Freightliner Cascadia Maintenance Manual

CASCADIA

®

Part Number STI 478

Publication Number STI-478-6

Maintenance Manual

CASCADIA MAINTENANCE MANUAL

Models: CA113DC

CA113SLP

CA125DC

CA125SLP

STI-478-6 (3/16)

Published by

Daimler Trucks North America LLC

4747 N. Channel Ave.

Portland, OR 97217

Printed in U.S.A.

Foreword

Scheduled maintenance provides a key element for the safe operation of your vehicle. A proper maintenance

program also helps to minimize downtime and to safeguard warranties. This maintenance manual provides

information necessary for years of safe, reliable, and cost-efficient vehicle operation.

IMPORTANT: The maintenance operations in this manual are not all-inclusive. Also refer to other

component and body manufacturers’ instructions for specific inspection and maintenance instructions.

Perform the operations in this maintenance manual at scheduled intervals. Perform the pretrip inspection and

daily/weekly/monthly maintenance, as outlined in the vehicle driver’s manual. Major components, such as

engines, transmissions, and rear axles, are covered in their own maintenance and operation manuals, that are

provided with the vehicle. Perform any maintenance operations listed at the intervals scheduled in those

manuals. Your Freightliner Dealership has the qualified technicians and equipment to perform this maintenance for you. They can also set up a scheduled maintenance program tailored specifically to your needs.

Optionally, they can assist you in learning how to perform these maintenance procedures.

IMPORTANT: Descriptions and specifications in this manual were in effect at the time of printing.

Freightliner Trucks reserves the right to discontinue models and to change specifications or design

at any time without notice and without incurring obligation. Descriptions and specifications contained

in this publication provide no warranty, expressed or implied, and are subject to revision and editions

without notice.

Refer to www.Daimler-TrucksNorthAmerica.com and www.FreightlinerTrucks.com for more information,

or contact Daimler Trucks North America LLC at the address below.

Environmental Concerns and Recommendations

Whenever you see instructions in this manual to discard materials, you should attempt to reclaim and recycle

them. To preserve our environment, follow appropriate environmental rules and regulations when disposing of

materials.

NOTICE: Parts Replacement Considerations

Do not replace suspension, axle, or steering parts (such as springs, wheels, hubs, and steering gears) with

used parts. Used parts may have been subjected to collisions or improper use and have undetected structural

damage.

© 2007–2016 Daimler Trucks North America LLC

All rights reserved. No part of this publication, in whole or in part, may be translated, reproduced, stored in a

retrieval system, or transmitted in any form by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of Daimler Trucks North America LLC. Daimler Trucks North

America is a Daimler company.

Daimler Trucks North America LLC

Service Systems and Documentation (CVI-SSD)

P.O. Box 3849

Portland, OR 97208–3849

Introduction

Descriptions of Service Publications

Daimler Trucks North America LLC distributes the following major service publications in paper and electronic

(via ServicePro®) formats.

Workshop/Service

Manual

Maintenance Manual Maintenance manuals contain routine maintenance procedures and intervals for

Troubleshooting Manual Troubleshooting manuals contain diagnostic procedures for determining causes

Driver’s/Operator’s

Manual

Service Bulletins Service bulletins provide the latest service tips, field repairs, product improve-

Workshop/service manuals contain service and repair information for all vehicle

systems and components, except for major components such as engines, transmissions, and rear axles. Each workshop/service manual section is divided into

subjects that can include general information, principles of operation, removal,

disassembly, assembly, installation, and specifications.

vehicle components and systems. They have information such as lubrication

procedures and tables, fluid replacement procedures, fluid capacities, specifications, and procedures for adjustments and for checking the tightness of fasteners. Maintenance manuals do not contain detailed repair or service information.

of problems in vehicle components and systems. Information on multiplexing

diagnosis is included. These manuals are organized by functional systems,

such as cab, chassis, and powertrain. Troubleshooting manuals do not contain

repair or service information.

Driver’s/operator’s manuals contain information needed to enhance the driver’s

understanding of how to operate and care for the vehicle and its components.

Each manual contains a chapter that covers pre-trip and post-trip inspections,

and daily, weekly, and monthly maintenance of vehicle components.

Driver’s/operator’s manuals do not contain detailed repair or service information.

ments, and related information. Some service bulletins are updates to information in the workshop/service manual. These bulletins take precedence over

workshop/service manual information, until the latter is updated; at that time, the

bulletin is usually canceled. The service bulletins manual is available only to

dealers. When doing service work on a vehicle system or part, check for a valid

service bulletin for the latest information on the subject.

IMPORTANT: Before using a particular service bulletin, check the current

service bulletin validity list to be sure the bulletin is valid.

Parts Technical Bulletins Parts technical bulletins provide information on parts. These bulletins contain

lists of parts and BOMs needed to do replacement and upgrade procedures.

Web-based repair, service, and parts documentation can be accessed using the following applications on the

AccessFreightliner.com website.

ServicePro ServicePro® provides Web-based access to the most up-to-date versions of the

publications listed above. In addition, the Service Solutions feature provides diagnostic assistance with Symptoms Search, by connecting to a large knowledge

base gathered from technicians and service personnel. Search results for both

documents and service solutions can be narrowed by initially entering vehicle

identification data.

PartsPro PartsPro® is an electronic parts catalog system, showing the specified vehicle’s

build record.

Cascadia Maintenance Manual, May 2011 I–1

Introduction

Descriptions of Service Publications

EZWiring EZWiring™makes Freightliner, Sterling, Western Star, Thomas Built Buses, and

Freightliner Custom Chassis Corporation products’ wiring drawings and floating

pin lists available online for viewing and printing. EZWiring can also be accessed from within PartsPro.

Warranty-related service information available on the AccessFreightliner.com website includes the following

documentation.

Recall Campaigns Recall campaigns cover situations that involve service work or replacement of

parts in connection with a recall notice. These campaigns pertain to matters of

vehicle safety. All recall campaigns are distributed to dealers; customers receive

notices that apply to their vehicles.

Field Service Campaigns Field service campaigns are concerned with non-safety-related service work or

replacement of parts. All field service campaigns are distributed to dealers; customers receive notices that apply to their vehicles.

I–2 Cascadia Maintenance Manual, May 2011

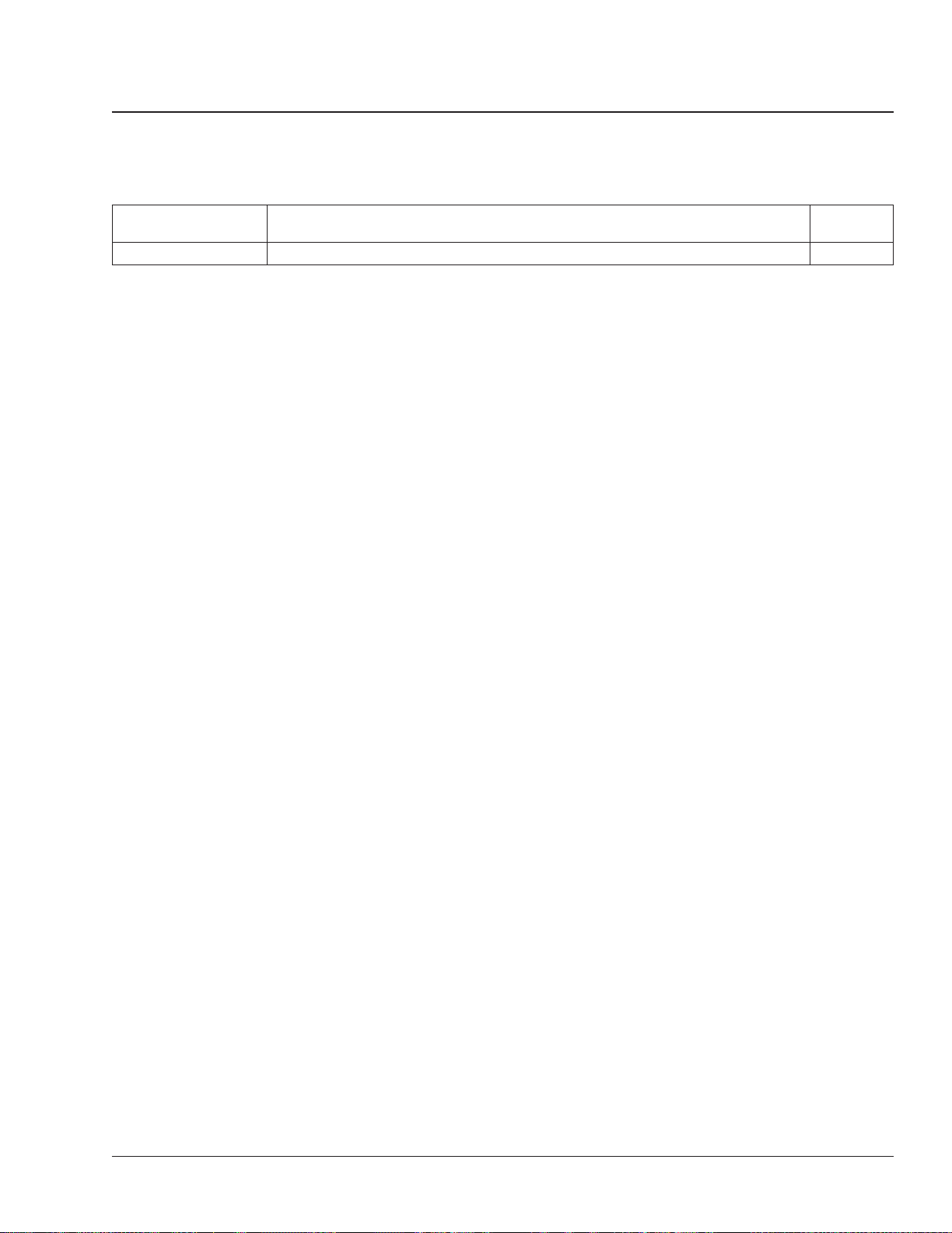

Page Description

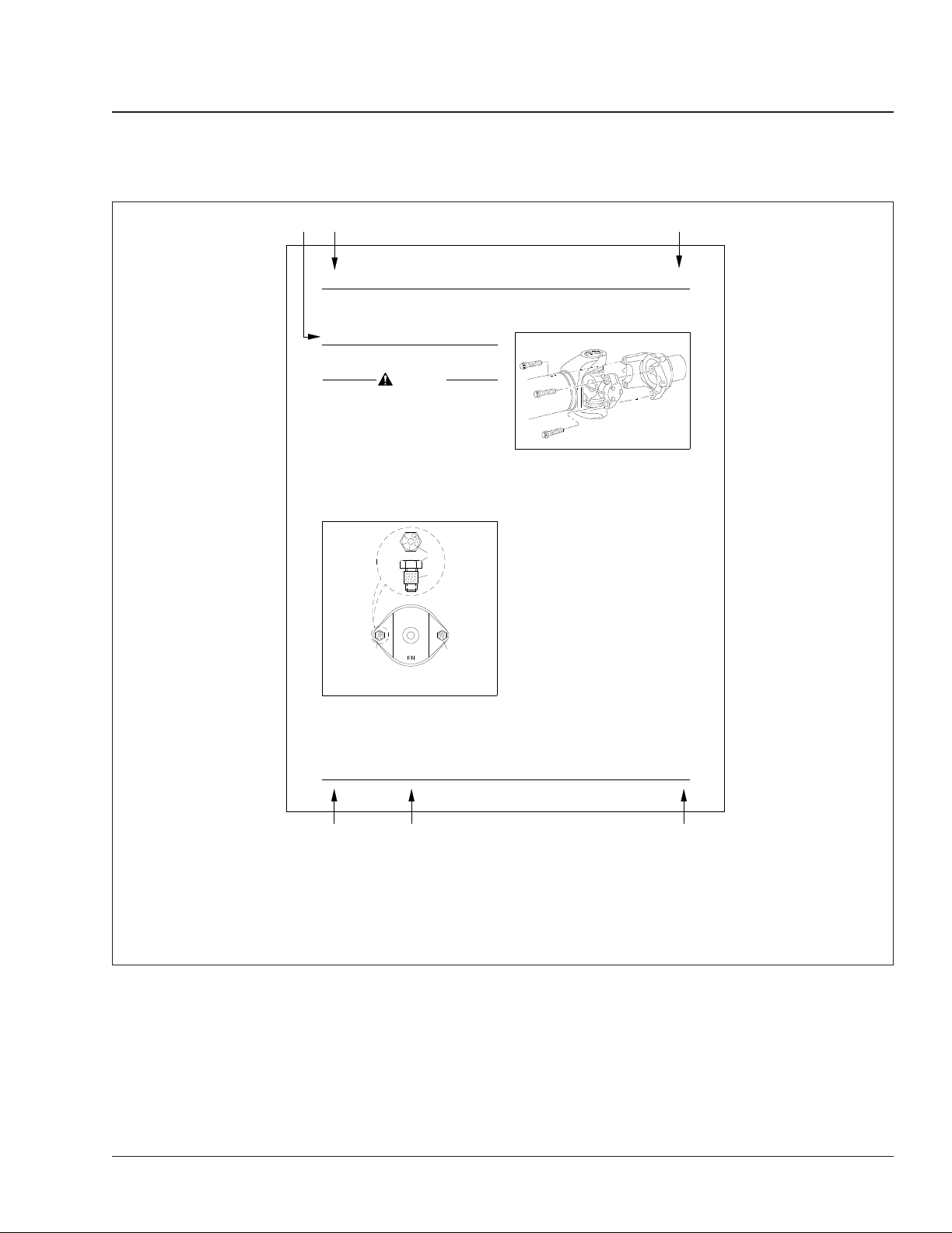

For an example of a Maintenance Manual page, see Fig. 1.

