Freightliner FLA COE, FLB COE, FLC 112 Conventional, FLD Conventional, FLL COE Maintenance Manual

HEAVY-DUTY TRUCKS MAINTENANCE MANUAL

Models: FLA COE

FLB COE

FLC 112 Conventional

FLD Conventional

FLL COE

STI-329-1 (10/09P)

Published by

Daimler Trucks North America LLC

4747 N. Channel Ave.

Portland, OR 97217

Printed in U.S.A.

Foreword

When performed on a regular basis, lubricating the parts of your vehicle is the least costly way

of obtaining safe and reliable vehicle operation. Added benefits and savings occur when you

check that the engine, undercarriage, and noise emission control parts are in good working order

during lubrication.

IMPORTANT: The maintenance operations in this manual are not all-inclusive. Also

refer to other component and body manufacturers’ instructions for specific inspection

and maintenance instructions.

Perform the operations in this maintenance manual at scheduled intervals. Perform the pretrip

and post-trip inspections, and daily/weekly/monthly maintenance, as outlined in the vehicle

driver’s manual. Major components, such as engines, transmissions, and rear axles, are covered

in their own maintenance and operation manuals, that are provided with the vehicle. Perform any

maintenance operations listed at the intervals scheduled in those manuals. Your Freightliner

Dealership has the qualified technicians and equipment to perform this maintenance for you.

They can also set up a scheduled maintenance program tailored specifically to your needs.

Optionally, they can assist you in learning how to perform these maintenance procedures.

IMPORTANT: Descriptions and specifications in thismanual were in effect at the time of

printing. Freightliner Trucks reserves the right to discontinue models and to change

specifications or design at any time without notice and without incurring obligation.

Descriptions and specifications contained in this publication provide no warranty,

expressed or implied, and are subject to revision and editions without notice.

Refer to www.Daimler-TrucksNorthAmerica.com and www.FreightlinerTrucks.com for more

information, or contact Daimler Trucks North America LLC at the address below.

Environmental Concerns and Recommendations

Whenever you see instructions in this manual to discard materials, you should attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and

regulations when disposing of materials.

NOTICE: Parts Replacement Considerations

Do not replace suspension, axle, or steering parts (such as springs, wheels, hubs, and steering

gears) with used parts. Used parts may have been subjected to collisions or improper use and

have undetected structural damage.

© 1993–2009 Daimler Trucks North America LLC

All rights reserved. No part of this publication, in whole or in part, may be translated, reproduced,

stored in a retrieval system, or transmitted in any form by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of Daimler Trucks

North America LLC. Daimler Trucks North America LLC is a Daimler company.

Daimler Trucks North America LLC

Service Systems and Documentation (POC-SSD)

P.O. Box 3849

Portland, OR 97208–3849

Descriptions of Service Publications

Introduction

Daimler Trucks North America LLC distributes the following major service publications in paper and electronic

(via ServicePro

Workshop/Service

Manual

®

) formats.

Workshop/service manuals contain service and repair information for all vehicle

systems and components, except for major components such as engines, transmissions, and rear axles. Each workshop/service manual section is divided into

subjects that can include general information, principles of operation, removal,

disassembly, assembly, installation, and specifications.

Maintenance Manual Maintenance manuals contain routine maintenance procedures and intervals for

vehicle components and systems. They have information such as lubrication

procedures and tables, fluid replacement procedures, fluid capacities, specifications, and procedures for adjustments and for checking the tightness of fasteners. Maintenance manuals do not contain detailed repair or service information.

Driver’s/Operator’s

Manual

Driver’s/operator’s manuals contain information needed to enhance the driver’s

understanding of how to operate and care for the vehicle and its components.

Each manual contains a chapter that covers pretrip and post-trip inspections,

and daily, weekly, and monthly maintenance of vehicle components.

Driver’s/operator’s manuals do not contain detailed repair or service information.

Service Bulletins Service bulletins provide the latest service tips, field repairs, product improve-

ments, and related information. Some service bulletins are updates to information in the workshop/service manual. These bulletins take precedence over

workshop/service manual information, until the latter is updated; at that time, the

bulletin is usually canceled. The service bulletins manual is available only to

dealers. When doing service work on a vehicle system or part, check for a valid

service bulletin for the latest information on the subject.

IMPORTANT: Before using a particular service bulletin, check the current

service bulletin validity list to be sure the bulletin is valid.

Parts Technical Bulletins Parts technical bulletins provide information on parts. These bulletins contain

lists of parts and BOMs needed to do replacement and upgrade procedures.

Web-based repair, service, and parts documentation can be accessed using the following applications on the

AccessFreightliner.com website.

®

ServicePro ServicePro

publications listed above. In addition, the Service Solutions feature provides diagnostic assistance with Symptoms Search, by connecting to a large knowledge

base gathered from technicians and service personnel. Search results for both

documents and service solutions can be narrowed by initially entering vehicle

identification data.

PartsPro PartsPro

build record.

EZWiring EZWiring

Freightliner Custom Chassis Corporation products’ wiring drawings and floating

pin lists available online for viewing and printing. EZWiring can also be accessed from within PartsPro.

provides Web-based access to the most up-to-date versions of the

®

is an electronic parts catalog system, showing the specified vehicle’s

™

makes Freightliner, Sterling, Western Star, Thomas Built Buses, and

Heavy-Duty Trucks Maintenance Manual, October 2009 I–1

Introduction

Descriptions of Service Publications

Warranty-related service information available on the AccessFreightliner.com website includes the following

documentation.

Recall Campaigns Recall campaigns cover situations that involve service work or replacement of

parts in connection with a recall notice. These campaigns pertain to matters of

vehicle safety. All recall campaigns are distributed to dealers; customers receive

notices that apply to their vehicles.

Field Service Campaigns Field service campaigns are concerned with non-safety-related service work or

replacement of parts. All field service campaigns are distributed to dealers; customers receive notices that apply to their vehicles.

I–2 Heavy-Duty Trucks Maintenance Manual, October 2009

Page Description

Introduction

For an example of a

Heavy-Duty Trucks Maintenance Manual

A

BC

page, see Fig. 1.

D

11/28/2001

A. Maintenance Operation Number consists of Group Number followed by Sequence Number

B. Group Title

C. Group Number

D. Release Date

E. Group/Page Number

Fig. 1, Example of a Heavy-Duty Trucks Maintenance Manual Page

Heavy-Duty Trucks Maintenance Manual, October 2009 I–3

E

f020034

Introduction

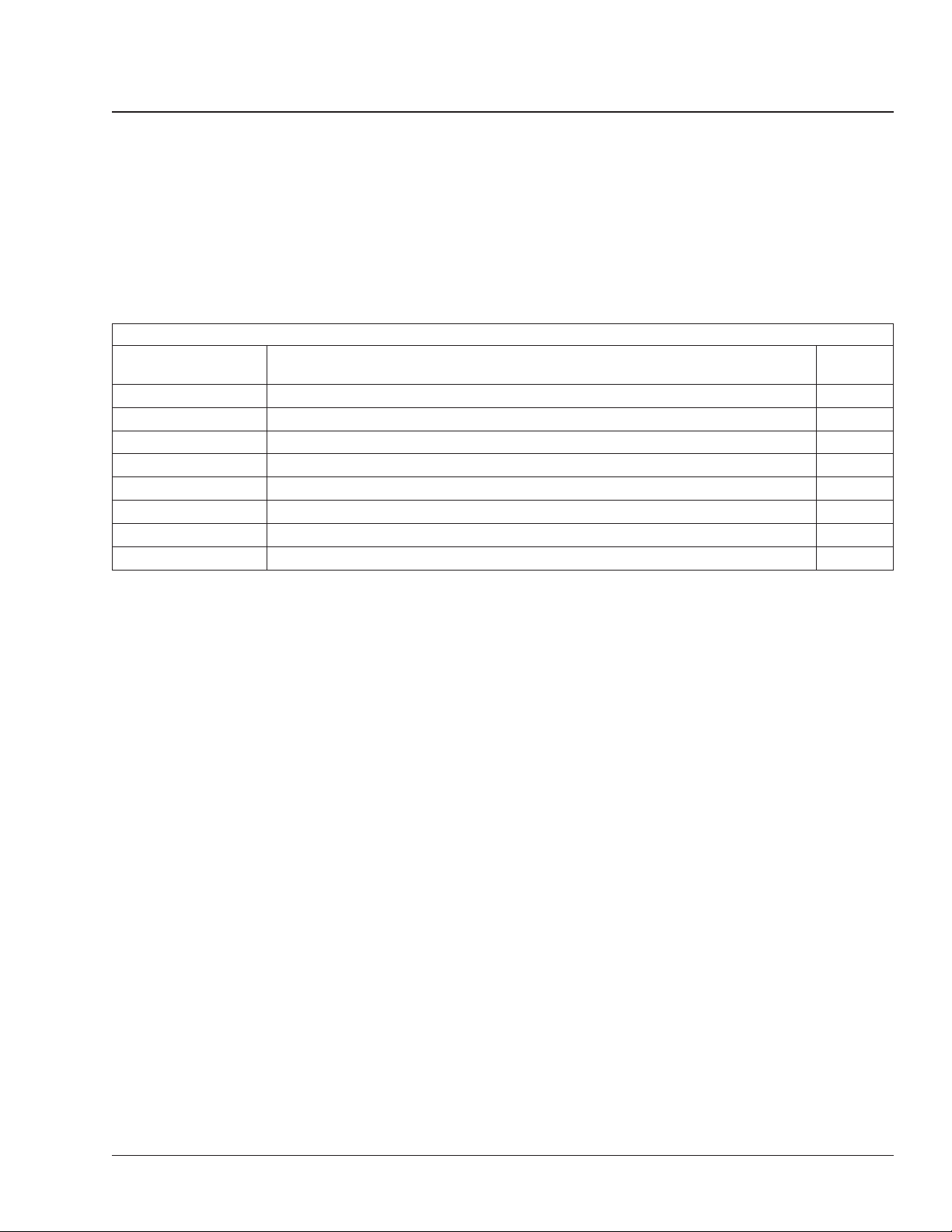

Group No. Group Title

00...................... General Information

01................................ Engine

09.............................. AirIntake

13......................... AirCompressor

15................... Alternators and Starters

20................... Engine Cooling/Radiator

25................................ Clutch

26........................... Transmission

31............. Frame and Frame Components

32............................ Suspension

33............................. Front Axle

35 ............................. Rear Axle

40........................ Wheels and Tires

41.............................. Driveline

42................................ Brakes

46............................... Steering

47 ................................. Fuel

49............................... Exhaust

54.......... Electrical, Instruments, and Controls

60.................................. Cab

72................................ Doors

83................. Heater and Air Conditioner

Maintenance Manual Contents

I–4 Heavy-Duty Trucks Maintenance Manual, October 2009

General Information 00

Index, Alphabetical

Title of Maintenance Operation (MOP) MOP Number

COE Cab Tilting, FLA/FLB ........................................................... 00–11

Determining Scheduled Maintenance Intervals.............................................00–01

Initial Maintenance (IM) Operations.....................................................00–06

Lubrication and Fluid Level Check ..................................................... 00–04

M1 Maintenance Interval Operations Table: 00-07..........................................00–07

M2 Maintenance Interval Operations Table: 00-08..........................................00–08

M3 Maintenance Interval Operations Table...............................................00–09

M4 Maintenance Interval Operations Table: 00-10..........................................00–10

Maintenance Operation Sets Table.....................................................00–05

Maintenance Service Table...........................................................00–02

Metric/U.S. Customary Conversion Tables................................................00–14

Noise Emission Controls Maintenance...................................................00–12

Torque Specifications Tables..........................................................00–15

Vehicle Maintenance Schedule Tables...................................................00–03

Verification of Inspections Log.........................................................00–13

Heavy-Duty Trucks Maintenance Manual, October 2009

General Information 00

Determining Scheduled Maintenance Intervals: 00–01

Determining Scheduled

Maintenance Intervals

Performing regular maintenance on your Freightliner

vehicle will help ensure that your vehicle delivers

safe reliable service and optimum performance for

years to come. Failure to follow a regular maintenance program can result in inefficient operation and

unscheduled down time.

To determine the correct maintenance intervals for

your vehicle you must first determine the type of service or conditions in which the vehicle will operate.

Generally, most vehicles operate under conditions

that fall within one of the three types of service described. Before placing your new vehicle in service,

determine the type of service (Service Schedule I, II,

or III) that applies to the intended use of the vehicle.

After determining the vehicle’s type of service, refer

to the Maintenance Service Table or the Vehicle

Maintenance Schedule Tables, to determine how

often maintenance should be performed.

When the vehicle reaches the distance given for a

maintenance interval, see the applicable Maintenance Interval Operations Table for a list of the maintenance operations to be performed at that maintenance interval. Use the maintenance operation

numbers to find detailed instructions in the manual

on each operation.

(100 000 kilometers) with minimal city or stop-and-go

operation. Examples of Schedule III usage are: regional delivery that is mostly freeway miles; interstate

transport; or any road operation with high annual

mileage.

NOTE: Maintenance instructions in this manual

are based on average vehicle use and normal

operating conditions. Unusual vehicle operating

conditions may require service at more frequent

intervals.

Types of Service

Service Schedule I (severe service) applies to vehicles that annually travel less than 6000 miles (10

or

000 kilometers)

tions. Examples of severe service, Schedule I usage

include: operation on extremely poor roads or where

there is heavy dust accumulation; constant exposure

to extreme hot, cold, salt-air, or other extreme climates; frequent short-distance travel; constructionsite operation; city operation (fire truck); or farm

operation.

Service Schedule II (short-haul transport) applies to

vehicles that annually travel less than 60,000 miles

(100 000 kilometers) and operate under normal conditions. Examples of Schedule II usage are: operation primarily in cities and densely populated areas;

local transport with infrequent freeway travel; or high

percentage of stop-and-go travel.

