Franke FSN 908 BK A, FSN 908 WH A Instructions For Use And Installation

Instructions for use and installation

Cooker Hood

Istruzioni per l’uso e l’installazione

Cappa

Mode d’emploi et installation

Hotte de Cuisine

Bedienungsanleitung und Einrichtung

Dunstabzugshaube

Kullanım ve montaj talimatları

Davlumbaz

FSN 908 BK A - FSN 908 WH A

GB

IT

FR

DE

TR

2

2

INDEX

RECOMMENDATIONS AND SUGGESTIONS ..................................................................................................................... 3

CHARACTERISTICS ............................................................................................................................................................. 4

INSTALLATION...................................................................................................................................................................... 5

USE ...................................................................................................................................................................................... 10

MAINTENANCE................................................................................................................................................................... 11

INDICE

CONSIGLI E SUGGERIMENTI............................................................................................................................................ 13

CARATTERISTICHE............................................................................................................................................................ 14

INSTALLAZIONE ................................................................................................................................................................. 15

USO...................................................................................................................................................................................... 20

MANUTENZIONE ................................................................................................................................................................ 21

SOMMAIRE

CONSEILS ET SUGGESTIONS.......................................................................................................................................... 23

CARACTERISTIQUES......................................................................................................................................................... 24

INSTALLATION.................................................................................................................................................................... 25

UTILISATION ....................................................................................................................................................................... 30

ENTRETIEN......................................................................................................................................................................... 31

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE ................................................................................................................................... 33

CHARAKTERISTIKEN......................................................................................................................................................... 34

MONTAGE ........................................................................................................................................................................... 35

BEDIENUNG........................................................................................................................................................................ 40

WARTUNG........................................................................................................................................................................... 41

IÇERIKLER

TAVSIYELER VE ÖNERILER.............................................................................................................................................. 43

ÖZELLIKLER........................................................................................................................................................................ 44

MONTAJ............................................................................................................................................................................... 45

KULLANIM ........................................................................................................................................................................... 50

BAKIM .................................................................................................................................................................................. 51

EN

IT

FR

DE

TR

EN

3

3

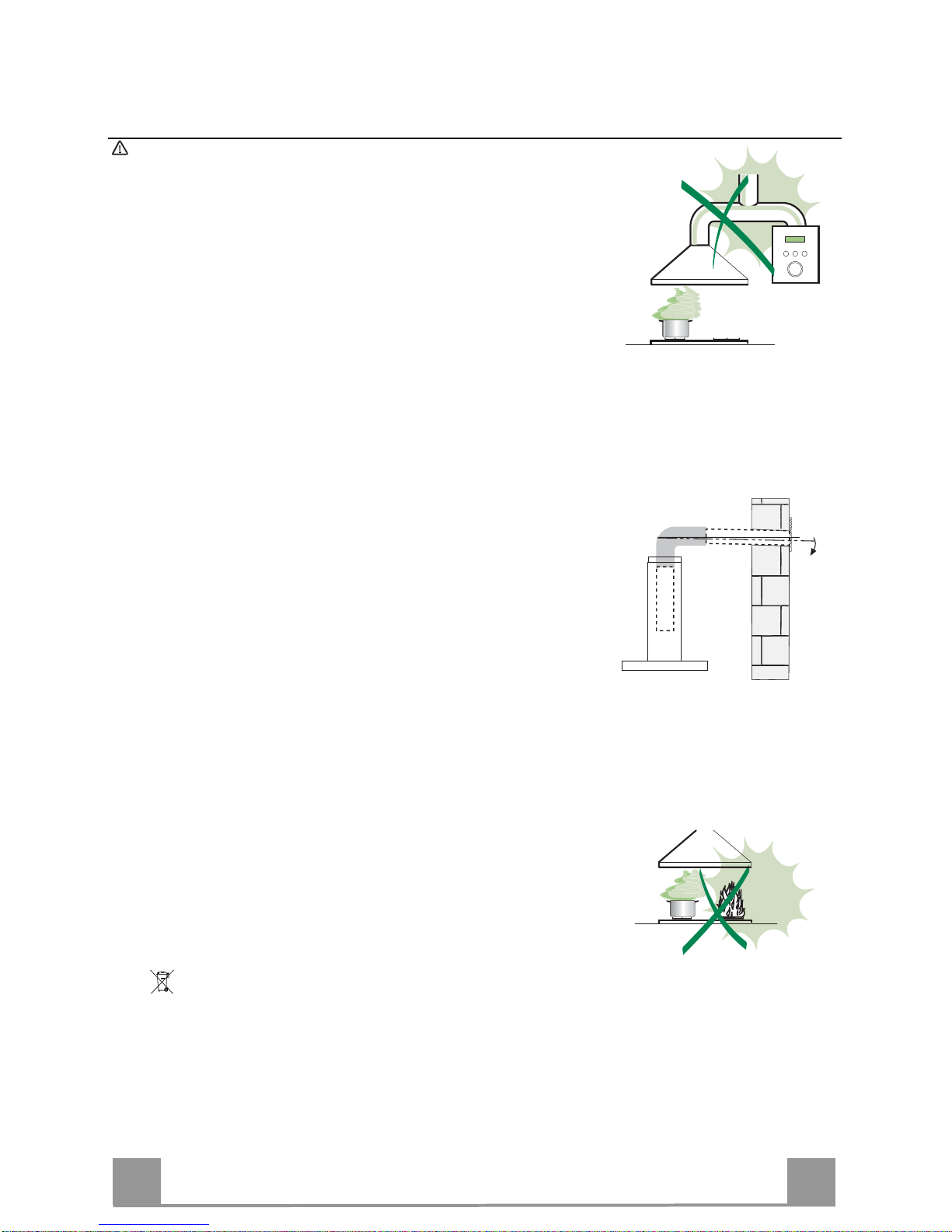

RECOMMENDATIONS AND SUGGESTIONS

The Instructions for Use apply to several versions of this appliance. Accordingly, you may find

descriptions of individual features that do not apply to your specific appliance.

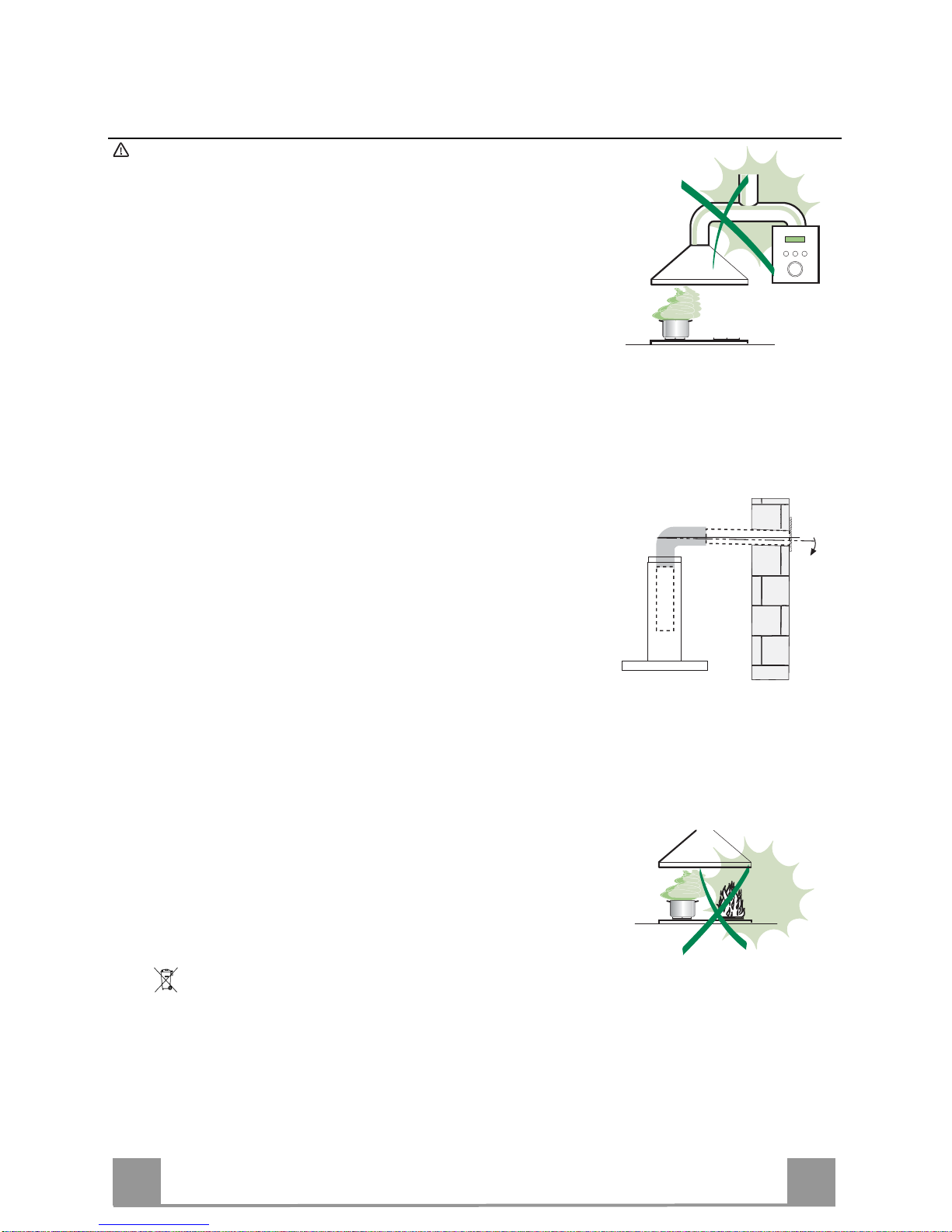

INSTALLATION

• The manufacturer will not be held liable for any damages resulting from incorrect or improper

installation.

