Freightliner Business Class M2 Driver's Manual

®

BUSINESS CLASS M2

STI-455-6

A24-01238-000

Driver’s Manual

Foreword

Introduction

This manual provides information needed to operate

and understand the vehicle and its components.

More detailed information is contained in the Owner’s

Warranty Information for North America booklet, and

in the vehicle’s workshop and maintenance manuals.

Custom-built Freightliner vehicles are equipped with

various chassis and cab components. Not all of the

information contained in this manual applies to every

vehicle. For details about components in your vehicle, refer to the chassis specification pages included in all new vehicles and to the vehicle specification decal, located inside the vehicle.

For your reference, keep this manual in the vehicle

at all times.

IMPORTANT: Descriptions and specifications in

this manual were in effect at the time of printing.

Freightliner Trucks reserves the right to discontinue models and to change specifications or

design at any time without notice and without

incurring obligation. Descriptions and specifications contained in this publication provide no

warranty, expressed or implied, and are subject

to revisions and editions without notice.

Environmental Concerns and

Recommendations

Whenever you see instructions in this manual to discard materials, you should first attempt to reclaim

and recycle them. To preserve our environment, follow appropriate environmental rules and regulations

when disposing of materials.

Event Data Recorder

This vehicle is equipped with one or more devices

that record specific vehicle data. The type and

amount of data recorded varies depending on how

the vehicle is equipped (such as the brand of engine,

if an air bag is installed, or if the vehicle features a

collision avoidance system, etc.).

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record

data in certain crash or near-crash situations, such

as air bag deployment or hitting a road obstacle, that

will assist in understanding how a vehicle’s systems

performed. The EDR is designed to record data related to vehicle dynamics and safety systems for approximately 60 seconds. This data can help provide

a better understanding of the circumstances in which

crashes and injuries occur. Data recorded includes

the following items:

•

how various systems in the vehicle were operating

•

engine system information

•

how far (if at all) the driver was depressing the

accelerator

•

if the driver was depressing the brake pedal

•

how fast the vehicle was traveling

NOTE: Data is not recorded by the EDR under

normal driving conditions. Personal data such

as name, gender, age, and crash location are

not recorded. However, other parties such as

law enforcement could combine the EDR data

with the type of personally identifying data routinely acquired during a crash investigation.

To read data recorded by an EDR, special equipment

is required, and access to the vehicle or the EDR is

needed. In addition to the vehicle manufacturer, other

parties that have the special equipment, such as law

enforcement, can read the information if they have

access to the vehicle or the EDR.

Emissions and Fuel Efficiency

Compliance

This vehicle must be regularly inspected and maintained as indicated in the Business Class M2 Mainte-

nance Manual, and in the Pretrip and Post-Trip Inspections and Maintenance chapter in this manual, in

order to continue satisfactory performance and ensure coverage of the vehicle under the manufacturer’s warranty. Many maintenance procedures ensure

that the vehicle and engine continue to comply with

applicable emissions standards. Maintenance procedures, using components engineered to comply with

greenhouse gas emissions and fuel efficiency regulations, may be performed by an authorized Daimler

Trucks North America dealer, an independent outlet,

or the vehicle owner or operator.

The vehicle owner is responsible for determining the

suitability of replacement components to maintain

STI-455-6 (11/14)

A24-01238-000

Printed in U.S.A.

Foreword

compliance with federal and local jurisdictional regulations. Components including, but not limited to,

tires, cab/sleeper side extenders, chassis fairings,

bumper, hood, vehicle speed limiters, and idle reduction timers are specifically designed and manufactured to exacting standards for regulatory fuel efficiency and greenhouse gas emissions compliance. It

is important that these components are always replaced with components that meet or exceed the performance of the originally installed components.

Customer Assistance Center

Having trouble finding service? Call the Customer

Assistance Center at 1-800-385-4357 or 1-800-FTLHELP. Call night or day, weekdays or weekends, for

dealer referral, vehicle information, breakdown coordination, or Fleetpack assistance. Our people are

knowledgeable, professional, and committed to following through to help you keep your truck moving.

Reporting Safety Defects

If you believe that your vehicle has a defect which

could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Daimler Trucks North America

LLC.

hotline 1-800-333-0510, or contact Transport

Canada by mail at: Transport Canada, ASFAD,

Place de Ville Tower C, 330 Sparks Street, Ottawa, Ontario, Canada K1A 0N5.

For additional road safety information, please visit

the Road Safety website at:

roadsafety

.

www.tc.gc.ca/

If the NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems

between you, your dealer, or Daimler Trucks North

America LLC.

To contact NHTSA, you may call the Vehicle

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to

write to: Administrator, NHTSA, 1200 New Jersey

Avenue, SE, Washington, DC 20590. You can also

obtain other information about motor vehicle safety

from

www.safercar.gov.

Canadian customers who wish to report a safetyrelated defect to Transport Canada, Defect Investigations and Recalls, may telephone the toll-free

© 2001–2015 Daimler Trucks North America LLC. All rights reserved. Daimler Trucks North America LLC is a Daimler

company.

No part of this publication, in whole or part, may be translated, reproduced, stored in a retrieval system, or transmitted

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Daimler Trucks North America LLC. For additional information, please contact Daimler Trucks North

America LLC, Service Systems and Documentation, P.O. Box 3849, Portland OR 97208–3849 U.S.A. or refer to

www.Daimler-TrucksNorthAmerica.comand www.FreightlinerTrucks.com.

www.safercar.gov;or

Contents

Chapter Page

Introduction, Environmental Concerns and Recommendations,

Event Data Recorder, Emissions and Fuel Efficiency Compliance,

Customer Assistance Center, Reporting Safety Defects

1 Vehicle Identification ...................................................... 1.1

2 Vehicle Access .......................................................... 2.1

3 Instruments ............................................................. 3.1

4 Controls ................................................................ 4.1

5 Cab Features ........................................................... 5.1

6 Heater, Ventilator and Air Conditioner ........................................ 6.1

7 Engines ................................................................ 7.1

8 Drivetrain ............................................................... 8.1

9 Steering and Brake Systems ............................................... 9.1

10 Fifth Wheels and Trailer Couplings ......................................... 10.1

11 Pretrip and Post-Trip Inspections and Maintenance ............................ 11.1

12 Cab Appearance ........................................................ 12.1

13 In an Emergency ....................................................... 13.1

14 Headlight Aiming ........................................................ 14.1

15 Hybrid Electric Vehicle ................................................... 15.1

16 Natural Gas Vehicle ..................................................... 16.1

Index .................................................................. I.1

.................... Foreword

1

Vehicle Identification

Component Information Label ....................................................... 1.1

Federal Motor Vehicle Safety Standard Labels .......................................... 1.1

Canadian Motor Vehicle Safety Standard Labels ........................................ 1.1

Component GWR Label ............................................................ 1.1

Emission Labels .................................................................. 1.2

Vehicle Identification

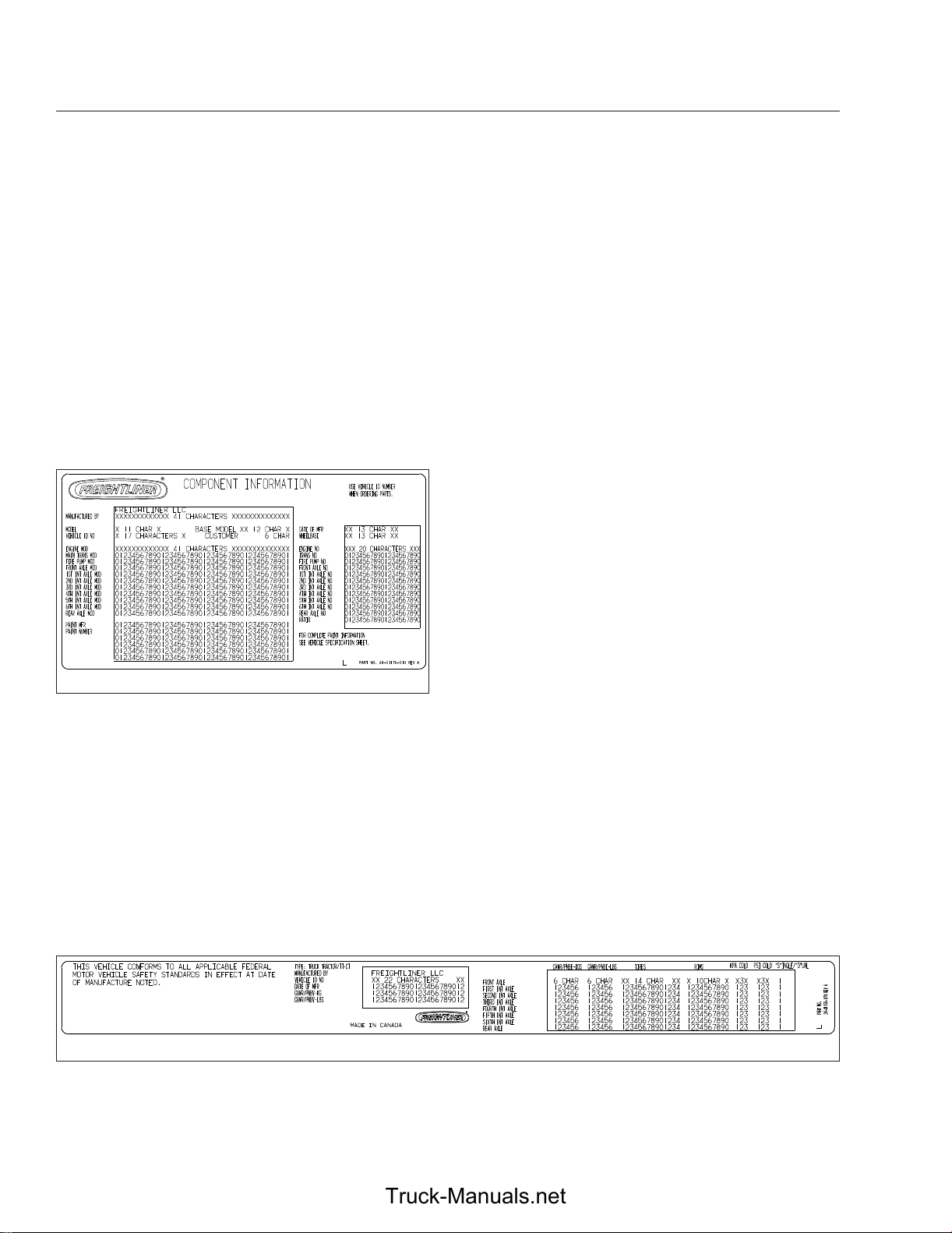

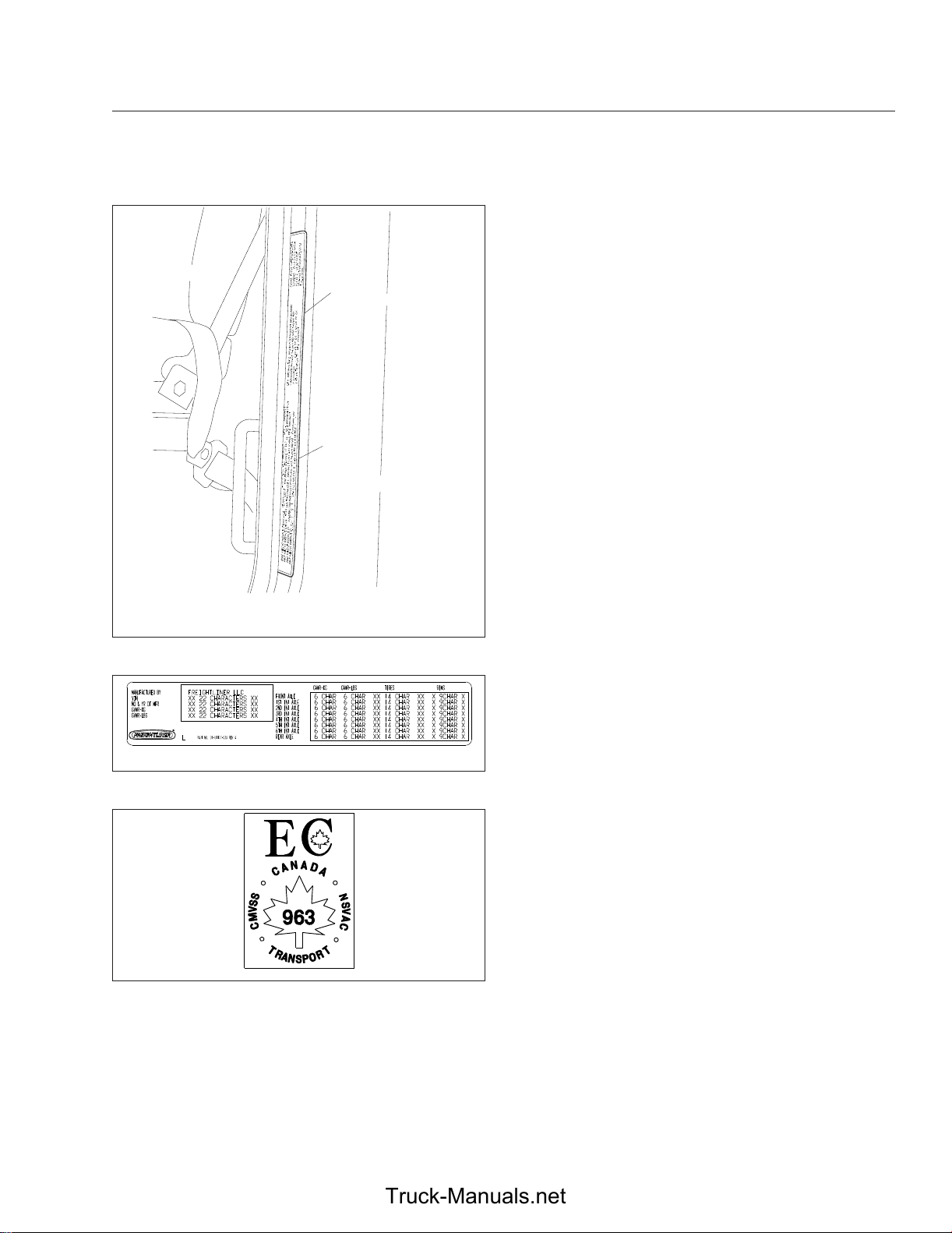

Component Information Label

NOTE: Labels shown in this chapter are examples only. Actual specifications may vary from

vehicle to vehicle.

The component information label lists the vehicle

model, identification number, and major component

models. It also lists the major assemblies and installations shown on the chassis specification sheet.

One copy of the component information label is installed on the right-side dash; another copy is inside

the rear cover of the Owner’s Warranty Information

for North America booklet. An illustration of the label

is shown in

02/20/2012 f080176

Fig. 1.1.

Fig. 1.1, Component Information Label

Federal Motor Vehicle Safety

Standard Labels

NOTE: Due to the variety of Federal Motor Vehicle Safety Standard (FMVSS) certification requirements, not all of the labels shown will apply

to your vehicle.

Tractors with or without fifth wheels purchased in the

U.S. are marked as certified by means of an FMVSS

certification label. See

to the driver-side B-pillar, as shown in

Fig. 1.2. This label is attached

Fig. 1.3.

The tire and rim portion of the FMVSS certification

label certifies suitable tire and rim combinations that

can be installed on the vehicle, for the given gross

axle weight rating. Tires and rims installed on the

vehicle at the time of manufacture may have a higher

load capacity than that certified by the tire and rim

label. If the tires and rims currently on the vehicle

have a lower load capacity than that shown on the

tire and rim label, then the tires and rims determine

the load limitations on each of the axles.

