Page 1

GF14 and GF40 Series Gas Fryers

Installation & Operation Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline

1-800-551-8633

* 8 1 9 5 8 8 7 *

MAR 2002

Page 2

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster DEAN Factory Authorized Service Center (FASC) or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of

this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed. See NATIONAL CODE

REQUIREMENTS in Chapter 2 of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating,

and service instructions thoroughly before installing or servicing this equipment. Only qualified

service personnel may convert this appliance to use a gas other than that for which it was

originally configured.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

Page 3

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

upon the gas line connection. Single fryers equipped with legs must be stabilized by installing

anchor straps. All fryers equipped with casters must be stabilized by installing restraining

chains. If a flexible gas line is used, an additional restraining cable must be connected at all

times when the fryer is in use.

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any

other appliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak

must be posted in a prominent location. This information can be obtained from the local gas

company or gas supplier.

DANGER

This product contains chemicals known to the state of California to cause cancer and/or birth

defects or other reproductive harm.

Operation, installation, and servicing of this product could expose you to airborne particles of

glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the State of California to cause cancer.

Inhalation of carbon monoxide is known to the State of California to cause birth defects or other

reproductive harm.

NOTICE

The Commonwealth of Massachusetts requires any and all gas products to be installed by a

licensed plumber or pipe fitter.

Page 4

GF14 and GF40 SERIES GAS FRYERS

TABLE OF CONTENTS

CHAPTER 1: General Information

1.1 Parts Ordering and Service Information .............................................................. 1-1

1.2 Safety Information ............................................................................................... 1-2

1.3 Equipment Description ........................................................................................ 1-2

1.4 Installation, Operating, and Service Personnel....................................................1-3

1.5 Definitions............................................................................................................ 1-3

1.6 Shipping Damage Claim Procedure..................................................................... 1-4

CHAPTER 2: Installation Instructions

2.1 General Installation Requirements....................................................................... 2-1

2.2 Caster/Leg Installation.........................................................................................2-2

2.3 Pre-Connection Preparations ............................................................................... 2-2

2.4 Connection to Gas Line ....................................................................................... 2-3

2.5 Converting to Another Gas Type......................................................................... 2-4

CHAPTER 3: Operating Instructions

3.1 Start-Up Procedures............................................................................................. 3-1

3.2 Boiling Out the Frypot......................................................................................... 3-2

3.3 Filling with Cooking Oil or Shortening ............................................................... 3-3

3.4 Shutting the Fryer Down...................................................................................... 3-3

3.5 Thermostat Operation .......................................................................................... 3-3

3.6 Draining and Filtering.......................................................................................... 3-4

CHAPTER 4: Preventive Maintenance and Operator Troubleshooting

4.1 Daily Checks and Services................................................................................... 4-1

4.2 Quarterly Checks and Services ............................................................................ 4-1

4.3 Semi-Annual Checks and Services ...................................................................... 4-3

4.4 Operator Troubleshooting.................................................................................... 4-4

i

Page 5

GF14 and GF40 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1.1 Parts Ordering and Service Information

