Forney 140 MP Quick Start Manual

WARNING: To prevent serious injury, read manual warnings and instructions before use.

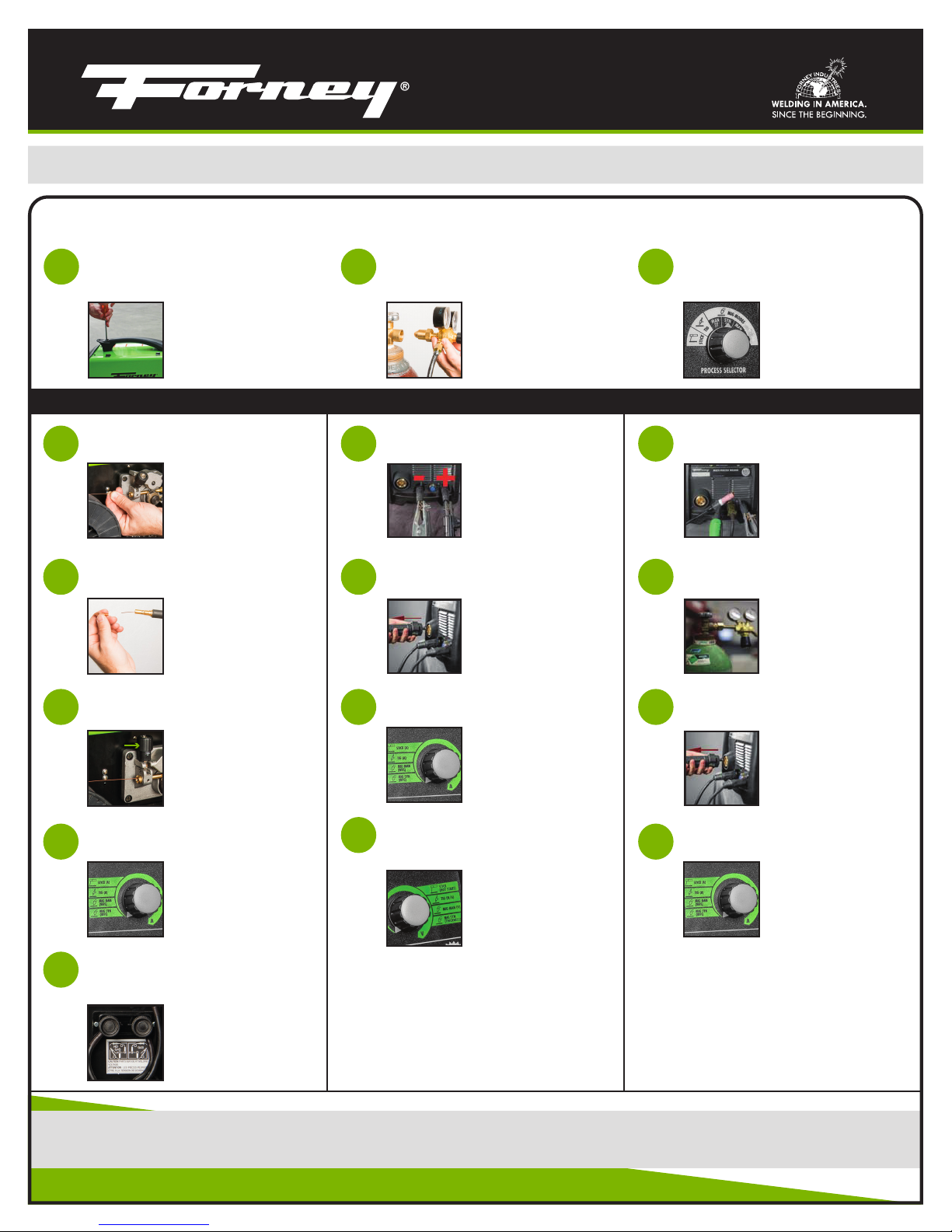

140 MP WELDER QUICK START GUIDE

Assemble top handle and bottom

1

supports. (Tools needed: screwdriver)

Install wire spool.

1

Install MIG gun, turn it on, and

2

squeeze trigger until wire comes out.

Adjust wire feed tension.

3

Attach gas bottle and regulator hose

2

assembly. (Tools needed: adjustable

wrench)

STICKMIG TIG

Adjust polarity for the stick electrode.

1

(Usually DCEP - Electrode

Positive).

Disconnect MIG gun as it will be

2

electrically “hot” while Stick welding.

Adjust amperage.

3

Use Process Selector Knob to select

3

desired process.

Attach TIG torch and Foot Pedal if

1

desired.

Verify proper shielding gas is used

2

for TIG welding.

(Most MIG shielding gases

will not work)

Disconnect MIG gun as it will be

3

electrically “hot” while Stick welding.

Adjust

Tension

Knob

Adjust wire feed speed and voltage

4

per chart on the inside of welder.

Verify drive rolls, liner and tips are

5

properly sized for desired wire

diameter.

WARNING: To prevent fire and serious injury: Keep torch and wire clear of grounded objects while welder is plugged in. Be sure to

follow safe welding proceedures and wear proper PPE (clothes, welding helmet, safety glasses, welding gloves, boots, etc.)

Verify polority is set

correctly for MIG or

Flux-core welding wire.

Adjust hot start if needed.

4

Adjust amperage.

