Forney 140 MIG WELDER, 190 MIG Owner's Manual

1

WWW.FORNEYIND.COM

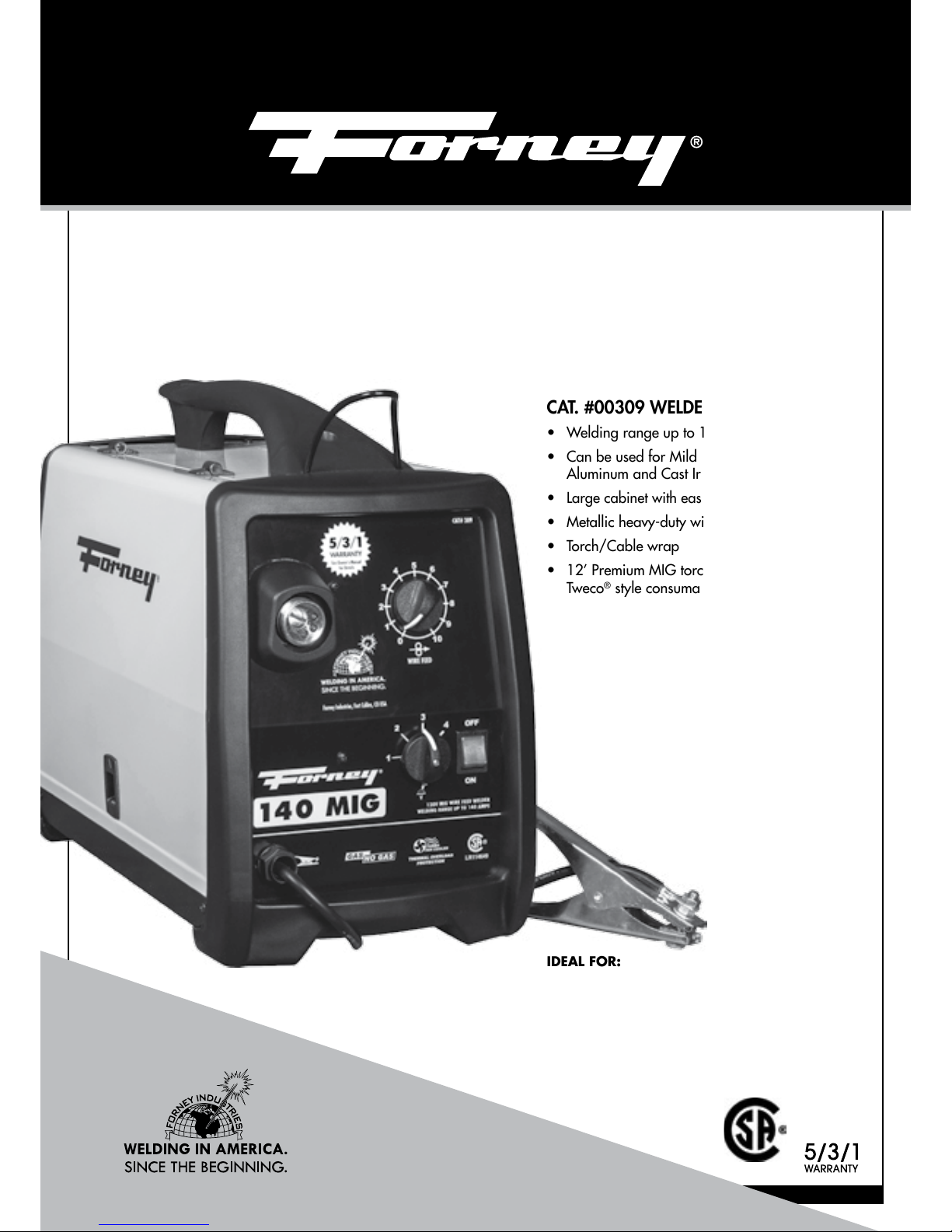

140 MIG WELDER

OWNER’S MANUAL

IDEAL FOR:

Do-It-Yourself, Agriculture, Maintenance & Repair,

Contractor, Automotive, Metal Fabrication Hobbyist and

More...

INCLUDES:

12’ Welding Torch; Ground Clamp; 8’ Power Cable; Gas

Hose and Regulator

CAT. #00309 WELDER FEATURES:

• Welding range up to 140 Amps / 120V Input

• Can be used for Mild Steel, Stainless Steel,

Aluminum and Cast Iron

• Large cabinet with easy access to 4” and 8” spools

• Metallic heavy-duty wire drive system

• Torch/Cable wrap

• 12’ Premium MIG torch with Euro disconnect and

Tweco® style consumables

LR114649

2

WWW.FORNEYIND.COM

STOP PLEASE!

