Page 1

Foreword

Introduction

This manual provides information needed to operate

and understand the vehicle and its components.

More detailed information is contained in the

Warranty Information for North America

in the vehicle’s workshop and maintenance manuals.

Custom-built Freightliner vehicles are equipped with

various chassis and cab components. Not all of the

information contained in this manual applies to every

vehicle. For details about components in your vehicle, refer to the chassis specification pages included in all new vehicles and to the vehicle specification decal, located inside the vehicle.

For your reference, keep this manual in the vehicle

at all times.

IMPORTANT: Descriptions and specifications in this

manual were in effect at the time of printing. Freightliner Trucks reserves the right to discontinue models

and to change specifications or design at any time

without notice and without incurring obligation. Descriptions and specifications contained in this publication provide no warranty, expressed or implied,

and are subject to revisions and editions without notice.

Owner’s

booklet, and

Environmental Concerns and

Recommendations

Whenever you see instructions in this manual to discard materials, you should first attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and regulations

when disposing of materials.

Event Data Recorder

This vehicle is equipped with one or more devices

that record specific vehicle data. The type and

amount of data recorded varies depending on how

the vehicle is equipped (such as the brand of engine,

if an air bag is installed, or if the vehicle features a

collision avoidance system, etc.).

dination, or Fleetpack assistance. Our people are

knowledgeable, professional, and committed to following through to help you keep your truck moving.

Reporting Safety Defects

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Daimler Trucks North America

LLC.

If the NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems

between you, your dealer, or Daimler Trucks North

America LLC.

To contact NHTSA, you may call the Vehicle

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to www.safercar.gov;or

write to: Administrator, NHTSA, 1200 New Jersey

Avenue, SE, Washington, DC 20590. You can also

obtain other information about motor vehicle safety

from www.safercar.gov.

Canadian customers who wish to report a safetyrelated defect to Transport Canada, Defect Investigations and Recalls, may telephone the toll-free

hotline 1-800-333-0510, or contact Transport

Canada by mail at: Transport Canada, ASFAD,

Place de Ville Tower C, 330 Sparks Street,

Ottawa, Ontario, Canada K1A 0N5.

For additional road safety information, please visit

the Road Safety website at: www.tc.gc.ca/

roadsafety.

Customer Assistance Center

Having trouble finding service? Call the Customer

Assistance Center at 1-800-385-4357 or 1-800-FTLHELP. Call night or day, weekdays or weekends, for

dealer referral, vehicle information, breakdown coor-

STI-405-2 (10/11)

A24-01034-000

Printed in U.S.A.

Page 2

Foreword

© 2001–2011 Daimler Trucks North America LLC. All rights reserved. Daimler Trucks North America LLC is a Daimler

company.

No part of this publication, in whole or part, may be translated, reproduced, stored in a retrieval system, or transmitted

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Daimler Trucks North America LLC. For additional information, please contact Daimler Trucks North

America LLC, Service Systems and Documentation, P.O. Box 3849, Portland OR 97208–3849 U.S.A. or refer to

www.Daimler-TrucksNorthAmerica.com and www.FreightlinerTrucks.com.

Page 3

Contents

Chapter Page

Introduction, Environmental Concerns and Recommendations,

Event Data Recorder, Customer Assistance Center, Reporting

Safety Defects ..................................................... Foreword

1 Vehicle Identification ...................................................... 1.1

2 Instruments and Controls Identification ....................................... 2.1

3 Vehicle Access .......................................................... 3.1

4 Heater and Air Conditioner ................................................. 4.1

5 Seats and Seat Belts ..................................................... 5.1

6 Steering and Brake Systems ............................................... 6.1

7 Engines and Clutches .................................................... 7.1

8 Transmissions ........................................................... 8.1

9 Rear Axles ............................................................. 9.1

10 Fifth Wheels and Trailer Couplings ......................................... 10.1

11 Pretrip and Post-Trip Inspections and Maintenance ............................ 11.1

12 Cab Appearance ........................................................ 12.1

13 In an Emergency ....................................................... 13.1

14 Headlight Aiming ........................................................ 14.1

Index .................................................................. I.1

Page 4

1

Vehicle Identification

Vehicle Specification Decal ......................................................... 1.1

Federal Motor Vehicle Safety Standard (FMVSS) Labels .................................. 1.1

Canadian Motor Vehicle Safety Standard (CMVSS) Labels ................................ 1.2

Tire and Rim Labels ............................................................... 1.2

EPA Emission Control ............................................................. 1.2

Page 5

Vehicle Identification

Vehicle Specification Decal

The vehicle specification decal lists the vehicle

model, identification number, and major component

models. It also recaps the major assemblies and installations shown on the chassis specification sheet.

One copy of the specification decal is attached to the

inside of the sliding storage/waste drawer; another

copy is inside the rear cover of the

Information for North America

of the decal is shown in Fig. 1.1.

COMPONENT INFORMATION

MANUFACTURED BY

MODEL

VEHICLE ID NO.

DATE OF MFR

ENGINE MODEL

TRANS MODEL MAIN

FRONT AXLE MODEL

REAR AXLE MODEL

IMRON PAINT−CAB

CAB COLOR A: WHITE (4775)

PAINT MFR

CAB COLOR B: BROWN (3295)

PAINT NO.

CAB COLOR C: BROWN (29607)

CAB COLOR D: DARK BROWN (7444)

11/21/96

Fig. 1.1, Vehicle Specification Decal (U.S.-built vehicle

shown)

Owner’s Warranty

booklet. An illustration

USE VEHICLE ID NO.

WHEN ORDERING PARTS

WHEELBASE

ENGINE NO.

TRANS NO.

FRT AXLE NO.

REAR AXLE NO.

REAR AXLE NO.

RATIO

FOR COMPLETE PAINT INFORMATION

SEE VEHICLE SPECIFICATION SHEET

PART NO. 24−00273−010

f080021

2

1

11/21/96

3

f080053

1. Date of Manufacture: by month and year

2. Gross Vehicle Weight Rating: developed by taking

the sum of all the vehicle’s gross axle ratings

3. Gross Axle Weight Ratings: developed by

considering each component in an axle system including suspension, axle, wheels, and tires - and

using the lowest component capacity as the value

for the system

Fig. 1.2, Certification Label, U.S.

1

NOTE: Labels shown in this chapter are examples only. Actual specifications may vary from

vehicle to vehicle.

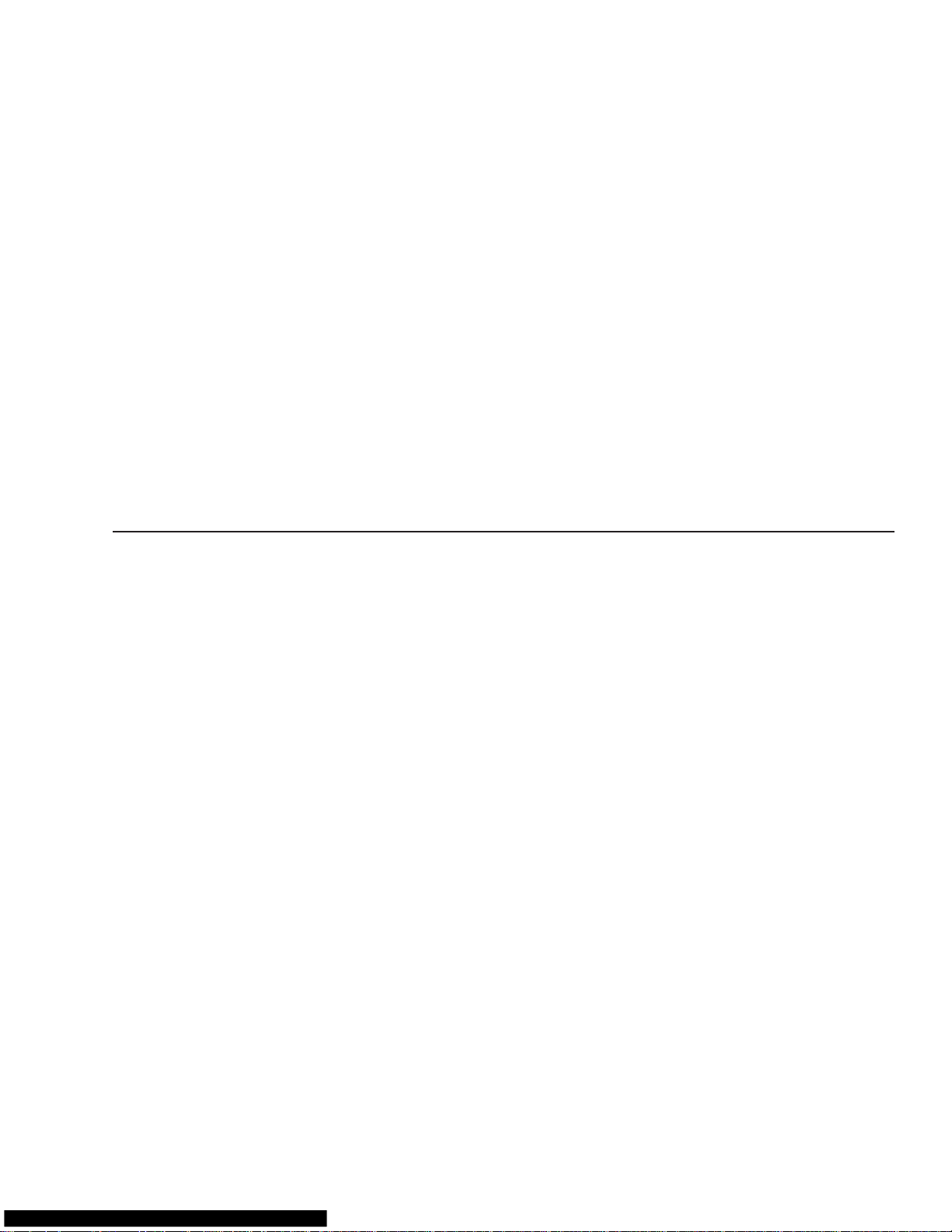

Federal Motor Vehicle Safety

Standard (FMVSS) Labels

NOTE: Due to the variety of FMVSS certification

requirements, not all of the labels shown will

apply to your vehicle.

Tractors with or without fifth wheels purchased in the

U.S. are certified by means of a certification label

(Fig. 1.2) and the tire and rim labels. These labels

are attached to the left rear door post, as shown in

Fig. 1.3.

If purchased for service in the U.S., trucks built without a cargo body have a certification label (Fig. 1.4)

attached to the left rear door post. See Fig. 1.3.In

addition, after completion of the vehicle, a certification label similar to that shown in Fig. 1.2 must be

attached by the final-stage manufacturer. This label

will be located on the left rear door post and certifies

2

11/01/95

f601086

1. Tire and Rim Labels 2. Certification Label

Fig. 1.3, Labels Location

09/28/98

f080023

Fig. 1.4, Incomplete Vehicle Certification Label, U.S.

that the vehicle conforms to all applicable FMVSS

regulations in effect on the date of completion.

1.1

Page 6

Vehicle Identification

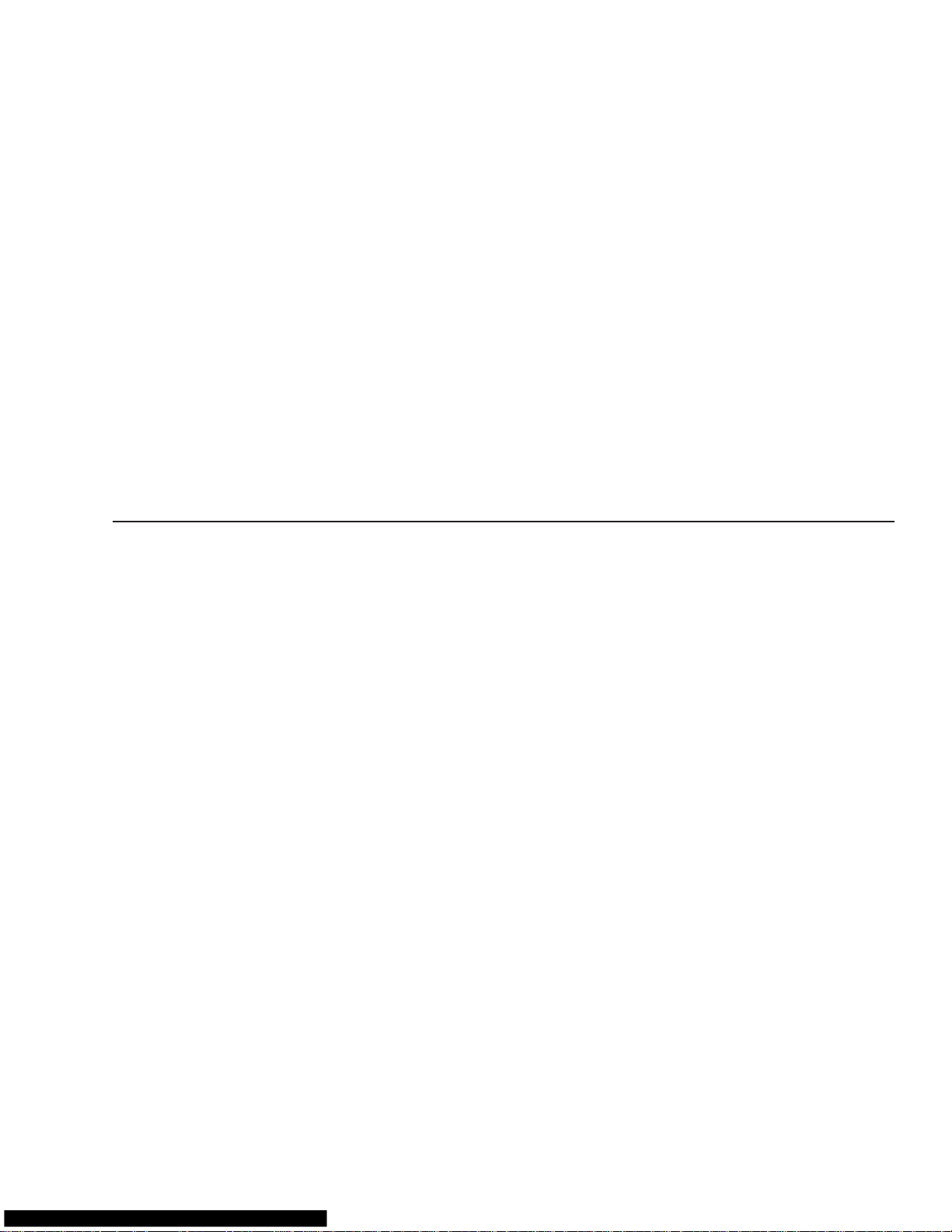

Canadian Motor Vehicle Safety

Standard (CMVSS) Labels

In Canada, tractors with fifth wheels are certified by

means of a "Statement of Compliance" label and the

Canadian National Safety Mark (Fig. 1.5), which are

attached to the left rear door post. In addition, tire

and rim labels (Fig. 1.6) are also attached to the left

rear door post.

f08002410/10/2006

Fig. 1.5, Canadian National Safety Mark

2

1

VEHICLE ID NO.

DATE OF MFR

GVWR

TIRES AND RIMS LISTED ARE NOT NECESSARILY THOSE INSTALLED ON THE VEHICLE.

10/31/95

FRONT AXLE

FIRST INTERMEDIATE AXLE

SECOND INTERMEDIATE AXLE

THIRD INTERMEDIATE AXLE

REAR AXLE

1. Date of Manufacture: by month and year

2. Gross Vehicle Weight Rating: developed by taking

the sum of all the vehicle’s gross axle ratings

3. Gross Axle Weight Ratings: developed by

considering each component in an axle system —

including suspension, axle, wheels, and tires — and

using the lowest component capacity as the value

for the system

Fig. 1.6, Tire and Rim Label

If purchased for service in Canada, trucks built without a cargo body and tractors built without a fifth

wheel are certified by a "Statement of Compliance"

label, similar to Fig. 1.2. This label must be attached

by the final-stage manufacturer after completion of

the vehicle. The label is located on the left rear door

post, and certifies that the vehicle conforms to all

applicable CMVSS regulations in effect on the date

of completion.

3

GAWR TIRES RIMS PSI COLD

24−00273−040

f080054

Tire and Rim Labels

Tire and rim labels certify suitable tire and rim combinations that can be installed on the vehicle, for the

given gross axle weight rating. Tires and rims installed on the vehicle at the time of manufacture may

have a higher load capacity than that certified by the

tire and rim label. If the tires and rims currently on

the vehicle have a lower load capacity than that

shown on the tire and rim label, then the tires and

rims determine the load limitations on each of the

axles.

See Fig. 1.6 for U.S. and Canadian tire and rim labels.

EPA Emission Control

Vehicle Noise Emission Control Label

A vehicle noise emission control label (Fig. 1.7)is

attached either to the left side of the dashboard or to

the top-right surface of the frontwall between the

dash and the windshield.

