Page 1

Thermal Printer

Model TSSP-TMPTR

Retrot / Installation Instructions

Manual # Revision Date Changes from Previous Revision

000-2080 C July 2012 Added Firmware update Instructions

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Printer Installation

The following instructions are for the addition of an internal

printer or replacement of an existing printer in a T5 Series

Fuel Management System.

Note: The thermal printer requires controller module

rmware rev 1.5 or higher. Refer to page 7

Updating Console Firmware.

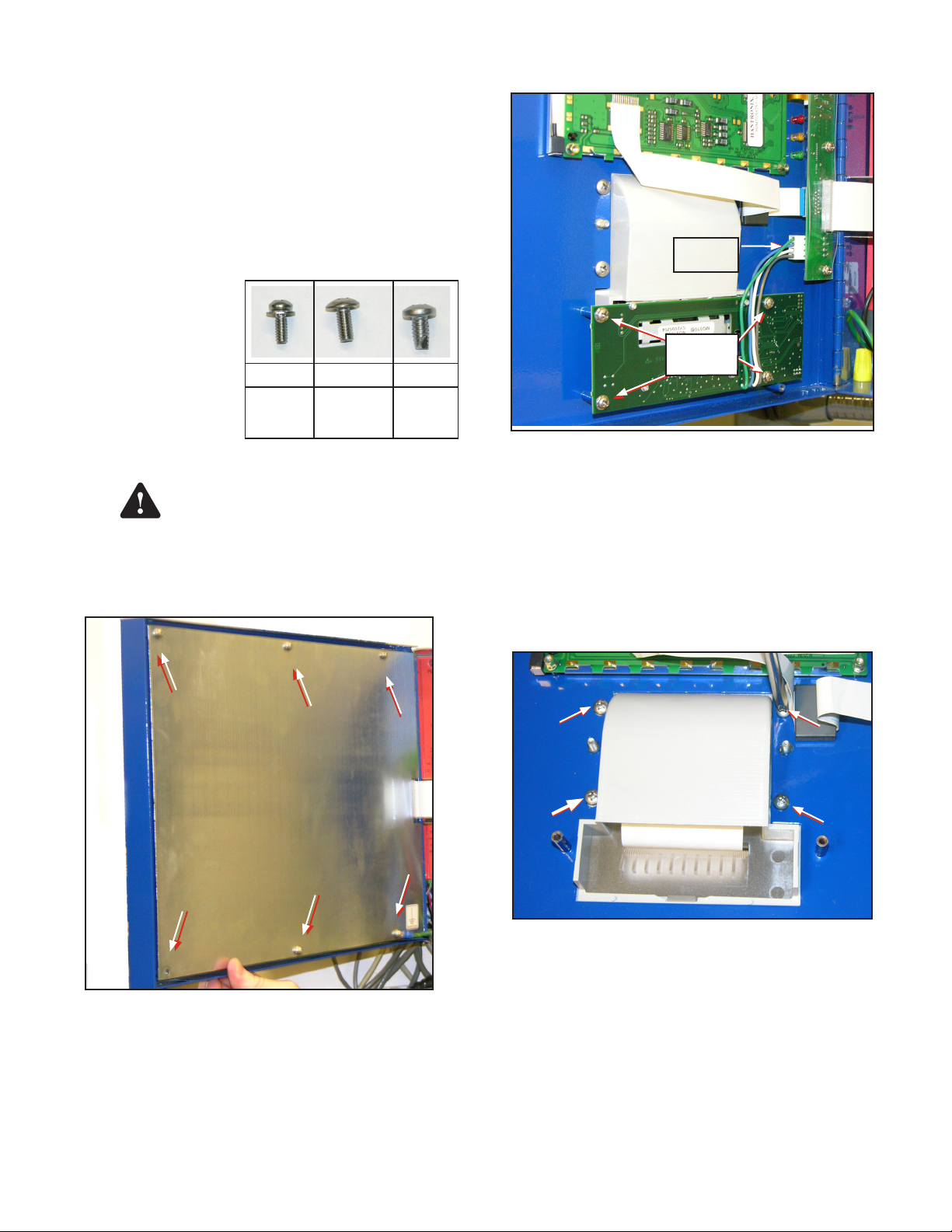

Included with Printer:

• Plastic Bezel

• Thermal Printer on PCB (Printed Circuit Board)

• Hardware includes:

• (2) stand-offs

• Mounting screws

(Quantity, size and

use shown in chart)

Note: Use only the

provided hardware

to mount the printer.

(4) #6 (2) #8 (2) #10

For lower

4 holes in

the PCB

For top of

PCB, in

stand-offs

For

Plastic

Bezel

Installation Procedure

Warning

1. Open the Tank Gauge front door.

2. Remove the front door’s inside cover plate by

unscrewing the screws located on the plate.

(Number of screws vary by model).

Disconnect power before opening the

console cover.