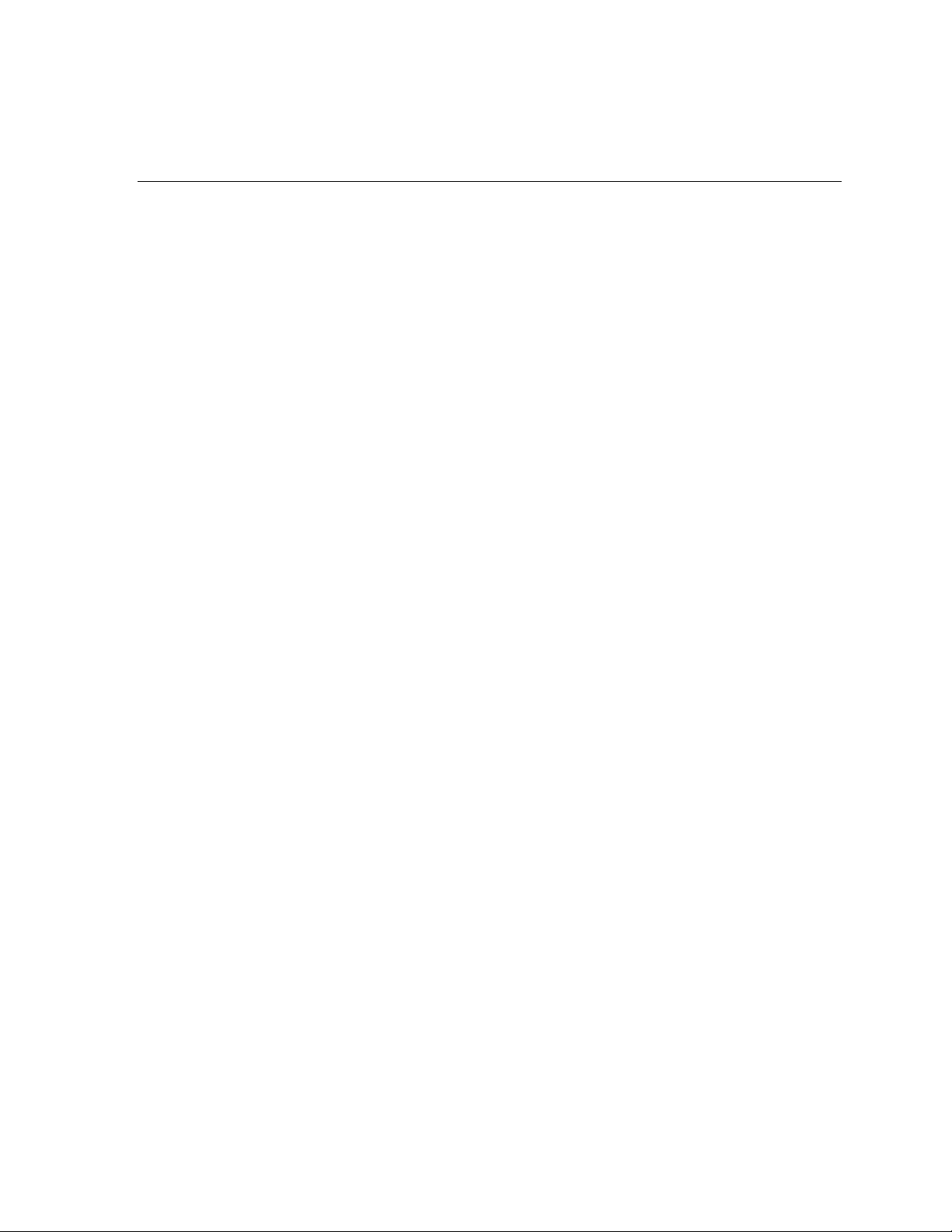

In order to assist you as quickly as possible, the Frymaster Factory Authorized Service Center

(FASC) or Service Department representative requires certain information about your equipment.

Most of this information is printed on a data plate affixed to the inside of the fryer door. A typical

data plate is illustrated below.

GF14SD 0201FM0208 AF NAT

1050 4.00 10000

1.65 000 .00

Parts orders must be placed directly with your local FASC or distributor. Included with fryers when

shipped from the factory is a list of Frymaster FASCs. If you do not have access to this list, contact

the Frymaster Technical Service Department at 1-800-551-8633 or 1-318-865-1711.

When ordering parts, the following information is required:

Model Number:

Serial Number:

Type of Gas:

Item Part Number:

Quantity Needed:

Service information may be obtained by contacting your local FASC. Information may also be

obtained by calling the Frymaster Technical Service Department at 1-800-551-8633 or 1-318-865-

1711.

When requesting service, please have the following information ready:

Model Number:

Serial Number:

Type of Gas:

In addition to the model number, serial number, and type of gas, please be prepared to describe the

nature of the problem and have ready any other information that you think may be helpful in solving

your problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-1

Page 6

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

ones below.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

CAUTION

Example of a CAUTION box.

WARNING boxes contain information about actions or conditions that may cause or result in dam-

age to your system, and which may cause your system to malfunction.

WARNING

Example of a WARNING box.

DANGER boxes contain information about actions or conditions that may cause or result in injury to

personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER

Hot cooking oil or shortening causes severe burns. Never attempt to move a fryer

containing hot cooking oil/shortening or to transfer hot cooking oil/shortening from

one container to another.

1.3 Equipment Description

The GF14 and GF40 Series gas fryers are designed for all-purpose frying. Other than the capacity of

the frypot, both fryers are virtually identical. The GF14 model holds up to 40 lbs. (20 liters) of

cooking oil or shortening. GF40 fryers hold up to 50 lbs. (25 liters). Both models must be manually

filtered or filtered with a portable filtration unit such as the Frymaster PF50 portable filter.

These fryers use a millivolt temperature control circuit, which requires no external power.

Both models use an open-pot design with no tubes and have a hand-sized opening into the deep cold

zone, which makes cleaning the frypot quick and easy.

The fryers require installation of legs or optional casters at point of use. All fryers are shipped with

a package of standard accessories. Each fryer is adjusted, tested, and inspected at the factory before

crating for shipment.

Frypots are constructed of welded, heavy-gauge stainless steel or cold-rolled steel. Heat is supplied

by a burner assembly having multiple gas jets, which are focused on deflectors (commonly referred

to as “targets”) located around the lower side of the frypot. The deflectors concentrate the heat

produced by the burners on the bottom of the frypot.

1-2

Page 7

The burner assembly can be configured for natural gas, propane, or manufactured gas, as required by

the customer. A drain is tapped into the center of the frypot, with a front-controlled manual ball

valve.

Each fryer is equipped with a thermostat for precise temperature control. The thermostat is located

near the centerline of the frypot for rapid response to changes in loads and to provide the most

accurate temperature measurement.

A high temperature thermostat (hi-limit) shuts off gas to the burner assembly if the controlling

thermostat fails.

1.4 Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or authorized personnel only, as defined in Section 1.5.

All installation and service on Frymaster equipment must be performed by qualified, certified,

licensed, and or/authorized installation or service personnel, as defined in Section 1.5.

1.5 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions, or who have had previous

experience with the operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, or firms, corporations, or companies which, either in

person or through a representative, are engaged in and are responsible for the installation of gasfired appliances. Qualified personnel must be experienced in such work, be familiar with all gas

precautions involved, and have complied with all requirements of applicable national and local

codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those that are familiar with Frymaster equipment and who have been

authorized by Frymaster to perform service on Frymaster equipment. All authorized service

personnel are required to be equipped with a complete set of service and parts manuals and stock a

prescribed minimum amount of Frymaster equipment parts.