Introduction

A

Driveline

41−01

Driveline

1.Parkthevehicle

par

kingbrakes,and

Duetotheextremeloadoccurringathigh−speed

rotation,alooseorbrokencapscr

inthedrivelinewill

tion,whichcould

hicledamage.Tightenbearing−capcapscrewsor

yoke−strapcapscrews tospecifedtorque,being

carefultonotovertighten.

2.

F

or

U−joints

cap

capscrews43

F

or

Ar

vin

bear

ing−cap

Fig.

2

.

F

or

U−joints

capscrews125

04/13/98

1.

Self−Locking

Capscre

w

Fig.1,Ar

vin

3.

Checkthedriv

end−y

okesfor

Replacecrackedyokes

Inspection

on a level

surf

chockthe

CA

UTION

weakenthedrivelineconnec−

eventuallyresultinseriousve

with

bear

ing

caps

lbf·ft

(49

Mer

capscrews125

with

1

Meritor

N·m).

itor

RPL

ser

ies

U−joints

lbf·ft

y

ok

e

str

aps

,

tighten y

lbf·ft

(169

N·m).

1

2

I

T

O

R

R

E

M

2.

AdhesiveBand

U−JointFastenersfor

Caps

elineyokesforcracks,

looseness.See.Fig.

.

ace,apply

tires

.

ew at anypoint

,

tighten bear

See.Fig.

,

tighten

(169

N·m).

ok

e−strap

See.Fig.

1

Bearing

and

3

the

ing−

1

3

f410155a

chec

−

12/09/97

If anyend−yoke

shaft,orcanberocked on

See

thedriv

checkthedrivecomponent’sshaft

ageorother

causedby

needed,

Gr

f

or

after

yoke

Replace

n

ut)

replacement,oranyother

CheckU−joint

4.

driveshaftupanddown,

an

ings

sembly.

5.

Chec

looseorhave

move

to

r

attles,replace

on

the

Casc

cations.Replace

the

6.

Checkslip

k

sleeve−yoke

See.If

cloc

Fig.2,Ar

vin

Meritor

canbemoved inoroutonits

eshaft

and U−joint

visibledamage

the

looseyoke.

then

tighten

oup41of

the

Casc

torque

specifications

tightening

theyok

andyok

e nut.

the

prevailing

if itwas

removedforyokereplacement,

assemb

ymov

ementofthe

canbef

eltorseen,

kif

the

midship

deter

thedriv

eshaftupanddown,

side.If

the

bear

ingislooseonits

it. If

theframe,tighten

proper

torquevalue.See

adiaYW

or

ks

hop

the

rub

ber

cushionisdeter

jointsfor

and

splined

the

slip

Fig.

4

kwise,or

countercloc

RPL Series

its

from

thatmayhavebeen

Replace

theyok

e nut.

adiaTMW

.If

the

enut,

replace

torque

reason.

liesfor

wearbymoving

and

from

U−joint

crossinthe

replace

bear

ing

and

ior

ated,by

the

bear

ing

the

mountingfasteners

Gr

Man

ual

midship

ior

atedoroil−soak

spline

wearbymoving

shaft

joint

canbetwisted

kwisemov

U−Joint

shaft,

disconnect

theyoke,

sealfor

the

Referto

or

ks

hop

y

ok

e

is still

the

locknut

(end−yoke

sidetoside.If

the

U−joint

mounting

attempting

and

shaft,

mountisloose

oup

41

f

or

torque

bear

ing

assemblyif

backandfor

ement

then

seal

Man

end−

bear−

to

from

of

specif−

in a

CB

41

f410182

leak−

if

ual

loose

seal

as−

are

side

or

to

the

ed.

the

th.

the

CascadiaTMMaintenance Manual, July 2007

41/1

FDE

06/11/2007

f020166

A. Maintenance Operation Number consists of the Group Number followed by the Sequence Number

B. Group Title

C. Group Number

D. Vehicle Name

E. Release Date

F. Group Number/Page Number

Fig. 1, Example of a Maintenance Manual Page

Cascadia Maintenance Manual, May 2011 I–3

Introduction

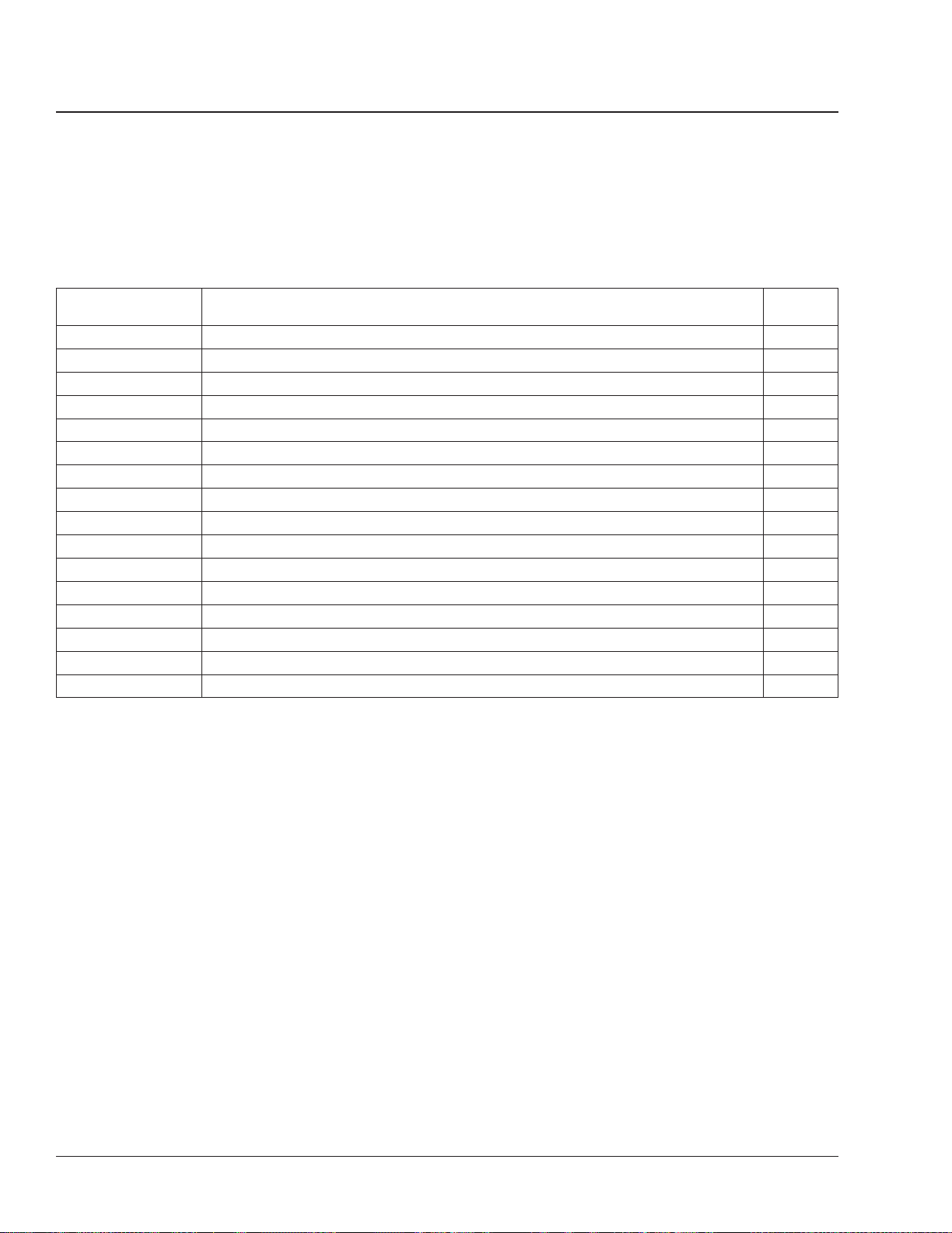

Group No. Group Title

00...................... General Information

09.............................. AirIntake

13 ......................... AirCompressor

15................... Alternators and Starters

20................... Engine Cooling/Radiator

25................................ Clutch

26........................... Transmission

31 ............. Frame and Frame Components

32............................ Suspension

33 ............................. Front Axle

35 ............................. Rear Axle

40........................ Wheels and Tires

41 .............................. Driveline

42................................ Brakes

46............................... Steering

47 ................................. Fuel

49............................... Exhaust

54.......... Electrical, Instruments, and Controls

60 .................................. Cab

83................. Heater and Air Conditioner

88.............. Hood, Grille, and Cab Fenders

Maintenance Manual Contents

I–4 Cascadia Maintenance Manual, May 2011

General Information 00

Index, Alphabetical

Title of Maintenance Operation (MOP) MOP Number

Determining Scheduled Maintenance Intervals.............................................00–01

Initial Maintenance (IM) Operations.....................................................00–04

M1 Maintenance Interval Operations....................................................00–05

M2 Maintenance Interval Operations....................................................00–06

M3 Maintenance Interval Operations....................................................00–07

Maintenance Operation Sets Table ..................................................... 00–08

Noise Emission Controls Maintenance...................................................00–09

Service Schedule Table ............................................................. 00–02

Vehicle Maintenance Schedule Table ................................................... 00–03

Verification of Inspections Log.........................................................00–10

Cascadia Maintenance Manual, August 2015

General Information 00

Determining Scheduled Maintenance Intervals: 00–01

Determining Scheduled

Maintenance Intervals

Performing regular maintenance on your Freightliner

vehicle will help ensure that your vehicle delivers

safe reliable service and optimum performance for

years to come. Failure to follow a regular maintenance program can result in inefficient operation and

unscheduled down time.

To determine the correct maintenance intervals for

your vehicle you must first determine the type of service or conditions the vehicle will be operating in.

Generally, over-the-road vehicles operate under conditions that fall within one of the two types of service

described. Before placing your new vehicle in service, determine the type of service (Service Schedule

I or II) that applies to the intended use of the vehicle.

After determining the vehicle’s type of service, refer

to the service schedule table or the vehicle maintenance schedule table, to determine how often maintenance should be performed.

When the vehicle reaches the distance given for a

maintenance interval, see the Maintenance Interval

Operation Table for a list of the maintenance operations to be performed at that maintenance interval.

Use the maintenance operation reference numbers to

find detailed instructions in the manual on each operation.

operating conditions. Unusual vehicle operating

conditions may require service at more frequent

intervals.

Types of Service

Service Schedule I (short-haul transport) applies to

vehicles that annually travel less than 60,000 miles

(100 000 kilometers) and operate under normal conditions. Examples of Schedule I usage are: operation

primarily in cities and densely populated areas; local

transport with infrequent freeway travel; or high percentage of stop-and-go travel.

Service Schedule II (long-haul transport) is for vehicles that annually travel more than 60,000 miles

(100 000 kilometers) with minimal city or stop-and-go

operation. Examples of Schedule II usage are: regional delivery that is mostly freeway miles; interstate

transport; or any road operation with high annual

mileage.