FREIGHTLINER CORPORATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY

THE NOISE CONTROL ACT OF 1972:

A. THE REMOVAL OR RENDERING INOPERATIVE, OTHER THAN FOR PURPOSES OF

MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR

ELEMENT OF DESIGN (LISTED IN THE OWNER’S MANUAL) INCORPORATED INTO THIS

VEHICLE IN COMPLIANCE WITH THE NOISE CONTROL ACT.

B. THE USE THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF DESIGN HAS

BEEN REMOVED OR RENDERED INOPERATIVE.

10/06/98

VEHICLE NOISE EMISSION CONTROL INFORMATION

DATE OF MANUFACTURE

Fig. 1.7, Vehicle Noise Emission Control Label

IMPORTANT: Certain Freightliner incomplete

vehicles may be produced with incomplete noise

control hardware. Such vehicles will not have a

vehicle noise emission control information label.

For such vehicles, it is the final-stage manufacturer’s responsibility to complete the vehicle in

conformity to U.S. EPA regulations (40 CFR Part

205) and label it for compliance.

EPA07 Exhaust Emissions

To meet January 2007 emissions regulations, vehicles with engines manufactured after January 1,

2007, are equipped with an emission aftertreatment

device. There is a warning label on the driver’s sunvisor, explaining important new warning indicators in

the driver’s message display, that pertain to the aftertreatment system. See Fig. 1.8.

01/96

24−00273−020

f080026

1.2

Page 7

Vehicle Identification

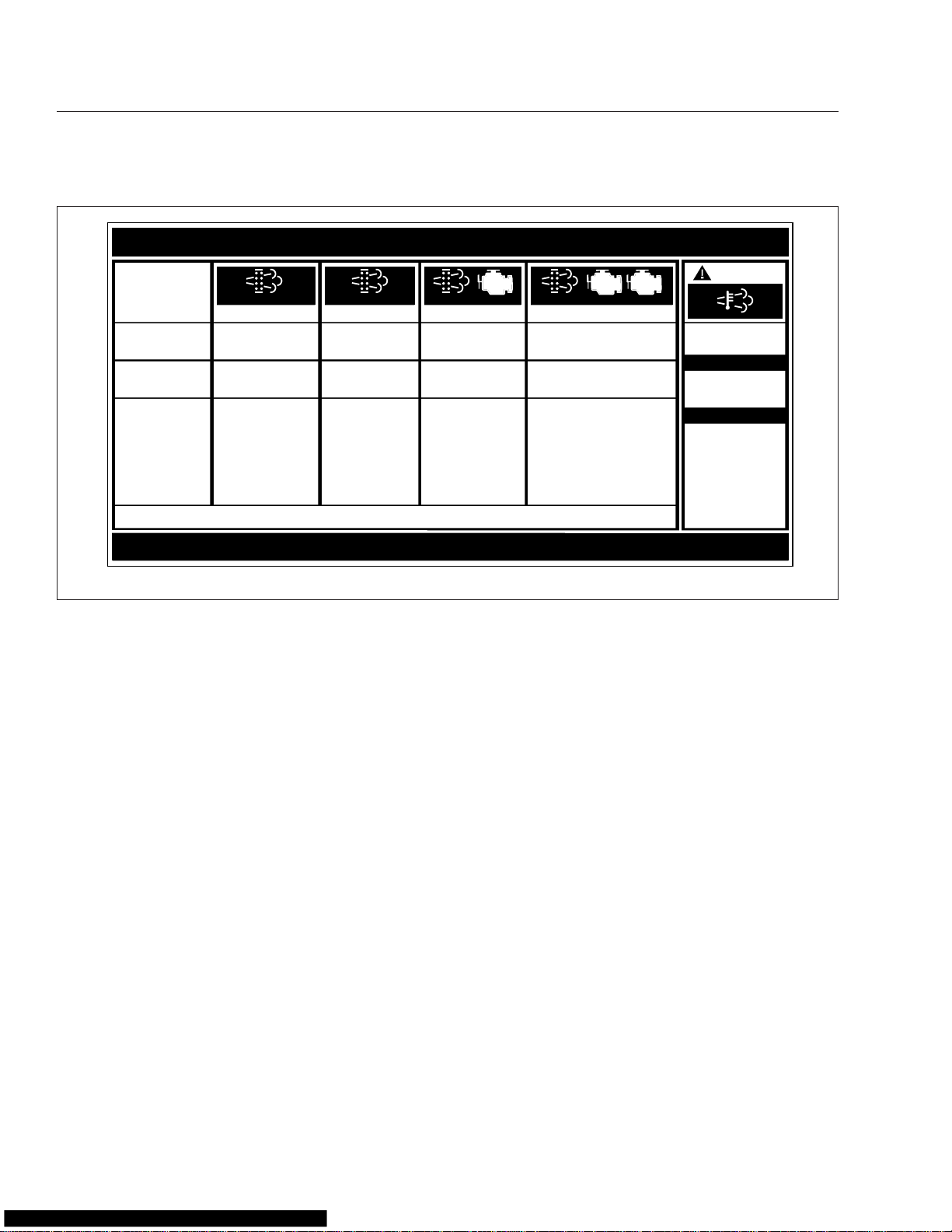

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

INDICATOR

LAMP(S)

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

(Solid)

Level 1 Level 3Level 2 Level 4

Filter Regeneration

Recommended

Filter is reaching

capacity

. .

Bring vehicle to

highway speeds to

allow for an Automatic

Regeneration or

perform a Parked

Regeneration.

(Flashing) (Flashing)

Filter Regeneration

Necessary

Filter is now

reaching maximum

capacity

Switch.

.

To avoid engine

derate bring vehicle

to highway speeds

to allow for an

Automatic

Regeneration or

perform a Parked

Regeneration as

soon as possible.

CHECK CHECK

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

Vehicle must be

parked and a Parked

Regeneration must

be performed −

engine will begin

derate.

(Flashing)

Parked Regeneration Required −

Engine Shut Down

Filter has exceeded

maximum capacity

.

Vehicle must be parked and a

Parked Regeneration or Service

Regeneration must be performed.

Check engine operator’s manual

for details −engine will shut down.

STOP

W

ARNING

HEST (High Exhaust

System Temperature)

Flashing

A regeneration is in

progress.

Solid

Exhaust Components

and exhaust gas are

at high temperature.

When stationary, keep

away from people and

flammable materials

or vapors.

See Engine Operator’s Manual for complete Regeneration Instructions.

06/29/2009

Fig. 1.8, Sunvisor Warning Label

It is a violation of federal law to alter exhaust plumbing or aftertreatment in any way that would bring the

engine out of compliance with certification requirements. (Ref: 42 U.S.C. S7522(a) (3).) It is the owner’s responsibility to maintain the vehicle so that it

conforms to EPA regulations.

24−01583−000B

f080147

1.3

Page 8

2

Instruments and Controls

Identification

Instrument and Control Panel ....................................................... 2.1

Instrumentation Control Unit 4 (ICU4 and ICU4-2) ....................................... 2.3

Instrumentation Control Unit 3 (ICU3 and ICU3 ’07) ...................................... 2.7

Instrumentation Control Unit 2L (ICU2L) .............................................. 2.11

Instruments ..................................................................... 2.12

Controls ........................................................................ 2.17

Collision Warning System (CWS), Eaton VORAD EVT–300, Optional ...................... 2.33

™

Lane Guidance

Roll Stability Control .............................................................. 2.39

System, Optional .................................................. 2.38

Page 9

Instruments and Controls Identification

Instrument and Control Panel

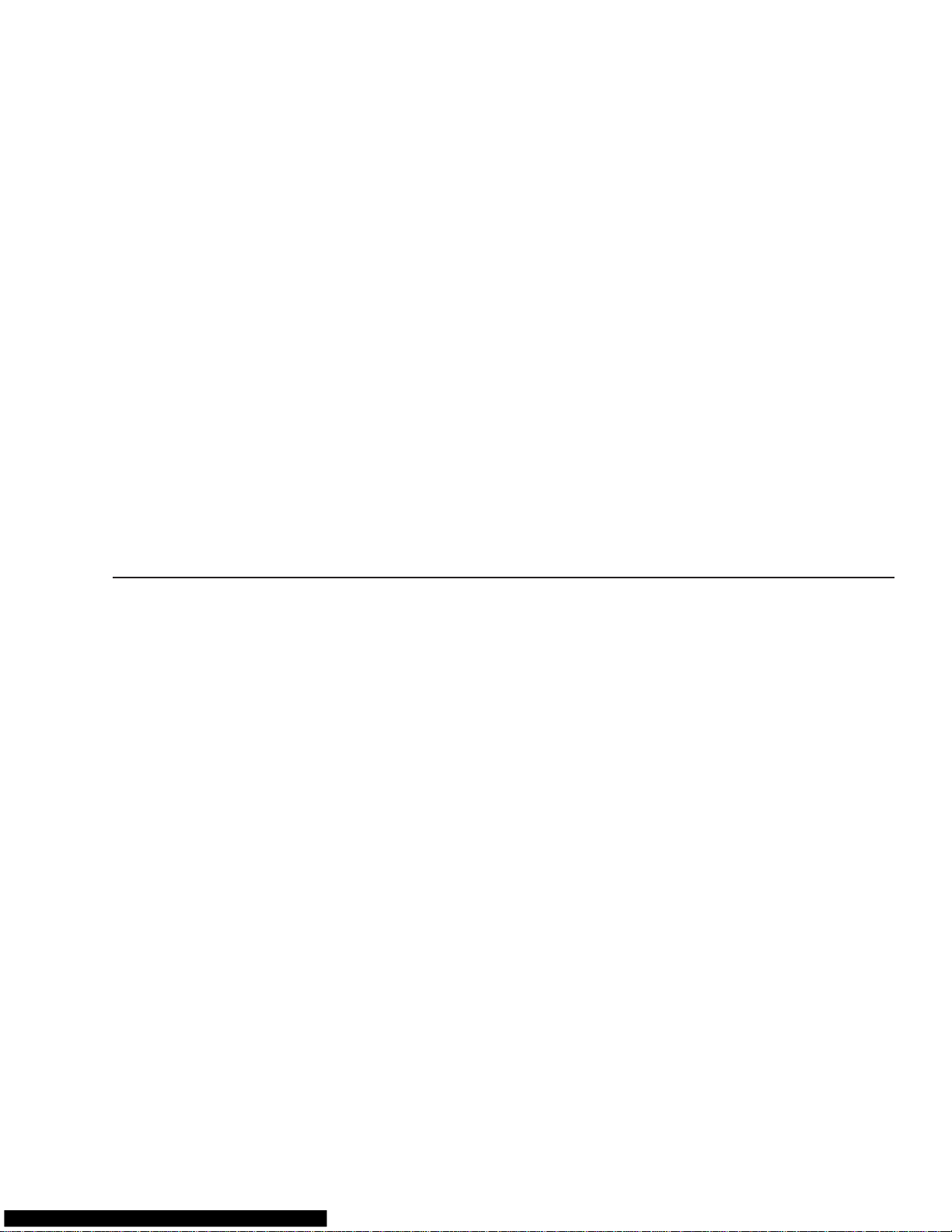

Engine Protection—Warning and

Shutdown Process

WARNING

When the red STOP engine or engine protection

light illuminates, most engines are programmed

to shut down automatically within 30 seconds.

The driver must immediately move the vehicle to

a safe location at the side of the road to prevent

causing a hazardous situation that could cause

bodily injury, property damage, or severe damage

to the engine.

The driver should be familiar with the vehicle warning

system, in order to bring the vehicle to a safe stop if

the engine malfunctions. If the driver doesn’t understand how the warning system works, an engine

shutdown could occur, causing a safety hazard.

If the engine coolant temperature, the coolant level,

the engine oil pressure, or the diesel particulate filter

for the exhaust aftertreatment system, (on some engines, the engine oil temperature, or the intake air

temperature also,) reach preset levels, the engine

will begin a warning and shutdown process. See the

engine manufacturer’s engine operation manual for

your vehicle, for specific details. See the "EPA07 Aftertreatment System" information in Chapter 7 in this

manual, for a description of the warning and shutdown modes associated with the exhaust aftertreatment system.

There are four customer-programmable levels for

electronic engine protection: OFF, WARNING, DERATE, and SHUTDOWN (factory default).

In the engine monitoring OFF mode, the individual

sensor indicator lights will illuminate if a problem exists, but no shutdown action will be started, and the

event will not be recorded.

The WARNING mode warns the driver, and the engine electronics will log the event for diagnostic purposes. The amber Check Engine lamp will flash, and

the buzzer will sound. The amber Check Engine

lamp will go out if the problem stops. See Fig. 2.1

CHECK

03/20/2008 f611000

1. Stop Engine Override Switch

2. Amber Check Engine Warning Lamp

3. Red Stop Engine Lamp

The DERATE and SHUTDOWN modes will reduce

the power to the engine, then shutdown the engine,

to avoid engine damage. The red Stop Engine light,

(ENG PROT or SHUT DOWN for older vehicles), will

illuminate when the problem is serious enough to

reduce the power or speed. The engine power will

ramp down, then shut down, if the problem continues.

The driver has about 30 seconds, after the red Stop

Engine light illuminates, to move the vehicle safely

off the road. If the vehicle cannot be moved to a safe

location within that time, the engine can be restarted

by turning the ignition switch to the OFF position for

at least 5 seconds, then back ON, or by pushing the

stop-engine-overide button if the vehicle is equipped

with one. This action can be repeated until the vehicle is safely off the road. Do not operate the vehicle until the problem has been corrected.

123

Fig. 2.1, Engine Lamps

STOP

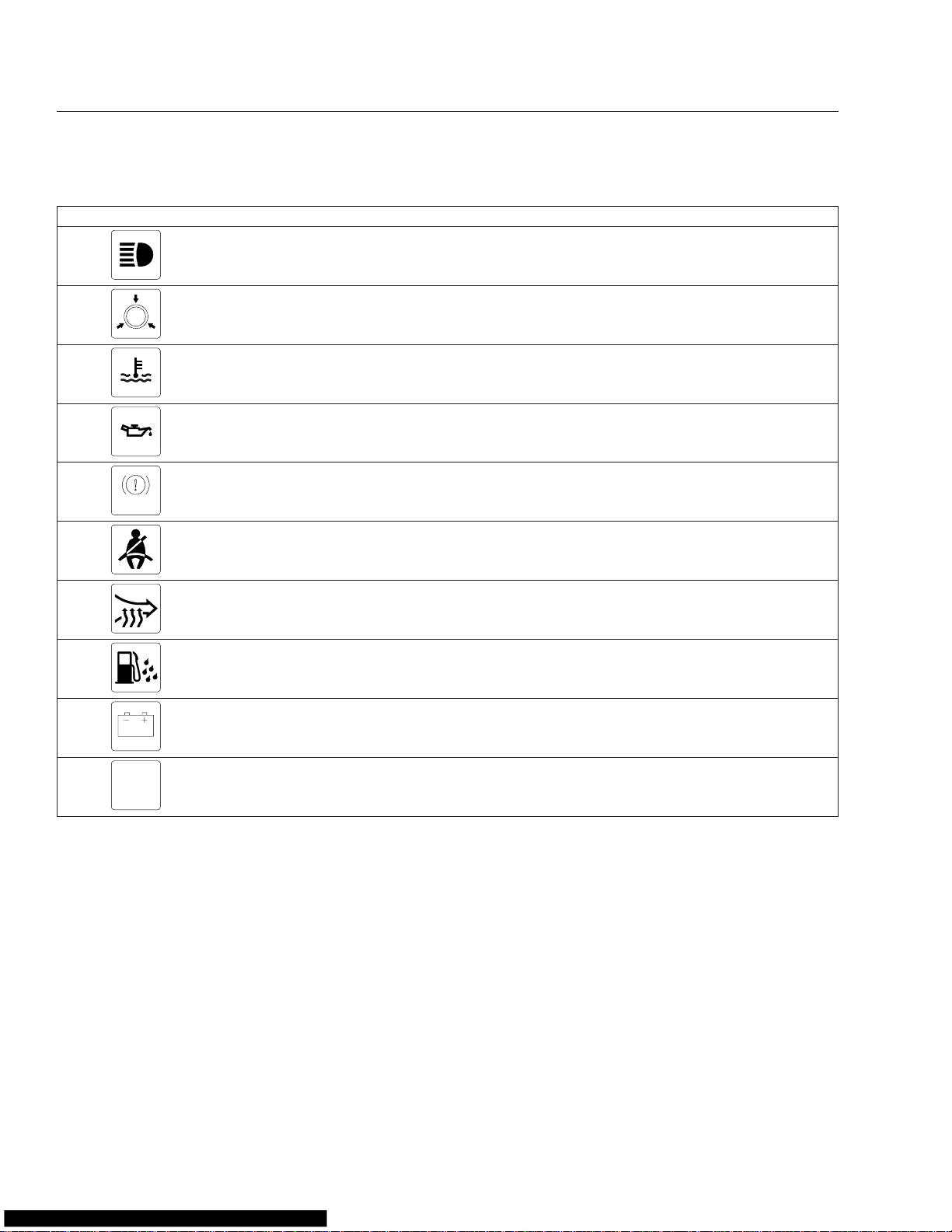

Warning and Indicator Lights

The dash lightbars have warning and indicator lights

that may be lettering or icons. Up until December 31,

2006, the warning and indicator lights are a mixture

of ISO icons, and lettering. Since January 2007, ISO

icons are used for all standard warning and indicator

lights on the dash lightbar. See the following table for

a full description of the icons used.

