Ford F-650 Owner's Manual

Table of Contents

Introduction 4

Safety and environment protection 5

Symbol glossary 8

Vehicle Inspection Guide 11

Instrument Cluster 23

Warning and control lights 23

Gauges 28

Entertainment Systems 33

AM/FM stereo 33

AM/FM stereo cassette with CD 39

AM/FM stereo with in-dash six CD 44

Climate Controls 50

Heater only 50

Manual heating and air conditioning 51

Lights 53

Headlamps 53

Turn signal control 54

Interior lamps 55

Bulb replacement 55

Driver Controls 58

Windshield wiper/washer control 58

Steering wheel adjustment 58

Power windows 59

Mirrors 61

Speed control 63

1

Table of Contents

Locks and Security 67

Keys 67

Locks 67

Seating and Safety Restraints 68

Seating 68

Safety restraints 74

Child restraints 83

Driving 91

Starting 91

Brakes 98

Air suspension 119

Transmission operation 121

Vehicle loading 136

Roadside Emergencies 143

Hazard flasher switch 144

Fuses and relays 144

Jump starting 151

Wrecker towing 155

Customer Assistance 159

Getting assistance outside the U.S. and Canada 161

Ordering additional owner’s literature 162

Reporting safety defects (U.S. only) 162

Cleaning 163

Cleaning your vehicle 163

Repairing paint chips 163

Underbody preservation 166

2

Table of Contents

Maintenance and Specifications 168

Hood 175

Engine oil 177

Battery 186

Fuel information 197

Lubricant specifications 218

Refill capacities 231

Scheduled Maintenance Guide 235

Motorcraft Premium Gold Coolant Change Record 265

Index 267

All rights reserved. Reproduction by any means, electronic or mechanical

including photocopying, recording or by any information storage and retrieval

system or translation in whole or part is not permitted without written

authorization from Ford Motor Company. Ford may change the contents without

notice and without incurring obligation.

Copyright © 2005 Ford Motor Company

3

Introduction

CALIFORNIA Proposition 65 Warning

WARNING: Engine exhaust, some of its constituents, and

certain vehicle components contain or emit chemicals known to

the State of California to cause cancer and birth defects or other

reproductive harm. In addition, certain fluids contained in vehicles and

certain products of component wear contain or emit chemicals known

to the State of California to cause cancer and birth defects or other

reproductive harm.

CONGRATULATIONS

Congratulations on acquiring your new Ford. Please take the time to get

well acquainted with your vehicle by reading this handbook. The more

you know and understand about your vehicle, the greater the safety and

pleasure you will derive from driving it.

For more information on Ford Motor Company and its products visit the

following website:

• In the United States: www.ford.com

• In Canada: www.ford.ca

• In Mexico: www.ford.com.mx

• In Australia: www.ford.com.au

Additional owner information is given in separate publications.

This Owner’s Guide describes every option and model variant available

and therefore some of the items covered may not apply to your

particular vehicle. Furthermore, due to printing cycles it may describe

options before they are generally available.

Remember to pass on the Owner’s Guide when reselling the vehicle. It

is an integral part of the vehicle.

4

Introduction

SAFETY AND ENVIRONMENT PROTECTION

Warning symbols in this guide

How can you reduce the risk of personal injury and prevent possible

damage to others, your vehicle and its equipment? In this guide, answers

to such questions are contained in comments highlighted by the warning

triangle symbol. These comments should be read and observed.

Warning symbols on your vehicle

When you see this symbol, it is

imperative that you consult the

relevant section of this guide before

touching or attempting adjustment

of any kind.

Protecting the environment

We must all play our part in

protecting the environment. Correct

vehicle usage and the authorized

disposal of waste cleaning and

lubrication materials are significant

steps towards this aim. Information in this respect is highlighted in this

guide with the tree symbol.

5

Introduction

SPECIAL NOTICES

Emission warranty

The New Truck Limited Warranty includes Basic Coverage, Corrosion

Coverage, Frame Coverage, Federal Emissions Defect Warranty and

California Defects Warranty. For a detailed description of what is covered

and what is not covered, refer to the Warranty Guide that is provided

to you along with your Owner’s Guide.

