USER'S MANUAL FOR GAS COOKER HOBS

Abstract

Foster spa

via M.S. Ottone, 18/20

42041 Brescello (RE) - Italy

tel. +39.0522.687425 - tel. Servizio Assistenza +39.0522.684450

fax +39.0522.686019 - fax Servizio Ricambi +39.0522.962166

e-mail: service@fosterspa.com

www.fosterspa.com

Dear Customer,

We thank you for having chosen a Foster cooker hob.

Your preference is our pride and satisfaction.

In this document are the recommendations and instructions that will enable you to make the best

ENGLISH

use of the purchased cooker hob and guarantee its best preservation in time. We ask that you take a

few minutes to protect the efficiency of the product and for your satisfaction.

With kind regards

Foster spa

Table of Contents

GENERAL WARNINGS

General recommendation to be consulted before installation

and use of the purchased cooker hob.

1. Usage warnings ...................................................................................................................21

2. Safety warnings .................................................................................................................... 22

3. Warnings for disposal .......................................................................................................... 22

4. Know your appliance ............................................................................................................ 23

INSTALLER INSTRUCTIONS

They are intended for the qualified technician that will complete

appliance installation, commissioning and initial testing.

5. First installation ................................................................................................................... 24

6. Positioning in the work top .................................................................................................. 24

7. Fastening the cooker hob to the cabinet ............................................................................... 26

8. Connecting the cooker hob to the gas network..................................................................... 29

9. Room ventilation .................................................................................................................. 30

10. Discharging combustion products (exhaust)........................................................................ 31

11. Adapting to different types of gasses .................................................................................... 31

12. Adjustment of the minimum ................................................................................................. 33

13. Electrical connection of the cooker hob ................................................................................ 33

USER INSTRUCTIONS

The indicate usage recommendations, a description of controls and the

correct cleaning and maintenance operations for the appliance.

14. Cooker hob use .................................................................................................................... 34

15. Cleaning and maintenance ................................................................................................... 37

Gas cooker hobs summary ........................................................................................................... 182

20

1. Usage warnings

This manual is and integral part of this appliance. It is necessary to keep it undamaged

and on hand for the entire life cycle of the hob. We recommend carefully reading

this document and all instructions contained within before using the appliance.

Installation must be completed by qualified personnel according to current

standards. This appliance is intended for domestic type use, and is conform with

CE Directives currently in force.

The appliance has been manufactured to carry out the following function: COOK-

ING AND HEATING FOOD, ANY OTHER USE MUST BE CONSIDERED IMPROPER.

The manufacturer declines any responsibility for uses that are different from those

indicated.

• Never use this appliance for heating environments.

• Do not leave packaging material waste unguarded in the household environment.

• Separate the various packaging waste materials and deliver them to the closest

selective waste collection centres.

GENERAL WARNINGS

ENGLISH

This appliance has a mark pursuant to European Directive 2002/96/EC with regard

to waste, electric and electronic appliances (waste electrical and electronic equipment - WEEE). This Directive defines the Standards for the collection and recycling of

dismissed appliances valid throughout the territory of the European Union.

The identification plate, with technical data, serial number and marking, is

positioned in view under the housing [Fig. 1].

THE PLATE MUST NEVER BE REMOVED.

Fig. 1:

position of the identification plate

21

GENERAL WARNINGS

2. Safety warnings

ENGLISH

In your interest and for your safety, by law it has been established that installation and service for all electric or gas appliances must be carried out

by qualified personnel, according to current regulations and the requirements of local companies supplying gas and electric power.

• Gas or electric appliances must always be disengaged by competent persons.

• The plug to be connected to the power supply cable and the related socket must

be of the same kind and conform to regulations in force.

• The socket must be accessible once the appliance is installed.

• Never detach the plug by pulling on the cord.

• It is mandatory to have an earth connection as per modes foreseen in the electrical

system safety standards.

• Do not block the openings and ventilation and heat dispersion slots.

Immediately after installation complete a short test on the appliance following the

instructions contained in subsequent pages in this manual. If it does not operate

correctly, disconnect the appliance from the power mains and contact

the closest technical assistance centre: NEVER ATTEMPT TO REPAIR THE

APPLIANCE.

During use the appliance becomes very hot. The use of proper thermal gloves is recommended for any type of operation. The appliance is to be used by adult persons.

DO NOT ALLOW CHILDREN TO COME CLOSE OR PLAY WITH IT.

The manufacturer declines any liability for damages to persons or property, caused by

the non observance of the following regulations or resulting from tampering with even

a single part of the appliance and using non original spare parts.

3. Warnings for disposal

OUR CARE FOR THE ENVIRONMENT

Our products are packaged using non polluting materials, that are therefore compatible with the environment and recyclable. We request your cooperation in making sure that packaging materials are

disposed of correctly. Contact your reseller or competent organizations in your area for information

about waste collection centres, recycling and disposal.

22

GENERAL WARNINGS

DO NOT ABBANDON THE PACKAGING MATERIAL OR PARTS OF IT. THEY

MAY CREATE A SUFFOCATION DANGER FOR CHILDREN, ESPECIALLY

PLASTIC BAGS.

Even your old appliance must be disposed of properly, this will contribute to avoiding negative environmental and health consequences, that would occur as a result of improper disposal.

IMPORTANT: this appliance cannot be treated as household waste. Deliver the old

appliance to the local company that is authorised to collect appliances that are no

longer in use. A proper disposal makes an intelligent recovery of precious materials. It

is also necessary to cut the cable connecting to the power mains and remove it along

with the plug.

