Freightliner Cargo Service Manual

Foreword

Introduction

This manual provides information needed to operate

and understand the vehicle and its components. More

detailed information is contained in the

ranty Information for North America

vehicle’s workshop and maintenance manuals.

Custom-built Cargo vehicles are equipped with various

chassis and cab components. Not all of the information

contained in this manual applies to every vehicle. For

details about components in your vehicle, refer to the

chassis specification pages included in all new vehicles

and to the vehicle specification decal, located inside the

vehicle.

For your reference, keep this manual in the vehicle at

all times.

IMPORTANT: Descriptions and specifications in this

manual were in effect at the time of printing. Freightliner

LLC reserves the right to discontinue models and to

change specifications or design at any time without notice and without incurring obligation. Descriptions and

specifications contained in this publication provide no

warranty, expressed or implied, and are subject to revisions and editions without notice.

Owner’s War-

booklet and in the

Environmental Concerns and

Recommendations

Whenever you see instructions in this manual to discard

materials, you should first attempt to reclaim and recycle them. To preserve our environment, follow appropriate environmental rules and regulations when disposing of materials.

Event Data Recorder

This vehicle is equipped with one or more devices that

record specific vehicle data. The type and amount of

data recorded varies depending on how the vehicle is

equipped (such as the brand of engine, if an air bag is

installed, or if the vehicle features a collision avoidance

system, etc.).

Customer Assistance Center

Having trouble finding service? Call the Freightliner

Customer Assistance Center at 1-800-385-4357 or

1-800-FTL-HELP, or the Sterling Customer Assistance

Center at 1-800-785-4357 or 1-800-STL-HELP. Call

night or day, weekdays or weekends for dealer referral,

vehicle information, breakdown coordination, or Fleetpack assistance. Our people are knowledgeable, professional, and committed to following through to help

you keep your truck moving.

Printed in U.S.A.

4/06P

Foreword

Reporting Safety Defects

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Freightliner LLC.

If the NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems

between you, your dealer, or the vehicle

manufacturer.

To contact NHTSA, you may call the Vehicle

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to http://www.safercar.gov; or

write to: Administrator, NHTSA, 400 Seventh

Street, SW, Washington, DC 20590. You can also

obtain other information about motor vehicle safety

from http://www.safercar.gov.

© 1998-2006 Freightliner LLC. All rights reserved.

Canadian customers who wish to report a safetyrelated defect to Transport Canada, Defect

Investigations and Recalls, may telephone the tollfree hotline 1-800-333-0510, or contact Transport

Canada by mail at: Transport Canada, ASFAD,

Place de Ville Tower C, 330 Sparks Street,

Ottawa, Ontario, Canada K1A 0N5.

For additional road safety information, please visit

the Road Safety website at: http://www.tc.gc.ca/

roadsafety/menu.htm

No part of this publication, in whole or part, may be translated, reproduced, stored in a retrieval system, or transmitted

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Freightliner LLC. For additional information, please contact Freightliner LLC, Service Systems and Documentation, P.O. Box 3849 Portland OR 97208–3849 U.S.A. or refer to http://www.Freightliner.com, http://www.

FreightlinerTrucks.com, or http://www.SterlingTrucks.com.

Contents

Chapter Page

Introduction, Environmental Concerns and Recommendations, Event

Data Recorder, Customer Assistance Center, Reporting Safety Defects ............. Foreword

1 Vehicle Identification ........................................................1.1

2 Vehicle Access and Features ................................................. 2.1

3 Driver Controls and Instruments ............................................... 3.1

4 Engines ................................................................. 4.1

5 Transmissions ............................................................ 5.1

6 Clutches, Rear Axles, and Steering ............................................. 6.1

7 Brakes .................................................................. 7.1

8 Cab Appearance .......................................................... 8.1

9 Pretrip Inspection and Daily Maintenance ........................................ 9.1

10 In an Emergency ......................................................... 10.1

11 Fifth Wheels ............................................................. 11.1

Index ................................................................... I.1

1

Vehicle Identification

Vehicle Specification Decal ........................................................... 1.1

Federal Motor Vehicle Safety Standard (FMVSS) Labels ...................................... 1.1

Canadian Motor Vehicle Safety Standard (CMVSS) Labels .................................... 1.2

Tire and Rim Labels ................................................................. 1.3

EPA Vehicle Noise Emission Control Label ................................................ 1.3

Vehicle Identification

Vehicle Specification Decal

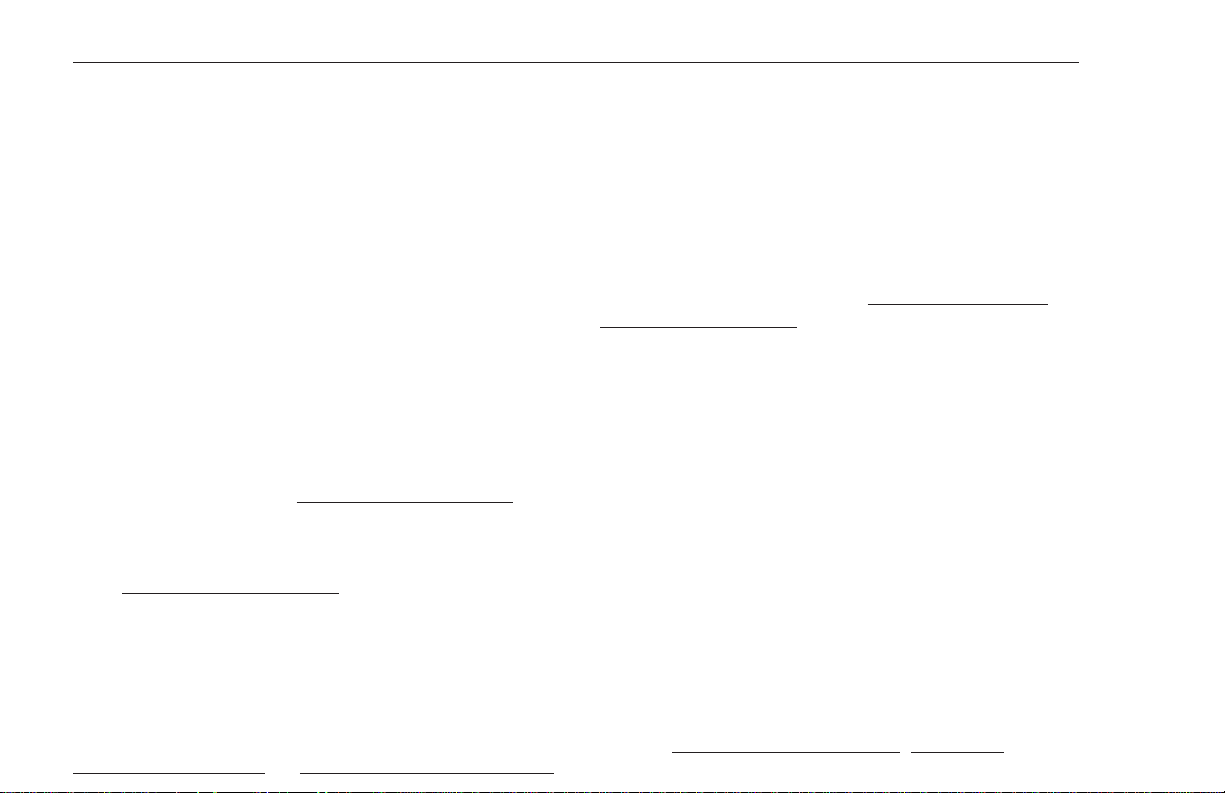

The vehicle specification decal (Fig. 1.1) identifies the

vehicle model, I.D. number, and major component models. It also lists the major assemblies and installations

shown on the chassis specification sheet. A copy of the

specification decal is inside the rear cover of the

er’s Warranty Information for North America

illustration of the decal is shown in Fig. 1.1.

COMPONENT INFORMATION

MANUFACTURED BY

MODEL

VEHICLE ID NO.

DATE OF MFR

ENGINE MODEL

TRANS MODEL MAIN

FRONT AXLE MODEL

REAR AXLE MODEL

PAINT MFR

PAINT NO.

02/12/98

USE VEHICLE ID NO.

WHEN ORDERING PARTS

WHEELBASE

ENGINE NO.

TRANS NO.

FRT AXLE NO.

REAR AXLE NO.

REAR AXLE NO.

RATIO

FOR COMPLETE PAINT INFORMATION

SEE VEHICLE SPECIFICATION SHEET

Fig. 1.1, Vehicle Specification Decal, U.S.-Built Vehicle

Shown

NOTE: Labels shown in this chapter are examples

only.

Own-

booklet. An

PART NO. 24−00273−010

f080077

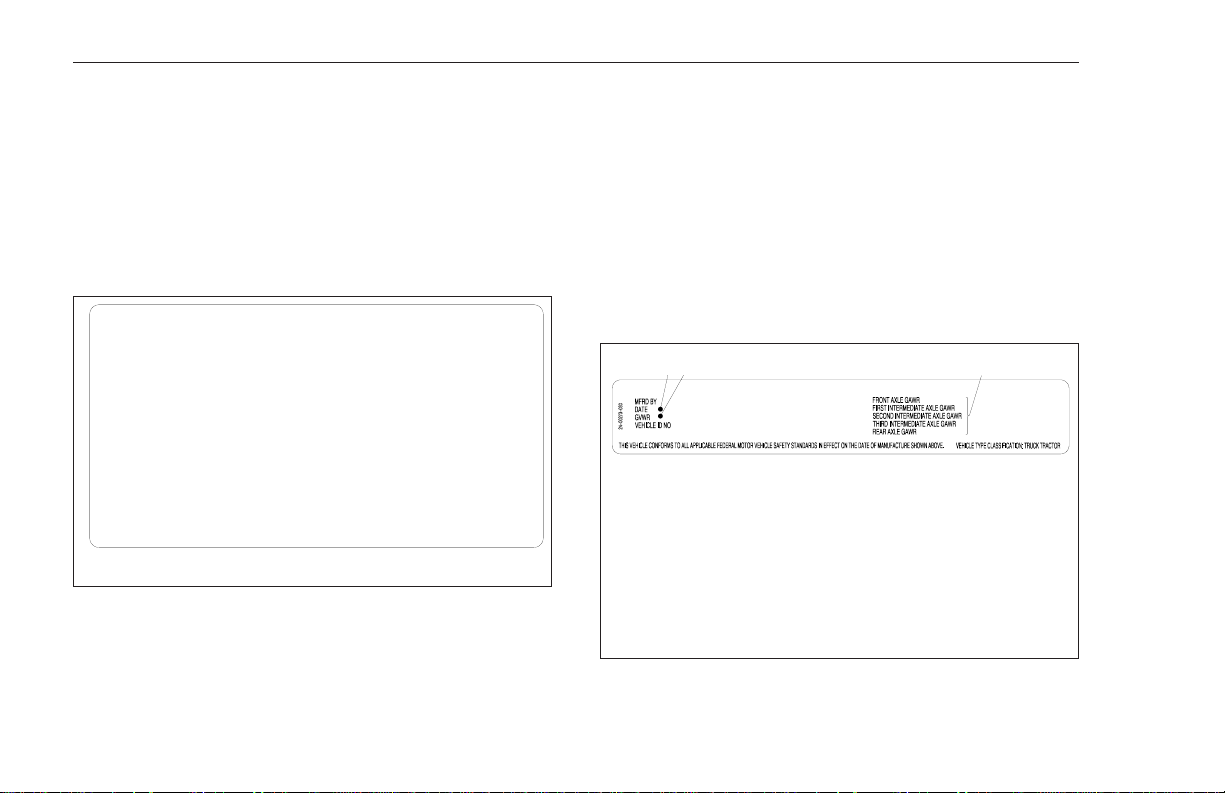

Federal Motor Vehicle Safety

Standard (FMVSS) Labels

NOTE: Due to the variety of FMVSS certification

requirements, not all of the labels shown will apply

to your vehicle.