Service Schedule III (long-haul transport) is for vehicles that annually travel

Heavy-Duty Trucks Maintenance Manual, October 2009 00/1

that operate under severe condi-

more than

60,000 miles

General Information00

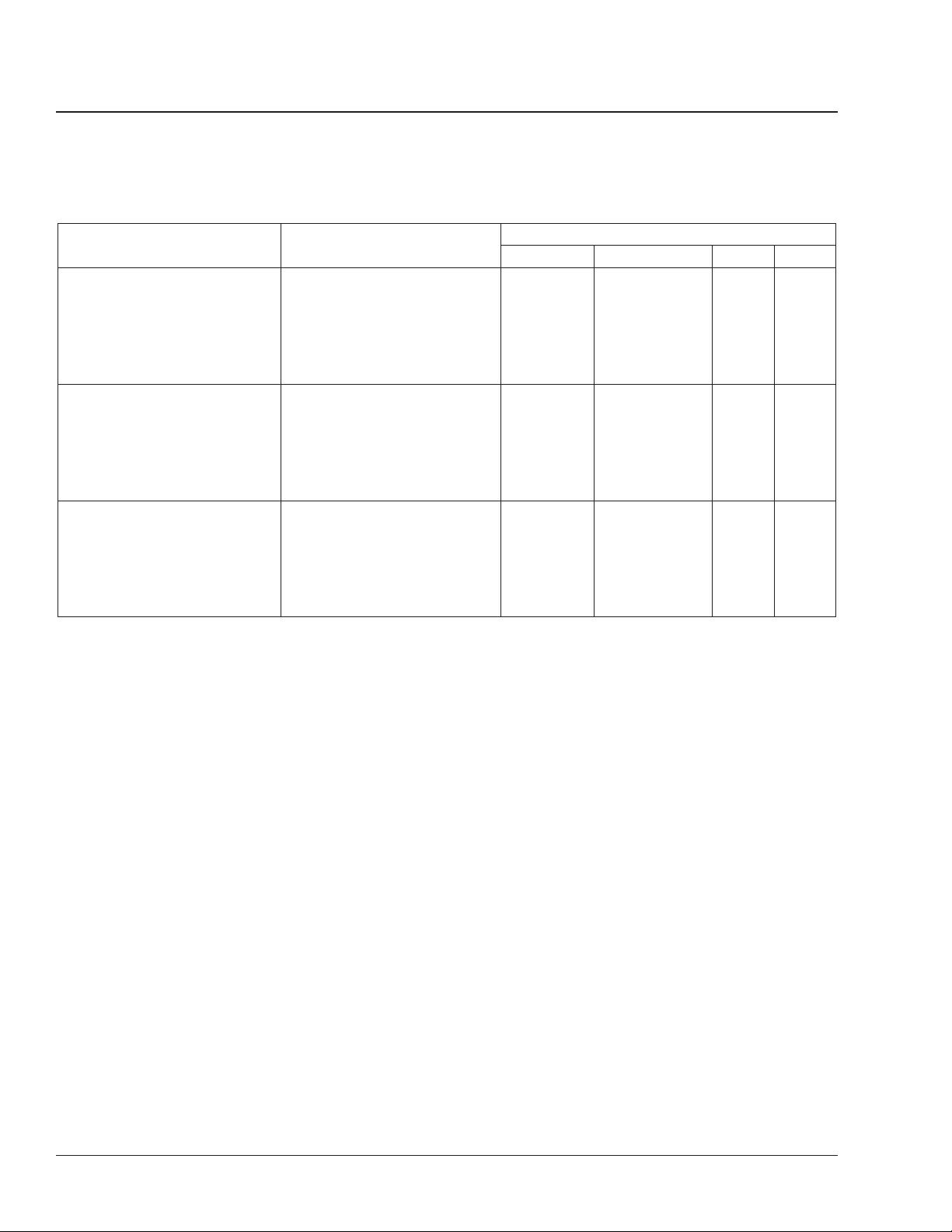

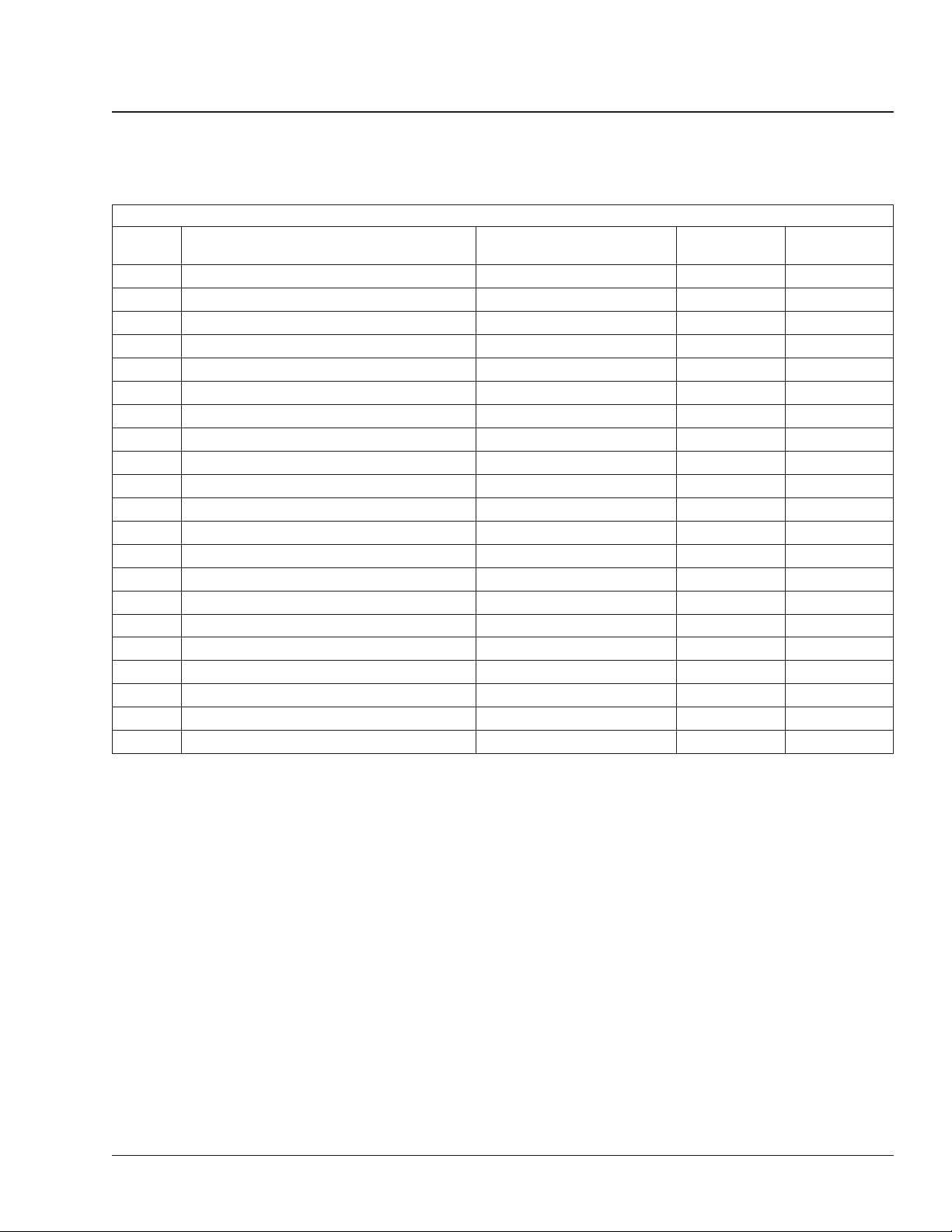

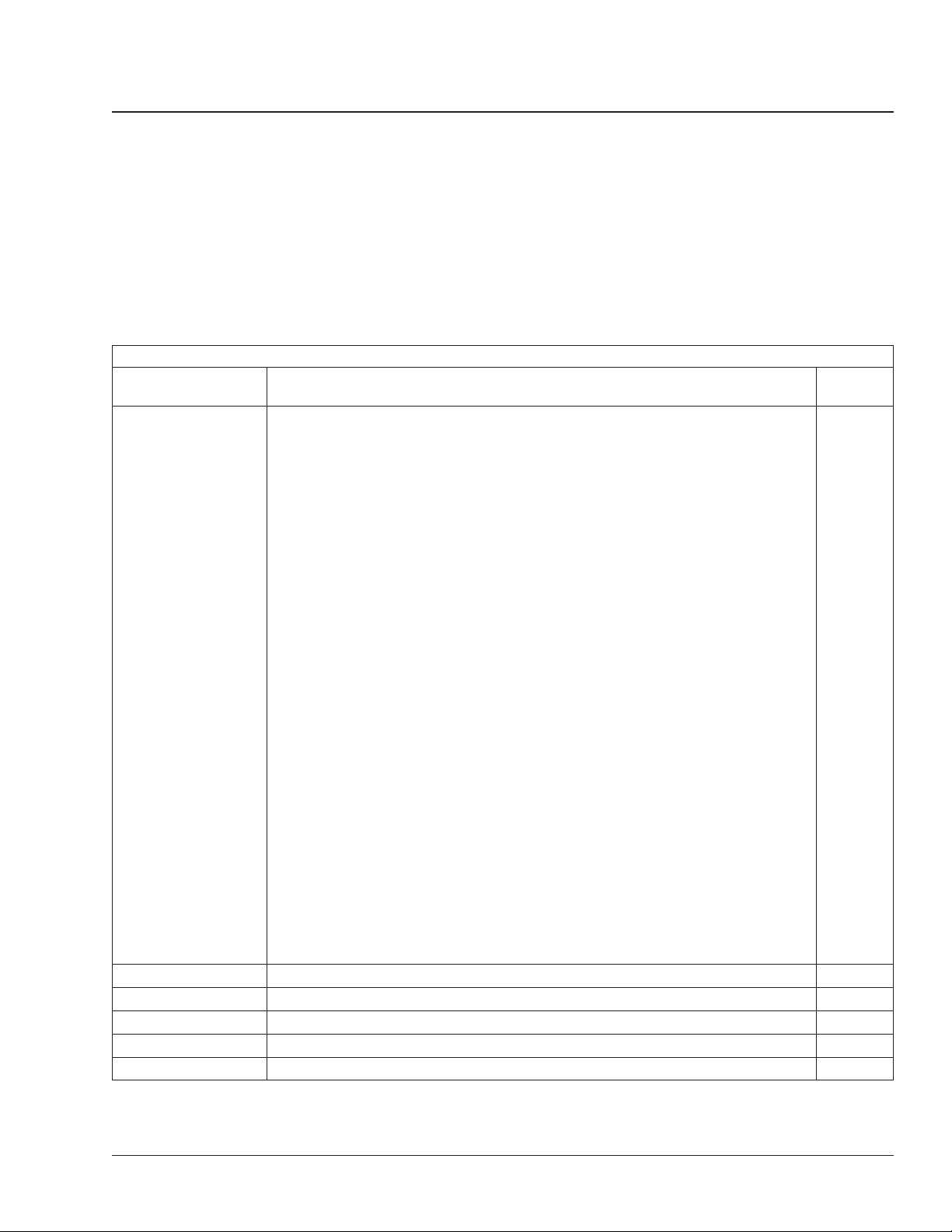

Maintenance Service Table: 00–02

Maintenance Service Table

Service Schedule Maintenance Interval Operation

Frequency Miles km Hours

Initial Maintenance (IM) first 1000 1600 100

Schedule I

(Severe Service)

vehicles that annually travel less

than 6000 miles (10 000 km)

*

Maintenance 1 (M1) every 1000 1600 100

Maintenance 2 (M2) every 5000 8000 500

Maintenance 3 (M3) every 10,000 16 000 1000

Maintenance 4 (M4) every 20,000 32 000 2000

Initial Maintenance (IM) first 9000 to 10,000 15 000

Schedule II

†

(Short-Haul Transport)

vehicles that annually travel less

than 60,000 miles (100 000 km)

Maintenance 1 (M1) every 9000 to 10,000 15 000

Maintenance 2 (M2) every 37,000 to 38,000 60 000

Maintenance 3 (M3) every 75,000 120 000

Maintenance 4 (M4) every 150,000 240 000

Initial Maintenance (IM) first 12,500 20 000

Schedule III

(Long-Haul Transport)

vehicles that annually travel over

60,000 miles (100 000 km)

†

Maintenance 1 (M1) every 12,500 20 000

Maintenance 2 (M2) every 50,000 80 000

Maintenance 3 (M3) every 100,000 160 000

Maintenance 4 (M4) every 300,000 480 000

*

For Schedule I (severe service) vehicles equipped with an hourmeter, use maintenance intervals based on hours of operation rather than distance traveled.

†

Use Schedule I (severe service) maintenance intervals for vehicles that operate under severe conditions, such as extremely poor roads, heavy dust accumu-

lation, extreme climate, frequent short distance travel, construction-site operation, city operation (garbage truck), or farm operation.