4. Know your appliance

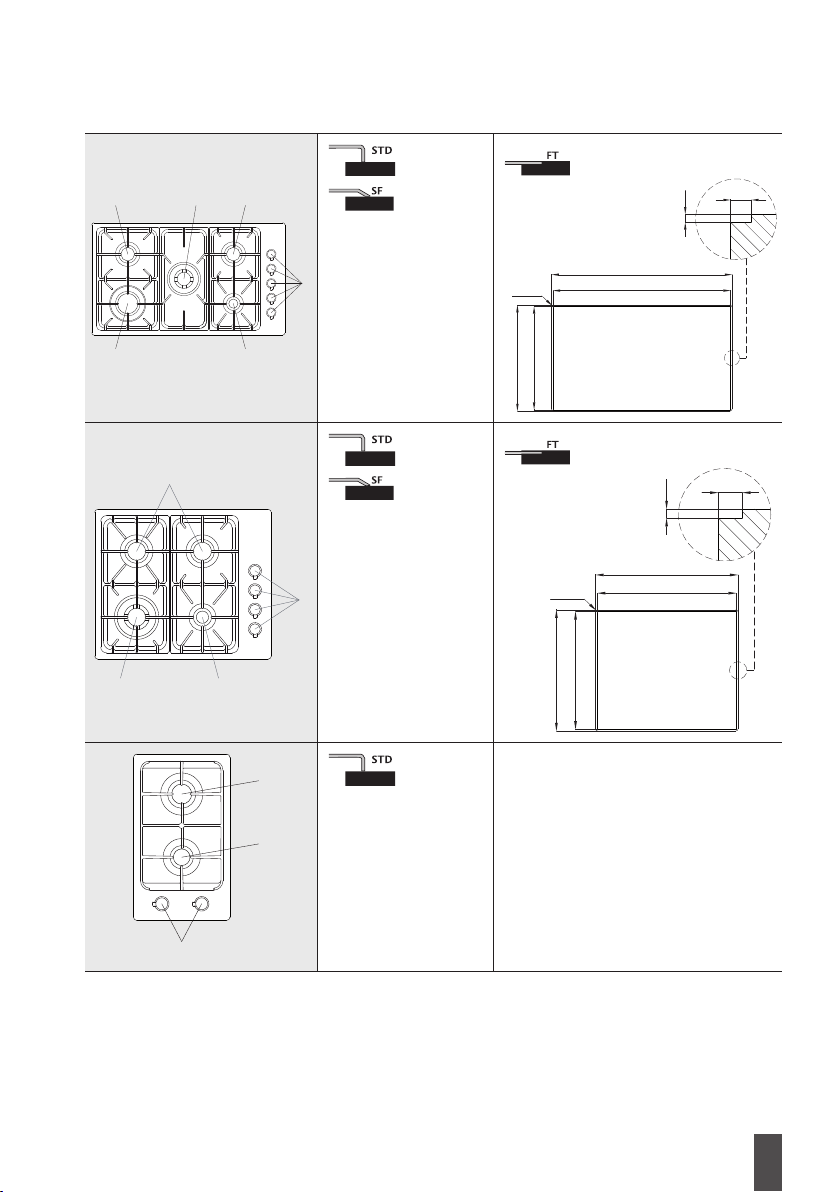

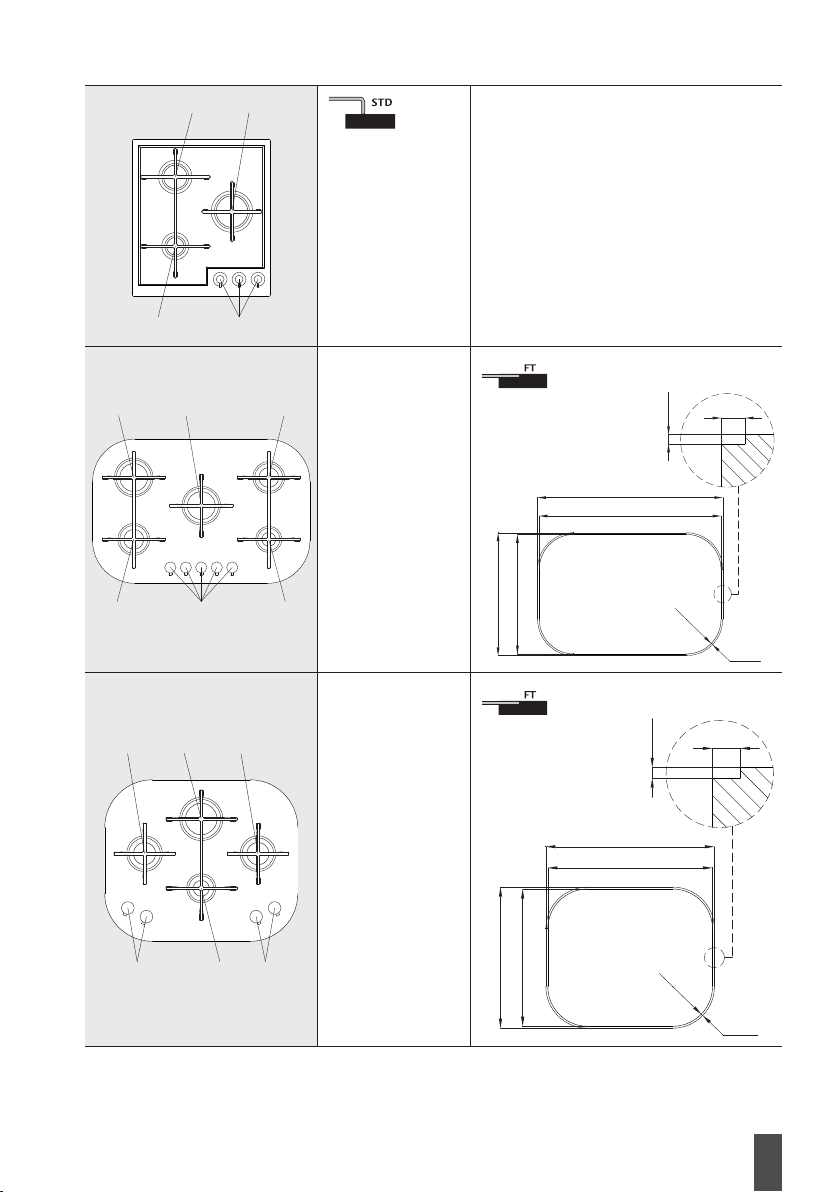

All drawings relating to the Foster cooker hobs manufactured today, are at the end of this manual, Gas

cooker hobs summary [Page 182].

We ask that you recognise the drawing of the cooker hob you have purchased to familiarise with the

main technical-functional features.

ENGLISH

For research practicality the cooker hobs are distinguished in two macro-families:

• Traditional built-in cooker hobs: “8 mm edge”, “Q4 edge” and “semi-flush edge”;

• Flush built-in cooker hobs: “flush-mount” edge.

Regardless of the type of edge, the first group has a simple traditional built-in hole. The cooker

hobs with "flush-mount" edge have a more detailed drawing to enable realisation of the "made to

measure" hole, or having a step necessary to house the edge of the cooker hub so it is "flush" with

the worktop.

Numbers in correspondence with the burners are present in all drawings. Such numbers identify the

type of burner depending on the key below. To know the powers of the burners of the gas cooker hub

you purchased, refer to reading the powers table depending on the type of gas used

[Page 182].

23

INSTALLER INSTRUCTIONS

5. First installation

ENGLISH

Do not leave packaging material waste unguarded in the household environment.

Separate the various packaging waste materials and deliver them to the

closest selective waste collection centres.

In order to remove all manufacturing residues, we recommend cleaning the appliance.

ENGLISH

For further information on cleaning see Chapter 15

[Page 37].

6. Positioning in the work top

The following interventions require masonry and/or carpentry work and must therefore be completed by a competent technician. Installation can be completed on different materials, such as masonry, metal, solid wood and plastic laminated wood, as

long as it is heat resistant (T 100°C).