Trucks built without a cargo body that are intended

for service in the U.S. have an incomplete vehicle

certification label attached by the final-stage manufacturer. See

the incomplete vehicle document included with the

vehicle, and certifies that the vehicle conforms to all

applicable FMVSS regulations in effect on the date of

completion.

Fig. 1.4. This label will be attached to

Canadian Motor Vehicle Safety

Standard Labels

In Canada, tractors with fifth wheels are marked as

certified by means of a statement of compliance label

with the Canadian National Safety Mark attached to

the driver-side door frame B-pillar. See

If purchased for service in Canada, trucks built without a cargo body and tractors built without a fifth

wheel are marked as certified by a "Statement of

Compliance" label, similar to Fig. 1.4. This label must

be attached by the final-stage manufacturer to certify

that the vehicle conforms to all applicable Canada

Motor Vehicle Safety Standard (CMVSS) regulations

in effect on the date of completion.

Fig. 1.5.

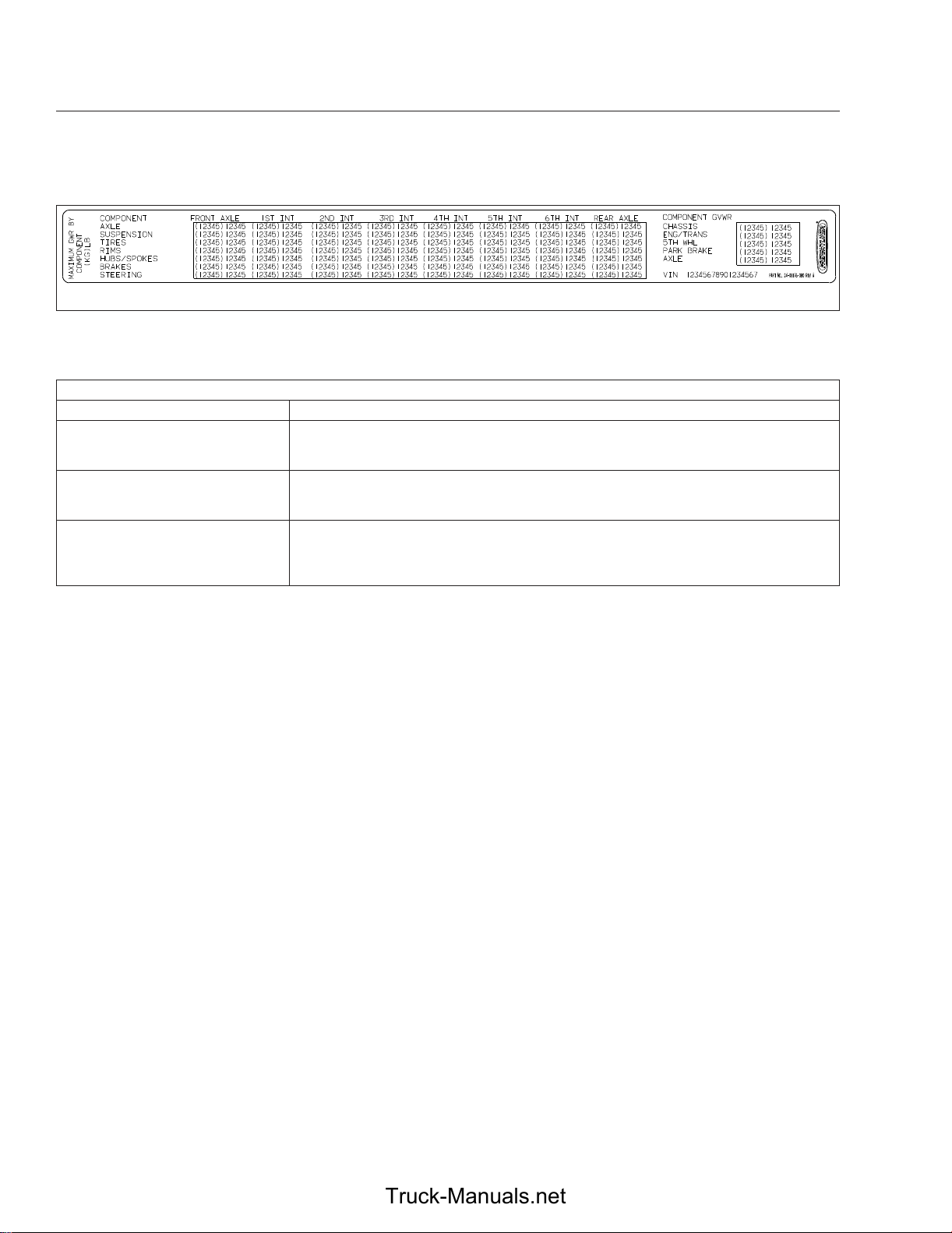

Component GWR Label

The component GWR label is located on the

passenger-side B-pillar. The label provides maximum

GWR ratings for each component.

02/20/2012 f080177

Fig. 1.2, Vehicle Certification Label

1.1

11/13/2001

1. Tire and Rim Information

2. FMVSS Certification Label

Vehicle Identification

Emission Labels

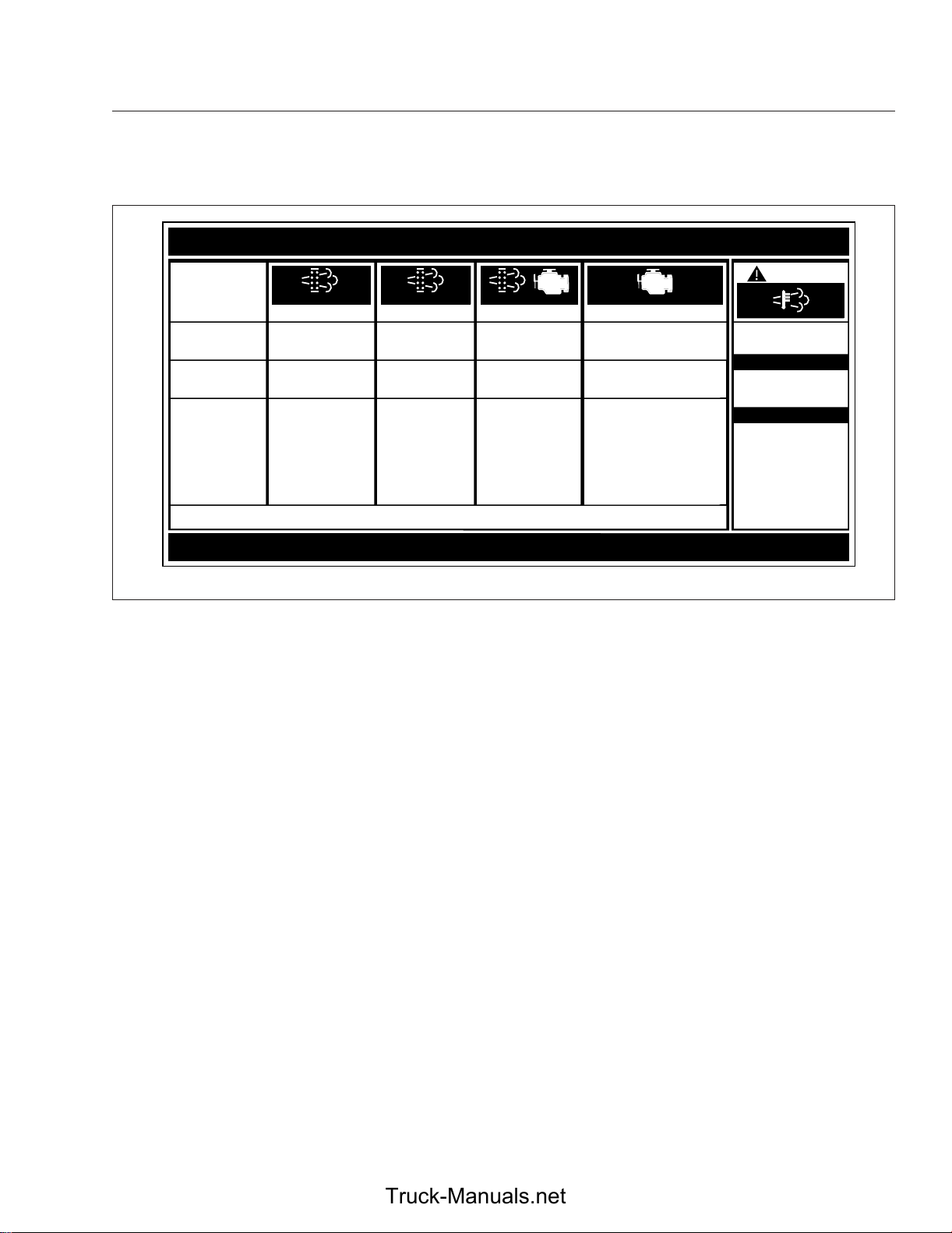

Aftertreatment System Indicators

Label

1

2

f080117

Engines and vehicles manufactured after December

31, 2006 and domiciled in the U.S. or Canada are

required to meet all EPA regulations effective as of

the vehicle build date, and are equipped with an

emission aftertreatment system (ATS). Vehicles domiciled outside of the U.S. and Canada may not

have aftertreatment equipment, depending upon local

statutory emissions guidelines. See

A warning label on the driver-side visor contains important warning indicators in the instrument cluster

that pertain to the ATS. See

It is a violation of U.S. federal law to alter exhaust

plumbing, ATS, or other components in any way that

would bring the engine/vehicle out of compliance with

certification requirements [Ref: 42 U.S.C. S7522(a)

(3)]. It is the owner’s responsibility to maintain the

vehicle so that it conforms to EPA regulations.

Fig. 1.7 or Fig. 1.8.

Table 1.1.

EPA Noise Emission Control Label

Fig. 1.3, Label Locations

02/28/2012

Fig. 1.4, Incomplete Vehicle Certification Label

10/10/2006

Fig. 1.5, Canadian National Safety Mark

See Fig. 1.6 for a typical component GWR label.

f080180

f080024

A vehicle noise emission control label (Fig. 1.9)is

located on the driver-side B-pillar as shown in

Fig. 1.3. It is the owner’s responsibility to maintain

the vehicle so that it conforms to EPA regulations.

IMPORTANT: Certain Freightliner incomplete

vehicles may be produced with incomplete noise

control hardware and will not have a noise

emission control information label. For such vehicles, it is the final-stage manufacturer’s responsibility to complete the vehicle in conformity

to EPA regulations (40 CFR Part 205) and label

it for compliance.

1.2

Vehicle Identification

02/20/2012 f080178

Fig. 1.6, Component GWR Label

Applicable Emissions System Based on Build Date and EPA Regulations

Build Date Regulation: Emissions Components

January 1, 2007–December 31,

2009

January 1, 2010–December 31,

2012

From March 5, 2012

*

Cummins, Detroit, and Mercedes-Benz ATD’s are also equipped with a diesel oxidation catalyst to break down pollutants.

Table 1.1, Applicable Emissions System Based on Build Date and EPA Regulations

EPA07 (reduce nitrogen oxides (NOx) emissions to 1.1 g/bhp-hr, and reduce

particulate matter emissions to 0.01 g/bhp-hr): Aftertreatment device (ATD) containing

a diesel particulate filter that traps soot and ash.

EPA10 (reduce NOx emissions to 0.2 g/bhp-hr): EPA07-type ATD, with additional

selective catalyst reduction (SCR) technology that utilizes diesel exhaust fluid (DEF)

to convert NOx to nitrogen and water vapor.

GHG14: Aerodynamic and fuel efficiency components including, but not limited to,

tires, cab/sleeper side extenders, chassis fairings, bumper, hood, vehicle speed

limiters, and idle reduction timers specifically designed to meet regulatory fuel

efficiency and greenhouse gas emissions standards.

*

Vehicle Emission Control Information

Label

Model year 2013 and later vehicles meet additional

requirements as specified by federal greenhouse gas

and fuel efficiency regulations (GHG14). These vehicles are equipped with components that increase

fuel efficiency and reduce GHG emissions. Components may include, but are not limited to, low-rolling

resistance tires; aerodynamic devices such as hood,

cab side extenders, and fuel tank fairings; vehicle

speed limiters; and idle shutdown timers.

A Vehicle Emission Control Information Label is located on the driver-side door. See Fig. 1.10.Itisthe

owner’s responsibility to maintain the vehicle so that

it conforms to EPA and NHTSA regulations.

Certified Clean Idle Label

The California Air Resources Board (CARB) requires

model year 2008 and newer heavy-duty diesel engines to be equipped with a non-programmable engine shutdown system that automatically shuts down

the engine after five minutes of idling in order to limit

emissions of particulate matter and NOx.

Certified vehicles are equipped with a label placed

near the bottom edge of the driver-side door. See

Fig. 1.11.

1.3

Vehicle Identification

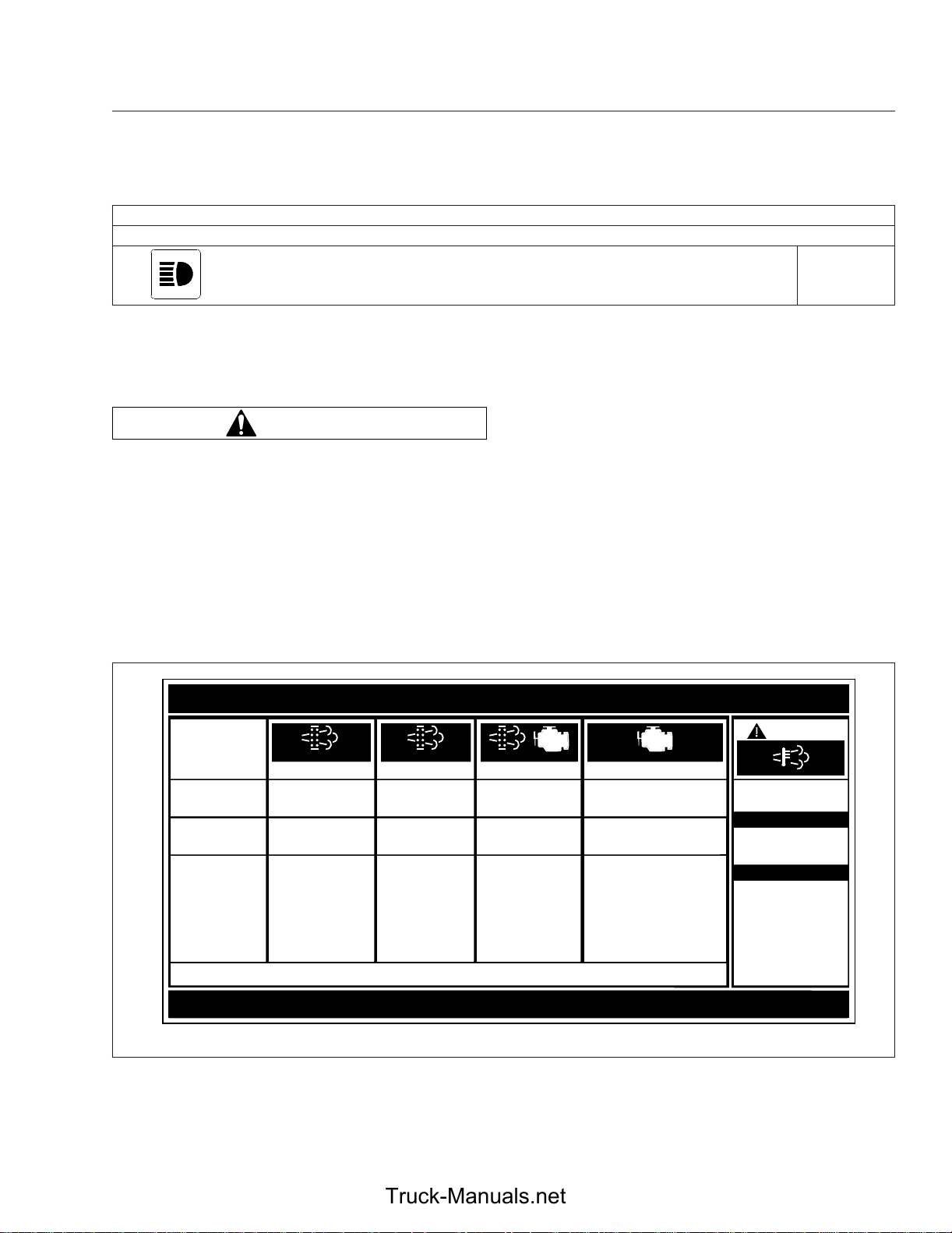

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

02/20/2009

INDICATOR

LAMP(S)

(Solid)

(Flashing) (Flashing)

CHECK

STOP

Level 1 Level 3Level 2 Level 4

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

Filter Regeneration

Recommended.

