Freightliner Columbia Driver's Manual

COLUMBIA

®

STI-405-2

A24-01034-000

Driver’s Manual

Foreword

Introduction

This manual provides information needed to operate

and understand the vehicle and its components.

More detailed information is contained in the Owner’s

Warranty Information for North America booklet, and

in the vehicle’s workshop and maintenance manuals.

Custom-built Freightliner vehicles are equipped with

various chassis and cab components. Not all of the

information contained in this manual applies to every

vehicle. For details about components in your vehicle, refer to the chassis specification pages included in all new vehicles and to the vehicle specification decal, located inside the vehicle.

For your reference, keep this manual in the vehicle

at all times.

IMPORTANT: Descriptions and specifications in this

manual were in effect at the time of printing. Freightliner Trucks reserves the right to discontinue models

and to change specifications or design at any time

without notice and without incurring obligation. Descriptions and specifications contained in this publication provide no warranty, expressed or implied,

and are subject to revisions and editions without notice.

Environmental Concerns and

Recommendations

Whenever you see instructions in this manual to discard materials, you should first attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and regulations

when disposing of materials.

Event Data Recorder

This vehicle is equipped with one or more devices

that record specific vehicle data. The type and

amount of data recorded varies depending on how

the vehicle is equipped (such as the brand of engine,

if an air bag is installed, or if the vehicle features a

collision avoidance system, etc.).

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record

data in certain crash or near-crash situations, such

as air bag deployment or hitting a road obstacle, that

will assist in understanding how a vehicle’s systems

performed. The EDR is designed to record data re-

lated to vehicle dynamics and safety systems for approximately 60 seconds. This data can help provide

a better understanding of the circumstances in which

crashes and injuries occur. Data recorded includes

the following items:

•

how various systems in the vehicle were operating

•

engine system information

•

how far (if at all) the driver was depressing the

accelerator

•

if the driver was depressing the brake pedal

•

how fast the vehicle was traveling

NOTE: Data is not recorded by the EDR under

normal driving conditions. Personal data such

as name, gender, age, and crash location are

not recorded. However, other parties such as

law enforcement could combine the EDR data

with the type of personally identifying data routinely acquired during a crash investigation.

To read data recorded by an EDR, special equipment

is required, and access to the vehicle or the EDR is

needed. In addition to the vehicle manufacturer, other

parties that have the special equipment, such as law

enforcement, can read the information if they have

access to the vehicle or the EDR.

Customer Assistance Center

Having trouble finding service? Call the Customer

Assistance Center at 1-800-385-4357 or 1-800-FTLHELP. Call night or day, weekdays or weekends, for

dealer referral, vehicle information, breakdown coordination, or Fleetpack assistance. Our people are

knowledgeable, professional, and committed to following through to help you keep your truck moving.

Reporting Safety Defects

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Daimler Trucks North America

LLC.

If the NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

STI-405-2 (10/16)

A24-01034-000

Printed in U.S.A.

Foreword

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems

between you, your dealer, or Daimler Trucks North

America LLC.

To contact NHTSA, you may call the Vehicle

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to

write to: Administrator, NHTSA, 1200 New Jersey

Avenue, SE, Washington, DC 20590. You can also

obtain other information about motor vehicle safety

from

www.safercar.gov.

Canadian customers who wish to report a safetyrelated defect to Transport Canada, Defect Investigations and Recalls, may telephone the toll-free

hotline 1-800-333-0510, or contact Transport

Canada by mail at: Transport Canada, ASFAD,

Place de Ville Tower C, 330 Sparks Street,

Ottawa, Ontario, Canada K1A 0N5.

www.safercar.gov;or

For additional road safety information, please visit

the Road Safety website at:

roadsafety

.

www.tc.gc.ca/

© 2001–2016 Daimler Trucks North America LLC. All rights reserved. Daimler Trucks North America LLC is a Daimler

company.

No part of this publication, in whole or part, may be translated, reproduced, stored in a retrieval system, or transmitted

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Daimler Trucks North America LLC. For additional information, please contact Daimler Trucks North

America LLC, Service Systems and Documentation, P.O. Box 3849, Portland OR 97208–3849 U.S.A. or refer to

www.Daimler-TrucksNorthAmerica.comand www.FreightlinerTrucks.com.

Contents

Chapter Page

Introduction, Environmental Concerns and Recommendations,

Event Data Recorder, Customer Assistance Center, Reporting

Safety Defects ..................................................... Foreword

1 Vehicle Identification ...................................................... 1.1

2 Instruments and Controls Identification ....................................... 2.1

3 Vehicle Access .......................................................... 3.1

4 Heater and Air Conditioner ................................................. 4.1

5 Seats and Seat Belts ..................................................... 5.1

6 Steering and Brake Systems ............................................... 6.1

7 Engines and Clutches .................................................... 7.1

8 Transmissions ........................................................... 8.1

9 Rear Axles ............................................................. 9.1

10 Fifth Wheels and Trailer Couplings ......................................... 10.1

11 Pretrip and Post-Trip Inspections and Maintenance ............................ 11.1

12 Cab Appearance ........................................................ 12.1

13 In an Emergency ....................................................... 13.1

14 Headlight Aiming ........................................................ 14.1

Index .................................................................. I.1

1

Vehicle Identification

Vehicle Specification Decal ......................................................... 1.1

Federal Motor Vehicle Safety Standard (FMVSS) Labels ................................. 1.1

Canadian Motor Vehicle Safety Standard (CMVSS) Labels ................................ 1.2

Tire and Rim Labels ............................................................... 1.2

EPA Emission Control ............................................................. 1.2

Vehicle Identification

Vehicle Specification Decal

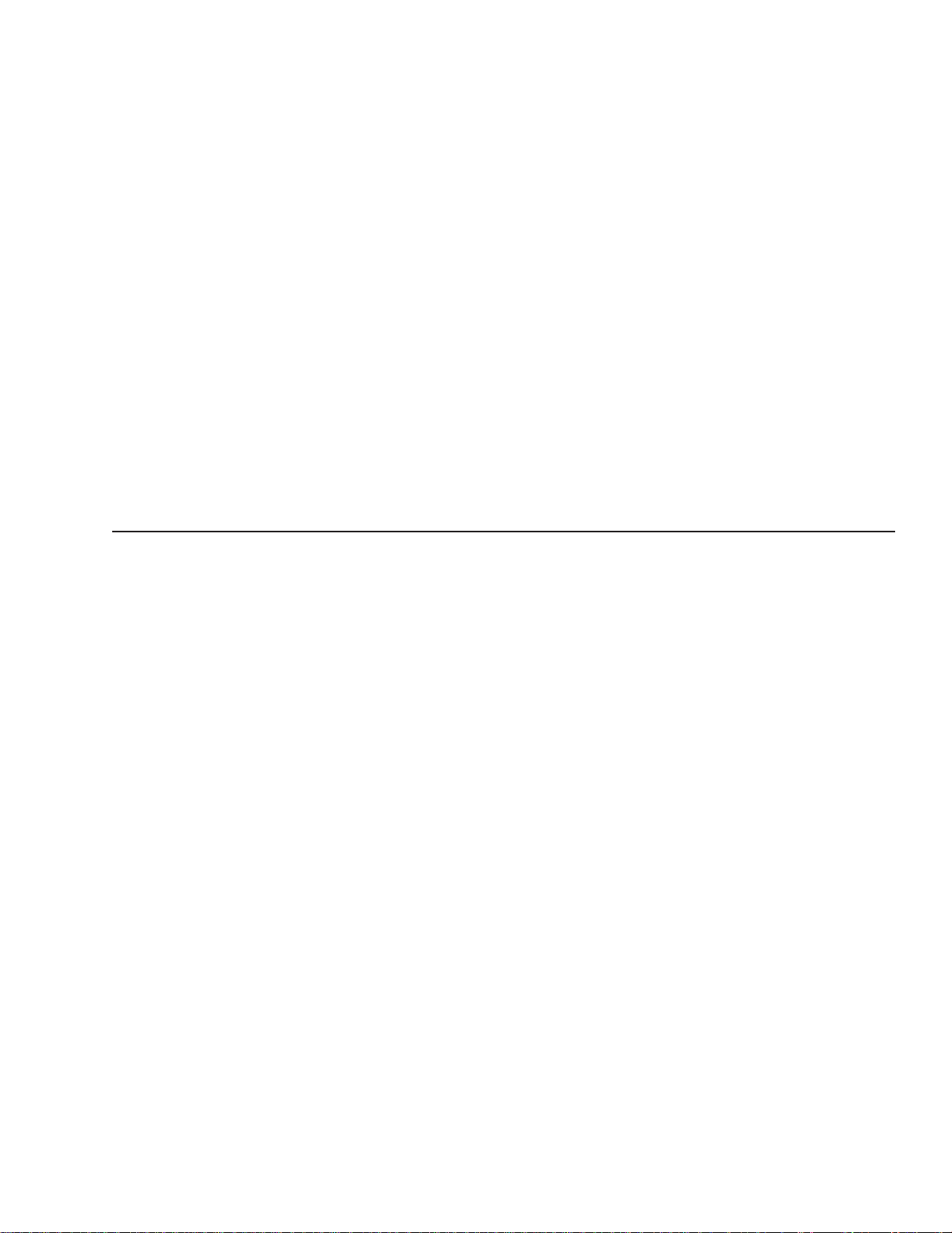

The vehicle specification decal lists the vehicle

model, identification number, and major component

models. It also recaps the major assemblies and installations shown on the chassis specification sheet.

One copy of the specification decal is attached to the

inside of the sliding storage/waste drawer; another

copy is inside the rear cover of the Owner’s Warranty

Information for North America booklet. An illustration

of the decal is shown in

MANUFACTURED BY

MODEL

VEHICLE ID NO.

DATE OF MFR

ENGINE MODEL

TRANS MODEL MAIN

FRONT AXLE MODEL

REAR AXLE MODEL

IMRON PAINT−CAB

CAB COLOR A: WHITE (4775)

PAINT MFR

CAB COLOR B: BROWN (3295)

PAINT NO.

CAB COLOR C: BROWN (29607)

CAB COLOR D: DARK BROWN (7444)

11/21/96

Fig. 1.1, Vehicle Specification Decal (U.S.-built vehicle

Fig. 1.1.

COMPONENT INFORMATION

USE VEHICLE ID NO.

WHEN ORDERING PARTS

WHEELBASE

ENGINE NO.

TRANS NO.

FRT AXLE NO.

REAR AXLE NO.

REAR AXLE NO.

RATIO

FOR COMPLETE PAINT INFORMATION

SEE VEHICLE SPECIFICATION SHEET

shown)

PART NO. 24−00273−010

f080021

2

1

11/21/96

3

f080053

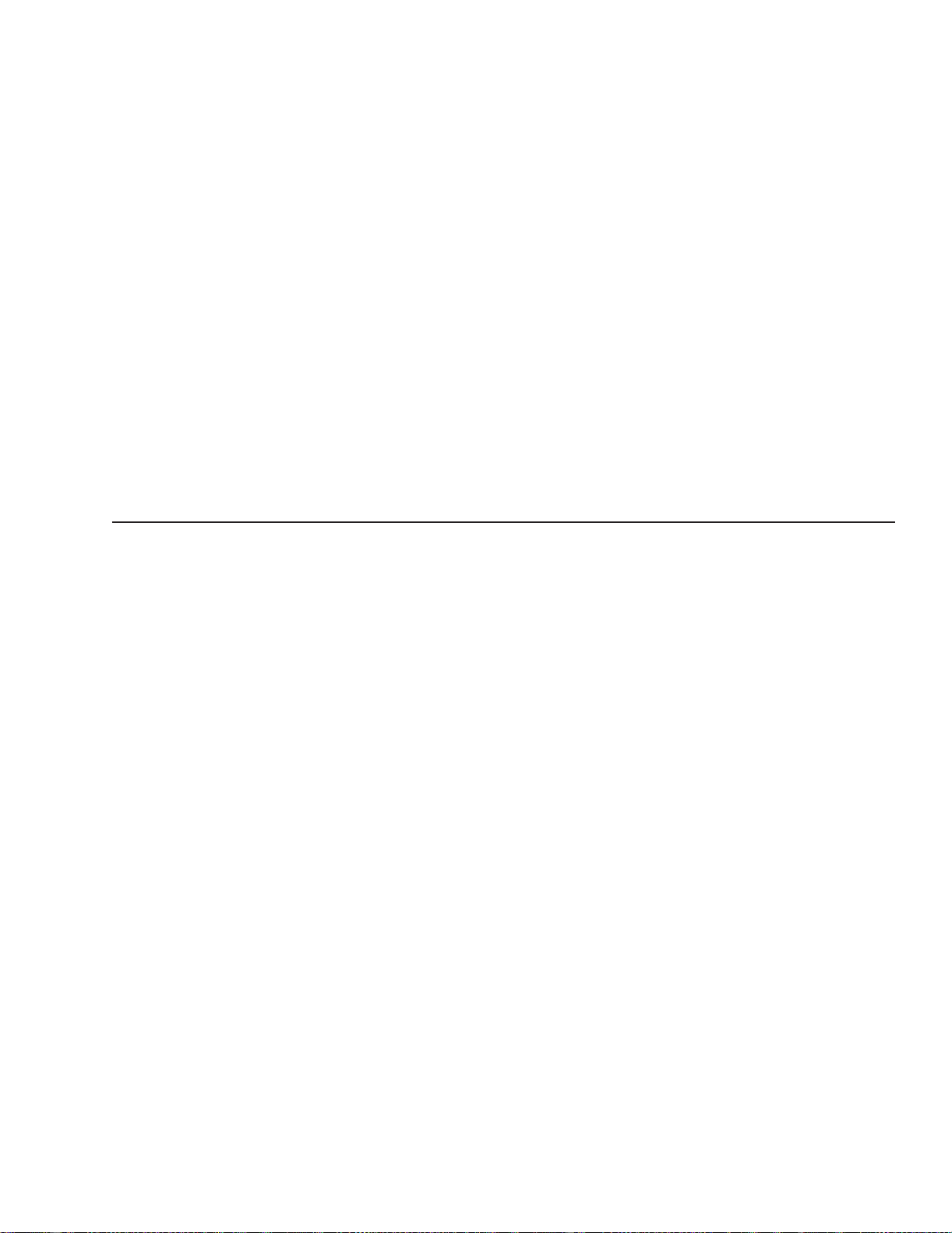

1. Date of Manufacture: by month and year

2. Gross Vehicle Weight Rating: developed by taking

the sum of all the vehicle’s gross axle ratings

3. Gross Axle Weight Ratings: developed by

considering each component in an axle system including suspension, axle, wheels, and tires - and

using the lowest component capacity as the value

for the system

Fig. 1.2, Certification Label, U.S.

1

NOTE: Labels shown in this chapter are examples only. Actual specifications may vary from

vehicle to vehicle.

Federal Motor Vehicle Safety

Standard (FMVSS) Labels

NOTE: Due to the variety of FMVSS certification

requirements, not all of the labels shown will

apply to your vehicle.

Tractors with or without fifth wheels purchased in the

U.S. are certified by means of a certification label

Fig. 1.2) and the tire and rim labels. These labels

(

are attached to the left rear door post, as shown in

Fig. 1.3.

