USER'S MA

cod. 7372 241

NUAL FOR INDUCTION HOBS

19

Dear customer!

The built-in induction cooktop is intended for household use only. Materials used

Instruction for use

Installation instruction

Rating plate

Fire hazard protection

Appliances are allowed to be mounted on one side next to a high kitchen

Important warnings

20

Mounting the built-in cooktop

21

Connection to the power supply

22

Tecnical information

23

Induction cooktop

25

Hob control

25

Safety functions and error displ ay

30

Cleaning and maintenance of cooktop

31

for packaging are nature friendly and may be recycled, deposited or destroyed

without any threats to the environment. In order to recognize these features, all

packing materials are marked with relevant symbols.

Once your appliance has become obsolete and you do not intend to use it any

longer, take adequate care not to litter the environment. Deposit your old

appliance with the authorized depot dealing with used household appliances.

Instructions for use have been prepared for the user, anddescribe the particu lars

and handling of the appliance.

he appliance should be connected to the power supply in accordance with the

instructions from the chapter “Electrical connections” and in line with the

standing regulations and standards. The connections should be carried out by a

qualified personnel only.

The rating plate with basic information is located underneath the appliance.

cabinet, the height of which may exceed that of the appliance. On the opposite

side however, only a kitchen cabinet of equal height as the appliance is allowed.

20

IMPORTANT WARNINGS

• The appliance may be built-in and connected to the power supply only by a

The symbol on the product or on its packaging indicates that this product

qualified technician.

• Particular areas of the cooktop surface (adjacent to the hotplates) are hot

during operation.

Prevent the children to hang around the appliance and warn them properly

against the danger of burns.

• Hot oil ignites readily, so be sure have the preparation of such food (fries)

under constant control.

• Hotplates may not be left in operation em pt y, without an y dishes on top.

• Never use the appliance for heating the ambience.

• Never use the induction cooktop as a working surface. Sharp objects may

damage the cooktop surface.

• Never place any metal objects upon the induction hotplate, such as knives,

forks, spoons, pot lids, and the like, as they may get very hot.

• Preparation of food in aluminium or plastic cookware is not allowed. Never

place any plastic objects or aluminium foil upon the cooktop surface.

• In case any other appliances are plugged in the electric mains close to the

cooktop, prevent the contact of the plug cable with the hot cooking zones.

• Never keep any flammable or temperature sensitive objects, like cleaning

agents, sprays, detergents, etc., below the appliance.

• Never use cracked or broken induction cooktop. In case you notice any visible

cracks on the surface, cut the power supply immediately.

• In case of any malfunctions, disconnect the appliance from the power supply

and call service department.

• Do not use high-pressure steam cleaner or hot steam to clean the appliance.

• The appliance is manufactured in compliance with the relevant effective safety

standards.

Nevertheless, we strongly recommend that persons with impaired physical,

motorial, or mental capacity, or persons with inadequate experience or

knowledge, do not use the appliance unless attended by a qualified person. The

same recommendation applies when the appliance is used by persons of lessthan-legal age.

• Be careful not to drop objects or crockery on the ceramic glass's surface. Even

light objects (e.g. a salt shaker) can crack or damage the ceramic plate.

• If the appliance is built in over an oven with a pyrolytic system, it should not be

operated while the pyrolytic process is in progress because it can trigger the

overheating protection of the cooktop.

• Don't connect the hob to the power supply with an extension cable or multiple

sockets, because they don't assure a sufficient safety (e.g. overheating risk of

multiple sockets).

may not be treated as household waste. Instead it shall be handed over to

the applicable

collection point for the recycling of electrical and electronic equip ment. By

ensuring this product is disposed of correctly, you will help prevent

potential negative

consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For

more detailed information about recycling of this product, please contact

your local city office, your hous ehold waste disposal service or the shop

where you purchased the product.