Tractors with or without fifth wheels purchased in the

U.S. are certified by means of a certification label

(Fig. 1.2) and the tire and rim labels. These labels are

attached to the left rear door post.

2

1

11/21/96

1. Date of manufacture by month and year.

2. Gross vehicle weight rating; developed by taking the

sum of all the vehicle’s gross axle ratings.

3. Gross axle weight ratings; developed by considering

each component in an axle system, including

suspension, axle, wheels, and tires. The lowest

component capacity is the value used for the

system.

Fig. 1.2, Certification Label, U.S.

3

f080053

1.1

If purchased for service in the U.S., trucks built without

a cargo body have a certification label (Fig. 1.3) attached to the left rear door post. In addition, after

completion of the vehicle, a certification label similar to

that shown in Fig. 1.2 must be attached by the finalstage manufacturer. This label will be located on the left

rear door post and certifies that the vehicle conforms to

all applicable FMVSS regulations in effect on the date

of completion.

09/30/93

Vehicle Identification

f080024

Fig. 1.4, Canadian National Safety Mark

09/28/98

f080023

Fig. 1.3, Incomplete Vehicle Certification Label, U.S.

Canadian Motor Vehicle Safety

Standard (CMVSS) Labels

In Canada, tractors with fifth wheels are certified by

means of a "Statement of Compliance" label and the

Canadian National Safety Mark (Fig. 1.4), which are

attached to the left rear door post. In addition, tire and

rim labels (Fig. 1.5) are also attached to the left rear

door post.

If purchased for service in Canada, trucks built without

a cargo body and tractors built without a fifth wheel are

certified by a "Statement of Compliance" label, similar to

2

1

VEHICLE ID NO.

DATE OF MFR

GVWR

TIRES AND RIMS LISTED ARE NOT NECESSARILY THOSE INSTALLED ON THE VEHICLE.

02/12/98

FRONT AXLE

FIRST INTERMEDIATE AXLE

SECOND INTERMEDIATE AXLE

THIRD INTERMEDIATE AXLE

REAR AXLE

3

GAWR TIRES RIMS PSI COLD

24−00273−040

f080079

1. Date of manufacture by month and year.

2. Gross vehicle weight rating; developed by taking the

sum of all the vehicle’s gross axle ratings.

3. Gross axle weight ratings; developed by considering

each component in an axle system, including

suspension, axle, wheels, and tires. The lowest

component capacity is the value used for the

system.

Fig. 1.5, Tire and Rim Label

1.2

Vehicle Identification

Fig. 1.2. This label must be attached by the final-stage

manufacturer after completion of the vehicle. The label

is located on the left rear door post, and certifies that

the vehicle conforms to all applicable CMVSS regulations in effect on the date of completion.

Tire and Rim Labels

Tire and rim labels certify suitable tire and rim combinations that can be installed on the vehicle, for the given

gross axle weight rating. Tires and rims installed on the

vehicle at the time of manufacture may have a higher

load capacity than that certified by the tire and rim label. If the tires and rims currently on the vehicle have a

lower load capacity than that shown on the tire and rim

label, then the tires and rims determine the load limitations on each of the axles.

Refer to Fig. 1.5 for U.S. and Canadian tire and rim

labels.

EPA Vehicle Noise Emission

Control Label

A vehicle noise emission control label (Fig. 1.6)isattached to the right rear door post.

It is the owner’s responsibility to maintain the vehicle so

that it conforms to EPA regulations.

FREIGHTLINER CORPORATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY

THE NOISE CONTROL ACT OF 1972:

A. THE REMOVAL OR RENDERING INOPERATIVE, OTHER THAN FOR PURPOSES OF

MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR

ELEMENT OF DESIGN (LISTED IN THE OWNER’S MANUAL) INCORPORATED INTO THIS

VEHICLE IN COMPLIANCE WITH THE NOISE CONTROL ACT.

B. THE USE THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF DESIGN HAS

BEEN REMOVED OR RENDERED INOPERATIVE.

09/28/98

VEHICLE NOISE EMISSION CONTROL INFORMATION

DATE OF MANUFACTURE

01/96

24−00273−020

f080078

Fig. 1.6, Vehicle Noise Emission Control Label

IMPORTANT: Certain incomplete vehicles may be

produced with incomplete noise control hardware.

Such vehicles will not have a vehicle noise emission control information label. For such vehicles, it

is the final-stage manufacturer’s responsibility to

complete the vehicle in conformity to U.S. EPA

regulations (40 CFR Part 205) and label it for

compliance.

1.3

2

Vehicle Access and Features

Cab Door Locks and Handles .......................................................... 2.1

Door Windows ..................................................................... 2.1

Cab Entry and Exit .................................................................. 2.2

Seats ............................................................................ 2.5

Seat Belts and Tether Belts ........................................................... 2.7

Seat Belt Operation ................................................................. 2.8

Fuse/Relay/Circuit Breaker Identification ................................................. 2.11

Cab Tilting ....................................................................... 2.12

Front Access Panel ................................................................ 2.15

Back-of-Cab Grab Handle, Step, and Deck Plate ........................................... 2.16

Vehicle Access and Features

Cab Door Locks and Handles

The same key that operates the ignition switch is used

to lock and unlock the cab doors from the outside.

IMPORTANT: Each key is numbered. Record the

number so that, if needed, a duplicate key can be

made.

To unlock a door from outside the cab, insert the key in

the lockset (Fig. 2.1), and turn the key counterclockwise

on the driver’s door and clockwise on the passenger’s

door. Pull out on the handle to open the door. To lock

the door, turn the key clockwise on the driver’s door

and counterclockwise on the passenger’s door. The lock

cannot be operated when the door is open.

To lock the door from inside the cab, close the door,

then push the lock button down. See Fig. 2.1.

To open the door from the inside, pull the door latch

handle toward you. This will unlatch the door whether or

not it was locked. To unlock the door without unlatching

it, push up on the bottom of the lock button.

Door Windows

1

2

02/11/98

1. Door Latch Handle

2. Lock Button

Fig. 2.1, Door Handles and Locks

3

4

f601446

3. Exterior Handle

4. Exterior Lock

To lower the driver’s side door window, turn its regulator

handle clockwise; to lower the passenger’s side window, turn its handle counterclockwise. See Fig. 2.2.

2.1

10/01/98

Fig. 2.2, Window Regulator Handle

f601445a

Vehicle Access and Features

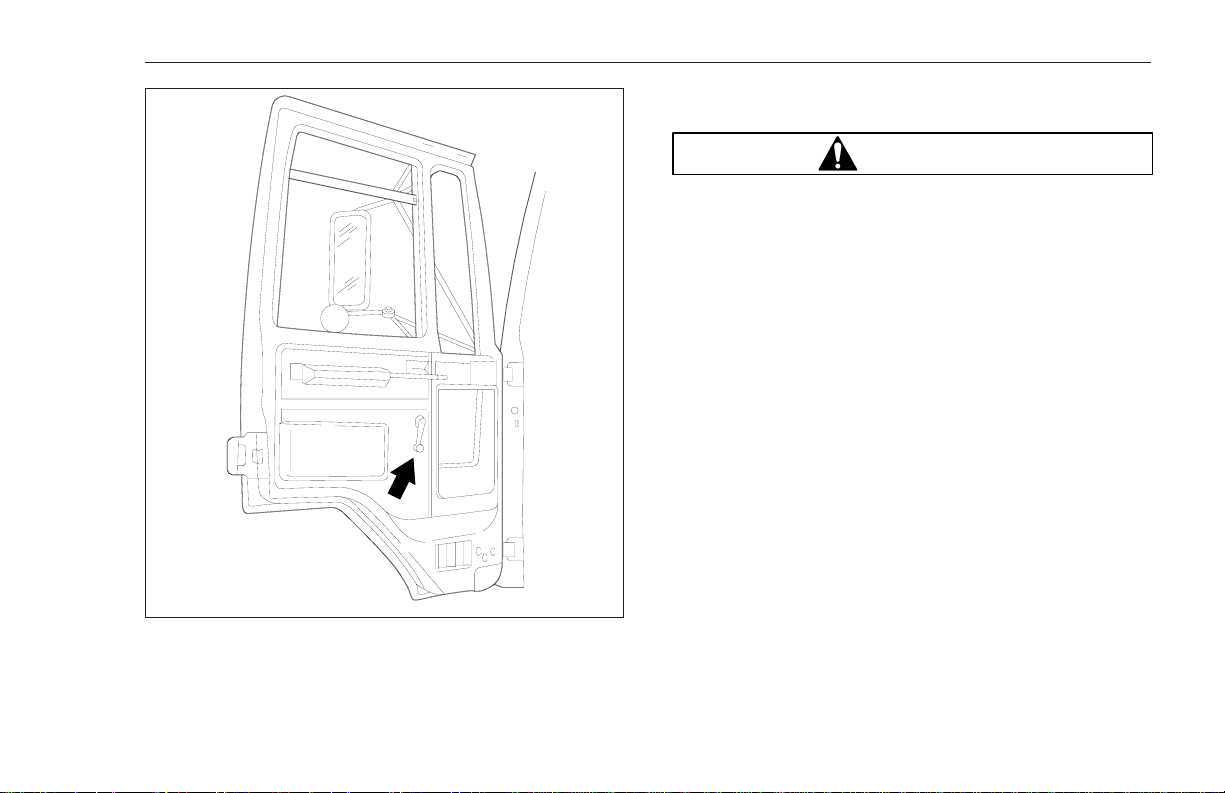

Cab Entry and Exit

WARNING

Wet or dirty shoe soles greatly increase the chance

of slipping or falling. If your soles are wet or dirty,

be especially careful when entering or exiting the

vehicle.

Always maintain three-point contact with the cab

access system while entering and exiting the cab.

Three-point contact means both feet and one hand,

or both hands and one foot.

Driver’s Side Entry and Exit

When entering or exiting the driver’s side of the cab,

use the grab handles and access steps as follows. See

Fig. 2.3.

1. Open the driver’s door, and place anything that you

are carrying in the cab.

