Ford LRG-423 Service Manual

@a

LRG-423

Power

Products

Worldwide TM

2.3 LITRE

INDUSTRIAL ENGINE

SERVICE MANUAL

Introduction

In general, this manual covers the servicing of the engine and associated standard equipment. In many cases, engines are supplied

with accessories and equipment that are unique to the application. If

service information is ever required on such unique accessories or

equipment it is suggested that Power Products Division/GRI be contacted. The proper information will either be forwarded or the Service Technician will be advised where it can be obtained.

The information in this manual is grouped in sections according to

the type of work being performed. The various sections are indicated in the index. In addition, each section is subdivided to include

topics such as diagnosis and testing, cleaning and inspection, overhaul, removal and installation procedures, disassembly and assembly procedures, and service specifications.

POWER PRODUCTS DIVISION/GRI

The Source for Power...

Worldwide TM

The descriptions and specifications contained in this -manual were in

effect at the time the book was released for printing. Power Products

Division/GRI reserves the right to discontinue models at any time, or

change specifications or design, without notice and without incurring

obligation.

NOTE:

publication are made to assist the distributor in improving his distrib-

utorship parts and/or service department operations. These recommendations and suggestions do not supersede or override the

provisions of the Warranty and Policy Manual and in any cases

where there may be a conflict, the provisions of the Warranty and

Policy Manual shall govern.

The recommendations and suggestions contained in this

28333 TELEGRAPH ROAD - #300

SOUTHFIELD, MICHIGAN 48034

01-I

Engine Service

01-I

SECTION TITLE

ENGINE SERVICE

ENGINE SERVICE, 2.3L

SECTION 01

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘......................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Engine Service

SUBJECT

DESCRIPTION AND OPERATION

Introduction

Engine Identification Nameplate

DIAGNOSIS AND TESTING

Inspection

Symptom Chart

SERVICE PROCEDURES

Positive Crankcase Ventilation (PCV) System

Closed-Type

Engine Oil Leaks

Fluorescent Oil Additive Method

Pressure Method

Testing Procedure

Leakage Points

Compression Test

Compression Gauge Check

Test Results

Compression Pressure Limit Chart

Compression Readings - Interpreting

Example Readings

Cylinder Leakage Detector

Oil Leak and Valve Guide Seal Test

Intake Manifold Vacuum Test

Vacuum

Oil Consumption Test

Oil Pressure Test

Valve Train Analysis -Static (Engine Off)

Rocker Arm/Camshaft Follower Cover

Rocker/Camshaft

Camshaft

Valve Springs

Valve Spring

Valves and Cylinder Head

Intake Valve Cleaning (Valves Installed)

Cleaning and Inspection

Camshaft Lobe Lift, 2.3L Overhead Camshaft

Engine (Camshaft Installed)

Hydraulic Valve Tappet/Lash Adjuster

Camshaft End Play

Timing Belt (2.3L)

Camshaft Timing and Cylinder Identification (CID)

Timing Check

Crankshaft End Play

Connecting Rod Side Clearance

Cylinder Block

Cleaning and Inspection

Cylinder Block Distortion

Cylinder Head Deck Flatness

Main Bearing Bore Alignment

Cylinder Walls, Refinishing

Cleaning

...............................................................................

..................................................................................

.........................................................................

............................................................................

.......................................................................

....................................................................

..................................................................

.......................................................................

.....................................................................

............................................................................

.................................................................

Readings

Gauge

- 2.3L Engine

Retainer and

.........................................................................

................................................................................

..........................................................

..................................................................

Follower

.......................................................................

.................................................................

....................................................................

.......................................................................

...............................................................

.............................................

..........................................

..................................................

......................................

.......................................................

........................................

..................................................

- Interpretation

Arm Assemblies..

.....................................................

Valve Spring

...................................................

......................................................

................................................

.................................

...........................................

......................................................

....................................................

..............................................

.............................................

....................................................

PAGE

................................

........................

..........................

Removed

Keys

...............................

............

..................

.................

01-I

02-l

SECTION TITLE

AUXILIARY SYSTEMS

SUBJECT

SERVICE PROCEDURES (Cont’d.)

3

3

4

4

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

.9

10

11

11

.l 1

.I 1

11

11

.I1

11

11

11

13

13

13

14

14

15

15

15

15

15

15

15

16

16

Inspection

Cylinder Bore

Cylinder Bore Taper

Cylinder Out-of-Round

Cylinder Bore

Cylinder Wall Honing

Engine Block Plugs

Removal and Installation

Expansion-Type

Cup-Type

Crankshaft Main and Connecting

Cleaning

Inspection

Crankshaft Main or Connecting Rod Bearings -

Fitting Plastigage@ Method

Bore Gauge Method

Crankshaft

Cleaning

Inspection

Crankshaft Runout

Crankshaft End Play

Crankshaft Main Journals and Connecting Rod

Journals

Journals Refinishing

Crankshaft Sprocket

Pistons, Piston Pins and Piston Rings

Cleaning

Inspection

Pistons

Piston Rings - Fitting

Piston and Piston Pin Fit

Connecting Rods

Cleaning

Inspection

Piston Pin Clearance

Camshaft

Cleaning

Inspection

Camshaft Bearings

Camshaft Bearing Journals

Camshaft Journals Oil Clearance

Camshaft Runout

Cam Lobe Lift (Camshaft Removed)

With Calipers

On a Camshaft Grinder or Lathe

Camshaft Sprocket

Hydraulic Roller Valve Tappets

Cleaning

Inspection

.............................................................................

..............................................................................

...............................................................................

.............................................................................

..............................................................................

...............................................................................

.............................................................................

................................................................................

...............................................................................

.............................................................................

- Fitting

...............................................................................

.............................................................................

.................................................................................

...............................................................................

.............................................................................

...............................................................................

.............................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.......................................................................

............................................................

........................................................

Diameter

........................................................................

.......................................................

..........................................................

................................................................

...................................................................

...................................................................

...................................................................

....................................................

Bearings..

Rod

........ ................

............................................................

..............................................................

............................................................

...........................................................

..............................................................

.................................................................

...........................................................

................................................................

................................................................

.....

................................

........................................................

....................................................

..................................................

......................................

....................................

........................................

............................................

...............

................

PAGE

03-l

PAGE

16

16

16

17

17

17

18

18

18

18

19

19

19

19

20

21

21

21

21

21

21

21

21

22

22

22

22

22

23

24

24

24

24

24

24

24

24

25

25

25

25

25

25

26

26

26

26

01-2 Engine Service

01-2

SECTION

01

- Engine Service

SUBJECT PAGE

SERVICE PROCEDURES (Cont’d.)

Leakdown Testing ...............................................................

Oil Pan .....................................................................................

Cleaning ................................................................................

Inspection .............................................................................

Cylinder Heads .......................................................................

Cleaning ................................................................................

Inspection .............................................................................

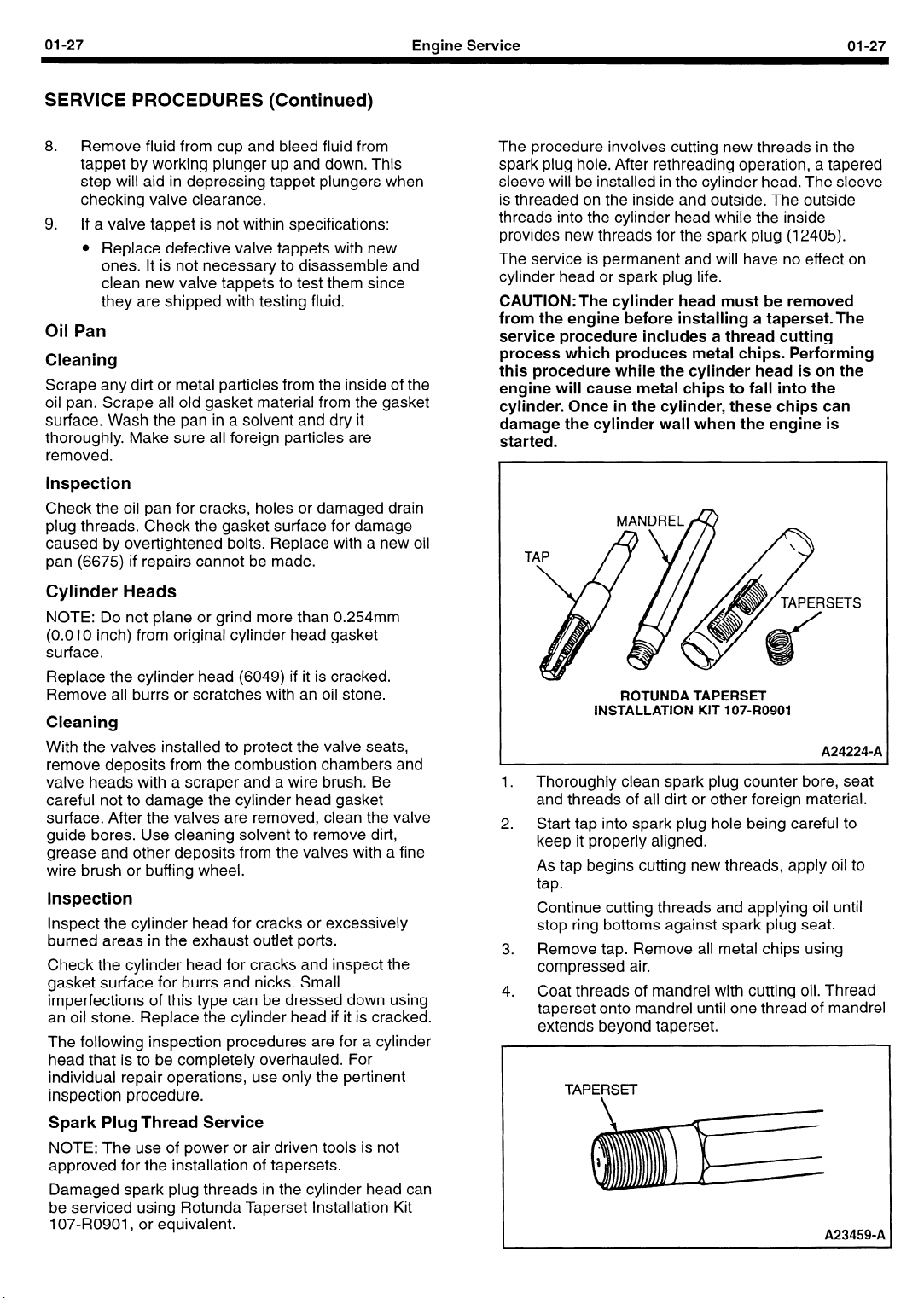

Spark Plug Thread Service

Cylinder Head Flatness

Valve Seat Runout ...............................................................

Valve Stem-to-Valve Guide Clearance

Valves, Select Fitting ...........................................................

Valve Guides, Reaming

Valve Seats, Refacing

Valves, Inspection ...............................................................

Valves, Refacing ..................................................................

Valve Spring Tension

Valve Spring Squareness

Camshaft Follower (2.3L)

Cleaning ................................................................................

Inspection .............................................................................

Intake Manifold .......................................................................

Cleaning

Inspection

Exhaust Manifold ....................................................................

Cleaning

Inspection

SPECIFICATIONS

SPECIAL SERVICE TOOLS/EQUIPMENT

................................................................................

.............................................................................

................................................................................

.............................................................................

.........................................................................

................................................. 27

.......................................................

............................... 28

.......................................................

.......................................................... 29

..........................................................

....................................................

.......................................................

................................... 33

26

27

27

27

27

27

27

28

28

29

29

30

30

31

31

31

31

31

31

31

31

32

32

32

32

01-3

DESCRIPTION AND OPERATION

Engine Service

01-3

Introduction

This section covers various engine tests, adjustments,

service procedures and cleaning/inspection

procedures. Engine assembly and service

specifications appear at the end of Section 02.

For engine disassembly, assembly, installation,

adjustment procedures and specifications, refer to

Section 02.

The 2.3L engine incorporates a closed-type crankcase

ventilation system. Other than the crankcase

ventilation system there are no exhaust emission

controls or engine/emission control systems used with

industrial versions of this engine.

To maintain the required performance level, the fuel

system, ignition system and engine must be kept in

good operating condition and meet recommended

adjustment specifications.

Before replacing damaged or worn engine

components such as the crankshaft (6303), cylinder

head (6049), valve guide (6510), valves, camshaft

(6251) or cylinder block (6010), make sure part(s) is

not serviceable.

WARNING: TO AVOID THE POSSIBILITY OF

PERSONAL INJURY OR DAMAGE, DO NOT

OPERATETHE ENGINE UNTILTHE FAN BLADE

(8600) HAS FIRST BEEN EXAMINED FOR

POSSIBLE CRACKS OR SEPARATION.

