Forney 220 AC/DC OPERATING MANUAL

220 AC/DC STICK/TIG ARC

WELDER OPERATING MANUAL

ENGLISH

ITEM# 420

REV 08.08.2019

FIVE WAYS TO ORDER

Forney Promise

Web: www.forneyind.com

Phone: 800-521-6038

Fax: 970-498-9505

Mail: Forney Industries

2057 Vermont Drive

Fort Collins, CO 80525

Email: sales@forneyind.com

U.S. Facilities:

- Fort Collins, CO

- Tipp City, OH

We are committed to your success regardless of location, size or

needs. We understand it is your goal to get the job done right,

and we are ready to help you do just that.

President's Message

We market the highest quality tools, equipment and accessories

for the do-it-yourselfer and professional. Our passion and

dedication in bringing new products to the industrial and retail

market, combined with our personal service, is unmatched in our

industry. Our ability to listen to our customers’ needs enables us to

create solutions to their problems.

Our dedication to the highest quality customer service within our

corporate headquarters and the service provided in the field is

unequaled. We are committed to creating the best solutions to our

customer’s needs. Above all, our employees will provide the same

respect and caring attitude within the organization as they are

expected to share with every Forney customer. Our goal will be to

exceed our customers’ expectations through empowered people,

guided by shared values and commitments.

Copyright© 2019 Forney Industries,

Inc. All rights reserved. Unauthorized

reproduction and/or distribution is

subject to US copyright laws.

2

We work hard so our customers trust us because of our integrity,

teamwork and innovation in the welding & metalworking industry.

80 years of unmatched product quality and an unwavering

commitment to our customers.

When our customers succeed we succeed.

Steven G. Anderson

STEVEN G. ANDERSON, President & CEO

WWW.FORNEYIND.COM

TECHNICAL ISSUES?

FORNEY CAN HELP!

Thank you for choosing Forney! Please note: The store you purchased

this m achine from DOES NOT handle product r eturns. F orney

Industries will repair or replace defective products at no charge to you!

When you call Forney's Technical Service department, you will speak

to a

to get your machine up and running in as little time as possible. In fact,

trained product and application expert. Forney's primary goal is

the majority of issues can be fixed over the phone! Please be near your

machine when you call, so the Forney technician can guide you.

Speaking to a Forney Technician directly helps us gather better data,

and i mprove our p roducts. I t is our h ighest priority t o ensure our

customers are cared for.

WE MAKE IT EASY!

Please contact Forney Industries Technical

Service at 800-521-6038 x2 or

customerservice@forneyind.com for inquires,

technical and general questions.

WWW.FORNEYIND.COM

3

Table of Contents

WARRANTY ..........................................................................................................................................................................3

TABLE OF CONTENTS ............................................................................................................................................................4

SYMBOLS LEGEND ................................................................................................................................................................5

SAFETY SUMMARY ...............................................................................................................................................................5

PRINCIPAL SAFETY STANDARDS .....................................................................................................................................5

CALIFORNIA PROPOSITION 65 WARNING .....................................................................................................................6

EMF INFORMATION .......................................................................................................................................................6

PERSONAL PROTECTION ...............................................................................................................................................6

FIRE PREVENTION ..........................................................................................................................................................7

HIGH FREQUENCY RADIATION ......................................................................................................................................8

ARC WELDING ..............................................................................................................................................................8

ELECTRIC SHOCK ...........................................................................................................................................................8

NOISE ...........................................................................................................................................................................9

ADDITIONAL SAFETY INFORMATION .............................................................................................................................9

INSTALLATION ....................................................................................................................................................................10

WELDER SPECIFICATIONS ............................................................................................................................................10

SITE SELECTION ...........................................................................................................................................................10

POWER SOURCE CONNECTION..................................................................................................................................10

GENERATORS ..............................................................................................................................................................11

EXTENSION CORDS .....................................................................................................................................................11

VENTILATION ..............................................................................................................................................................11

ADDITIONAL WARNINGS ............................................................................................................................................11

GETTING TO KNOW YOUR WELDER ....................................................................................................................................13