2. Place your left foot on the bottom step. Grasp the

instrument panel grab handle with your left hand

and the steering wheel with your right hand (Ref.

A).

3. Place your right foot on the top step (Ref. B).

4. Bring your left foot up to the cab floor (Ref. C).

2.2

Vehicle Access and Features

09/02/97

A

Fig. 2.3, Driver’s Side Steps and Grab Handle

5. Place your right foot into the cab and seat yourself

(Ref. D).

6. To exit the cab on the driver’s side, grasp the instrument panel grab handle with your left hand and

the steering wheel with your right hand.

BC

IMPORTANT: Do not attempt to exit the cab while

carrying any items in your hand.

7. Place your right foot on the top step.

2.3

D

f060165

8. Bring your left foot to the bottom step.

9. Bring your right foot down to the ground, then bring

your left foot down to the ground.

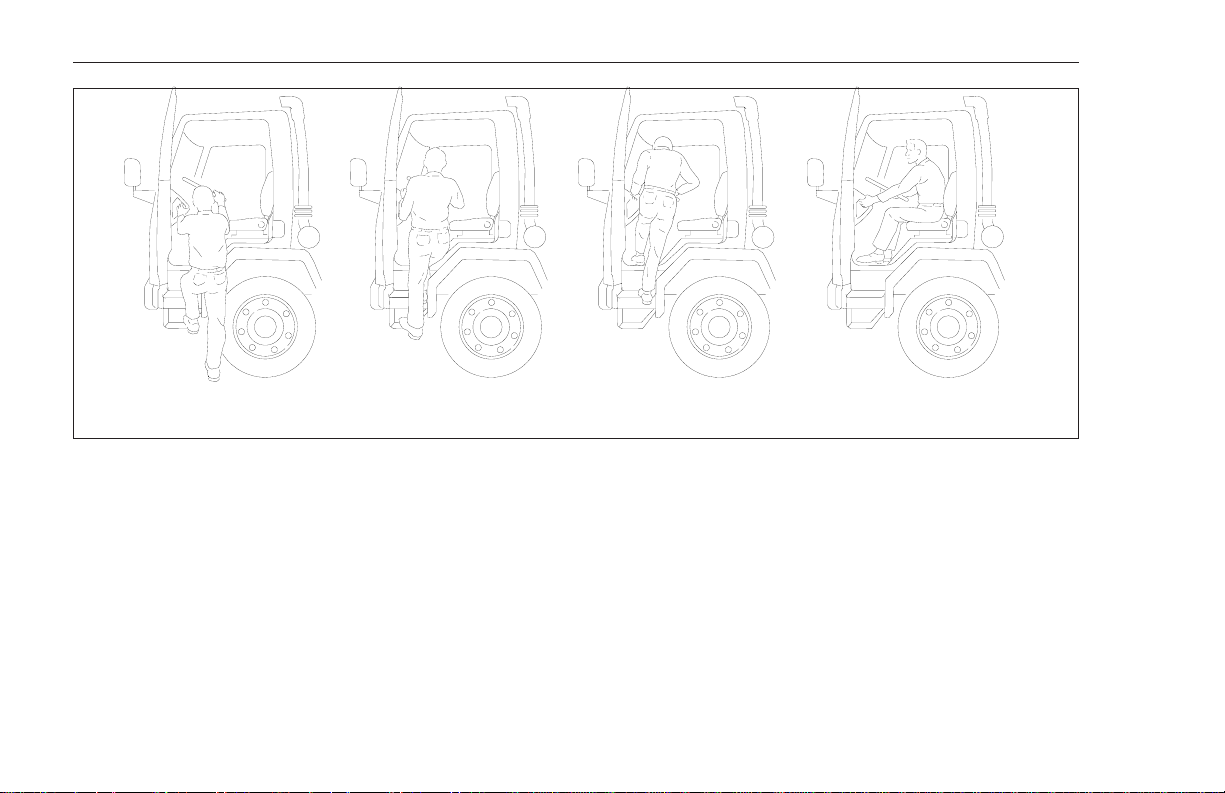

Passenger’s Side Entry and Exit

When entering or exiting the passenger’s side of the

cab, use the grab handles and access steps as follows,

refer to Fig. 2.4.

Vehicle Access and Features

A

09/02/97

Fig. 2.4, Passenger’s Side Steps and Grab Handles

1. Open the passenger’s door, and place anything that

you are carrying in the cab.

2. Place your left foot on the bottom step. Grasp the

instrument panel upper grab handle with your left

hand and the lower grab handle with your right

hand (Ref. A).

3. Place your right foot on the top step (Ref. B).

4. Bring your left foot up to the cab floor (Ref. C).

B

C

5. Place your right foot into the cab and seat yourself

(Ref. D).

6. To exit the cab on the driver’s side, grasp the upper

grab handle with your left hand and the lower grab

handle with your right hand.

D

f060166

IMPORTANT: Do not attempt to exit the cab while

carrying any items in your hand.

2.4

Vehicle Access and Features

7. Place your right foot on the top step.

8. Bring your left foot to the bottom step.

9. Bring your right foot down to the ground, then bring

your left foot down to the ground.

Seats

IMPORTANT: When adjusting the seats, unless

otherwise noted, make all adjustments while

seated and before the engine is started.

WARNING

Keep hands, tools, and other objects away from the

scissor points under the seats. Failure to do so

could cause personal injury.

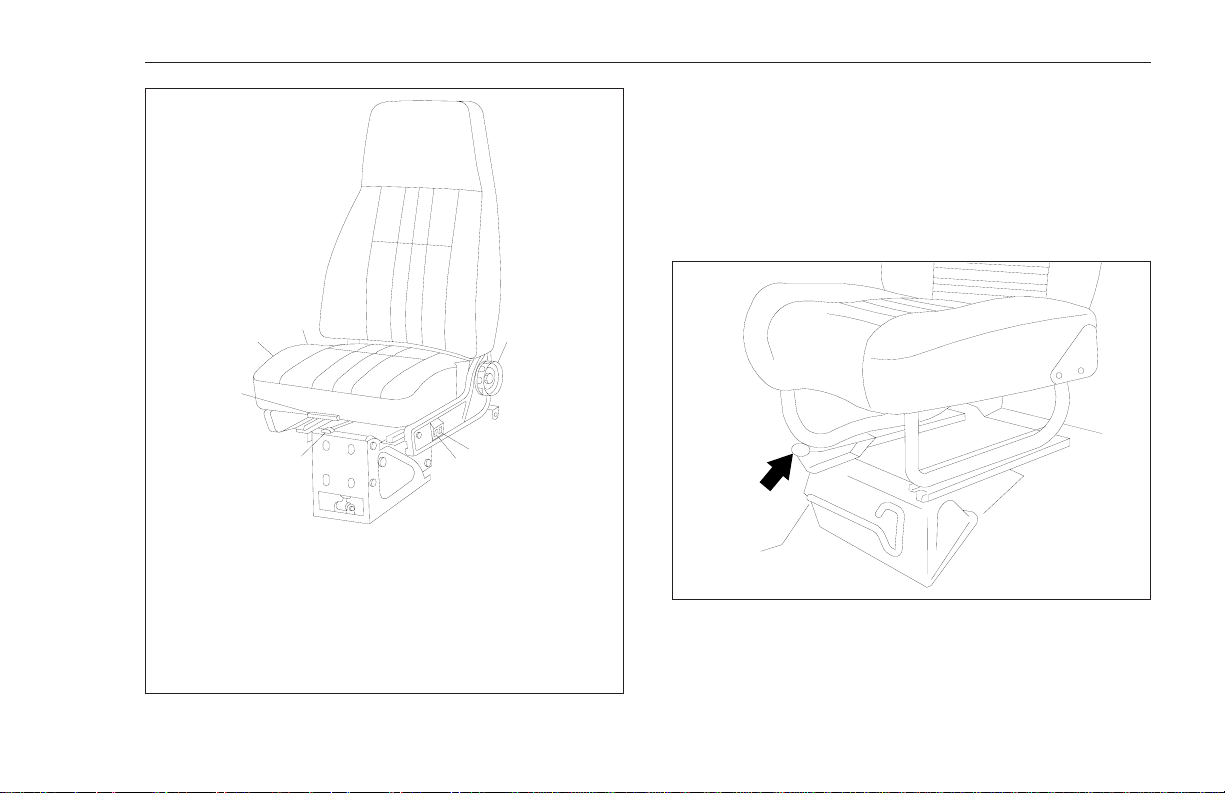

National Cush-N-Aire II Seat

Back Cushion Tilt

To tilt the back cushion, turn the knob and lean forward

or backward. See Fig. 2.5.

Height Adjustment

To raise the seat, push the rocker switch on the side of

the seat up until the seat reaches the desired height. To

lower the seat, push the rocker switch down until the

seat reaches the desired height.

Fore and Aft Seat Adjustment

Move the lever to the left and slide the seat forward or

backward to the desired position.

Bottom Cushion Front Height

To adjust the height of the front of the bottom cushion,

lift the handle, and pull forward or push back to the desired setting.

Lumbar Support

Push the rocker switch on the side of the seat up to

inflate lumbar support. Push the rocker switch down to

deflate lumbar support.

Back-of-Cushion Height

To adjust the height at the back of the cushion, rotate

the lever to the desired setting.

Isolator, Optional

Also called a Chugger-Snubber, the isolator is locked

out by moving the handle down.

2.5

Vehicle Access and Features

Non-Suspended Driver’s Seat

Fore-Aft Seat Adjustment

Move the control lever at the front of the seat to release

the locking mechanism, then exert slight body pressure

to move the seat forward or rearward, as desired. See

Fig. 2.6.

7

6

5

4

11/02/95 f910128

1. Back Cushion Tilt Knob

2. Lumbar Support Switch

3. Height Adjustment Switch

4. Fore-Aft Seat Adjustment Lever

5. Bottom Cushion Front Height Handle

6. Isolator Handle

7. Back-of-Cushion Height Adjustment Handle

Fig. 2.5, National Cush-N-Aire II Seat

1

2

3

09/09/97

Fig. 2.6, Non-Suspended Driver’s Seat Control Lever

f910246

Release the lever to lock the seat in place. Push the

seat back and forth to ensure that it is locked in place.