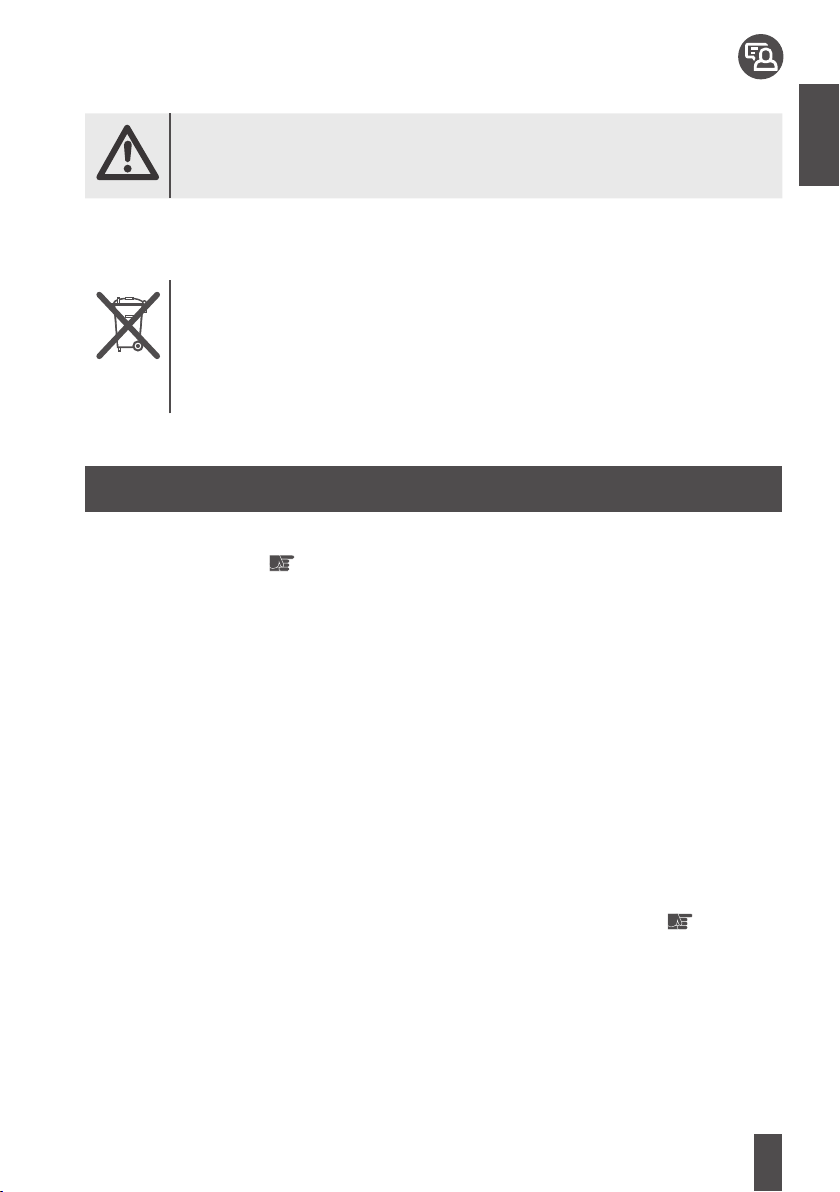

6.1 Installation on the support structure (worktop) of a traditional built-in

cooker hob (8 mm edge, Q4 edge, semi-flush edge)

Cut an opening on the top surface of the

cabinet with the dimensions and position

indicated here below and represented in

the drawing [Fig. 2].

The dimensions of the built-in hole are

shown in the Gas cooker hobs sum-

mary - models with traditional builtin [Page 182], in correspondence of the

drawing of the purchased cooker hob.

B

A

Fig. 2:

cutting the hole for the built-in

24

INSTALLER INSTRUCTIONS

• The distance of the cooker hob

from the back edge must be at least

50mm;

• The distance of the cooker hob from

the walls that exceed worktop height

must be at least 100 mm;

• Make sure that there is a minimum

distance of 750 mm from the burner

50

750

100

to any shelf placed vertically above it;

Fig. 3:

cooker hob distances

• Make sure that any exhaust appliances installed above the cooker hob are positioned according to the measurements indicated in the hood instructions booklet.

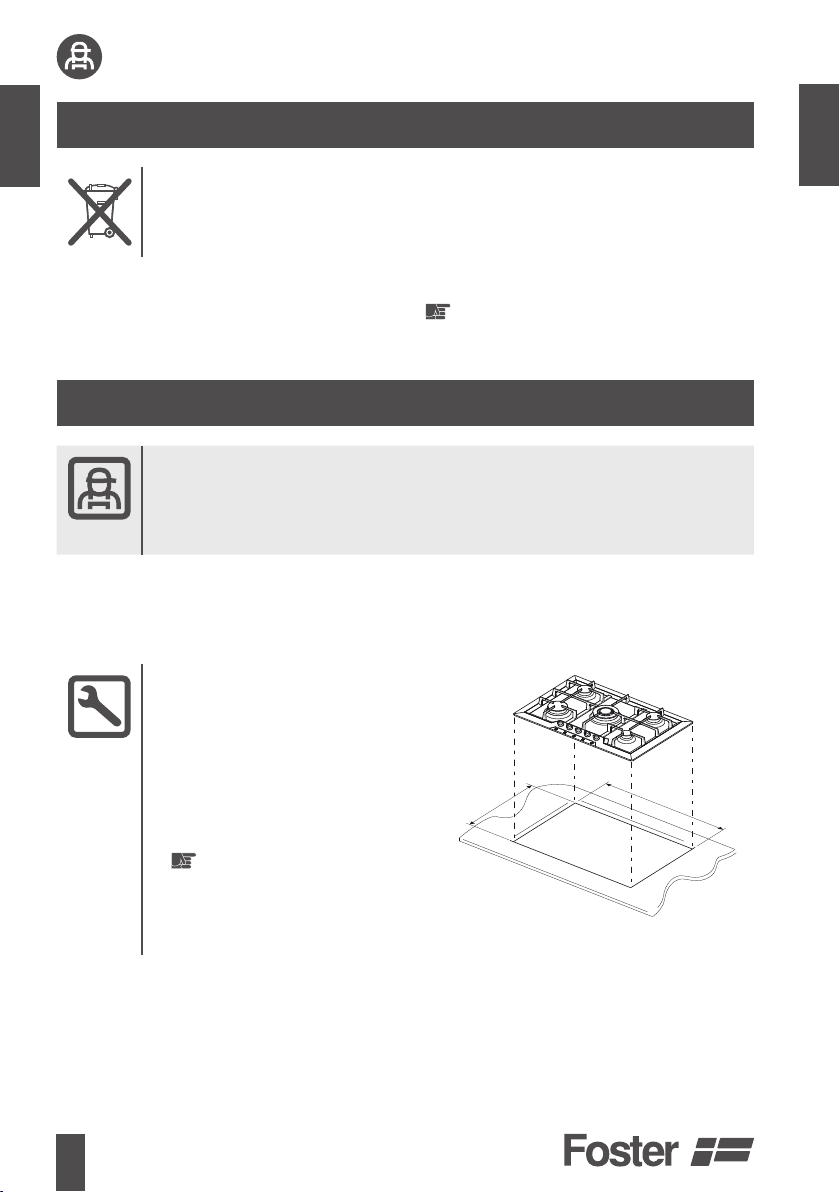

• Carefully position the supplied insulating gasket along the external

perimeter of the hole created on the

worktop, trying to make it adhere

along the entire surface by slightly

pressing it by hand [Fig. 4].

• Once these operations have been

completed, use the supplied brackets to fasten the hob to the structure.

Refer to the “Fastening the cook-

er hob to the cabinet” paragraph

[Page 26].

Fig. 4:

positioning the insulating gasket

ENGLISH

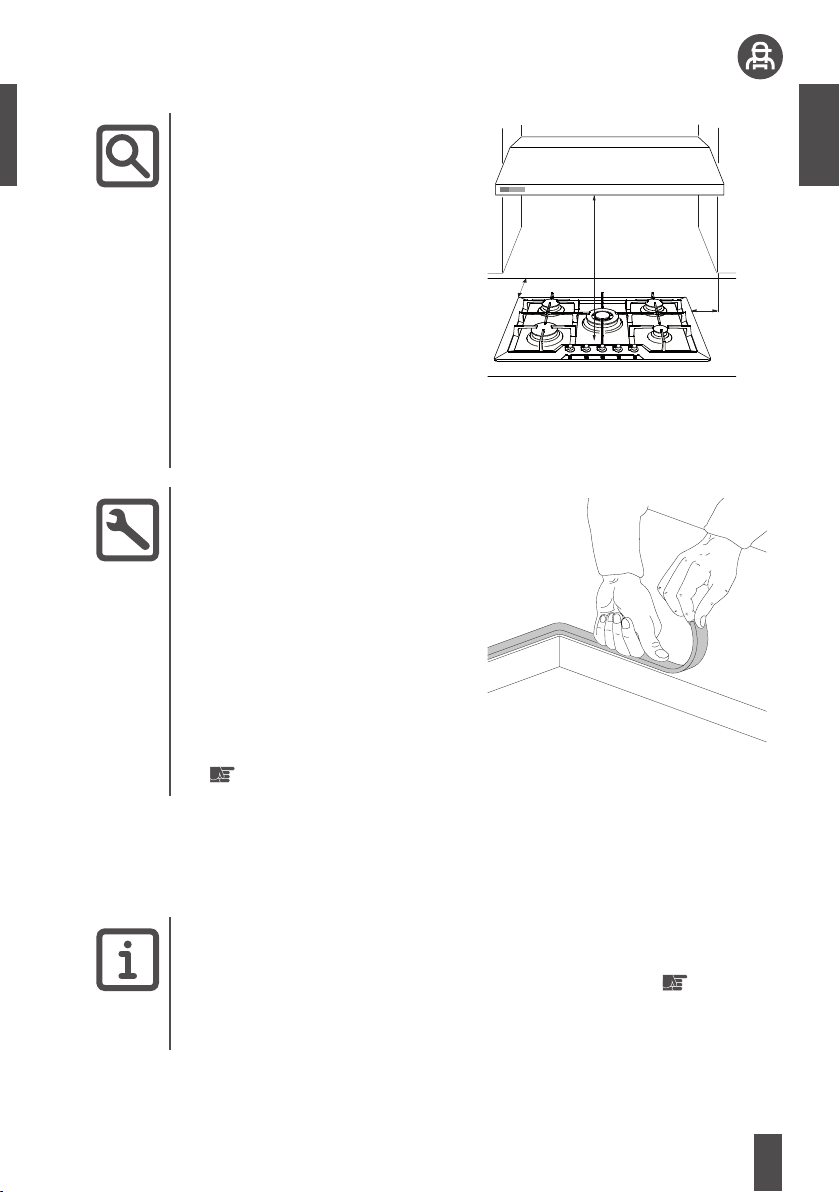

6.2 Installation on the support structure (worktop) of a flush built-in cooker

hob (flush-mount edge)

This type of appliance requires milling on the 1.5 mm deep worktop,

which measurements are indicated in the top drawing, identifiable in the section

Gas cooker hobs summary - models with "flush" built-in [Page 182].

The step is necessary to house the cooker hub edge so that it is "flush" with the

worktop.

25

ENGLISH

INSTALLER INSTRUCTIONS

• Accurately clean milling.

• Before positioning the top, lay the

sealer gasket provided on the entire

milling surface [

Fig. 5].

• Once these operations have been

completed, use the supplied brackets

to fasten the hob to the structure. Refer to the “Fastening the cooker

hob to the cabinet” paragraph

[Page 26].

Fig. 5:

positioning the insulating gasket

A constant light of at least 0.5 mm is envisioned between the external dimensions of the

stainless steel platform and the internal dimensions of the lowering that must be respected

during assembly. The temperatures that develop during use of the cooker hub induce a

slight elongation on the stainless steel platform, therefore, the envisioned light enables

avoiding any interferences. With regard to the kitchen worktop, the temperatures induced

by the cooker hub - whether in the section and on the contact top - are very contained.

We recommend assembling the cooker hubs with flush-mount edge on water-repellent materials.

7. Fastening the cooker hob to the cabinet

Fasten the supplied hooks to the brackets under the appliance, as shown here below.

The supplied hooks make it possible to fasten to a top whose thickness is between

30 and 40 mm.

IMPORTANT:

• For fastening this product to the support structure, the use of mechanical or

electric screwdrivers is not recommended and only moderate pressure

must be exerted by hands to the clamping parts.

• The surface under the appliance must be at at least 5 mm from the bottom of it

and must have an opening for passing gas and electric conduit that is

at least 50x50 mm.

• If this product is installed above an oven, it must be equipped with a

cooling fan.

26

INSTALLER INSTRUCTIONS

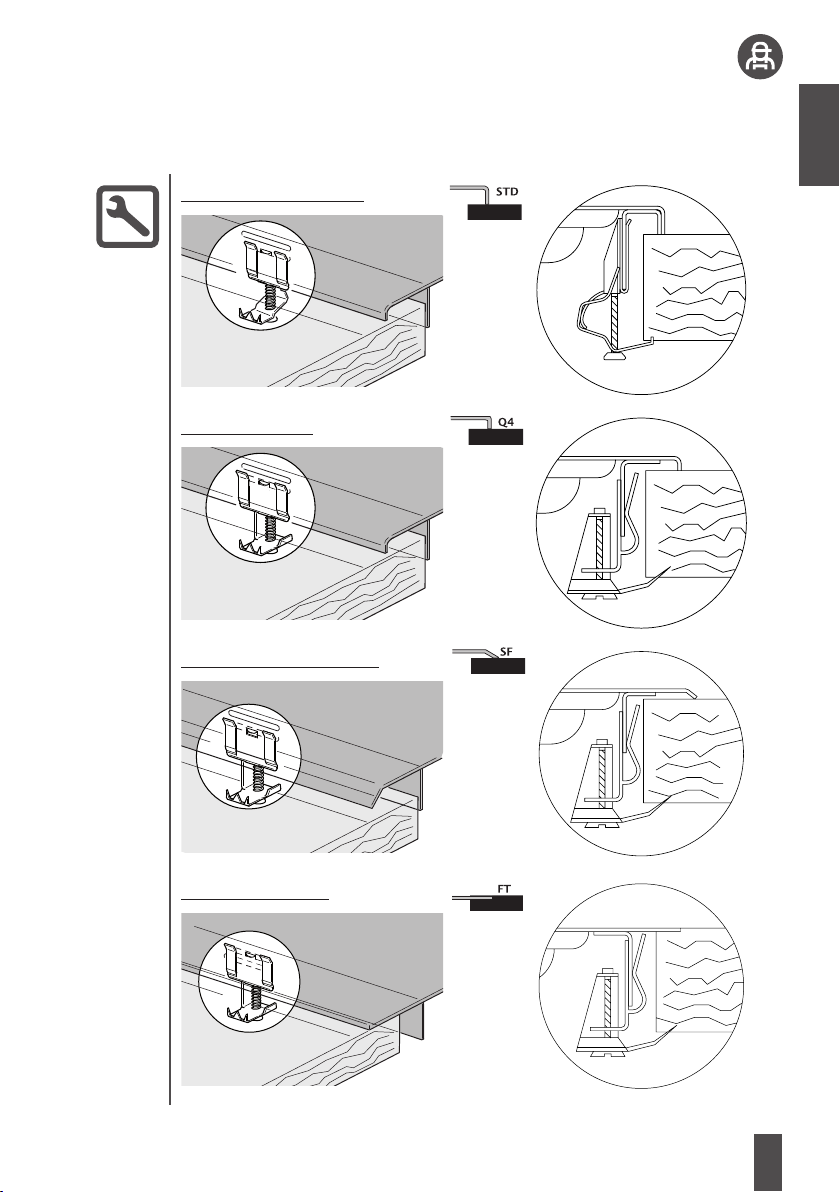

7.1 Fixed hooks

They make it possible to fasten the cooker hob using fixing frames pre-set along specific points.