CAUTION: Use of abrasive grinding discs to

remove gasket material from the engine sealing

surfaces during repair procedures can contribute

to engine damage and wear. Airborne debris and

abrasive grit from the grinding disc may enter the

engine through exposed cavities causing

premature wear and eventual engine damage.

Ford Motor Company does not recommend using

abrasive grinding discs to remove engine gasket

material. Use manual gasket scrapers for

removing gasket material from the engine sealing

surfaces.

Take added care to prevent scratching or gouging

aluminum sealing surfaces.

Engine Identification Nameplate

For quick engine identification, refer to the Engine

Identification Nameplate. The nameplate lists engine

information required for proper servicing of the engine.

The Engine Identification Nameplate and identification

label provide information pertaining to engine

displacement, serial number, model number, S.O./

Options, and model code.

PPD0060

ENGINE PLANT CODE

ENGINE BUILD DATE

--

L - LIMA

\

MADE IN LIMA,OHIO

1

A24340-A

01-4

DIAGNOSIS AND TESTING

Inspection

1.

Inspect to determine if any of the following

mechanical concerns apply:

l

Engine oil leaks.

l

Damaged and/or severely worn parts.

l

Loose mounting bolts, studs and nuts.

Symptom Chart

Engine Service

ENGINE DIAGNOSIS

01-4

CONDITION

l

Difficult Starting

l

Poor Idling

l

Abnormal Combustion

l

Excessive Oil Consumption

POSSIBLE SOURCE

l

Burnt valve.

l

Worn piston.

l

Worn piston ring(s).

l

Worn cylinder.

l

Damaged cylinder head gasket.

l

Malfunctioning or damaged fuel

l

l

l

l

l

l

system.

l

Malfunctioning or damaged ignition

l

system. System.

l

Damaged hydraulic valve tappet.

l

Damaged hydraulic valve tappet

l

l

guide. guide.

l

Improper valve-to-valve seat

l

contact.

l

Damaged cylinder head gasket.

l

Malfunctioning or damaged fuel

l

l

system.

l

Malfunctioning or damaged ignition

l

system.

l

Damaged hydraulic valve tappet.

l

Damaged hydraulic valve tappet

l

l

bore.

l

Burnt or sticking valve.

l

Weak or broken valve spring.

l

Carbon accumulation in

l

l

l

combustion chamber.

l

Malfunctioning or damaged fuel

l

system.

l

Malfunctioning or damaged ignition

l

system.

l

Worn piston ring groove.

l

Sticking piston ring(s).

l

Worn piston or cylinder.

l

Worn valve stem seal.

l

Worn valve stem or valve guide.

l

Leaking oil.

l

Worn piston rings.

l

Plugged PCV system.

l

l

l

l

l

l

l

l

ACTION

REPLACE valve.

REPLACE piston.

REPLACE piston ring(s).

SERVICE or REPLACE cylinder

block.

REPLACE cylinder head gasket.

REFER to section on Fuel System.

REFER to section on Ignition

REPLACE hydraulic valve tappet.

REPLACE hydraulic valve tappet

REPLACE valve and/or valve seat.

REPLACE cylinder head gasket.

REFER to section on Fuel System.

REFER to section on Ignition

System.

REPLACE hydraulic valve tappet.

REPLACE cylinder block.

SERVICE or REPLACE valve.

REPLACE valve spring.

ELIMINATE carbon buildup.

REFER to section on Fuel System.

REFER to section on Ignition

System.

REPLACE piston.

SERVICE or REPLACE piston

ring(s).

SERVICE and/or REPLACE piston

or cylinder block.

REPLACE valve stem seal.

REPLACE valve stem and guide.

SERVICE oil leakage.

REPLACE piston rings.

SERVICE PCV System.

01-5

DIAGNOSIS AND TESTING (Continued)

Engine Service

01-5

l

Engine Noise

CONDITION

POSSIBLE SOURCE

l

Excessive main bearing oil

clearance.

l

Seized or heat damaged crankshaft

main bearing.

l

Excessive crankshaft end play.

l

Excessive connecting rod bearing

oil clearance.

l

Heat damaged connecting rod

bearing.

l

Damaged connecting rod bushing.

l

Worn cylinder.

l

Worn piston or piston pin.

l

Damaged piston ring(s).

l

Bent connecting rod.

l

Malfunctioning hydraulic valve

tappet.

l

Excessive hydraulic valve tappet

clearance.

l

Broken valve spring.

l

Excessive valve guide clearance.

l

Malfunctioning or damaged cooling

system.

l

Malfunctioning or damaged fuel

system.

l

Leaking exhaust system.

l

Improper drive belt tension.

l

Malfunctioning generator bearing.

l

Loose timing belt.

l

Damaged timing belt tensioner.

l

Malfunctioning water pump bearing.

ACTION

l

ADJUST clearance or REPLACE

crankshaft main bearing.

REPLACE crankshaft main bearing.

l

l

ADJUST end play or REPLACE

crankshaft.

l

ADJUST clearance or REPLACE

connecting rod.

l

REPLACE connecting rod bearing.

l

REPLACE connecting rod bushing.

l

SERVICE or REPLACE cylinder

block.

l

REPLACE piston or piston pin.

l

REPLACE piston ring(s).

l

REPLACE connecting rod.

l

REPLACE hydraulic valve tappet.

l

ADJUST clearance or REPLACE

hydraulic valve tappet.

l

REPLACE valve spring.

l

SERVICE clearance or REPLACE

valve guide/stem.

l

REFER to section on Cooling

System.

l

REFER to section on Fuel System.

l

SERVICE exhaust leakage.

l

REFER to section on Access ry

Drivebelts.

l

REFER to section on Chargi

System.

l

ADJUST or REPLACE timing belt.

l

REPLACE timing belt tensioner.

REFER to section on Cooling

l

System.

:g

l

lnsuff

icient

Power

l

Malfunctioning hydraulic valve

tappet.

l

Damaged hydraulic valve tappet

bore.

l

Seized valve stem.

l

Weak or broken valve spring.

l

Damaged cylinder head gasket.

l

Cracked or distorted cylinder head.

l

Damaged, worn or sticking piston

ring(s).

l

Worn or damaged piston.

l

Malfunctioning or damaged fuel

system.

l

Malfunctioning or damaged ignition

system.

l

REPLACE hydraulic valve tappet.

l

REPLACE cylinder block.

l

SERVICE or REPLACE valve, valv

seat and/or cylinder head.

l

REPLACE valve spring.

l

REPLACE cylinder head gasket.

l

REPLACE cylinder head.

l

SERVICE or REPLACE piston

ring(s).

l

REPLACE piston.

l

REFER to section on Fuel System

l

REFER to section on Ignition

System.

01-6

SERVICE PROCEDURES

Engine Service

01-6

Positive Crankcase Ventilation (PCV) System

Closed-Type

A malfunctioning closed crankcase ventilation system

may be indicated by loping or rough engine idle. Do

not attempt to compensate for this idle condition by

disconnecting the crankcase ventilation system and

making an air bypass or idle speed adjustment.

The

removal of the crankcase ventilation system from the

engine will adversely affect fuel economy and engine

crankcase ventilation with resultant shortening of

engine life.

Engine Oil Leaks

NOTE: Due to their remote location, rear engine oil

leaks may be very difficult to pinpoint. This area is also

very difficult to clean. Make sure to eliminate all other

possibilities before removing the engine to repair a

suspected leak in this area.

When diagnosing engine oil leaks, it is important that

the source and location of the leak be positively

identified prior to service. There are two methods of

diagnosing engine oil leaks. The following procedure

has been found to be very effective and requires only

a minimum of equipment. Prior to using this

procedure, it is important to clean the cylinder block

(6010), cylinder heads (6049), valve covers (6582), oil

pan (6675) and flywheel housing areas with a suitable

solvent to remove all traces of oil.

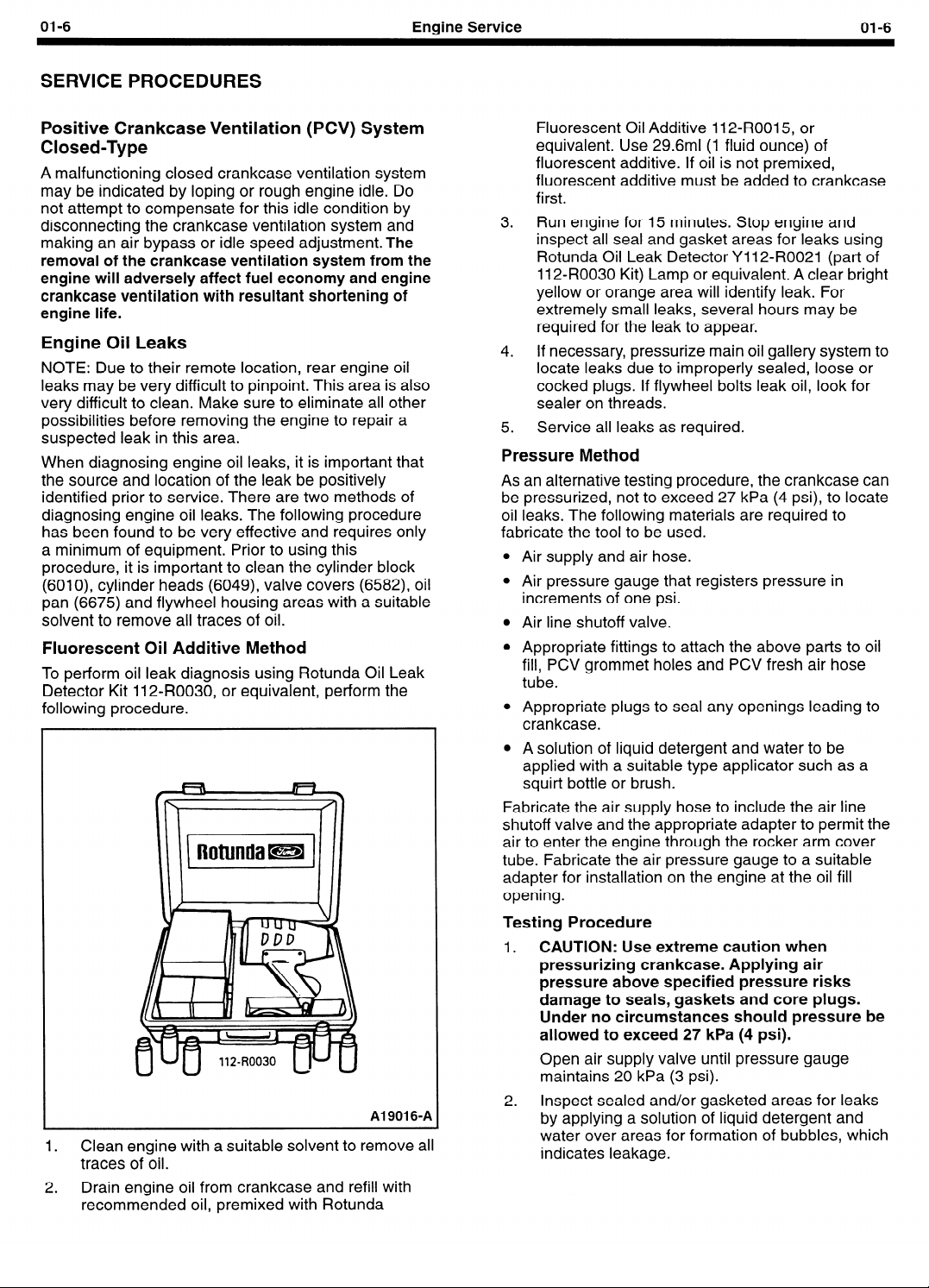

Fluorescent Oil Additive Method

To perform oil leak diagnosis using Rotunda Oil Leak

Detector Kit 112.R0030, or equivalent, perform the

followina procedure.

Al 9016-A

1. Clean engine with a suitable solvent to remove all

traces of oil.

2. Drain engine oil from crankcase and refill with

recommended oil, premixed with Rotunda

Fluorescent Oil Additive 112-ROOI 5, or

equivalent. Use 29.6ml (1 fluid ounce) of

fluorescent additive. If oil is not premixed,

fluorescent additive must be added to crankcase

first.

3. Run engine for 15 minutes. Stop engine and

inspect all seal and gasket areas for leaks using

Rotunda Oil Leak Detector Y 112-R0021 (part of

112-R0030 Kit) Lamp or equivalent. A clear bright

yellow or orange area will identify leak. For

extremely small leaks, several hours may be

required for the leak to appear.

4. If necessary, pressurize main oil gallery system to

locate leaks due to improperly sealed, loose or

cocked plugs. If flywheel bolts leak oil, look for

sealer on threads.