2.6

Vehicle Access and Features

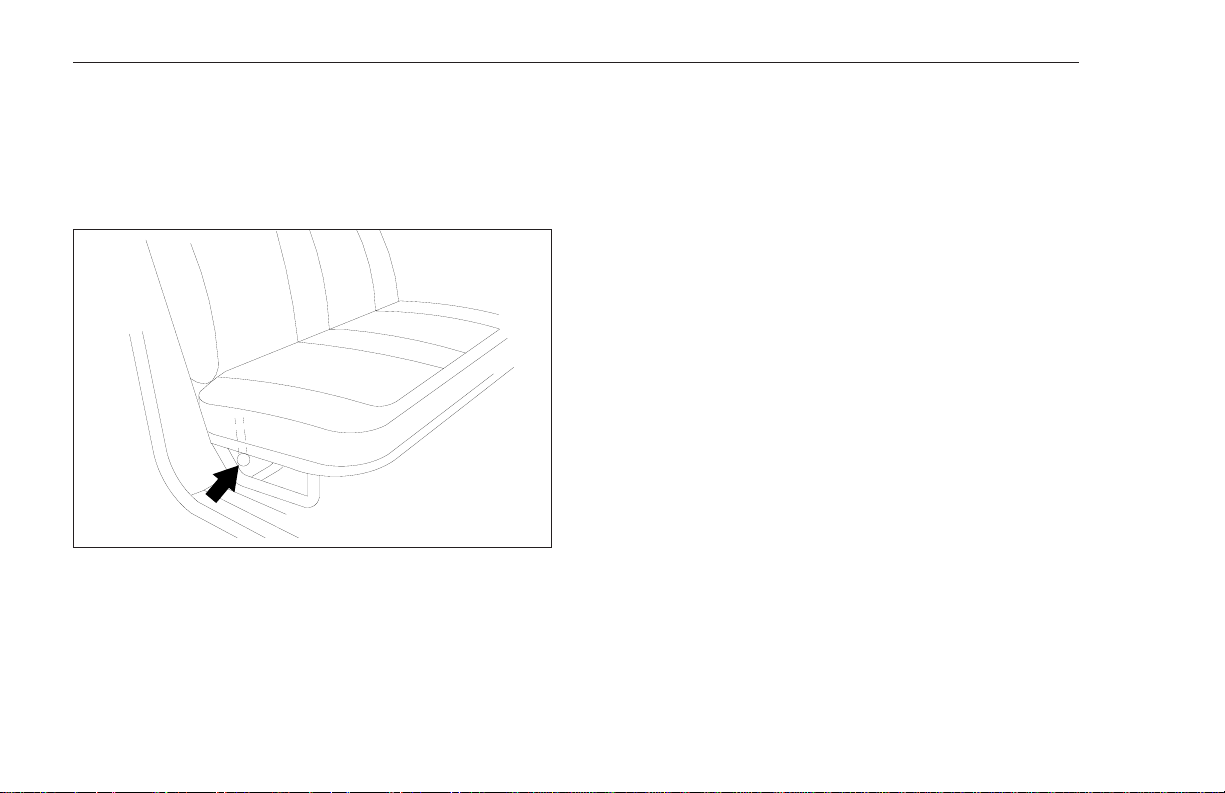

Passenger’s Seat

The passenger’s seat is not adjustable. See Fig. 2.7.

Access to the storage compartment under the seat is

obtained by moving the release lever and tilting the

seatback forward.

09/09/97

Fig. 2.7, Passenger’s Seat Release Lever (typical)

f910247

Seat Belts and Tether Belts

General Information

Seat belt assemblies are designed to secure persons in

the vehicle to help lessen the chance of injury or the

amount of injury resulting from accidents or sudden

stops. For this reason, the manufacturer urges that the

driver and all passengers, regardless of age or physical

condition, use seat belts when riding in the vehicle.

Seat belt assemblies in the vehicle meet Federal Motor

Vehicle Safety Standard 209, "Type 1," and "Type 2"

requirements. They are recommended for all persons

weighing over 50 pounds (23 kg).

A child restraint system should also be provided for

each child weighing 50 pounds (23 kg) or less. It should

meet the requirements of Federal Motor Vehicle Safety

Standard 213, "Child Restraint Systems." When providing such a restraint system, carefully read and follow all

instructions pertaining to installation and usage for the

child. Make certain the child remains in the restraint

system at all times when the vehicle is in motion.

In addition to seat belt assemblies, tether belts are installed on suspension-type seats. Tether belts help secure the seat to the floor and are intended to restrain

the seat and seat belt in case of an accident or sudden

stop.

IMPORTANT: Seat belts have a finite life which

may be much shorter than the life of the vehicle.

Regular inspections and replacement as needed

are the only assurance of adequate seat belt security over the life of the vehicle.

2.7

Seat Belt Operation

Three-Point Seat Belt with Komfort

Latch

WARNING

Wear three-point seat belts only as described below. In case of an accident or sudden stop, injuries

could result from misuse. Three-point seat belts are

designed to be worn by one person at a time.

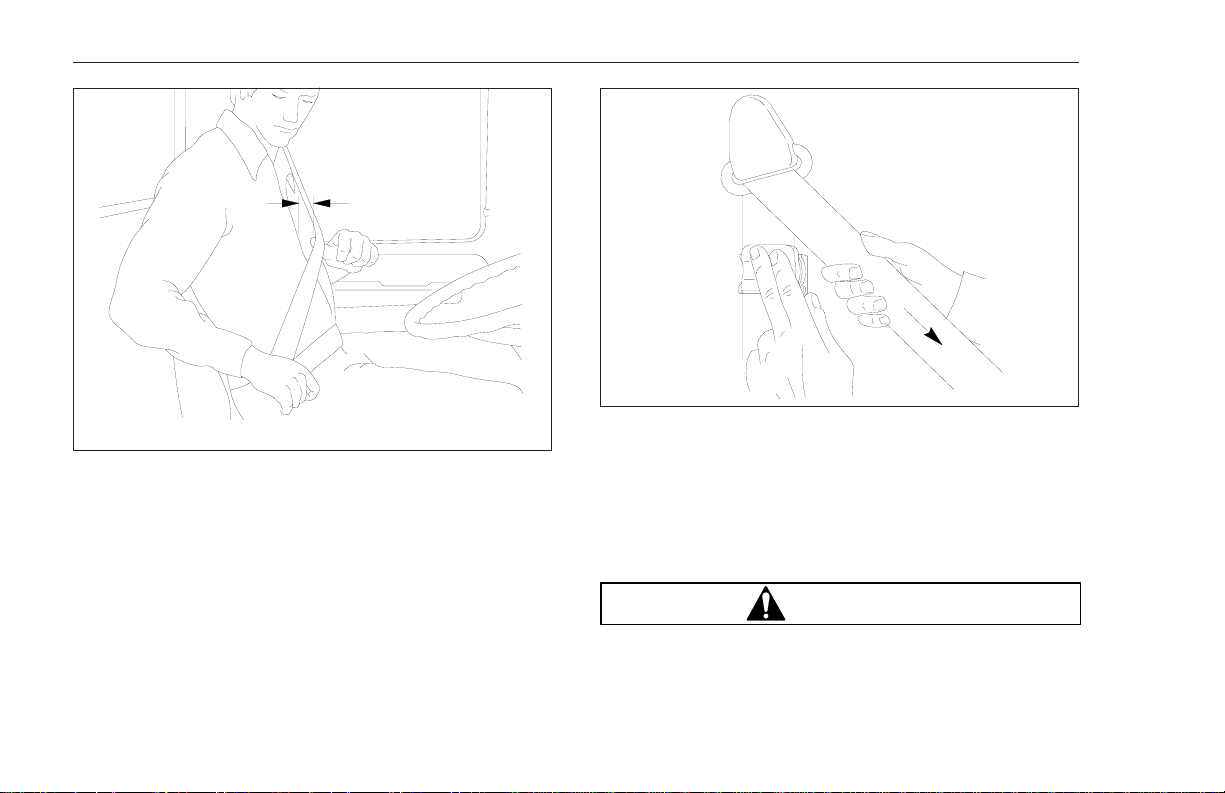

1. Before driving the vehicle, slowly pull the link end of

the three-point seat belt out of the retractor and pull

it across your lap (from outboard to inboard) far

enough to engage the buckle. If the retractor locks

too soon, allow the belt to retract slightly, then

slowly pull it out again.

2. Fasten the three-point seat belt by pushing the link

into the buckle until it latches. See Fig. 2.8. Give

the belt a tug at the buckle. If the buckle unlatches,

repeat this step. If the problem continues, replace

the three-point seat belt.

3. Position the shoulder strap diagonally across your

chest. If desired, engage the Komfort Latch as follows:

Vehicle Access and Features

01/18/95

Fig. 2.8, Fastening the Three-Point Seat Belt (typical)

Pull on the shoulder strap to lessen the pressure of

the strap on your shoulder and chest. Allow no

more than one inch (2.5 cm) of slack between your

chest and the shoulder harness. More slack can

significantly reduce the seat belt’s effectiveness in

an accident or a sudden stop. While holding the

belt slack, press the Komfort Latch lever up, clamping the belt’s webbing. See Fig. 2.9 and Fig. 2.10.

f910004a

2.8

Vehicle Access and Features

A

01/06/95

A. 1 Inch (2.5 cm) Maximum

Fig. 2.9, Adjusting Shoulder Harness Clearance

4. To unbuckle the three-point seat belt, push the button on the buckle. See Fig. 2.11. If the Komfort

Latch was used, release it by giving the shoulder

belt a quick tug. If you lean forward against the

shoulder belt, the Komfort Latch will automatically

release, and will need to be reset.

f910048a

NOTE: The Komfort Latch does not have to be

released in an emergency situation. The Komfort

Latch will release by itself under rough road or

2.9

01/06/95

Fig. 2.10, Locking Komfort Latch

f910006a

other abnormal conditions. Make sure the threepoint seat belt is completely retracted when it is

not in use.

Lap Belt

WARNING

Wear lap belts only as described below. In case of

an accident or sudden stop, injuries could result

Vehicle Access and Features

2

01/18/95

Fig. 2.11, Releasing the Three-Point Seat Belt (typical)

f910049a

from misuse. Lap belts are designed to be worn by

one person at a time.