Filter is reaching

capacity

.

Bring vehicle to

highway speeds to

allow for an

Automatic

Regeneration or

perform a Parked

Regeneration.

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

Filter

Regeneration

Necessary

Filter is now

reaching maximum

Switch.

capacity

.

To avoid engine

derate, bring vehicle

to highway speeds

to allow for an

Automatic

Regeneration, or

perform a Parked

Regeneration as

soon as possible.

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

Vehicle must be

parked, and a Parked

Regeneration must

be performed.

Engine will begin

derate.

Service Regeneration Required.

Engine Derate To Idle Only.

Filter has exceeded maximum

.

capacity.

Vehicle must be parked, and a

Service Regeneration must be

performed. Check engine

operator’s manual for details.

Engine will shut down.

Fig. 1.7, ATS Indicators, EPA07

W

ARNING

HEST (High Exhaust

System Temperature)

Flashing

A regeneration is in

progress.

Solid

Exhaust components

and exhaust gas are at

high temperature. When

stationary, keep away

from people and

flammable materials or

vapors.

f080156

1.4

Vehicle Identification

IMPORTANT

DPF Regen Needed

Diesel Particulate Filter (DPF)

regeneration is needed.

If flashing, regenerate as soon as

possible. Engine derate possible.

Hot Exhaust

Hot exhaust can cause fire.

Keep flammables and people away

from exhaust.

DEF Refill Needed

DEF

Diesel Exhaust Fluid (DEF) level is

low. Engine derate likely.

Refill tank with certified DEF.

See operator’s manual for complete instructions.

11/30/2010 f080162

Fig. 1.8, ATS Indicators, EPA10 and Newer

FREIGHTLINER CORPORATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY

THE NOISE CONTROL ACT OF 1972:

A. THE REMOVAL OR RENDERING INOPERATIVE, OTHER THAN FOR PURPOSES OF

MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR

ELEMENT OF DESIGN (LISTED IN THE OWNER’S MANUAL) INCORPORATED INTO THIS

VEHICLE IN COMPLIANCE WITH THE NOISE CONTROL ACT.

B. THE USE THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF DESIGN HAS

BEEN REMOVED OR RENDERED INOPERATIVE.

10/06/98

VEHICLE NOISE EMISSION CONTROL INFORMATION

DATE OF MANUFACTURE

Fig. 1.9, Vehicle Noise Emission Control Label

01/96

24−00273−020

f080026

CERTIFIED

CLEAN IDLE

24−01656−000

MANUFACTURED BY:

VIN:

VEH FAMILY CD:

GVWR−KG

GVWR−LBS

02/29/2012

THIS VEHICLE COMPLIES WITH U. S. EPA REGULATIONS FOR XXXX HEAVY DUTY VEHICLES.

SEE OWNER’S MANUAL FOR PROPER MAINTENANCE OF THIS VEHICLE. U PART NO. 24−01177−060 REV A

VEHICLE EMISSION CONTROL INFORMATION

REGULATORY CLASS:

EMISSION CONTROL IDENTIFIERS:

DATE OF MANUFACTURE:

f080181

Fig. 1.10, Vehicle Emission Control Information Label

1.5

02/20/2012 f080179

Fig. 1.11, CARB Clean Idle Label

2

Vehicle Access

Cab Door Locks and Handles ....................................................... 2.1

Grab Handles and Access Steps ..................................................... 2.1

Cab Entry and Exit, Vehicles With Two Steps .......................................... 2.2

Cab Entry and Exit, Vehicles With One Step ........................................... 2.4

Back-of-Cab Access ............................................................... 2.5

Battery Access ................................................................... 2.6

Hood Opening and Closing ......................................................... 2.7

Fuse Identification ................................................................ 2.8

Vehicle Access

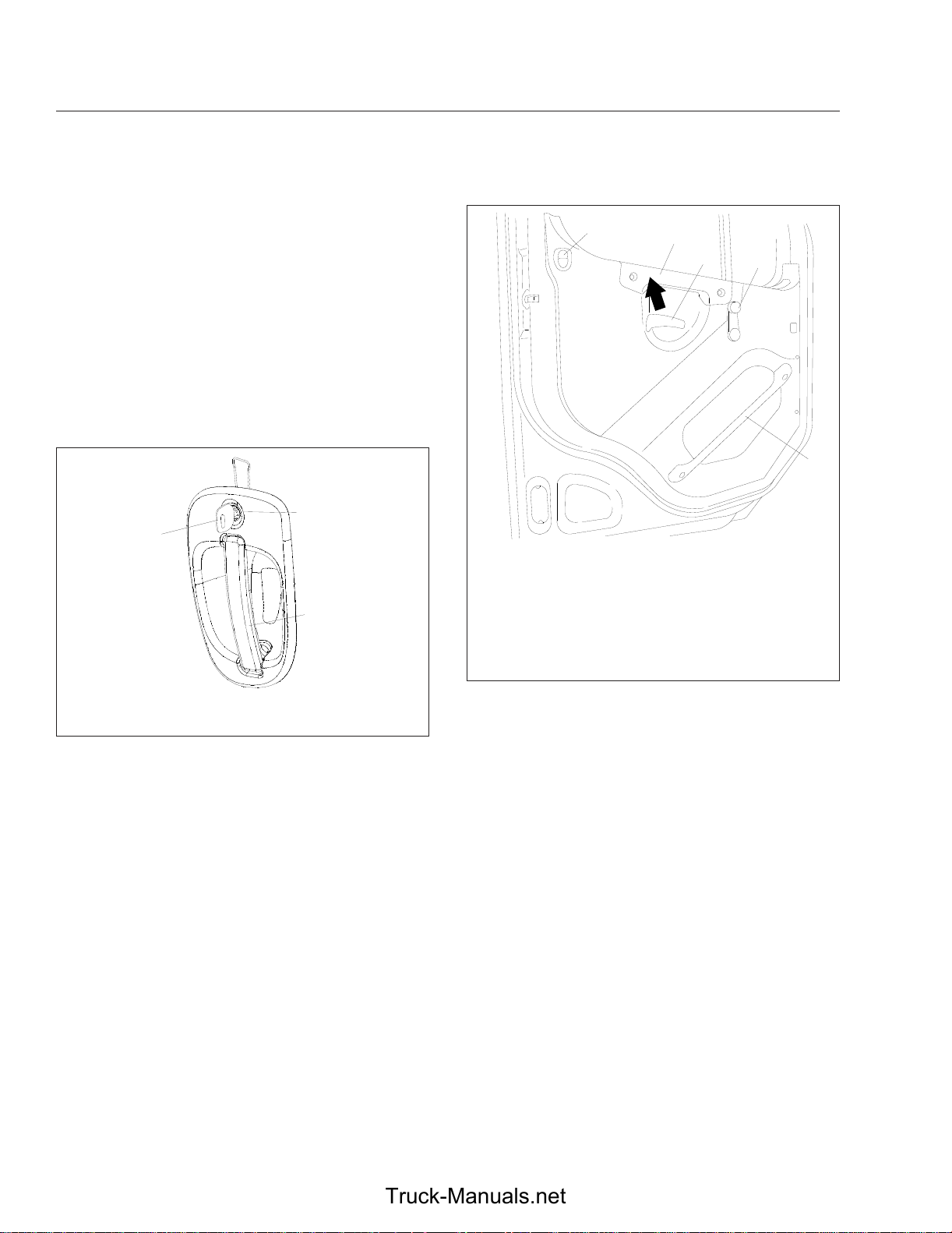

Cab Door Locks and Handles

One key operates the ignition switch and all of the

door locks.

IMPORTANT: Each key is numbered. Record

the number so a duplicate key can be made, if

needed.

To unlock the driver’s door from outside the cab, insert the key in the lockset and turn it one-quarter turn

clockwise (

terclockwise to its original position. Pull out on the

door pull handle to open the door.

10/22/2001

1. Key

2. Lock

To unlock the passenger’s door from outside the cab,

insert the key in the lockset and turn it one-quarter

turn counterclockwise. Turn the key clockwise to the

original position to remove it.

NOTE: The cab door locks can be operated

when the doors are open.

Fig. 2.1). To remove the key, turn it coun-

2

1

3

f720397

3. Door Pull Handle

Fig. 2.1, Exterior Door Handle

1

10/25/2001

To open the door from the inside, lift up on the door lever

(arrow).

1. Lock Button

2. Armrest/Handle

3. Door Lever

4. Window Crank

5. Inner Door Grab Handle (optional)

Fig. 2.2, Door Interior

To open the door from the inside, lift up on the door

lever. This will unlatch the door whether or not it is

locked. If it is open, close the door by pulling the

inner door grab handle.

To lock either door from inside the cab, slide the lock

button downwards (

without unlatching it, push the lock button upwards. A

red dot will show below the lock button when it is

unlocked.

Fig. 2.3). To unlock the door

2

3

4

5

f720398

To lock a door from outside the cab, do either one of

the following:

•

Insert the key in the lockset and turn it in the

direction opposite to the unlocking direction

(counterclockwise for the driver’s door, clockwise for the passenger’s door). Close the door

if it is open.

•

Push down the inside lock button (Fig. 2.2).

Close the door.

2.1

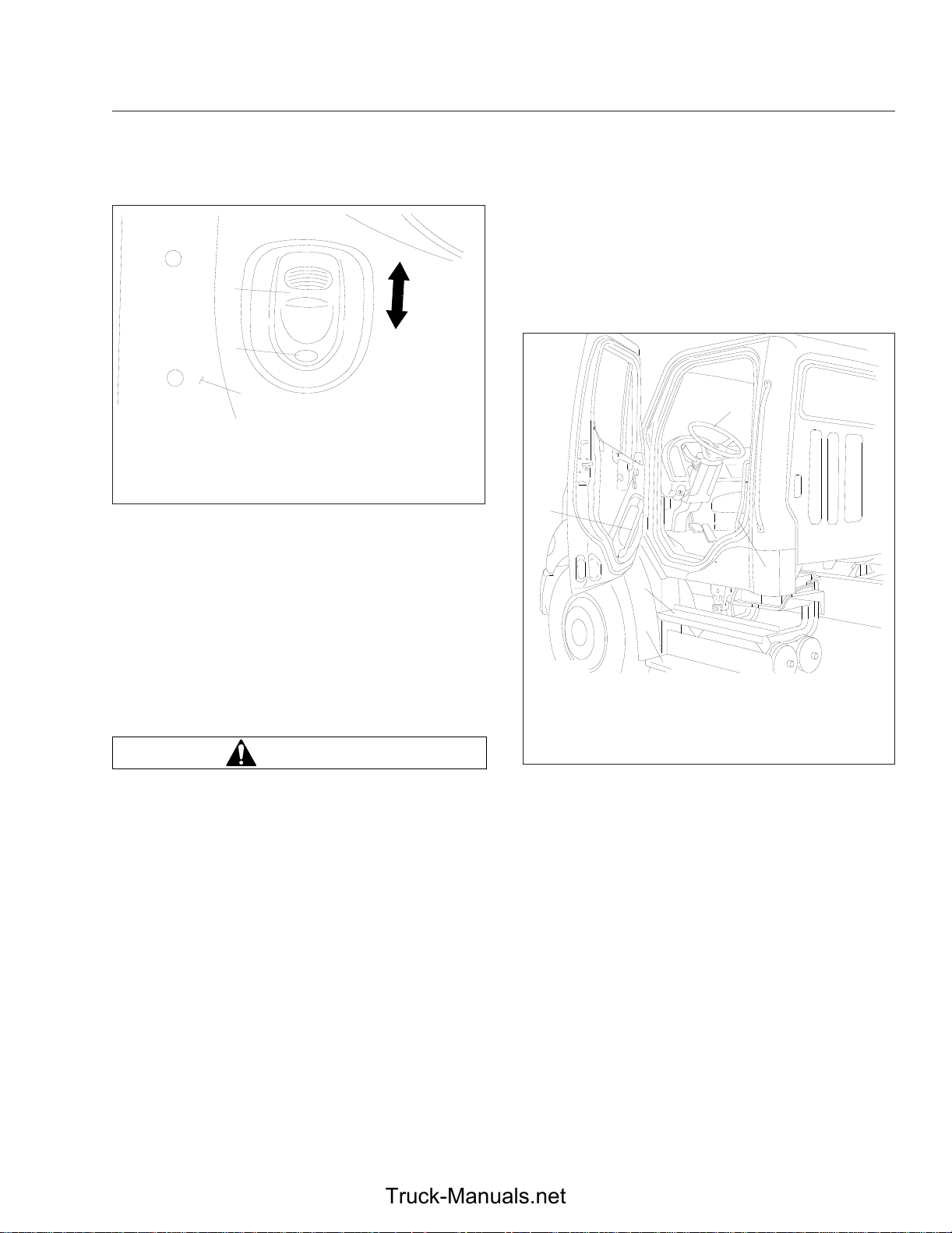

Grab Handles and Access

Steps

For ease of entry and exit, there are three grab

handles, one on the A-pillar, one on the inner B-pillar,

and an optional one on the inside of the door. In addition, the steering wheel may be used to provide

secure handholds. There are one or two access

steps to provide secure footholds.

Vehicle Access

Use the cab access system (grab handles, access

steps, and steering wheel) to enter or exit the cab.

Entering from the Driver’s Side

2

3

To enter the cab from the driver’s side, do the following steps (

Fig. 2.4):

1

10/24/2001

Move the button down to lock, and up to unlock (arrows).

The door is unlocked when the red dot shows.

1. Door

2. Lock Button

Fig. 2.3, Door Lock Button

3. Red Dot

f720401

NOTE: The A-pillar grab handle is not installed

on the driver’s side.

The grab handles, access steps, and steering wheel

are all part of the cab access system. Use these

"helping hands" when getting into, or out of, the cab.

They will increase your security and comfort.

Cab Entry and Exit, Vehicles

With Two Steps

WARNING

Wet or dirty shoe soles greatly increase the

chance of slipping or falling. If your soles are wet

or dirty, be especially careful when climbing

onto, or down from, the back-of-cab area.