A list of Frymaster Factory Authorized Service Centers (FASC) is included with the fryer when it

ships from the factory. Failure to use qualified service personnel will void the Frymaster

Warranty on your equipment.

1-3

Page 8

1.6 Shipping Damage Claim Procedure

Your Frymaster equipment was carefully inspected and packed before leaving the factory. The

transportation company assumes full responsibility for safe delivery upon acceptance of the

equipment for transport.

What to do if your equipment arrives damaged:

1. File a claim for damages immediately, regardless of the extent of damages.

2. Inspect for and record all visible loss or damage, and ensure that this information is noted on

the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed loss or damage that was unnoticed until the equipment was unpacked should be

recorded and reported to the freight company or carrier immediately upon discovery. A

concealed damage claim must be submitted within 15 days of the date of delivery. Ensure that

the shipping container is retained for inspection.

Frymaster DOES NOT ASSUME

RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1-4

Page 9

GF14 and GF40 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

PROPER INSTALLATION IN ACCORDANCE WITH THE INSTRUCTIONS THAT FOLLOW IS ESSENTIAL

FOR EFFICIENT, TROUBLE-FREE OPERATION OF YOUR FRYER. ANY UNAUTHORIZED

ALTERATIONS MADE TO THIS EQUIPMENT WILL VOID THE FRYMASTER WARRANTY.

Upon arrival, inspect the fryer carefully for visible or concealed damage. (See Shipping Damage

Claim Procedure in Chapter 1.)

CLEARANCE AND VENTILATION

The fryer(s) must be installed with a 6” (150 mm) clearance at both sides and back when installed

adjacent to combustible construction; no clearance is required when installed adjacent to

noncombustible construction. A minimum of 24” (600 mm) clearance should be provided at the

front of the fryer.

One of the most important considerations of efficient fryer operation is ventilation. Make sure the

fryer is installed to efficiently remove combustion by-products, and the kitchen ventilation system

does not produce drafts that interfere with proper burner operation.

The fryer flue opening must not be placed close to the intake of the exhaust fan, and the fryer must

never have its flue extended in a “chimney” fashion. An extended flue will change the combustion

characteristics of the fryer, causing longer recovery time. It also frequently causes delayed ignition.

To provide the airflow necessary for good combustion and burner operation, the areas surrounding

the fryer front, sides, and rear must be kept clear and unobstructed.

Fryers must be installed in an area with an adequate air supply and adequate ventilation. Adequate

distances must be maintained from the flue outlet of the fryer to the lower edge of the ventilation

filter bank. Filters should be installed at an angle of 45º. Place a drip tray beneath the lowest edge

of the filter. For U.S. installation, NFPA standard No. 96 states, “A minimum distance of 18 in.

(450 mm) should be maintained between the flue outlet and the lower edge of the grease filter.”

Frymaster recommends that the minimum distance be 24 in. (600 mm) from the flue outlet to the

bottom edge of the filter.

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster/Dean Service

Hotline at 1-800-551-8633.

Information on construction and installation of ventilating hoods can be found in the NFPA standard

cited above. A copy of the standard may be obtained from the National Fire Protection Association,

Battery March Park, Quincy, MA 02269.

2-1

Page 10

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable,

tip over, and cause injury. The appliance area must be kept free and clear of

combustible material at all times.

NATIONAL CODE REQUIREMENTS

The type of gas for which the fryer is equipped is marked on the data plate attached to the inside of

the fryer door. Connect a fryer marked “NAT” only to natural gas, those marked “PRO” only to

propane gas, and those marked “MFG” only to manufactured gas.

When installing this equipment in the UNITED STATES, the installation must conform to the latest

edition of the National Fuel Gas Code, ANSI Z223.1. In CANADA, installation must conform to

the latest edition of Standard CAN-/GCA-B149.1 or .2, “Installation Codes for Gas Burning

Appliances & Equipment”. In addition to the applicable national code or standard, installation must

also be in accordance with any local codes for the area in which the equipment is installed.

In AUSTRALIA, this appliance must be installed by an authorized person, in accordance with the

manufacture’s instructions, local gas regulations, and requirements of AA601, “Installation

Requirements for Gas Burning Appliances”.

Installation shall be made with a gas connector that complies with national and local codes. In the

UNITED STATES, the applicable code is ANSI Z21.69 with Addenda, “Standard for Connectors

for Movable Gas Appliances”. Quick-Disconnect devices, if used, shall likewise comply with

national and local codes. In the UNITED STATES, the code is ANSI Z21.41, “Standard for QuickDisconnect Devices for Use with Gas Fuel”.

2.2 Caster/Leg Installation

Depending upon the specific configuration ordered, your fryer may have been shipped without

installed casters or legs. If casters or legs are installed, you may skip this section and proceed to

Section 2.3, Pre-Connection Preparations. Fryers must have casters or legs. Fryers cannot be curb

mounted.

Install the casters/legs in accordance with the instructions included in your accessory package.

2.3 Pre-Connection Preparations

DANGER

Do not connect fryer to gas supply before completing each step

in this section.

After the fryer has been positioned under the fry station exhaust hood, ensure the following has been

accomplished:

1. Adequate means must be provided to limit the movement of fryers without depending upon the

gas line connections. If a flexible gas hose is used, a restraining cable must be connected at all

2-2

Page 11

times when the fryer is in use. The restraining cable and installation instructions are packed with

the flexible hose in the accessories box that was shipped with your unit.

