Freightliner AMT3 Service Manual

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

26.03

General Troubleshooting

IMPORTANT: Always use ServiceLink when attempting to diagnose problems with the AGS

(Automated Gear Shift) transmission.

How To Start

To gain a baseline for troubleshooting when there is

no definite problem, when the malfunction is erratic

or intermittent, or to determine the general health of

the electrical system, start with the electrical pre-test

in Subject 301.

In a few cases there will be a definite problem and

no J1587 fault code will be sent (engine will not

crank, no information on gear display, fluid level

fault). For these problems, see the appropriate table

in Subject 301.

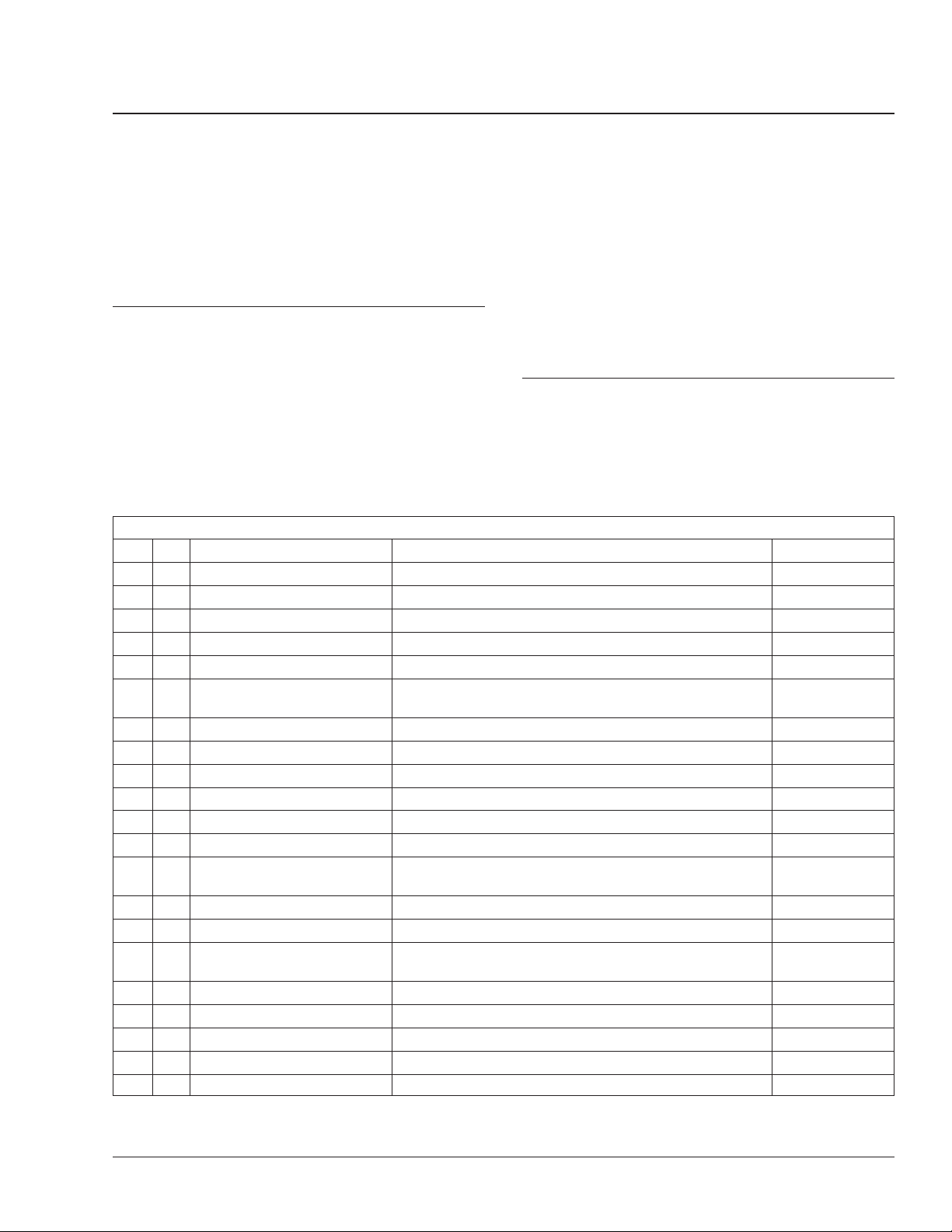

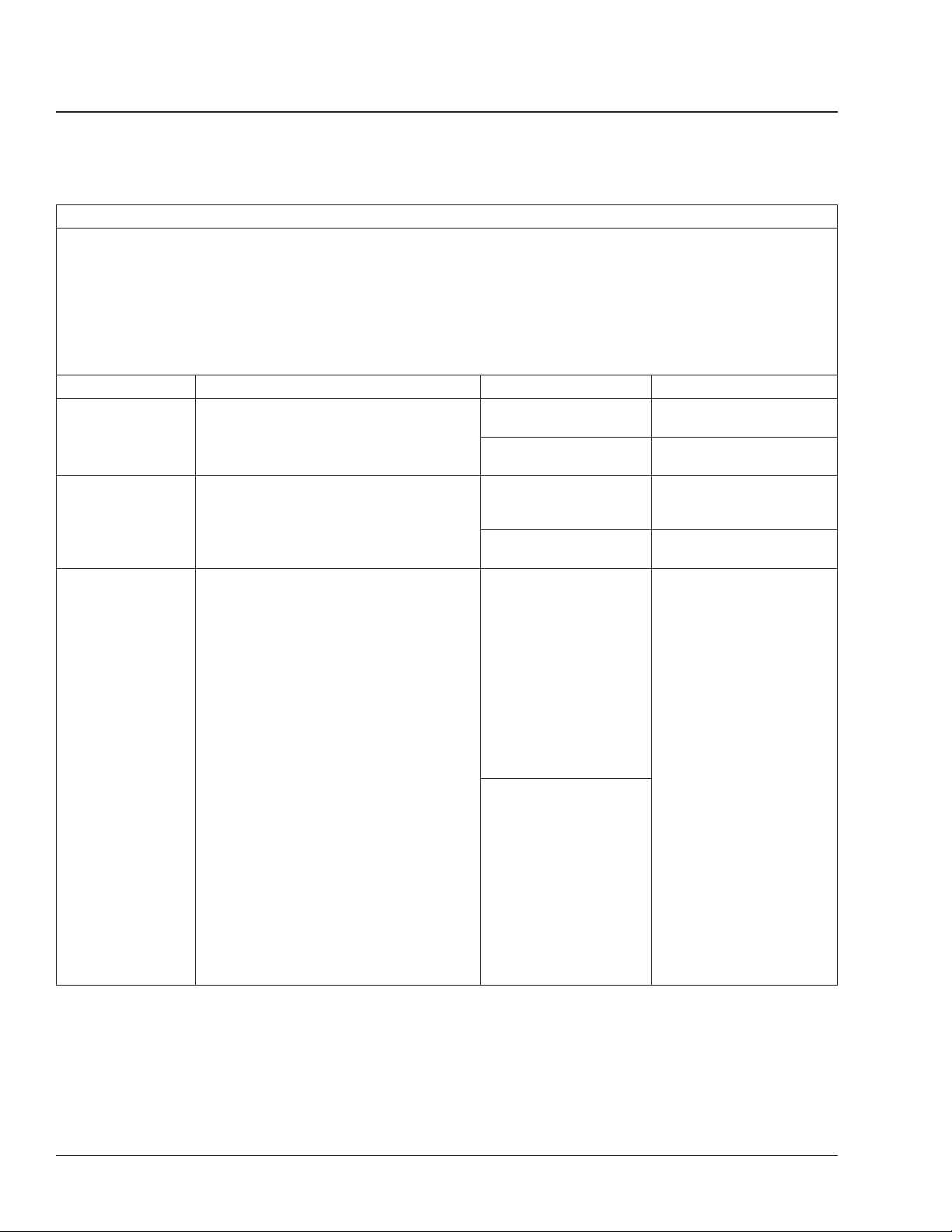

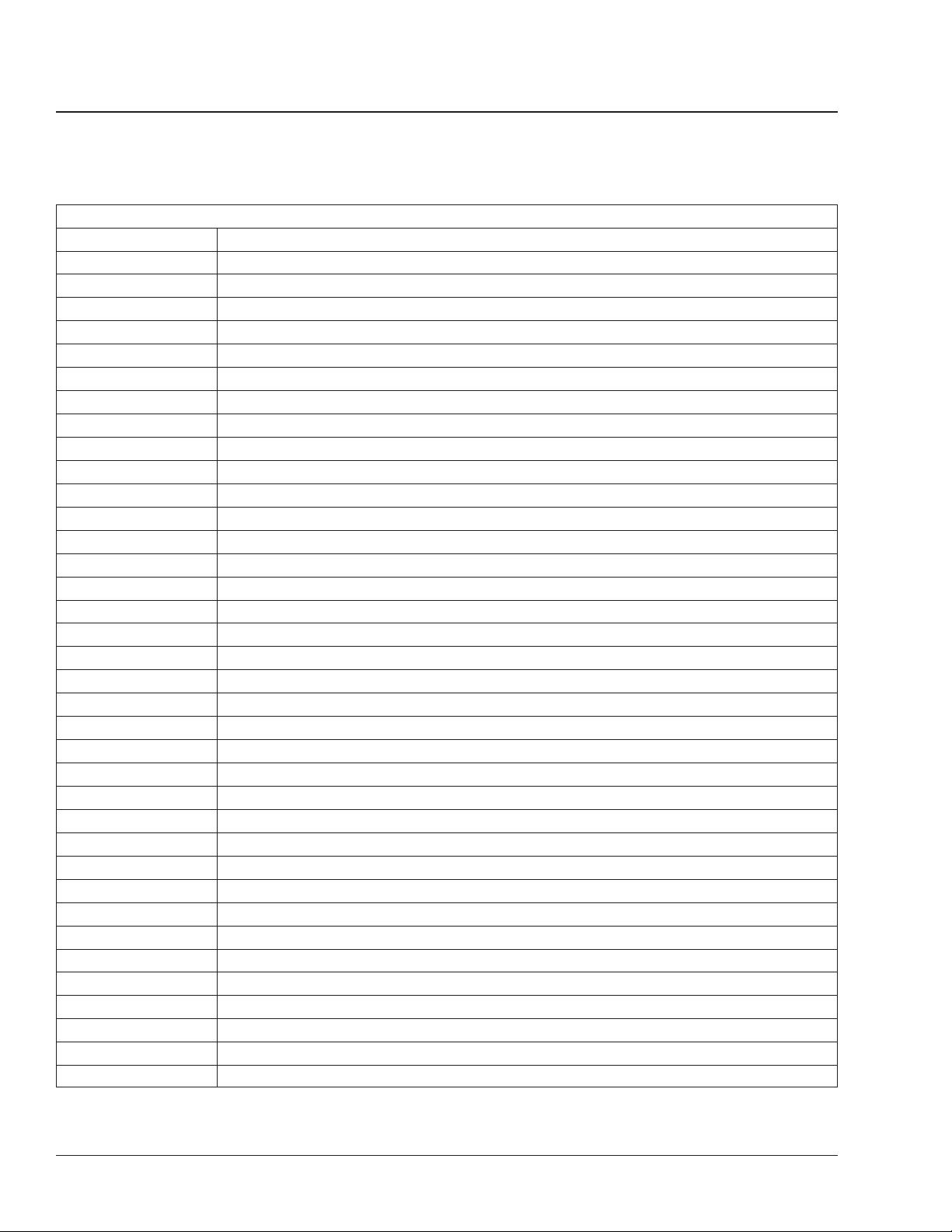

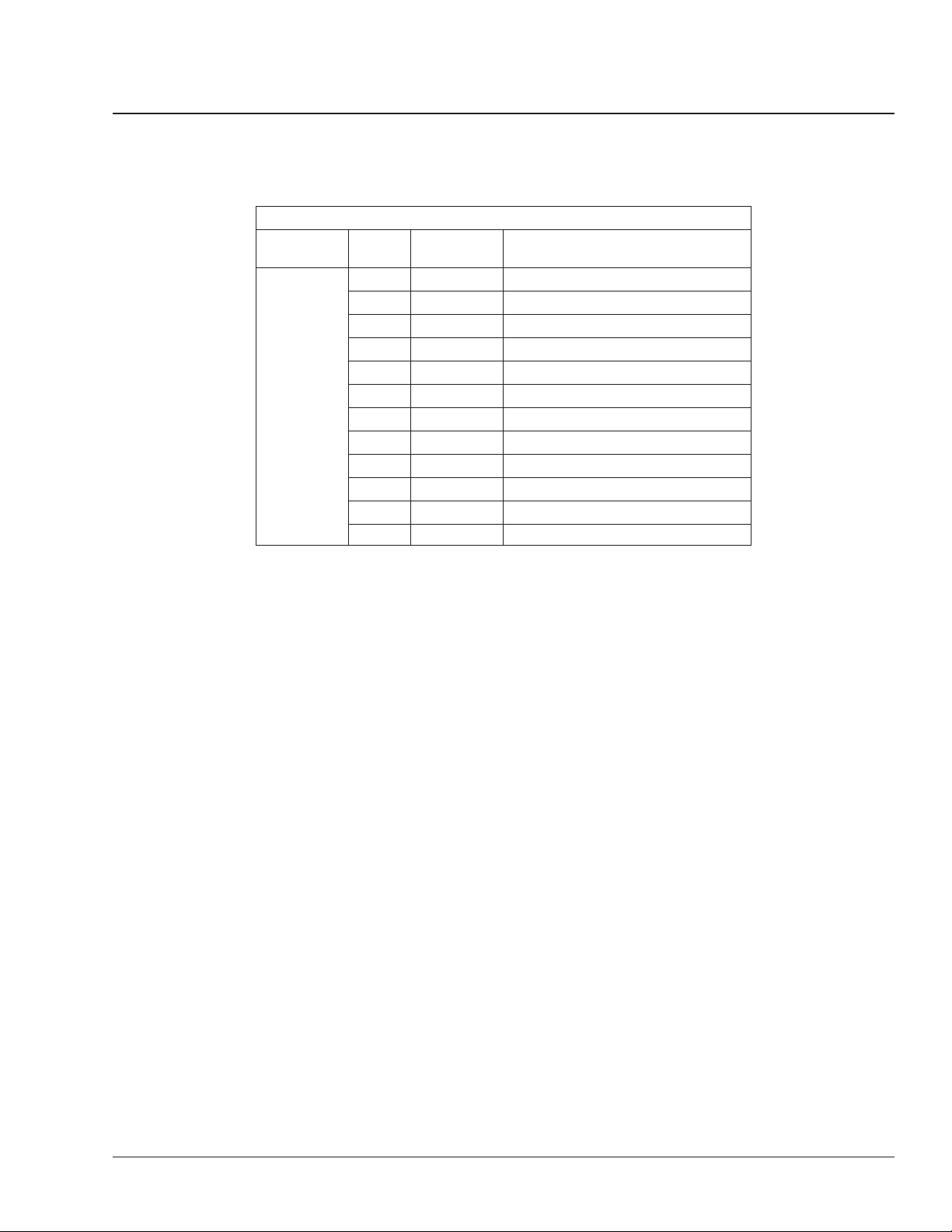

Fault Code Guide (MID 130 SIDs)

SID FMI Text Message Failure Reason Procedure

18 02 Prim Selector Erratic The shift lever does not shift gears. See Subject 302.

33 03 MultiPress Ind Short Hi The hydraulic pressure sensor circuit is shorted to power. See Subject 303.

33 04 MultiPress Ind Short Lo The hydraulic pressure sensor circuit is shorted to ground. See Subject 303.

33 05 MultiPress Ind OPEN The hydraulic pressure sensor circuit is open. See Subject 303.

52 05 Hydraulic Sys OPEN The hydraulic pump circuit is open. See Subject 304.

52 07 Hydraulic Sys NoRESPONSE

52 11 Clutch Act Not Known The hydraulic pump temperature is too high. See Subject 304.

55 00 Clutch Act HIGH The clutch is too hot. See Subject 305.

55 07 Clutch Act NoRESPONSE The clutch does not operate properly. See Subject 305.

55 13 Clutch Act Calibrate The clutch needs to be calibrated. See Subject 305.

231 02 SAE J1939 Datalink Erratic The J1939 datalink is not communicating properly. See Subject 306.

231 09 SAE J1939 Datalink UPDATE The J1939 datalink has timed out. See Subject 306.

231 12 SAE J1939 Datalink Bad

251 00 POWER SUPPLY HIGH The power supply voltage is too high. See Subject 307.

251 01 POWER SUPPLY Low The power supply voltage is too low. See Subject 307.

251 05 POWER SUPPLY OPEN

251 14 POWER SUPPLY RSRVD The power supply is not properly grounded. See Subject 307.

253 02 Calibration Memory Erratic The transmission needs to be recalibrated. See Subject 308.

253 12 Calibration Memory Bad The transmission needs to be recalibrated. See Subject 308.

253 13 Calibration Memory Calibrate The transmission needs to be recalibrated. See Subject 308.

253 14 Calibration Memory RSRVD The transmission needs to be recalibrated. See Subject 308.

The hydraulic pressure does not increase even though the

hydraulic pump is activated.

The J1939 datalink is not communicating with the

transmission.

There is no power to the transmission with the engine

running.

But in most cases, the J1587 fault code is the starting point for the troubleshooting procedures. See

Table 1 to find information for SID fault codes. See

Table 2 to find information for PID fault codes.

Before starting any procedures, use ServiceLink to

depressurize the AGS hydraulic system. For detailed

procedures, see Subject 160.

Fault Code Guide

To troubleshoot a given fault code, look up the subject number in Table 1 (for SIDs) and Table 2 (for

PIDs). Follow the procedures for that fault code until

the fault is corrected.

See Subject 304.

See Subject 306.

See Subject 307.