DO NOT RETURN

TO THE STORE

If you have questions or problems with your new Welder, please

call customer service at 1-800-521-6038 Monday through

Friday from 7am-5pm Mountain Time or at

www.forneyind.com/customer_service.

Please take time to register your product at

www.forneyind.com/customer_service/register_your_product/.

This qualifies you for our industry leading 5/3/1 warranty.

Thank you, enjoy your new Welder.

3

WWW.FORNEYIND.COM

Forney Promise

We are committed to your success regardless of location, size or

needs. We understand it is your goal to get the job done right,

and we are ready to help you do just that.

President's Message

We market the highest quality tools, equipment and accessories

for the do-it-yourselfer and professional. Our passion and

dedication in bringing new products to the industrial and retail

market, combined with our personal service, is unmatched in our

industry. Our ability to listen to our customers’ needs enables us to

create solutions to their problems.

Our dedication to the highest quality customer service within our

corporate headquarters and the service provided in the field is

unequaled. We are committed to creating the best solutions to our

customer’s needs. Above all, our employees will provide the same

respect and caring attitude within the organization as they are

expected to share with every Forney customer. Our goal will be to

exceed our customers’ expectations through empowered people,

guided by shared values and commitments.

We work hard so our customers trust us because of our integrity,

teamwork and innovation of Forney products, and Forney’s

80 years of unmatched product quality and an unwavering

commitment to our customers.

When our customers succeed we succeed.

STEVEN G. ANDERSON, President & CEO

Copyright© 2014 Forney Industries,

Inc. All rights reserved. Unauthorized

reproduction and/or distribution is

subject to US copyright laws.

U.S. Warehouses:

- Fort Collins CO

- Tipp City OH

FIVE WAYS TO ORDER

Web: www.forneyind.com

Phone: 80 0-521-6038

Fax: 970-498-9505

Mail: Forney Industries

1830 Laporte Avenue

Fort Collins, CO 80521

Email: sales@forneyind.com

4

WWW.FORNEYIND.COM

Forney 5/3/1 Limited Warranty

Effective August 1st, 2009

1) Limited Warranty: Subject to the terms and conditions below, Forney Industries, Inc., Fort Collins,

Colorado, warrants to its original retail purchaser that the new Forney equipment sold after the effective date

of this limited warranty is free of defects in material and workmanship at the time it is shipped by Forney. This

is in lieu of all other warranties, express or implied.

2) Notification: Please call 1-800-521-6038 with your warranty questions. You can also visit www.

forneyind.com for additional information about your new welder.

3) Length of Warranty: Within the warranty periods listed below, Forney will repair or replace any

warranted parts or components that fail due to defects in material or workmanship. Warranty is effective

from the date of original retail purchase. Warranty duration is as follows:

A) 5 years: Original main power rectifiers only to include SCRs, diodes and discrete rectifier modules,

transformers, stabilizers and reactors.

B) 3 years: Drive Systems, PC Boards, Motors, Switches and Controls.

C) 1 year: MIG guns, relays, contractors and regulators, plasma cutting torches, and accessories.

D) 90 days: Replacement parts. Does not include labor.

4) Non-Applicable Parts: Forney’s limited warranty shall not apply to consumables such as contact tips,

cutting nozzles, felt wire cleaner, drive rollers, gas diffusers, plasma torch tips and electrodes, weld cables,

tips and parts that fail due to normal wear. In addition, this warranty does not extend to any damage caused

by the untimely replacement or maintenance of any of the previously listed consumable parts.

5) Warrantor:

Forney Industries

1830 Laporte Avenue

Fort Collins, CO 80521

1-800-521-6038

www.forneyind.com.

6) Purchaser / Warranty: The original purchaser of the Forney Industries product. The warranty is

not transferable. Forney Industries products are intended for purchase and use by persons trained and

experienced in the use and maintenance of welding equipment.

7) What is not covered under the warranty:

A) Implied warranties, including those of merchantability and fitness for a particular purpose are limited in

duration to this express warranty. After this period, all risks of loss, from whatever reason, shall be on the

purchaser.