2. These fryers must be stabilized by installing restraining chains on fryers equipped with casters or

anchor straps on fryers equipped with legs. Follow the instructions shipped with the casters/legs

to properly install the chains or straps.

3. Level fryers equipped with legs by extending the adjustable portion of the leg out approximately

1 inch, and then further adjust the legs, ensuring the fryer is level and at the proper height in the

exhaust hood. Frymaster recommends that the minimum distance from the flue outlet to the

bottom edge of the filter be 24 in. (600 mm).

For fryers equipped with casters, there are no built-in leveling devices. The floor where the fryer

is to be installed must be level.

4. Refer to the data plate on the inside of the fryer door to verify that the fryer is configured for the

proper type of gas before connecting the fryer quick-disconnect device or piping from the gas

supply line.

5. Verify that the minimum and maximum gas supply pressures for the type of gas to be used are in

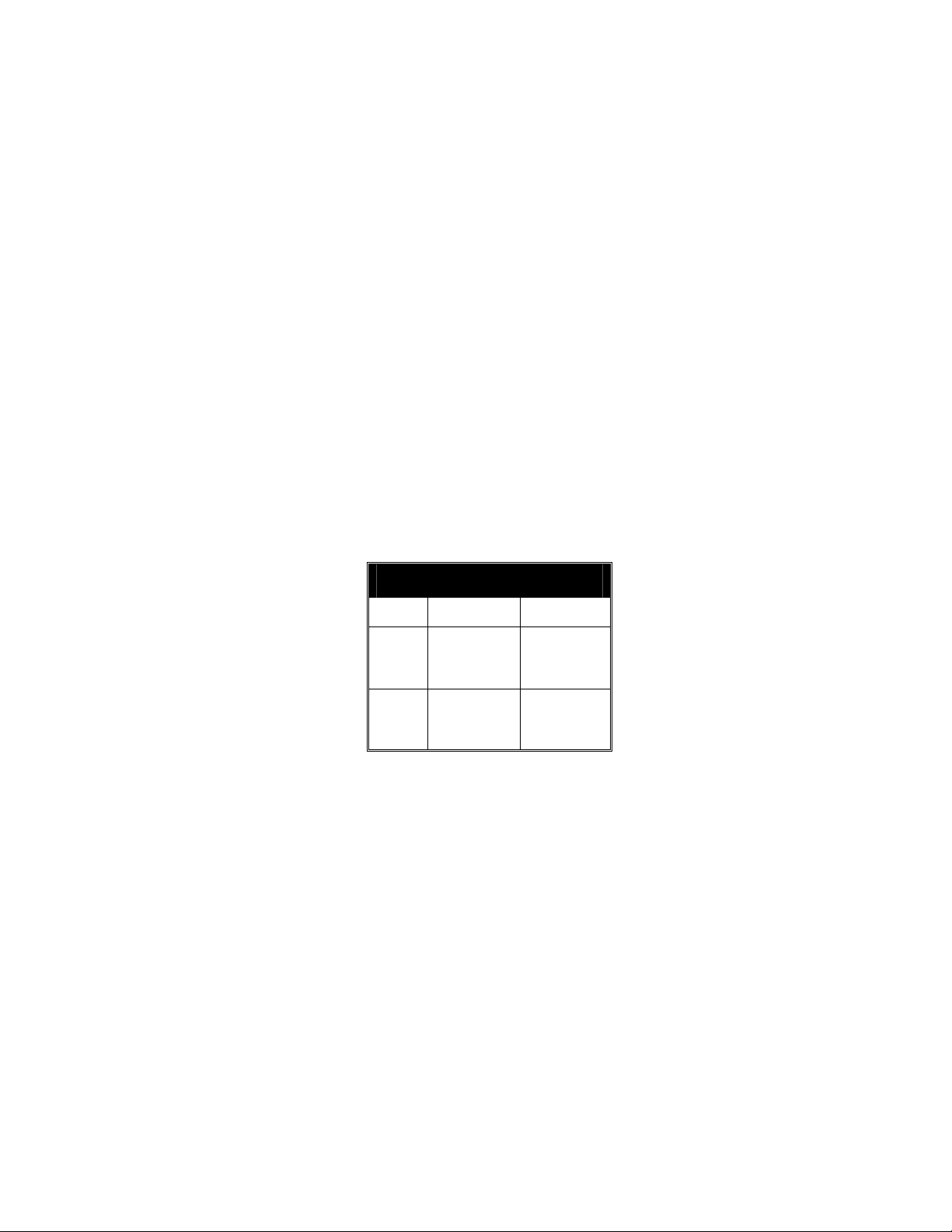

accordance with the table below.

Standard for Incoming Gas

Pressure

Gas Minimum Maximum

Natural

LP

6” WC

1.49 kPa

14.94 mbar

11” WC

2.74 kPa

27.37 mbar

14” WC

3.49 kPa

34.87 mbar

14” WC

3.49 kPa

34.87 mbar

2.4 Connection to Gas Line

The size of the gas line used for installation is very important. If the line is too small, the gas

pressure at the burner manifold will be low. This may cause pilot outage, slow recovery and delayed

ignition. The incoming gas supply line should be a minimum of 1½” (38 mm) in diameter. All

single GF14/GF40 fryers using natural gas require a ¾” connection. Batteries of two and three

fryers require a 1” connection. For fryers using LP gas, one pipe size smaller may be used. If in

doubt about the correct pipe size, consult the local gas company.