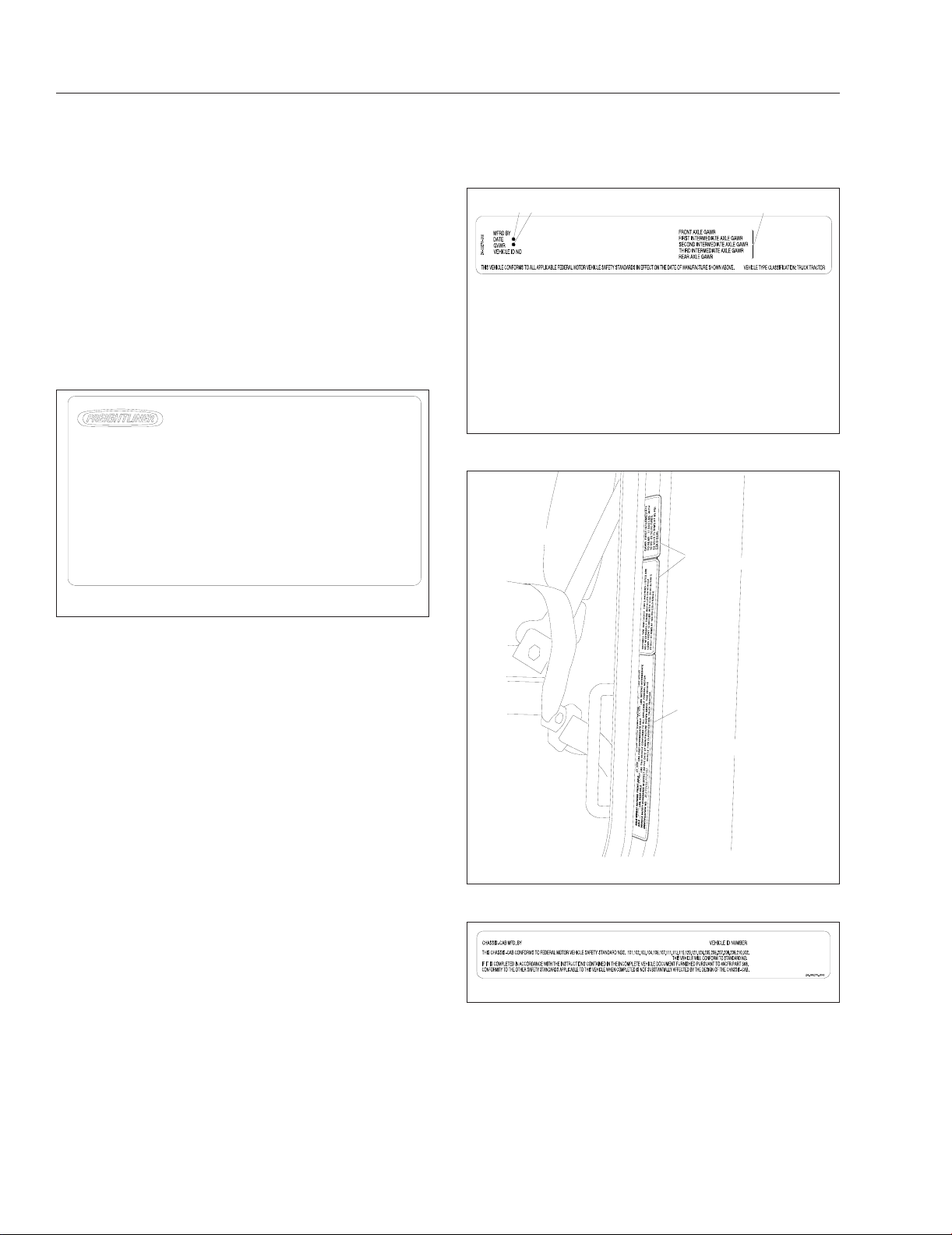

If purchased for service in the U.S., trucks built without a cargo body have a certification label (

attached to the left rear door post. See Fig. 1.3.In

addition, after completion of the vehicle, a certification label similar to that shown in

Fig. 1.2 must be

attached by the final-stage manufacturer. This label

will be located on the left rear door post and certifies

that the vehicle conforms to all applicable FMVSS

regulations in effect on the date of completion.

Fig. 1.4)

2

11/01/95

f601086

1. Tire and Rim Labels 2. Certification Label

Fig. 1.3, Labels Location

09/28/98

f080023

Fig. 1.4, Incomplete Vehicle Certification Label, U.S.

1.1

Vehicle Identification

Canadian Motor Vehicle Safety

Standard (CMVSS) Labels

In Canada, tractors with fifth wheels are certified by

means of a "Statement of Compliance" label and the

Canadian National Safety Mark (

Fig. 1.5), which are

attached to the left rear door post. In addition, tire

and rim labels (

Fig. 1.6) are also attached to the left

rear door post.

10/10/2006

Fig. 1.5, Canadian National Safety Mark

2

1

VEHICLE ID NO.

DATE OF MFR

GVWR

TIRES AND RIMS LISTED ARE NOT NECESSARILY THOSE INSTALLED ON THE VEHICLE.

10/31/95

FRONT AXLE

FIRST INTERMEDIATE AXLE

SECOND INTERMEDIATE AXLE

THIRD INTERMEDIATE AXLE

REAR AXLE

3

GAWR TIRES RIMS PSI COLD

1. Date of Manufacture: by month and year

2. Gross Vehicle Weight Rating: developed by taking

the sum of all the vehicle’s gross axle ratings

3. Gross Axle Weight Ratings: developed by

considering each component in an axle system —

including suspension, axle, wheels, and tires — and

using the lowest component capacity as the value

for the system

Fig. 1.6, Tire and Rim Label

f080024

24−00273−040

f080054

If purchased for service in Canada, trucks built without a cargo body and tractors built without a fifth

wheel are certified by a "Statement of Compliance"

label, similar to

Fig. 1.2. This label must be attached

by the final-stage manufacturer after completion of

the vehicle. The label is located on the left rear door

post, and certifies that the vehicle conforms to all

applicable CMVSS regulations in effect on the date

of completion.

Tire and Rim Labels

Tire and rim labels certify suitable tire and rim combinations that can be installed on the vehicle, for the

given gross axle weight rating. Tires and rims in-

stalled on the vehicle at the time of manufacture may

have a higher load capacity than that certified by the

tire and rim label. If the tires and rims currently on

the vehicle have a lower load capacity than that

shown on the tire and rim label, then the tires and

rims determine the load limitations on each of the

axles.

See

Fig. 1.6 for U.S. and Canadian tire and rim la-

bels.

EPA Emission Control

Vehicle Noise Emission Control Label

A vehicle noise emission control label (Fig. 1.7)is

attached either to the left side of the dashboard or to

the top-right surface of the frontwall between the

dash and the windshield.

FREIGHTLINER CORPORATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY

THE NOISE CONTROL ACT OF 1972:

A. THE REMOVAL OR RENDERING INOPERATIVE, OTHER THAN FOR PURPOSES OF

MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR

ELEMENT OF DESIGN (LISTED IN THE OWNER’S MANUAL) INCORPORATED INTO THIS

VEHICLE IN COMPLIANCE WITH THE NOISE CONTROL ACT.

B. THE USE THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF DESIGN HAS

BEEN REMOVED OR RENDERED INOPERATIVE.

10/06/98

VEHICLE NOISE EMISSION CONTROL INFORMATION

DATE OF MANUFACTURE

Fig. 1.7, Vehicle Noise Emission Control Label

IMPORTANT: Certain Freightliner incomplete

vehicles may be produced with incomplete noise

control hardware. Such vehicles will not have a

vehicle noise emission control information label.

For such vehicles, it is the final-stage manufacturer’s responsibility to complete the vehicle in

conformity to U.S. EPA regulations (40 CFR Part

205) and label it for compliance.

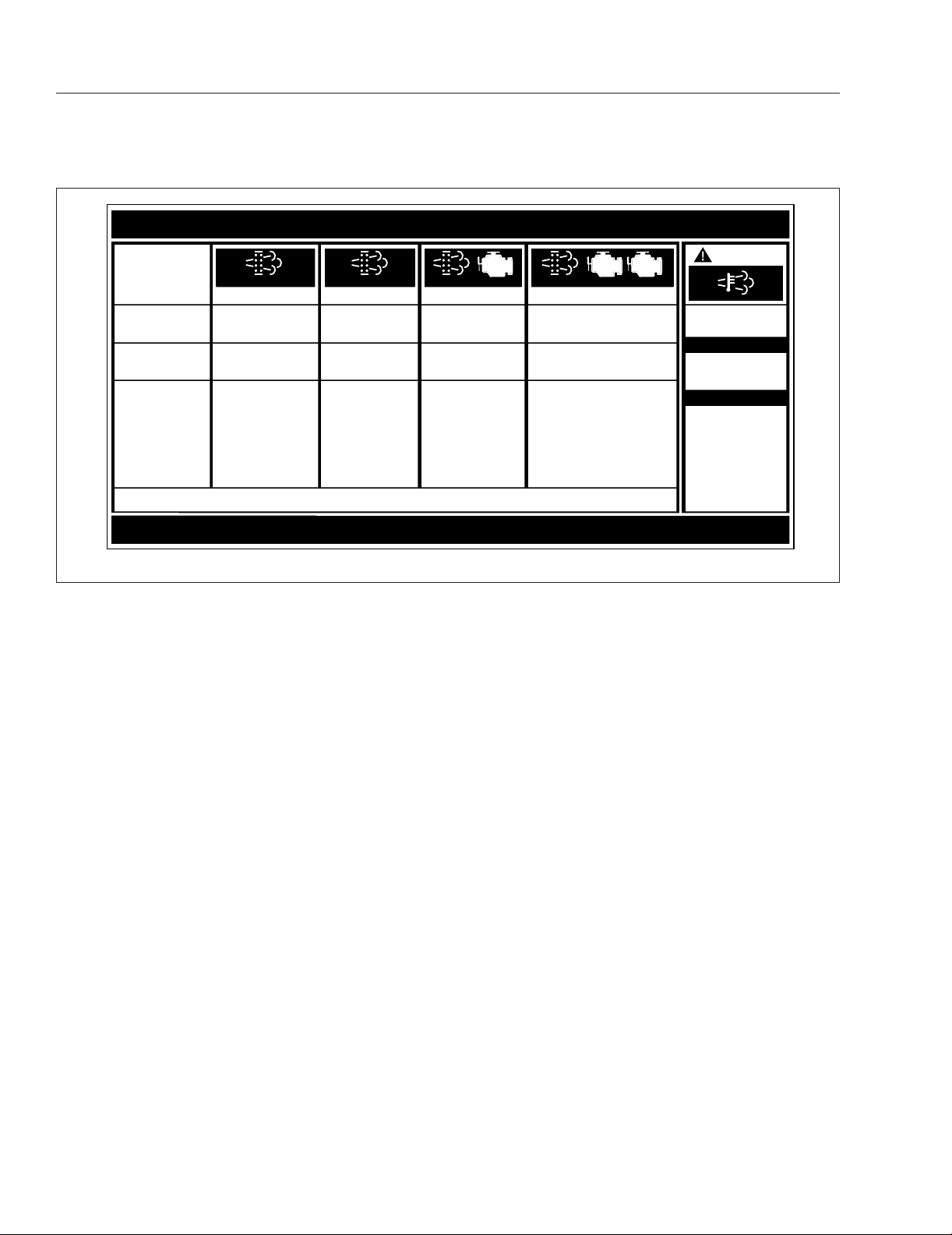

EPA07 Exhaust Emissions

To meet January 2007 emissions regulations, vehicles with engines manufactured after January 1,

2007, are equipped with an emission aftertreatment

device. There is a warning label on the driver’s sunvisor, explaining important new warning indicators in

the driver’s message display, that pertain to the aftertreatment system. See

It is a violation of federal law to alter exhaust plumbing or aftertreatment in any way that would bring the

engine out of compliance with certification requirements. (Ref: 42 U.S.C. S7522(a) (3).) It is the owner’s responsibility to maintain the vehicle so that it

conforms to EPA regulations.

Fig. 1.8.

01/96

24−00273−020

f080026

1.2

Vehicle Identification

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

INDICATOR

LAMP(S)

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

(Solid)

Level 1 Level 3Level 2 Level 4

Filter Regeneration

Recommended

Filter is reaching

capacity

. .

Bring vehicle to

highway speeds to

allow for an Automatic

Regeneration or

perform a Parked

Regeneration.

(Flashing) (Flashing)

Filter Regeneration

Necessary

Filter is now

reaching maximum

Switch.

capacity

.

To avoid engine

derate bring vehicle

to highway speeds

to allow for an

Automatic

Regeneration or

perform a Parked

Regeneration as

soon as possible.

CHECK CHECK

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

Vehicle must be

parked and a Parked

Regeneration must

be performed −

engine will begin

derate.

(Flashing)

Parked Regeneration Required −

Engine Shut Down

Filter has exceeded

.

maximum capacity

Vehicle must be parked and a

Parked Regeneration or Service

Regeneration must be performed.

Check engine operator’s manual

for details −engine will shut down.

STOP

W

ARNING

HEST (High Exhaust

System Temperature)

Flashing

A regeneration is in

progress.

Solid

Exhaust Components

and exhaust gas are

at high temperature.

When stationary, keep

away from people and

flammable materials

or vapors.

06/29/2009

See Engine Operator’s Manual for complete Regeneration Instructions.

Fig. 1.8, Sunvisor Warning Label

24−01583−000B

f080147

1.3

2

Instruments and Controls

Identification

Instrumentation Control Units ....................................................... 2.1

Warning and Indicator Lights ........................................................ 2.3

Driver Message Center ............................................................ 2.7

Instruments ..................................................................... 2.17

Controls ........................................................................ 2.20

Roll Stability Advisor and Control System ............................................. 2.27

Instruments and Controls Identification

Instrumentation Control Units

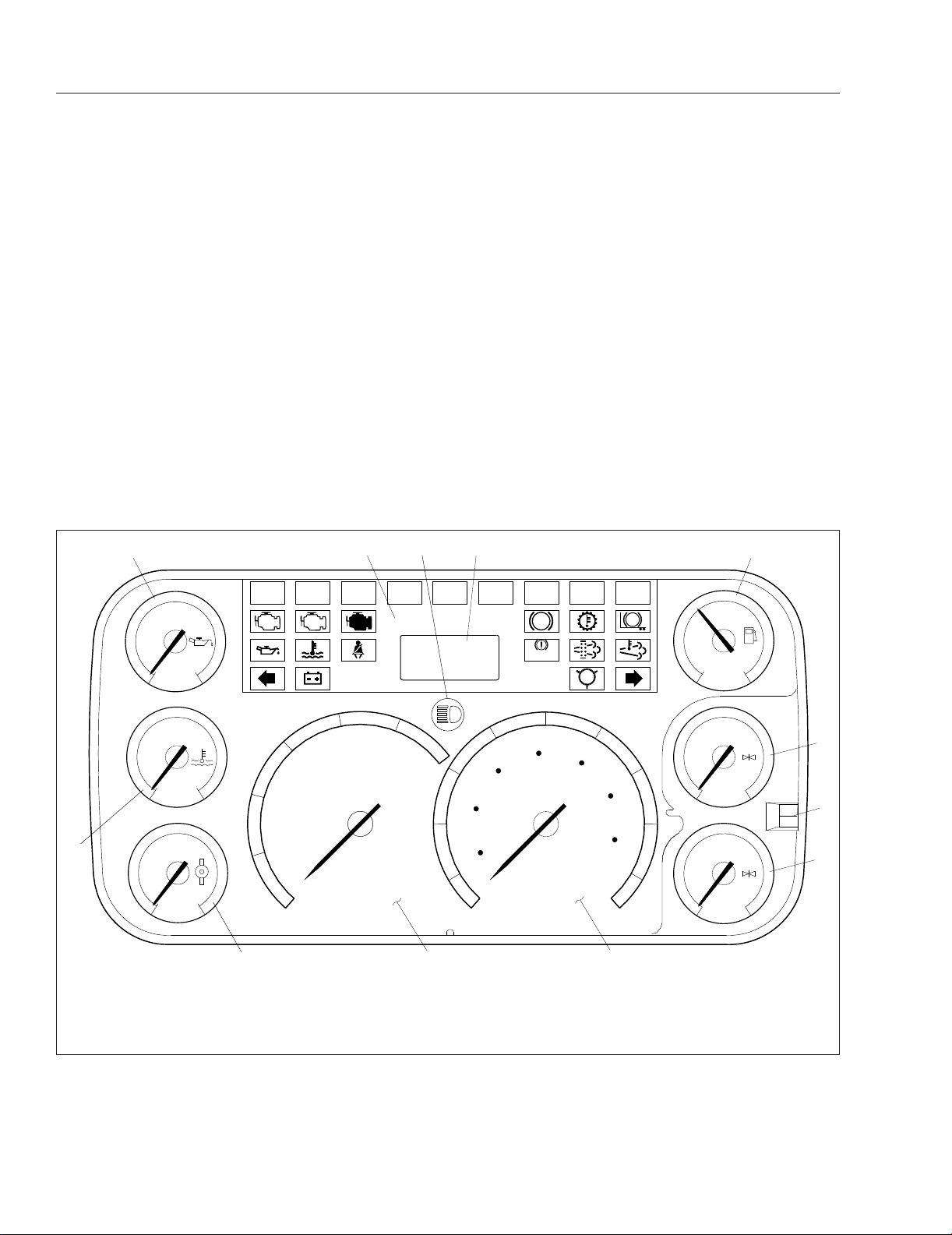

The instrumentation control unit (ICU) provides the

driver with engine and vehicle information. It is comprised of standard and optional gauges, an audible

warning, a driver message center, and a lightbar containing warning and indicator lamps (also known as

telltales). Warning and indicator lamps illuminate in

red (danger), amber (caution), green (status advisory), or blue (high-beam headlights activated).

