Page 1

TSP-LL2

Magnetostrictive Probe

Installation

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Page 2

Safety

Warning

Warning

Always lock out and tag electrical

circuit breakers while installing or

servicing this equipment and any

related equipment. A potentially

lethal electrical shock hazard and

the possibility of an explosion or re

from a spark can result if the electrical

circuit breakers are accidentally turned

on during installation or servicing.

Please refer to the Installation and

Owner’s Manual for this equipment,

and the appropriate documentation

for any other related equipment,

for complete installation and safety

information.

Follow all federal, state and local

laws governing the installation of this

product and its associated systems.

When no other regulations apply, follow

NFPA codes 30, 30A and 70 from the

National Fire Protection Association.

Failure to follow these codes could

result in severe injury, death, serious

property damage and/or environmental

contamination.

Overview of LL2 Probe

The INCON LL2 probes are advanced instruments that

use magnetostrictive position measurement technology to

accurately report inventory levels in storage tanks

The probes are installed in USTs (underground Storage

Tanks) and ASTs (above ground storage tanks). Leak

Detection probes are suspended by a chain from a cap on

the riser pipe. Inventory probes may be suspended by a chain

and cap or alternatively be mounted on the bottom of the

tank. Bottom mount hardware is provided on all inventory

probes.

Types of Probes

• Leak Detection

• Inventory Specic

Length of Probes

The probe model number indicates its length. The model

numbers are in the form TSP-LL2-xxx, where xxx = the

tank diameter in inches plus 5.

For example, the TSP-LL2-101 is for 8’ (96”) tanks.

TSP-LL2-xxx, Leak Detection and Inventory probes are

available in lengths up to 12' tanks.

TSP-LL2-xxx-I, Inventory Specic probes are available in

lengths up to 18' tanks.

Warning

Warning

Warning

Warning

Always secure the work area from

moving vehicles. The equipment

in this manual is usually mounted

underground, so reduced visibility

puts service personnel working on

this equipment in danger from moving

vehicles entering the work area. To

help eliminate these unsafe conditions,

secure the area by using a service

truck to block access to the work

environment, or by using any other

reasonable means available to ensure

the safety of service personnel.

When the console system is used to

monitor tanks containing gasoline or

other ammable substances, you may

create an explosion hazard if you do

not follow the requirements in this

manual carefully.

All wiring must enter the console’s

enclosure through the designated

knockouts. An explosion hazard may

result if other openings are used.

All wiring from probes to the console

must be run in conduit separate from

all other wiring. Failure to do so will

create an explosion hazard.

TSP-MLGK-xx, Moorman Level Gauge Kits are available

for tanks up to 35' and up to 50'. Refer to manual

000-2033 for Moorman Gauge installation.

Float Kits Available

Model Description

TSP-IDF2 2" oat set for diesel tanks

TSP-IGF2 2" oat set for gasoline tanks

TSP-IDF3 3" oat set for diesel tanks

TSP-IGF3 3" oat set for gasoline tanks

TSP-IDF4 4" oat set for diesel tanks

TSP-IGF4 4" oat set for gasoline tanks

TSP-LPGF 2" oat for LPG tanks, with or without

isolation sleeve. See manual

000-0251 for more information.

TSP-SSP 2-1/16" OD, #316 stainless steel oat

for chemical applications only

Each oat kit includes a product and water oat. Order one

oat set for each LL2 Mag probe.

• Product oats are white (clear)

• Gasoline water oats are red.