NOTE: Runs of more than 20 feet and more than 4 fittings or elbows require an increase of one

pipe size, i.e., ¾” to 1” or 1” to 1¼”.

Before connecting new pipe to your unit, the pipe must be thoroughly blown out to remove any

foreign particles. If these foreign particles get into the burner and controls, they will cause improper

and sometimes dangerous operation.

2-3

Page 12

1. Connect the quick-disconnect hose to the fryer quick-disconnect fitting at the rear of the fryer

and to the building gas line.

NOTE: Some fryers are configured for a rigid connection to the gas supply line. These units

are connected directly to the gas supply line.

When using thread compound, use very small amounts on male threads only. Use a pipe thread

compound that is not affected by the chemical action of LP gases (Loctite™ PST56765 Sealant

is one such compound). DO NOT apply compound to the first two threads. This will ensure that

the burner orifices and control valve do not become clogged.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks. A

soap and water solution should be used for this purpose.

DANGER

Never use matches, candles, or any other ignition source to check for leaks.

If gas odors are detected, shut off the gas supply to the fryer at the main shut-off

valve and contact the local gas company or an authorized service agency for service.

NOTE: The fryer must be disconnected from the gas supply piping during any pressure testing

of the gas supply piping a pressures equal to or greater than ½ psig (3.45kPa or 13.84 in. W.C.).

3. Close the fryer drain valve and fill the frypot with water or boil-out solution to the bottom OIL-

LEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures that are

described in the “Start-Up Procedure” and “Boiling Out the Frypot” topics found in Chapter 3 of

this manual.

WARNING

“Dry-firing” your unit will cause damage to the frypot. Always ensure that melted

shortening, cooking oil, or water is in the frypot before firing your unit.

4. It is suggested that the burner manifold pressure be checked at this time by the local gas

company or an authorized service agent. Refer to “Check Burner Manifold Pressure” in Section

4.3 of this manual for the proper procedure.

5. Check the thermostat calibration in accordance with the instructions in Section 4.3 of this

manual.

2.5 Converting to Another Gas Type

DANGER

Switching to a different type of gas without installing the proper conversion kit may

result in fire or explosion.

NEVER ATTACH YOUR FRYER TO A GAS SUPPLY FOR WHICH IT IS NOT

CONFIGURED!

2-4

Page 13

Your fryer is configured at the factory for either natural gas or Propane (LP) gas. If you desire to

switch from one type of gas to another, a Factory Authorized Service Center technician must

install a gas conversion kit.

Call Frymaster Service (1-800-551-8633) to determine the conversion kit appropriate for your

configuration and altitude. Contact your local FASC to order the kit and arrange for installation.

2-5

Page 14

GF14 and GF40 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.1 Start-Up Procedure

CAUTION

If this is the first time the fryer is being used after installation, refer to Section

3.2, Boil-Out Procedure.

CAUTION

The cooking oil/shortening capacity of the GF14 Series fryer is 40 lbs. (20

liters) at 70ºF (21ºC).

The cooking oil/shortening capacity of the GF40 Series fryer is 50 lbs. (25

liters) at 70°F (21°C).

Before lighting the fryer, make sure the fryer is OFF and the frypot drain valve

is closed. Remove the basket support rack, if installed, and fill the frypot to

the bottom OIL-LEVEL line.

To prevent scorching, if solid shortening is being used, make sure it is tightly

packed down into the bottom of the frypot.

Operating the Gas Valve

:

The knob on the Honeywell gas valve is placed in the PILOT or ON position by rotating it

counter-clockwise. To return the knob to the OFF position, the knob must be depressed

slightly to disengage its stop tab, then rotated clockwise.

Lighting the Pilot and Burner:

WARNING

Frypot must be filled with water or cooking oil/shortening before lighting.

1. Open the door and turn the thermostat knob to the desired frying temperature (or

275°F/135°C if boiling out the frypot).

2. Rotate the gas valve knob to the PILOT position (see Figure 1).

Lighting the Pilot and Burner

PILOT

ON

OFF

Figure 1 Figure 2

ON

PILOT

OFF

3-1

Page 15

3. Push the knob in and light the pilot. Continue to hold the knob in for about 60 seconds

after the flame appears on the pilot. Release the knob. The pilot should remain lit.

CAUTION

If the pilot fails to remain lit, wait five minutes before attempting to re-light.

4. With the pilot lit, push down and slowly turn the knob to the ON position (see Figure 2

on Page 3-1).

5. The burner should light and burn with a strong blue flame. Once the burner has been lit,

it is controlled by the thermostat.

CAUTION

If the pilot and main burner go out, the fryer(s) must be completely shut down

at least five minutes before re-lighting.

3.2 Boiling Out the Frypot

To ensure that the frypot is free of any contamination resulting from its manufacture,

shipping, and handling during installation, the frypot must be boiled out before first use.

Frymaster recommends boiling out the frypot each time the oil or shortening is changed.

1. Before lighting the burner, close the frypot drain valve and fill the frypot with a mixture

of cold water and boil-out solution or detergent. Fill to the lower oil-level line.

2. Light the fryer in accordance with the lighting instructions in Section 3.1.

3. Simmer the solution for one hour.

DANGER

Never leave the fryer unattended during the boil-out process. If the boil-out

solution boils over, turn the fryer off immediately and let the solution cool for

a few minutes before resuming the process. To lessen the chance of boil

over, turn the fryer’s gas valve knob to the PILOT position occasionally.