Business Class M2 Workshop Manual, Supplement 20, September 2011 300/1

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Transmissions

General Troubleshooting

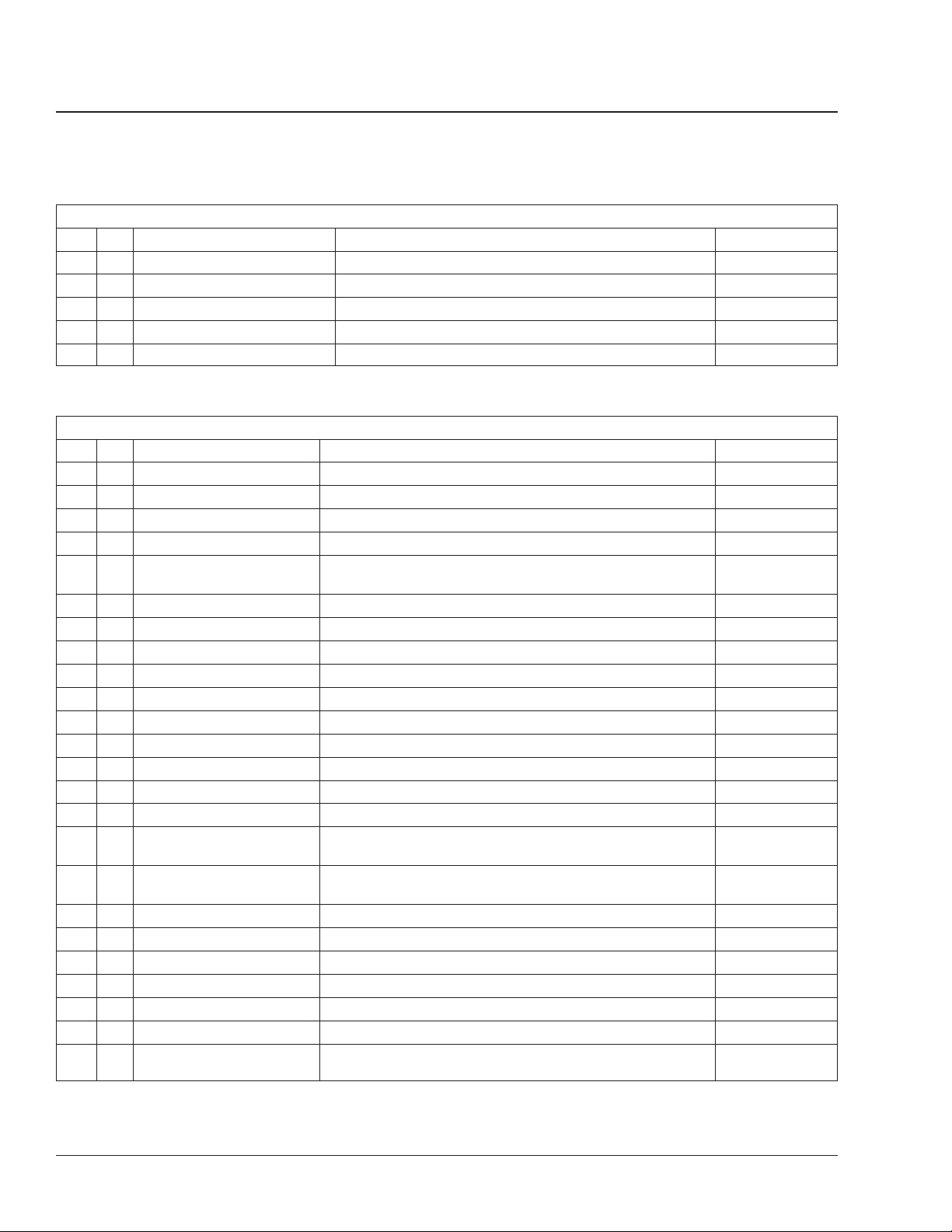

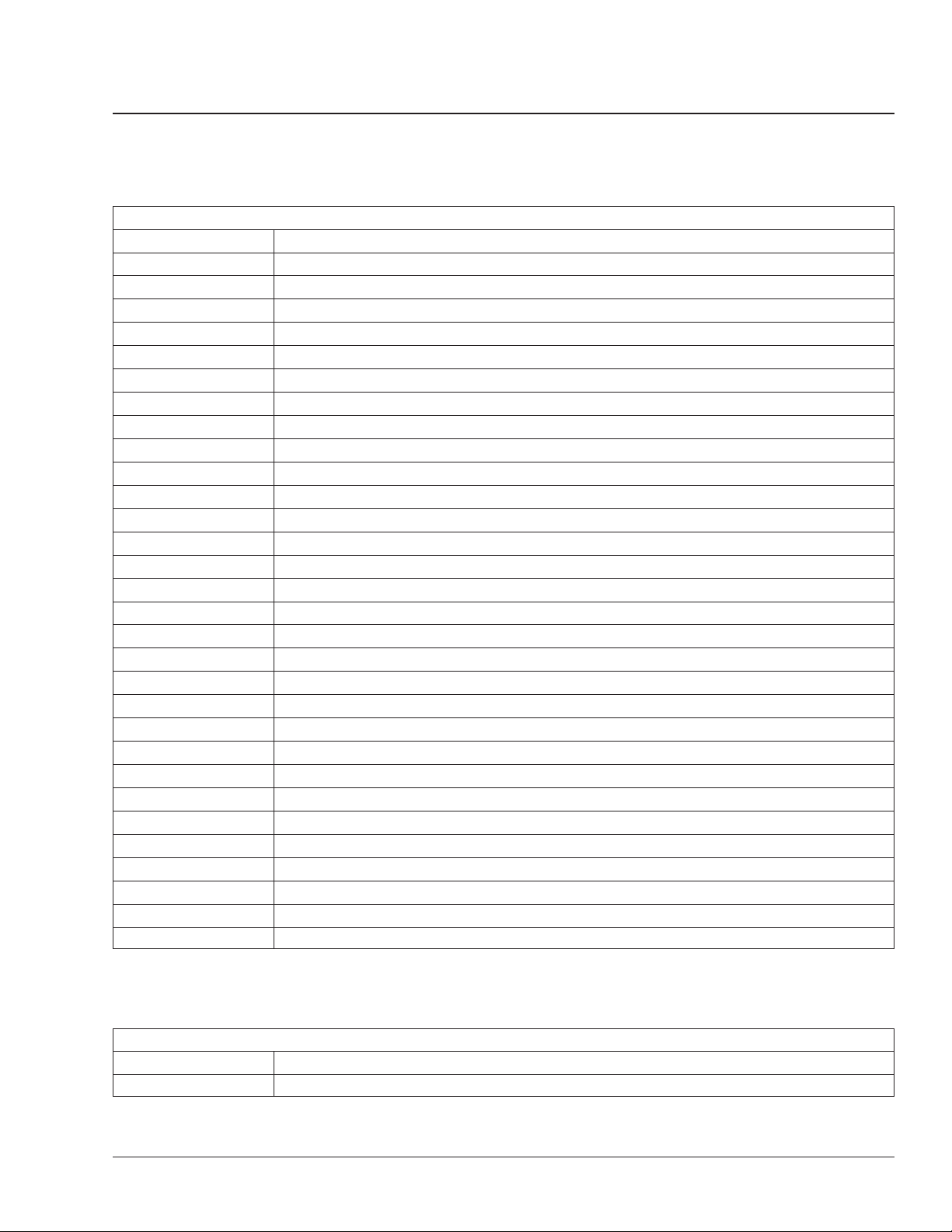

Fault Code Guide (MID 130 SIDs)

SID FMI Text Message Failure Reason Procedure

254 04 Controller Short Lo The TCU is shorted to ground. See Subject 309.

254 05 Controller OPEN The TCU has an open circuit. See Subject 309.

254 11 Controller Not Known The TCU AUTO mode software module has an error. See Subject 309.

254 12 Controller Bad The TCU has a hardware problem. See Subject 309.

254 13 Controller Calibrate The TCU has a software memory problem. See Subject 309.

Table 1, Fault Code Guide (SIDs)

Fault Code Guide (MID 130 PIDs)

PID FMI Text Message Failure Reason Procedure

33 02 Erratic The clutch position sensor gives invalid data. See Subject 310.

33 03 Short Hi The clutch position sensor circuit is shorted to power. See Subject 310.

33 04 Short Lo The clutch position sensor circuit is shorted to ground. See Subject 310.

33 05 OPEN The clutch position sensor circuit is open. See Subject 310.

33 14 RSRVD

59 02 Shift FNGR Gear Erratic The shift rod position sensor gives invalid data. See Subject 311.

59 03 Shift FNGR Gear Short Hi The gear position sensor circuit is shorted to power. See Subject 311.

59 04 Shift FNGR Gear Short Lo The gear position sensor circuit is shorted to ground. See Subject 311.

59 05 Shift FNGR Gear OPEN The gear position sensor circuit is open. See Subject 311.

59 14 Shift FNGR Gear RSRVD The gear position sensor gives incorrect resistance readings. See Subject 311.

60 02 Shift FNGR Rail Erratic The rail position sensor circuit gives invalid data. See Subject 312.

60 03 Shift FNGR Rail Short Hi The rail position sensor circuit is shorted to power. See Subject 312.

60 04 Shift FNGR Rail Short Lo The rail position sensor circuit is shorted to ground. See Subject 312.

60 05 Shift FNGR Rail OPEN The rail position sensor circuit is open. See Subject 312.

60 14 Shift FNGR Rail RSRVD The rail position sensor gives incorrect resistance readings. See Subject 312.

64 09 Dir Switch Update

64 11 Dir Switch Not Known

158 00 Volts (BattSw) HIGH The voltage in the ignition power circuit is too high. See Subject 314.

158 01 Volts (BattSw) Low The voltage in the ignition power circuit is too low. See Subject 314.

161 02 In shaft SPEED Erratic The input shaft speed sensor circuit gives invalid data. See Subject 315.

161 03 In shaft SPEED Short Hi The input shaft speed sensor circuit is shorted to power. See Subject 315.

161 04 In shaft SPEED Short Lo The input shaft speed sensor circuit is shorted to ground. See Subject 315.

161 05 In shaft SPEED OPEN The input shaft speed sensor circuit is open. See Subject 315.

161 08 In shaft SPEED Update

The clutch position sensor gives incorrect resistance

readings.

The output shaft speed sensor is not providing accurate

directional information.

The output shaft speed sensor is not providing accurate

directional information.

The input shaft speed sensor circuit is broadcasting an

abnormal frequency.

See Subject 310.

See Subject 313.

See Subject 313.

See Subject 315.

Business Class M2 Workshop Manual, Supplement 20, September 2011300/2

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

26.03

General Troubleshooting

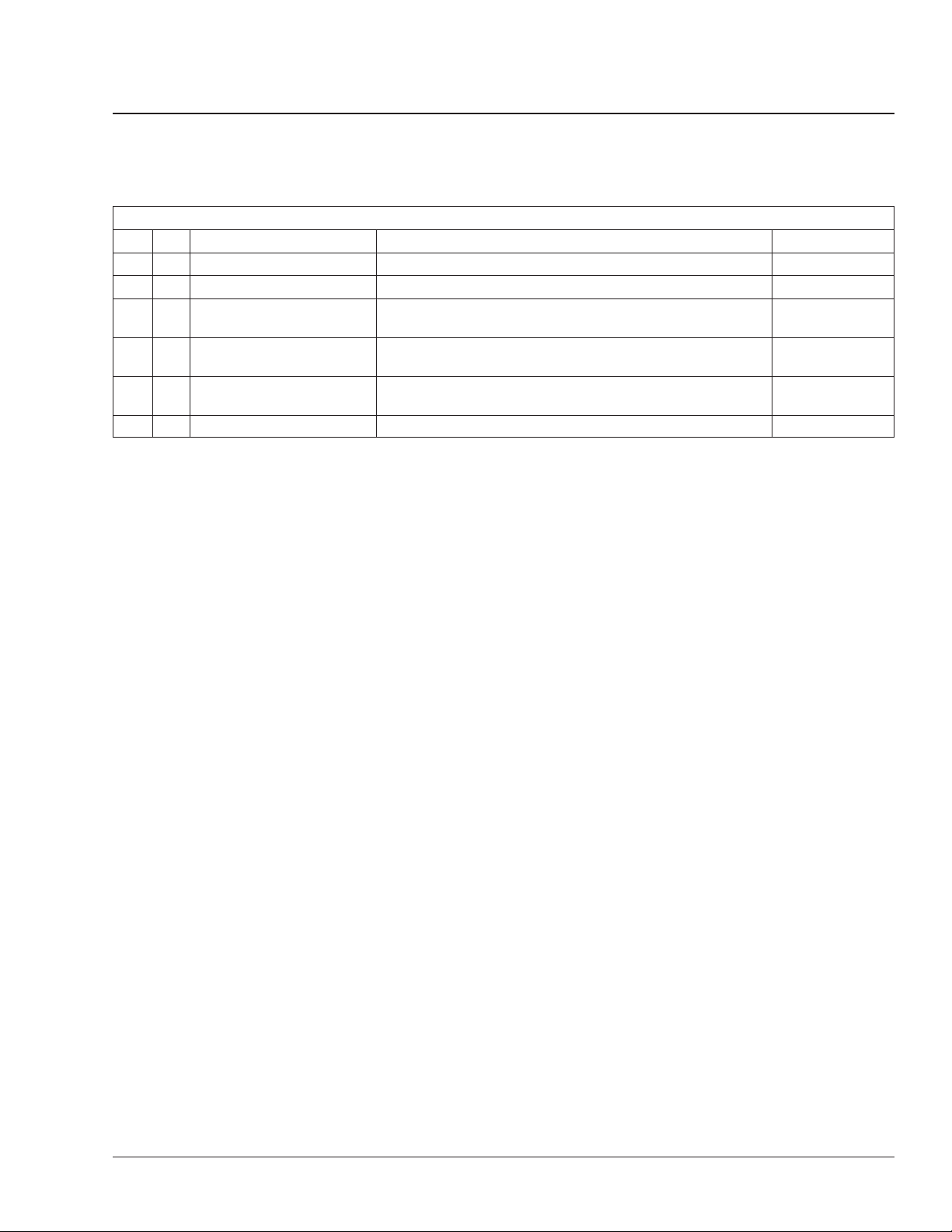

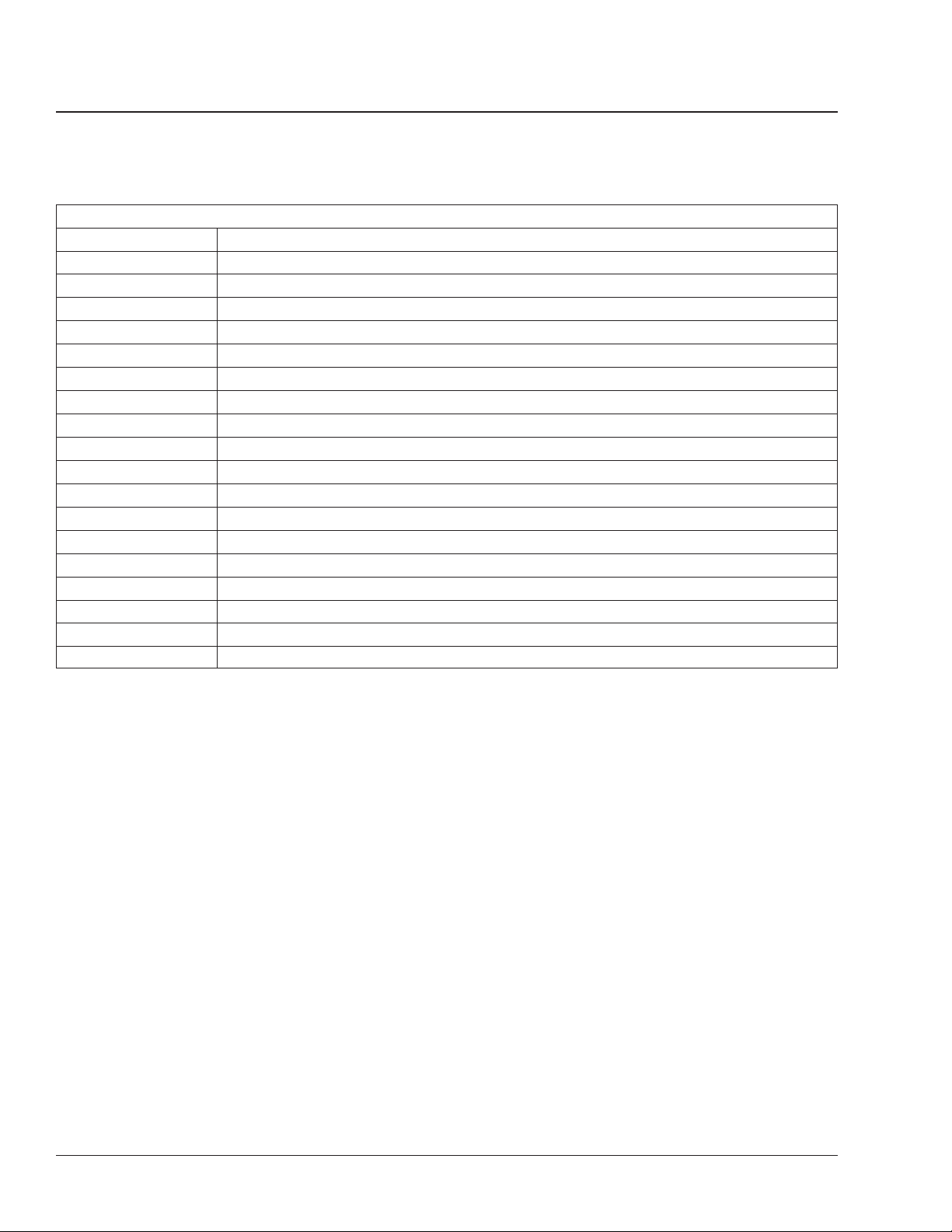

Fault Code Guide (MID 130 PIDs)

PID FMI Text Message Failure Reason Procedure

162 02 RANGE Selected Erratic The transmission is not properly calibrated. See Subject 316.

163 02 RANGE Attained Erratic The gears do not shift properly. See Subject 316.

191 02 OUTPUT SPEED Erratic

191 05 OUTPUT SPEED OPEN

191 08 OUTPUT SPEED SIGNAL

191 14 OUTPUT SPEED RSRVD The output shaft speed sensor is providing invalid data. See Subject 317.

One or both of the output shaft speed sensor circuits give

invalid data.

One or both of the output shaft speed sensor circuits are

open.

There is no signal coming from one or both output shaft

speed sensors.

Table 2, Fault Code Guide (PIDs)

See Subject 317.

See Subject 317.

See Subject 317.

Business Class M2 Workshop Manual, Supplement 20, September 2011 300/3

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

IMPORTANT: Always use ServiceLink when attempting to diagnose problems with the automated gear shift (AGS) transmission.

In most cases, the J1587 fault code is the starting

point for the troubleshooting procedures. See Sub-

ject 300 for a list of fault codes and the location of

troubleshooting procedures for each code.