Special instructions

For your added safety, your vehicle is fitted with sophisticated electronic

controls.

Service Data Recording

Service data recorders in your vehicle are capable of collecting and

storing diagnostic information about your vehicle. This potentially

includes information about the performance or status of various systems

and modules in the vehicle, such as engine, throttle, steering or brake

systems. In order to properly diagnose and service your vehicle, Ford

Motor Company, Ford of Canada, and service and repair facilities may

access vehicle diagnostic information through a direct connection to your

vehicle when diagnosing or servicing your vehicle.

6

Introduction

Cell phone use

The use of Mobile Communications Equipment has become increasingly

important in the conduct of business and personal affairs. However,

drivers must not compromise their own or others’ safety when using

such equipment. Mobile Communications can enhance personal safety

and security when appropriately used, particularly in emergency

situations. Safety must be paramount when using mobile communications

equipment to avoid negating these benefits.

Mobile Communication Equipment includes, but is not limited to cellular

phones, pagers, portable email devices, in-vehicle communications

systems, telematics devices and portable two-way radios.

A driver’s first responsibility is the safe operation of the vehicle.

The most important thing you can do to prevent a crash is to

avoid distractions and pay attention to the road. Wait until it is safe to

operate Mobile Communications Equipment.

7

Introduction

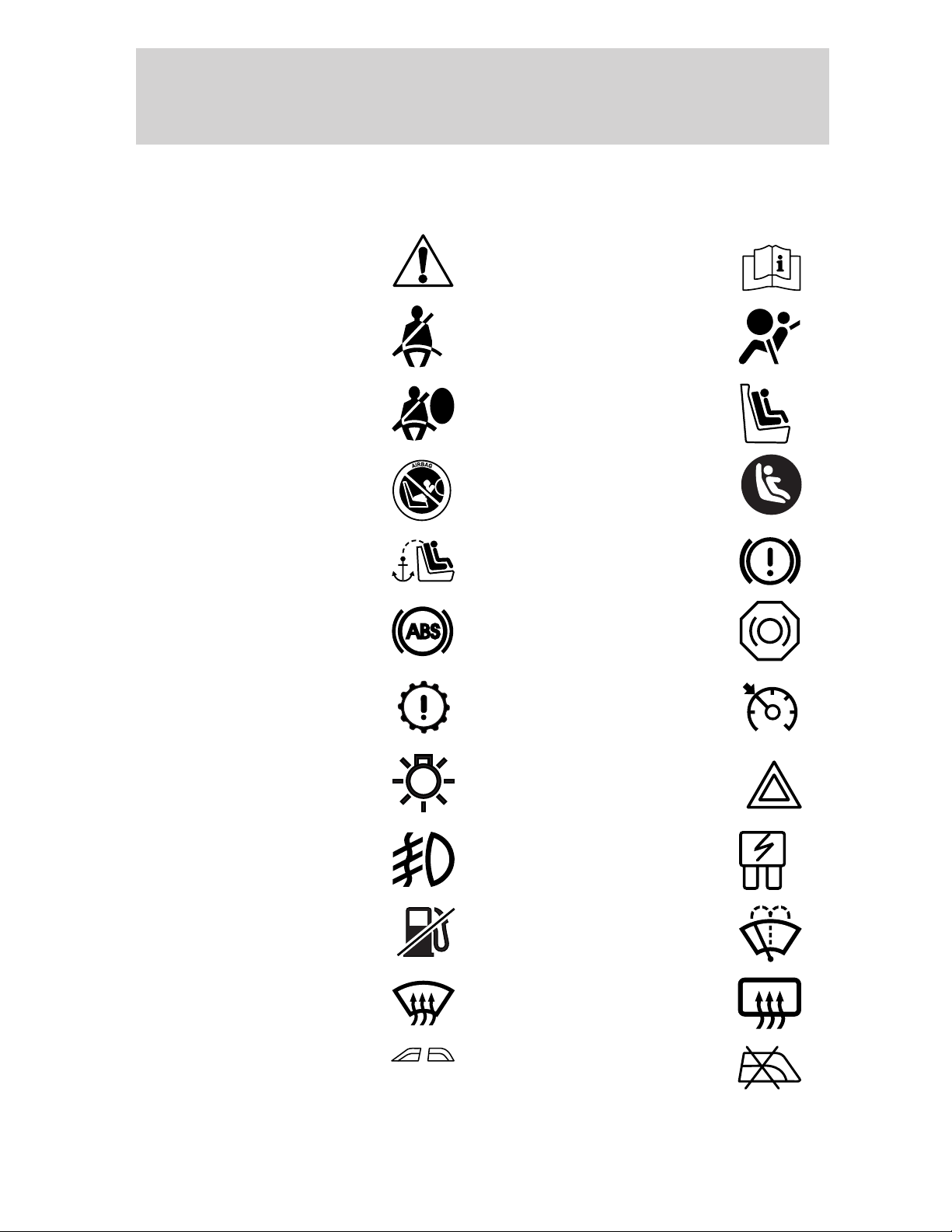

VEHICLE SYMBOL GLOSSARY

These are some of the symbols you may see on your vehicle.