Always maintain three-point contact with the

back-of-cab access supports while entering and

exiting the back-of-cab area. Three-point contact

means both feet and one hand, or both hands

and one foot, on the grab handles, steps, and

deck plates. Other areas are not meant to support back-of-cab access, and grabbing or stepping in the wrong place could lead to a fall, and

personal injury.

Be careful not to get hands or feet tangled in

hoses or other back-of-cab equipment. Carelessness could cause a person to trip and fall, with

possible injury.

1

5

4

3

11/02/2001

1. Steering Wheel

2. B-Pillar Grab Handle

3. Bottom Step

4. Top Step

5. Inner Door Grab Handle (optional)

Fig. 2.4, Cab Access System, Driver’s Side

1.

Use the door pull handle to open the driver’s

2

door, and place anything that you are carrying in

the cab.

2.

Grasp the B-pillar grab handle with both hands.

Reach up as far as is comfortable.

3.

Place your right foot on the bottom step, and pull

yourself up.

4.

Place your left foot on the top step.

5.

Grasp the steering wheel with your left hand, and

step up.

6.

Step into the cab with your right foot first, and

grasp the steering wheel with your right hand.

f720399

2.2

Vehicle Access

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

Exiting from the Driver’s Side

To exit the cab from the driver’s side, do the following steps (

IMPORTANT: Do not attempt to exit the cab

while carrying any items in your hands.

1.

Fig. 2.4):

If you wish to take any items with you, after you

exit the cab, place them in an accessible location

on the seat or cab floor. Make sure they will not

get in your way as you exit.

5

4

3

WARNING

Always face in when exiting the cab. Do not attempt to exit with your back to the cab, as you

would going down a flight of stairs. It is easier to

slip or lose your balance. If you slip when exiting

in this way, there is a greater likelihood of personal injury.

2.

Grasp the steering wheel with both hands. Place

your left foot on the top step, and stand on the

threshold, facing into the cab.

3.

Move your right hand to the B-pillar grab handle.

4.

Move your right foot to the bottom step.

5.

Move your left hand to the B-pillar grab handle.

6.

Step to the ground with your left foot first.

7.

Retrieve from the cab any items that you wish to

take with you.

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

Entering from the Passenger’s Side

2

10/23/2001

1. Bottom Step

2. Top Step

3. B-Pillar Grab Handle

4. Sidewall Grab Handle (optional)

5. A-Pillar Cover Grab Handle

Fig. 2.5, Cab Access System, Passenger’s Side and

3.

Place your left foot on the bottom step and step

up to the upper step with your right foot.

4.

Move your right hand to the A-pillar cover grab

handle.

5.

Place your left foot on the top step and step up.

6.

Move your left hand to the A-pillar cover grab

handle.

7.

Step into the cab with your left foot first.

1

f720400

Back of Cab

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

To enter the cab from the passenger’s side, do the

following steps (

1.

Open the passenger’s door, and place anything

that you are carrying in the cab.

2.

Grasp the B-pillar grab handle on the door with

both hands.

2.3

Fig. 2.5):

Exiting from the Passenger’s Side

To exit the cab from the passenger’s side, do the following steps (

IMPORTANT: Do not attempt to exit the cab

while carrying any items in your hands.

1.

If you wish to take any items with you, after you

exit the cab, place them in an accessible location

Fig. 2.5):

Vehicle Access

on the seat or cab floor. Make sure they will not

get in your way as you exit.

WARNING

Always face in when exiting the cab. Do not attempt to exit with your back to the cab, as you

would going down a flight of stairs. It is easier to

slip or lose your balance. If you slip when exiting

in this way, there is a greater likelihood of personal injury.

2.

Grasp the A-pillar cover grab handle with both

hands, then place your right foot on the top step

while standing up from the seat facing inward.

3.

Place your left foot on the top step.

4.

Move your left hand to the B-pillar grab handle.

5.

Move your left foot to the bottom step.

6.

Move your right hand to the B-pillar grab handle.

7.

Step to the ground with your right foot first.

8.

Retrieve from the cab any items that you wish to

take with you.

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

ness could cause a person to trip and fall, with

possible injury.

Use the cab access system (grab handles, access

steps, and steering wheel) to enter or exit the cab.

Entering from the Driver’s Side

To enter the cab from the driver’s side, do the following steps (

1.

2.

3.

4.

5.

6.

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

Fig. 2.4):

Use the door pull handle to open the driver’s

door, and place anything that you are carrying in

the cab. Use the door armrest/handle and, if

available, the inner door grab handle, as a support if needed.

Grasp the B-pillar grab handle with both hands.

Reach up as far as is comfortable.

Place your right foot on the step, and pull yourself up.

Step into the cab with your left foot.

Grasp the steering wheel with your left hand.

Step into the cab with your right foot, and grasp

the steering wheel with your right hand.

Cab Entry and Exit, Vehicles

With One Step

WARNING

Wet or dirty shoe soles greatly increase the

chance of slipping or falling. If your soles are wet

or dirty, be especially careful when climbing

onto, or down from, the back-of-cab area.

Always maintain three-point contact with the

back-of-cab access supports while entering and

exiting the back-of-cab area. Three-point contact

means both feet and one hand, or both hands

and one foot, on the grab handles, steps, and

deck plates. Other areas are not meant to support back-of-cab access, and grabbing or stepping in the wrong place could lead to a fall, and

personal injury.

Be careful not to get hands or feet tangled in

hoses or other back-of-cab equipment. Careless-

Exiting from the Driver’s Side

To exit the cab from the driver’s side, do the following steps (

Fig. 2.4):

IMPORTANT: Do not attempt to exit the cab

while carrying any items in your hands.

1.

If you wish to take any items with you, after you

exit the cab, place them in an accessible location

on the seat or cab floor. Make sure they will not

get in your way as you exit.

WARNING

Always face in when exiting the cab. Do not attempt to exit with your back to the cab, as you

would going down a flight of stairs. It is easier to

slip or lose your balance. If you slip when exiting

in this way, there is a greater likelihood of personal injury.

2.4

Vehicle Access

2.

Grasp the steering wheel with both hands. Place

your left foot on the step, and stand on the

threshold, facing into the cab.

3.

Move your right hand to the B-pillar grab handle.

4.

Move your left hand to the B-pillar grab handle.

5.

Move your right foot onto the step.

6.

Step to the ground with your left foot first.

7.

Retrieve from the cab any items that you wish to

take with you.

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

Entering from the Passenger’s Side

To enter the cab from the passenger’s side, do the

following steps (

1.

Open the passenger’s door, and place anything

that you are carrying in the cab.

2.

Grasp the B-pillar grab handle with both hands.

3.

Place your left foot on the step and step up to

the cab with your right foot.

4.

Move your right hand to the A-pillar cover grab

handle.

5.

Move your left hand to the A-pillar cover grab

handle.

6.

Step into the cab with your left foot.

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

Fig. 2.5):

WARNING

Always face in when exiting the cab. Do not attempt to exit with your back to the cab, as you

would going down a flight of stairs. It is easier to

slip or lose your balance. If you slip when exiting

in this way, there is a greater likelihood of personal injury.

2.

Grasp the A-pillar cover grab handle with both

hands, then place your right foot on the step

while standing up from the seat facing inward.

3.

Place your left foot on the step.

4.

Move your left hand to the B-pillar grab handle.

5.

Move your right hand to the B-pillar grab handle.

6.

Step to the ground with your right foot first.

7.

Retrieve from the cab any items that you wish to

take with you.

NOTE: You can also use the inner door grab

handle, if available, as a support when getting

up or down from the bottom step.

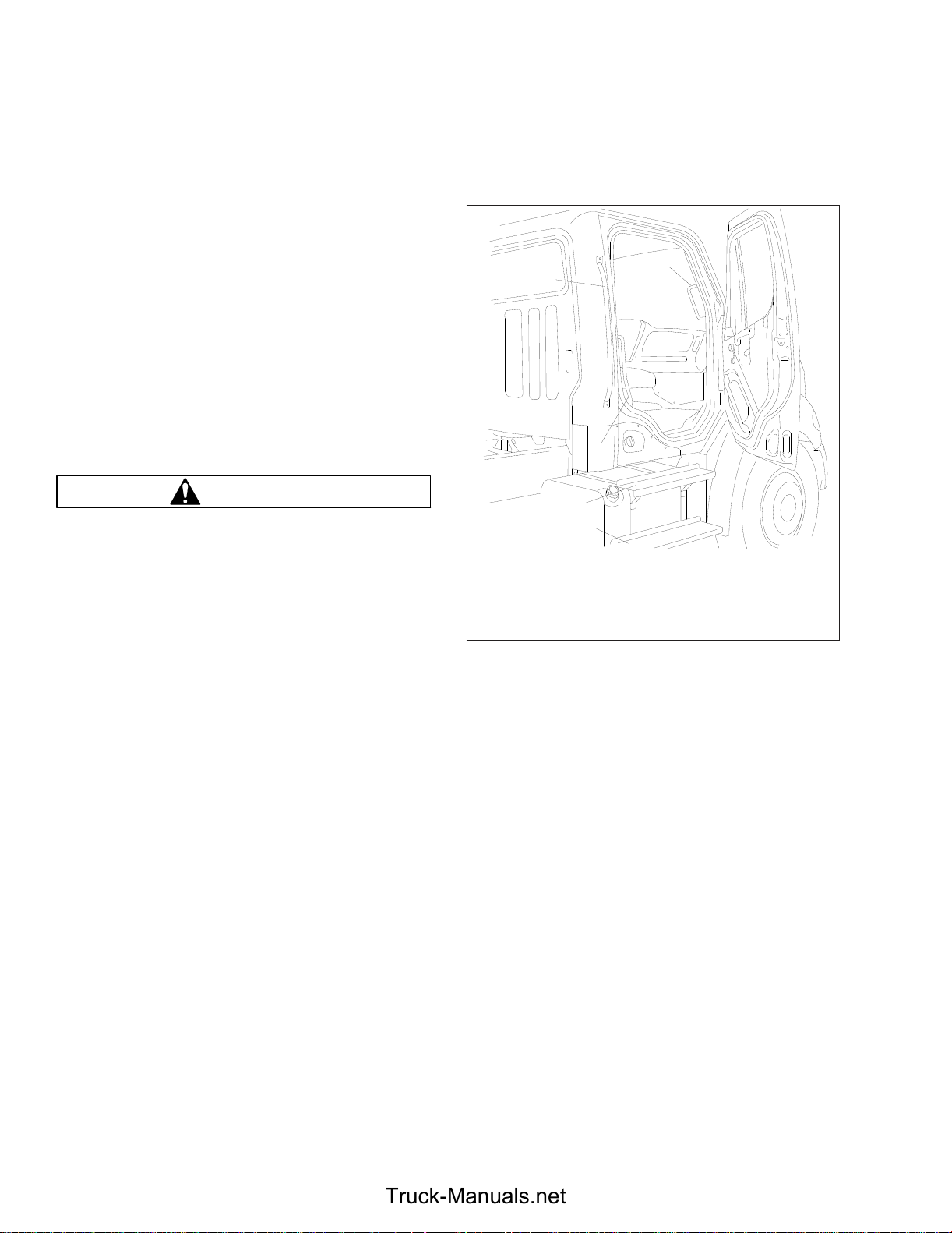

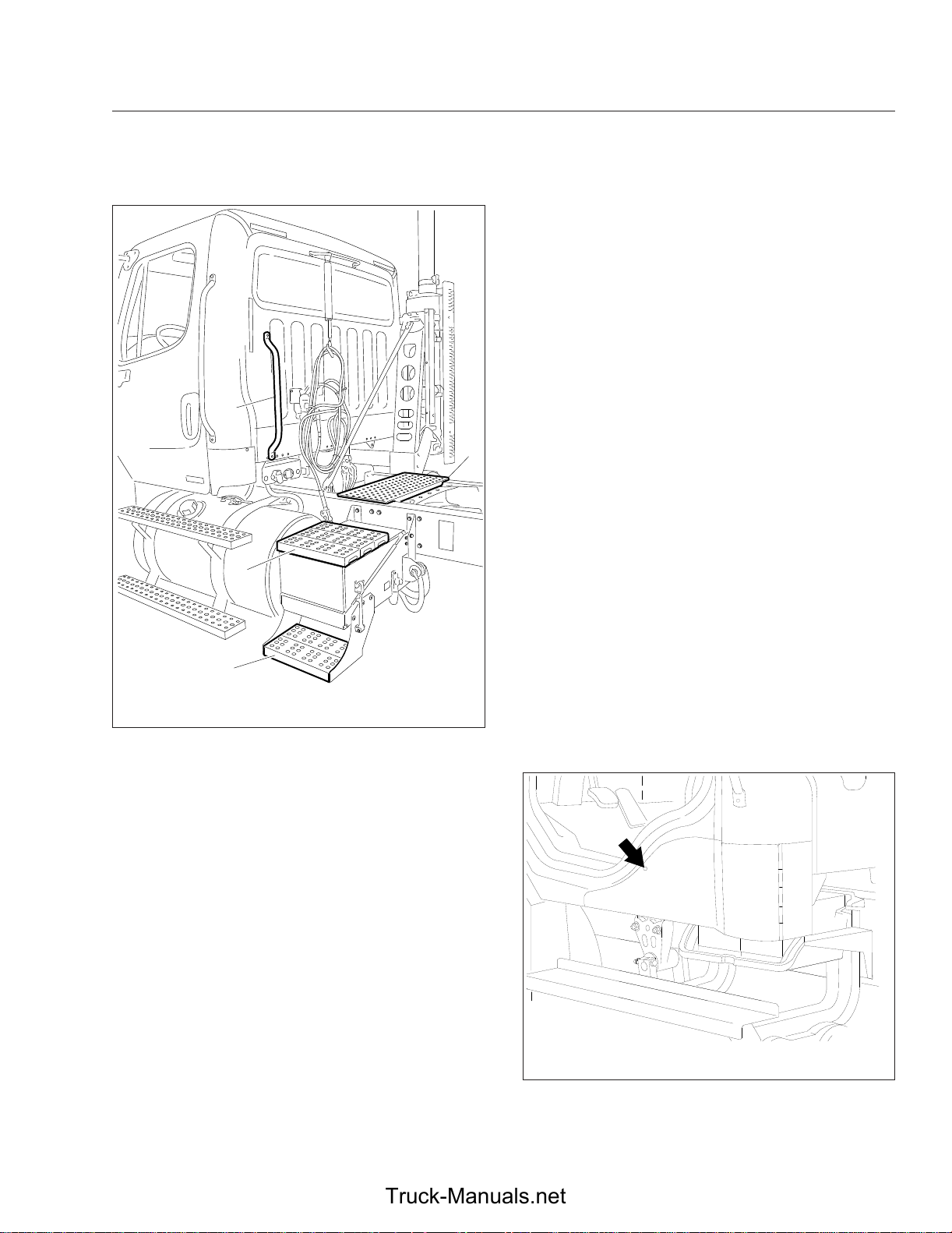

Back-of-Cab Access

When trailer air and electrical connections cannot be

reached conveniently from the ground, Federal Motor

Carrier Safety Regulations require commercial carriers to provide back-of-cab access.

Optional grab handles are mounted on each cab

sidewall, or on the left sidewall only. See

Steps are mounted either on the fuel tank(s) or on

metal brackets. When a deck plate is necessary, it is

mounted across the top of the frame rails.

Fig. 2.6.

Exiting from the Passenger’s Side

To exit the cab from the passenger’s side, do the following steps (

Fig. 2.5):

IMPORTANT: Do not attempt to exit the cab

while carrying any items in your hands.

