Page 1

FREIGHTLINER FLD 120

FREIGHTLINER FLD 120

CPL SYSTEMS / GROENEVELD

CPL SYSTEMS / GROENEVELD

AUTOMATIC GREASING SYSTEM

AUTOMATIC GREASING SYSTEM

INSTALLATION MANUAL FOR

INSTALLATION MANUAL FOR

CUSTOMER SERVICE TECHNICIANS

CUSTOMER SERVICE TECHNICIANS

May 6, 1999 1

Page 2

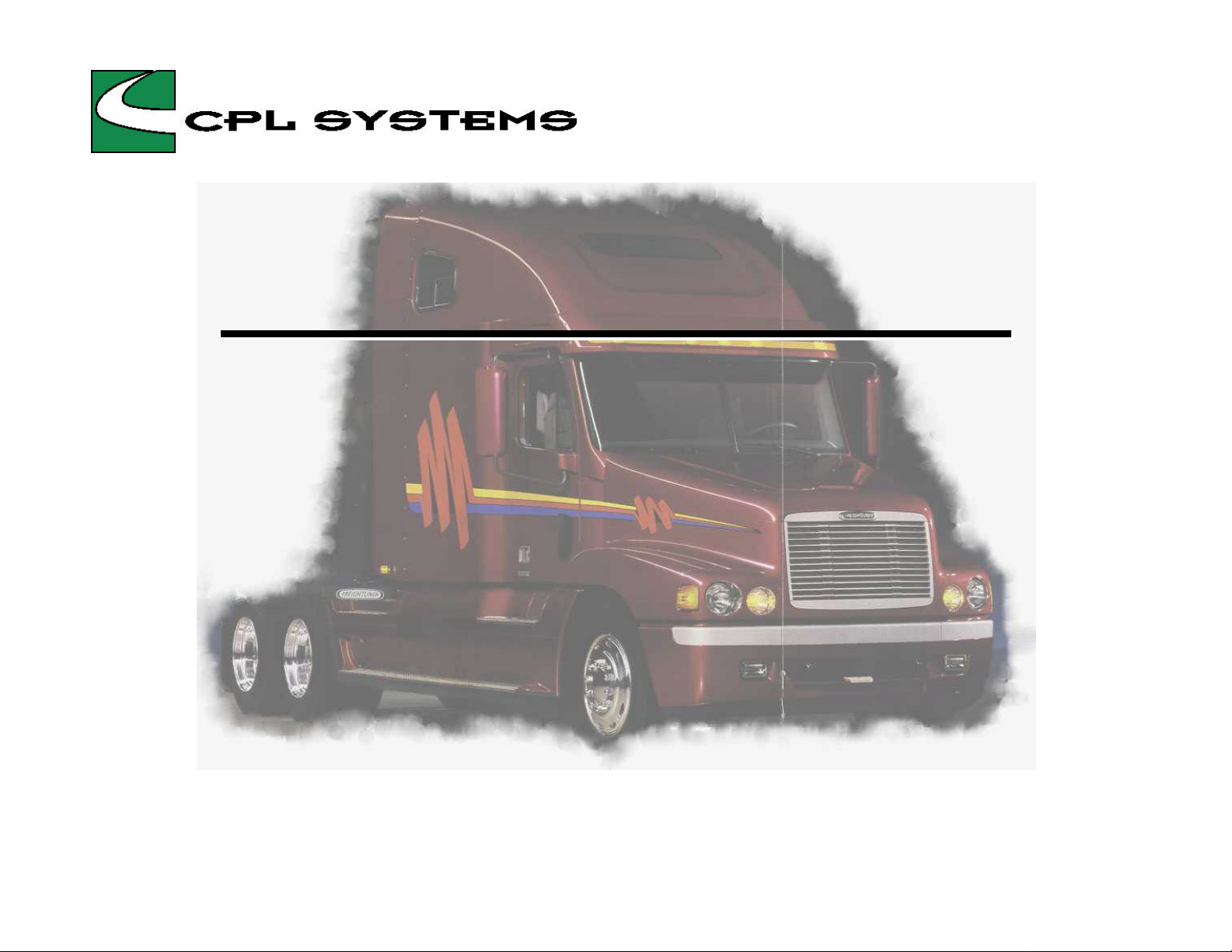

Mount bracket with 5/16” - 18 x 1”

bolt, 5/16” flat washer and lockwasher through existing hole

PUMP MOUNTING - FLD 120

Use drill template DT003 to

drill two 11/32” holes in stack

support to mount pump

large tyraps two spots

Pump mounted on the exhaust stack support using ‘FREIGHT’ bracket, 5/16” - 18 x 1 1/2” bolts, nuts & washers

