Freightliner Conventional Service Manual

Foreword

Introduction

This manual provides information needed to operate

and understand the vehicle and its components.

More detailed information is contained in the

Warranty Information for North America

in the vehicle’s service and maintenance manuals.

Custom-built Freightliners are equipped with various

chassis and cab components. Not all of the information contained in this manual applies to every vehicle. For details about components in your vehicle,

refer to the chassis specification pages included in all

new vehicles and to the vehicle specification decal,

located inside the vehicle.

For your reference, keep this manual in the vehicle

at all times.

IMPORTANT: Descriptions and specifications in this

manual were in effect at the time of printing. Freightliner Trucks reserves the right to discontinue models

and to change specifications or design at any time

without notice and without incurring obligation. Descriptions and specifications contained in this publication provide no warranty, expressed or implied,

and are subject to revisions and editions without notice.

Owner’s

booklet, and

Environmental Concerns and

Recommendations

Whenever you see instructions in this manual to discard materials, you should first attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and regulations

when disposing of materials.

down coordination, or Fleetpack assistance. Our

people are knowledgeable, professional, and committed to following through to help you keep your truck

moving.

Reporting Safety Defects

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Daimler Trucks North America

LLC.

If the NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems

between you, your dealer, or Daimler Trucks North

America LLC.

To contact NHTSA, you may call the Vehicle

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to www.safercar.gov; or write

to: Administrator, NHTSA, 1200 New Jersey

Avenue, SE, Washington, DC 20590. You can also

obtain other information about motor vehicle safety

from www.safercar.gov.

Canadian customers who wish to report a safetyrelated defect to Transport Canada, Defect Investigations and Recalls, may telephone the toll-free

hotline 1-800-333-0510, or contact Transport

Canada by mail at: Transport Canada, ASFAD,

Place de Ville Tower C, 330 Sparks Street,

Ottawa, Ontario, Canada K1A 0N5.

Event Data Recorder

This vehicle is equipped with one or more devices

that record specific vehicle data. The type and

amount of data recorded varies depending on how

the vehicle is equipped (such as the brand of engine,

if an air bag is installed, or if the vehicle features a

collision avoidance system, etc.).

Customer Assistance Center

Having trouble finding service? Call the Customer

Assistance Center at 1–800–385–4357 or 1–800–

FTL–HELP. Call night or day, weekdays or weekends, for dealer referral, vehicle information, break-

For additional road safety information, please visit

the Road Safety website at:

www.tc.gc.ca/roadsafety/menu.htm.

STI-203-1 (1/10P)

A24-00509-000

Printed in U.S.A.

Foreword

© 1989–2010 Daimler Trucks North America LLC. All rights reserved. Daimler Trucks North America LLC is a Daimler

company.

No part of this publication, in whole or part, may be translated, reproduced, stored in a retrieval system, or transmitted

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Daimler Trucks North America LLC. For additional information, please contact Daimler Trucks North

America LLC, Service Systems and Documentation, P.O. Box 3849, Portland OR 97208–3849 U.S.A. or refer to

www.Daimler-TrucksNorthAmerica.com and www.FreightlinerTrucks.com.

Contents

Chapter Page

Introduction, Environmental Concerns and Recommendations,

Event Data Recorder, Customer Assistance Center, Reporting

Safety Defects ..................................................... Foreword

1 Vehicle Identification ...................................................... 1.1

2 Instruments and Controls Identification ....................................... 2.1

3 Vehicle Access .......................................................... 3.1

4 Heater and Air Conditioner ................................................. 4.1

5 Seats and Seat Belts ..................................................... 5.1

6 Steering and Brake Systems ............................................... 6.1

7 Engines and Clutches .................................................... 7.1

8 Transmissions ........................................................... 8.1

9 Rear Axles ............................................................. 9.1

10 Fifth Wheels and Trailer Couplings ......................................... 10.1

11 Pretrip and Post-Trip Inspections and Maintenance ............................ 11.1

12 Cab Appearance ........................................................ 12.1

13 In an Emergency ....................................................... 13.1

Index .................................................................. I.1

1

Vehicle Identification

Vehicle Specification Decal ......................................................... 1.1

Federal Motor Vehicle Safety Standard (FMVSS) Labels .................................. 1.1

Canadian Motor Vehicle Safety Standard (CMVSS) Labels ................................ 1.2

Tire and Rim Labels .............................................................. 1.2

EPA Emission Control Labels ........................................................ 1.2

Vehicle Identification

Vehicle Specification Decal

The vehicle specification decal (Fig. 1.1) lists the vehicle model, identification number, and major component models. It also recaps the major assemblies

and installations shown on the chassis specification

sheet. One copy of the specification decal is attached to the inside of the glove box; another copy is

inside the rear cover of the

mation for North America

COMPONENT INFORMATION

MANUFACTURED BY

MODEL

VEHICLE ID NO.

DATE OF MFR

ENGINE MODEL

TRANS MODEL MAIN

FRONT AXLE MODEL

REAR AXLE MODEL

IMRON PAINT−CAB

CAB COLOR A: WHITE (4775)

PAINT MFR

CAB COLOR B: BROWN (3295)

PAINT NO.

CAB COLOR C: BROWN (29607)

CAB COLOR D: DARK BROWN (7444)

11/21/96

Fig. 1.1, Vehicle Specification Decal, U.S.-Built Vehicle

Owner’s Warranty Infor-

booklet.

USE VEHICLE ID NO.

WHEN ORDERING PARTS

WHEELBASE

ENGINE NO.

TRANS NO.

FRT AXLE NO.

REAR AXLE NO.

REAR AXLE NO.

RATIO

FOR COMPLETE PAINT INFORMATION

SEE VEHICLE SPECIFICATION SHEET

Shown

PART NO. 24−00273−010

f080021

2

1

11/21/96

3

f080053

1. Date of manufacture by month and year.

2. Gross vehicle weight rating; developed by taking the

sum of all the vehicle’s gross axle ratings.

3. Gross axle weight ratings; developed by considering

each component in an axle system, including

suspension, axle, wheels, and tires. The lowest

component capacity is the value used for the

system.

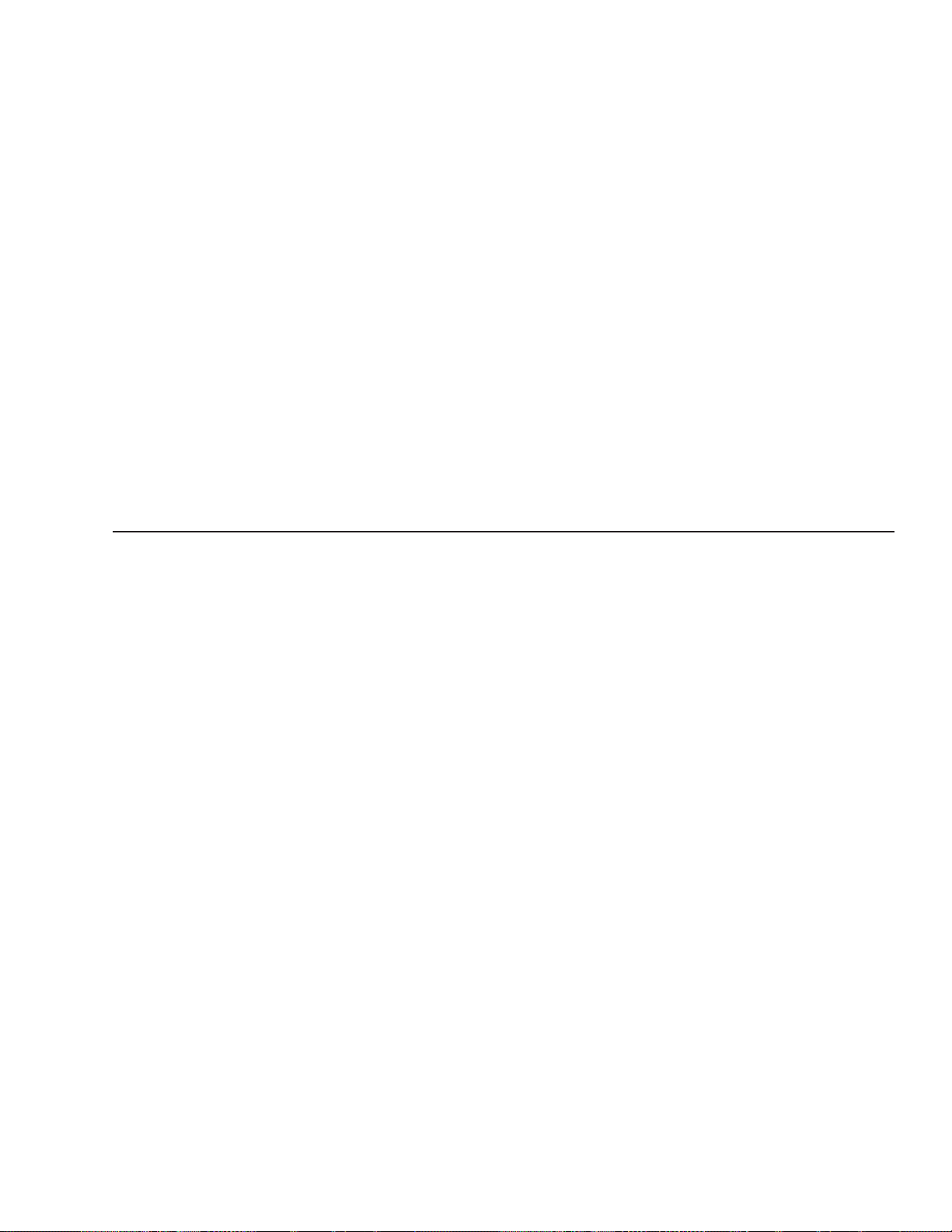

Fig. 1.2, Certification Label, U.S.

1

NOTE: Labels shown in this chapter are examples only. Actual specifications may vary from

vehicle to vehicle.

Federal Motor Vehicle Safety

Standard (FMVSS) Labels

NOTE: Due to the variety of FMVSS certification

requirements, not all of the labels shown will

apply to your vehicle.

Tractors with or without fifth wheels purchased in the

U.S. are certified by means of a certification label

(Fig. 1.2) and the tire and rim labels. These labels

are attached to the left rear door post, as shown in

Fig. 1.3.

If purchased for service in the U.S., trucks built without a cargo body have a certification label (Fig. 1.4)

attached to the left rear door post. See Fig. 1.3.In

addition, after completion of the vehicle, a certification label similar to that shown in Fig. 1.2 must be

attached by the final-stage manufacturer. This label

will be located on the left rear door post and certifies

2

02/02/95

f600061b

1. Tire and Rim Labels 2. Certification Label

Fig. 1.3, Location of Labels

09/28/98

f080023

Fig. 1.4, Incomplete Vehicle Certification Label, U.S.

that the vehicle conforms to all applicable FMVSS

regulations in effect on the date of completion.

1.1

Vehicle Identification

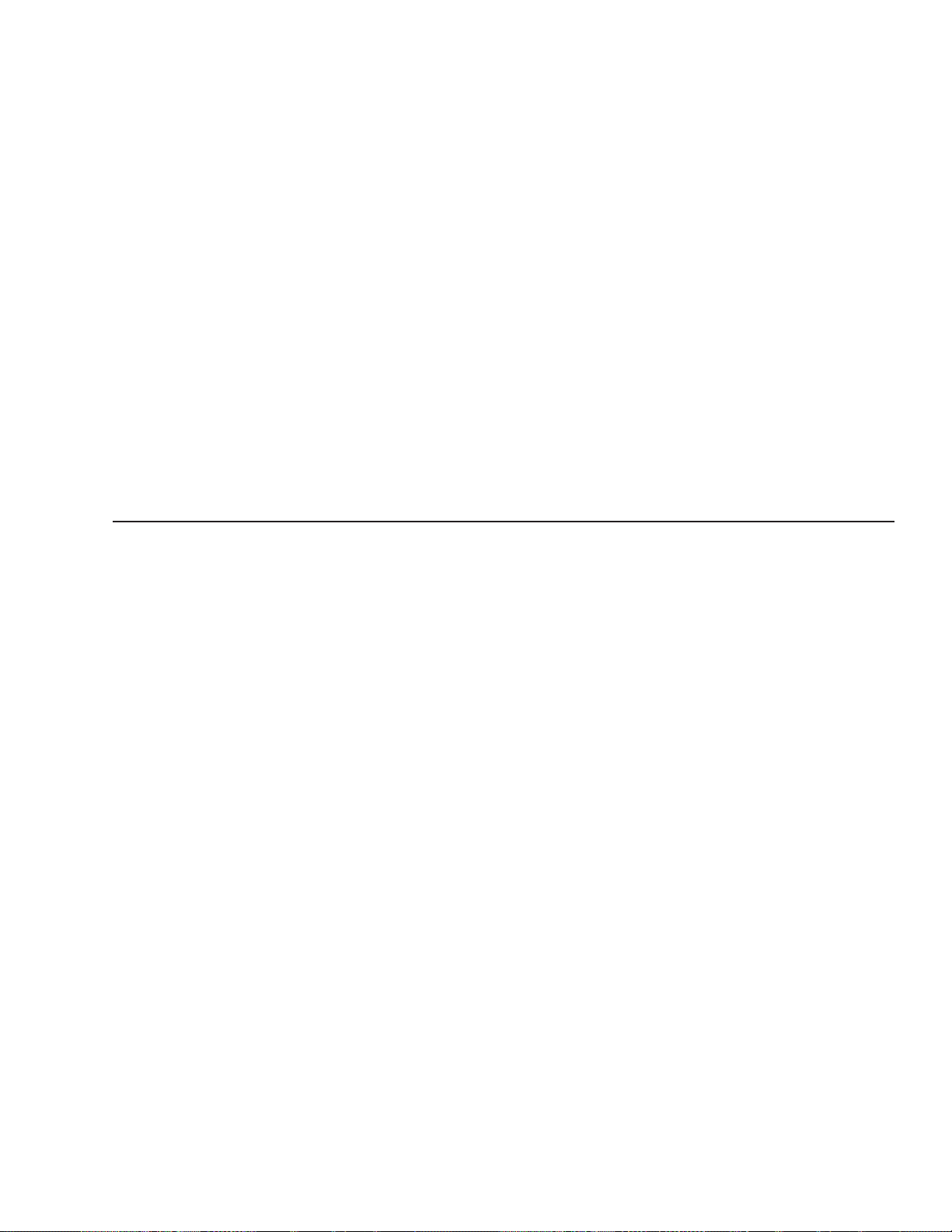

Canadian Motor Vehicle Safety

Standard (CMVSS) Labels

In Canada, tractors with fifth wheels are certified by

means of a "Statement of Compliance" label and the

Canadian National Safety Mark (Fig. 1.5), which are

attached to the left rear door post.

10/10/2006

Fig. 1.5, Canadian National Safety Mark

f080024

If purchased for service in Canada, trucks built without a cargo body and tractors built without a fifth

wheel are certified by a "Statement of Compliance"

label, similar to Fig. 1.2. This label must be attached

by the final-stage manufacturer after completion of

the vehicle. The label is located on the left rear door

post, and certifies that the vehicle conforms to all

applicable CMVSS regulations in effect on the date

of completion.