• The minimum safety distance between the cooker top and the extractor hood is 650 mm (some

models can be installed at a lower height, please refer to the paragraphs on working dimensions

and installation).

• Check that the mains voltage corresponds to that indicated on the rating plate fixed to the inside of

the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum diameter 120 mm. The route

of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces,

etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas burning appliances), a

sufficient degree of aeration must be guaranteed in the room in order to prevent the backflow of

exhaust gas. The kitchen must have an opening communicating directly with the open air in order

to guarantee the entry of clean air. When the cooker hood is used in conjunction with appliances

supplied with energy other than electric, the negative pressure in the room must not exceed 0,04

mbar to prevent fumes being drawn back into the room by the cooker hood.

• In the event of damage to the power cable, it must be replaced by the manufacturer or by the

technical service department, in order to prevent any risks.

• If the instructions for installation for the gas hob specify a greater distance specified above, this has

to be taken into account. Regulations concerning the discharge of air have to be fulfilled.

USE

• The extractor hood has been designed exclusively for domestic use to eliminate kitchen smells.

• Never use the hood for purposes other than for which it has been designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that it does not

engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• Do not flambè under the range hood; risk of fire

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

• “ CAUTION: Accessible parts may become hot when used with cooking appliances.”.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance

work.

• Clean and/or replace the Filters after the specified time period (Fire hazard).

• Clean the hood using a damp cloth and a neutral liquid detergent.

The symbol on the product or on its packaging indicates that this product may not be treated as household waste. Instead it shall be handed over to the

applicable collection point f or the recycling of electrical and electronic equipment. By ensuring this product is di sposed of correctly, you will help prevent pote ntial negative

consequences for the environme nt and human health, which could otherwi se be caused by inappropriate waste handling of this product. For more detailed information

about recycling of this pr oduct, please contact your local city office, your household wa ste disposal service or the shop where you purchased the prod uct

.