4

* Torch & Foot Pedal sold seperately

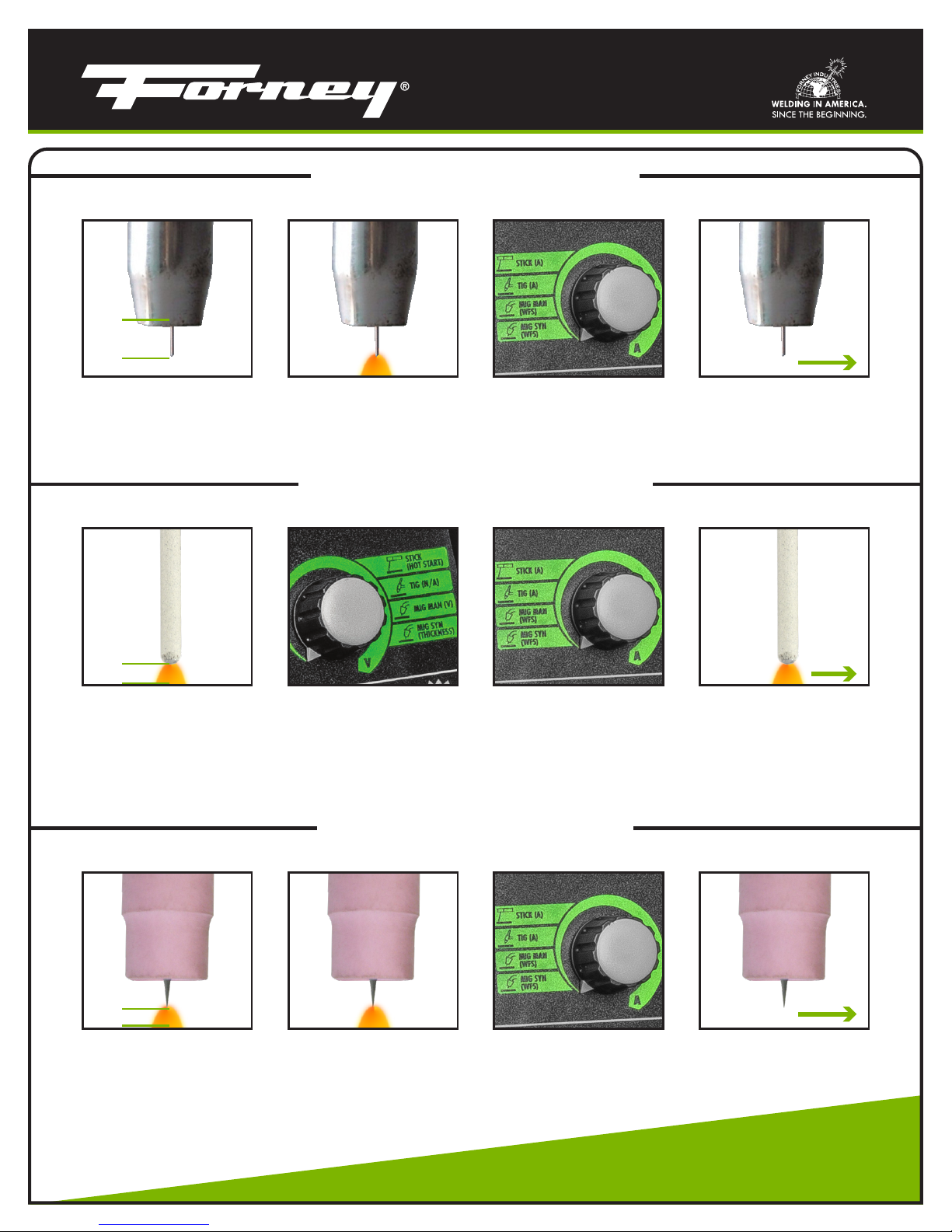

MIG WELDING TIPS

OPTIMAL STICKOUT VOLTAGE

1/2”

WIRE FEED SPEED

(WFS)

TRAVEL SPEED

• Stickout

• Short stickout = more

current and more

penetration

OPTIMAL STICKOUT HOT START

• Optimal stickout varies

by electrode type and

diameter but is usually

approximately 1/16”

1/2” +/- 1/8

1/16”

”

• Affects the arc shape

• Less voltage = tighter

arc and potentially

more spatter

STICK WELDING TIPS

STICK WELDING TIPS

• Provides higher

amperage at arc start

to prevent electrode

sticking

TIG WELDING TIPS

OPTIMAL STICKOUT ARC START

• Higher wire feed speed

equals more amperage

• Can also affect arc

shape and penetration

AMPERAGE

• Affects penetration and

bead width

• Can also affect spatter,

electode starting and

ability to weld vertical

or overhead

AMPERAGE

• Affects bead width

and height

• Can also affect

penetration

TRAVEL SPEED

• Affects bead width

and height

• Can also affect

penetration

TRAVEL SPEED

1/16”

• Optimal stickout varies

by electrode type and

diameter but is usually

approximately 1/16”

• A scratch or lift Start is

often used to initiate

the arc

Try to minimize

•

electrode and tungsten

contamination

• Affects penetration and

bead width

• Amperage is often

referred to as “heat” in

TIG Welding

• Affects bead width and

height

•

Can also affect penetration

Loading...

Loading...