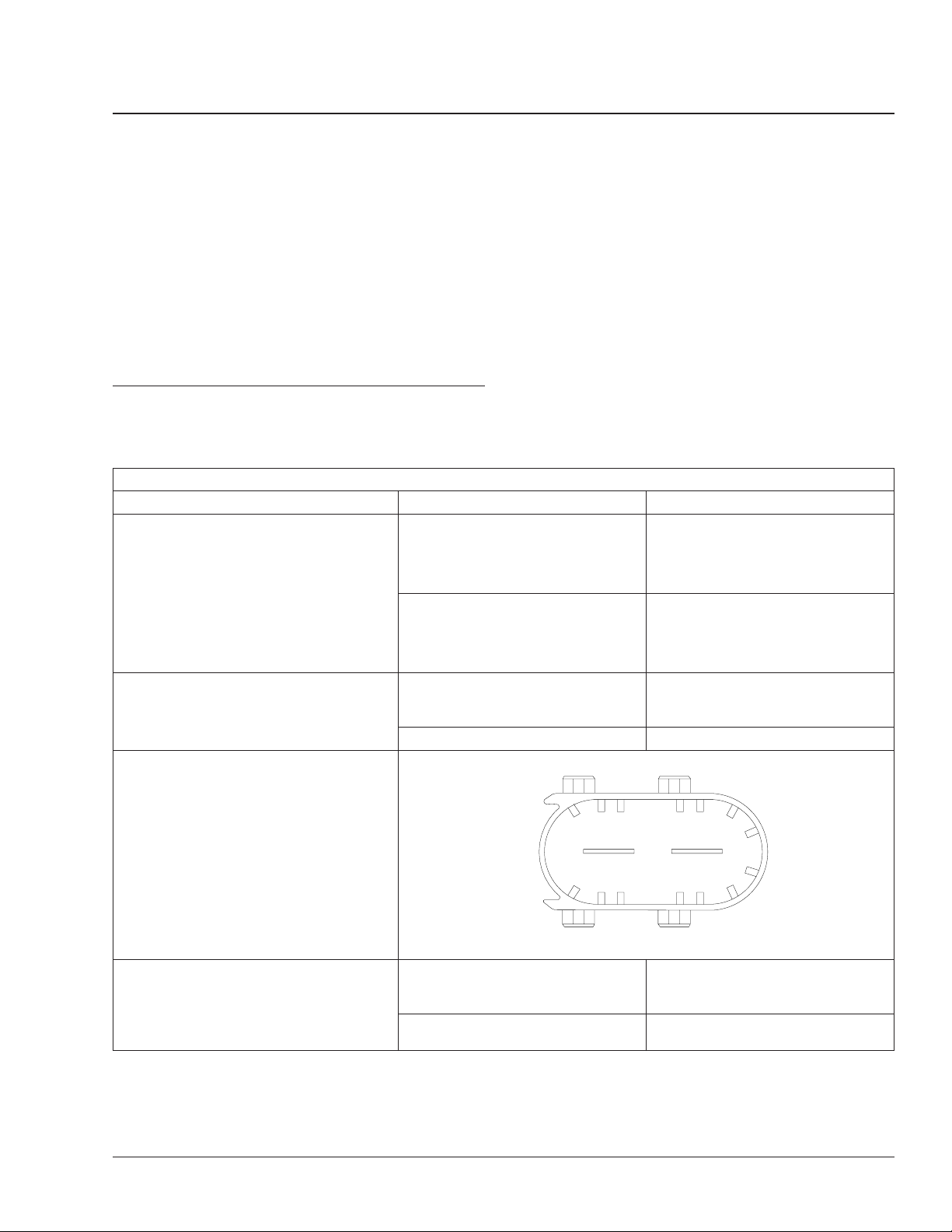

Electrical Pre-Test Instructions

Before starting any procedures, use ServiceLink to

depressurize the AGS hydraulic system. For detailed

procedures, see Subject 160.

Electrical Pre-Test

Procedure Result Action

Make sure that the selector switch on the

SmartShift lever is set to N. Turn on the

ignition switch to power up the

transmission.

NOTE: If the hydraulic pump starts up with

its characteristic humming noise, this

means the main power cables are OK (see

the steps below to check the X3

connector).

With the ignition switch off, check the

voltage at the battery.

Remove the X3 (electric motor 2-pin)

connector from the transmission control unit

(TCU). Check the electric motor power

circuit.

The current gear indicator does not

power up normally. No fault codes

display.

The current gear indicator goes

through its normal power-up

sequence, ending by displaying "N."

Voltage is less than 11 or greater

than 13 volts.

Voltage is between 11 and 13 volts. Go to the next row in the table.

26.03

Troubleshooting Without Fault Codes

Use the electrical pre-test instructions given in

Table 1 as a baseline for troubleshooting when there

is no definite problem, the malfunction is erratic or

intermittent, or as an informational step to determine

the general health of the electrical system. To record

your findings, a result sheet is provided at the end of

this subject. For locations of serial numbers, see

Fig. 1 and Fig. 2.

Troubleshoot the current gear

indicator. See Table 4.

Turn off the ignition switch and go to

the next row in the table.

Charge or replace the battery. For

battery charging procedures, see

Section 54.12, Subject 150.

2

06/01/2004 f544485

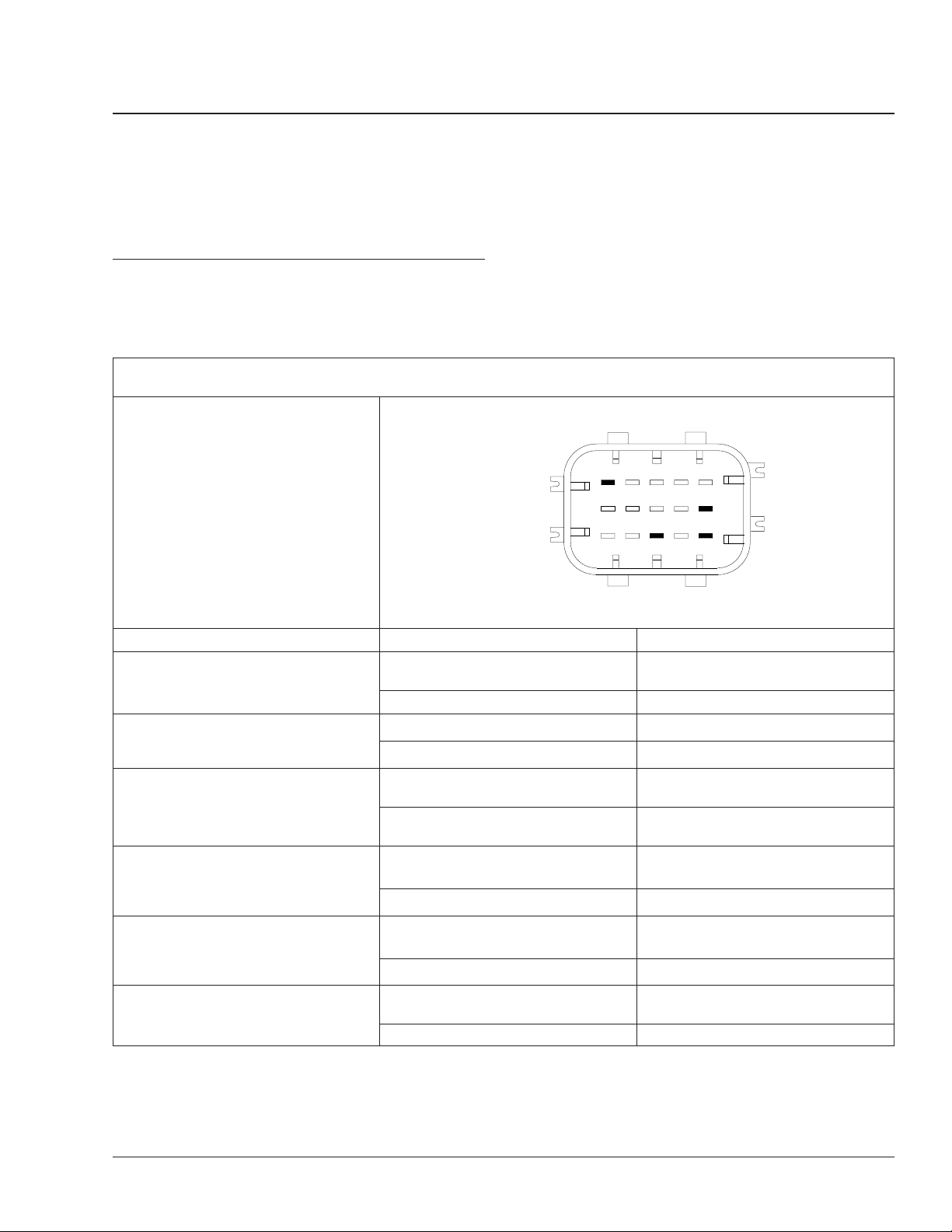

Check for voltage between pin 1 (power

circuit 232) of the X3 connector and the

battery ground terminal.

Business Class M2 Workshop Manual, Supplement 20, September 2011 301/1

Voltage drops more than 0.2 volts

from the voltage measured at the

battery.

Voltage is within 0.2 volts of the

voltage measured at the battery.

X3

1

Repair or replace the wiring as

needed. See Section 54.06, Subject

100.

Go to the next row in the table.

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Troubleshooting Without Fault Codes

Electrical Pre-Test

Procedure Result Action

Check for resistance between pin 2

(ground) of the X3 connector and the

battery ground terminal.

Remove the X1 (vehicle 21-pin) connector

from the transmission control unit (TCU).

Check the battery power circuit.

Resistance is greater than 0.3 ohms. Repair or replace the wiring as

Resistance is 0.3 ohms or less. Go to the next row in the table.

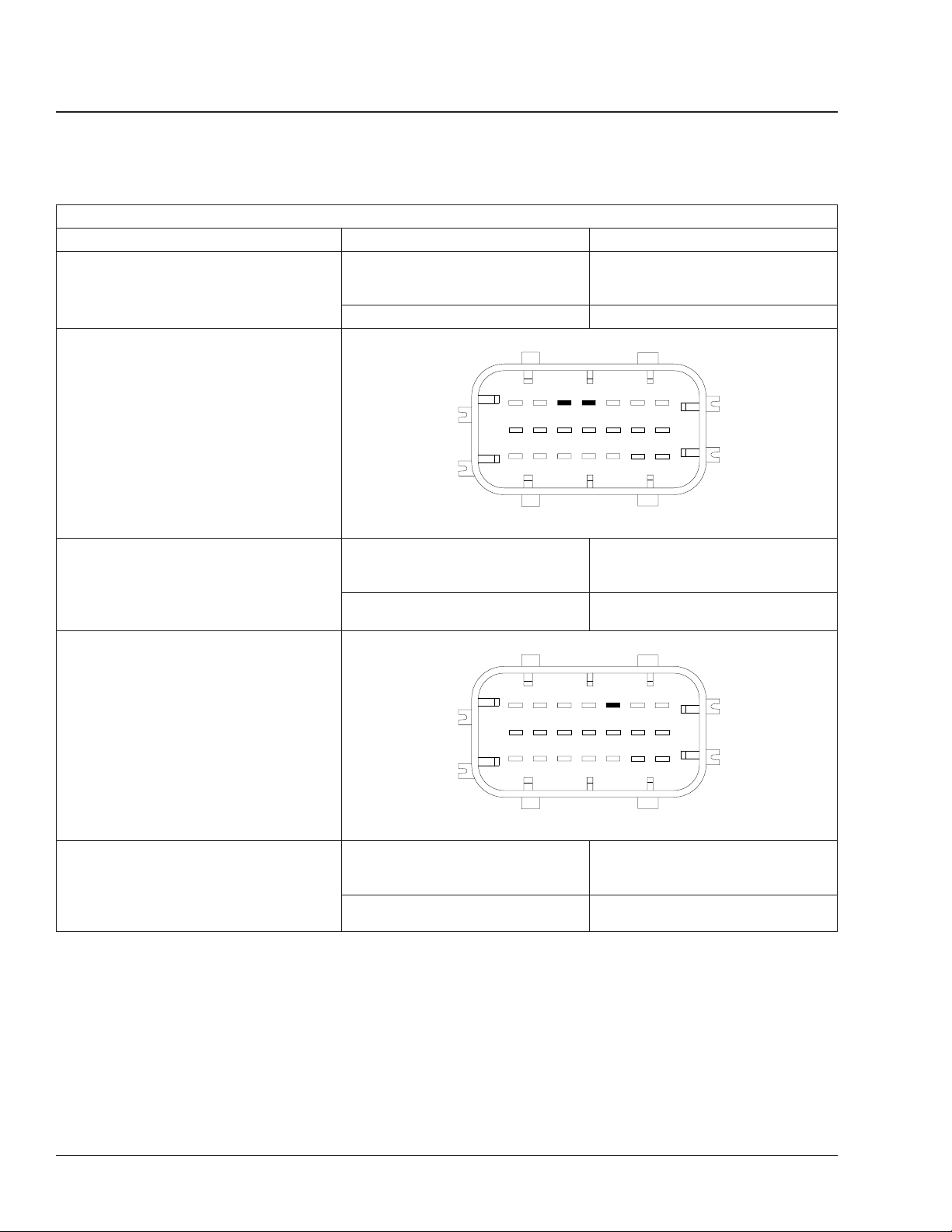

07/16/2004 f544483b

21

20

19

18

17

16

Transmissions

needed. See Section 54.06, Subject

100.

3

15

14

13

12

11

10

X1

6

9

2

5

8

1

4

7

Check for voltage from pins 12 and 15

(battery power circuit 232D) of the X1

connector to the battery ground terminal.

Turn on the ignition switch. Check the

ignition power circuit.

Check for voltage from pin 9 (ignition power

circuit 232E) of the X1 connector to the

battery ground terminal.

Voltage drops more than 0.2 volts

from the voltage measured at the

battery.

Voltage is within 0.2 volts of the

voltage measured at the battery.

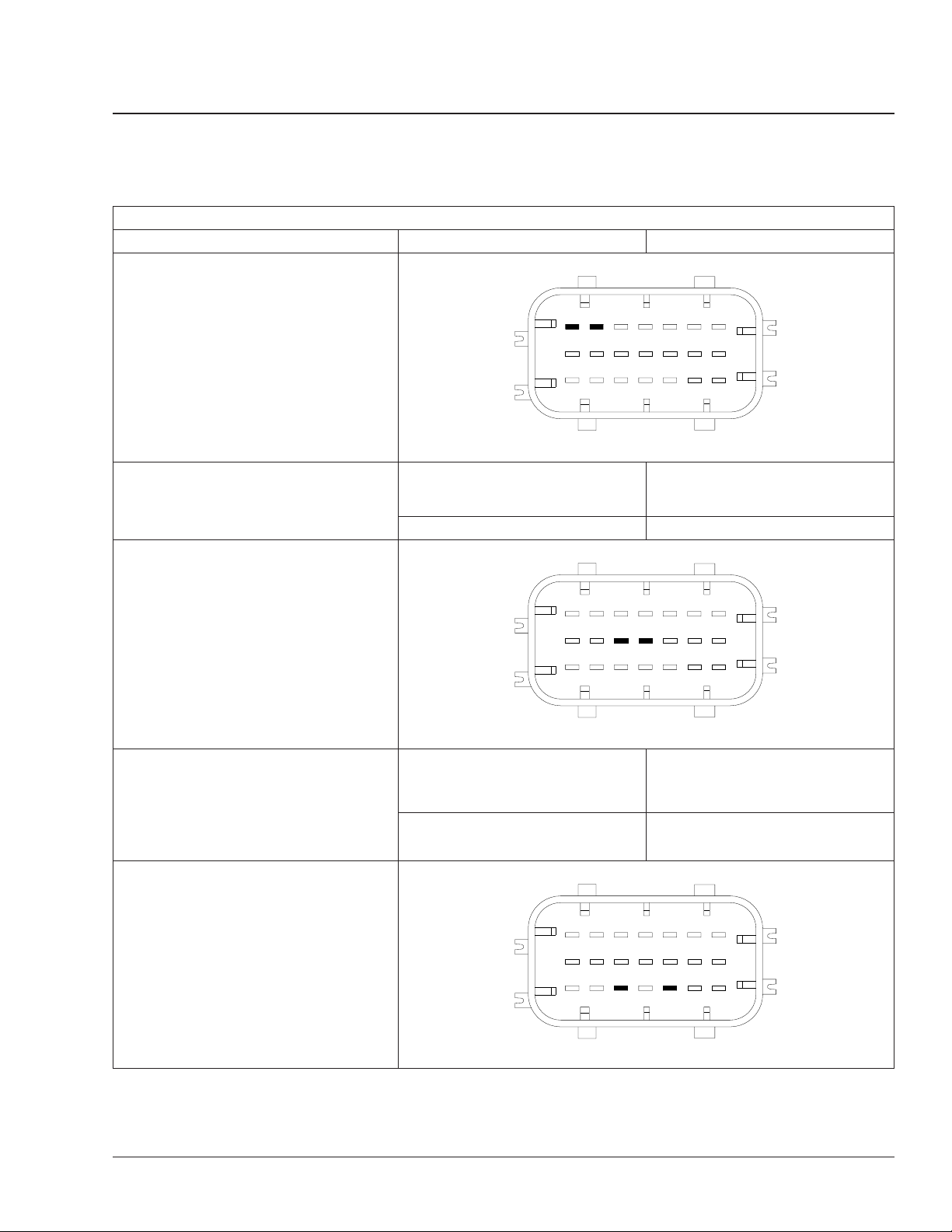

18

21

17

20

16

19

07/16/2004 f544483c

Voltage drops more than 0.2 volts

from the voltage measured at the

battery.

Voltage is within 0.2 volts of the

voltage measured at the battery.

Repair or replace the wiring as

needed. See Section 54.06, Subject

100.

Go to the next row in the table.

3

15

14

13

12

11

10

X1

6

9

2

5

8

1

4

7

Repair or replace the wiring as

needed. See Section 54.06, Subject

100.

Go to the next row in the table.

Business Class M2 Workshop Manual, Supplement 20, September 2011301/2

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

Procedure Result Action

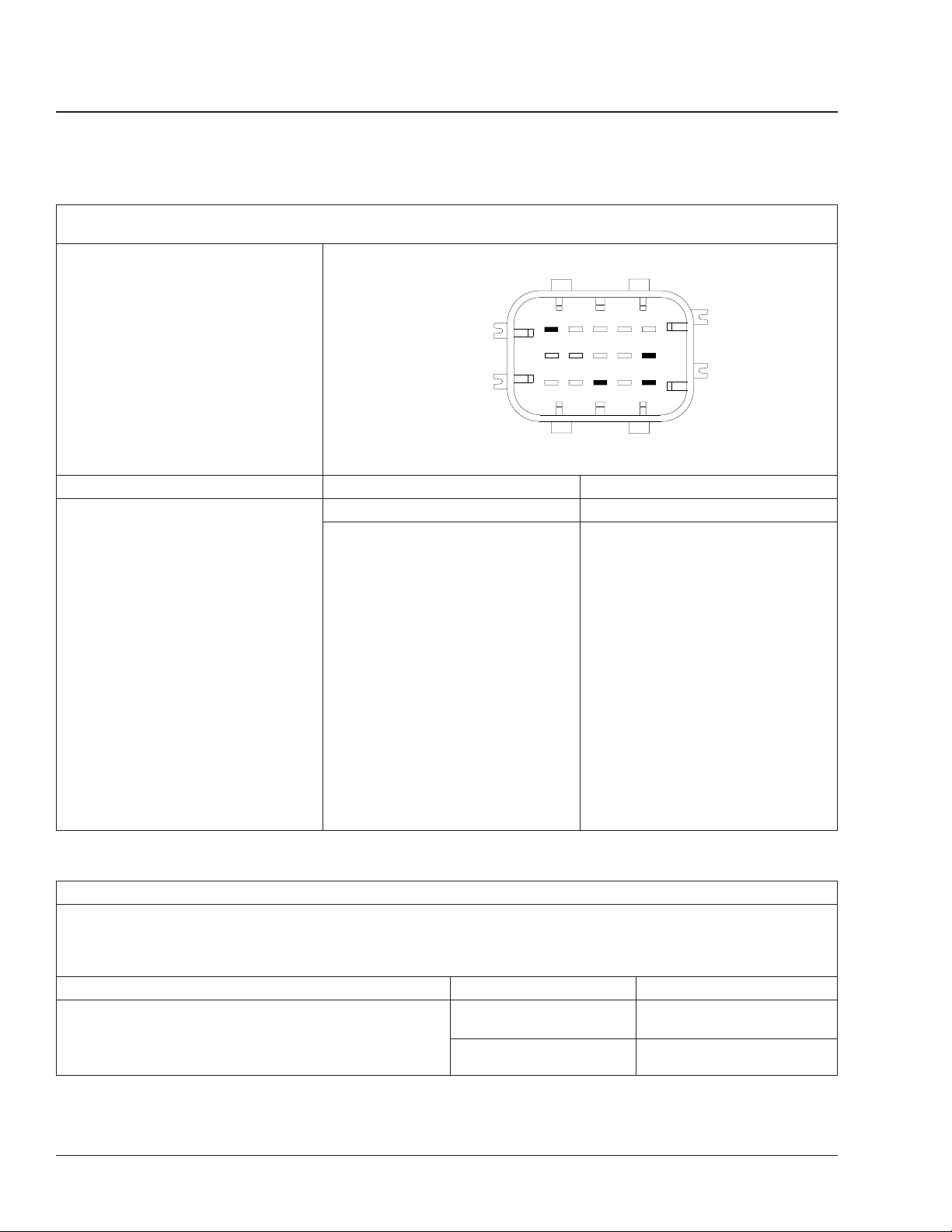

Turn off the ignition switch. Check the

ignition ground circuit.

