.

CAUTION

Never operate the filter unit unless the cooking oil/shortening in the fryers has been brought up to cooking

temperature.

NOTE: Exercise care when using the Fryer's Friend to prevent damage to the frypot and the drain valve.

Do not drain more than one frypot at a time. To do so will cause overfilling of the filter pan.

DANGER

Except when using the rear flush option, do not operate without power shower. Hot cooking oil/

shortening can splash and cause injury.

NOTE: Filter motor is equipped with a manual reset switch in case the filter motor overheats or an

electrical fault occurs.

CAUTION

Turn off power to the filter system and allow pump motor to cool 20-30 minutes before attempting to

reset switch on the pump motor

WARNING!

The crumb tray must be emptied into a fireproof container at the end of each day. Some food

particles can spontaneously combust if left in certain shortening.

12-4

Page 38

CHAPTER 13

CARE AND CLEANING OF THE FILTER SYSTEM

DANGER:

WARNING:

NEVER use the filter pan to dispose or

transport old cooking oil/shortening to the

disposal area.

Never operate the filter system without

cooking oil in the system.

Always allow cooking oil to cool below 100°F (38°C) before transporting to the disposal area. A

Shortening Disposal Unit (SDU), available from your local distributor, is available and highly

recommended for safety.

1. Do not drain water into the filter pan. Water will damage the filter pump. Perform the following

to drain the frypot:

A. Footprint III

1) Pull the filter carriage forward.

2) Remove the empty filter pan assembly.

3) Push the filter carriage back into the fryer.

4) Place suitable container under the drain.

5) Open the drain valve.

A. Footprint III - the o-ring is on the bottom of

the filter pan.

3. Immediately after use, drain the power shower completely. If you suspect blockage, unscrew the

plugs at each corner of the power shower frame. Use a long narrow bottle brush with hot water

and detergent to clean the inside of the power shower. Rinse, dry thoroughly, and reinsert plugs

before using.

Page 39

CHAPTER 13

CARE AND CLEANING OF THE FILTER SYSTEM

13.1 Filtration Problems

One of the most common errors is placing the filter

paper on the bottom of the filter pan rather than on

top of the filter screen.

Whenever the complaint is “the pump is running,

but no oil is returning,” check the installation of the

filter paper, and ensure that the correct size paper is

being used. While you are checking the filter

paper, verify that the o-ring on the bottom of the

filter pan (and on the suction tube if applicable) is

present and in good condition. A missing or worn

o-ring allows the pump to suck air and decrease its

efficiency.

The filter screen must go in the bottom of the pan

first. The filter paper goes on top of the screen.

For Filter Magic Systems, if the pump runs, but does not return oil, the most likely causes are that the

filter carriage is not properly positioned all the way to the rear of the fryer or the suction tube o-rings

are missing or worn.

If the pump motor overheats, the thermal overload will trip and the motor will not start until it is

reset. If the pump motor does not start, press the red reset switch located on the end of the motor.

If the pump then starts, something caused the motor to overheat. If the motor runs for a prolonged

period, it may overheat. Allow the motor to cool down for at least 30 minutes and press the reset

button.

The pump may also overheat for one of the fo llowing reasons:

• Shortening solidified in the pan or filter lines.

• The operator attempted to filter oil or shortening that was not heated. Cold oil and shortening are

thicker and cause the pump motor to work harder and overheat.

If the pump will not return oil and you hear a humming sound just before the overload trips, the pump

is blocked. Paper which is incorrectly sized or installed will allow food particles and sediment to

pass through the filter pan and into the pump. When sediment enters the pump, the gears may bind

causing the motor to overload, tripping the reset circuit breaker. Solidified shortening in the pump

may also prevent it from turning, with the same result.

Page 40

CHAPTER 13

CARE AND CLEANING OF THE FILTER SYSTEM

FREEING A SIEZED PUMP

Freeing a Seized Pump

Sediment Particle

Up for reverse

Down for forward

A pump seized by debris or hard shortening can usually be freed by manually moving the gears with

a screwdriver or other instrument.