5. Service all leaks as required.

Pressure Method

As an alternative testing procedure, the crankcase can

be pressurized, not to exceed 27 kPa (4 psi), to locate

oil leaks. The following materials are required to

fabricate the tool to be used.

l

Air supply and air hose.

l

Air pressure gauge that registers pressure in

increments of one psi.

l

Air line shutoff valve.

l

Appropriate fittings to attach the above parts to oil

fill, PCV grommet holes and PCV fresh air hose

tube.

l

Appropriate plugs to seal any openings leading to

crankcase.

l

A solution of liquid detergent and water to be

applied with a suitable type applicator such as a

squirt bottle or brush.

Fabricate the air supply hose to include the air line

shutoff valve and the appropriate adapter to permit the

air to enter the engine through the rocker arm cover

tube. Fabricate the air pressure gauge to a suitable

adapter for installation on the engine at the oil fill

opening.

Testing Procedure

CAUTION: Use extreme caution when

1.

pressurizing crankcase. Applying air

pressure above specified pressure risks

damage to seals, gaskets and core plugs.

Under no circumstances should pressure be

allowed to exceed 27 kPa (4 psi).

Open air supply valve until pressure gauge

maintains 20 kPa (3 psi).

Inspect sealed and/or gasketed areas for leaks

2.

by applying a solution of liquid detergent and

water over areas for formation of bubbles, which

indicates leakage.

01-7

SERVICE PROCEDURES (Continued)

Engine Service

01-7

Leakage Points

Examine the following areas for oil leakage.

l

Rocker cover sealant or gaskets

l

Intake manifold gaskets/end seals

l

Cylinder head gaskets

l

Oil bypass filter (6714)

l

Oil level indicator (dipstick) tube connection

l

Oil pressure sensor (9278)

l

Cup plugs and/or pipe plugs at end of oil

passages

l

Oil pan gasket (6710)

l

Oil pan front and rear end seals

l

Crankshaft front seal (6700)

l

Crankshaft rear oil seal (6701)

l

Oil pump

l

Crankshaft rear oil seal (6701)

Air leakage in area around a crankshaft rear oil seal

(6701) does not necessarily indicate a rear seal leak.

However, if no other cause can be found for oil

leakage, it can be assumed that rear seal is the cause

of the oil leakage.

l

Rear main bearing cap parting line.

l

Rear main bearing cap and seals.

l

Flywheel mounting bolt holes.

l

Rear cup plugs and/or pipe plugs at the end of oil

passages.

Oil leaks at crimped seams in sheet metal parts and

cracks in cast or stamped parts can be detected when

pressurizing the crankcase.

Light foaming equally around rocker arm cover bolts

and crankshaft seals is not detrimental and no

corrections are required in such cases.

Compression Test

Compression Gauge Check

1.

Make sure oil in crankcase is of the correct

viscosity and at proper level, and battery (10655)

is properly charged. Operate the engine until it is

at normal operating temperature. Turn off ignition

switch (11572), then remove all spark plugs

(12405).

Set throttle plates in wide-open position.

Install a compression gauge such as Rotunda

Compression Tester 059-R0009, or equivalent, in

No. 1 cylinder.

Install an auxiliary starter switch in starting circuit.

With ignition switch (11572) in the OFF position,

and using auxiliary starter switch, crank engine at

least five compression strokes and record highest

reading. Note the approximate number of

compression strokes required to obtain the

highest reading.

5.

Repeat test on each cylinder, cranking the engine

approximately the same number of compression

strokes.

Test Results

The indicated compression pressures are considered

within specification if the lowest reading cylinder is

within 75 percent of the highest. Refer to the chart

below.

Compression Pressure Limit Chart

Maximum Minimum

psi

734 707 764 723 794 745 224 768

136 102 766 724 796 147 226 169

738 704 768 726 798 748 228 171

140 105 170 127 200 750 230 772

742 707 772 129 202 157 232 774

744 708 174 131 204 753 234 775

746 170 776 132 206 754 236 777

748 771 178 133 208 156 238 778

750 173 180 135 270 757 240 180

752 774 782 736 212 758 242 787

754 775 184 138 214 160 244 783

156 777 186 140 216 762 246 184

758 718 188 141 218 163 248 186

160 120 190 742 220 165 250 187

762 121 192 144 222 166

psi psi psi psi

Maximum Minimum Maximum

Minimum Maximum Minimum

psi psi

psi

I

,

01-8

-

SERVICE PROCEDURES (Continued)

Compression Readings - Interpreting

It is recommended the Compression Pressure Limit

Chart be used when checking cylinder compression so

that the lowest reading number is 75 percent of the

highest reading.

If one or more cylinders reads low, squirt

approximately one tablespoon of SAE 50 weight, or

equivalent, engine oil on top of the pistons in the low

reading cylinders. Repeat compression pressure

check on these cylinders.

1. If compression improves considerably, piston

rings are at fault.

2. If compression does not improve, valves are

sticking or seating poorly.

3. If two adjacent cylinders indicate low

compression pressures and squirting oil on

pistons does not increase compression, cause

may be a cylinder head gasket leak between

cylinders. Engine oil and/or coolant in cylinders

could result from this problem.

Example Readings

If, after checking the compression pressures in all

cylinders, it was found that the highest reading

obtained was 1351 kPa (196 psi) and the lowest

pressure reading was 1069 kPa (155 psi), the engine

is within specification and the compression is

considered satisfactory.

Cylinder Leakage Detector

When a cylinder produces a low reading, the use of

Rotunda Pressurization Kit 014-00705, or equivalent,

will be helpful in pinpointing the exact cause.

The leakage detector is inserted in the spark plug

hole, the piston is brought up to top dead center on the

compression stroke, and compressed air is admitted.

Once the combustion chamber is pressurized, a

special gauge will read the percentage of leakage.

Leakage exceeding 20 percent is considered

excessive.

While the air pressure is retained in the cylinder, listen

for the hiss of escaping air. A leak by the intake valve

(6507) will be audible in the carburetor. A leak by the

exhaust valve (6505) can be heard at the exhaust

pipe. Leakage past the rings will be audible at the

positive crankcase ventilation (PCV) connection. If air

is passing through a blown gasket to an adjacent

cylinder, the noise will be evident at the spark plug

hole of the cylinder into which the air is leaking. Cracks

in the cylinder block (6010), or gasket leakage into the

cooling system may be detected by a stream of

bubbles in the radiator (8005).

Engine Service

Oil Leak and Valve

The cylinder leakage detector can be used to test for

engine oil leaks and to check the valve seals for

leakage.

1. Plug all crankcase openings except the one used

2. Connect the detector to a crankcase opening.

3. Using a solution of liquid soap and water, brush

4.

Intake Manifold Vacuum Test

Bring the engine to normal operating temperature.

Connect Rotunda Vacuum/Pressure Tester

059-00008, or equivalent, to the intake manifold. Run

the engine at the specified idle speed.

The vacuum gauge should read between -51 and

-74 kPa (15 and 22 in-Hg) depending upon the engine

01-8

ROTUNDA

PRESSURIZATION

KIT

014-00705

A23452-A

Guide Seal Test

for connecting the leakage detector.

The oil level indicator tube (6754) is convenient.

Adjust the air pressure to approximately 34 kPa

(5 psi).

the solution along the gasket sealing surfaces

and bearing seals. Look for bubbles or foam.

Remove the spark plugs (12405) and rotate the

engine slowly with a wrench. Check for large

amounts of air escaping into the cylinders as

each intake and exhaust valve opens.

The spark plugs (12405) on the leaking cylinders

will probably show deposits of burned oil.

condition and the altitude at which the test is

performed. SUBTRACT 5.5 kPa FROM THE

SPECIFIED READING FOR EVERY 500 METERS

(1 in-Hg for every 1,000 feet) OF ELEVATION ABOVE

SEA LEVEL.

01-9

Engine Service

SERVICE PROCEDURES (Continued)

The reading should be quite steady. It may be

necessary to adjust the gauge damper control (where

used) if the needle is fluttering rapidly. Adjust damper

until needle moves easily without excessive flutter.

Vacuum Gauge Readings - Interpretation

A careful study of the vacuum gauge reading while the

engine is idling will help pinpoint trouble areas. Always

conduct other appropriate tests before arriving at a

final diagnostic decision. Remember that vacuum

gauge readings, although helpful, must be interpreted

with care.

Most vacuum gauges have a “normal” band indicated

on the aauae face.

VACUUM/

PRE

TE

059

A23453-A

Following are potential gauge readings. Some should

be considered as normal; others should be

investigated further.

1.

NORMAL READING: Needle between -51 and

-74 kPa (15 and 20 in-Hg) and holding steady.

2.

NORMAL READING DURING RAPID

ACCELERATION AND DECELERATION: When

engine is rapidly accelerated (dotted needle),

needle will drop to a low (not to 0) reading. When

throttle is suddenly released, the needle will snap

back up to a higher than normal figure.

NORMAL FOR HIGH LIFT CAM WITH LARGE

3.

OVERLAP: Needle will register as low as -50

kPa (15 in-Hg) but will be relatively steady. Some

oscillation is normal.

WORN RINGS OR DILUTED OIL: When engine

4.

is accelerated (dotted needle), needle drops to 0

kPa (0 in-Hg). Upon deceleration, needle runs

slightly above 74 kPa (22 in-Hg).

STICKING VALVE(S): When the needle (dotted)

5.

remains steady at a normal vacuum but

occasionally flicks (sharp, fast movement) down

and back about 13 kPa (4 in-Hg), one or more

valves may be sticking.

BURNED OR WARPED VALVES: A regular,

6.

evenly spaced, downscale flicking of the needle

indicates one or more burned or warped valves.

lnsuff icient hydraulic lash adjuster clearance will

also cause this action.

POOR VALVE SEATING: A small but regular

7.

downscale flicking can mean one or more valves

are not seating.

WORN VALVE GUIDES: When the needle

8.

oscillates (swings back and forth) over a 13 kPa

(4 in-Hg) range at idle speed, the valve guides

(6510) could be worn. As engine speed is

increased, the needle will become steady if the

guides are responsible.

WEAK VALVE SPRINGS: When the needle

9.

oscillation becomes more violent as engine rpm

is increased, weak valve springs (6513) are

indicated. The reading at idle could be relatively

steady.

LATE VALVE TIMING: A steady but low reading

10.

could be caused by late valve timing.

11. IGNITION TIMING RETARDING: Retarded

ignition timing will produce a steady but low

reading.

INSUFFICIENT SPARK PLUG GAP: When plugs

12.

are gapped too close, a regular, small pulsation

of the needle can occur.

13. INTAKE LEAK: A low, steady reading can be

caused by an intake manifold or carburetor

mounting flange gasket leak.

BLOWN HEAD GASKET A regular drop of

14.

approximately 33-50 kPa (1 O-l 5 in-Hg) can be

caused by a blown head gasket or warped headto-block mounting surface.

01-9

Al 0428-P

01-10 Engine Service 01-10

SERVICE PROCEDURES (Continued)

5.

15. RESTRICTED EXHAUST SYSTEM: When the

engine is first started and is idled, the reading

may be normal. But, as the engine rpm is

increased, back pressure caused by a clogged

exhaust pipe, etc., will cause the needle to slowly

drop to 0. The needle then may slowly rise.

Excessive exhaust clogging will cause the needle

to drop to a low point even if the engine is only

idled.

When vacuum leaks are indicated, search out and

correct the condition. Excess air leaking into the

system will upset the fuel mixture and cause

conditions such as rough idle, missing, or burned

valves. ALWAYS SERVICE VACUUM LEAKS.

Oil Consumption Test

The following diagnostic procedure is intended to be

used to determine the source of excessive internal oil

consumption.

1. Determine what is considered to be excessive oil

consumption. Note hours of engine service and

the following observations:

a. How many hours of engine use per 0.95 liter

(1 U.S. quart) of oil used?

b. How is the engine being used (e.g., sustained

high-speed operation, heavy loads, high

ambient temperature, etc.)?

c. What is the expected normal oil consumption?

2. Verify that the engine has no external oil leak as

described under Engine Oil Leaks in this section.

3. Verify that the oil level dipstick (6750) and oil

level indicator tube (6754) are unmodified and in

good condition. Verify that the oil level indicator

tube (6754) is properly seated in the block, and

the dipstick seats properly in the oil level indicator

tube (6754).

4. Verify that the engine is not being run in an

overfilled condition. Check the oil level at least

five minutes after a hot shutdown (engine must

be level). Under no circumstances should the oil

level be above the FULL line. If a significant

overfill is indicated, perform Steps 5a through 5d

to verify the dipstick calibration. If the dipstick

calibration checks OK, instruct the operator to

avoid overfilling the engine and return the engine

to service. To verify the engine’s actual oil

consumption, perform Steps 5e and 5f only after

the dipstick has been calibrated.