1.

If you wish to take any items with you, after you

exit the cab, place them in an accessible location

on the seat or cab floor. Make sure they will not

get in your way as you exit.

2.5

IMPORTANT: Climb onto, and down from, backof-cab access facing in toward the vehicle, as

you would on a ladder. Do not climb up or down

facing out away from the vehicle.

WARNING

Wet or dirty shoe soles greatly increase the

chance of slipping or falling. If your soles are wet

or dirty, be especially careful when climbing

onto, or leaving, the back-of-cab area.

Always maintain three-point contact with the

back-of-cab access supports while entering and

Vehicle Access

2.

Place one foot on the bottom step and pull yourself up.

3.

Place your other foot on the top step.

4.

Move your lower hand to a higher position on the

grab handle.

5.

Step onto the deck plate.

Climbing Down from Back-of-Cab

To climb down from the back-of-cab area:

2

3

1

1.

Grasp the sidewall grab handle with both hands.

2.

Step one foot at a time onto the top step.

3.

Move your upper hand to a lower position on the

grab handle.

4.

Move one foot to the bottom step.

5.

Move your upper hand to a lower position on the

grab handle.

6.

Step to the ground with your upper foot first.

09/28/2007 f602336

1. Steps

2. Grab Handle

Fig. 2.6, Back-of-Cab Access Supports (typical)

exiting the back-of-cab area. Three-point contact

means both feet and one hand, or both hands

and one foot, on the grab handles, steps, and

deck plates. Other areas are not meant to support back-of-cab access, and grabbing or stepping in the wrong place could lead to a fall, and

personal injury.

Be careful not to get hands or feet tangled in

hoses or other back-of-cab equipment. Carelessness could cause a person to trip and fall, with

possible injury.

1

3. Deck Plate

Entering Back-of-Cab

When climbing onto the deck plate, do the following:

1.

Grasp the sidewall grab handle with both hands.

Reach up as far as is comfortable.

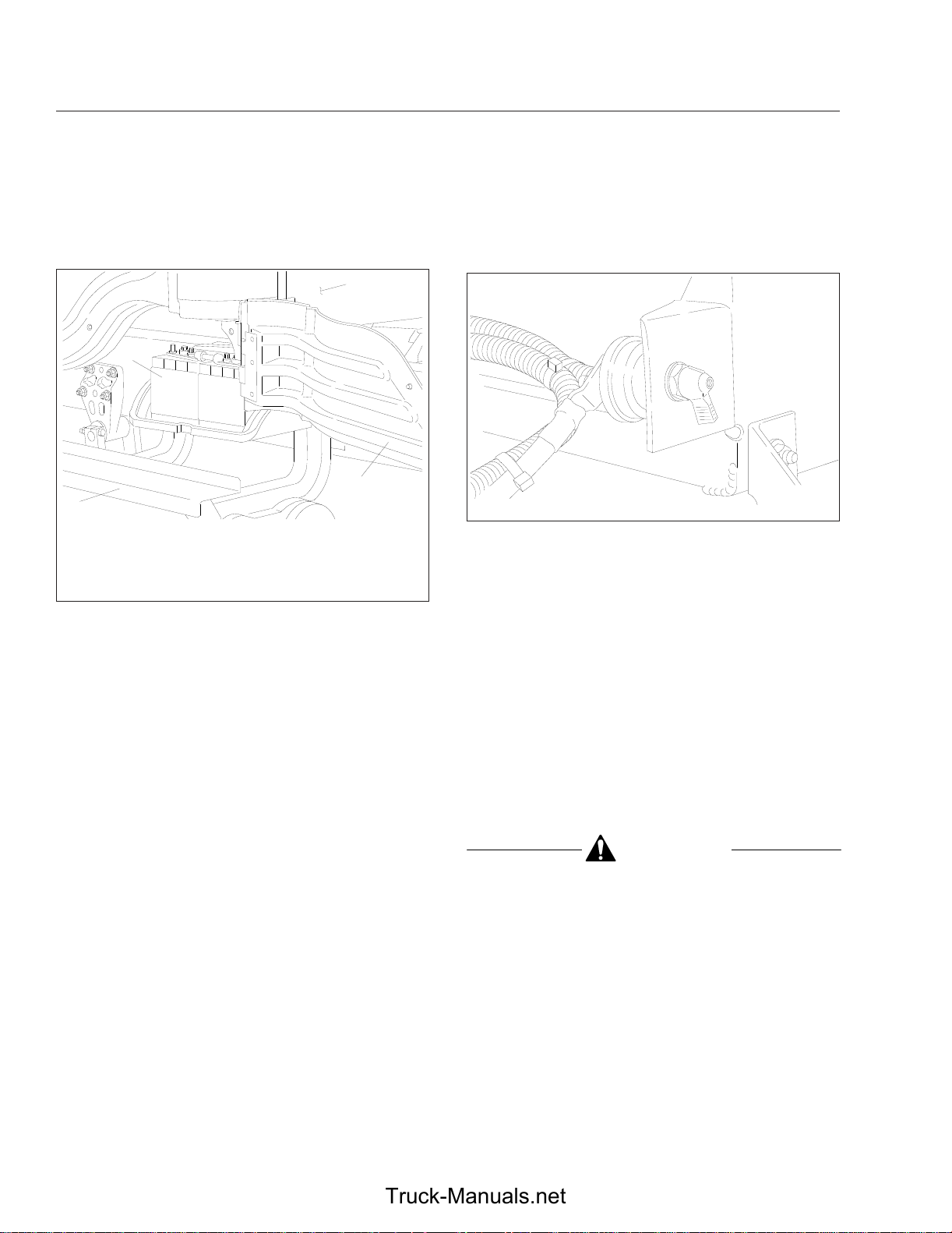

Battery Access

Battery Compartment

The battery compartment is located in the lower part

of the cab beneath and to the rear of the driver’s

door. It is fastened by a quarter-turn fastener. To

open the battery access door, turn the quarter-turn

fastener with a small screwdriver. See

10/25/2001

Open the battery access door by turning the quarter-turn

fastener (arrow) with a small screwdriver.

Fig. 2.7, Battery Compartment, Closed

Fig. 2.7.

f543934

2.6

Vehicle Access

With the battery access door open (Fig. 2.8), it is

easy to get access to the battery terminals for cleaning, charging, or emergency jump starting.

3

2

4

1

10/24/2001

1. Top Step

2. Battery

3. Cab

4. Battery Access Door

Fig. 2.8, Battery Compartment, Open

To close the battery access door, do the following

steps:

1.

Swing the battery access door to line up the

quarter-turn fastener with the hole in the cab

door frame.

2.

Close the battery access door and check to be

sure the quarter-turn fastener is engaged with

the hole.

3.

Turn the fastener one-quarter turn.

f543933

NOTE: Whenever battery power is disconnected, clocks and electronically tuned radios

must be reset.

01/18/95

Fig. 2.9, Cab (Battery) Isolation Switch

f600150a

Hood Opening and Closing

The hood can be raised to a full-open position. A torsion bar helps you to raise the hood, and to lower it

to the operating position. Hood restraint cables prevent the hood from overtravel. A hood damper limits

the closing speed. In the operating position, the hood

is secured to the cab-mounted half-fenders by a

hold-down latch on each side of the hood.

To Open the Hood

1.

Apply the parking brakes.

2.

Release both hood hold-down latches by pulling

the ends outward. See

Fig. 2.10.

Cab (Battery) Isolation Switch

The cab isolation switch (see Fig. 2.9) is located on

the cab floor at the left of the driver’s seat, or inside

the battery box. The battery isolation switch reduces

the power to the cab and engine power wiring. Use it

whenever the vehicle is to be put out of service for

extended periods.

IMPORTANT: The battery disconnect switch

does not completely isolate the batteries from

the electrical system. For service operations that

require that the batteries be disconnected, always shut down the engine and remove the

negative battery cables.

2.7

CAUTION

Do not let the hood free-fall to the full-open position. To do so could cause damage to the hood

or hood straps.

3.

Standing in front of the hood, raise the rear of

the hood upward until it reaches the over-center

position (45 degrees from vertical). Then slowly

bring it to a stop.

To Close the Hood

1.

Push the hood over center.

3

2

4

1

10/24/2001

1. Fender

2. Latch Hook

Fig. 2.10, Hood Hold-Down Latch

2.

As the hood goes over center, the damper auto-

3. Latch Handle

4. Half-Fender

f880555

matically slows its rate of descent. If needed, you

can also slow its rate of descent with your hand.

3.

Make sure the hood is flush with the cowl, then

secure the hood by engaging both hood holddown latches.

IMPORTANT: Make sure that both hold-down

latches are fully engaged before operating the

vehicle.

Fuse Identification

Main Fuse Box/PDM

The main fuse box, also known as the power distribution module, or PDM, is located under the hood on

the left front fender just forward of the bulkhead module. See

on the wire clips holding the lid on the fuse box.

A sticker inside the lid of the fuse box shows the locations of the fuses and describes the circuit(s) that

each fuse protects (see

descriptions of a typical set of fuses. The fuses in the

main fuse box are mini blade-type fuses. Battery

power fuses, located near the batteries, are bolt-in

megafuses.

Because the electrical system is multiplexed, no relays are needed. The multiplexing module performs

the functions normally provided by relays.

Fig. 2.11. To open the fuse box, pull down

Fig. 2.12). See Table 2.1 for

Vehicle Access

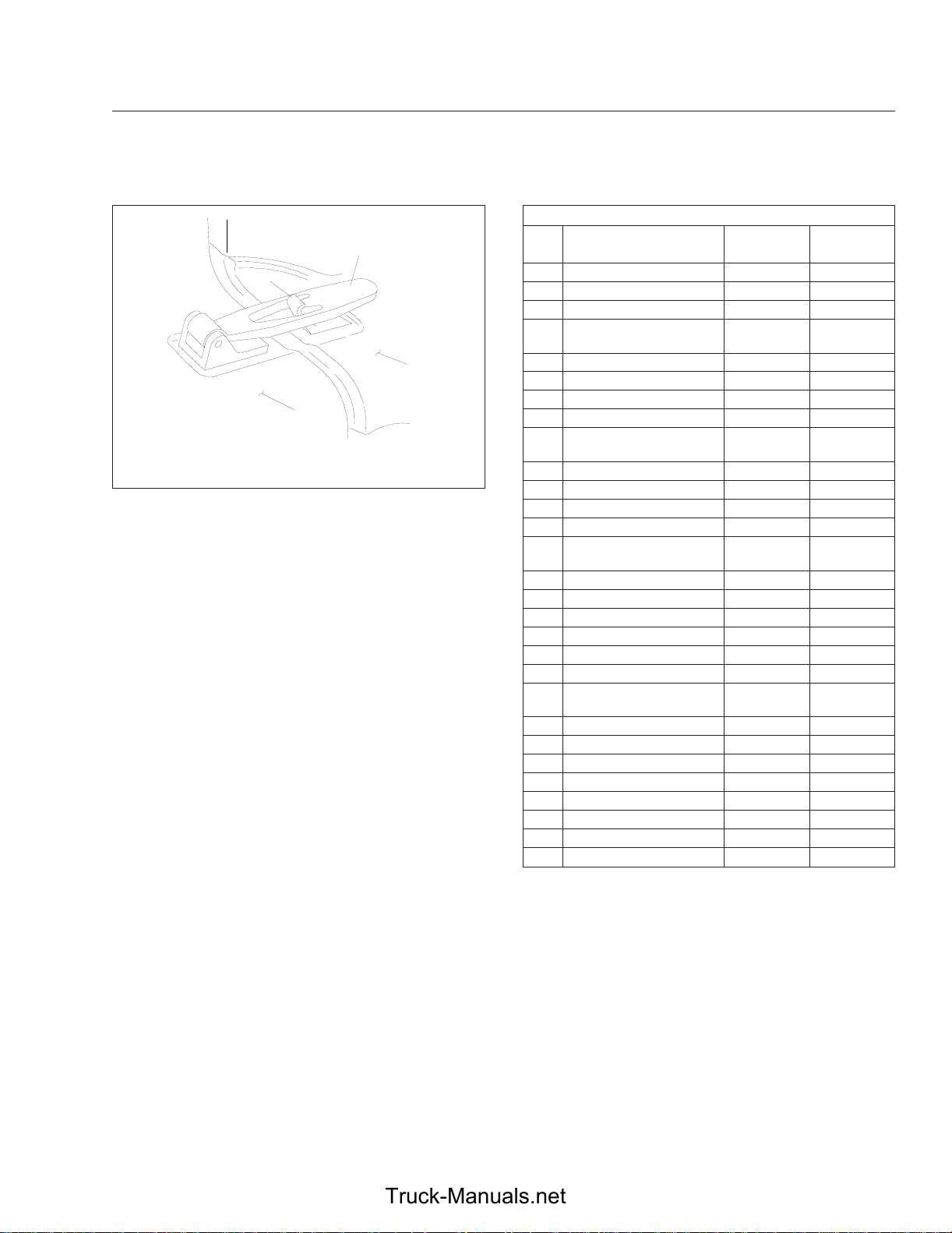

Fuse Identification, Main Fuse Box

Pos.

No.