1. Disconnect power to the filter system.

2. Remove the input plumbing from the pump.

3. Use a screwdriver to manually turn the gears.

• Turning the pump gears backward will release a hard particle.

• Turning the pump gears forward will push softer objects and solid shortening through the pump

and allow free movement of the gears.

Incorrectly sized or installed paper will also allow food particles and sediment to pass through and

clog the suction tube on the bottom of the filter carriage. Particles large enough to block the suction

tube may indicate that the crumb tray is not being used.

Pan blockage can also occur if shortening is left in the pan and allowed to solidify. The heater strip

on the suction tube is designed to prevent solidification of residual shortening left in the tube. It will

not melt or prevent solidification of shortening in the pan.

A blockage can be removed by forcing the item out with a stiff wire or drain snake. Compressed air

or other pressurized gases should not be used to force out the blockage.

Possible problems with the Power Shower include clogged openings, solidified shortening or debris

in the tubes, missing clean-out plugs, and missing or worn O-rings. Cleaning the unit and replacing

missing plugs and missing or worn O-rings will correct these problems.

The electronics of the filter system are simple and straightforward. Micro-switches, attached to

handles for each vat and wired in parallel, provide the 24 VAC required to energize the pump relay

coil when the oil return handles are moved to the ON position. The energized pump relay supplies

the power to the pump motor.

The suction tube heater and flexible hose heater are wired directly into the 24 VAC source. They

remain energized as long as the unit is plugged into an outlet.

Page 41

CHAPTER 13

Return Micro

CARE AND CLEANING OF THE FILTER SYSTEM

Line Voltage

24 VAC

Heater

Micro-switches

Switches

Pump Relay Coil

Pump Motor Switch

Pump Motor

M

FootPrint III Wiring

Page 42

CHAPTER 14 FILTER SYSTEM TROUBLESHOOTING

Directions for Troubleshooting Flow Chart

1. Always start at the first condition and follow each step in sequence.

2. Perform the test set-up at the beginning of each condition.

3. Normal Operation (“yes” after each decision block) flows down the page in sequence.

4. Abnormal Operation (a “no” answer) branches to the right side of the page where you will

find the steps for problem resolution.

Warning:

Inspection, testing and repair of electrical equipment should be performed by qualified service

personnel. Unplug the unit before servicing, except when electrical test are required.

DANGER

USE EXTREME CARE DURING ELECTRICAL CIRCUIT TESTS. LIVE CIRCUITS WILL BE

EXPOSED.

OFF CONDITION

Are

heater tapes

warm/hot?

YES

OFF conditon

is normal

NO

1. Missing line voltage.

a. No power supplied to fryer.

b. Broken or improper wire wire connection.

2. Defective heater tape.

14-1

Page 43

CHAPTER 14 FILTER SYSTEM TROUBLESHOOTING

Pump Motor Activation

Momentarily turn filter

handle to the ON position.

1. No line voltage to the motor.

a. Broken or improper wire connection.

b. Relay not closing.

1) Missing 24V

Does

pump

start?

YES

NO

2) Broken or improper wire connection.

3) Pump microswitch open or defective.

4) Defective 24V filter transformer.

c. Defective relay.

2. Thermal overload tripped.

3. Clogged pump preventing motor from turning.

4. defective motor.

Pump/motor

actuation is normal

Filter System Operation

Assemble filter pan, drain

hot cooking oil, and turn

pump handle on selected

fryer to the ON position.

Does

oil return to

the selected

frypot?

YES

NO

No Oil Returned

1. Pump to cabinet oil return hose kinked or blocked.

2. Misadjusted oil return valve linkage.

3. Blocked or plugged drain pan check valve.

4. Oil return line plugged.

Oil Returns Slowly

1. Pump to cabinet oil return hose kinked or blocked.

2. Misadjusted oil return valve linkage.

3. blocked or plugged drain pan check valve.