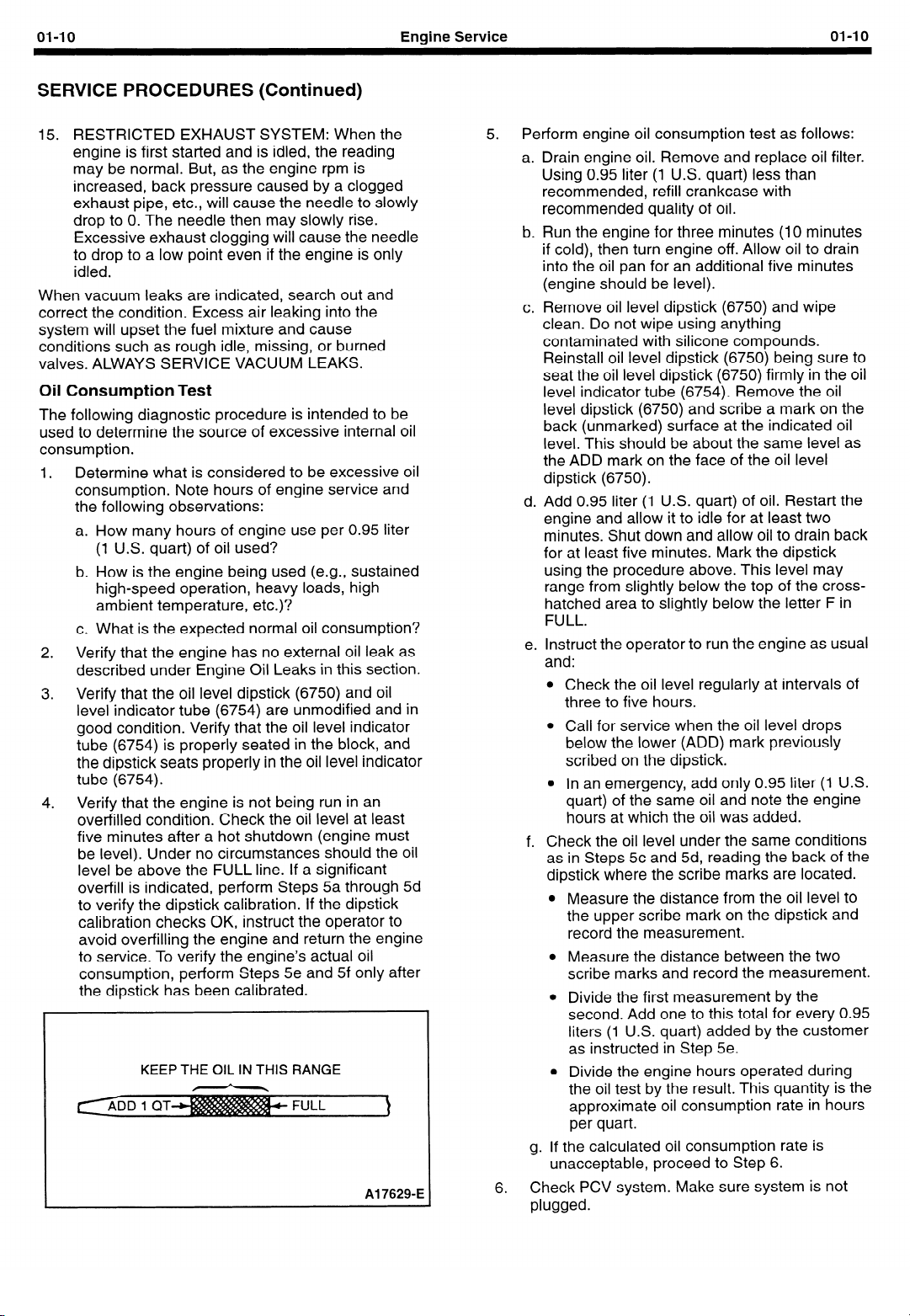

KEEP THE OIL IN THIS RANGE

Al 7629-E

Perform engine oil consumption test as follows:

a. Drain engine oil. Remove and replace oil filter.

Using 0.95 liter (1 U.S. quart) less than

recommended, refill crankcase with

recommended quality of oil.

b. Run the engine for three minutes (10 minutes

if cold), then turn engine off. Allow oil to drain

into the oil pan for an additional five minutes

(engine should be level).

c. Remove oil level dipstick (6750) and wipe

clean. Do not wipe using anything

contaminated with silicone compounds.

Reinstall oil level dipstick (6750) being sure to

seat the oil level dipstick (6750) firmly in the oil

level indicator tube (6754). Remove the oil

level dipstick (6750) and scribe a mark on the

back (unmarked) surface at the indicated oil

level. This should be about the same level as

the ADD mark on the face of the oil level

dipstick (6750).

d. Add 0.95 liter (1 U.S. quart) of oil. Restart the

engine and allow it to idle for at least two

minutes. Shut down and allow oil to drain back

for at least five minutes. Mark the dipstick

using the procedure above. This level may

range from slightly below the top of the crosshatched area to slightly below the letter F in

FULL.

e. Instruct the operator to run the engine as usual

and:

l

Check the oil level regularly at intervals of

three to five hours.

l

Call for service when the oil level drops

below the lower (ADD) mark previously

scribed on the dipstick.

l

In an emergency, add only 0.95 liter

quart) of the same oil and note the engine

hours at which the oil was added.

f. Check the oil level under the same conditions

as in Steps 5c and 5d, reading the back of the

dipstick where the scribe marks are located.

l

Measure the distance from the oil level to

the upper scribe mark on the dipstick and

record the measurement.

l

Measure the distance between the two

scribe marks and record the measurement.

l

Divide the first measurement by the

second. Add one to this total for every 0.95

liters (1 U.S. quart) added by the customer

as instructed in Step 5e.

l

Divide the engine hours operated during

the oil test by the result. This quantity is the

approximate oil consumption rate in hours

per quart.

g. If the calculated oil consumption rate is

unacceptable, proceed to Step 6.

Check PCV system. Make sure system is not

6.

plugged.

(1

U.S.

01-11

SERVICE PROCEDURES (Continued)

Check for plugged oil drain-back holes in cylinder

7.

heads (6049) and cylinder block (6010).

If condition still exists, perform a cylinder

compression test as described in this section,

and/or perform a cylinder leak detection test with

Rotunda Pressurization Kit 014-00705, or

equivalent. This can be helpful in determining the

source of oil consumption, as an example,

valves, piston rings, etc.

Check valve guides (6510) for excessive

clearance. Replace all valve stem seals (6A517)

after correct valve guide clearance has been

verified.

IO.

NOTE: After checking for worn parts, if it is

determined parts should be replaced, make sure

correct replacement parts are used. Worn or

damaged internal engine components can cause

excessive oil consumption. Small deposits of oil

on tip of spark plugs (12405) can be a clue to

internal oil consumption. If internal oil

consumption still persists, proceed as follows:

a. Remove intake manifold(s), cylinder heads

(6049), oil pan and oil pump.

b. Check piston ring clearance, ring gap and ring

orientation as outlined in this section. Service

as required.

c. Check for excessive bearing clearance as

outlined in this section. Service as required.

Perform Step 5 again to verify that the oil

11.

consumption concern has been resolved.

Oil Pressure Test

SPECIAL SERVICE TOOL(S) REQUIRED

Description

1 Engine Oil Pressure Gauge

1.

Disconnect and remove the oil pressure sensor

(9278) from the engine.

2.

Connect an Engine Oil Pressure Gauge

T73L-6600-A and Transmission Test Adapter

D87C-77000-A, or equivalent, to the oil pressure

sensor screw port.

Run the engine until normal operating

3.

temperature is reached.

4.

Run the engine at 3,000 rpm and record the

gauge reading.

5.

The oil pressure should be:

l

250-490 kPa (36-71 psi) at 3,000 rpm.

6.

If the pressure is not within specification, check

the following possible sources:

l

Insufficient oil

l

Oil leakage

l

Worn or damaged oil pump (6621)

l

Clogged oil pump screen cover and tube

(6622)

l

Excessive main bearing clearance

0 Excessive connecting rod bearing clearance

Tool Number

I

1 T73L-6600-A

Engine Service

-

I

I

01-l 1

ValveTrain Analysis

- Static (Engine Off)

Rocker Arm/Camshaft Follower Cover Removed

NOTE: Static Valve Train Analysis, with the engine off,

is to be performed before Dynamic Valve Train

Analysis, which is performed with engine running.

NOTE: Remove valve cover (6582) as outlined in this

section.

Check for damaged and/or severely worn parts,

correct assembly, and use of correct parts by

proceeding with the static engine analysis.

Rocker/Camshaft Follower Arm Assemblies

l

Check for loose mounting bolts, studs and nuts.

l

Check for a plugged oil feed in the rocker arm

(6564), or cylinder head (6049).

Camshaft - 2.3L Engine

Inspect camshaft, camshaft lobes and journals for

excessive wear or scoring. Repair or replace as

necessary.

Valve Springs

l

Check for broken or damaged parts.

Valve Spring Retainer and Valve Spring Keys

l

Check for proper seating of valve spring retainer

keys (6518) on valve stem and in valve spring

retainer (6514).

Valves and Cylinder Head

l

Check for signs of improper head gasket (6051)

installation, such as the shape of the head and

block and shape of the gasket not matching.

l

Check for signs of cylinder head gasket leakage

such as coolant or oil leaking between the cylinder

block (6010) and cylinder head (6049).

l

Check for plugged oil drain-back holes.

l

Check for worn or damaged valve tips.

l

Check for missing or damaged intake and exhaust

valve stem seals (6A517).

l

Check valve clearance.

0 Check installed spring height.

l

Check for missing or worn valve spring seats, if

equipped.

Intake Valve Cleaning (Valves Installed)

Cleaning and Inspection

NOTE: The intake valve cleaning procedure is to be

used if there is a concern with engine hesitation, rough

idle, long crank times, and stall at idle and engine

engagement after cold starts.

NOTE: Many fluids are available to clean carburetors.

Some cleaning fluids also claim to remove intake valve

deposits (IVD). Engineering evaluation of these fluids

indicates no ability to remove the intake valve

deposits. If engine performance concerns have been

affected by cleaning fluids, it is most likely due to

cleanup of carburetor deposits. IVD is more difficult to

01-12

SERVICE PROCEDURES (Continued)

Engine Service

01-l 2

remove than carburetor deposits. IVD must be

COMPLETELY removed to restore cold start and

normal engine performance.

CAUTION:The overuse of cleaning fluids may

cause engine damage not covered under warranty.

CAUTION: Only walnut shell blasting using

Rotunda 014-00975 Carbon Blaster and

Automotive Borescope, or equivalent, is

recommended for removing carbon from engine

valves with the engine assembled. Other abrasives

may cause engine damage on start-up if not

completely removed.

1.

Perform engine inspection of vacuum lines and

wiring.

2. Perform normal engine diagnostics. Check fuel

and ignition systems.

3. If normal diagnostics have not resolved the

engine performance concerns, proceed with the

following IVD inspection steps.

4.

Remove any two spark plugs (12405).

5.

CAUTION: Do not bump the engine with the

remote starter switch or ignition switch with

the borescope in the spark plug hole or

attempt to view the valve while rotating the

engine. Damage to the borescope or engine

may result.

Use a remote starter switch to bump the engine

over until the intake valve (6507) is fully open in

the cylinder to be inspected.

6.

CAUTION: Do not power the borescope light

source from a vehicle battery (10655) while it

is being charged. For example, if the engine is

running or the battery (10655) is connected to

a charger, the lamp may fail.

Using the Rotunda Carbon Blaster and

Automotive Borescope 014-00975, or equivalent

automotive borescope, inspect the backside of

the intake valves (6507) through the spark plug

holes for the presence of carbon deposits.

Compare the deposits with the deposit rating

system chart. If any of the intake valves (6507)

appear to have a carbon deposit level of 7 or less

(lower number rating), intake valve cleaning is

required. If no carbon deposits are seen or the

deposit level is 8 or cleaner, the drive concern

may be the result of low volatility fuel.

Intake Valve Deposit Rating System

9

6

8

5

7

4

3

2

1

A239094

01-13

SERVICE PROCEDURES (Continued)

7.

Remove the intake manifold assembly as

outlined in Section 02.

8.

Remove flex hose and manifold adapter from the

hand-held vacuum included with the Rotunda

014-00975 Carbon Blaster and Automotive

Borescope. Insert tapered end of vacuum hose

into intake port of cylinder head using a twisting

motion to ensure a tight fit.

9.

NOTE: Detailed written instructions and a

procedural video tape are included with the

Rotunda 014-00975 Carbon Blaster and

Automotive Borescope. Perform the intake valve

carbon cleaning procedure, using the Rotunda

014-00975 Carbon Blaster or equivalent. The

intake valves should be in the closed position.

Cleaning takes approximately 1 to 1 -i/2 minutes

per valve.