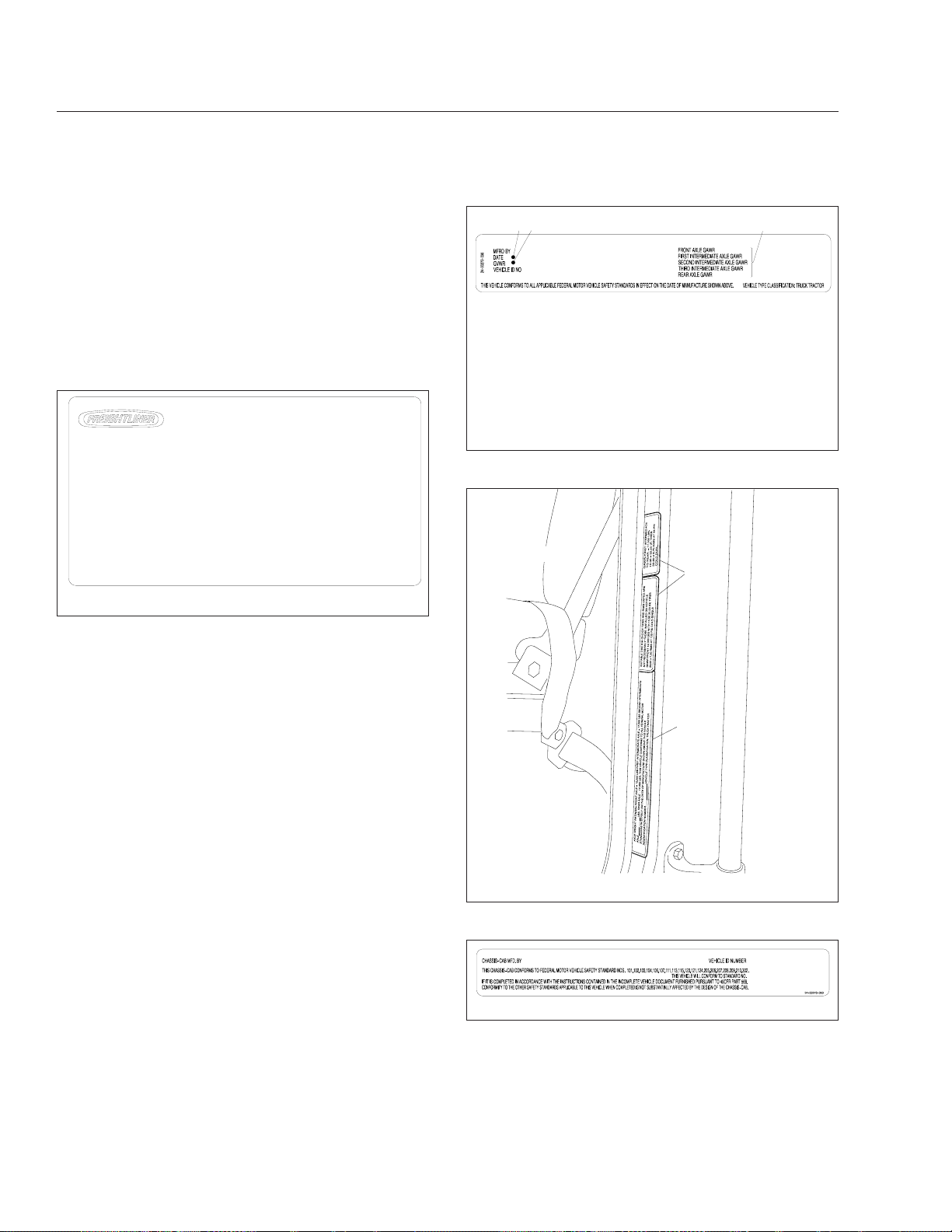

Tire and Rim Labels

Tire and rim labels (attached to the left rear door

post) certify suitable tire and rim combinations that

can be installed on the vehicle, for the given gross

axle weight rating. See Fig. 1.6. Tires and rims installed on the vehicle at the time of manufacture may

have a higher load capacity than that certified by the

tire and rim label. If the tires and rims currently on

the vehicle have a lower load capacity than that

shown on the tire and rim label, then the tires and

rims determine the load limitations on each of the

axles.

Refer to Fig. 1.6 for U.S. and Canadian tire and rim

labels.

2

1

VEHICLE ID NO.

DATE OF MFR

GVWR

TIRES AND RIMS LISTED ARE NOT NECESSARILY THOSE INSTALLED ON THE VEHICLE.

10/31/95

FRONT AXLE

FIRST INTERMEDIATE AXLE

SECOND INTERMEDIATE AXLE

THIRD INTERMEDIATE AXLE

REAR AXLE

3

GAWR TIRES RIMS PSI COLD

24−00273−040

f080054

1. Date of manufacture by month and year.

2. Gross vehicle weight rating; developed by taking the

sum of all the vehicle’s gross axle ratings.

3. Gross axle weight ratings; developed by considering

each component in an axle system, including

suspension, axle, wheels, and tires. The lowest

component capacity is the value used for the

system.

Fig. 1.6, Tire and Rim Label

EPA Emission Control Labels

Vehicle Noise Emission Control Label

A vehicle noise emission control label (Fig. 1.7)is

attached either to the left side of the dashboard or to

the top-right surface of the frontwall between the

dash and the windshield.

FREIGHTLINER CORPORATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY

THE NOISE CONTROL ACT OF 1972:

A. THE REMOVAL OR RENDERING INOPERATIVE, OTHER THAN FOR PURPOSES OF

MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR

ELEMENT OF DESIGN (LISTED IN THE OWNER’S MANUAL) INCORPORATED INTO THIS

VEHICLE IN COMPLIANCE WITH THE NOISE CONTROL ACT.

B. THE USE THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF DESIGN HAS

BEEN REMOVED OR RENDERED INOPERATIVE.

10/06/98

VEHICLE NOISE EMISSION CONTROL INFORMATION

DATE OF MANUFACTURE

Fig. 1.7, Vehicle Noise Emission Control Label

IMPORTANT: Certain Freightliner incomplete

vehicles may be produced with incomplete noise

control hardware. Such vehicles will not have a

vehicle noise emission control information label.

For such vehicles, it is the final-stage manufacturer’s responsibility to complete the vehicle in

conformity to U.S. EPA regulations (40 CFR Part

205) and label it for compliance.

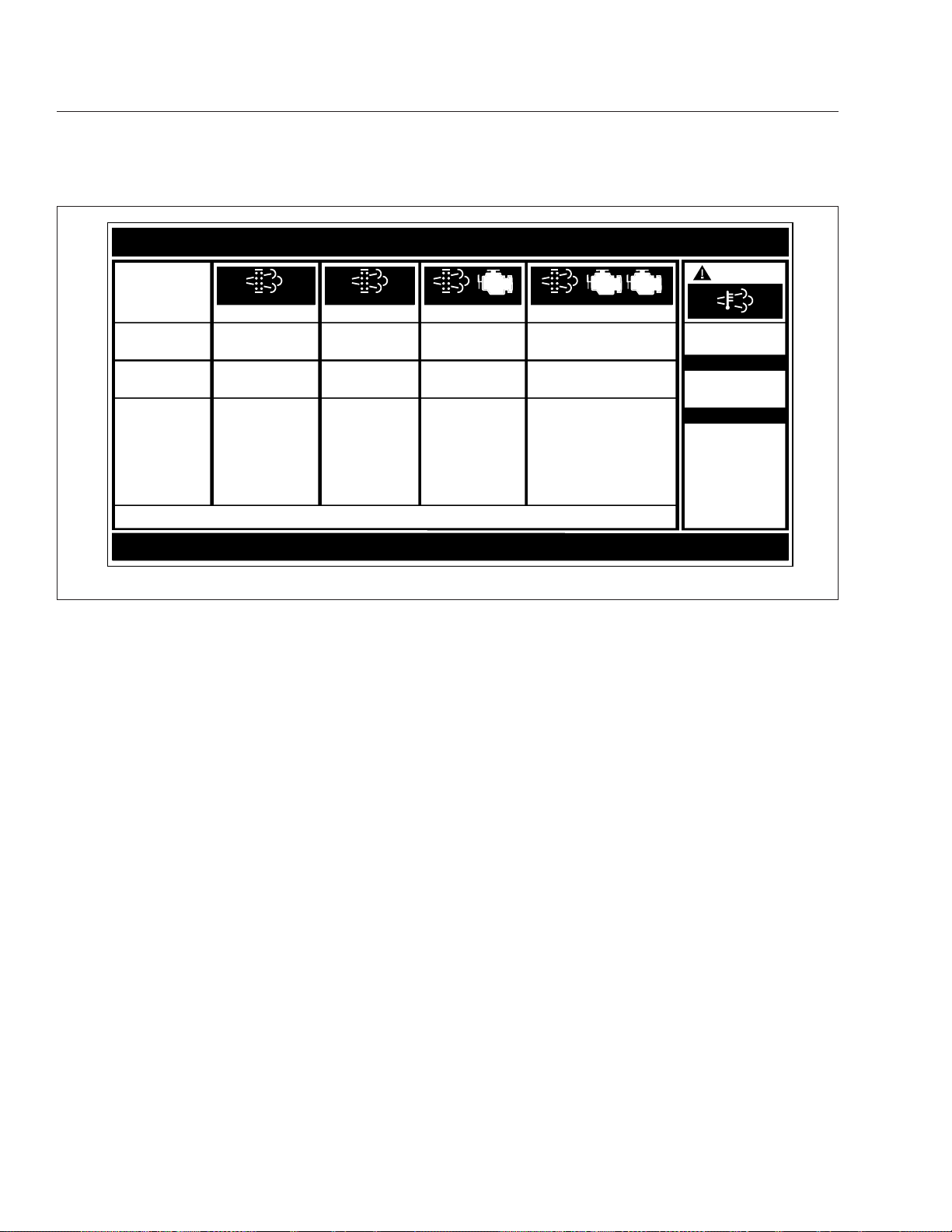

EPA07 Exhaust Emissions

To meet January 2007 emissions regulations, vehicles with engines manufactured after January 1,

2007, are equipped with an emission aftertreatment

device. There is a warning label on the driver’s sunvisor, explaining important new warning indicators in

the driver’s message display, that pertain to the aftertreatment system. See Fig. 1.8.

01/96

24−00273−020

f080026

1.2

Vehicle Identification

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

INDICATOR

LAMP(S)

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

(Solid)

Level 1 Level 3Level 2 Level 4

Filter Regeneration

Recommended

Filter is reaching

capacity

. .

Bring vehicle to

highway speeds to

allow for an Automatic

Regeneration or

perform a Parked

Regeneration.

(Flashing) (Flashing)

Filter Regeneration

Necessary

Filter is now

reaching maximum

capacity

Switch.

.

To avoid engine

derate bring vehicle

to highway speeds

to allow for an

Automatic

Regeneration or

perform a Parked

Regeneration as

soon as possible.

CHECK CHECK

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

Vehicle must be

parked and a Parked

Regeneration must

be performed −

engine will begin

derate.

(Flashing)

Parked Regeneration Required −

Engine Shut Down

Filter has exceeded

maximum capacity

.

Vehicle must be parked and a

Parked Regeneration or Service

Regeneration must be performed.

Check engine operator’s manual

for details −engine will shut down.

STOP

W

ARNING

HEST (High Exhaust

System Temperature)

Flashing

A regeneration is in

progress.

Solid

Exhaust Components

and exhaust gas are

at high temperature.

When stationary, keep

away from people and

flammable materials

or vapors.

See Engine Operator’s Manual for complete Regeneration Instructions.

06/29/2009

Fig. 1.8, Sunvisor Warning Label

It is a violation of federal law to alter exhaust plumbing or aftertreatment in any way that would bring the

engine out of compliance with certification requirements. (Ref: 42 U.S.C. S7522(a) (3).) It is the owner’s responsibility to maintain the vehicle so that it

conforms to EPA regulations.

24−01583−000B

f080147

1.3

2

Instruments and Controls

Identification

Instrument and Control Panel ....................................................... 2.1

Controls ......................................................................... 2.1

Warning and Indicator Lights ....................................................... 2.13

Collision Warning System (CWS), Eaton VORAD EVT–300, Optional ...................... 2.20

Instruments ..................................................................... 2.25

Exterior Switches ................................................................ 2.31