2°

EN

4

4

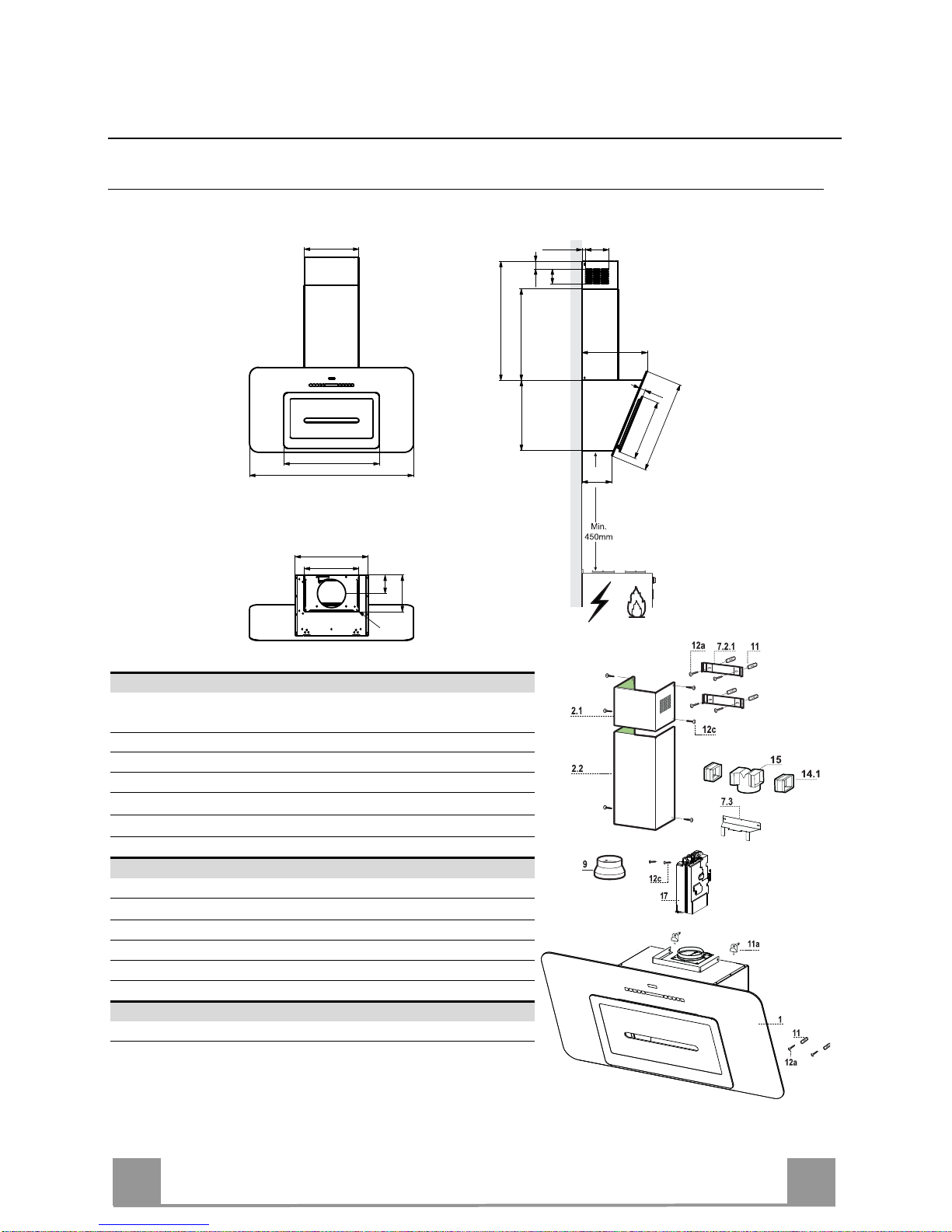

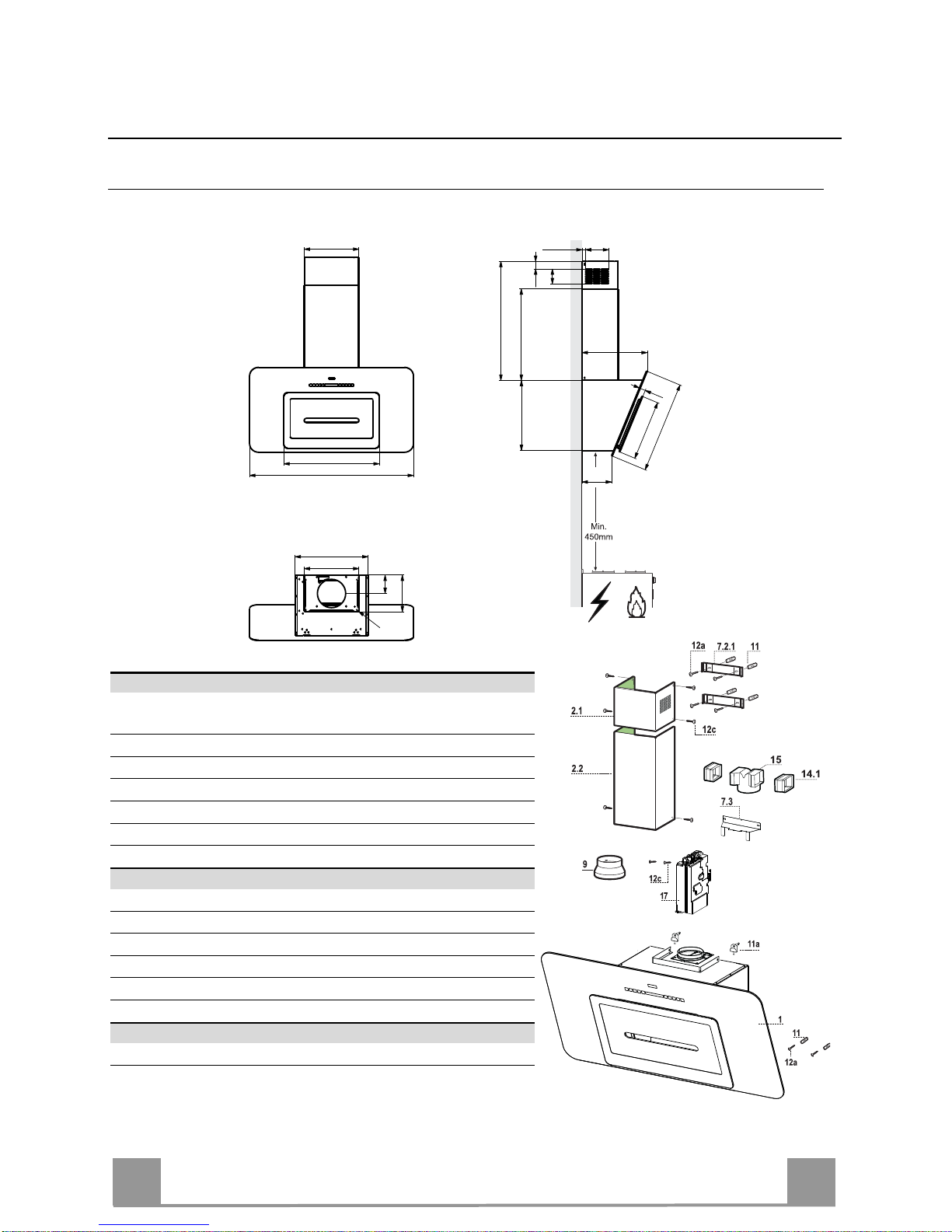

CHARACTERISTICS

Dimensions

898

300

520

41.5

81

19.2 126

Min.625 - Max.980

380

500

330

35

357

160

500

300

200

R

5

400

100

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

Filters

2.1 1 Upper Section

2.2 1 Lower Section

9 1 Flange

14.1 2 Air Outlet Connection Extension

15 1 Air Outlet Connection

17 1 Control board unit

Ref. Q.ty Installation Components

7.2.1 2 Upper Chimney Section Fixing Brackets

7.3 1 Air Outlet Connection Support

11 6 Wall Plugs

11a 2 Wall Plugs SB 12/10

12a 6 Screws 4,2 x 44,4

12c 8 Screws 2,9 x 6,5

Q.ty Documentation

1 Instruction Manual

EN

5

5

INSTALLATION

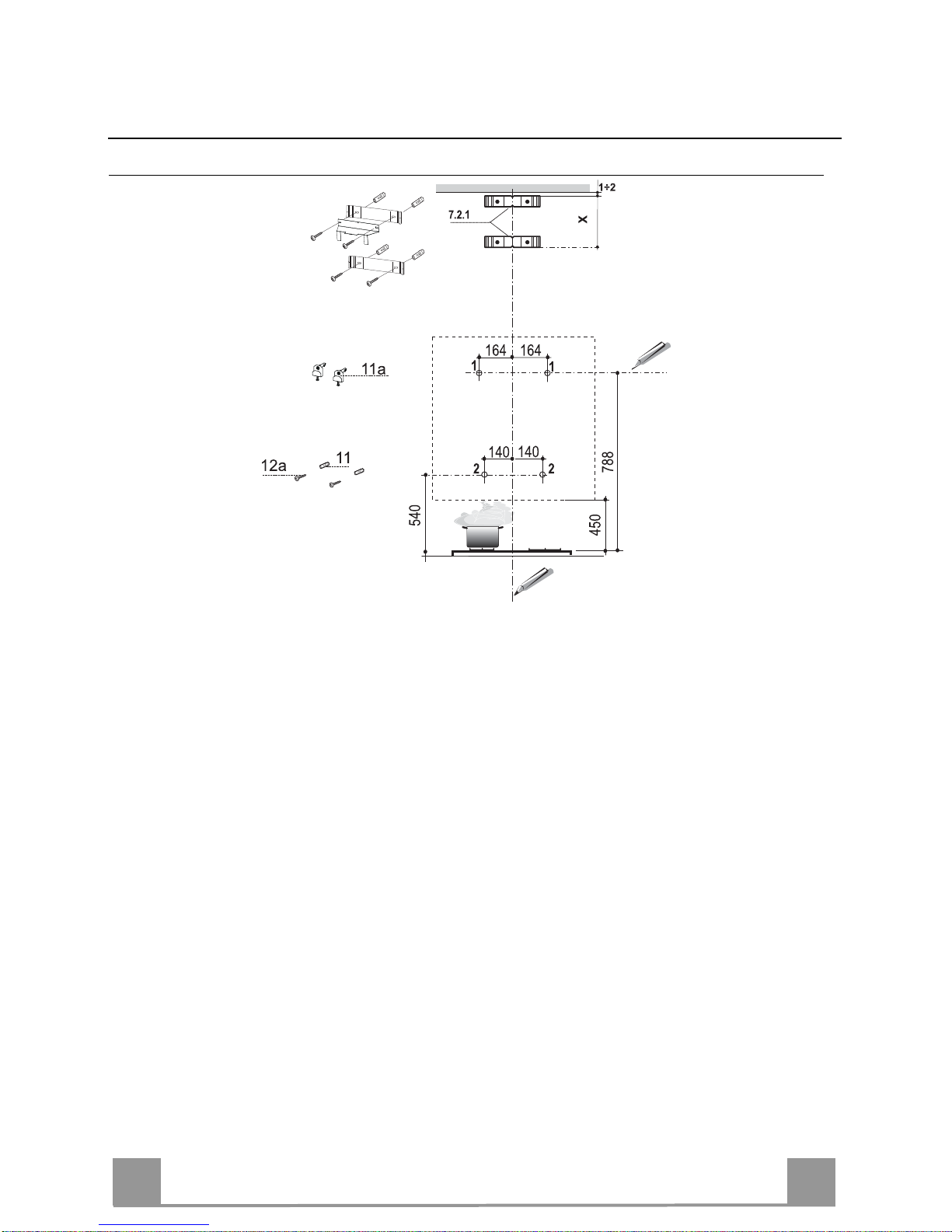

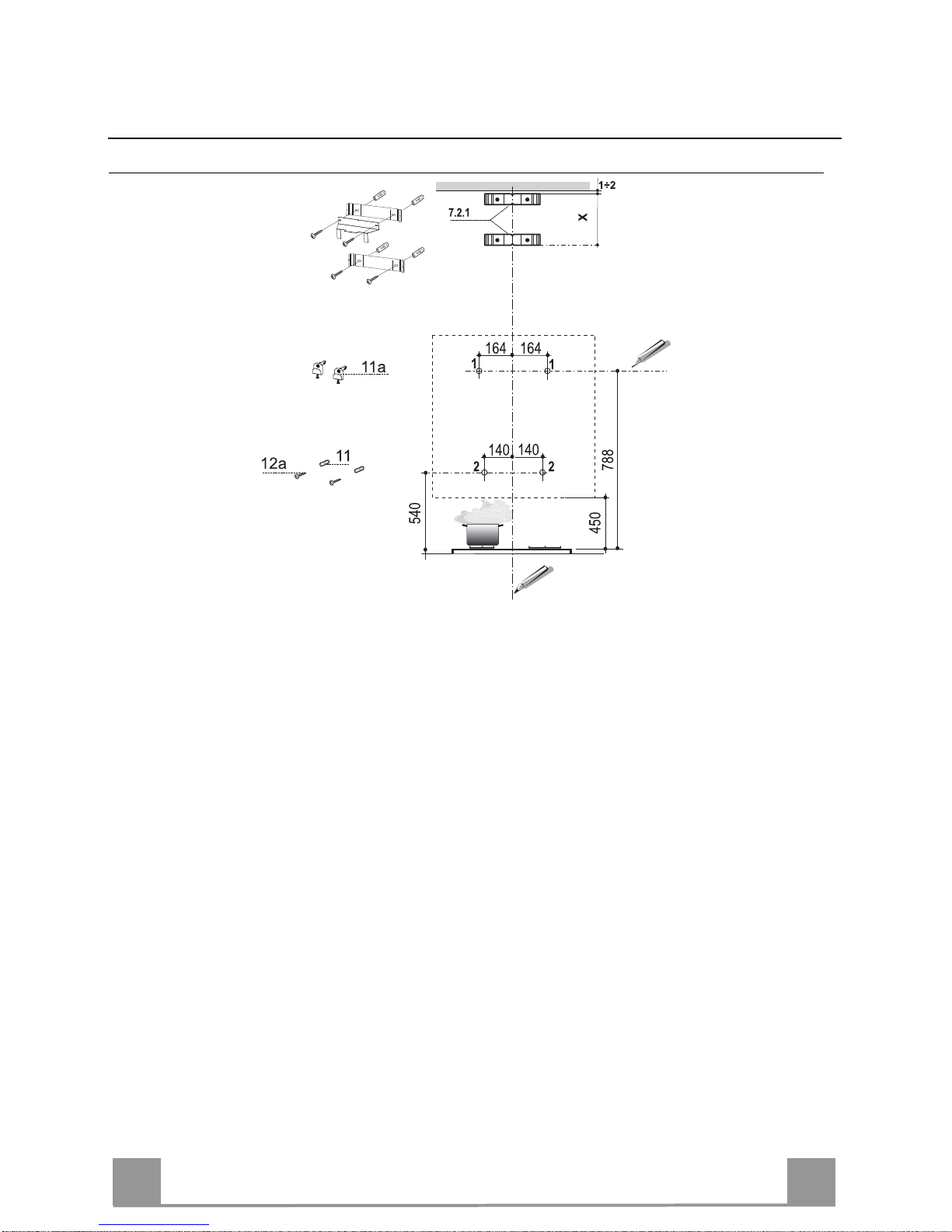

Wall drilling and bracket fixing

As a first step, proceed with the following drawings:

• a vertical line up to the ceiling or up to the upper limit, at the centre of the area in which the hood

is to be fitted;

• a horizontal line at a minimum 788 mm above the cooker top.