Confirm the intake valve (6507) is clean using

10

Rotunda 014-00975, or equivalent automotive

borescope.

11

Using a remote starter switch, bump the engine

over until the remaining intake valves to be

cleaned, are in the closed position, and clean

them as outlined above.

13

Install the intake manifold as outlined in Section

. -.

02.

Camshaft Lobe Lift, 2.3L Overhead Camshaft

Engine (Camshaft Installed)

This procedure is for checking lift with the camshaft

(6251) installed. For checking with camshaft removed,

refer to service procedure, Cam Lobe Lift (Camshaft

Removed) in this section.

Check the lift of each lobe in

make a note of the readings.

1.

Remove valve cover (6582) as outlined in

Section 02.

2.

Remove spark plugs (12405) as outlined in

Section 02.

3.

Inspect the camshaft lobes for scoring and signs

of abnormal wear.

Lobe pitting, except in the general area of the

lobe toe, is not detrimental to the operation of the

camshaft. The camshaft should not be replaced

unless lobe lift loss has exceeded the

specifications or pitting has occurred in the lobe

lift area.

4.

Inspect for signs of camshaft bearing wear.

5.

Using ratchet handle and socket on vibration

damper bolt, rotate engine so cylinder number

one exhaust valve is fully open (heel of cam at

top).

6.

Install TOOL-4201-C, or equivalent, Dial Indicator

with Bracketry, so tip of dial indicator is on heel of

cam.

7.

Zero dial indicator.

8.

Slowly rotate engine until tip of dial indicator is on

tip of cam and read. This is cam lift.

consecutive order and

Engine Service

9.

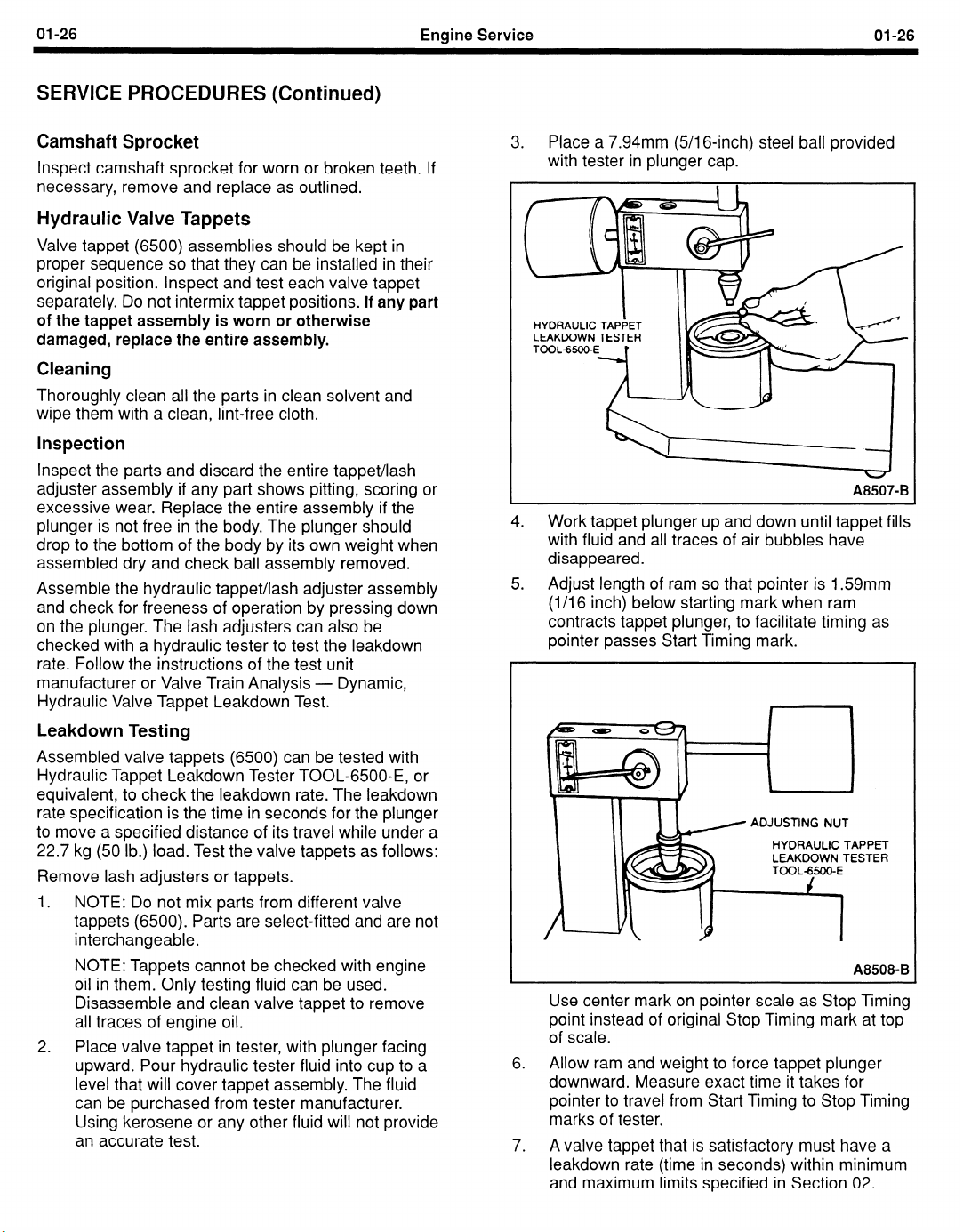

Hydraulic Valve Tappet/Lash Adjuster

The hydraulic lash adjusters used in the overhead cam

2.3L engine are zero-lash hydraulic devices similar in

construction and operation to the hydraulic valve

tappets (6500) used on push rod engines. They are

cleaned, inspected and checked in the same manner

as hydraulic valve tappets The instructions below

apply equally to the lash adjuster and the valve tappet.

Hydraulic tappet noise may be caused by any of the

following:

1. Excessive collapsed tappet gap

2.

3.

4.

5.

6.

Excessive collapsed tappet gap may be caused by

loose valve train parts such as wear of tappet face,

worn roller finger follower (6529), or worn valve tip.

With valve tappet (6500) collapsed, check gap

between valve tip and roller finger follower to

determine if any other valve train parts are damaged,

or worn. Replace any worn or damaged parts.

A sticking tappet plunger may be caused by dirt, chips,

or varnish inside the tappet. The sticking can be

corrected by disassembling the valve tappet and

removing the dirt, chips or varnish that are causing the

condition.

A tappet check valve that is not functional may be

caused by an obstruction such as dirt or chips

preventing it from closing when operated, or it may be

caused by a broken check valve spring within the

tappet.

Air bubbles in the lubrication system will prevent the

valve tappet from supporting the valve spring load and

may be caused by an oil level that is too high or too

low, or by air being drawn into the system through a

hole, crack or leaking gasket on the oil pump screen

cover and tube (6622).

01-13

Write down cam lift and repeat for the rest of the

cam lobes. If any lobe’s lift is below the minimum

lift specified in Section 02, replace the camshaft.

Sticking tappet plunger

Tappet check valve not functioning properly

Air in lubrication system

Leak-down rate too rapid

Excessive valve guide wear

If the leakdown time is below the specified time for

used valve tappets, noisy operation may result. If no

other cause for noisy valve tappets can be found, the

leakdown rate should be checked, and any outside the

specification should be replaced.

Camshaft End Play

CAUTION: Prying against the camshaft sprocket

(6256) with valve train load on the camshaft

(6251), can break or damage the camshaft

sprocket. Therefore, on 2.3L engines, remove the

cam followers as outlined in Section 02.

After checking camshaft end play, reinstall or retighten

valve train components as outlined in Section 02.

01-14

SERVICE PROCEDURES (Continued)

Engine Service

01-14

Timing Belt (2.3L)

NOTE: If the timing belt has greater than 3,000 hours

of use, the timing belt will need to be replaced. Refer

to Section 02 for service procedures.

Camshaft Timing and Cylinder Identification

(CID) Timing Check

1.

Remove the rubber access cap from the outer

timing cover to expose the camshaft sprocket.

2.

Rotate the crankshaft so that number one

cylinder is at Top Dead Center (TDC) of the

compression stroke. TDC will be indicated when

the two timing marks are aligned:

a. The timing mark on the crankshaft damper

assembly will align with “TC” on the outer

timing cover.

b. The triangular timing mark on the camshaft

sprocket will align with the timing mark on the

inner timing cover.

3. If the triangle timing mark cannot be seen through

the access hole of the outer timing cover, rotate

the crankshaft one revolution. TDC will be

indicated when the two timing marks are aligned.

4. If the triangle timing mark cannot be properly

aligned, set the timing mark of the crankshaft

damper assemblv on “TC” of the outer timing

cover. Remove the crankshaft damper assembly

and outer timing cover as outlined in Section 02.

VIEW IN CIRCLE A

C

0

Item

Part

Number

6256

N801658-S

6K282

6K254

6303

6306

9

d

8

0

Description

Camshaft Sprocket

Pointer Triangle (Part of

Camshaft Sprocket)

Pointer Triangle (on Inner

Timing Belt Cover)

Stud, M8 x 1.25

Spring Pivot Bolt

Stud (Part of 6K254)

Timing Belt Tensioner

Crankshaft

Crankshaft Sprocket

Item

IO

11

12

13

A

B

C

D

E

NOTE:

Part

Number

N806700-S

N800112-52

B

TO PAN

RAIL

VIEW IN

CIRCLE 8

Description

Key

Adjusting Bolt, M8 - 1.25 x 20

Pointer Line (Part of 6019)

Pointer Circle (on 6306)

Tighten to 20-30 Nom

(15-22 Lb-Ft) (See Text)

Tighten to 40-55 N*m

(30-40 Lb-Ft) (See Text)

Tighten to 35-45 Nom

(26-33 Lb-Ft) (See Text)

Direction of Rotation

29”

PPDA21101-6

J

01-15

SERVICE PROCEDURES (Continued)

Engine Service

0145

Crankshaft End Play

Install Dial Indicator with Bracketry TOOL-4201 -C,

1.

or equivalent, so contact point rests against the

end of the crankshaft post and indicator axis is

parallel to crankshaft axis.

2. Force crankshaft (6303) toward rear of engine.

INDICATOR

STYLUS AGAINST

AND PARALLEL

A211234

Zero dial indicator. Push crankshaft (6303)

3.

forward and note reading on dial.

4. If the end play exceeds the wear limit listed in the

specification section, replace the thrust bearing.

Inspect the crankshaft for damage to the thrust

face before installing the new bearing. If the end

play is less than the minimum limit, inspect the

thrust bearing faces for scratches, burrs, nicks, or

dirt. If the thrust faces are not damaged or dirty,

the main thrust bearing may not be aligned

properly. Lubricate and install the thrust bearing

and align the faces, following Main Bearing

Replacement procedure in the appropriate

engine section. Check crankshaft end play.

.

Connecting Rod Side Clearance

1.

Install Rotunda Dial Indicator with Bracketry

TOOL-4201-C, or equivalent, so that the contact

point rests against the connecting rod cap.

Pull cap toward front of engine and zero the dial

2.

indicator.

3. Push cap toward rear of engine and observe

amount of side clearance on dial indicator.

4. If side clearance exceeds specification, replace

connecting rod and cap. Refer to the specification

section.

If side clearance is less than specification,

remove rod and cap and inspect for scratches,

burrs, nicks or dirt between crankshaft and

connecting rod.

Cylinder Block

Cleaning and Inspection

If the engine has been removed and disassembled,

remove all core plugs and pipe plugs. Clean the

cylinder block (6010) using solvent, preferably in a hot

tank. Follow all safety and environmental precautions

with regard to the solvent. Make sure all oil and dirt is

cleaned from the cylinder block.

Make sure all oil passageways are clean. A rifle-

cleaning brush is useful for this purpose.

Use a long, thin screwdriver to scrape the bottom of

the water jackets through the openings in the top deck

to make sure all scale and deposits are removed. Most

engines have a “dead spot” at the back of the block

where the coolant makes a U-turn and drops any

deposits. If the water jackets are not thoroughly

cleaned, overheating will result.

Cylinder Block Distortion

Cylinder block distortion is rare because cylinder

blocks are normalized after casting, and before

machining, to relieve internal stresses from the casting

process.

The most probable cause of cylinder block distortion

would be extreme overheating which would probably

be accompanied by other damage such as scored

bearings or cylinder walls, warped cylinder heads

(6049) and possible cylinder block cracks.

Cylinder Head Deck Flatness

Place a straightedge across the cylinder head

1.

deck in three positions and check for any gaps

between the straightedge and the deck with a

feeler gauge. The deck should be flat within

0.76mm (0.003 in.) over 152mm (6 inches) and

0.152mm (0.006 in.) overall.

If necessary, resurface or replace cylinder block

2.

(6010).