2.1

Page 10

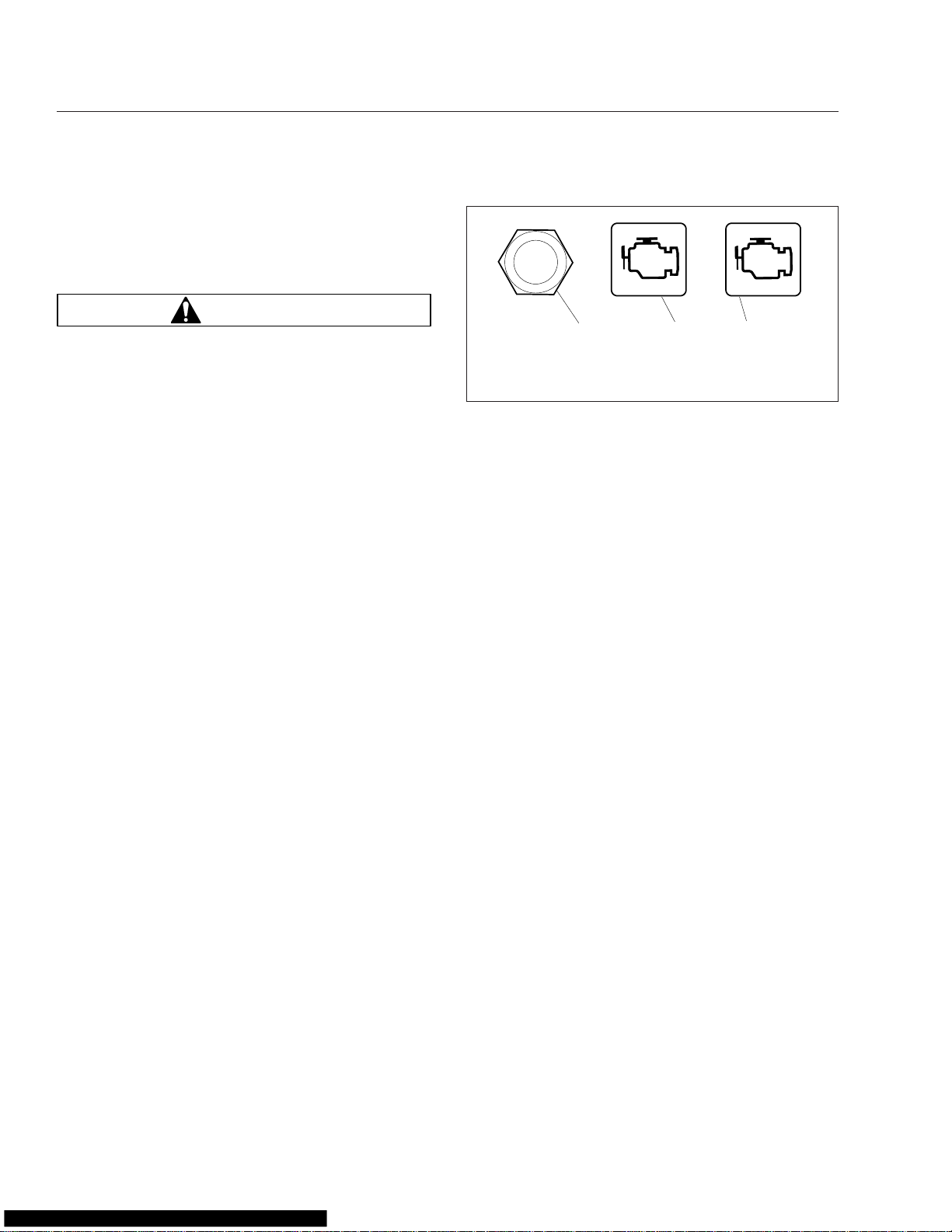

CHECK

STOP

Instruments and Controls Identification

Warning and Indicator Lights

Check Engine Lamp (amber)

Stop Engine or Engine Protect

Lamp (red)

High Exhaust System Temperature

(HEST) Lamp (amber)

Diesel Particulate Filter (DPF)

Status Lamp (amber)

Malfunction Indicator Lamp (MIL)

(amber)

Indicates an undesirable engine condition is detected or

recorded. If the condition gets worse, the stop engine or

engine protection light will illuminate.

Indicates a serious fault that requires the engine shut down

immediately. The engine ECU will reduce the maximum

engine torque and speed, and, if the condition does not

improve, will shut down the engine within 30 seconds of the

light illuminating. The driver must safely bring the vehicle to

a stop on the side of the road and shut down the engine as

soon as the red light is seen. If the engine shuts down while

the vehicle is in a hazardous location, the engine can be

restarted after turning the key to the OFF position for a few

seconds.

Slow (10-second) flash, indicates a regeneration is in

progress, and the driver is not controlling the engine idle

speed.

Steadily illuminated indicates a regeneration is in progress,

with high exhaust temperatures at the outlet of the tail pipe,

if the speed is below 5 mph (8 km/h). It does not signify the

need for service; it only alerts the vehicle operator of high

exhaust temperatures. See the engine operation manual for

details.

Steadily illuminated indicates a regeneration is required.

Change to a more challenging duty cycle, such as highway

driving, to raise exhaust temperatures for at least 20

minutes, or perform a parked regeneration. See the engine

operation manual for details.

Blinking indicates that a parked regeneration is required

immediately.An engine derate and shutdown will occur. See

the instructions in the manufacturer’s

manual

Indicates an engine emissions-related fault, including, but not

limited to the aftertreatment system. See the engine

operation manual for details.

for instructions to perform a stationary regeneration.

engine operation

Tractor ABS Lamp (amber)

Trailer ABS Lamp (amber) Indicates a fault is detected with the trailer ABS.

Left-Turn Signal (green)

Right-Turn Signal (green)

Indicates a problem with the ABS is detected. Repair the

tractor ABS immediately to ensure full antilock braking

capability.

Flashes on and off whenever the outside turn signal lights

are flashing.

Flashes on and off whenever the outside turn signal lights

are flashing.

2.2

Page 11

Instruments and Controls Identification

Warning and Indicator Lights

High-Beam Indicator (blue) Indicates the headlights are on high beam.

BRAKE

Low Air Pressure Warning Lamp

(red)

High Coolant Temperature Warning

Lamp (red)

Low Engine Oil Pressure Warning

Lamp (red)

Parking/Emergency Brake Lamp

(BRAKE!) (red)

Fasten Seat Belt Warning Lamp

(red)

Intake Heater Warning Lamp

(amber)

Water in Fuel Warning Lamp

(amber)

Low Battery Voltage Warning Lamp

(red)

Activates with a buzzer when air pressure in the primary or

secondary air reservoir falls below 64 to 76 psi (440 to 525

kPa).

Activates with a buzzer when the coolant temperature goes

above a maximum level specified by the engine

manufacturer (see the engine manual).

Activates with a buzzer when engine oil pressure goes below

a minimum level specified by the engine manufacturer (see

the engine manual).

Indicates the parking brake is engaged, or hydraulic brake

fluid pressure is low. A buzzer activates when the vehicle is

moving over 2 mph (3 km/h) with the parking brake set.

Illuminates for 15 seconds when the ignition key is turned to

the ON position.

Indicates the intake air heater is active.

Indicates that the fuel could contain water.

Indicates battery voltage is 11.9 volts or less.

NO

CHARGE

No Charge Warning Lamp (amber) Indicates an alternator charge output failure.

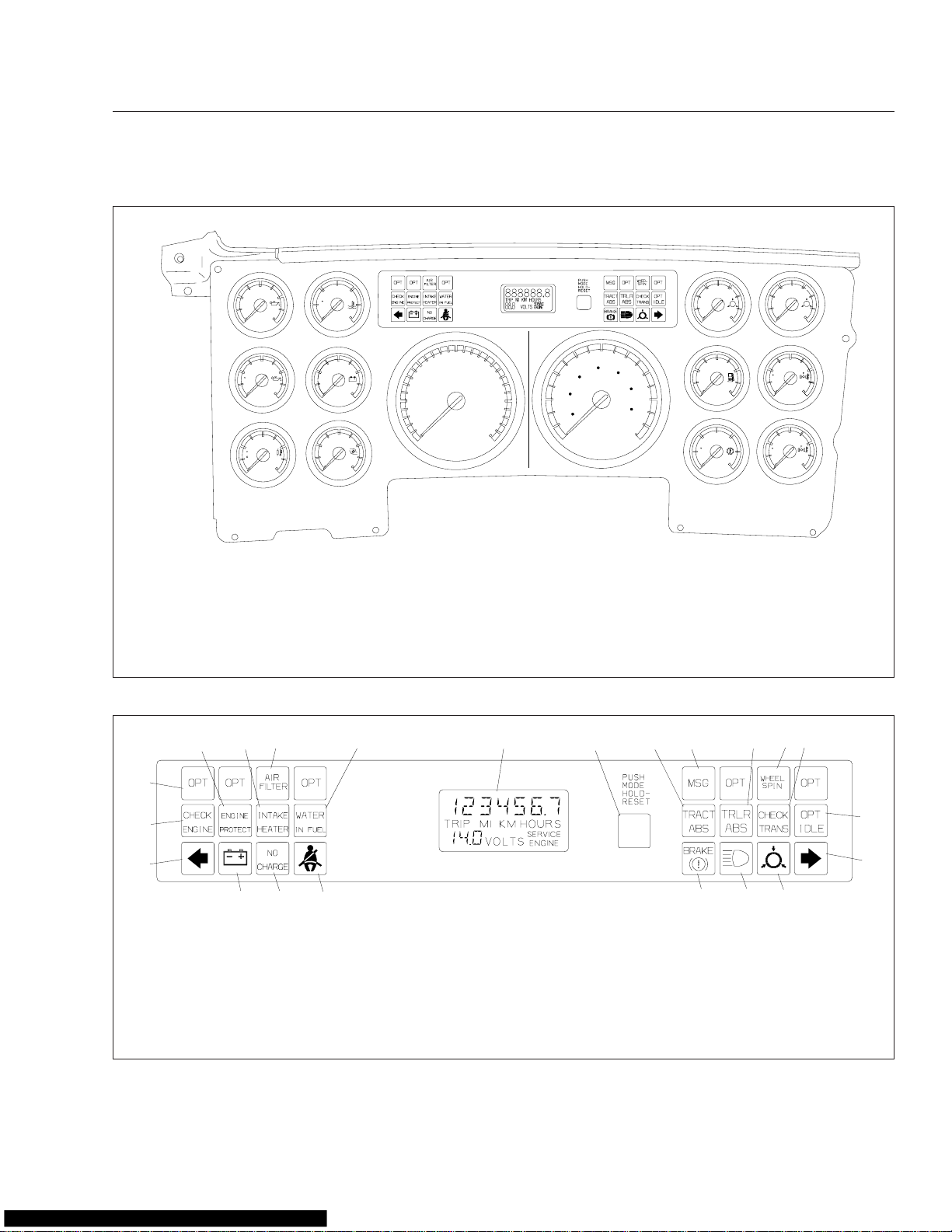

Instrumentation Control Unit 4

(ICU4 and ICU4-2)

The ICU4 and ICU4-2 instrument clusters are

individual-gauge clusters, with intelligent lightbars

(ILB) and integrated warning and indicator lights. See

Fig. 2.2 for a typical layout of the gauges. The ICU4

is on vehicles with engines that were manufactured

up until December 31, 2006, and the ICU4-2 is on

vehicles with engines that were manufactured January 1, 2007 or later, that are EPA07 compliant. They

can be differentiated by the ISO icons on the ICU4-2.

See Fig. 2.3 and Fig. 2.4. Also, on the ICU4, the

message display shows voltmeter readings.

2.3

Standard gauges are:

•

speedometer

•

engine coolant temperature

•

engine oil pressure

•

battery voltmeter

•

fuel level

Gauges with a warning light on the gauge are listed

below, with an indication of how the warning light is

activated:

•

engine coolant temperature (high)

•

engine oil pressure (low)

Page 12

Instruments and Controls Identification

40

PSI

0

100

OIL

200

150

F

100

250

WATER

12

200

F

100

300

OIL

3

90

F

10

30

150

PYRO

12

8

16

VOLTS

4

40

PSI

0

80

TURBO

56

10060

PSI

P

7

8

0 160

AIR

11 12

15

25

5

MPH

45

55

35

70

65

90

50

110

30

10

75

130

85

km/h

13

1/2

EF

FUEL

190

270

F

110

350

TRANS

15

RPM

X 100

20

25

30

10

10

5

0

9

15

14

16

PSI

0 160

200

F

100

AXLE

200

F

100

AXLE

10060

S

AIR

300

300

04/01/2004 f610706

1. Engine Oil Pressure Gauge

2. Engine Coolant Temperature

Gauge

3. Engine Oil Temperature Gauge

4. Battery Voltage Gauge

5. Pyrometer

6. Turbo Boost Air Pressure Gauge

7. Dash Message Center

8. Mode/Reset Switch

9. Tachometer

10. Speedometer

11. Primary Air Pressure Gauge

12. Secondary Air Pressure Gauge

13. Fuel Level Gauge

14. Axle Temperature Gauge

15. Transmission Oil Temperature

Gauge

16. Axle Temperature Gauge

Fig. 2.2, ICU4/ICU4-2 Instrument Cluster (ICU4 shown)

4

56

3

2

1

2122

06/22/2004

1. Left-Turn Signal

2. Check Engine Indicator

3. Optional Indicator

4. Engine Protection Indicator

5. Intake Heater Indicator

6. Air Filter Indicator

7. Water in Fuel Indicator

8. Message Display Screen

78

910

20

9. Mode/Reset Switch

10. Tractor ABS Indicator

11. Message Indicator

17. Low Air System Pressure Warning

18. High-Beam Indicator

19. Parking/Emergency Brake

12. Trailer ABS Indicator

13. Wheel Spin Indicator

14. Check Transmission Indicator

15. Optimized Idle Indicator

20. Fasten Seat Belt Warning

21. No Charge Indicator (alternator)

22. Low Vehicle Battery Voltage

16. Right-Turn Signal

Fig. 2.3, ICU4 Dash Message Center (typical), Pre-2007

11

19

Warning

12 13

14

15

16

1718

f610707

2.4

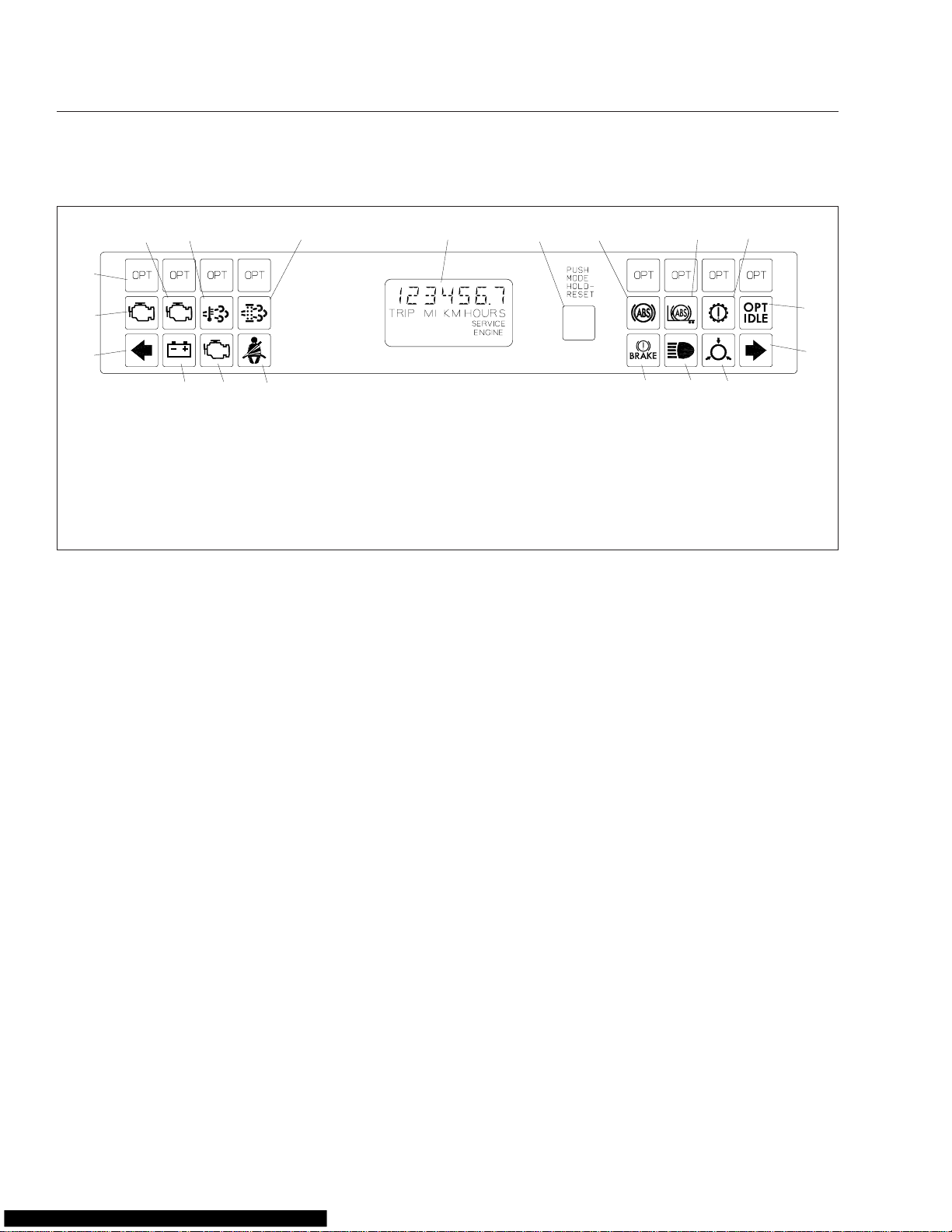

Page 13

Instruments and Controls Identification

4

5

3

2

1

09/05/2006

1. Left-Turn Signal

2. Check Engine Indicator

3. Optional Indicator

4. Stop Engine Warning

5. High Exhaust System

6. Diesel Particulate Filter Status

•

•

CHECK STOP

1819

Temperature (HEST) Warning

Lamp (DPF)