21

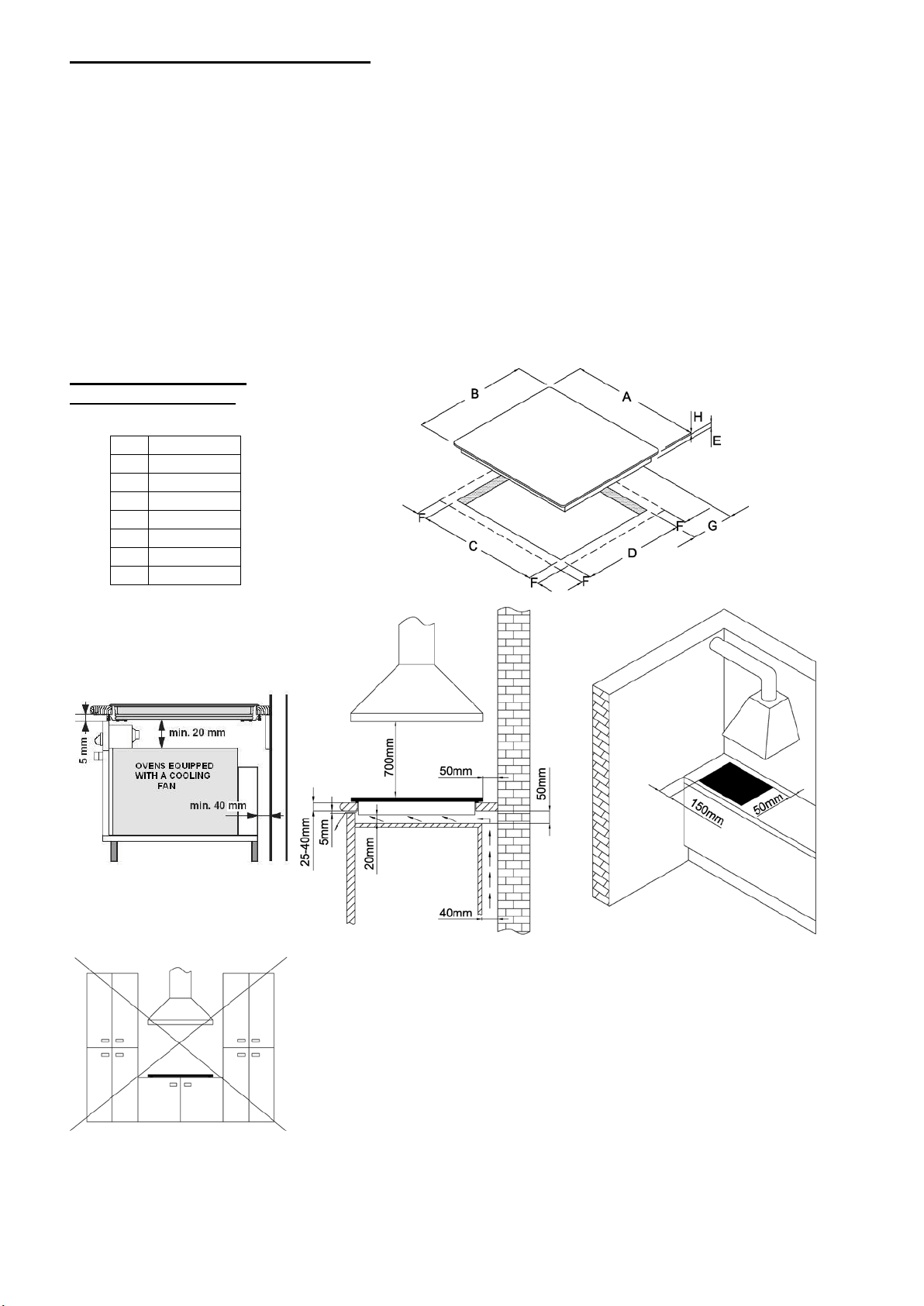

MOUNTING THE BUILT-IN COOKTOP

Caution !

• To avoid any possible hazard, the appliance may be installed by qualified personnel only.

Built-in induction hob

A

590mm

B

520mm

C

560mm

D

490mm

E

53mm

F

10mm

G

50mm

H

5mm

• Panels and furniture lining of the kitchen cabinet receiving the hob must be treated with temperature resistant

adhesives 100°C (otherwise they might be discoloured or deformed because of inadequate temperature

resistance).

• The cooking hob is intended for building into the worktop above the kitchen element of ≥600 mm depth.

After the installation of built-in hob make sure that there is free access to the two fixing elements in front.

• Suspended kitchen elements above the cooktop must be installed at such distance to provide enough room for

comfortable working process.

• The distance between the worktop and the hood must be at least such as indicated in the instructions for

installation of the kitchen hood, but in no case it may be less than 700 mm.

• The use of hard wood decorative borders around the worktop behind the appliance is allowed, in case the

minimum distance remains as indicated on the installation illustrations.

• Minimum distance between the built-in cooktop and rear wall is indicated at the illustration for the installation of

the built-in cooktop.

opening dimensions

• Induction hob may be built into the 25 to 40 mm thick worktops.

• Bottom kitchen element must not have a drawer. It must be fitted with a

horizontal plate 20 mm away from the worktop bottom surface. Space between

the plate and the hob must be empty and no objects may be stored or kept

there.

• Rear side of the kitchen element must also have a 50 mm high opening along

the entire width of the element, and the front part must have an opening of no

less than 5 mm.

• Incorporation of the oven under the induction hob is permissible for ovens

equipped with a cooling fan.