• Diesel water oats are blue

2

Page 3

Probe Installation Kits

Suspended Probe Kits

Model Description

TSP-K2A Mag Probe install kit for 2" riser pipe

TSP-K2B Mag Probe install kit for 2" riser pipe with

BSP threads

TSP-K4A Mag Probe install kit for 4" riser pipe

TSP-K4B Mag Probe install kit for 4" riser pipe with

BSP threads

TSP-K4AS #316 Stainless Steel mag probe install kit

for 4" riser pipes

TSP-LPGK LPG Probe install kit, 149" maximum

LL2 probe length

Inventory Control Probe Caps and Adapters

(for bottom-mounted probes)

Model Description

TSP-C2A Inventory Probe 2" Riser Cap and Adaptor

TSP-C2B Inventory Probe 2" Riser Cap and Adaptor

with BSP threads

TSP-C4A Inventory Probe 4" Riser Cap and Adaptor

TSP-C4B Inventory Probe 4" Riser Cap and Adaptor

with BSP threads

A locally supplied riser cap for Inventory Control Probes

should meet all applicable codes and approvals. The cord

grip must be for use with a cable diameter of 0.19 inches

(4.8 mm) and must also be compatible with the liquid

installed in the tank.

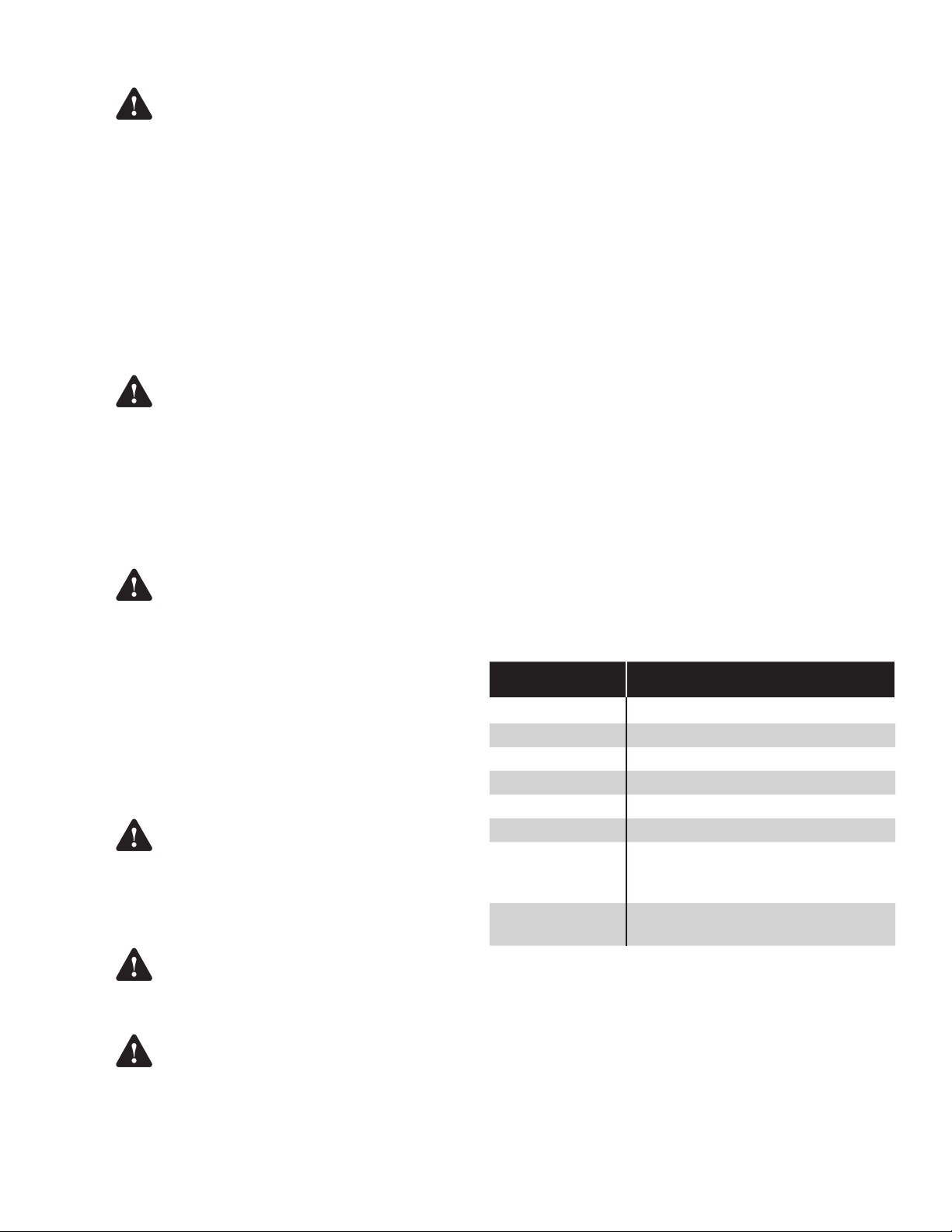

Installing Floats

For TSP-LL2 probes the oat(s) will need to be installed on

the probe.