DESCRIPTION ..............................................................................................................................................................12

WELDER LAYOUT AND CONTROLS ..............................................................................................................................12

OPERATION ........................................................................................................................................................................16

PERFORMANCE DATA PLATE & DUTY CYCLE .................................................................................................................14

INTERNAL THERMAL PROTECTION ...............................................................................................................................14

WELDING PREPARATION..............................................................................................................................................15

SETUP FOR STICK WELDING (SMAW) ...........................................................................................................................15

SETUP FOR TIG WELDING (GTAW) WITH LIFT ARC ........................................................................................................16

GAS SELECTION ..........................................................................................................................................................16

MAINTENANCE & SERVICING .............................................................................................................................................19

GENERAL MAINTENANCE ...........................................................................................................................................19

TROUBLESHOOTING ...........................................................................................................................................................21

MACHINE PARTS DIAGRAM & CONSUMABLES LIST ..............................................................................................................23

TIG TORCH & TIG CONSUMABLES LIST (SOLD SEPARATELY) ..................................................................................................20

USER NOTES ......................................................................................................................................................................24

4

WWW.FORNEYIND.COM

CAUTION!

BEFORE INSTALLING, OPERATING OR CARRYING OUT MAINTENANCE ON THE MACHINE, READ THE CONTENTS

OF THIS MANUAL CAREFULLY, PAYING PARTICULAR ATTENTION TO THE SAFETY RULES AND HAZARDS.

In the event of these instructions not being clear, please contact your

Forney Authorized Dealer or Forney Customer Service 1-800-521-6038.