Safety Alert

Fasten Safety Belt Air Bag-Front

Air Bag-Side Child Seat

Child Seat Installation

Warning

Child Seat Tether

Anchor

Anti-Lock Brake System

Powertrain Malfunction Speed Control

See Owner’s Guide

Child Seat Lower

Anchor

Brake System

Brake Fluid Non-Petroleum Based

Master Lighting Switch Hazard Warning Flasher

Fog Lamps-Front Fuse Compartment

Fuel Pump Reset Windshield Wash/Wipe

Windshield

Defrost/Demist

Power Windows

Front/Rear

8

Rear Window

Defrost/Demist

Power Window Lockout

Introduction

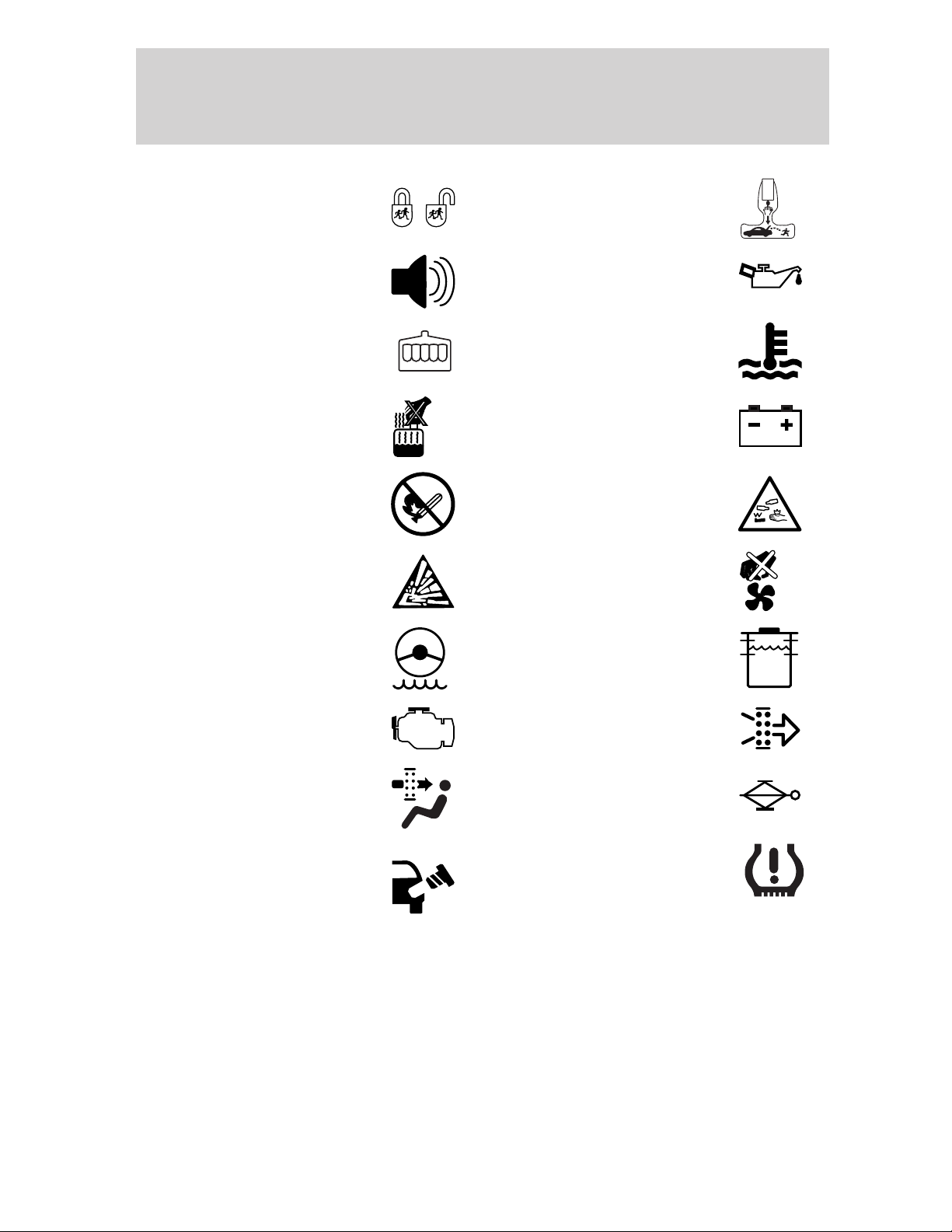

Child Safety Door

Interior Luggage

Compartment Release

Lock/Unlock

Symbol

Panic Alarm Engine Oil

Engine Coolant

Engine Coolant

Temperature

Do Not Open When Hot Battery

Avoid Smoking, Flames,

Battery Acid

or Sparks

Explosive Gas Fan Warning

Power Steering Fluid

Maintain Correct Fluid

Level

Emission System Engine Air Filter

Passenger Compartment

Jack

Air Filter

Low Tire Pressure

Check Fuel Cap

Warning

MAX

MIN

9

Introduction

FEDERAL HIGHWAY ADMINISTRATION REGULATION

Regulations such as those issued by the Federal Highway Administration

or issued pursuant to the Occupational Safety and Health Act (OSHA),

and/or state and local laws and regulations may require additional

equipment for the way you intend to use the vehicle. It is the

responsibility of the registered owner to determine the applicability of

such laws and regulations to your intended use for the vehicle, and to

arrange for the installation of required equipment. Your dealer has

information about the availability of equipment which may be ordered for

your vehicle.