1. Carefully remove the E-Clip and washer / bottom

mount foot.

2. Install the oats as shown in gure 2.

3. Reinstall the Washer / bottom-mount foot and

E-Clip.

E-Clip

Figure 1: Probe C-Clip and Washer

Float orientation

Density Floats

Density oats are two-part oats. The inner and outer oat

are calibrated at manufacture and must be used together.

Model Description

TSP-IDF4D Diesel / Fuel Oil Density Kit

TSP-IGF4D Gasoline density oat kit

Refer to manual 000-0527 for more information about

density oat installation.

Riser Pipe

Below is a example for determining riser length.

92" Tank 96" Tank

TSP-LL2-101 Probe Overall

Length

Suspension chain allowance +5 +5

Total +116 +116

Tank Diameter -92 -96

Minimum Riser Length 24 20

+111 +111

Product

Float

(Magnet

End Up)

Water /Interface

Float

(Magnet End Up)

2 Inch Floats 3 or 4 Inch Floats

Figure 2: Float Orientation

3

Page 4

Suspended Probe Installation

R

This procedure must be done with leak detection probes

and is optional for inventory probes. Before starting the

probe installation, be sure that you have the necessary

hardware:

• Level probe(s)

• Product and water oats,

• Probe installation kit.

For each tank, locate the following:

• LL2 level probe

• Product oat

• Water oat-optional, is identied by color:

(Blue – Diesel, Red – Gasoline)

• Threaded adjustment eye bolt and suspension chain

(with wing nut and split ring attached)*

• Steel support plate (with rubber grommet and insulating

washer installed)*

• Four Inch NPT riser adaptor*

• Riser cap*

• Compression gland seal tting (cord grip)*

• (3) Moisture resistant, no strip, electrical wire splice

connector*

* Included in the TS-K4A probe installation kit.

Installation

1. Measure from the top of the riser pipe to the

bottom of the tank-record value in inches.

2. Measure the overall length of Probe.

3. Subtract the probe length from the distance

measured from the top of the riser pipe to the

bottom of the tank, and then add 1/2 inch to this

distance. This value is the TOTAL LENGTH OF

THE CHAIN INCLUDING THE SPLIT RING AND

ADJUSTMENT EYEBOLT.

4. The suspension chain must be cut to the exact

length required.

emove the split ring from the end of the chain and

5. R

cut the chain to the correct length.

6. Reattach the split ring to its end and measure the

total overall length to make certain that it is within

Note; When using a 2" or 3" riser you will replace the

one half inch of correct value.

bottom spacer with the 3" spacer included in the

oat kit. When using a 2" riser, cut back the spacer

at the marks. The 4" probes are installed with no

modication.

Probe Cable

Rubber Grommet

Riser Cap

Support Plate

Eyebolt

Riser Pipe

Figure 3: Installation of Suspended Probe

7. Apply pipe sealant to the male riser threads.

8. Screw the riser cap adapter into the top of the riser

pipe. Tighten to 20-25 ft-lbs.

9. Connect the probe to the split ring on the chain.

10. Carefully position the steel support plate

containing the rubber grommet and insulating

shoulder washer into the riser cap.

11. Guide the probe cable through the rubber

grommet.

12. Unscrew the adjusting eyebolt so the probe just

touches the bottom of the tank.

13. Turn the wing nut clockwise, 4 full turns (only).

This will raise the probe approximately ¼” above

the bottom of the tank.

14. Push the probe cable through the compression

tting on the probe cap.

15. Install the probe cap on the riser cap adapter such

that the compression tting is aligned with the

rubber grommet.