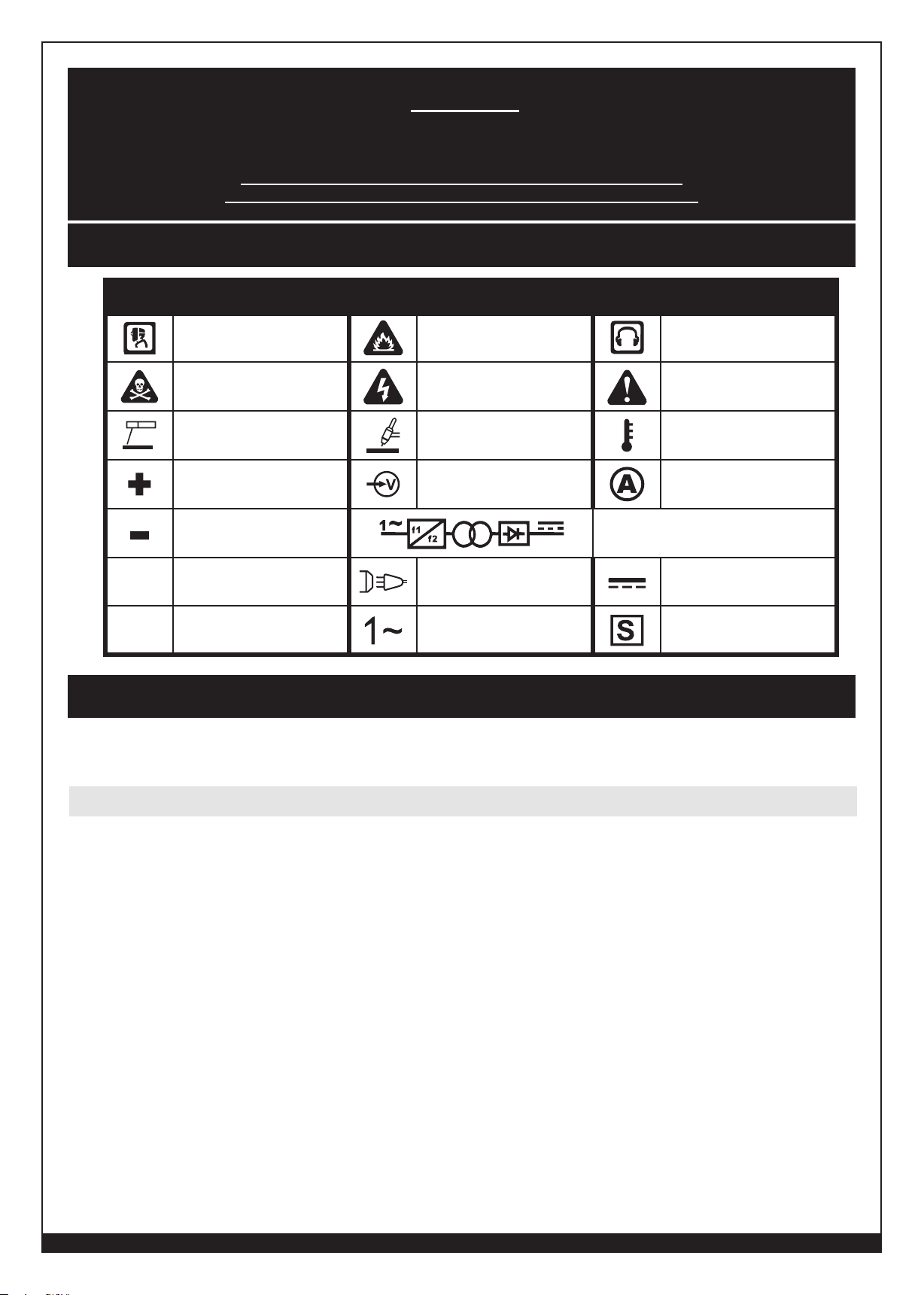

Symbols Legend

SYMBOL

I

O

ARC RAYS HAZARD

POISON

STICK (SMAW) TIG (GTAW) TEMPERATURE

POSITIVE DINSE INPUT VOLTAGE AMPERAGE

NEGATIVE DINSE

ON LINE CONNECTION DIRECT CURRENT (DC)

OFF

MEANING

HAZARD

Safety Summary

SYMBOL MEANING SYMBOL MEANING

FIRE HAZARD NOISE HAZARD

ELECTRICAL HAZARD WARNING/CAUTION

SINGLE PHASE STATIC FREQUENCY

CONVERTER TRANSFORMER RECTIFIER

SINGLE PHASE ALTERNATING

CURRENT (AC)

SUITABLE FOR WELDING IN AN

ENVIRONMENT WITH INCREASED

RISK OF ELECTRIC SHOCK

The data within this safety summary are highlights of various safety standards. It is

recommended that you familiarize yourself with the standards listed below before beginning

welding.

Principal Safety Standards

• ANSI Z49.1: SAFETY IN WELDING AND CUTTING - Obtainable from the American Welding Society, 550 NW Le Jeune

Road, Miami, FL 33126 Telephone (800) 443-9353, Fax (305) 443-7559 - www.aws.org.

• OSHA 29 CFR, Part 1910, Subpart Q.: WELDING, CUTTING AND BRAZING - Obtainable from your state OSHA office

or U.S. Dept. of Labor OSHA, Office of Public Affairs, Room N3647, 200 Constitution Ave., Washington, DC 20210 www.osha.gov.

• AWS F4.1: SAFE PRACTICES FOR THE PREPARATION FOR WELDING AND CUTTING OF CONTAINERS AND PIPING

FOR WELDING AND CUTTING. - Obtainable from the American Welding Society, 550 NW Le Jeune Road, Miami, FL

33126 Telephone (800) 443-9353, Fax (305) 443-7559 - www.aws.org.

• AWS A6.0. WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES - Obtainable from the

American Welding Society, 550 NW Le Jeune Road, Miami, FL 33126 Telephone (800) 443-9353, Fax (305) 443-7559

- www.aws.org.

• NFPA 70: NATIONAL ELECTRICAL CODE - Obtainable from the National Fire Protection Association, 1 Batterymarch

Park, P.O. Box 9101, Quincy, MA 02269-9101 Telephone (617) 770-3000 Fax (617) 770-0700 - www.nfpa.org.