Prior inserting the oven, it is necessary to remove the rear kitchen element panel

in the area of the oven opening.

Equally, the front part of the element must have an opening of no less than 5

mm.

22

Installation procedure

• Worktop must be placed absolutely horizontal.

• Press the hob firmly towards the worktop from above.

CONNECTION TO THE POWER SUPPLY

Basic adjustment of

ATTENTION !

Installation diagram

• Suitably protect the edges of the cut aperture.

• Connect the cooking hob to the mains power supply (see instructions for the

connection of the cooking hob to mains power supply).

• Insert the hob into the cut aperture.

• Connections may be carried out by a qualified technician only. The earthing

protection must comply with the standing regulations.

• Connection terminals are revealed when the connection box cover is removed.

• Prior any attempted connection check that the voltage indicated on the rating

plate is in line with your home power supply.

• The rating plate is located underneath the appliance.

• The appliance is manufactured for use with the power supply voltage

230-240 V ~.

• The electric wiring should be equipped with a circuit breaker able to isolate the

appliance from the mains in all points, with the distance between terminals of at

least 3 mm in open position. This may be done by means of fuses, safety

switches, etc.

• The connection should be selected in accordance with the declared charge

capacity of the mains and the fuse power.

• Such appliances are allowed to be mounted on one side next to a high kitchen

cabinet, the height of which may exceed that of the appliance. On the opposite

side however, only a kitchen cabinet of equal height as the appliance is allowed.

• Upon the completion of installation, live wires and isolated cables must be

adequately protected against accidental touching.

sensors to the ambience

Upon each connection to the power supply the sensors of the appliance are

automatically adjusted to the environment to ensure their proper function. All

displays turn on and are fully illuminated for a few seconds.

During the adjustment procedure the sensors must be free of any objects,

otherwise the adjustment procedure will be interrupted until such objects are

removed from the sensor surface. During this period the regulation of the

cooktop is impossible.

Before attempting any repairs on the appliance, disconnect the power supply. In

accordance with the mains voltage the appliance should be connected in line

with the attached diagram.

The earthing wire (PE) must be connected to the terminal marked with the

earthing symbol .

The connection cable must lead through the relief safety device, protecting it

from accidental pulling out. Upon the completion of installation switch all the

hotplates on for about 3 minutes to check the proper functioning.

Connection must be carried out by means of harmonized cables as H05V2V2-F

(90°C), or with equal or better features.

23

TECNICAL INFORMATION

Type

7372241

Width

590 mm

Electrical connection

230-240 V~ or 400-415 V 2N~, 50/60 Hz

Working voltage

230-240 V~, 50/60 Hz

Type of switch

Electronic sensors

Cooking zones ( Ø, mm/W )

Forward left

Rear left

Forward right

210 , 1500 (P=2000)

145 , 1200 (P=1600)

Total power (W)

2800

P= extra powerful setting

Hotplate function

Hob surface is completely flat and smooth, without edges to accumulate dirt.

IMPORTANT!

Appropriate cookware for

• Induction hotplate will function perfectly only if appropriate cookware is used.

Cooking zones

Min. pan bottom Ø

Max. pan bottom Ø

Ø 145 mm

Ø 90 mm

Ø 145 mm

Ø 210 mm

Ø 130 mm

Ø 210 mm

Magnet test

At the moment you remove the dish from the hotplate, power is suspended. If

Rear right

145 , 1200 (P=1600)

210 , 1500 (P=2000)

principle

induction hotplates

• The hob is fitted with high power induction hotplates. Heat is generated directly

at the bottom of the dish, where it is most needed, without any losses through

the ceramic glass surface.

This way the required extent of energy is considerably smaller compared to

traditional heaters, which operate on radiation principle.

• Glass ceramic hotplate is not heated directly, but only by return heat

transmitted by the dish. This heat figures as “remaining heat” after the hotplate is

turned off. The induction hotplate generates heat from the induction coil,

installed underneath the ceramic glass surface. The coil creates magnetic field

at the bottom of the dish (which can me magnetized) which in turn originates

whirling fl ows of current which then heat the hotplate.

In case sugar or other heavily sweetened substance is spilled on the hotplate,

wipe it immediately and remove the sugar residues with a scraper although the

cooking zone is still hot, otherwise the hotplate may be damaged.

Avoid cleaning the cooktop while the cooking zones are still hot, as you may

damage the hob.

• Dish should be in the middle of the hotplate during cooking.

• The appropriate cookware is the one which enables induction, for example

steel, enamel or steel alloy cookware. Pots made from steel alloy with copper or

aluminium bottom, or glass pots are inappropriate.

• If you use the pressure cooker (“economy pot”) keep it under close surveillance

until proper pressure is obtained. Hotplate should fi rst operate on maximum

power, then follow the manufacturer’s instructions and use the appropriate

sensor to decrease the power.