Instruments and Controls Identification

Instrument and Control Panel

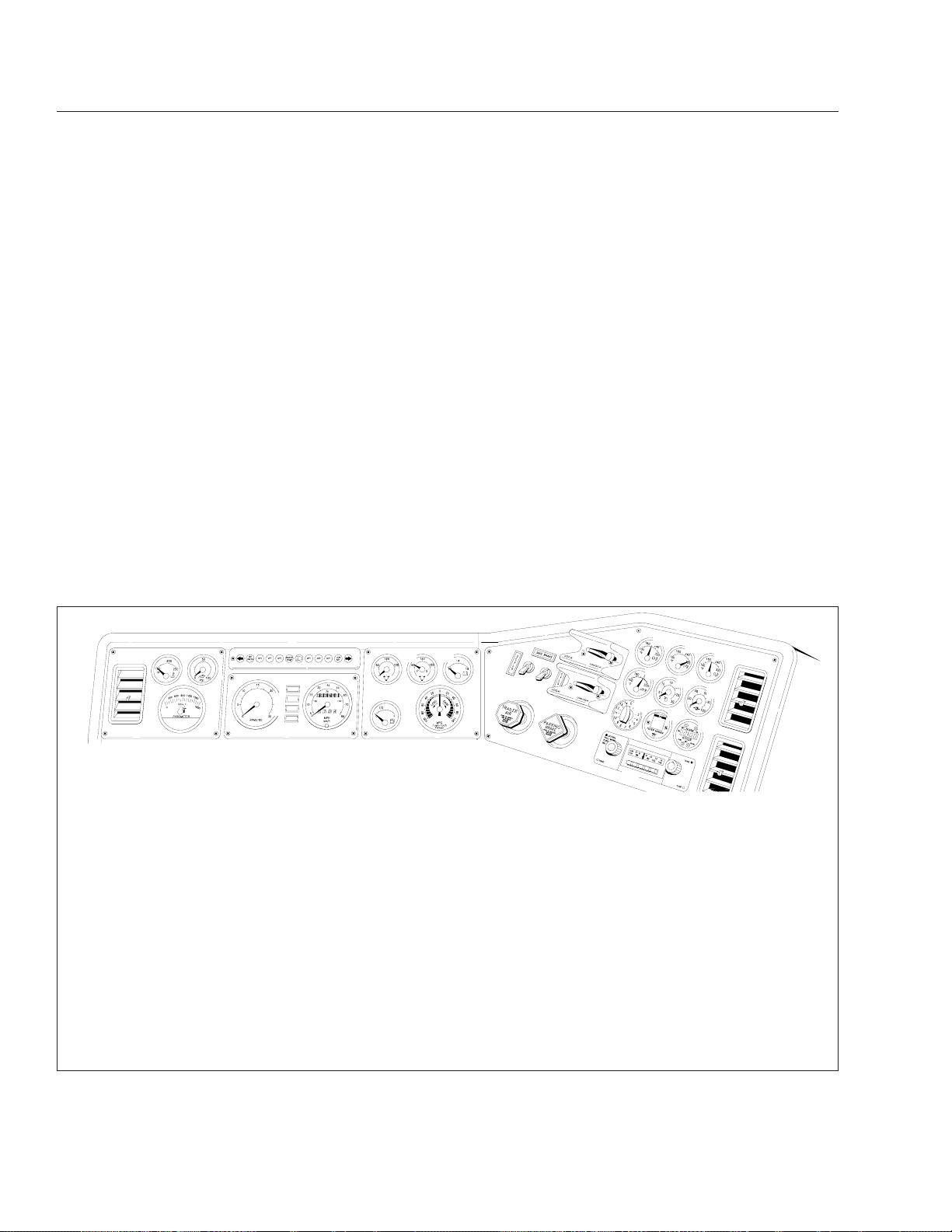

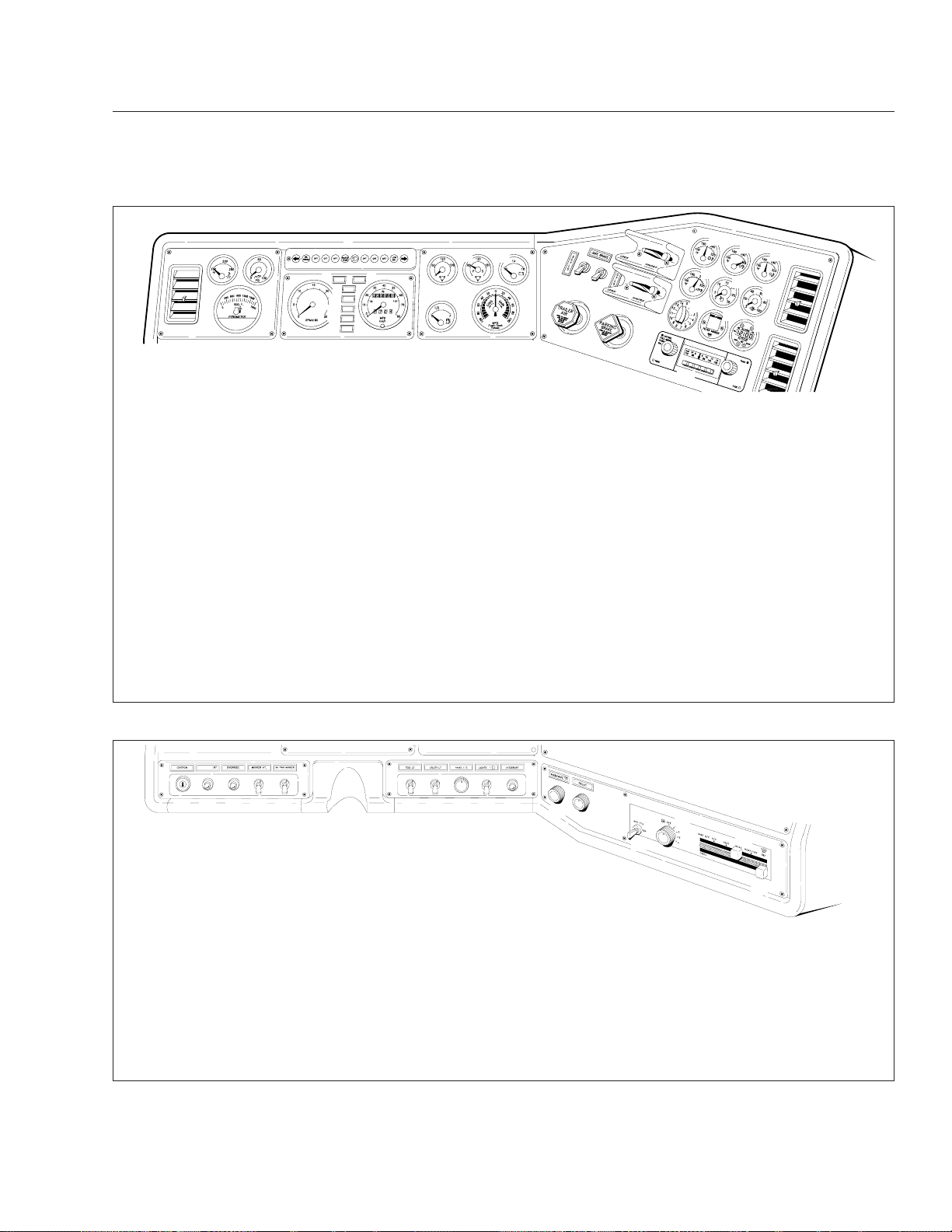

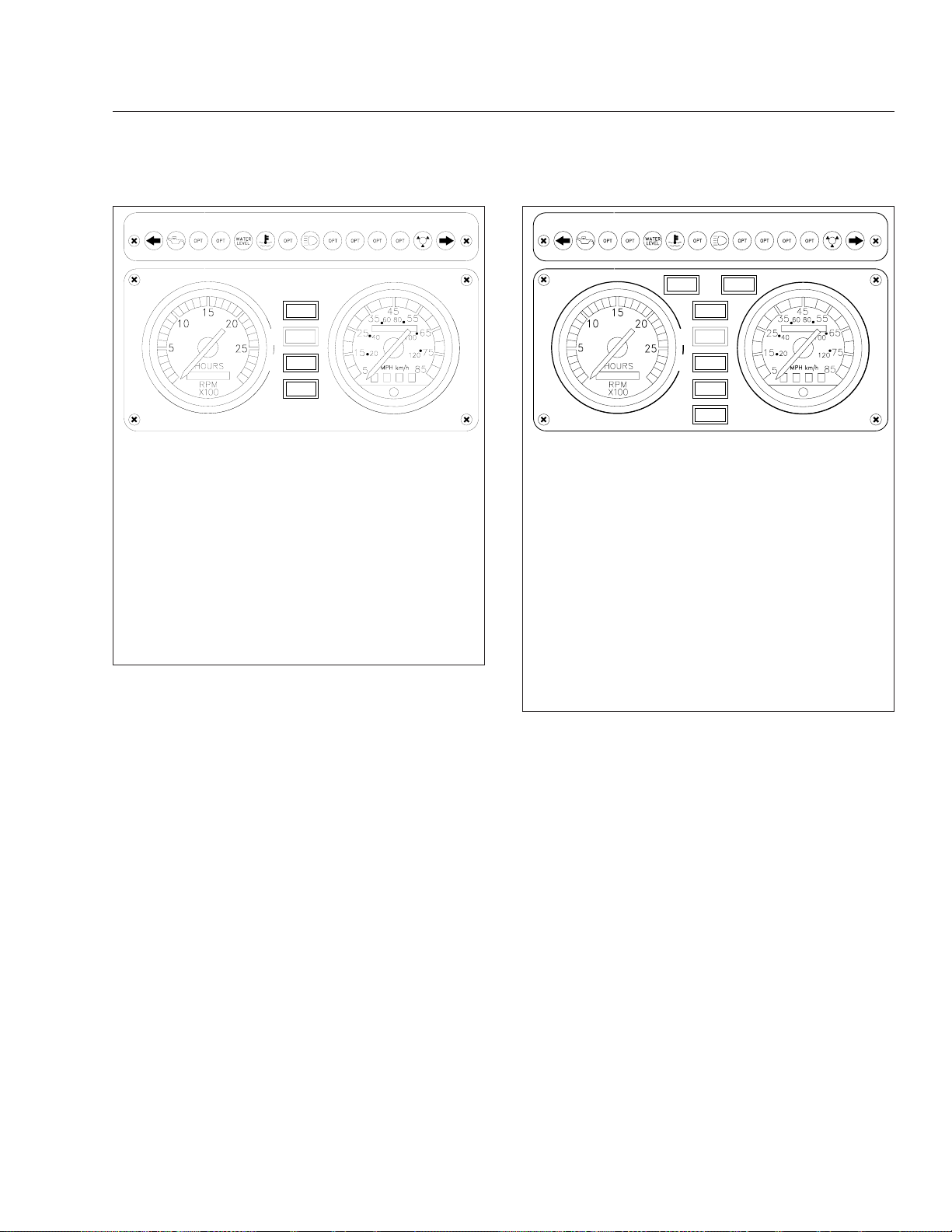

Figure 2.1, Figure 2.2, and Figure 2.3 represent a

portion of a typical Freightliner dash equipped with all

of the standard and many of the optional instruments

and accessories. Most standard and optional instrument gauges and switches can be mounted in this

dash.

NOTE: On SilverAero models, switches for

cruise control and manual control for the engine

fan are standard. If these features are not requested, dummy switches with blank labels are

installed.

A warning and indicator light module, located above

the speedometer and tachometer, houses all of the

standard and optional warning and indicator lights.

Some of the controls discussed in this chapter are

not dash-mounted.

2

1

3

4

5

6

7

8

9

10

12

11

14 15

Controls

Ignition Switch and Key

The ignition switch (Fig. 2.4) can be turned to three

positions: "Off," "Accessory," and "On." In addition,

the same key locks and unlocks the cab doors, baggage door(s), and, if equipped, the bunk door(s).

In the "Off" position, the key slot is vertical; the key

can be inserted and removed only in this position.

The low beam headlights, taillights, brake lights, fog

lights, dome lights, clearance lights, turn signals,

hazard warning lights, utility and baggage lights,

spotlights, electric wipers, horn, CB radio, power mirrors, cigarette lighter, clock, refrigerator, fuel heater,

electric oil pan heater, and electric or diesel-fired

engine-coolant preheaters can be operated in the off

position (regardless of whether the key is inserted or

not).

In the "Accessory" position, the key is turned counterclockwise. The auxiliary (bunk) fan, windshield

fan(s), radio or stereo system, mirror heat, ether start

20

21

22

25

23

26

29

13

17

16

18

19

27

24

28

02/02/95

NOTE: Instruments and controls, and their locations, may vary from those shown.

1. Water Temperature Gauge

2. Engine Oil Pressure Gauge

3. Pyrometer

4. Tachometer

5. Warning and Indicator Light Module (VIGIL and Kysor

shown)

6. Parking Brake Indicator Light

7. Antilock Braking System (ABS) Tractor Warning Light

8. ABS Wheel Spin Indicator Light

9. ABS Trailer Warning Light (dash light for DDEC

Optimized Idle

10. Speedometer/Odometer

11. Application Air Pressure Gauge

12. Dual System Air Pressure Gauge

13. Voltmeter

14. Fuel Gauge

2.1

®

, if so equipped)

Fig. 2.1, Instrument and Control Panel Layout (upper dash) Pre-EPA07

15. Fuel Tach

16. Engine Brake Switches

17. Trailer Air Supply Valve

18. Parking Brake Control Valve

19. Fifth Wheel Air Slider Control Valve Switch

20. Interaxle Differential Lockout Control Valve Switch

21. Transmission Oil Temperature Gauge

22. Forward Differential Oil Temperature Gauge

23. Rear Differential Oil Temperature Gauge

24. Engine Oil Temperature Gauge

25. Turbocharger Boost Pressure Gauge

26. Fuel Pressure Gauge

27. Automatic Engine Idler/Timer

28. Intake-Air Restriction Gauge

29. Digital Clock

30. Radio (optional)

30

f600831

Instruments and Controls Identification

23

10

11

12

5

76

8

9

13

15

14

17 18

16

20

19

21

22

2

1

3

4

30

27

24

31

28

25

26

29

32

03/14/2007

NOTE: Instruments and controls, and their locations, may vary from those shown.

1. Water Temperature Gauge

2. Engine Oil Pressure Gauge

3. Pyrometer

4. Tachometer

5. Warning and Indicator Light Module (VIGIL and Kysor

shown)

6. Engine Malfunction Indicator Light (MIL)

7. DPF Regen Warning Light

8. High Temperature Exhaust Warning Light (HEST)

9. Parking Brake Indicator Light

10. Antilock Braking System (ABS) Tractor Warning Light

11. ABS Trailer Warning Light (dash light for DDEC

Optimized Idle

®

, if so equipped)

12 Air Suspension Warning Light

13. Speedometer/Odometer

14. Application Air Pressure Gauge

15. Dual System Air Pressure Gauge

17. Fuel Gauge

18. Fuel Tach

19. Engine Brake Switches

20. Trailer Air Supply Valve

21. Parking Brake Control Valve

22. Fifth Wheel Air Slider Control Valve Switch

23. Interaxle Differential Lockout Control Valve Switch

24. Transmission Oil Temperature Gauge

25. Forward Differential Oil Temperature Gauge

26. Rear Differential Oil Temperature Gauge

27. Engine Oil Temperature Gauge

28. Turbocharger Boost Pressure Gauge

29. Fuel Pressure Gauge

30. Automatic Engine Idler/Timer

31. Intake-Air Restriction Gauge

32. Digital Clock

33. Radio (optional)

16. Voltmeter

Fig. 2.2, Instrument and Control Panel Layout (upper dash) EPA07

1

23

45

6

8

7

910

11

12

13

14

33

f600831a

15

02/02/95

NOTE: Instruments and controls, and their locations, may vary from those shown.