Maintenance Intervals

—

—

Heavy-Duty Trucks Maintenance Manual, October 200900/2

General Information 00

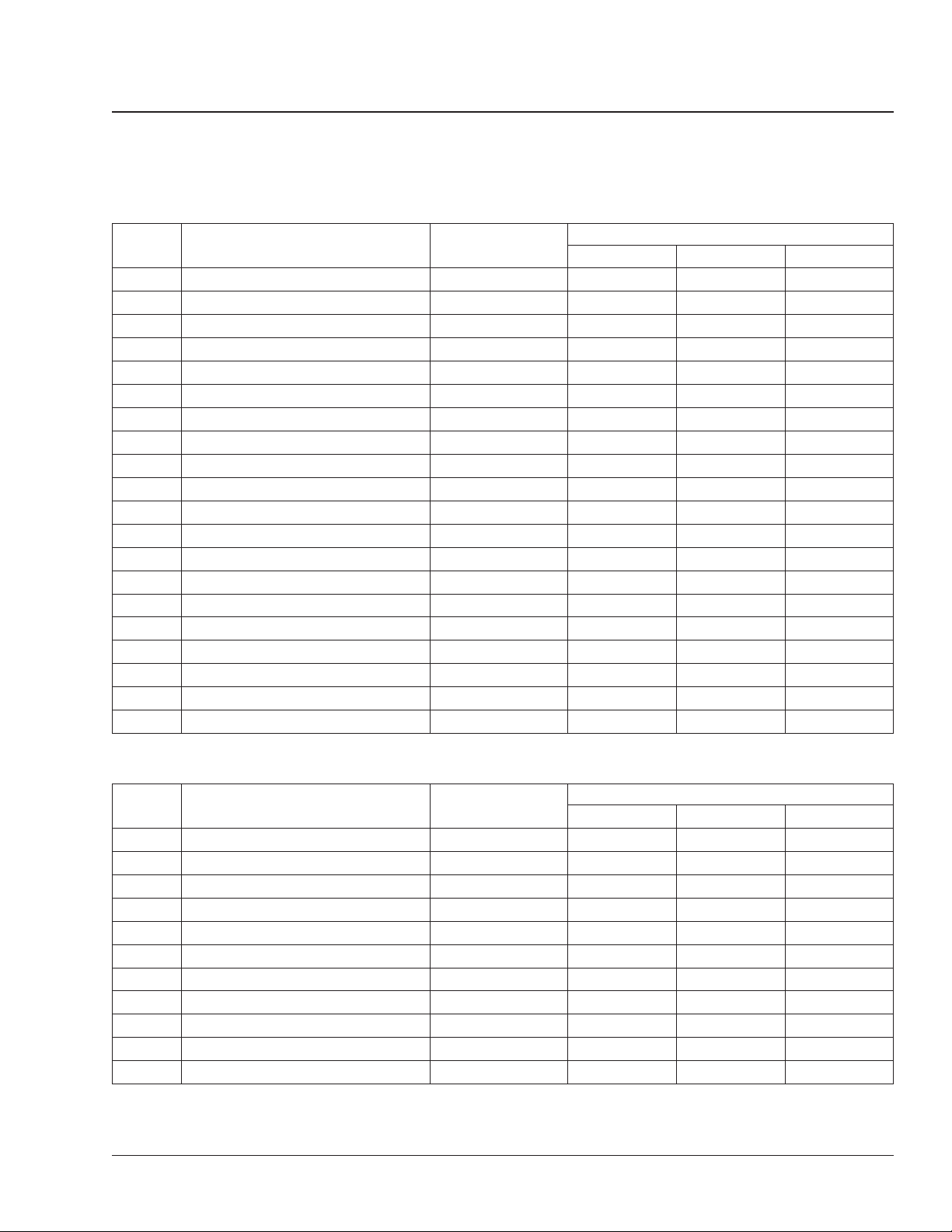

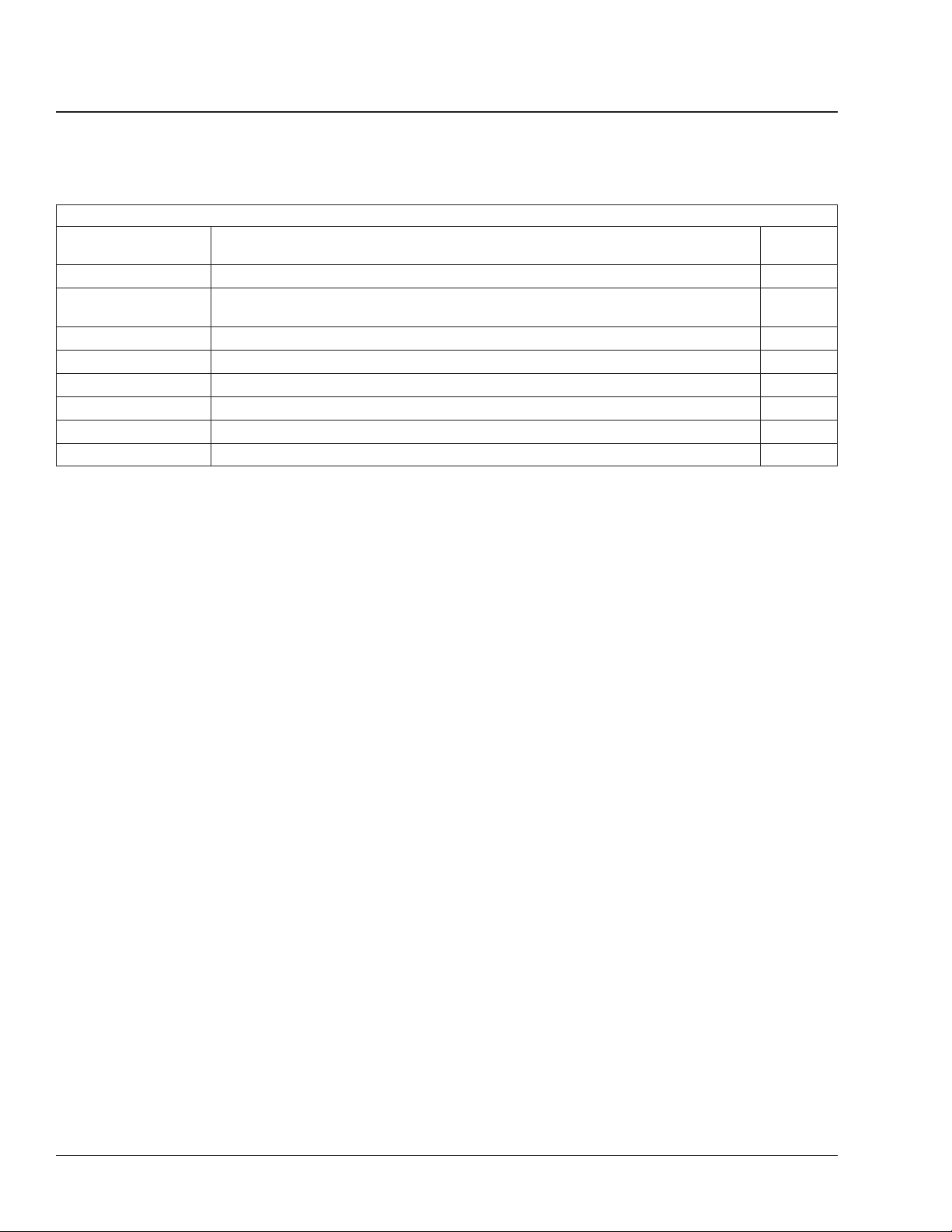

Vehicle Maintenance Schedule Tables: 00–03

1st through 20th Maintenance for Service Schedule I Vehicles

Maint.

No.

1st Initial Maintenance (IM)/M1 1000 1600 100

2nd M1 2000 3200 200

3rd M1 3000 4800 300

4th M1 4000 6400 400

5th M1 and M2 5000 8000 500

6th M1 6000 9600 600

7th M1 7000 11 200 700

8th M1 8000 12 800 800

9th M1 9000 14 400 900

10th M1, M2, and M3 10,000 16 000 1000

11th M1 11,000 17 600 1100

12th M1 12,000 19 200 1200

13th M1 13,000 20 800 1300

14th M1 14,000 22 400 1400

15th M1 and M2 15,000 24 000 1500

16th M1 16,000 25 600 1600

17th M1 17,000 27 200 1700

18th M1 18,000 28 800 1800

19th M1 19,000 30 400 1900

20th M1, M2, M3, and M4 20,000 32 000 2000

Required Maintenance Operation

Interval

Service Date

Miles km Hours

Service I

21st through 40th Maintenance for Service Schedule I Vehicles

Maint.

No.

21st M1 21,000 33 600 2100

22nd M1 22,000 35 200 2200

23rd M1 23,000 36 800 2300

24th M1 24,000 38 400 2400

25th M1 and M2 25,000 40 000 2500

26th M1 26,000 41 600 2600

27th M1 27,000 43 200 2700

28th M1 28,000 44 800 2800

29th M1 29,000 46 400 2900

30th M1, M2, and M3 30,000 48 000 3000

31st M1 31,000 49 600 3100

Heavy-Duty Trucks Maintenance Manual, October 2009 00/3

Required Maintenance Operation

Interval

Service Date

Miles km Hours

Service I

Vehicle Maintenance Schedule Tables: 00–03

General Information00

Maint.

No.

32nd M1 32,000 51 200 3200

33rd M1 33,000 52 800 3300

34th M1 34,000 54 400 3400

35th M1 and M2 35,000 56 000 3500

36th M1 36,000 57 600 3600

37th M1 37,000 59 200 3700

38th M1 38,000 60 800 3800

39th M1 39,000 62 400 3900

40th M1, M2, M3, and M4 40,000 64 000 4000

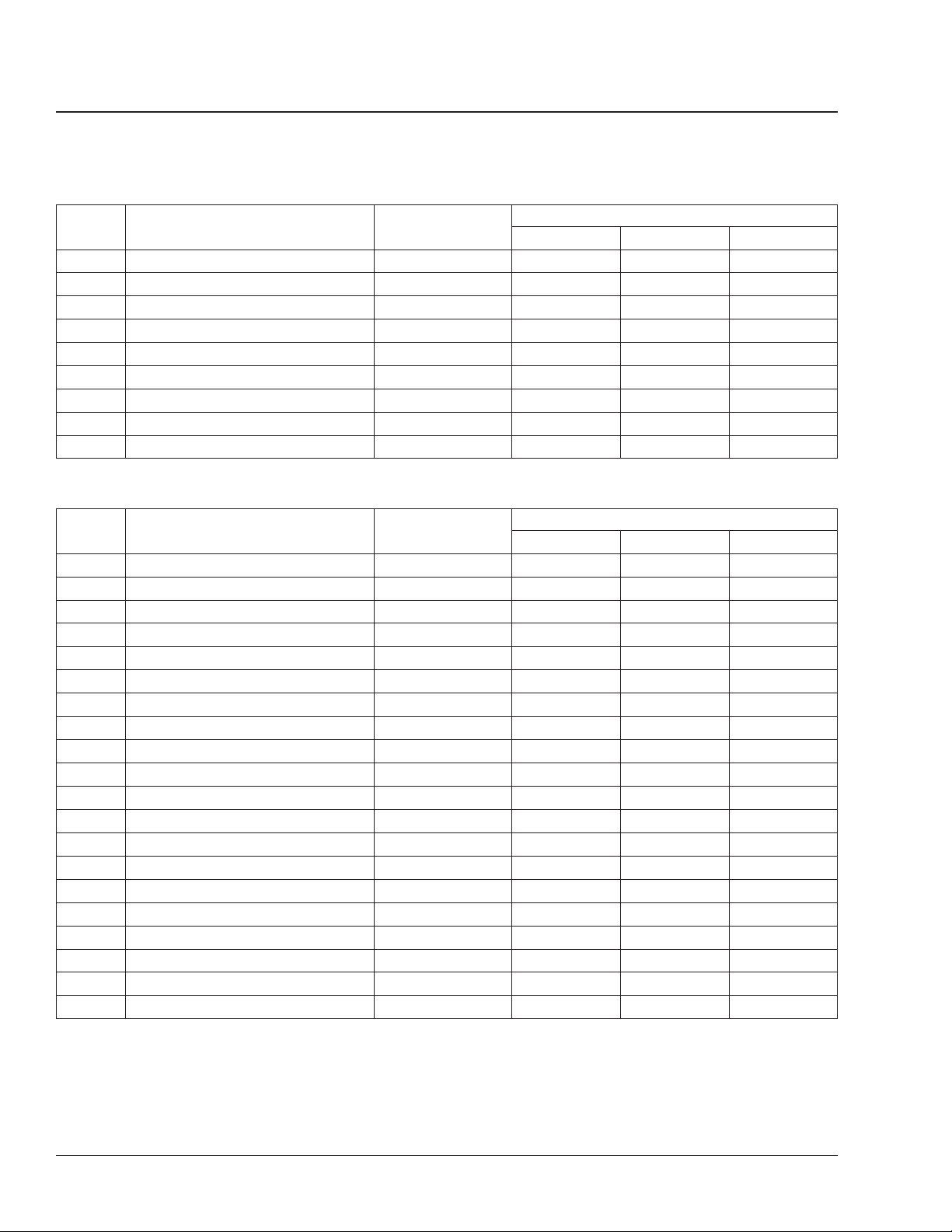

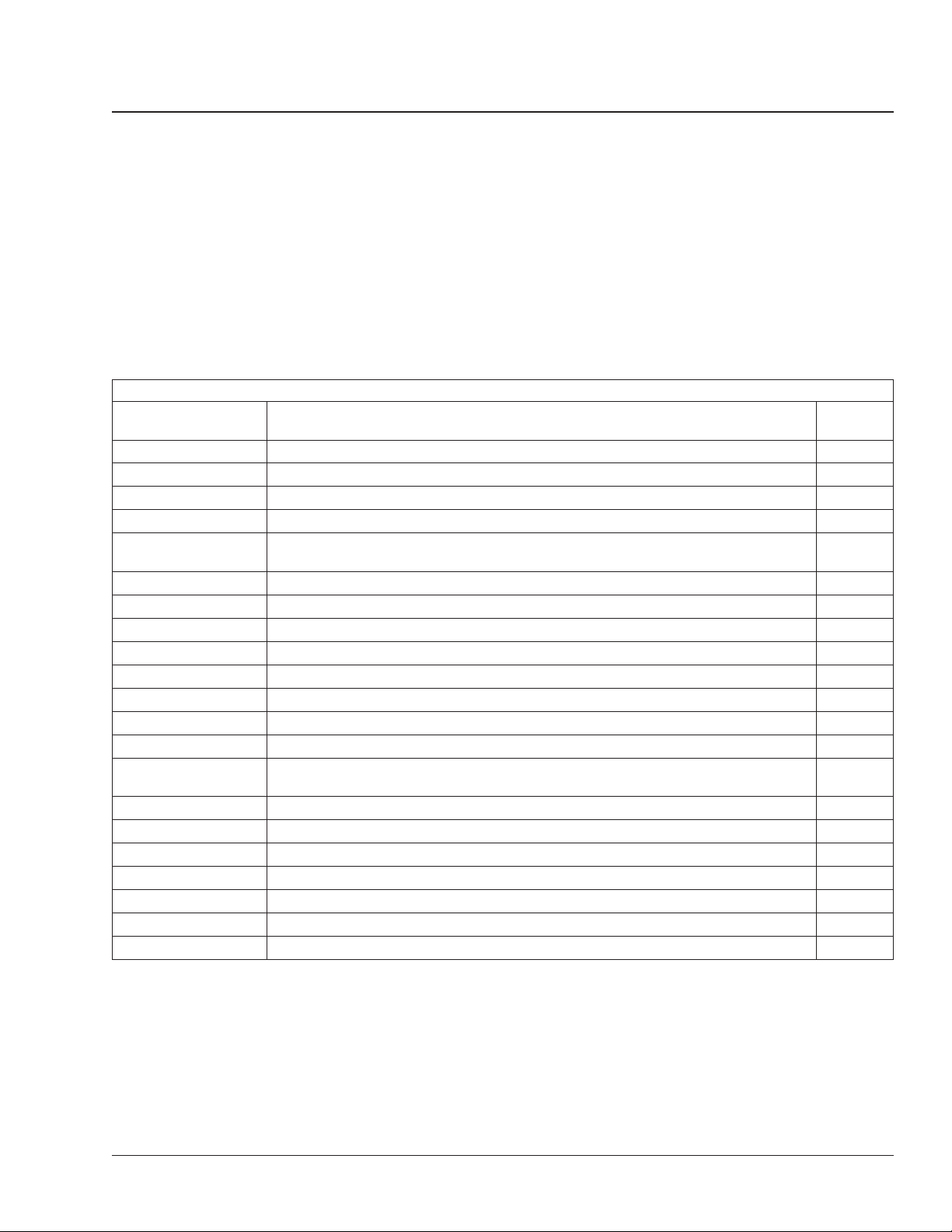

41st through 60th Maintenance for Service Schedule I Vehicles

Maint.

No.

41st M1 41,000 65 600 4100

42nd M1 42,000 67 200 4200

43rd M1 43,000 68 800 4300

44th M1 44,000 70 400 4400

45th M1 and M2 45,000 72 000 4500

46th M1 46,000 73 600 4600

47th M1 47,000 75 200 4700

48th M1 48,000 76 800 4800

49th M1 49,000 78 400 4900

50th M1, M2, and M3 50,000 80 000 5000

51st M1 51,000 82 000 5100

52nd M1 52,000 83 700 5200

53rd M1 53,000 85 300 5300

54th M1 54,000 86 900 5400

55th M1 and M2 55,000 88 500 5500

56th M1 56,000 90 100 5600

57th M1 57,000 91 700 5700

58th M1 58,000 93 300 5800

59th M1 59,000 94 900 5900

60th M1, M2, M3, and M4 60,000 96 500 6000

Required Maintenance Operation

Interval

Required Maintenance Operation

Interval

Service Date

Service Date

Miles km Hours

Miles km Hours

Service I

Service I

Heavy-Duty Trucks Maintenance Manual, October 200900/4

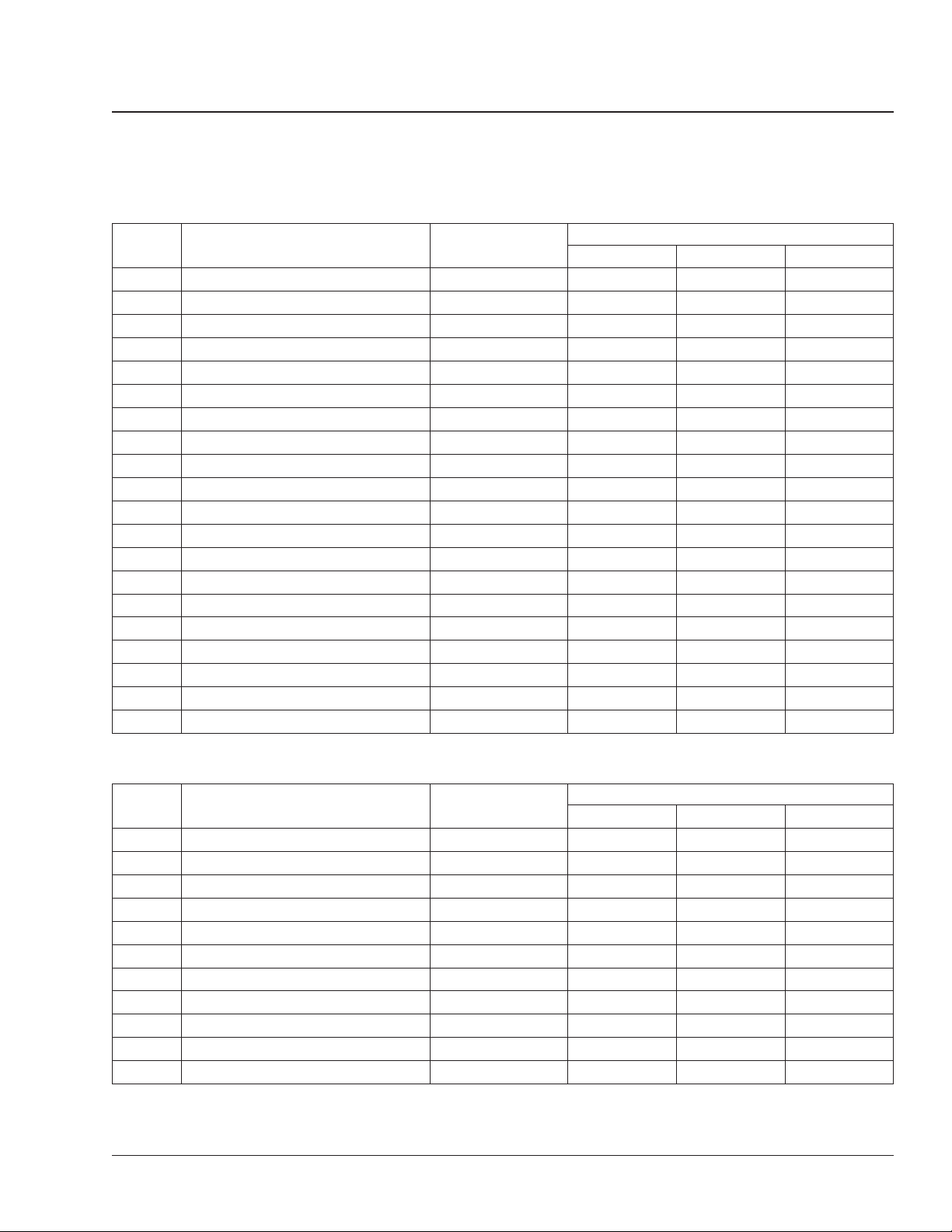

General Information 00

Vehicle Maintenance Schedule Tables: 00–03

61st through 80th Maintenance for Service Schedule I Vehicles

Maint.