With the ignition switch off, check for

resistance between pins 18 and 21

(ground) of the X1 connector and the

battery ground terminal.

Turn off the ignition switch. Check the

J1587 wiring.

26.03

Troubleshooting Without Fault Codes

Electrical Pre-Test

3

12

15

18

21

11

14

17

20

10

13

16

19

07/21/2004 f544483d

Resistance is greater than 0.3 ohms. Repair or replace the wiring as

Resistance is 0.3 ohms or less. Go to the next row in the table.

X1

6

9

2

5

8

1

4

7

needed. See Section 54.06, Subject

100.

Check for DC voltage from pins 11 and 14

(J1587 datalink) of the X1 connector to the

battery ground terminal.

NOTE: If the meter cannot display the

rapidly shifting DC voltage, measure AC

voltage instead.

Turn off the ignition switch. Check the

J1939 wiring.

15

18

21

14

17

20

13

16

19

07/21/2004 f544483e

Voltage is less than 1 or more than 4

volt(s) for DC (less than 1 or more

than 3 for AC).

Voltage is between 1 and 4 volts for

DC (1–3 volts AC).

15

18

21

14

17

20

13

16

19

07/16/2004 f544483a

3

12

11

10

X1

12

11

10

X1

6

9

2

5

8

1

4

7

Troubleshoot the J1587 datalink.

Go to the next row in the table.

3

6

9

2

5

8

1

4

7

Business Class M2 Workshop Manual, Supplement 20, September 2011 301/3

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Troubleshooting Without Fault Codes

Electrical Pre-Test

Procedure Result Action

With the ignition switch off, remove the X1

connector from the TCU and check for

resistance between pins 7 and 13 (J1939

datalink).

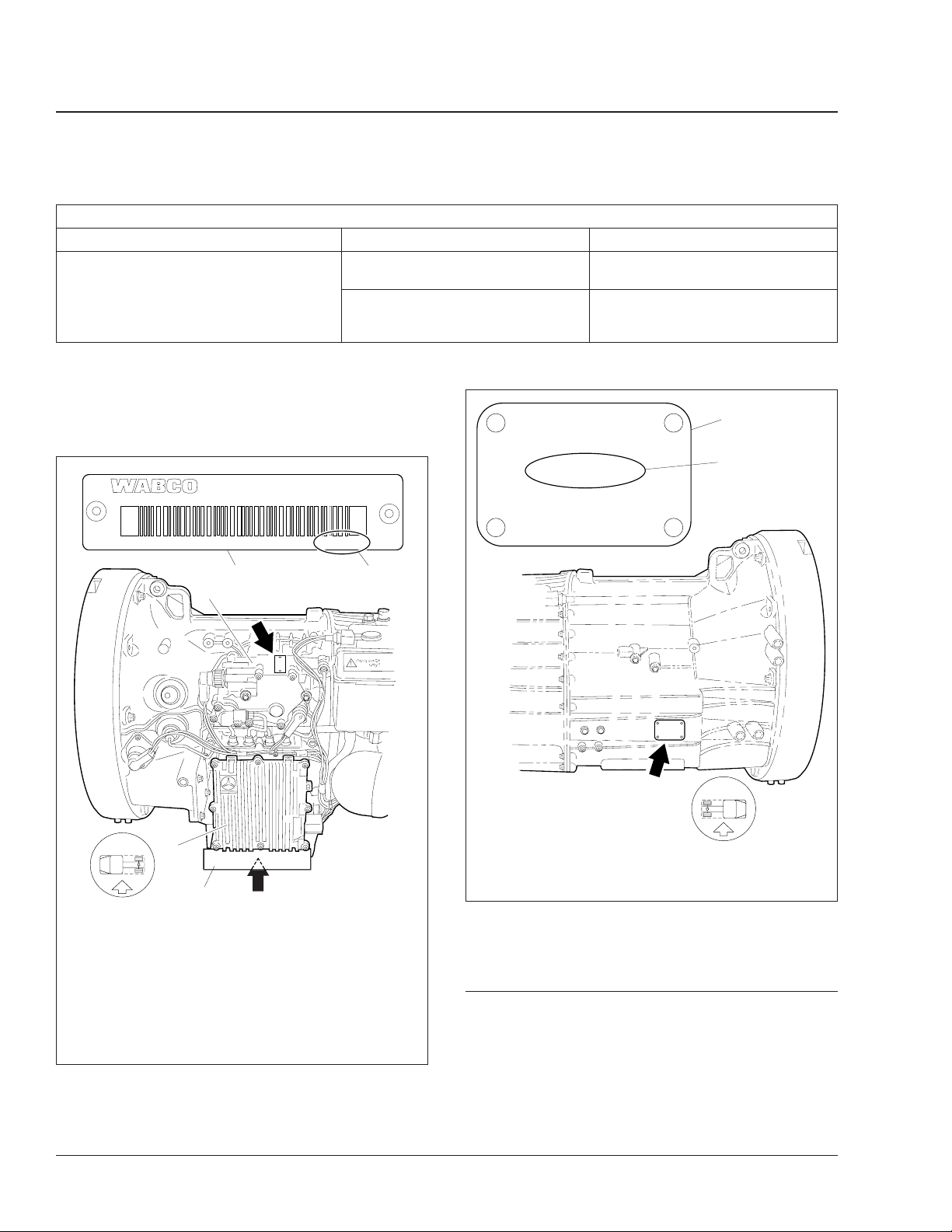

NOTE: To see the identification plate on the

TCU it may be necessary to remove the splash

guard.

20 0 3 0 0 4

0 0 6 00 0 14 7 7

Resistance is less than 55 or greater

than 65 ohms.

Resistance is between 55 and 65

ohms.

Table 1, Electrical Pre-Test

0005255 90 32 6 09 7 0A

Troubleshoot the J1939 datalink. See

Freightliner Service Bulletin 54-133.

The vehicle has passed the electrical

pre-test. Troubleshoot active fault

codes, if any.

DaimlerChrysler

Bez: G 60−6

IdNr 715053 123456

Code C07−00036−031

M−C

Var. 041962

Transmissions

1

2

3

5

1

2

10/05/2006

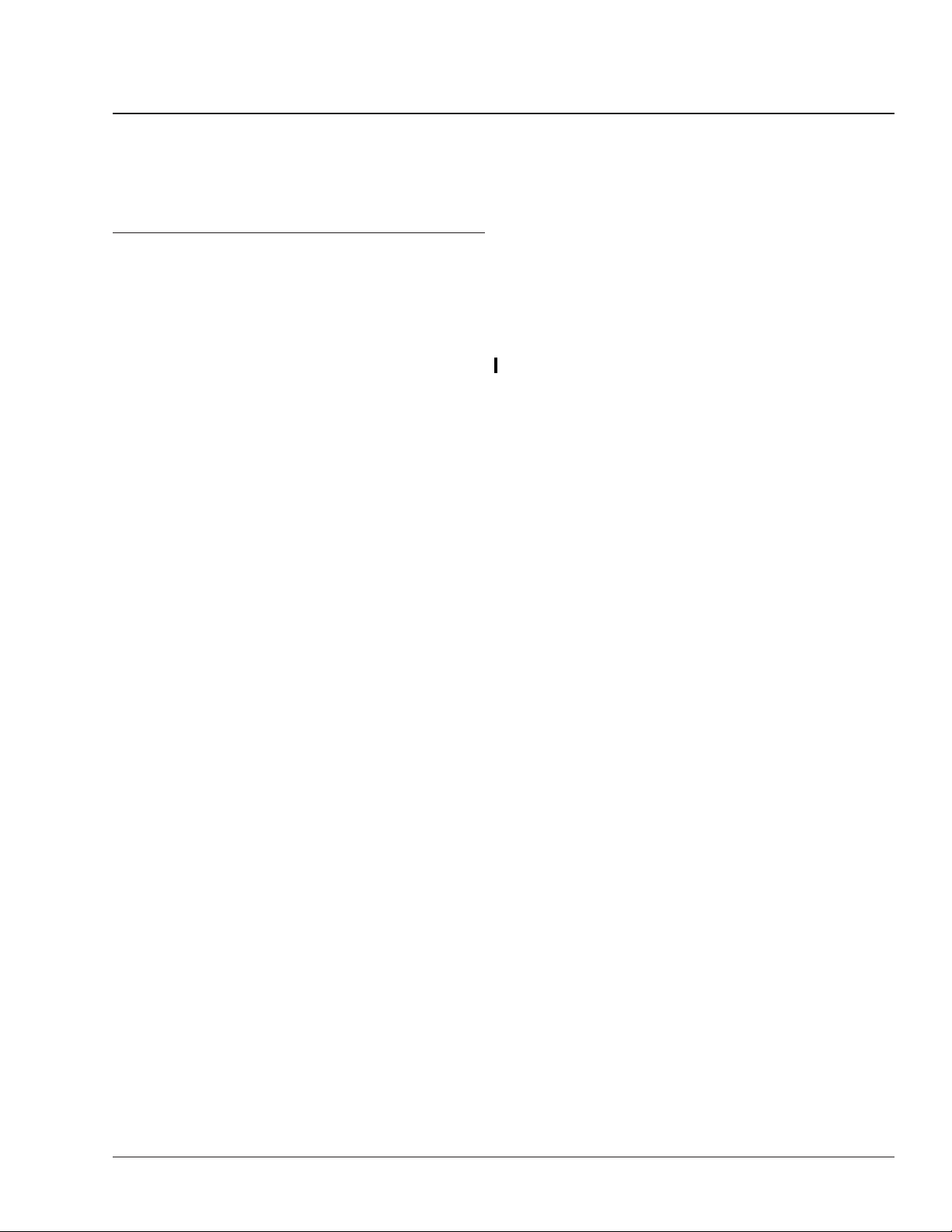

NOTE: The TCU and X-Y Actuator each have their own

WABCO identification plate (arrows) with unique serial

numbers.

1. TCU (Transmission

Control Unit)

2. Splash Guard

3. WABCO

Identification Plate

Fig. 1, Serial Numbers for TCU and X-Y Actuator

4. Serial Number

5. X-Y Actuator

4

f261384

DaimlerChrysler

Bez: G 60−6

IdNr 715053 123456

Code C07−00036−031

M−C

Var. 041962

10/05/2006

1. Transmission

Identification Plate

Fig. 2, Transmission Serial Number

2. Serial Number

f261383

Troubleshooting Tables, No

Fault Codes

In a few cases there will be a definite problem and

no J1587 fault code will be sent.

• If the engine will not crank and there are no

transmission fault codes, see Table 2.

Business Class M2 Workshop Manual, Supplement 20, September 2011301/4

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

Transmission Range Faults (PID 162 and 163)

Transmission Range Faults

Transmission Range-Selected

Faults (PID 162)

There is one transmission range-selected fault covered in these procedures.

• For PID 162, FMI 02, see Table 1 for proce-

dures.

PID 162, FMI 02—The Transmission Is Not Properly Calibrated

Failure Reason:

• The gears are caught in an intermediate position.

• The transmission software does not allow shifting.

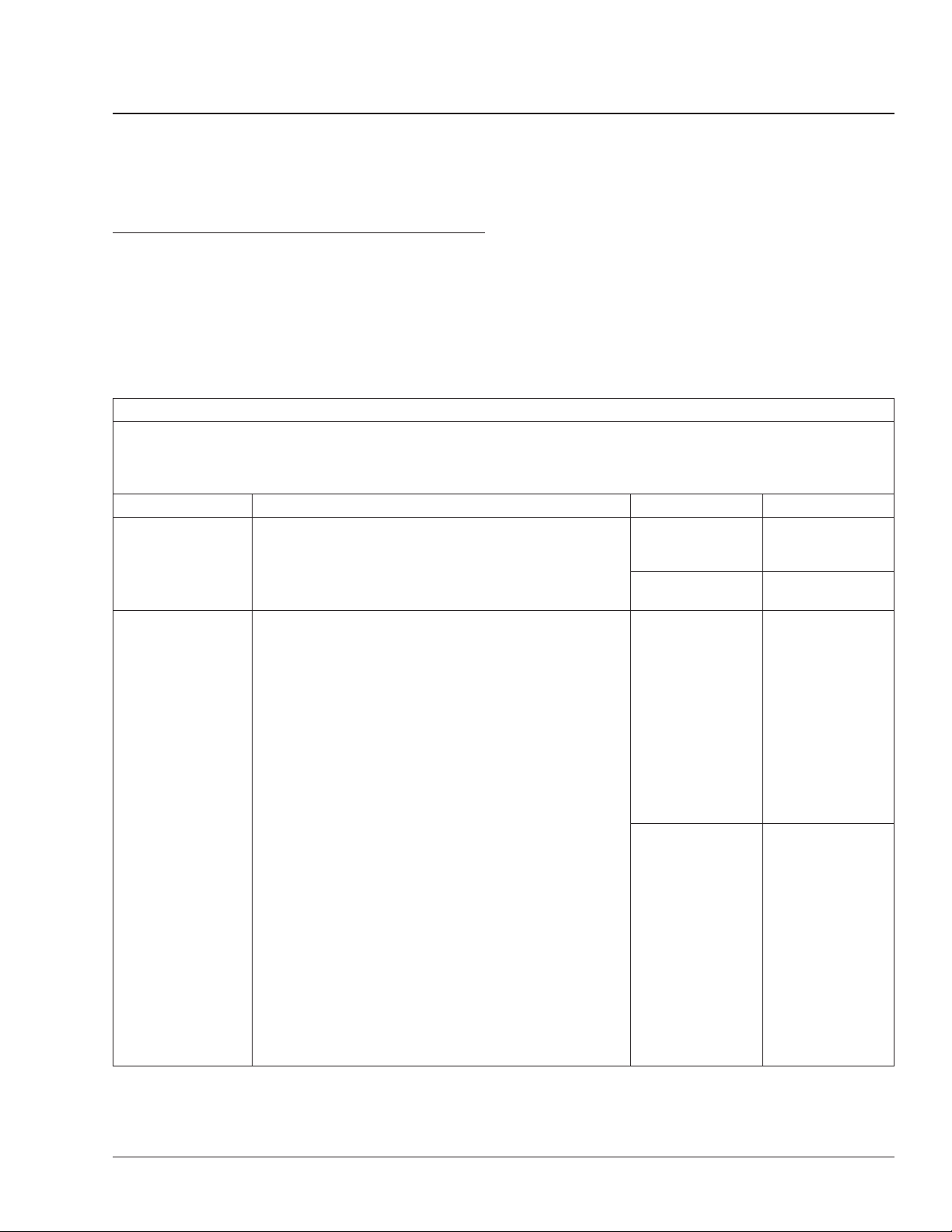

Problem Procedure Result Action

There are other

active transmission

faults.

The transmission

needs to be

recalibrated.

Check for other MID 130 fault codes. Other fault codes

Complete a learning procedure using either ServiceLink or

the SmartShift control.

To complete a learning procedure using the SmartShift

control:

1. Ensure that the parking brake is set.

2. With the ignition turned off, pull and hold the SmartShift

control toward steering wheel.

NOTE: The SmartShift control must be kept in this position

until the gear display clears at the end of the procedure.

3. Turn on the ignition. The normal warm up procedure will

initiate and an ’X’ will display on the current gear indicator.

Your transmission may be heard shifting.

4. Wait until the current gear indicator displays an ’N’

(about 30 seconds) and an audible alert sounds. Start the

engine within 10 seconds of the audible alert.

5. The engine will raise a few rpm, then fall back to idle,

and an audible alert will sound. Turn off the engine within

10 seconds of audible alert. When the gear display clears,

this procedure is complete.

NOTE: If during this procedure an ’SM’ or ’X’ (after the

warm up procedure) appears in the gear display, stop, turn

off the ignition, and wait for the gear display to go dark.

Then start over. This may need to be repeated several

times.

Table 1, The Transmission Is Not Properly Calibrated

Transmission Range-Attained

Faults (PID 163)

There is one transmission range-attained fault covered in these procedures.

• For PID 163, FMI 02, see Table 2 for proce-

dures.

are active.

No other fault

codes are active.

The fault is no

longer active.

The fault is still

active.

26.03

Troubleshoot the

other active fault

codes.

Go to the next step

in the table.

No further action is

needed.

Contact

Freightliner

Technical Service

Support.

Business Class M2 Workshop Manual, Supplement 20, September 2011 316/1

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Transmission Range Faults (PID 162 and 163)

PID 163, FMI 02—The Gears Do Not Shift Properly

Failure Reason:

• There is a defect in the TCU.

• There is a defect in the speed sensor.

• There is a defect in the actuator.

• The transmission software is not properly programmed.

• The datalink does not recognize the transmission type.

Problem Procedure Result Action

There are other

active transmission

faults.

There is a

transmission

software problem.

There is component

damage in the

transmission.

Check for other MID 130 fault codes. Other fault codes are

Using the ServiceLink diagnostics template,

view the different gear positions, check that

the clutch opens and closes, and that the

x-y actuator moves from reverse, 1st, and

2nd gears.

Do a visual inspection of the x-y actuator,

the hydraulic system, and the transmission

shift system.

Table 2, The Gears Do Not Shift Properly

active.

No other fault codes are

active.

The x-y actuator

responds properly and

the fault clears.

The fault is still active. Go to the next step in the

Damaged components

are found.

No damaged

components are found.

Troubleshoot the other

active fault codes.

Go to the next step in the

table.

No further action is needed.

table.

Contact Mercedes-Benz

Transmissions Service

Support with the AGS

codes and results of the

electrical pre-test.

NOTE: One hour of

troubleshooting time is

alloted for printing the AGS

codes and completing the

electrical pre-test.