May 6, 1999 2

Page 3

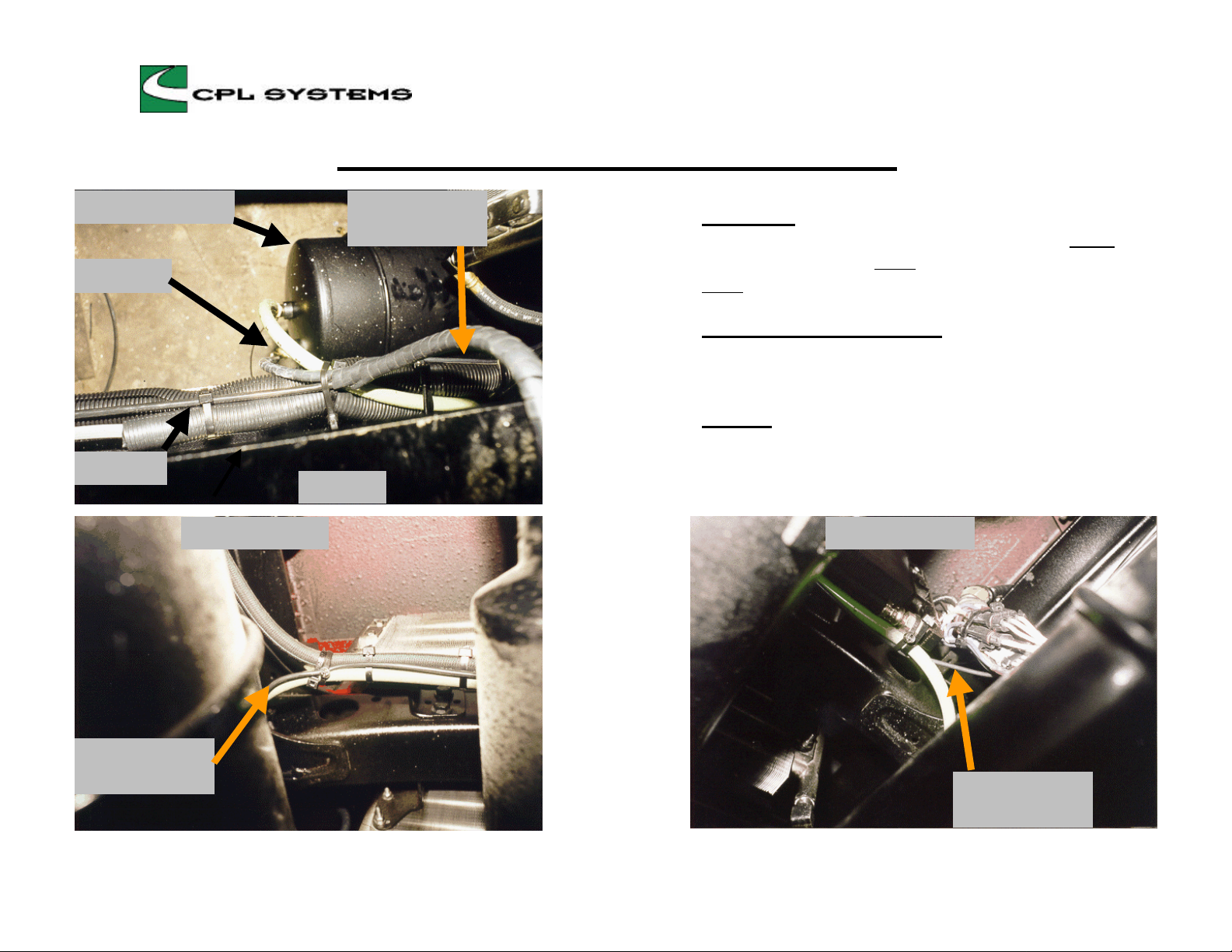

AIR & ELECTRICAL - FLD 120

secondary air tank

air supply

main line

bottom view L/S

electrical, timer

to solenoid

top view

Air Supply: take it from the highest outlet available

in a ‘secondary’ air tank (i.e.. Top, end or side). Never

connect to the bottom, never connect to a ‘wet’ tank,

never connect to a ‘primary’ tank

Electrical - Timer to Solenoid: route with

existing hoses etc. where possible - do not crush

any air lines or wiring with tyraps

General: avoid sharp bends and corners, protect