B) Any incidental, indirect, or consequential loss, damage, or expense that may result from any defect,

failure or malfunction of the Forney product.

C) Any failure that results from accident, purchaser’s abuse, neglect or failure to operate products in

accordance with instructions provided in the owner’s manual(s) supplied with the product.

D) Pre-delivery service, i.e. assembly and adjustment.

8) Claim: In the event of a warranty claim under this warranty, the exclusive remedies shall be, at Forney

Industries sole option:

A) Repair; or

B) Replacement; or

C) Where authorized in writing by Forney Industries, the cost of repair or replacement at an authorized

Forney Industries Service Center; or

D) Payment of or credit for the purchase price less reasonable depreciation based on actual use upon the

return of the goods at the customer’s risk and expense.

9) Purchaser will:

A) Contact Forney’s Customer Service at 1-800-521-6038 within 30 days of the defect or failure.

B) Provide dated proof of purchase (typically a purchase receipt).

C) Provide the serial number. Registering your welder at registration.forneyind.com:442 will speed up this

process.

D) Deliver or ship welder to a Forney authorized Service Center. Freight &/or packaging costs, if any, must

be borne by the purchaser.

5

WWW.FORNEYIND.COM

WARRANTY .................................................................................................................................. 4

TABLE OF CONTENTS .................................................................................................................... 5

SAFETY INFORMATION ................................................................................................................. 6

ASSEMBLY AND MAJOR COMPONENTS ...................................................................................... 11

SET UP CHART ............................................................................................................................ 14

FRONT PANEL OPERATION..........................................................................................................15

GENERAL OPERATING INSTRUCTIONS ......................................................................................... 16

TROUBLESHOOTING ................................................................................................................... 18

SPARE PARTS AND DIAGRAMS .................................................................................................... 20

TABLE OF CONTENTS

6

WWW.FORNEYIND.COM

CAUTION!

BEFORE INSTALLING, OPERATING OR CARRYING OUT MAINTENANCE ON THE 210 WELDER,

READ THE CONTENTS OF THIS MANUAL CAREFULLY, PAYING PARTICULAR ATTENTION TO THE

SAFETY RULES AND HAZARDS.

In the event of these instructions not being clear, please contact your

Forney Authorized Dealer or Forney Customer Service 1-800-521-6038

Safety Information READ BEFORE USING

Principal Safety Standards

• Safety in Welding and Cutting, ANSI Standard Z49.1, from American Welding Society, 8669 Doral

Boulevard, Suite 130, Doral, FL 33166 Safety and Health Standards, OSHA 29 CFR 1910, from

Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402.

• Recommended Safe Practices for the Preparation for Welding and Cutting of Containers That Have

Held Hazardous Substances, American Welding Society Standard AWS F4.1, from American

Welding Society, 8669 Doral Boulevard, Suite 130, Doral, FL 33166

• National Electrical Code, NFPA Standard 70, from National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269.

• Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1, from Compressed Gas

Association, 1235 Jefferson Davis Highway, Suite 501, Arlington, VA 22202.

• Code for Safety in Welding and Cutting, CSA Standard W117.2, from Canadian Standards

Association, Standards Sales, 178 Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3.

• Safe Practices For Occupation And Educational Eye And Face Protection, ANSI Standard Z87.1,

from American National Standards Institute, 1430 Broadway, New York, NY 10018.

• Cutting And Welding Processes, NFPA Standard 51B, from National Fire Protection Association,

Batterymarch Park, Quincy, MA 02269

EMF Information

Considerations about Welding or Cutting and the Effects of Low Frequency Electric and Magnetic Fields

Welding or cutting current, as it flows through the welding or cutting cables, will cause electromagnetic

fields. There has been and still is some concern about such fields. However, after examination the

committee of the National Research Council concluded that: “The body of evidence, in the committee’s

judgment, has not demonstrated that exposure to power-frequency electric and a magnetic field is a

human health hazard.” However, studies are still going forth and evidence continues to be examined.

Until the final conclusions of the research are reached, you may wish to minimize your exposure to

electromagnetic fields when welding or cutting.

To reduce magnetic fields in the workplace, use the following procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around your body.

4. Keep welding or cutting power source and cables as far away from operator as practical.

5. Connect work clamp to work piece as close to the cut or weld as possible.

About Pacemakers & Hearing Aids:

Pacemaker & Hearing Aid wearers consult your doctor first. If cleared by your doctor, then following

the above procedures is recommended.