1. Using ServiceLink, print

the AGS codes (130).

2. Complete the electrical

pre-test result sheet in

Subject 301.

3. With the results, contact

Mercedes-Benz

Transmissions Service

Support by fax

(503.961.8435), email

(MBTServiceSupport@

Freightliner.com), or phone

(503.745.4965 or

503.745.4988).

Transmissions

Business Class M2 Workshop Manual, Supplement 20, September 2011316/2

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

26.03

Output Shaft Speed Sensor Faults (PID 191)

Output Shaft Speed Sensor

Faults (PID 191)

There are four output shaft speed sensor faults covered in these procedures. One troubleshooting procedure is used to correct FMI 02, 05, and 08. A

separate procedure is used for FMI 14.

PID 191, FMI 02, 05, 08—The Output Shaft Speed Sensor Circuit Gives Invalid Data, Is Open, or Not Broadcasting

Failure Reason:

• The TCU has a hardware prob-

lem.

• The sensor is mounted too loose

(air gap too big).

• The sensor connectors are dam-

aged or bent.

• The wiring harness has had an

electrical failure.

• Either one of the sensors or the

TCU has failed.

Procedure Results Action

Turn on the ignition switch and wait for

the current gear display to power up.

Remove both output shaft speed

sensors. Reinstall and tighten the sensor

28 lbf·ft (38 N·m).

Turn off the ignition switch and wait for

the current gear display to power down.

Remove both sensor connectors and

visually inspect the pins.

Check the upper sensor for continuity:

(1) X2 connector pin 1 to sensor pin 2;

(2) X2 connector pin 15 to sensor pin 1;

(3) X2 connector pin 14 to sensor pin 4.

Check the lower sensor for continuity:

(1) X2 connector pin 1 to sensor pin 2;

(2) X2 connector pin 15 to sensor pin 1;

(3) X2 connector pin 9 to sensor pin 3.

Check all four pins of each sensor

connector for voltage and for continuity

to ground.

Fault code SID 254, FMI 12 is active. Go to Subject 309 and troubleshoot

SID 254, FMI 12 is not active. Go to the next row in the table.

The fault clears after a test drive. No further action needed.

The fault remains active. Go to the next row in the table.

The connector pins are damaged or

bent.

There is no damage to either

connector.

There is an open circuit. Replace the transmission wiring

The wiring is OK. Go to the next row in the table.

There is an open circuit. Replace the transmission wiring

The wiring is OK. Go to the next row in the table.

Voltage or continuity is found. Replace the transmission wiring

There is zero voltage and no continuity. Go to the next row in the table.

a Signal

07/16/2004 f544484k

• For PID 191, FMI 02, 05, and 08 see Table 1

for procedures and pin identification.

• For PID 191, FMI 14, see Table 2 for proce-

dures.

1

4

2

5

3

6

X2

SID 254, FMI 12.

Repair or replace the damage.

Go to the next row in the table.

harness (see Subject 180).

harness (see Subject 180).

harness (see Subject 180).

13

7

10

14

11

8

15

9

12

Business Class M2 Workshop Manual, Supplement 20, September 2011 317/1

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Transmissions

Output Shaft Speed Sensor Faults (PID 191)

PID 191, FMI 02, 05, 08—The Output Shaft Speed Sensor Circuit Gives Invalid Data, Is Open, or Not Broadcasting

Failure Reason:

• The TCU has a hardware prob-

lem.

• The sensor is mounted too loose

(air gap too big).

• The sensor connectors are dam-

aged or bent.

• The wiring harness has had an

electrical failure.

• Either one of the sensors or the

TCU has failed.

Procedure Results Action

Using a sensor known to be good,

replace each sensor in turn (see

Subject 120 for procedures).

Table 1, The Output Shaft Speed Sensor Circuit Gives Invalid Data, Is Open, or Not Broadcasting a Signal

The fault becomes inactive. No further action needed.

The fault is still active. Contact Mercedes-Benz Transmissions

a Signal

1

4

2

5

3

6

07/16/2004 f544484k

X2

Service Support with the AGS codes

and results of the electrical pre-test.

NOTE: One hour of troubleshooting

time is alloted for printing the AGS

codes and completing the electrical

pre-test.

1. Using ServiceLink, print the AGS

codes (130).

2. Complete the electrical pre-test

result sheet in Subject 301.

3. With the results, contact MercedesBenz Transmissions Service Support

by fax (503.961.8435), email

(MBTServiceSupport@

Freightliner.com), or phone

(503.745.4965 or 503.745.4988).

13

7

10

14

11

8

15

9

12

PID 191, FMI 14—The Output Shaft Speed Sensor Is Providing Invalid Data

Failure Reason

• The antilock brake system (ABS) is not broadcasting wheel speed data.

• There is a defective output shaft speed sensor.

Procedure Result Action

Check for other PID 191 fault codes. Other PID 191 fault codes

are active.

No other PID 191 fault

codes are active.

Business Class M2 Workshop Manual, Supplement 20, September 2011317/2

Troubleshoot PID 191. See

Table 1.

Go to the next step in the

table.

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

Output Shaft Speed Sensor Faults (PID 191)

PID 191, FMI 14—The Output Shaft Speed Sensor Is Providing Invalid Data

Failure Reason

• The antilock brake system (ABS) is not broadcasting wheel speed data.

• There is a defective output shaft speed sensor.

Procedure Result Action

Check for active fault codes in MID 136 (ABS). Active MID 136 fault codes

are found.

Table 2, The Output Shaft Speed Sensor Is Providing Invalid Data

26.03

Troubleshoot the ABS system

(see the applicable section in

Group 42).

Business Class M2 Workshop Manual, Supplement 20, September 2011 317/3

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

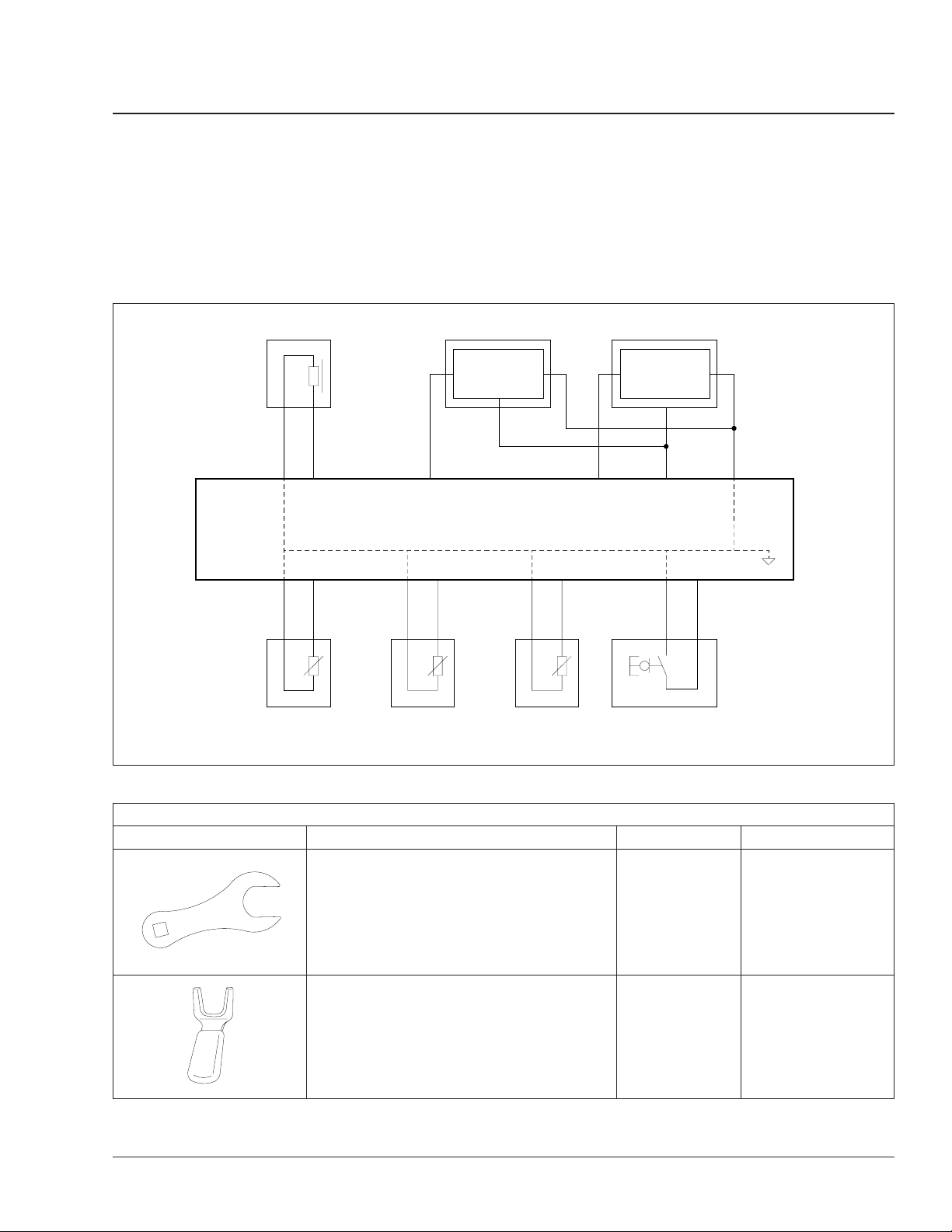

For a schematic of the AGS transmission wiring behind the X2 (transmission) connector, see Fig. 1. For

a schematic of the AGS transmission wiring behind

the X1 (main vehicle) and X3 (electric motor) connectors, see drawing G06-49466.

Input Shaft Speed

Sensor

2

13

11 9 14

11

Output Shaft Speed Sensor

3

SS

X2 Connector

For a list of special tools, see Table 1.

(9:00 position)

22

GND GND

+12V +12V

Output Shaft Speed Sensor

(11:00 position)

1

15

26.03

Specifications

1

02/01/2005

3

111 1

Gear Position Sensor

(Front)

2

Rail Position Sensor

(Rear)

67

10 12

222

Clutch Position Sensor Fluid Level Sensor

45

2

(Pentosin)

Circuit is closed when full

f544529

Fig. 1, AGS Transmission Wiring, X2 Connector

Special Tools for AGS Transmission

Tool Description Manufacturer Part Number

Accumulator Torque Adaptor Kent-Moore J-47291

f580381

Low-Pressure Hose Disconnect Tool Kent-Moore J-47202

f580379a

Business Class M2 Workshop Manual, Supplement 20, September 2011 400/1

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Specifications

Tool Description Manufacturer Part Number

Transmissions

Special Tools for AGS Transmission

High-Pressure Line Disconnect Tool Kent-Moore J-47201

f580379

Shift Finger Alignment Fork Kent-Moore J-47204

f580380

Shift Mechanism End Guide Kent-Moore J-47203

f580382

Table 1, Special Tools for AGS Transmission

For transmission installation torque values, see

Table 2.

Transmission Installation Torque Values

Description Size Class Torque: lbf·ft (N·m)

Midship Bearing Bracket Capscrews 3/4–11 — 91 (123)

Power Takeoff Unit (PTO) Mounting Capscrews M10 10.9 43 (58)

Transmission Fluid Drain Plug M24 — 42 (57)

Transmission Fluid Fill Plug M24 — 42 (57)

Transmission Mounting Bolts M10 x 1.5 8.8 33 (45)

U-Joint End Cap Bolts

Table 2, Transmission Installation Torque Values

For AGS assembly torque values, see Table 3.

AGS Assembly Torque Values

Description Size Torque: lbf·ft (N·m) Torque: lbf·in (N·cm)

Accumulator Hydraulic Fitting M30 59 (80) —

X-Y Actuator Mounting Capscrews M8 17 (23) —

3/8–24 — 50 (68)

1/2–20 — 110 (149)

Business Class M2 Workshop Manual, Supplement 20, September 2011400/2

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

26.03

Specifications

AGS Assembly Torque Values

Description Size Torque: lbf·ft (N·m) Torque: lbf·in (N·cm)

AGS Central Unit Mounting Capscrews M8 17 (23) —

Clutch Actuator Hydraulic Fittings M30 37 (50) —

Clutch Actuator Mounting Capscrews M8 17 (23) —

Pressure-Limiting Valve Adjusting Screw M6 — 63–71 (700–800)

Reservoir Base Fasteners M8 11 (15) —

Reservoir Top Fasteners M6 — 71 (800)

Rotational Speed (RPM) Sensors — 28 (38) —

Shift Rod Setscrew M12 22 (30) —

Transmission Control Unit (TCU) Mounting Screws M8 — 44–53 (500–600)

TCU Splash Guard Mounting Capscrews M8 17 (23) —

Table 3, AGS Assembly Torque Values

For AGS transmission gear ratios, see Table 4.

AGS Transmission Gear Ratios

Model Gear Ratio

MBT520-6DA

MBT660-6OA

Table 4, AGS Transmission Gear Ratios

For a list of proprietary fault codes viewable on ServiceLink, see Table 5.

1 9.201

2 5.230

3 3.145

4 2.034

5 1.374

6 1.000

R 8.649

1 6.700

2 3.810

3 2.290

4 1.480

5 1.000

6 0.730

R 6.290

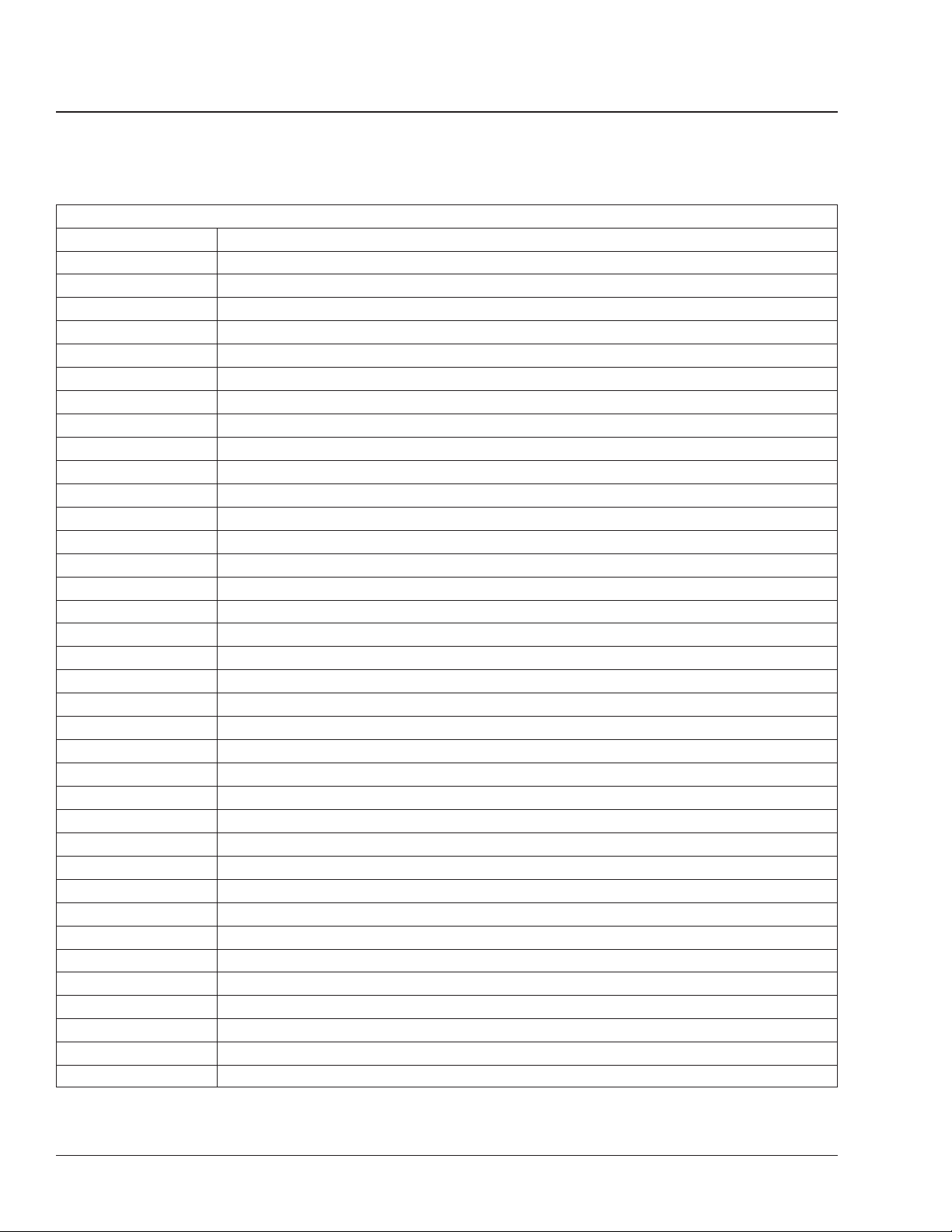

AGS Proprietary Fault Codes (J1708)

Fault Code Description

3000109 High voltage supply voltage—external (connector X1/12 and X1/15)

Business Class M2 Workshop Manual, Supplement 20, September 2011 400/3

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Specifications

AGS Proprietary Fault Codes (J1708)

Fault Code Description

3000113 High voltage ignition key line—external (connector X1/9)

3000209 Low voltage supply voltage—external (connector X1/12 and X1/15)

3000213 Low voltage ignition key line—external (connector X1/9)

3001210 EEPROM parameter values error—internal

3001510 Clutch displacement control module parameter error—internal

3001781 Clutch calibration offset off limit—internal

3002009 Open load supply voltage—external (connector X1/12 and X1/15)

3002016 Open load/Short circuit VCC temperature sensor circuit board—internal

3002017 Open load/Short circuit VCC temperature sensor pump—internal

3002116 Short circuit GND temperature sensor circuit board—internal

3002117 Short circuit GND temperature sensor pump—internal

3002214 Short circuit VCC peripherals supply—external (connector X2/15)

3003001 EBC1 message timeout—external (J1939)

3003101 EEC1 message timeout—external (J1939)

3003201 EEC2 message timeout—external (J1939)

3003301 EEC3 message timeout—external (J1939)

3003401 ERC1 message timeout—external (J1939)

3003501 Wheel speed information message timeout—external (J1939)

3003601 CruiseControl (VCU) message timeout—external (J1939)

3003701 CruiseControl (bulkhead) message timeout—external (J1939)

3003801 Engine configuration message timeout—external (J1939)

3003901 Retarder configuration message timeout—external (J1939)

3004001 Component identification message timeout—external (J1939)

3004101 PTO information message timeout—external (J1939)

3006101 Incorrect engine data—external (J1939)

3006201 Timeout converted engine data for clutch module (low priority)—internal

3006701 Incorrect retarder data—external (J1939)

3006801 Incorrect ABS data—external (J1939)

3006901 Incorrect internal data—internal

3007001 Incorrect clutch module data—internal

3007101 Incorrect automated gear shift module data—internal

3007201 Incorrect internal data—internal

3008881 Clutch overload—internal

3009280 Plausibility error actual transmission gear ratio—internal

3009710 Test software—internal

3009810 Test electronic—internal

Transmissions

Business Class M2 Workshop Manual, Supplement 20, September 2011400/4

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

AGS Proprietary Fault Codes (J1708)

