Fostex CR-300 Service manual

Service Manual

Model

COMPACT DISC RECORDER

FOR U.S. MODELS

NECESSARY INFORMATION FOR DHHS

RULES MARKED ON THE REAR BASE AND ON

THE TOP OF CD MECHANISM AS BELOW.

DANGER - LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO PREVENT ELECTRIC SHOCK, MATCH

WIDE BLADE OF PLUG TO WIDE SLOT,

FULLY INSERT.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

The lightening flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product's enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

“WARNING”

“TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.”

SAFETY INSTRUCTIONS

Read instructions - All the safety and operating instruc-

1.

tions should be read before the appliance is operated.

Retain instructions - The safety and operating instructions

2.

should be retained for future reference.

Heed warnings - All warnings on the appliance and in the

3.

operating instructions should be adhered to.

Follow instructions - All operating and use instructions

4.

should be followed.

Water and Moisture - The appliance should not be used

5.

near water - for example, near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement, or near a

swimming pool, and the like.

Carts and Stands - The appliance should be used only

6.

with a cart or stand that is recommended by the manufacturer.

An appliance and cart combination should be moved with

care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

Wall or Ceiling Mounting - The appliance should be

7.

mounted to a wall or ceiling only as recommended by the

manufacturer.

Ventilation - The appliance should be situated so that its

8.

location or position does not interfere with its proper ventilation. For example, the appliance should not be situated on a bed, sofa, rug, or similar surface that may block

the ventilation openings; or, placed in a built-in installation, such as a bookcase or cabinet that may impede the

flow of air through the ventilation openings.

ATTENTION:

POUR ÉVITER LES CHOCS ÉLECTRIQUES,

INTRODUIRE LA LAME LA PLUS LARGE DE

LA FICHE DANS LA BORNE CORRESPONDANTE DE LA PRISE ET POUSSER

JUSQU' AU FOND.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Heat - The appliance should be situated away from heat

9.

sources such as radiators, heat registers, stoves, or other

appliances (including amplifiers) that produce heat.

Power Sources - The appliance should be connected to a

10.

power supply only of the type described in the operating

instructions or as marked on the appliance.

Grounding or Polarization - The precautions that should

11.

be taken so that the grounding or polarization means of

an appliance is not defeated.

Power Cord Protection - Power supply cords should be

12.

routed so that they are not likely to be walked on or

pinched by items placed upon or against them, paying

particular attention to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

Cleaning - The appliance should be cleaned only as rec-

13.

ommended by the manufacturer.

Nonuse Periods - The power cord of the appliance should

14.

be unplugged from the outlet when left unused for a long

period of time.

Object and Liquid Entry - Care should be taken so that

15.

objects do not fall and liquids are not spilled into the enclosure through openings.

Damage requiring Service - The appliance should be ser-

16.

viced by qualified service personnel when:

The power supply cord or the plug has been damaged;

A.

or

Objects have fallen, or liquid has been spilled into the

B.

appliance; or

The appliance has been exposed to rain; or

C.

The appliance does not appear to operate normally or

D.

exhibits a marked changed in performance; or

The appliance has been dropped, or the enclosure

E.

damaged.

Servicing - The user should not attempt to service the ap-

17.

pliance beyond that described in the operating instructions. All other servicing should be referred to qualified

service personnel.

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 Ð Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÉLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

CR300

(FOR USA MODEL ONLY)

SAFETY PRECAUTIONS

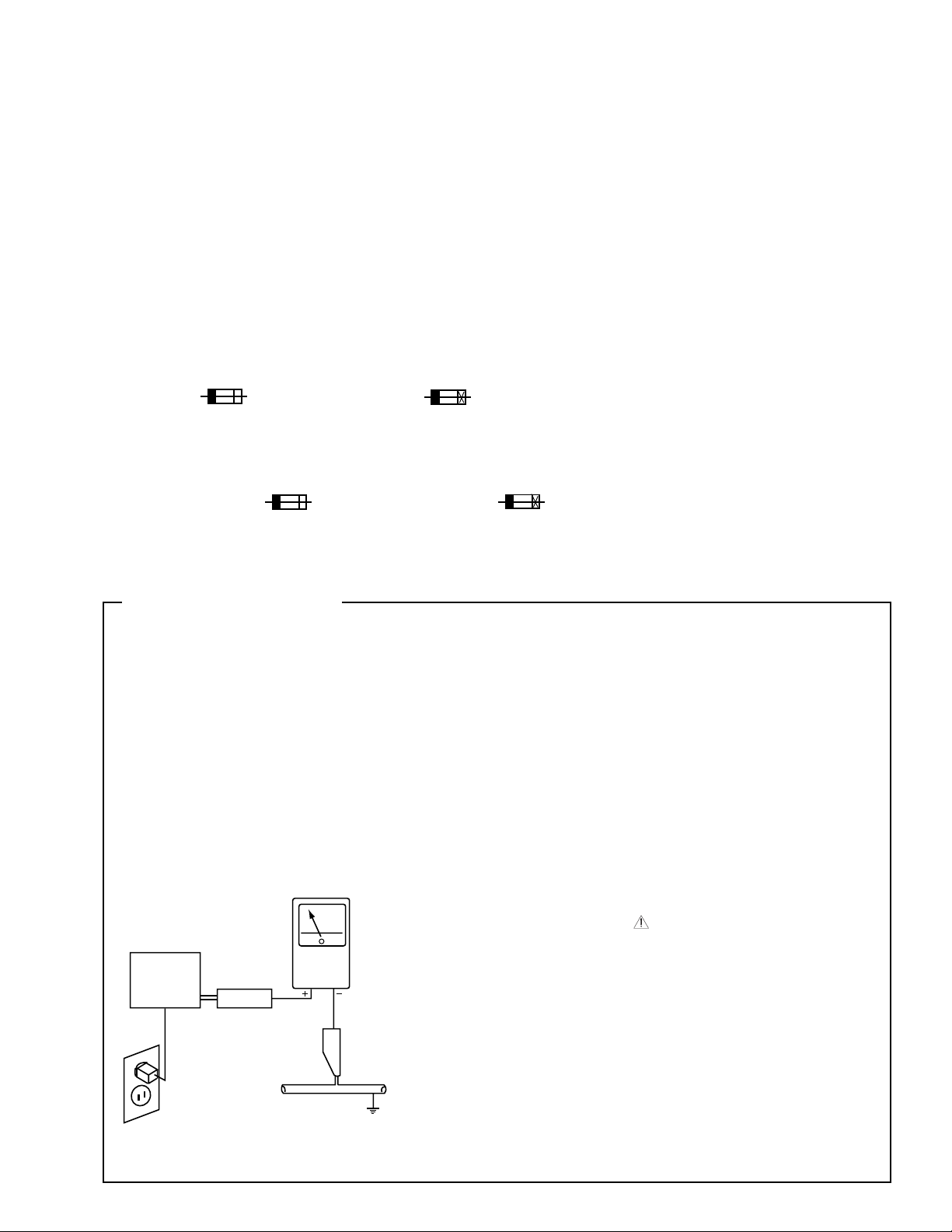

The following check should be performed for the continued

protection of the customer and service technician.

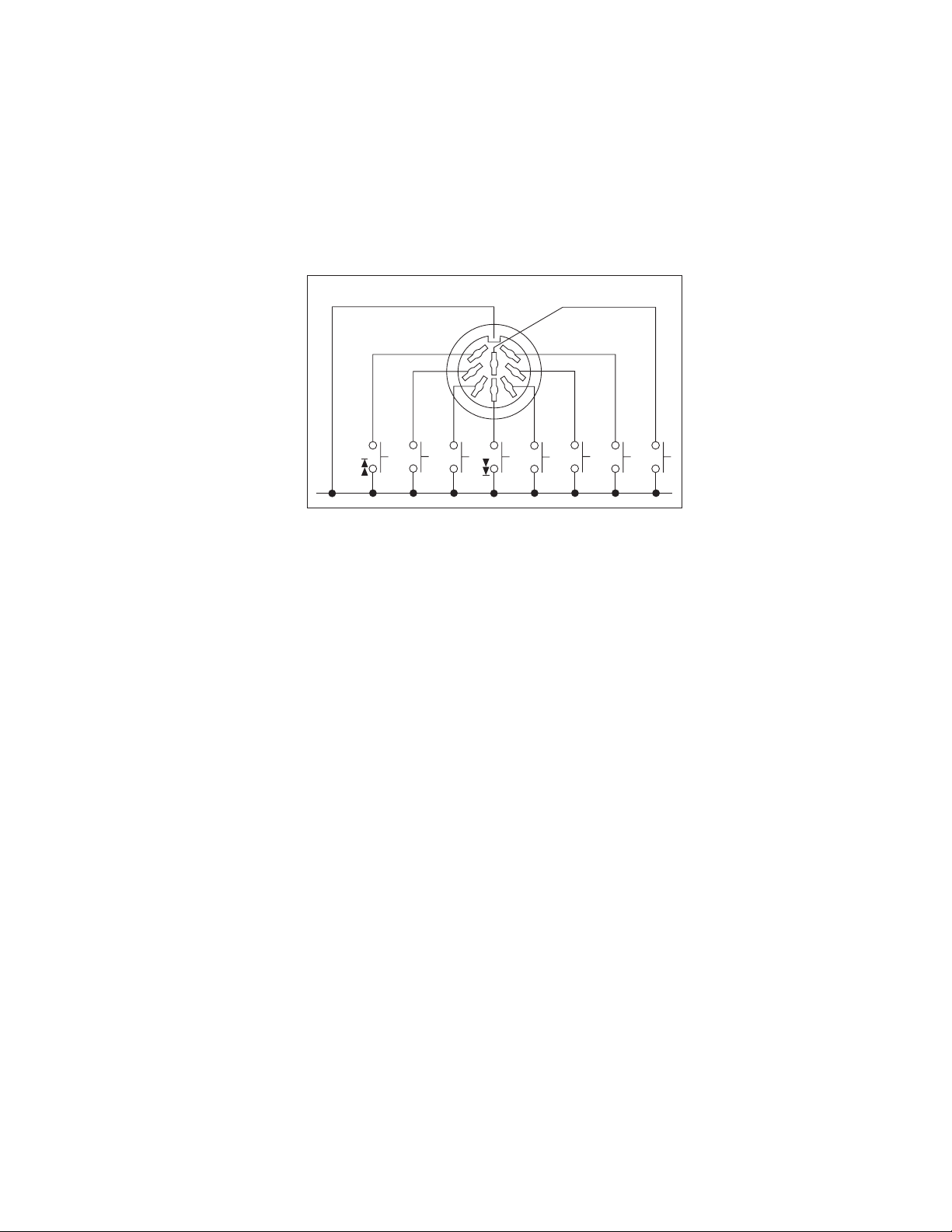

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screw heads, metal overlays,