4. After the solution has simmered for one hour, turn the gas valve knob to the PILOT

position and allow the solution to cool.

5. Add one gallon (3.8 liters) of cold water and stir. Drain the solution into a suitable

container and clean the frypot thoroughly.

WARNING

Do not drain boil-out solution into a shortening disposal unit or portable filter

unit. These units are not intended for this purpose, and will be damaged by

the solution.

3-2

Page 16

6. Rinse the frypot at least twice by filling the frypot with clean water and draining. Dry the

frypot thoroughly with a clean, dry towel.

DANGER

Remove all drops of water from the frypot before filling with cooking oil or

shortening. Failure to do so may cause spattering of hot liquid when the oil or

shortening is heated to cooking temperature.

3.3 Filling With Cooking Oil or Shortening

The GF14 Series fryer holds a minimum of 30 lbs. (15 liters) and a maximum of 40 lbs. (20

liters) of cooking oil or shortening at 70°F (21°C).

The GF40 Series fryer holds a minimum of 40 lbs. (20 liters) and a maximum of 50 lbs. (25

liters) of cooking oil or shortening at 70°F (21°C).

1. Ensure the fryer’s gas valve is off or in the pilot position.

2. Close the frypot drain valve; remove the basket support rack if required.

3. Fill the frypot to the lower oil-level line. When solid shortening is used, it must be

thoroughly packed down into the frypot’s cold zone.

4. To melt solid shortening without scorching, the gas valve knob should be turned to the

ON position for about three seconds and then to the PILOT position for about 10

seconds repeatedly until the shortening is completely melted. If any smoke is seen during

this process, the oil is heating too quickly and scorching. This melting process is not

necessary with liquid shortening.

3.4 Shutting the Fryer Down

For short-term shut down during the workday, rotate the gas valve knob clockwise to the

PILOT position (see Figure 1 on Page 3-1) and put the frypot covers in place (if the fryer is

so equipped).

When shutting the fryers down at closing time, rotate the gas valve knob to the PILOT

position (see Figure 1 on Page 3-1). Depress the gas valve knob and rotate slightly

clockwise. Release and continue rotating clockwise to the OFF position (see Figure 2 on

Page 3-1). Put the frypot covers in place (if the fryer is so equipped).

3.5 Thermostat Operation

The thermostat on GF14/GF40 fryers is connected to a graduated knob located inside the

fryer door. On GF14 models, the knob is on the left side; in GF40 models, the knob is on the

right side. Rotating the knob clockwise to the desired cooking temperature (setpoint)

directly adjusts the thermostat to that temperature. The thermostat controls the frypot

temperature by regulating the gas supply to the burner via the gas valve.

3-3

Page 17

The thermostat is in the full OFF position when the word OFF is at the top of the knob. A

“click” will be heard when the knob is rotated from the OFF position to a temperature, or

when it is rotated back to the OFF position.

The thermostat may require calibration from time to time. To determine if it requires

calibration, refer to Check Thermostat Calibration in Section 4.2 of this manual.

3.6 Draining and Filtering

DANGER

Draining and filtering of cooking oil or shortening must be accomplished with

care to avoid the possibility of a serious burn caused by careless handling.

Frymaster recommends that elbow-length, heat-resistant rubber gloves be

worn when draining or filtering cooking oil or shortening.

Cooking oil or shortening should be filtered at least twice daily and more often if a heavy

volume of breaded product is fried. Filtering will greatly increase the life of the cooking oil

or shortening and will produce a higher quality product. Frymaster recommends the use of

the Frymaster PF50 Portable Filter.

NOTE: When using a portable filtration unit, refer to the unit manufacturer’s operating

instructions for the proper filtering procedures.

The following procedure is recommended to drain and filter your cooking oil or shortening

when a portable filtration unit is not available.

DANGER

NEVER attempt to drain cooking oil or shortening from the fryer with the

burner lit! Doing so may result in a flash fire if the oil or shortening splashes

onto the burner. Also, applying burner heat to an empty frypot will severely

damage the frypot and void the Frymaster warranty.

1. Rotate the gas valve knob to the PILOT or OFF position. Screw the drain extension

supplied with the fryer securely into the drain valve, making sure the opening is pointing

down (see illustration below).

Drain Extension in

stowed position.

Drain Extension screwed

into drain valve.

3-4

Page 18

NOTE: If draining the fryer to dispose of the cooking oil or shortening, Frymaster

recommends the use of a wheeled disposal unit equipped with a pump, such as the

Frymaster SDU 50. When using a disposal unit, follow the unit manufacturer’s

instructions.

2. Position a metal container with a sealable cover under the drain extension. The metal

container must be capable of withstanding the hot cooking oil or shortening without

leaking. Frymaster recommends that a Frymaster filter cone holder and filter cone be

used when a portable filtration unit is not available. If you are using a Frymaster filter

cone holder and filter cone, be sure that the cone holder rests securely on the metal

container.

3. Open the drain valve slowly to avoid splattering.

4. If the drain valve becomes clogged with food particles, use a cleanout rod, available from

Frymaster, to clear the valve by inserting it into the drain opening from the INSIDE of

the frypot.

DANGER

NEVER attempt to clear a clogged valve from the front of the valve! Hot oil or

shortening will rush out creating the potential for severe burns.

DO NOT hammer on the drain valve with the rod or other objects. Damage to

the ball inside will result in leaks and will void the Frymaster warranty.