Fault Code Description

3009910 Test bench mode activated—internal

3010390 Automatic module: signal group cruise control / retarder—internal

3010690 Automatic module: signal output speed—internal

3010790 Automatic module: signal group MR—internal

3010890 Automatic module: signal group gear ratio—internal

3010990 Automatic module: learning values engine—internal

3011081 Plausibility error intended clutch position can not be reached within specified time—internal

3011090 Automatic module: learning values transmission—internal

3011310 Clutch calibration data missing/error—internal

3011410 Clutch parameter error—internal

3011590 Automatic module: signal group shifting time—internal

3011690 Automatic module: signal group ABS—internal

3011790 Automatic module: signal group pedal activation—internal

3011890 Automatic module: signal group lever—internal

3011990 Automatic module: error target system—internal

3012014 Open load peripherals supply—external (connector X2/15)

3012019 Plausibility error valve relay V-V2 on—internal

3012035 Open load power stage solenoid valve (clutch open 1)—internal

3012036 Open load power stage solenoid valve (clutch open 2)—internal

3012037 Open load power stage solenoid valve (clutch close 1)—internal

3012038 Open load power stage solenoid valve (clutch close 2)—internal

3012050 Open load speed sensor transmission output (DZ1)—external (connector X2/14)

3012051 Open load speed sensor transmission input—external (connector X2/11)

3012052 Open load speed sensor transmission output (D3)—external (connector X2/9)

3012090 Automatic module: system identification gearshift module—internal

3012114 Short circuit to GND peripherals supply—external (connector X2/15)

3012118 Plausibility error valve relay V-V1 off—internal

3012119 Plausibility error valve relay V-V2 off—internal

3012136 Short circuit GND power stage solenoid valve (clutch open 2)—internal

3012138 Short circuit GND power stage solenoid valve (clutch close 2)—internal

3012151 Short circuit GND speed sensor transmission input—external (connector X2/11

3012251 Short circuit VCC speed sensor transmission input—external (connector X2/11)

3012461 Hydraulic level too low external—external

3016201 Timeout converted engine data for clutch module (medium priority)—internal

3016401 Timeout driving direction information—internal

3016501 Timeout internal communication shift module to clutch module (medium priority)—internal

26.03

Specifications

Business Class M2 Workshop Manual, Supplement 20, September 2011 400/5

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Specifications

AGS Proprietary Fault Codes (J1708)

Fault Code Description

3018681 Plausibility error clutch open request while inlet valves are closed—internal

3018781 Plausibility error clutch open request while outlet valves are closed—internal

3019480 Plausibility error driving direction—internal

3019621 SmartShift lever data invalid—external (connector X1/8, X1/11, X1/14)

3019650 Tooth signal interruption speed sensor transmission output (DZ1)—external (connector X2/14)

3019651 Tooth signal interruption speed sensor transmission input—external (connector X2/11)

3019652 Tooth signal interruption speed sensor transmission output (D3)—external (connector X2/9)

3020110 High voltage distance sensor supply—internal

3020111 Power supply high voltage—external (connector X3/1)

3020210 Low voltage distance sensor supply—internal

3020211 Power supply low voltage—external (connector X3/1)

3021010 Flash checksum error—internal

3021110 EEPROM calibration values error—internal

3021610 Clutch displacement offset failure—internal

3022011 Supply voltage open load—external (connector X3/1)

3022012 Open load GND connection—external (connector X1/18 and X1/21)

3022015 Open load pressure sensor signal—internal

3022018 Plausibility error valve relay V-V1 on—internal

3022020 Open load GND pump motor—external (connector X3/2)

3022030 Open load power stage solenoid valve (selection direction R)—internal

3022031 Open load power stage solenoid valve (selection direction 5/6)—internal

3022032 Open load power stage solenoid valve—internal

3022033 Open load power stage solenoid valve (gear direction 1,3,5)—internal

3022034 Open load power stage solenoid valve (pressure regulation)—internal

3022041 Open load distance sensor (gear)—internal

3022042 Open load distance sensor (selection)—internal

3022044 Open load distance sensor (clutch)—internal

3022060 Open loop power stage pump motor—internal

3022115 Short circuit GND pressure sensor signal—internal

3022130 Short circuit GND power stage solenoid valve (selection direction R)—internal

3022131 Short circuit GND power stage solenoid valve (selection direction 5/6)—internal

3022132 Short circuit GND power stage solenoid valve (gear direction R,2,4,6)—internal

3022133 Short circuit GND power stage solenoid valve (gear direction 1,3,5)—internal

3022134 Short circuit GND power stage solenoid valve (pressure regulation)—internal

3022135 Short circuit GND power stage solenoid valve (clutch open 1)—internal

3022137 Short circuit GND power stage solenoid valve (clutch close 1)—internal

Transmissions

Business Class M2 Workshop Manual, Supplement 20, September 2011400/6

Freightliner AMT3and Mercedes-Benz Automated-Manual

Transmissions

AGS Proprietary Fault Codes (J1708)

Fault Code Description

3022141 Short circuit GND distance sensor (gear)—internal

3022142 Short circuit GND distance sensor (selection)—internal

3022144 Short circuit GND distance sensor (clutch)—internal

3022160 Short circuit GND power stage pump motor—internal

3022215 Short circuit VCC pressure sensor signal—internal

3022241 Short circuit VCC distance sensor (gear)—internal

3022242 Short circuit VCC distance sensor (selection)—internal

3022244 Short circuit VCC distance sensor (clutch)—internal

3022317 Over temperature power stage pump motor—internal

3022590 Automatic module: no signal vehicle speed—internal

3022690 Automatic module: signal group MR (high priority)—internal

3022790 Automatic module: signal group gear ratio (high priority)—internal

3022890 Automatic module: learning values engine (high priority)—internal

3022990 Automatic module: learning values transmission (high priority)—internal

3024341 Erratic distance sensor (gear)—internal

3024342 Erratic distance sensor (selection)—internal

3024344 Erratic distance sensor (clutch)—internal

3024441 Wrong coil resistance value distance sensor (gear)—internal

3024442 Incorrect coil resistance value distance sensor (selection)—internal

3024444 Incorrect coil resistance value distance sensor (clutch)—internal

3024610 Timeout displacement sensor value—internal

3026001 CAN bus off—external (connector X1/13 and X1/7)

3026301 Timeout converted engine data for clutch module (high priority)—internal

3026501 Timeout internal communication shift module to clutch module (high priority)—internal

3027401 No J1939 communication—internal / external (connector X1/13 and X1/7)

3027501 Timeout internal communication shift module to clutch module (high priority)—internal

3028581 Clutch displacement control failure—internal

3029180 No calculation of redundant transmission output speed—internal

3029380 Incorrect transmission type—internal

3029580 Plausibility error pressure build up—internal

Table 5, AGS Proprietary Fault Codes (J1708)

26.03

Specifications

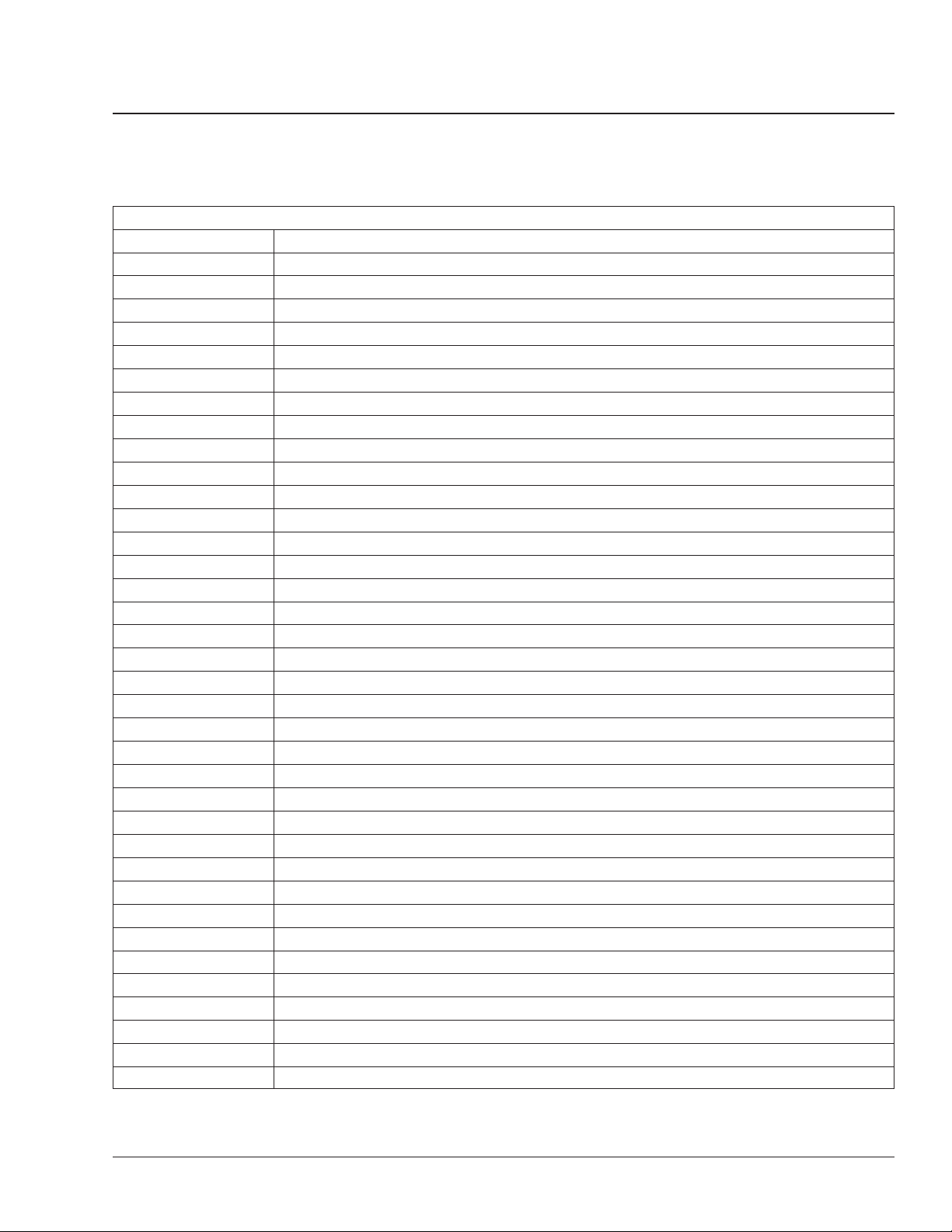

For a list of learning procedure errors, see Table 6.

Learning Procedure Errors

Error Description

56 Offset of clutch position out of range

Business Class M2 Workshop Manual, Supplement 20, September 2011 400/7

Freightliner AMT3and Mercedes-Benz Automated-Manual

26.03

Specifications

Error Description

57 Offset of pressure modulation valve out of range

58 Gear position "neutral" out of range

61 Low gear position out of range

62 High gear position out of range

63 Low select position out of range

66 High select position out of range

68 Valve or sensor failure

69 Vehicle is moving

70 Low voltage or high voltage

71 Clutch open/closed

72 Stalk lever position changed during learning procedure

73 Type of gear box invalid

74 Park brake not activated

76 Engine is running

77 Engine torque invalid or out of range

78 Engine was not started in time

80 Accelerator pedal not idle

82 Countershaft speed not zero

Transmissions

Learning Procedure Errors

Table 6, Learning Procedure Errors

Business Class M2 Workshop Manual, Supplement 20, September 2011400/8

Mercedes-Benz Manual Transmission

26.04

General Information

General Information

The Mercedes-Benz transmission (MBT) is offered in

two 6-speed models:

• MBT520S-6D, direct drive, 520 lb·ft torque rating

• MBT660S-6O, overdrive, 660 lb·ft torque rating

The gear case holds 9.5 quarts (9.0 liters) of oil. MobilTrans SHC

Both models are fully synchronized for reduced shifting effort. Equipped with six forward speeds and one

reverse speed, both models show a particularly large

overall ratio between low and top gear. See Specifi-

cations, 400 for gear ratios for each model.

To reduce fluid change intervals and to increase

bearing life, MBT transmissions are designed with

"clean" bearings. These bearings have covers on

both sides. They cannot be damaged by the wear

particles that accumulate in the fluid. The geometry

of the gear teeth has been optimized to provide lownoise operation and extended gear life.

The bell housing has been designed around standard

SAE bolt patterns. SAE2 is standard on both

MBT660S-6O and MBT520S-6D models.

Other features of the MBT transmissions include:

• Light metal gear cases with integrated bell

housings;

• Low installation height (the shift interface is

positioned laterally);

• Double synchronization from 1st gear to 4th

gear;

• Electronic vehicle speed sensor;

• Longer oil change intervals;

• Full range of PTO units available.

Each model requires a hydraulic clutch system. No

clutches with manual control can be installed for use

on MBT transmissions. With the hydraulic system

installed, the clutch linkage is self-adjusting.

The hydraulic clutch system consists of the following

parts:

• Hydraulic fluid reservoir;

• Clutch pedal unit;

• Master cylinder;

®

DC is the approved oil.

• Slave cylinder;

• Hydraulic lines connecting the various parts of

the system.

The MBT transmission removal and installation procedures have been moved to Subject 100 from their

previous location in Section 26.00.

The teardown procedures included in this section

also apply to the AGS automated transmission, with

slight changes which are indicated at appropriate

places in the procedures. If it is necessary to tear

down the AGS transmission, be sure to remove the

AGS assembly before proceeding. See Sec-

tion 26.03, Subject 200 for procedures.

On all transmissions, disassembly of the transmission main shaft is not recommended except when it

is necessary to check for synchronizer wear. Disassembly of the countershaft is not recommended in

any case.

It is important to check main shaft end play if either

gear case half, the main shaft bearings, or the input

shaft is replaced. For detailed procedures, see Sub-

ject 250.

To prevent premature tool wear, use extreme pressure lubricant such as Kent-Moore J 23444-A or

equivalent on tool threads and at all friction and contact points.

Business Class M2 Workshop Manual, Supplement 10, September 2006 050/1

Mercedes-Benz Manual Transmission

Transmission Removal and Installation

Removal

1. Park the vehicle on a level surface. Shut down

the engine, set the parking brake, and chock the

rear tires.

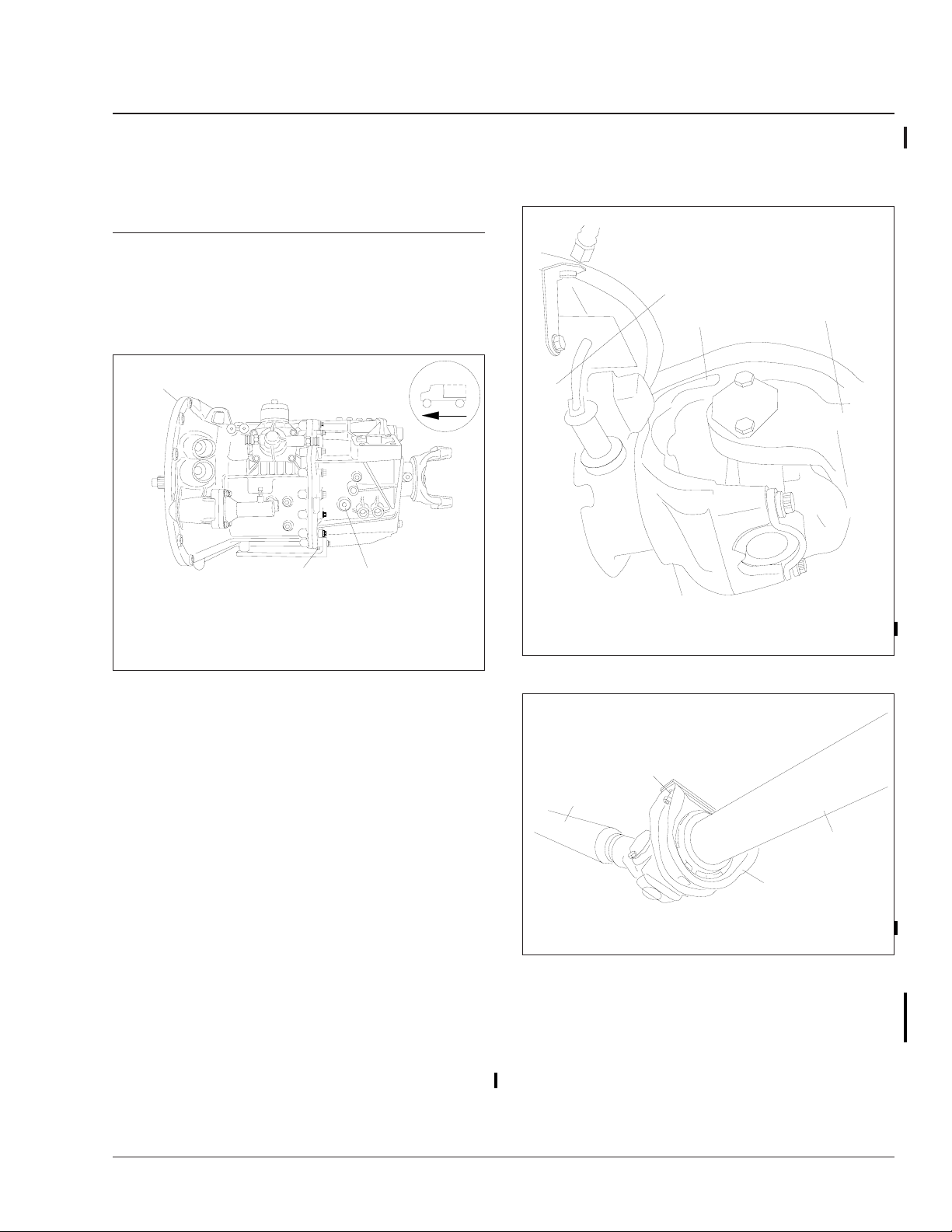

2. Drain the transmission fluid. See Fig. 1 for the

location of the drain plug.

1

26.04

1

2

3

05/22/2001

NOTE: The transmission is shown from the left-hand

side.