with spirap where necessary

bottom view R/S

electrical, timer

to solenoid

May 6, 1999 3

electrical, timer

to solenoid

Page 4

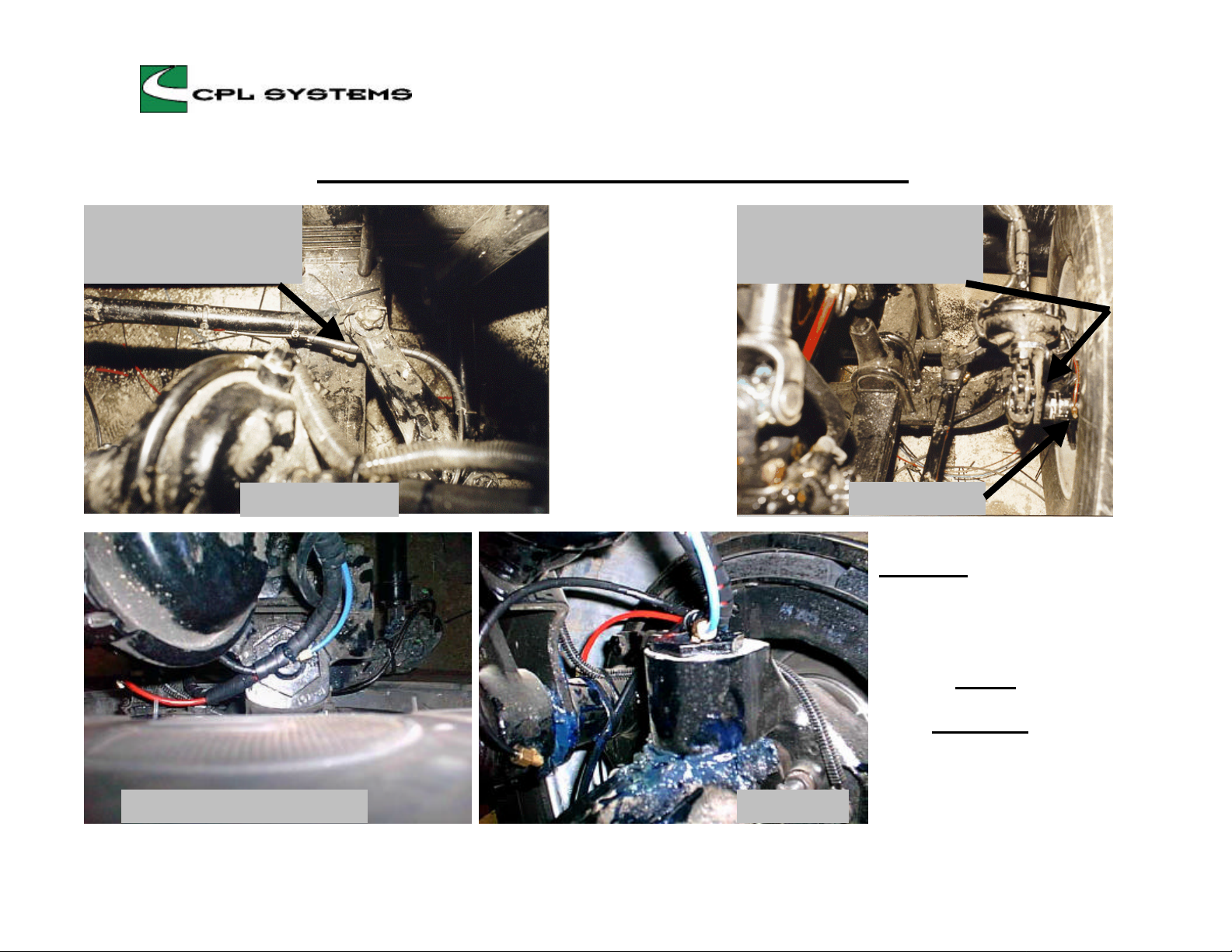

LEFT FRONT WHEEL - FLD 120

Most Freightliners have

shocks - this routing will

help avoid an interference

draglink, top view

kingpin & cam tube, top view

See note on right front wheel

page about the direction of

the slack fitting

cam tube, front

Important: fill cam tube with

grease before removing the zerk

fitting. Fill until grease can be seen

squeezing out between the cam

tube bushing and the slack