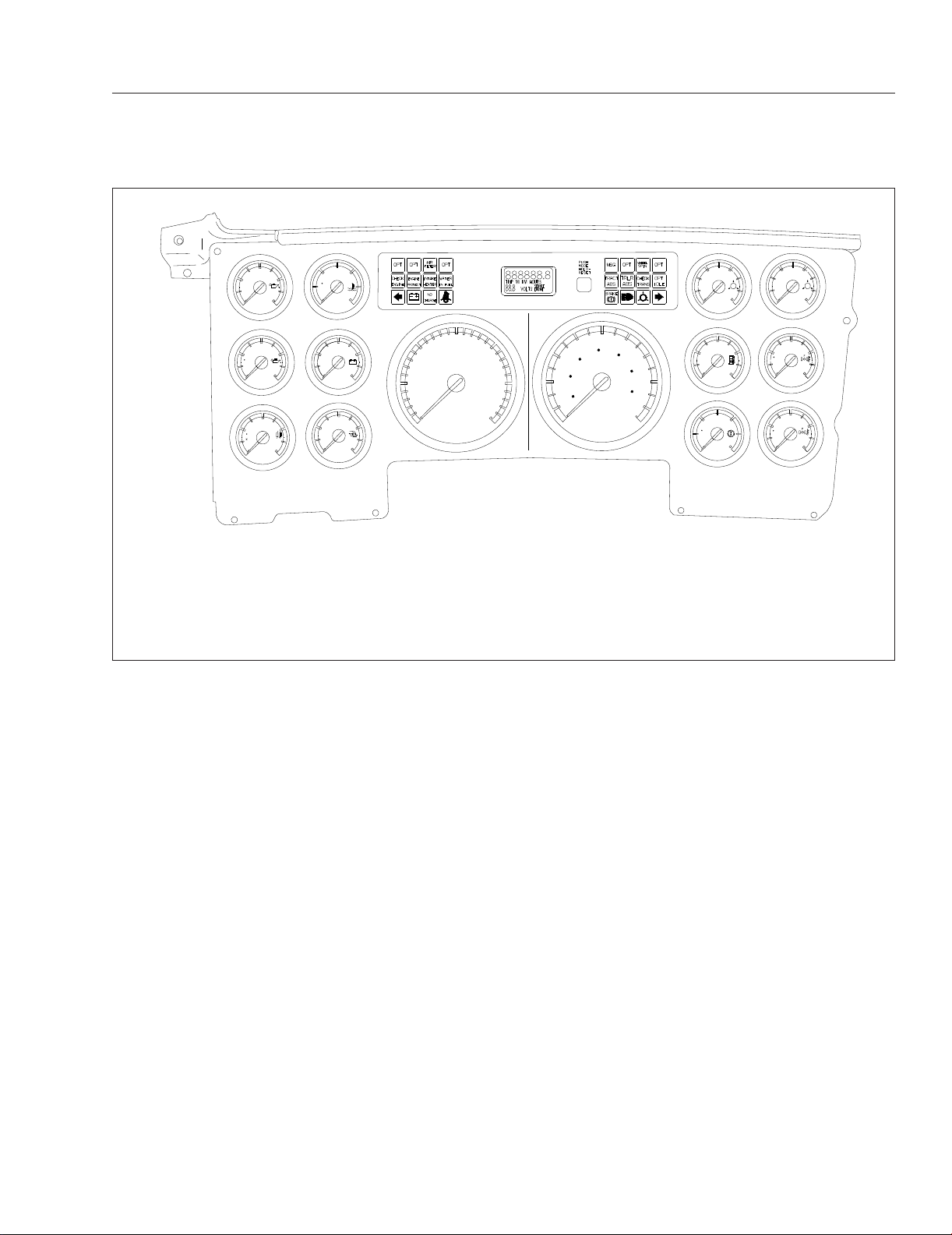

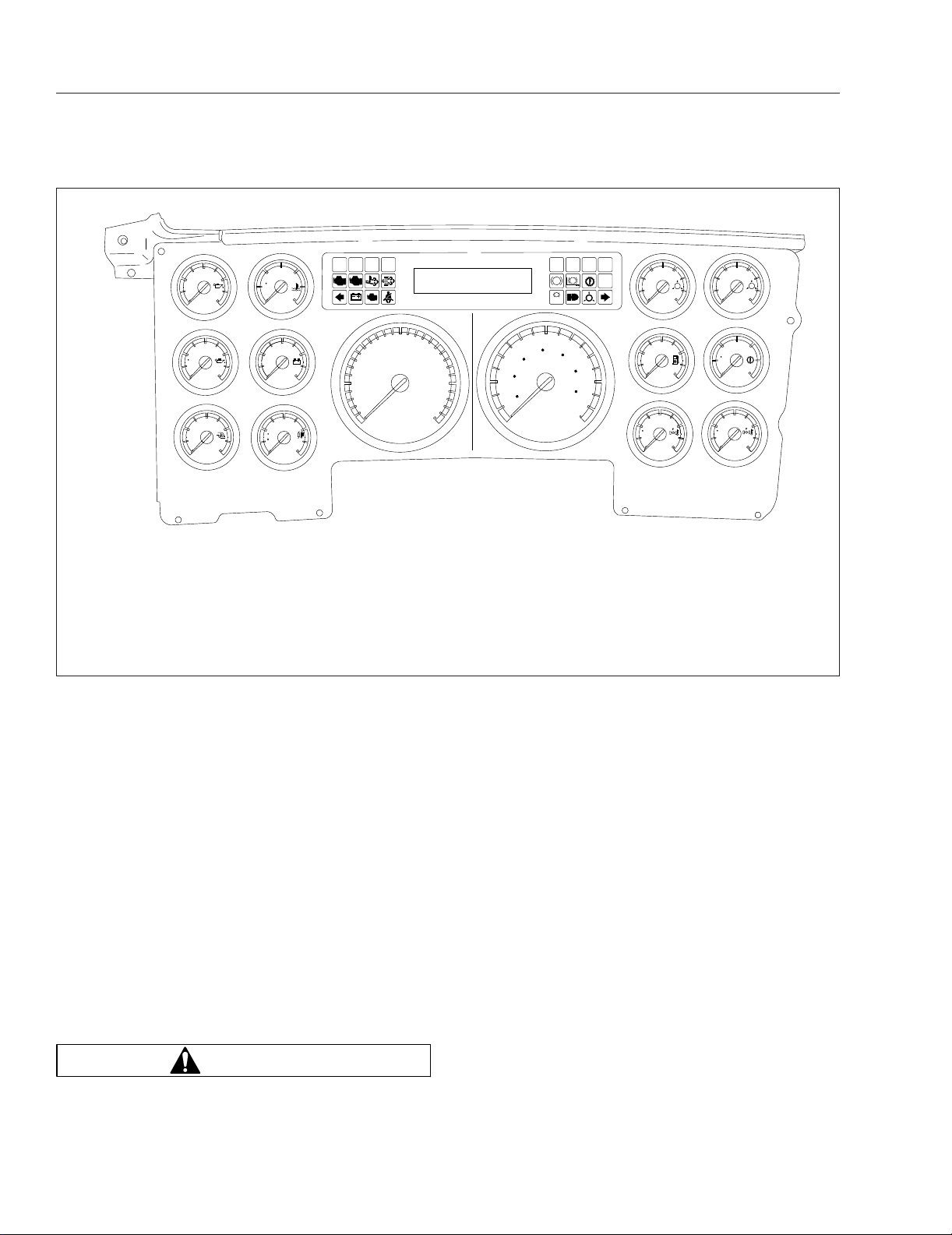

Columbia vehicles are equipped with either an ICU3

Fig. 2.1), ICU4 (Fig. 2.2), or ICU4M (Fig. 2.3).

(

The following headings in this chapter provide additional information and operating instructions for ICU

components:

•

"Warning and Indicator Lights"

•

"Driver Message Center"

124 5

50

PSI

0

100

OIL

CHECK

STOP

3

Ignition Sequence

When the ignition is turned on, the ICU runs a selfcheck. Observing the ignition sequence is a good

way to ensure the ICU is functioning properly.

IMPORTANT: Do not crank the engine until the

ICU gauge sweep is complete.

NOTE: Air gauges do not complete a sweep of

their dials during the ignition sequence.

When the ignition is turned on, the following actions

should occur:

•

electronic gauges complete a full sweep of

their dials

•

some warning and indicator lamps illuminate,

then are extinguished

OPT

OPTOPTOPTOPTOPTOPTOPTOPT

E

FUEL

1/2

F

ABS

BRAKE

ABS

200

150

F°

100

250

WATER

F°

100

225

350

TRANS

11

12

10/26/2006

1. Engine Oil Pressure Gauge

2. Dash Message Center

3. Headlight High-Beam Indicator

4. Dash Message Center

5. Fuel Level Gauge

•

"Instruments"

2.1

10

5

20

25

15

30

25

15

5

RPM

0

X100

10

6. Primary Air Pressure Gauge

7. Mode/Reset Switch

8. Secondary Air Pressure Gauge

9. Speedometer

Fig. 2.1, ICU3 Instrument Cluster

30

35

10

50

45

70

km/h

MPH

50

100

90

55

65

110

PSI

150

0

AIR

75

130

85

9

10. Tachometer

11. Tranismission Fluid Temperature

Gauge

12. Coolant Temperature Gauge

50

100

PSI

150

0

AIR

PUSH−

MODE

HOLD−

RESET

f610837b

6

7

8

Instruments and Controls Identification

40

PSI

0

100

OIL

200

150

F

100

250

WATER

12

200

F

100

300

OIL

3

90

F

10

30

150

PYRO

12

8

16

VOLTS

4

40

PSI

0

80

TURBO

56

10060

PSI

P

7

8

0 160

AIR

11 12

15

25

5

MPH

45

55

35

70

65

90

50

110

30

10

75

130

85

km/h

13

1/2

EF

FUEL

190

270

F

110

350

TRANS

15

RPM

X 100

20

25

30

10

10

5

0

9

15

14

16

PSI

0 160

200

F

100

AXLE

200

F

100

AXLE

10060

S

AIR

300

300

04/01/2004 f610706

1. Engine Oil Pressure Gauge

2. Engine Coolant Temperature

Gauge

3. Engine Oil Temperature Gauge

4. Battery Voltage Gauge

5. Pyrometer

6. Turbo Boost Air Pressure Gauge

7. Dash Message Center

8. Mode/Reset Switch

9. Tachometer

10. Speedometer

11. Primary Air Pressure Gauge

12. Secondary Air Pressure Gauge

13. Fuel Level Gauge

14. Axle Temperature Gauge

15. Transmission Oil Temperature

Gauge

16. Axle Temperature Gauge

Fig. 2.2, ICU4 Instrument Cluster

•

audible alert sounds until sufficient air pressure

builds up in the primary and secondary air systems

•

software revision level of the ICU is displayed

on the driver message center, followed by any

active faults

IMPORTANT: If any red or amber warning or

indicator lamps do not illuminate during the ICU

self-check or do not extinguish after the selfcheck completes, take the action outlined in

Table 2.1, or take the vehicle to an authorized

Daimler Trucks service facility as soon as possible.

NOTE: If active faults are present, take the vehicle to an authorized Daimler Trucks service

facility as soon as possible.

If the ICU receives active fault codes, it displays

them one after the other until the parking brake is

released or the ignition is turned off. Once the parking brake is completely released, the ICU displays

the odometer. If there are no active faults, the ICU

When the self-check is complete on an ICU4M, the

fasten seat belt screen displays if the engine is off. If

the engine is running, the idle hours screen displays.

Audible Alerts

An audible alert sounds during the ignition sequence

and whenever one of the following conditions exists:

•

Engine oil pressure falls below the minimum

preset value.

•

Coolant temperature rises above the maximum

preset value.

•

Air pressure falls below approximately 70 psi

(483 kPa).

•

Parking brake is set with the vehicle moving

faster than two miles per hour.

•

System voltage falls below 12

volts.

•

Door is open or the headlights are on, with the

parking brake off.

displays the odometer after the self-check completes.

2.2

Instruments and Controls Identification

40

PSI

0

100

OIL

200

150

F

100

250

WATER

12

200

F

100

300

OIL

3

40

PSI

0

80

TURBO

12

8

16

VOLTS

4

90

F

10

30

150

PYRO

56

8

STOPCHECK

15

RPM

X 100

20

10

5

0

30

9

7

FASTEN SEATBELTS

0000432 MILES

25

15

10

25

5

35

50

30

10

MPH

8

OPT OPT OPT OPTOPT OPT OPT OPT

BRAKE

PSI

0 160

AIR

10060

P

OPT

ABS

ABS

IDLE

!