16. Tighten the compression tting to make a

watertight seal.

4

Page 5

Adjusting the probe height (¼" off the bottom of tank)

14" (356 mm) Minimum

PRODUCT

Ullage

Probe end held

1/4" (6.4 mm) Above

Bottom of Tank

Water Float

Product

Float

6.0" (152 mm) Minimum

14" (356 mm) Minimum

Manhole Cover

8.0" (203 mm)

Reference

3" (76 mm)

Minimum

N.T.S.

Spacers

Make sure the probe is sitting on the bottom of the tank

by loosening the wing nut until you feel slack in the chain

(the probe is resting on the bottom of the tank).Then turn

the wing nut clockwise until you feel that there is no slack

in the suspension chain. Hold the end of adjustment rod

and turn the wing nut clockwise, 4 full turns (only). This

will raise the probe approximately ¼ of an inch above the

bottom of the tank.

Manhole Cover

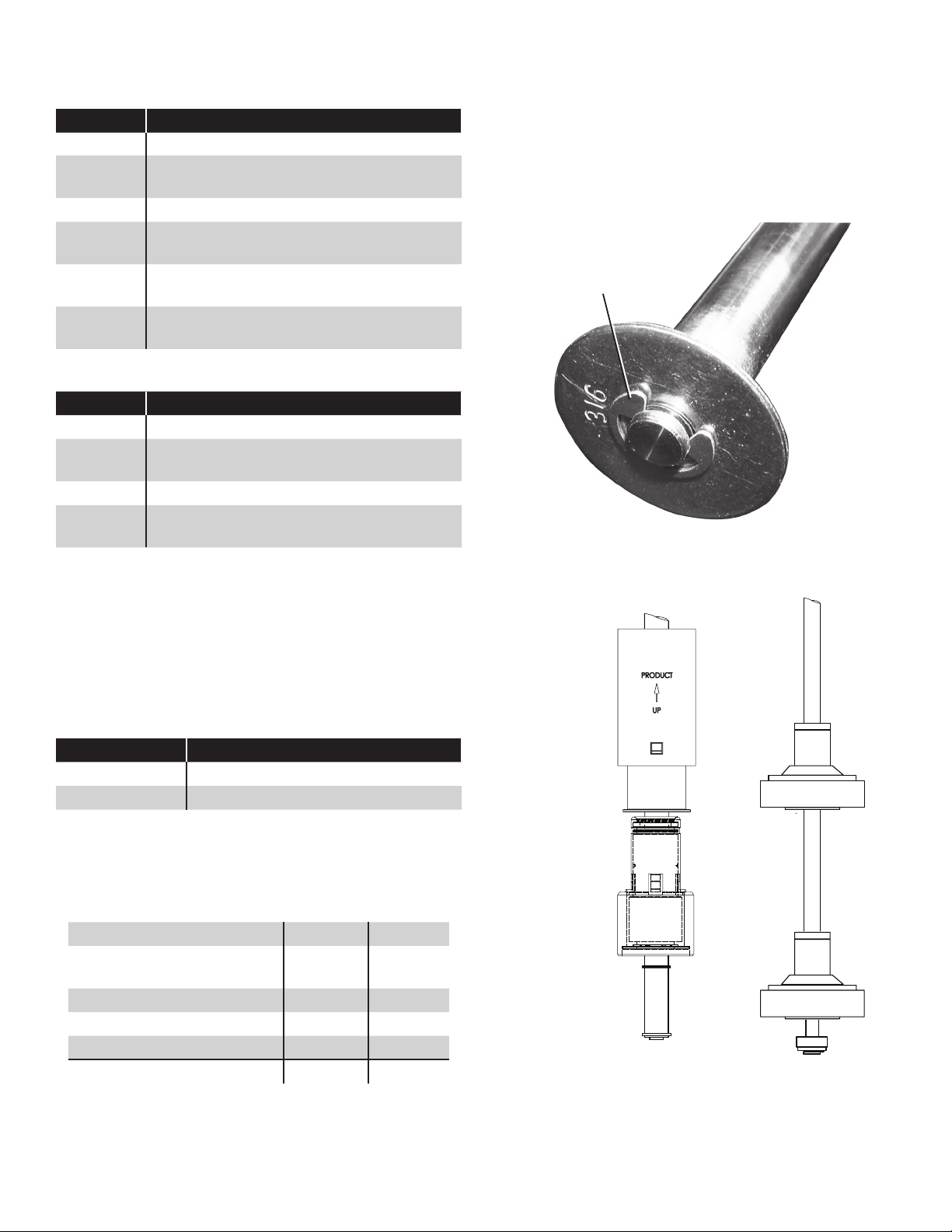

Bottom-Mount Probe Installation

The bottom-mount probe option is for inventory control

probes. Tank leak testing and density probes need to be

suspended from the riser cap.

The bottom-mount assembly consists of:

•

Top spacer on the top of the probe head for 3" or 4" probes

• Bottom spacer below the probe head

• Probe foot mounts at the bottom of the probe shaft

The foot is ¼" thick so when installed the probe end will be

¼" off the bottom of the tank.

6.0" (152 mm) Minimum

18.0" (457 mm) Maximum

5"(127 mm)

Minimum

8.0" (203 mm)

Reference

Ullage

PRODUCT

Product Float

Water Float

Figure 4: Suspended Probe Installed

Final Suspended Probe Installation Steps

NTS

Install Probe

1/4" (6.4 mm) Above

Bottom of Tank

1. Push the probe’s cable though the compression

gland tting at the waterproof junction box. Make

sure that you leave enough cable from the level

probe to the junction box (tie-wrap a coiled service

loop) so that the probe can be easily removed and

reinstalled without rewiring and splicing.

2. Tighten the compression gland tting at the

junction box so that it grips the cable tightly and

creates a watertight seal.

3. Position the lockable TSP-K4A probe cap on the

riser cap adapter such that the compression tting is

aligned with the rubber grommet and snap it in place.

4. Tighten the riser cap compression tting so that it

grips the cable tightly and forms a watertight seal

When using a 2" riser you will remove the top spacer and