• Mark a point (1) on the horizontal line, 164 mm to the right of the vertical reference line.

• Repeat this operation on the other side, checking that the two marks are levelled.

• Mark a reference point (2) as indicated at 140 mm from the vertical reference line and 540 mm

above the cooker top.

• Repeat this operation on the other side, checking that the two marks are levelled.

• Drill at the marked points (1), using a ø 12 mm drill bit.

• Drill at the marked points (2) using a ø 8 mm drill bit.

• Insert the bracket plugs 11a into the holes (1) and tighten the screws.

• Insert plug 11 into holes (2).

• Place bracket 7.2.1 on the wall, about 1-2 mm from the ceiling or from the upper limit, aligning

the centre (notch) with the vertical reference line.

• Mark the wall at the centres of the bracket holes.

• Place the bracket 7.2.1 on the wall at X mm below the first bracket (X = height of the upper

chimney section), aligning the centre (notch) with the vertical line.

• Mark the wall at the centres of the bracket holes.

• Drill ø 8 mm holes at all the marked centre points.

• Insert the wall plugs 11 in the holes.

• Fix the lower bracket 7.2.1 using the 12a screws (4,2 x 44,4) supplied.

• Fix the upper bracket 7.2.1 and the air outlet connection support 7.3 together using the 2 screws

12a (4,2 x 44,4) supplied.