PSI

0 160

AIR

10060

S

11 12

45

55

70

65

90

110

75

130

85

km/h

13

15

1/2

EF

FUEL

200

F

100

300

AXLE

14

16

190

270

F

110

350

TRANS

200

F

100

300

AXLE

09/29/2010 f610706b

1. Engine Oil Pressure Gauge

2. Engine Coolant Temperature

Gauge

3. Engine Oil Temperature Gauge

4. Battery Voltage Gauge

5. Turbo Boost Air Pressure Gauge

6. Pyrometer

7. Dash Message Center

8. Warning and Indicator Lights

9. Tachometer

10. Speedometer

11. Primary Air Pressure Gauge

12. Secondary Air Pressure Gauge

13. Fuel Level Gauge

14. Transmission Fluid Temperature

Gauge

15. Forward Drive Axle Temperature

Gauge

16. Rearmost Drive Axle Temperature

Gauge

Fig. 2.3, ICU4M Instrument Cluster

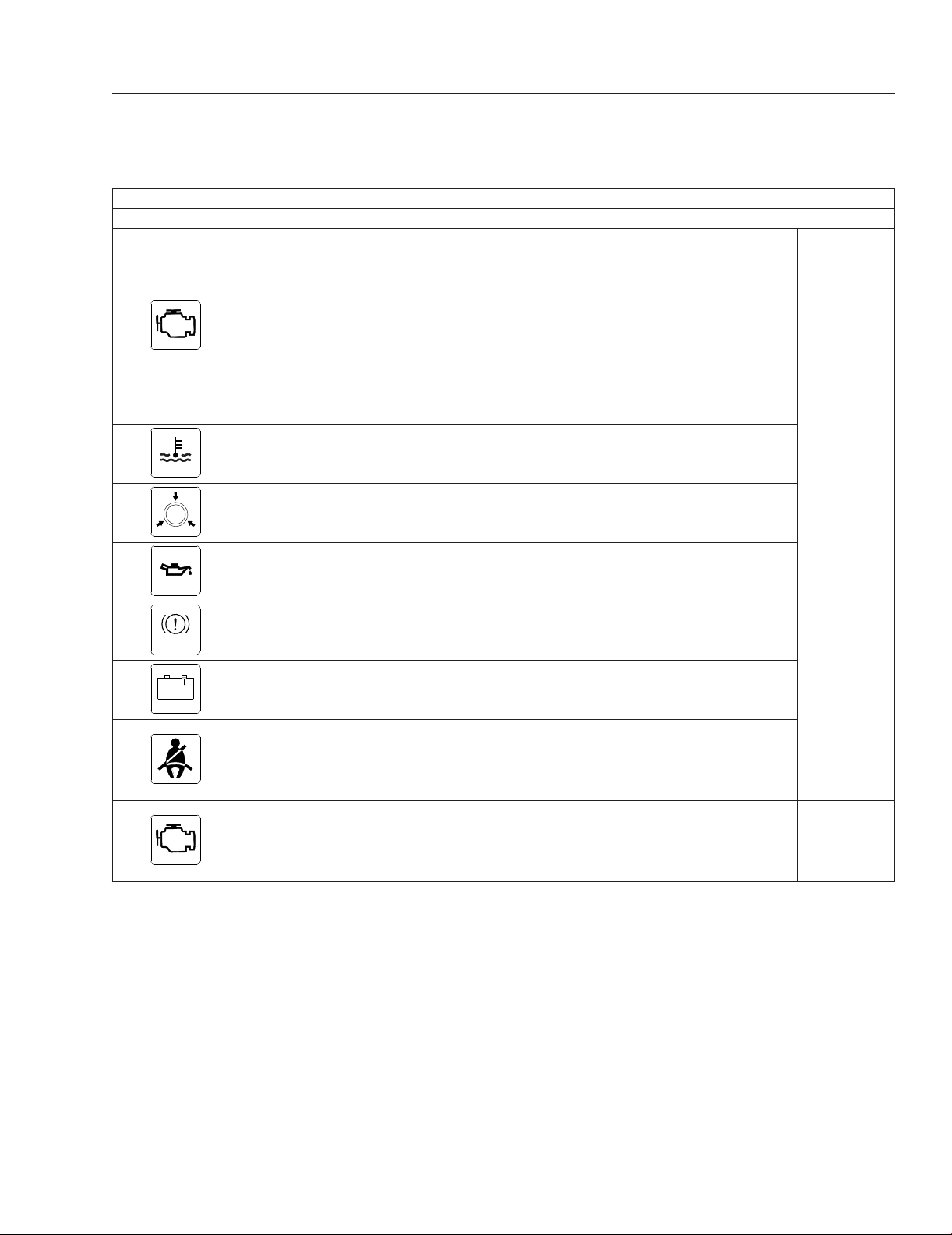

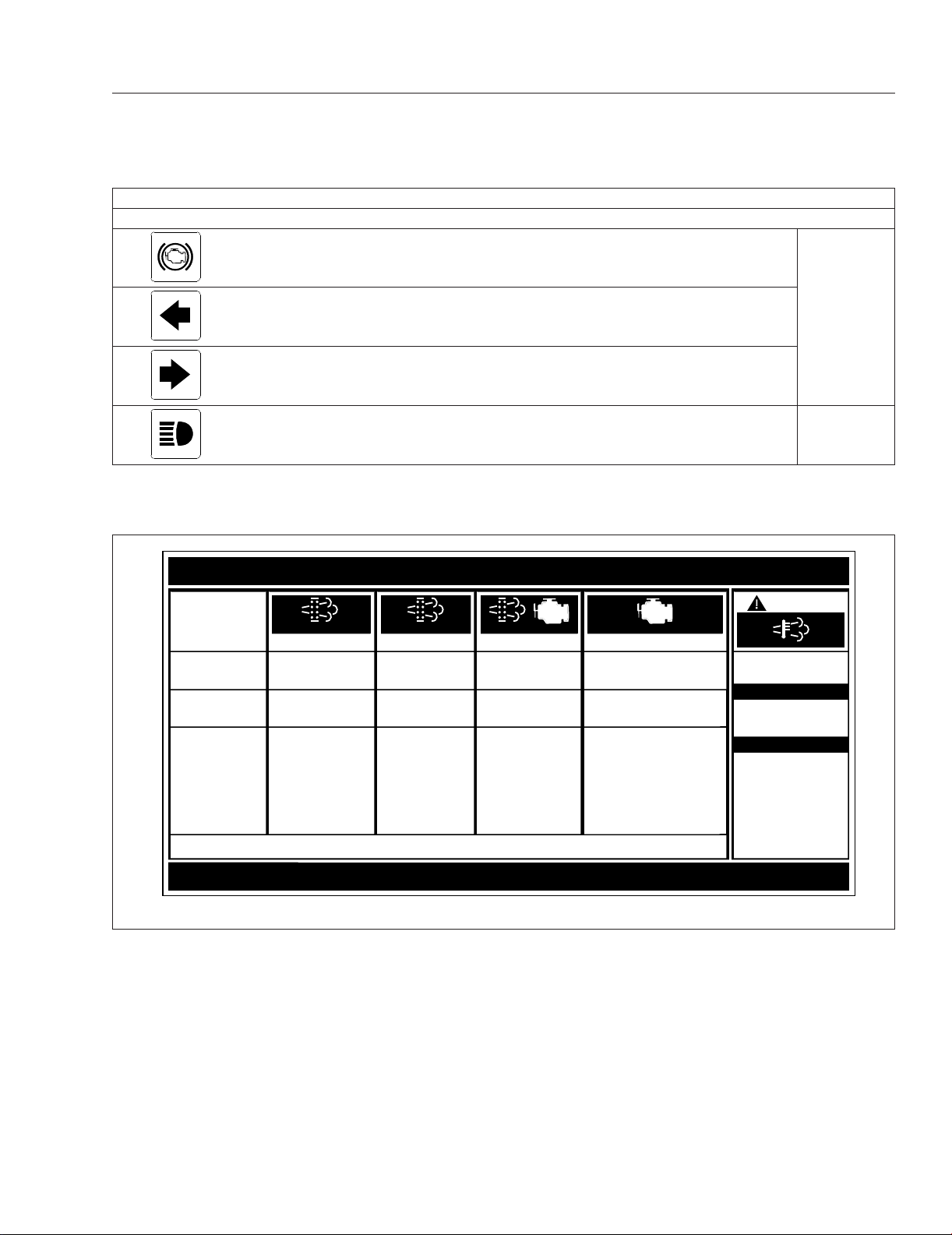

Warning and Indicator Lights

The ICU lightbar has three or four rows of warning

and indicator lights with icon symbols, depending on

the ICU. The positions of the lights may vary for the

different ICU’s, but the telltales are standard for all

applications. See

and commonly used warning and indicator lamps.

Warning and indicator lamps illuminate in red (danger), amber (caution), green (status advisory), or

blue (high-beam headlights active).

IMPORTANT: Depending upon local jurisdictional emissions guidelines, vehicles may not be

equipped with all of the lamps shown in

Table 2.1.

Engine Protection System

When the red STOP engine lamp illuminates,

most engines are programmed to shut down au-

2.3

Table 2.1 for a listing of standard

WARNING

tomatically within 30 seconds. The driver must

immediately move the vehicle to a safe location

at the side of the road to prevent causing a hazardous situation that could cause bodily injury,

property damage, or severe damage to the engine.

See

Fig. 2.4 for an explanation of the aftertreatment

system (ATS) warning indicators, and actions required to avoid further engine protection steps.

The STOP engine lamp illuminates when the engine

protection system is activated in one of two ways. On

some engines, the engine protection system derates

the engine, allowing it to run at lower rpm and slower

vehicle speed. Drive the vehicle to a safe location or

to a service facility.

IMPORTANT: Safely bring the vehicle to a stop

on the side of the road and shut down the engine as soon as the red light is seen. If the engine shuts down while the vehicle is in a hazardous location, turn the key to the OFF position

for a few seconds, then restart the engine and

move the vehicle to a safer location.

STOP

STOP Engine

Instruments and Controls Identification

Common Warning and Indicator Lamps

Lamp Description Color

Indicates a serious fault that requires engine shutdown

immediately. The engine protection system reduces the

maximum engine torque and speed, and, if the condition

does not improve, shuts down the engine within 30 to 60

seconds.

*

Safely bring the vehicle to a stop on the side of the road

and shut down the engine as soon as the red light is seen.

IMPORTANT: If the engine shuts down while the vehicle

is in a hazardous location, turn the key to the OFF

position for a few seconds, then restart the engine and

move the vehicle to a safer location.

BRAKE

CHECK

High Coolant Temperature

Low Air Pressure

Low Engine Oil Pressure

Indicates the coolant temperature is above the maximum

allowable temperature.

Indicates air pressure in the primary or secondary reservoir

is below 70 psi (483 kPa).

Indicates the engine oil pressure is below the minimum

allowable pressure.

Indicates the parking brake is engaged. An audible alert

Parking Brake

activates when the vehicle is moving over 2 mph (3 km/h)

with the parking brake set.

Low Battery Voltage Indicates that battery voltage is 11.9 volts or less.

Activates with an audible alert when the system detects that

the parking brake is off and the driver seat belt is not

Unfastened Seat Belt

fastened on some vehicles. On other vehicles, this lamp

illuminates for 15 seconds when the ignition is first turned

on.

Indicates an engine condition (low oil pressure, low coolant

level, high coolant temperature, high DPF soot level, or

CHECK Engine

*

uncontrolled DPF regeneration) that requires correction.

Correct the condition as soon as possible. If the condition

worsens, the STOP engine lamp illuminates.

Red

Amber

2.4

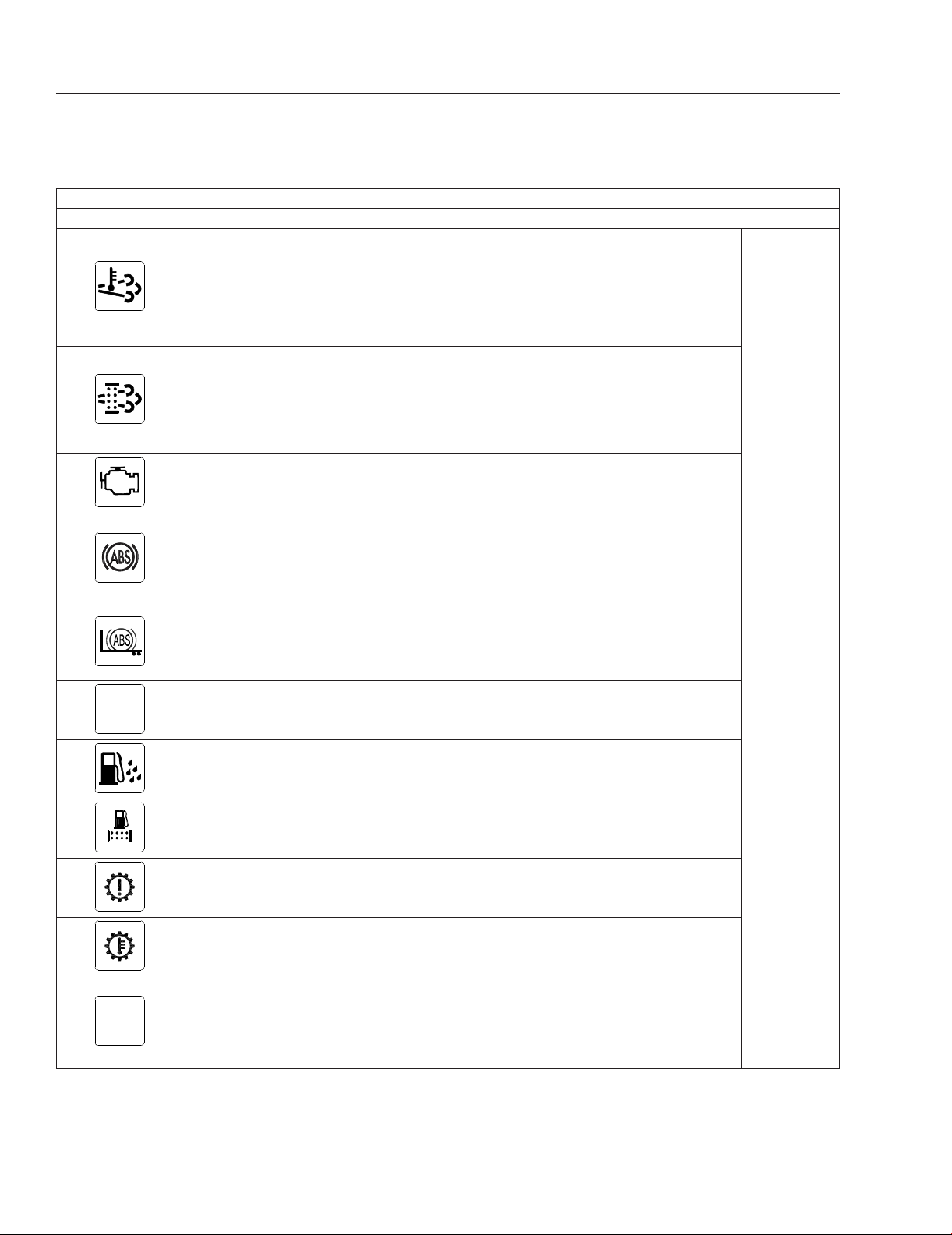

Instruments and Controls Identification

Common Warning and Indicator Lamps

Lamp Description Color

Slow (10-second) flashing indicates a regeneration (regen)

is in progress.

High Exhaust System

Temperature (HEST)

Diesel Particulate Filter

(DPF) Status

IMPORTANT: When the HEST lamp is illuminated, do

*

not park the vehicle near flammable material.

Solid illumination indicates high exhaust temperatures at the

outlet of the tail pipe when speed is below 5 mph (8 km/h).

Solid illumination indicates a regen is required. Change to a

more challenging duty cycle (such as highway driving) to

raise exhaust temperatures for at least twenty minutes, or

perform a parked regen.

Blinking indicates that a parked regen is required

immediately. An engine derate and shutdown occurs.

NO

CHARGE

Malfunction Indicator

Lamp (MIL)

Vehicle ABS

Trailer ABS

No Charge

Water in Fuel

Fuel Filter Restriction Indicates the fuel filter is clogged and requires service.

Check Transmission Indicates an undesirable transmission condition.

Indicates an emissions-related fault. See the engine

operation manual for details.

Momentary illumination indicates the vehicle ABS is

engaged.

Solid illumination indicates a problem with the vehicle ABS.

Repair the ABS immediately to ensure full braking

capability.

Momentary illumination indicates the trailer ABS is engaged.

Solid illumination indicates a problem with the trailer ABS.

Repair the ABS immediately to ensure full braking

capability.

Indicates the alternator is not properly powering the

electrical system.

Indicates the fuel may contain water. Drain any water

collected in the fuel/water separators.

Amber

2.5

WHEEL

SPIN

Transmission Overheat Indicates high transmission temperature.

Flashing indicates the ATC system is active, or the ATC

button has been pressed to allow wheel slip.

Wheel Spin

Solid illumination indicates a problem with the ATC system.

Repair the ATC system immediately to ensure full braking

capability.

Instruments and Controls Identification

Common Warning and Indicator Lamps

Lamp Description Color

Engine Brake Indicates the engine brake is enabled.

Flashing indicates the outside left-turn signal lights are

activated.

Right-Turn Signal

Flashing indicates the outside right-turn signal lights are

activated.

High-Beam Headlights Indicates the high-beam headlights are on. Blue

*

See Fig. 2.4 for an explanation of the aftertreatment system (ATS) warning indicators, and actions required to avoid further engine protection steps.

Table 2.1, Common Warning and Indicator Lamps

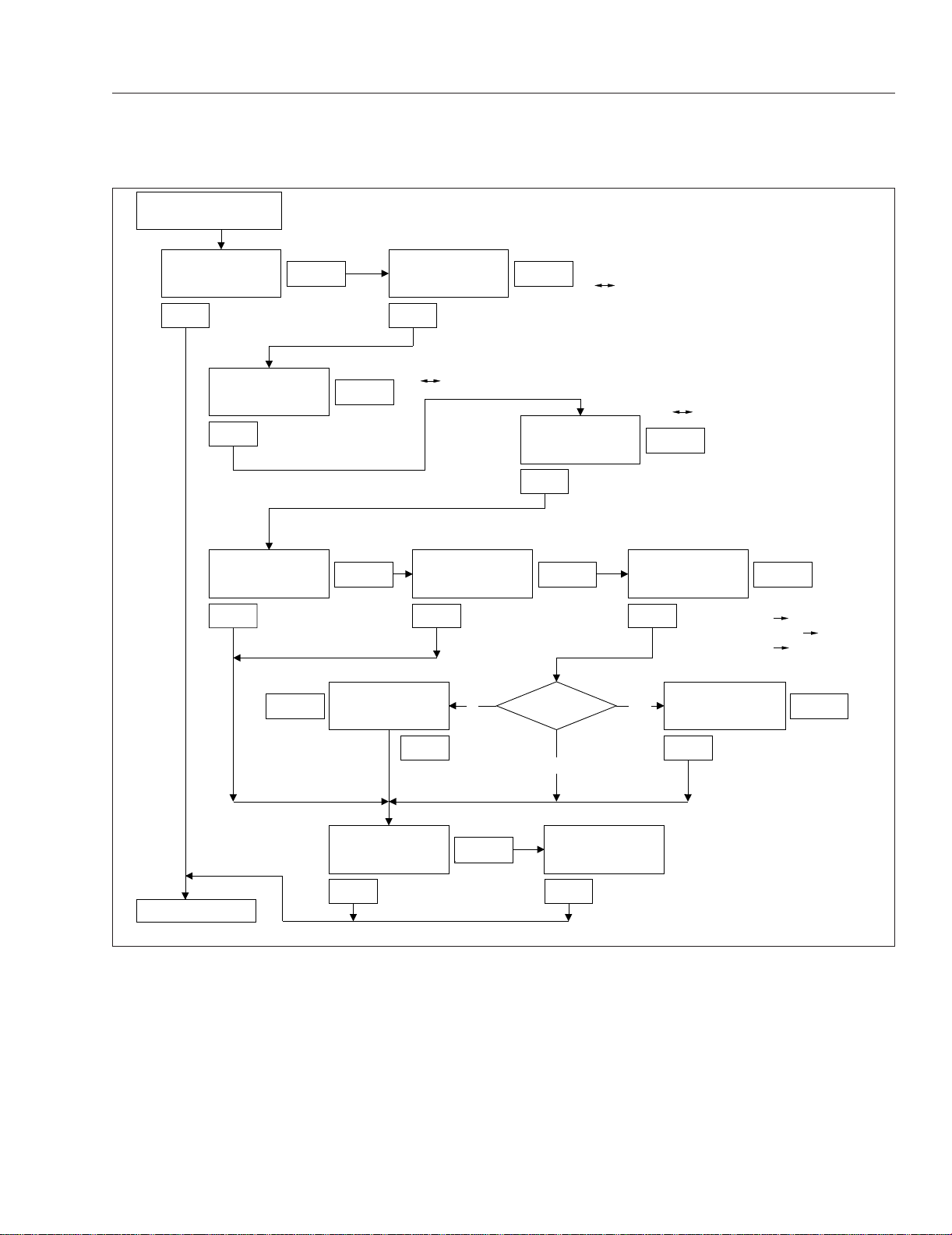

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

INDICATOR

LAMP(S)

(Solid)

(Flashing) (Flashing)

CHECK

STOP

Level 1 Level 3Level 2 Level 4

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

Filter Regeneration

Recommended.