NOTE: Maintenance instructions in this manual

are based on average vehicle use and normal

Cascadia Maintenance Manual, August 2015 00/1

Service Schedule Table: 00–02

General Information00

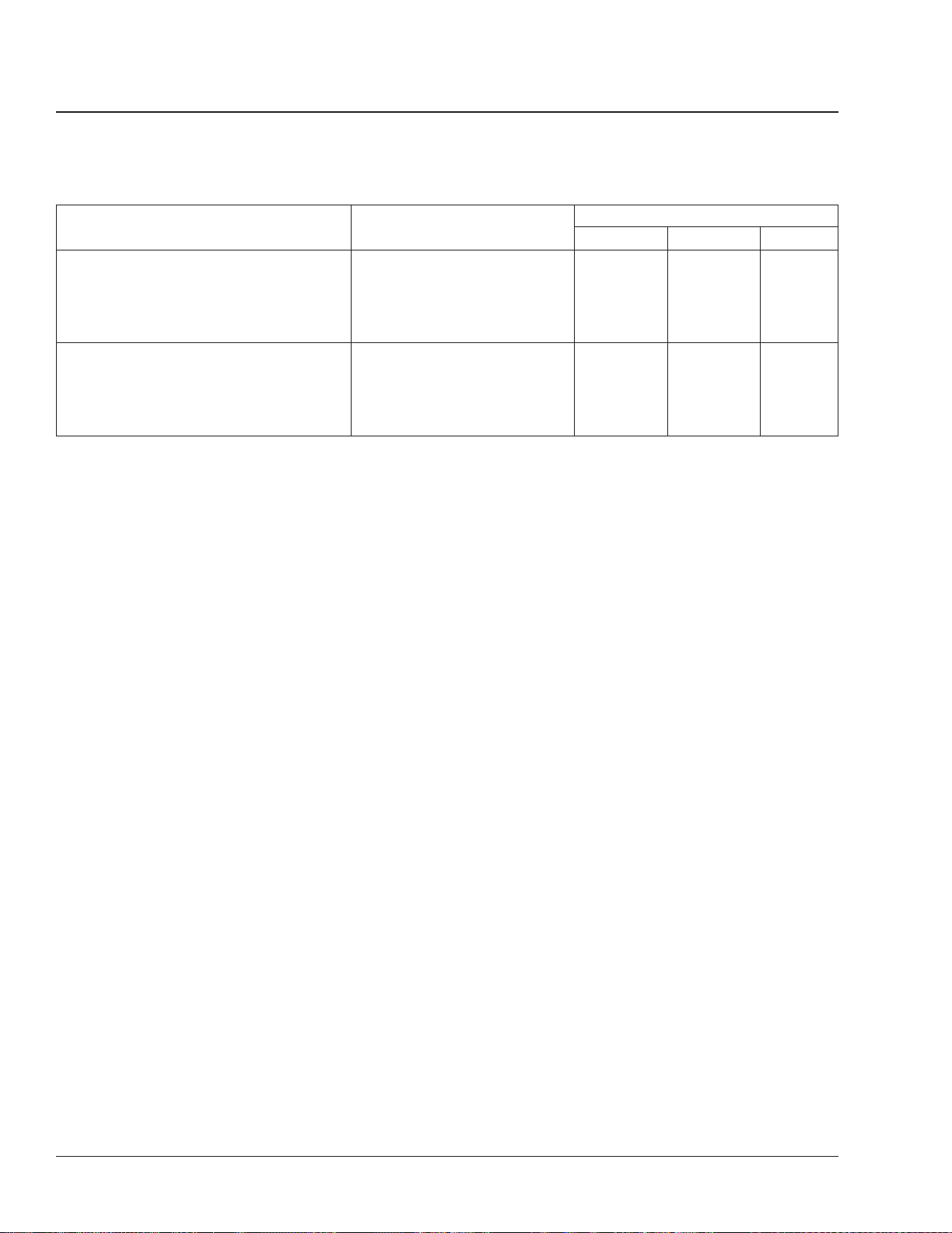

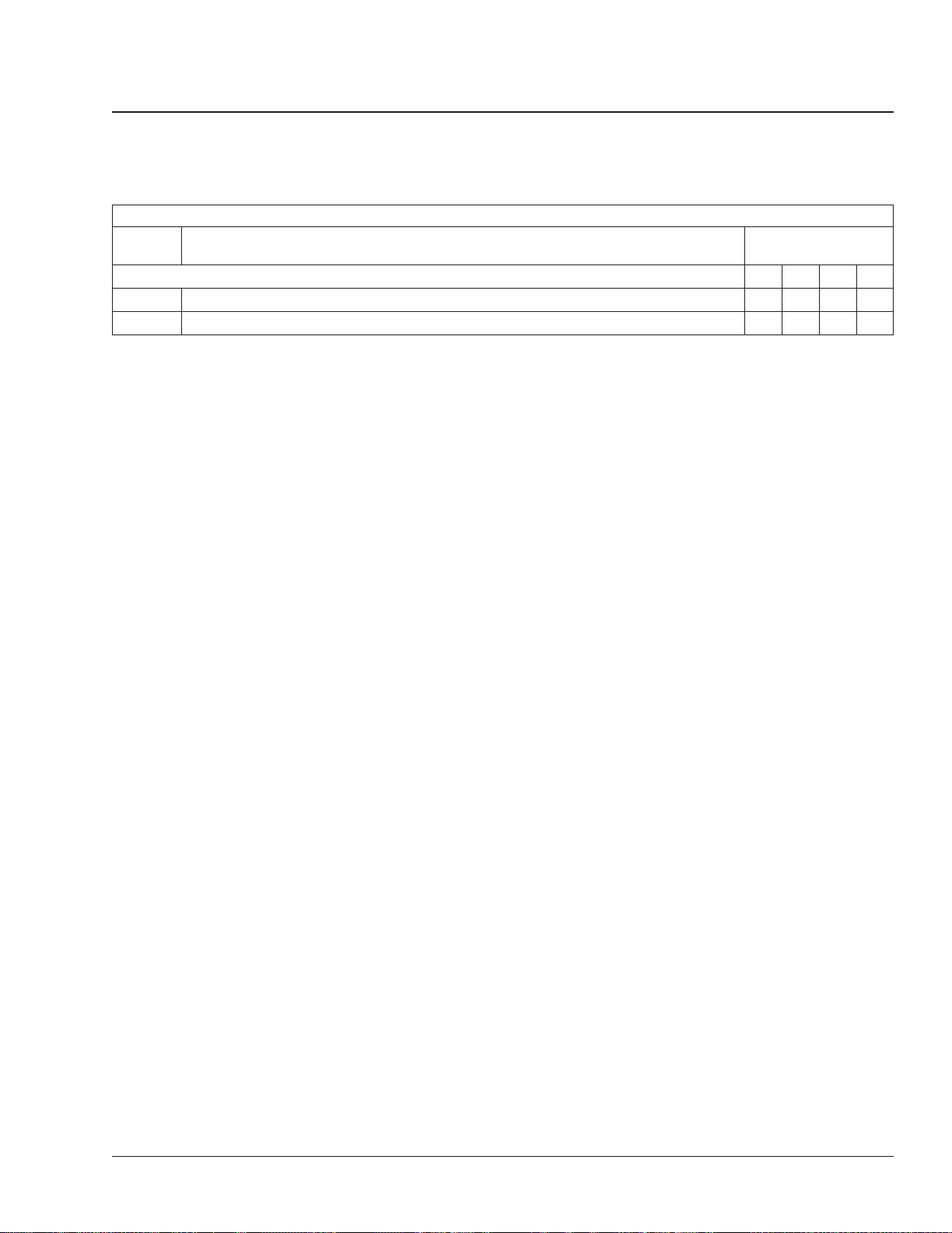

Service Schedule Maintenance Interval Operation

Schedule I

(Short-Haul Transport)

vehicles that annually travel less than 60,000

miles (100 000 km)

Schedule II

(Long-Haul Transport)

vehicles that annually travel over 60,000

miles (100 000 km)