replace the bottom spacer with the 2" spacer included in

the oat kit. When using a 3" riser, cut back the top spacer

and replace the bottom spacer with one included in the

oat kit. The 4" probes are installed with no modication.

This is solely for the I-probes, all leak detection and density

probes MUST BE Suspended.

Single Thermistor Probe

The probe will have one RTD near the bottom of the

probe shaft. The Net Volume will be based on the one

temperature reading vs. the average of the 5 RTDs in

current Inventory probes.

Note: The Inventory Probes MUST NOT be used for Leak

Detection.

A sticker on the head of the I-probe indicates that it is for

inventory use only. An extra sticker is provided to be kept

near the console for gradient programming. Installers must

be aware of the probe type in sites that have a mix of

inventory-specic and leak detection probes.

Note: When removing the probe, loosen the cable

compression tting.

Figure 5: Bottom-Mount (I-Probe) Installed

5

Page 6

Above Riser Probes

For above-riser probes or ASTs, install the stainless steel

TSP-K4AS riser adapter by tightening the lower swage

lock tting. (Figure 6)

Probe Wiring

LL2 Probe Splice Kit – Installation Instructions

The Liquid Level Probe Splice Kit includes 2 Electrical

Connectors for installation inside the manhole junction box

only. It is not intended for direct burial applications.

Figure 6: TSP-K4AS cap with Swage-Lock Fitting

Slide the oats onto the probe shaft after the probe has

been inserted through the cap. Refer to manual 000-0113,

TSP-K4AS with TSP-UVPK Installation Instructions for more

information about mounting probes above the riser cap.

Recording Probe Information:

Gradient, Model # and Serial Number

For each tank, record the probe model number, serial

number, and the probe gradient value (propagation

constant), The TS-LL2 has two labels. The label included

with the splice kit in the shipping tube contains the same

information that is on the probe head label:

• Model (TSP-LL2-X)

• Serial #

• Gradient

• Probe length

• Max. Tank size

• Temperature sensor locations

For every installed probe, use indelible ink pen and

mark the tank number where it was installed on each

label. Save labels and make sure they are kept near

the tank monitor for correct programming.