ENTERING, EXITING AND/OR CLIMBING ON THIS VEHICLE

You must be careful and deliberate to minimize the possibility of personal

injury from a slip and fall when entering, exiting and/or climbing on this

vehicle. Always use the steps and assist handles before climbing. Do not

skip any steps or assist handles. Use three point contact at all times with

at least two feet and one hand or two hands and one foot firmly placed

during all phases of entering, exiting and/or climbing. Always keep your

shoe soles and hands clean. Keep the steps and assist handles free of

snow, ice, oil, grease, substances or debris. Be sure to use extra care in

bad weather. Avoid wearing thick gloves. Always perform trailer hook-up

while standing on the ground.

Do not carry items while entering, exiting, and/or climbing. Make

sure you keep a firm grip. Always FACE the VEHICLE STEP and

HANDLE SYSTEM while climbing up and down. Do not climb behind

the cab unless you have three point contact with a step and handle

system at all times.

10

Vehicle Inspection Guide

To be sure your vehicle is ready to operate, conduct a pre-trip inspection

at the beginning of each work period. Follow the steps listed in this

section to ensure a proper vehicle inspection procedure. The pages in

this section may be produced locally and used on a regular basis.

VEHICLE INSPECTION INFORMATION

Note: Always make sure the parking brake is applied before starting the

engine.

Engine compartment (with engine stopped)

Engine oil level: Use the engine oil dipstick to verify that the

engine oil level is between the ADD and

OPERATING RANGE marks.