4. Oil return line plugged.

5. O-ring missing or defective.

6. Incorrect filter paper or pad.

7. Filter screen/paper/pad clogged.

8. Filter pan incorrectly set up (assemble per this manual).

Filter system

operation is normal

Oil Returns to the Wrong Frypot

1. Operated the wrong filter handle.

2. Misadjusted oil return valve linkage.

3. Defective oil return valve (did not close all the way).

14-2

Page 44

CHAPTER 15 WIRING DIAGRAMS

Electric Interface Board

Diagnostic Chart

The following diagram and charts provide ten quick system checks

that can be performed using only a multimeter.

AL AL

D22

SOUND

1

2

3

R19

R15

D13

R7

R29

Frymaster

MADE IN U.S.A.

C

1994

R23

R20

R16

C5

R12R11

D14

D11

R9

C1 C2 C4C3

34

D9

D7

D1

R5

5 2

1

7

10

8

11

9

12

4

5

6

5 2

1

2

3

24V

D21

R27

R26 D18

123

456

789

101112

131415

K3K2K1

34

1

J1

1 1

5 2

R4

R3

R2

R1

31 2

Q1

HIHT CMP HTHI

R28 D20

D17

1

J3

F1

C6

34

10

11

12

5 2

7

8

9

1

D4D3D2

D16

D15

D12

K4

D5

R31R30

R25

R21

R17

R13

R10

1

4

5

6

D29

34

D19

R24

R22

R18

R14

R8

D10

D8

D6

R6

1

2

J2

3

Note: The sealed relays are not

replaceable. If a relay fails the

interface board must be replaced.

Diagnostic LED Legend

CMP indicates power from 12V transformer

24 indicates power from 24V transformer

HI (RH) indicates output (closed) from right Latch

relay

HI (LH) indicates output (closed) from left Latch

relay

HT (RH) indicates output from right Heat relay

HT (LH) indicates output from left Heat relay

AL (RH) indicates output (open) from right Latch

relay

AL (LH) indicates output (open) from left Latch

relay

Meter Setting Test Pin Pin Results

12 VAC Power 50 VAC Scale 1 of J2 3 of J2 12-16 VAC

24 VAC Power 50 VAC Scale 2 of J2 Chassis 24-30 VAC

*Probe Resistance (RH) R X 1000 OHMS 11 of J2 12 of J2 See Chart

*Probe Resistance (LH) R X 1000 OHMS 3 of J1 2 of J1 See Chart

Hi-Limit Continuity (RH) R X 1 OHMS 7 of J2 4 of J2 0 - OHMS

Hi-Limit Continuity (LH) R X 1 OHMS 4 of J1 7 of J1 0 - OHMS

Latch Contactor Coil (RH) R X 1 OHMS 8 of J2 Chassis 3-10 OHMS

Latch Contactor Coil (LH) R X 1 OHMS 5 of J1 Chassis 3-10 OHMS

Heat Contactor Coil (RH) R X 1 OHMS 9 of J2 Chassis 18-25 OHMS

Heat Contactor Coil (LH) R X 1 OHMS 6 of J1 Chassis 18-25 OHMS

*Disconnect 15-Pin harness from the computer/controller before testing the probe circuit.

15-1

Page 45

CHAPTER 15 WIRING DIAGRAMS

H14/H17/H22

NAVY Shipboard

Common Electric

L3

L1 L2

3 Phase Power Terminals

Series - Full Vat

312

GND

1

C

C1-8

Latching

Contactor

until

is activated

De-energized

Alarm circuit

Detail "A"

3

2

2C

1

Heating

Contactor

C6-8

SD

Contactor Box

J1-1

24VAC (Alarm Circuit)

INSTALL SHUNT

TO PINS 4 AND 8

TRIP DISCONNECT

OF THE TERMINAL

from

R

12VDC

(V

Computer)

J2-5

IN THE THE

BLOCK LOCATED

CONTACTOR BOX.