control shaft, etc.). Plug the AC line cord of the appliance

directly into a 120V AC 60Hz outlet and turn the AC power

switch on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Device

under

test

Test all

exposed metal

surfaces

Leakage

current

tester

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded

by them necessarily can be obtained by using replacement

components rated for voltage, wattage, etc. Replacement

parts which have these special safety characteristics are

identified in this Service Manual.

Electrical components having such features are identified

by marking with a on the schematics and on the parts list

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other

hazards.

Also test with

plug reversed

(Using AC adapter

plug as required)

AC Leakage Test

Earth

ground

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

3

CR300

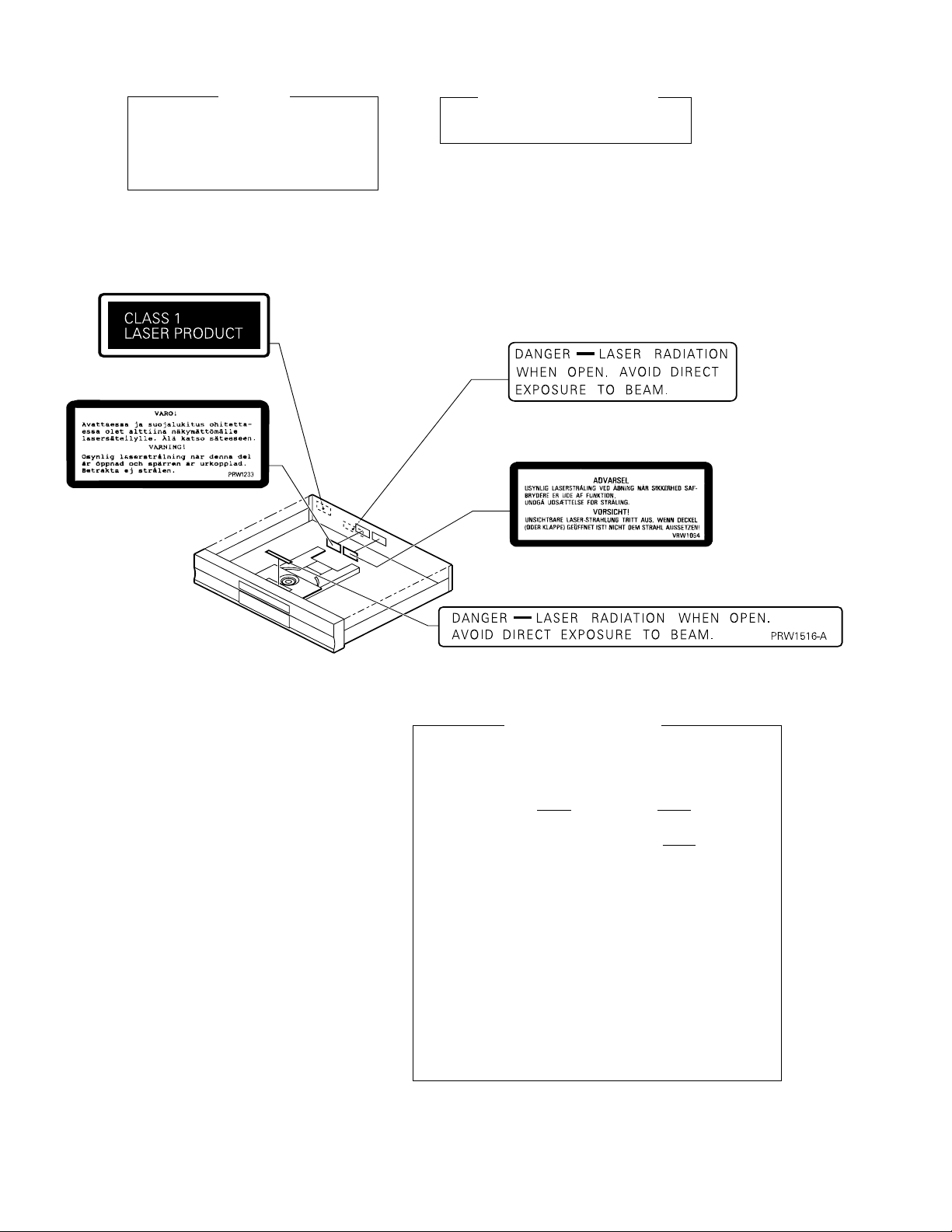

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS ΙΙΙ b.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LABEL CHECK

CR300 EUR

Printed on Rear Panel

CR300 EUR

IMPORTANT

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 23 mW

WAVELENGTH: 778 - 787 nm

CR300 USA

Printed on Rear Panel

CR300 EUR

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S601) for detecting loading

state is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch

(S601) is not on CLMP terminal side (CLMP signal is OFF

or high level.). Thus, the interlock will no longer function if

the switch (S601) is deliberately set to CLMP terminal side

(low level).

The interlock also does not function in the test mode *.

Laser diode oscillation will continue, if pin 1 of M51593FP

(IC101) on the PRE-AMP BOARD ASSY mounted on the

pickup assembly is connected to GND, or pin 19 is

connected to low level (ON), or else the terminals of Q101

are shorted to each other (fault condition).

2. When the cover is opened with the servo mechanism block

removed and turned over, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

* Refer to page 13.

4

TABLE OF CONTENTS

CR300

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONTROLS, INDICATORS & CONNECTORS . . . . . . . . . . .

3. ADJUSTMENT PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . .

4. ASSEMBLING & DISASSEMBLING . . . . . . . . . . . . . . . . . .

5. EXPLODED VIEW, PCB ASSEMBLY & PARTS LIST . . . . .

6. CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . .

6

9

13

19

25

37

50

NOTES

Adjusting procedures, assembling & disassembling, exploded view, PCB assembly, parts list, circuit diagrams

*

and general information are given in this manual to assist the service technician in maintaining the Model

CR300.

CAUTION

Parts marked with this sign are safety critical components. They must always be replaced with identical

components. Refer to the Fostex Parts List and ensure exact replacement.

5

CR300

1. SPECIFICATIONS

FUNCTION LIST

Automatic Disk Recognition

Sampling Rate Converter Automatic conversion (48 kHz, 32 kHz → 44.1 kHz)

Synchronous Recording Synchronous to one song / all songs / DAT ID

Auto Stop Delay in Digital Synchro 0 sec, 10 sec, off

Copy Bit Setting No restriction / one time only / prohibited

Auto Track Increment 6 levels

Manual Track Increment

REC MUTE

Fade In / Fade Out Fade time: 6 sec, 9 sec, 12 sec, 18 sec

PREVIOUS End section of previous track can be played back while in

Erase Mode (CD-RW) Last Track, All Track, Disc, TOC

Direct Search Operational through remote controller only

Track Search

Manual Search

One Song / All Song / Program Repeat Operational through remote controller only

Program Playback

Skip Playback

Sampling Monitor

Displayed Time Elapsed playback time, Remaining playback time,

Laser Hour Meter

Margin Display

Auto Pause

Auto Power Calibration

Remote Controller On / Off

Digital Out On / Off

Balanced Input Sensitivity Switching + 4 dBu / -10 dBV

ON/OFF switchable (44.1 kHz)

REC PAUSE mode

Total remaining playback time, Total playback time,

Elapsed recording time, Remaining recording time,

Total recording time

DISPLAY

FL Display Play, Pause, REC (Rec), RPT-1 (Repeat, 1-Repeat),

AUTO TRACK (Auto Track No.), PGM (Program),

FADER (Fader), SKIP ON (Skip ON/OFF),

32/44/48 (Input sampling frequency),

SYNC (Digital Synchronous Recording),

CD-RW/FINALIZE (Disc Type)

LED Display Track number, Level meter, Elapsed playback time,

Remaining playback time, Total remaining playback time,

Total playback time, Elapsed recording time,

Remaining recording time, Total recording time

INPUT/OUTPUT TERMINAL

Audio Input (Input Impedance) RCA pin (27 kΩ or more)

Balanced XLR-3 (10 kΩ)

Audio Output (Output Impedance) RCA pin (1 kΩ)

Balanced XLR-3 (1 kΩ or less)

6

INPUT/OUTPUT TERMINAL (continued)

Digital Input (Input Impedance) Optical EIAJ CP-1201 TYPE2

Coaxial RCA IEC958 (75 Ω)

AES/EBU XLR-3 (110 Ω)

Digital Output (Output Impedance) Optical EIAJ CP-1201 TYPE2

Coaxial RCA IEC958 (75 Ω)