adjuster. Do Not assume it has been

done already even if someone says

it has. Make sure! Always cycle the

steering from ‘lock to lock’ to make

sure sufficient clearance is

left knuckle

available between fittings and lines

to all components

May 6, 1999 4

Page 5

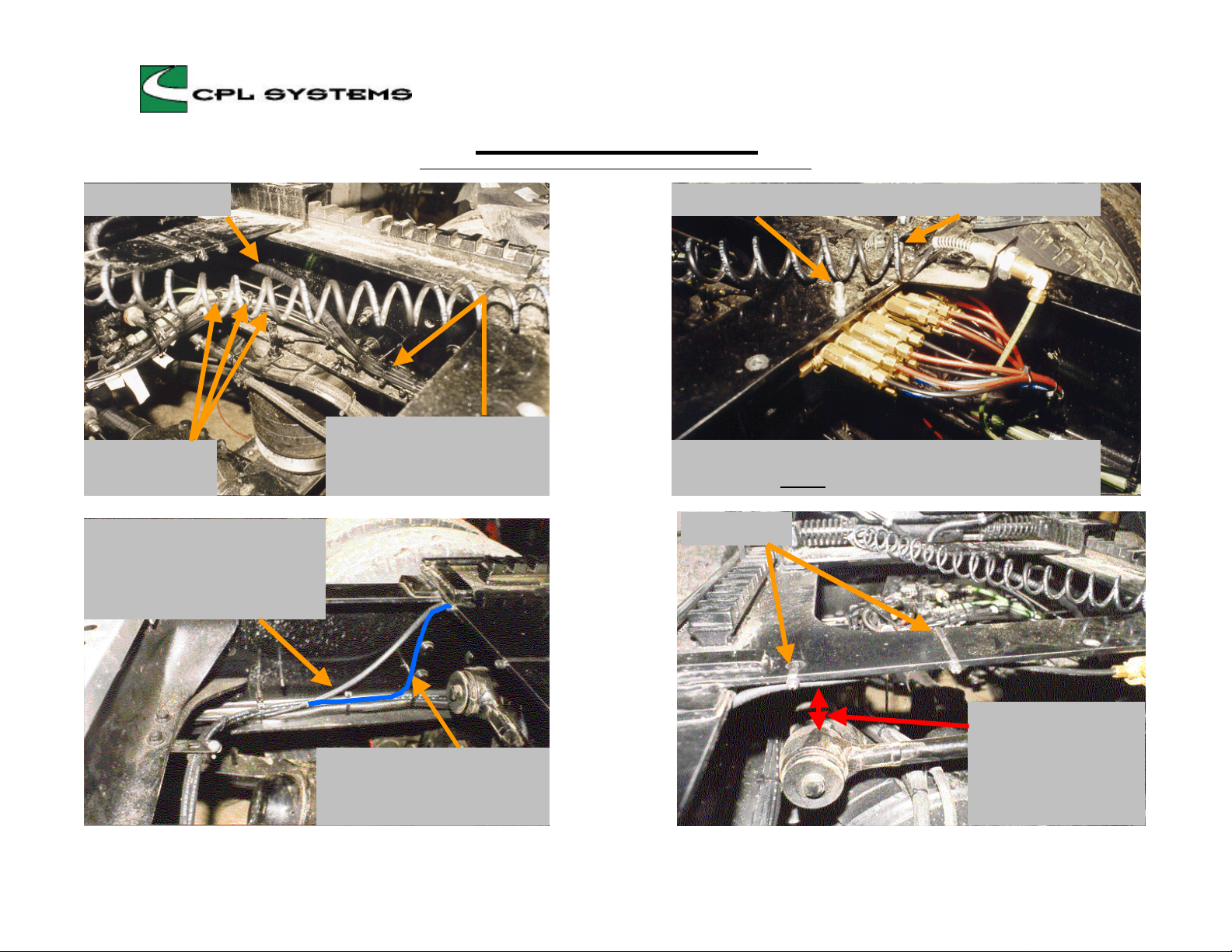

LEFT FRONT FRAME RAIL - FLD120

12 port block electrical, timer

to pressure switch

follow brake hose to

brake chamber

Electrical - timer to pressure switch: coil some

extra wire at the manifold so the pressure switch and

waterproof connector can be serviced easily.