• When buying cookware, check if it bears the label “allows induction”.

Use small magnet to test if the dish bottom is magnetic. Only dishes where

magnet sticks to the bottom are suitable for induction cooking.

Dish recognition

One of great advantages of the induction hotplate is dish recognition. Even if

there are no dishes upon the hotplate, or the dish diameter is smaller than the

diameter of the relevant hotplate, there are no thermal energy losses. When the

hotplate is on, the power indicator displays letter “U”. If you place the dish over

that hotplate within the following 10 minutes, the hotplate recognizes the dish

and turns on to the preset power value.

24

you place smaller dish upon the hotplate and it is recognized, the hotplate will

only use the amount of energy required to heat the dish according to its size.

Power regulation

Heating power of the hotplates may be set at nine different levels.

Power

Setting

Purpose

0

Off, using remaining heat

1-2

Maintaining warm food, slow simmer of smaller quantities

3

Slow simmer (continuation of cooking after a powerful start-up)

Slow cooking (continuation) of larger quantities, roasting larger

6

Roasting, browning

7-8

Roasting

9

Start of cooking, roasting

A

Automatic initial setting

P

Especially powerful setting for extremely large quantities of food

ENERGY SAVING TIPS

• When buying cookware be careful in selecting size: pot diameter usually refers

Hotplate may be damaged if:

• it is turned on and left empty, or an empty dish is placed on it;

• you use clay dishes which leave scratches on the ceramic glass surface;

• you fail to wipe the dish bottom dry prior placing it on the ceramic glass

hotplate; heat induction is obstructed and the hotplate may be damaged;

• you fail to use the appropriate dishes that can be magnetized: steel dishes,

enamel or steel alloy dishes; induction hotplate will not function otherwise.

The following chart indicates illustrative use of each power setting.

4-5

chunks

to the top edge of the dish, which is often larger than the dish bottom.

• Steam-pressure pots (economic pots), which use pressure in tightly sealed

interior, are especially economic, and save both time and energy. Shorter

cooking time leaves more vitamins in food.

• Always leave enough water in steam-pressure pots, otherwise it may result in

overheating which may damage both the pot and the hotplate.

• Always cover the cookware with lids of appropriate size.

• Use such dish size to accommodate the quantity of food to be prepared. If you

use excessively large pot for small amount of food, you will consume

considerably more energy.

25

INDUCTION COOKTOP

1.Induction hotplate front left

Hob control elements

A.