EN

6

6

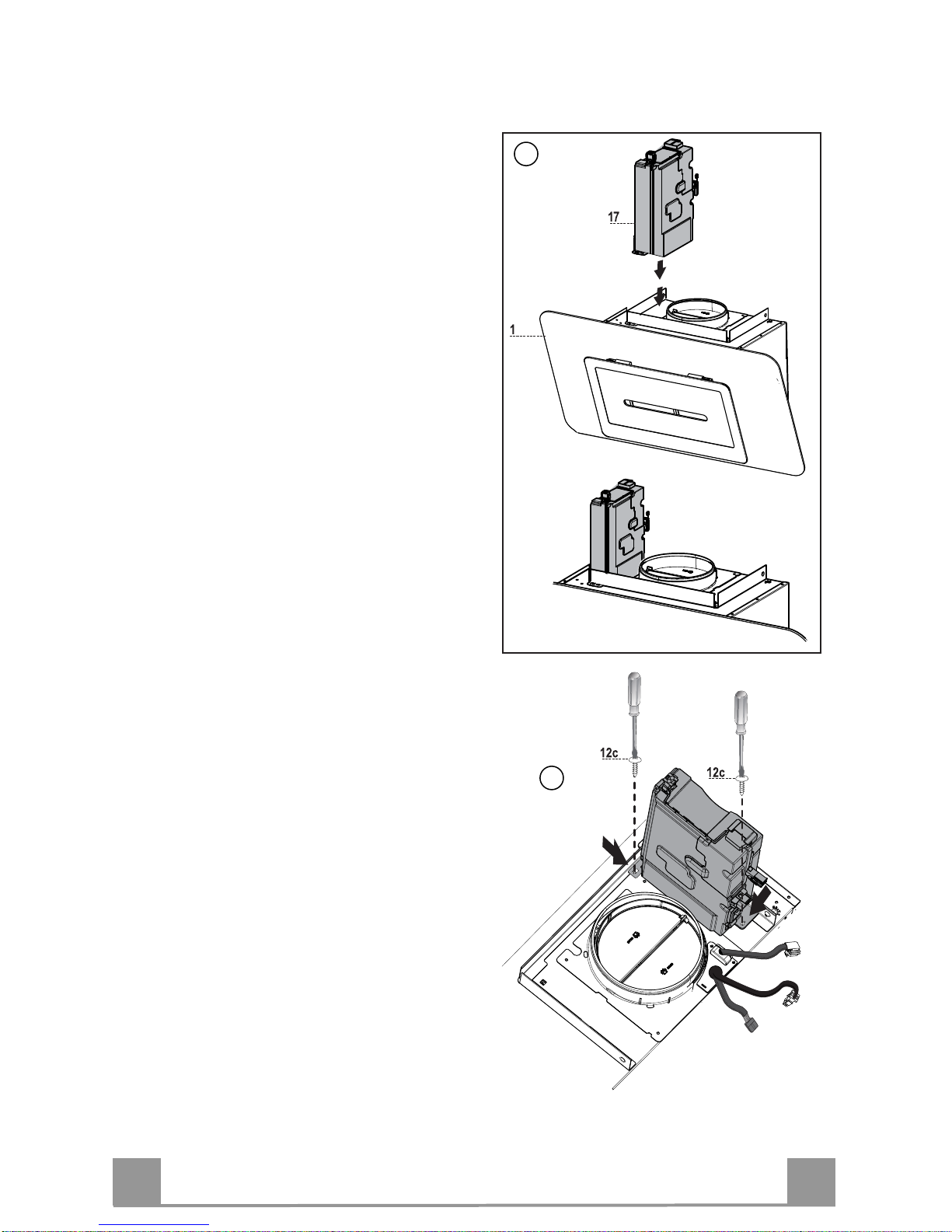

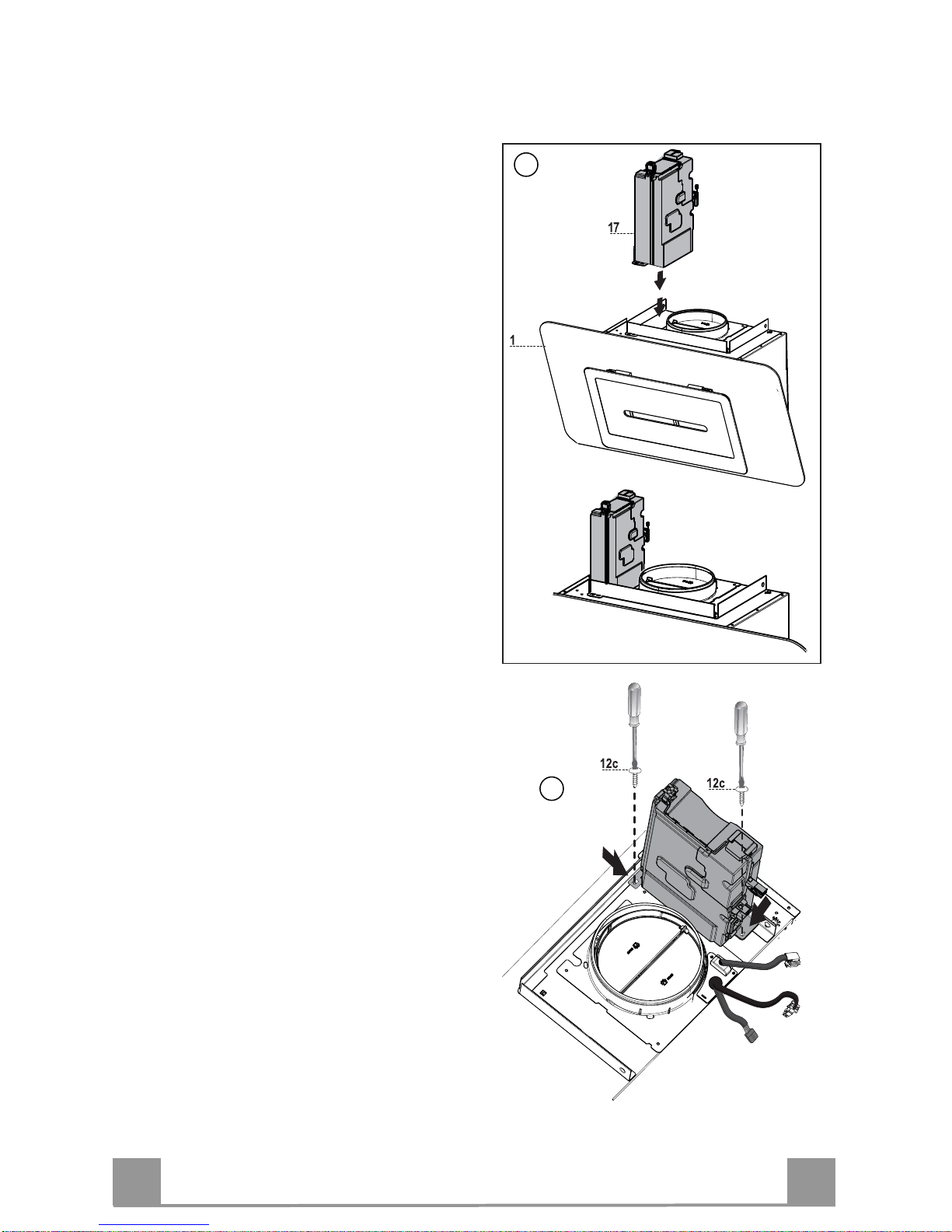

INSTALLATION OF CONTROL BOARD UNIT

1-Rest the control unit 17 on the hood can-

opy 1, positioning the unit so that the

connectors are turned towards the back of

the hood canopy

2-Fix the unit to the hood canopy, using the

2 screws 12c provided

1

2

EN

7

7

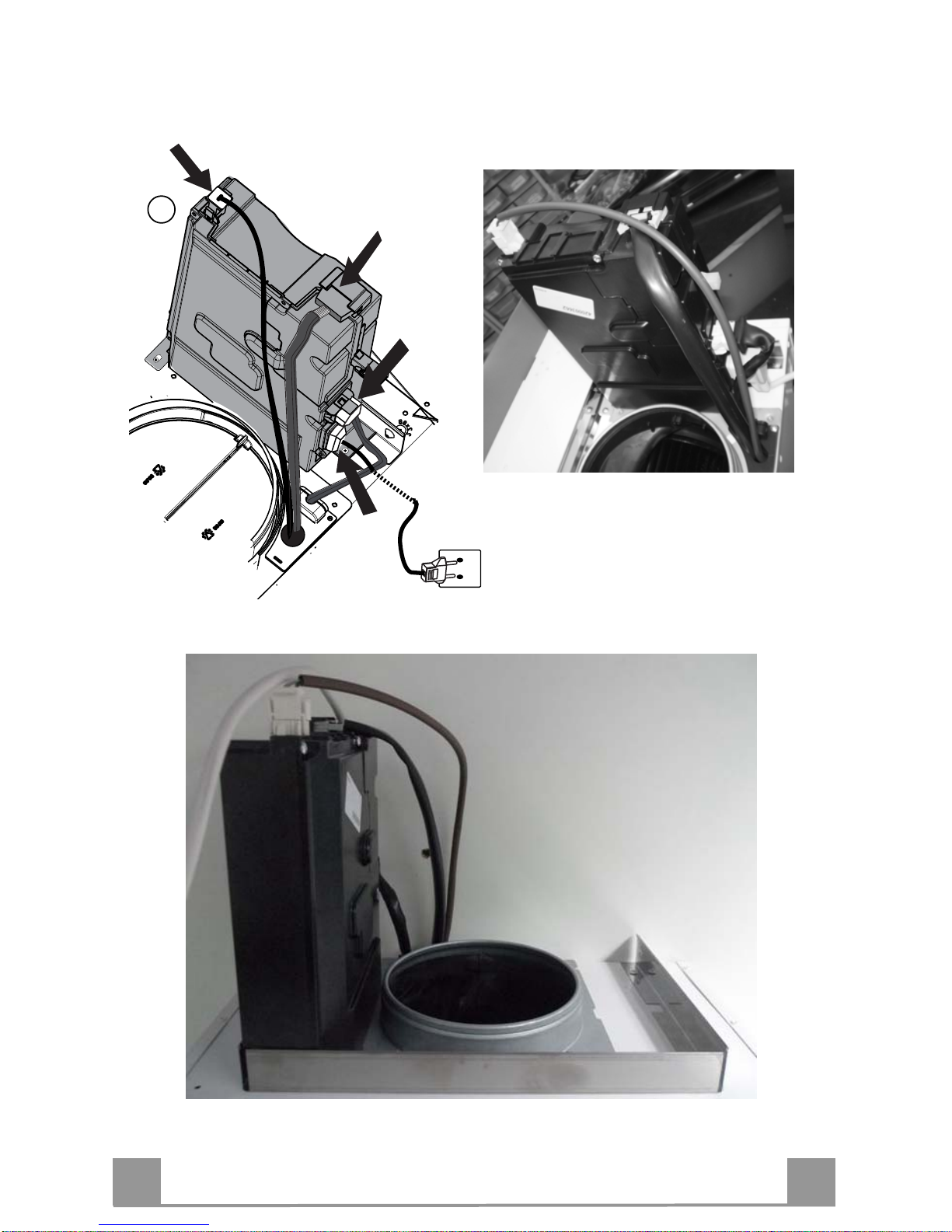

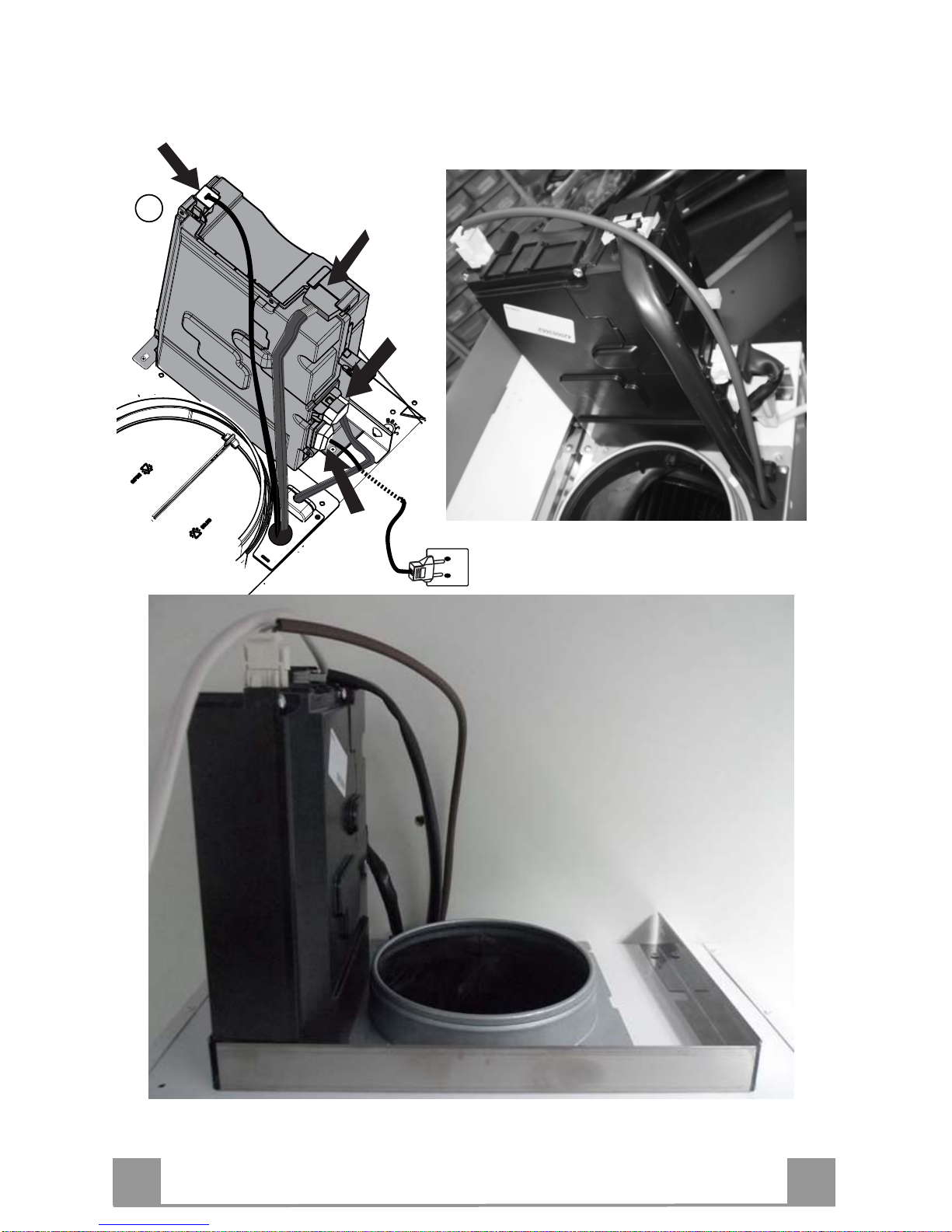

3-Make the electrical connections

3

EN

8

8

Fitting the hood body

• Open the doors/the door (See section Open

Panels).

• Remove the Metal grease filters using the

handles provided.

• Adjust the two screws Vr, in the brackets 11a,

so that they are at the start of their travel.

• Hook the hood body to the two brackets 11a.

• From the inside of the hood body, turn screws

Vr to level the hood body itself.

• Fasten the safety screw 12a.

• Close the doors/the door again.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the

hood to the chimney using either a flexible or

rigid pipe ø 150 or 120 mm, the choice of which

is left to the installer.

• To install a ø 120 mm air exhaust connection,

insert the reducer flange 9 on the hood body

outlet.

• Fix the pipe in position using sufficient pipe

clamps (not supplied).

• Remove any activated charcoal filters.