General: grease lines are to be routed along the brake hose

from end to end. Install a large tyrap on the brake hose

fitting at the frame end, small tyraps every 3 or 4” along the

brake hose and a large tyrap, double wrapped, on the brake

hose fitting at the brake chamber end. Tyrap to the brake

hose only,do not include any ABS wiring in CPL tyraps.

May 6, 1999 5

triple grease line, blue and black to the spring

shackle, red to the transmission cross shaft

large tyrap to

huck bolt

spring shackle points

Page 6

FIFTH WHEEL

(3500 series on a Freightliner FLD 120, manifold mounted at the front of the slide plate)

secondary lining

large tyraps on

main line

This mainline to manifolds

on fifth wheel deck could be

routed a little different to

improve the installation

Lines to be spiraped back

to where movement

begins, tyrap there too

These studs need to be ground off flush with the nuts

keep manifold mounted close to the frame rail, out of

harm’s way. Never drill holes in the frame rail flange.

large tyraps

do not put anything

between the torque

This blue line represents

ideal routing to minimize

movement and vibration

rod / bracket and the

fifth wheel deck - it

may get crushed !

May 6, 1999 6

Page 7

RIGHT FRONT WHEEL - FLD 120

note that this fitting in the slack is pointing

upward so it and the lining will not hit the

axle ‘I’ beam when the wheels are turned

top view

rear view

Important !

Fill the cam tube with grease before removing

the zerk fitting. Fill until grease can be seen

squeezing out between the cam tube bushing

and the slack adjuster.

Do Not assume it has been done

already even if someone says it has.

Make sure!

Always cycle the steering from ‘lock to lock’

to make sure sufficient clearance is available

front view

between fittings and lines to all components.

May 6, 1999 7

Page 8

RIGHT FRONT FRAME RAIL - FLD 120

frame end, small tyraps every 3 or 4” along the brake hose and a large tyrap

triple grease line - blue

and black to the shackle,

red to the clutch cross shaft

tyrap to Huck bolt

9 port block

follow brake hose

to knuckle area

clamp to stud

mainline can go through the frame rail protect with spirap and

secure with tyraps

OR it can be routed with the line going

to the front spring pin and go under the

rail to cross to the other side like this

blue line

Spring

shackle

points

May 6, 1999 8

General: grease lines to the knuckle area are to be routed along the brake

hose from end to end. Install a large tyrap on the brake hose fitting at the

on the hose fitting at the brake chamber end. Tyrap to the brake hose only,

do not include any ABS wiring in CPL tyraps.

Page 9

DRIVE AXLE - FLD 120

large tyrap on brake hose fitting, both ends

and also on brake chamber clamp

Our tyraps

ABS bundle

Follow the brake lines down to the brake

chamber, do not put our tyraps around the

ABS wiring bundle

Important !

Fill cam tubes with grease before removing zerk fittings.

Fill until grease can be seen squeezing out between

the cam tube bushing and the slack adjuster.

Do Not assume it has been done

already even if someone says it has.

Make sure!

General: grease lines are to be routed along the brake hoses

from end to end. Install a large tyrap, double wrapped, on the

brake hose fitting at the frame end, small tyraps every 3 or 4”

along the brake hose and a large tyrap, double wrapped, on the

brake hose fitting at the brake chamber end. Tyrap to the

brake hose only, do not include any ABS wiring in CPL tyraps.

May 6, 1999 9

Page 10

CLUTCH CROSS SHAFT - FLD 120

passenger side clutch cross shaft optional

must be on the Customer sales

to clutch release bearing

order

driver’s side clutch cross shaft

May 6, 1999 10

Page 11

TIMER & ELECTRICAL - FLD 120

wiring for solenoid and pressure switch entering

cab through firewall under windshield

ground

terminal

Electrical - timer to solenoid and pressure switch:

route through grommet with existing wiring and tyrap

without crushing the bundle - route our wires so they are

protected - avoid sharp edges - use grommets if necessary.