Fig. 2.4, ICU4-2 Dash Message Center (typical), EPA07 Compliant

fuel level (low)

transmission oil temperature (high)

67

17

7. Message Display Screen

8. Mode/Reset Switch

9. Tractor ABS Indicator

10. Trailer ABS Indicator

11. Check Transmission Indicator

12. Optimized Idle Indicator

13. Right-Turn Signal

Other available gauges include:

•

tachometer

•

engine oil temperature

•

transmission oil temperature

•

axle temperature; forward-rear, and rear-rear

•

ammeter

•

air pressure; primary, secondary, application,

and suspension

•

pyrometer

•

turbo boost

Buzzer and Chime

A buzzer sounds for three seconds during the selftest at start-up, and when the following conditions

exist:

•

low air pressure

•

low oil pressure

•

high coolant temperature

89

16

14. Low Air System Pressure Warning

15. High-Beam Indicator

16. Parking/Emergency Brake

Warning

17. Fasten Seat Belt Warning

18. Malfunction Indicator Light (MIL)

19. Low Vehicle Battery Voltage

•

the parking brake is applied and the vehicle is

10

11

12

13

1415

f610817

moving at a speed of at least 2 mph (3 km/h)

A chime sounds when the parking brake is off and

the door is open, or when the headlights are on and

the door is open.

Ignition Sequence

When the ignition key is turned on, the ICU4/ICU4-2

begins a self-test. During this process, all gauges

controlled by the cluster sweep to full scale and return, the buzzer sounds for three seconds, the fasten

seat belt warning light illuminates for 15 seconds,

and the battery voltage, low air pressure, and parking

brake warning lights illuminate then turn off. Then the

software revision level of the ICU4/ICU4-2 is displayed, followed by active faults, if any, then the

odometer display.

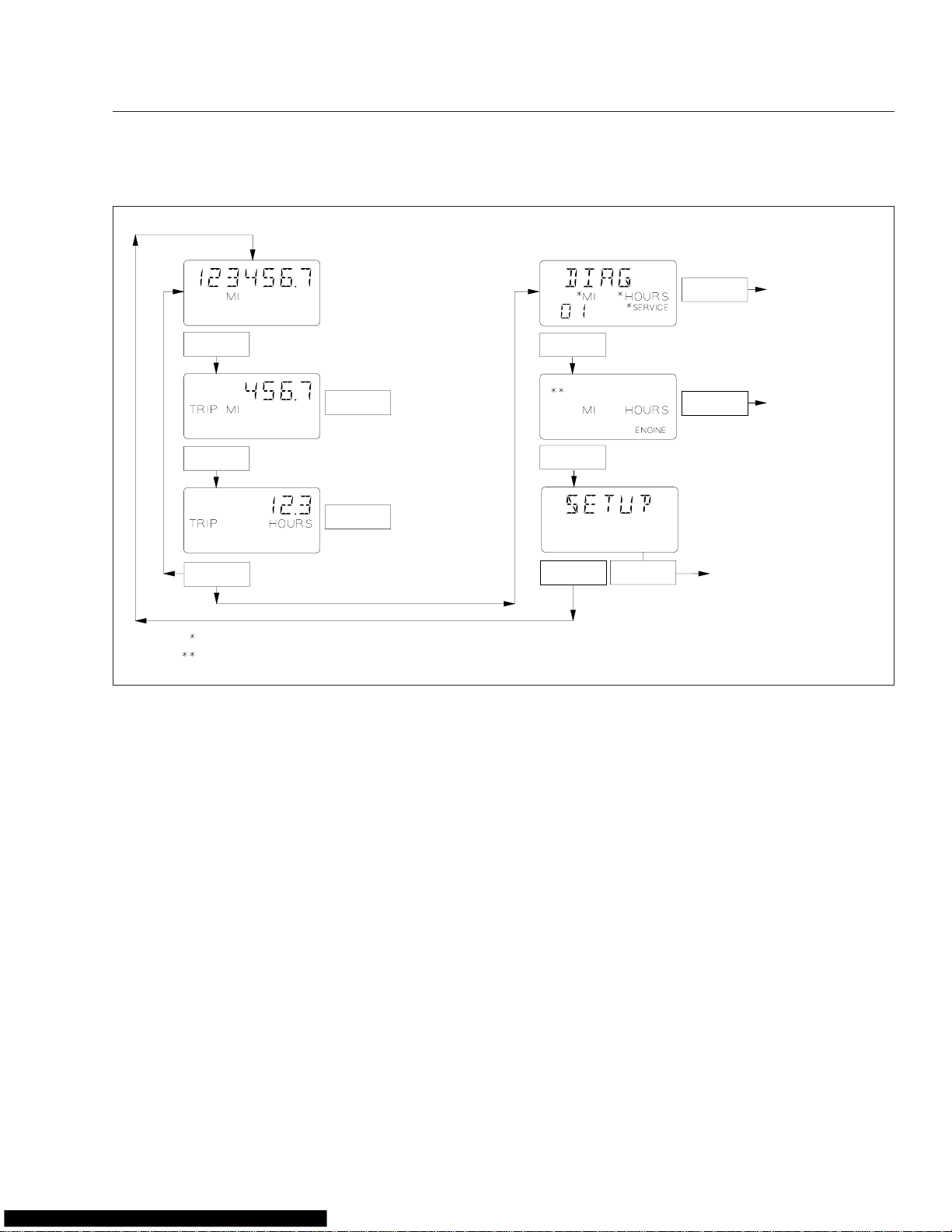

Mode/Reset Switch Functions

The mode/reset switch controls the display of the

odometer, trip miles and hours, engine miles and

hours, service cycle screens, fault code screens, and

oil level screens (on some Mercedes-Benz engines;

if equipped and enabled).

Push the switch to scroll through mode selections,

and hold the switch to reset trip miles or hours while

they are displayed. See Fig. 2.5. With the parking

2.5

Page 14

Instruments and Controls Identification

With park brake off

06/01/2004

Default Odometer

Display Screen

Push

Hold

Push

Hold

Push

With park brake on

If "SERVICE" is displayed Service Cycle screens are enabled and either "MI" or "HOURS" is also displayed.

On some vehicles "OIL LVL" appears in the top row of the display, if equipped and enabled.

Fig. 2.5, ICU4/ICU4-2 Mode/Reset Switch Basic Functions

To Reset Trip Miles

To Reset Trip Hours

Push

Push

Push

Hold

Go to the Diagnostic

Hold

Hold

For setup screens.

and Engine Display

Screens figure.

Go to the Diagnostic

and Engine Display

Screens figure.

f040693

brake released, only the odometer, trip miles, and trip

hours can be accessed. Park the vehicle and set the

parking brake to access additional screen functions.

See Fig. 2.6.

Trip Miles, Trip Hours

When the odometer is displayed, push the mode/

reset switch once to display trip distance. Push it

again to display trip hours. Both numbers are calculated from the last time the value was reset. Hold the

switch when each number is displayed to reset trip

miles or hours to zero.

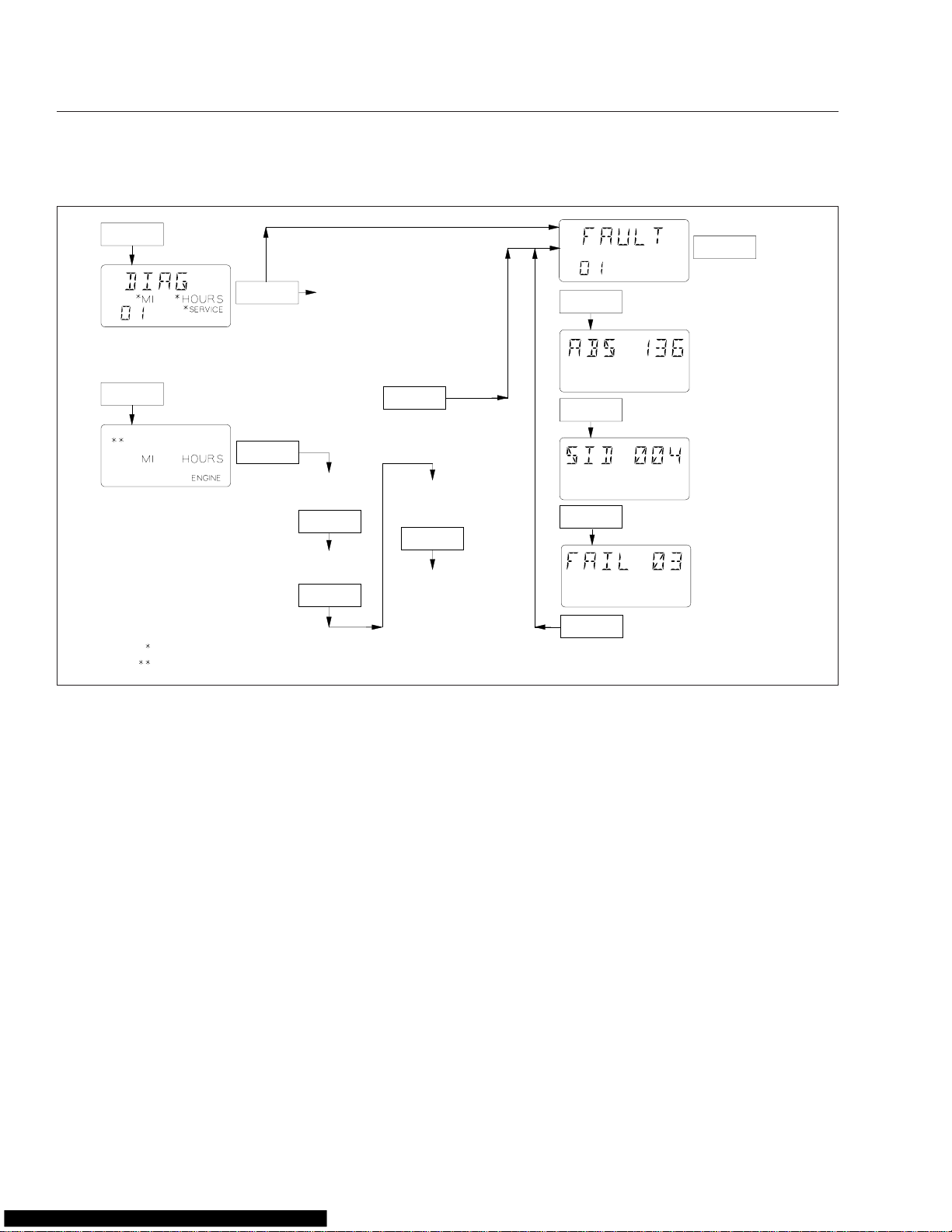

Diagnostic Screens

During vehicle start-up, with the parking brake on,

the ICU4 or ICU4-2 display any active fault codes for

three seconds each until the parking brake is released. With active fault codes on display, push the

mode/reset switch once to display the initial diagnostic screen (DIAG) and the total number of active

faults. If service cycle screens are enabled, and ser-

vice distance or time has been exceeded, the text

SERVICE will be displayed with the other fault messages. This will inform the vehicle operator that the

service interval has been exceeded and vehicle service is required.

Specific fault code information can be displayed only

with the vehicle parked and the parking brake set. If

the odometer screen is displayed, push the mode/

reset switch until the DIAG screen is displayed, then

hold the switch to enter the fault code screen sequence. Once the initial fault code is displayed, push

the switch to cycle through additional diagnostic

codes relating to the first fault. Hold the switch to display additional faults or return to the DIAG screen. If

service cycle screens are enabled, service interval

information is displayed before fault code information

is displayed.

If the word SERVICE appears on the DIAG message

display screen, service cycle screens are enabled.

Hold the mode/reset switch at the DIAG screen to

2.6

Page 15

Instruments and Controls Identification

If Service Cycle screens not enabled

Push

Or

Hold

Push

Hold

Service Cycle Screens (if enabled):

Holding the button displays Service

Miles or Service Hours, remaining or

exceeded, to service target. If

numbers flash, the service target is

exceeded and service is overdue.

Also, the "SERVICE" screen will be

displayed as an active Fault Code

when service miles or hours are ex−

ceeded.

Then

Hold

Push

Push

Hold

For additional faults,

if any, or return to

DIAG screen.

To display total

engine miles.

Hold

To display tolal

engine hours.

Hold

If "SERVICE" is displayed Service Cycle screens are enabled and either "MI" or "HOURS" is also displayed.

04/28/2004 f040695

On some vehicles "OIL LVL" appears in the top row of the display, if equipped and enabled.

To display OIL LVL

screens (if equipped

and enabled).

Hold

To display specific

OIL LVL amount

over or under full.

Push

Push

Fig. 2.6, ICU4/ICU4-2 Mode/Reset Switch Diagnostic and Engine Display Screens

display miles or hours remaining until the next scheduled service. If MI appears on the DIAG screen, service miles are enabled; if HOURS appears on the

screen, service hours are enabled. Either service

miles or hours can be enabled, but not both. If service miles or hours has been exceeded, the number

flashes to indicate service is overdue.

Engine Screens

Push the mode/reset switch once following the DIAG

screen and the word ENGINE is displayed in the

lower right corner of the digital display. Hold the

switch to display total engine miles. Hold it again to

display total engine hours. If OIL LVL is displayed

earlier with ENGINE (only on vehicles with

Mercedes-Benz engines; if equipped and enabled)

hold the switch again to access oil level screens.