ø 150

9

ø 120

EN

9

9

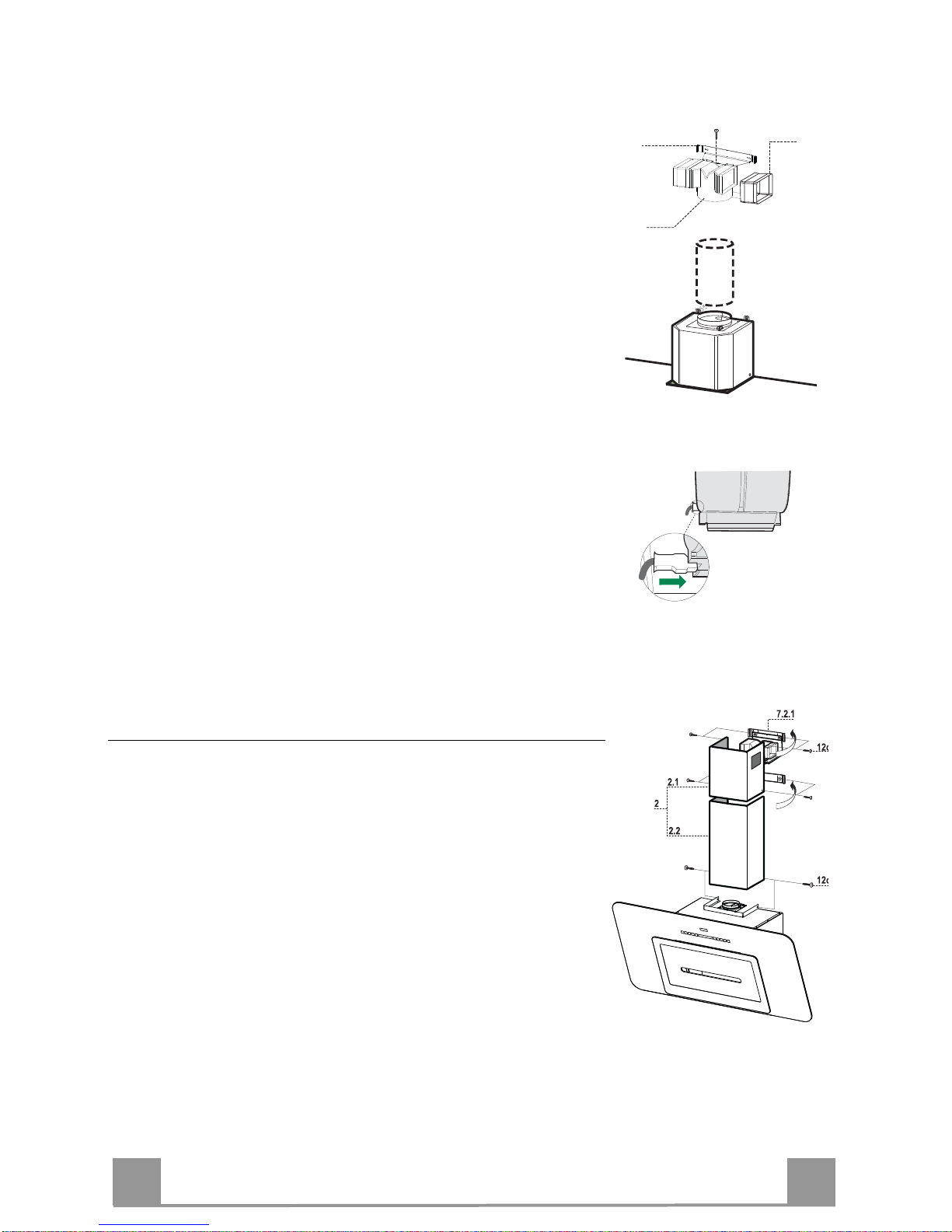

RECIRCULATION VERSION AIR OUTLET

• Insert the connection extension pieces laterally 14.1 in connection 15.

• Insert the Connector 15 into the Support bracket 7.3 and fix it

with a screw.

• Make sure that the outlet of the extension pieces 14.1 is horizontally and vertically aligned with the chimney outlets.

• Connect the air outlet connection 15 to the hood body outlet

using either a flexible or rigid pipe ø 150 mm, the choice of

which is left to the installer.

• Ensure that the activated charcoal filters have been inserted.

ø 150

15

14.1

7.3

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Remove the grease filters (see paragraph Maintenance) being

sure that the connector of the feeding cable is correctly inserted

in the socket placed on the side of the fan.

Flue assembly

Upper exhaust flue

• Slightly widen the two sides of the upper flue and hook them

behind the brackets 7.2.1, making sure that they are well

seated.

• Secure the sides to the brackets by using the 4 screws 12c (2,9

x 9,5) supplied.

• Make sure that the outlet of the extensions pieces is aligned

with the chimney outlets.

Lower exhaust flue

• Slightly widen the two sides of the flue and hook them between the upper flue and the wall, making sure that they are

well seated.

• Fix the lower part laterally to the hood body by using the 2

screws 12c (2,9 x 9,5) supplied.

EN

1

10

USE

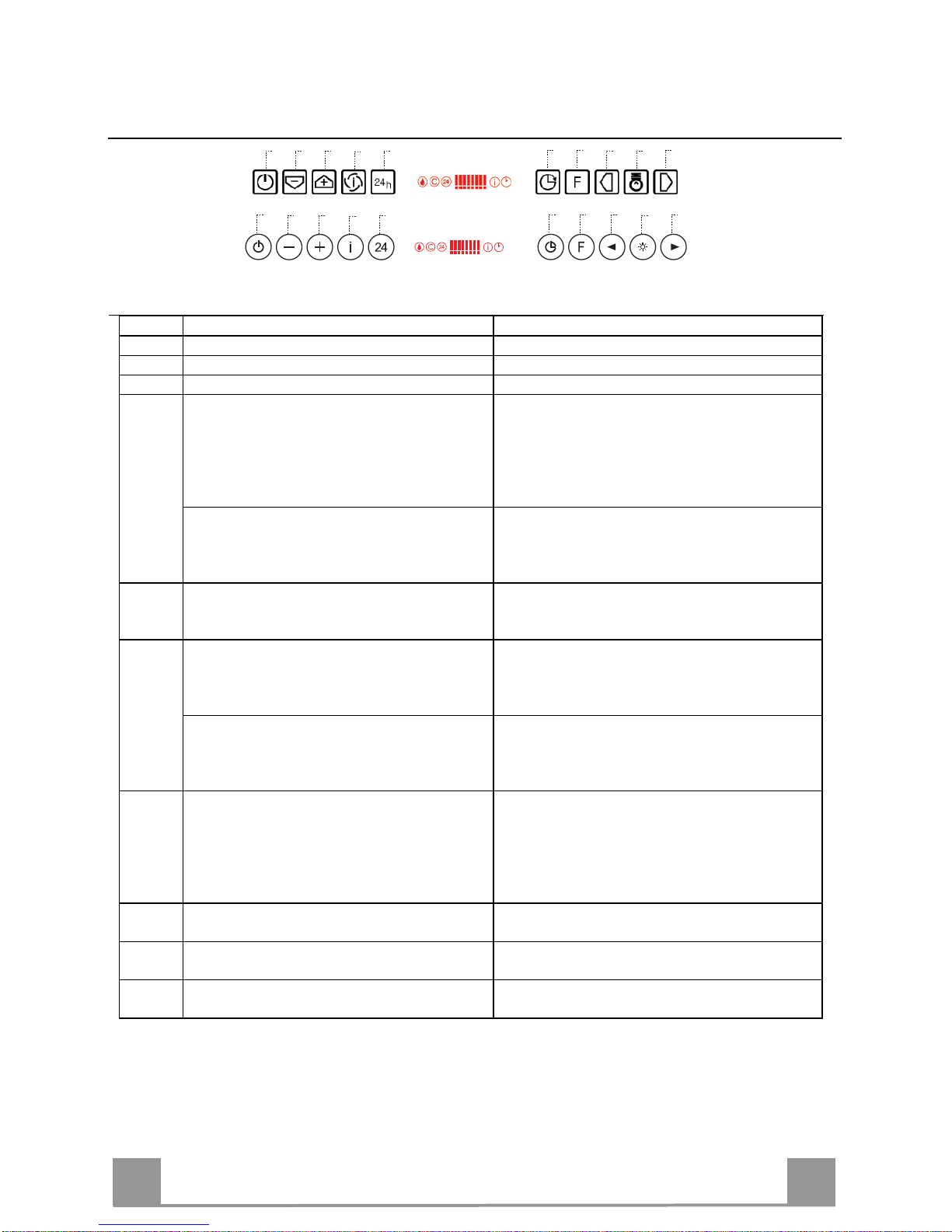

Control panel

Button Function Display

A Turns the suction motor on and off. -

B Decreases the working speed. The number of lighted segments decreases.

C Increases the working speed. The number of lighted segments increases.

D Activates Intensive speed from any other speed,

with the exception of Delay and 24H. This speed

is set to operate for 10 minutes, after which the

system returns to the speed that was set before.

Suitable to deal with maximum levels of cooking

fumes.

The indicator

I flashes and all the segments on the

Display are lit.

It is disabled by pressing the Button.

Pressing and holding the button for approximately

5 seconds, with all functions turned off

(Motor+Light), Enables / Disables the Activated

Charcoal Filter alarm.

2 Flashes of symbol C – Alarm Enabled.

1 Flash of symbol C – Alarm Disabled.

E Starts the Motor in Air Change mode, at a speed

that allows suction 10 minutes for hour, after

which the Motor will stop.

Displays

24 and the segments on the Display all light

up and then turn off one at a time in cycle.

It is disabled by pressing the Button.

F Activates automatic switch-off with a 30’ delay.

Suitable to complete elimination of residual

odours. Can only be activated with the motor

turned on at a Speed other than 24H and Intensive.

Displays a flashing

Clock symbol.

It is disabled by pressing the Button.

Press and hold the button for approximately 5

seconds to Enable / Disable the Remote control.

2 Flashes of the Horizontal Bars – Remote Control

Enabled.