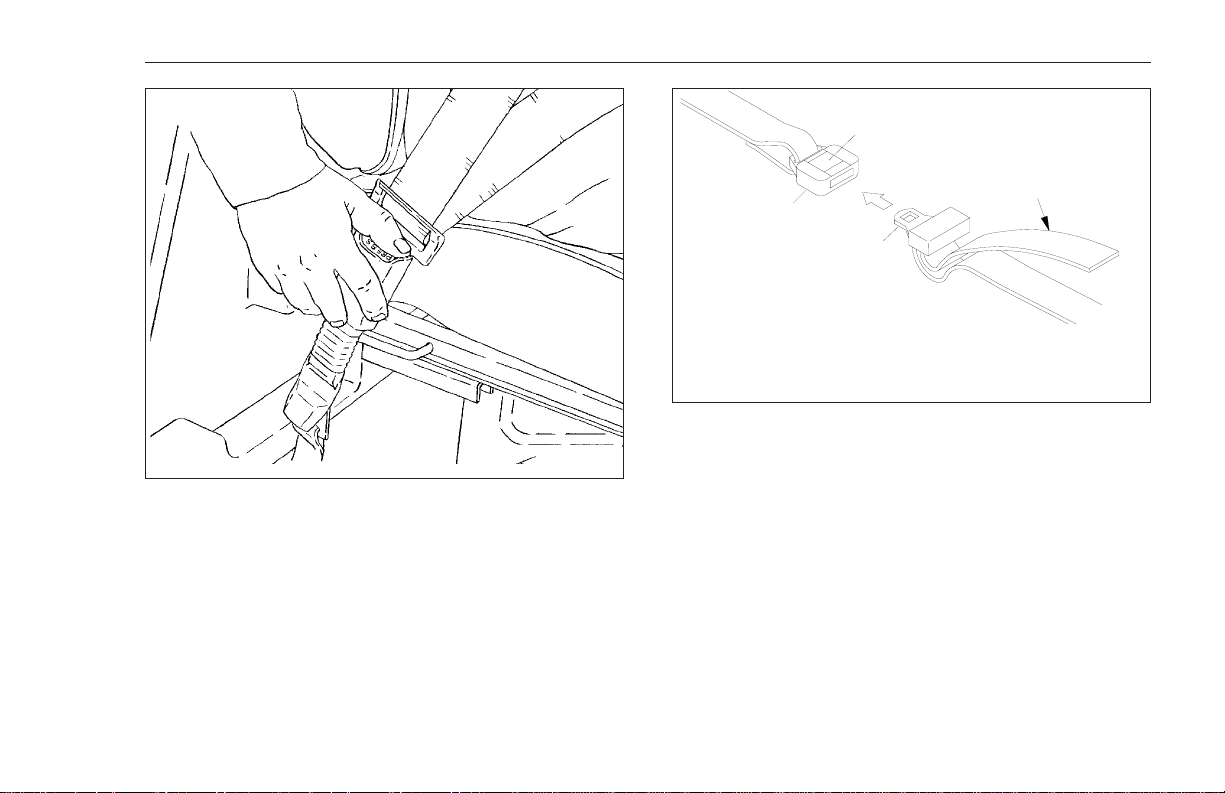

1. Slowly pull the link end of the lap belt across your

lap. See Fig. 2.12. If it is necessary to lengthen the

belt, tip the link end downward and pull the link until

it connects with the buckle.

2. Fasten the lap belt by pushing the link into the

buckle until they latch. Make sure the belt is not

1

3

01/06/95

A. Pull on loose end to shorten belt.

1. Buckle

2. Belt Release Button

Fig. 2.12, Lap Belt Adjustment

3. Link

A

f910068a

twisted. Check the engagement by trying to pull the

link out of the buckle. If they come apart, repeat

this step. If the problem continues, replace the belt.

NOTE: The belt can be shortened after it is connected by pulling on the loose end until the belt is

snug, but comfortable.

3. To release the belt, push the release button on the

buckle and pull the link from the buckle.

2.10

Vehicle Access and Features

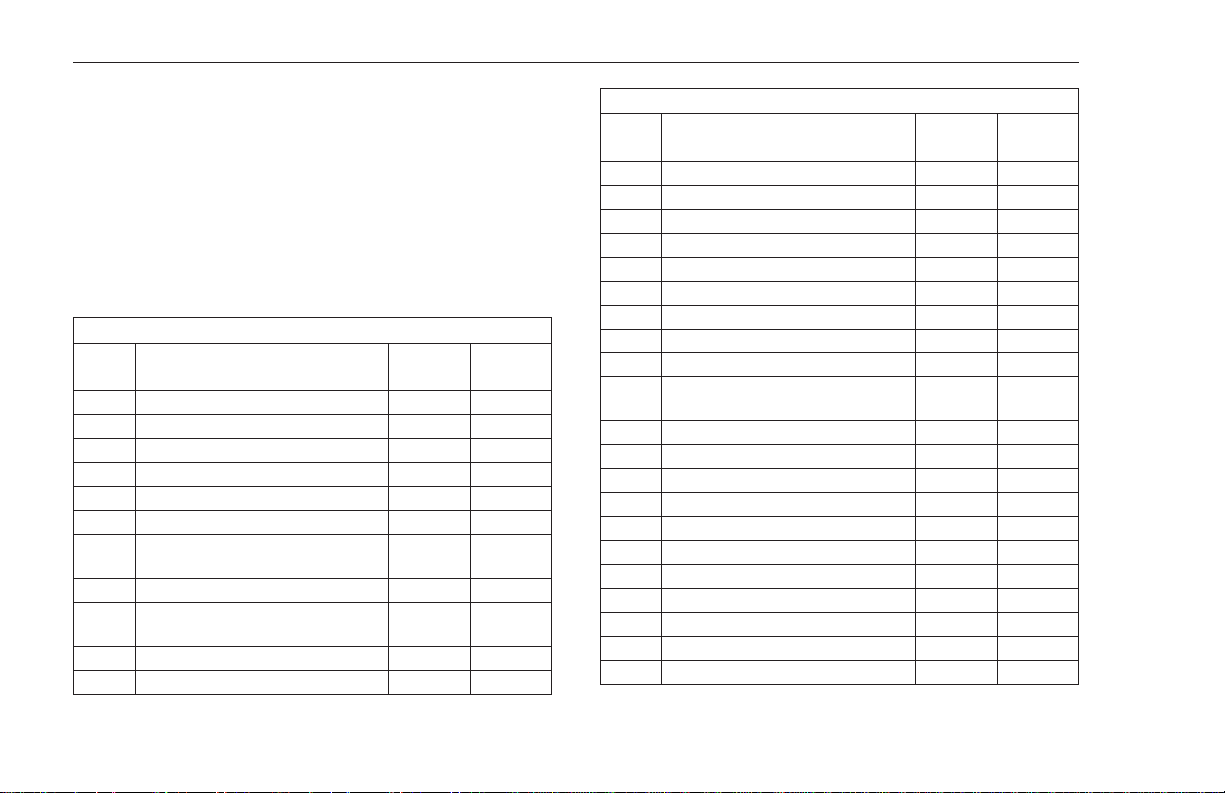

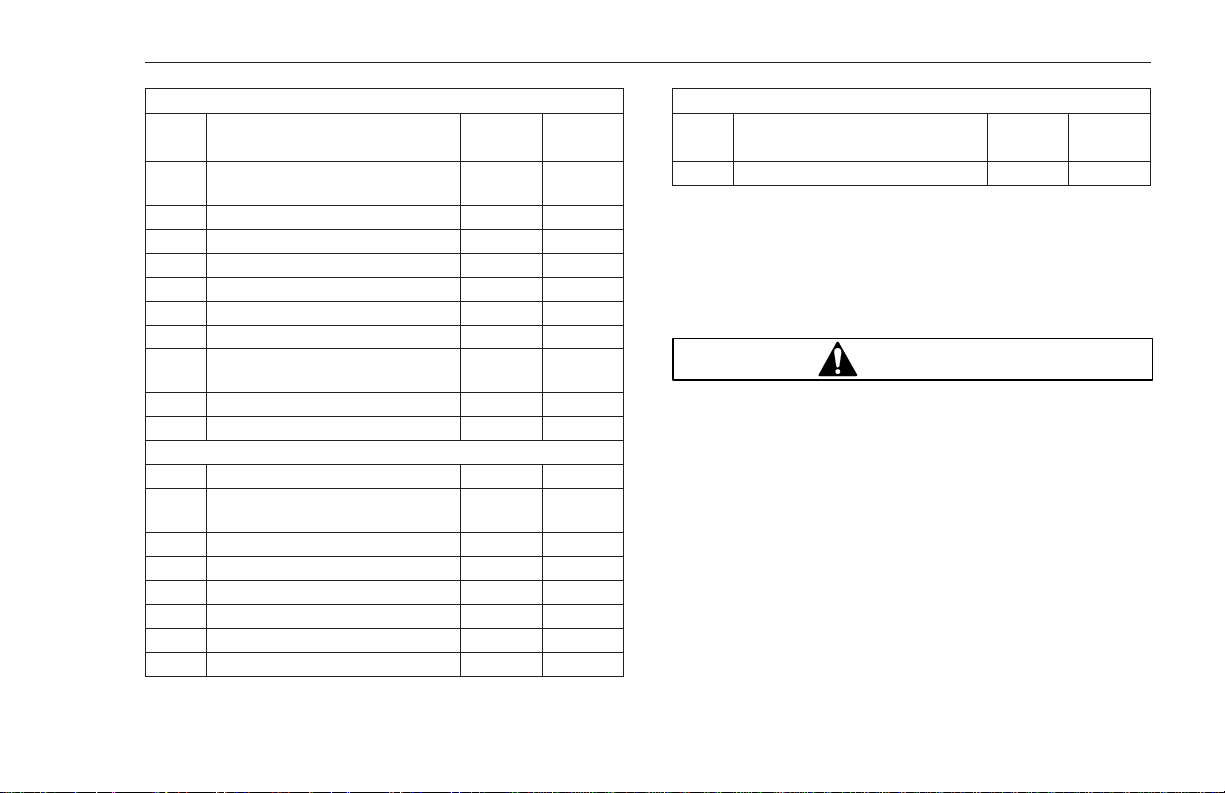

Fuse/Relay/Circuit Breaker

Identification

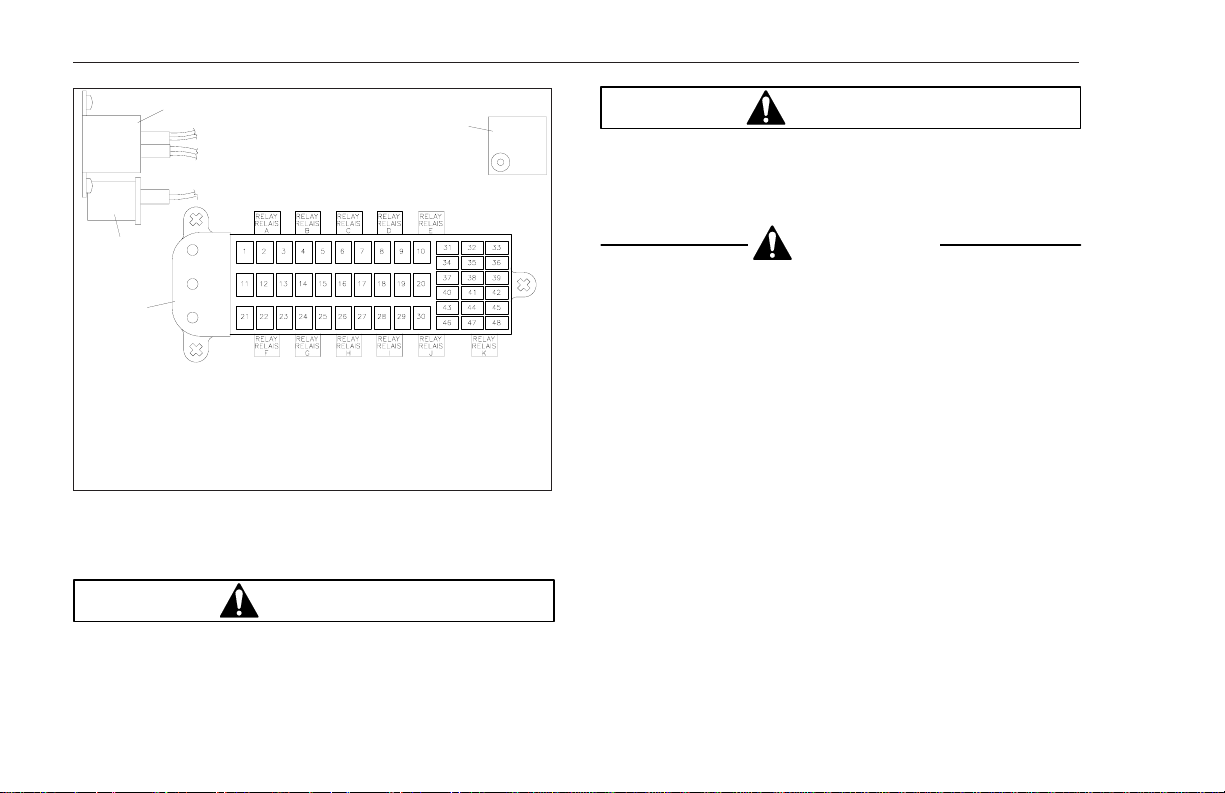

NOTE: The fuse/relay/circuit breaker panel

(Fig. 2.13) is located under the glove box. Depending on vehicle options, fuse/relay/circuit

breaker locations may vary from those shown. Refer to

Fig. 2.13 or Table 2.1 for the Fuse/Relay/

Circuit Breaker Identification information.