Headphone Output ∅ 6 (1/4 inch) standard stereo phone jack

Paralell Remote Control DIN 8-pin

PARALLEL REMOTE TERMINAL

6

7

8

3

1

5

4

2

CR300

GND

PLAY

MANUAL TRACK

No. WRITE

PAUSE

REC

STOP

DIMENSIONS & WEIGHT

Maximum Dimensions 482 (W) x 105 (H) x 393 (D) mm

19 (W) x 4 - 1/8 (H) x 15 - 1/2 (D) inch

Weight (w/o package) 7.0 kg (15.4 lb)

POWER REQUIREMENT

Power Supply AC120 V, 60 Hz

AC220 ~ 230 V, 50/60 Hz

Power Consumption 24 W

AUDIO UNIT CHARACTERISTICS

CD Playback (Analog RCA Output)

Frequency Response 4 Hz ~ 20 kHz ± 1.0 dB (EIAJ)

S/N 100 dB or more (EIAJ)

Dynamic Range 90 dB or more (EIAJ)

Total Harmonic Distortion 0.01 % or less (EIAJ)

Channel Separation 90 dB or more (EIAJ)

De-emphasis Deviation 0 ± 1.5 dB or less (EIAJ)

Level Difference between Channels 1 dB or less (EIAJ)

Output Voltage 2.0 ± 0.3 Vrms (Load impedance: 10 kΩ, EIAJ)

Monitor (Analog RCA Input

→→

→ Analog RCA Output)

→→

Frequency Response 4 Hz ~ 20 kHz ± 1.0 dB (EIAJ)

S/N 83 dB or more (EIAJ)

Dynamic Range 83 dB or more (EIAJ)

Total Harmonic Distortion 0.01 % or less (EIAJ)

Maximum Input Level 3.2 Vrms or more (EIAJ)

Minimum Input Level 0.4 Vrms or less (EIAJ)

7

CR300

AUDIO UNIT CHARACTERISTICS (continued)

Record & Playback (Analog RCA Input

→→

→ Analog RCA Output)

→→

Frequency Response 4 Hz ~ 20 kHz ± 1.0 dB (EIAJ)

S/N 83 dB or more

Dynamic Range 83 dB or more

Total Harmonic Distortion 0.01 % or less

Monitor (Digital Coaxial Input

→→

→ Analog RCA Output)

→→

Frequency Response 4 Hz ~ 20 kHz ± 1.0 dB (EIAJ)

S/N 95 dB or more (EIAJ)

Dynamic Range 90 dB or more (EIAJ)

Total Harmonic Distortion 0.01 % or less (EIAJ)

Maximum Input Level 0.6 Vp-p or more (EIAJ)

Minimum Input Level 0.2 Vp-p or less (EIAJ)

Record & Playback (Digital Coaxial Input

→→

→ Analog RCA Output)

→→

Frequency Response 4 Hz ~ 20 kHz ± 1.0 dB (EIAJ)

S/N 95 dB or more

Dynamic Range 90 dB or more

Total Harmonic Distortion 0.01 % or less

CD Playback (Analog XLR-3 +4 dBu Output)

Frequency Response 4 Hz ~ 20 kHz + 1.0, -1.5 dB (EIAJ)

S/N 100 dB or more (EIAJ)

Dynamic Range 90 dB or more (EIAJ)

Total Harmonic Distortion 0.01 % or less (EIAJ)

Channel Separation 90 dB or more (EIAJ)

De-emphasis Deviation 0 ± 1.5 dB or less (EIAJ)

Level Difference between Channels 1 dB or less (EIAJ)

Output Voltage 20 ± 1.5 dBm (Load impedance: 100 kΩ, EIAJ)

Output Voltage (-10 dBV) 8 ± 1.0 dBm (Load impedance: 100 kΩ, EIAJ)

Monitor (Analog XLR-3 +4 dBu Input

→→

→ Analog XLR-3 +4 dBu Output)

→→

Frequency Response 4 Hz ~ 20 kHz + 1.0, -1.5 dB (EIAJ)

S/N 83 dB or more (EIAJ)

Dynamic Range 83 dB or more (EIAJ)

Total Harmonic Distortion 0.01 % or less (EIAJ)

Maximum Input Level 13 Vrms or more (EIAJ)

Minimum Input Level (-10 dBV) 0.4 Vrms or less (EIAJ)

Record & Playback (Analog XLR-3 +4 dBu Input

→→

→ Analog XLR-3 +4 dBu Output)

→→

Frequency Response 4 Hz ~ 20 kHz + 1.0, -1.5 dB (EIAJ)

S/N 83 dB or more

Dynamic Range 83 dB or more

Total Harmonic Distortion 0.01 % or less

Specifications and appearance are subject to change without notice for product improvement.

8

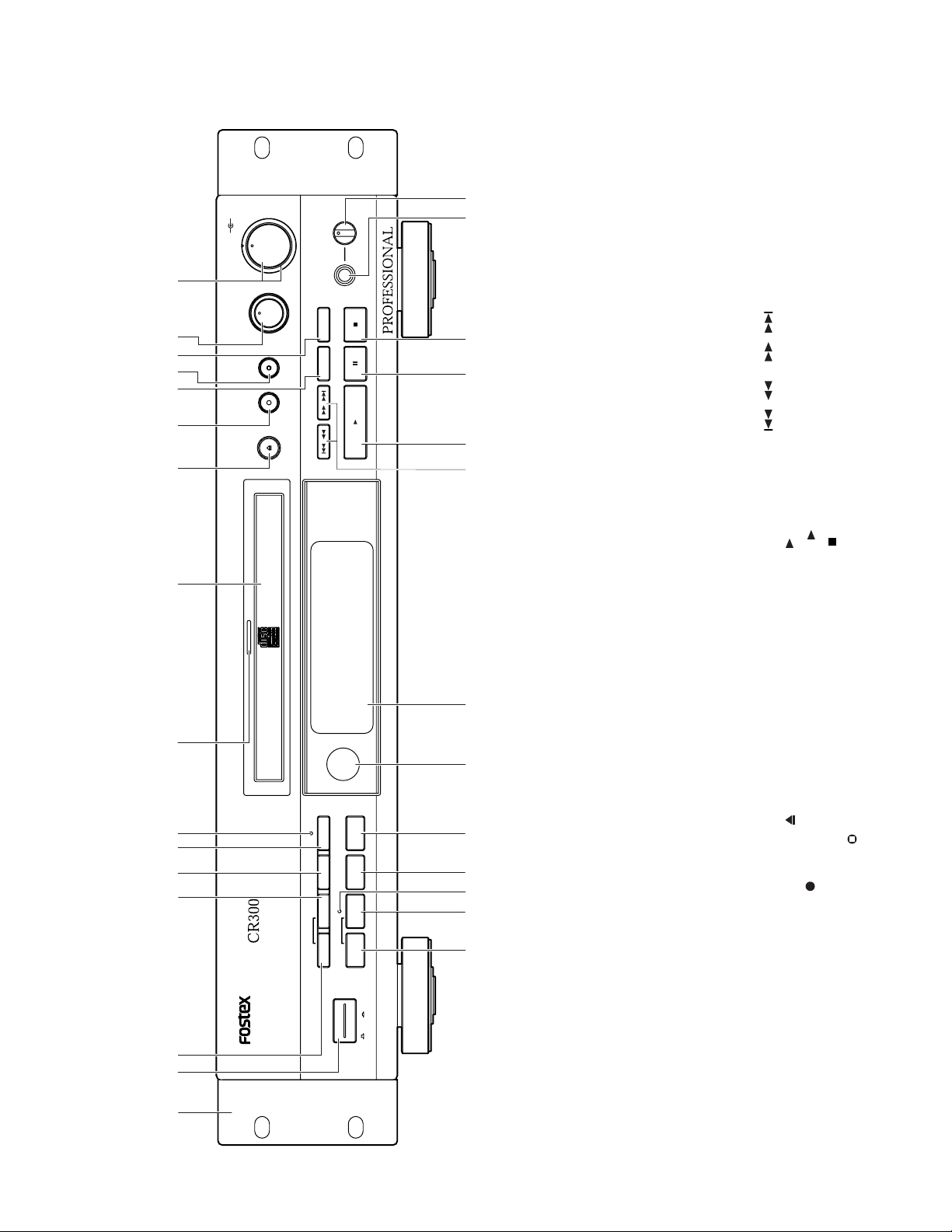

2. CONTROLS, INDICATORS & CONNECTORS

8

•

•

7

9

•

6

LR

5

••

4

•

•

ANALOG

•

XLR / +4

•

COAX XLR / -10

INPUT SELECTOR REC LEVELREC LEVEL

DIGITAL

REC

MUTE

RECORD

OPEN /

CLOSE

•

10

0

•

1

3

•

•

2

LINE

•

•

•

OPT

EBU

AES /

DIGITAL

TIME

LEVEL

PHONES

SYCHRO

/MARGIN

MAXMIN

]

DIGITAL SYNCHRO

[

]

]

]

REC LEVEL

]

TRACK NO. WRITE (MANUAL)

[

TRACK NO. AUTO/MANUAL

[

]

]

(outer: L ch, inner: R ch) [

FINALIZE

[

ERASE

[

CR300

]

[ ]

]

LEVEL MIN/MAX

[

PHONES

[

INPUT SELECTOR - DIGITAL (AES/EBU, OPT, COAX)

[

ANALOG (XLR/+4, XLR/-10, LINE)

14. Digital synchro button

15. Input selector

16. Record level knobs

17. Track number auto / manual button

18. Track number write (manual) button

19. Track number write (manual) indicator

20. Finalize button

21. Erase button

22. Remote control sensor

23. Display panel

24. Track / manual search buttons

25. Play button [ ]

26. Pause button [ ]

27. Stop button [ ]

28. Headphones jacks

29. Headphones level control

22 23 25 26 27 2924 28

]

7

MENUSET

FINALIZE ERASE

]

]

]

]

]

]

19

]

SKIP ID CLEAR

[

SKIP ID SET

[

POWER

[

]

SKIP PLAY

[

MENU

[

Recording : Light in read

Recording mute : Blinks in red

Playback : Lights in green

Erasing : Lights in orange

TIME/MARGIN

[

OPEN/CLOSE

[

REC MUTE

[

RECORD

[

COMPACT DISC RECORDER

WRITE

CLEAR SKIP PLAY

SKIP ID

(MANUAL)

TRACK NO.