Instrumentation Control Unit 3

(ICU3 and ICU3 ’07)

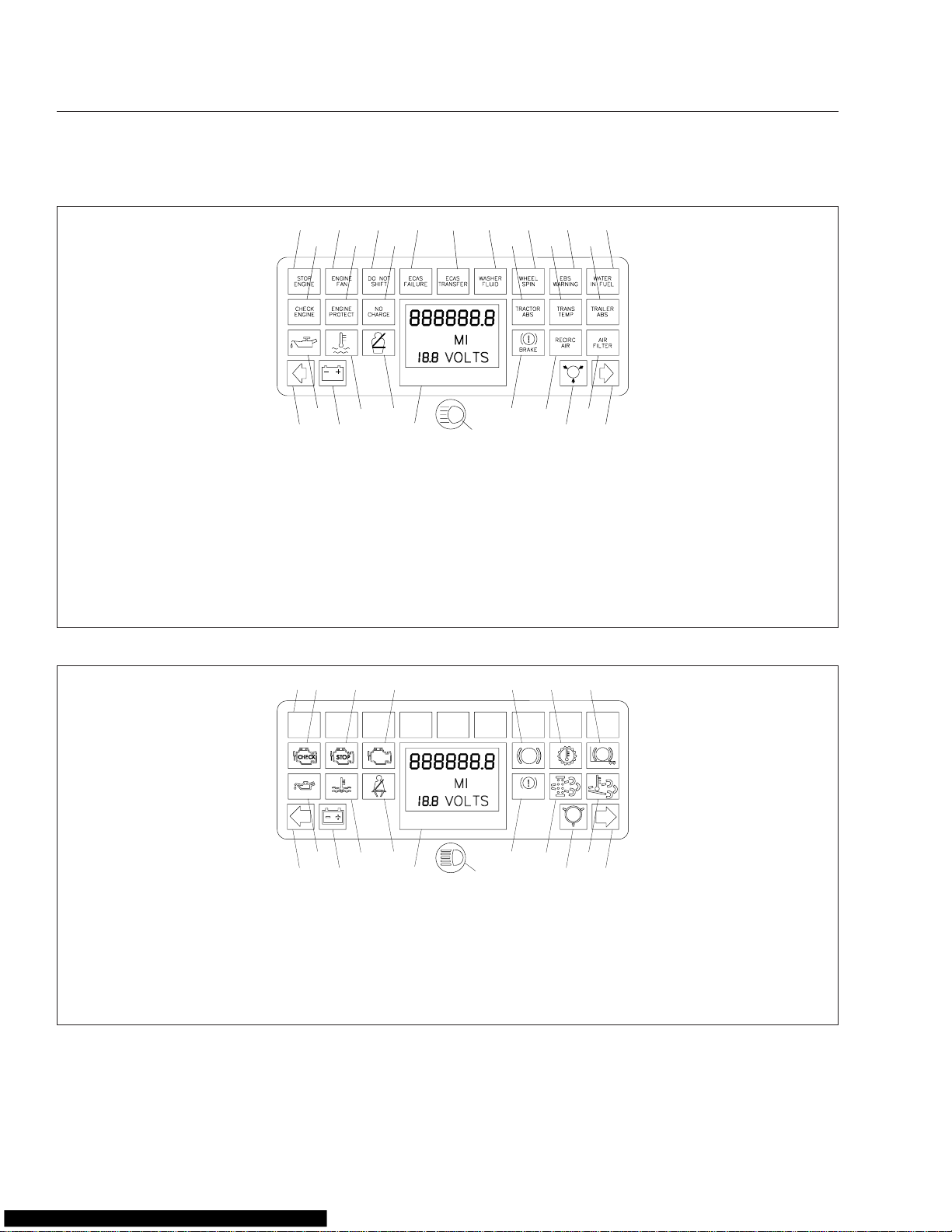

Figure 2.7 shows the instrument panel for Columbia

vehicles equipped with the ICU3 and ICU3 ’07. The

ICU3 is on vehicles with engines that were manufactured up until December 31, 2006, and the ICU3 ’07

is on vehicles with engines that were manufactured

January 1, 2007 or later. They can be differentiated

by the ISO icons used on the ICU3 ’07.

The ICU3 and ICU3 ’07 electronic dashboards can

accept information from the various sensors installed

on the vehicle and feed it to electronic gauges. Only

air gauges operate mechanically.

There can be up to eight gauges on the driver’s instrument panel (six electronic and two mechanical).

The ICU3 or ICU3 ’07 can not drive gauges located

on the auxiliary instrument panel.

The dash message center is the heart of the ICU3

and ICU3 ’07. It has a set of warning and indicator

2.7

Page 16

Instruments and Controls Identification

65

75

85

1/2

5

E

F

FUEL

6

50

100

PSI

150

0

AIR

50

100

PSI

8

150

0

AIR

f610205b06/02/99

™

System is

7

50

3

PSI

0

100

OIL

200

150

2

F°

100

250

WATER

225

1

F°

100

350

TRANS

4

20

25

15

10

5

0

RPM

X100

30

10

45

55

35

70

90

50

25

15

5

110

30

130

10

km/h

9

MPH

1. Transmission Temperature Gauge

2. Water Temperature Gauge

3. Engine Oil Pressure Gauge

4. Dash Message Center

5. Fuel Gauge

6. Primary Air Pressure Gauge

7. Optional Mode/Reset Push Button

8. Secondary Air Pressure Gauge

9. Speedometer

10. Tachometer

Fig. 2.7, ICU3/ICU3 ’07 Gauge Layout (ICU3 shown)

lights, and a driver display screen. The driver display

screen is a one-line by seven-character liquid crystal

display (LCD) that normally shows odometer readings.

There are four rows of lights in the dash message

center. Lights installed in the top row are optional

and their positions may vary. The lights in the bottom

three rows are installed in fixed positions on all vehicles. Most are standard, but a few are optional.

See Fig. 2.8 and Fig. 2.9.

NOTE: The functions of the ABS/ATC warning

lights are explained under "Meritor WABCO Antilock Braking System (ABS)", later in this chapter.

NOTE: The amber LANE SRCHNG warning

light for the optional Lane Guidance

explained later in this chapter.

Buzzer

A buzzer sounds for three seconds during the selftest at start-up, and when the following conditions

exist:

•

low air pressure

•

low oil pressure

•

high coolant temperature

•

the parking brake is applied and the vehicle is

moving at a speed of at least 2 mph (3 km/h)

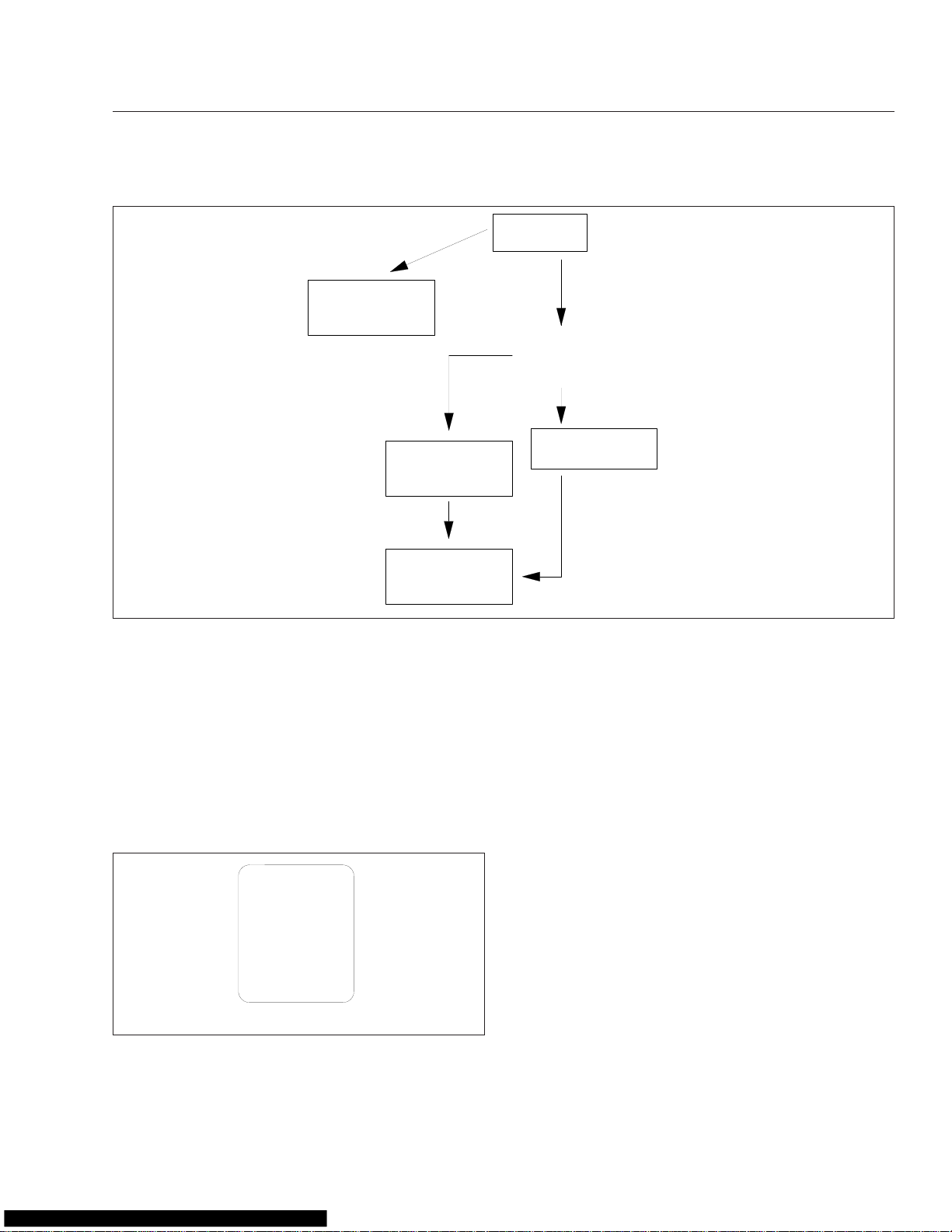

ICU3/ICU3 ’07 Ignition Sequence

If the headlights are turned on, the screen displays

the odometer and waits for the ignition to be turned

on.

When the ignition is turned on, all the electronic

gauges complete a full sweep of their dials, the

warning and indicator lights light up, and the buzzer

sounds for three seconds.

NOTE: The air gauges do not sweep.

The following lights illuminate during the ignition sequence:

•

Fasten Seat Belt Warning

•

Low Battery Voltage Warning

•

High Coolant Temperature Warning

•

Low Engine Oil Pressure Warning

•

Low Air Pressure Warning

•

Parking Brake On Indicator

•

All engine warning lights, including engine protection, check engine, and (Cummins only)

stop engine

•

All ABS warning lights, including wheel spin,

tractor ABS, and (if installed) trailer ABS

See Fig. 2.10 for the ICU3/ICU3 ’07 ignition

sequence.

NOTE: Although the engine and ABS warning

lights illuminate during the ignition sequence,

they are not controlled by the ICU, but by their

own system ECU (electronic control unit).

When the ignition switch has been turned on, the

ICU3 performs a self-test, looking for active faults.

During the first half of the self-test, all segments of

the display illuminate as follows: 888888.8. The ICU3

voltmeter display also illuminates, but with the value

18.8. During the second half of the self-test, the software revision level is displayed.

2.8

Page 17

Instruments and Controls Identification

11/10/2006

1. Stop Engine Warning

2. Engine Fan On Indicator (optional)

3. Do Not Shift Indicator (optional)

4. ECAS Failure Warning (optional)

5. ECAS Transfer Indicator (optional)

6. Low Washer Fluid Indicator

(optional)

7. Wheel Spin Indicator (optional)

8. EBS Warning (optional)

9. Water In Fuel Indicator (optional)

10. Check Engine Indicator

3

4

12

18

24

22

2

1

10

11

16

17

23

11. Engine Protection Warning

(optional)

5

25

6

13 14

19

78

15

21

20

26 27

19. Parking Brake On Warning

20. Recirculated Air Indicator

12. No Charge Indicator (optional)

13. Tractor ABS Warning

14. Transmission Temperature

Warning (optional)

15. Trailer ABS Warning

16. Low Oil Pressure Warning

17. High Coolant Temperature

Warning

21. Air Restriction Indicator (optional)

22. Left-Turn Signal

23. Low Battery Voltage Warning

24. Dash Driver Display Screen

25. High Beams On Indicator

26. Low Air Pressure Warning

27. Right-Turn Signal

18. Fasten Seat Belt Warning

Fig. 2.8, ICU3 Dash Message Center, Pre-2007

9

f610231a

(optional)

4

3

10

9

Status Lamp

Temperature (HEST) Warning

08/31/2006

1. Optional Indicator

2. Check Engine Indicator

3. Stop Engine Indicator

4. Malfunction Indicator Light (MIL)

5. Tractor ABS Indicator

6. Transmission Temperature

Indicator

7. Trailer ABS Indicator

2

1

OPT OPT OPT OPT OPT OPT OPT OPT OPT

8

14

15

8. Low Oil Pressure Warning

9. High Coolant Temperature

10. Fasten Seat Belt Warning

11. Parking Brake On Warning

12. Diesel Particulate Filter (DPF)

13. High Exhaust System

Fig. 2.9, ICU3 ’07 Dash Message Center, EPA07 Compliant

If there are no active faults, the ICU3/ICU3 ’07 displays the odometer. However, if the ICU3/ICU3 ’07

16

56

11

17

ABS

BRAKE

12

7

ABS

13

18 19

f610836

14. Left-Turn Signal

15. Low Battery Voltage Warning

16. Driver Display Screen

17. High Beams On Indicator

18. Low Air Pressure Warning

19. Right-Turn Signal

has received active fault codes from other devices, it

displays them one after the other until the parking

2.9

Page 18

Instruments and Controls Identification

HEADLIGHTS ON

888888.8

MI

ODOMETER

SCREEN

IF NO FAULTS

WERE DETECTED

123456.7

MI

12.3 VOLTS

PARK BRAKE

RELEASED − MOVING

123456.7

MI

02/14/2003

Fig. 2.10, ICU3/ICU3 ’07 Ignition Sequence

12.3 VOLTS

brake is released or the ignition switch is turned off.

Once the parking brake is released, the ICU3/ICU3

’07 displays the odometer again.

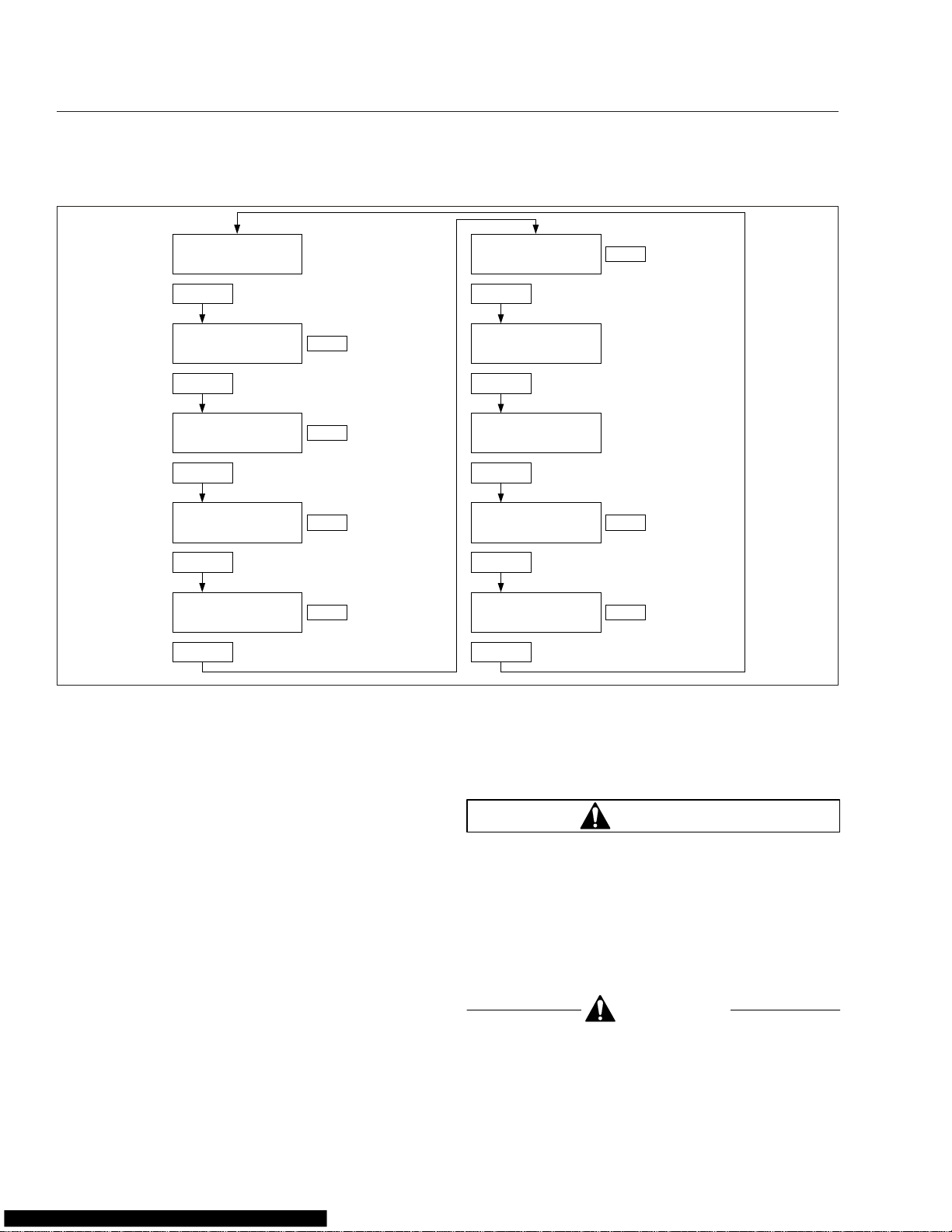

Mode/Reset Switch

The mode/reset switch (Fig. 2.11) is located on the

right side of the instrument cluster. The mode/reset

switch is used to scroll through the displays on the

message display screen, and to reset the trip distance and trip hours values to zero.