• CGA Publication P-1: SAFE HANDLING OF COMPRESSED GASES IN CONTAINERS - Obtainable from Compressed

Gas Association, 14501 George Carter Way, Suite 103, Chantilly, VA 20151 Telephone (703) 788-2700 Fax (703)

961-1831 - www.cganet.com.

• CSA W117.2 - Code for SAFETY IN WELDING AND CUTTING. - Obtainable from Canadian Standards Association,

178 Rexdale Blvd., Etobicoke, Ontario M9W 1R3 - www.csa.ca.

WWW.FORNEYIND.COM

5

• ANSI Z87.1 - SAFE PRACTICE FOR OCCUPATION AND EDUCATIONAL EYE AND FACE PROTECTION - Obtainable

from the American National Standards Institute, 11 West 42nd St., New York, NY 10036 Telephone (212) 642-900, Fax

(212) 398-0023 - www.ansi.org.

• NFPA 51B: STANDARD FOR FIRE PREVENTION DURING WELDING, CUTTING, AND OTHER HOT WORK- Obtainable

from the National Fire Protection Association, 1 Batterymarch Park, P.O. Box 9101, Quincy, MA 02269-9101 Telephone

(617) 770-3000 Fax (617) 770-0700 - www.nfpa.org.

California Proposition 65 Warning

WARNING: This product can expose you to chemicals, including lead, which are known to the State of California to

cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov. P65

details at forneyind.com. Wash hands after use.

EMF Information

Welding current, as it flows through the welding cables, will cause electromagnetic fields. There has been and still is some

concern about such fields. However, after examination, the committee of the National Research Council concluded that:

“The body of evidence, in the committee’s judgment, has not demonstrated that exposure to power-frequency electric and

a magnetic field is a human health hazard.” However, studies are still going forth and evidence continues to be examined.

Until the final conclusions of the research are reached, you may wish to minimize your exposure to electromagnetic fields

when welding.

To reduce magnetic fields in the workplace, use the following procedures:

1. Keep electrode and ground cables close together by twisting or taping them when possible.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around your body.

4. Keep welding power source and cables as far away from operator as practical.

5. Connect ground clamp to workpiece as close to the cut or weld as possible.

ABOUT PACEMAKERS & HEARING AIDS:

Pacemaker and hearing aid wearers consult your doctor first. If cleared by your doctor, then following the above

procedures is recommended.

Personal Protection

Weld

ing processes of any kind can be dangerous not only to the operator but to any person situated near the

equipment, if safety and operating rules are not strictly observed.

THE WELDING ARC PRODUCES VERY BRIGHT ULTRAVIOLET AND INFRARED LIGHT. THESE

ARC RAYS WILL DAMAGE YOUR EYES AND BURN YOUR SKIN IF YOU ARE NOT

PROPERLY PROTECTED. To reduce the risk of injury from arc rays, read, understand, and follow the safety

instructions. In addition, make certain that anyone else that uses this welding equipment, or is a bystander in the

welding area understands and follows these safety instructions as well. Helmets and filter should conform to ANSI Z87.1

stan dards.

• Do not look at an electric arc without proper protection. A welding arc is extremely bright and intense and, with

inadequate or no eye protection, the retina can be burned, leaving a permanent dark spot in the field of vision. A

shield or helmet with a #10 shade filter lens (minimum) must be used.

• Provide bystanders with shields or helmets fitted with an appropriate shade filter lens.

• Do not strike a welding arc until all bystanders and you (the welder) have welding shields and/or helmets in place.

• Do not wear a cracked or broken helmet and replace any cracked or broken filter lenses immediately.

• Do not allow the uninsulated portion of the TIG torch to touch the ground clamp or grounded workpiece to prevent an

arc flash from being created on contact.

• Wear protective clothing. The intense light of the welding arc can burn the skin in much the same way as the sun, even

through lightweight clothing. Wear dark clothing of heavy material. The shirt worn should be long sleeved and the

collar kept buttoned to protect chest and neck.