May 6, 1999 11

Timer can’t get hit or wet,

12 volts (+),

ignition ‘on’

terminal

Always confirm both the ground and the 12 volt “ignition”

source in the electrical panel with a multimeter

keep wires neat

Page 12

TIMER & ELECTRICAL - FLD 120

wiring for solenoid and pressure switch entering

cab through firewall under windshield

(Special timer location - Stone Transport)

Electrical - timer to solenoid and pressure switch:

route through grommet with existing wiring and tyrap

without crushing the bundle - route our wires so they are

protected - avoid sharp edges - use grommets if necessary.

May 6, 1999 12

ground

terminal

timer tyrapped

12 volts (+),

ignition ‘on’

terminal

Always confirm both the ground and the 12 volt “ignition”

source in the electrical panel with a multimeter

in place

Page 13

IM002-1

A B

REVISIONS

ZONE REV DESCRIPTION DATE APPROVED

A

B

A

1 2 2

3 2

3 2

B1,2

#2 injector size, rear cams, were #1

C

04/29/99 Murray

3

3

3 3

2

1 2 2 1 3

3 3

1

3 3 3

2

2

A

B

3

2

2

2

1

3 3

3 3

2

3 1

1

optional

0

release bearing

1

33

SECONDARY

AIR TANK

- Freightliner FLD120

stack brkt

Used on

1

8

2 2 2

9 9 8 2

2 2

C

2

2

2

2

2

2

2

2

NOTE - see the "5th Wheel Manual"

for specifics on the secondary routing

2

2

2

2

2

1

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

pump

main grease line

air supply line

A

INSTALLATION SCHEMATIC

(with Holland 351 series, 4 points on top, 2 on pivot pockets

manifold chassis mounted, with pins, shackles and release bearing)

SIZE DWG NO. REV

DATE DRAWN

04/24/98 IM002-1

A

SCALE SHEET

none M Ouellette 1 1

BY OF

B

new

May 6, 1999 13

Page 14

MA001

A B

ZONE REV DESCRIPTION DATE APPROVED

B2 A

441.01 was 145.01 04/28/99 Murray

REVISIONS

438.01

2

draglink - black

2.6 M

2.2 M

1.8 M

1

draglink - red

k/pin btm - black

tie rod - red

slack - black

brake cam - red

k/pin top - blue

225.01

125.01

441.01

438.01

2

2

3

2

2

1

3

1

3

3

3

072.01

009.01

frt s/pin - black

clutch c/shaft - red

spring shackle - blue

spring shackle - black

wrap with teflon

1.4 M

2.6 M

USED ON

- Freightliner FLD120

- Mack CH w/14K frt axle

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

2

1

# 1 injector - 010.01

# 2 injector - 011.01

# 3 injector - 012.01

A

MANIFOLD ASS'Y, L/F

(with spring pins & shackles)