1 Flash of the Horizontal Bars – Remote Control

Disabled.

G Performs a Reset of the Filter saturation alarm

when the Button is pressed for approximately 3

seconds.

After 100 hours in operation the

Drop symbol is

displayed to indicate saturation of the Metal Grease

Filters.

After 200 hours in operation the letter

C is displayed

to indicate saturation of the Activated Charcoal

filters.

H Decreases the intensity of the Lighting each time

the Button is pressed, in cycle.

I Turns the lighting system on and off at maximum

intensity.

L Increases the intensity of the Lighting each time

the Button is pressed, in cycle.

Keyboard Lock: it is possible to lock the keyboard, for example when cleaning the Glass surface, when the

Hood has Motor and Lights turned off.

Press A for approximately 5 Seconds to enable or disable the Keyboard Lock, which is always confirmed

by a Beep and an animation on the display motor bar.

B

A

D

C

E

G

F

I

H

L

B

A

D

C

E

G

F

I

H

L

EN

1

11

MAINTENANCE

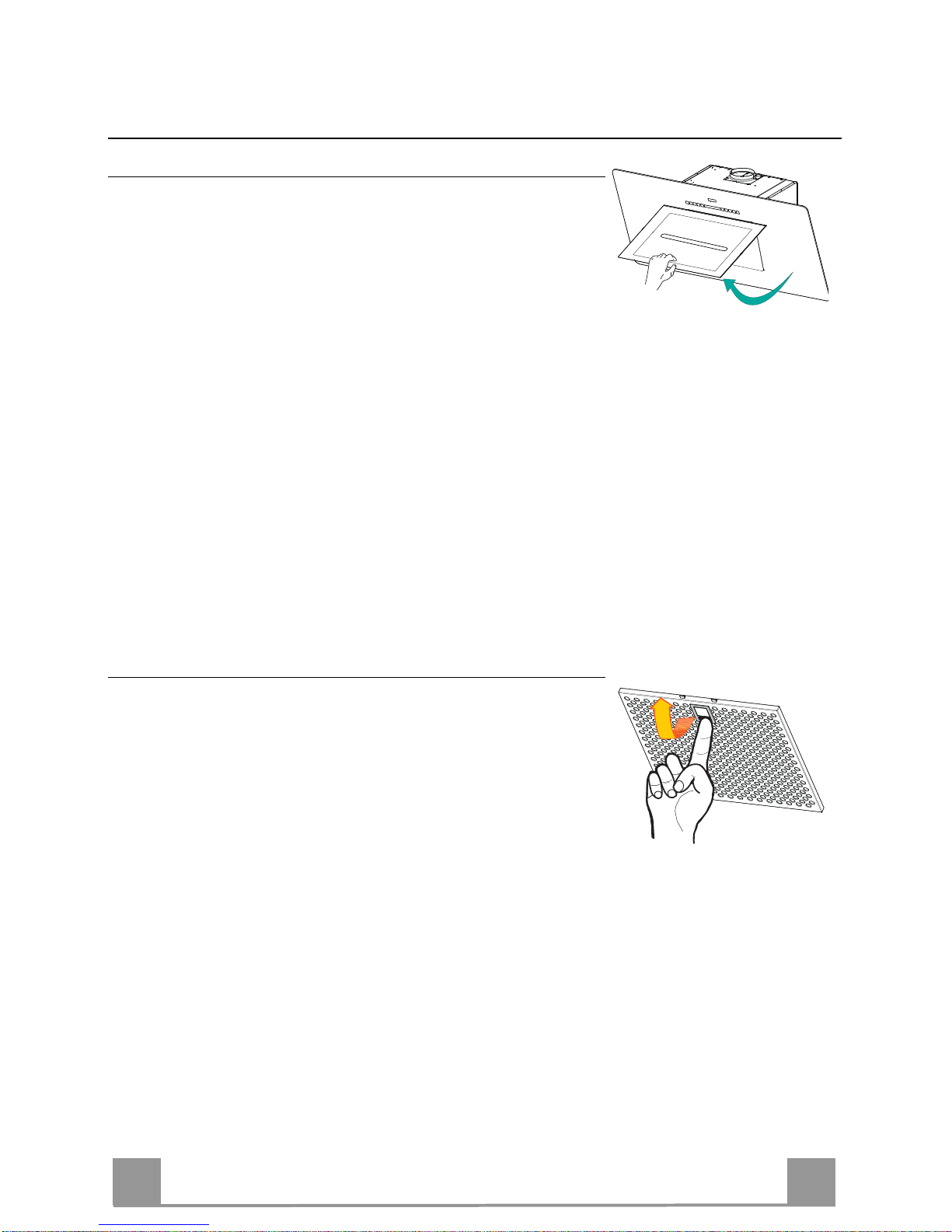

Opening Panel

• Open the Panel by pulling it.

• The panel can be locked in any position.

• Clean the outside with a damp cloth and neutral detergent.

• Clean the inside using a damp cloth and neutral detergent; do

not use wet cloths or sponges, or jets of water; do not use

abrasive substances.

Metal grease filters

Metal filters can be washed also in a dish machine. They need to

be washed every time a drop-symbol appears in the display or at

least every two months. In case of very frequent use these have to

be washed even more often.

Alarm reset

• Press the G-key for at least 2 seconds.

Cleaning

• Pull the comfort panels to open them.

• Remove the filters one at a time holding them up with one

hand and pulling the handle downwards with the other hand at

the same time.

• Wash the filters. Pay attention not to bend them. Make sure

that filters are completely dry before putting them into their

seat. (a possible modification of the filter surface doesn’t influence its efficiency).

• Place the filters again into their seats and make sure that the

handle of the filter remains outside.

• Close the comfort panel.

EN

1

12

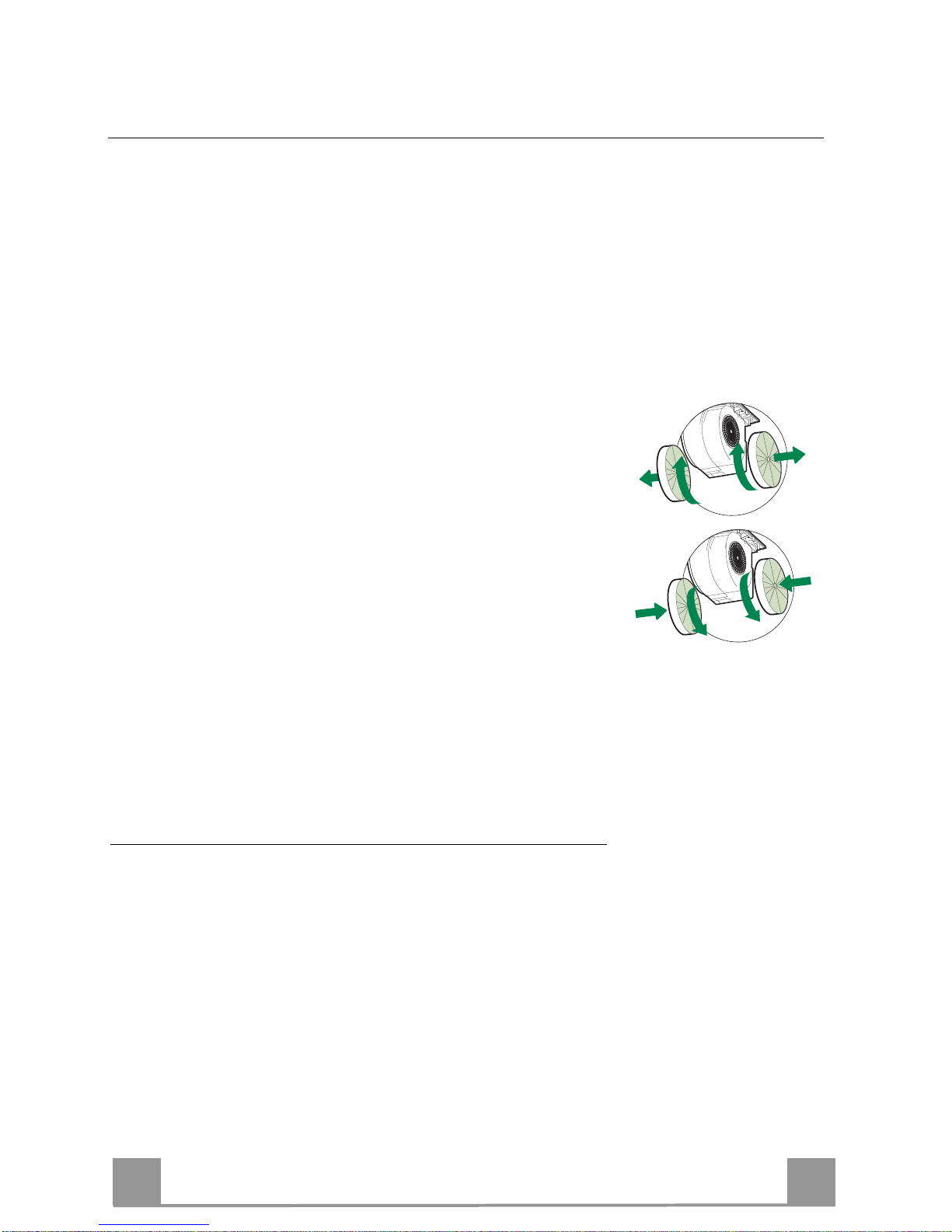

Charcoal filter (recycling version)

This filter cannot be washed or regenerated. It must be replaced when the C appears on the

display or at least once every 4 months. The filter saturation alarm has to be activated already

before.