Standard edge (8 mm)

Q4 edge (4 mm)

ENGLISH

Semi-flush edge (3 mm)

Flush-mount edge

27

INSTALLER INSTRUCTIONS

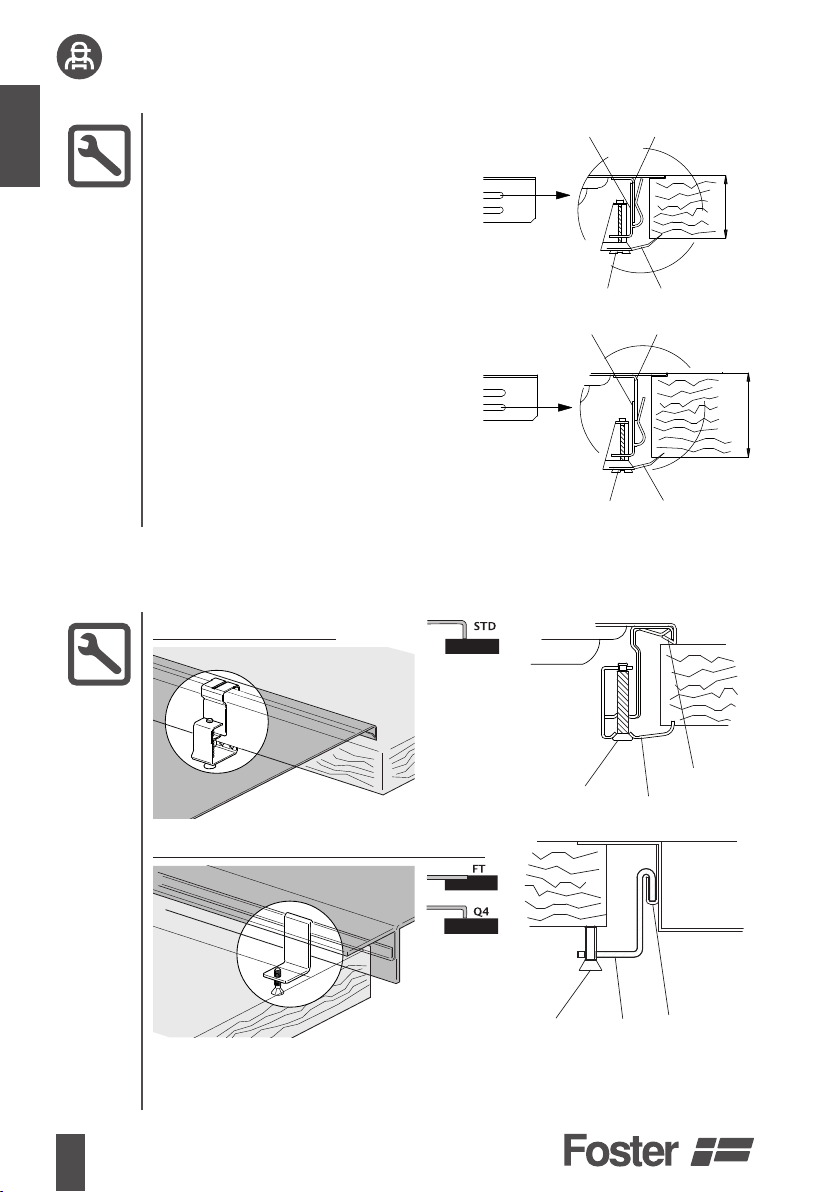

B A

Set hook B in frame A welded to the hob,

ENGLISH

making sure that it is blocked in the specific holes based on top thickness (for a

30 mm thick top, lock the hook in the the

highest hole in the frame; for a 40 mm thick

top, block the hook in the lowest hole of the

frame).

Rotate tongue CA until it is positioned

above the top, then tighten screw D.

7.2 Sliding hooks

Make it possible to fasten the cooker hob without pre-set fastening points.

Standard edge (8 mm)

30

CD

B A

40

CD

28

Flush-mount edge - Q4 (only for S4000 series)

Insert hook B in the sliding guide CA.

Manually lock the hook using screw A.

A

A B C

B

C

INSTALLER INSTRUCTIONS

A

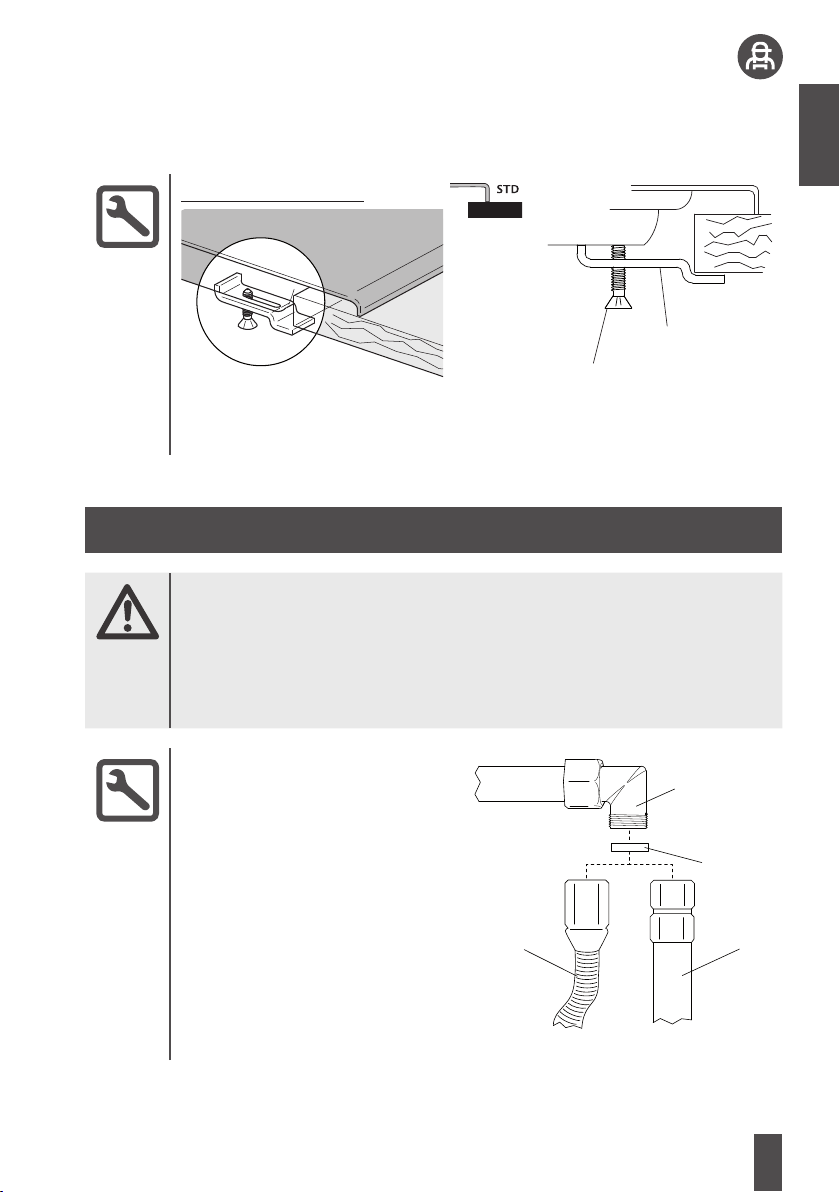

7.3 Fixed brackets

Make it possible to fasten the cooker hob in pre-set fastening points.

Standard edge (8 mm)

B

Introduce the bracket B in appropriate top seat.

Manually lock the bracket using screw A.