Fuses

Control Circuit

Temp

Probe

Circuit.

See Detail "A"

Shunt Trip Disconnect

High

Limit

24V

Drain

12V

C6

7

6

Safety

24V

Fuse

Switch

J2

11 1221 4

7

3

HI

24V

J2-8

K3

HEAT

RELAY

K4

LATCH

AL

RELAY

J2-9

Board

Interface

HT

11

4

13

14

10

3

1

J3

11

4

14

10 13

5

3

1

HEAT

TROUBLE

ON/OFF

POWER ON

Fire

Cut-off

2

5

COMP

2 5

Computer / Controller

J3

15-2

Page 46

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14

Sub

11

1

4

3

12

5

6

2

8

13

10

7

3

9

16-1

Page 47

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Cabinet and Controllers

(Refer to Figure 16-1)

ITEM NO. PART NO. DESCRIPTION

1 824-0532

* 824-0534

* 824-0535

* 824-0536

2 824-0638

* 910-3122 Tilt Housing Cover Joining Strip (2, 3, or 4 fryers)

3 803-0028 Basket Hanger, all units

4 809-0171 Basket Hanger Screw

* 809-0015 Cage Nut

5 806-9166

* 809-0079

6 806-3798

7 806-9215

* 807-3308 Toggle Switch

8 810-0387 Thermostat Knob, (all analog controllers)

9 806-8991

10 824-0697 Top Cap. Single (SUB)

* 824-0572

* 824-0571

* 824-0573

* 824-0574

11 823-2901

* 823-2908

* 900-07431

12 823-2718

* 806-7543

* 806-8536

13 823-2353

Tilt Housing Cover, Single Unit, SHIP

Tilt Housing Cover, Double Unit, SHIP

Tilt Housing Cover, Triple Unit, SHIP

Tilt Housing Cover, Quad Unit, SHIP

Element Housing, (SUB ONLY)

Basket Hanger Bracket (SUB ONLY)

Nut-sert (Submarine Basket Hanger)

Analog Controller, (SURFACE SHIP)

Analog Controller (SUB ONLY)

Controller Mounting Frame (SUB ONLY)

Top Cap, Single (SURFACE SHIP)

Top Cap, Double (SURFACE SHIP)

Top Cap, Triple (SURFACE SHIP)

Top Cap, 4 fryers (SURFACE SHIP)

Handle, Front, Triple, 47” (SURFACE SHIP)

Handle, Front, Double, 31.4” (SURFACE SHIP)

Door Hinge, (SURFACE SHIP)

Handle, Front, single, 15.1” (SUB ONLY)

High limit Thermostat, H14, H17

High limit Thermostat, H22

Leg, (Surface Ship)

FRYPOTS

Surface Ship Fryers

Part #

Without Built-in Filtration 823-2450

Built-in Filtration 823-2451

*Not illustrated.

**Submarine fryers made 6/99 and later have a 4” deeper frypot than earlier models.

16-2

Page 48

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Contactor Boxes and Associated Components

1

2

8

9

Surface Ship Fryer Contactor Box

1

2

3

4

11

13

12

Submarine Fryer Contactor Box

5

6

10

15

7

5

6

9

8

7

10

14

16-3

Page 49

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Contactor Boxes

(Refer to Figure 16-3

ITEM # PART NO. DESCRIPTION FRYER MODEL

1 807-0064

2 807-2464 3-Phase Power Input Terminal Block ALL

3 807-2181

4 807-0855

5 807-0070 Terminal Lug, Ground ALL

6 810-2284 Contactor, Heating 3-pole, 50 Amp ALL

7 810-1202 Contactor, Latching 3-pole, 40 Amp ALL

8 807-0012 Relay , 18 Amp, 24 Volt coil ALL

9 807-1683 Relay , 12 Volt Coil ALL

10 807-0067 Terminal Block, 8 Pin ALL

11 807-0069 Circuit Breaker for 440 or 480V fryers ALL

12 806-7935 Interface Board ALL

13 809-0349 Spacer, Interface Board ALL

14 806-8364 Mounting Bracket, Interface Board

15 807-0875 Connector, female 15-pin, Panel Mount

* 806-2071 Wire Harness, (Control Panel to Interface Board)