Filter is reaching

capacity

.

Bring vehicle to

highway speeds to

allow for an

Automatic

Regeneration or

perform a Parked

Regeneration.

Filter

Regeneration

Necessary

Filter is now

reaching maximum

Switch.

capacity

.

To avoid engine

derate, bring vehicle

to highway speeds

to allow for an

Automatic

Regeneration, or

perform a Parked

Regeneration as

soon as possible.

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

Vehicle must be

parked, and a Parked

Regeneration must

be performed.

Engine will begin

derate.

.

Service Regeneration Required.

Engine Derate To Idle Only.

Filter has exceeded maximum

capacity.

Vehicle must be parked, and a

Service Regeneration must be

performed. Check engine

operator’s manual for details.

Engine will shut down.

W

ARNING

HEST (High Exhaust

System Temperature)

Flashing

A regeneration is in

progress.

Solid

Exhaust components

and exhaust gas are at

high temperature. When

stationary, keep away

from people and

flammable materials or

vapors.

GreenLeft-Turn Signal

02/20/2009

Fig. 2.4, ATS Warning Lamps

On other engines, the engine protection system

shuts down the engine. It first derates the engine,

then shuts it down completely 30 to 60 seconds after

the indicator illuminates (depending on the critical

fault type) if the condition does not improve. Bring

the vehicle to a stop on the side of the road before

the engine shuts down.

f080156

Some vehicles may have a shutdown-override

switch, which may be used to momentarily override

the shutdown sequence. See

Chapter 7 for detailed

information regarding the shutdown process.

IMPORTANT: Do not attempt to restart the engine while the vehicle is moving. Bring the vehicle to a safe stop, then restart the engine.

2.6

Instruments and Controls Identification

To restart the engine, turn the ignition switch to OFF

for a few seconds, then turn the ignition switch to ON

and let the gauge sweep complete before starting the

engine. The engine will run for a short period and

shut down again if the condition does not improve.

Driver Message Center

The dash message centers for the following instrument clusters are described below:

•

ICU3

•

ICU4

•

ICU4M

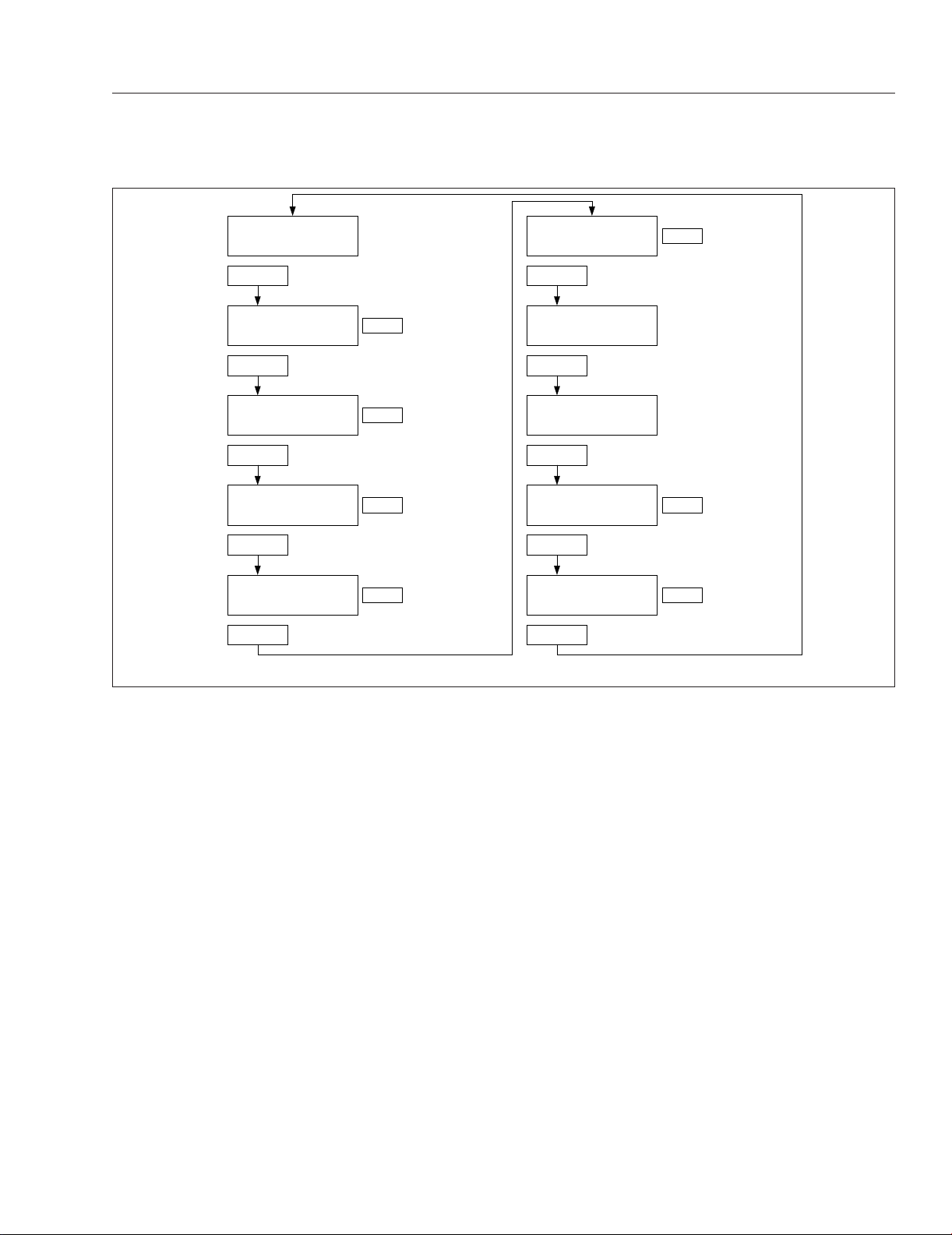

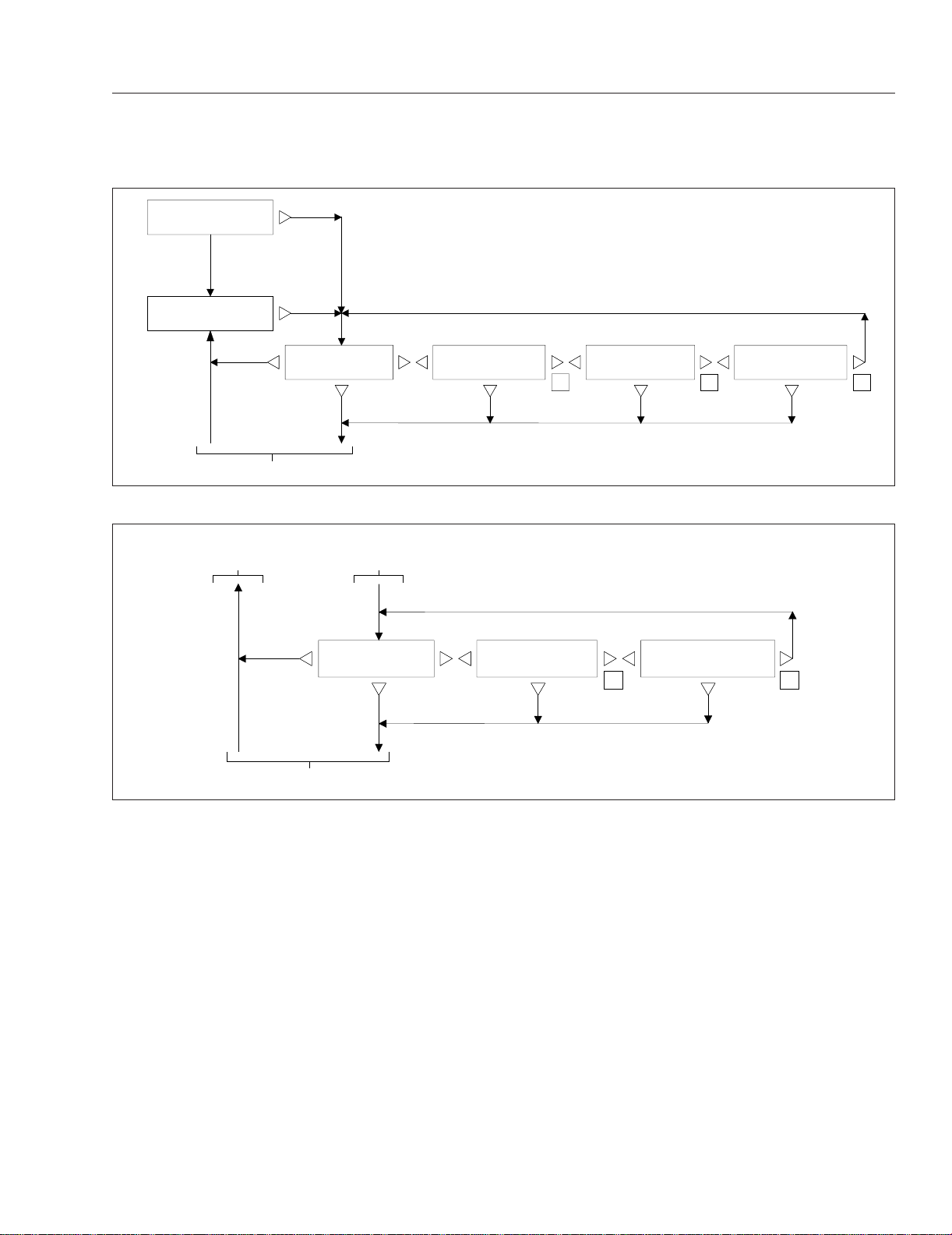

ICU3

A mode/reset button, located on the right side of the

ICU instrument cluster, is used to control the driver

message center. See

button to advance one screen; press and hold the

button to select a menu choice or reset the display.

When the display resets, an audible chirp sounds.

Only four screens are accessible when the parking

brake is off (mobile screens). All screens are accessible when the parking brake is on (stationary

screens).

Mobile Screens

The following screens are available when the parking

brake is off (when the vehicle is mobile) and no active fault codes are found. Tap the mode/reset button

to scroll through the mobile screens.

i.

Odometer

ii.

Trip distance

iii.

Trip hours

iv.

Back to odometer

Stationary Screens

The following screens are available when the parking

brake is on (when the vehicle is stationary) and no

active fault codes are found. Tap the mode/reset button to scroll through the stationary screens. See

Fig. 2.5.

i.

Odometer

ii.

Trip distance

iii.

Trip hours

iv.

Select units

Fig. 2.1. Tap the mode/reset

v.

Diagnostics

vi.

Clear screen (on vehicles with less than 255

miles on the odometer)

vii.

Engine miles

viii.

Engine hours

ix.

Engine oil level

x.

Setup

xi.

Back to odometer

Trip Distance

When the odometer reading is displayed, tap the

mode/reset button once for trip distance. Press and

hold the mode/reset button to reset trip miles to zero.

Trip Hours

When trip distance is displayed, tap the mode/reset

button once for trip hours. Press and hold the mode/

reset button to reset trip hours to zero.

Diagnostic Information

When the DIAG screen is displayed, press and hold

the mode/reset button to access the various diagnostic screens.

Trained technicians use the diagnostic screens to

retrieve fault codes and other diagnostic information

pertaining to the vehicle. If active fault codes display

during start-up or at any other time, make a note of

the fault code and take the vehicle to an authorized

Freightliner service facility as soon as possible.

If fault codes are displayed, press and hold the

mode/reset button to view the next fault code until

reaching the DIAG screen.

If service intervals are enabled and service distance

or time has been exceeded, the text SERVICE

HOUR/MI (KM) will display at start-up to indicate vehicle service is required.

Engine Information

When the DIAG screen is displayed, tap the mode/

reset button once to access the engine miles/hours

screen. When the engine miles/hours screen is displayed, press and hold the mode/reset button to access the engines screen sub-menu.

Setup Information

The setup screen allows the driver to manage ICU

parameters. When the engine hours/miles screen is

displayed, tap the mode/reset button to access the

2.7

Instruments and Controls Identification

123456.7

MI

12.3 VOLTS

Push

123456.7

TRIP MI

12.3 VOLTS

Push

123456.7

TRIP HOURS

12.3 VOLTS

Push

SELECt

MI

Push

dIAG

MI HOURS

n

Push Push

03/26/2004 f040636a

Default Odometer

Dispay Screen

Hold

To Reset Trip Miles

Hold

To Reset Trip Hours

To Toggle between Units

Hold

MI<−−−−>KM

Hold

Dispay Diagnostics

n = Number of Active Fault Codes

MI = CYCLE Miles Enabled

HOURS = Cycle Hours Enabled

EC

EC

*Lo

**MI **HOURS

**no

Push

Push

Push

Push

CLEAr

123456.7

MI

123456.7

EnG oIL

SEtUP

Hold

Clear Defaults

To Dispay Total Engine Miles

EC = Engine Control

To Dispay Total Engine Hours

HOURS

EC = Engine Control

Hold

Dispay Oil Level

*Lo = Oil Level Low

HI = Oil Level High

Blank = Oil Level OK

− − = No Message

Dispay Service Interval

Hold

Cycle Screens

**MI = CYCLE Miles Active Mode

**HOURS = CYCLE Hours Active Mode

**no = Service CYCLE Inactive

Note: The engine oil level screen displays for Mercedes-Benz engines only (if equipped and enabled).

Fig. 2.5, ICU3 Stationary Screens

setup screen. The setup screen submenu allows the

driver to enable and change service intervals.

For each parameter, press and hold the mode/reset

button to navigate to the parameter change screen.

In each change screen, tap the mode/reset button to

toggle between options.

When the setup screen is displayed again, tap the

mode/reset button to view the odometer.