• Protect against reflected arc rays. Arc rays can be reflected off shiny surfaces such as a glossy painted surface,

aluminum, stainless steel, and glass. It is possible for your eyes to be injured by reflected arc rays even when wearing

a protective helmet or shield. If welding with a reflective surface behind you, arc rays can bounce off the surface and

off the filter lens. It can get inside your helmet or shield and into your eyes. If a reflective background exists in your

6

WWW.FORNEYIND.COM

welding area, either remove it or cover it with something non-flammable and non- reflective. Reflective arc rays can

also cause skin burn in addition to eye injury.

• Flying sparks can injure. Wear proper safety equipment to protect eyes and face. Shape tungsten electrode on grinder

wearing proper protection and in a safe location. Keep flammables away and prevent fire from flying sparks.

FUMES, GASSES, AND VAPORS CAN CAUSE DISCOMFORT, ILLNESS, AND DEATH!

To reduce the risk, read, understand, and follow the safety instructions. In addition, make certain that anyone else that uses

this welding equipment or is a bystander in the welding area, understands and follows these safety instructions as well.

• Read and understand manufacturers Safety Data Sheets (SDS) and Material Safety Data Sheets (MSDS).

• Do not weld in an area until it is checked for adequate ventilation as described in ANSI standard Z49.1. If ventilation

is not adequate to exchange all fumes and gasses generated during the welding process with fresh air, do not weld

unless you (the welder) and all bystanders are wearing air-supplied respirators.

• Do not heat metals coated with, or that contain, materials that produce toxic fumes (such as galvanized steel), unless

the coating is removed. Make certain the area is well ventilated, and the operator and all bystanders are wearing airsupplied respirators.

• Do not weld, cut or heat lead, zinc, cadmium, mercury, beryllium, antimony, cobalt, manganese, selenium, arsenic,

copper, silver, barium, chromium, vanadium, nickel, or similar metals without seeking professional advice and

inspection of the ventilation of the welding area. These metals produce extremely toxic fumes which can cause

discomfort, illness and death.

• Do not weld or cut in areas that are near chlorinated solvents. Vapors from chlorinated hydrocarbons, such as

trichloroethylene and perchloroethylene, can be decomposed by the heat of an electric arc or its ultraviolet radiation.

These actions can cause phosgene, a highly toxic gas to form, along with other lung and eye- irritating gasses. Do

not weld or cut where these solvent vapors can be drawn into the work area or where the ultraviolet radiation can

penetrate to areas containing even very small amounts of these vapors.

• Do not weld in a confined area unless it is being ventilated or the operator (and anyone else in the area) is wearing

an air-supplied respirator.

• Stop welding if you develop momentary eye, nose, or throat irritation as this indicates inadequate ventilation.

Stop work and take necessary steps to improve ventilation in the welding area. Do not resume welding if physical

discomfort persists.

Fire Prevention

FIRE OR EXPLOSION CAN CAUSE DEATH, INJURY, AND PROPERTY DAMAGE! To reduce these

risks, read, understand and follow the safety instructions. In addition, make certain that anyone else that uses this welding

equipment, or is a bystander in the welding area, understands and follows these safety instructions as well. Remember:

arc welding by nature produces sparks, hot spatter, molten metal drops, hot slag and hot metal parts that can start fires,

burn skin and damage eyes.

• Do not wear gloves or other clothing that contains oil, grease, or other flammable substances.

• Do not wear flammable hair preparations.

• Do not touch the hot weld bead or weld puddle until fully cooled.

• Do not weld in an area until it is checked and cleared of combustible and/or flammable materials. Be aware that

sparks and slag can fly 35 feet and can pass through small cracks and openings. If work and combustibles cannot be

separated by a minimum of 35 feet, protect against ignition with suitable, snug-fitting, fire resistant, covers or shields.

• Do not weld on walls until checking for and removing combustibles touching the other side of the walls.

• Connect the ground cable to the workpiece as close as possible to the welding area. Do not connect ground cables

to building framing or other locations away from the welding area. This increases the possibility of welding current

passing through alternate circuits, creating fire hazards and other safety hazards.