Maintenance Interval

Frequency Miles km

Initial Maintenance (IM) first 10,000 16 000

Maintenance 1 (M1) every 10,000 16 000

Maintenance 2 (M2) every 50,000 80 000

Maintenance 3 (M3) every 150,000 240 000

Initial Maintenance (IM) first 25,000 40 000

Maintenance 1 (M1) every 25,000 40 000

Maintenance 2 (M2) every 100,000 161 000

Maintenance 3 (M3) every 300,000 483 000

Table 1, Service Schedule

Cascadia Maintenance Manual, August 201500/2

General Information 00

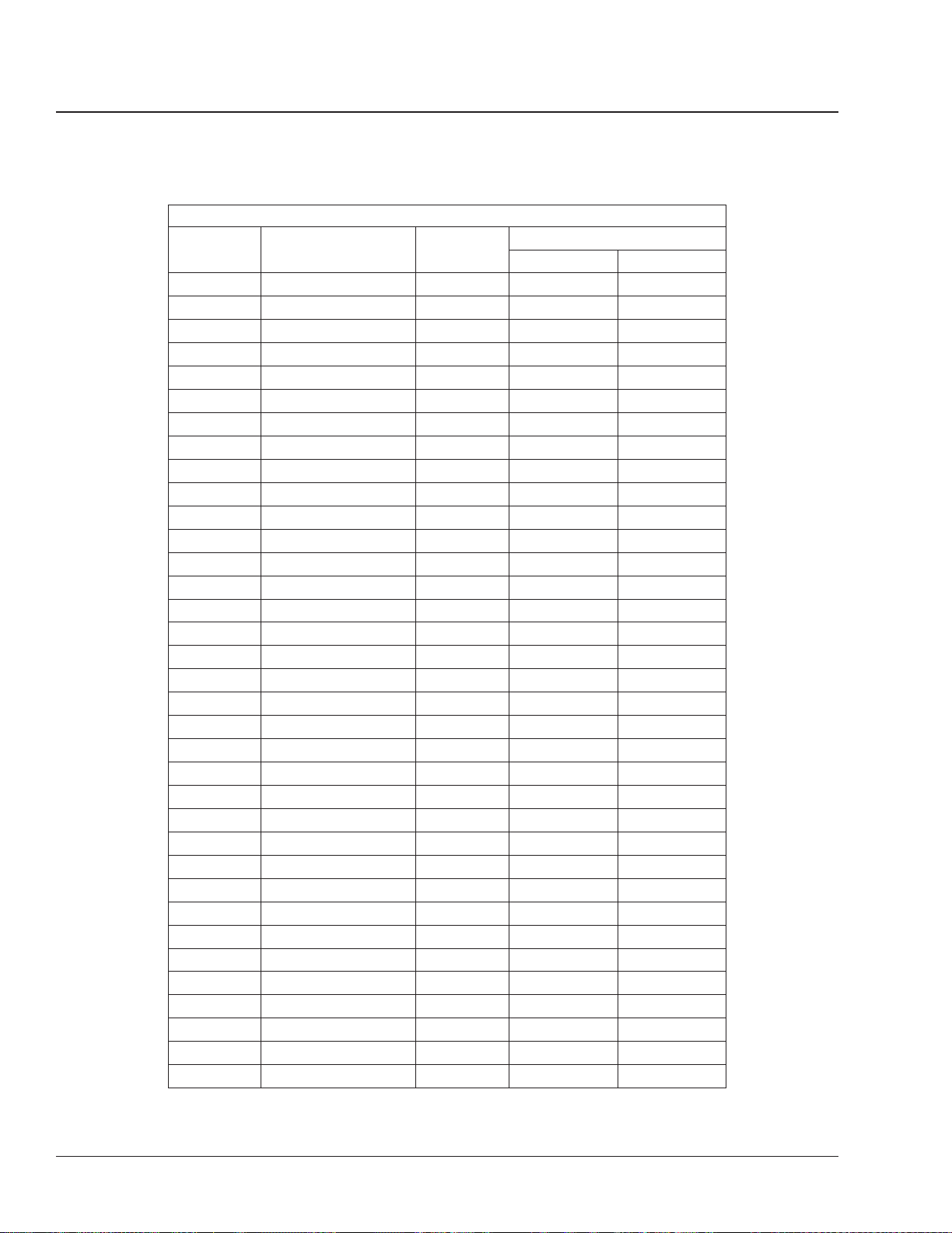

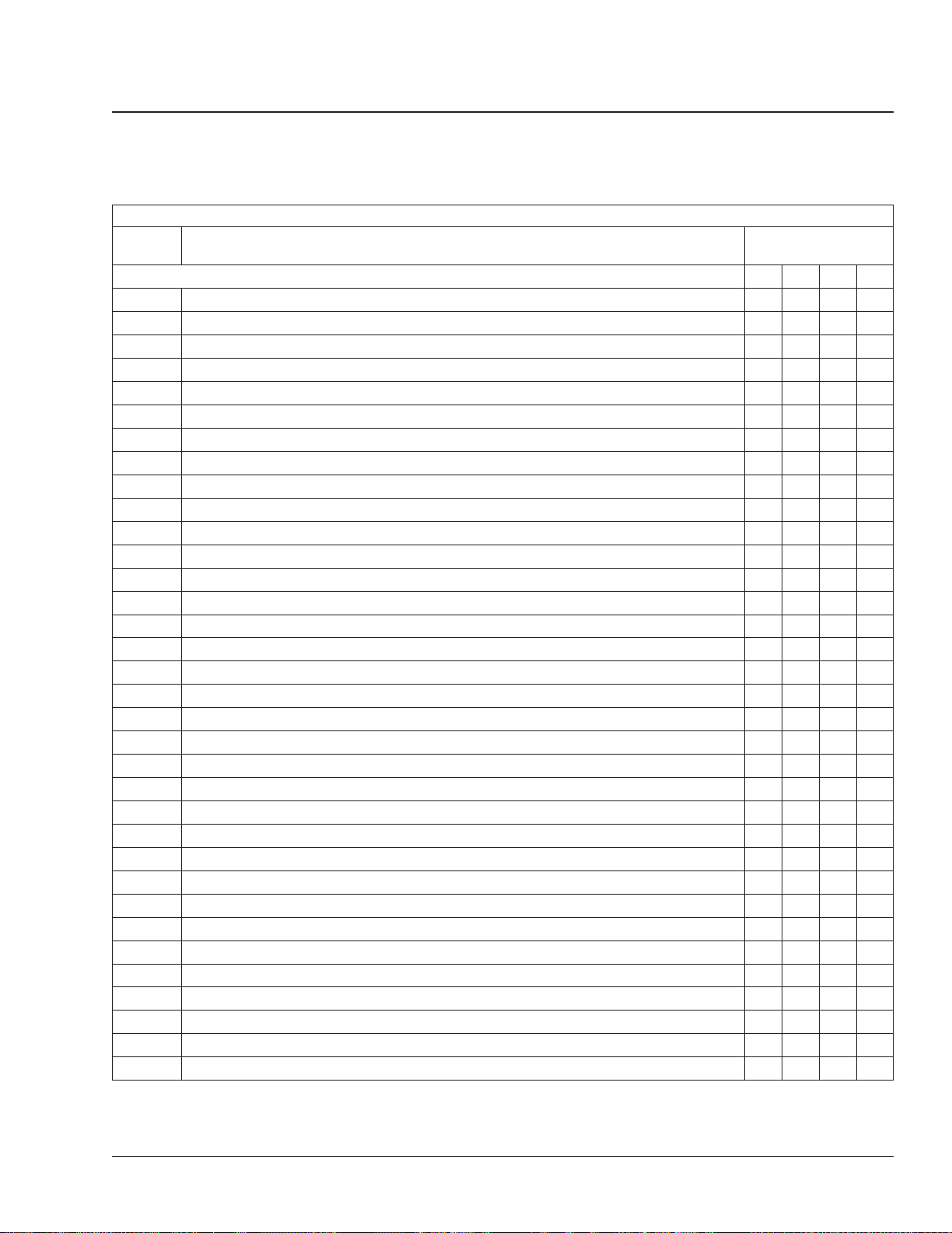

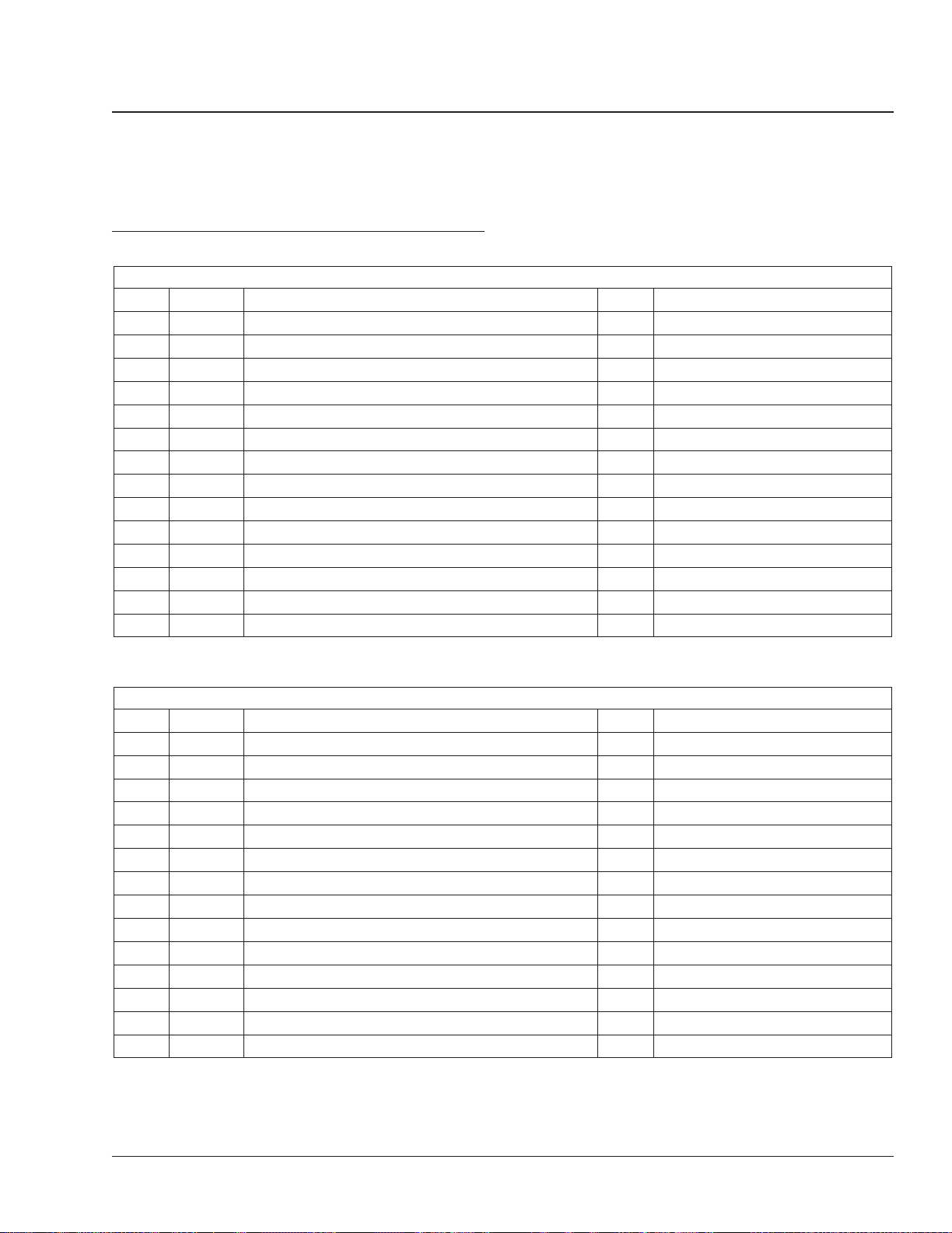

Vehicle Maintenance Schedule Table: 00–03

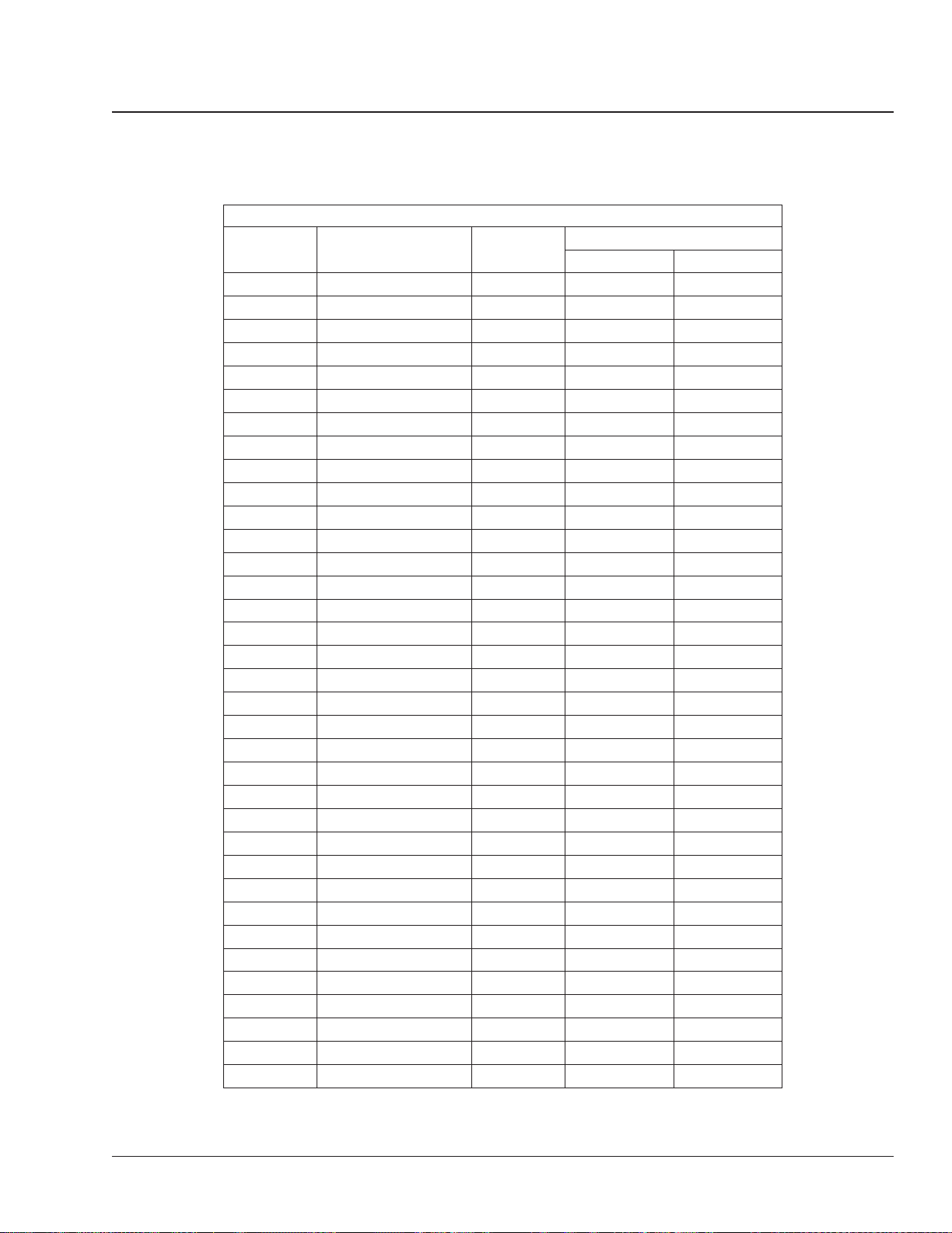

Maintenance for Service Schedule I

Maint. No.

1st IM and M1 10,000 16 000

2nd M1 20,000 32 000

3rd M1 30,000 48 000

4th M1 40,000 64 000

5th M1 and M2 50,000 80 000

6th M1 60,000 96 000

7th M1 70,000 112 000

8th M1 80,000 128 000

9th M1 90,000 144 000

10th M1 and M2 100,000 160 000

11th M1 110,000 176 000

12th M1 120,000 192 000

13th M1 130,000 208 000

14th M1 140,000 224 000

15th M1, M2, and M3 150,000 240 000

16th M1 160,000 256 000

17th M1 170,000 272 000

18th M1 180,000 288 000

19th M1 190,000 304 000

20th M1 and M2 200,000 320 000

21st M1 210,000 336 000

22nd M1 220,000 352 000

23rd M1 230,000 368 000

24th M1 240,000 384 000

25th M1 and M2 250,000 400 000

26th M1 260,000 416 000

27th M1 270,000 432 000

28th M1 280,000 448 000

29th M1 290,000 464 000

30th M1, M2, and M3 300,000 480 000

31st M1 310,000 496 000

32nd M1 320,000 512 000

33rd M1 330,000 528 000

34th M1 340,000 544 000

35th M1 and M2 350,000 560 000

Maintenance

Interval

Service

Date

Service Schedule I

Miles km

Cascadia Maintenance Manual, August 2015 00/3

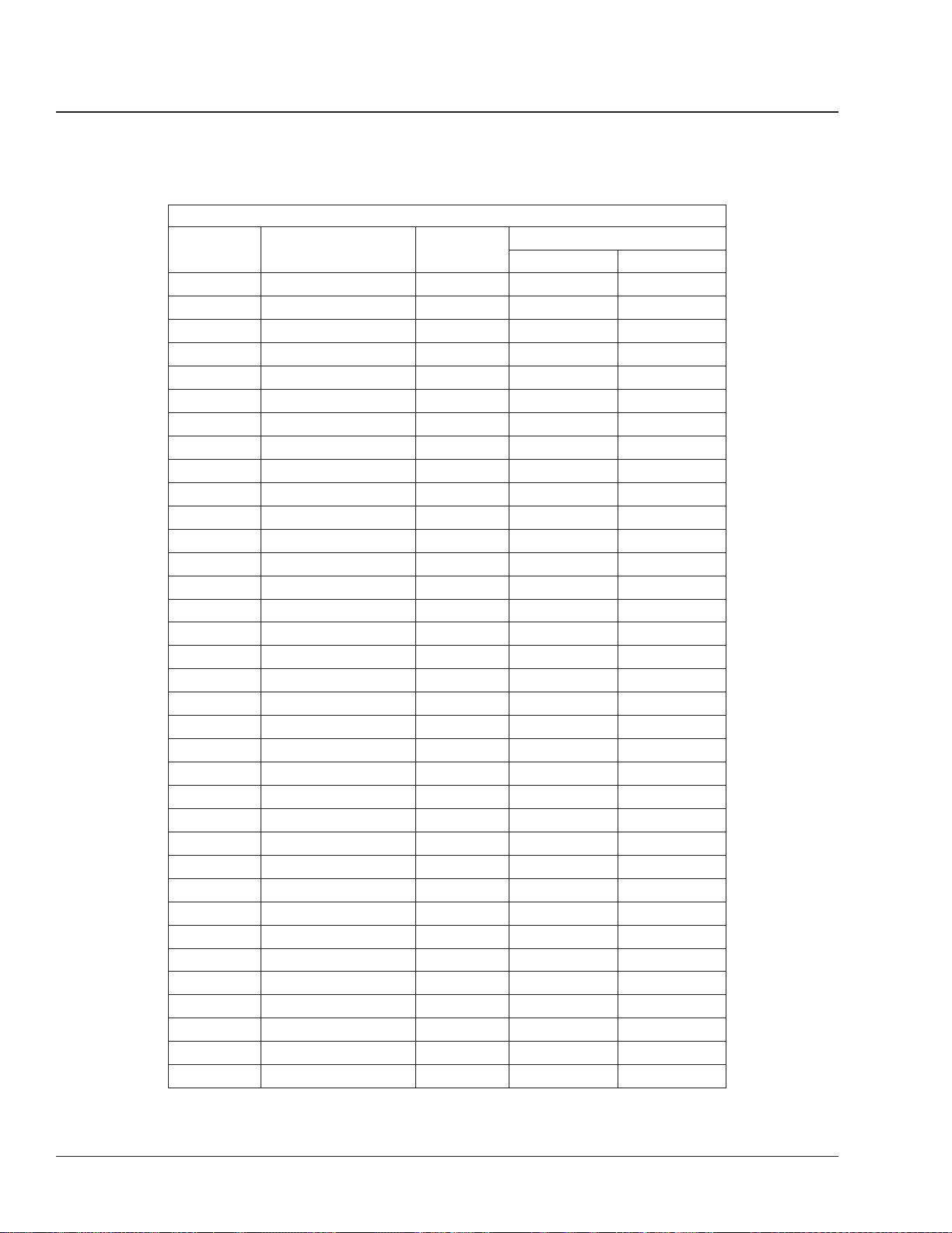

Vehicle Maintenance Schedule Table: 00–03

Maintenance for Service Schedule I

Maint. No.

36th M1 360,000 576 000

37th M1 370,000 592 000

38th M1 380,000 608 000

39th M1 390,000 624 000

40th M1 and M2 400,000 640 000

41st M1 410,000 656 000

42nd M1 420,000 672 000

43rd M1 430,000 688 000

44th M1 440,000 704 000

45th M1, M2, and M3 450,000 720 000

46th M1 460,000 736 000

47th M1 470,000 752 000

48th M1 480,000 768 000

49th M1 490,000 784 000

50th M1 and M2 500,000 800 000

51st M1 510,000 820 000

52nd M1 520,000 837 000

53rd M1 530,000 853 000

54th M1 540,000 869 000

55th M1 and M2 550,000 885 000

56th M1 560,000 901 000

57th M1 570,000 917 000

58th M1 580,000 933 000

59th M1 590,000 949 000

60th M1, M2, and M3 600,000 965 000

61st M1 610,000 982 000

62nd M1 620,000 998 000

63rd M1 630,000 1 014 000

64th M1 640,000 1 030 000

65th M1 and M2 650,000 1 046 000

66th M1 660,000 1 062 000

67th M1 670,000 1 078 000

68th M1 680,000 1 094 000

69th M1 690,000 1 110 000

70th M1 and M2 700,000 1 127 000

Maintenance

Interval

Service

Date

General Information00

Service Schedule I

Miles km

Cascadia Maintenance Manual, August 201500/4

General Information 00

Vehicle Maintenance Schedule Table: 00–03

Maintenance for Service Schedule I

Maint. No.