PUSH−

MODE

HOLD−

RESET

09/25/99

Fig. 2.11, ICU3/ICU3 ’07 Mode/Reset Switch

f610340

POWER ON

IGNITION ON

ICU INITIALIZES

ELECTRONIC GAUGE NEEDLES

SWEEP, WARNING/INDICATOR

LIGHTS COME ON, BUZZER SOUNDS

IF FAULT DETECTED

ABS 136

FAULT CODE

SCREEN

RELEASE PARK BRAKE

f040420a

See Fig. 2.12 for the state diagram for the LCD display cycle.

NOTE: The systems diagnostics test is used by

trained personnel to retrieve fault codes and

other diagnostic information pertaining to the

vehicle.

When the odometer reading is displayed and the

parking brake is applied:

•

Press the mode/reset switch once and the trip

distance will display.

•

Press the mode/reset switch a second time

and the trip hours (engine hours) will display.

•

Press the mode/reset switch a third time and

the SELECT screen and the current units, MI

or KM, will display.

•

Press the mode/reset switch a fourth time to

return to the odometer reading.

To reset trip miles and/or trip hours to zero, press the

mode/reset switch for 1 second or longer. To toggle

between MI (miles) and KM (kilometers), press the

mode/reset switch while in the SELECT screen.

2.10

Page 19

Instruments and Controls Identification

123456.7

MI

12.3 VOLTS

Push

123456.7

TRIP MI

12.3 VOLTS

Push

123456.7

TRIP HOURS

12.3 VOLTS

Push

SELECt

MI

Push

dIAG

MI HOURS

n

Push Push

03/26/2004 f040636a

Default Odometer

Dispay Screen

Hold

To Reset Trip Miles

Hold

To Reset Trip Hours

To Toggle between Units

Hold

MI<−−−−>KM

Hold

Dispay Diagnostics

n = Number of Active Fault Codes

MI = CYCLE Miles Enabled

HOURS = Cycle Hours Enabled

EC

EC

*Lo

**MI **HOURS

**no

Push

Push

Push

Push

CLEAr

123456.7

MI

123456.7

EnG oIL

SEtUP

Hold

Clear Defaults

To Dispay Total Engine Miles

EC = Engine Control

To Dispay Total Engine Hours

HOURS

EC = Engine Control

Hold

Dispay Oil Level

*Lo = Oil Level Low

HI = Oil Level High

Blank = Oil Level OK

− − = No Message

Dispay Service Interval

Hold

Cycle Screens

**MI = CYCLE Miles Active Mode

**HOURS = CYCLE Hours Active Mode

**no = Service CYCLE Inactive

Fig. 2.12, ICU3/ICU3 ’07 Mode Reset LCD Display Cycle

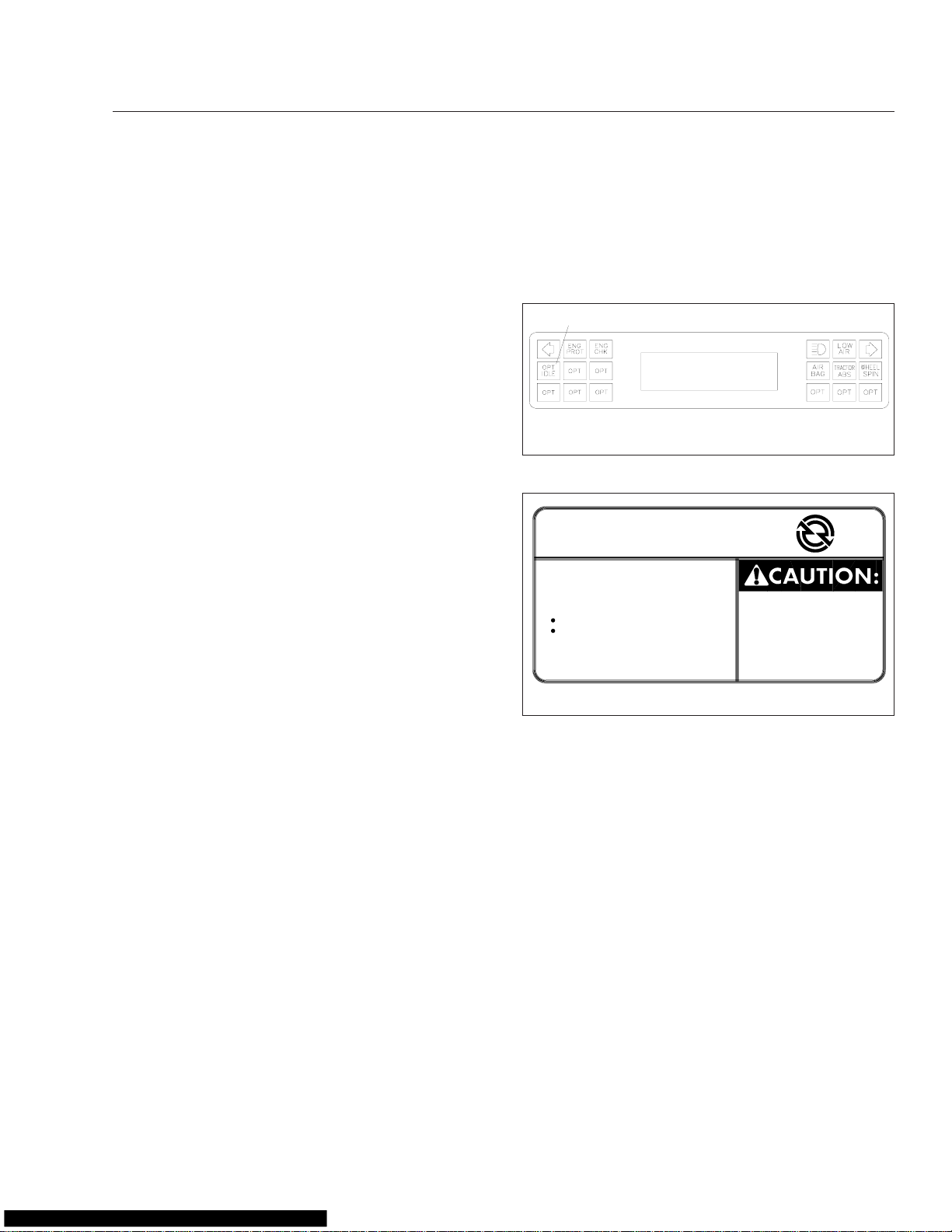

Instrumentation Control Unit

2L (ICU2L)

The ICU2L is a basic electronic dashboard. It can

accept information from the various sensors installed

on the vehicle and feed it to electronic gauges. Only

air gauges operate mechanically.

There can be up to 14 removable gauges on the

driver’s instrument panel (11 electronic, one electromechanical, and two mechanical). The ICU2L can

not drive gauges located on the auxiliary instrument

panel.

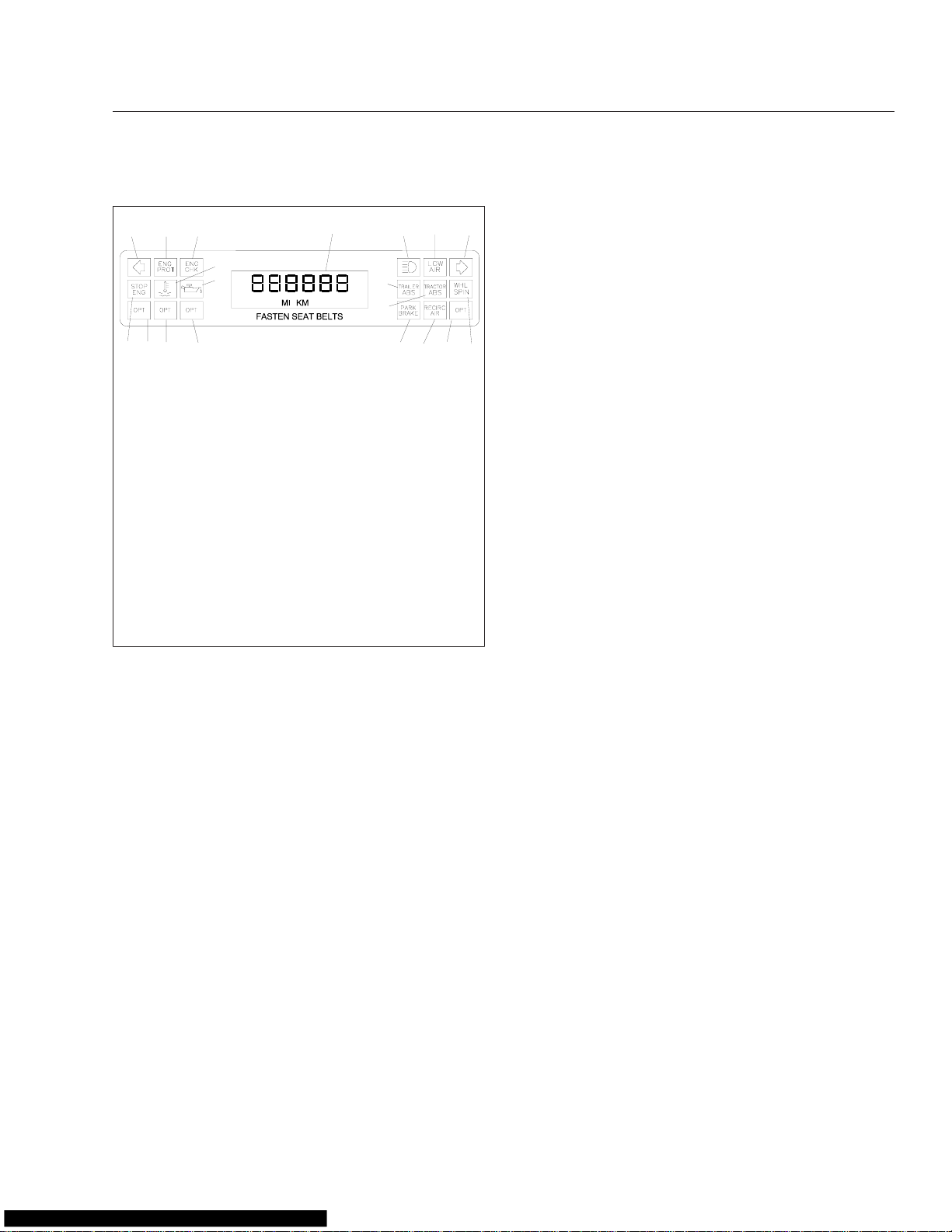

The dash message center is the heart of the ICU2L.

It has a set of 18 warning and indicator lights, and a

message display screen. The message display

screen is a one-line by six-character vacuum fluorescent display.

Warning and Indicator Lights

There can be up to 18 warning and indicator lights

installed in the ICU2L. See Fig. 2.13.

WARNING

When the red STOP engine lamp illuminates,

most engines are programmed to shut down automatically within 30 seconds. The driver must

immediately move the vehicle to a safe location

at the side of the road to prevent causing a hazardous situation that could cause bodily injury,

property damage, or severe damage to the engine.

CAUTION

Because operating the engine when the red engine protection light is illuminated can lead to

2.11

Page 20

Instruments and Controls Identification

1

4

7

06/26/98

Typical installation shown. Location and function of

optional lights may vary.

1. Left-Turn Indicator

2. Engine Protection

Warning and Indicator

3. Check Eng. Indicator

4. Stop Engine Warning

5. High Coolant Temp.

Warning (optional)

6. Low Oil Pressure

Warning (optional)

7. Optional Indicator 3

8. Optional Indicator 2

9. Optional Indicator 1

10. Message Display

Screen

3

2

5

6

9

8

Fig. 2.13, Dash Message Center, ICU2L

10

11. High-Beam Indicator

12. Low Air Warning

13. Right-Turn Indicator

14. Trailer ABS Warning

15. Tractor ABS Warning

16. Wheel Spin Warning

17. Park Brake On

Indicator

18. Recirc Air Warning

(optional)

19. Optional Indicator 4

11 12 13

14

15

18

17

19

16

f601458

severe engine damage, the driver must move the

vehicle to a safe location as quickly as possible.

NOTE: The functions of the ABS/ATC warning

lights are explained under "Meritor WABCO Antilock Braking System (ABS)", later in this chapter.

NOTE: The amber LANE SRCHNG warning

™

light for the optional Lane Guidance

System is

explained later in this chapter.

Ignition Sequence

If the headlights are turned on, the screen displays

the odometer and waits for the ignition to be turned

on. See Fig. 2.14.

When the ignition is turned on, all the electronic

gauges complete a full sweep of their dials, the

warning and indicator lights light up, and the buzzer

sounds for three seconds.

NOTE: The air gauges do not sweep.

The following lights illuminate during the ignition sequence:

•

Fasten Seat Belt Warning

•

Low Battery Voltage Warning

•

High Coolant Temperature Warning

•

Low Engine Oil Pressure Warning

•

Low Air Pressure Warning

•

Parking Brake On Indicator

•

All engine warning lights, including engine protection, check engine, and (Cummins only)

stop engine

•

All ABS warning lights, including wheel spin,

tractor ABS, and (if installed) trailer ABS

NOTE: Although the engine and ABS warning

lights illuminate during the ignition sequence,

they are not controlled by the ICU but by their

own system ECU (electronic control unit).

When the ignition switch has been turned on, the

ICU performs a self-test, looking for active faults.

During the first half of the self-test, all segments of

the display illuminate as follows: 888888.8. During

the second half of the self-test, the software revision

level is displayed.

Instruments

Tachometer

The tachometer indicates engine speed in revolutions

per minute (rpm) and serves as a guide for shifting

the transmission and keeping the engine in the appropriate rpm range. For low idle and rated rpm, see

the engine identification plate. The green band on

the tachometer indicates the best fuel economy

range. The yellow band indicates lower fuel

economy, the orange band indicates much lower fuel

economy, and the red band indicates poor fuel

economy. See Fig. 2.15.

Speedometer

The speedometer registers speed in both miles per

hour (mph) and kilometers per hour (km/h). See

Fig. 2.15.

2.12

Page 21

Instruments and Controls Identification

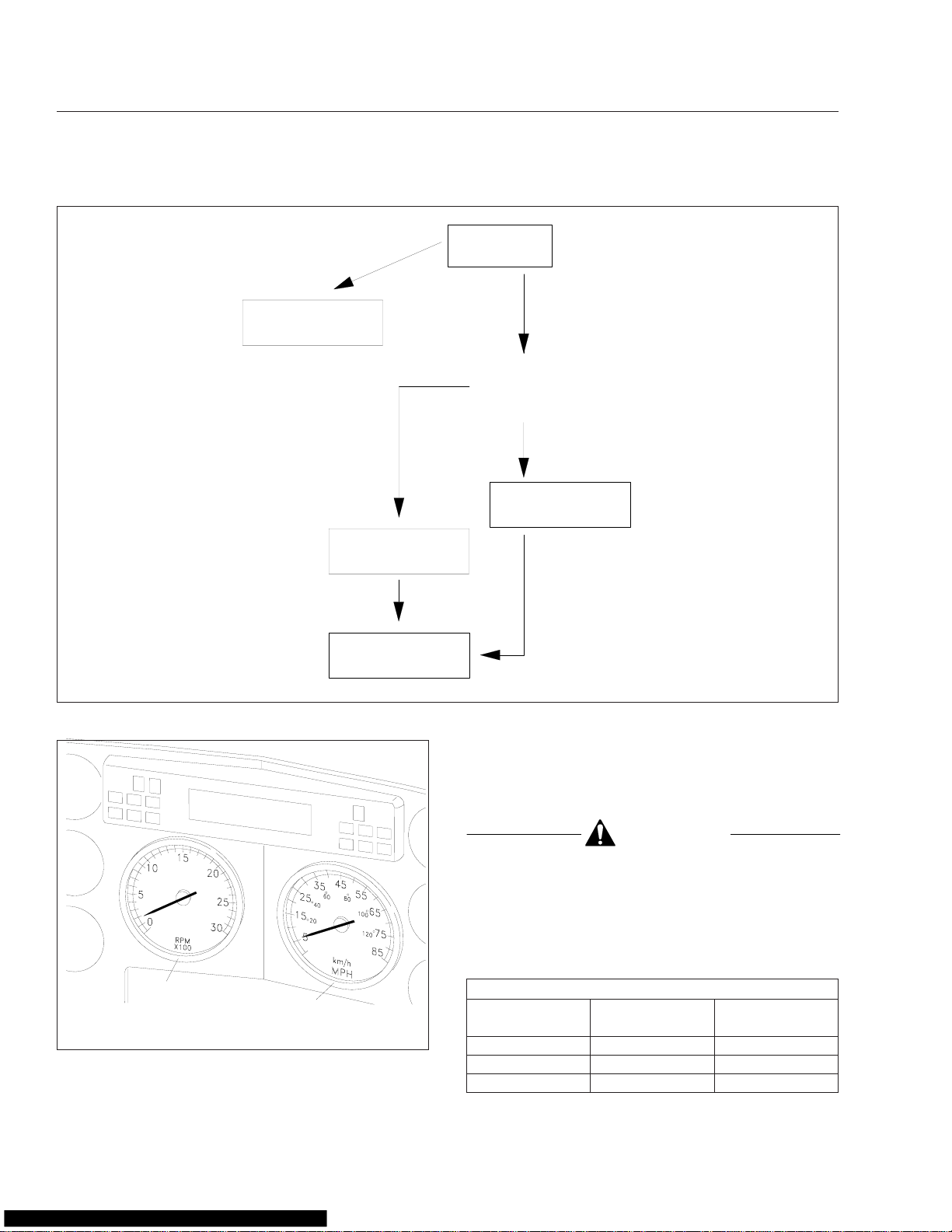

10/03/97

123456

ODOMETER

SCREEN

PARK BRAKE

RELEASED − MOVING

HEADLIGHTS ON

MI

IF NO FAULTS

WERE DETECTED

123456

123456

MI

MI

POWER ON

IGNITION ON

ICU PERFORMS SELFTEST:

ELECTRONIC GAUGE NEEDLES

SWEEP, WARNING/INDICATOR

LIGHTS COME ON, BUZZER SOUNDS

IF FAULT DETECTED

A/C 190

FAULT CODE

SCREEN

RELEASE PARK BRAKE

f040395

Fig. 2.14, ICU2L Ignition Sequence

1

2

1. Tachometer 2. Speedometer

Fig. 2.15, Instrument Panel, Level II (center)

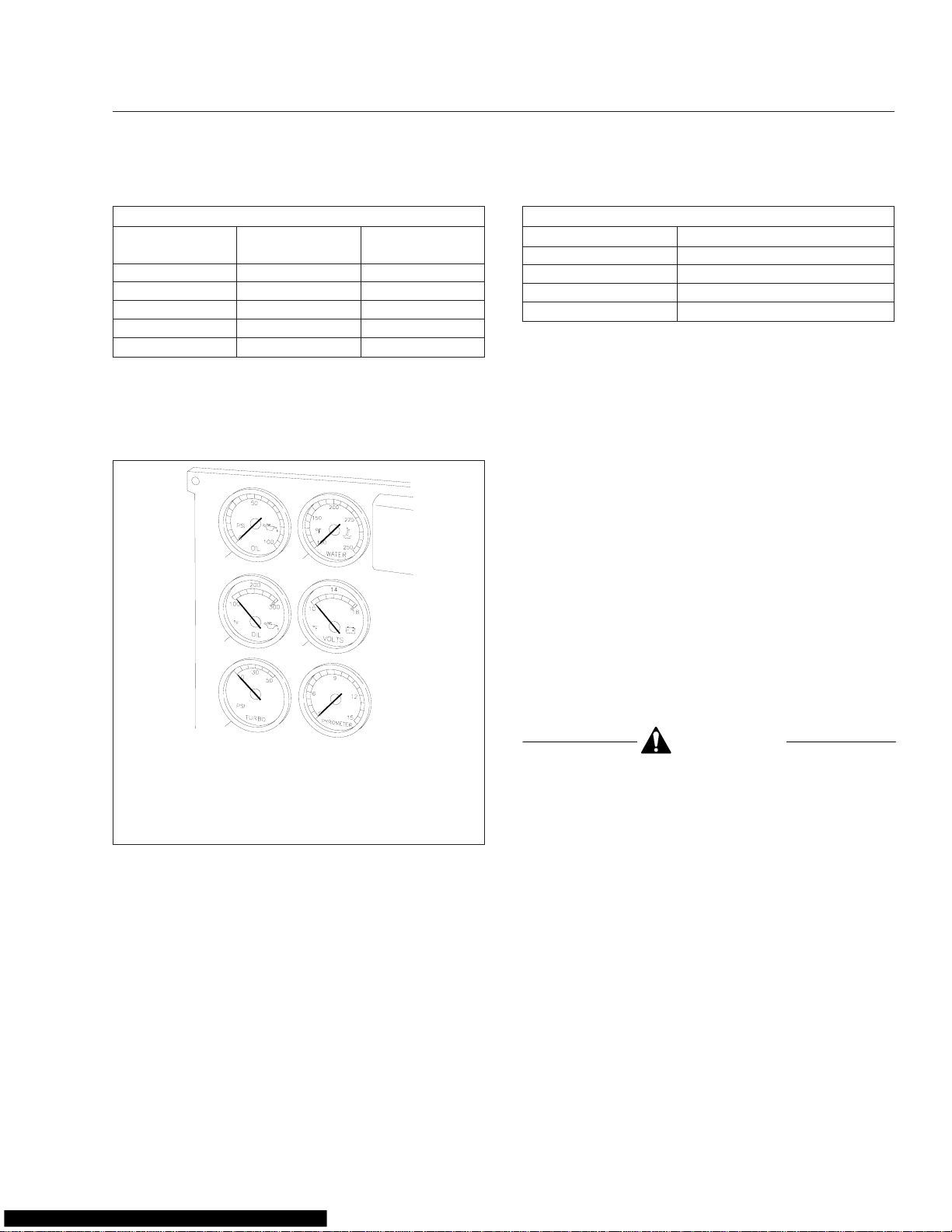

Engine Oil Pressure Gauge

The oil pressure gauge should read as shown in

Table 2.1. See Fig. 2.16.

CAUTION

A sudden decrease or absence of oil pressure

may indicate mechanical failure. Bring the vehicle

to a safe stop and investigate the cause to prevent further damage. Do not operate the engine

until the cause has been determined and corrected.

Oil Pressure

f60099309/25/95

Engine Model

Caterpillar C–10 10–20 (69–138) 30–45 (207–310)

Caterpillar C–12 10–20 (69–138) 30–45 (207–310)

Caterpillar 3406E 15 (100) min. 40 (275) min.

At Idle Speed:

psi (kPa)

*

At Rated RPM:

psi (kPa)

2.13

Page 22

Instruments and Controls Identification

Oil Pressure

Engine Model

Cummins ISX 10 (69) min. 35–45 (241–310)

Cummins ISM 10 (69) min. 35–45 (241–310)

Cummins N14 10 (69) min. 35–45 (241–310)

Detroit Diesel S60 12 (83) min. 50 (345) min.

MBE4000 7 (50) 36 (250) min.

*

Oil pressures are given with the engine at operating temperature. With

the engine cold, oil pressure may be higher. Individual engines may vary

from the listed pressures; observe and record pressures when the engine

is new to create a guide for checking engine condition.

Table 2.1, Oil Pressure Specifications

At Idle Speed:

psi (kPa)

1

3

*

At Rated RPM:

psi (kPa)

2

4

Maximum Coolant Temperature

Engine Make Temperature: °F (°C)

Caterpillar 215 (101)

Cummins 220 (104)

Detroit Diesel 215 (101)

Mercedes-Benz 221 (105)

Table 2.2, Maximum Coolant Temperature

Engine Oil Temperature Gauge,

Optional

During normal operation, the engine oil temperature

gauge should read:

•

190 to 220°F (88 to 104°C) for Caterpillar engines;

•

180 to 225°F (82 to 107°C) for Cummins engines;

•

200 to 230°F (93 to 110°C) for Detroit Diesel

engines;

•

181 to 203°F (83 to 95°C) for Mercedes-Benz

diesel engines.

Under heavy loads, such as when climbing steep

grades, temperatures that exceed the normal oil temperature range for a short period are not unusual.

See Fig. 2.16.

5

1. Engine Oil Pressure Gauge

2. Coolant Temperature Gauge

3. Engine Oil Temperature Gauge (optional)

4. Voltmeter

5. Turbocharger Boost Pressure Gauge (optional)

6. Pyrometer (optional)

Fig. 2.16, Instrument Panel Gauges (left side)

6

f60112602/12/96

Coolant Temperature Gauge

During normal engine operation, the coolant temperature gauge should read 175 to 195°F (79 to

91°C). See Fig. 2.16. If the temperature remains

below 160°F (71°C) or exceeds the maximum temperature shown in Table 2.2, inspect the cooling sys-

tem to determine the cause. See the

Workshop Manual

for troubleshooting and repair pro-

Columbia

cedures.

®

CAUTION

A sudden increase in oil temperature that is not

caused by a load increase may indicate mechanical failure. Bring the vehicle to a safe stop and

investigate the cause to prevent further damage.

Do not operate the engine until the cause has

been determined and corrected.

Voltmeter

The voltmeter indicates the vehicle charging system

voltage when the engine is running and the battery

voltage when the engine is stopped. By monitoring

the voltmeter, the driver can be aware of potential

charging system problems and have them fixed before the batteries discharge enough to create starting

difficulties. See Fig. 2.16.

The voltmeter will normally show approximately 13.7

to 14.1 volts when the engine is running. The voltage

of a fully charged battery is 12.7 to 12.8 volts when

2.14

Page 23

Instruments and Controls Identification

the engine is stopped. A completely discharged battery will produce only about 12.0 volts. The voltmeter

will indicate lower voltage as the vehicle is being

started or when electrical devices in the vehicle are

being used.

If the voltmeter shows an undercharged or overcharged condition for an extended period, have the

charging system and batteries checked at a repair

facility.

NOTE: Some vehicles may be equipped with a

digital display voltmeter integrated into the message display screen, instead of a voltmeter

gauge.

Turbocharger Boost Pressure Gauge,

Optional

A turbocharger boost pressure gauge measures the

pressure in the intake manifold, in excess of atmospheric pressure, being created by the turbocharger.

See Fig. 2.16.

Pyrometer, Optional

A pyrometer registers the exhaust temperature near

the turbocharger. See Fig. 2.16. Normal exhaust

temperatures are listed in Table 2.3.

Variations in engine load can cause exhaust temperatures to vary. If the pyrometer reading shows

that exhaust temperature exceeds normal, reduce

fuel to the engine until the exhaust temperature is

reduced. Shift to a lower gear if the engine is overloaded.

Exhaust Temperature

Engine Model

Caterpillar C–10, C–12 935–1290 (500–700)

Caterpillar 3406E 900–1100 (480–595)

Cummins M11 800–1000 (430–540)

Cummins N14 750–950 (400–510)

Detroit Diesel S60 700–950 (370–510)

MBE4000 750–1022 (400–550)

Table 2.3, Typical Pyrometer Exhaust Temperature

Readings

Exhaust Temperature:

°F (°C)

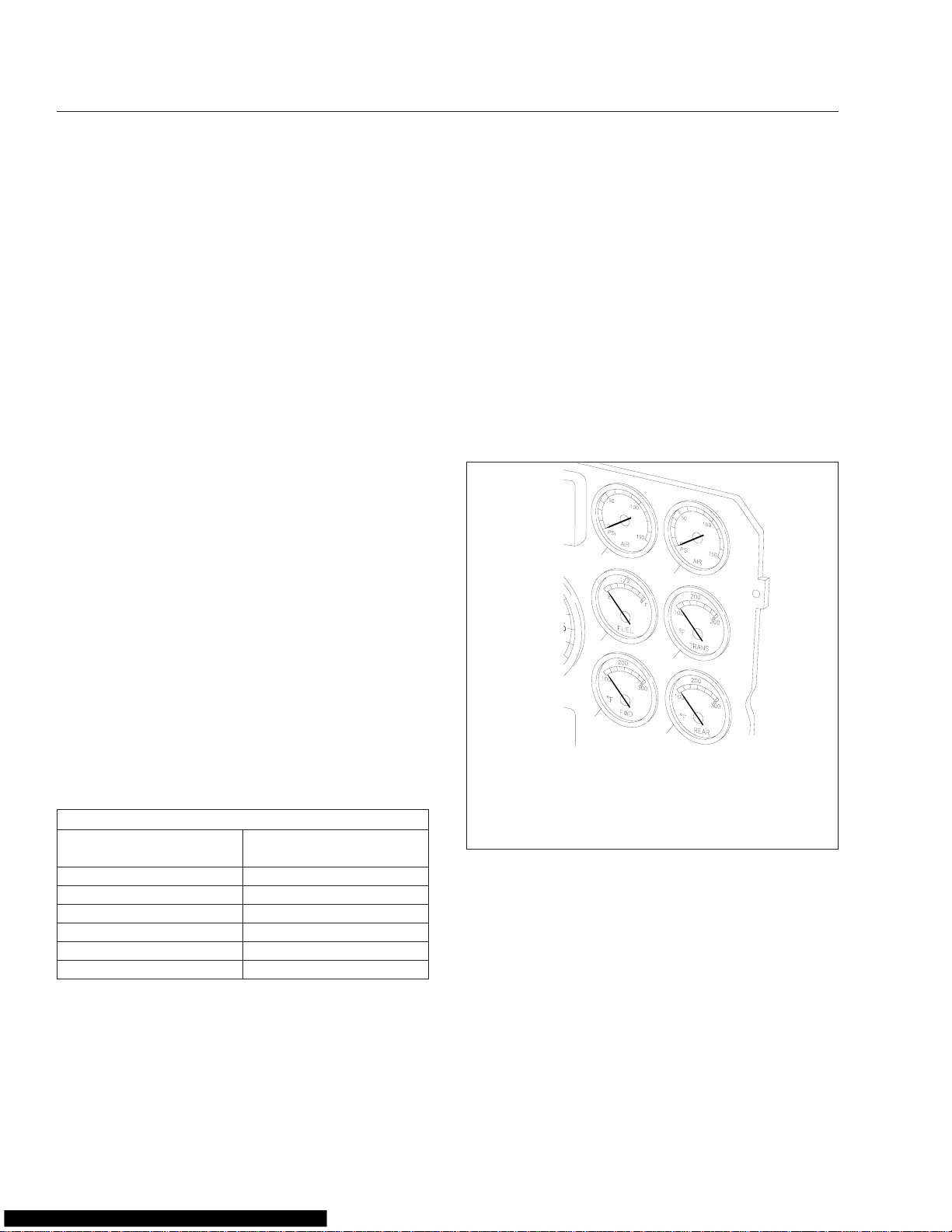

Primary and Secondary Air Pressure

Gauges

Air pressure gauges register the pressure in the primary and secondary air systems. See Fig. 2.17. Normal pressure, with the engine running, is 100 to 120

psi (689 to 827 kPa) in both systems. A low-airpressure warning light and buzzer, connected to both

the primary and secondary systems, activate when

air pressure in either system drops below a minimum

pressure of 64 to 76 psi (441 to 524 kPa). When the

engine is started, the warning light and buzzer remain on until air pressure in both systems exceeds

minimum pressure.

1

2

3

4

02/12/96

1. Primary Air Pressure Gauge

2. Secondary Air Pressure Gauge

3. Fuel Gauge

4. Transmission Oil Temperature Gauge (optional)

5. Forward Axle Oil Temperature Gauge (optional)

6. Rear Axle Oil Temperature Gauge (optional)

Fig. 2.17, Instrument Panel Gauges (right side)

5

6

f601127

Fuel Gauge

The fuel gauge indicates the level of fuel in the fuel

tank(s). See Fig. 2.17. If equipped with a second

(optional) fuel gauge, each fuel tank level is indicated

on a separate gauge.

Transmission Oil Temperature Gauge,

Optional

2.15

During normal operation, the transmission oil temperature gauge reading should not exceed 250°F

Page 24

Instruments and Controls Identification

(121°C) for Eaton®Fuller®transmissions. See

Fig. 2.17.

CAUTION

A sudden increase in oil temperature that is not

caused by a load increase may indicate mechanical failure. Bring the vehicle to a safe stop and

investigate the cause to prevent further damage.

Do not operate the engine until the cause has

been determined and corrected.

Forward and Rear Axle Oil

Temperature Gauges, Optional

During normal operation, forward and rear axle oil

temperature gauges should read between:

•

160 and 220°F (71 and 104°C) for Meritor

drive axles;

•

180 and 200°F (82 and 93°C) for Dana Spicer

drive axles.

Under heavy loads, such as when climbing steep

grades, temperatures up to a maximum of 250°F

(121°C) are not unusual. See Fig. 2.17.

™

vice inH

replaced.

O

,inTable 2.4, the air cleaner needs to be

2

NOTE: Rain or snow can wet the filter and

cause a higher than normal reading temporarily.

Intake-Air Restriction Indicator

An intake-air restriction indicator measures the

vacuum on the engine side of the air cleaner at the

air cleaner outlet. See Fig. 2.18. If the yellow signal

stays locked at or above the values shown in

Table 2.4 after the engine is shut down, the air

cleaner needs to be serviced. The indicator then

needs to be reset by pressing the yellow button.