7

WWW.FORNEYIND.COM

Personal Protection

Welding processes of any kind can be dangerous not only to the operator but to any person situated

near the equipment, if safety and operating rules are not strictly observed.

Arc rays can injure your eyes and burn your skin. The welding arc produces very

bright ultraviolet and infrared light. These arc rays will damage your eyes and

burn your skin if you are not properly protected.

• Wear closed, non-flammable protective clothing without pockets or turned up trousers, gloves

and shoes with insulating sole and steel toe. Avoid oily greasy clothing.

• Wear a non-flammable welding helmet with appropriate filter lenses, designed so as to shield

the front and sides of the neck and face. Keep protective lens clean and replace them when

broken, cracked or spattered.

• Weld in a closed, but well ventilated area that does not open into other working areas.

• Never look at the arc without correct lens.

Gases and fumes produced during the welding process can be dangerous and hazardous to

your health.

• Adequate local exhaust ventilation must be used in the area. It should be provided through a

mobile hood or through a built-in system on the workbench that provides exhaust ventilation

from the sides, the front and below, but not from above the bench so as to avoid raising

dust and fumes. Local exhaust ventilation must be provided together with adequate general

ventilation and air circulation, particularly when work is done in a confined space.

• Welding process must be performed on metal surfaces thoroughly cleaned from rust or paint,

or zinc coatings to avoid production of harmful fumes. Parts degreased with a solvent must be,

thoroughly dried before welding.

• Be very careful when welding any metals which may contain one or more of the following:

Antimony Beryllium Cobalt Manganese Selenium Arsenic Cadmium

Copper Mercury Silver Barium Chromium Lead Nickel

Vanadium Zinc

• Remove all chlorinated solvents from the welding area before welding. Certain chlorinated

solvents decompose when exposed to ultraviolet radiation to form phosgene gas (nerve gas).

Fire and explosion can be caused by hot slag, sparks or the welding arc.

• Keep an approved fire extinguisher of the proper size and type in the working area. Inspect it

regularly to ensure that it is in proper working order.

• Remove all combustible materials from the working area. If you can not remove them, protect

them with fire-proof covers.

• Ventilate welding work areas adequately. Maintain sufficient air flow to prevent accumulation

of explosive or toxic concentrations of gases.

• Do not weld on containers that may have held combustibles.

•

Continually monitor check welding area to make sure it is free of lingering sparks, slag or

glowing metal and flames.

• The work area must have a fireproof floor.

Fire Prevention

8

WWW.FORNEYIND.COM

WARNING: ELECTRIC SHOCK CAN KILL!

• A person qualified in First Aid techniques should always be present in the working area; If a

person is found unconscious and electric shock is suspected, do not touch the person if she or

he is in contact with cable or electric wires. Disconnect power from the machine, then use First

Aid. Use dry wood or other insulating materials to move cables, if necessary, away from the

person.

• Wear dry gloves and clothing. Insulate yourself from the work piece or other parts of the

welding circuit.

• Make sure the main line is properly grounded.

• Do not coil the torch or the ground cables around your body.

• Never touch or come in physical contact with any part of the input current circuit and welding

current circuit.

Electric Warning:

• Repair or replace all worn or damaged parts.

• Extra care must be taken when working in moist or damp areas.

• Install and maintain equipment according to local regulations.

• Disconnect power supply before performing any service or repair.

• Should you feel the slightest electrical shock, stop any welding immediately and do not use the

welder until the fault has been found and corrected.

Noise can cause permanent hearing loss. Welding processes can cause noise levels that exceed

safe limits. You must protect your ears from loud noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear protective ear plugs and/or ear muffs.

• Noise levels should be measured to be sure the decibels (sound) do not exceed safe levels.

Before installing your welder, carry out an inspection of the surrounding area, observing the

following guidelines:

• Make sure that there are no other power supply cables, control lines, telephone leads or other

equipment near the unit.

• Make sure that there are no radio receivers, electrical appliances, computers or other control

systems near the unit.

• People with pacemakers or hearing-aids should keep far from the welder.

! In particular cases special protection measures may be required.

Interference can be reduced by following these suggestions:

• If there is interference in the power source line, an E.M.F. filter can be mounted between the

outlet and the welder.

• The output cables of the welder should not be too long, kept together or connected to ground;

• After any maintenance all the panels of the welder must be securely fastened in place.

Electric Shock

Noise

Electromagnetic Compatibility

Loading...

Loading...