End view of splice

Before Crimp

After Crimp

Figure 8: Splice Kit for Probe Wiring

Red wire

of probe

Red wire of

field cable

To

Console

Connect bare metal shielding together

Black wire of probe

Both shield wires

Black wire of

field cable

To

Probe

1. Use 2 moisture-resistant connectors (provided) for

each probe installation.

2. Insert 2 red unstripped wires into two separate

openings of the rst connector. Make sure the

wires are fully inserted and seated at the end of

the connector.

Note: Belden cable # 89182 (for runs longer than 400

feet) has a yellow wire. Wire the YEL wire to the

+ (RED) probe terminal inside the console.

3. Insert 2 black unstripped wires into two separate

openings of the second connector and then insert

the 2 shield wires into the remaining opening of the

second connector. Make sure the wires are fully

inserted and seated at the end of the connector.

4. The white wire inside the yellow probe cable is not

used. Do not insert it into any connector. Cut the

white wire back ush to the jacket of the yellow

probe cable.

5. Use 8” slip-joint pliers and squeeze each

connector together (position the plier’s jaws on

the connector perpendicular to the wires and drive

the black cap down almost ush to the edge of the

connector body).

For a supply of moisture-resistant splice connectors,

Order:

• TSPKW30 for a pack of 30 splices.

For direct burial cable applications or for applications that

don’t use a junction box, order:

• TSP-DB1 for a single kit

• TSP-DB10 for 10 kits.

For information about direct-burial applications, refer

to manual 000-1041, Direct Burial Cable Installation

Instructions and 000-1133, Direct Burial Splice Kit

Installation Guide.

Figure 7: Sample Probe Information Label

6

Page 7

Probe

Module

RUN

12

11

10

ERR

–Blk

+Red

–Blk

+Red

–Blk

+Red

–Blk

9

+Red

–Blk

8

+Red

–Blk

7

+Red

–Blk

6

+Red

–Blk

5

+Red

–Blk

4

+Red

–Blk

3

+Red

–Blk

2

+Red

–Blk

1

+Red

Non-Hazardous

Location

SHLD

- (BLK)

+ (RED)

Hazardous Location

Class I, Division 1, Group

D, Group IIA, Zone 0

SHLD

- (BLK)

+ (RED)

Probe

Figure 9: Probe Module Wiring

Refer to manual 000-2142, Fuel Management System

Programming guide and 000-2150 Fuel Management

System Installation guide for information about setting up

the probe with the tank gauge.

For Colibri Tank Gauge Consoles, refer to manual

000-2153, Colibri Automatic tank Gauge Installation Guide,

and 000-2155, Colibri Set-Up and Operation Guide. For

Colibri manuals on the web, go to:

www.franklinfueling.com/colibri/literature.aspx

Tank Tilt / Offset Calculations

If the data to calculate tank tilt is not known, or if the tank is

not seriously tilted, then use +/– offsets to adjust the probe

readings to match the stick readings at ll.

Figure 10 shows the tank tilt formula to use when the ll

tube and probe are on opposite sides of the tank centerline. Figure 11 shows the formula to use when the ll tube

and probe are on the same side of the tank center-line.

CENTER OF TANK

level

Probe

Fill & Probe on

opposite sides of

Tank

Center...