71st M1 710,000 1 143 000

72nd M1 720,000 1 159 000

73rd M1 730,000 1 175 000

74th M1 740,000 1 191 000

75th M1, M2, and M3 750,000 1 207 000

76th M1 760,000 1 223 000

77th M1 770,000 1 239 000

78th M1 780,000 1 255 000

79th M1 790,000 1 271 000

80th M1 and M2 800,000 1 287 000

81st M1 810,000 1 304 000

82nd M1 820,000 1 320 000

83rd M1 830,000 1 340 000

84th M1 840,000 1 352 000

85th M1 and M2 850,000 1 370 000

86th M1 860,000 1 384 000

87th M1 870,000 1 400 000

88th M1 880,000 1 416 000

89th M1 890,000 1 432 000

90th M1, M2, and M3 900,000 1 448 000

91st M1 910,000 1 465 000

92nd M1 920,000 1 481 000

93rd M1 930,000 1 500 000

94th M1 940,000 1 513 000

95th M1 and M2 950,000 1 530 000

96th M1 960,000 1 550 000

97th M1 970,000 1 561 000

98th M1 980,000 1 577 000

99th M1 990,000 1 593 000

100th M1 and M2 1,000,000 1 609 000

Maintenance

Interval

Table 2, Maintenance for Service Schedule I

Service

Date

Service Schedule I

Miles km

Cascadia Maintenance Manual, August 2015 00/5

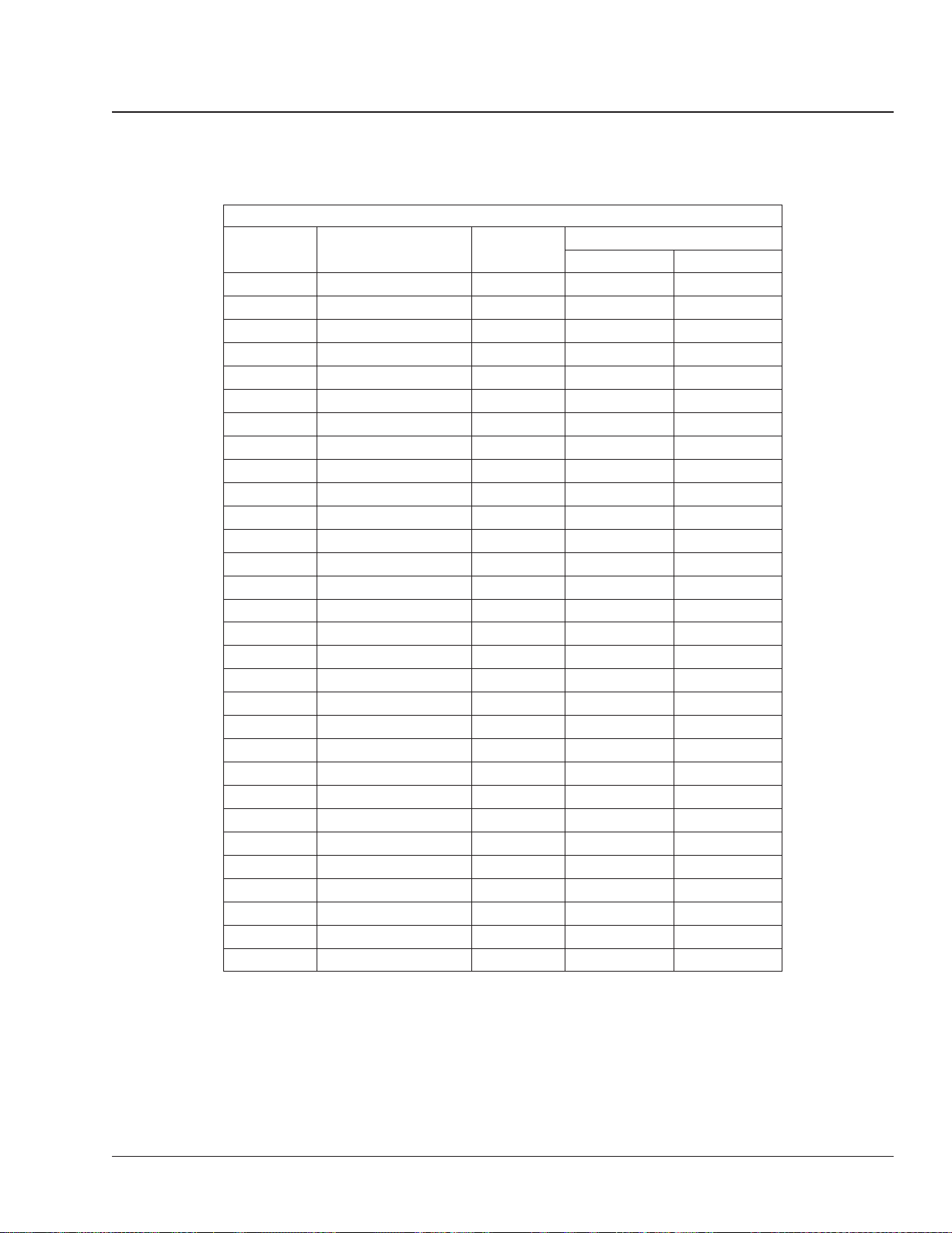

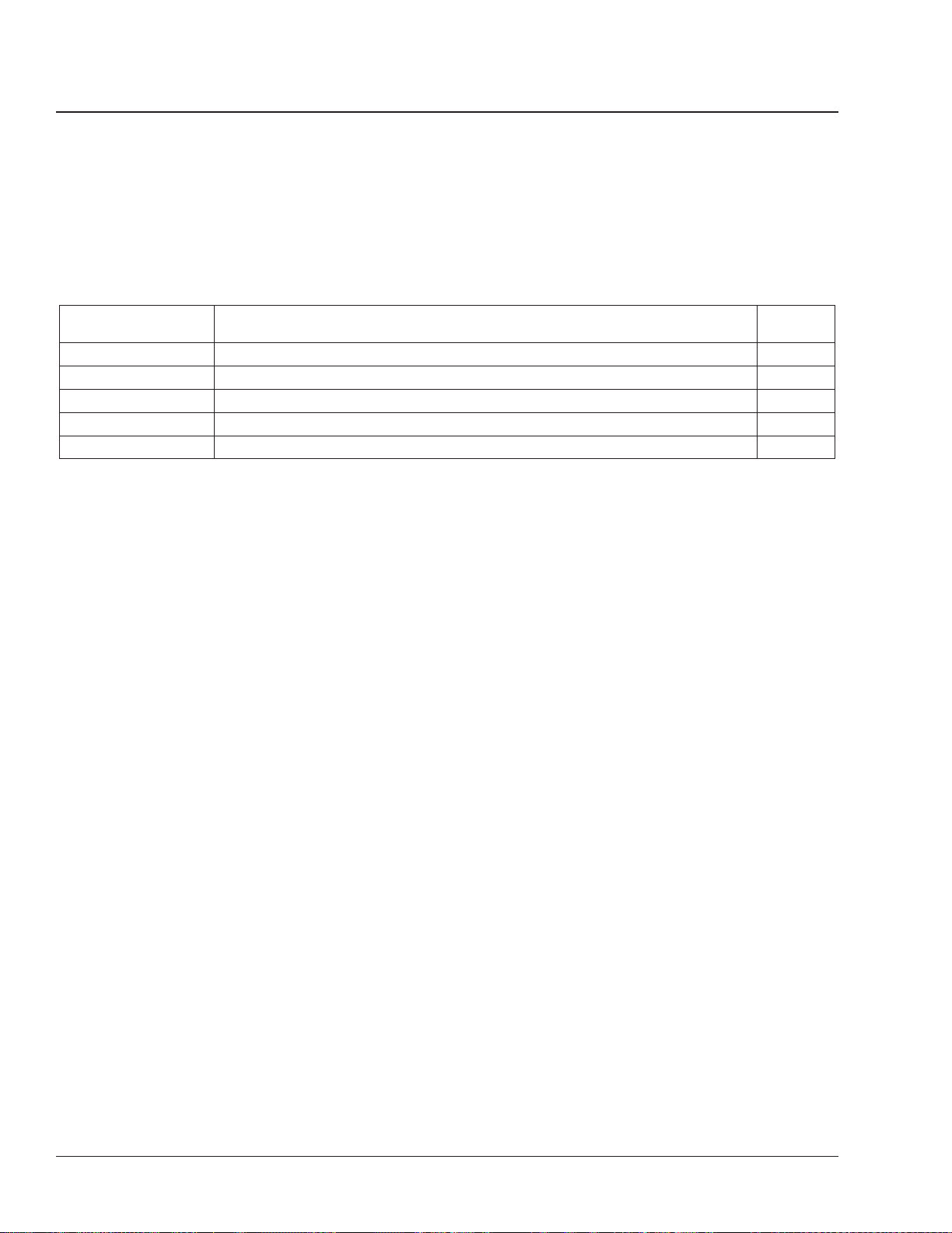

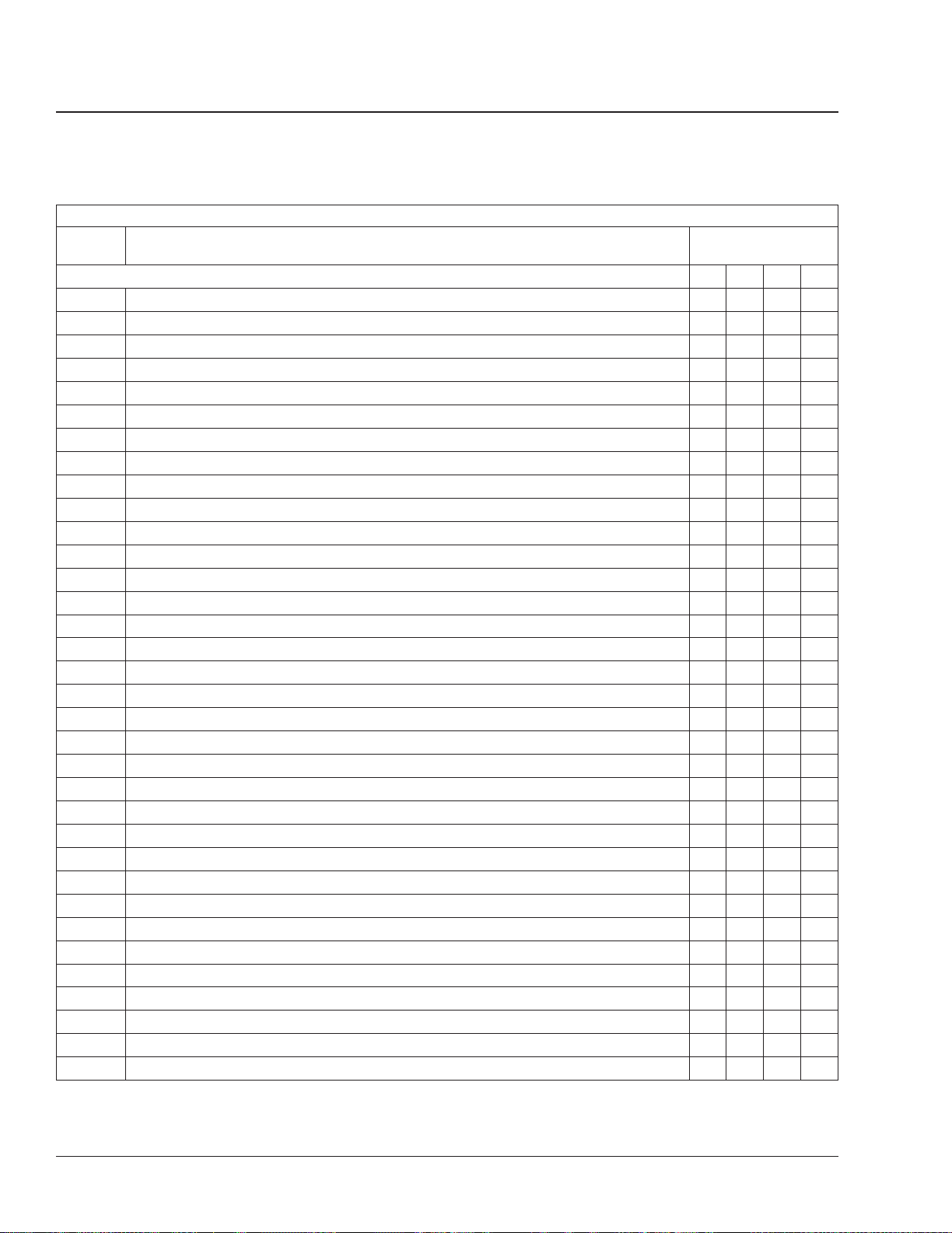

Vehicle Maintenance Schedule Table: 00–03

Maintenance for Service Schedule II

Maint. No. Maintenance Interval

1 IM and M1 25,000 40 000

2 M1 50,000 80 000

3 M1 75,000 121 000

4 M1 and M2 100,000 161 000

5 M1 125,000 201 000

6 M1 150,000 241 000

7 M1 175,000 281 000

8 M1 and M2 200,000 322 000

9 M1 225,000 362 000

10 M1 250,000 402 000

11 M1 275,000 443 000

12 M1, M2, and M3 300,000 483 000

13 M1 325,000 523 000

14 M1 350,000 563 000

15 M1 375,000 604 000

16 M1 and M2 400,000 644 000

17 M1 425,000 684 000

18 M1 450,000 724 000

19 M1 475,000 764 000

20 M1 and M2 500,000 805 000

21 M1 525,000 845 000

22 M1 550,000 885 000

23 M1 575,000 925 000

24 M1, M2, and M3 600,000 966 000

25 M1 625,000 1 005 800

26 M1 650,000 1 046 000

27 M1 675,000 1 086 000

28 M1 and M2 700,000 1 127 000

29 M1 725,000 1 167 000

30 M1 750,000 1 207 000

31 M1 775,000 1 248 000

32 M1 and M2 800,000 1 287 000

33 M1 825,000 1 328 000

34 M1 850,000 1 368 000

35 M1 875,000 1 408 000

Service

Date

General Information00

Service Schedules II

Miles km

Cascadia Maintenance Manual, August 201500/6

General Information 00

Vehicle Maintenance Schedule Table: 00–03

Maintenance for Service Schedule II

Maint. No. Maintenance Interval

36 M1, M2, and M3 900,000 1 448 000

37 M1 925,000 1 490 000

38 M1 950,000 1 529 000

39 M1 975,000 1 569 000

40 M1 and M2 1,000,000 1 609 000

Table 3, Maintenance for Service Schedule II

Service

Date

Service Schedules II

Miles km

Cascadia Maintenance Manual, August 2015 00/7

Initial Maintenance (IM) Operations: 00–04

General Information00

The Initial Maintenance table lists all maintenance

operations that are to be performed at the initial

maintenance (IM) interval. Maintenance operation

numbers are reference numbers used to help you

find detailed instructions in this manual on the main-

Maintenance

Operation Number

00–05 Perform all M1 Operations

31–03 Frame Fastener Torque Check

32–02 Suspension U-Bolt Torque Check

33–04 All-Axle Alignment Check

47–03 Fuel Tank Band-Nut Tightening

Table 4, Initial Maintenance (IM) Operations for Service Schedules I and II

Initial Maintenance (IM) Operations for Service Schedules I and II Check

tenance operations to be performed. All operations

listed in the table, along with the operations listed in

the applicable M1 maintenance interval table, must

be performed to complete the initial maintenance

(IM).

Cascadia Maintenance Manual, August 201500/8

General Information 00

M1 Maintenance Interval Operations: 00–05

The M1 Maintenance Interval Operations tables list

all maintenance operations that are to be performed

at the M1 maintenance interval. Maintenance operation numbers are reference numbers used to help

you find detailed instructions in this manual on the

IMPORTANT: After performing all operations listed in

this table, perform all daily, weekly, and monthly

maintenance operations listed in the "Pretrip and

Post-Trip Inspections and Maintenance" chapter of

™

the Cascadia

Driver’s Manual.

maintenance operations to be performed.

Maintenance

Operation Number

13–01 Air Compressor Inspection

25–01 Clutch Release Bearing Lubrication

31–01 Fifth Wheel Inspection

31–02 Fifth Wheel Lubrication

32–03 Lubrication of Front Suspensions with Grease Fittings

40–01 Wheel Nut Check

40–02 Tire Check

41–01 Driveline Inspection

41–02 Driveline Lubrication

42–02 Bendix Air Dryer Desiccant Replacement (with an oil-coalescing desiccant cartridge)

42–05 Brake Inspection

42–06 Dana Spicer, Haldex, and Gunite Slack Adjuster Lubrication

42–07 Meritor Camshaft Bracket Lubrication

42–10 WABCO System Saver Air Dryer Desiccant Cartridge Replacement

42–11 Versajust Slack Adjuster Inspection and Lubrication

47–04 LNG Fuel System Inspecting

47–06 CNG Fuel System Inspecting

47–07 CNG High-Pressure Fuel Filter Element Replacing

49–01 Exhaust System Inspection (noise emission control)

60–02 Cab Shock Absorber Bracket Torque Check

60–03 Aerodynamic Component Inspection

83–03 ParkSmart™Inspection

88–01 Hood Rear Support Lubrication

*

On vehicles equipped with Detroit transmissions, the release bearing does not need to be lubricated. On vehicles equipped with Eaton Fuller UltraShift PLUS