F1 VCU (MBE900 only) Red 10 Amp

F2 Blower Motor Green 30 Amp

F3 Engine ECU Yellow 20 Amp

F4

F5 Ignition Switch Tan 5 Amp

F6 Spare — —

F7 Bulkhead Module Green 30 Amp

F8 ICU Red 10 Amp

F9

F10 Door Locks (optional) Red 10Amp

F11 Mirrors (optional) Blue 15 Amp

F12 Radio/Diagnostics Yellow 20 Amp

F13 Chassis Module Green 30 Amp

F14

F15 Bulkhead Module Green 30 Amp

F16 ABS ECU Blue 15 Amp

F17 Chassis Module Green 30 Amp

F18 Bulkhead Module Green 30 Amp

F19 Chassis Module Green 30 Amp

F20 Bulkhead Module Green 30 Amp

F21

F22 Bulkhead Module Green 30 Amp

F23 Spare — —

F24 Spare — —

F25 Spare — —

F26 Spare — —

M1 Battery Power — 125 Amp

M2 Battery Power — 125 Amp

M3 Battery Power — 150 Amp

Table 2.1, Fuse Identification, Main Fuse Box

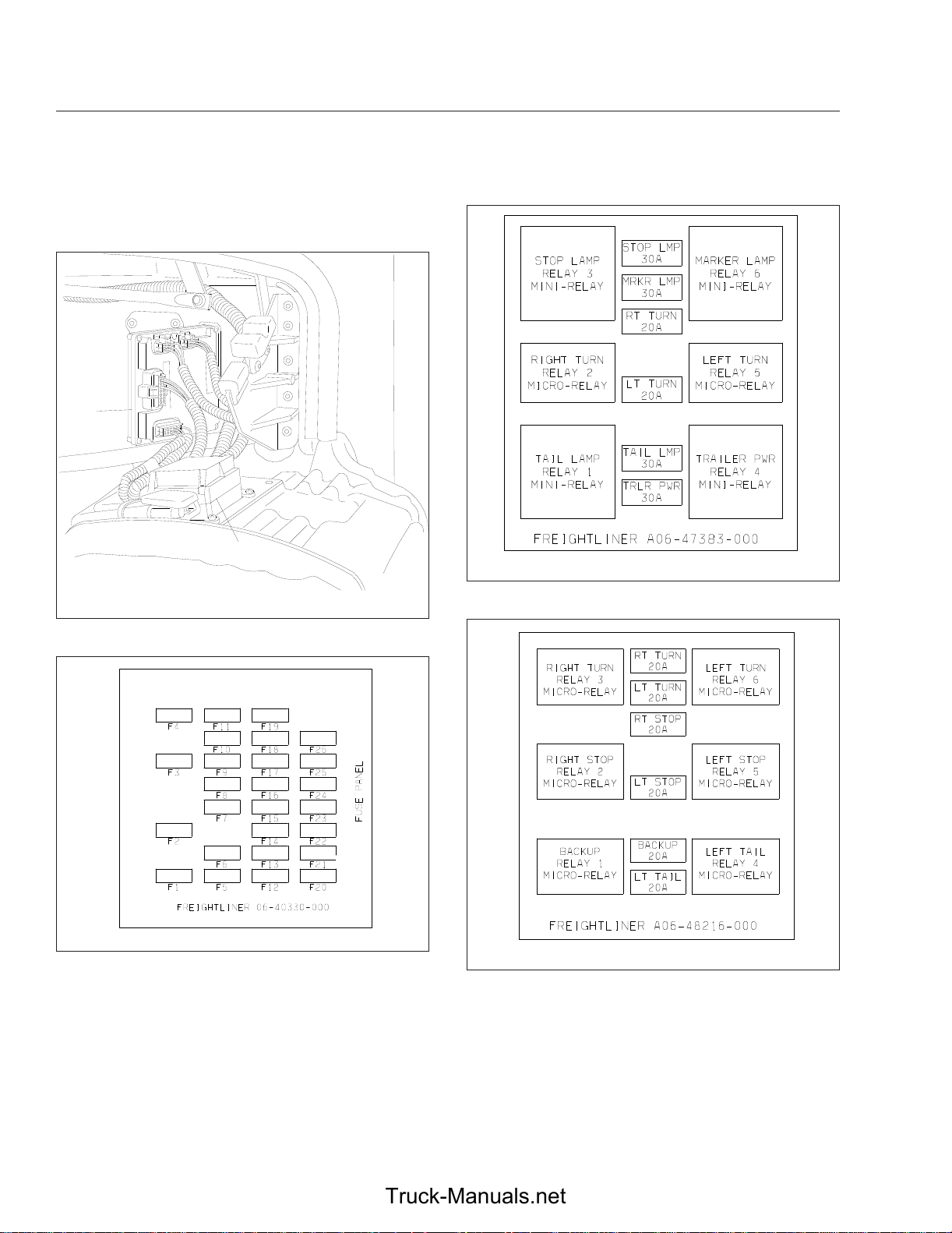

Trailer and Taillight Fuse Boxes

The trailer fuse box and the taillight fuse box, on vehicles so equipped, are mounted on a bracket with

the chassis module on the left-hand frame rail aft of

the cab, or on a crossmember at the end of the

frame rail. These may be referred to as the chassis

fuse box or chassis PDM. See Fig. 2.13 for trailer

fuse and relay information, and

fuse and relay information.

Description Fuse Color Rating

Transmission Control

Unit

Transmission Control

Unit

L/H Power Windows

(optional)

R/H Power Windows

(optional)

Green 30 Amp

Yellow 20 Amp

Blue 15 Amp

Blue 15 Amp

Fig. 2.14 for taillight

2.8

Vehicle Access

These fuse boxes contain mini blade-type fuses, 12volt mini relays, and 12-volt micro relays.

1

2

09/25/2001

1. Bulkhead Module 2. Main Fuse Box

Fig. 2.11, Location of the Main Fuse Box

10/25/2001

Fig. 2.12, Main Fuse Box Diagram

09/28/2004 f544528

f543935

Fig. 2.13, Trailer Fuse Box Diagram

f543936

10/07/2004 f544541

Fig. 2.14, Taillight Fuse Box Diagram

2.9

3

Instruments

Instrumentation Control Unit ........................................................ 3.1

Warning and Indicator Lights ........................................................ 3.2

Driver Message Center ............................................................ 3.7

Instruments ...................................................................... 3.8

Overhead Instrument Panel ........................................................ 3.13

Instruments

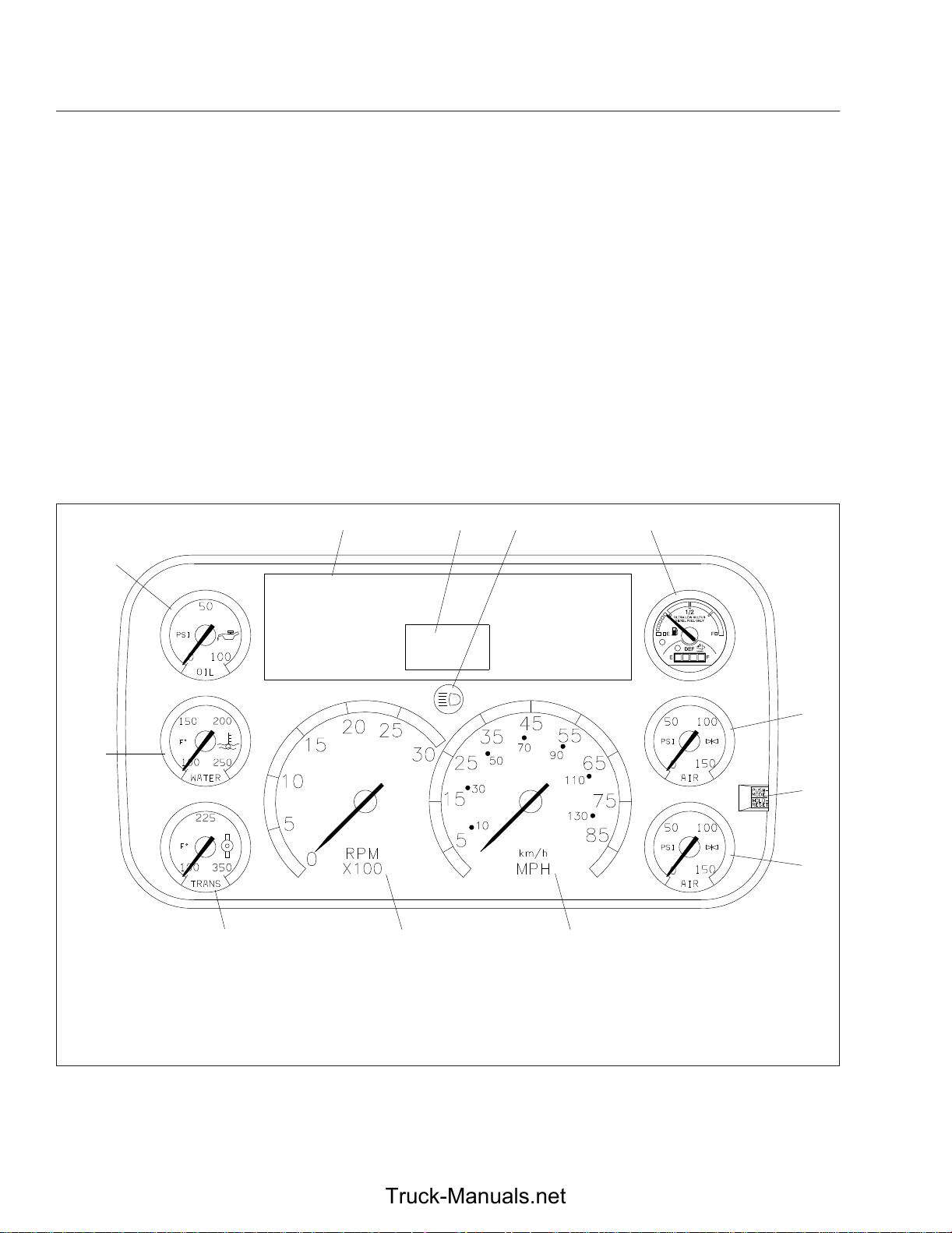

Instrumentation Control Unit

The instrumentation control unit (ICU) provides the

driver with engine and vehicle information. It is comprised of standard and optional gauges, an audible

warning, a driver message center, and a lightbar containing warning and indicator lamps (also known as

telltales). Warning and indicator lamps illuminate in

red (danger), amber (caution), green (status advisory), or blue (high-beam headlights active).

The following headings in this chapter provide additional information and operating instructions for ICU

components:

•

"Warning and Indicator Lights"

•

"Instruments"

234 5

•

"Driver Message Center"

Figure 3.1 shows a typical ICU3 instrument cluster.

Ignition Sequence

When the ignition is turned on, the ICU runs a selfcheck. See

is a good way to ensure the ICU is functioning

properly.

IMPORTANT: Do not crank the engine until the

ICU self-check is complete.

When the ignition is turned on, the following actions

should occur:

Fig. 3.2. Observing the ignition sequence

1

6

12

7

8

09/10/2009

NOTE: This instrument cluster is shown with the U.S. speedometer, which shows miles per hour (mph) more prominently

than kilometers per hour (km/h).

1. Engine Oil Pressure Gauge

2. Lightbar

3. Driver Message Center

4. Headlight High-Beam Indicator

11 10 9

5. Fuel/DEF Level Gauge

6. Primary Air Pressure Gauge

7. Mode/Reset Button

8. Secondary Air Pressure Gauge

f610525a

9. Speedometer (U.S. version)

10. Tachometer

11. Transmission Temperature Gauge

12. Coolant Temperature Gauge

3.1

Fig. 3.1, Typical Gauge Layout, U.S. (EPA10 and newer shown)

Instruments

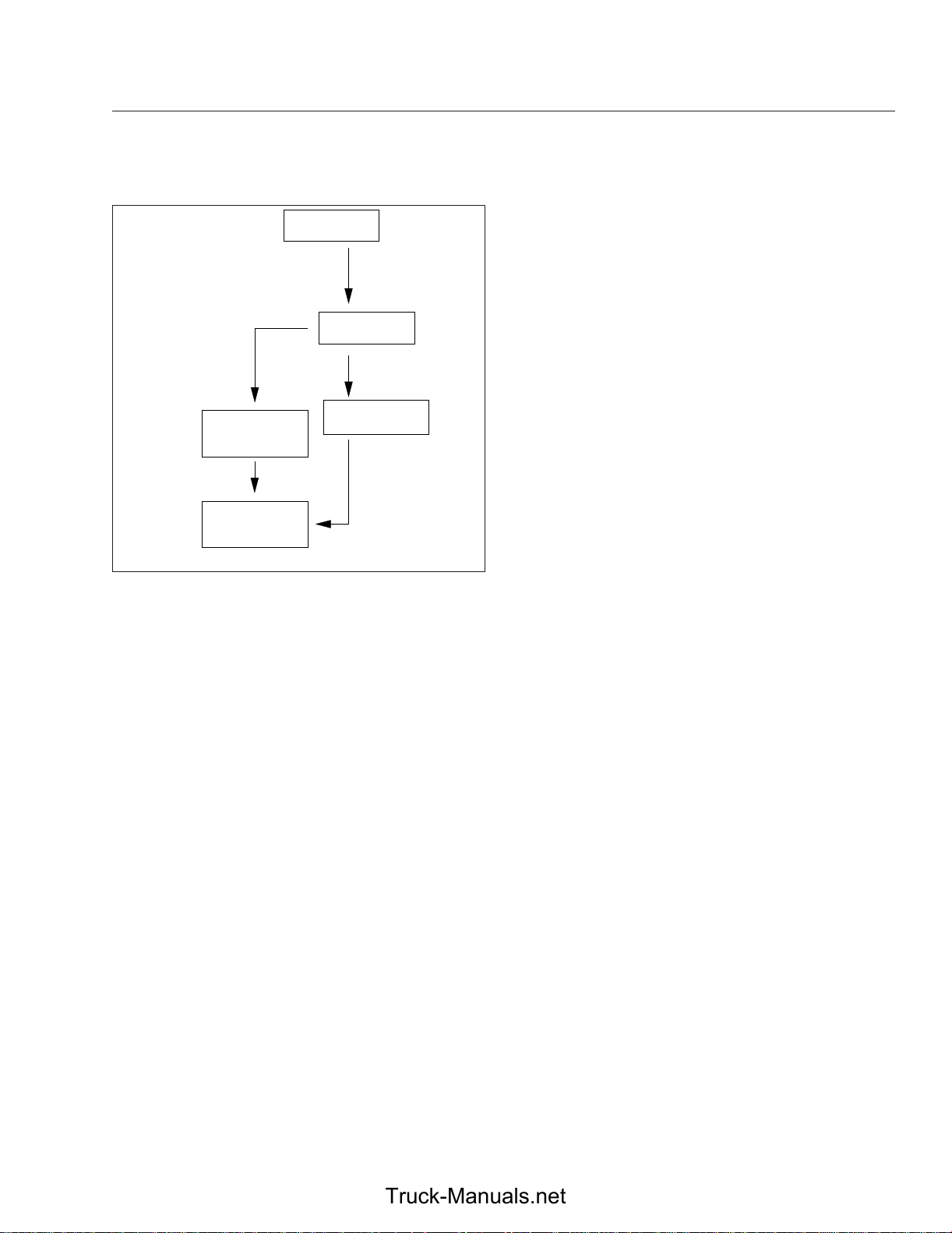

IGNITION SWITCH

TURNED TO ON

ICU PERFORMS

SELF−TEST

IF NO FAULTS

WERE DETECTED

123456.7

MI

12.3 VOLTS

PARKING BRAKE

RELEASED

123456.7

MI

12.3 VOLTS

01/18/2012 f040420c

Fig. 3.2, Ignition Sequence

•

electronic gauges complete a full sweep of

IF FAULT DETECTED

APU 190

PARKING BRAKE

RELEASED

their dials

•

some warning and indicator lamps illuminate,

then are extinguished

•

audible alert sounds until sufficient air pressure

builds up in the primary and secondary air systems

•

DEF level indicator illuminates all segments

green, then turns them off one at a time before

turning the leftmost segment amber, then red

•

software revision level of the ICU is displayed

on the driver message center, followed by active faults

NOTE: Air gauges do not complete a sweep of

their dials during the ignition sequence.

IMPORTANT: If any red or amber warning and

indicator lamps, or telltales, do not illuminate

during the ICU self-check, take the vehicle to an

authorized Freightliner service facility as soon

as possible. If any of the red or amber telltales

or do not go out after the self-check completes,

use

Table 3.1 to determine if the lamp illumi-

nated indicates a problem requiring service.

If the ICU receives active fault codes, it displays

them one after the other until the parking brake is

released or the ignition is turned off. Once the parking brake is completely released, the ICU displays

the odometer. If there are no active faults, the ICU

displays the odometer after the self-check completes.

NOTE: If active faults are present, take the vehicle to an authorized Freightliner service facility

as soon as possible.

Audible Alerts

An audible alert sounds during the ignition sequence

and whenever one of the following conditions exists:

•

Engine oil pressure falls below the minimum

preset value.

•

Coolant temperature rises above the maximum

preset value.

•

Air pressure falls below about 70 psi (483

kPa).

•

Parking brake is set with the vehicle moving

faster than two miles per hour.

•

System voltage falls below 12 volts.

•

Door is open with the headlights on and the

parking brake off.

•

Driver seat belt is not fastened with the parking

brake off (optional).

•

Outside temperature falls below 35°F (1.7°C)

(optional).

Warning and Indicator Lights

There can be up to 28 telltales installed in the ICU. If

an optional lamp is not requested, the position is

blank.