Fuse/Relay/Circuit Breaker Identification

Pos.

No.

1 Daytime Running Lights 10A

2 Interior Lamps 10A

3 Turn Signal 25A

4 Customer Use (Battery) — —

5 Cigar Lighter 10A

6 Horn 10A

Trailer: Clearance Marker

7

Lamps

8 Not Used — —

Headlamps

9

10 Not Used — —

11 Warning Lamps 10A

Description

Part

Number

Rating

20A

15A

*

CB

Fuse/Relay/Circuit Breaker Identification

Pos.

No.

12 Stop Lamps 25A

13 Backup Lamps 10A

14 Washer Pump 10A

15 Fuel Shutoff 15A

16 Two-Speed Axle 25A

17 Wheel/Wheel and Diff Lock 10A

18 Exhaust Brake 10A

19 Customer Use (Start/Run) — —

20 Air Dryer 10A

21 Windshield Wipers

22 Blower Motor 10A

23 Radio 15A

24 Not Used — —

25 I/P Illumination Lamps 5A

26 Trailer: Tail/License Lamps 10A

27 Park and S/M Lamps 10A

28 Cab Roof Marker 10A

29 Not Used — —

30 Not Used — —

A Fuel Shutoff Relay

B Exterior Lighting Relay

Description

Part

Number

Rating

8.25A

CB

*

2.11

Vehicle Access and Features

Fuse/Relay/Circuit Breaker Identification

Pos.

No.

Brake Low Air Warning

C

Prove-out

D Cab Latch Warning Prove-out Relay

E Windshield Wiper Timer Relay

F Not Used — —

G Marker Lamps Relay

H Headlamp Dimmer — Radio Relay

I Two-Speed Axle Relay

Trans Temp Warning Prove-

J

out

K Not Used — —

L Not Used — —

Customer Use Terminals

31 Accessory/Run Non-Fused — —

Trailer Park and Marker

32

Lamps

33 Accessory/Run Fused — —

34-39 Not Used — —

40 Accessory/Marker Lamps — —

41-45 Not Used — —

46 Trailer Lamps — —

47 Accessory/Run Non-Fused — —

Description

Part

Number

——

Rating

Relay

Relay

Fuse/Relay/Circuit Breaker Identification

Pos.

No.

48 Battery — —

*

Special Cycling Circuit Breakers—Replace with authorized service parts

or equivalent.

Table 2.1, Fuse/Relay/Circuit Breaker Identification

Description

Part

Number

Rating

Cab Tilting

WARNING

Never stand in front of the cab or under the cab

when the cab is being tilted. Doing so could result

in serious personal injury.

Easy access to the engine and transmission is provided

by tilting the cab. The cab can be tilted 40 degrees for

normal repair situations, or 50 degrees for removing

larger components. Torsion bars under the cab make it

easy to raise the cab by hand. A latching support arm

holds the cab in the tilted positions.

2.12

Vehicle Access and Features

1

2

3

4

09/09/97

1. Signal Flasher (located at upper left of fuse panel)

2. Warning Chime (located at right side of fuse panel)

3. Warning Buzzer (located at lower left of fuse panel)

4. Fuse/Relay/Circuit Breaker Panel

Fig. 2.13, Fuse/Relay/Circuit Breaker Identification

f541760

To Tilt the Cab

WARNING

Do not release the cab until the transmission has

been put into neutral, the ignition turned off, and

the parking brake set. Failure to observe these precautions could result in serious personal injury.

WARNING

Do not allow loose clothing to get near moving engine parts. To do so could result in serious personal injury.

CAUTION

Ensure the shift lever will clear the floor opening

when the cab is tilted to prevent damage to the shift

lever.

Do not raise the cab until all loose items inside the

cab are removed or fastened down and the doors

are closed. If the cab is equipped with exterior air

lines, be sure the air lines will be clear of the body

lock.

1. Apply the parking brakes and chock the tires.

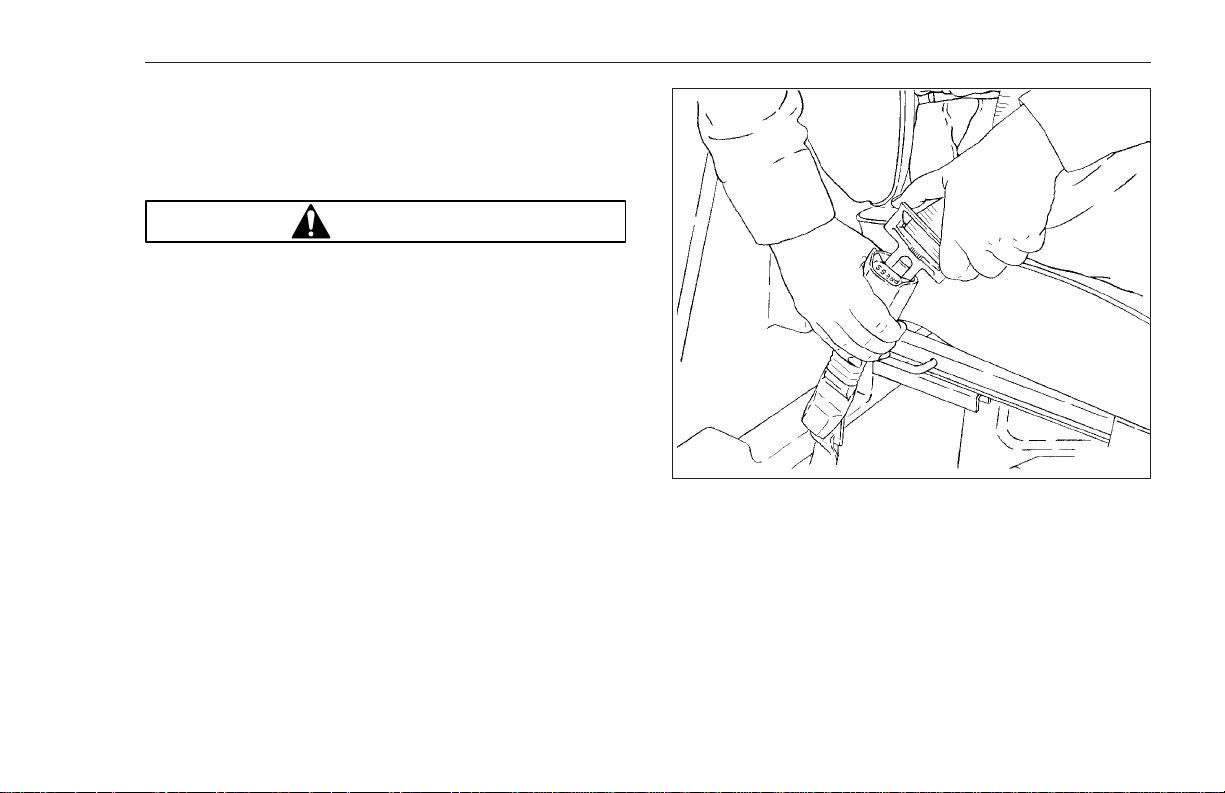

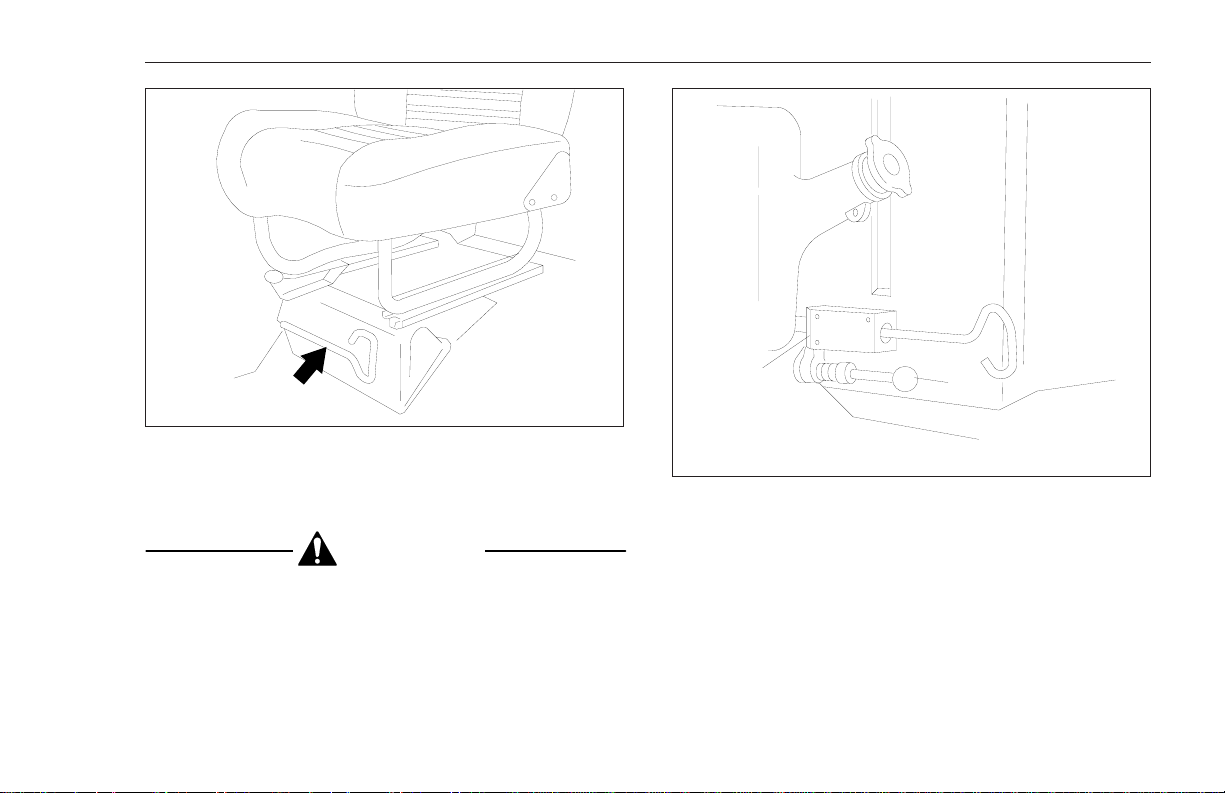

2. The handle for the cab lock control is located on

the lower front face of the driver’s seat (Fig. 2.14).