AUTO /

MANUAL

OFF ON

POWER

17 18 20 21

1 2 3 4 5 6 8 10 11 1213 1614 159

< FRONT PANEL >

1. Rack mount angle

2. Power switch

3. SKIP ID set button

4. SKIP ID clear button

5. SKIP PLAY button

6. Menu button

7. Copy bit indicator

8. Function indicator

9. Disc tray

10. Open / close button

11. Record button

12. Time / margin button

13. Record mute button

9

CR300

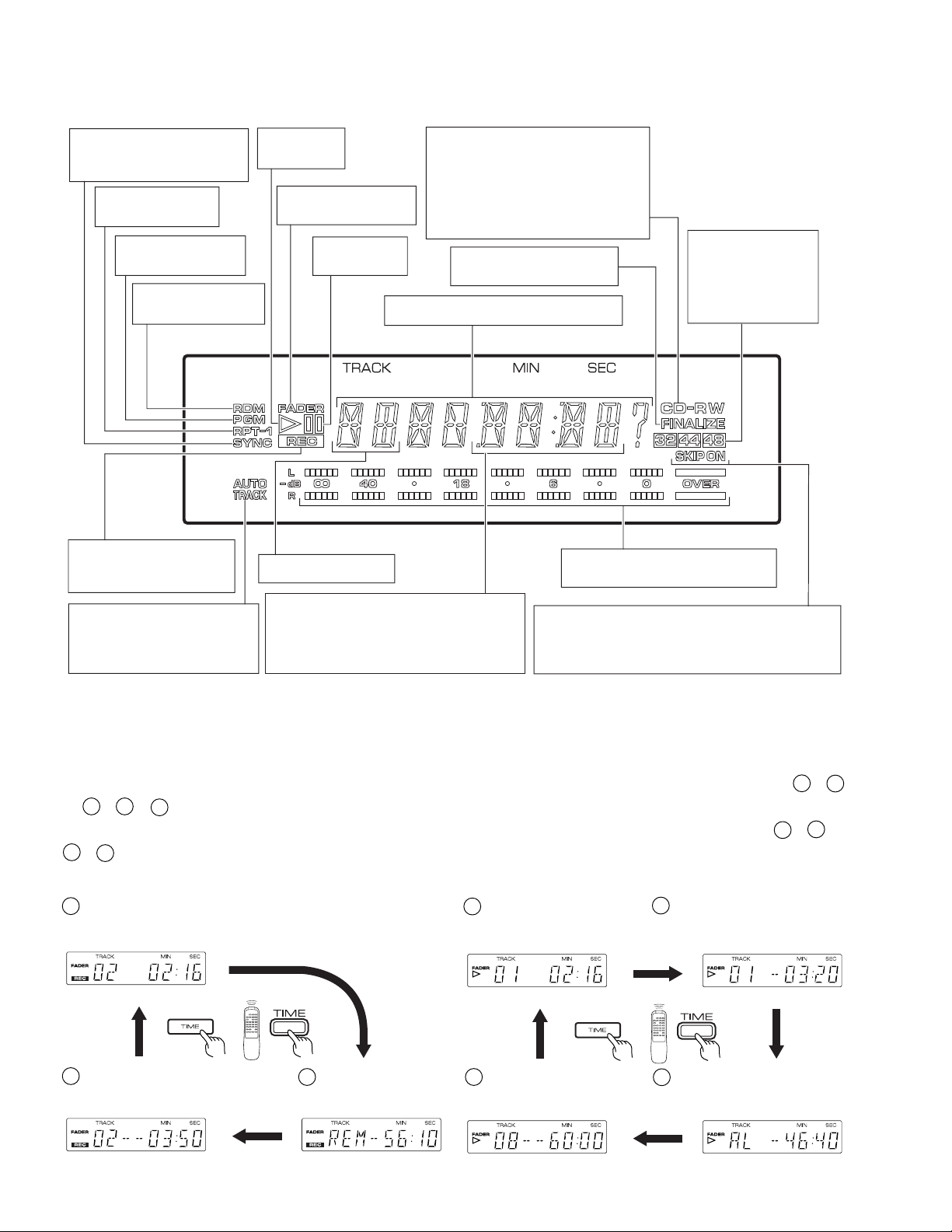

< DISPLAY PANEL >

Lights when automatic digitalsource synchro recording is

activated.

Lights during repeat

playback.

Lights in the program

mode.

Lights during random

playback.

Lights during record mode.

Blinks in the record muting

mode.

Lights when automatic track

number write during recording

is activated.

Lights during

playback.

Blinks during fade-in/out.

Lights or blinks

during pause.

Displays the track No.

Displays the elapsed playing time, remaining

playing time, total playing time, elapsed

recording time, remaining recording time,

total recording time and remaining time

until the end of finalization. (See below.)

Blinks during disc identification and

lights steadily.

CD: Lights when a disc is loaded.

CD-R: Lights if the loaded disc is a

CD-R disc before finalization.

CD-RW: Lights if the loaded disc is a

CD-RW disc

Lights if the loaded disc is a

finalized CD-RW disc.

Displays messages.

Displays the sampling

frequency (Fs) of the

current digital input.

All indicators are off

when the input signal

is interrupted.

Displays the input level during record

or the play level during playback

Lights, goes off or blinks during skip ID setting or

clearing.

The disc contains skip ID data, the SKIP ON indicator

lights automatically.

Switching the time display

The following operation allows you to check the recording time information during recording or playing time information

during playback. Every time the TIME button is pressed, the time information contents are switched in the order of A → B

→ C → D → A • • •.

The display mode varies depending on whether the current operation is recording or playing back (in the order of A → B →

C → A → • • • during recording).

During recording

A : Elapsed recording time

(2 min. 16 sec. after the

start of track No. 2)

C : Total recording time

(3 min. 50 sec. of 2track recording )

Remaining recording

B :

time (56 min. 10 sec.

remaining on the disc)

During playback

A : Elapsed playing time

(2 min. 16 sec. after the

start of track No. 1)

Total playing time

D :

(60 min. 0 sec. for 8

tracks)

B : Remaining playing time of track

being played (3 min. 20 sec.

remaining for track No.1)

Remaining playing time of all track

C :

on disc being played (46 min. 40

sec. remaining on the disc)

10

CR300

]

]

]

12

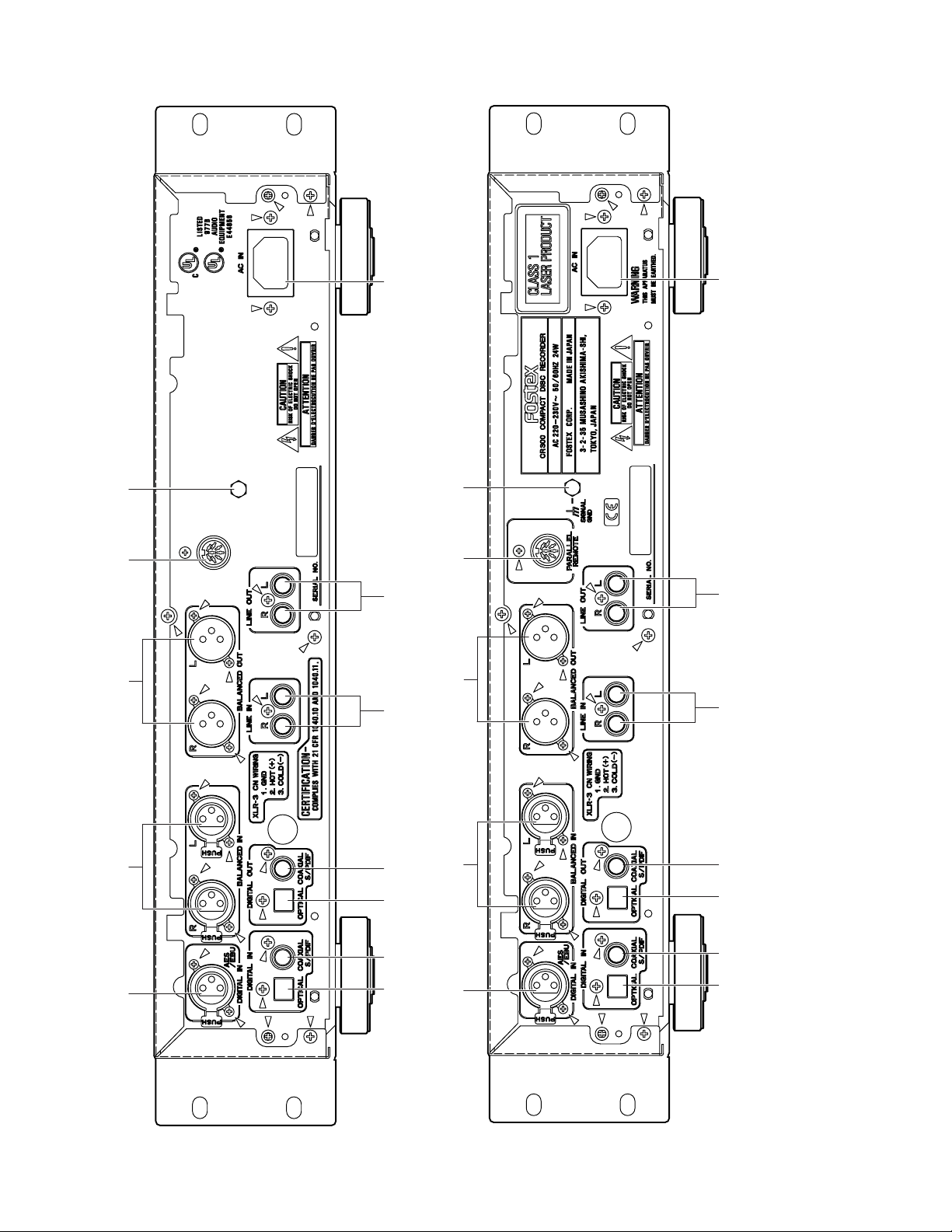

< REAR PANEL (USA version) >

11

10

< REAR PANEL (EUR version) >

12

]