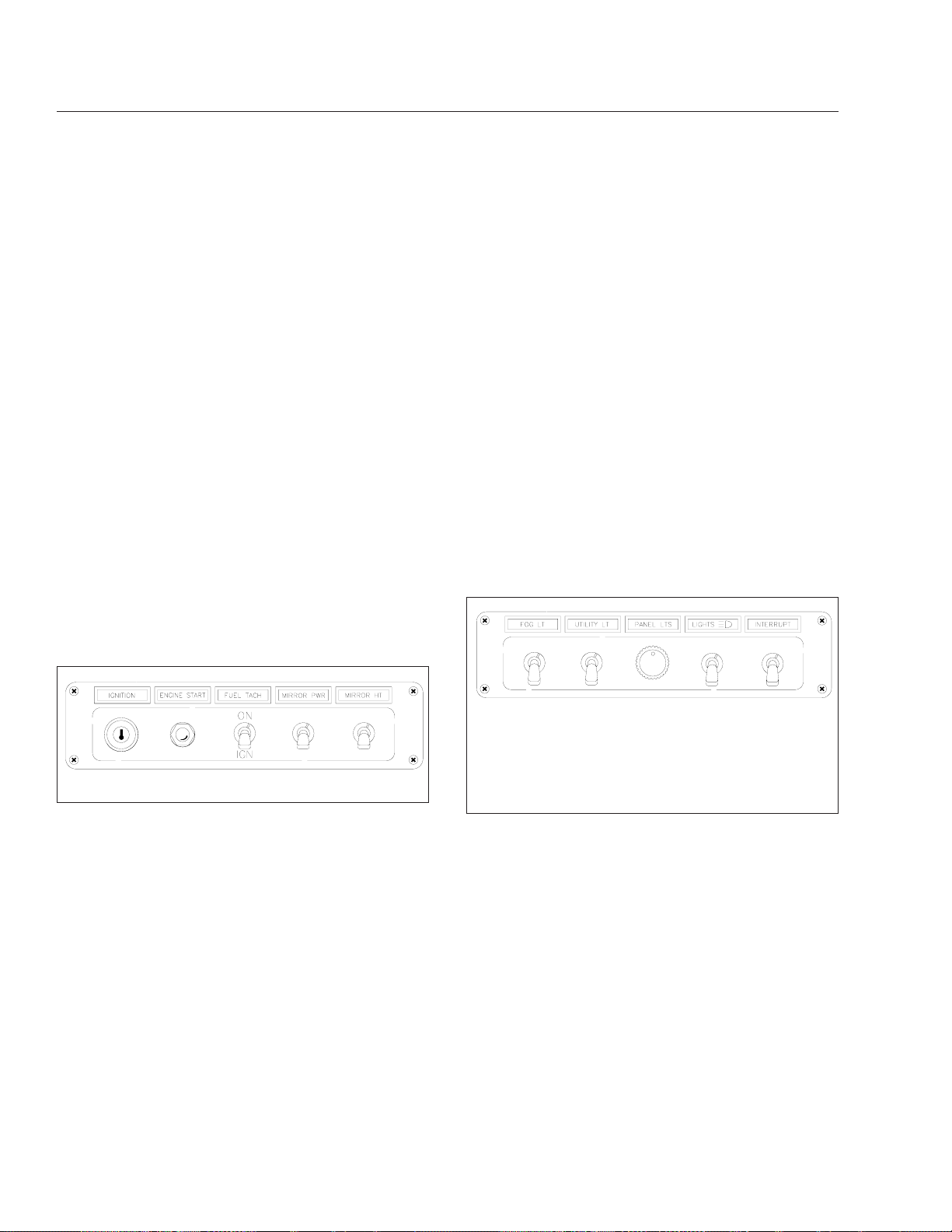

1. Ignition Switch

2. Engine Start Button

3. Engine Shutdown Override Button

4. Mirror Heat Switch

5. Right Side Power Mirror

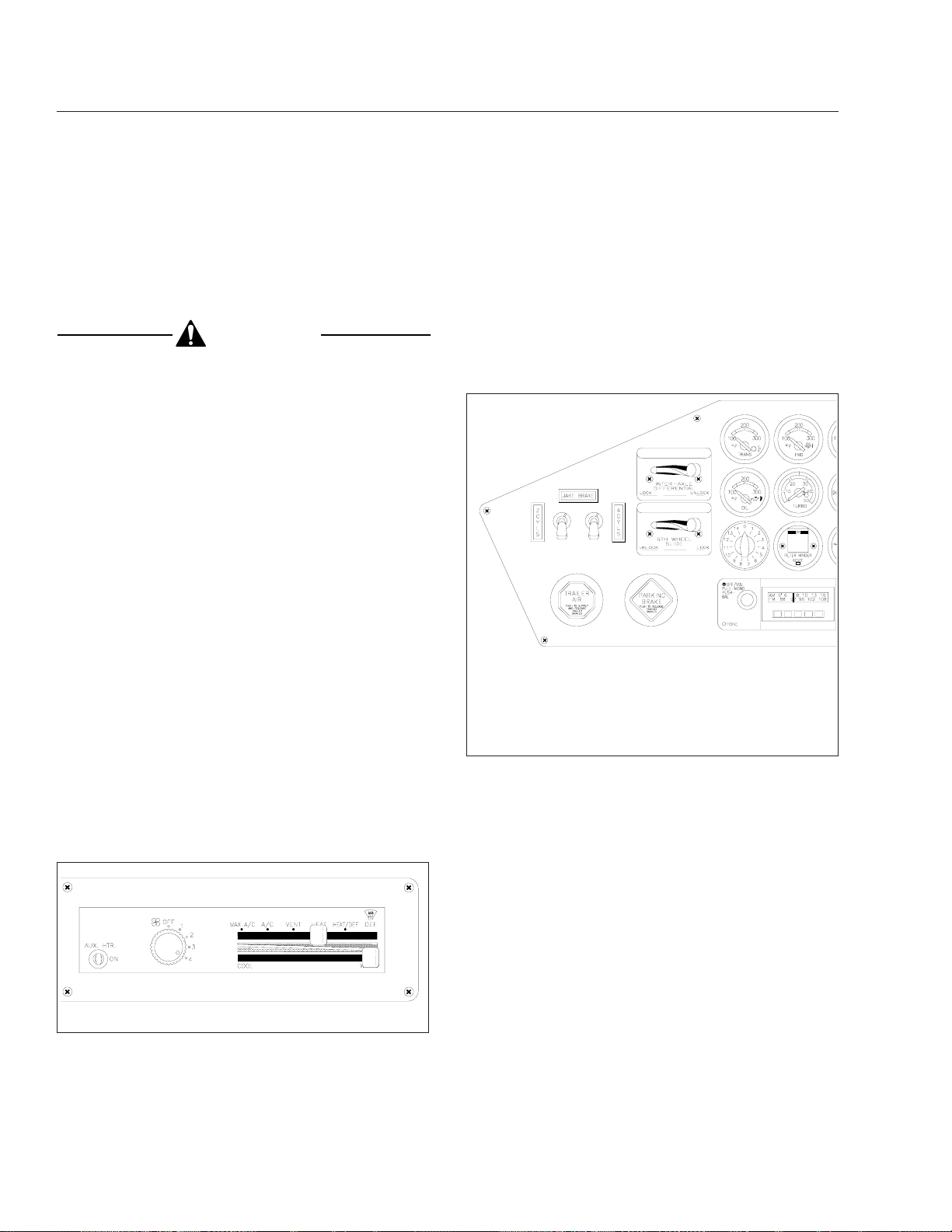

6. Fog Light Switch

7. Utility Light Switch

8. Panel Light Control Knob

9. Headlight/Parking Light Switch

10. Marker Light/Taillight Interrupt Switch

11. Windshield Wiper/Washer Control Knob

12. Intermittent (delay) Wiper Control Knob

13. Auxiliary Heater Fan Switch

14. Heater/Air Conditioner Fan Switch

15. Airflow Lever Slide Control

16. Temperature Lever Slide Control

Fig. 2.3, Instrument and Control Panel Layout (lower dash)

16

f600832

2.2

Instruments and Controls Identification

Manual Override Push Button,

Optional Engine Shutdown System

1234

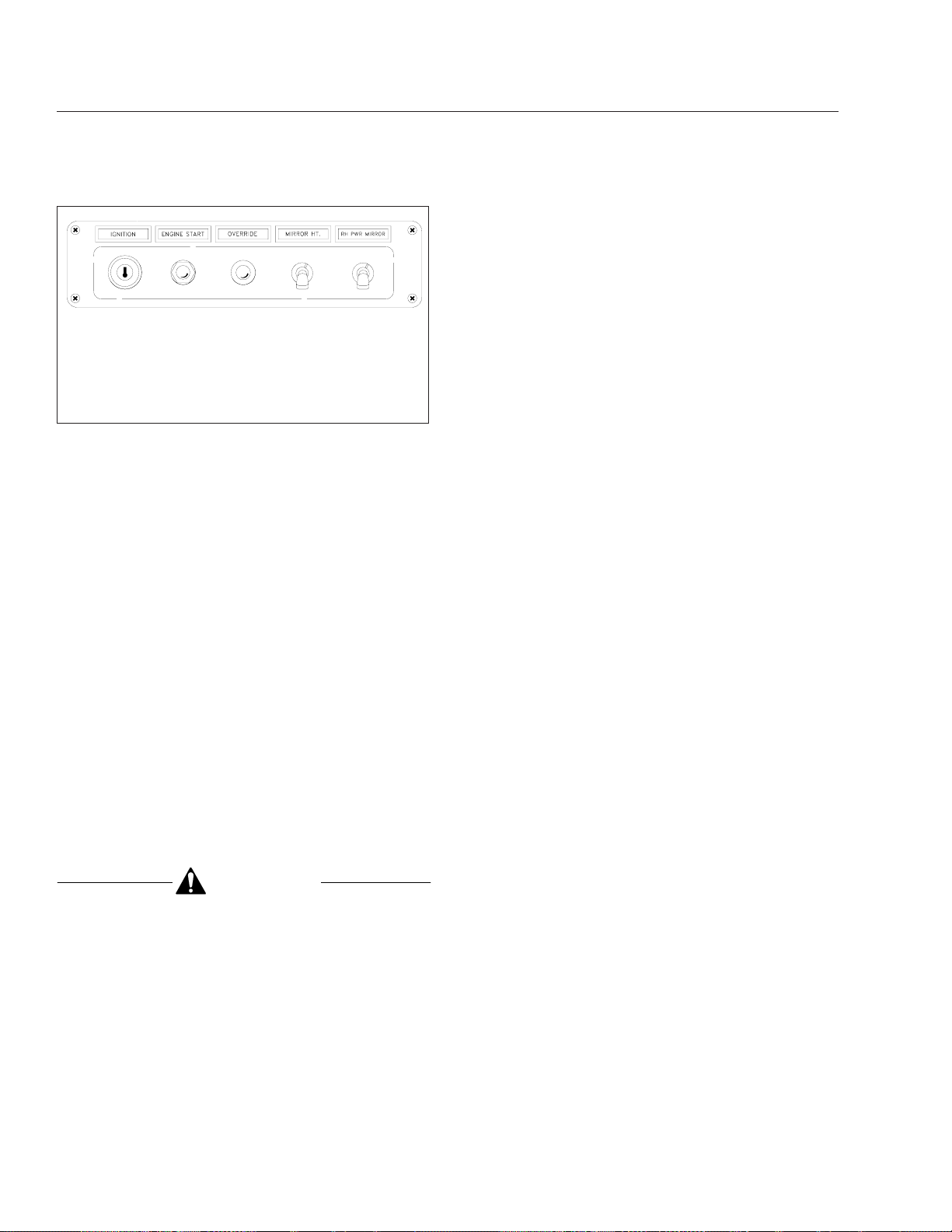

01/18/95

1. Ignition Switch

2. Engine Start Button

3. Manual Override Push Button

4. Mirror Heat Switch

5. Right-Side Power Mirror Switch

Fig. 2.4, Ignition/Start/Override/Mirror Switches

system, air dryer, backup lights, and all of the electrical systems that are operable in the "Off" position

are operable in the "Accessory" position.

In the "On" position, the key is turned clockwise. All

electrical systems are operable. Low air- and oilpressure warning lights and buzzer operate until the

engine is started and pressure is built up. The engine

can be started and operated only when the ignition

switch is on.

For vehicles built to operate in Canada, switching on

the ignition and releasing the parking brakes automatically activates the headlight low beams (later

model vehicles) or high beams (earlier model vehicles) at half voltage as daytime running lights. The

daytime running lights will operate until the parking

brakes are applied; then they will switch off. Turning

on the regular headlights will override the daytime

running lights. The vehicle cannot be driven unless

either the headlights or daytime running lights are

activated.

Engine Start Button

CAUTION

Do not push the engine start button with the engine running. To do so could result in starter

damage.

With the ignition switch on, push the engine start button (Fig. 2.4) to engage the electric or air starter.

See the applicable engine operating instructions in

Chapter 7 for complete starting instructions.

On vehicles equipped with a Neutral start switch, the

transmission must be in Neutral before the engine

can be started.

5

f600068a

If the vehicle is equipped with an engine shutdown

system with a manual override push button

(Fig. 2.4), simultaneously depress the engine start

button and the manual override push button. Once

the engine has started, release the engine start button, but continue to depress the override push button

until the warning bell stops.

Mirror Heat Switch, Optional

One or both outside door mirrors can be heated to

keep them defrosted. Whenever the mirror heat

switch (Fig. 2.4) is on, an indicator light illuminates

on the warning and indicator light module.

Power Mirrors

Both outside mirrors can be equipped with an electrical remote control. Move the toggle switch (Fig. 2.4)

to adjust the mirror.

Detroit Diesel Electronic Engine

Control (DDEC) Operator Control

The DDEC system is centered around a computer

that is programmed to automatically control engine

timing and fuel injection, providing maximum engine

performance and fuel economy.

Some DDEC II

shutdown option. This option will shut down the engine if potentially damaging conditions are detected.

An override button (on DDEC II engines, this button

is labelled "Override") is provided for emergency situations. It is mounted to the right of the ignition

switch, and provides the driver with an extra 30 seconds of engine operating time.

Standard DDEC III

gine if sensors indicate an emergency engine condition such as low coolant level, high coolant temperature, or high oil temperature. If such a condition

occurs, the yellow "Check Engine" light in the lightbar

will glow. If the problem gets bad enough to cause

possible engine damage, the DDEC III will gradually

cut engine power down to 70 percent of original

power. At that point, the red "Shutdown Engine" light

will turn on, and 30 seconds later, DDEC III will shut

down the engine.

®

systems have an automatic engine

®

systems will shut down the en-

2.3

Instruments and Controls Identification

If DDEC III detects low oil pressure, both the "Check

Engine" and "Shutdown Engine" lights will go on, and

the engine will shut down in 30 seconds.

NOTE: If the vehicle is in a hazardous place

when the "Shutdown Engine" light goes on, the

driver must immediately press the "Override/

Chk" button or the engine will shut down in 30

seconds. Pressing the button will give the driver

an additional 30 seconds to move the vehicle. If

this is still not enough time, the driver must

press the button again for another 30-second

delay before engine shutdown.

Once the engine has shut down, cycle the ignition

key off and then on, and press the "Override/Chk"

button to restart the engine.

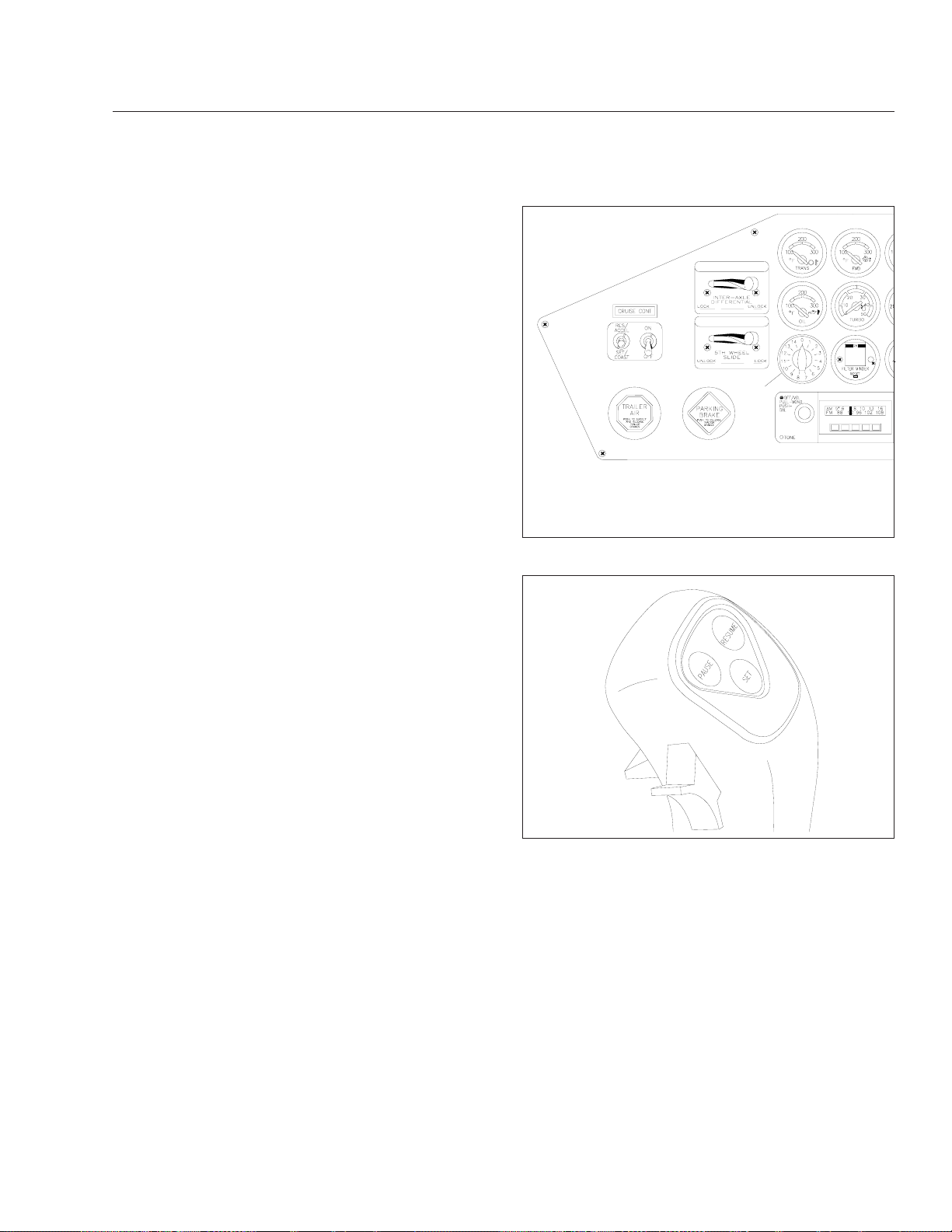

The cruise control and PTO governor options are

controlled in one of two ways:

By two switches on the instrument control panel

(Fig. 2.5). The "On/Off" switch turns on the cruise

control option, and the spring-loaded "Set/Resume"

switch selects the cruise speed or resumes cruise

control after slowing down. For PTO operation, the

"On/Off" switch turns on the PTO, and the "Set/

Resume" switch either selects or resumes the engine

operating speed.

or

By three optional buttons on the transmission shift

knob

(Fig. 2.6). The "Pause" button allows the driver

to temporarily interrupt cruise control. The "Resume"

button allows the driver to resume the cruise speed

after slowing down. The "Set" button allows the

driver to select the cruise speed. For PTO operation,

the "Pause" button temporarily interrupts PTO operation, the "Resume" button resumes PTO operation at

the previously selected engine speed, and the "Set"

button is used to select the engine operating speed.