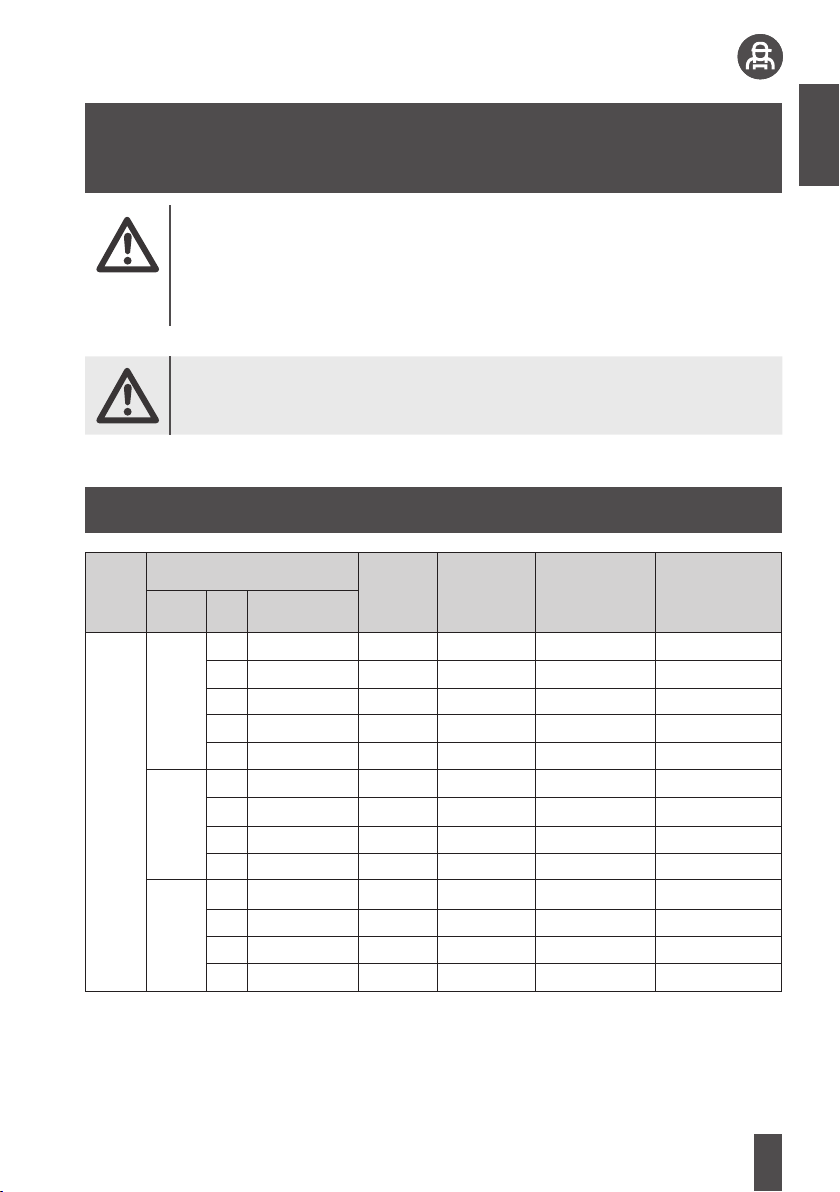

8. Connecting the cooker hob to the gas network

It is necessary for the gas supply system to conform to local regulations in force.

It is necessary to verify that local distribution conditions (gas nature and pressure)

and the appliance adjustment status are compatible.

ENGLISH

IMPORTANT: If the appliance is installed above an oven, it is necessary to avoid

passing the gas tube behind the oven in order to avoid overheating.

The connection to the gas supply network can be completed us-

cooker hob

fitting

ing rigid copper piping or with a

continuous flexible steel pipe

on the wall, according to established

gasket

regulations that are parts of the regulations in force [Fig. 6]. In any case

every pipe connected to the

stainless steel

flexible pipe

copper

rigid pipe

gas supply network must be

equipped with a safety interception valve.

connection to the gas supply network

Fig. 6:

29

INSTALLER INSTRUCTIONS

IMPORTANT: Always place the gasket between the hob fitting and the connection

ENGLISH

pipe.

• If using a stainless steel flexible pipe, it must be installed so that it does not

come in contact with any part of the cabinet, but passes through an unoccupied

area where its entire length can be inspected. Maximum extension of the flexible

pipe must be less than 2 metres.

• The gas fitting is the type with a 1/2” gas ISO R7 tapered thread.

After connecting the appliance to the gas supply network always verify fittings

seal using a soapy solution.

VERIFYING THE SEAL USING NAKED FLAMES IS ABSOLUTELY PROHIBITED.

The cooker hob is tested for methane gas G20 (2H) at a pressure of

20mbar. For supplying with other types of gas, see the Adapting to the different

types of gas table [Page 31]

8.1 Connection to liquid gas

Use a pressure regulator and realise connection on cylinder in compliance with the

prescriptions established by the current Standards.

Ensure the supply pressure respects the values indicated in the table

Adapting to different types of gasses

must be carried out with copper rigid pipe or with stainless steel flexible pipe with

continuous wall.

9. Room ventilation

IMPORTANT: The appliance can only be installed in rooms that are permanently

ventilated, as required by standards in force.

30

[Page 31]. In this case also, connection

INSTALLER INSTRUCTIONS

INSTALLER INSTRUCTIONS

10. Discharging combustion products

(exhaust)

Discharge of combustion products must be ensured through hoods connected to an

efficient natural draught flue, or through a forced exhaust.

An efficient exhaust system requires an accurate design by a specialist that is approved for this work, following positions and distances contained in regulations.

IMPORTANT: At the end of the intervention the installer must issue a conformity

certificate.

11. Adapting to different types of gasses

ENGLISH

Gas

type

Series No. Ref.

2 Auxiliary 1,00 73 0,50 0,52

3 Semi-quick 1,75 127 0,65 0,52

4 Quick 2,70 196 0,80 0,90

II

5 Triple crown 3,50 254 0,95 1,80

10 Dual 4,50 328 i 0.46 / and 0.66 i 0.46 / and 0.66

6 Auxiliary 1,10 80 0,52 0,52

7 Semi-quick 1,75 127 0,65 0,52

LPG GAS

III

8 Quick 3,00 218 0,85 0,90

9 Triple crown 3,80 276 0,98 1,80

G30/G31 28÷30/37 mbar

11 Auxiliary 1,00 73 0,50 0,52

12 Semi-quick 1,75 127 0,65 0,52

AE

13 Quick 3,00 218 0,85 0,90

14 Dual gear 5,00 364 i 0.46 / and 0.95 i 0.30 / and 1.40

Burner

Rated

capacity

(KW)

Rated con-

sumption

(g/h)

Injector

(ø mm)

Min

rated capacity

(KW)

31

INSTALLER INSTRUCTIONS

ENGLISH

Gas

type

Series No. Ref.

II

III

G20 20 mbar

METHANE GAS

AE

The appliance is tested for methane gas G20 (2H) at a pressure of 20 mbar. When

using with other types of gas it is necessary to replace the burner nozzles, and adjust

the minimum flame on the gas taps. For nozzle replacement, proceed as described in

the following paragraphs.

Burner

Rated

capacity

(KW)

Rated con-

sumption

(l/h)

Injector

(ø mm)

Min

rated capacity

(KW)

2 Auxiliary 1,00 95 0,72 0,52

3 Semi-quick 1,75 167 0,97 0,52

4 Quick 2,70 257 1,08 0,90

5 Triple crown 3,50 333 1,35 1,80

10 Dual 4,50 429 i 0.72 / and 1.02 i 0.46 / and 0.66

6 Auxiliary 1,10 105 0,73 0,52

7 Semi-quick 1,75 167 0,98 0,52

8 Quick 3,00 285 1,26 0,90

9 Triple crown 3,80 362 1,35 1,80

11 Auxiliary 1,00 95 0,72 0,52

12 Semi-quick 1,75 167 0,97 0,52

13 Quick 3,00 285 1,32 0,90

14 Dual gear 5,00 476 i 0.75 / and 1.58 i 0.30 / and 1.40

11.1 Cooker hob nozzle replacement

IMPORTANT: Before completing the following operations, always make sure that the

appliance is disconnected from the power mains.

1. Remove the grids, remove all flame spreading

caps and crowns.

2. Using a 7 mm tube spanner, unscrew the burner

nozzles [

3. Proceed with burner nozzle replacement based on

the type of gas to be used (table “Adapting to

different types of gasses”

4. Correctly reposition the burner in its seat.

32

Fig.7].

[Page 31]).

Fig. 7:

nozzle replacement

IMPORTANT: After adjusting for use with a gas that is different from the initial testing

one, replace the label on appliance housing with the one that corresponds to the new

gas type.