5. The drained shortening should be allowed to cool to 100°F (38°C) or lower before

transporting the container and removing the drain extension. Cooking oil or shortening at

a temperature of 140°F (60°C) or higher will result in severe burns if it comes in contact

with your skin.

6. After draining the cooking oil or shortening, clean all food particles and residual

oil/shortening from the frypot before refilling. Be careful! The residual oil/shortening

remains hot enough to cause severe burns if it comes in contact with your skin.

7. Close the drain valve and refill the frypot with clean, filtered cooking oil or shortening to

the lower oil level line.

3-5

Page 19

GF14 and GF40 SERIES GAS FRYERS

CHAPTER 4: PREVENTIVE MAINTENANCE AND

OPERATOR TROUBLESHOOTING

4.1 Daily Checks and Services

Inspect Fryer and Accessories for Damage

Look for loose or frayed wires, leaks, foreign material in frypot or inside cabinet, and any other

indications that the fryer and accessories are not ready and safe for operation.

Inspect the burner deflectors or targets to verify that each is positioned directly above its orifice, and

that the flame ignites approximately 2½ inches (60mm) above the orifice. The flame should strike

the center of the deflector and be a rich blue color. Call your Factory Authorized Service Center

(FASC) if you see any problems.

Clean Fryer Cabinet Inside and Out

Clean inside the fryer cabinet with dry, clean cloth. Wipe all accessible metal surfaces and

components to remove accumulations of oil or shortening and dust.

Clean the outside of the fryer cabinet with a clean, damp cloth soaked with dishwashing detergent,

removing oil/shortening, dust, and lint from the fryer cabinet.

DANGER

Never attempt to clean the fryer during the cooking process or when the frypot is

filled with hot oil/shortening. If water comes in contact with oil/shortening heated to

cooking temperature, it can cause the oil/shortening to splatter and severely burn

nearby personnel.

Filter Cooking Oil/Shortening

The cooking oil/shortening used in your fryer should be filtered at least twice every day (more often

if the fryer is in constant use). Refer to Section 3.6, “Draining and Filtering”, for details.

4.2 Quarterly Checks and Services

Drain and Clean Frypot

During normal usage of your fryer, a deposit of carbonized cooking oil or shortening will gradually

form on the inside of the frypot. This deposit must be periodically removed to maintain your fryer’s

efficiency.

Follow the procedures for draining the frypot in Section 3.6, the follow the “Boiling Out the Frypot”

procedures in Section 3.2.

4-1

Page 20

Clean Detachable Parts and Accessories

As with the frypot, a deposit of carbonized oil/shortening will accumulate on detachable parts and

accessories such as baskets and sediment trays.

Wipe all detachable parts and accessories with a clean cloth dampened with a detergent solution.

(Frymaster recommends the use of Frymaster Fryer ‘N’ Griddle Cleaner, available through your local distributor, for best results.) Rinse and thoroughly dry each part.

Check Thermostat Calibration

1. Set the temperature control knob to 375°F (191°C), i.e., fully clockwise.

2. Let the burner cycle on and off automatically three times in order for the cooking oil/shortening

temperature to become uniform. If necessary, stir to get all shortening in the bottom of the frypot melted.

3. Insert a good-grade thermometer or pyrometer probe into the oil/shortening, with the end near

the fryer temperature-sensing probe. NOTE: The temperature-sensing probe is held by clips

welded to the frypot. In GF14 fryers, the probe is on the left side of the frypot; in GF40 models,

it is on the right side.

4. When the burner starts for the fourth time, the thermometer/pyrometer reading should be within

the range 355-385°F (185-196°C). If it is not, calibrate as follows:

a. Remove the thermostat knob by pulling straight out on the knob with a firm, steady pull.

b. Using a small-bladed flat-tipped screwdriver inserted into the slot in the thermostat adjusting

screw, turn the adjusting screw in ¼-turn increments to adjust the temperature. Turning the

screw clockwise decreases the temperature; turning it counter-clockwise increases the

temperature. DO NOT allow the thermostat shaft to turn while turning the adjusting screw.

c. Recheck the thermometer/pyrometer reading the next time the burner comes on.

d. Repeat steps 4.b. through 4.c. until the thermometer/pyrometer reading remains within the

range 355-385°F (185-196°C) through several cycles. If calibration cannot be obtained for

any reason, call a Factory Authorized Service Center for assistance.

e. Reinstall the thermostat knob.

5. Remove the thermometer or pyrometer.

Clean Gas Valve Vent Tube

1. Carefully unscrew the vent tube from the gas valve. NOTE: The vent tube may be straightened

for ease in removal.

2. Pass a piece of ordinary binding wire (.052 inch diameter) through the tube to remove any

obstruction.

3. Remove the wire and blow through the tube to ensure it is clear.

4-2

Page 21

4. Reinstall tube and bend it so that the opening is pointing downward.

4.3 Semi-Annual Checks and Service

Check Burner Manifold Pressure

WARNING

This task should be performed by qualified service personnel only.

WARNING

The frypot must be filled with water or cooking oil/shortening during this procedure.

1. Ensure that the gas valve knob is in the OFF position.

2. Remove the pressure tap plug from burner manifold.

Pressure

Tap Plug

3. Insert the fitting for a manometer or pressure gauge into the pressure tap hole.

4. Place the gas valve in the PILOT position and light the pilot. When the pilot lights and

continues to burn, increase the setting on the thermostat knob until the burner lights. Compare

the manometer or gauge reading to the appropriate table below.