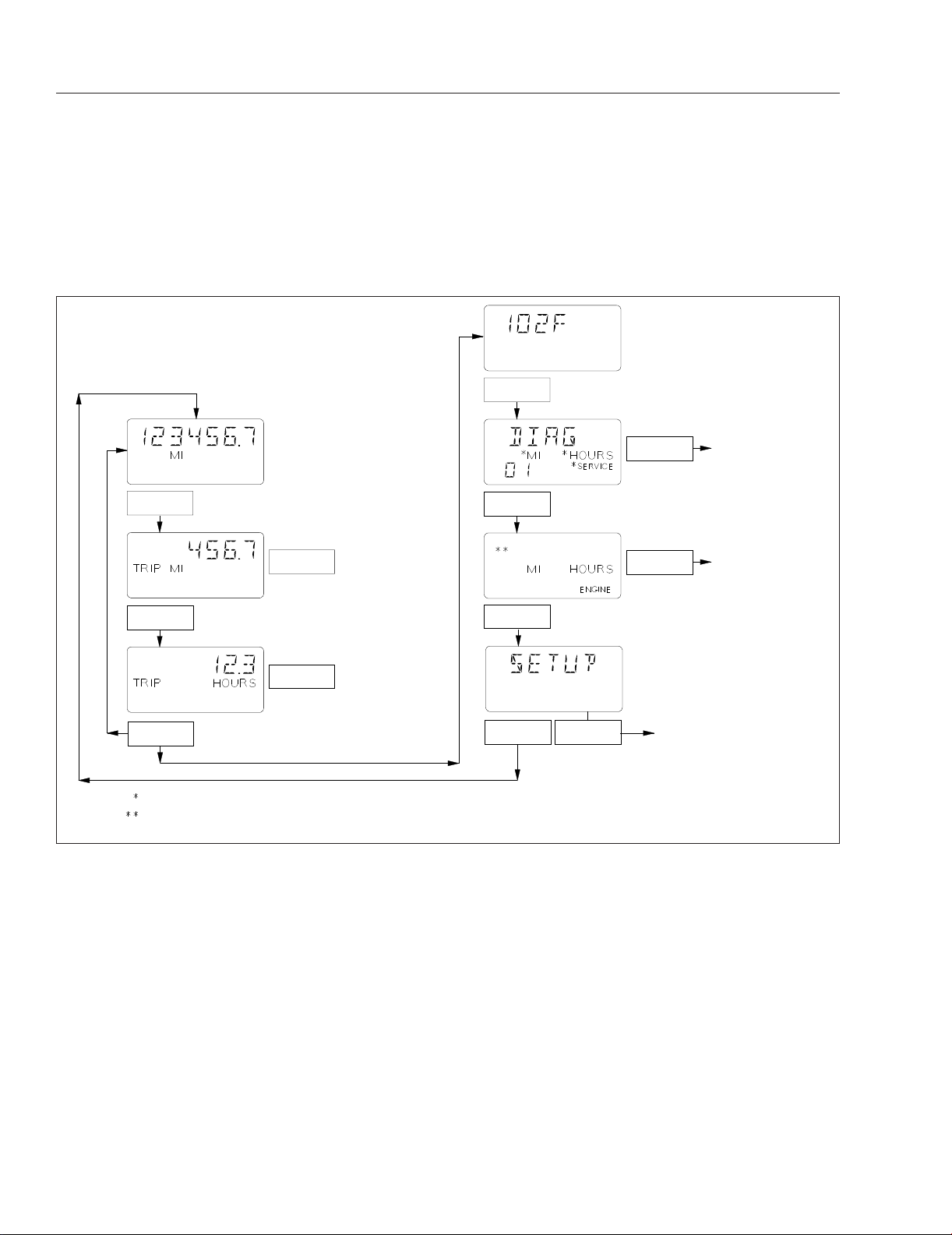

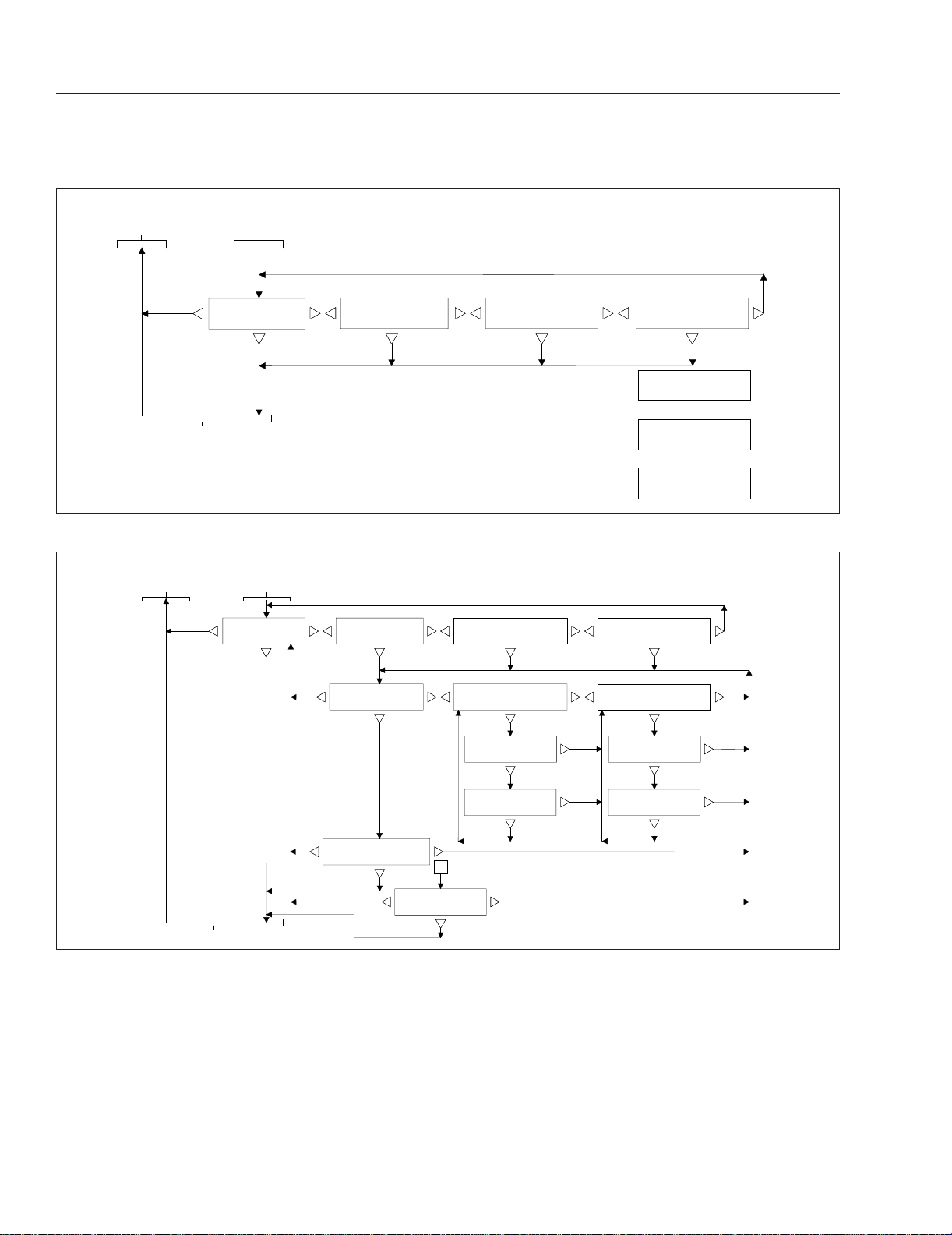

ICU4

Functions

The mode/reset button, located on the right side of

the lightbar, controls the driver message center. See

Fig. 2.2. Press the mode/reset button to advance

one screen; hold the button down to select a menu

choice or reset the display. When the display is

reset, an audible chirp sounds.

Direct Access Screens

When the parking brake is not set, pressing the

mode/reset button will scroll through the direct access screens.

i.

Trip distance

ii.

Trip hours

iii.

Outside temperature

iv.

Back to odometer

Stationary Access Screens

When the parking brake is set, pressing the mode/

reset button will scroll through the stationary access

screens. See

i.

Odometer

ii.

Trip distance

iii.

Trip hours

iv.

Outside temperature

Fig. 2.6.

2.8

Instruments and Controls Identification

v.

Diagnostic screen

vi.

Engine miles/hours/oil level

vii.

Setup screen

viii.

Back to odometer

Ambient Air Temperature

When the ambient air temperature drops below 35°F

(1.7°C), the ICU displays a caution text at 1-second

intervals for five seconds and a chime sounds if the

Push

With park brake off

02/06/2007

Default Odometer

Display Screen

Push

Hold

Push

Hold

Push

With park brake on

If "SERVICE" is displayed Service Cycle screens are enabled and either "MI" or "HOURS" is also displayed.

On some vehicles "OIL LVL" appears in the top row of the display, if equipped and enabled.

To Reset Trip Miles

To Reset Trip Hours

Fig. 2.6, ICU4 Stationary Access Screens

Push

Push

Push

Hold

Go to the Diagnostic

Hold

Hold

For setup screens.

and Engine Display

Screens figure.

Go to the Diagnostic

and Engine Display

Screens figure.

f040756

Trip Information

Trip information allows you to view trip mileage and

time.

When the odometer reading is displayed, press the

mode/reset button once for trip distance. Press the

mode/reset button a second time for trip hours (engine hours).

Press and hold the mode/reset button to reset trip

miles or hours to zero.

2.9

ambient temperature alarm is enabled. The driver

can acknowledge the message by pressing the

mode/reset button. The chime will not sound again

unless the temperature cycles above 37°F (4°C) and

back below 35°F (1.7°C).

When the parking brake is set, the ambient air temperature display can be changed from °F to °C by

changing the MI or KM selection in the SETUP

menus. The warning message can be disabled or

enabled in the SETUP menus.

Instruments and Controls Identification

Diagnostic Screens

The diagnostic screens are used by trained technicians to retrieve fault codes and other diagnostic information pertaining to the vehicle. Active faults are

current problems that require attention. If active fault

codes display during start-up or at any other time,

make a note of the fault code and text message,

then call an authorized Freightliner service facility for

assistance.

During vehicle start-up, with the parking brake set,

the ICU4 will display any active fault codes for three

seconds each until the parking brake is released. If

service cycle screens are enabled and service distance or time has been exceeded, the text SERVICE

HOUR/MI (KM) will be displayed to inform the driver

that the service interval has been exceeded and vehicle service is required. See

of the diagnostic and engine display screens.

To access the diagnostic screens, press and hold the

mode/reset button when the DIAG screen is

displayed.

If the word SERVICE appears on the diagnostic message display screen, service cycle screens are enabled. Either service miles or hours can be enabled,

but not both. Hold the mode/reset button to display

miles or hours remaining until the next scheduled

service. If MI (KM) appears on the DIAG screen, service miles are enabled; if HOURS appears on the

screen, service hours are enabled. If service miles or

hours have been exceeded, the number flashes to

indicate service is overdue.

Fig. 2.7 for a diagram

Engine Screens

The engine screen displays total engine miles or

hours. Press and hold the mode/reset button to display total engine miles. Press and hold it a second

time to display total engine hours.

To access the engine screens, press and hold the

mode/reset button when the engine miles/hours

screen is displayed.

Setup Screens

The setup screens are used to manage ICU4 parameters. See Fig. 2.8.

To access the setup screens, press and hold the

mode/reset button when the SETUP screen is displayed.

For each parameter, press and hold the mode/reset

button to navigate to the parameter change screen.

In each change screen, use the mode/reset button to

toggle between options.

The last screen in the setup menu, RESET EE,isfor

resetting certain parameters to the original settings.

Hold the mode/reset button to reset the antilock braking system (ABS), SAMS roll call, automated transmission display, transmission heartbeat, sensor fault

codes, and engine oil level screens. Press the mode/

reset button to sequence back to the odometer.

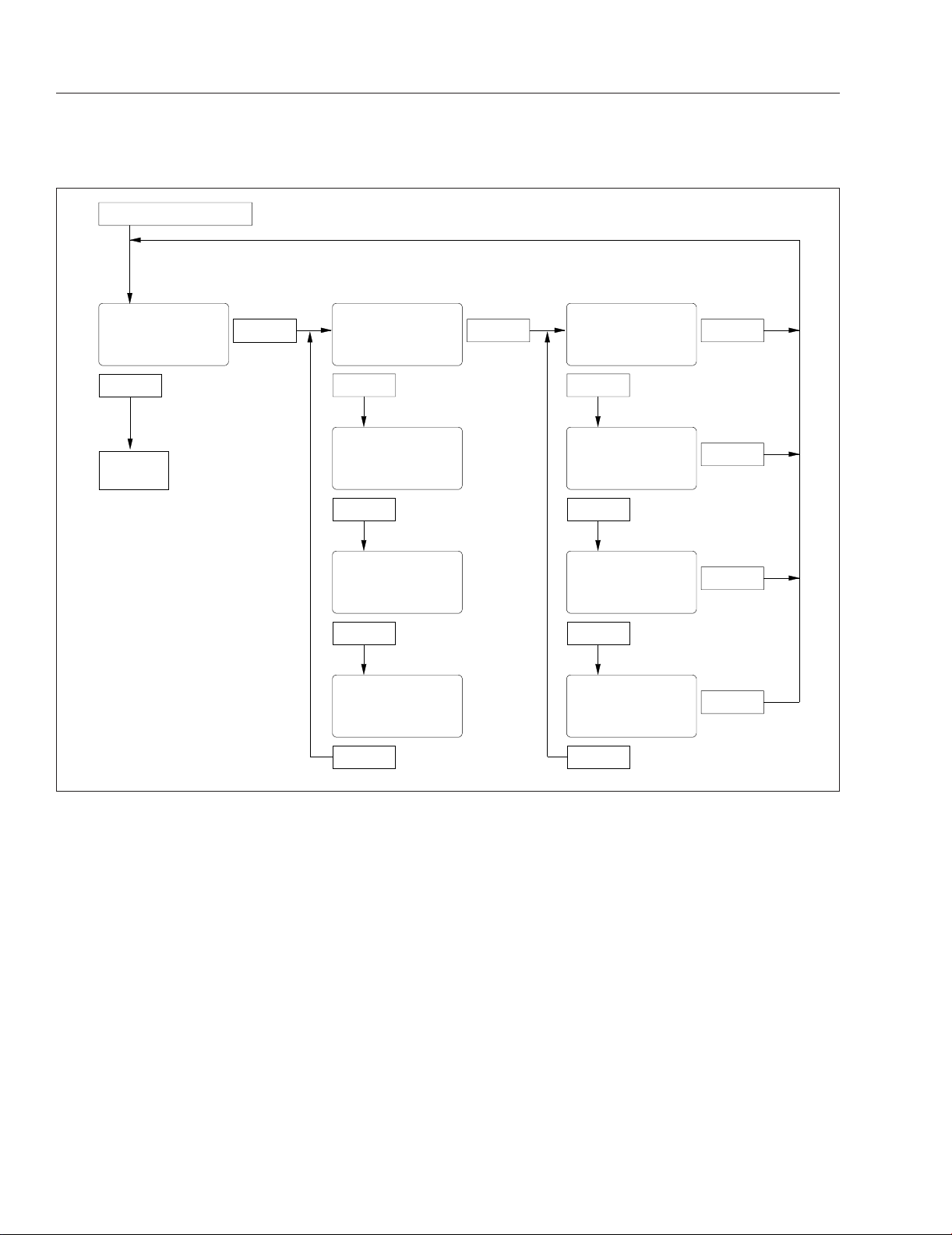

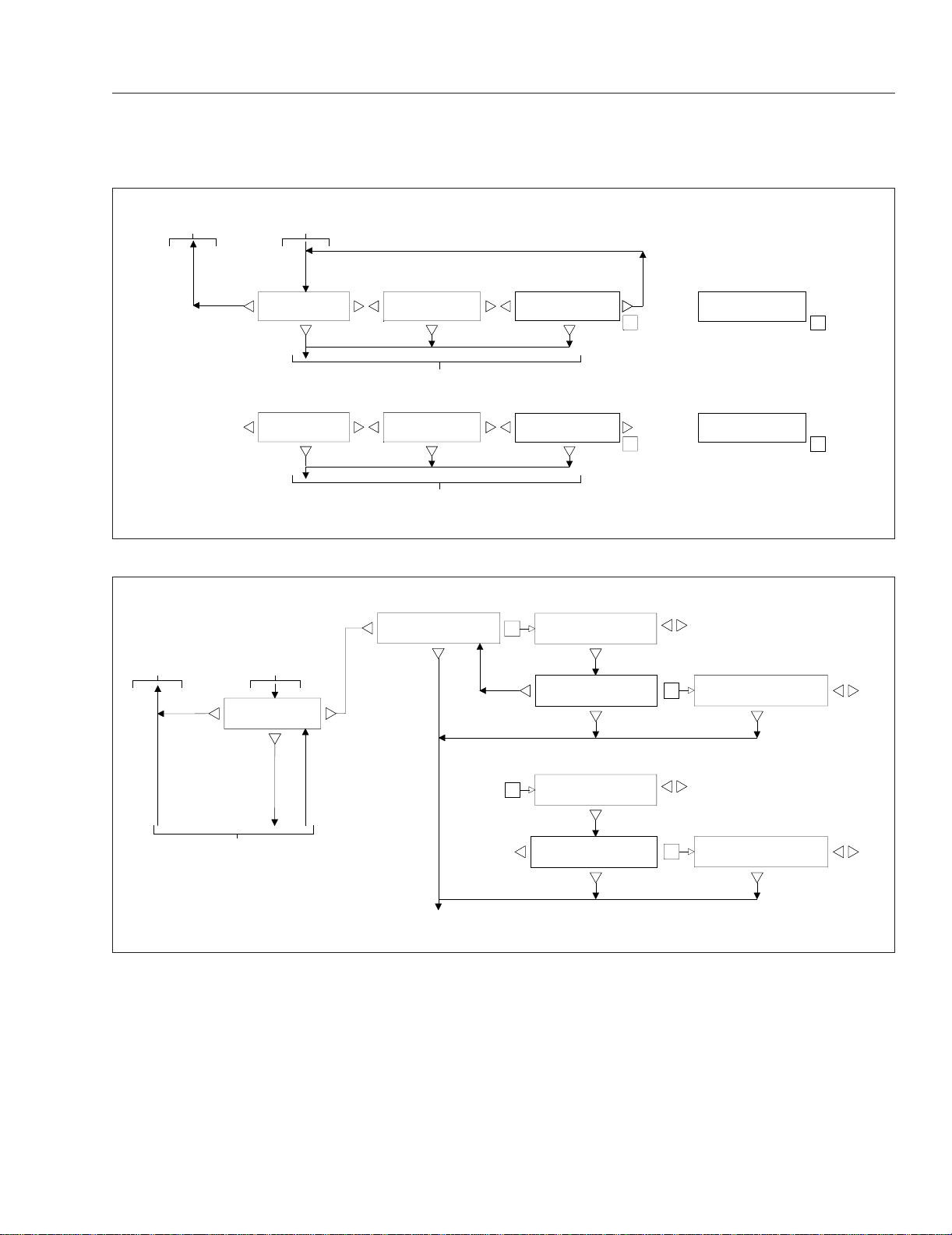

ICU4M

Functions

A keypad located on the auxiliary dash panel controls

the ICU4M. See Fig. 2.9.