No.

61st M1 61,000 98 200 6100

62nd M1 62,000 99 800 6200

63rd M1 63,000 101 400 6300

64th M1 64,000 103 000 6400

65th M1 and M2 65,000 104 600 6500

66th M1 66,000 106 200 6600

67th M1 67,000 107 800 6700

68th M1 68,000 109 400 6800

69th M1 69,000 111 000 6900

70th M1, M2, and M3 70,000 112 700 7000

71st M1 71,000 114 300 7100

72nd M1 72,000 115 900 7200

73rd M1 73,000 117 500 7300

74th M1 74,000 119 100 7400

75th M1 and M2 75,000 120 700 7500

76th M1 76,000 122 300 7600

77th M1 77,000 123 900 7700

78th M1 78,000 125 500 7800

79th M1 79,000 127 100 7900

80th M1, M2, M3, and M4 80,000 128 700 8000

Required Maintenance Operation

Interval

Service Date

Miles km Hours

Service I

81st through 100th Maintenance for Service Schedule I Vehicles

Maint.

No.

81st M1 81,000 130 400 8100

82nd M1 82,000 132 000 8200

83rd M1 83,000 134 000 8300

84th M1 84,000 135 200 8400

85th M1 and M2 85,000 137 000 8500

86th M1 86,000 138 400 8600

87th M1 87,000 140 000 8700

88th M1 88,000 141 600 8800

89th M1 89,000 143 200 8900

90th M1, M2, and M3 90,000 144 800 9000

91st M1 91,000 146 500 9100

Heavy-Duty Trucks Maintenance Manual, October 2009 00/5

Required Maintenance Operation

Interval

Service Date

Miles km Hours

Service I

Vehicle Maintenance Schedule Tables: 00–03

General Information00

Maint.

No.

92nd M1 92,000 148 100 9200

93rd M1 93,000 150 000 9300

94th M1 94,000 151 300 9400

95th M1 and M2 95,000 153 000 9500

96th M1 96,000 155 000 9600

97th M1 97,000 156 100 9700

98th M1 98,000 157 700 9800

99th M1 99,000 159 300 9900

100th M1, M2, M3, and M4 100,000 160 900 10 000

1st through 16th Maintenance for Service Schedule II Vehicles

Maint.

No.

1st Initial Maintenance (IM)/M1 10,000 16 000

2nd M1 19,000 30 000

3rd M1 28,000 45 000

4th M1 and M2 38,000 60 000

5th M1 47,000 75 000

6th M1 56,000 90 000

7th M1 66,000 105 000

8th M1, M2, and M3 75,000 120 000

9th M1 84,000 135 000

10th M1 94,000 150 000

11th M1 103,000 165 000

12th M1 and M2 112,000 180 000

13th M1 122,000 195 000

14th M1 131,000 210 000

15th M1 141,000 225 000

16th M1, M2, M3, and M4 150,000 240 000

Required Maintenance Operation

Interval

Required Maintenance Operation Interval Service Date Miles km

Service Date

Miles km Hours

Service I

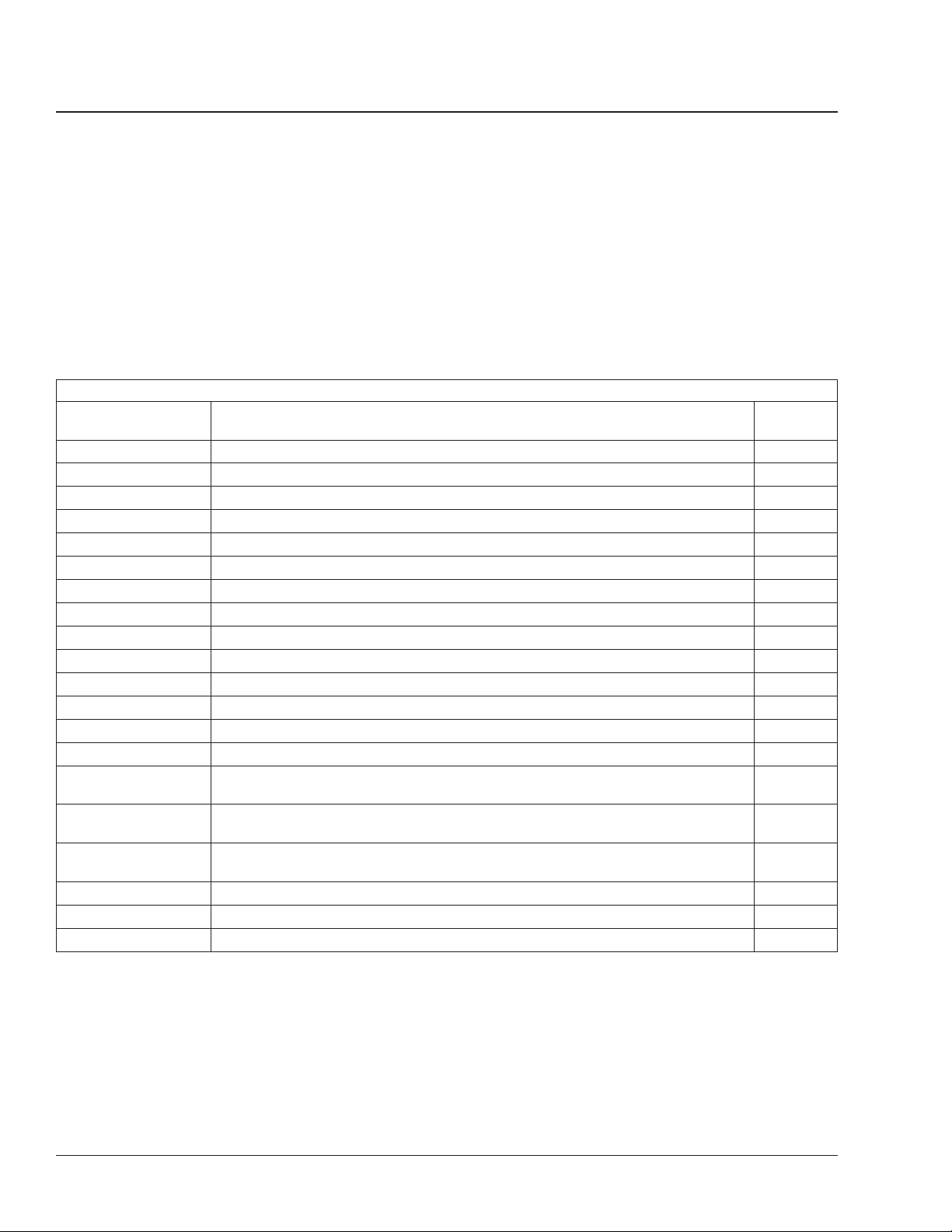

1st through 24th Maintenance for Service Schedule III Vehicles

Vehicle Maintenance Schedule for Service Schedule III

Maint.

No.

1st Initial Maintenance (IM)/M1 12,500 20 000

2nd M1 25,000 40 000

3rd M1 37,000 60 000

Required Maintenance Operation Interval Service Date Miles km

Heavy-Duty Trucks Maintenance Manual, October 200900/6

General Information 00

Vehicle Maintenance Schedule Tables: 00–03

Vehicle Maintenance Schedule for Service Schedule III

Maint.

No.

4th M1 and M2 50,000 80 000

5th M1 62,000 100 000

6th M1 75,000 120 000

7th M1 87,000 140 000

8th M1, M2, and M3 100,000 160 000

9th M1 112,000 180 000

10th M1 125,000 200 000

11th M1 137,000 220 000

12th M1 and M2 150,000 240 000

13th M1 162,000 260 000

14th M1 175,000 280 000

15th M1 187,000 300 000

16th M1, M2, and M3 200,000 320 000

17th M1 212,000 340 000

18th M1 225,000 360 000

19th M1 237,000 380 000

20th M1 and M2 250,000 400 000

21st M1 262,000 420 000

22nd M1 275,000 440 000

23rd M1 287,000 460 000

24th M1, M2, M3, and M4 300,000 480 000

Required Maintenance Operation Interval Service Date Miles km

Heavy-Duty Trucks Maintenance Manual, October 2009 00/7

Lubrication and Fluid Level Check: 00–04

General Information00

Table 1 summarizes all operations that must be per-

formed to complete Lubrication and Fluid Level

Check Operation 00–04 called for as an M1 maintenance interval for Service Schedule I, II, and III ve-

Maintenance operation numbers given in the table

are reference numbers used to help you find detailed

instructions in the manual on the lubrication or fluid

check.

hicles.

Maintenance Operation 00–04, Lubrication and Fluid Level Check for Service at M1

Maintenance

Operation No.

25–01 Clutch Release Bearing Lubricating

25–02 Clutch Release Cross-Shaft Lubricating

25–03 Clutch Linkage Components Lubricating

26–01 Shift Control Telescoping Tubes Lubricating and Inspecting, FLA/FLB

26–02 Shift Control Latch Lubricating and Cylinder Inspecting, FLA/FLB

26–04 Selection Lever and Pivot Rod Ball Stud Lubricating, FLA/FLB

26–08 Transmission Oil Level Checking and Breather Checking

31–02 Fifth Wheel Lubricating

31–05 Trailer Electrical Connector Lubricating

32–02 Suspension Lubricating

33–01 Knuckle Pin Lubricating

33–02 Tie-Rod End Inspecting and Lubricating

35–01 Axle Breather and Lubricant Level Checking

41–02 Driveline Lubricating

42–03 Manual/Automatic Slack Adjuster Lubricating and Checking (All Models)

46–01 Steering Driveline Lubricating

46–02 Ross Manual Steering Gear Lubricant Checking, Model 503

46–04 Drag Link and Power Steering Cylinder Lubricating

46–05 Power Steering Reservoir Fluid Level Checking

46–08 Ross Power Steering Gear Lubricating, TAS Series

46–09 Sheppard Power Steering Gear Bearing Cap Lubricating

60–01 Cab-Tilt System Checking, FLA/FLB

72–01 Door Seal, Door Latch, and Door Hinge Lubricating

Table 1, Maintenance Operation 00-04, Lubrication and Fluid Level Check for Service Schedules I, II, and III

Operation Description Check

Heavy-Duty Trucks Maintenance Manual, October 200900/8

General Information 00

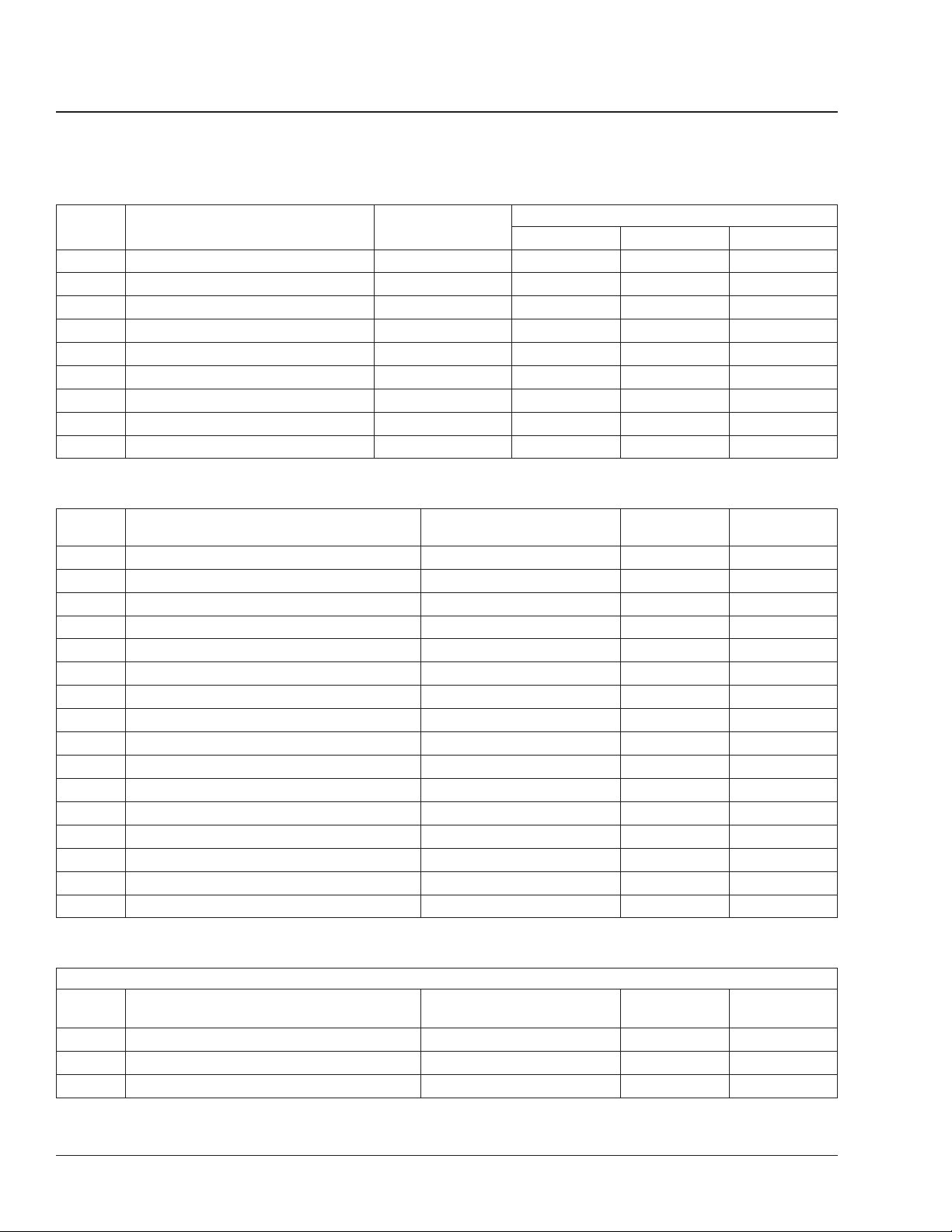

Maintenance Operation Sets Table: 00–05

IMPORTANT: At each Maintenance Operation Set, in

addition to the maintenance operations listed in this

table, perform all daily, weekly, and monthly maintenance operations listed in the "Pretrip and Post-Trip

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are reference numbers match-

ing those in the text of this manual.