* 806-5095 Wire Harness, 5’ (Controller to Contactor Box)

* 806-8346 Wire Harness, (Interface board to 15-pin connector)

Transformer, 480,440/120V

Transformer, 120/24V for 440 or 480 fryers

Transformer, 120/12V for 440 or 480V fryers only

*Not illustrated.

ALL

ALL

ALL

Submarine

Surface Ship

Surface Ship

Submarine

Submarine

16-4

Page 50

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Front Component Box (Surface Ship Fryers ONLY)

1

2

3

Figure 16-3

ITEM # PART NO. DESCRIPTION FRYER MODEL

1

2 807-0855

807-2181

Transformer, 120/24V for 440 or 480 fryers

Transformer, 120/12V for 440 or 480V fryers only

3 807-0069 Circuit Breaker, 10A, 120V All

4 807-1321 Fuse Holder All

807-1597 Fuse, 3A All

5 806-7935 Interface Board All

* 809-0349 Interface Board Spacers (behind interface board) All

6 900-2462 Component Box All

7 810-1164 Terminal Block All

8 807-1084 Grommet All

*Not illustrated.

8

AL HL HE CM P 24VK4HE HL AL

5

K1 K2 K3

6

4 7

All

All

16-5

Page 51

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Heating Elements and Associated Components

ITEM # PART NO. DESCRIPTION FRYER

1

1 807 3269

2 810-0297 Heating Element Tilt Spring

* 910-3177 Cabinet Rear Access Cover ALL

* 810-1233 Heating Element Lift Handle

* 810-1212 Lift Handle Lock Pin

3 811-0208 Insulator Tubing Sleeve (by the foot) ALL

4 806-8286 Upper Tilt Spring Bracket, Left (Viewed from back)

5 806-8285 Upper Tilt Spring Bracket, Right (Viewed from back)

6

6

6

*

6

* 826-1459 Adapter kit—pin terminals to older-style fryers H14 & H17

* 826-1289 Adapter kit—pin terminals to older-style fryers H22

* Not illustrated

**Submarine fryers made 6/99 and later have a 4” deeper frypot than earlier models.

1

826-1526

807-3268

807-2649

807-2650

807-3100

807-3176

4

6

Figure 16-4

Temperature Probe, (Ship and pre-6/99 submarine)

Temperature Probe (Submarine only - After 6/99) **

Element, (after 6/99) 440v, 7kW (pin terminals) **

Element, 440v, 7 kW (with pin terminals)

Element, 440v, 8.5 kW (with pin terminals)

Element, 440v, 8.5 kW (with spade terminals)

Element, 440v, 11 kW (with pin terminals)

2 3

5

MODEL

Submarine

(Ship Only)

(Ship Only)

(Ship Only)

(Ship Only)

(Ship Only)

Submarine only

ALL

Ship Only

Ship Only

Ship Only

16-6

Page 52

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Doors and Accessories

9

8

16

7

9a

10

11

15

13

14

1

2

3

4

12

5

6

Figure 16-5

16-7

Page 53

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Doors and Accessories

(Refer to Figure 16-5)

ITEM # PART NO. DESCRIPTION FRYER MODEL

1 823-2109 Military Drain Pan ALL

2 806-3068

3 806-8558

4 803-0132 Basket Support Rack ALL

5 823-2353 Leg ALL

* 826-1113 Leg Mounting Hardware ALL

6 803-0072 Filter Cone Holder (Top View) ALL

* 803-0042 Filter Cone (Paper Filter Cones) ALL

7 810-1422 Door Handle ALL

8 806-4487 Door Pin Assembly ALL

9

9a

10 810-0275 Door Pin Spring ALL

* 810-0066 Magnetic Door Catch ALL

* 806-4487SP Door Hinge Pin ALL

* 810-0658 Pin Retaining Ring ALL

11 812-1226SP Drain Nipple ALL

12 803-0047 Clean-out Rod ALL

* 803-0022

* 812-1386 Twin Basket ALL

* 803-0099 Full Basket ALL

13 806-4505

14 809-0415

15 814-0001

16 816-0026

* Not illustrated.