Main features of the ICU4M include:

•

Gauges that sweep 270 degrees and have

pointers lit by an LED.

•

Service intervals that are programmable via the

keypad.

•

An audible warning and alert message to warn

the driver if the door is opened without first setting the parking brake.

•

A flashing alert message that appears on the

driver message center in low engine oil pressure or high coolant temperature conditions.

With the parking brake off, only the odometer and

alert screens will display. Park the vehicle and set

the parking brake to access additional screens.

The dash message center displays alert screens

when certain conditions occur. They are warnings,

cautions, or other messages that require the driver’s

attention, but not all of them are critical to the operation of the vehicle. Warning messages always display

at full brightness.

More important messages take priority over less important messages. The order of priority is:

1.

parking brake set (with the vehicle moving)

2.

parking brake off (with the door open)

3.

low oil pressure or high coolant temperature

4.

hard brake warnings (if equipped with roll stability advisor)

5.

low battery voltage

6.

turn signal on

7.

service warnings

2.10

Instruments and Controls Identification

From Temperature Screen

n = Number of

Active Fault Codes

dlAG

n

Tap

To Engine

Miles/Hour

Press & Hold

*If fault goes inactive,

display "noFault 1"

*FAULT

Press & Hold

01

Tap

AbS 11 ECU 0

Tap Tap

123456

SPN SPN

Tap Tap

FAIL 03 FAIL 00

*If fault goes inactive,

display "noFault n"

nn

*FAULT

Press & Hold

Tap

Press & Hold

123456

Press & Hold

Press & Hold

Tap Tap

08/13/2012

Fig. 2.7, ICU4 Diagnostic and Engine Display Screens

8.

no datalink activity

Alert Screens

NOTE: If there is more than one alert message

to display, tap any key to access the next message, and so on, until all the messages have

been viewed.

Parking Brake On

This warning message and an audible warning come

on whenever the parking brake is applied and the

vehicle is moving faster than 2 mph (3 km/h). The

screen and audible warning go away only when the

parking brake is released, or speed is reduced below

2 mph.

2.11

f040802a

Low Oil Pressure

This warning message and an audible warning come

on whenever the oil pressure falls below the minimum oil pressure, whether the vehicle is idling or in

motion. Tap any key to dismiss the message.

If the fault is still active 30 seconds after the message is dismissed, the warning message will come

on again.

High Coolant Temp

This message and an audible warning come on

whenever the engine coolant temperature exceeds

the maximum allowable temperature.

From Engine

Miles/Hours Screen

Instruments and Controls Identification

SET UP SELECT

Press & Hold

*MI

Press & Hold

To toggle

MI

TapTap

WARN°T

Press & Hold

*on

Tap

To toggle

ON

OFF

LCD LMP

*on

Tap

Press & Hold to reset all

Service Interval counters

SET UP

**MI **HOURS

**no

Press & Hold Press & Hold

SERVICE SERVICE SERVICE

RESET

**MI **HOURS

*no

Tap Tap Tap

*12345

MI

SERVICE

MI

Selection?

no

Select NO

to disable

Service Intervals

KM

*no

HRS

To toggle

ON OFF

Press & Hold

SELECT

*MI *HOURS

TapTap

*12345

HOURS

SERVICE

Press & Hold

To toggle

MI

HOURS

no

Press & HoldPress & Hold

RESET

EE

Tap

To Odometer

01/30/2012

Fig. 2.8, ICU4 Setup Screens

If the fault is still active 30 seconds after the message is dismissed, the warning message will come

on again.

Press & Hold

DONE

Tap

NOTE:

* Flash screen text

**Display active mode

f040755

Low Voltage

On some vehicles, this optional message and an audible warning come on whenever the ICU detects a

low voltage condition.

2.12

Instruments and Controls Identification

vi.

Leg distance/hours

vii.

Leg advisory

viii.

Outside air temperature

Dedicated Keys

08/08/96

To reset a value, press the SET/RESET button twice.

Fig. 2.9, ICU4M Keypad

General Keys

Control Keys

f601009

Turn Signal On

This warning message and audible warning come on

whenever the turn signal remains on for four minutes

or five miles of travel.

To dismiss this message, either turn off the turn signal or tap any key.

Service Warnings

Service warning screens display during the ignition

sequence and indicate that a service interval has

been reached or exceeded and maintenance is required. The messages may indicate the number of

miles (KM) or hours until the next required service or,

once passed, the number of miles (KM) or hours ago

that maintenance should have been performed.

Automated Transmission Display

The ICU4M can display current gear information for

vehicles with an automated transmission. The last

three digits at the far right on the lower line of the

driver display screen are reserved for this information.

If there is a request to shift, an up or down arrow is

also displayed, depending on the shift direction.

On vehicles with conventional manual or automatic

transmissions, the gear and shift direction are not

displayed. For more information about specific

models of automated transmissions, see

Chapter 8.

ix.

Fuel used/average MPG (KM/L)

Stationary Screens

NOTE: Metric unit screens are similar. AMT=

Current gear information for automated manual

transmissions.

The following screens are available when the parking

brake is on (when the vehicle is stationary).

i.

Odometer

ii.

Trip information including trip miles/hours, idle

hours, average speed, leg miles/hours

iii.

Fuel information including fuel used, fuel

economy, idle/PTO fuel usage

iv.

Engine information including engine miles/hours,

engine/PTO gallons, oil level

v.

Diagnostic information

vi.

Service information including mileage or time to

next service

vii.

Setup information

viii.

Vehicle information including Datalink status, ICU

serial number, software version

ix.

Fasten seat belt warning

Trip Information

When idle hours are displayed, tap the any key to

access the main trip information screen. See

Fig. 2.10.

Tap the arrow keys on the 10-key keypad to advance

through the screens. Press and hold the SET/RESET

key to reset any of the screens.

Mobile Screens

The following screens are available when the parking

brake is off (when the vehicle is mobile).

i.

Fasten seat belt (rpm<100)

ii.

Fuel economy (rpm>100)

iii.

Odometer

iv.

Trip distance/hours

v.

Trip advisory

2.13

Fuel Information

Fuel information allows you to view total fuel usage

since the last reset, fuel mileage, and fuel consumed

while idling or running the PTO. See

the arrow keys on the 10-key keypad to advance

through the screens. Press and hold the SET/RESET

key to reset any of the screens.

Fig. 2.11.Tap

FASTEN SEATBELTS

123456.7 MILES AMT

Instruments and Controls Identification

Engine Idling

(100 RPM or more)

IDLE HOURS 1234:56

12.3GAL123456.7MI AMT

TRIP

INFORMATION AMT

12/01/2004 f040699

Go to Fuel Information Screens

Press Right Arrow Key and Set the Parking Brake

TRIP MILES 123456.7

TRIP HR 1234:56 AMT

R R R

IDLE HOURS 1234:56

AVG MPH 12.3 AMT

LEG MILES 123456.7

LEG HR 1234:56 AMT

Fig. 2.10, ICU4M Trip Information Screens

Return to

Idle Hours

Screen

From Trip

Information

FUEL

INFORMATION AMT

FUEL USED 12345.6

AVG MPG 12.34 AMT

IDLE GALLONS

PTO GAL 12345.6 AMT

R R

12.3

12/17/2004

Go to Engine Information Screens

Fig. 2.11, ICU4M Fuel Information Screens

Engine Information

The engine information screens allow you to view

engine mileage and hours, and total fuel consumption. See

Fig. 2.12. Tap the arrow keys on the 10-

key keypad to advance through the screens. Press

and hold the SET/RESET key to reset any of the

screens.

Diagnostic Information

If active fault codes are displayed on the diagnostic

information screens–See

the fault code and text message, then take the vehicle to an authorized Freightliner service facility as

soon as possible.

Fig. 2.13, make a note of

f040700

Service Information

Service information allows you to view the next recurring service interval, expressed in either miles or

hours. See

deactivated, so they do not display at all.

For programming service intervals, see Setup Infor-

mation, below.

NOTE: If the vehicle has gone past the service

interval, the miles (km)/hours remaining

screen is replaced by the service was due

screen, followed by the number of miles(km)/

hours since the service was due.

Fig. 2.14. Service intervals can also be

2.14

Instruments and Controls Identification

Return to

Idle Hours

Screen

Go to Diagnostic Information Screens

12/01/2004

Return to

Idle Hours

Screen

From Fuel

Information

ENGINE

INFORMATION AMT

From Engine

Information

DIAGNOSTIC

INFORMATION AMT

ENG MILES 123456.7

ENG HOUR1234:78AMT

ENG GALLONS 123456.7

PTO GAL 12345.6 AMT

If Oil Level Low

If Oil Level OK

If Oil Level High

Fig. 2.12, ICU4M Engine Information Screens

ACTIVE FAULTS

12 or NONE AMT

MID(text) PID/SID(text)

FMI(text) MID#sPID#FMI#AMT

Fault # 1 Fault # n

ENG OIL LEVEL

LO −1 QTS AMT

ENG OIL LEVEL

LO −1 QTS AMT

ENG OIL LEVEL

OK AMT

ENG OIL LEVEL

HI 1 QTS AMT

MID(text) PID/SID(text)

FMI(text) MID#sPID#FMI#AMT

f040701

12 HIST DASH FAULTS

LAST CLR 123456.7AMT

2

PUSH RESET TO

CLEAR DASH FAULTS AMT

CLEARED AMT

12/17/2004

Go to Service Information Screens

Fig. 2.13, ICU4M Diagnostic Information Screens

Setup Information

See Fig. 2.15 and Fig. 2.16 for diagrams of the

setup information screens.

Setup information allows you to program various features of the ICU4M environment, including:

A.

Service intervals (OFF/MILES/HOURS);

MID(text) PID/SID(text)

FMI(text) MID#sPID#FMI#AMT

LAST OCCUR 123456.7

1234 TIMES AMT

FIRST OCCUR 123456.7

1234 TIMES AMT

R

ALL FAULTS

B.

C.

D.

E.

F.

Hist Fault # 1

MID(text) PID/SID(text)

FMI(text) MID#sPID#FMI#AMT

LAST OCCUR 123456.7

1234 TIMES AMT

FIRST OCCUR 123456.7

1234 TIMES AMT

Hist Fault # n

Target MPG;

LCD Lamp (ON/OFF);

Driver message center brightness;

Language (English/French/Spanish);

Units of measurement (English/Metric);

f040702

2.15

Instruments and Controls Identification

12/17/2004

Return to

Idle Hours

Screen

From Diagnostic

Information

SERVICE

INFORMATION AMT

SERVICE

INFORMATION AMT

Distance prior to reaching the

Distance traveled beyond the

set Service Interval

INTERVAL IS SET TO

XXXXX MILES AMT

Go to Set−up Information Screens

12345 MILES

TO NEXT SERVICE AMT

Time prior to reaching the

OR

R

Time accumulated beyond the

set Service Interval

INTERVAL IS SET TO

XXXX HOURS AMT

Go to Setup Information Screens

1234 HOURS

TO NEXT SERVICE AMT

OR

R

set Service Interval

SERVICE WAS DUE

12345 MILES AGO AMT

set Service Interval

SERVICE WAS DUE

1234 HOURS AGO AMT

R

R

NOTE: Service information screens only appear if the service interval is set to MILES or HOURS in Setup Information.

Fig. 2.14, ICU4M Service Information Screens

Return to

Idle Hours

Screen

From Service

Information

SETUP

INFORMATION AMT

PUSH SET KEY TO

CHANGE SERVICE AMT

SERVICE INTERVAL

S

OFF/

MILES

PUSH SET KEY TO

CHANGE SERVICE MI

/HOURS AMT

AMT

If Service Interval is set to MILES

INTERVAL

S

<−−LESS MORE−−> AMT

XXXXX MILES

f040703

Go to Vehicle Information Screens

To more Setup Information

12/17/2004

Fig. 2.15, ICU4M Setup Information Screens (for service intervals)

G.

Driver select (ON/OFF)

H.

Reset parameters to original settings.

Vehicle Information Screens

The vehicle information screens display hardware

and software information, including the Freightliner

part number and switch ID of the ICU. See

Fig. 2.17.

SERVICE INTERVAL

S

OFF/

MILES / HOURS

PUSH SET KEY TO

CHANGE SERVICE HR

OR

AMT

If Service Interval is set to HOURS

AMT

INTERVAL

S

<−−LESS MORE−−> AMT

XXXX

HOURS

f040704

2.16

Instruments and Controls Identification

12/17/2004

Return to

Idle Hours

Screen

Go to Setup Information Screens

PUSH SET KEY TO

CHANGE TARGET MPG AMT

PUSH SET KEY TO

CHANGE LCD LAMP AMT

PUSH SET KEY TO

CHANGE BRIGHTNESS AMT

PUSH SET KEY TO

CHANGE LANGUAGE AMT

PUSH SET KEY TO

CHANGE UNITS AMT

PUSH SET KEY TO

CHANGE PARAMETERS AMT

Go to Vehicle Information Screens

TARGET MPG:

S

<−−LESS MORE−−>AMT

LCD LAMP

S

<−−OFF

ON

DISPLAY BRIGHTNESS

S

<−−DARK LIGHT−−>AMT

LANGUAGE:

S

FRENCH/SPANISH AMT

UNITS

S

S

/ METRIC AMT

ENGLISH

RESET PARAMETERS

<−−

NO−−> AMT

YES

Fig. 2.16, Other Setup Information

From Setup

Information

12.3

−−> AMT

ENGLISH

f040705

alphabetical order to make the information easier to

find.

Air Intake Restriction Gauge

The air intake restriction gauge indicates the vacuum

on the engine side of the air cleaner. See

On standard installations, it is mounted on the air

cleaner. As an option for easier viewing, an air intake

restriction indicator can be mounted on the auxiliary

dash panel.

NOTE: Rain or snow can wet the filter element

and cause a temporary high reading.

Air intake restriction vacuum is measured in inches

of water (inH2O). For vehicles equipped with a

graduated indicator or a restriction gauge on the

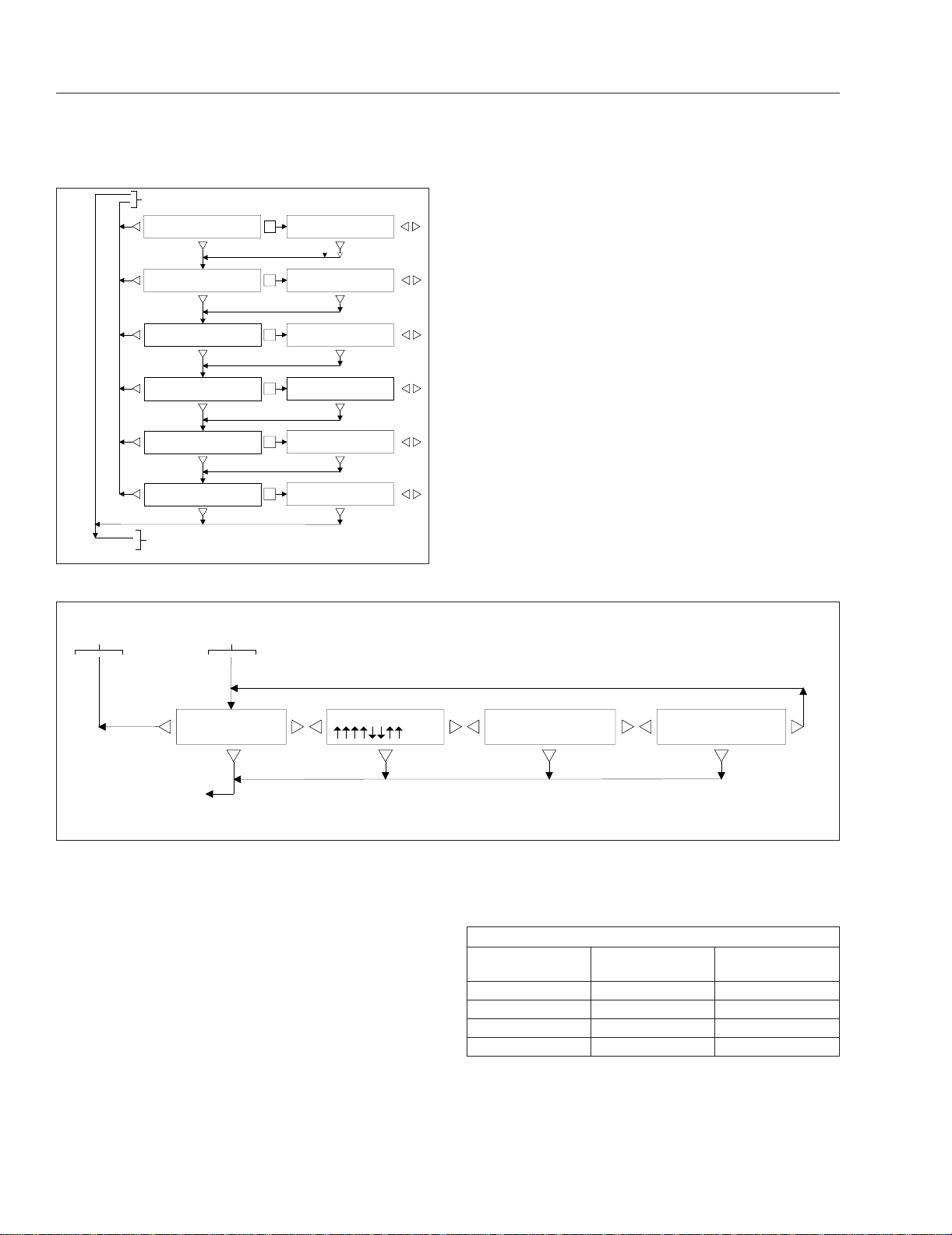

dash, check the gauge with the engine off. If the yellow signal stays locked in the red zone once the engine is shut down, or is at or above the values

shown in

replacement.