Inspections and Maintenance" chapter of the vehicle

driver’s manual.

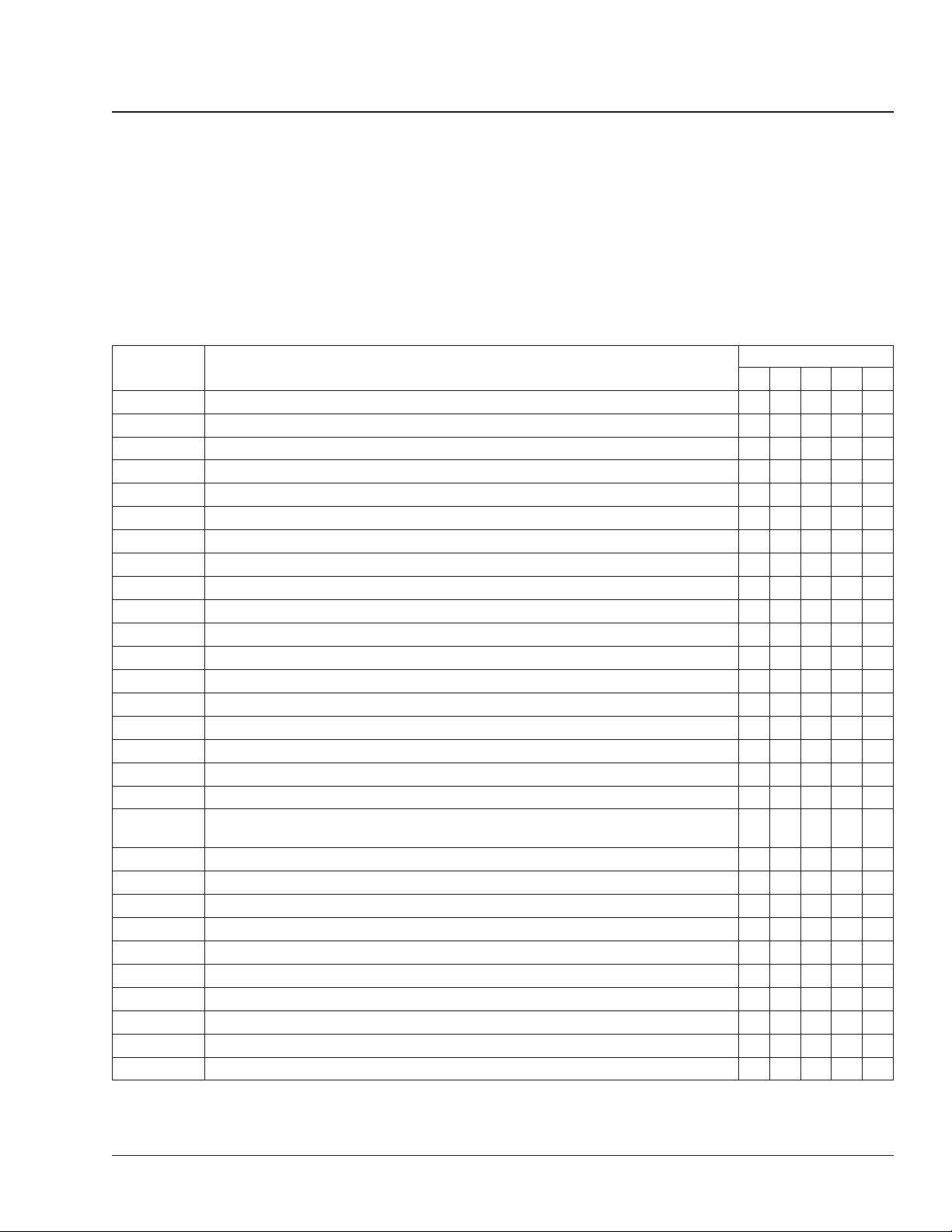

Maintenance Operation Sets for Groups 00 through 83

Maint. Oper.

No.

01–01

01–02

01–03 Jacobs Engine Brake Wiring Inspecting • • •

01–04 Engine Drive Belt Inspecting ••

09–01 Air Cleaner Element Inspecting and Replacing • •

13–01 Bendix Air Compressor Inspecting •••••

15–01 Alternator, Battery, and Starter Checking • • •

20–01 Radiator Cap Checking •••

20–02 Radiator Pressure Flushing and Coolant Changing •

20–03

25–01 Clutch Release Bearing Lubricating •••••

25–02 Clutch Release Cross-Shaft Lubricating •••••

25–03 Clutch Linkage Components Lubricating •••••

26–01 Shift Control Telescoping Tubes Lubricating and Inspecting, FLA/FLB •••••

26–02 Shift Control Latch Lubricating and Cylinder Inspecting, FLA/FLB •••••

26–03 Shift Lever Pivot Yokes Inspecting, FLA/FLB • •

26–04 Selection Lever and Pivot Rod Ball Stud Lubricating, FLA/FLB •••••

26–05 Allison Transmission Fluid and Filter Changing •

26–06 Manual Transmission Magnetic Plug Cleaning, Oil Changing, and Oil Filter Element

26–07 Transmission Air Filter/Regulator Checking, and Cleaning or Replacing • • •

26–08 Transmission Oil Level Checking and Breather Checking • •

31–01 Fifth Wheel Inspecting •••••

31–02 Fifth Wheel Lubricating •••••

31–03 Frame Fastener Torque Checking •

31–04 Holland Fifth Wheel Sliding Mechanism Inspecting • • •

31–05 Trailer Electrical Connector Lubricating •••••

32–01 Suspension Inspecting •••••

32–02 Suspension Lubricating •••••

32–03 Suspension U-bolt Torque Checking • • •

Engine Rear-Support Assembly Checking

Engine Noise Panel Inspecting

Fan Drive and Clutch Checking

Changing

Operation Description

Maintenance Interval

IM M1 M2 M3 M4

•••

••••

••

••

Heavy-Duty Trucks Maintenance Manual, October 2009 00/9

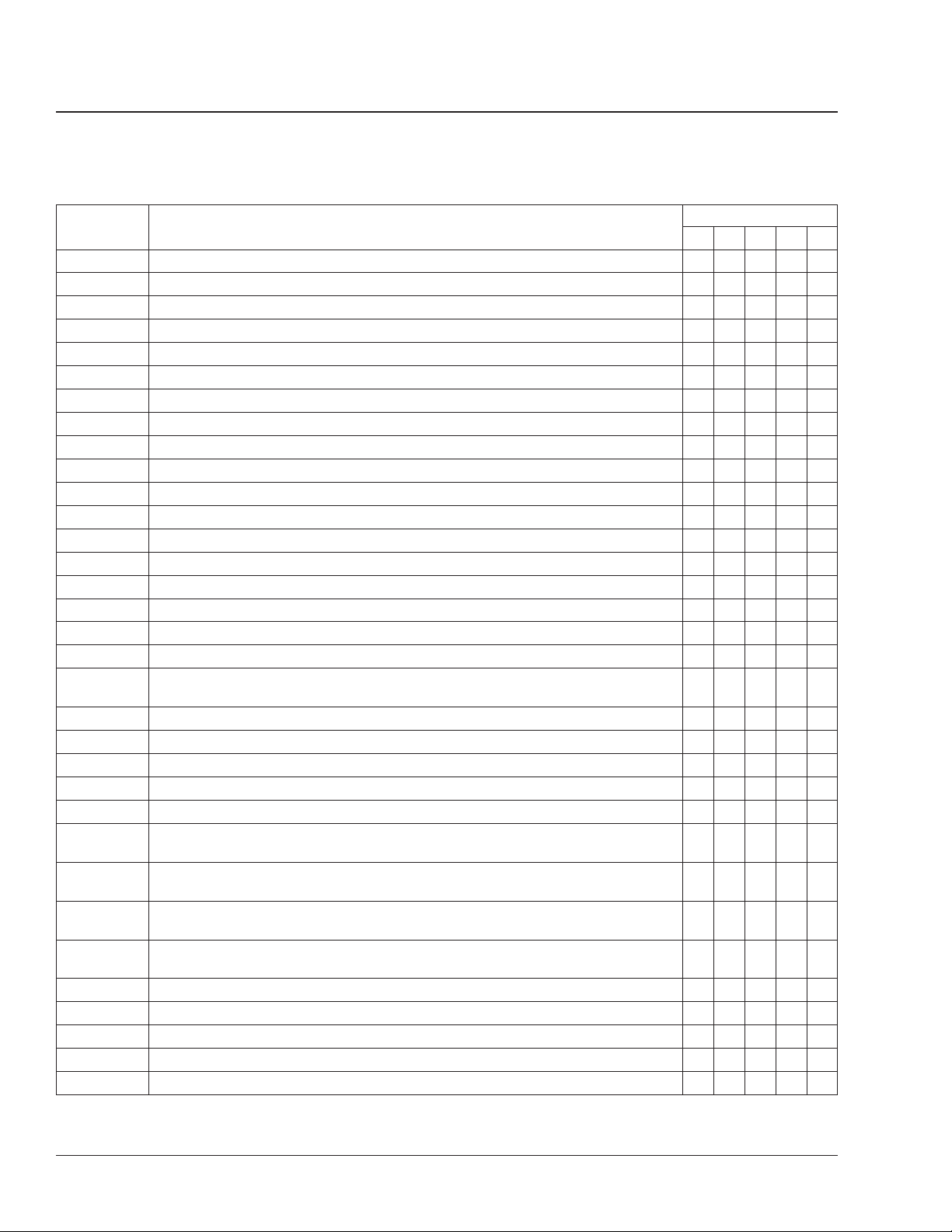

Maintenance Operation Sets Table: 00–05

General Information00

Maint. Oper.

No.

33–01 Knuckle Pin Lubricating •••••

33–02 Tie-Rod End Inspecting and Lubricating •••••

33–03 All-Axle Alignment Checking •

35–01 Axle Breather and Lubricant Level Checking • • • •

35–02 Axle Lubricant Changing, Oil Filter Replacing and Magnetic Strainer Cleaning • • •

40–01 Wheel Nut and Rim Nut Checking • • •

41–01 Driveline Inspecting •••••

41–02 Driveline Lubricating •••••

42–01 Brake Adjusting—Cam Brakes with Manual Slack Adjusters •••••

42–02 Camshaft Bracket Bushing Lubricating • • •

42–03 Manual/Automatic Slack Adjuster Lubricating and Checking (All Models) •••••

42–04 Meritor Automatic Slack Adjuster Inspecting • • •

42–05 Wedge Brake Checking •••••

42–06 Wedge Brake Inspecting and Lubricating • •

42–07 Alcohol Evaporator Checking • • •

42–08 Bendix Alcohol Evaporator Cleaning • • •

42–09 Bendix Alcohol Evaporator Gasket Replacing • •

42–10 Bendix Air Dryer Checking (AD–2, AD–4, or AD–9) • •

42–11 Bendix Air Dryer or Anchorlok Aftercooler Inspecting (Bendix AD–2, AD–4, AD–9, or

Anchorlok)

42–12 Bendix Air Dryer Desiccant Replacing (AD–2) •

42–13 Bendix Air Dryer Desiccant Replacing (AD–4 or AD–9) •

42–14 CR Brakemaster Air Dryer Cleaning (Model 62 or 68) •••••

42–15 Anchorlok Aftercooler Automatic Ejector Valve Clearing • • •

42–16 Bendix Air Brake Valve Operation Checking (BP–R1 and E–12) • •

42–17 Bendix Air Brake Valve Disassembly, Cleaning, and Inspecting (BP–1, Double

Check Valve, E–6, PP–7, QR–1, R–6, R–14, SR–1, ST–3, TC–7, TP–5, TR–3)

42–18 Bendix Air Brake Valve Disassembly, Cleaning, Inspecting, and Lubricating (DV–2,

PP–3, and Single Check Valve)

42–19 Bendix Air Brake Valve Inspecting and Testing (BP–1, BP–R1, LQ–5, PP–7, R–14,

and TC–7)

42–20 Bendix Foot Brake Valve Actuator Lubricating (E–6 or E–12) and Leak-Testing (E–

12)

42–21 Sealco Moisture Ejection Valve Operation- and Leak-Testing (Model 6300) • • •

42–22 Midland Quick Release and Flipper Valve Checking •••••

42–23 Meritor WABCO System Saver 1000 Air Dryer Desiccant Replacing •

42–24 Brake Inspection •••••

46–01 Steering Driveline Lubricating •••••

Operation Description

Maintenance Interval

IM M1 M2 M3 M4

•••••

••

•••

••

••

Heavy-Duty Trucks Maintenance Manual, October 200900/10

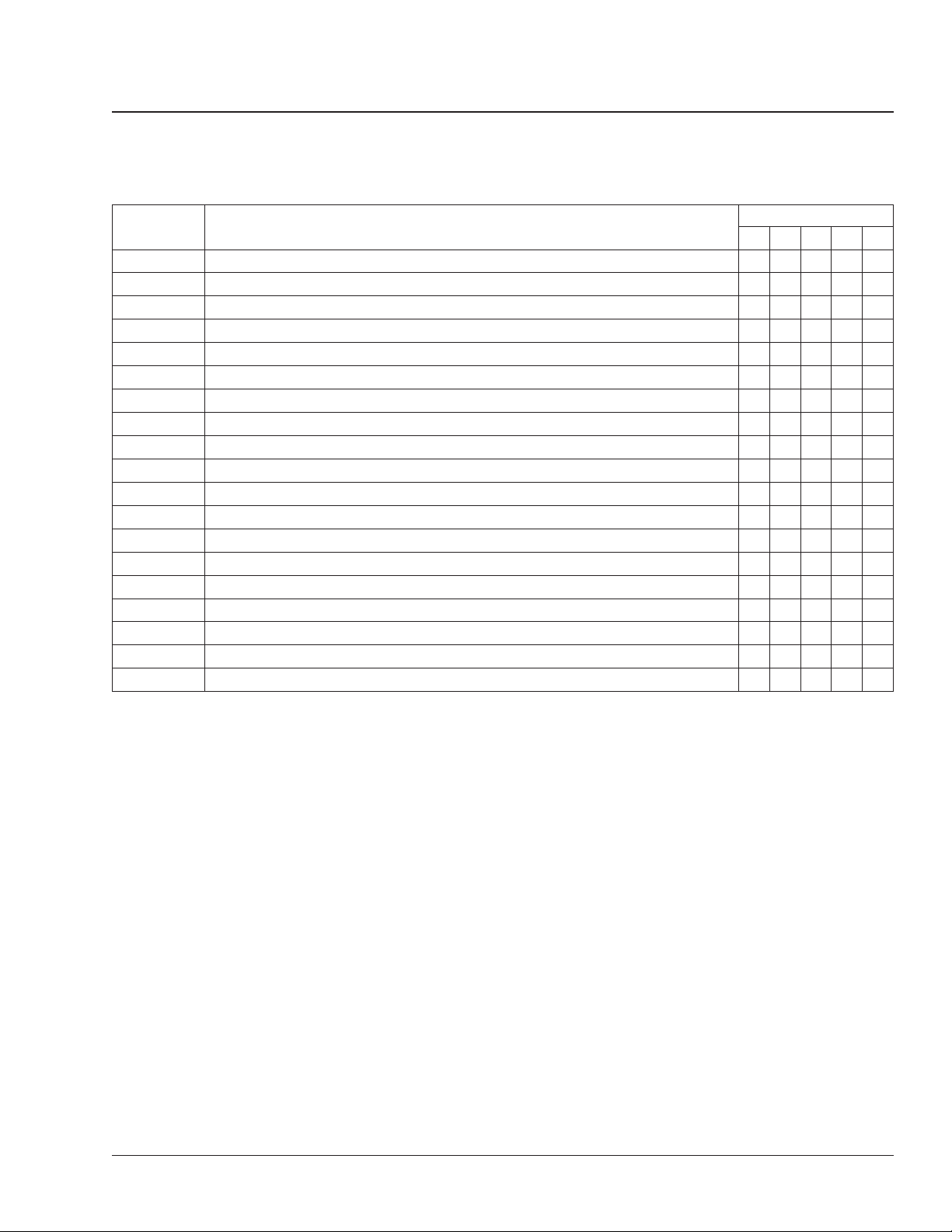

General Information 00

Maintenance Operation Sets Table: 00–05

Maint. Oper.