Hob control

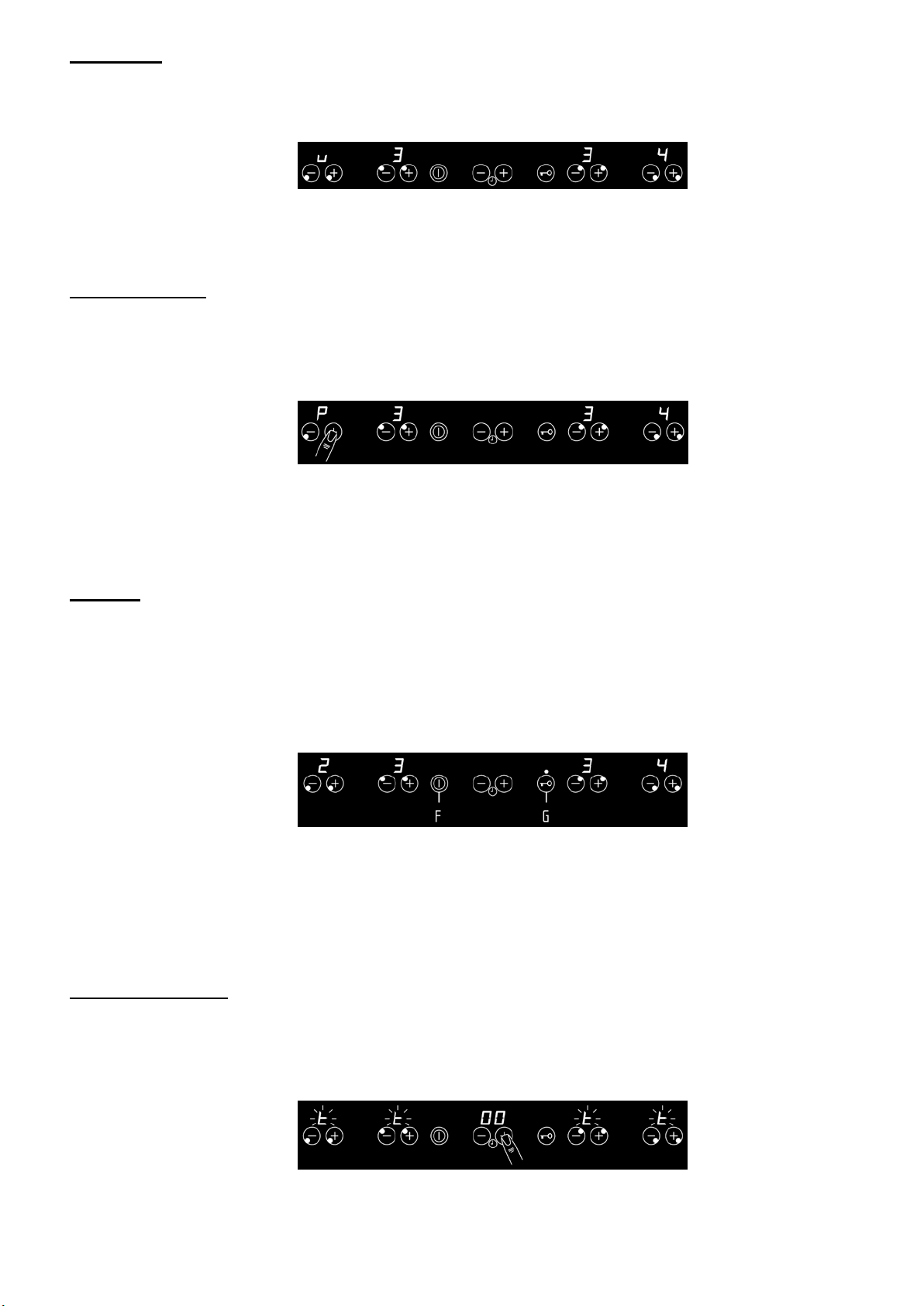

• After turning the induction hob on all displays come on for a moment. The hob

Activating the hob

When the cooktop is connected to the power supply, the key lock is always and

Selecting a power level

With the control on, the first time the sensor (+) is pressed, the heater switches

2.Induction hotplate rear left

3.Induction hotplate rear right

4.Induction hotplate front right

5.Hob control panel

Keys (+ e -) to increase/decrease power level of cooking zone 1

B. Keys (+ e -) to increase/decrease power level of cooking zone 2

C. Keys (+ e -) to increase/decrease power level of cooking zone 3

D. Keys (+ e -) to increase/decrease power level of cooking zone 4

E. Keys (+ e -) of timer to increase/decrease time setting (99min)

F. ON/OFF sensor to turn on/off cooktop

G. Key Lock (with LED)

is ready for operation.

• The hob is fitted with electronic sensors which are switched on if you touch the

relevant circle for at least one second.

• Each sensor activation is followed by a sound signal.

• Avoid placing any objects on sensor surface (The hob turns off after 10

seconds).

• Always keep the sensor surface clean.

immediately on. To turn the cooktop on, first of all you must remove the lock by

pressing the key (G), then press the key ON/OFF (F), you will hear an acoustic

signal with the consequent turning on of the control bar.

It will not come on if the key lock function is activated indicated by a pilot light.

The heaters remain off (all the digits show »0«) until a power level is selected. If

the selection is not made in 10 seconds, and if the timers are off, the control

turns off automatically.

for a certain heater

on at level 1.

The sensor (+) raises the cooking level to a maximum of 9, whereas the sensor

(-) reduces the cooking level to 0 (heater off).

With the heater at position 0, the sensor (-) raises the cooking level to 9.

If the sensor is held down, the action is repeated twice every second.

26

Pan sensor

Each burner is com plete with its o wn sensor f or detec ting the pre se nce of a pan.

this generally means that the size or shape of the pan concerned is

eck whether the type of pan is suitable for

Booster function

Activating the Booster function

Key lock

Holding the key lock sensor (G) down turns the key lock function on or off. If the

Operating the timer

The timer value can be selected between 1 and 99 minutes, and can be modified

The system is fine-adjus ted to recognize the presence of a pan that, acc ording

to the scale of the EN standards, is one s ize smaller than the nom inal diameter

of the burner. If the hot plat e f ails to det ect a ny pan or detec ts a n alum inium pan,

power level flashes on its display. After 60 seconds power level backs to 0.

If power level flashes on the display when a pan is actually on the hotplate,

unsuitable. In this case, ch

induction cooking (see the pan manufacturer’s trademark or instructions).

This function can be activated if the touch control is on. It takes the cooking level

to the maximum power for 10 minutes and then returns to level 9.

The display shows the function has been activated by the letter ‘P’.

After setting the cooking zone to level 9, just press the key (+) and the booster is

activated, the power display shows a 'P'.

Cancelling the Booster function

The Booster function can be cancelled automatically after the preset period of 10

minutes, or before this time if the user wishes.