Vehicles may be equipped with a go/no-go restriction

Table 2.2, the air cleaner element requires

Fig. 2.18.

VEHICLE

INFORMATION AMT

Return to Trip Information Screens

01/11/2005

DATALINK ACTIVE

AMT

Fig. 2.17, ICU4M Vehicle Information Screens

Instruments

Standard instruments are present on every vehicle.

Optional instruments, typically located on the auxiliary dash panel or right-hand control panel, are not

found on every vehicle. Instruments are listed here in

2.17

DATA LINK STATUS

USAGE 12% ERR1%AMT

indicator without graduations (see

DASH# XXX−XXXXX−XXX

SW# P1.2.3 AMT

Fig. 2.19) instead

of a graduated indicator.

Air Intake Maximum Restriction Values: (inH2O)

Engine Make

Pre-EPA07

Engines

Caterpillar 25 —

Cummins 25 25

™

Detroit

20 22

Mercedes-Benz 22 22

Table 2.2, Air Intake Maximum Restriction Values

EPA07 Engines

f040706

10/10/2001

Fig. 2.18, Air Intake Restriction Indicator

Instruments and Controls Identification

ter air pressure until the foot brake pedal is depressed or the trailer hand brake is applied.

Coolant Temperature Gauge

NOTICE

A sudden increase in coolant temperature may

indicate engine or cooling system failure. Bring

the vehicle to a safe stop and investigate the

cause to prevent further damage. Do not operate

the engine until the cause has been determined

and corrected.

During normal engine operation, the coolant temperature gauge should read between 175 and 195°F

(79 and 91°C). If the temperature remains below

160°F (71°C), inspect the cooling system to deter-

f610568

mine the cause.

If the temperature exceeds the maximum temperature shown in

to determine the cause. See the Century Class

Trucks Workshop Manual for troubleshooting and

repair procedures.

Table 2.3, inspect the cooling system

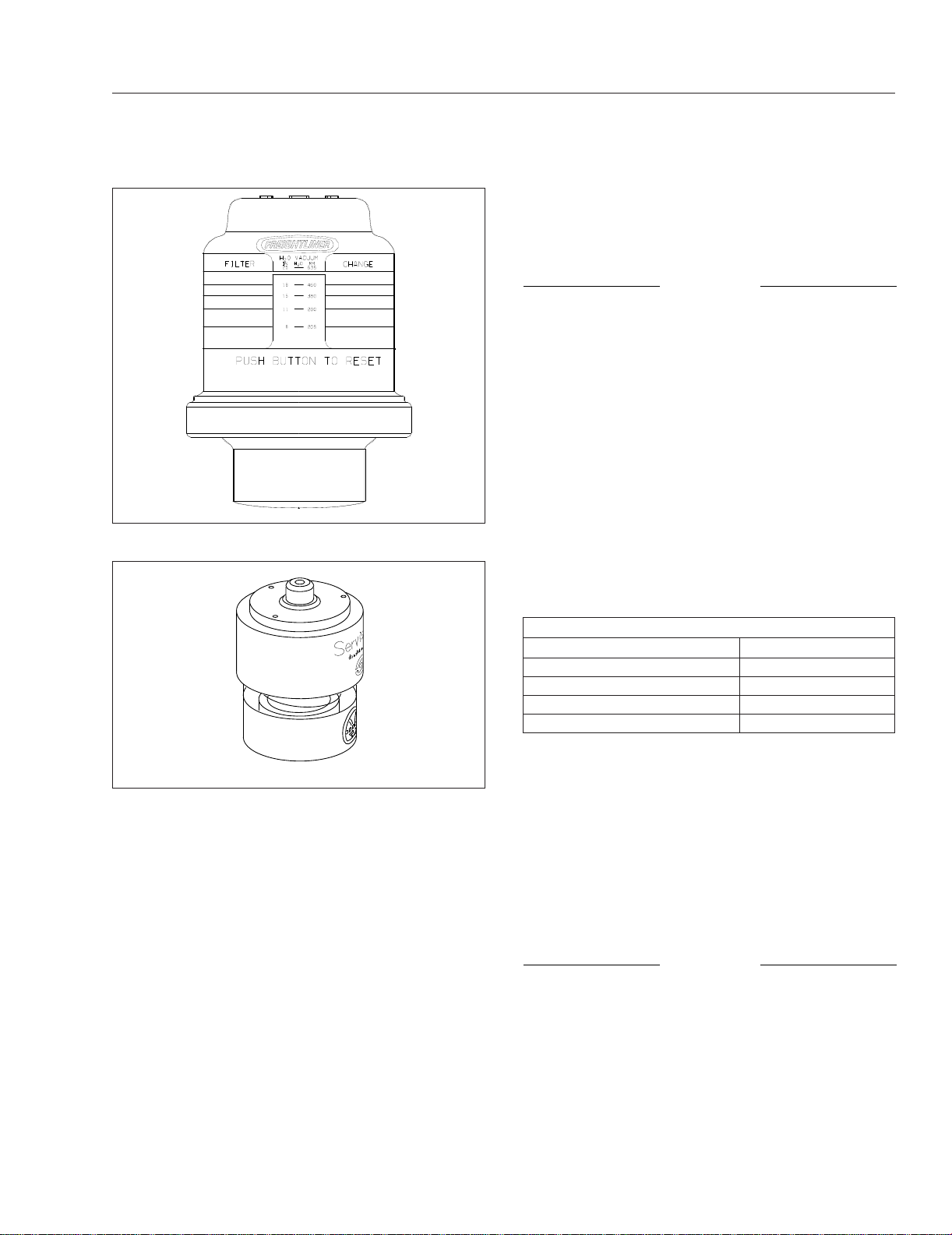

04/08/2005 f090431

Fig. 2.19, Manual-Reset Air Restriction Indicator, Go/

No-Go

If air restriction exceeds the maximum allowable

value, operate the vehicle for one more day, making

sure not to run the engine over rated rpm. Refer to

the engine operation manual for more information on

rated rpm for your engine.

If air restriction exceeds the maximum value again,

replace the air cleaner element. For instructions,

refer to Group 09 of the Century Class Trucks Work-

shop Manual.

Application Air Pressure Gauge

An application air pressure gauge registers the air

pressure being used to apply the brakes, and should

be used for reference only. The gauge will not regis-

Maximum Coolant Temperature

Engine Make Temperature: °F (°C)

Caterpillar 215 (101)

Cummins 225 (107)

Detroit 215 (101)

Mercedes-Benz 221 (105)

Table 2.3, Maximum Coolant Temperature

If coolant temperature rises above the maximum

temperature listed in

the CHECK engine lamp will illuminate. If the condition does not improve, the STOP engine lamp will

also illuminate and an audible warning will sound.

The engine will then derate or shut down, depending

on the type of engine protection system installed.

Table 2.3 on EPA07 engines,

Drive Axle Oil Temperature Gauges

NOTICE

A sudden increase in oil temperature that is not

caused by a load increase may indicate mechanical failure. Bring the vehicle to a safe stop and

investigate the cause to prevent further damage.

Do not operate the vehicle until the cause has

been determined and corrected.

2.18

Instruments and Controls Identification

During normal operation, drive axle oil temperature

gauges should read as follows:

•

160 to 220°F (71 to 104°C) for Detroit™and

Meritor

•

180 to 200°F (82 to 93°C) for Dana Spicer®

drive axles

Under heavy loads, such as when climbing steep

grades, temperatures that exceed the normal oil temperature range for a short period are not unusual. If

the temperature returns to normal when the load decreases, there is no problem.

™

drive axles

Engine Oil Pressure Gauge

NOTICE

A sudden decrease or absence of oil pressure

may indicate mechanical failure. Bring the vehicle

to a safe stop and investigate the cause to prevent further damage. Do not operate the engine

until the cause has been determined and corrected.

The engine oil pressure gauge displays the current

engine oil pressure. If engine oil pressure falls below

the minimum levels shown in

engine lamp will illuminate. If the condition does not

improve, the STOP engine lamp will also illuminate

and an audible warning will sound. The engine will

then derate or shut down, depending on the type of

engine protection system installed.

Minimum Oil Pressure

Engine Model

Caterpillar 10–20 (69–138) 30–45 (207–310)

Cummins 15 (103) 35 (241)

Detroit 14 (97) 55 (350)

Mercedes-Benz 7 (50) 36 (250)

*

Pressures apply with the engine at operating temperature. Oil pressure

may be higher on a cold engine. Observe and record pressures when the

engine is new to create a guide for checking engine condition.

Table 2.4, Minimum Engine Oil Pressure

At Idle Speed:

psi (kPa)

Table 2.4, the CHECK

*

At Rated RPM:

psi (kPa)

Engine Oil Temperature Gauge

NOTICE

A sudden increase in oil temperature that is not

caused by a load increase may indicate mechanical failure. Bring the vehicle to a safe stop and

investigate the cause to prevent further damage.

Do not operate the engine until the cause has

been determined and corrected.

During normal operation, the optional engine oil temperature gauge should read:

•

190 to 220°F (88 to 104°C) for Caterpillar engines;

•

200 to 260°F (93 to 126°C) for Detroit and

Cummins engines

•

177 to 203°F (81 to 95°C) for Mercedes-Benz

engines

Under heavy loads, such as when climbing steep

grades, temperatures that exceed the normal oil temperature range for a short period are not unusual. If

the temperature returns to normal when the load decreases, there is no problem.

Fuel Gauge

The fuel gauge indicates the level of fuel in the fuel

tank(s). A single fuel gauge is standard. If equipped

with an optional second fuel tank, each fuel tank

level is indicated on a separate gauge.

Primary and Secondary Air Pressure

Gauges

WARNING

If air pressure falls below minimum pressure, the

braking ability of the vehicle will be limited. Slow

the vehicle down and bring it to a gradual stop.

Do not attempt to move the vehicle until air pressure has risen above the minimum level. Moving

a vehicle without adequate braking power could

cause an accident resulting in property damage,

personal injury, or death.

Air pressure gauges register the pressure in the primary and secondary air systems. Normal pressure,

with the engine running, is 100 to 120 psi (689 to

827 kPa) in both systems.

A low-air-pressure warning light and audible alert,

connected to both the primary and secondary systems, activate when air pressure in either system

drops below 64 to 76 psi (441 to 524 kPa).

When the engine is started, the warning light and

audible warning remain on until air pressure in both

systems exceeds minimum pressure.

2.19

Instruments and Controls Identification

Pyrometer

A pyrometer registers the exhaust temperature near

the turbocharger. Variations in engine load can cause

exhaust temperatures to vary. If the pyrometer reading shows that exhaust temperature exceeds normal,

reduce fuel to the engine until the exhaust temperature is reduced. Shift to a lower gear if the engine is

overloaded.

Speedometer

The speedometer registers speed in both miles per

hour (mph) and kilometers per hour (km/h).

Tachometer

The tachometer indicates engine speed in revolutions

per minute (rpm) and serves as a guide for shifting

the transmission and keeping the engine in the appropriate rpm range. For low idle and rated rpm, see

the engine identification plate.

Transmission Fluid Temperature

Gauge

The transmission fluid temperature gauge indicates

the transmission lubricant operating temperature.

Temperatures vary by application, but the transmission fluid temperature gauge reading should not exceed 250°F (121°C).

Under heavy loads, such as when climbing steep

grades, temperatures that exceed the normal oil temperature range for a short period are not unusual. If

the temperature returns to normal when the load decreases, there is no problem.

NOTICE

A sudden increase in transmission fluid temperature that is not caused by a load increase may

indicate mechanical failure. Bring the vehicle to a

safe stop and investigate the cause to prevent

further damage. Do not operate the vehicle until

the cause has been determined and corrected.

Voltmeter

The voltmeter indicates the vehicle charging system

voltage when the engine is running and the battery

voltage when the engine is off. By monitoring the

voltmeter, the driver can stay aware of potential battery charging problems and have them fixed before

the batteries discharge enough to create starting difficulties. Vehicles are equipped with either a voltmeter

gauge, or a digital voltmeter readout located on the

bottom line of the dash message center.

The voltmeter will normally show approximately 13.7

to 14.1 volts when the engine is running. The voltage

of a fully charged battery is 12.7 to 12.8 volts when

the engine is off. Battery voltage under 12.0 volts is

considered a low battery, and a completely discharged battery will produce only about 11.0 volts.

If the voltmeter shows an undercharged or overcharged condition for an extended period, have the

charging system and batteries checked at an authorized Freightliner service facility.

On a vehicle equipped with a battery isolator system,

the voltmeter measures the average voltage of all the

batteries when the engine is running. When the engine is off, the voltmeter shows only the isolated battery voltage and does not indicate the voltage of the

engine-starting batteries.

Controls

Controls and switches are listed here in alphabetical

order.

Axle Switches

Differential Lock Switch

The differential lock switch provides maximum traction for slippery conditions by forcing the wheels on

each drive axle governed by the switch to rotate together. Engagement can be at any speed, provided

the wheels are not slipping or spinning. See

Fig. 2.20.

Interaxle Lock Switch

Turbocharger Boost Pressure Gauge

A turbocharger boost pressure gauge indicates the

pressure in the intake manifold, in excess of atmospheric pressure, being created by the turbocharger.

The interaxle lock, standard on all dual-drive vehicles, is driver-actuated by means of a LOCK/

UNLOCK control valve switch. See

indicator illuminates when the interaxle lock is engaged.

Fig. 2.20. A red

2.20

Instruments and Controls Identification

Parking Brake Control Valve

NOTICE

1

2

3

4

01/05/2012 f611158

1. Interaxle Differential Lock Switch

2. Fifth Wheel Slide Switch

3. Rearmost Axle Differential Lock Switch

4. Air Suspension Dump Control Switch

Fig. 2.20, Axle and Suspension Switches

Do not step on the service brake pedal while the

parking brakes are applied. To do so can cause

damage to the brake mechanisms.

The yellow diamond-shaped knob operates the parking brake valve. See

apply the tractor and the trailer spring parking

brakes. Push the knob in to release the spring parking brakes. Before the spring parking brakes can be

released, the air pressure in either air brake system

must be at least 65 psi (447 kPa).

If the trailer is not equipped with spring parking

brakes, pull the parking brake valve out to apply the

tractor parking brakes and the trailer service brakes.

03/10/99

1. Trailer Air Supply Valve (red knob)

2. Parking Brake Control Valve (yellow knob)

Fig. 2.21, Brake Valve Control Knobs

Fig. 2.21. Pull the knob out to

1

f610291

2

Trailer Air Supply Valve

NOTICE

The interaxle lock should only be engaged when

the vehicle is moving slowly at low throttle. Engagement at high speed or power can damage

the axle(s).

Do not permit rear wheels to spin freely for more

than ten seconds when traction is lost. Shift into

LOCK to prevent damage to interaxle and main

differentials.

Brake Controls

NOTE: See Chapter 6 for detailed information

about brake systems.

2.21

The red octagonal-shaped knob operates the trailer

air supply valve, which charges the trailer air supply

system and releases the trailer spring parking

brakes. See

After the vehicle and its air hoses are connected to a

trailer and the pressure in the air system is at least

65 psi (447 kPa), push the trailer air supply valve

knob in (and leave it in) to charge the trailer air supply system and release the trailer spring parking

brakes. Pull the trailer air supply valve out before

disconnecting a trailer or when operating a vehicle

without a trailer.

Fig. 2.21.

Trailer Brake Lever

The trailer brake lever is used to apply the trailer service brakes without applying the truck or tractor service brakes. It is usually mounted on the right-hand

Loading...

Loading...