No.

46–02 Ross Manual Steering Gear Lubricant Checking, Model 503 • • •

46–03 Ross Manual Steering Gear Lubricant Changing, Model 503 • •

46–04 Drag Link and Power Steering Cylinder Lubricating •••••

46–05 Power Steering Reservoir Fluid Level Checking • •

46–06 Power Steering Reservoir Fluid and Filter Changing • • •

46–07 Steering Driveline Deck Bearing Lubricating, FLA/FLB • • •

46–08 Ross Power Steering Gear Lubricating, TAS Series •••••

46–09 Sheppard Power Steering Gear Bearing Cap Lubricating •••••

47–01 Fuel Tank Vent Checking •••

47–02 Fuel Tank Band Nut Tightening, FLA, FLB, and FLD •••••

47–03 Fuel Separator Sight Bowl Cleaning and Element Replacing • • •

49–01

54–01 Electrical System Checking • • •

54–02 Speedometer/Tachometer Cable Lubricating • •

60–01 Cab-Tilt System Checking, FLA/FLB •••••

60–02 Cab-Suspension Spring Center-Bolt Torque Checking, FLC • • •

60–03 Cab Latch Checking, FLA/FLB •••••

72–01 Door Seal, Door Latch, and Door Hinge Lubricating •••••

83–01 Air Conditioner Inspecting • • •

Exhaust System Inspecting

Operation Description

Maintenance Interval

IM M1 M2 M3 M4

•••••

Heavy-Duty Trucks Maintenance Manual, October 2009 00/11

Initial Maintenance (IM) Operations: 00–06

General Information00

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

NOTE: Numbers in this table are reference numbers

matching those in the text of this manual.

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

the vehicle driver’s manual.

Initial Maintenance (IM) Operations for Service Schedules I, II, and III

Initial Maintenance (IM) Operations for Service Schedules I, II, and III

Maintenance

Operation Number

00–07 Perform all MI Operations

15–01 Alternator, Battery, and Starter Checking

26–06 Manual Transmission Magnetic Plug Cleaning, Oil Changing, and Oil Filter Element

Changing

31–03 Frame Fastener Torque Checking

32–03 Suspension U-bolt Torque Checking

33–03 All-Axle Alignment Checking

35–02 Axle Lubricant Changing, Oil Filter Replacing, and Magnetic Strainer Cleaning

54–01 Electrical System Checking

Operation Description Check

Heavy-Duty Trucks Maintenance Manual, October 200900/12

General Information 00

M1 Maintenance Interval Operations Table: 00-07

The M1 Maintenance Interval Operations table lists

all maintenance operations that are to be performed

at the M1 maintenance interval. Maintenance operation numbers are reference numbers used to help

you find detailed instructions in this manual on the

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

the vehicle driver’s manual.

maintenance operations to be performed.

M1 Maintenance Interval Operations for Service Schedules I, II, and III

M1 Maintenance Interval Operations for Service Schedules I, II, and III

Maintenance

Operation Number

00–04 Lubrication and Fluid Level Check (includes the following)

• Clutch Release Bearing Lubricating

• Clutch Release Cross-Shaft Lubricating

• Clutch Linkage Components Lubricating

• Shift Control Telescoping Tubes Lubricating and Inspecting, FLA/FLB

• Shift Control Latch Lubricating and Cylinder Inspecting, FLA/FLB

• Selection Lever and Pivot Rod Ball Stud Lubricating, FLA/FLB

• Transmission Oil Level Checking and Breather Checking

• Fifth Wheel Lubricating

• Trailer Electrical Connector Lubricating

• Suspension Lubricating, Front and Rear

• Knuckle Pin Lubricating

• Tie-Rod End Inspecting and Lubricating

• Axle Breather and Lubricant Level Checking

• Driveline Lubricating

• Manual/Automatic Slack Adjuster Lubricating and Checking (All Models)

• Steering Driveline Lubricating

• Ross Manual Steering Gear Lubricant Checking, Model 503

• Drag Link and Power Steering Cylinder Lubricating

• Power Steering Reservoir Fluid Level Checking

• Ross Power Steering Gear Lubricating, TAS Series

• Sheppard Power Steering Gear Bearing Cap Lubricating

• Cab-Tilt System Checking, FLA/FLB

• Door Seal, Door Latch, and Door Hinge Lubricating

13–01 Bendix Air Compressor Inspecting

31–01 Fifth Wheel Inspecting

32–01 Suspension Inspecting

41–01 Driveline Inspecting

42–01 Brake Adjusting—Cam Brakes With Manual Slack Adjusters

Operation Description Check

Heavy-Duty Trucks Maintenance Manual, October 2009 00/13

M1 Maintenance Interval Operations Table: 00-07

M1 Maintenance Interval Operations for Service Schedules I, II, and III

Maintenance

Operation Number

42–05 Wedge Brake Checking

42–11 Bendix Air Dryer or Anchorlok Aftercooler Inspecting (Bendix AD–2, AD–4, AD–9, or

42–14 CR Brakemaster Air Dryer Cleaning (Model 62 or 68)

42–22 Midland Quick Release and Flipper Valve Checking

42–24 Brake Inspection

47–02 Fuel Tank Band Nut Tightening, FLA, FLB, and FLD

60–03 Cab Latch Checking, FLA/FLB

49–01

Anchorlok)

Exhaust System Inspecting

Operation Description Check

General Information00

Heavy-Duty Trucks Maintenance Manual, October 200900/14

General Information 00

M2 Maintenance Interval Operations Table: 00-08

The M2 Maintenance Interval Operations table lists

all maintenance operations that are to be performed

at the M2 maintenance interval. Maintenance operation numbers are reference numbers used to help

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are reference numbers match-

ing those in the text of this manual.

you find detailed instructions in this manual on the

maintenance operations to be performed. Perform all

M1 maintenance interval operations at the M2 maintenance interval.

M2 Maintenance Interval Operations for Service Schedules I, II, and III

M2 Maintenance Interval Operations for Service Schedules I, II, and III

Maintenance

Operation Number

00–07 Perform all M1 Operations

01–03 Jacobs Engine Brake Wiring Inspecting

20–01 Radiator Cap Checking

20–03

26–06 Manual Transmission Magnetic Plug Cleaning, Oil Changing, and Oil Filter Element

26–07 Transmission Air Filter/Regulator Checking, and Cleaning or Replacing

31–04 Holland Fifth Wheel Sliding Mechanism Inspecting

40–01 Wheel Nut and Rim Nut Checking

42–02 Camshaft Bracket Bushing Lubricating

42–04 Meritor Automatic Slack Adjuster Inspecting

42–07 Alcohol Evaporator Checking

42–08 Bendix Alcohol Evaporator Cleaning

42–15 Anchorlok Aftercooler Automatic Ejector Valve Clearing

42–18 Bendix Air Brake Valve Disassembly, Cleaning, Inspecting, and Lubricating (DV–2,

42–21 Sealco Moisture Ejection Valve Operation- and Leak-Testing (Model 6300)

46–06 Power Steering Reservoir Fluid and Filter Changing

46–07 Steering Driveline Deck Bearing Lubricating, FLA/FLB

47–01 Fuel Tank Vent Checking

47–03 Fuel Separator Sight Bowl Cleaning and Element Replacing

60–02 Cab-Suspension Spring Center-Bolt Torque Checking, FLC

83–01 Air Conditioner Inspecting

Fan Drive and Clutch Checking

Changing

PP–3, and Single Check Valve)

Operation Description Check

Heavy-Duty Trucks Maintenance Manual, October 2009 00/15

M3 Maintenance Interval Operations Table: 00–09

General Information00

The M3 Maintenance Interval Operations table lists

all maintenance operations that are to be performed

at the M3 maintenance interval. Maintenance operation numbers are reference numbers used to help

NOTE: Maintenance operations appearing in italics in

this table are for noise emission control components.

Numbers in this table are reference numbers match-

ing those in the text of this manual.

you find detailed instructions in this manual on the

maintenance operations to be performed. Perform all

maintenance interval operations in M1 and M2 when

performing M3 maintenance interval operations.

M3 Maintenance Interval Operations for Service Schedules I, II, and III

M3 Maintenance Interval Operations for Service Schedules I, II, and III

Maintenance

Operation Number

00–07 Perform all MI Operations

00–08 Perform all M2 Operations

01–01

01–02

01–04 Engine Drive Belt Inspecting

09–01 Air Cleaner Element Inspecting and Replacing

15–01 Alternator, Battery, and Starter Checking

26–03 Shift Lever Pivot Yokes Inspecting, FLA/FLB

32–03 Suspension U-Bolt Torque Checking

35–02 Axle Lubricant Changing, Oil Filter Replacing, and Magnetic Strainer Cleaning

42–06 Wedge Brake Inspecting and Lubricating

42–09 Bendix Alcohol Evaporator Gasket Replacing

42–10 Bendix Air Dryer Checking (AD–2, AD–4, or AD–9)

42–16 Bendix Air Brake Valve Operation Checking (BP–R1 and E–12)

42–17 Bendix Air Brake Valve Disassembly, Cleaning, and Inspecting (BP–1, Double Check

42–19 Bendix Air Brake Valve Inspecting and Testing (BP–1, BP–R1, LQ–5, PP–7, R–14

42–20 Bendix Foot Brake Valve Actuator Lubricating (E–6 or E–12) and Leak-Testing (E–

46–03 Ross Manual Steering Gear Lubricant Changing, Model 503

54–01 Electrical System Checking

54–02 Speedometer/Tachometer Cable Lubricating

Engine Rear-Support Assembly Checking

Engine Noise Panel Inspecting

Valve, E–6, PP–7, QR–1, R–6, R–14, SR–1, ST–3, TC–7, TP–5, and TR–3)

and TC–7)

12)

Operation Description Check

Heavy-Duty Trucks Maintenance Manual, October 200900/16

General Information 00

M4 Maintenance Interval Operations Table: 00-10

The M4 Maintenance Interval Operations table lists

all maintenance operations that are to be performed

at the M4 maintenance interval. Maintenance operation numbers are reference numbers used to help

maintenance operations to be performed. Perform all

maintenance interval operations in M1, M2, and M3

when performing M4 maintenance interval operations.

you find detailed instructions in this manual on the

M4 Maintenance Interval Operations for Service Schedules I, II, and III

M4 Maintenance Interval Operations for Service Schedules I, II, and III

Maintenance

Operation Number

00–07 Perform all M1 Operations

00–08 Perform all M2 Operations

00–09 Perform all M3 Operations

20–02 Radiator Pressure Flushing and Coolant Changing

26–05 Allison Transmission Fluid and Filter Changing

42–12 Bendix Air Dryer Desiccant Replacing (AD–2)

42–13 Bendix Air Dryer Desiccant Replacing (AD–4 or AD–9)

42–23 Meritor WABCO System Saver 1000 Air Dryer Desiccant Replacing

Operation Description Check

Heavy-Duty Trucks Maintenance Manual, October 2009 00/17

COE Cab Tilting, FLA/FLB: 00–11

General Information00

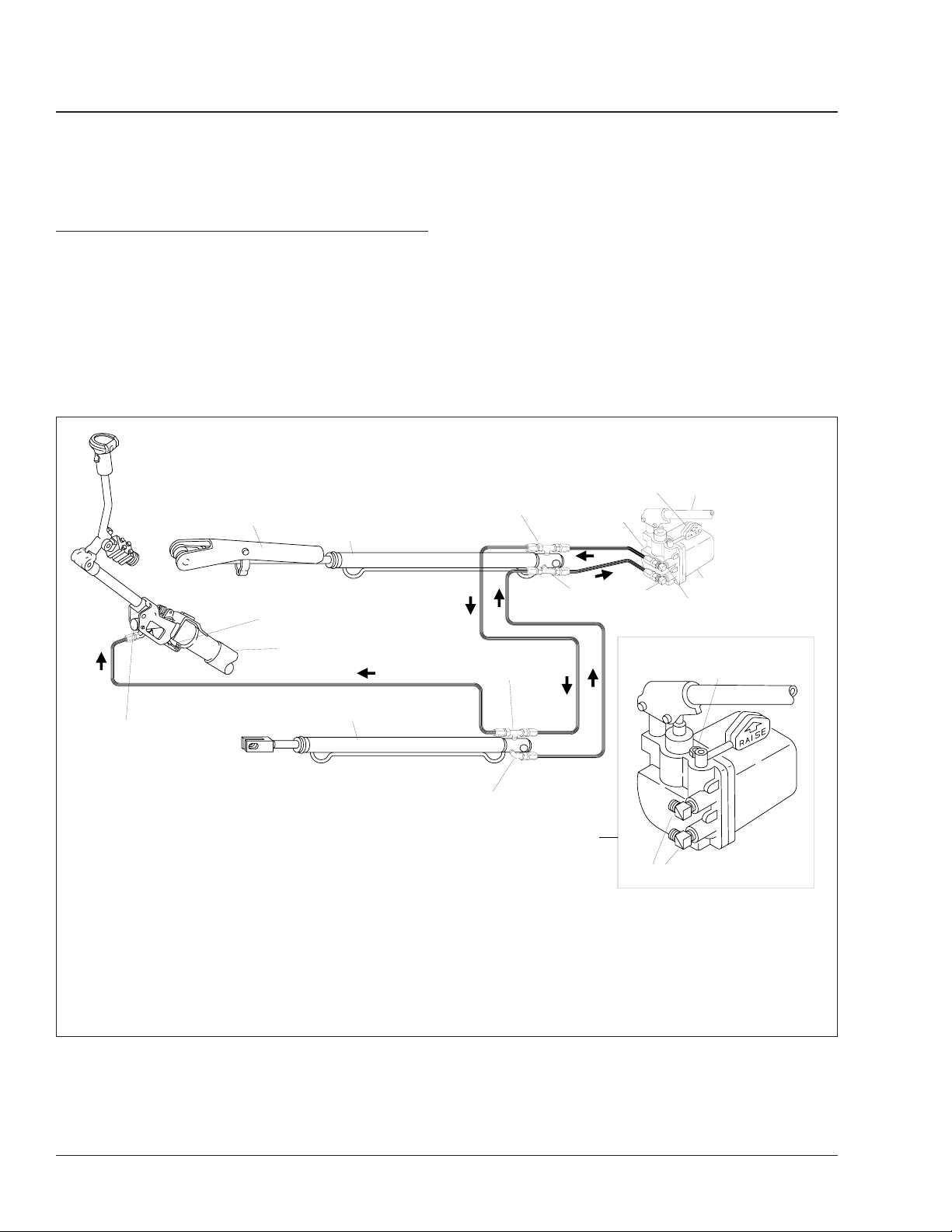

Cab-Tilt System

The Power-Packer®cab-tilt system has four major

parts (see Fig. 1):

• A hydraulic pump consisting of a pump body, a

reservoir, and a pump control lever.

• Two hydraulic tilt cylinders that raise and lower

the cab.