See Chapter 7 for complete instructions.

If the vehicle is equipped with Optimized Idle®, the

cruise control "On/Off" switch is also used to control

this option. Optimized Idle can be used to keep the

engine oil warm, recharge the battery, and maintain

sleeper temperature when the vehicle is parked for

long periods. See Chapter 7 for more information

and complete operating instructions.

A

03/30/94

A. If equipped with Jacobs engine brake controls, the

cruise switches may be installed here. The location

may vary depending on other vehicle options.

Fig. 2.5, Cruise Control Switches, Standard Location

05/23/95

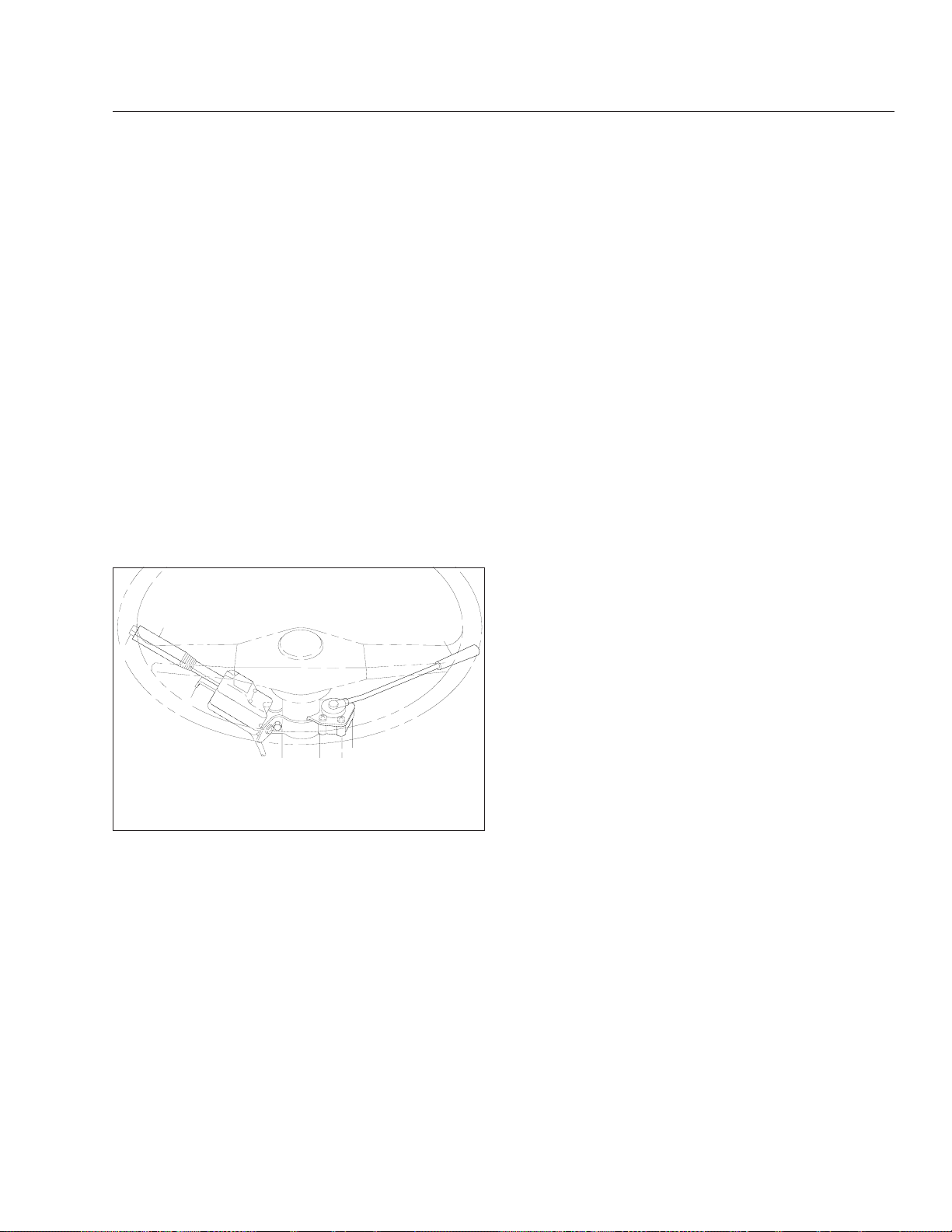

Fig. 2.6, Transmission Shift Knob Buttons

f600705

f260316

Caterpillar C-10, C-12, and C-15

Electronic Engine Operator Control

The Caterpillar C-10, C-12, and C-15 electronic engines use a computer (electronic control module) to

automatically control engine timing and fuel injection.

The electronic features of these engines include an

electronic governor, fuel-to-air ratio control, programmable engine ratings, injection timing control, fault

analysis and recording, and a data link used for programming the electronic control module and troubleshooting the system.

2.4

Instruments and Controls Identification

All Caterpillar electronic engines have an engine

check light in the lightbar located above the speedometer and tachometer. This warning light comes on

or flashes if the engine oil pressure is low, the coolant temperature is high, the intake manifold air temperature is high, the coolant level is low (optional), or

whenever there is a problem within the electronic

engine system. Some vehicles equipped with Caterpillar electronic engines have an automatic engine

shutdown option. This option will shut off fuel to the

engine if potentially damaging conditions are detected. See the engine manufacturer’s service literature for troubleshooting procedures.

The cruise control and PTO governor options are

controlled in one of two ways:

By two switches on the instrument control panel

(Fig. 2.5). The "On/Off" switch turns on the cruise

control option, and the spring-loaded "Set/Resume"

switch selects the cruise speed or resumes cruise

control after slowing down. For PTO operation, the

"On/Off" switch turns on the PTO, and the "Set/

Resume" switch either selects or resumes the engine

operating speed.

By three optional buttons on the transmission shift

knob

(Fig. 2.6). The "Pause" button allows the driver

to temporarily interrupt cruise control. The "Resume"

button allows the driver to resume the cruise speed

after slowing down. The "Set" button allows the

driver to select the cruise speed. For PTO operation,

the "Pause" button temporarily interrupts PTO operation, the "Resume" button resumes PTO operation at

the previously selected engine speed, and the "Set"

button is used to select the engine operating speed.

See Chapter 7 for complete instructions.

BrakeSaver Control, Optional

The BrakeSaver (optional on Caterpillar C-15 engines) is operated by a lever mounted in the cab.

The lever controls the amount of oil being directed

through the BrakeSaver. The time required to fill the

BrakeSaver with pressure oil to the point of maximum braking in the BrakeSaver is about 1.8 seconds.

Cummins PACE and CELECT

™

Electronic Engines, Operator Control

Cummins PACE, CELECT, and CELECT IV are electronic fuel control systems installed on model L10

and, for PACE only, Big Cam IV engines. These elec-

tronic engines are controlled by a microprocessorbased computer. This computer controls specific engine and vehicle speed modes of operation to

maximize vehicle fuel economy and performance.

Vehicles with these engine systems have a yellow

engine check light and a red engine stop light in the

lightbar located above the speedometer and tachometer. With the ignition switch on, both lights come on

for about two seconds; then, if there is no problem

with the engine system, the lights will go out. Whenever there is a problem within the electronic engine

system, one of the lights will come on and stay on as

long as the problem exists.

If the yellow engine check light comes on while driving, some features will not work, but the vehicle can

still be driven. If the red engine stop light comes on

while driving, and if the engine will not accelerate,

pull off of the road and shut down the engine. In either situation, have the problem repaired as soon as

possible.

With the CELECT IV system—if the system is programmed to shut down—the engine shuts down 30

seconds after the red engine stop light comes on.

The ignition switch will restart the engine after shutdown, but if the potentially damaging problem still

exists, the engine will operate at the reduced speed

or torque level allowed just prior to shutdown. To

check whether a vehicle is equipped with CELECT or

with CELECT IV, see the vehicle service manual.

The cruise control and PTO governor options are

controlled in one of two ways:

By two switches on the instrument control panel

(Fig. 2.5). The "On/Off" switch turns on the cruise

control option, and the spring-loaded "Set/Resume"

switch selects the cruise speed or resumes cruise

control after slowing down. For PTO operation, the

"On/Off" switch turns on the PTO, and the "Set/

Resume" switch either selects or resumes the engine

operating speed.

or

By three optional buttons on the transmission shift

knob

(Fig. 2.6). The "Pause" button allows the driver

to temporarily interrupt cruise control. The "Resume"

button allows the driver to resume the cruise speed

after slowing down. The "Set" button allows the

driver to select the cruise speed. For PTO operation,

the "Pause" button temporarily interrupts PTO operation, the "Resume" button resumes PTO operation at

the previously selected engine speed, and the "Set"

2.5

Instruments and Controls Identification

button is used to select the engine operating speed.

See Chapter 7 for complete instructions.

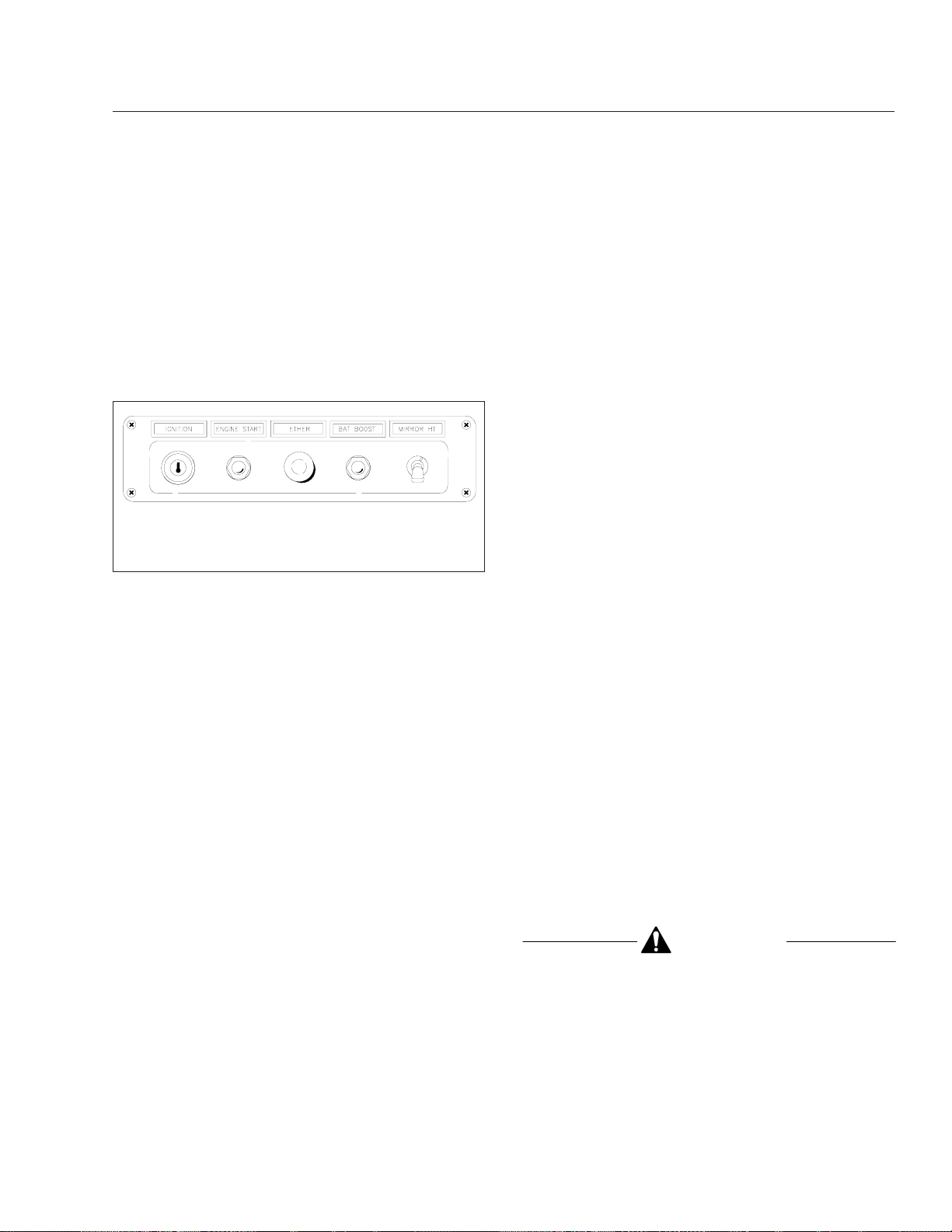

Ether Start Push Button, Optional

For cold weather starting, the vehicle may be

equipped with one of several manual-control, ether

start systems. To start the engine in cold weather,

push the ether button (Fig. 2.7), then start the engine. See the engine operating instructions in Chap-

ter 7 for additional information.

12

01/18/95

1. Ether Start Push Button

2. Battery Boost Push Button

Fig. 2.7, Ether Start and Battery Boost Controls,

Optional

f600648a

Low Voltage Disconnect, Optional

The optional Sure Power Low Voltage Disconnect

(LVD) system monitors battery power when accessories are being used when the engine is shut down.

The system automatically turns off cab and sleeper

accessories when voltage drops to 12.3 volts to ensure that there is enough battery power to start the

vehicle. An alarm sounds for one minute before accessories are turned off. If no action is taken within

that minute, the LVD module will shut off power to

predetermined cab and sleeper circuits, and illuminate an LED indicator on the LVD module, located

inside the baggage compartment. These circuits will

remain off until the LVD measures 13.0 volts applied

to the system, which can be done by starting the engine. After the engine is started, the system will

reset.

All vehicles equipped with LVD should have a sticker

on the dash indicating the presence of the system.

Another sticker is located inside of the baggage compartment, along with the LVD module.

Battery Boost Push Button and

Optional Battery Isolator System

A battery isolator system has two or three regular

batteries to turn the starter motor, and one or two gel

cell batteries to provide power for cab and sleeper

accessories when the engine is off. The system uses

an isolator relay, which is normally open. The relay

isolates the engine-starting batteries while the engine

is not running, so that the engine can still be started

even if the gel cell battery has been used to the point

of complete discharge.

When all four batteries have a charge, the engine

can be started in the normal manner, by turning the

ignition key to the "Start" position and pressing the

starter push button.

To start the engine when the gel cell battery is

drained, press and hold the BATT BOOST push button (Fig. 2.6) while pressing the starter push button.

This will temporarily close the isolator relay, and connect the engine-starting batteries to the ignition

switch for engine starting.

The isolator relay is closed only while the engine is

running or the BATT BOOST push button is depressed. With the engine running, all four batteries

are connected in parallel, allowing the alternator to

charge them all, in addition to supplying power for all

vehicle loads.