Product / Water

Offset =

(LF - LP) * XP

XP + XF

AIR

FUEL

PRODUCT

LEVEL

Tank shown

FUEL

tilted

WATER

Fill & Probe on

the same side of

the tank

Product / Water

Offset =

(LF - LP) * XP

XP - XF

C

L

Tank

Diameter

TANK

DIAMETER

Product

Level

Tank

shown

tilted

DROP TUBE

level

Probe

AIR

FUEL

FUEL

WATER

Fill

" LF "

Level

at Fill

" XF " " XP "

C

L

TOP OF TANK

" LP "

Level

at Probe

LENGTH OF TANK

Figure 10: Tank Tilt Calculation

Probe and Fill on Opposite Sides

" XP "

TOP OF TANK

" LP "

Level

at Probe

LENGTH OF TANK

CENTER OF TANK

" XF "

Fill

C

L

DROP TUBE

" LF "

Level

at Fill

Figure 11: Tank Tilt Calculation

Probe and Fill on Same Side

7

Page 8

Troubleshooting

When troubleshooting a probe problem, it is important not

to presume any particular cause. Follow the steps outlined

below to properly and quickly troubleshoot probes:

Note: Do not start troubleshooting by swapping probes. It

may cause confusion in the process of identifying

the problem.

Float Missing:

1. Check programming of probe for correct number

of oats

2. Look for active High water or Float Missing Alarms

in the run status at the ATG.

3. If possible, have the technician stick the tank and

compare the measurement with the level reported

by the ATG.

4. Is the level correct? If not, is the ATG measuring

in reverse (the lower the actual product level the

higher it reads on the ATG)? Verify the Probe ratio

is programmed correctly. If programming is correct it

may be a probe issue, continue with the next steps.

5. Check the water level does the ATG list it as oat

missing? If it is listed as missing, it could be a

probe issue, but again continue to troubleshoot.

6. Try to cycle power. If previously noted, check to

see if High water alarm or oat missing alarm

changed from “ACTIVE” to “CLEARED”. If they

clear, again this could be a probe issue, but

acknowledge and continue to troubleshoot.

7. After completing the above steps, replace the

probe.

No Probe, Probe Sync and Unstable Probe

(New Install or Replacement Probe)

1. Check Wiring. Ensure that the Red, Black and

Shield wires are connected to the correct terminals

to the ATG. There should be two connections in

the junction box, (refer to gure 8).

(Probe Alarms on Multiple Channels or Only One Probe

Connected)

6. Try another Probe Channel. Once the eld wiring

has been checked and the junction box connection

remade, try moving the eld wiring to another

channel.

7. Connect the Probe Directly to the ATG. If possible,

bring the probe inside and wire directly to the ATG.

(If this probe has a quick disconnect pigtail then

the white wire should be connected to shield or

ground).

Listed below are additional steps for troubleshooting

the probe. For missing oat or incorrect level problems,

consider the following actions:

•

Pull probe from tank and manually raise and lower oats.

Does the ATG accurately report the change in level?

• Are the right number of oats installed on the probe

(verify number of oats programming)

• Is oat too close to the end of the probe? (Was tank

overlled or is the oat stuck in riser)? If oat is too close

to the probe head a oat missing alarm will occur.

• Is there debris on the magnets? If so, clean debris from

magnet and check operation of ATG.

• Are the magnets cracked or broken? If so replace oat

• Are the oats installed correctly? Product oat on top,

closest to the probe head. Product oat will have a white

collar. Water oats have colored collars (Red for use in

gasoline, blue for use in diesel)

• Is the probe shaft clean? If dirty use an abrasive pad to

clean the probe shaft.

• Check that wire connections from probe cable to eld

wiring are good and dry.

• Are the oats compatible with the probe? LL and LL2

oats are NOT interchangeable.

2. Check Main Board Power Supply. There should be

approximately 21 VDC loaded (probe connected)

and 24 VDC unloaded across the Red and Black

terminals of the probe channel in the ATG.

3. Check Field Wiring. Ensure that the voltage is

getting to the probe by checking at the junction box

splice or quick disconnect pigtail. With the pigtail

end facing you, keyslot up, there should be 24

VDC across the two bottom pins. Test eld wiring

for a short or open.

4. Remake Splice. Cutback and remake the splice

connection in the junction box using the approved

seal pack and connectors.

(Quick Disconnect Pigtail)

5. Try a New Pigtail. If this probe has a quick

disconnect pigtail, try replacing it.

8

Page 9

Page Intentionally blank

9

Page 10

©2010 FFS 000-2081 Rev A

Loading...

Loading...