S/P DIF COAXIAL DIGITAL IN

S/P DIF OPTICAL DIGITAL OUT

[

[

S/P DIF COAXIAL DIGITAL IN

[

]

]

LINE OUT

[

LINE IN

[

AC IN

[

7. Coaxial digital input

8. Optical digital output

9. Coaxial digital output

10. Line input

11. Line output

11

12. AC inlet

]

10

]

]

]

9

87

9

AES/EBU DIGITAL IN

[

BALANCED OUT

87

BALANCED IN

[

S/P DIF OPTICAL DIGITAL IN

[

output [

1 2 3 4 5

6

1 2 3 4 5

6

1. AES/EBU digital input

2. XLR balanced input

3. XLR balanced

4. Parallel remote connector

5. Earth terminal

6. Optical digital input

11

CR300

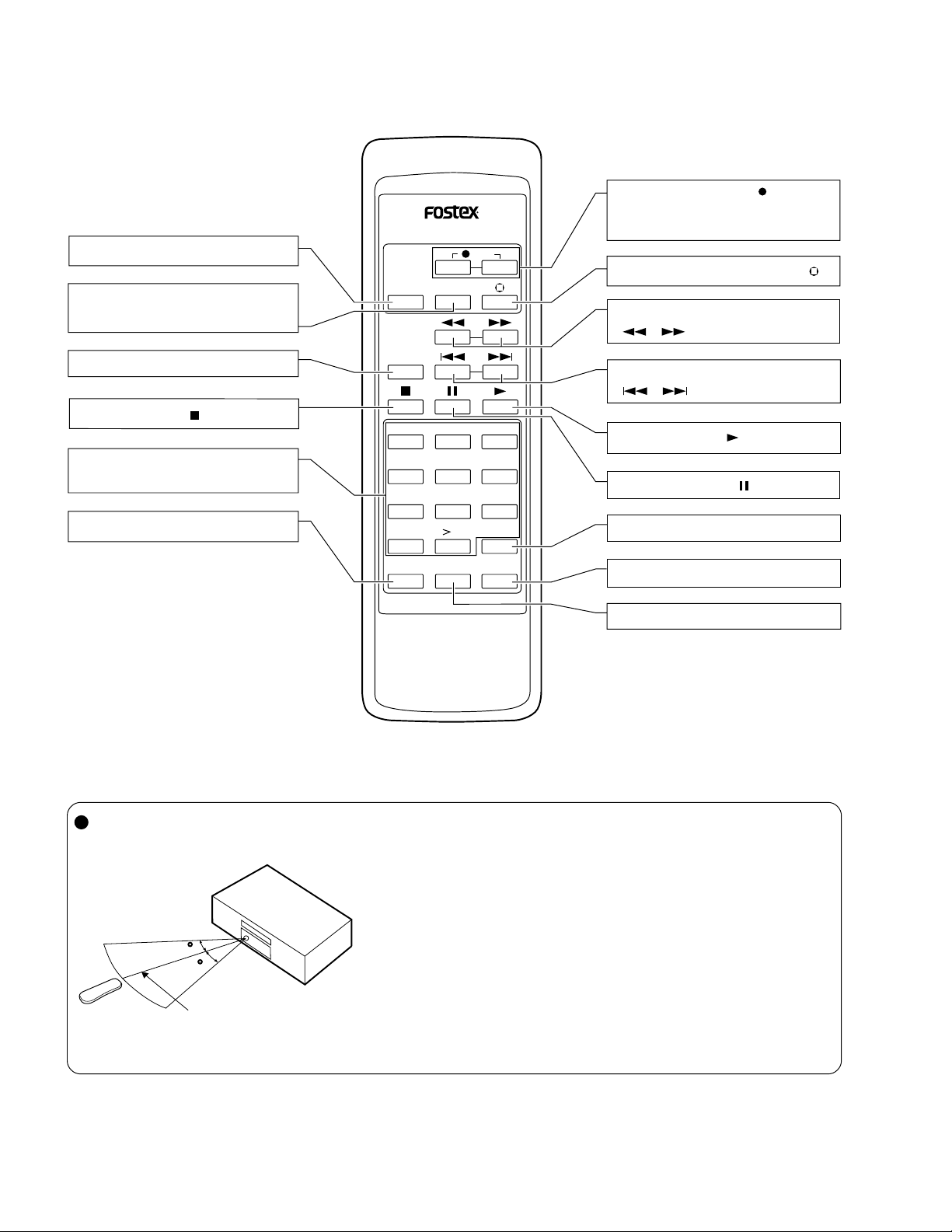

< REMOTE CONTROL UNIT MODEL 8317 >

FADER button

*TRACK No. WRITE

(MANUAL) button

REPEAT button

*Stop button ( )

Numeric buttons

(1 to 10, >10)

MODEL 8317

REC

TRACK NO.

FADER

REPEAT

WRITE

123

456

789

*Record buttons ( REC)

For recording, press the two

buttons simultaneously.

*Record muting button ( )

*Manual search buttons

,

( )

*Track search buttons

,

( )

*Play button ( )

*Pause button ( )

PGM (Program) button

Remote controllable range

30

30

7m(23 ft)

10

PGM CHECK CLEAR

10

TIME

*TIME button

CLEAR button

CHECK button

·

Remote control may be impossible if there is an obstacle between the

remote control unit and main unit or if the remote control unit is operated

at too great of an angle from the remote control sensor.

·

Erroneous operation may occur if strong light such as direct sunlight or

fluorescent lamp light is incident to the remote control sensor.

·

The main unit may operate erroneously if it is used near equipment

radiating infrared rays or if it is used near control unit of other equipment

is used near the unit. On the contrary, if this remote control unit is operated

near another piece of equipment which can be control wit infrared rays,

the equipment may operate erroneously.

·

Replace batteries when the remote controllable range decreases noticeably.

12

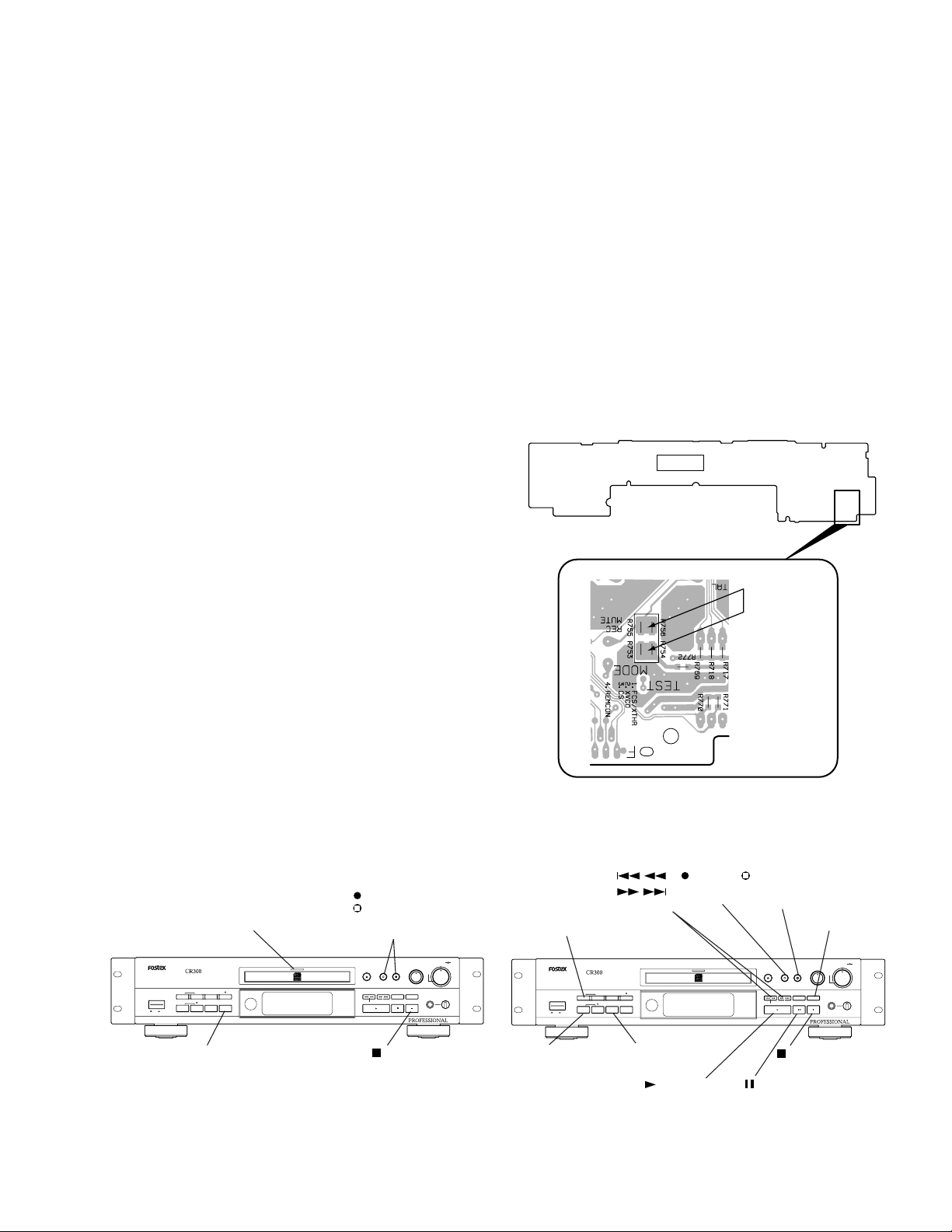

3. ADJUSTMENT PROCEDURES

Short-circuit

Fig. 1 Enter the Test mode

SIDE B

FUNCTION ASSY

+ key

– key

Stop

Focus in

Fig.3 During adjustment of servo system (Input selector: optical)