Intake-Air Restriction Vacuum Readings

*

Engine Make

Cummins 12 25

Detroit Diesel 12 20

®

Caterpillar 15 25

Mercedes-Benz 10 22

*

Turbocharged engines must be checked at full load and governed en-

gine speed.

Table 2.4, Intake-Air Restriction Vacuum Readings

Initial inH2O

Service inH

O

2

CAUTION

A sudden increase in oil temperature that is not

caused by a load increase may indicate mechanical failure. Bring the vehicle to a safe stop and

investigate the cause to prevent further damage.

Do not operate the engine until the cause has

been determined and corrected.

Application Air Pressure Gauge,

Optional

An application air pressure gauge registers the air

pressure being used to apply the brakes and should

be used for reference only. The gauge will not register air pressure until the foot brake pedal is depressed or the trailer hand brake is applied.

Intake-Air Restriction Gauge, Optional

An intake-air restriction gauge measures the vacuum

on the engine side of the air cleaner at the air

cleaner outlet. Vacuum is measured in inH

of water). When the vacuum reading in normal operation equals the applicable level shown under

O (inches

2

Ser-

01/18/95

Fig. 2.18, Intake-Air Restriction Indicator

f600148a

NOTE: Rain or snow can wet the filter and

cause a higher than normal reading temporarily.

Ammeter, Optional

An ammeter measures current flowing to and from

the battery. When the batteries are being charged,

the meter needle moves to the plus side of the

gauge; when the batteries are being discharged, the

2.16

Page 25

Instruments and Controls Identification

needle moves to the minus side. A consistent negative reading when the engine is running indicates a

possible problem with the charging system.

Analog Clock

The analog clock features electronic setting. Do not

pull the set knob. The time can be set either forward

(turn knob to the right) or backward (turn the knob to

the left). A slight turn of the knob either right or left

will change the setting of the clock one minute at a

time. Holding the knob to either the right or the left

will allow accelerated sweeping of the hands for setting the hour.

Digital Clock, Optional

The digital clock has black characters on a constantly backlighted green display, with a brightness

that automatically adjusts for day or night. The clock

has a 24-hour alarm with a three-minute snooze feature.

1.

To set the time of day:

1.1

Push the run/set (lower) switch to the right

(TIME-SET position).

NOTE: When the hour setting is for a time

between noon and midnight, the small letters

PM will appear in the lower left corner of the

display; no PM indicates an a.m. setting.

1.2

Advance the hour setting to the correct

number by pushing and releasing the hour

button as many times as needed. Or if the

button is pressed and held in for longer

than two seconds, the numbers will continue to advance until the button is released.

1.3

Advance the minute setting by repeatedly

pushing, or pushing and holding the

minute button as needed.

1.4

Push the run/set switch to the middle

(RUN) position.

2.

To set the alarm time:

2.1

Push the run/set switch to the left

(ALARM-SET position).

2.2

Set the alarm time by using the same procedure that you used to set the time of

day. Remember to set the hour for a.m.

(no letters in the corner of the display) or

p.m. as desired.

2.3

Return the run/set switch to the middle

(RUN) position. The readout will return to

the time-of-day setting.

3.

To operate the alarm:

3.1

With the alarm time set, push the alarm

(upper) switch to the left. An alarm

symbol, and the letters AL, will appear in

the upper left corner of the display when

the alarm is on.

3.2

When the displayed time of day coincides

with the alarm time, the alarm will sound.

If the SNOOZ button is not pushed or the

alarm switch is not moved, the alarm will

automatically stop sounding after one

minute and will not sound again for 24

hours.

3.3

If desired, press the SNOOZ button while

the alarm is sounding to shut the alarm off

for three minutes. The alarm symbol will

flash in the display when the button is

pushed and will continue to flash until the

alarm switch is moved or the alarm has

sounded for one minute. The snooze procedure can be done as many times as

desired.

3.4

Move the alarm switch to the right when

you wish to shut off or cancel the alarm;

the alarm symbol will disappear.

wave

Controls

Ignition Switch and Key

The ignition switch has four positions: ACCESSORY,

OFF, ON, and START. The ignition key locks and unlocks the cab doors, baggage door(s), and if

equipped, the bunk door(s).

In the OFF position, the key slot is vertical; the key

can be inserted and removed only in this position.

The low-beam headlights, taillights, brake lights, road

lights, dome lights, clearance lights, turn signals,

hazard lights, refrigerator, fuel heater, electric oil pan

2.17

Page 26

Instruments and Controls Identification

heater, and electric or diesel-fired engine-coolant preheaters can be operated in the off position (regardless of whether the key is inserted).

In the ACCESSORY position, the key is turned counterclockwise. The auxiliary (bunk) fan, windshield

fan(s), radio or stereo system, mirror heat, ether start

system, air dryer, backup lights, and all of the electrical systems that are operable in the off position are

operable in the accessory position.

In the ON position, the key is turned clockwise and

all electrical systems are operable. The low air pressure and low oil pressure warning lights (or messages) and buzzer operate until the engine is started

and pressure is built up.

05/23/95

f260316

Cruise Control

IMPORTANT: On vehicles with Eaton VORAD

Collision Warning System (CWS) with SmartCruise, see the "Collision Warning System"

headings in this chapter before operating cruise

control.

The cruise control is activated by the SPD CNTL (on/

off) and RSM/ACC–SET/CST switches on the dash

or

(Fig. 2.19),

SET buttons on the transmission shift knob

(Fig. 2.20). The minimum speed at which cruise control can be used is 30 mph (48 km/h). The minimum

and maximum speed cruise control set limits can be

programmed, by authorized personnel, into the engine electronics.

1

07/29/98

1. RSM/ACC–SET/CST Switch

2. SPD CNTL (On/Off) Switch

Fig. 2.19, Cruise Control Switches, Dash-Mounted

by optional PAUSE, RESUME, and

2

f541126

Fig. 2.20, Cruise Control, Transmission Shift Knob

Buttons

WARNING

Do not use the cruise control system when driving conditions do not permit maintaining a constant speed, such as in heavy traffic or on roads

that are winding, icy, snow-covered, slippery, or

roads with a loose driving surface. Failure to follow this precaution could cause a collision or

loss of vehicle control, possibly resulting in personal injury or property damage.

CAUTION

Do not attempt to shift gears without using the

clutch pedal when the cruise control is engaged.

Failure to follow this precaution will result in a

temporarily uncontrolled increase in engine

speed; transmission damage and gear stripping

could result.

1.

To cruise at a particular speed:

1.1

Press the upper half of the SPD CNTL

(on/off) rocker switch on the instrument

control panel.

1.2

Hold the throttle down until the speedometer reaches the desired speed.

1.3

Momentarily flip the RSM/ACC–SET/CST

paddle switch on the instrument control

panel down to SET/CST.

1.4

or

—Push the SET button on the transmis-

sion shift knob.

2.18

Page 27

Instruments and Controls Identification

2.

To disengage the cruise control:

2.1

Depress the brake pedal or clutch pedal.

2.2

or

—Press the lower half of the SPD CNTL

rocker switch on the instrument control

panel.

2.3

or

—Push the PAUSE button on the transmission shift knob.

3.

To resume a preselected cruise speed:

3.1

If the SPD CNTL rocker switch on the instrument control panel is off, turn it on.

3.2

Momentarily flip the RSM/ACC–SET/CST

paddle switch on the instrument control

panel to RSM/ACC.

3.3

or

—Push the RESUME button on the

transmission shift knob. Cruise will return

to the last speed selected.

NOTE: The resume vehicle speed memory is

not maintained if the ignition is shut off.

4.

To adjust cruise speed up or down:

4.1

Hold the paddle switch on the instrument

control panel at RSM/ACC to accelerate,

or at SET/CST to decelerate, until the desired speed is reached.

4.2

or

—Press the SET button on the transmission shift knob to accelerate, or the RESUME button to decelerate, until the desired speed is reached.

1.3

Momentarily flip the paddle switch on the

instrument control panel down to SET/

CST.

1.4

or

—Push the SET button on the transmis-

sion shift knob.

2.

To disengage the PTO:

2.1

Depress the brake pedal or clutch pedal.

2.2

or

—Press the lower half of the SPD CNTL

rocker switch on the instrument control

panel.

2.3

or

—Press the PAUSE button on the shift

knob.

3.

To resume a previously selected engine speed:

3.1

If the SPD CNTL switch on the instrument

control panel is turned off, turn it on.

3.2

Momentarily flip the paddle switch on the

instrument control panel up to RSM/ACC.

3.3

or

—Press the RESUME button on the

transmission shift knob.

4.

To adjust engine speed up or down:

4.1

Hold the RSM/ACC–SET/CST paddle

switch up to accelerate, or down to decelerate, until the desired speed is reached.

4.2

or

—Press the SET button on the transmission shift knob to accelerate, or the RESUME button to decelerate, until the desired speed is reached.

Power Takeoff (PTO) Governor

Caterpillar electronic engines may be equipped with

a PTO governor. This mode is used only when the

vehicle is parked. The PTO mode is activated by the

SPD CNTL and RSM/ACC–SET/CST switches on the

dash (Fig. 2.19) or by optional PAUSE, RESUME,

and SET buttons on the transmission shift knob

(Fig. 2.20).

1.

To engage the PTO:

1.1

Press the upper half of the SPD CNTL

rocker switch on the instrument control

panel.

1.2

Hold the throttle down until the tachometer

reaches the desired engine speed.

2.19

NOTE: The resume engine speed memory is

not maintained if the ignition is shut off.

Detroit Diesel Electronic Engine

Control (DDEC IV

IMPORTANT: This vehicle is equipped with an

Instrumentation Control Unit (ICU) that provides

warning messages and diagnostic fault codes.

See "Instrumentation Control Unit", depending

on the type of unit installed in your vehicle.

The DDEC IV system uses a computer that is programmed to automatically control engine timing and

fuel injection.

DDEC IV systems will shut down the engine if sensors indicate an emergency engine condition such as

low coolant level, high coolant temperature, or high

®

) Operator Control

Page 28

Instruments and Controls Identification

oil temperature. If such a condition occurs, the yellow

Check Engine light on the dash will illuminate. If the

problem gets bad enough to cause possible engine

damage, the DDEC IV will gradually cut engine

power down to 70 percent of original power. At that

point, the red Engine Protection (ENG PROT) light

will turn on and thirty seconds later, DDEC IV will

shut down the engine (if programmed). If DDEC IV

detects low oil pressure, both the Check Engine and

Engine Protection lights will come on, and the engine

will shut down in thirty seconds (if programmed). See

"Engine Protection—Warning and Shutdown Process" at the beginning of this chapter, for more information.

Optimized Idle

®

The Optimized Idle option on DDEC IV-equipped vehicles is a system that automatically stops and restarts the engine to accomplish the following:

•

Keep the engine oil temperature between 60 to

104°F (16 to 40°C)

•

Keep the battery charged

•

Keep the cab or sleeper at a constant, desired

temperature (if equipped with a thermostat)

The benefits of the system include reduced engine

idle time, fuel savings, reduction of exhaust emissions and noise, increased starter and engine life,

and less chance of dead batteries due to electrical

loads.

Optimized Idle operates in two modes. They are the

engine mode or the thermostat mode. The engine

mode keeps the battery charged and the engine oil

temperature within factory set limits. The thermostat

mode is the same as the engine mode, but also

keeps the cab and sleeper at a constant preset temperature.

The engine mode is always activated when the system is operated. The thermostat mode is activated

when the thermostat is turned on.

The thermostat mode controls the set point, which is

the desired temperature of the cab and sleeper, and

the comfort zone, which is the number of degrees

from the set point before the engine needs to heat or

cool the cab. There are three comfort zones: 4°F

(2°C), 7°F (4°C), or 10°F (6°C).

Vehicles equipped with Optimized Idle have a label

and a dash light. The dash light is on the dash mes-

sage center or the Driver Message Center, on the A

panel. See Fig. 2.21. See Fig. 2.22 for the dash

label detail. If equipped with the thermostat mode, a

thermostat is located in the sleeper, above the bunk.

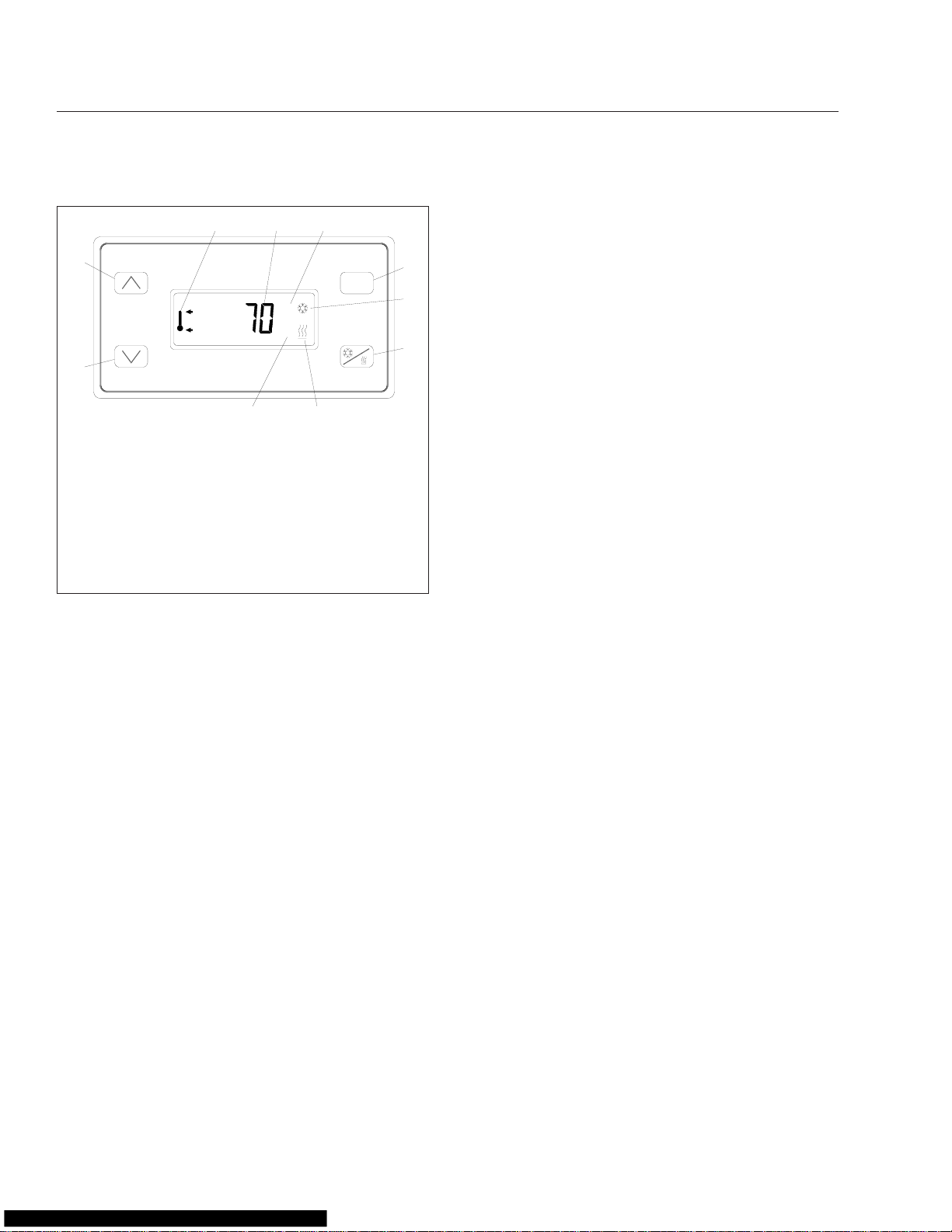

See Fig. 2.23.

1

FASTEN SEATBELTS

0000432 MILES

02/11/97

1. Optimized Idle Light

Fig. 2.21, Optimized Idle Light Location

OPTIMIZED IDLE

TO USE:

− IDLE ENGINE

− CLOSE HOOD

− ENGAGE PARKING BRAKES

− PUT TRANSMISSION IN

NEUTRAL AND

HI RANGE (IF EQUIPPED)

− THEN, MOVE CRUISE SWITCH

FROM OFF TO ON

− IF DESIRED, TURN CAB

THERMOSTAT ON (IF EQUIPPED)

11/13/96

Fig. 2.22, Optimized Idle Dash Label

TM

TO AVOID

UNINTENTIONAL

VEHICLE MOVEMENT,

DO NOT MOVE SHIFT

LEVER OR RANGE

SELECTOR WHEN

OPTIMIZED IDLE IS ON

f601264

f080062

The thermostat consists of an LCD readout and four

buttons.

The display normally shows the temperature of the

sleeper, but changes accordingly as the buttons are

pressed.

The button functions are as follows:

•

Up button: increases the set point and comfort

zone.

•