Main Bearing Bore Alignment

Main bearing bore misalignment may be suspected in

cases of premature bearing wear if one bearing wears

considerably more than the others or bearings wear

cone-shaped.

NOTE: Bearings are not available with oversize

outside diameters to allow line boring.

If bearing misalignment is suspected:

Acquire a gauge bar the same diameter as the

1.

crankshaft journals and straight within 0.076mm

(0.003 in.).

Put a thin coating of Prussian Blue or similar die

2.

on gauge bar.

Insert good bearings in block.

3.

Insert gauge bar in bearings and rotate one turn.

4.

Remove gauge bar.

5.

Inspect bearings. Blue die should be deposited

6.

evenly on all bearings. If die appears on only one

side or bottom of bearing or not at all, block is

distorted and should be replaced.

01-16

SERVICE PROCEDURES (Continued)

Engine Service

01-16

Cylinder Walls, Refinishing

Cleaning

If the entire engine has NOT been disassembled,

clean the individual cylinder bore(s) with a cloth

soaked in solvent. Dry with a clean, lint-free cloth.

If the entire engine HAS been disassembled, refer to

Cylinder Block Cleaning in this section.

After any cylinder bore service operation, such as

honing or deglazing, clean the bore(s) with soap or

detergent and water. Then thoroughly rinse the bore(s)

with clean water to remove the soap or detergent, and

wipe the bore(s) dry with a clean lint-free cloth. Finally,

wipe the bore(s) with a clean cloth dipped in

X0-1 OW30-QSP or -DSP, or equivalent, motor oil

meeting Ford specification ESE-M2C153-E.

Inspection

Before removing the piston (6108):

1. Check the amount of ridge at the top of the bore.

A thick ridge is a sign of considerable wear.

2. Look for signs of coolant in the bore, especially

rust on the bore surface indicating possible

leaking head gasket or a crack in the cylinder

bore.

3. Check the top of the piston for possible oversize.

If oversize pistons have been installed, the

oversize will be stamped in the top of the piston

(6110).

After the piston is removed and the bore cleaned:

4.

Look for scoring. These are parallel gouges

usually on the piston thrust side, that is, at right

angles to the piston pin. If scored, the cylinder will

have to be refinished.

5.

Look for cracks. If unsure about a crack, tiny

cracks may be detected by coating the bore with

a mixture of 25 percent kerosene and 75 percent

light engine oil. Wipe the bore dry and

immediately apply a coating of zinc oxide

dissolved in wood alcohol. Do not use rubbing

alcohol as a substitute. If cracks are present, the

coating will become discolored at the damaged

area. Replace the cylinder block if it is cracked.

Magnafluxing may also be used.

6.

Check for cylinder wall glazing. When refinished,

the cylinder bore is given a slightly rough finish

with a cylinder hone to help seat the new piston

rings. This finish is worn away as the rings and

cylinder bore “mate” and the bore becomes

glassy smooth. If the engine has been run

enough for this to have happened, the cylinder

will at least have to be honed to seat the new

rings on the piston. New rings should be installed

when the piston is removed and reinstalled

because piston rings are given a special finish by

the factory to help them wear-in and seat. In

seating, the special finish is worn off. Reusing

piston rings will result in high oil consumption.

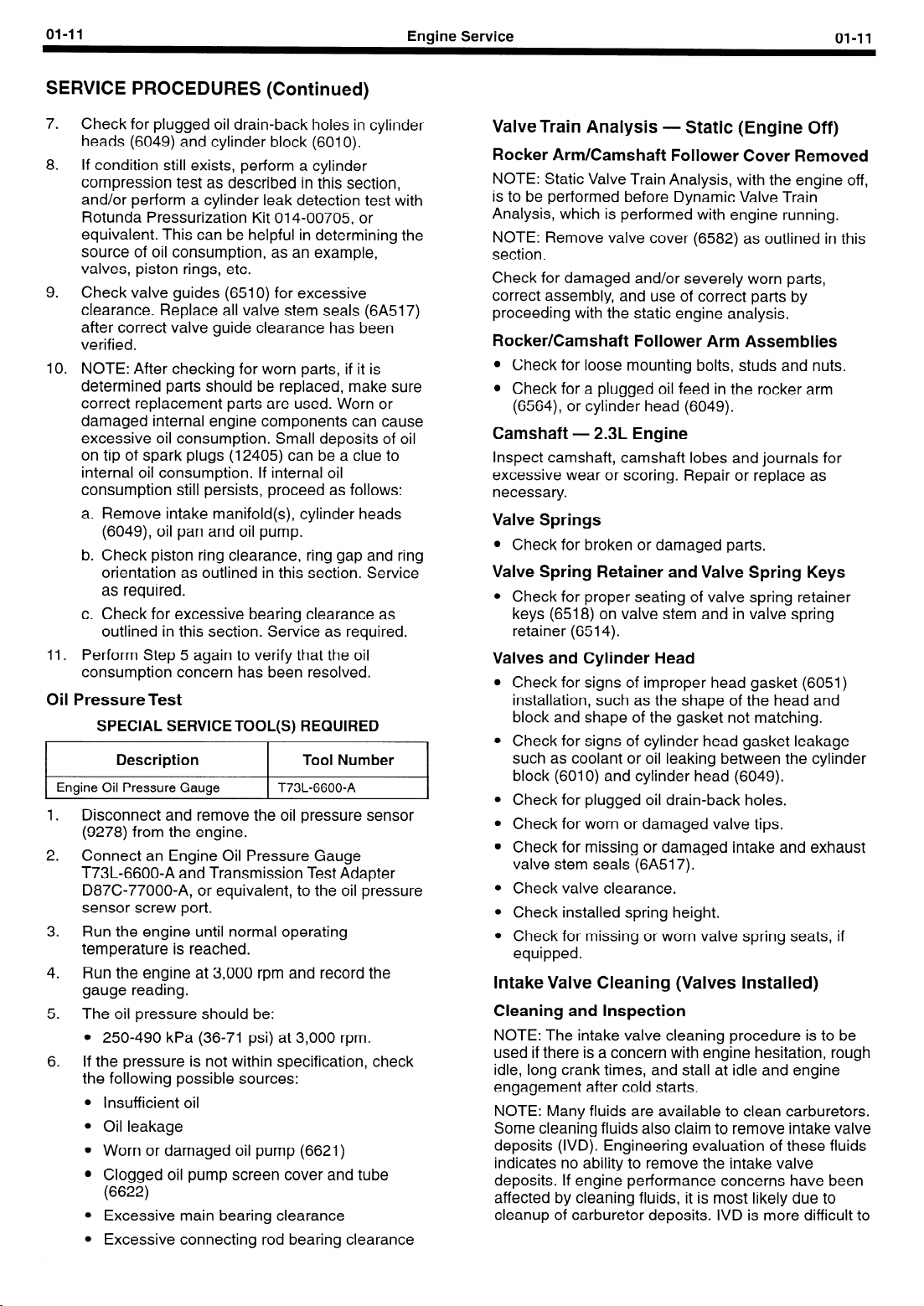

Cylinder Bore

Make sure cylinder bore is clean and dry before

measuring.

Using a suitable cylinder bore micrometer or gauge,

measure the cylinder bore(s) in the X and Y directions

(90 degrees apart) at points A, B, and C. The X

direction is parallel to the piston pin. The Y direction is

perpendicular to the piston pin and is the direction of

piston thrust.

CYLINDER

.

CYLINDER

WALLS

A

B

1

.

t

Al 4470-B

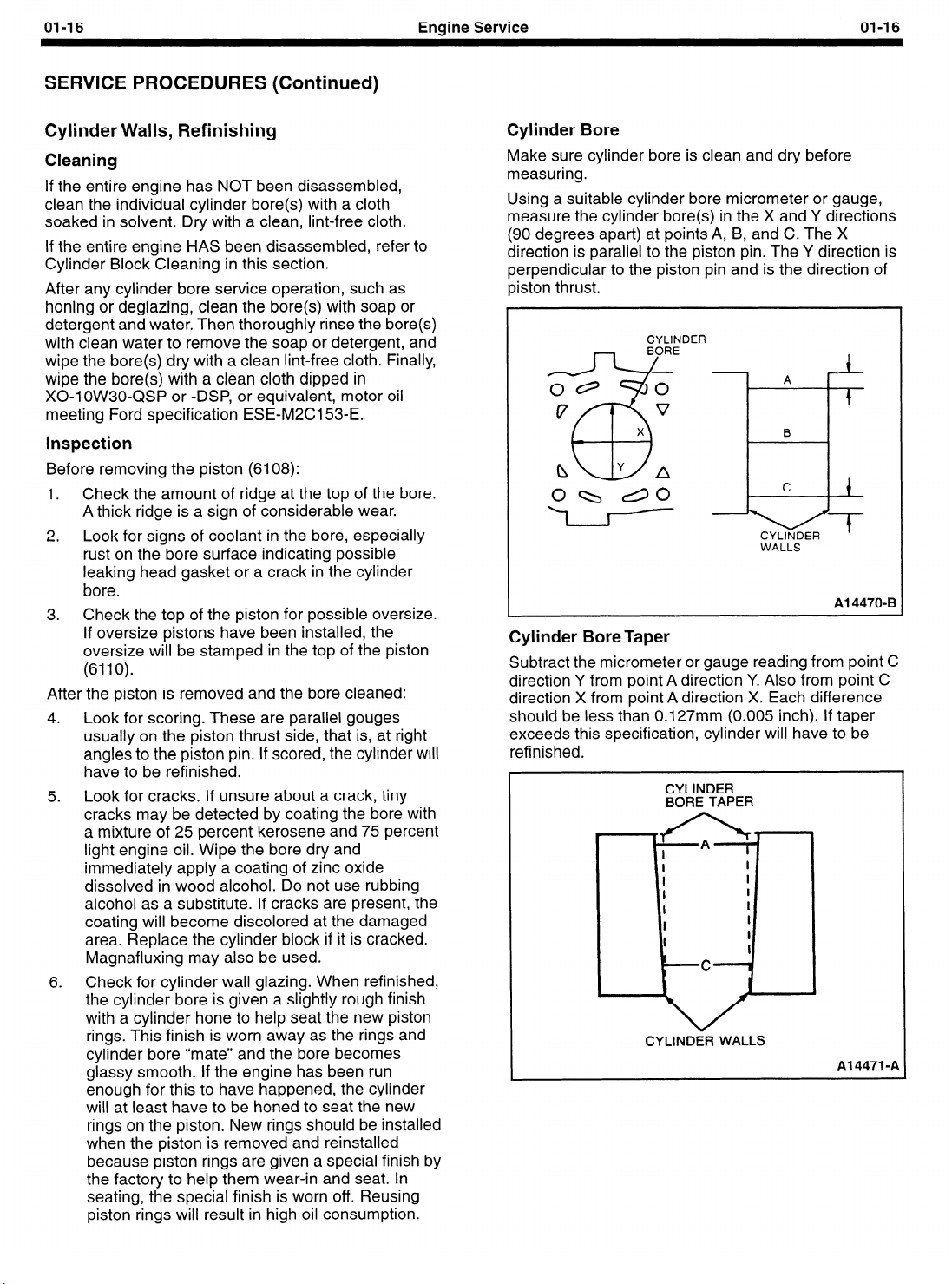

Cylinder Bore Taper

Subtract the micrometer or gauge reading from point C

direction Y from point A direction Y. Also from point C

direction X from point A direction X. Each difference

should be less than 0.127mm (0.005 inch). If taper

exceeds this specification, cylinder will have to be

refinished.

CYLINDER

BORE TAPER

CYLINDER WALLS

Al 4471 -A

01-17 Engine Service

SERVICE PROCEDURES (Continued)

Cylinder Out-of-Round

Subtract the reading in direction X (non-thrust) from

direction Y (thrust side) at all points A, B, and C. All

readings should be less than 0.127mm (0.005 inch). If

out-of-round exceeds this specification, cylinder will

have to be refinished.

FRONT

OF

Egz

NDER

CYLI

BORE

A23876-A

Cylinder Bore Diameter

1.

Measure the diameter of the piston on the thrust

side at right angles to the piston pin - 254mm

(1 .OO inch) below the oil ring groove.

PISTON

GR

A24225-A

2. Measure the cylinder bore diameter at right

angles to the piston pin at points A, B, and C as

described under cylinder taper.

Subtract the piston diameter from the cylinder

3.

bore diameter. The difference should not exceed

the maximum piston-to-bore clearance found in

Specifications in Section 02.

:I3

Cylinder Wall Honing

Hone the cylinder bore:

l

l

1. Measure the diameter of the piston on the thrust

2.

3.

4.

01-17

PISTON

6108

PISTON-TO-CYLINDER 1 f-CLEARANCE

Al 4479-B

When reinstalling a piston with new rings.