1. Transmission

2. Fill Plug

Fig. 1, Transmission Drain and Fill Plugs

3

3. Drain Plug

2

f261102

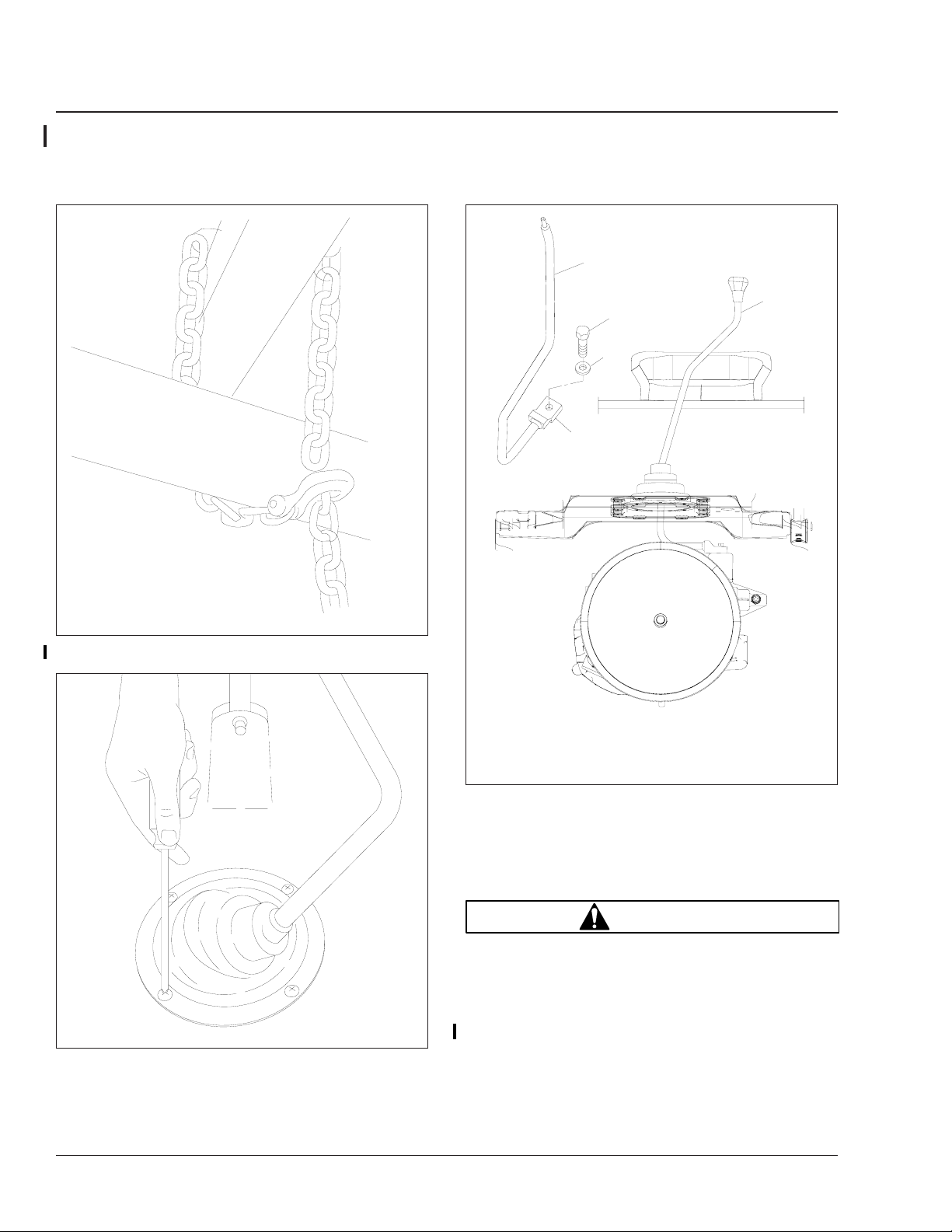

3. Disconnect the driveshaft from the transmission.

3.1 Support the midship bearing.

3.2 Remove the bolts from the U-joint end

caps and slide the front of the driveshaft

out of the transmission output yoke. See

Fig. 2.

3.3 Remove the midship bearing bracket. See

Fig. 3.

3.4 Support the disconnected driveshaft and

chain it out of the way. See Fig. 4.

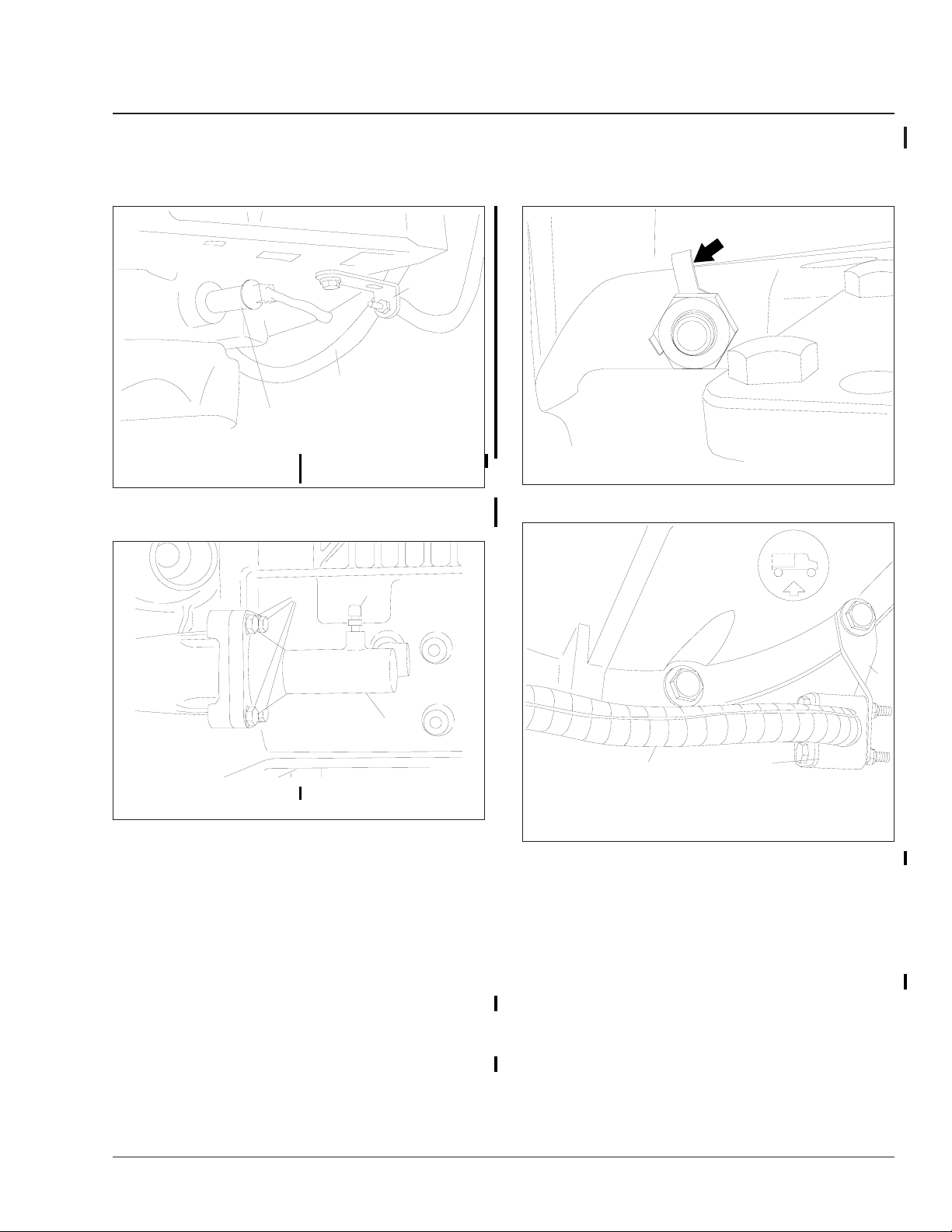

4. Remove the shift lever from the transmission.

4.1 Before removing the shift lever, place the

transmission in high gear.

4.2 Remove the four screws from the retaining

ring around the shift lever boot. See

Fig. 5. Remove the ring and the boot.

4.3 Remove the head of the shift lever from

the transmission. See Fig. 6. For ease of

06/05/2001

1. Transmission

2. Output Yoke

3

01/28/99

1. Midship Bracket

2. Mounting Bolt

Fig. 3, Midship Bearing Bracket

3. Driveshaft

Fig. 2, Output Yoke

2

1

3. Driveshaft

f261005

3

f261006

installation, mark the head of the shift lever and the attachment point on the transmission with a paint pen.

5. Remove the fuel lines and the fuel line standoff

bracket from the transmission. See Fig. 7.

Business Class M2 Workshop Manual, Supplement 8, September 2005 100/1

26.04

Mercedes-Benz Manual Transmission

Transmission Removal and Installation

1

1

2

3

4

01/28/99

07/14/94

Fig. 4, Supporting the Driveshaft

Fig. 5, Shift Lever and Boot

f261007

f260074a

06/06/2001

1. Shift Lever

2. Shift Lever Mounting Bolt

3. Thick Washer

4. Head of Shift Lever

Fig. 6, Shift Lever Connection

6. Disconnect the electrical connectors for the reverse gear switch and the optional starter lock

switch (if installed). Mark with a paint pen for

ease of installation.

f261108

WARNING

Do not press down on the clutch pedal after removing the slave cylinder. Hydraulic brake fluid

may squirt out, causing personal injury and damage to the vehicle.

7. Remove the bolts that attach the clutch slave

cylinder to the mounting flange on the gear case.

Move the slave cylinder out of the way. See

Fig. 8.

Business Class M2 Workshop Manual, Supplement 8, September 2005100/2

Mercedes-Benz Manual Transmission

Transmission Removal and Installation

3

2

1

06/05/2001

1. Speedometer Sensor

2. Fuel Line

Fig. 7, Fuel Line Standoff Bracket and Speedometer

3. Standoff Bracket

Sensor

f261009

26.04

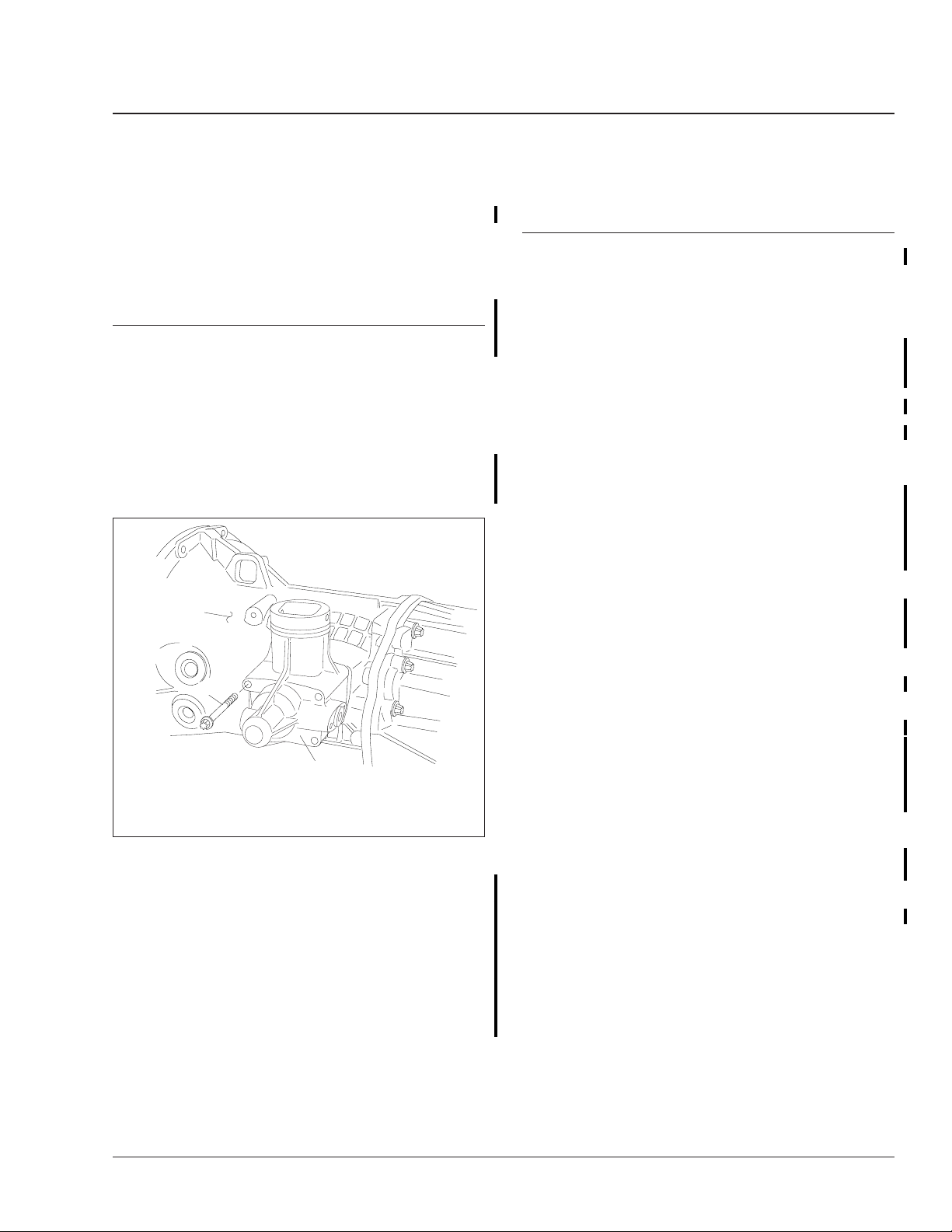

05/14/2001

Bend back the nut retainer (arrow).

Fig. 9, Power Take-Off Unit (PTO) Nut Retainers

f261105

2

3

f261107

05/24/2001

1. M8 Bolts

2. Bleed Valve

Fig. 8, Hydraulic Clutch Slave Cylinder

1

3. Slave Cylinder

8. Bend back the nut retainers and remove the

power take-off unit (PTO), if installed. See Fig. 9.

9. If the vehicle is equipped with optional dual fuel

tanks, remove the fuel cross-over line and its

support between the tanks.

10. Disconnect the electrical cable from the speedometer sensor and mark it with a paint pen for

ease of installation. See Fig. 7.

11. Remove the battery cable bracket(s) around the

transmission and move the battery cables out of

the way. See Fig. 10.

3

05/14/2001

1. Battery Cable

2. Battery Cable Clamp

3. Battery Cable Bracket

1

Fig. 10, Battery Cable Routing

2

f261106

12. Remove the exhaust clamp at the exhaust elbow.

For ease of transmission removal and installation, move the exhaust pipe to the side and out

of the way.

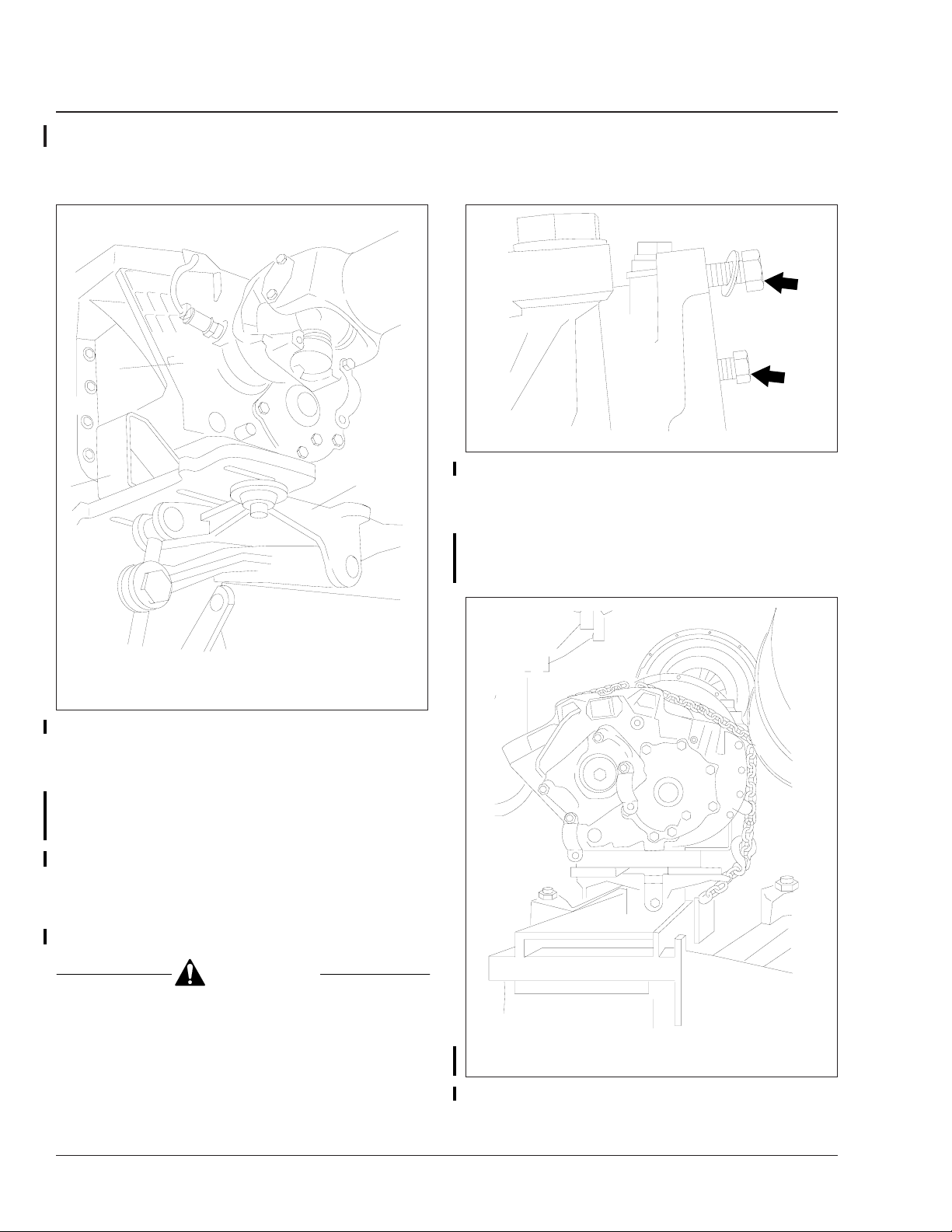

13. Support the transmission with a jack. See

Fig. 11.

13.1 Position a transmission jack under the

transmission and raise its support plates

against the base of the transmission.

13.2 Adjust the support plates to cradle the

transmission.

Business Class M2 Workshop Manual, Supplement 8, September 2005 100/3

26.04

Mercedes-Benz Manual Transmission

Transmission Removal and Installation

1

2

03/01/99

1. Transmission

2. Support Plate

Fig. 11, Supporting the Transmission

13.3 Using a chain, secure the transmission to

the jack.

14. Remove the 16-mm transmission mounting capscrews that attach the timing case to the bell

housing. See Fig. 12.

14.1 Remove the eleven transmission mounting

capscrews.

14.2 After removing the transmission, insert the

capscrews into the holes in the timing

case, rather than in the bell housing.

3. Jack

3

f261014

01/29/99

Fig. 12, Capscrews Left in the Timing Case

flywheel. Taking these precautions will prevent

damage to the input shaft, flywheel, and clutch.

15. After making sure that the transmission is firmly

secured and well supported, remove the transmission from the vehicle. See Fig. 13.

f261011

CAUTION

Do not allow the rear of the transmission to drop,

and do not allow the transmission to hang unsupported. Keep the flange of the bell housing

parallel (all the way around) to the flange of the

timing case, until the input shaft is clear of the

01/29/99

Make sure that the transmission is firmly secured and

well supported.

Fig. 13, Transmission Ready To Remove

Business Class M2 Workshop Manual, Supplement 8, September 2005100/4

f261013

Mercedes-Benz Manual Transmission

Transmission Removal and Installation

26.04

15.1 Pull the transmission and jack straight

back until the transmission input shaft is

clear of the clutch.

15.2 Turn the left-hand front wheel to allow

room for the transmission to pass. If necessary, lower the jack supporting the

transmission. It might also be necessary

to jack up the truck to get enough clearance to allow the transmission to pass.