transmissions, lubricate the release bearing every 50,000 miles (80 000 km) or 3 months.

†

If equipped with an oil-coalescing desiccant cartridge, replace the cartridge once a year, regardless of mileage. Otherwise use the M3 maintenance interval.

‡

Complete this procedure every 25,000 miles (40 225 km), 3 months, or 500 operating hours, whichever comes first.

§

M1 maintenance interval should be used as a general guideline; the actual frequency of filter element replacement will vary depending on cleanliness ofthe

fuel station system.

Table 5, M1 Maintenance Interval Operations for Service Schedules I and II

M1 Maintenance Interval Operations for Service Schedules I and II Check

*

†

‡

§

Cascadia Maintenance Manual, August 2015 00/9

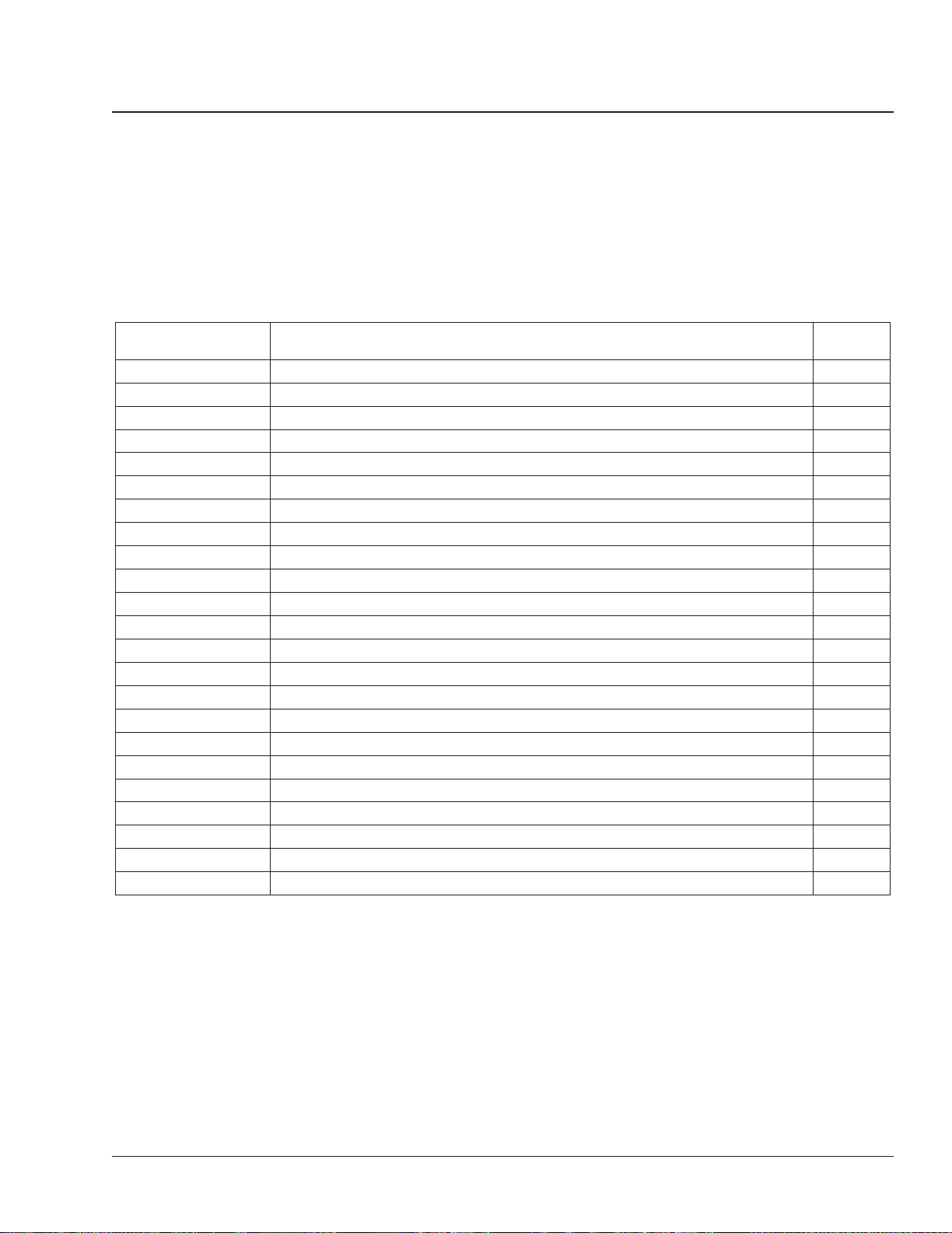

M2 Maintenance Interval Operations: 00–06

General Information00

The M2 Maintenance Interval Operations tables list

all maintenance operations that are to be performed

at the M2 maintenance interval. Maintenance operation numbers are reference numbers used to help

Maintenance

Operation Number

00–05 Perform All M1 Operations

15–01 Alternator, Battery, and Starter Check

20–01 Pressure Relief Cap Check

20–03 Fan Clutch Check (noise emission control)

25–02 Fluid Level Check, Hydraulic Clutch Control

26–02 Detroit™Automated Transmission Fluid Level Inspection

26–03 Detroit™Automated Transmission Air Filter Replacement

26–05 Eaton Fuller Transmission Fluid Level Inspection

26–06 Eaton Fuller Manual Transmission Air Filter/Regulator Check, Cleaning, or

31–04 Fairing Bumper Wear Check

32–01 Suspension Inspection

32–02 Suspension U-Bolt Torque Check

33–01 Knuckle Pin Lubrication

33–02 Tie Rod Inspection

33–03 Tie Rod Lubrication

35–02 Axle Breather and Axle Lubricant Level Inspection

42–01 Air Brake System Valve Inspection

42–03 Air Dryer Inspection

42–04 Alcohol Evaporator Cleaning and Inspection

42–08 Meritor Slack Adjuster Lubrication

46–01 Drag Link Inspection

46–03 Power Steering Fluid Level Inspection

46–04 Power Steering Gear Lubrication

46–05 Drag Link Lubrication

46–06 Rack and Pinion Steering Gear Inspection

47–01 Fuel Filter Replacement

47–02 Fuel/Water Separator Element Checking and Replacement

47–08 CNG Fuel Cylinder Inspecting

54–01 Trailer Cable Inspection and Cleaning

60–01 Mirror Folding Check

60–04 Baggage Door and Sleeper Access Door Release Cable and Latch Lubrication

83–01 Air Conditioner Inspection

M2 Maintenance Interval Operations for Service Schedules I and II Check

Replacement

*

*

†

you find detailed instructions in this manual on the

maintenance operations to be performed. Perform all

M1 maintenance interval operations at the M2 maintenance interval.

Cascadia Maintenance Manual, August 201500/10

General Information 00

M2 Maintenance Interval Operations: 00–06

Maintenance

Operation Number

83–02 Air Filter Replacement

*

For Schedule I vehicles with Detroit axles, complete this procedure once a year or every 25,000 miles (40 000 km), whichever comes first.

†

The fuel cylinder should be inspected every year or 100,000 miles (160 900 km), whichever comes first.

Table 6, M2 Maintenance Interval Operations for Service Schedules I and II

M2 Maintenance Interval Operations for Service Schedules I and II Check

Cascadia Maintenance Manual, August 2015 00/11

M3 Maintenance Interval Operations: 00–07

General Information00

The M3 Maintenance Interval Operations table lists

all maintenance operations that are to be performed

at the M3 maintenance interval. Maintenance operation numbers are reference numbers used to help

Maintenance

Operation Number

00–05 Perform All M1 Operations

00–06 Perform All M2 Operations

09–01 Air Cleaner Inspection

20–02 Radiator Pressure-Flushing and Coolant Change

25–03 Fluid Change, Hydraulic Clutch Control

25–04 Clutch Replacement, Detroit™Automated Transmissions

26–01 Detroit™Automated Transmission Fluid Change and Magnetic Plug Cleaning

26–04 Eaton Fuller Transmission Fluid Change and Magnetic Plug Cleaning

35–01 Axle Lubricant and Filter Change, and Magnetic Strainer Cleaning

42–02 Bendix Air Dryer Desiccant Replacement

42–09 Bendix E–6 Foot Control Valve Inspection and Lubrication

42–10 WABCO System Saver Air Dryer Desiccant Cartridge Replacement

46–02 Power Steering Fluid and Filter Change

46–07 Bellows Replacement, Rack and Pinion Steering Gear

47–05 LNG Vacuum Integrity Testing

49–02 CAT CGI Bellows Replacement

*

Replace the clutch assembly for Detroit automated transmissions at 750,000-mile (1 200 000-km) intervals.

†

For Schedule II vehicles with Detroit automated transmissions spec’d to haul more than 80,000 lb (36 000 kg), change the transmission fluid at 200,000-mile

(322 000-km) intervals.

‡

For Eaton Fuller transmissions, fluid change intervals are extended to 500,000 miles (800 000 km) on vehicles filled with synthetic transmission fluid.

Table 7, M3 Maintenance Interval Operations for Service Schedules I and II

M3 Maintenance Interval Operations for Service Schedules I and II Check

you find detailed instructions in this manual on the

maintenance operations to be performed. Perform all

M1 and M2 maintenance interval operations at the

M3 maintenance interval.