When the engine is not running, the gel cell provides

all of the vehicle’s electrical needs except for turning

the starter motor. The gel cell is longer-lived and

cheaper to use than a standard wet cell, but it can

take a charge only within an extremely narrow

range—13.8 to 14.1 volts.

At 14 volts, a gel cell has a very high charge acceptance rate. Because a truck charging system operates at approximately 14 volts, under normal conditions a gel cell will never need to be recharged with

an external charger.

CAUTION

Do not attempt to charge a gel cell with a standard battery charger. All standard battery chargers supply at least 16 volts to the battery. This

will damage the gel cell.

IMPORTANT: To recharge a gel cell, see an authorized Freightliner dealer or the instructions in

2.6

Instruments and Controls Identification

Group 54 of the

Manual

.

Heavy-Duty Trucks Service

However, the single gel cell, like any other single battery, has limited current-supply capability, and will

drain down faster than a standard multiple-battery

installation that has no battery isolator system. Avoid

ultra-deep discharging. Repeated ultra-deep discharging of a gel cell will reduce its life significantly.

To protect against ultra-deep discharging, a low voltage warning alarm and indicator light activate when

the battery voltage falls to 12.0 volts or less. To silence the alarm, turn off all cab electrical loads or

start the engine.

Fuel-Tach™Switch, Optional

The FloScan Fuel-Tach is an electronic monitoring

system that records fuel consumption and displays

average miles per gallon. The Fuel-Tach gauge provides you with immediate feedback, showing a percentage difference between the current fuel consumption rate and the total trip miles per gallon

average.

The system is controlled by a toggle switch. See

Fig. 2.8.

for example, "F37." Fault codes are also stored in a

history file for later viewing. For engine fault code

instructions, see "Fuel Tach Gauge" in this chapter.

The "Reset" toggle switch cancels the information in

memory used for calculating average miles per gallon and erases the fault code history file. To reset,

press and hold the reset switch. The average MPG

reading slowly blinks on and off for about 10 seconds, indicating that you are in the reset mode. After

erasing the memory, the display blinks "Er" until you

release the reset switch. If you release the reset

switch before the display changes to "Er," the engine

fault code history will be displayed and the memory

will not be erased. After being reset, the display will

show "0" MPG until you drive at least 150 feet (46

m).

Fog Light Switch, Optional

The fog light switch (Fig. 2.9) operates the fog lights,

mounted on the bottom edge of the front bumper or

recessed into the front bumper.

12

3

45

01/18/95

Fig. 2.8, Fuel-Tach Switch, Optional

f600070b

With nonelectronically controlled engines the "On"

position allows you to receive average miles per gallon information for specific periods of time. In this

position, the Fuel-Tach system stays on and stores

the average miles per gallon information in memory,

even if the engine is shut down.

In the IGN position, the Fuel-Tach system is on only

when the ignition switch is on. Shutting down the engine cancels the information in memory.

With electronically controlled engines the digital display normally shows trip average miles per gallon. If

the engine datalink sends an electronic fault code,

the Fuel-Tach interrupts the miles per gallon display

for 60 seconds, showing an "F" plus the fault code,

01/18/95

1. Fog Light Switch

2. Utility Light Switch

3. Panel Lamp Control Knob

4. Headlight/Parking Light Switch

5. Marker Light/Taillight Interrupt Switch

Fig. 2.9, Light Controls

f600071a

For vehicles built to operate in the United States, the

low beam headlights must be turned on before the

fog lights can be turned on. The fog lights won’t go

on if the high beam headlights are already on, and

switching from low beams to high beams will switch

off the fog lights.

For vehicles built to operate in Canada, the taillights

and clearance lights must be on before the fog lights

can be turned on. Unless the headlight switch is all

the way up (headlights, taillights, clearance lights,

marker lights, and panel lights on) or down (taillights,

clearance lights, marker lights, and panel lights on),

the fog light switch will not turn on the fog lights.

2.7

Instruments and Controls Identification

Utility Light Switch, Optional

Utility lights can be swivel-mounted on top of the

cab, mounted on the intake/exhaust support, or flushmounted in the back of the cab or bunk. They are

operated by the utility light switch (Fig. 2.8) which,

when turned on, also illuminates a red indicator light

on the dash.

Panel Lamp Control Knob

The circuit to the panel lamps is activated by the

headlight switch. When the headlights are on, the

panel lamp knob (Fig. 2.8) controls the intensity of

the instrument panel lamps. Turn the knob counterclockwise to brighten them and clockwise to dim

them. Turning the knob counterclockwise to the peg

will also turn off the panel lamps.

Headlight Switch and Daytime

Running Lights

A three-position headlight switch (Fig. 2.8) is used to

operate the exterior lights. When the switch is up the

headlights, and all other vehicle lights, are on. All

vehicle lighting is off when the switch is in the middle

position. When down, the switch activates only the

clearance, instrument panel, and marker lights, and

the taillights. The switch for the headlight high beams

is built into the turn signal lever. When the headlights

are on high beam, a green light in the warning and

indicator light module goes on. The ignition switch

must be on for the high beams to operate.

For vehicles built to operate in Canada, switching on

the ignition and releasing the parking brakes automatically activates the headlight low beams (later

model vehicles) or high beams (earlier model vehicles) at half voltage as daytime running lights. The

daytime running lights will operate until the parking

brakes are applied; then they will switch off. Turning

on the regular headlights will override the daytime

running lights. The vehicle cannot be driven unless

either the headlights or daytime running lights are

activated.

Interrupt Switch

A spring-loaded interrupt switch (Fig. 2.8) temporarily

deactivates the marker lights and taillights. With the

vehicle lights on, raise and release the interrupt

switch to briefly turn off the marker lights and taillights.

Windshield Wiper/Washer Controls

Air Wipers

To operate the air wipers, turn the "Wash-Wipe" knob

(Fig. 2.10) clockwise. To increase wiper speed, continue to turn the knob clockwise. Turning the knob

counterclockwise decreases wiper speed. To turn the

windshield wipers off, turn the knob counterclockwise

to its full stop. When the wiper blades are parked,

release the knob.

1

01/18/95

1. Windshield Wiper/Washer Control Knob

2. Intermittent (delay) Wiper Control Knob

Fig. 2.10, Windshield Wiper/Washer Controls

The "Delay" switch controls intermittent operation

with air wipers. Rotating the knob clockwise increases the time interval between wiper strokes. Turn

the knob clockwise until the desired interval is

reached. The longest delay is approximately 10 seconds between strokes.

The delay knob operates the delay feature only; it

will not turn the wipers on.

IMPORTANT: After using the intermittent windshield wipers, turn off the wiper control

and

(Fig. 2.9)

the intermittent (delay) control. If

the wiper control is off, but the intermittent control remains on, that control will continue to

cycle whenever the ignition is in the on or accessory position. Continued, constant cycling

will shorten the life of the intermittent wiper control.

Electric Wipers

To operate the electric wipers, turn the knob clockwise to the first position for low speed. Turn the knob

to the second position for high-speed operation.

2

f600433

2.8

Instruments and Controls Identification

In electric wiper systems, the delay feature is integrated with the wiper switch between the stop and

low-speed positions. Turn the knob between the stop

and low speed until the desired interval is reached.

The longest delay is approximately 10 seconds between strokes.

CAUTION

Do not move the wiper arms manually. Wiper

motor damage will occur if the arms are moved.

Windshield Washer Control

To operate the windshield washers, turn the windshield wipers to the desired speed. Push the "WashWipe" knob in to actuate the washers. Hold the knob

in for a constant stream of washer fluid. Push the

knob in and release it for intermittent streams of fluid.

Left and Right Windshield-Fan

Switches, Optional Ceiling-Mounted

Fans

Ceiling-mounted defogger fans are operated by

"Low/Off/High" toggle switches located in the base of

the fan.

Heater/Air-Conditioner Controls

(Standard) and Auxiliary Heater

Switch (Optional)

Jacobs Engine Brake Switches,

Optional

Jake Brake controls consist of two dash-mounted

toggle switches (Fig. 2.12) which control the degree

of engine braking. In conjunction with these switches,

an engine-mounted microswitch (controlled by the

throttle pedal) and an under-deck-mounted microswitch (controlled by the clutch pedal) actuate the

engine brake.

2

3

1

5

10/26/98

1. Engine Brake Switch

2. Interaxle Differential Lockout Control Valve Switch

3. Fifth Wheel Air Slider Control Valve Switch

4. Parking Brake Control Valve Knob

5. Trailer Air Supply Valve Knob

4

f600507b

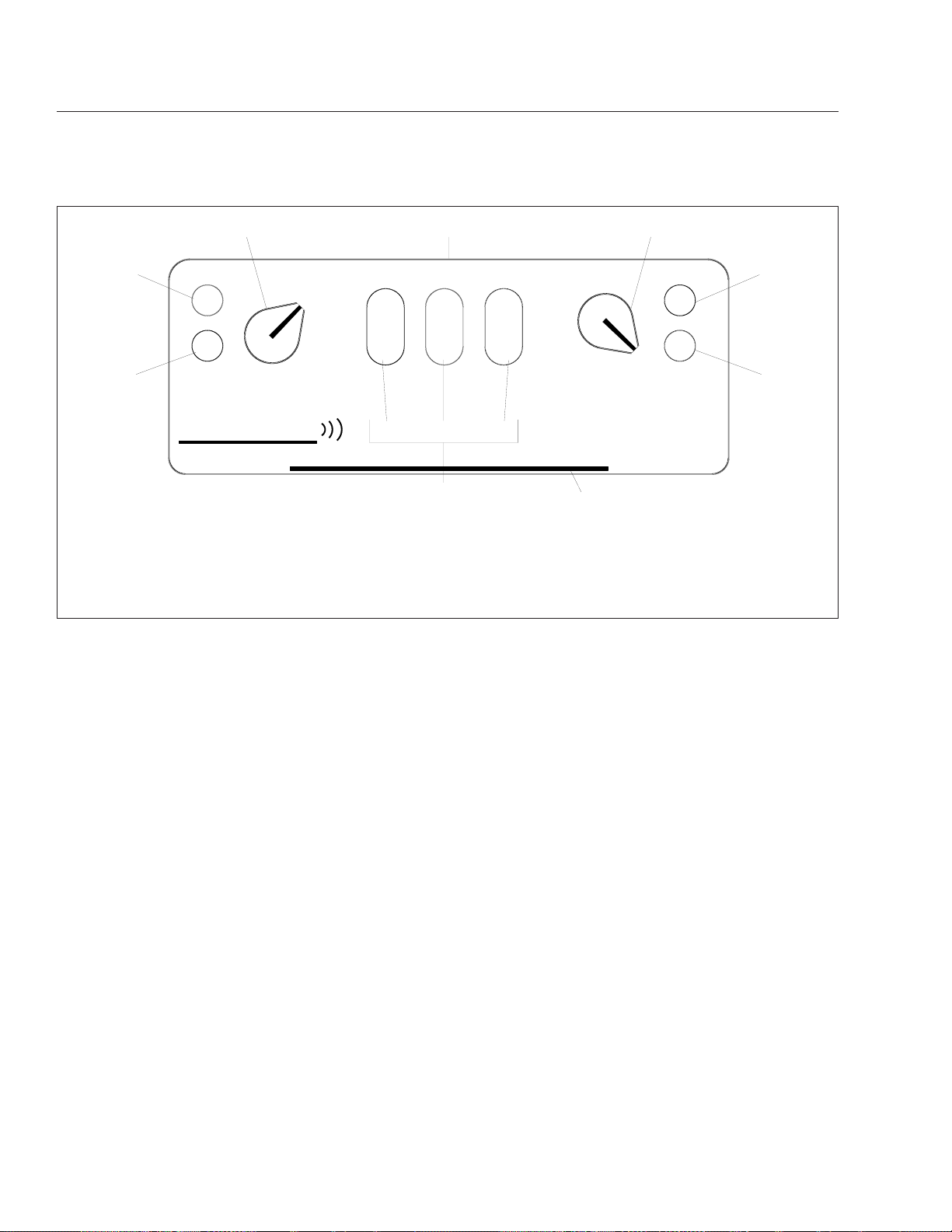

Heater/air-conditioner controls (Fig. 2.11) consist of

two lever slide controls, a four-speed fan control

switch, and a switch for the optional auxiliary heater

fan. See Chapter 4 for detailed operating instructions

of the heater/air-conditioner and the auxiliary heater.

01/18/95

Fig. 2.11, Heater/Air-Conditioner Controls

2.9

f600497

Fig. 2.12, Brake Switches and Control Valves

See Chapter 7, under the heading "Engine Braking

System, Optional," for additional information.

Interaxle Differential Lockout Control

Valve Switch

Differential lockout, standard on all dual-drive vehicles, is driver-actuated by means of a "Lock/

Unlock" control valve switch (Fig. 2.12) mounted on

the control panel. A red indicator light comes on

whenever the interaxle differential is locked out

(switch is in the lock position; no differential action

between the drive axles). A guard around the switch

prevents it from being accidentally activated.

Instruments and Controls Identification

Fifth Wheel Air Slider Control Valve

Switch, Optional Air-Operated Sliding

Fifth Wheel

WARNING

Do not activate the fifth wheel air slider control

valve when the vehicle is in motion. Doing so

could result in damage to the fifth wheel member,

kingpin, cab, or trailer, and ultimately, to the drivetrain. A guard is positioned around the switch to

prevent it from being accidentally activated.

The fifth wheel air slider valve permits repositioning

of the sliding fifth wheel from inside of the cab. Moving the air slider control valve switch (Fig. 2.12)to

the lock position deactivates the control valve and

locks the fifth wheel to the baseplate. Moving the

switch to the unlock position activates the control

valve and unlocks the fifth wheel slide mechanism,

allowing changes to the total length of the tractortrailer and changes to axle loads, to comply with

varying state or provincial laws. A red indicator light,

if so equipped, is illuminated whenever the fifth

wheel slider is unlocked.

Parking Brake Control Valve and

Trailer Air Supply Valve

The yellow diamond-shaped knob (Fig. 2.12) operates the parking brake valve. Pull the knob out to

apply both the tractor and the trailer spring parking

brakes. Push the knob in to release the tractor spring

parking brakes. Before the spring parking brakes can

be released, the air pressure in either air brake system must be at least 65 psi (447 kPa).

The red octagonal-shaped knob (Fig. 2.12) operates

the trailer air supply valve. After the vehicle and its

air hoses are connected to a trailer, and the pressure

in the air system is at least 65 psi (447 kPa), push

the trailer air supply valve knob in (it should stay in)

to charge the trailer air supply system and release

the trailer spring parking brakes. Before disconnecting a trailer, or when operating a vehicle without a

trailer, pull the trailer air supply valve knob out.

See Chapter 6, under the heading "Brake System,"

for instructions regarding use of the trailer air supply

valve and parking brake valve.