Engine coolant

level:

Power steering fluid: Verify that the fluid level is between the

Brake fluid (master

cylinder):

Hydraulic clutch

fluid:

Look through the plastic reservoir or the clear

sight glass on the reservoir, depending upon

vehicle equipment, and make sure the fluid is

within the minimum and maximum fluid level

range as marked on the reservoir. Do not

remove pressure cap until the coolant has

cooled.

proper operating range Refer to Power

steering fluid in the Maintenance and

specifications chapter.

Remove the master cylinder caps and inspect

the fluid level. The full mark is at the bottom

of the opening of the port ring.

Check for adequate amount of hydraulic clutch

fluid. Fluid level should be at the step of the

reservoir; refer to Clutch fluid/linkage

adjustments in the Maintenance and

Specifications chapter.

Belts (Fan,

alternator, water

pump and A/C

compressor):

Check for glazing, fraying or cracking. There

should be no more than five - seven cracks per

rib per inch.

11

Vehicle Inspection Guide

Engine compartment (with engine stopped)

Any leaks: Check for signs of fluid puddles, dripping fluid

on the ground under the engine or the

underside of the engine.

HVAC air inlet: Check for debris, leaves, etc. that may have

collected on the HVAC air inlet grille or inside

the exterior module as this may cause reduced

system performance.

HVAC fresh air filter

(if equipped):

Exercise great caution when working on vehicle equipped with

an automatic fan clutch. The fan starts in motion only after the

engine coolant reaches a predetermined temperature or the refrigerant

pressure (if equipped with air conditioning) reaches a predetermined

setting. The fan will start at this point with no advance warning. Never

reach near, or permit objects to protrude into, the fan blade radius

while the engine is running as this could result in vehicle damage,

personal injury or death.

Periodically check the HVAC fresh air filter for

cleanliness.

12

Vehicle Inspection Guide

Engine starting (parking brake applied)

Safety/Emergency

equipment:

Starting the engine: Verify the parking brake is set. Depress the

Prior to entering the cab, verify that the

vehicle is equipped with spare electrical fuses

(if used), three red reflective triangles, a

properly charged and rated fire extinguisher

and wheel chocks. Walk around the vehicle

and check that all steps and grab handles,

inside and out as well as behind, are tight and

clean. Use extreme caution and a three-point

stance at all times. Check door latches for

positive closing, latching and locking.

clutch (if equipped with a manual

transmission) and verify the transmission is in

neutral. Vehicles equipped with an automatic

transmission should be in N (Neutral).

When the WAIT TO START indicator light in

the instrument cluster turns off, turn the key

to START.

Oil pressure builds: Make sure engine oil pressure is building to

normal operating range.

Air chime sounds (if

equipped with air

compressor):

Accelerator: Depress the accelerator and verify that it

The low air pressure warning chime should

sound immediately after the engine starts but

before the compressor has built up pressure.

The low air pressure warning chime should

stop when the air pressure reaches 70 psi (483

kPa) (or more). Let the air pressure build to

governed cut-out pressure, which should occur

between 115–130 psi (793–896 kPa).

operates smoothly without any binding or

irregular feel. Remove your foot from the

pedal and make sure the engine returns to idle

speed immediately.

13

Vehicle Inspection Guide

Engine starting (parking brake applied)

Ammeter/Voltmeter: Check the gauge to see if the alternator is

charging.

Steering linkage

free play:

Hydraulic brake

check:

Check for excessive free play in the steering

linkages. The steering wheel should have less

than two inches (five cm) of free play at rim

of steering wheel.

Pump the brake pedal three times, then apply

firm pressure to the pedal and hold it for five

seconds. The pedal should move (due to the

HydroMax pump operation); if it does not,

there may be a leak or another problem. Do

not drive the vehicle until the problem is

fixed.

14

Vehicle Inspection Guide

Engine starting (parking brake applied)

Air brake check: Check the air brakes in the following manner

(Chock the wheels, if necessary. Push in the

parking brake and on tractors, also push in the

tractor parking brake knob):

1. Check the air compressor or governor

cut-out pressure (approximately 120 psi [827

kPa]).