Remove the handle from the housing.

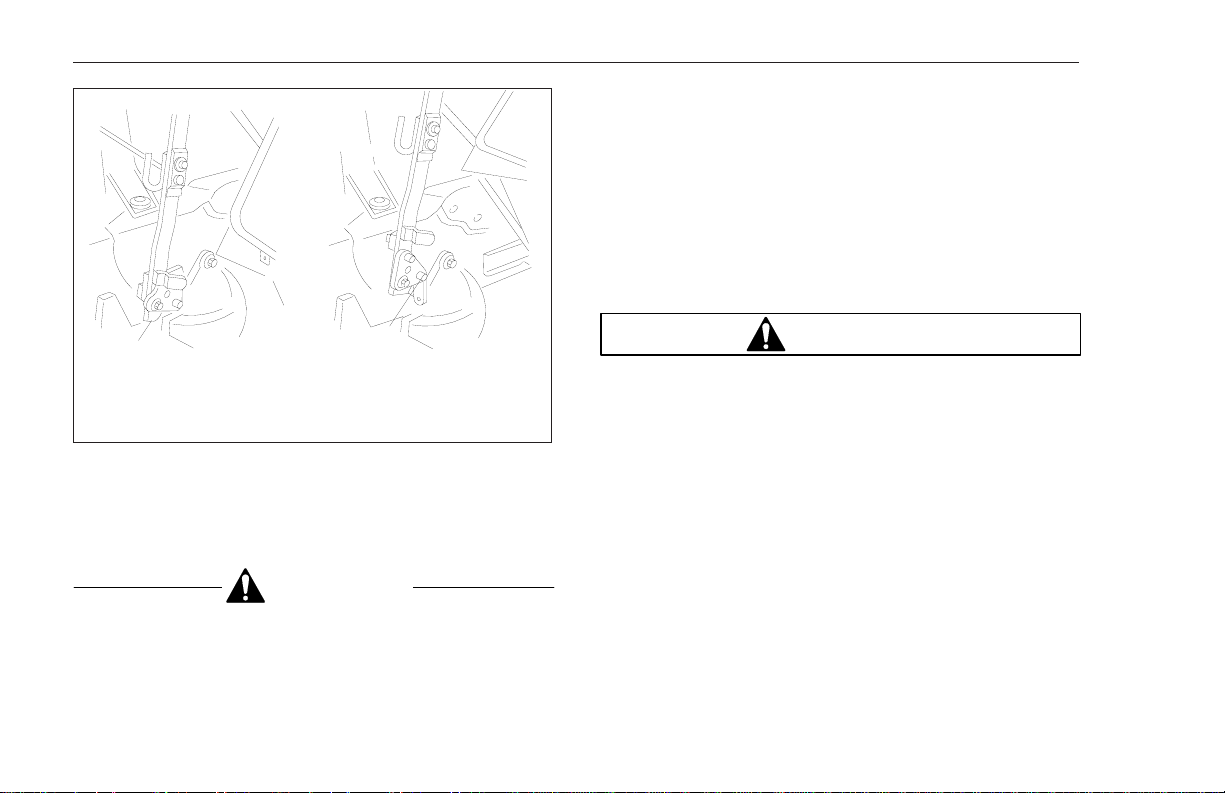

3. Insert the cab lock handle in the lock control located on the passenger’s side of the rear cab panel

(Fig. 2.15). Push the safety hook knob inward, then

rotate the handle counterclockwise and pull the

handle outward. The handle will still be engaged.

2.13

Vehicle Access and Features

09/09/97

Fig. 2.14, Cab Lock Handle

4. Lift the rear part of the cab and let it tip up to the

first position.

f910245

CAUTION

To avoid damage to the handle, do not put pressure

on the lock handle, or use the handle to lift the cab.

5. To tilt the cab to the second position, remove the

lower limiting rod triangular support bolt. Place the

support bolt in the opening in the arm connection

1

09/08/97

1. Cab Lock Control 2. Safety Hook Knob

Fig. 2.15, Back of Cab

near the central pin (Fig. 2.16). The cab can now

be pushed forward to the second position.

2

f310618

To Lower the Cab

1. Make sure the lock indicator is retracted to permit

correct cab locking, then push the cab back to the

first tilting position.

2.14

Vehicle Access and Features

3. Lift the rear part of the cab slightly, then pull downward to lower the cab completely. Remove the cab

lock handle and secure it in its original position.

4. To check for proper locking of the cab, turn the ignition to the ON position. An indicator light on the instrument panel will light if the cab is not locked securely.

Front Access Panel

1

09/08/97

1. First Position, 40 Degree Tilt

2. Second Position, 50 Degree Tilt

Fig. 2.16, Cab Tilt Arm

2. Remove the bolt previously placed near the central

pin. Return the bolt to its original position in the

lower opening of the triangular support.

2

f310619

CAUTION

Be sure the shift lever is in neutral and the shift

knob will clear the floor opening when the cab is

being lowered to avoid damage to the shift lever.

2.15

WARNING

The parking brake must be fully set before opening

the front access panel. Failure to do so could result

in serious personal injury.

If your vehicle has an automatic transmission,

place the gear shift lever in N (neutral), shut the

engine off, and set the parking brake. If your vehicle has a manual transmission, place the gear

shift lever in R (reverse), shut the engine off, and

set the parking brake.

To open the front access panel, use a coin to turn the

locks located at each end of the outside surface of the

panel one quarter turn counterclockwise.

After tilting the panel open, support the panel with the

rod.

To close the front access panel, lift the panel slightly to

release the support rod. Secure the support rod, and

press the panel down until it locks.

Back-of-Cab Grab Handle,

Step, and Deck Plate

When climbing onto the frame rails or deck plate, use

the grab handle and step. Always maintain three-point

contact with the back-of-cab access system.

A grab handle is mounted on the cab. When an optional

deck plate is included, it is mounted across the top of

the frame rails.

Vehicle Access and Features

2.16

3

Driver Controls and Instruments

Instrument and Control Panel .......................................................... 3.1

Controls .......................................................................... 3.1

Warning and Indicator Lights .......................................................... 3.10

Instruments ...................................................................... 3.12

Heater and Ventilation System ........................................................ 3.17

Driver Controls and Instruments

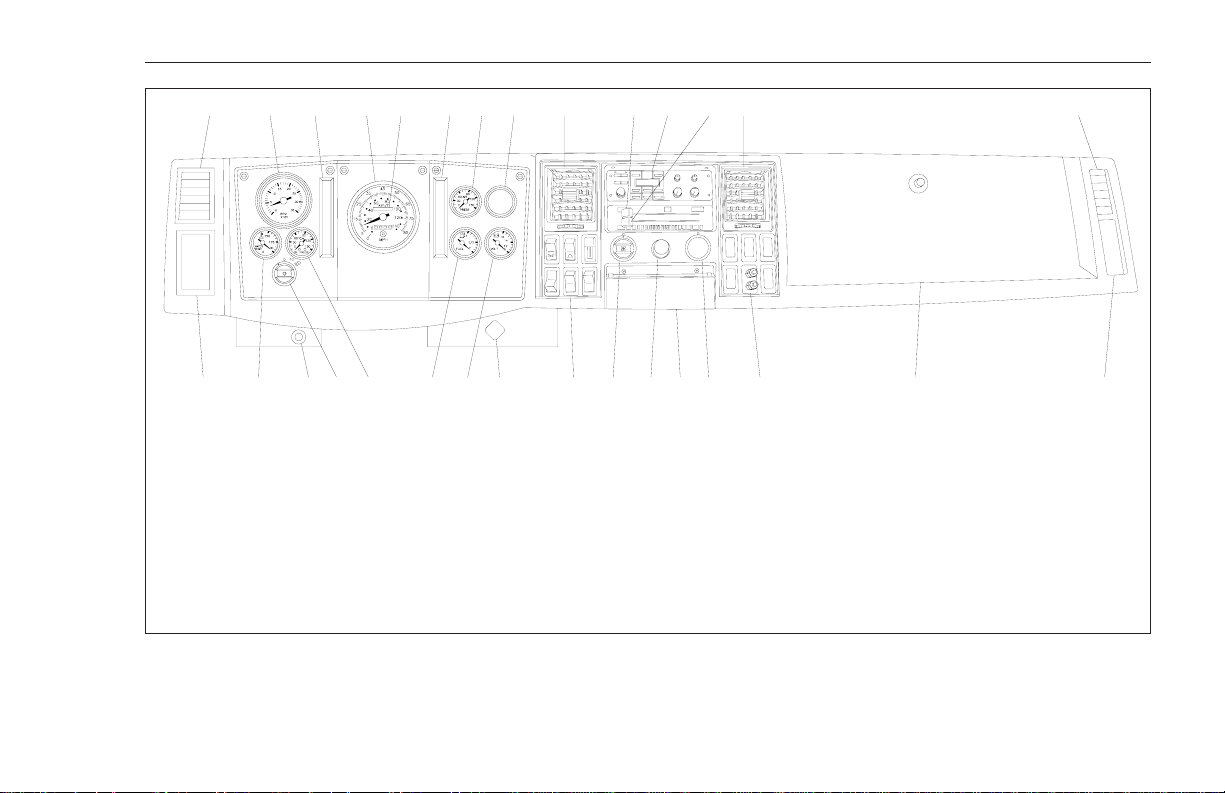

Instrument and Control Panel

Figure 3.1 represents a typical dash equipped with all

of the standard and many of the optional instruments

and controls.