• A shift-disconnect cylinder that allows the shift

tube to extend during cab tilting.

1

2

14

13

• A tilt strut on the right-side tilt cylinder , which

must be used when working under a cab that

has not been fully tilted.

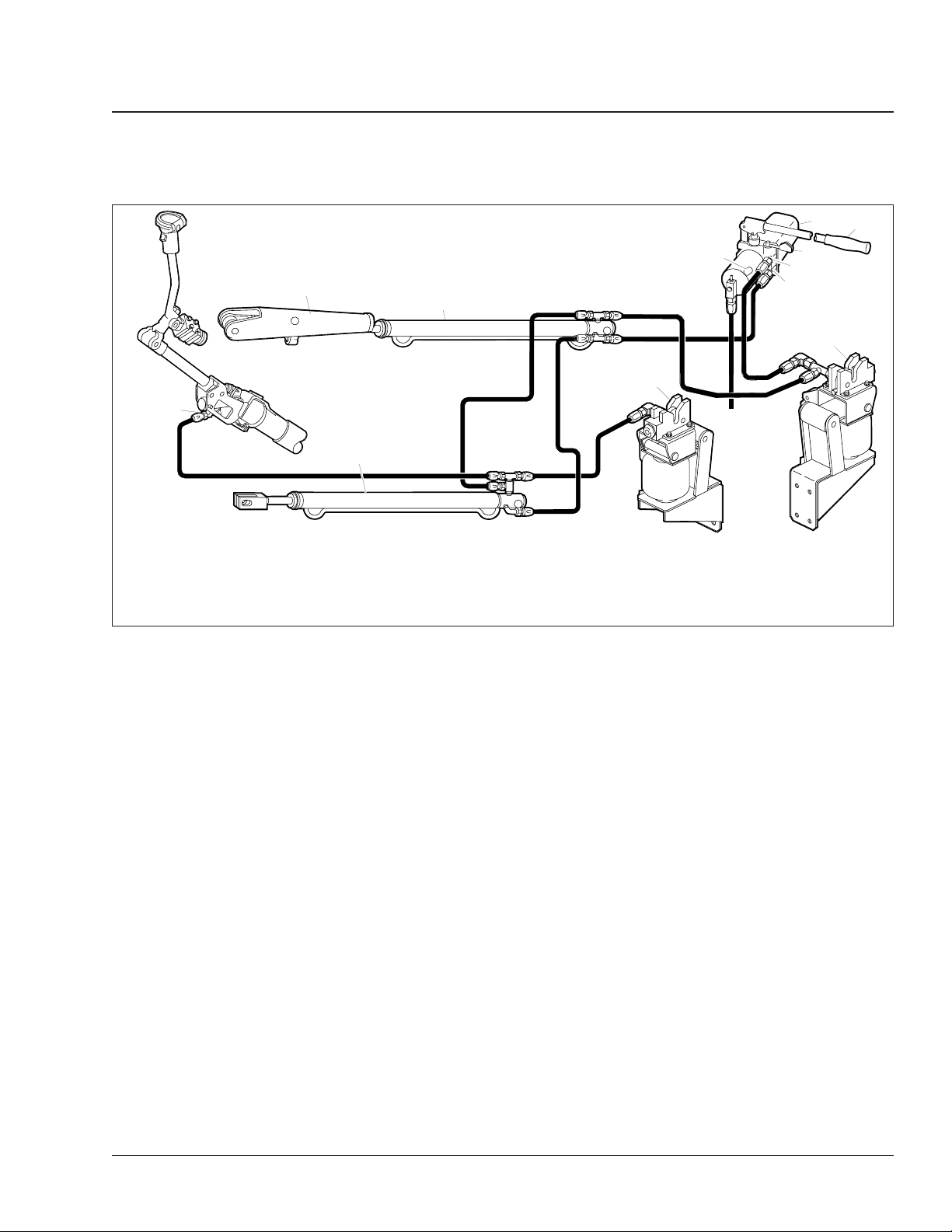

The optional air/hydraulic system has the same

major parts as the hydraulic-only system, but has an

additional air motor assembly attached to the tilt

pump. See Fig. 2. The air motor normally operates

the tilt pump in place of the manual pump control

lever. If for any reason the air motor is not working,

the tilt pump can be operated with the manual pump

lever.

5

6

3

10

4

9

9

7

8

16

15

07/03/97

A. Tilt Pump Enlargement

1. Tilt Strut

2. Right Tilt Cylinder

3. "Push" Port Fitting

4. Pump Body

5. Pump Control Lever

6. Pump Lever

Fig. 1, Hydraulic-Only System, Equipped With Mechanical Cab Latches

12

7. Reservoir

8. "Push" Port Fitting

9. "Pull" Port Fitting

10. "Push" Port Fitting

11. "Pull" Port Fitting

12. Left Tilt Cylinder

11

A

17

f310031a

13. Shift Tube

14. Shift Tube Latch Mechanism

15. Shift-Disconnect Cylinder

16. Fill Plug

17. Fittings

Heavy-Duty Trucks Maintenance Manual, October 200900/18

General Information 00

COE Cab Tilting, FLA/FLB: 00–11

5

6

2

1

12

03/02/98

A. Air supply connects here.

1. Shift-Disconnect Cylinder

2. Tilt Strut

3. Right Tilt Cylinder

4. Air Motor Assembly and Button

Fig. 2, Optional Air/Hydraulic System, Equipped With Hydraulic Cab Latches and Cab Air Suspension

5. Reservoir

6. Manual Pump Lever

7. Pump Control Lever

8. "Push" Port

3

On FLBs, cab latches are hydraulic, and are

plumbed into the cab-tilt system.

The tilt cylinders are connected to the pump by flexible high-pressure lines. Velocity fuses are built into

the tilt cylinder ports. They act as check valves to

prevent the cab from free-falling in case of hydraulic

system damage, such as a ruptured line.

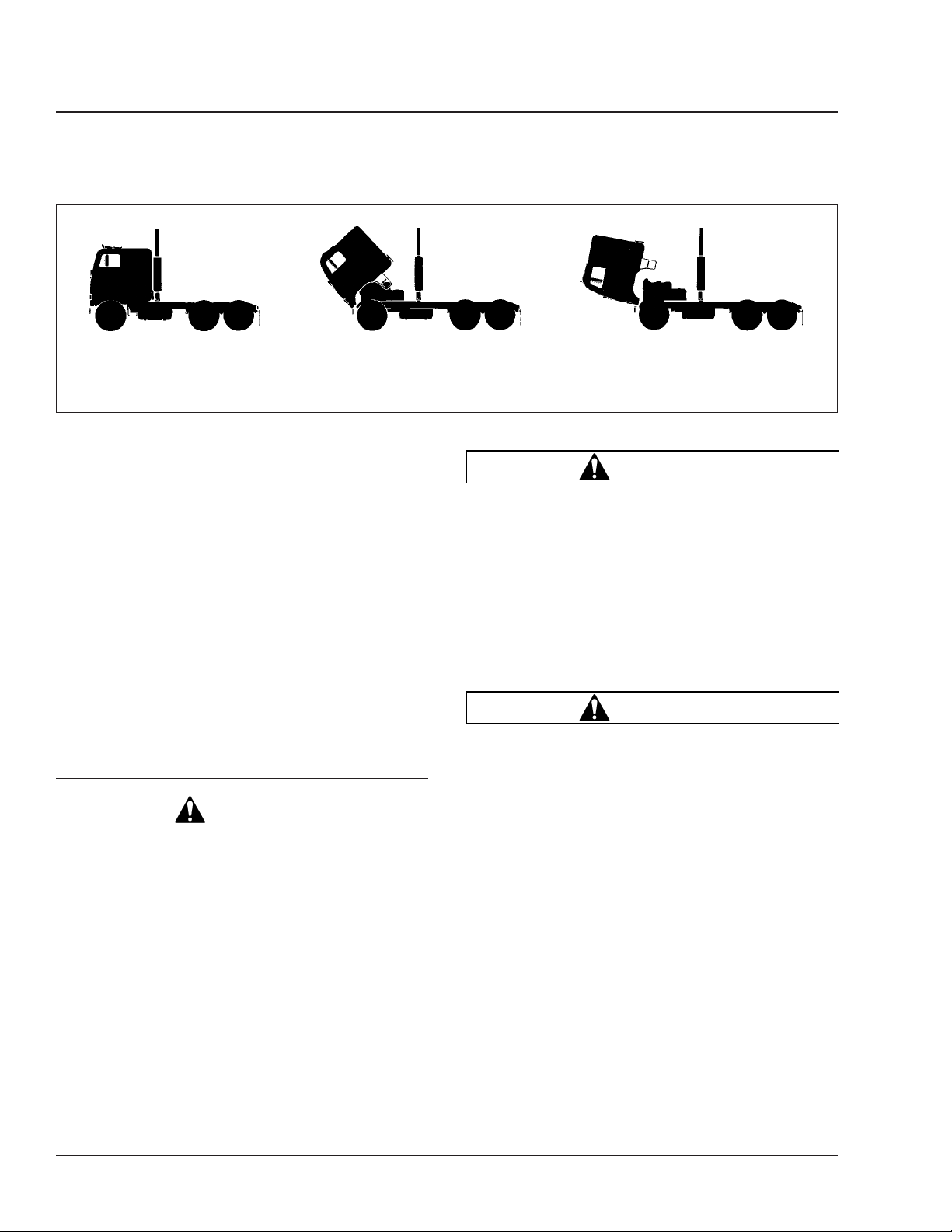

There are two hydraulic circuits in the Power-Packer

push

system: the

ered position to the desired tilt position, and the

circuit raises the cab from the low-

pull

circuit brings the cab from a tilted position up and

over center. See Fig. 3.

Placing the control lever in the "Raise" position

push

opens the

circuit in the hydraulic system. When

the mechanical cab-hold-down latches are released

and the pump is operated, hydraulic pressure builds

in the tilt cylinders and the shift-disconnect cylinder. If

equipped with hydraulic cab latches, hydraulic pressure releases the latches. As pressure increases, the

shift-disconnect cylinder releases to allow the shift

tube to telescope out. Then the tilt cylinder piston

rods extend, raising the cab. When the cab goes

4

11

A

9. "Pull" Port

10. Right Hydraulic Cab Latch

11. Left Hydraulic Cab Latch

12. Left Tilt Cylinder

7

8

9

10

f310359a

over center, it falls at a controlled rate to the full-tilt

position, automatically relieving hydraulic system

pressure.

When the control lever is placed in the "Lower" position, the

pull

circuit in the hydraulic system opens.

When the pump is operated, hydraulic pressure

forces the cab back up and over center. The cab

then falls at a controlled rate until it settles onto the

rear mounts.

NOTE: Whenever raising or lowering the cab,

stop working the pump once the cab goes over

center. The cab falls at a controlled rate, and

continued pumping could cause hydraulic

lock-up of the tilt cylinders.

Hydraulic lock-up of the tilt cylinders can occur during very cold weather. It can also occur when the

wrong hydraulic fluid is used, when there is air in the

system, when there is sudden cab movement, or

when a hydraulic line is ruptured. Any of these situations will cause the velocity fuses to function as

safety check valves, and lock up the tilt cylinders.

IMPORTANT: If the tilt cylinders lock up, check

for a major problem (such as a ruptured line or

Heavy-Duty Trucks Maintenance Manual, October 2009 00/19

COE Cab Tilting, FLA/FLB: 00–11

General Information00

A B

06/15/93

A. Lowered (Operating) Position B. 45-Degree-Tilt Position C. Full-Tilt Position (80 Degrees)

Fig. 3

C

leaking fitting) before trying to unlock the tilt cylinders. If such a problem is found, make any

necessary repairs before unlocking the cylinder.

To unlock the cylinders, the cab must be moved in

the opposite direction of travel (back toward the 45degree position). If the cab is moving toward the fulltilt position when the lock-up occurs, move the control lever to "Lower," and work the pump a few

strokes to unlock the cylinders. Move the control

lever to "Raise," and allow the cab to descend to a

full-tilt position. If the cab is moving toward the lowered (operating) position when the lock-up occurs,

move the control lever to "Raise," and work the

pump a few strokes to unlock the cylinders. Move the

control lever to "Lower," and allow the cab to descend to the operating position.

Tilting the FLB Cab

CAUTION

Before tilting the cab, make sure the vehicle is

parked on level ground, both side-to-side and

front-to-rear. Tilting the cab while the vehicle is

parked on unlevel ground (such as a sloping highway shoulder) may damage the cab mounts and

prevent you from returning the cab to the operating position.

1. Apply the parking brakes. Place the transmission

shift lever in neutral. Shut down the engine if it is

running.

Before tilting the cab, make sure that there is adequate clearance in front of the vehicle, and that

the area is free of people and all objects.

Do not tilt the cab with the engine running. Tilting

the cab could engage the transmission. If the engine is running, the vehicle can move, causing an

accident that could result in personal injury or

property damage.

2. Secure all loose articles in the cab and bunk,

and make sure the doors are securely latched.

Objects falling in the cab, or a door flying open,

could damage the vehicle or cause personal injury .

3. Move the pump control lever to "Raise."

4. Operate the pump (using the manual pump

handle, or the air control button if so equipped)

to disengage the hold-down latches.

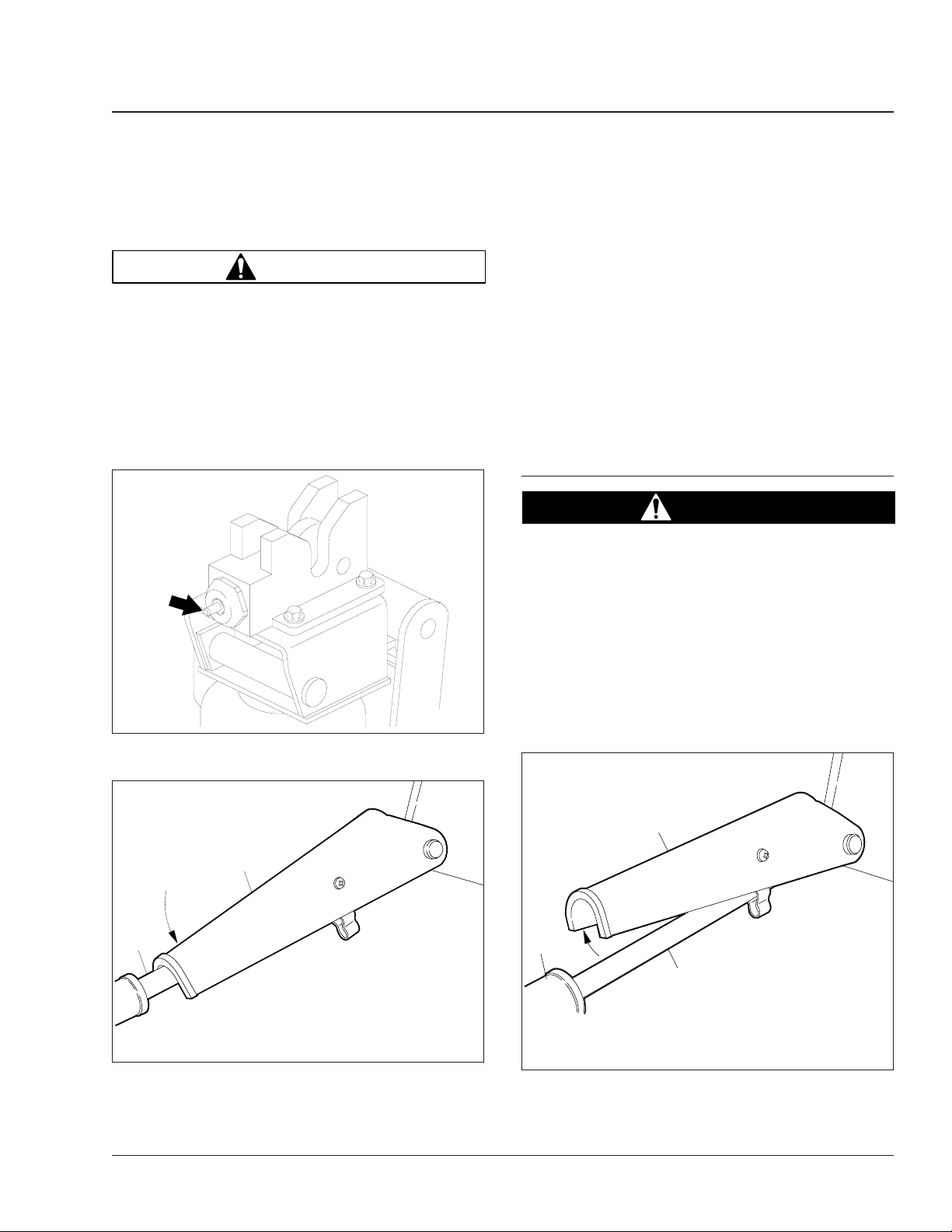

IMPORTANT: Check the indicator pin on each

cab latch. The latches have disengaged if the

pins are out. See Fig. 4.