FINALIZE button

Set

SET button

Average

DIGITAL

SYNCHRO

button

Mode switch

AUTO/MANUAL

button

(RECORD)

button

Sled move

buttons

(REC MUTE)

button

(STOP) button

Tracking close

(PAUSE) button

Spindle kick

(PLAY) button

,

TIME

/MARGIN

DIGITAL

SYCHRO

ANALOG

0

8

6

7

9

5

10

4

1

2

3

DIGITAL

REC

MUTE

OPEN /

CLOSE

RECORD

INPUT SELECTOR REC LEVELREC LEVEL

OPT

AES /

EBU

LINE

LR

COAX XLR / -10

XLR / +4

•

•

•

•

•

••••

•

•

•

•

•

•

•

PHONES

LEVEL

MAXMIN

MENUSET

POWER

OFF ON

COMPACT DISC RECORDER

CLEAR SKIP PLAY

FINALIZE ERASE

AUTO /

MANUAL

WRITE

(MANUAL)

SKIP ID

TRACK NO.

3-1. TEST DISCS

When adjusting the servo system, the following CD test discs should be used.

STD-903 or equivalent

STD-914 or equivalent

3-2. TEST EQUIPMENT

Laser Power Meter

(1)

The following power meter manufactured by Advantest Corporation, LEADER Corporation or equivalent:

TQ8210 + TQ82017 (Advantest Corporation)

TQ8215 + TQ82021 (Advantest Corporation)

TQ8215 + TQ82010 + TQ82017 (Advantest Corporation)

LE8010 (LEADER Corporation)

Audio Analyzer

(2)

Oscilloscope

(3)

Distortion Factor Meter

(4)

CD Jitter Meter

(5)

Block Error Rate Counter

(6)

CR300

3-3. TEST MODE

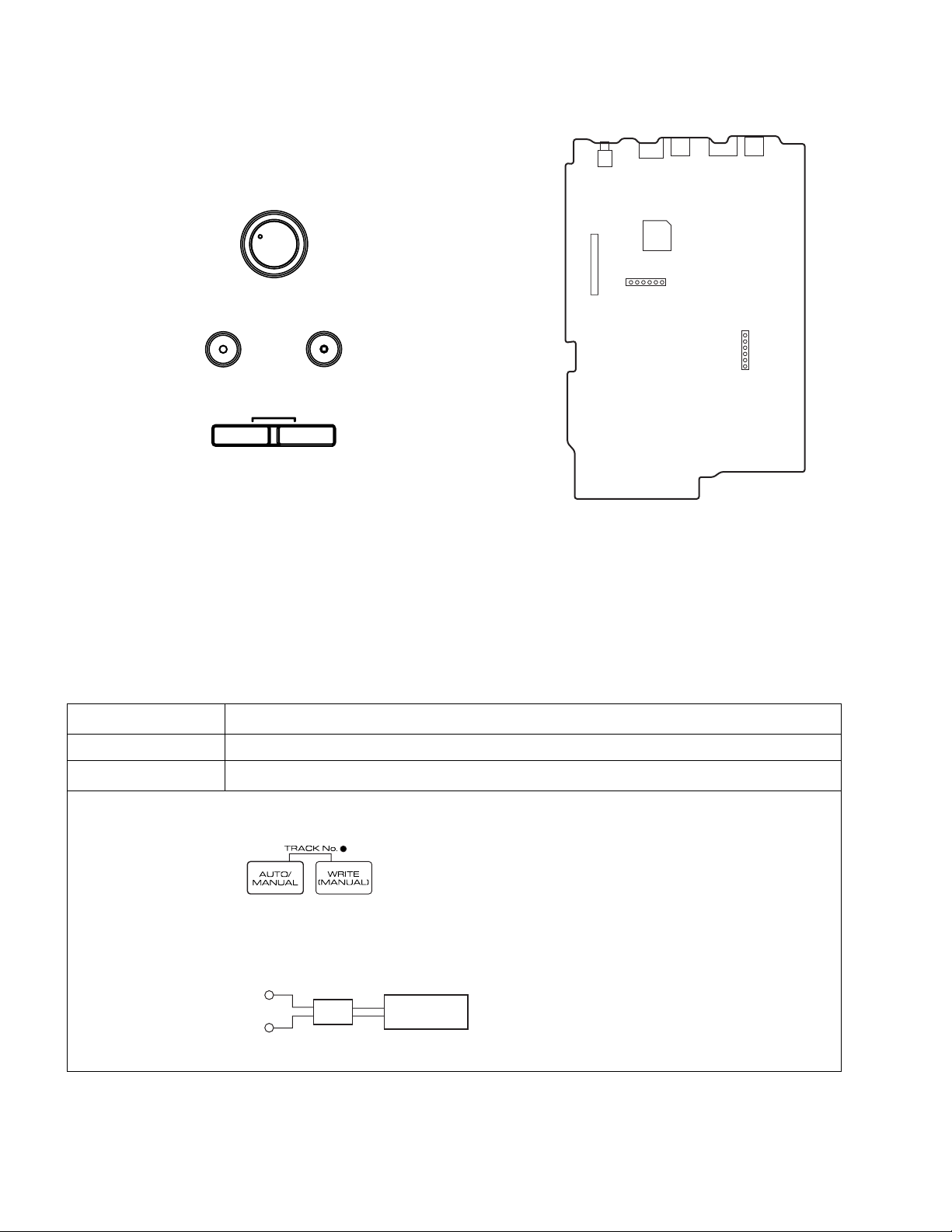

3-3-1. Test Mode

For adjustment, set the unit to the Test Mode. Referring to the Fig.

1 on the right, turn on the unit with the Test Mode short-circuit

pattern on the FUNCTION PCB Ass’y to enter the Test Mode. In

the Test Mode, all the displays (FL, LEDs) on the unit should be

lit. If not, turn the power off and repeat the same steps again.

3-3-2. Operation in Test Mode

In the Test Mode, the following adjustment functions are assigned

to the buttons, as explained in the Fig. 2 & 3.

LED for confirmation of

LD emission

COMPACT DISC RECORDER

SKIP ID

MENUSET

CLEAR SKIP PLAY

POWER

AUTO /

MANUAL

OFF ON

TRACK NO.

WRITE

FINALIZE ERASE

(MANUAL)

ERASE button

Switching CD, CD-R and CD-RW

Fig.2 During adjustment of LD power (Input selector: analog)

(RECORD) and

(REC MUTE)

buttons

LD emitting

REC

OPEN /

RECORD

MUTE

CLOSE

AES /

EBU

TIME

/MARGIN

(STOP) button

LD not emitting

INPUT SELECTOR REC LEVELREC LEVEL

ANALOG

DIGITAL

XLR / +4

•

COAX XLR / -10

•

•

OPT

LINE

•

•

•

DIGITAL

SYCHRO

PHONES

3

•

2

•

1

4

••••

•

0

LR

5

6

7

•

8

•

9

•

10

LEVEL

MAXMIN

13

CR300

3-3-3. How to Playback a Disc in Test Mode

In the Test Mode, since each servo circuit operates independently, playing back a disc

requires that your operate the keys in the correct order to close the servo circuits.

Here is the key operation sequence for playing back a disc in the Test Mode.

Wait at least 2 ~ 3 seconds between each of these operations.

3-4. ADJUSTMENT 1 (LASER DIODE POWER ADJUSTMENT)

SERVO DIGITAL ASSY

CN354

1

6

CN102

1

6

VR102

R REC. PW1

VR101

PB. PW

VR106

RW REC.

PW2

VR103

R REC.PW2

VR104

RW REC.PW0

Fig. 4 Adjustment points

VR105

RW REC.

PW1

Playback power

Playback CD-R recording

Fig.5 Output power of the laser diode

Note 1: Attach the remote sensor of the laser power meter to a point angled away

about 10 degrees against the pickup lens and where the maximum power

is detected, so that there will be no light reflected onto the pickup.

Note 2: When adjusting with VR101 to VR106, first turn them completely counter-

clockwise and then adjust clockwise, so that the value to be reached is not

exceeded.

Note 3: Set the wavelength of laser power meter to 780 nm.

Note 4: The following adjustments 1 through 3 must be

done with the Input Selector set to the Analog position

(LD power adjustment mode).

CD-R overdrive

CD-RW erase

power

CD-R record

power

CD-RW recording

FINALIZE

CD-RW record power

CD-RW bias

power

INPUT SELECTOR

ANALOGDIGITAL

XLR / +4

•

COAX XLR / -10

•

•

AES /

EBU

OPT

•

•

LINE

•

3-4-1. Playback Power Adjustment

Pickup objective lens

VR101 (PB. PW)

0.60 mW ± 0.05 mW

14

Test Point

Adjustment Point

Adjustment Value

[Procedure]

Check that “CD” is displayed on the FL display. If “CD-R” or “CD-RW” is displayed, press the STOP button repeatedly

(1)

until “CD” is displayed.