SIZE DWG NO. REV

DATE DRAWN

04/28/98 MA001

A

SCALE SHEET

none M Ouellette 1 1

BY OF

B

A

May 6, 1999 14

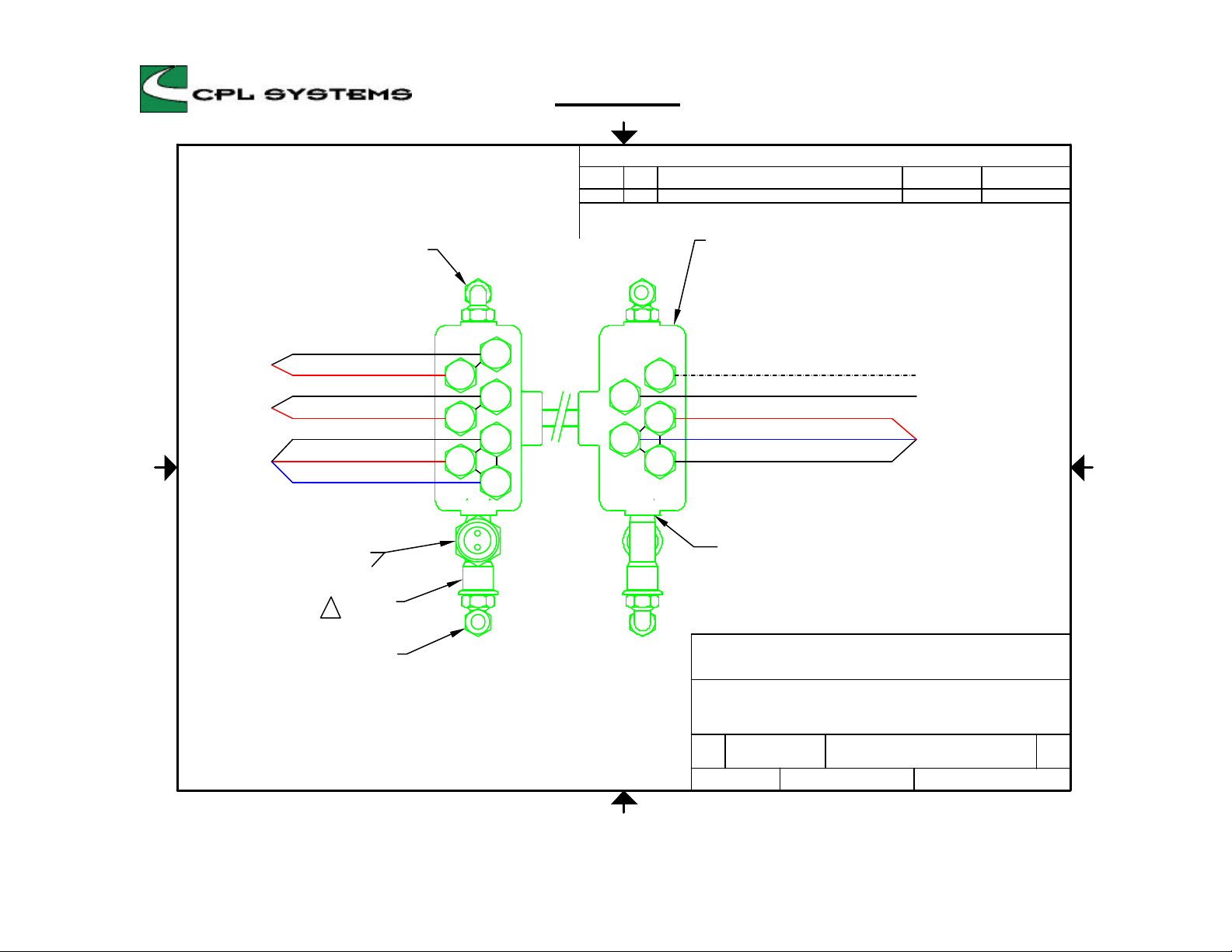

Page 15

MA002

A B

ZONE REV DESCRIPTION DATE APPROVED

A1 A 442.01 was 127.01 04/28/99

REVISIONS

Murray

438.01

2

brake cam - red

1.9 M

2.2 M

1.5 M

1.4 M

1

k/pin top - blue

slack - black

k/pin btm - black

tie rod - red

spring shackle - black

clutch c/shaft -red

spring shackle - blue

frt spring pin - black

442.01

1

3

2

3

2

3

1

3

3

071.01

USED ON

- Freightliner FLD120

- Mack CH w/14K frt axle

2

1

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

# 1 injector - 010.01

# 2 injector - 011.01

# 3 injector - 012.01

A

MANIFOLD ASSEMBLY, R/F

(with spring pins & shackles)

SIZE DWG NO. REV

DATE DRAWN

04/29/98 MA 002

A

SCALE SHEET

none M Ouellette 1 1

BY OF

B

A

May 6, 1999 15

Page 16

MA003

A B

REVISIONS

ZONE REV DESCRIPTION DATE APPROVED

A,B 1 A

B1 B rear was side, front was top 04/22/99

A2

C

439.01

2

069.01

F122-B

wrap with teflon

both ends

lining colour and location added 08/18/98 MO

Murray

C 439.01 was 112.01, #2's were #1's 04/28/99 Murray

069.01

438.01

2

right side left side

8

2 2 2

9

5th wheel front, blue

5th wheel pivot, red

to right

side

# 1 injector - 010.01

# 2 injector - 011.01

1

# 8 injector - 017.01

# 9 injector - 124.02

5th wheel rear, black

NOTE: secondary lining shown for

installers reference only - to be

completed during installation

A

9

5th wheel front, blue

5th wheel pivot, red

to left

side

C

2

8

BB

slack - black

cam - red

5th wheel rear, black

to right side

2

slack - black

C C C

2

2

2 2

cam - red

slack - black

cam - red

to left side

2

slack - black

cam - red

1

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

MANIFOLD ASS'Y, REAR

(Holland or Fontaine, 4 points on top, 2 on pivot

pockets, manifold chassis mounted)