2. Cut-off the engine and turn the key back to

ON, without starting the engine.

3. Without the brake pedal applied, note the

air pressure drop for one minute. It should be

less than 2 psi (14 kPa) for single vehicle and

3 psi (21 kPa) for combination vehicles.

4. Depress and hold the brake pedal with 90

psi (621 kPa) or more and make sure there is

no more than a 3 psi (21 kPa) per minute

leak. For combination vehicles, no more than 4

psi (28 kPa) per minute.

5. Pump the brake pedal to deplete the system

air pressure. The warning light and chime

should activate 57 psi (393 kPa).

6. Pump the brake pedal and make sure the

parking brake and trailer parking brake knobs

pop out at 20 psi (138 kPa) or higher.

Parking brake: Check that the parking brake will hold the

vehicle by gently trying to pull forward with

the parking brake applied.

15

Vehicle Inspection Guide

Engine starting (parking brake applied)

Automatic

transmission fluid:

Lights: Make sure all lights illuminate and are clean.

Steering gear: Look for missing or loose fasteners, power

With the engine idling at normal operating

temperature and the parking brake applied,

check the automatic transmission fluid. If fluid

needs to be added, place the transmission in

the appropriate gear as specified in the

transmission operator’s manual and refer to

Transmission fluid in the Maintenance and

specifications chapter.

Front of vehicle

Make sure headlights function on both high

and low beams. Make sure reflectors are clean

and unbroken and of proper color (red on

rear, amber elsewhere). Make sure the running

lights are also clean and unbroken.

steering fluid leaks and damage to power

steering hoses.

Steering linkage: Make sure connecting links, arms and rods are

not worn or cracked; joints, sockets and boot

seals are not worn or loose and that there are

no loose or missing cotter keys, nuts or bolts.

Tow hooks: Front and rear tow hooks should be inspected

for damage or loose mounting. This is

particularly important on vehicles where tow

hooks are frequently used.

16

Vehicle Inspection Guide

Front suspension

Spring: Inspect for missing, broken or shifted leaves or

leaves that are in contact, or nearly contacting

a tire, rim, brake drum, frame or body

components.

Spring mount: Inspect spring hangers, bolts, bushings, axle

mounting bolts and nuts for cracks, breaks,

wear, damage and tightness.

Shock absorber: Inspect for cracks, leaks and missing or broken

bolts or bushings.

Note: Never apply grease to spring pads.

Do not operate the vehicle if any suspension conditions listed in

the Front suspension chart are evident. Loss of steering or

suspension could result in property damage, personal injury or death.

Front brakes

Hoses: Checked for cracked, worn or frayed hoses.

Make sure all couplings are secured.

Chambers: Make sure brake chambers are not cracked or

dented and that they are securely mounted.

Slack adjuster: Check for broken, loose or missing parts; the

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push

rod should not move more than approximately

one inch (2.5 cm).

Drum: Make sure there are no cracks, dents or holes

and no loose or missing bolts. Make sure brake

linings are not worn or dangerously thin or

contaminated by lubricant.

17

Vehicle Inspection Guide

Front wheels

Rims: Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts: Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

Hub oil seal: Check wheel hub oil seal for leaks, and if sight

glass if present, check to see that the oil level

is adequate.

Oil-lubricated front

wheel bearing:

If a wheel must be changed, obtain expert tire service help.

Mounting and un-mounting of tires should only be performed by

a qualified technician using necessary safety procedures and

equipment, otherwise the result could be property damage, personal

injury or death.

Fuel tank: Make sure the fuel tank and caps are secure.

Leaks: Check for any leaks from the fuel tanks.

If the hubcap has a transparent window, check

for proper lubrication level. If the hubcap does

not have a transparent window, remove the

rubber fill-plug and check for proper level.

Driver/Fuel area

Make sure there is no damage to the tank.

18

Vehicle Inspection Guide

Underbody of vehicle

Driveshaft: Make sure that the driveshaft is not bent or

cracked. Ensure all driveshaft couplings are

secure.

Exhaust system: Make sure the outside visible parts are

securely mounted. Make sure there are no

cracks, holes or severe dents.