** Submarine fryers made 6/99 and later have a 4” deeper frypot than earlier models.

806-8470

806-6545

Cover, Frypot (Surface Ship)

Cover, Frypot (Submarine)

Door Assembly, (Sub Only)

Door, SS, Left or Right, (Surface Ship)

Twin Basket (Ship & pre-6/99 sub fryers)**

Power Shower (Surface Ship)

Clean-out Screw (Surface Ship)

Handle Grip (Surface Ship)

Power Shower Seal (Surface Ship)

ALL

SUB

SUB

ALL

ALL

ALL

ALL

ALL

ALL

16-8

Page 54

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Footprint III Filter Pan

6

1

11

10

9

8

4

Figure 16-6

Item # Part Number Description

1 810-0948 Ball, Check Valve

2 810-1408 Hold-Down Ring

3 823-1979 Inner Filter Pan

4 816-0597 O-Ring

5 823-2027 Filter Pan Cover

6 810-1387 Retainer, Check Valve

7 900-8827 Filter Screen

8 809-0422 Cover Screw

9 810-0946 Spring, Check Valve

10 900-5448 Strainer, Check Valve

11 810-1388 Inner Tube, Check Valve

5

2

7

3

16-9

Page 55

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Filter Magic II Filter Pan

1

2

3

4

5

* Not shown

6

Figure 16-7

Item # Part Number Description

1 810-1406 Hold-down Ring

2 900-8827 Filter Screen

3 810-0181 Handle

4 809-0024 Screw, Handle

5 823-2751 Pan, Weld Assembly

6 810-0006 Caster, Swivel

7 810-0005 Caster, Non-swivel

* 809-0256 Nut (Caster mounting)

7

16-10

Page 56

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

2

1

3

4

5

6

7

3 1

4 2

8

9

T1

T2

10

11

13

12

Figure 16-8

Item # Part # Description

1 826-1712 Motor (with gasket 816-0093)

2 816-0093 Gasket, Pump/Motor

3 826-1264 Pump (with gasket 816-0093)

4 809-0194 Washer

5 809-0514 Cap Screw, 5/16 – 18

6 823-1356 Disconnect, Filter magic

7 826-1392 O-ring (pkg. of 5)

8 807-0156 Connector, 9-Pin

9 810-1164 Terminal Block

10 807-2434 Relay, 18 Amp, 24V Coil

11 807-0800 Transformer, 120-24 AC

12 900-5250 Box, Filter Control

13 810-1569 Drain Valve, Non-Filtration System

16-11

Page 57

CHAPTER 16: PARTS LISTS - H14, H17, H22, FPH17, H14 Sub

Drain Valve Assembly for Built-In Filtration Systems

3

COMPRESSION WASHERS

Side View

Item # Part # Description

1 810-1020 Drain Valve, 1-1/4” x 1”

2 823-8137 Bracket, Drain Switch

3 814-0047 Grip, Handle

4 900-2609 Handle, Drain Valve

5 809-0540 Nut, Lock

6 809-0237 Nut, Hex 4-40 (external tooth lock nuts)

7 900-2841 Cover, Drain Valve Switch

8 807-2103 Switch, Drain Safety

9 816-0220 Insulation, Micro switch

5

6

7

4

8

6

9

2

PLASTIC WASHER

1

Figure 16-9

16-12

Page 58

Frymaster, L.L.C., 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-31 8-219-7140 (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-5184