Press the RECORD button. The LED for confirmation of LD emission will light in orange.

(2)

Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this

(3)

status.

Turn VR101 clockwise until the adjustment value to be reached is obtained.

(4)

Press the STOP button to shut off the LD.

(5)

DANGER - LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

3-4-2. CD-R Record Power Adjustment

DANGER - LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

CR300

Test Point

Adjustment Point

Adjustment Value

[Procedure]

Turn VR102 and VR103 fully counterclockwise to set their power output to minimum.

(1)

Press the ERASE button once so that “CD-R” appears on the FL display. If the indication is “CD” or “CD-RW”,

(2)

press the ERASE button repeatedly until “CD-R” is displayed on the FL display.

Press the RECORD button. The LED for confirmation of LD emission will light in orange.

(3)

Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this

(4)

status.

CD-R record power adjustment

Turn VR102 clockwise until the adjusted value is 4.60 mW ± 0.1 mW.(5)

CD-RW overdrive power adjustment

Turn VR103 clockwise until the adjusted value becomes adjusted value at Step 5 above + (0.1 mW ± 0.01 mW).

(6)

Press the STOP button to shut off the LD.

(7)

Pickup objective lens

VR102 (R REC. PW1), VR103 (R REC. PW2)

VR102: 4.60 mW ± 0.1 mW

VR103: Addition of 0.1 mW ± 0.01 mW to the adjustment value of VR102

3-4-3. CD-RW Record Power Adjustment

DANGER - LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

Test Point

Adjustment Point

Adjustment Value

[Procedure]

Turn VR104, VR105 and VR106 fully counterclockwise to set their power output to minimum.

(1)

Press the ERASE button twice so that “CD-RW” appears on the FL display. If the indication is “CD” or “CD-R”,

(2)

press the ERASE button repeatedly until “CD-RW” is displayed on the FL display.

Press the RECORD button. The LED for confirmation of LD emission will light in orange.

(3)

Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this

(4)

status.

Turn the VR104 clockwise until the adjusted value is 0.40 mW ± 0.05 mW.

(5)

CD-RW record power adjustment

Turn VR106 clockwise until the adjusted value is 2.40 mW ± 0.1 mW.(6)

Pickup objective lens

VR104 (RW REC. PW0), VR106 (RW REC. PW2), VR105 (RW REC. PW1)

VR104: 0.40 mW ± 0.05 mW

VR106: 2.40 mW ± 0.1 mW

VR105: 5.90 mW ± 0.1 mW

CD-RW erase power adjustment

Turn VR105 clockwise until the adjusted value is 5.90 mW ± 0.1 mW.

(7)

Press the STOP button to shut off the LD.

(8)

15

CR300

3-5. ADJUSTMENT 2 (SERVO SYSTEM ADJUSTMENT)

For servo adjustment, set the INPUT SELECTOR to OPTICAL.

INPUT SELECTOR

COAX XLR / -10

OPT

•

AES /

•

EBU

Use the RECORD and REC MUTE buttons to make the adjustments.

RECORD

To register an adjustment, press the (SKIP ID) SET button.

SET CLEAR

To reset the adjusted values to the initial settings, press and hold the

(SKIP ID) CLEAR button for 4 seconds.

•

XLR / +4

SKIP ID

ANALOGDIGITAL

•

•

LINE

•

REC

MUTE

SERVO DIGITAL ASSY

CN354 (TP201)

1

6

CN354

1 : RF

2 : TE

3 : TEIN

4 : VC

5 : FEIN

6 : FE

CN102

1

6

CN102

1 : VC

2 : TESTEQRFP

3 : TE

4 : MPP

5 : MPXOUT

6 : FMOUT

Fig. 6 Adjustment points

3-5-1. Focus Offset Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

Press the AUTO/MANUAL button until “01_F4” appears on the FL display.(1)

Adjust with the RECORD and REC MUTE buttons until the value for Pin 6 of CN354 is 0 mV ± 10 mV.

(2)

Press the SET button to register the adjustment. Once the adjustment is registered with the SET button, “?” will

(3)

disappear.

CN354 - pin 6 (FE)

RECORD and REC MUTE buttons

0 mW ± 10 mW

16

FE

VC

10 : 1

10:1 probe

Oscilloscope

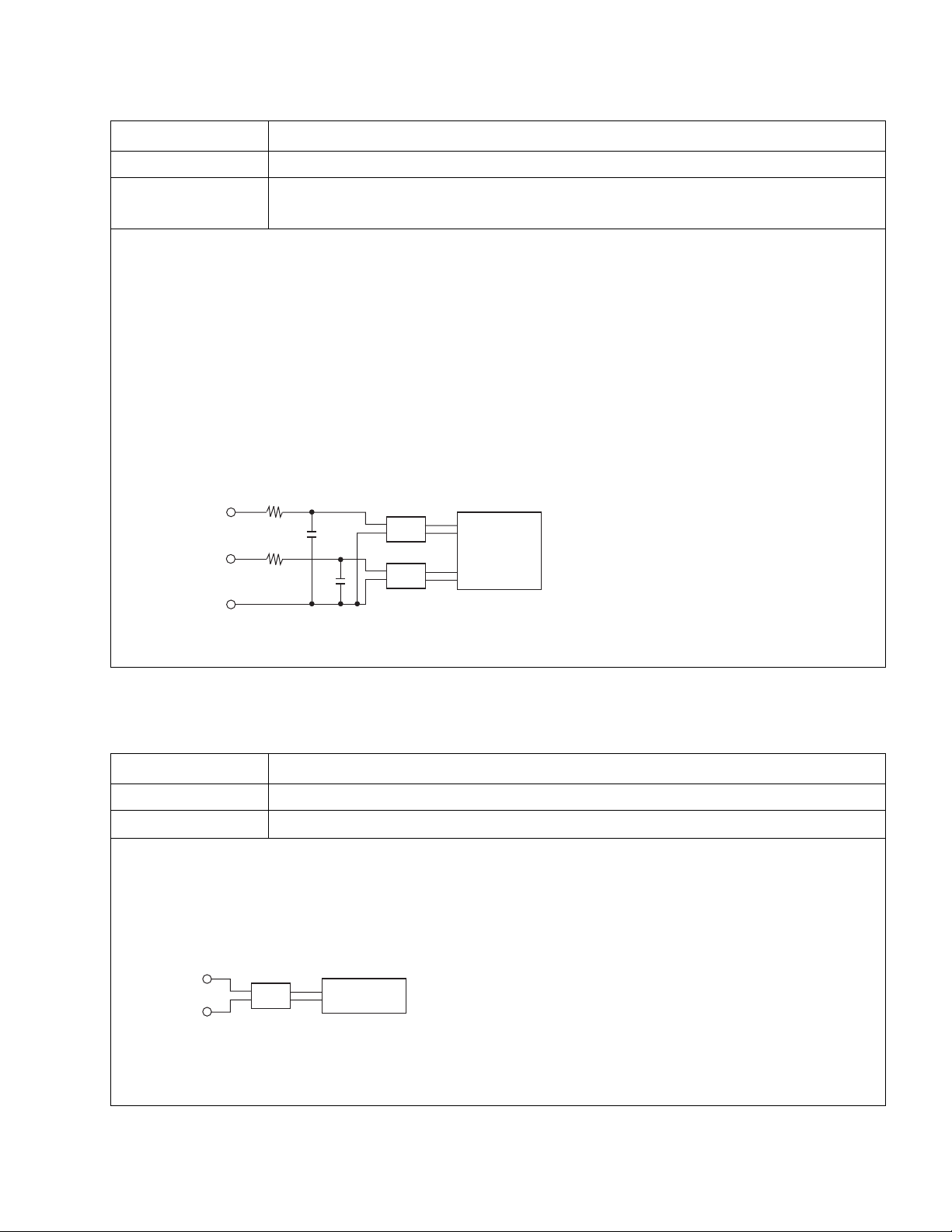

3-5-2. M-S Mix Ratio Adjustment

CR300

Test Point

Adjustment Point

Adjustment Value

CN102 - pin 3 (TE) and pin 4 (MPP)

RECORD and REC MUTE buttons

Adjust until the value of output signal from pin 3 (TE) and pin 4 (MPP) of CN102 are the same,

or the differential output of these signals is minimal.

[Procedure]

Press the AUTO/MANUAL button so that “02_F3” appears on the FL display.

(1)

Press the FINALIZE button for focus-in.

(2)

Press the PLAY button for CAV-servo spindle kick (the status where the spindle rotates with the focus servo on and

(3)

tracking servo off).

Adjust with the RECORD and REC MUTE buttons until the value to be reached is obtained.

(4)

Press the SET button to register the adjustment.

(5)

Once the adjustment is registered with the SET button, “?” on the FL display will disappear.

Press the STOP button to stop the unit.

(6)

NOTE: For adjustment, use the following circuits.

TE

MPP

VC

39kΩ

39kΩ

0.001µF

0.001µF

10 : 1

10 : 1

10:1 probe

CH1

CH2

Oscilloscope

NOTE: Adjustment must be done around mid-radius on a disc.