If air is present in the hydraulic tilt system,

pump operation will seem "spongy" or ineffective. If this happens, bleed the air from the system; for instructions, see Group 60 of the

Heavy-Duty Trucks Service Manual

WARNING

WARNING

.

f000131

If the cab stops moving while it is being raised,

do not force it to move with the tilt pump. The

Heavy-Duty Trucks Maintenance Manual, October 200900/20

General Information 00

COE Cab Tilting, FLA/FLB: 00–11

velocity fuses have locked up the tilt cylinders;

unlock them.

WARNING

Make sure the tilt strut is pushed down onto the

right tilt-cylinder rod. If the tilt strut is not engaged, and the cab drops, the result could be serious injury or death.

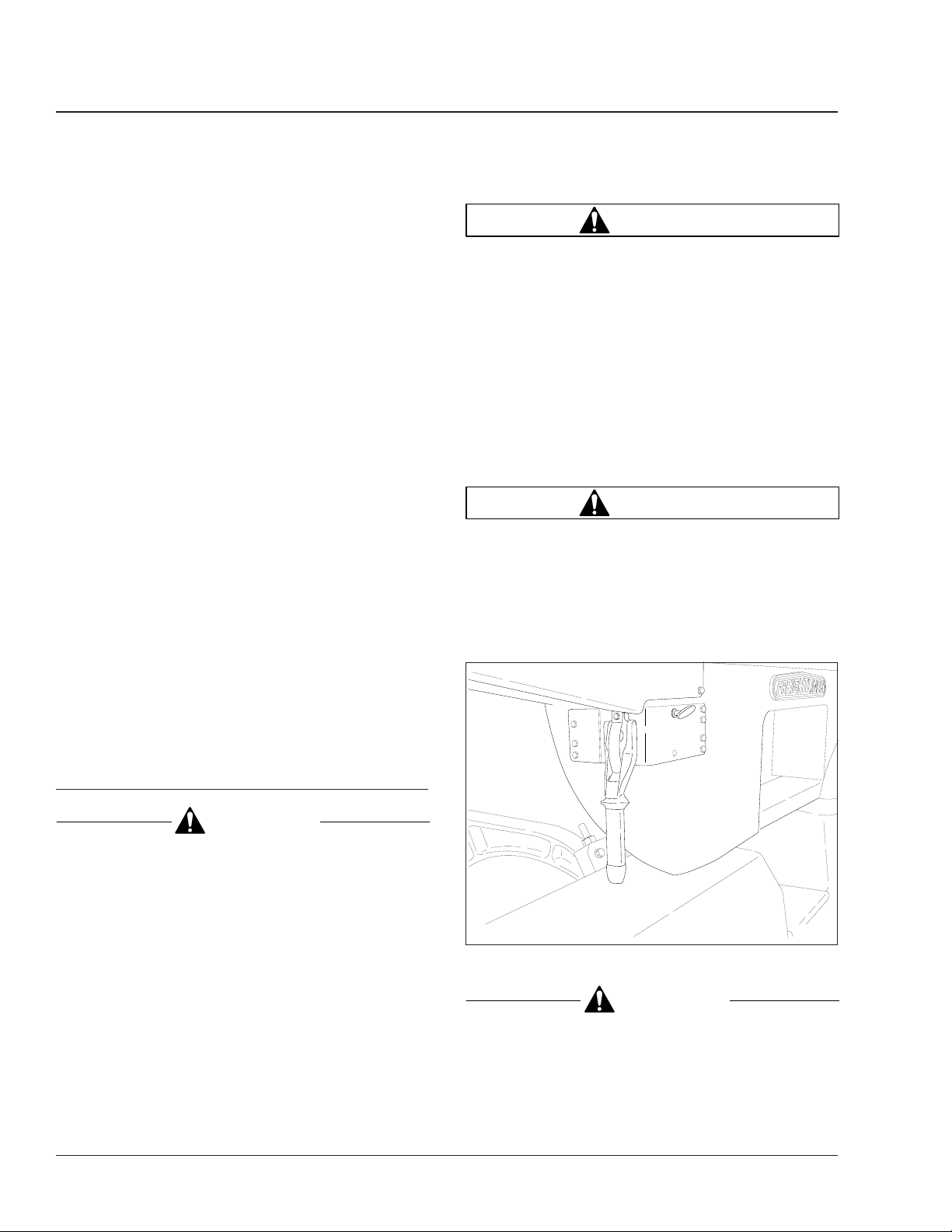

5. When the cab reaches a 30-degree angle, stop

working the pump. Push the free end of the tilt

strut down onto the right tilt-cylinder rod. See

Fig. 5. The tilt strut prevents the cab from acci-

dently dropping below this position.

07/26/93

Fig. 4, Cab Latch Indicator Pin

f310360a

6. To tilt the cab all the way, continue working the

pump until the cab nears a 45-degree angle. Reduce pumping speed. Once the cab goes beyond

45 degrees, stop working the pump. The cab will

gently descend to a full-tilt position. To stop the

cab at any position between 45-degrees and fulltilt, move the control lever to "Lower."

IMPORTANT: If the cab unintentionally stops

after it has gone beyond 45 degrees, do not

force it down with the tilt pump. The velocity

fuses have locked the tilt cylinders; unlock them.

Returning the FLB Cab from

the Tilted Position

DANGER

Stay completely clear of the cab’s travel path at all

times. Once the tilt strut has been released, do

not lean over the frame rails, the engine, or the

transmission for any reason. To do so could result

in serious injury or death.

1. Move the tilt strut away from the right tilt-cylinder

rod, and lock it in the spring catch.

If the cab was tilted less than 45 degrees, raise it

enough to release the tilt strut. Move the tilt strut

away from the tilt-cylinder rod, and lock it in the

spring catch before lowering the cab. See Fig. 6.

1

2

1

04/15/93

1. Tilt-Cylinder Rod 2. Tilt Strut

Fig. 5, Tilt Strut Positioning

Heavy-Duty Trucks Maintenance Manual, October 2009 00/21

f310357a

3

04/15/93

1. Tilt Strut

2. Tilt-Cylinder Rod

Fig. 6, Releasing the Tilt Strut

2

f310358a

3. Tilt Cylinder

COE Cab Tilting, FLA/FLB: 00–11

General Information00

2. Set the pump control lever at "Lower," and work

the pump until the cab nears a 45-degree angle.

Reduce pumping speed. Once the cab goes over

center, stop working the pump. The cab will gently descend to the operating position.

To stop the cab at any position between 45 degrees and 30 degrees, move the control lever to

"Raise," and push the tilt strut down onto the

right tilt-cylinder rod.

IMPORTANT: If the cab unintentionally stops

after it has gone beyond 45 degrees, do not

force it down with the tilt pump. The tilt strut is

in the locked position, or the velocity fuses have

locked the tilt cylinders. Release the tilt strut, or

unlock the velocity fuses.

3. When the cab is lowered all the way, make sure

the pump control lever is set at "Lower."

4. Check the indicator pin on each cab latch. See

Fig. 4. The latches are locked when the pins

have moved back into the piston and cylinder

spring assembly.

5. Push the transmission shift lever forward to lock

the shift tube latch mechanism.

NOTE: Maintain the hydraulic fluid level at the

oil fill plug. Add fluid only when the cab is in the

operating position. Use only Freightlinerapproved hydraulic fluid; see Group 60 for

specified fluid.

WARNING

Before tilting the cab, make sure that there is adequate clearance in front of the vehicle, and that

the area is free of people and all objects.

Do not tilt the cab with the engine running. Tilting

the cab could engage the transmission. If the engine is running, the vehicle can move, causing an

accident that could result in personal injury or

property damage.

2. Remove the pump handle from the baggage

compartment, and insert it into the pump shank.

3. Secure all loose articles in the cab and bunk,

and make sure the doors are securely latched.

WARNING

Objects falling in the cab, or a door flying open,

could damage the vehicle or cause personal injury .

4. Move the pump control lever to "Raise."

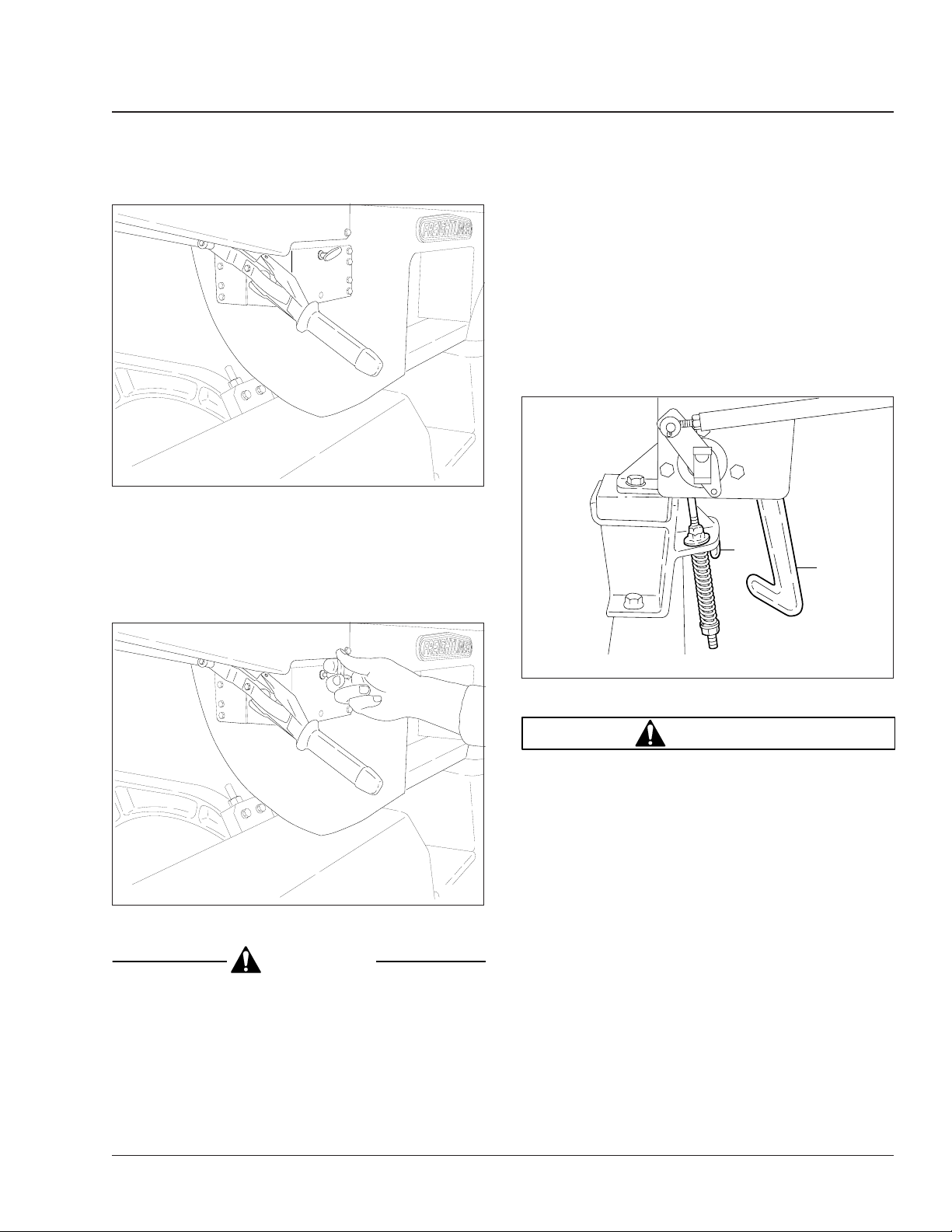

5. Unlock the back-of-cab latch handles (Fig. 7)by

pulling them outward. See Fig. 8.

Tilting the FLA Cab

CAUTION

Before tilting the cab, make sure the vehicle is

parked on level ground, both side-to-side and

front-to-rear. Tilting the cab while the vehicle is

parked on unlevel ground (such as a sloping highway shoulder) may damage the cab mounts and

prevent you from returning the cab to the operating position.

1. Apply the parking brakes. Place the transmission

shift lever in neutral. Shut down the engine if it is

running.

f31003907/22/93

Fig. 7, Latch Handle (Locked Position)

CAUTION

Do not work the tilt pump while the cab latches

are locked. Doing this causes stress in the back

of the cab, which could cause rivet and cab-skin

damage.

Heavy-Duty Trucks Maintenance Manual, October 200900/22

General Information 00

COE Cab Tilting, FLA/FLB: 00–11

system; for instructions, see Group 60 of the

Heavy-Duty Trucks Service Manual

If the cab stops moving while it is being raised,

do not force it to move with the tilt pump. The

velocity fuses have locked up the tilt cylinders;

unlock them.

7. After the safety hook has been raised above the

safety catch (Fig. 10), let go of the release

handle. Tilt the cab to a 30-degree angle.

.

07/22/93

Fig. 8, Latch handle (Unlocked Position)

6. Pull the safety hook release handle (Fig. 9) while

working the hydraulic pump. If the cab does not

begin to raise during the first 10 to 15 strokes,

stop what you are doing. Make sure the shift

tube latch mechanism has released.

07/22/93

Fig. 9, Safety Hook Release Handle

f310040

f310041

CAUTION

Continued application of force to tilt the cab when

the shift tube latch mechanism has not released

could result in transmission or shift tube damage.

NOTE: If air is present in the hydraulic tilt system, pump operation will seem "spongy" or ineffective. If this happens, bleed the air from the

1

2

07/22/93

1. Safety Catch 2. Safety Hook

Fig. 10, Safety Catch Mechanism

f310042

WARNING

Make sure the tilt strut is pushed down onto the

right tilt-cylinder rod. If the tilt strut is not engaged, and the cab drops, the result could be serious injury or death.

8. When the cab reaches a 30-degree angle, push

the free end of the tilt strut down onto the right

tilt-cylinder rod. See Fig. 11. The tilt strut prevents the cab from accidently dropping below

this position.

9. To tilt the cab all the way, continue working the

pump until the cab nears a 45-degree angle. Reduce pumping speed. Once the cab goes beyond

45 degrees, stop pumping. The cab will gently

descend to a full-tilt position. To stop the cab at

any position between 45-degrees and full-tilt,

move the control lever to "Lower."

IMPORTANT: If the cab unintentionally stops

after it has gone beyond 45 degrees, do not

Heavy-Duty Trucks Maintenance Manual, October 2009 00/23

Loading...

Loading...