IMPORTANT: Watch closely the clearance

between the bell housing and the leaf

spring.

15.3 Pull the transmission out through the

space behind the front wheel.

Installation

IMPORTANT: Before installing the transmission,

make sure that the rear tires are chocked and

that the transmission is securely chained to the

support plates on the transmission jack.

1. Install the transmission. See Fig. 14.

1.1 Align the jack and the transmission behind

the engine.

1.2 Raise the transmission and adjust the

angle of the jack until the bell housing and

the timing case flange are parallel.

1.3 Push the transmission and jack straight

forward.

NOTE: While installing the transmission

mounting capscrews, also install the battery

cable bracket(s), as removed.

1.4 Install the eleven M10 transmission

mounting capscrews. Use a crossover pattern. Do a final tightening of the capscrews to 33 lbf·ft (45 N·m).

1.5 Remove the chain around the transmission and the jack; then remove the jack.

2. Install the exhaust clamp at the exhaust elbow,

as removed.

3. If the vehicle is equipped with the optional dual

fuel tanks, install the fuel cross-over line and its

support between the tanks. Tighten the clamps

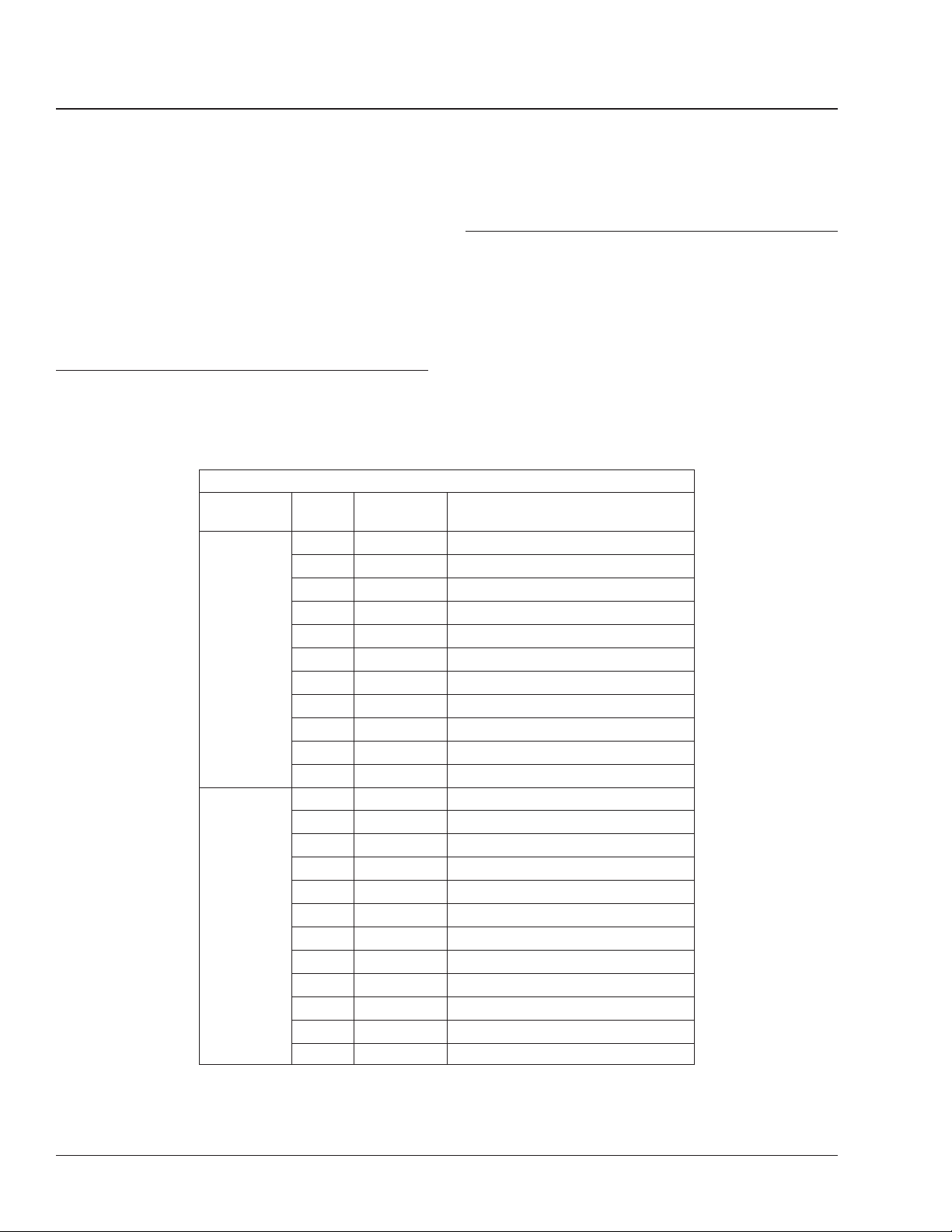

3

2

1

11

07/25/2005

NOTE: The transmission is shown from the left-hand

side.

1. Transmission Mounting Capscrews

2. Reverse Gear Switch

3. Shift Lever Mounting Bolt

4. Starter Lock Switch

5. Nameplate

6. Output Yoke Pressure Plate Mounting Capscrew

7. U-Joint End Cap Bolts

8. Speedometer Sensor Lock

9. Transmission Fluid Fill Plug

10. Transmission Fluid Drain Plug

11. PTO Mounting Capscrews

12. Clutch Slave Cylinder Mounting Bolts

40 lbf·ft (54 N·m) and the mounting bolts 95 lbf·ft

(129 N·m).

4. If removed, coat the mating surface of the PTO

cover with Loctite®509 or equivalent sealing

compound. Install the PTO cover on the transmission. Tighten the M10 hardened mounting

capscrews 43 lbf·ft (58 N·m). Lock the nut retainers in place.

5. Connect the driveshaft.

5.1 Slide the front of the driveshaft into the

5.2 Install the U-joint end caps on the output

5.3 Install the midship bearing bracket, as re-

12

Fig. 14, Transmission Fasteners

transmission output yoke.

yoke. Tighten the bolt heads 50 lbf·ft (68

N·m) for 3/8-inch end cap bolts and 110

lbf·ft (149 N·m) for 1/2-inch end cap bolts.

moved. Tighten the nuts 95 lbf·ft (129

N·m).

10

4

5

6

8

9

f261103a

7

Business Class M2 Workshop Manual, Supplement 8, September 2005 100/5

26.04

Mercedes-Benz Manual Transmission

Transmission Removal and Installation

6. Install the fuel line standoff bracket and connect

the fuel lines to the bracket.

7. Connect the electrical connectors. Connect the

electrical cable to the speedometer sensor. Connect the electrical connector(s) on the shift lever.

8. Install the shift lever.

8.1 Fit the shift lever over the cone of the

transmission tower.

8.2 Coat the hardened M10 x 20 shift lever

mounting bolt with Loctite 242 or equivalent thread-locking compound.

8.3 Insert the M10 bolt and a thick washer

into the hole in the shift lever. See Fig. 6.

Use the markings made during removal to

install the shift lever in the correct orientation, so as to avoid cab floor interference.

IMPORTANT: Don’t forget to install the

washer. Without the washer, the shift lever

may loosen. The driver could lose control of

the vehicle.

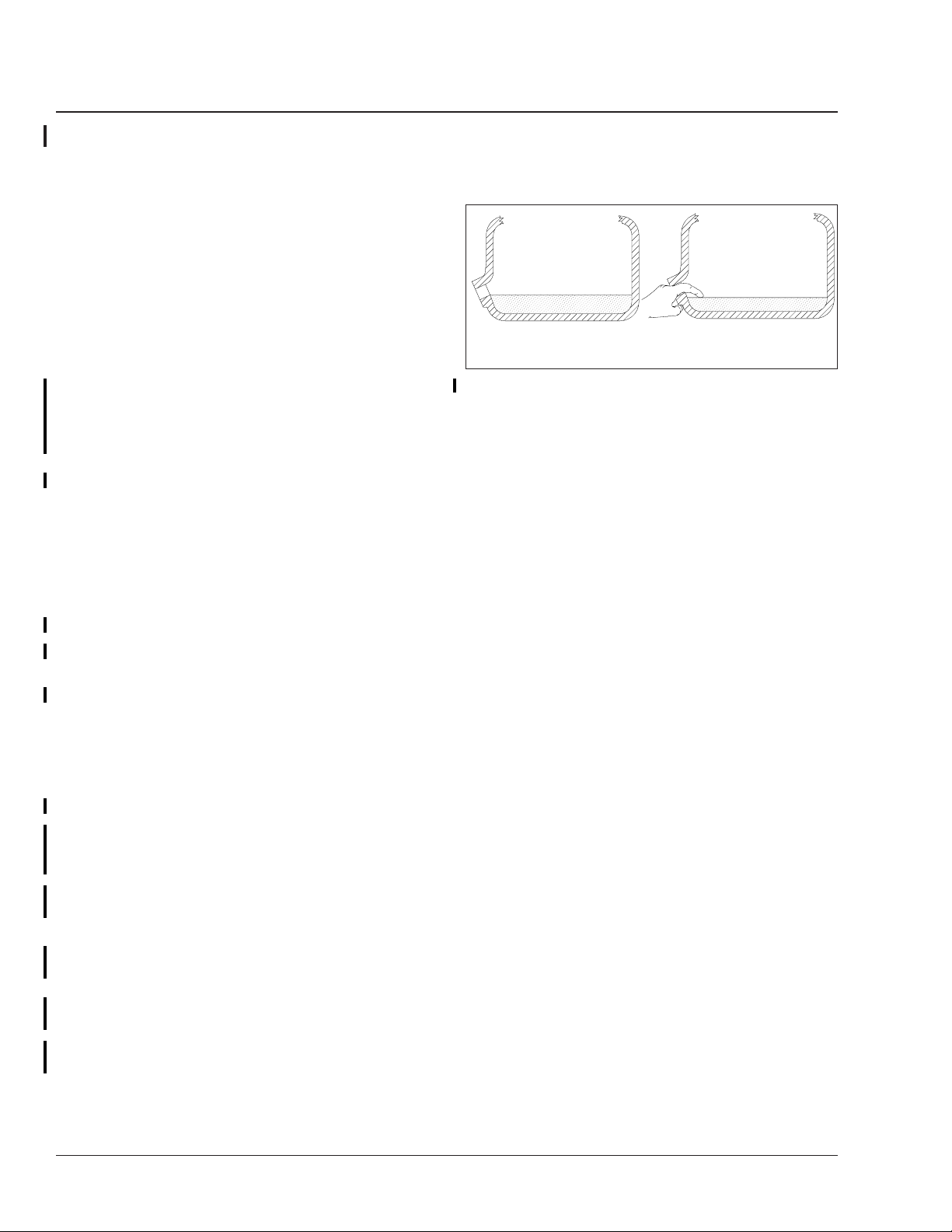

10/05/94

A. Full B. Low

14. Remove the chocks from the rear tires.

A

Fig. 15, Transmission Fluid Level Checking

B

f260006b

8.4 Tighten the M10 bolt 50 lbf·ft (68 N·m).

8.5 Work the shift lever around to make sure

it shifts comfortably in all gears.

8.6 Install the rubber boot and the metal re-

taining ring. Install the four screws and

tighten against the cab floor 28 lbf·ft (38

N·m). See Fig. 5.

9. Fasten the clutch slave cylinder to the mounting

flange on the gear case and tighten the four M8

slave cylinder mounting bolts 15 lbf·ft (20 N·m).

10. If necessary, bleed the hydraulic clutch system.

See Section 25.02, Subject 140 for detailed instructions.

11. Clean the transmission drain plug and install it in

the gear case, along with a new aluminum gasket. Tighten the drain plug 42 lbf·ft (57 N·m).

®

12. Add Mobiltrans SHC

fluid is level with the lower edge of the fill opening. See Fig. 1 for the location of the fill plug and

Fig. 15 for checking the correct level. About 9.5

quarts (9.0 liters) is needed.

13. Clean the transmission fill plug and install it in

the gear case, along with a new aluminum gasket. Tighten the fill plug 42 lbf·ft (57 N·m).

DC until the transmission

Business Class M2 Workshop Manual, Supplement 8, September 2005100/6

Mercedes-Benz Manual Transmission

Shift Mechanism Removal and Installation

26.04

NOTE: These procedures are for the manual

transmission with shift lever only. For the automated AGS transmission, see Sec-

tion 26.03, Subject 200.

Removal

1. Remove the transmission. For detailed procedures, see Subject 100.

2. Secure the transmission on a wooden pallet, or

other device to keep it from moving.

3. Make sure the transmission is in neutral.

4. Remove the four capscrews that attach the shift

rod housing to the flange on the front gear case.

See Fig. 1.

1

2

03/01/2005

1. Front Gear Case

2. Shift Rod Housing Capscrew

3. Shift Rod Housing

Fig. 1, Shift Mechanism

5. Remove the shift rod from the front gear case.

5.1 From the right-hand side of the transmis-

sion, remove the setscrew that holds the

end of the shift rod. Discard the old setscrew.

5.2 Remove and discard the shift rod cover

from the right-hand side of the gear case.

5.3 Pull the shift rod all the way out of the

gear case.

3

f261178

Installation

NOTE: See the installation procedure in Sec-

tion 26.03, Subject 200 for more information on

the proper alignment of the shift finger in the

shift rod.

1. Make sure that the indent in the shift rod end

(shown by the arrow in Fig. 2) is facing aft for

proper engagement with the setscrew.

2. Install the shift rod in the front gear case.

2.1 Insert the shift rod into the front gear

case.

2.2 Turn the shift rod until the dimple is at the

9 o’clock position.

3. Install the shift rod housing on the front gear

case.

3.1 Push the housing in until the indent in the

rod end is showing in the setscrew hole.

3.2 Coat the threads of a new setscrew with

3.3 Install a new shift rod cover in the shift

3.4 Position the shift rod housing over the

3.5 Install the four capscrews that attach the

4. Install the transmission. For detailed procedures,

see Subject 100.

®

Loctite

compound. Insert the new setscrew and

tighten it 30 lbf·ft (40 N·m). See Fig. 3.

cover housing.

flange in the front gear case. Coat the

mating surfaces with a bead of Loctite 509

or equivalent sealing compound.

shift rod housing to the front gear case.

Coat the threads of the two lower capscrews with Loctite 242 or equivalent

thread-locking compound. Tighten all four

capscrews 18 lbf·ft (25 N·m).

242 or equivalent thread-locking

Business Class M2 Workshop Manual, Supplement 8, September 2005 110/1

Meritor WABCO Pneumatic Antilock Braking System

42.00

Testing

6. Turn the ignition switch off.

7. If the voltage at the ECU is not within the specified range, check the battery voltage and test the

wiring to the ECU and to ground.

8. Connect the X1 connector to the ECU and remove the chocks from the tires.

ABS Pneumatic System Test

To check for air leaks in the ABS pneumatic system,

listen for the sound of escaping air at each valve. To

confirm a slow air leak, apply a soap-and-water solution to air line fittings and watch for bubbles.

ABS/ATC Circuit Pin and Wire Numbers

Pin

Connector

X1

Gray

X2

Black

Pin

Number

1 376C ECU Ignition Supply

2 376C ECU #2 Positive 12 Volt Supply

3 376T Wheel Spin Light and ATC Switch

4 1587+ J1587+

5 376R Retarder Interrupt Signal

6 1922-/1939- J1922–/1939–

7 1922+/1939+ J1922+/1939+

9 1587 J1587–

10 376L ABS Light

11 XGRD ECU Ground

12 XGRD ECU Ground

1 — Not used

2 378LFI Left Front Modulator Valve, In

3 378RF0 Right Front Modulator Valve, Out

4 378RFI Right Front Modulator Valve, In

5 377RF+ Right Front Sensor, High

6 377RF– Right Front Sensor, Low

7 377LF– Left Front Sensor, Low

8 377LF+ Left Front Sensor, High

9 378RF– Right Front Modulator Valve, Ground

10 378LF0 Left Front Modulator Valve, Out

11 378LF– Left Front Modulator Valve, Ground

12 — Not used

Wire

Number

(ABS)

Wheel Speed Sensor Tests

Wheel Speed Sensor and Circuit

Resistance

To check the resistance in a wheel speed sensor circuit, perform the following test:

1. Park the vehicle on a level surface, set the parking brake, and shut down the engine. Chock the

rear tires.

2. Disconnect the sensor cable connector from the

ABS ECU. See Table 1.

Circuit Description

Business Class M2 Workshop Manual, Supplement 0, January 2002170/2

Meritor WABCO Pneumatic Antilock Braking System

(ABS)

Pin

Connector

X3

Green

ABS/ATC Circuit Pin and Wire Numbers

Pin

Number

1 377LR+ Left Rear Sensor, High

2 377LR– Left Rear Sensor, Low

3 377RR+ Right Rear Sensor, High

4 377RR– Right Rear Sensor, Low

5 378T+ ATC Valve, High

6 378T– ATC Valve, Low

7 378RR0 Right Rear Modulator Valve, Out

8 378RR– Right Rear Modulator Valve, Ground

9 378RRI Right Rear Modulator Valve, In

10 378LR0 Left Rear Modulator Valve, Out

11 378LR– Left Rear Modulator Valve, Ground

12 378LRI Left Rear Modulator Valve, In

Table 1, ABS/ATC Circuit Pin and Wire Numbers

Wire

Number

Circuit Description

42.00

Testing

3. Connect ohmmeter probes to the sensor connector terminals and read the resistance.

• If the resistance is 900 to 2000 ohms, the

cable and the sensor circuit are good. Proceed to the "Wheel Speed Sensor Voltage"

test.

• If the resistance is less than 900 ohms or

greater than 2000 ohms, perform the next

test, "Wheel Speed Sensor Resistance."

Wheel Speed Sensor Resistance

To check the resistance in a wheel speed sensor,

perform the following test:

1. Park the vehicle on a level surface, set the parking brake, and shut down the engine. Chock the

rear tires.

2. Disconnect the wheel sensor cable from the

chassis harness.

3. Connect ohmmeter probes to the pins on the

sensor and read the resistance.

• If the resistance reading is 900 to 2000

ohms but the resistance noted in the previous test, "Wheel Speed Sensor and Circuit

Resistance" was not, repair or replace the

chassis harness wiring.

• If the resistance is less than 900 ohms or

greater than 2000 ohms, clean the terminals and check the resistance again.

• If the resistance reading is still not correct,

replace the sensor. See Subject 110 for

instructions.

4. Install the connectors and remove the chocks

from the tires.

Wheel Speed Sensor Voltage

NOTE: PC diagnostics can be used for this test

to compare speed signal output of all sensors. A

problem will be indicated by low or erratic output.

To check the voltage output of a wheel speed sensor:

1. Park the vehicle on a level surface, set the parking brake, and shut down the engine.

2. Chock the tires of the axle not being tested.

Raise the vehicle and put jack stands under the

axle so the wheels can rotate.

3. Disconnect the applicable connector from the

ABS ECU for the sensor being tested. See

Table 1.

Business Class M2 Workshop Manual, Supplement 0, January 2002 170/3

Loading...

Loading...