Table 3.1 for a list of standard and commonly

See

used warning and indicator lamps.

Warning and indicator lamps illuminate in red (danger), amber (caution), green (status advisory), or

blue (high-beam headlights active).

IMPORTANT: Depending upon local jurisdictional emissions guidelines, vehicles and/or engines that are domiciled outside of the U.S. and

Canada may not be compliant with EPA07,

EPA10, or GHG14 regulations. Noncompliant

3.2

Instruments

vehicles may not be equipped with all of the

lamps shown in

STOP

Table 3.1.

STOP Engine

Common Warning and Indicator Lamps

Lamp Description Color

Indicates a serious fault that requires engine shutdown

immediately. The engine protection system will reduce the

maximum engine torque and speed, and, if the condition

does not improve, will shut down the engine within 30 to 60

seconds.

*

Safely bring the vehicle to a stop on the side of the road

and shut down the engine as soon as the red light is seen.

If the engine shuts down while the vehicle is in a

hazardous location, turn the key to the OFF position for

a few seconds, then restart the engine and move the

vehicle to a safer location.

BRAKE

CHECK

High Coolant Temperature

Low Air Pressure (EPA07)

Low Air Pressure (EPA10

and Newer)

Low Engine Oil Pressure

Parking Brake (EPA07)

Parking Brake (EPA10

and Newer)

Low Battery Voltage Indicates that battery voltage is 11.9 volts or less.

Unfastened Seat Belt

CHECK Engine

*

Indicates the coolant temperature is above the maximum

allowable temperature.

Indicates air pressure in the primary or secondary reservoir

has dropped below approximately 70 psi (483 kPa).

Indicates air pressure in the primary or secondary reservoir

has dropped below approximately 70 psi (483 kPa).

Indicates the engine oil pressure is below the minimum

allowable pressure.

Indicates the parking brake is engaged, or hydraulic brake

fluid level is low. An audible alert activates when the vehicle

is moving over 2 mph (3 km/h) with the parking brake set.

Indicates the parking brake is engaged.

Activates with an audible alert when the system detects that

the parking brake is off and the driver seat belt is not

fastened on some vehicles. On other vehicles, this lamp

illuminates for 15 seconds when the ignition is first turned

on.

Indicates an engine condition (low oil pressure, low coolant

level, high coolant temperature, high DPF soot level, or

uncontrolled DPF regeneration) that requires correction.

Correct the condition as soon as possible. If the condition

worsens, the STOP engine lamp will illuminate.

Red

Amber

3.3

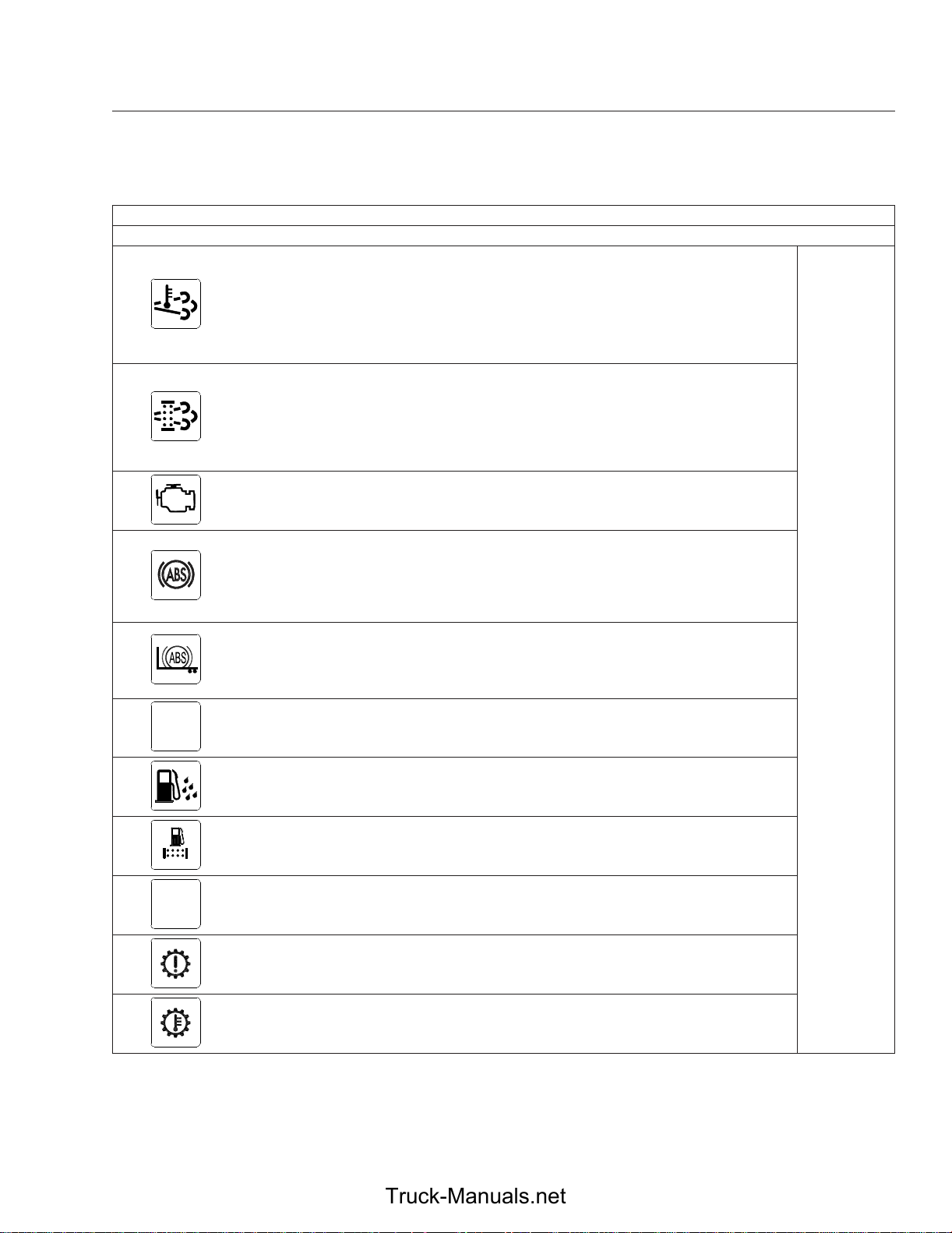

Common Warning and Indicator Lamps

High Exhaust System

Temperature (HEST)8

Diesel Particulate Filter

(DPF) Status

Instruments

Lamp Description Color

Slow (10-second) flashing indicates a regeneration (regen)

is in progress.

IMPORTANT: When the HEST lamp is illuminated, do

*

not park the vehicle near flammable material.

Solid illumination indicates high exhaust temperatures at the

outlet of the tail pipe when speed is below 5 mph (8 km/h).

Solid illumination indicates a regen is required. Change to a

more challenging duty cycle (such as highway driving ) to

raise exhaust temperatures for at least twenty minutes, or

perform a parked regen.

Blinking indicates that a parked regen is required

immediately.An engine derate and shutdown will occur.

NO

CHARGE

IDLE

MGMT

Malfunction Indicator

Lamp (MIL)

Vehicle ABS

Trailer ABS

No Charge

Water in Fuel

Fuel Filter Restriction Indicates the fuel filter is clogged and requires service.

Optimized Idle Indicates optimized idle is enabled.

Indicates an emissions-related fault. See the engine

operation manual for details.

Momentary illumination indicates the vehicle ABS is

engaged.

Solid illumination indicates a problem with the vehicle ABS.

Repair the ABS immediately to ensure full braking

capability.

Momentary illumination indicates the trailer ABS is engaged.

Solid illumination indicates a problem with the trailer ABS.

Repair the ABS immediately to ensure full braking

capability.

Indicates the alternator is not properly powering the

electrical system.

Indicates the fuel may contain water. Drain any water

collected in the fuel/water separators.

Amber

Check Transmission Indicates an undesirable transmission condition.

Transmission Overheat Indicates high transmission temperature.

3.4

Instruments

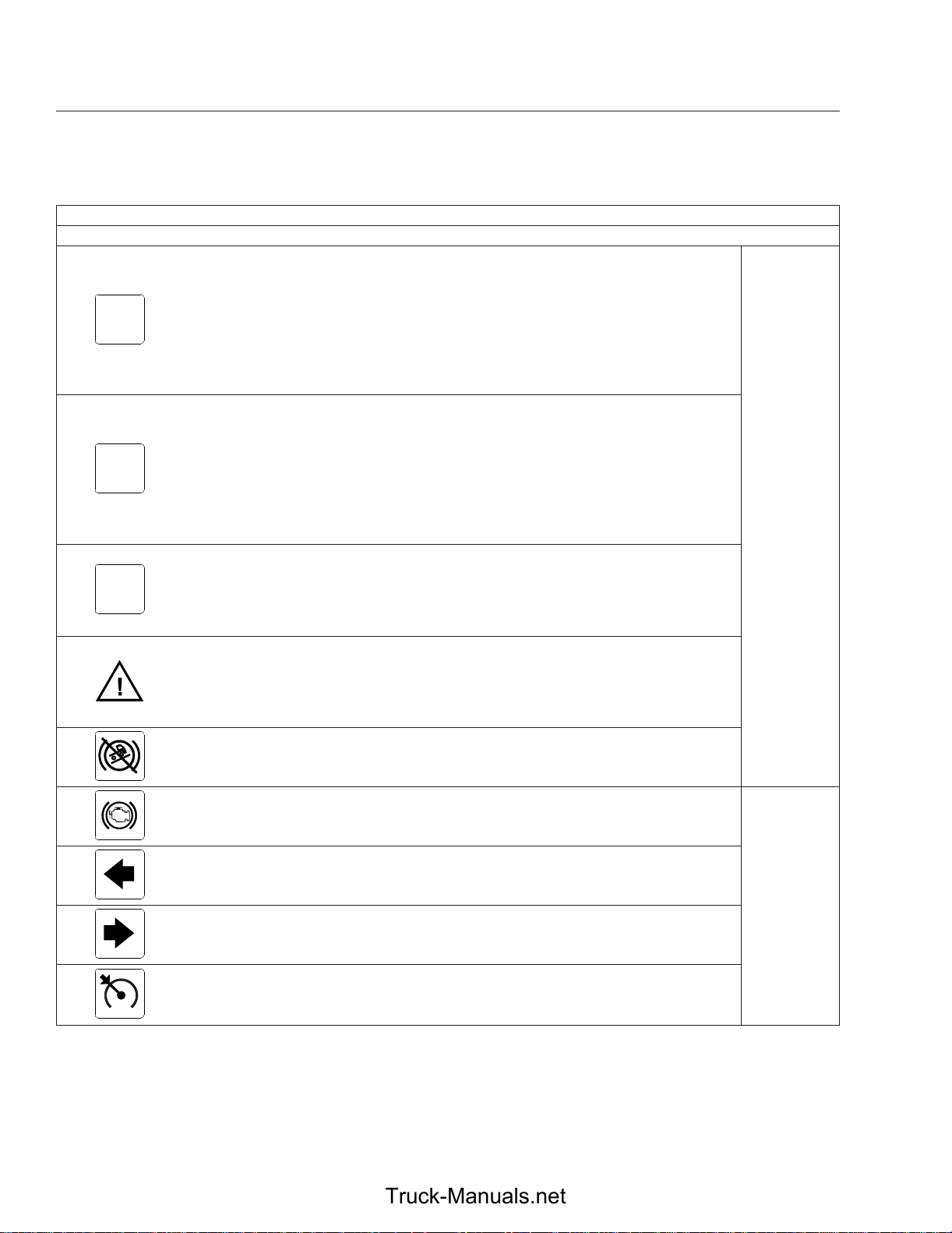

WAIT

TO START

START

BLOCKED

WHEEL

SPIN

Wait To Start (EPA07/

EPA10)

Start Blocked (GHG14

Detroit engines)

Wheel Spin

Roll Stability

Common Warning and Indicator Lamps

Lamp Description Color

EPA10 Detroit engines: Indicates that the system is

preventing the starter from cranking. This can occur when

the ignition switch is turned to START before the gauge

sweep has completed, or if the starter has overheated.

Cummins/Mercedes-Benz engines: Indicates that the intake

warmer is active.

Turn the ignition switch back to ON, wait for the lamp to go

out, then turn the ignition switch to START again.

Indicates that the system is preventing the starter from

cranking. This can occur when the ignition switch is turned

to START before the gauge sweep has completed, or if the

starter has overheated.

NOTE: Illumination of the Start Blocked lamp does not

indicate a problem with the starter.

Turn the ignition switch back to ON, wait for the lamp to go

out, then turn the ignition switch to START again.

Flashing indicates the ATC system is active, or the ATC

button has been pressed to allow wheel slip.

Solid illumination indicates a problem with the ATC system.

Repair the ATC system immediately to ensure full braking

capability.

Momentary illumination indicates that a stability event has

occurred.

On vehicles that are also equipped with ATC, flashing

indicates the ATC button has been pressed to allow wheel

slip.

Amber

3.5

Hill Start Aid (HSA)

Override

Indicates the HSA switch has been pressed to override the

hill start assist feature.

Engine Brake Indicates the engine brake is enabled.

Left-Turn Signal

Right-Turn Signal

Flashing indicates the outside left-turn signal lights are

activated.

Flashing indicates the outside right-turn signal lights are

activated.

Indicates the cruise control is enabled.

Cruise Control

NOTE: The ICU4Me does not have a green cruise control

telltale.

Green

Instruments

Common Warning and Indicator Lamps

Lamp Description Color

High-Beam Headlights Indicates the high-beam headlights are on. Blue

*

See Fig. 3.3 for an explanation of the aftertreatment system (ATS) warning indicators, and actions required to avoid further engine protection steps.

Table 3.1, Common Warning and Indicator Lamps

Engine Protection System

WARNING

When the red STOP engine lamp illuminates,

most engines are programmed to shut down automatically within 30 seconds. The driver must

immediately move the vehicle to a safe location

at the side of the road to prevent causing a hazardous situation that could cause bodily injury,

property damage, or severe damage to the engine.

Fig. 3.3 for an explanation of the aftertreatment

See

system (ATS) warning indicators, and actions required to avoid further engine protection steps.