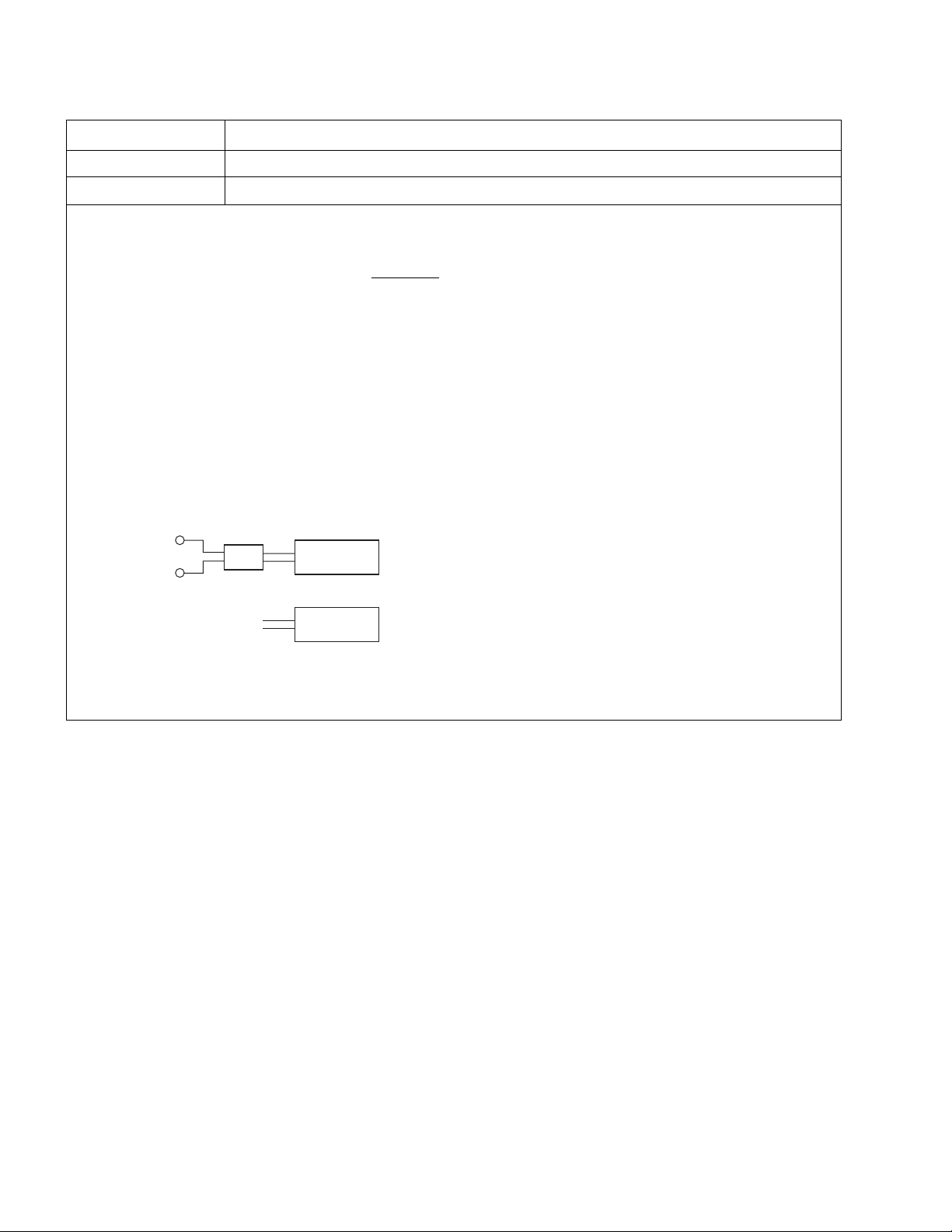

3-5-3. Tracking Offset Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

Press the AUTO/MANUAL button so that “03_F6” appears on the FL display.

(1)

Press the RECORD and REC MUTE buttons until the above adjustment value to be reached is obtained.

(2)

Press the SET button to register the adjustment.

(3)

Once the adjustment is registered with the SET button, “?” on the FL display will disappear.

FE

VC

NOTE: Perform the adjustment in STOP mode.

This adjustment is possible with the low-pass filter used in adjustment 5 above attached.

CN354 - pin 2 (TE) or CN102 - pin 3 (TE)

RECORD and REC MUTE buttons

0 mV ± 10 mV

10 : 1

10:1 probe

Oscilloscope

17

CR300

3-5-4. Focus Bias Adjustment

Test Point

Adjustment Point

Adjustment Value

CN354 - pin 1 (RF)

DIGITAL SYNCHRO, RECORD and REC MUTE buttons

Adjust until the RF jitter is minimal or that the eye pattern of the RF waveform is most open.

[Procedure]

Press the DIGITAL SYNCHRO button in Stop mode.

(1)

NOTE: Make sure that the unit is in Stop mode.

Check that “48” appears on the FL display.

(2)

Press the AUTO/MANUAL button so that “04_34” appears on the FL display.

(3)

Press the FINALIZE button for focus-in.

(4)

Press the PLAY button for CAV-servo spindle kick.

(5)

Press the PAUSE button to close the tracking servo, then set the unit to Playback mode.

(6)

Adjust with the RECORD and REC MUTE buttons until the above adjustment value to be reached is obtained.

(7)

Press the SET button to register the adjustment. Once the adjustment is registered with the SET button, “?” on the FL

display will disappear.

Press the STOP button to stop the unit.

(8)

RF

VC

10 : 1

10:1 probe

Jitter Meter

or

Oscilloscope

NOTE: Perform the adjustment in STOP mode.

This adjustment is possible with the low-pass filter used in adjustment 5 above attached.

18

4. ASSEMBLING & DISASSEMBLING

Please refer to the following drawings for assembling & disassembling the CR300.

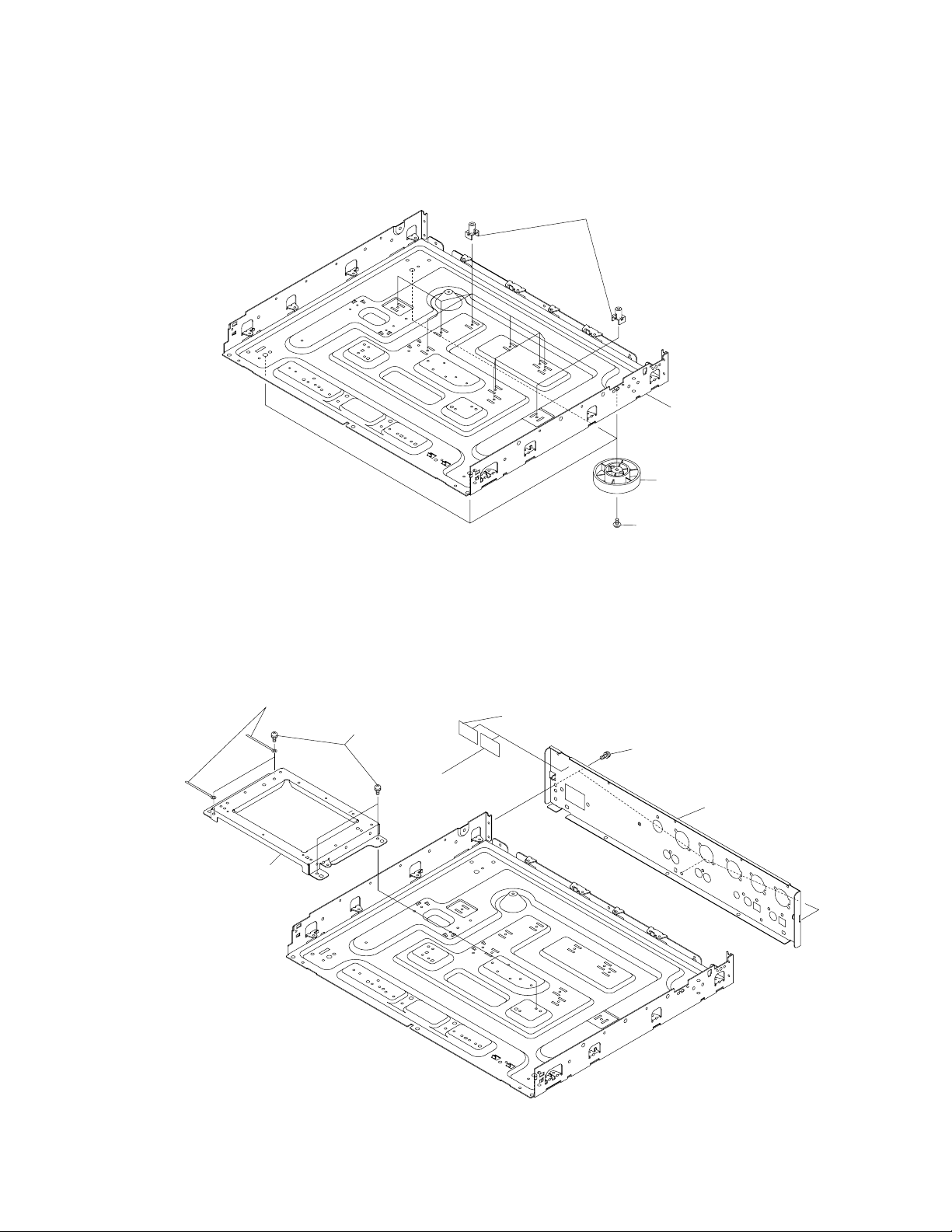

4-1. Under Base, PCB Mold & Insulator

PCB mold (N/A)

CR300

Under base (N/A)

Insulator, CR300

(8207013100)

4-2. Under Base, Mecha Base & Rear Base

Clamper, cord

(8221114000)

Screw, PBA1112

(8204188000)

Label, caution, EUR *

Mecha base

(N/A)

*: EUR version only

Label, caution, HE, CR300 *

(8218764000)

Screw, ABA1011

(8204178000)

(8218787000)

Screw, ABA1011

(8204178000)

Rear base

(EUR: 8221307006)

(USA: 8221307003)

19

Loading...

Loading...