When a burner is running at “P” (booster) level and:

▪ Booster is deactivated by pressing key (-), its power is reduced to level 9.

pilot light associated with the key lock sensor is on, the keypad is locked.

The locking function can be activated when the cooking levels are activated or

when the cook top is off. If the cook top is on, the key lock function locks all the

sensors except the general on/off sensor and the key lock. When the cook top is

off, the key lock function locks all the sensors and the general on/off (F).

If the cooktop is turned off while the "key lock" is active, this will be still active at

the next turning on.

When the cooktop is connected to the power supply, the "key lock" is

active.

Unlocking the keypad

If the keypad is locked, the pilot light associated with the key lock sensor is on,

holding down the key lock sensor (G) turns the key lock function off and the pilot

light goes off.

at any time.

Initial default setting of the tim er

The hob must turn on.

If the timer is off, it is activated by pressing one of its two keys (E+ o E-).

Heater on timer

The user can select the heater on which the timer function is to operate. The

27

timer can only operate on one heater each time.

Automatic safety off

If the power level is n ot changed d uring a preset time, the cor responding h eater

Level

1 2 3 4 5 6 7 8 9

Set the hotplate to power level 5 and let it operate for som e time. If you don’t

The heater must always be selected (the display must be viewed “0”) before the

time is set; otherwise, the timer will switch off.

If we take longer than 10 seconds to select the heater, the timer will switch off.

If, after selecting the heater, the time is not defined (T=00) in 5 sec., the timer

switches off.

When the timer value runs out, the heater associated with the timer switches off.

Indication of the heater on timer

The touch control indicates the heater on which the timer is operating. This

indication consists of a LED next to the heater display.

This option reminds the user at all times that the heater is on timer.

Increasing the value of the timer

If the sensor (+) or (-) associated with the timer is held down, The value

increases/decreases automatically. This makes it possible to reach the desired

timer setting more quickly. From the tenth consecutive increase/decrease of the

timer setting, the speed at which the value changes increases.

Timer Countdown End

The countdown begins 5 seconds after the last operation on the keys (+ and -) of

the timer (E). You will hear an acoustic signal, and timer's display and the LED of

the zone where you have activated the timer stop flashing.

The last minute will be displayed in seconds.

Switching the timer off

To cancel the operation of the timer, select a timer value of <00> using the

sensor (-), or switch off the timer by pressing the corresponding sensors (E+ and

E-).

Duration of the alarm

When the time set on the timer has run out, a beep sounds for 1 minute. After 1

minute from when the timer alarm starts, the beep stops. The timer displays

continue to flash with the indication <00>. The alarm can be cancelled by the

user at any time, even during the first minute of the alarm, by pressing any

sensor on the touch control.

ATTENTION: The timer can also be set up for a cooking zone that is at the

level "0", LED will remain flashing a ll the time of the countdown. In this

case the timer can have alarm function.

turns off automatically.

The maximum time a heater can stay on depends on the selected cooking level.

Max. time on (hours)

10 10 10 10 10 10 10 10 3

Uninterrupted operat ion at every power le vel of each cooking zone is lim ited in

time (see the table above). When the cooking zone turns off by the safety

mechanism, the display shows the symbol "0" or "H", if there is residual heat.

The cooking zone can be turned off by the sensor (A-) for setting the level

cooking.

Example:

28

change the level, the safety mechanism will switch the hotplate off after 10

hours.

Switching a heater off

Pressing the heater keys (+ and -) at the same time switches off the

General off

The general off function can be performed regardless of the operating mode of the

Displaying power levels

Power level 0:

Power Management

In cases where the cooktop is already in operation for some time, to change the

Protection against overheating

Induction cooktop is also fitted with safety device against overheating which

protects electronic parts from damages. This device operates on several levels.

When cooking zone’s temperature increases excessively, the two-stage fan

switches first. If this is not enough, extra powerful heating is deactivated, and

finally the safety device either reduces the heating power of certain cooking

zones or turns them off completely. When the hotplate cools off, the full power of

hotplate is again available. So during the operation you can hear an steady hum

due to the turning on of the cooling fan. It is possible that the cooling fan

continues to operate even after the cooktop turning off.

manually

corresponding heater and the display shows the power level as 0. We can also

switch off the heater by pressing the key (-) until the display shows the power

level as 0.

cook top by pressing the on/off sensor (F).

When the cook top is turned off, a beep sounds and the displays turn off, as long

as an ‘H’ is not being shown on the corresponding display as a result of residual

heat or an alarm.

A constant “0” is displayed on the heater display. If the induction generator

indicates residual heat, the display alternates between “0” and “H”. This

indication only disappears when there is no longer any danger (at 50 °C).