3. Disconnect the cable that connects the impact

printer to the interface board in the front door.

Remove

Cable

Remove

Screws

Figure 2: Disconnect Old Printer

4. Remove the roll of paper from the printer.

5. Remove the 4 screws that hold the impact printer

to the front door.

Note: Be careful not to damage the ribbon cable.

6. Pull the printer gently and slowly a couple of

inches away from the door. Completely remove the

impact printer board.

7. Remove the 4 screws that hold the printer’s plastic

cover printer to the front door.

Figure 1: Remove Inside Cover Screws

To Retrot a Printer in a Console Without One

a. Remove the 4 nuts that secure the blank-off

plate.

b. Remove the plate (blank-off plate may stick to

the overlay).

c. Carefully cut out the part of the overlay that

covers the printer opening using a sharp knife.

Go to step 9.

2

Figure 3: Remove Plastic Cover

8. Remove the plastic cover.

9. Place the new plastic bezel over the cutout in the

front door. Fasten the bezel to the enclosure using

the two #10 self-tapping screws supplied Start the

screws in the lower two mounting holes. Do not

tighten screws all the way at this time. These screws

will be tightened after installing the printer assembly.

10. Install the 2 stand-offs on the studs located next to

the printer opening (Figure 4).

Page 3

Figure 4: Install Stand-offs

11. Mount the printer so that the clear printer cover

faces outward of the front door.

16. Replace the metal inside cover plate on the front

door and fasten the screws. Make sure to reattach

the ground connector to the plate.

17. Lift up on the green panel to open the printer and

load paper (Figures 7-9). Make sure the roll is

oriented as shown.

Figure 7: Load Paper

Plastic Bezel

Figure 5: Mount Printer in Door

12. Attach the 6 screws for the thermal printer board to

the front door (Figure 6). Refer to the screw chart

on the previous page.

Foam Pad

Cable Connected

Figure 6: Printer Circuit Board Installed

13. Connect the cable from the thermal printer board

to the interface board of the front door (Figure 6).

14. Tighten the two screws that hold the plastic bezel

by inserting a screwdriver through the access

holes in the circuit board.

15. Check to make sure the foam pad covers the corner

of the circuit board where the power cables connect.

Figure 8: Do NOT load paper from door, Do NOT have paper

wound loosely

Figure 9: Paper Loaded Correctly

18. Close the printer door.

19. Restore power to the tank gauge.

Paper Specications

Type: Thermal Printer Paper

Width: 58 mm (2.28")

FFS part #: TS-TP2 (box of 5 rolls)

TS-TP2C (Carton of 20 boxes = 100 rolls)

3

Page 4

To print a test page

1. Once the tank gauge is on, press the Main Menu

key on the LCD with the gure of a table

(Figure 10).

Figure 10: Select Main Menu

2. Press the arrow on the right side bar once.

4. Press Print Test Page.

Figure 13: Print Test Page

Printer Operation Notes

• On rare occasions, when printing excessively long

reports at high ambient temperature, the printer may

need to pause momentarily. Printing will resume

automatically after a few seconds.

• An open printer door or no-paper will generate an out-ofpaper alarm.

• If you are trying to print and the paper is spooling but no

text is printing, check paper roll orientation per Figure 7.

• The paper tear-bar is located at the top. Tear the paper

with a lifting motion (Figure 14).

3. Press Diagnostics.

4

Figure 11: Select Arrow Down

Figure 14: Tear Paper with Lifting Motion

Figure 12: Select Diagnostics

Page 5

To Setup a New Printer on a Console That Had No Printer

To physically install the printer, follow Printer Installation steps starting with step 9 on page 2.

The following steps illustrate how to program the T5 system through the computer connection when adding an internal

printer. Log on to the console using a web browser interface (Refer to FMS Operator’s Guide for further information).

From the System Screen, click on Setup

Select System Conguration

Select Modules Expected

A list of all potential modules will be displayed. The number next to the module represents the number of modules that

should be installed. When adding any module to the system, you must increase that module number by 1.

Click on the 0 next to Printer.

5

Page 6

Change the 0 to a 1

Click Yes to Save Changes

If prompted, enter the administrative password

Conrm that the Printer number is now 1. The system will now “look” for an internal printer

6

Page 7

To Replace an Existing Thermal Printer

Warning

1. Remove the back panel shown in Figure 1.

2. Remove the 6 screws as shown in Figure 6.

3. Remove the cable connection.

4. If the existing plastic bezel will still be used, follow installation instructions starting with step 12 on page 3.

5. Print a test page to verify operation.

Disconnect power before opening the console cover.

Updating Console Firmware

To update the rmware on the console, on the internet, go to http://www.franklinfueling.com/ and select

Service and then Software Downloads. After you select the type of console you have, you will also be able

to download the Upgrade Installation Instructions and Release Notes.

7

Page 8

©2012 FFS 000-2080 Rev C

Loading...

Loading...