12. Adjustment of the minimum

Instructions for urban and methane gas

1. Light the burner and bring it to the minimum

position.

2. Remove the gas tap knob and turn the adjust-

ment screw [

tap rod (depending on the model), until a regular

minimum flame is obtained.

3. Re-assemble the knob and verify burner flame

stability (when quickly rotating the hand from

maximum to minimum position the flame must

not shut off).

4. Repeat the operation on all gas taps.

Fig. 8] inside or on the side of the

INSTALLER INSTRUCTIONS

Fig. 8:

adjustment of the minimum

ENGLISH

Instructions for liquid gas (LPG)

Tighten the screw inside, or on the side of the tap (depending on the mode), rod

clockwise completely.

13. Electrical connection of the cooker hob

IMPORTANT: Before completing the following operation, always make sure that the

voltage and sizing of the power supply line correspond to the characteristics indicated

on the place located under the housing of the appliance. This plate must never be

removed.

33

USER INSTRUCTIONS

It is mandatory to have an earth connection as per modes foreseen in the electrical

ENGLISH

system safety standards.

• If using a fixed connection, it is necessary to pre-set an omnipolar interruption

device on the appliance power supply line with a contacts distance that is equal

to or greater than 3 mm, located in a position that can be reached easily and is in

proximity of the appliance.

• If using a connection with a plug and socket, verify that they are of the same type.

Avoid using reducers, adaptors or diverters because they may cause

overheating or burns.

IMPORTANT: The manufacturer declines any liability for damages to persons or

property, caused by the non observance of the following regulations or resulting from

tampering with even a single part of the appliance.

14. Cooker hob use

14.1 Lighting the burners

Before lighting hob burners, make sure

that the flame spreading crowns are po-

parallel and centred

tilted

sitioned in their seat with the respective

caps.

not centred

Fig. 9:

tilted

crown position

The new burners called "Series III" are assembled on certain cooker hobs. The lock system

between cover (B) and flame spreading (A)

guarantees perfect positioning and large

cleaning ability.

Fig. 10:

positioning of the series III burner

34

USER INSTRUCTIONS

OFF

USER INSTRUCTIONS

The upper cover (B) of the burners must be placed in opposite seat with the two introductions notches in correspondence of the two cylinders below (C) and tighten clockwise.

The associated burner is indicated near each knob.

The appliance is equipped with an electric ignition

device. It is sufficient to press the knob and rotate it

anti-clockwise to the maximum flame symbol, until

MAX

it is lit. If it does not ignite within the first 15seconds, bring the knob on [chiuso] (closed)

and do not try to re-ignite for 60 seconds.

Once it is lit, keep the knob pressed for a few seconds in order for thermocouple to heat up. It is

MIN

Fig. 11:

standard burner knob

CHIUSO

1 INSIDE BURNER

2 EXTERNAL CROWNS

possible that the burner shuts off when the knob

is released: this means that the thermocouple was

not sufficiently heated. Wait a few seconds and repeat the operation, keeping the knob pressed for a

little longer. Once the burner is lit, it is possible to

adjust the flame based on need.

After every use of the hob, always verify that the

control knobs are in [chiuso] (closed) position.

MAX 1

MAX 2

MAX 1

MIN 2

Fig. 12:

burner knob

dual (S4000)/dual gear

CHIUSO

MIN 1

CHIUSO 2

MAX 1

CHIUSO 2

1 INSIDE BURNER

2 EXTERNAL CROWNS

If the burners were to shut off accidentally, after

about 20 seconds a safety device intervenes and

blocks gas output, even when the tap is open. In

this case bring the knob to

[chiuso] (closed)

position and do not try to light the burner for at

least 60seconds.

1 MAX

2 CHIUSO

1 MIN

2 CHIUSO

Fig. 13:

burner knob

dual (GIOTTO/VULCANO)

1 MAX

2 MAX

1 MIN

2 MIN

ENGLISH

35

USER INSTRUCTIONS

14.2 Practical recommendations for burner use

ENGLISH

For better burner yield, and minimum

gas consumption, it is necessary to use

fl at and regular bottom pots, equipped

with a cover and proportioned to the

burner, in order to avoid that the fl ame

goes up their sides (see the “Pots

diameter” paragraph [Page 36]).

When boiling, reduce the fl ame as much

as needed to make sure that the liquid

does not overfl ow.

During cooking, all containers or steak pans, also to avoid burns or damage to the

hob, must not exceed the measurements indicated in the paragraph “Pot diameter”

[Page 36]). Do not heat empty pots or pans, because they may overheat.

When using greases or oils, pay careful attention because, when overheating, they

may catch on fi re. If a pan containing greases or oil catches on fi re, do not pour water

on it because it may cause burns; extinguish the fi re by covering the pan with a wet

cloth and disconnect the appliance from the power mains.

14.3 Pot diameter

• Auxiliary burner: from 6 to 14 cm

• Semi-quick burner: from 15 to 20 cm

• Quick burner: from 21 to 26 cm

• Double crown, triple crown, dual burners: from 24 to 28 cm

Fig. 14:

pots use

During operation, the cooker hob generates heat and humidity in the room it is installed in. Make sure that the kitchen is well ventilated. A prolonged used of the appliance with some or all burners may require additional ventilation such as opening a

window and/or a greater suction power from the exhaust hood.

36

USER INSTRUCTIONS

15. Cleaning and maintenance

Do not use a steam jet to clean the appliance.

Before any intervention it is necessary to disengage the appliance power supply.

Avoid leaving acid or alkaline (vinegar, lemon juice, salt, tomato juice,...) substances

on the steel, grids and other parts of the appliance.

15.1 Cleaning the stainless steel

In order to properly preserve the stainless steel, it is necessary to regularly clean it after each use,

once it has cooled down.

15.1.1 Daily ordinary cleaning

In order to clean and preserve stainless steel surfaces, only use specific products that do not contain

abrasives or chlorine based acid substances.

Usage mode: pour the product on a wet cloth and pass it over the surface, carefully rinse and dry using

a soft cloth or a deerskin.

15.1.2 Food stains or residue

Absolutely avoid using metal sponges and sharp scrapers to avoid damaging the surfaces. Use normal products for steel, non abrasives, using wood or plastic material

tools if needed. Carefully rinse and dry using a soft cloth or a deerskin.

We recommend using Foster Steel Clean to clean the steel; for information on where it

can be obtained, contact the after-sales technical assistance centre.

Do not use chemical detergents such as oven sprays or stain removers.

ENGLISH

15.2 Cleaning gas components

The grids, caps and flame spreading crowns are removable in order to simplify cleaning: wash then

in hot water with non abrasive detergent, making sure that any crud is removed and dry them immediately using a cloth. Re-assemble the caps on their crowns. The cast iron components, like the grids

and the burners, must never be washed in dishwashers.

For the ignition glow plugs to work correctly, the thermocouples must always be clean. Frequently

check them and, if necessary, clean using a wet cloth and then dry them. Any dry residue must be

removed using a wood toothpick or a needle.

Foster S.P.A. will not answer for the possible inaccuracies contained in this manual attributable to printing

or transcription errors. The right is reserved to make amendments to own products considered necessary or

useful, also in the interest of the utility, without jeopardising its functional and safety features.