To resize a cylinder to accept a service parts piston

going into it.

side at right angles to the piston pin - 254mm

(1 .OO inch) below the oil ring groove.

Measure the cylinder bore diameter at right

angles to the piston pin at points A, B, and C as

described under cylinder taper.

Subtract the piston diameter from the maximum

cylinder bore diameter to determine the

maximum amount of material that can be

removed.

Hone the cylinder according to the hone

manufacturer’s instructions to obtain the proper

bore surface finish of 18-38 RMS.

l

Keep the hone moving up and down to

achieve the proper crosshatch pattern.

l

Measure frequently to make sure that you do

not remove too much of the cylinder wall,

creating excess clearance.

01-18

SERVICE PROCEDURES (Continued)

Engine Service

01-18

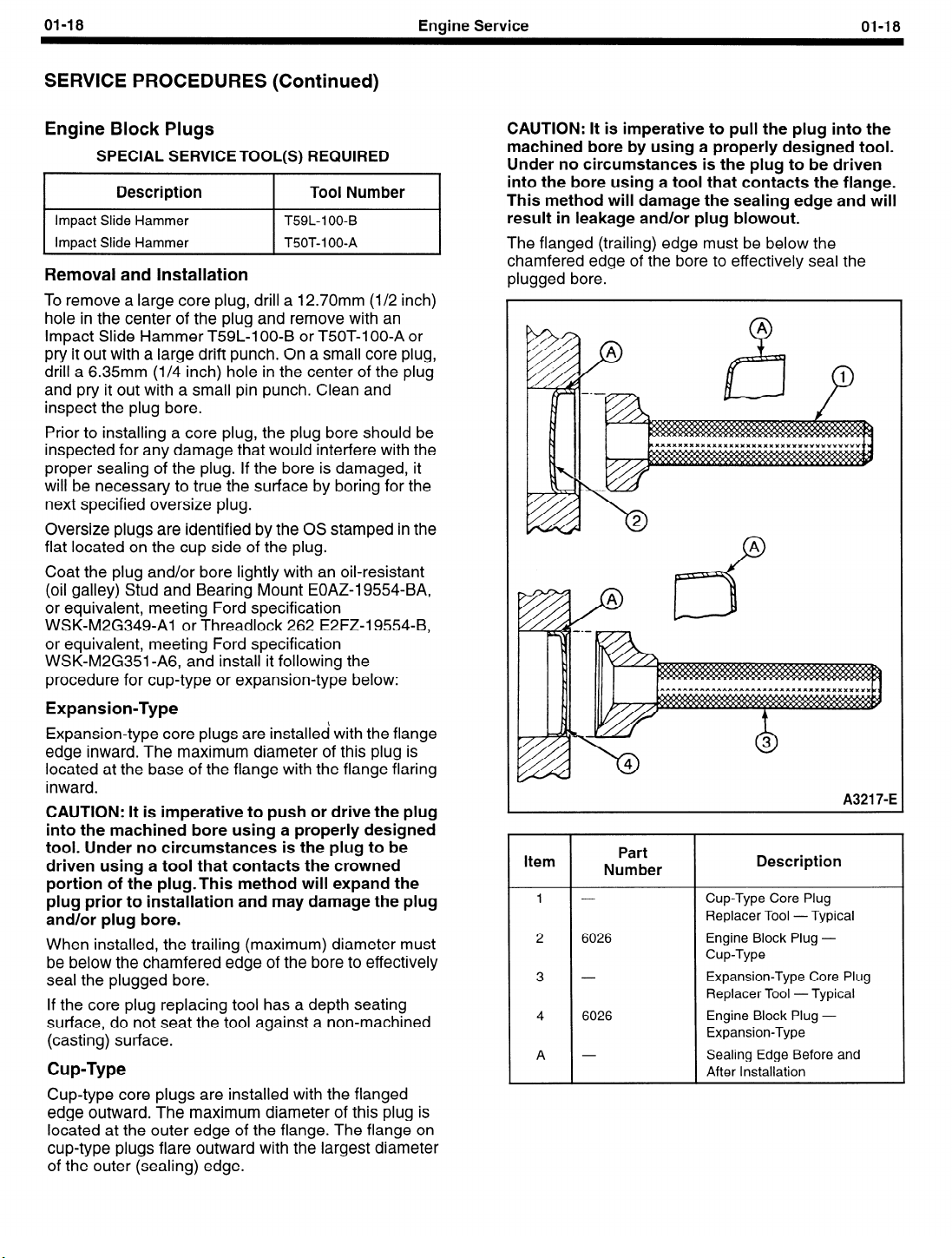

Engine Block Plugs

SPECIAL SERVICE TOOL(S) REQUIRED

Description

Impact Slide Hammer

Impact Slide Hammer

Removal and Installation

To remove a large core plug, drill a 12.70mm (l/2 inch)

hole in the center of the plug and remove with an

Impact Slide Hammer T59L-100-B or T50T-100-A or

pry it out with a large drift punch. On a small core plug,

drill a 6.35mm (l/4 inch) hole in the center of the plug

and pry it out with a small pin punch. Clean and

inspect the plug bore.

Prior to installing a core plug, the plug bore should be

inspected for any damage that would interfere with the

proper sealing of the plug. If the bore is damaged, it

will be necessary to true the surface by boring for the

next specified oversize plug.

Oversize plugs are identified by the OS stamped in the

flat located on the cup side of the plug.

Coat the plug and/or bore lightly with an oil-resistant

(oil galley) Stud and Bearing Mount EOAZ-19554-BA,

or equivalent, meeting Ford specification

WSK-M2G349-Al or Threadlock 262 E2FZ-19554-B,

or equivalent, meeting Ford specification

WSK-M2G351 -A6, and install it following the

procedure for cup-type or expansion-type below:

Tool Number

T59L-100-B

T50T-100-A

CAUTION: It is imperative to pull the plug into the

machined bore by using a properly designed tool.

Under no circumstances is the plug to be driven

into the bore using a tool that contacts the flange.

This method will damage the sealing edge and will

result in leakage and/or plug blowout.

The flanged (trailing) edge must be below the

chamfered edge of the bore to effectively seal the

plugged bore.

Expansion-Type

Expansion-type core plugs are installed with the flange

edge inward. The maximum diameter of this plug is

located at the base of the flange with the flange flaring

inward.

CAUTION: It is imperative to push or drive the plug

into the machined bore using a properly designed

tool. Under no circumstances is the plug to be

driven using a tool that contacts the crowned

portion of the plug.This method will expand the

plug prior to installation and may damage the plug

and/or plug bore.

When installed, the trailing (maximum) diameter must

be below the chamfered edge of the bore to effectively

seal the plugged bore.

If the core plug replacing tool has a depth seating

surface, do not seat the tool against a non-machined

(casting) surface.

Cup-Type

Cup-type core plugs are installed with the flanged

edge outward. The maximum diameter of this plug is

located at the outer edge of the flange. The flange on

cup-type plugs flare outward with the largest diameter

of the outer (sealing) edge.

Item

1 -

2 6026

3 -

4 6026

A -

Part

Number

A321 7-E

Description

Cup-Type Core Plug

Replacer Tool - Typical

Engine Block Plug Cup-Type

Expansion-Type Core Plug

Replacer Tool - Typical

Engine Block Plug -

Expansion-Type

Sealing Edge Before and

After Installation

01-19

SERVICE PROCEDURES (Continued)

Enaine Service

01-19

Crankshaft Main and Connecting Rod

Bearings

Cleaning

NOTE: Do not scrape gum or varnish deposits from

the bearing shells.

Bearings that are to be reused should be identified so

they can be installed in their original locations.

Clean the bearing inserts and caps thoroughly in

solvent, and dry them with compressed air.

Inspection

Inspect each bearing carefully. Bearings that have a

scored, chipped or worn surface should be replaced.

Typical examples of unsatisfactory bearings and their

causes are shown in the illustration. The copper lead

bearing base may be visible through the bearing

overlay. If the base showing is less than 20 percent of

the total area, the bearing is not excessively worn. It is

not necessary to replace the bearing if the bearing

clearance is within recommended limits. Check the

clearance of bearings that appear to be satisfactory

with Plastigage@ as described in this section.

n

Item

1

A -

B -

c - Dirt Scratching, lmbedding

D - Overlay Wiped Out - Lack of

E -

F G - Overlay Gone from Mating

Part

Number

6333 Connecting Rod Bearing

Description

Fatigue Failure - Craters or

Pockets

Improper Seating - Bright

(Polished) Sections

Oil or Improper Clearance

Hourglass -

from Edges

Radius Ride

Edge, One Side Only. Rod Cap

Shift.

Overlay Gone

Crankshaft Main or Connecting Rod Bearings

- Fitting Plastigage@ Method

1.

Clean crankshaft journals. Inspect journals and

thrust faces for nicks, burrs or roughness that

would cause premature bearing wear.

replacing standard bearings with new bearings,

it is good practice to fit bearing to minimum

specified clearance.

be obtained with a standard bearing, try a

0.050mm (0.002-inch) undersize bearing set to

obtain proper clearance.

2.

CAUTION: Do not position jack under crankshaft

pulley. Crankshaft post damage will result.

If fitting main bearing in-equipment, position a

jack under counterweight adjoining bearing which

is being checked. Support crankshaft (6303) with

jack so its weight will not compress Plastigage@

and cause an incorrect reading.

Place a piece of Plastigage@ D81 L-6002-B, or

3.

equivalent, on bearing surface across full width of

bearing cup and about 6.35mm (l/4 inch) off

center.

If desired clearance cannot

When

1

00

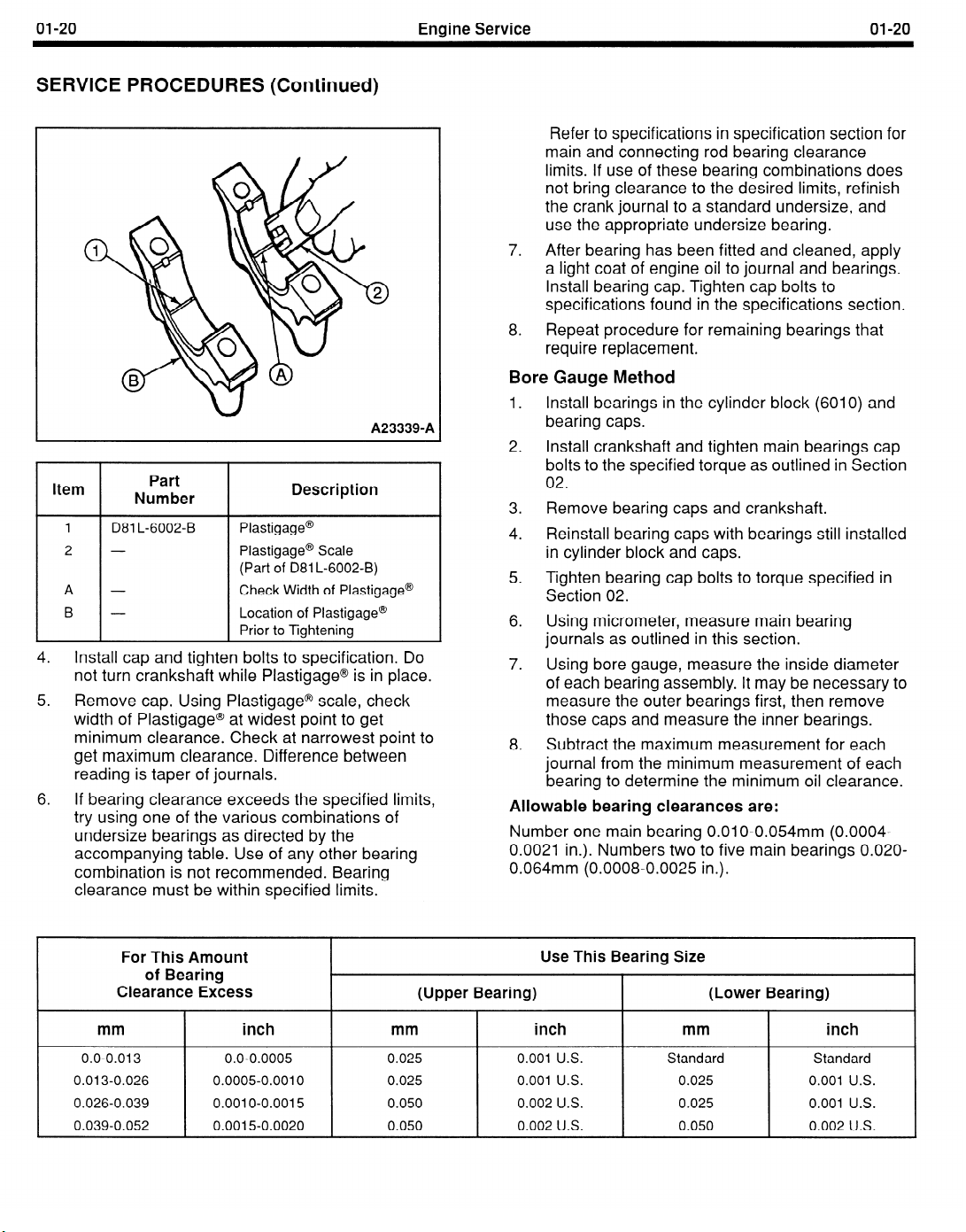

A2333843

01-20

Engine Service

SERVICE PROCEDURES (Continued)