SIZE DWG NO. REV

DATE DRAWN

04/29/98 MA003

A

SCALE SHEET

none M Ouellette 1 1

BY OF

B

C

May 6, 1999 16

Page 17

MA013

A B

ZONE REV DESCRIPTION DATE APPROVED

A1 A 441.01 was 145.01 04/28/99 Murray

REVISIONS

438.01

2

draglink - black

2.6 M

2.2 M

1.8 M

1

draglink - red

k/pin btm - black

tie rod - red

slack - black

brake cam - red

k/pin top - blue

225.01

125.01

441.01

A

438.01

# 0 injector - 030.01

# 1 injector - 010.01

# 2 injector - 011.01

# 3 injector - 012.01

2

2

3

2

2

1

0

3

1

3

3

3

A

072.01

clutch release bearing - black ? M

frt spring pin - black

clutch c/shaft - red

spring shackle - blue

spring shackle - black

wrap with teflon

1.4 M

2.6 M

USED ON

- Freightliner FLD120

- Mack CH w/14K frt axle

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

MANIFOLD ASS'Y, L/F

w/spring pins, shackles & clutch release bearing

SIZE DWG NO. REV

DATE DRAWN

01/07/99 MA013

A

SCALE SHEET

none M Ouellette 1 1

BY OF

B

2

1

A

May 6, 1999 17

Page 18

B

FS3749-4A

MA021

A B

ZONE REV DESCRIPTION DATE BY

B2

A2, B1 B FS3748-4B & 3749-4B removed, 518B

A FS3749-4B and FS3749-4A added

was IR503, Parker re-usables added

REVISIONS

04/06/99 Murray

05/14/99 Murray

9

2

2

front

pivot

rear

SL059

This kit is set up to cover most situations. Parts

in the list below with an 'asterisk' (*) are loose.

See the Power Point presentation for the manifold

sub-assembly detail. It can be found in

F:\Inventory\Sub-assemblies\MA021.ppt

2

8

1

B

*

B

*

*

B

1

2

8

9

pivot

rear

SL060

front

ITEM QUAN

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

MANIFOLD ASSEMBLY

(Holland 351 series, 4 on top, 2 pivot, block

mounted on 5th wheel)

SIZE DWG NO. REV

04/23/99 MA021

A

SCALE SHEET

none M Ouellette 1 1

A

20151-4-3 reusable, 3/16 Parflex, 1/4 npt

1

441.01

MA019

1

1 SL059 secondary line, 3/16 triple

1 SL060

011.01

2

017.01

2

2

124.02 injector, #9

1 FS3749-4A connector, 90, 1/8npt - 1/4JIC

6.5 518B-3

1 20651-4-3 reusable, 3/16 Parflex, 1/4 JIC

1

SB16-05971 plug, 1/8npt

1

SB16-00344

1

W-179

1 SB16-00518 washer, lock, 3/8"

2 TY27MX tyrap, large

2 TY25MX tyrap, small

DATE DRAWN

P.N.

BY OF

tee, male run, 'O' ring*

manifold, 6 port

secondary line, 3/16 triple

injector, #2

injector, #8

Parflex, 3/16" I.D. (feet)

bolt, 3/8"-16 x 1 1/4"

washer, flat, fender, 3/8"

DESCRIPTION

B

1

A

May 6, 1999 18

Page 19

MA024

A B

ZONE REV DESCRIPTION DATE APPROVED

B1 A plug 442.01 removed

071.01

REVISIONS

04/06/99 Murray

2

Secondary lining shown for

illustration only. Lining to be

provided and installed by

a CST.

1

slack - black

cam bushing - red

slack - black

cam bushing - red

009.01

cam bushing - red

slack - black

cam bushing - red

slack - black

# 2 injector - 011.01

A

438.01

2

2

2

2

2

2

2

2

2

A

ITEM QUAN

1 009.01 plug, injector location

011.01 injector, #2

8

438.01

1

1

071.01

P.N.

connector, 90, 'O' ring - 3/16"

manifold, transport, 9 PORT

DESCRIPTION

1

CPL SYSTEMS

PHONE (905)875-1017 FAX (905)875-2125

MANIFOLD ASSEMBLY, REAR

(used along with a manifold mounted on fifth wheel)

SIZE DWG NO. REV

DATE DRAWN

04/27/99 MA024

A

SCALE SHEET

none M Ouellette 1 1

BY OF

B

A

May 6, 1999 19

Loading...

Loading...