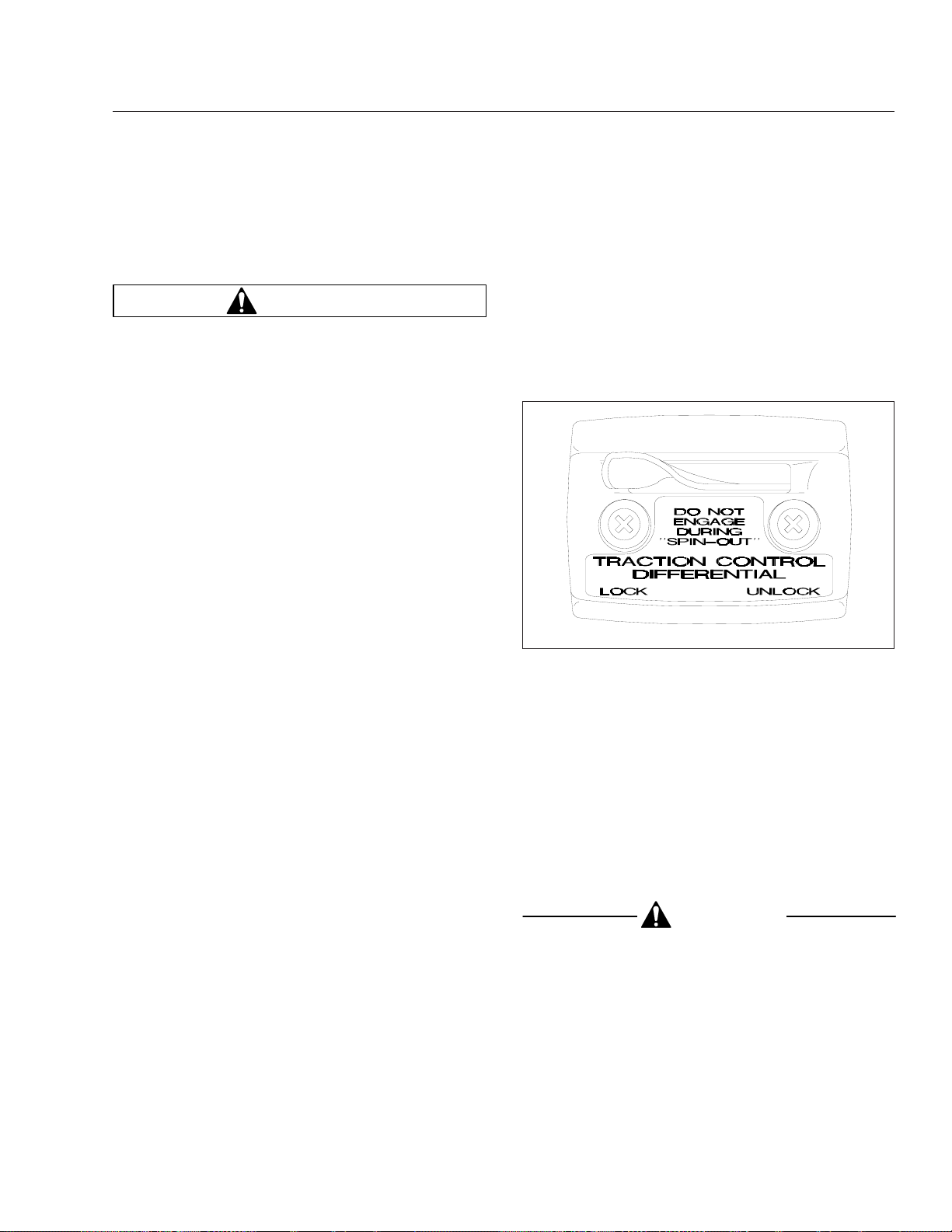

Controlled Traction Differential Control

Valve Switch

On vehicles equipped with an Eaton single-drive rear

axle, a controlled traction differential feature is standard. A control valve switch (Fig. 2.13) engages and

disengages the controlled traction feature. A guard is

positioned around the switch to prevent it from being

accidentally activated.

See Chapter 9 for complete operating instructions.

10/04/93

Fig. 2.13, Controlled Traction Differential Control Valve

Switch

f600307

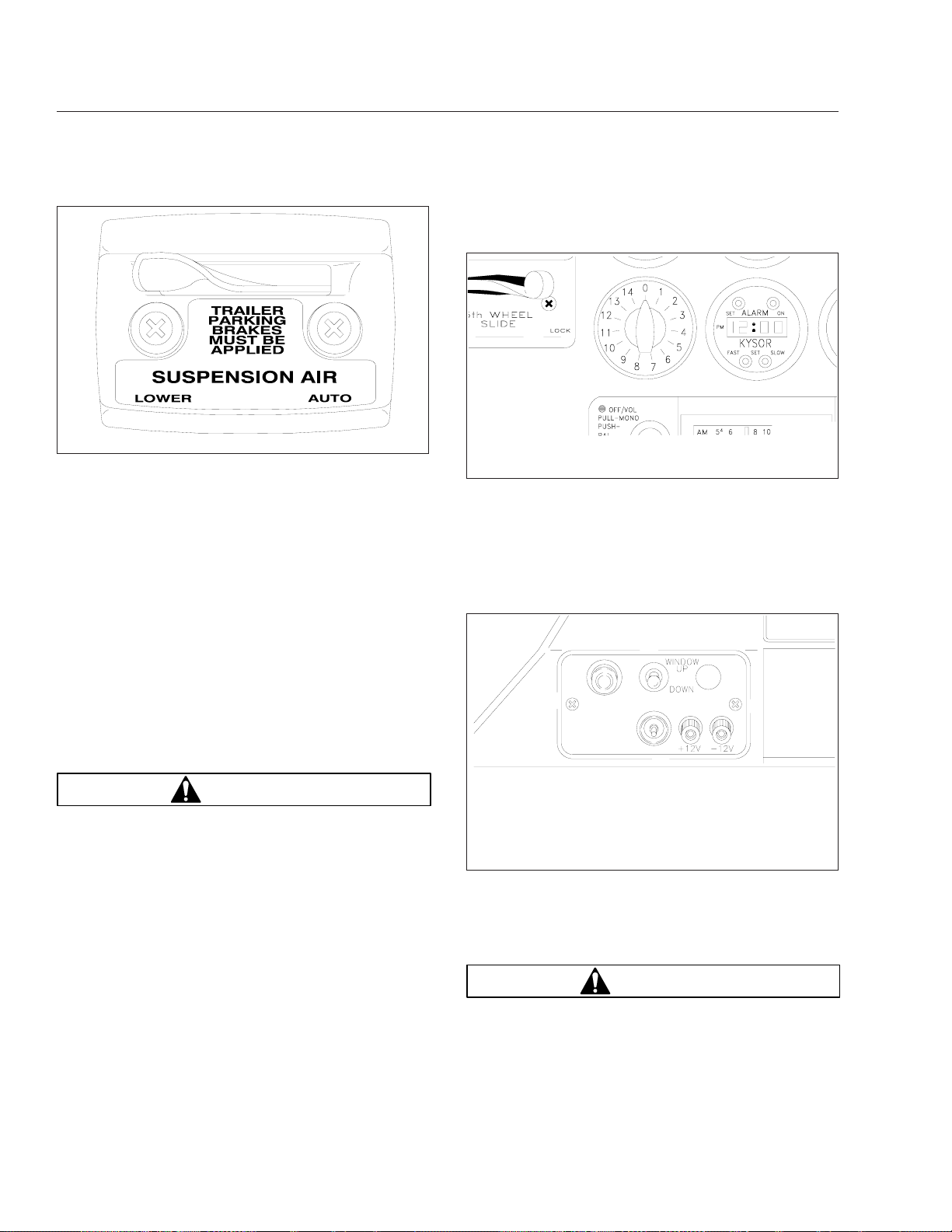

Air Suspension Dump Valve, Optional

The air suspension dump valve allows the air in the

vehicle air suspension to be quickly exhausted, lowering the rear of the vehicle. This makes it easier to

connect to or disconnect from a trailer. A control

valve switch (Fig. 2.14) exhausts and fills the air suspension. To exhaust air from the suspension, move

the switch to LOWER. A guard is positioned around

the switch to prevent it from being accidentally

activated.

CAUTION

Never exhaust air from the suspension while

driving. If the air is exhausted, the suspension

will not absorb road shocks and could be damaged.

2.10

Instruments and Controls Identification

with the engine idling. The automatic timer will shut

the engine off at the end of the selected time.

01/18/95

Fig. 2.14, Air Suspension Dump Valve Switch, Optional

f600545a

AirLiner Plus Suspension, Optional

The AirLiner Plus suspension is used on vehicles

with pusher or tag axles to improve traction performance. The system maintains an accurate leveling of

frame height whether the vehicle is in motion or

parked. The Meritor WABCO

Controlled Air Suspension) system uses a height

sensor mounted between the frame and the drive

axle housing as well as other sensors to provide

frame height information to a control unit mounted

inside of the cab. The electronic control unit quickly

lowers or raises the frame height, as necessary. Altering the height of the frame while the vehicle is

parked can be performed using a hand-held remote

control unit.

®

ECAS (Electronically

1

01/18/95

1. Automatic Engine Idler/Timer

2. Kysor Digital Clock

Fig. 2.15, Engine Idler/Timer and Clock

2

f600508a

Cigarette Lighter

Push the lighter in (Fig. 2.16) to heat the element.

The lighter will stay in and will automatically pop out

when the element is hot.

12

3

4

WARNING

Stand away from the rear of the vehicle when

raising or lowering the height of the frame. The

ECAS system operates quickly, and contact

could result in personal injury.

For the optional automatic function to work, the vehicle must be equipped with a rear axle air suspension and ABS. Automatic Traction Control is recommended for optimal vehicle traction control.

Automatic Engine Idler/Timer,

Optional

A Henke automatic engine idler/timer (Fig. 2.15) allows the driver to select the idle time required for engine shutdown. The driver can turn off the ignition,

remove the ignition key, lock the vehicle, and leave it

2.11

01/18/95

1. Cigarette Lighter

2. Air Window Control Valve Switch

3. Antenna Connection

4. CB Radio Connections

Fig. 2.16, Window Control Switch

f600146a

Air Window Control Valve Switch,

Optional Right-Hand Air Window

WARNING

Before raising the window, be sure that hands,

fingers, and other body parts or objects are away

from the window frame. Otherwise, serious physical injury could result.

Instruments and Controls Identification

A toggle switch (Fig. 2.16) controls the air window.

Push the switch up to raise the window, or push it

down to lower the window.

CB Radio Connections

An antenna connection and positive (+) and negative

(–) power connections are provided for a CB radio.

See Fig. 2.16.

Turn Signal Lever

The turn signal lever (Fig. 2.17) is mounted on the

steering column. Pushing the lever counterclockwise

turns on the left-turn signal lights; pushing it clockwise turns on the right-turn signal lights. When one

of the turn signal lights is on, a green indicator light

flashes at the far left or far right of the warning and

indicator light panel. To cancel the signal, return the

lever to the neutral position, except when equipped

with an optional self-canceling switch.

1

3

2

01/18/95

1. Turn Signal Lever

2. Hazard Warning Light Tab

3. Headlight Dimmer Push Button

4. Trailer Brake Hand Control Lever

Fig. 2.17, Turn Signal Lever

4

f460194a

Hazard Warning Light Tab

The hazard warning light tab (Fig. 2.17) is located

below the lever on the turn signal switch. Activate the

hazard warning lights by pulling the tab out. When

the hazard warning light tab is pulled out, all of the

turn signal lights and both of the indicator lights on

the control panel will flash. To cancel the warning

lights, move the turn signal lever up or down.

Headlight Dimmer

The headlight dimmer (Fig. 2.17) may be a push button at the end of the turn signal lever, or a lift-handle

type built into the turn signal lever.

To operate the push button type dimmer, press the

button once to change from low beam to high beam

headlights; press it again to cancel the high beam

lights.

To operate the lift-handle type dimmer, pull the turn

signal lever up to change from low beam to high

beam headlights, or from high beam back to low

beam.

When the headlights are on high beam, a green light

on the indicator light panel comes on. For vehicles

built to operate in the United States, switching from

low beams to high beams will switch off the fog

lights.

NOTE: The ignition switch must be on for the

high beams to work.

Trailer Brake Hand Control Valve

Lever

This lever is used for applying the trailer brakes without applying the truck or tractor brakes and is

mounted on the steering column. See Fig. 2.17. See

Chapter 6 under the heading "Brake System," for

operating instructions.

Transmission Controls

If so equipped, the transmission range control valve

and splitter valve are attached to the gearshift knob.

Transmission shift pattern labels are located on the

header or sun visor above the driver’s windshield.

See Chapter 8 for complete transmission operating

instructions.

Suspension Seat Adjustment Controls

All adjustment controls for a suspension seat are located on the seat base. See Chapter 5 for complete

instructions.

IMPORTANT: Due to the maximum adjustability

of mid- and high-back air suspension seats, it is

possible to combine the seat back recline adjustment and the seat slide adjustment so that

the seat back contacts the backwall. It is the

2.12

Instruments and Controls Identification

responsibility of the driver to adjust the seat to

prevent damage to the seat and the cab interior.

Dome Light Switches

For vehicles with a single dome light mounted on the

roof inside of the cab, the light is operated by a

three-position switch mounted in the dome light. The

switch provides both a low- and a high-intensity setting; in the middle position, the dome light is off.

For vehicles with a single dome light and two reading

lights mounted on the roof inside of the cab, each

light is operated by its own on/off switch, mounted in

the dome light.

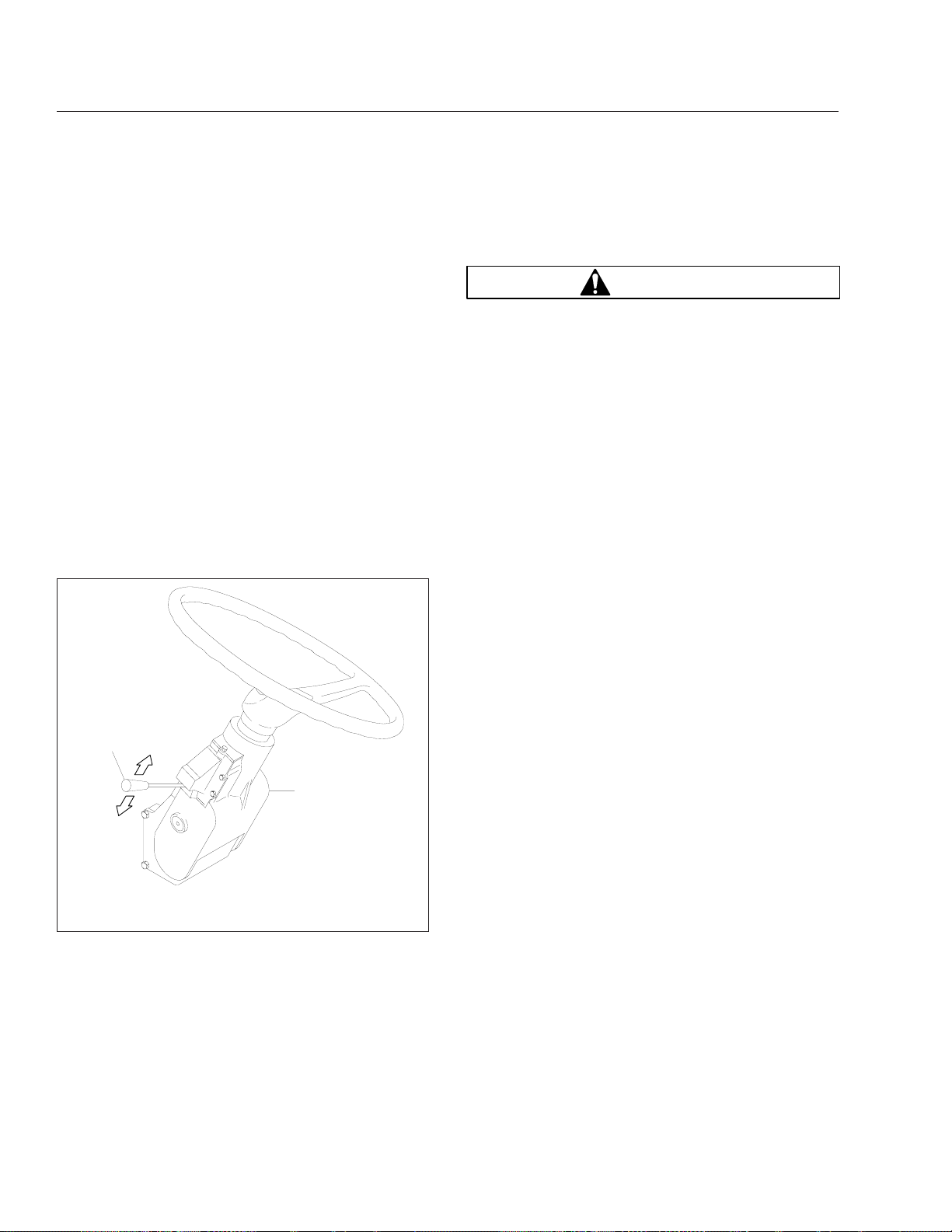

Tilt Steering Wheel

The tilt steering wheel (Fig. 2.18) has a tilt range of

15 degrees, and a telescoping range of 2-5/8 inches

(67 mm). A control lever is located just below the turn

signal switch on the steering column.