A233390A

Item

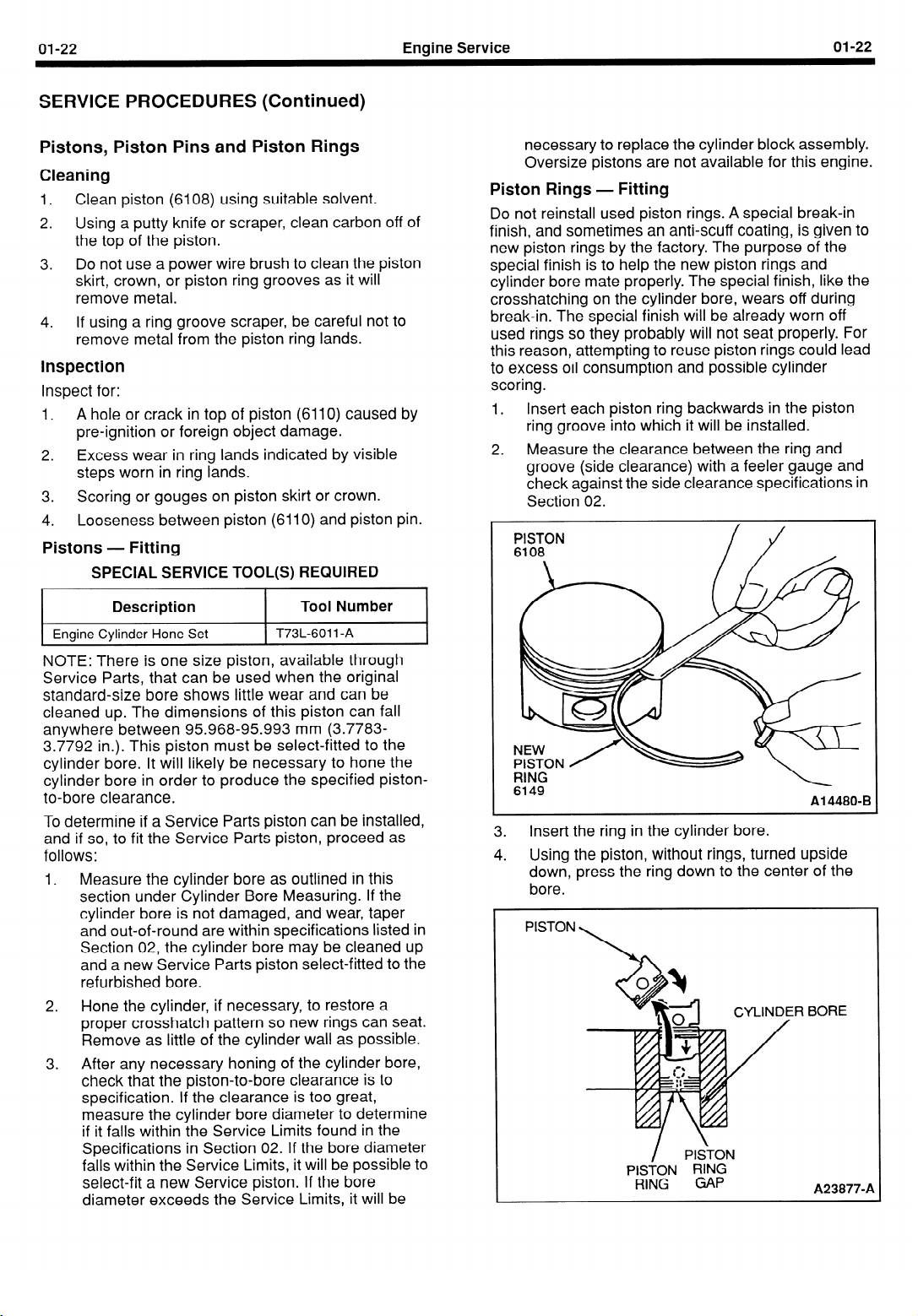

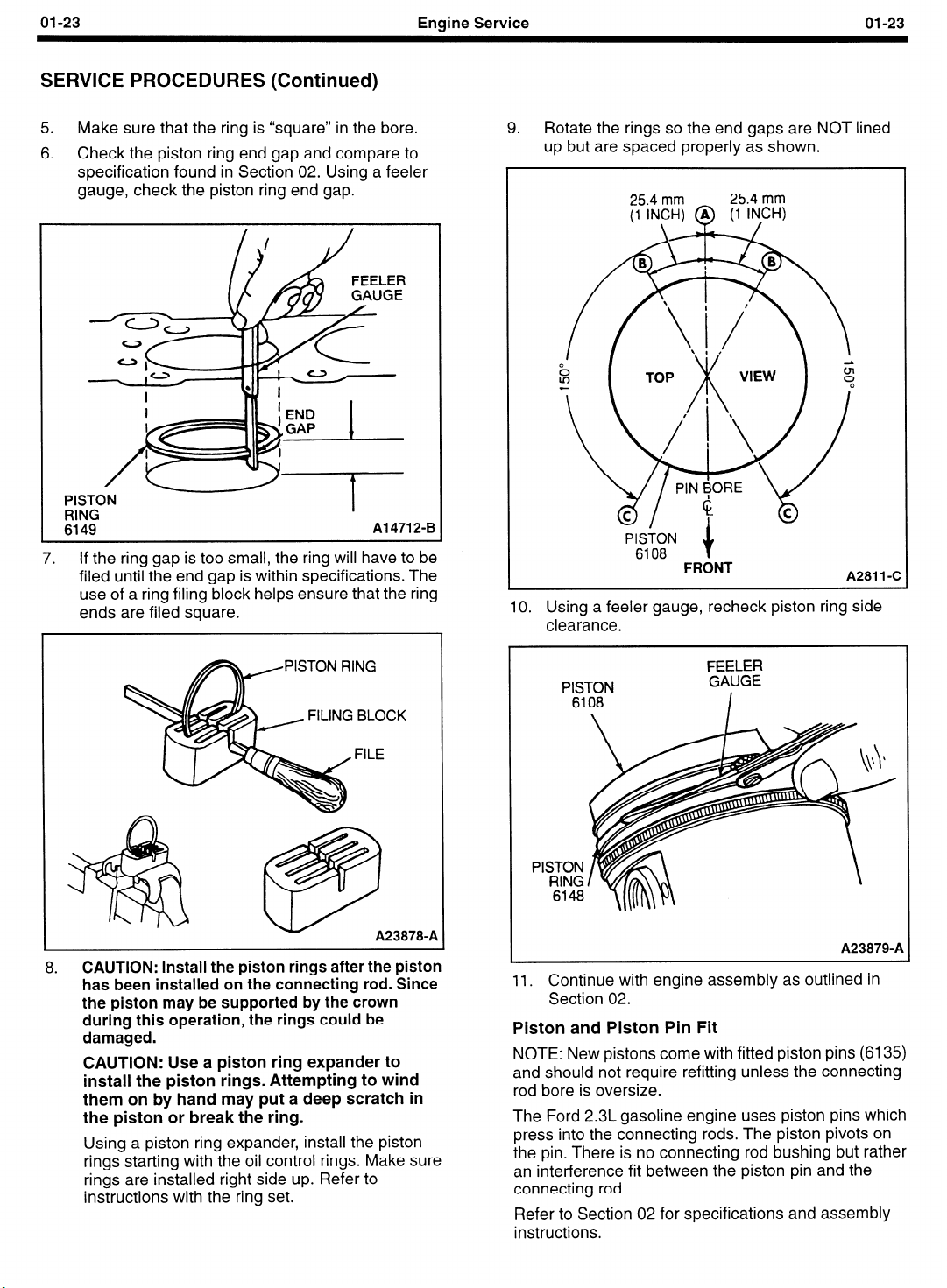

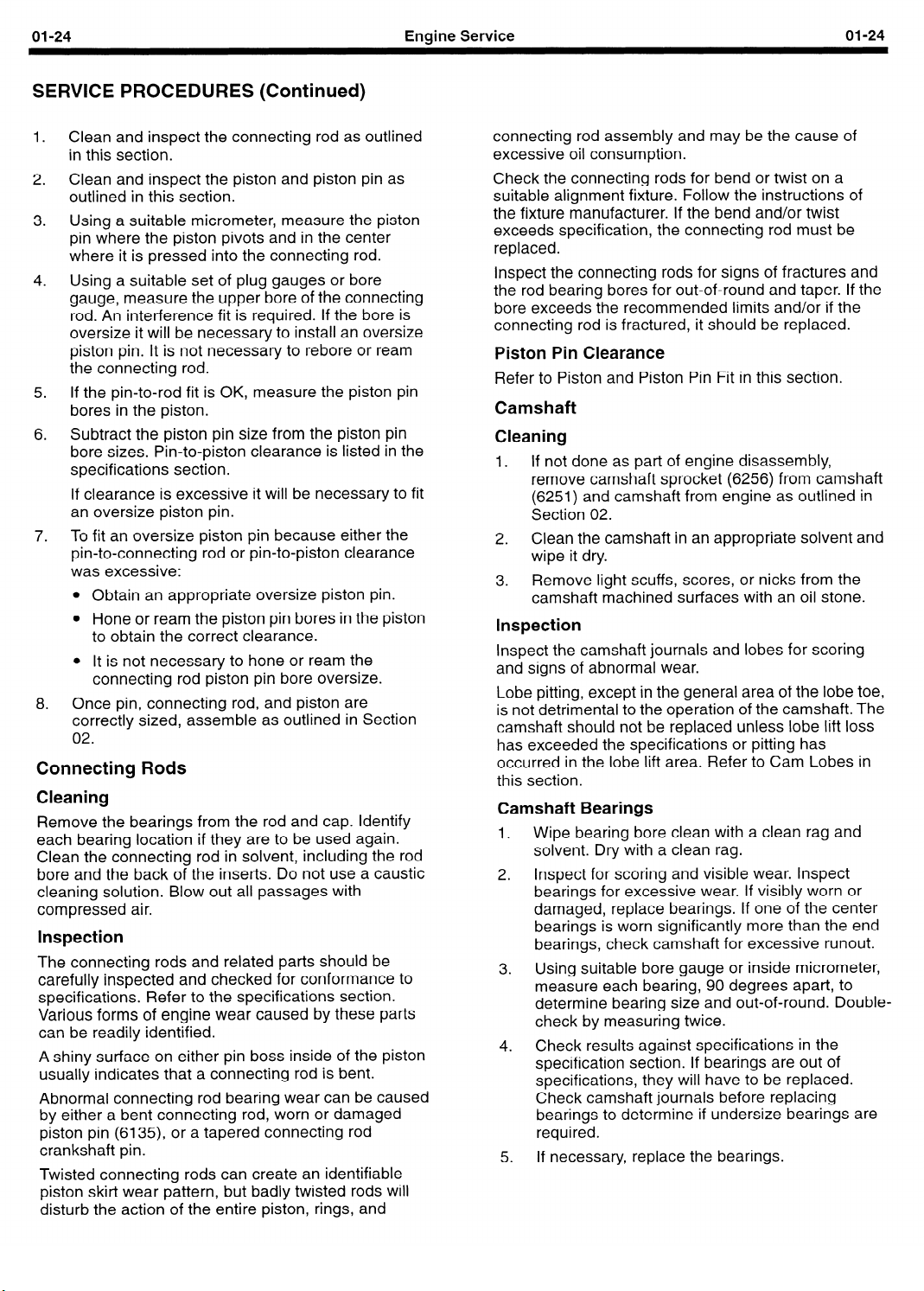

1

2 -

A - Check Width of Plastigage@

B - Location of Plastigage@

4.

Install cap and tighten bolts to specification. Do

Part

Number

D81 L-6002-B

not turn crankshaft while Plastigage@ is in place.

5. Remove cap. Using Plastigage@ scale, check

width of Plastigage@ at widest point to get

minimum clearance. Check at narrowest point to

get maximum clearance. Difference between

reading is taper of journals.

6. If bearing clearance exceeds the specified limits,

try using one of the various combinations of

undersize bearings as directed by the

accompanying table. Use of any other bearing

combination is not recommended. Bearing

clearance must be within specified limits.

Description

Plastigage@

Plastigage@ Scale

(Part of 081 L-6002-B)