37

Riepilogo piani cottura a gas

Legenda

Serie N. Bruciatore Potenza (W)

1 Manopola di comando

2 Ausiliario 1.000

3 Semirapido 1.750

II

4 Rapido 2.700

5 Tripla corona 3.500

10 Dual 4.500

6 Ausiliario 1.100

7 Semirapido 1.750

III

8 Rapido 3.000

9 Tripla corona 3.800

11 Ausiliario 1.100

12 Semirapido 1.750

AE

13 Rapido 3.000

14 Doppia corona 5.000

Gas cooker hobs summary

ENGLISH ITALIANO

Series No. Burner Power (W)

II

III

AE

Key

1 Control knob

2 Auxiliary 1.000

3 Semi-quick 1.750

4 Quick 2.700

5 Triple crown 3.500

10 Dual 4.500

6 Auxiliary 1.100

7 Semi-quick 1.750

8 Quick 3.000

9 Triple crown 3.800

11 Auxiliary 1.100

12 Semi-quick 1.750

13 Quick 3.000

14 Dual gear 5.000

Tipo di bordo

Bordo standard (8 mm)

Bordo Q4 (4 mm)

Bordo semifilo (3 mm)

Bordo filotop

Fori da incasso

Standard edge (8 mm)

Q4 edge (4 mm)

Semi-flush edge (3 mm)

Flush-mount edge

- -

B

A = larghezza - B = profondità

Edge type

Holes for built-in

- -

B

A = width - B = depth

A

A

182

1.1 4000

7899

789

7

8 9

6 7

6 7

A = 1160 mm

B = 480 mm

1

A = 860 mm

B = 480 mm

1

A = 860 mm

B = 480 mm

1

N7272V

N7252V

N7270V

R10.5

R10.5

0

+1

521

R10.5

0

+1

521

+1

0

500

+1

0

500

N7272V

N7252V

N7270V

921

900

1221

1200

921

900

10.5

1.5

+1

0

+1

0

10.5

1.5

+1

0

+1

0

10.5

1.5

+1

0

+1

0

0

0

+1

6

7

+1

500

521

187

8 6 7

787

78

6978

A = 830 mm

B = 480 mm

1

N7253V

R10.5

0

+1

521

+1

0

500

N7253V

851

830

10.5

1.5

+1

0

+1

0

6 7

N7251V

N7251V

10.5

A = 560mm

B = 480 mm

R10.5

621

600

1.5

+1

0

+1

0

1

0

+1

0

+1

521

500

N7254V

A = 1159 mm

N7254V

9

1.5

B = 348 mm

+1

1180

0

1

R10.5

1162

+1

0

N7254V

0

+1

0

A = 1162

B = 351 mm

369

+1

351

188

1

14

10

12

11

1

N7278V-AEO

A = 430 mm

B = 480 mm

N7277V

A = 430 mm

B = 480 mm

N7276V-AEO

A = 360 mm

B = 480 mm

1

189

1.2 QUADRA

2534

253

369

3

468

+1

A = 1162 mm

B = 351 mm

1

A = 862 mm

B = 351 mm

1

A = 309 mm

B = 454 mm

N7215V

N7211V

N7221V

R10.5

0

+1

369

R10.5

0

+1

0

+1

351

0

+1

351

N7214V

N7211V

N7221V

1.5

926

908

1180

1162

9

1.5

+1

0

+1

0

9

1.5

+1

0

+1

0

7

+1

0

323

+1

0

R11

1

0

309

0

+1

454

190

5

N7223V

468

+1

1

252

157.8

R10.5

A = 309 mm

N7223V

1.5

7

B = 454 mm

+1

0

323

+1

0

R11

1

0

+1

0

N7238V

1

45°

351

4

309

0

+1

454

0

+1

351

0

+1

955.5

+1

0

955.5

+1

0

3

N7238V

157.8

+1

0

99

45°

R10.5

R9.5

9

9

1.5

955.5

973.5

+1

0

+1

0

0

+1

0

+1

351

369

9

191

1.3 KE

7 79

+1

7 79

87

1.4 KS

N7603VKE

N7600VKE

1.5

7

A = 840 mm

B = 480 mm

+1

804

0

+1

790

R10.5

0

N7600VKE

N7600VKE

1 66

A = 770 mm

0

514

0

+1

500

B = 480 mm

N7610V

A = 770 mm

B = 480 mm

192

1 67

N7615V

A = 560 mm

B = 480 mm

7

11 6

1.5 PROFESSIONALE

33

5

514

+1

3

+1

R10.5

0

0

+1

500

N7055V-10

874

860

N7053V-10

7

1.5

+1

0

+1

0

1.5

7

N7055V-10

N7055V-10

A = 840 mm

B = 480 mm

1

4

2

N7053V-10

A = 560 mm

+1

B = 480 mm

1

5

2

R10.5

0

514

0

+1

500

604

590

0

+1

0

3

N7062V-08

A = 270 mm

2

1

B = 480 mm

193

5

1.6 LISA

58 7

587

N7061V-08

A = 270 mm

B = 480 mm

1

828.8

N7290V

506.8

R161

303

6

7

N7290V

R168

R93.5

200.5

842.8

828.8

506.8

R1262.5

+1

0

+1

0

R1269.5

7

1.5

1

303

R161

R93.5

200.5

R1262.5

R100.5

0

0

+1

+1

587

601

194

1.7 FAUST

3 35

3 35

770

480

1 23

1.8 ELEONORA

N7075V

N7048V

A = 770 mm

B = 480 mm

N7095V

A = 770 mm

B = 480 mm

R10.5

0

+1

514

0

+1

500

N7047VFT1

804

790

N7295V

1.5

+1

0

+1

0

7

R135

N7296VFT

1.5

+1

0

1 23

0

+1

0

+1

500

514

874

860

+1

0

7

R145

R152

195

1.9 VULCANO

1010

514

5

3

3

4 3

3

1

1.10 VERONIKA

1 24

N7097V

A = 950 mm

B = 480 mm

N7067V

A = 560 mm

B = 480 mm

N7297V

7

1.5

+1

0

984

+1

0

970

0

0

+1

+1

500

R145

R152

3

N7066V

A = 560 mm

B = 480 mm

2

196

1

87

N7063V

78 8

87 7

A = 420 mm

B = 480 mm

6

1

N7367V

1.5

+1

774

0

+1

760

0

0

0

+1

+1

514

1 67

500

7

R145

R152

N7266V

7

614

600

1.5

+1

0

+1

0

1 16

+1

0

514

+1

0

500

R145

R152

197

1.11 ELETTRA - PANDORA

5 33

5 33

3 4

1 24

1 24

N7064V

A = 560 mm

B = 480 mm

N7065V

A = 560 mm

B = 480 mm

1.12 MAGIC

198

N7024V

N7044V

1.5

7

A = 740 mm

B = 480 mm

+1

774

0

+1

760

0

0

0

+1

+1

500

1 23

514

R145

R152

3

N7021V

3

3

3

A = 740 mm

B = 480 mm

1 45

N7023V

A = 560 mm

N7042V

1.5

7

B = 480 mm

+1

614

0

+1

600

1

0

0

+1

+1

24

514

500

0

R145

R152

1.13 ALIEN

N7017VA

4

1

5

A = 840 mm

B = 480 mm

199

1.14 ANGOLARE

5

810

+4

33

5

33

1.15 F2000

N7038V

0

3

619

2

191x45°

0

+4

1

3

810

619

N7053000V

480

20x45°

+4

0

810

330

+4

0

0

+4

480

A = 560 mm

B = 480 mm

1

5

2

N7055000V

A = 840 mm

B = 480 mm

4

2

200

1

1.16 RONDÒ - GIOTTO

4

10

5

87

1

1

N7052V

Ø 500 mm

23

N7051VG

Ø 500 mm

1.17 ALFA

R10.5

0

514

+1

0

500

N7260V

874

860

1.5

+1

0

+1

0

7

N7260V

N7260V

A = 840 mm

B = 480 mm

1

67

+1

201

Loading...

Loading...