GF14 Standard

for Burner Manifold Pressure

Gas Type Pressure

Natural

LP

(1.00 kPa or 9.96 mbar)

(2.49 kPa or 24.91 mbar)

4.0” WC

10.0” W.C

for Burner Manifold Pressure

Gas Type Pressure

Natural

LP

GF40 Standard

3.5” WC

(0.87 kPa or 8.72 mbar)

8.25” W.C.

(2.06 kPa or 20.55 mbar)

4-3

Page 22

5. If the burner manifold pressure does not meet the specifications in the tables in Step 4, unscrew

the slotted cap from the top of the gas valve regulator (adjacent to the gas valve vent tube) and

turn the adjusting screw to obtain the correct pressure. Turn the screw clockwise to increase

pressure, counter-clockwise to decrease pressure.

6. After adjusting the manifold pressure to the correct value, reinstall the regulator cap and turn the

gas valve knob to the OFF position.

7. Remove the manometer or pressure gauge fitting from the pressure tap hole and reinstall the pipe

plug.

8. Place the gas valve in the PILOT position and check for gas leaks. If no leaks are found, re-light

the pilot and return the unit to operation.

4.4 Operator Troubleshooting

The tables that follow provide operators with a list of possible malfunctions, the probable causes of

the malfunctions, and the corrective actions to take to correct the problem.

In some cases the operator may not be able to correct the problem, but will at least be able to

accurately diagnose the problem, and that will assist a qualified service technician in restoring the

equipment to full operation in the shortest possible time.

4-4

Page 23

Problem Probable Cause Corrective Action

A. Pilot is not lit. A. Light pilot.

Burner does

not light at all.

B. Loose, dirty, or corroded terminals

on gas valve.

C. Loose, dirty, or corroded terminals

on thermostat.

D. Thermostat, gas valve, or hi-limit

wires broken or shorted.

E. Thermostat out of calibration. E. Check calibration of thermostat in

F. If the above causes have all been

ruled out, the probable causes are

a failed thermostat or a failed gas

valve.

A. One or more burner orifices

clogged.

B. Clean and tighten terminals on gas

valve.

C. Clean and tighten terminals on

thermostat.

D. Examine wires for signs of

abrasions, cuts, kinks, etc. If the

wiring is obviously damaged, it

will probably be necessary to

replace the associated component.

Call FASC.

accordance with procedures in

Section 4.2 of this manual.

F. Call FASC.

A. Turn gas valve knob to OFF

position. Use thin wire to clear

obstruction from burner orifices.

Burner does

not light all the

way around.

B. Blocked flue. B. Clear blockage from flue.

C. Fryer flue connected directly to

vent hood with a chimney-like

duct.

D. If the above causes have all been

ruled out, the probable causes are

a broken or missing target (GF40),

a bent or missing flame deflector

(GF14), or incorrect burner gas

pressure.

C. Remove chimney-like duct and

allow for at least 18” (45.7cm) between flue outlet and vent hood

filters.

D. Call FASC.

4-5

Page 24

Problem Probable Cause Corrective Action

A. Too little make-up air in kitchen. A. Adjust kitchen ventilation system

to increase make-up air.

Burner

experiences

delayed

ignition.

Flame rolling

out from under

fryer.

B. Pilot flame directed away from

first orifice of burner.

C. One or more burner orifices

clogged.

D. If the above causes have all been

ruled out, the probable causes are

low pilot flame (less than 1”

(25mm)), low incoming gas pressure, or a too small incoming gas

line.

A. Flue obstructed. A. Remove obstruction from flue.

B. Too little make-up air in kitchen. B. Adjust kitchen ventilation system

A. Clogged pilot orifice. A. Use a small wire to clear

B. Pilot flame blowing away from

pilot generator (excessive draft in

kitchen).

B. Reposition pilot hood to direct

flame toward first burner orifice.

C. Use a thin wire to clear

obstruction from orifices.

D. Call FASC

to increase make-up air.

obstruction from pilot orifice.

B. Eliminate draft in kitchen.

Pilot repeatedly

goes out.

C. Pilot generator not inserted fully

into pilot burner.

D. Corroded connection where pilot

generator connects to gas valve.

E. If all of the above causes have

been ruled out, the probable

causes are low pilot flame, pilot

generator low millivolt output,

high resistance in hi-limit

thermostat contacts, or a defective

pilot magnet in the gas valve.

C. Reinsert pilot generator into pilot

burner until flame surrounds tip.

D. Clean pilot generator connection

at gas valve.

E. Call FASC.

4-6

Page 25

Problem Probable Cause Corrective Action

Pilot remains lit

when gas valve

knob is pushed

in, but goes out

when released.

Thermostat

does not control

at set point.

A. Loose, dirty or corroded hi-limit

wires.

B. If the above does not correct the

problem, the probable causes are a

weak gas valve pilot magnet, pilot

generator low millivolt output, or

a high-limit thermostat stuck open.

A. Thermostat out of calibration. A. Check calibration of thermostat in

B. Failed thermostat. B. Call FASC.

A. Clean/tighten hi-limit wires on gas

valve.

B. Call FASC.

accordance with procedures in

Section 4.2 of this manual.

4-7

Page 26

Frymaster, L.L.C., 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

Price: $5.00

819-5887

MAR 2002

Loading...

Loading...