1

2

f460309a03/09/94

1. Control Lever

2. Tilt Wheel Assembly

Fig. 2.18, Tilt Steering Wheel

After adjusting the seat to the desired ride position,

unlock the steering column by pushing the control

lever and holding it all the way down. Tilt the steering

column to the desired position, then release the control lever to lock the steering column in place.

To adjust the height of the steering wheel, pull upward on the control lever. While holding the control

lever in this position, move the steering wheel upward or downward to the desired position. Release

the control lever to lock the steering wheel in place.

WARNING

Make sure that the control lever is in the locked

(neutral) position before driving the vehicle.

Never try to adjust the height of the steering

wheel or tilt the steering column while driving the

vehicle. Doing so could cause loss of vehicle

control, personal injury, and property damage.

Warning and Indicator Lights

All of the standard and optional warning and indicator

lights are housed in a lens and bezel assembly, located above the speedometer and tachometer.

For pre-EPA07 vehicles, up to six rectangular indicator lights may be installed on the center dash panel

between the tachometer and speedometer. See

Fig. 2.19. The pre-EPA07 standard installation in-

cludes one parking brake indicator light and two antilock braking system (ABS) lights, the tractor warning light and the wheel spin indicator light. One other

ABS light, the trailer warning light, is optional. The

other two lights represent a variety of optional functions that may not be installed on all models.

For EPA07 vehicles, up to ten rectangular indicator

lights may be installed on the center dash panel between the tachometer and speedometer. See

Fig. 2.20. The EPA07 standard installation includes

three indicator lights for the after treatment device;

an engine malfunction indicator light (MIL), a diesel

particulte filter (DPF) regen light, and a high exhaust

system temperature (HEST) light. Details of the aftertreatment lights can be found in Chapter 7, under

the heading

The other standard lights are the parking brake indicator light, and two antilock braking system (ABS)

lights. The other lights are for optional functions that

may not be installed on all models.

EPA07 Aftertreatment System (ATS)

Parking Brake Indicator Light

The red parking brake indicator light (Fig. 2.19)

comes on whenever the parking brakes are activated

and the ignition is on.

Additional optional lights may be installed in the center dash.

.

2.13

Instruments and Controls Identification

4

1

2

89

10/26/98

A. Parking Brake Indicator Light

B. Tractor ABS Warning Light

C. Wheel Spin Indicator Light

D. Trailer ABS Warning Light

1. Left-Turn Signal Light

2. Oil Pressure Warning Light

3. Low-Water Warning Light

4. Water Temperature Warning Light

5. High-Beam Indicator Light

6. Low Air Pressure Warning Light

7. Right-Turn Signal Light

8. Tachometer

9. Speedometer

Fig. 2.19, Dash Assembly for VIGIL and Kysor Warning

3

Systems Pre-EPA07

5

A

B

C

D

6

f600769b

7

4

1

2

8

03/14/2007

A. MIL Engine Warning Light

B. DPF Regen Warning Light

C. Hi-Temperature Exhaust Warning Light

D. Parking Brake Indicator Light

E. Tractor ABS Warning Light

F. Trailer ABS Warning Light

G. Air Suspension Warning Light

1. Left-Turn Signal Light

2. Oil Pressure Warning Light

3. Low-Water Warning Light

4. Water Temperature Warning Light

5. High-Beam Indicator Light

6. Low Air Pressure Warning Light

7. Right-Turn Signal Light

8. Tachometer

9. Speedometer

3

AB

5

C

D

E

F

G

6

f600769c

7

9

Meritor WABCO®Antilock Braking

System (ABS)

The Meritor WABCO®Antilock Braking System (ABS)

may have up to three of the following amber lights

(the first two are standard: a tractor warning light

(TRAC ABS), a wheel spin indicator light (WHL

SPIN), and an optional trailer warning light (TRLR

ABS). Vehicles built before July, 1994, also have a

DEEP SNOW/MUD indicator light.

With the tractor ABS system, the tractor warning light

(TRAC ABS) comes on after the engine is started

(Fig. 2.19). Once the vehicle moves faster than

about 4 mph (6 km/h), the warning light goes out

only if all of the tractor’s ABS components are working.

With the tractor and trailer ABS system, the vehicle

also has a trailer warning light labelled TRLR ABS

(Fig. 2.19).

After the engine is started, the TRLR ABS light

comes on if the trailer is equipped with a compatible

Fig. 2.20, Dash Assembly for VIGIL and Kysor Warning

Systems EPA07

ABS system. Once the vehicle moves faster than

about 4 mph (6 km/h), the TRLR ABS warning light

goes out only if all of the trailer’s ABS components

are working. For more detailed information about

TRLR ABS light operation, see Chapter 6.

IMPORTANT: If any of the ABS warning lights

do not work as described above, or come on

while driving, repair the ABS system immediately to ensure full antilock braking capability.

The wheel spin indicator light (WHL SPIN) comes on

flashing if one of the drive wheels spins during acceleration (Fig. 2.19). The flashing light goes out when

the wheel stops spinning. A label (Fig. 2.21)onthe

dash explains what actions should be taken when

the WHL SPIN indicator light starts to flash.

If equipped with an electronic engine, an automatic

traction control (ATC) system may be installed. On

2.14

Instruments and Controls Identification

blink code diagnostics are activated. See Group 42

of the

IF REAR WHEEL SPIN OCCURS,

PARTIALLY RELEASE THROTTLE

PEDAL UNTIL WHEEL SPIN

AMBER LIGHT EXTINGUISHES,

THEN ENGAGE AXLE LOCK.

09/22/98

Fig. 2.21, Dash Label

these vehicles, the ATC system automatically controls wheel spin during reduced-traction starts.

An "ATC Function" switch (if equipped), allows the

driver to select from two levels of drive axle tractioncontrol assistance:

•

NORMAL—which reduces drive axle wheel

spin on icy, wet, or sand covered roads.

•

DEEP SNOW/MUD—which allows a higher

threshold of drive axle wheel spin to help burn

through a thin layer of ice, or to help throw off

accumulated mud or snow.

The Deep Snow/Mud mode is indicated by a flashing

WHL SPIN light. To engage this mode, the ATC function switch must be in the Normal position when the

vehicle is initially powered up. Once the vehicle is

started, the ATC function switch can be set to the

Deep Snow/Mud position. The ECU indicates this

change by a constant flashing of the WHL SPIN

lamp (or by illumination of the Deep Snow/Mud light

on vehicles built before July, 1994).

If the ATC function switch is in the Deep Snow/Mud

position when the vehicle is powered up, the ECU

will not accept this function change and will remain in

the Normal mode. Indication of this condition will be

the absence of the flashing WHL SPIN light (on vehicles built before July, 1994, the absence of an illuminated Deep Snow/Mud light). To engage the Deep

Snow/Mud mode in this situation, change the position

of the ATC function switch to the Normal mode. After

two seconds, move the switch to the Deep Snow/

Mud position. When this occurs, the indicator light

will activate as previously described.

The "ABS Chk" switch (if equipped), activates blink

code diagnostics, which are used to read ABS and

ATC system fault codes on the WHL SPIN light. This

switch is located in the lower dash panel cover, just

below the ignition switch, on the left side of the steering wheel. When turned on (in the "up" position),

f600311a

Heavy-Duty Trucks Service Manual

shooting procedures.

IMPORTANT: ABS and ATC blink code diagnostics should only be performed when the vehicle

is stopped. If the vehicle is equipped with ATC,

turning "on" the ABS CHK switch will reduce

engine speed to idle for three seconds and affect ATC function performance. If the vehicle is

driven with the ABS CHK switch "on" (in the

"up" position), the WHL SPIN light will illuminate

continuously. Under this condition, turning the

ABS CHK switch "off" (in the "down" position),

while the vehicle is still in motion, will only turn

off the WHL SPIN light, but will not restore ATC

function performance. To fully restore engine

and ATC function capability, the vehicle must be

brought to a complete stop. Then, move the

ABS CHK switch to "off" (in the "down" position).

See the brake system operating instructions in Chap-

ter 6 for more information.

Bendix Antilock Braking System

(ABS)

With the Bendix Antilock Braking System (ABS), the

tractor warning light (TRAC ABS) comes on after the

key is turned on (Fig. 2.19). The warning light goes

out only if all of the tractor’s ABS components are

working properly.

If the tractor is attached to a trailer with a compatible

ABS system, the trailer ABS warning lamp (TRLR

ABS) will also come on momentarily after the key is

turned on.

Vehicles equipped with a Bendix ABS system may

also be equipped with an automatic traction control

(ATC) system. The ATC system automatically controls wheel spin during reduced-traction starts.

The wheel spin indicator light (WHL SPIN) comes on

if one of the drive wheels spins during acceleration

(Fig. 2.19). The light goes out when the wheel stops

spinning. The Bendix system will either reduce engine torque or apply gentle brake pressure to force

the differential to drive the stationary or slowly spinning wheel. If slippery road conditions continue, engage the axle lock.

for trouble-

2.15

Instruments and Controls Identification

IMPORTANT: If any of the ABS warning lights

do not work as described above, or come on

while driving, repair the ABS system immediately to ensure full antilock braking capability.

See Group 42 of the

vice Manual

See the brake system operating instructions in Chap-

ter 6 for more information.

for troubleshooting procedures.

Heavy-Duty Trucks Ser-

VIGIL I Warning System

Standard Indicator Lights

Standard indicator lights (Fig. 2.19) include:

1.

The green right- and left-turn signal lights flash

on and off whenever the outside turn signal lights

are flashing.

2.

The green high-beam indicator light comes on

when the headlights are on high beam.

Standard Warning Lights

Standard red warning lights (Fig. 2.19) are for oil

pressure, water temperature, and low air pressure.

Whenever conditions cause one or more of these

lights to come on, a warning buzzer also alerts the

driver:

1.

The water temperature warning light and buzzer

activate whenever the engine coolant temperature exceeds a preset point determined by the

engine manufacturer. See the engine manual for

this temperature.

2.

The oil pressure warning light and buzzer activate whenever the oil pressure falls below the

minimum oil pressure recommended by the engine manufacturer.

3.

The low air pressure warning light and buzzer

activate whenever air pressure in the primary or

secondary air reservoir falls below 64 to 76 psi

(441 to 524 kPa).

When the ignition is turned on, oil- and air-pressure

warnings activate until the engine starts and minimum pressures are exceeded. If the low-oil warning

light remains lit after running the engine for 15 seconds, shut off the engine and determine the cause.

See the

procedures.

Heavy-Duty Trucks Service Manual

for repair

WARNING

If the warning system does not activate when the

ignition is turned on, repair the system to provide

warning protection for oil pressure, coolant temperature, and brake system air pressure.

Optional Warning and Indicator Lights

The most common optional warning and indicator

lights (Fig. 2.19) consist of any combination of the

following:

•

Interaxle differential indicator light, which is

standard on all dual-drive vehicles. An indicator

light illuminates whenever the interaxle differential is locked out (switch is in the lock position).

•

Automatic sludge ejector (moisture ejection

valve) indicator light. An indicator light comes

on whenever the ejector is operating.

•

Utility light(s) indicator light. If utility lights are

installed in the back of the vehicle, an indicator

light comes on when they are in use.

•

Mirror heat indicator light. An indicator light

comes on whenever the mirror heat switch is

on.

•

Low-water warning light, which is standard

when a low-water probe warning system or a

four-way engine shutdown system is installed.

A warning light comes on whenever the coolant

level in the radiator drops below the low-water

probe.

•

Fifth wheel slider indicator light. An indicator

light comes on whenever the air-operated lockpins on a fifth wheel are retracted from the

baseplate (the fifth wheel slider is unlocked).

Optional warning and indicator lights and their locations may vary, because of different optional equipment installed. Other optional accessories and standard equipment that are or can be equipped with

warning or indicator lights include: engine heater,

parking brakes, tire sanders, spotlights, oil level, oil

temperature, cruise-control system, engine fan, and

other options.

2.16

Instruments and Controls Identification

VIGIL II Warning System, Optional

The VIGIL II system is an electronically controlled

warning and engine shutdown system. It controls the

turn signal functions and various optional functions. A

solid state lightbar (Fig. 2.22) in the instrument panel

contains displays for the functions.

12 3456 78

10/26/98

1. Left-Turn Signal Light

2. Oil Pressure Warning Light

3. Low-Water Warning Light

4. Water Temperature Warning Light

5. Engine Shutdown Light

6. High-Beam Indicator Light

7. Low Air Pressure Warning Light

8. Right-Turn Signal Light

Fig. 2.22, VIGIL II and Kysor VIP Warning System,

Optional

Engine Functions

The system monitors engine coolant temperature,

coolant level, and oil pressure.

•

If the engine overheats, a warning light comes

on and a buzzer sounds. The temperature that

triggers the warning light and buzzer varies

with engine type and is programmed into the

system at the factory. If the temperature continues to rise to critical levels, the engine shutdown light comes on, and the engine will be

shut down.

•

If the coolant level drops below a sensor in the

cooling system, the low water level light comes

on. After 5 seconds, a buzzer sounds, and

after 30 seconds, the system will shut down

the engine.

•

If the oil pressure drops below a preset level,

the low oil pressure light comes on and a

warning buzzer sounds. If the oil pressure

drops to a preset critical level, the engine shutdown light comes on, and the engine will be

shut down.

•

All shutdown features have an automatic override. If the vehicle needs to be moved to a safe

location after a shutdown, just crank the en-

f600630b

gine. It will run for about 30 seconds before

shutting down again.

Turn Signal Functions

The system operates the turn signal relay and the indicators.

Other Functions

The system also controls several functions such as

the headlight high beam indicator, low air pressure

warning light, and control of indicators for six optional

features. The optional features can be any combination of the following:

•

transmission temperature

•

axle temperature

•

engine heater

•

alternator no charge

•

fifth wheel lock

•

parking brake

•

sand

•

antilock

•

mirror heater

•

utility lights

•

axle lock

•

sludge ejector

or any six that are specially ordered.

Additional Features

When the ignition is turned on, all of the LEDs in the

lightbar will light and the low air and low oil pressure

alarms will sound. The lights and alarms will activate

for two one-second periods, separated by a half second pause. This is a self-test to indicate whether or

not the lightbar is working. After the test, the LEDs

not in use will turn off. The low air and oil pressure

warnings will not sound again until the starter is

cranked. Once the starter is cranked, the alarms will