Activation of the alarm signal

• In the recycling version hoods the filter saturation alarm must be activated during the installation or later.

• Switch off the hood and the lights.

• Press the D-key for about 5 seconds.

• 2 flash C-symbol lit - charcoal filter saturation alarm ACTIVATED.

• 1 flash C-symbol lit - charcoal filter saturation alarm DEACTIVATED.

CHANGING THE ACTIVATED CHARCOAL FILTER

Resetting the alarm signal

• Turn the Lights and the Suction Motor off.

• Press button G and hold it for at least 2 seconds.

Changing the Filter

• Pull the comfort panels to open them.

• Remove the grid by pulling it from the side.

• Remove the saturated Activated Charcoal Filters, as indicated (A).

• Fit the new Filters, as indicated (B).

• Replace the Grid.

• Close the comfort panel.

A

B

Lighting unit

Warning: This appliance is fitted with a white LED lamp classed

as 1M according to EN 60825-1: 1994 + A1:2002 + A2:2001

standards; maximum optical power emitted @439nm: 7µW. Do

not look directly at the light through optical devices (binoculars,

magnifying glasses…).

• For replacement contact technical support. ("To purchase contact technical support")

IT

1

13

CONSIGLI E SUGGERIMENTI

Questo libretto di istruzioni per l'uso è previsto per più versioni dell' apparecchio. É possibile che siano

descritti singoli particolari della dotazione, che non riguardano il Vostro apparecchio.

INSTALLAZIONE

• Il produttore declina qualsiasi responsabilità per danni dovuti ad installazione non corretta o non conforme

alle regole dell’arte.

• La distanza minima di sicurezza tra il Piano di cottura e la Cappa deve essere di 650 mm, (alcuni modelli

possono essere installati ad un’altezza inferiore, fare riferimento ai paragrafi ingombro e installazione).

• Verificare che la tensione di rete corrisponda a quella riportata nella targhetta posta all’interno della Cappa.

• Per Apparecchi in Classe I

a

accertarsi che l’impianto elettrico domestico garantisca un corretto scarico a

terra.

• Collegare la Cappa all’uscita dell’aria aspirata con tubazione di diametro pari o superiore a 120 mm. Il

percorso della tubazione deve essere il più breve possibile.

• Non collegare la Cappa a condotti di scarico dei fumi prodotti da combustione (caldaie, caminetti, ecc.).

• Nel caso in cui nella stanza vengano utilizzati sia la Cappa che apparecchi non azionati da energia elettrica

(ad esempio apparecchi utilizzatori di gas), si deve provvedere ad una aerazione sufficiente dell’ambiente.

Se la cucina ne fosse sprovvista, praticare un’apertura che comunichi con l’esterno, per garantire il richiamo d’aria pulita. Un uso proprio e senza rischi si ottiene quando la depressione massima del locale non

supera i 0,04 mBar.

• In caso di danneggiamento del cavo alimentazione, esso deve essere sostituito dal costruttore o dal servizio di assistenza tecnica, in modo da prevenire ogni rischio.

• Se le istruzioni di installazione del dispositivo di cottura a gas indicano che è necessaria una distanza

maggiore di quella indicato sopra, è necessario tenerne conto. Bisogna rispettare tutte le normative relative

allo scarico dell’aria.

USO

• La Cappa è stata progettata esclusivamente per uso domestico, per abbattere gli odori della cucina.

• Non fare mai uso improprio della Cappa.

• Non lasciare fiamme libere a forte intensità sotto la Cappa in funzione.

• Regolare sempre le fiamme in modo da evitare una evidente fuoriuscita laterale delle stesse rispetto al

fondo delle pentole.

• Controllare le friggitrici durante l’uso: l’olio surriscaldato potrebbe infiammarsi.

• Non preparare alimenti flambè sotto la cappa da cucina; pericolo d'incendio.

• Questo apparecchio non deve essere utilizzato da persone (bambini inclusi) con ridotte capacità psichiche,

sensoriali o mentali, oppure da persone senza esperienza e conoscenza, a meno che non siano controllati

o istruiti all’uso dell’apparecchio da persone responsabili della loro sicurezza.

• I bambini devono essere supervisionati per assicurarsi che non giochino con l’apparecchio.

• “ATTENZIONE: Le parti accessibili possono diventare molto calde se utilizzate con degli apparecchi di

cottura”.

MANUTENZIONE

• Prima di procedere a qualsiasi operazione di manutenzione, disinserire la Cappa togliendo la spina elettrica o spegnendo l’interruttore generale.

• Effettuare una scrupolosa e tempestiva manutenzione dei Filtri secondo gli intervalli consigliati (Rischio di

incendio).

• Per la pulizia delle superfici della Cappa è sufficiente utilizzare un panno umido e detersivo liquido neutro.

Il simbolo sul prodotto o sulla confezione indica che il prodotto non deve essere considerato come un normale

rifiuto domestico, ma deve essere portato nel punto di raccolta appropriato per il riciclaggio di apparecchiature elettriche

ed elettroniche. Provvedendo a smaltire questo prodotto in modo appropriato, si contribuisce a evitare potenziali conseguenze negative per l’ambiente e per la salute, che potrebbero derivare da uno smaltimento inadeguato del prodotto.

Per informazioni più dettagliate sul riciclaggio di questo prodotto, contattare l’ufficio comunale, il servizio locale di smaltimento rifiuti o il negozio in cui è stato acquist ato il prodotto.

2°

IT

1

14

CARATTERISTICHE

Ingombro

898

300

520

41.5

81

19.2 126

Min.625 - Max.980

380

500

330

35

357

160

500

300

200

R

5

400

100

Componenti

Rif. Q.tà Componenti di Prodotto

1 1 Corpo Cappa completo di: Comandi, Luce, Gruppo

Ventilatore, Filtri

2.1 1 Camino Superiore

2.2 1 Camino Inferiore

9 1 Flangia riduzione 150-120

14.1 2 Prolunga Raccordo Uscita Aria

15 1 Raccordo Uscita Aria

17 1 Gruppo Controlli

Rif. Q.tà Componenti di Installazione

7.2.1 2 Staffe Fissaggio Camino Superiore

7.3 1 Staffa Sostegno Raccordo

11 6 Tasselli

11a 2 Tasselli SB 12/10

12a 6 Viti 4,2 x 44,4

12c 8 Viti 2,9 x 6,5

Q.tà Documentazione

1 Libretto Istruzioni

IT

1

15

INSTALLAZIONE

Foratura Parete e Fissaggio Staffe

Tracciare sulla Parete:

• una linea Verticale fino al soffitto o al limite superiore, al centro della zona prevista per il montaggio

della Cappa;

• una linea Orizzontale a 788 mm min. sopra il Piano di Cottura.

• Segnare un punto (1) sulla linea orizzontale a 164 mm alla destra della linea verticale di riferimento.

• Ripetere questa operazione dalla parte opposta, verificandone il livellamento.

• Segnare come indicato, un punto di riferimento (2) a 140 mm dalla linea Verticale di riferimento, e

540 mm sopra il Piano di Cottura.

• Ripetere questa operazione dalla parte opposta, verificandone il livellamento.

• Forare ø 12 mm i punti (1) segnati.

• Forare ø 8 mm i punti (2) segnati.

• Inserire i tasselli con staffa 11a nei fori (1) e avvitare.

• Inserire il tassello 11 nei fori (2).

• Appoggiare come indicato la Staffa 7.2.1 a 1-2 mm dal soffitto o dal limite superiore, allineando il

suo centro (intagli) sulla linea Verticale di riferimento.

• Segnare i centri dei Fori della Staffa.

• Appoggiare come indicato la Staffa 7.2.1 a X mm sotto la prima staffa (X = altezza Camino Superio-

re in dotazione), allineando il suo centro (intagli) sulla linea Verticale di riferimento.

• Segnare i centri dei Fori della Staffa.

• Forare ø 8 mm i punti segnati.

• Inserire i tasselli 11 nei fori.

• Fissare la Staffa inferiore 7.2.1 utilizzando le Viti 12a (4,2 x 44,4 ) in dotazione.

• Fissare insieme la Staffa superiore 7.2.1 e la Staffa sostegno raccordo 7.3 utilizzando le 2 viti 12a

(4,2 x 44,4) in dotazione.

IT

1

16

INSTALLAZIONE GRUPPO CONTROLLI

1-Appoggiare il gruppo controlli 17 al cor-

po cappa 1, posizionando il gruppo in

modo che i connettori siano rivolti verso

il lato posteriore del corpo cappa

2-Fissare il gruppo al corpo cappa, utiliz-

zando le 2 viti 12c in dotazione

1

2

IT

1

17

3-Effettuare le connessioni elettriche

3

Loading...

Loading...