*

†

‡

Cascadia Maintenance Manual, August 201500/12

General Information 00

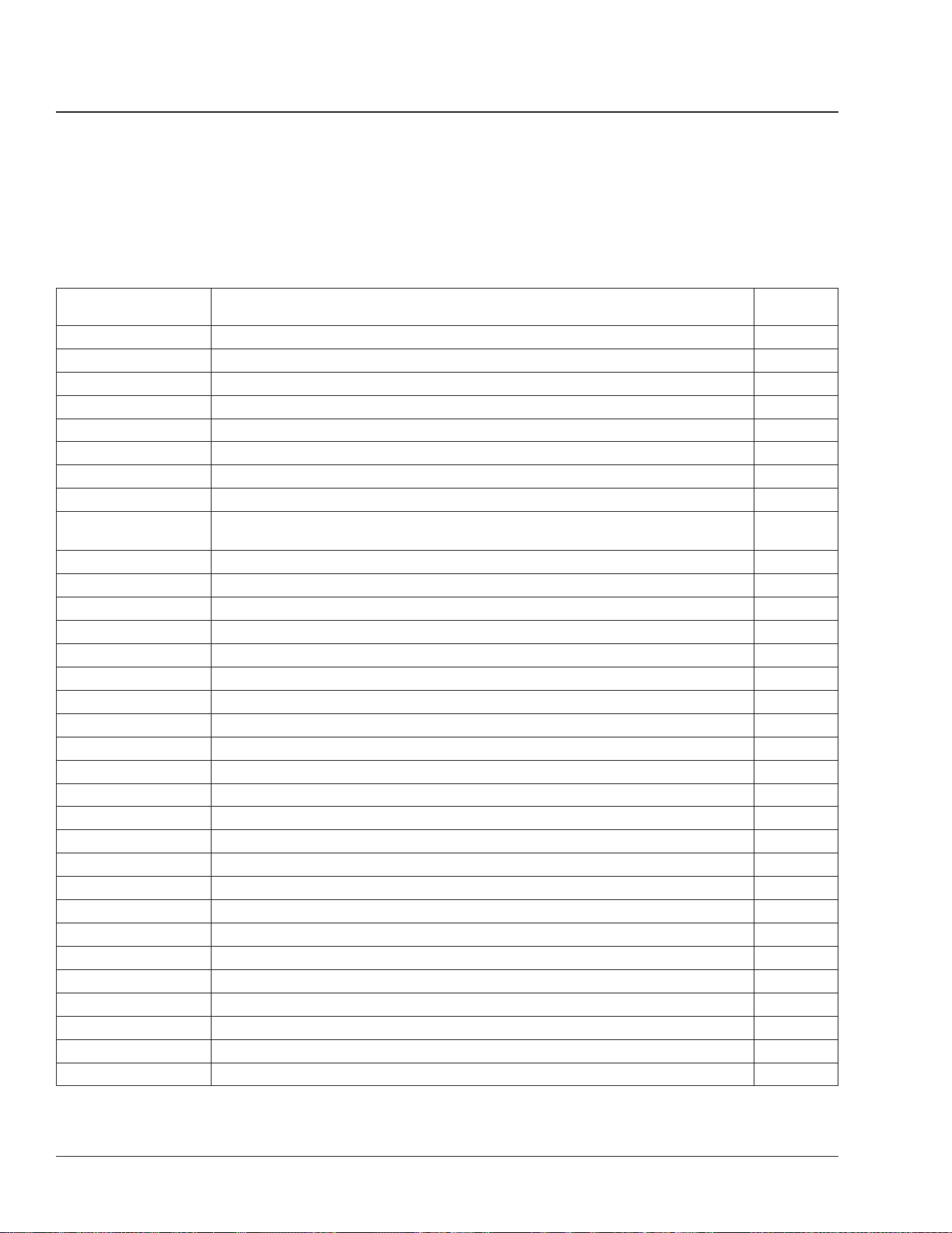

Maintenance Operation Sets Table: 00–08

Maintenance Operation Sets

Maint.

No.

09–01 Air Cleaner Inspection •

13–01 Air Compressor Inspection • • • •

15–01 Alternator, Battery, and Starter Check • •

20–01 Pressure Relief Cap Check ••

20–02 Radiator Pressure-Flushing and Coolant Change •

20–03 Fan Clutch Check (noise emission control) • •

25–01 Clutch Release Bearing Lubrication

25–02 Fluid Level Check, Hydraulic Clutch Control • •

25–03 Fluid Change, Hydraulic Clutch Control •

25–04 Clutch Replacement, Detroit™Automated Transmissions

26–01 Detroit™Automated Transmission Fluid Change and Magnetic Plug Cleaning

26–02 Detroit™Automated Transmission Transmission Fluid Level Inspection • •

26–03 Detroit™Automated Transmission Air Filter Replacement • •

26–04 Eaton Fuller Transmission Fluid Change and Magnetic Plug Cleaning

26–05 Eaton Fuller Transmission Transmission Fluid Level Inspection • •

26–06 Eaton Fuller Manual Transmission Air Filter/Regulator Check, Cleaning, or Replacement • •

31–01 Fifth Wheel Inspection • • • •

31–02 Fifth Wheel Lubrication • • • •

31–03 Frame Fastener Torque Check •

31–04 Fairing Bumper Wear Check ••

32–01 Suspension Inspection ••

32–02 Suspension U-Bolt Torque Check • • •

32–03 Lubrication of Front Suspensions with Grease Fittings • • • •

33–01 Knuckle Pin Lubrication

33–02 Tie Rod Inspection ••

33–03 Tie Rod Lubrication

33–04 All-Axle Alignment Check •

35–01 Axle Lubricant and Filter Change, and Magnetic Strainer Cleaning •

35–02 Axle Breather and Axle Lubricant Level Inspection • •

40–01 Wheel Nut Check ••••

40–02 Tire Check ••••

41–01 Driveline Inspection ••••

41–02 Driveline Lubrication ••••

42–01 Air Brake System Valve Inspection • •

¶

¶

Operation Description

*

†

‡

§

Service Schedules I

and II

IM M1 M2 M3

••••

•

•

•

••

••

Cascadia Maintenance Manual, August 2015 00/13

General Information00

Maintenance Operation Sets Table: 00–08

Maintenance Operation Sets

Maint.

No.

42–02 Bendix Air Dryer Desiccant Replacement

42–03 Air Dryer Inspection ••

42–04 Alcohol Evaporator Cleaning and Inspection • •

42–05 Brake Inspection ••••

42–06 Dana Spicer, Haldex, and Gunite Slack Adjuster Lubrication • • • •

42–07 Meritor Camshaft Bracket Lubrication • • • •

42–08 Meritor Slack Adjuster Lubrication • •

42–09 Bendix E–6 Foot Control Valve Inspection and Lubrication •

42–10 WABCO System Saver Air Dryer Desiccant Cartridge Replacement

42–11 Versajust Slack Adjuster Inspection and Lubrication

46–01 Drag Link Inspection ••

46–02 Power Steering Fluid and Filter Change •

46–03 Power Steering Fluid Level Inspection • •

46–04 Power Steering Gear Lubrication • •

46–05 Drag Link Lubrication ••

46–06 Rack and Pinion Steering Gear Inspection • •

46–07 Bellows Replacement, Rack and Pinion Steering Gear •

47–01 Fuel Filter Replacement ••

47–02 Fuel/Water Separator Element Checking and Replacement • •

47–03 Fuel Tank Band-Nut Tightening •

47–04 LNG Fuel System Inspecting • • •

47–05 LNG Vacuum Integrity Testing •

47–06 CNG Fuel System Inspecting • • •

47–07 CNG High-Pressure Fuel Filter Element Replacing • • •

47–08 CNG Fuel Cylinder Inspecting •

49–01 Exhaust System Inspection (noise emission control) • • • •

49–02 CAT CGI Bellows Replacement •

54–01 Trailer Cable Inspection and Cleaning • •

60–01 Mirror Folding Check ••

60–02 Cab Shock Absorber Bracket Torque Check • • • •

60–03 Aerodynamic Component Inspection • • • •

60–04 Baggage Door and Sleeper Access Door Release Cable and Latch Lubrication • •

83–01 Air Conditioner Inspection ••

83–02 Air Filter Replacement ••

Operation Description

**

**

††

Service Schedules I

and II

IM M1 M2 M3

••••

••••

•••

Cascadia Maintenance Manual, August 201500/14

General Information 00

Maintenance Operation Sets Table: 00–08

Maintenance Operation Sets

Maint.

No.

Operation Description

83–03 ParkSmart™Inspection • • • •

88–01 Hood Rear Support Lubrication • • • •

*

On vehicles equipped with Detroit transmissions, the release bearing does not need to be lubricated. On vehicles equipped with Eaton Fuller UltraShift PLUS

transmissions, lubricate the release bearing every 50,000 miles (80 000 km) or 3 months.

†

Replace the clutch assembly for Detroit automated transmissions at 750,000-mile (1 200 000-km) intervals.

‡

For Schedule II vehicles with Detroit automated transmissions spec’d to haul more than 80,000 lb (36 000 kg), change the transmission fluid at 200,000-mile

(322 000-km) intervals.

§

For Eaton Fuller transmissions, fluid change intervals are extended to 500,000 miles (800 000 km) on vehicles filled with synthetic transmission fluid.

¶

For Schedule I vehicles with Detroit axles, complete this procedure once a year or every 25,000 miles (40 000 km), whichever comes first.

**

If equipped with an oil-coalescing desiccant cartridge, replace the cartridge once a year, regardless of mileage. Otherwise use the M3 maintenance interval.

††

Complete this procedure every 25,000 miles (40 225 km), 3 months, or 500 operating hours, whichever comes first.

Table 8, Maintenance Operation Sets

Service Schedules I

and II

IM M1 M2 M3

Cascadia Maintenance Manual, August 2015 00/15

Noise Emission Controls Maintenance: 00–09

General Information00

Noise Emission Control

Maintenance

Federal Law, Part 205:

Transportation Equipment Noise

Emission Controls

Part 205, Transportation Equipment Noise Emission

Controls, requires the vehicle manufacturer to furnish, with each new vehicle, such written instructions

for the proper maintenance, use, and repair of the

vehicle by the ultimate purchaser to provide reasonable assurance of the elimination or minimization of

noise-emission-control degradation throughout the

life of the vehicle. In compliance with the law, the

noise emission controls maintenance information in

each applicable group of this manual, in conjunction

with the vehicle workshop manual, provides these

instructions to owners.

Recommendations for

Replacement Parts

Replacement parts used for maintenance or repair of

noise emission controls should be genuine Freightliner parts. If other than genuine Freightliner parts

are used for replacement or repair of components

affecting noise emission control, the owner should be

sure that such parts are warranted by their manufacturer to be equivalent to genuine Freightliner parts in

performance and durability.

Freightliner Noise Emission

Controls Warranty

Refer to the vehicle owner’s warranty information

book for warranty information concerning noise emission controls.

the purpose of noise control, prior to its sale or

delivery to the ultimate purchaser, or while it is in

use.

2. The use of the vehicle after such device or element of design has been removed or rendered

inoperative by any person.

Among those acts presumed to constitute tampering are the acts listed below:

A. Removal of engine noise-deadening panels.

B. Removal of cab-tunnel or hood noise-

deadening panels.

C. Removal of, or rendering inoperative, the en-

gine speed governor so as to allow engine

speed to exceed manufacturer’s specifications.

D. Removal of, or rendering inoperative, the fan

clutch, including bypassing the control on

any thermostatic fan drive to cause it to operate continuously.

E. Removal of the fan shroud.

F. Removal of, or rendering inoperative, ex-

haust components, including exhaust pipe

clamping.

G. Removal of air intake components.

Maintenance Instructions

Scheduled intervals are in the maintenance tables in

this group. A "Verification of Inspections Log" for

Groups 20 and 49 follows, and should be filled in

each time noise emission controls on the vehicle are

maintained or repaired.

Tampering with Noise Controls is

Prohibited

Federal law prohibits the following acts or the causing thereof:

1. The removal or rendering inoperative by any person (other than for purposes of maintenance,

repair, or replacement) of any device or element

of design incorporated into any new vehicle for

Cascadia Maintenance Manual, August 201500/16

General Information 00

Verification of Inspections Log: 00–10

Verification of Inspections Log

Verification of Inspections Log, Group 20

Verification of Inspections Log — Group 20 — Fan Clutch

Date Mileage Item Cost Maintenance Facility

Verification of Inspections Log, Group 49

Verification of Inspections Log — Group 49 — Exhaust System Components

Date Mileage Item Cost Maintenance Facility

Cascadia Maintenance Manual, August 2015 00/17

Air Intake 09

Index, Alphabetical

Title of Maintenance Operation (MOP) MOP Number

Air Cleaner Inspection .............................................................. 09–01