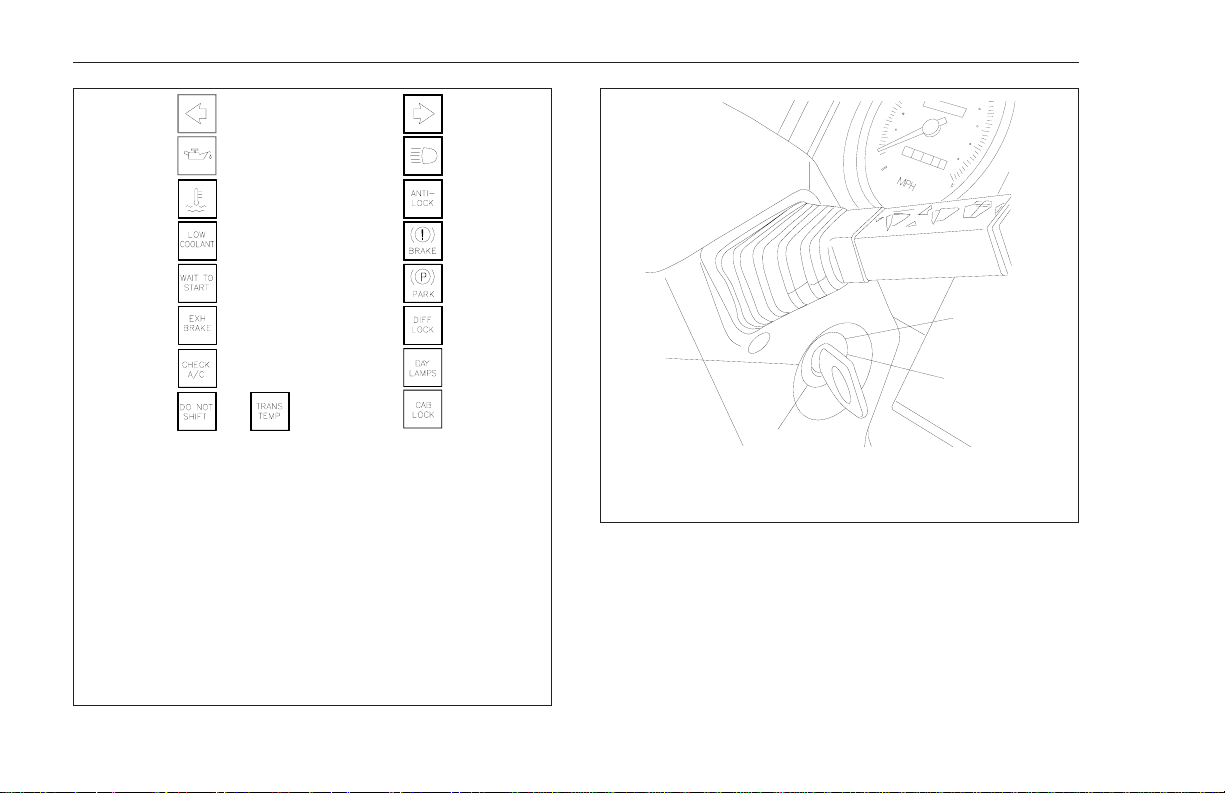

Warning and indicator light modules, located on each

side of the speedometer, house all of the standard and

optional warning and indicator lights. Figure 3.2 identifies the warning and indicator lights.

Controls

Ignition Switch and Key

The ignition switch can be turned to four positions: OFF,

ACCESSORY, ON, and START. See Fig. 3.3. The ignition switch key also locks and unlocks the cab doors.

The key can be inserted and removed only from the

OFF position. The headlights (low beam only), brake

lights, fog lights, dome lights, clearance lights, turn signals, hazard warning lights, parking lights, and the cigar

lighter operate with the ignition switch off, regardless of

whether the key is inserted.

In the ACCESSORY position, the wipers, heated mirrors, backup lamps, radio, ether start system, and all

electric gauges operate.

Turn the key fully clockwise to the START position, only

when starting the engine. When the engine starts, re-

lease the key. When released, the key will move to the

ON position.

In the ON position, all electrical systems are operable.

Warning lights and buzzer for low air pressure and low

oil pressure operate until the engine is started and minimum pressures are built up.

Panel Light Control

The panel lights (see Fig. 3.4) are turned on by the

headlight switch. The panel light control lever adjusts

the brightness of the instrument panel lights. Slide the

control lever up to brighten the lights, and down to dim

them. Move the control lever all the way down to turn

them off.

Headlight Switch and Daytime

Running Lights

In the up position all of the lights are off. See Fig. 3.5.

Turning the switch clockwise one position turns on the

marker/clearance lights, taillights, parking lights, license

plate light, and panel lights. Turning the switch clockwise another position turns on the headlights, marker/

clearance lights, taillights, parking lights, license plate

light, and panel lights.

3.1

Driver Controls and Instruments

23 4 6

1

26 25 24 23 22 21 20 19 18 17 16 15 14 13 12

12

12/18/97 f610041

1. Face Level Vent

2. Tachometer

3. Warning and Indicator Light

Module

4. Speedometer

5. Odometer

6. Warning and Indicator Light

Module

7. Dual Air Pressure Gauge

8. Not Used

5781 1910

9. Heater/Ventilation Mode Selector

10. Radio (optional)

11. Temperature Control

12. Interior Grab Handle

13. Glove Compartment

14. Radio Hot Post (optional)

15. Not Used

16. Ashtray

17. Cigar Lighter

18. Fan Speed

Fig. 3.1, Instrument and Control Panel Layout (typical)

11

1

19. Left Switch Bank

20. Parking Brake Control

21. Voltmeter

22. Fuel Gauge

23. Oil Pressure Gauge

24. Headlamp Switch

25. Hand Throttle, Vernier Type

(optional)

26. Water Temperature Gauge

To change the headlights from low to high beam, or

high to low beam, push the control lever away from the

instrument panel (Fig. 3.6). When the headlights are on

high beam, an indicator light on the instrument panel

3.2

Driver Controls and Instruments

A

07/15/99

NOTE: Not all vehicles with daytime running lights are

equipped with the in-dash indicator.

A. Left Side Bank B. Right Side Bank

1. Left-Turn Indicator

2. Low Oil Pressure

3. High Coolant Temp

4. Low Coolant Level

5. Wait To Start

6. Exhaust Brake

7. Check A/C

8. Do Not Shift or Trans

Temp

Fig. 3.2, Warning and Indicator Lights

3.3

OR

1

2

3

4

5

6

7

8

B

9. Right-Turn Indicator

10. High Beam

11. ABS

12. Brake

13. Parking Brake

14. Differential Lockout

15. Daytime Running

Lights

16. Cab Lock

9

10

11

12

13

14

15

16

f080071a

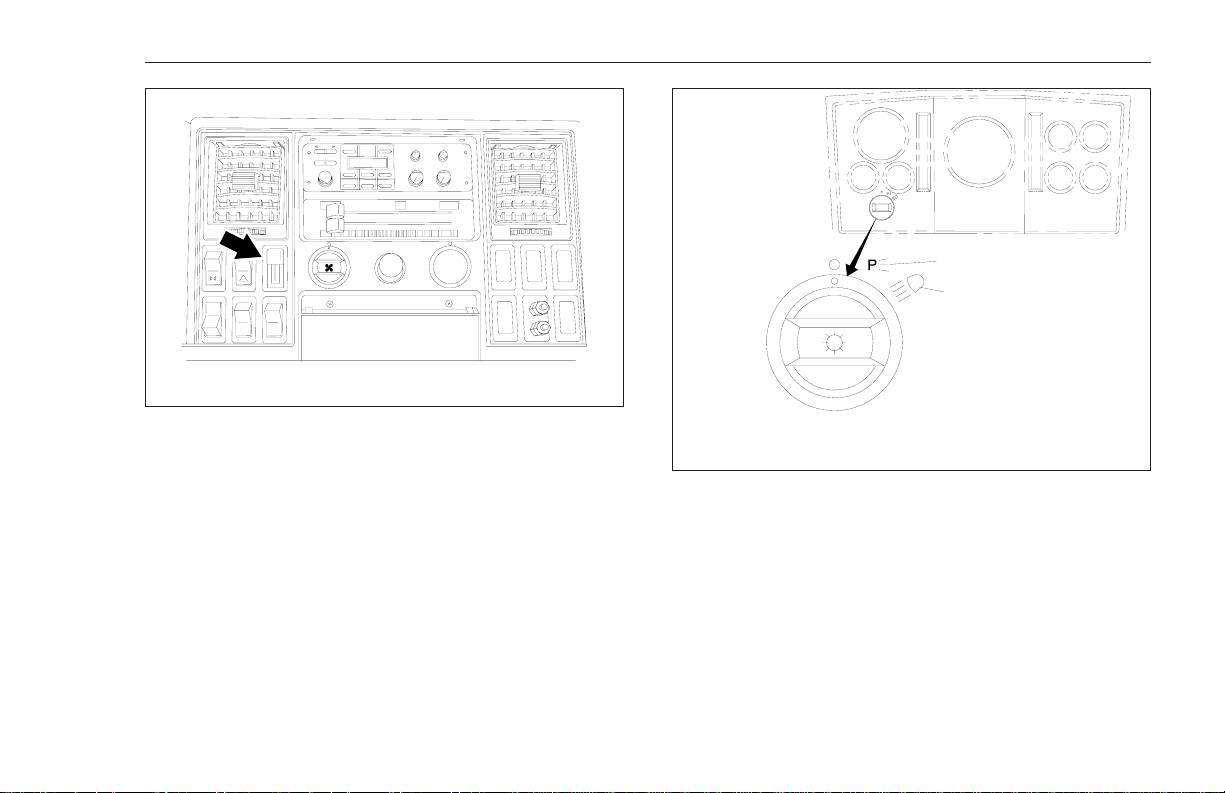

1

4

2

09/04/97

1. Accessory

2. On

3

3. Start

4. Off

Fig. 3.3, Ignition Switch

f541752

comes on. The ignition switch must be on for the high

beams to operate.

For vehicles equipped with daytime running lamps

(DRL), switching on the ignition and releasing the parking brakes automatically activates the headlight low

beams at reduced voltage. Some vehicles are equipped

Driver Controls and Instruments

1

2

10/01/98

Fig. 3.4, Panel Light Control Lever

with a daytime running lights in-dash indicator, which

will illuminate when the daytime running lights are in

operation. The daytime running lights will operate until

the parking brakes are applied, then they will switch off.

Turning on the regular headlights will override the daytime running lights. The vehicle cannot be driven unless

either the headlights or daytime running lights are

activated.

f601426a

Dome Light Switch

The dome light switch is located on the dome light. In

addition to the ON and OFF positions, a third intermedi-

08/27/97

1. All Lights On (except headlights)

2. All Lights On (including headlights)

Fig. 3.5, Headlight Switch

ary position makes the dome light turn on whenever the

doors are opened.

f601435

Windshield Wipers

To operate the wipers at low speed, move the control

lever up one position. See Fig. 3.7. To operate the

wipers at high speed, move the control lever up two

3.4

Driver Controls and Instruments

positions. To operate the wipers in delay mode, move

the control lever down one position.

1

2

f541756

1. Steering Column 2. Control Lever

Fig. 3.6, High/Low Beam Control

Windshield Washer

Depress the button on the wiper/washer control lever to

activate the windshield washer. See Fig. 3.7.

Interrupt Switch

A spring-loaded interrupt rocker switch operates the

marker lights. See Fig. 3.8. With the vehicle lights on,

depress and release the interrupt rocker switch to

briefly turn off the marker lights.

Cummins Electronic Engine

The Cummins electronic engine has a fuel control system controlled by a microprocessor-based computer.

1

5

1. High Speed

2. Low Speed

3. Off

Fig. 3.7, Windshield Wiper and Washer Control

This computer controls specific engine and vehicle

speed modes of operation to maximize vehicle fuel

economy and performance.

A yellow engine check light and a red engine stop light

are located on the instrument panel. With the ignition

switch on, both lights come on for about two seconds;

then, if there is no problem with the electronic engine

system, the lights will go out. Whenever there is a problem within the electronic engine system, one of the

4. Delay Mode

5. Washer Button

2

3

4

f820210

3.5

Loading...

Loading...