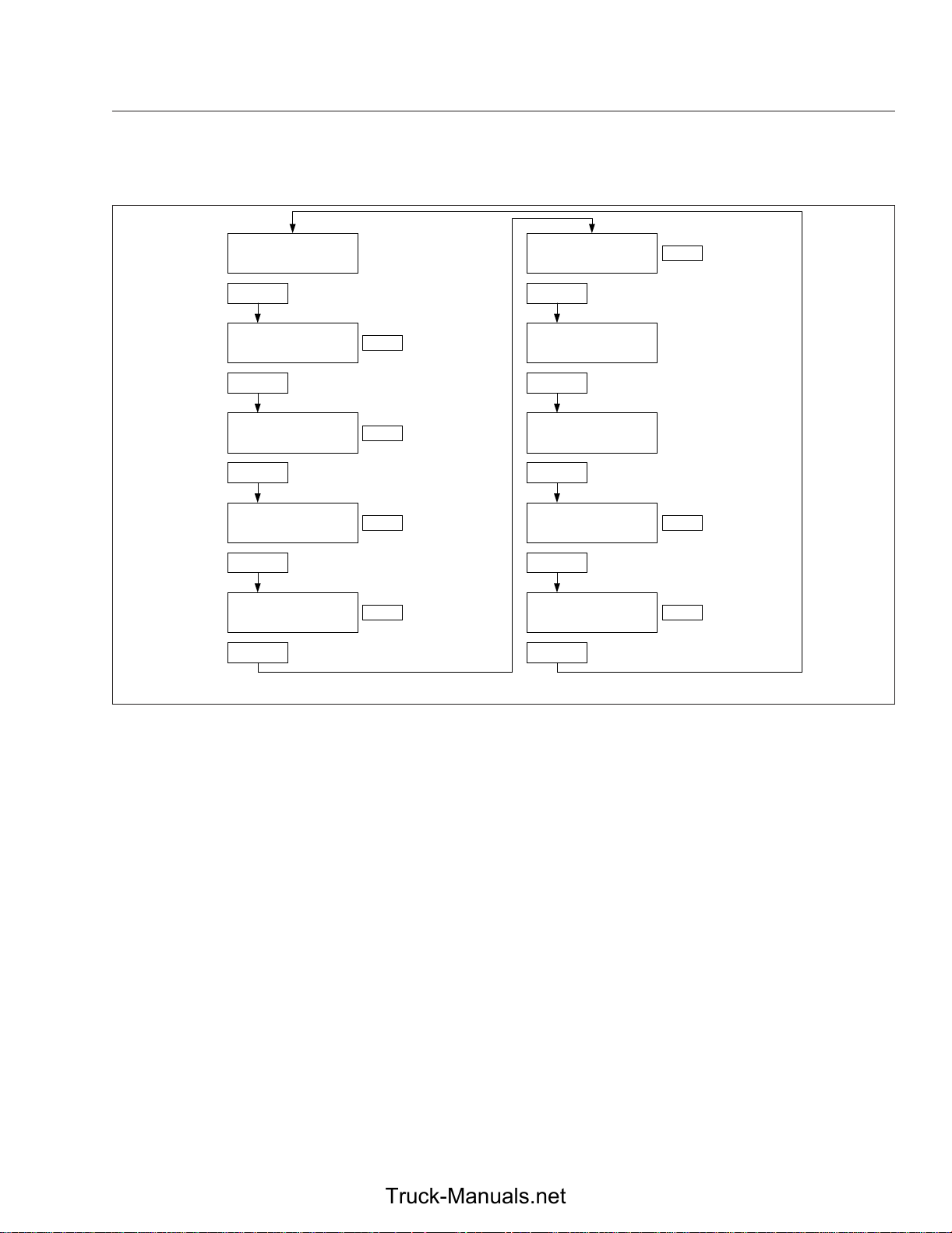

EXHAUST AFTERTREATMENT SYSTEM INFORMATION

INDICATOR

LAMP(S)

Indicator Lamp

Message(s)

Diesel Particulate

Filter Condition

Required Action

For a driver performed Parked Regeneration, vehicle must be equipped with a dash mounted Regeneration Switch.

(Solid)

Level 1 Level 3Level 2 Level 4

Filter Regeneration

Recommended.

Filter is reaching

capacity

.

Bring vehicle to

highway speeds to

allow for an

Automatic

Regeneration or

perform a Parked

Regeneration.

(Flashing) (Flashing)

Filter

Regeneration

Necessary

Filter is now

reaching maximum

Switch.

capacity

.

To avoid engine

derate, bring vehicle

to highway speeds

to allow for an

Automatic

Regeneration, or

perform a Parked

Regeneration as

soon as possible.

The STOP engine lamp illuminates when the engine

protection system is activated in one of two ways. On

some engines, the engine protection system will derate the engine, allowing it to run at lower rpm and

slower vehicle speed. Drive the vehicle to a safe location or to a service facility.

IMPORTANT: Safely bring the vehicle to a stop

on the side of the road and shut down the engine as soon as the red light is seen. If the engine shuts down while the vehicle is in a hazardous location, turn the key to the OFF position

for a few seconds, then restart the engine and

move the vehicle to a safer location.

W

CHECK

Parked Regeneration

Required − Engine

Derate

Filter has reached

maximum capacity

Vehicle must be

parked, and a Parked

Regeneration must

be performed.

Engine will begin

derate.

STOP

Service Regeneration Required.

Engine Derate To Idle Only.

Filter has exceeded maximum

.

capacity.

Vehicle must be parked, and a

Service Regeneration must be

performed. Check engine

operator’s manual for details.

Engine will shut down.

ARNING

HEST (High Exhaust

System Temperature)

Flashing

A regeneration is in

progress.

Solid

Exhaust components

and exhaust gas are at

high temperature. When

stationary, keep away

from people and

flammable materials or

vapors.

02/20/2009

f080156

Fig. 3.3, ATS Warning Lamps

3.6

Instruments

On other engines, the engine protection system will

shut down the engine. It will first derate the engine,

then shut it down completely 30 to 60 seconds after

the indicator illuminates (depending on the critical

fault type) if the condition does not improve. Bring

the vehicle to a stop on the side of the road before

the engine shuts down.

Some vehicles may have a shutdown-override

switch, which may be used to momentarily override

the shutdown sequence. See

information regarding the shutdown process.

Chapter 7 for detailed

IMPORTANT: Do not attempt to restart the engine while the vehicle is moving. Bring the vehicle to a safe stop, then restart the engine.

To restart the engine, turn the ignition to OFF, leave

it there a few seconds, then turn the ignition to

START. The engine will run for a short period and

shut down again if the condition does not improve.

Driver Message Center

The driver message center is controlled using the

mode/reset switch, located on the right side of the

ICU. See

vance one screen; press and hold the switch to select a menu choice or reset the display. When the

display resets, an audible chirp sounds.

Driving Screens

The following screens are available when the parking

brake is off (when the vehicle is mobile) and no active fault codes are found. Use the mode/reset switch

to scroll through the screens. To reset any values,

press and hold the mode/reset switch. The driving

screens appear in the following order:

i.

ii.

iii.

iv.

Parked Screens/Menus

The parked screens and menus are available when

the parking brake is on and no active fault codes are

found. See

scroll through the parked screens. To reset any values, press and hold the mode/reset switch. The

parked screens appear in the following order:

Fig. 3.1. Tap the mode/reset switch to ad-

Odometer

Trip distance

Trip hours

Outside temperature

Fig. 3.4. Use the mode/reset switch to

i.

Odometer

ii.

Trip distance

iii.

Trip hours

iv.

Outside temperature

v.

Select units

vi.

Temperature alert

vii.

Diagnostics

viii.

Engine miles

ix.

Engine hours

x.

Setup

Temperature Alert

When the outside temperature drops to 34°F (1.7°C)

or less, the ICU displays a caution text at onesecond intervals for five seconds, and an audible

alert sounds. Tap the mode/reset switch to acknowledge the message. The audible alert will not sound

again unless the temperature cycles above 37°F

(4°C) and back to 34°F (1.7°C) or less. This warning

only occurs while the ignition is on and the parking

brake is released.

The temperature alert message allows the driver to

enable or disable the ambient temperature warning.

Press and hold the mode/reset switch to toggle between on and off. Release the mode/reset switch,

then tap it to select the displayed choice.

Diagnostics

When the DIAG screen is displayed, press and hold

the mode/reset switch to access the various diagnostic screens.

The diagnostic screens are used by trained technicians to retrieve fault codes and other diagnostic information pertaining to the vehicle. If active fault

codes display during start-up or at any other time,

make a note of the fault code and take the vehicle to

an authorized Freightliner service facility

If fault codes are displayed, press and hold the

mode/reset switch to view the next fault code until

reaching the DIAG screen.

3.7

Instruments

123456.7

MI

12.3 VOLTS

Push

123456.7

TRIP MI

12.3 VOLTS

Push

123456.7

TRIP HOURS

12.3 VOLTS

Push

SELECt

MI

Push

dIAG

MI HOURS

n

Push Push

08/29/2012 f040636b

Default Odometer

Dispay Screen

Hold

To Reset Trip Miles

Hold

To Reset Trip Hours

To Toggle between Units

Hold

MI<−−−−>KM

Hold

Dispay Diagnostics

n = Number of Active Fault Codes

MI = CYCLE Miles Enabled

HOURS = Cycle Hours Enabled

*Lo

**MI **HOURS

**no

Push

Push

Push

Push

CLEAr

123456.7

MI

ENGINE

123456.7

ENGINE

EnG oIL

SEtUP

HOURS

Hold

Clear Defaults

To Dispay Total Engine Miles

To Dispay Total Engine Hours

Hold

Dispay Oil Level

*Lo = Oil Level Low

HI = Oil Level High

Blank = Oil Level OK

− − = No Message

Dispay Service Interval

Hold

Cycle Screens

**MI = CYCLE Miles Active Mode

**HOURS = CYCLE Hours Active Mode

**no = Service CYCLE Inactive

NOTE: The engine oil level screen displays for Mercedes-Benz engines only (if equipped and enabled).

Fig. 3.4, ICU3 Stationary Screens

Engine Miles/Hours

When the engine miles/hours screen is displayed,

press and hold the mode/reset switch to access the

engines screen submenu.

Setup

The setup menu allows the driver to manage ICU

parameters. The setup screen submenu allows the

driver to enable and change service intervals.

If service intervals are enabled and service distance

or time has been exceeded, the text SERVICE

HOUR/MI (KM) will display at start-up to indicate vehicle service is required.

For each parameter, press and hold the mode/reset

switch to navigate to the parameter change screen.

In each change screen, tap the mode/reset switch to

toggle between options.

The last screen in the setup menu, RESET EE,isfor

resetting certain parameters to the original settings.

Press and hold the mode/reset switch to reset the

antilock braking system (ABS), SAMs roll call, automated transmission display, transmission heartbeat,

sensor fault codes, seat belt switch learning, and engine oil level.

Instruments

Standard instruments are present on every vehicle.

They are listed here in alphabetical order to make

the information easier to find.

Optional instruments, typically located on the auxiliary dash panel or right-hand control panel, are not

found on every vehicle. They are listed here in alphabetical order, to make the information easier to find.

3.8

Instruments

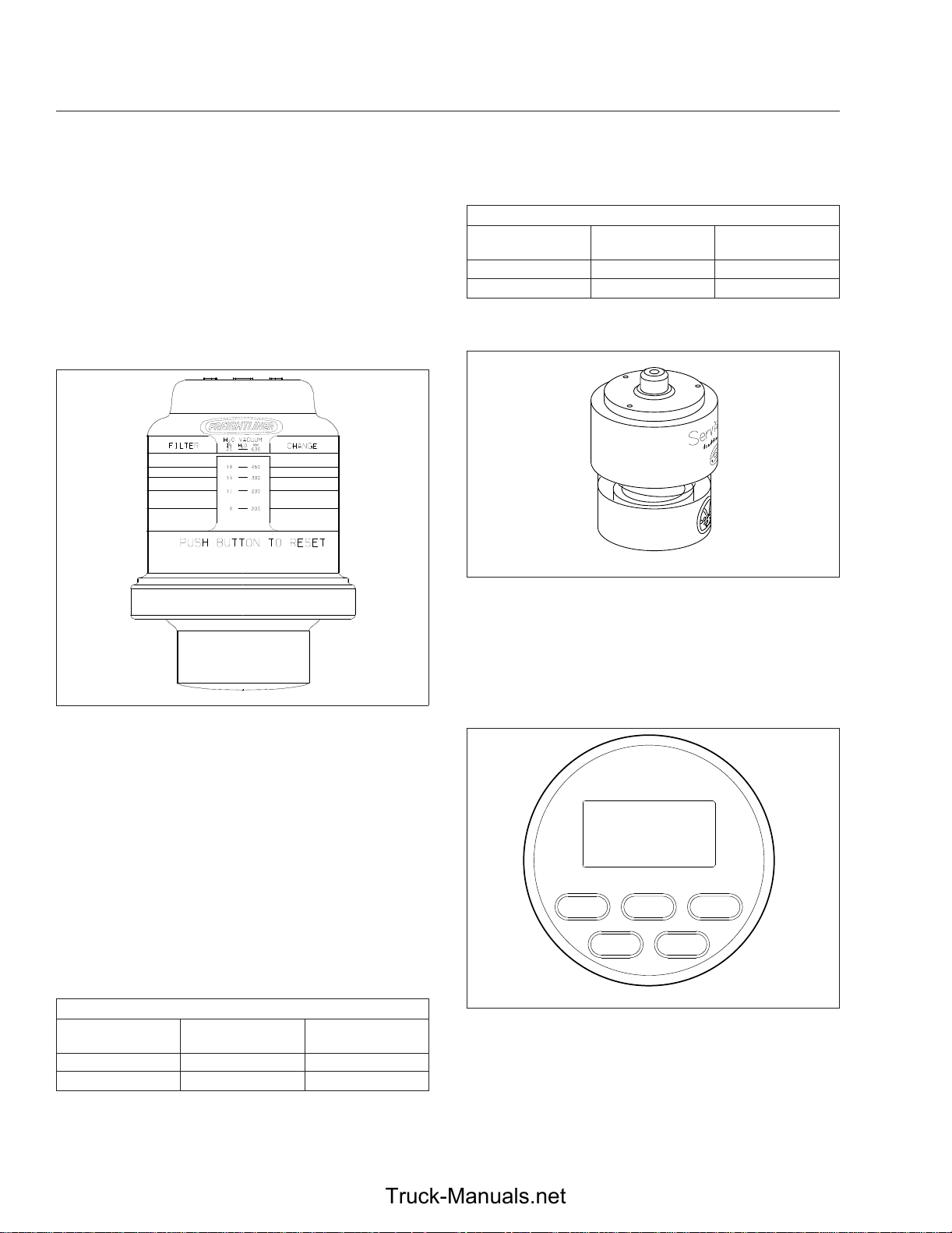

Air Intake Restriction Gauge

The air intake restriction gauge indicates the vacuum

on the engine side of the air cleaner. On standard

installations, it is mounted on the air intake duct in

the engine compartment. As an option for easier

viewing, the air intake restriction indicator (see

Fig. 3.5) can be mounted on the dash, usually on the

right-hand control panel.

Air Intake Maximum Restriction Values (inH2O)

Engine

™

Detroit

Mercedes-Benz 22 22

Table 3.2, Air Cleaner Element Maximum Restriction

04/08/2005 f090431

Fig. 3.6, Manual-Reset Air Restriction Indicator, Go/

Pre-EPA07

Engines

20 22

No-Go

EPA07 and

Newer Engines

Ambient Temperature Gauge

10/10/2001

Fig. 3.5, Air Intake Restriction Indicator

f610568

NOTE: Rain or snow can wet the filter and

cause a temporary high reading.

Air intake restriction vacuum is measured in inches

of water (inH

graduated indicator or a restriction gauge on the

dash, check the gauge with the engine off. If the yellow signal stays locked in the red zone once the engine is shut down, or is at or above the values

shown in

be replaced.

Vehicles may be equipped with a go/no-go restriction

indicator without graduations (see

a graduated indicator.

Air Intake Maximum Restriction Values (inH2O)

Engine

Caterpillar 25 —

Cummins 25 25

O). For vehicles equipped with a

2

Table 3.2, the air cleaner element needs to

Fig. 3.6) instead of

Pre-EPA07

Engines

EPA07 and

Newer Engines

The ambient temperature gauge, shown in Fig. 3.7,

displays the in-cab or outside temperature, depending on the settings selected.

SET ADJ ALARM

IN OUT

12/14/2011 f611153

Fig. 3.7, Ambient Temperature Gauge

When the alarm is enabled, the ambient temperature

gauge will sound an audible alert and the amber

3.9

Loading...

Loading...