Cascadia Maintenance Manual, November 2014

Air Intake 09

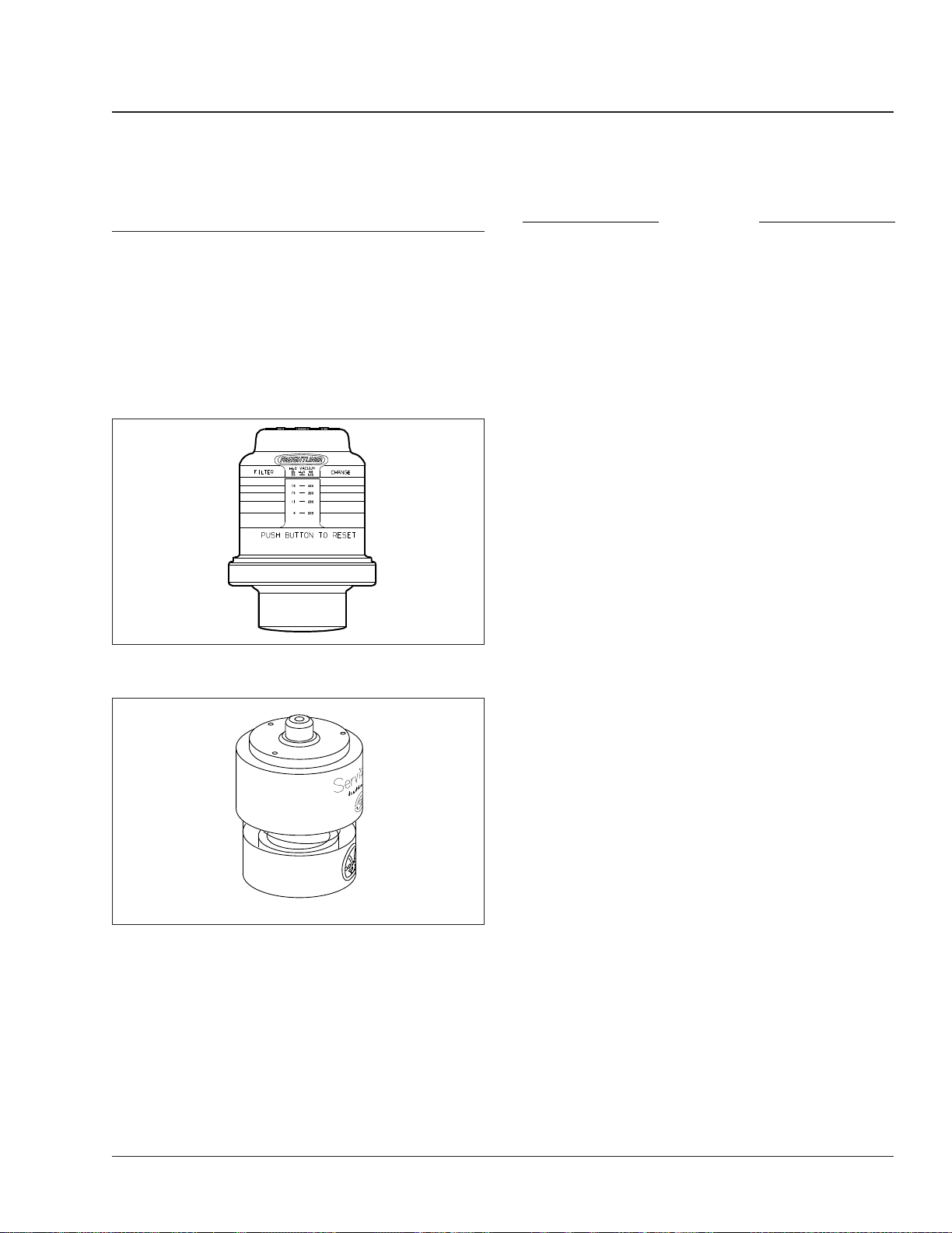

09–01 Air Cleaner Inspection

Restriction of air flow through the air cleaner element

is measured at the tap in the air cleaner outlet.

Check the restriction indicator at the air cleaner or in

the cab if the vehicle is equipped with a dashmounted restriction gauge.

Vehicles may be equipped with either a manual-reset

restriction indicator with graduations (

go/no-go restriction indicator without graduations

Fig. 2).

(

08/07/2007 f090452

Fig. 1, Manual-Reset Air Restriction Indicator,

Graduated

Fig. 1), or a

NOTICE

Do not use aftermarket air-cleaner elements. Aftermarket air-cleaner elements may not seal the

housing correctly, which can lead to engine damage and potentially the loss of warranty. When replacing an air-cleaner element, use only the part

listed in PartsPro for the serial number of the vehicle.

2. If necessary, replace the air cleaner element. For

air cleaner element replacement instructions, see

Group 09 of the Cascadia Workshop Manual.

3. Inspect the air cleaner housing for cracks, leaks,

or any other damage. If the air cleaner housing

or element is damaged, replace it.

4. Inspect the forward and rear mounting isolators

for damage. See

tween the rubber and the steel plates are completely intact. See

If a mounting isolator is damaged, replace it. For

isolator replacement instructions, see Section

09.01 of the Cascadia Workshop Manual.

5. Remove the pre-cleaners (if so equipped) from

the hood plenum, then clean them with compressed air.

6. Reset the air restriction indicator.

7. Each time the air cleaner housing is replaced,

perform the procedures in

Fig. 3. Ensure the bonds be-

Fig. 4.

MOP 13–01.

04/08/2005 f090431

Fig. 2, Manual-Reset Air Restriction Indicator, Go/

1. Inspect the air restriction indicator to see if air

restriction equals or exceeds the maximum allowable restriction. For instructions, see Group

09 of the Cascadia Workshop Manual.

Cascadia Maintenance Manual, November 2014 09/1

No-Go

Air Intake09

6

4

5

2

3

2

1

7

2

08/08/2007 f090453

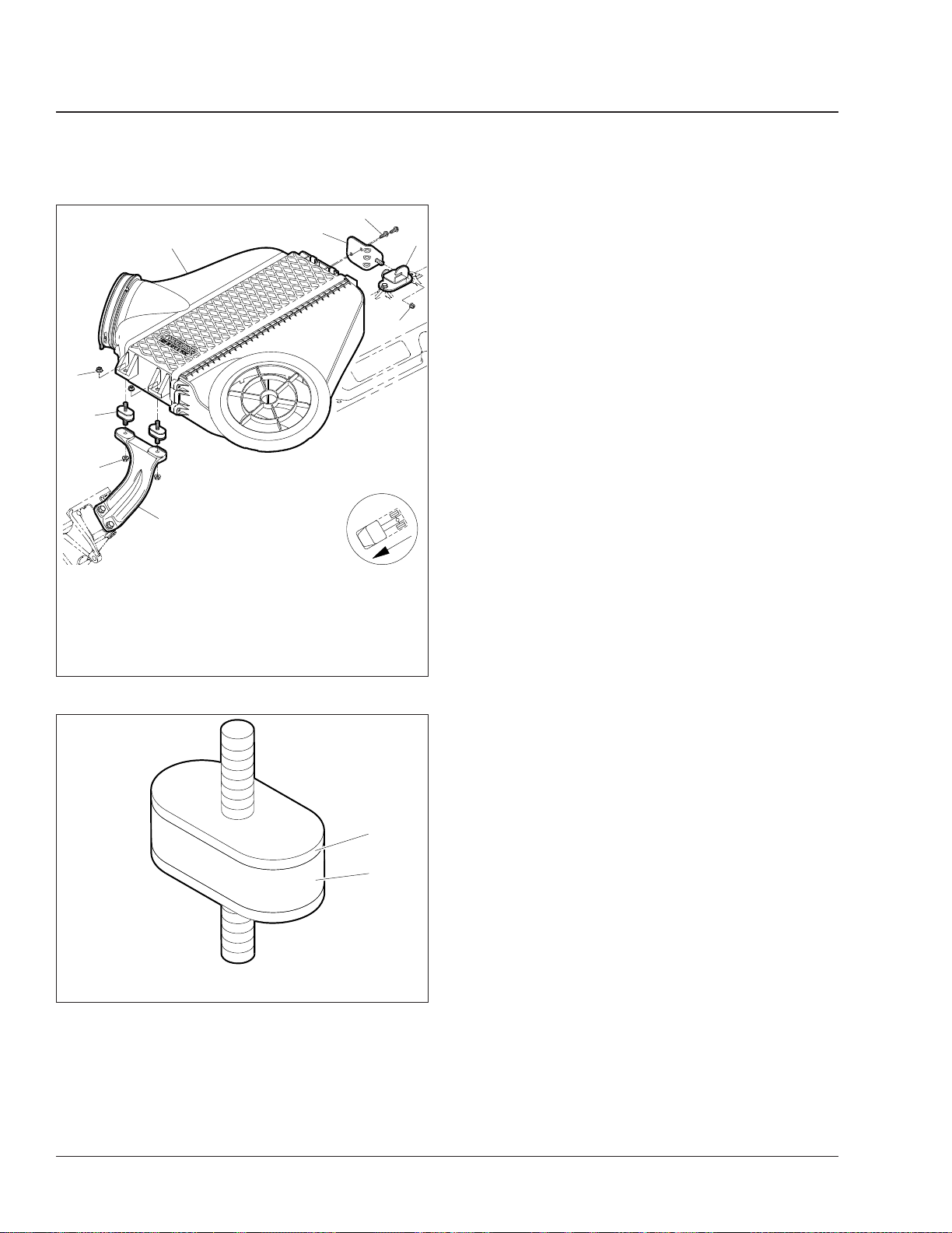

1. Forward Mounting

Bracket

2. Nut

3. Forward Mounting

Isolator

Fig. 3, Air Cleaner Assembly

01/17/2012 f090496

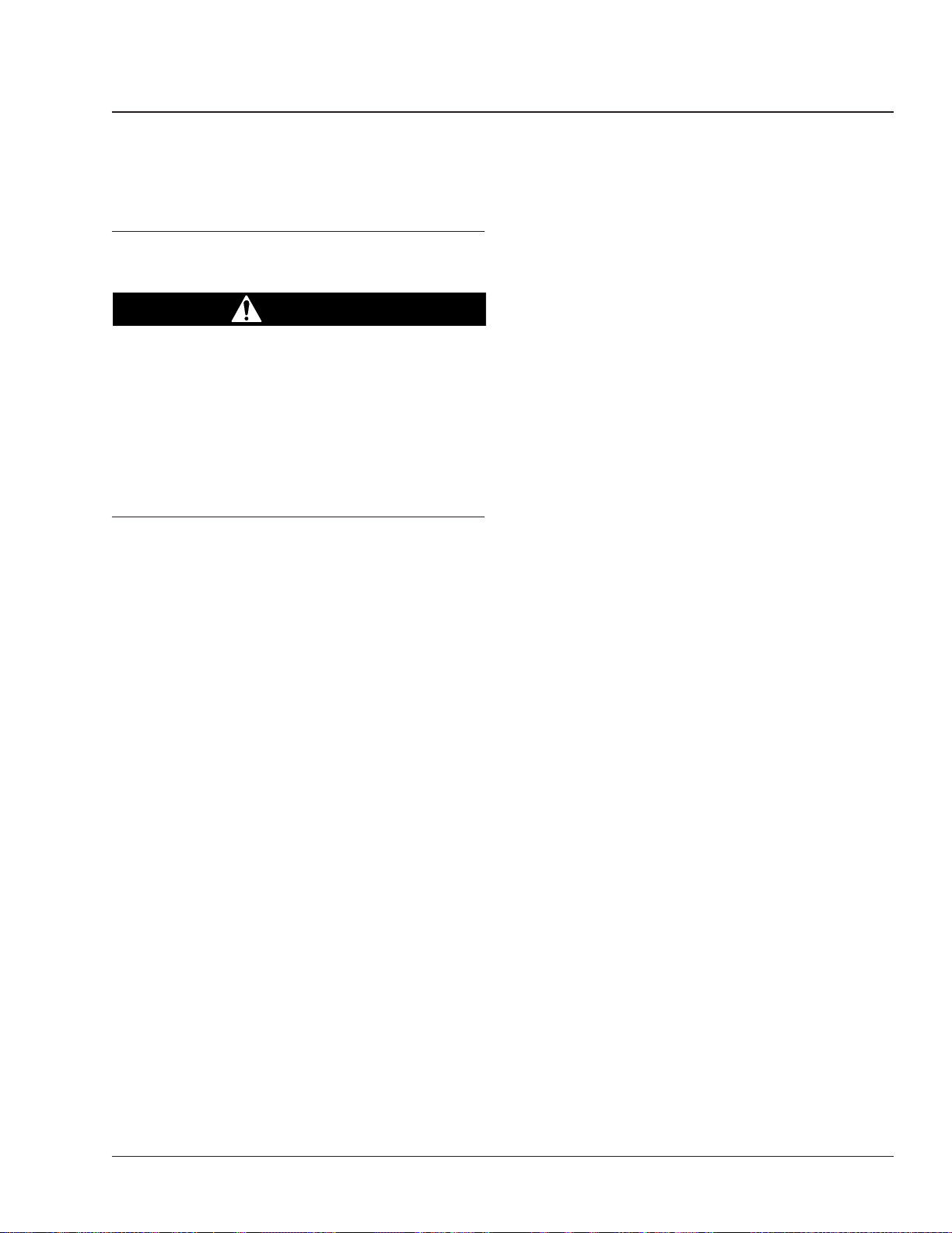

1. Steel Plate 2. Rubber

Fig. 4, Mounting Isolator

4, Air Cleaner Housing

5 Aft Mounting Bracket

6. Capscrews

7. Aft Mounting Isolator

1

2

Cascadia Maintenance Manual, November 201409/2

Air Compressor 13

Index, Alphabetical

Title of Maintenance Operation (MOP) MOP Number

Air Compressor Inspection ...........................................................13–01

Safety Precautions .................................................................13–00

Cascadia Maintenance Manual, August 2015

Air Compressor 13

13–00 Safety Precautions

Safety Precautions in this section apply to all

procedures within this group.

DANGER

When working on the vehicle, shut down the engine, set the parking brake, and chock the tires.

Before working under the vehicle, always place

jack stands under the frame rails to ensure the

vehicle can not drop. Failure to follow these steps

could result in serious personal injury or death.

13–01 Air Compressor

Inspection

1. Inspect the air compressor intake hoses and

connections at the air intake and air compressor

for physical damage. If needed, change the

hoses, and/or tighten or replace the connections.

2. Inspect the coolant supply and return lines for

tight connections. Tighten the connections and

replace the lines and fasteners if needed.

3. For the air governor, inspect the piping and connections for leaks. Replace gaskets and faulty

components as needed.

Cascadia Maintenance Manual, August 2015 13/1

Loading...

Loading...