• Do not weld, cut, or perform other such work on used barrels, drums, tanks, or other containers that had a flammable

or toxic substance. The techniques for removing flammable substance and vapors, to make a used container safe for

welding or cutting, are quite complex and require special education and training.

• Do not strike an arc on a compressed gas or air cylinder, and never allow any electrically “hot” parts to touch a

cylinder. Doing so will create a brittle area that can result in a violent rupture immediately or at a later time as a result

of rough handling.

• Ensure any compressed gas cylinders in the work area have properly operating regulators rated for the gas and

pressure used. All hoses, fittings, etc. should be in good condition.

• Do not stand in front of or put your head or face in front of a cylinder valve outlet when opening the valve.

• If a cylinder is not in use or connected for use, keep a valve protection cap in place to protect the valve.

WWW.FORNEYIND.COM

7

• Keep cylinders upright and securely chain them to a fixed support to prevent tipping.

• Keep cylinders away from areas where they may be subjected to physical damage or accidentally struck. Keep them

a safe distance from any source of flame, sparks, or heat.

• Do not weld or cut in an area where the air may contain flammable dust (such as grain dust), gas, or liquid vapors

(such as gasoline).

• Do not handle hot metal, such as the workpiece or electrode stubs, with bare hands.

• Wear leather gloves, heavy long sleeve shirt, cuff-less pants, high-topped shoes, helmet, and cap. As necessary, use

additional fire-resistant protective clothing to cover and protect the upper and lower body. Hot sparks or metal can

lodge in rolled up sleeves, pant cuffs, or pockets. Sleeves and collars should be kept buttoned and pockets eliminated

from the shirt front.

• Have fire extinguisher equipment handy for immediate use. A portable chemical fire extinguisher, type ABC, is

recommended.

• Wear ear plugs when welding overhead to prevent spatter or slag from falling into ear.

• Make sure welding area has a good, solid, safe floor, preferably concrete or masonry, not tiled, carpeted, or made of

any other flammable material.

• Protect flammable walls, ceilings, and floors with heat resistant covers or shields.

• Check welding area to make sure it is free of sparks, glowing metal or slag, and flames before leaving the welding

area.

• Wear garments free of oil or other flammable substances such as leather gloves, thick cotton shirts with no synthetic

materials, cuffless trousers, closed toed shoes. Keep long hair pulled back.

• Remove any combustibles such as lighters and matches before doing any welding.

• Follow requirements in OSHA and NFPA for hot work and have an extinguisher nearby.

High Frequency Radiation

• High Frequency (H.F) can interfere with radio navigation, safety services, computers and communication equipment.

• It is the user’s responsibility to have a qualified electrician promptly correct any interference problem resulting from the

installation. Electrician should regularly check and maintain installation.

• Stop using the equipment if notified by the FCC about interference.

• Keep H.F. source doors and panels tightly shut and keep spark gaps at correct setting.

Arc Welding

• Computers and computer driven equipment can be harmed with electromagnetic energy.

• Be sure all equipment is compatible with electromagnetic energy.

• Keep welding cables short to reduce interference.

• Follow manual to install and ground machine.

• If interference continues, shield the work area or move the welding machine.

Electric Shock

WARNING: ELECTRIC SHOCK CAN KILL! To reduce the risk of death or serious injury from shock, read,

understand, and follow the safety instructions. In addition, make certain that anyone else who uses this welding

equipment, or who is a bystander in the welding area understands and follows these safety instructions as well.

IMPORTANT! TO REDUCE THE RISK OF DEATH, INJURY, OR PROPERTY DAMAGE, DO NOT

ATTEMPT OPERA TION of this welding equipment until you have read and understand the following safety summary.

• Do not, in any manner, come into physi cal contact with any part of the welding current circuit. The welding current

circuit includes:

a. the workpiece or any conductive material in contact with it,

b. the ground clamp,

c. the electrode or welding wire,

d. any metal parts on the electrode holder, or TIG torch.

• Do not weld in a damp area or come in contact with a moist or wet surface.

• Do not attempt to weld if any part of clothing or body is wet.

8

WWW.FORNEYIND.COM

Loading...

Loading...