The display shows a “0” as long as the temperature remains below 50 °C,

whereas it shows an “H” whenever the temperature exceeds 50 °C.

To save energy, turn off the burner in advance, in order to exploit the residual

heat.

Power level 1…9, P:

If no pan is detected or if an aluminium pan is detected, the power level flashes

on the heater display. After 30 seconds, if a non-aluminium pan is not detected,

the power level returns to 0.

When a non-aluminium pan is detected, the power level is shown constant on

the heater display.

limit of power, before proceeding with the planning, unplug it, then reinsert the

plug after a couple of minutes.

The power drawn is 2800 W, but you can increase it at 3500 W, 6000 W or

7200W.

29

Power management for a

Limited Power Cooktop

The sequence to set a new Cooktop Power Limit is:

Power management for a

Induction

plate

1 2 3

4

Level

Power (W)

0

0 0 0 0 1

100

75

100

75 2 200

150

200

150 3 300

300

300

300 4 500

400

500

400 5 700

500

700

500 6 900

600

900

600 7 1100

800

1100

800 8 1300

1000

1300

1000

9

1500

1200

1500

1200

P

2000

1600

2000

1600

(ECO)

▪ During the first 30 seconds after plugging the appliance

▪ The Touch has to be unlocked and all Heaters Off

▪ Push at the same time (A+,A-,D-,D+) keys

▪ Once this is done, a beep sounds and “Po” Characters will be in the timer

display and the “actual Cooktop Power Limit” will be in the display 1 and in the

display 4.

For selecting a new Power Limit:

▪ With any Heater (+ or -) key, the Power Limit is increased/decreased. The

selectable powers are: 2800 W, 3500 W, 6000 W or 7200W.

The sequence to finish recording the new Cooktop Power Limit is :

▪ Push at the same time (A+,A-,D-,D+) keys.

▪ Once this is done, new Cooktop Power Limit is recorded and there is a system

reset.

To finish without recording changes:

▪ If during 60 seconds there is no action, changes are not recorded and there is

a system reset

Limited Power Cooktop

(ECO)

Ø (mm) 210 145 210 145

For reduced power cooktops, each time the user tries to increase the power, the total

power level of the cooktop is calculated. If this total power level is greater than the

cooktop power limit, the power increase is not allowed. An error beep sounds and

the heater display shows the actual power level and an ‘r’ blinking.

30

Safety functions and error display.

ERROR CODE

ERROR DESCRIPTION

INSTRUCTION MANUAL

FA

Anomaly of infrared signal, of on/off key -

all cooking zones are deactivated

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

FC

Receiver infrared anomaly of button

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

FE

Touch control ntc sensor: short circuit on

deactivated

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

FT

deactivated

SPECIFYING THE ERROR CODE

Fc

Touch control ntc sensor: ntc sensor

Switch the hob off and in case also the

SPECIFYING THE ERROR CODE

FH

Eprom (memory) of Touch control:

cooking zones are deactivated

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

FJ

Anomaly of adc, of on/off key - all

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

FO

Touch Control Sotware: anomaly on the

zones are deactivated

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

SPECIFYING THE ERROR CODE

FU

deactivated

SPECIFYING THE ERROR CODE

F5

Anomaly in the communication between

visualised on all displays

CONTACT AUTHORIZED CENTER

F1

Short circuit of temperature sensor of

error is visualised on the relating display

CONTACT AUTHORIZED CENTER

F2

Opening of ntc sensor- the only cooking

display

CONTACT AUTHORIZED CENTER

F8

the relating display

the relating display

F9

Over-current generator - all cooking

visualised on all displays

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

Alternate flashing of cooking

Over-temperature of generator due to

IF HOLD OVER, CONTACT

SPECIFYING THE ERROR CODE

F3

Short circuit of NTC sensor - all cooking

CONTACT AUTHORIZED CENTER

FOR TECHNICAL ASSISTANCE -

FL

on/off - all cooking zones are deactivated

ntc sensor.- all cooking zones are

Touch control ntc sensor: ntc sensor

opening - all cooking zones are

overheating - all cooking zones are

deactivated

anomaly of touch control eprom. - All

cooking zones are deactivated

touch control software. - All cooking

Touch Control luminosity: excessive

external luminosity that hampers t/c

sensors (push buttons) calibration - All

cooking zones are deactivated

FOR TECHNICAL ASSISTANCE -

FOR TECHNICAL ASSISTANCE CONTACT AUTHORIZED CENTER

FOR TECHNICAL ASSISTANCE -

underbuilt-in ofen since completely

cooling. Turn on the hob to check all

functions. If the problem remains

CONTACT AUTHORIZED CENTER

FOR TECHNICAL ASSISTANCE -

FOR TECHNICAL ASSISTANCE -

FOR TECHNICAL ASSISTANCE -

FOR TECHNICAL ASSISTANCE Remove or replace the external

luminosity source. If the problem remains

despite the calibration conditions have

been respected : CONTACT

AUTHORIZED CENTER FOR

TECHNICAL ASSISTANCE -

F7

Touch Control Divider: anomaly on the

t/c Divider. - All cooking zones are

touch and power board - - all cooking

zones are deactivated an error is

heating elements - the only cooking zone

with the anomaly is deactivated - and

zone with the anomaly is deactivated and error is visualised on the relating

Anomaly on the NTC sensor - the only

cooking zone with the anomaly is

deactivated - and error is visualised on

Anomaly on the NTC sensor - the only

cooking zone with the anomaly is

deactivated - and error is visualised on

zones are deactivated an error is

CONTACT AUTHORIZED CENTE R

FOR TECHNICAL ASSISTANCE -

FOR TECHNICAL ASSISTANCE SPECIFYING THE ERROR CODE

FOR TECHNICAL ASSISTANCE SPECIFYING THE ERROR CODE

FOR TECHNICAL ASSISTANCE SPECIFYING THE ERROR CODE

CONTACT AUTHORIZED CENTER

FOR TECHNICAL ASSISTANCE SPECIFYING THE ERROR CODE

CONTACT AUTHORIZED CENTER

FOR TECHNICAL ASSISTANCE SPECIFYING THE ERROR CODE

FOR TECHNICAL ASSISTANCE -

level set by user and of the

letter “C”

intensive use or another use different

from domestic use

AUTHORIZED CENTER FOR

TECHNICAL ASSISTANCE -

31

zones are deactivated an error is

visualised on all displays

SPECIFYING THE ERROR CODE

F4

Opening of NTC - all cooking zones are

displays

CONTACT AUTHORIZED CENTER

SPECIFYING THE ERROR CODE

F6

Tension missing on a generator part

displays

CONTACT AUTHORIZED CENTER

CLEANING AND MAINTENANCE OF COOKTOP

Ceramic glass hob should be cleaned only when completely cooled down,

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

FOR TECHNICAL ASSISTANCE -

deactivated an error is visualised on all

(right or left) - all cooking zones are

deactivated an error is visualised on all

preferably after each use, otherwise even the slightest stains remaining after

cooking may burn into the hob surface with each following use.

For regular maintenance of ceramic-glass hob use special cleansing agents,

produced in such way to create protective film upon the surface.

Before each use, wipe the dust and other particles from the hob, they may

scratch the surface (Fig. 1).

Caution: use of steel wool, abrasive cleaning sponges, and abrasive detergents

can scratch the surface of the hob. The surface may also be damaged by the

use of aggressive sprays and inappropriate liquid chemicals (Fig.1 and 2).

Pattern marks can be erased by the use of aggressive cleansing agents or rough

and damaged cookware bottoms (Fig. 2).

Minor stains are removed with moist soft cloth; after that the surface should be

wiped dry (Fig. 3).

Water stains are removed with gentle vinegar solution, but you must not wipe the

frame with it (certain models only), since it may lose its glow. Never use any

aggressive sprays or limestone removers (Fig. 3).

Major stains are removed with special ceramic-glass cleansers.

Follow strictly the manufacturer’s instructions.

Be careful to remove any remains of cleansing agent from the hob surface,

otherwise they will be heated during the next use and can damage the hob (Fig.

3).

Stubborn and burnt stains are removed with special ceramic-glass scraper. Be

careful, however, not to touch the hotplate surface with the scraper handle (Fig.

4).

Handle the scraper with utmost care to avoid injuries!

Sugar and sugar containing food may permanently damage the ceramic-glass

hob surface (Fig. 5), so the remains of sugar and sugar containing food must be

scraped off from the hob surface immediately, when the hotplates are still hot

(Fig. 4).

Discoloring of ceramic-glass hob has no effect whatsoever on its operation and

stability. In most cases, it appears as the consequence of burnt in food remains,

or as a result of dragging pots and pans (especially aluminium or copper bottom

cookware) across the surface, and such discoloring is rather hard to remove.

Note: All described faults are mostly esthetical and do not affect directly the

operation of the appliance. Remedy of such faults is not covered by warranty.

FOR TECHNICAL ASSISTANCE -

FOR TECHNICAL ASSISTANCE SPECIFYING THE ERROR CODE

Fost

er sp

a

42041 Brescello (RE) - Italy

tel. +39.0522.687425 - tel. Servizio Assistenza +39.0522.684450

fax +39.0522.686019 - fax Servizio Ricambi +39.0522.962166

e-mail: service@fosterspa.com

.

www.fosterspa.com

Loading...

Loading...