Frame: Check for cracks or bends in longitudinal

frame members. Make sure there are no loose,

cracked, bent, broken or missing

crossmembers or crossmember fasteners.

Maintain adequate clearance between all parts of the exhaust

system and all hoses, wires and lines for engine cooling, brake

system, fuel system, power steering system and electrical system, Heat

damage to hoses, wires or lines may cause vehicle malfunction that

could result in property damage, personal injury or death.

Rear of vehicle

Air/Electric lines: Make sure that air hoses are not cut, cracked,

chafed or worn. Listen for audible air leaks,

Make sure air and electrical lines are not

tangled, crimped or pinched or being dragged

against any truck parts. Electrical line

insulation should not be cut, cracked, chafed

or worn. None of the air or electrical line

should be spliced or taped. Check for

corrosion on pins and in electrical sockets to

ensure continuity and reduced heat build-up

potential.

Deck plate: Make sure deck plate is clean, securely bolted

to the frame and clear of loose objects.

Signal/Brake lights: Make sure both brake lights illuminate when

the brake pedal is applied. Also, make sure

each signal flashes. Make sure that four-way

flashers work properly.

19

Vehicle Inspection Guide

Rear of vehicle

Lights, reflectors: Make sure all lights illuminate and are clean.

Make sure headlights function on both high

and low beams. Make sure reflectors are clean

and unbroken and of proper color (red on

rear, amber elsewhere). Make sure the running

lights are also clean and unbroken. Rear

running lights must be checked separately

from signal, flasher and brake lights.

Tractor - coupling system

Mounting bolts: Check for loose or missing mounting brackets,

clamps, bolts or nuts. Both fifth wheel and

slide mounting must be solidly attached.

Platform: Check for cracks or breaks in the platform

structure.

Safety latch: Make sure safety latch is engaged.

Release arm: Make sure safety latch is in the engaged

position and that any safety latch is in place.

Kingpin/Apron: Make sure kingpin is not bent or worn. Also

make sure that the apron lies flat on the fifth

wheel skid plate and that the visible part of

the apron is not bent, worn, cracked or

broken.

Rear springs

Springs: Check for broken or shifted leaves or leaves

that are in contact, or nearly contacting a tire,

rim, brake drum, frame or body components.

Check for missing or broken leaves in the leaf

spring.

Spring mounts: Check for cracked or broken spring hangers,

broken, missing or loose bolts, missing or

damaged bushings, broken, loose or missing

axle mounting parts.

20

Vehicle Inspection Guide

Rear springs

Torsion, shocks: Make sure torsion arm is not cracked, broken

or missing. Check the shock absorber for

cracks or leaks; there should be no missing or

broken mounting bolts or worn bushings.

Rear brakes

Hoses: Checked for cracked, worn or frayed hoses.

Make sure all couplings are secured.

Chambers: Make sure brake chambers are not cracked or

dented and that they are securely mounted.

Slack adjuster: Check for broken, loose or missing parts; the

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push

rod should not move more than approximately

one inch (2.5 cm).

Drum: Make sure there are no cracks, dents or holes

and no loose or missing bolts. Make sure brake

linings are not worn or dangerously thin or

contaminated by lubricant.

Rear wheels

Spacers: Make sure dual wheels are evenly separated

and that tires are not touching one another.

Rims: Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts: Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

21

Vehicle Inspection Guide

Trailer

If you are pulling a trailer, an inspection of the trailer similar to that of

the tractor should be done. Such an inspection should follow trailer

manufacturer recommendation and should include at a minimum: general

condition, landing gear, doors, sides, lights, reflectors, suspension,

brakes, tires, wheels, cargo placement, stability and tie-downs.

Transmission

If your vehicle is equipped with an automatic transmission, regularly

check the transmission’s neutral start switch. The engine should only

start in the N (Neutral) or P (Park) positions.

If the unit starts in gear and/or the neutral start switch is not

functioning correctly, the vehicle may inadvertently move which

could result in property damage, personal injury or death.

Check the transmission fluid level and shift linkage for proper operation.

22

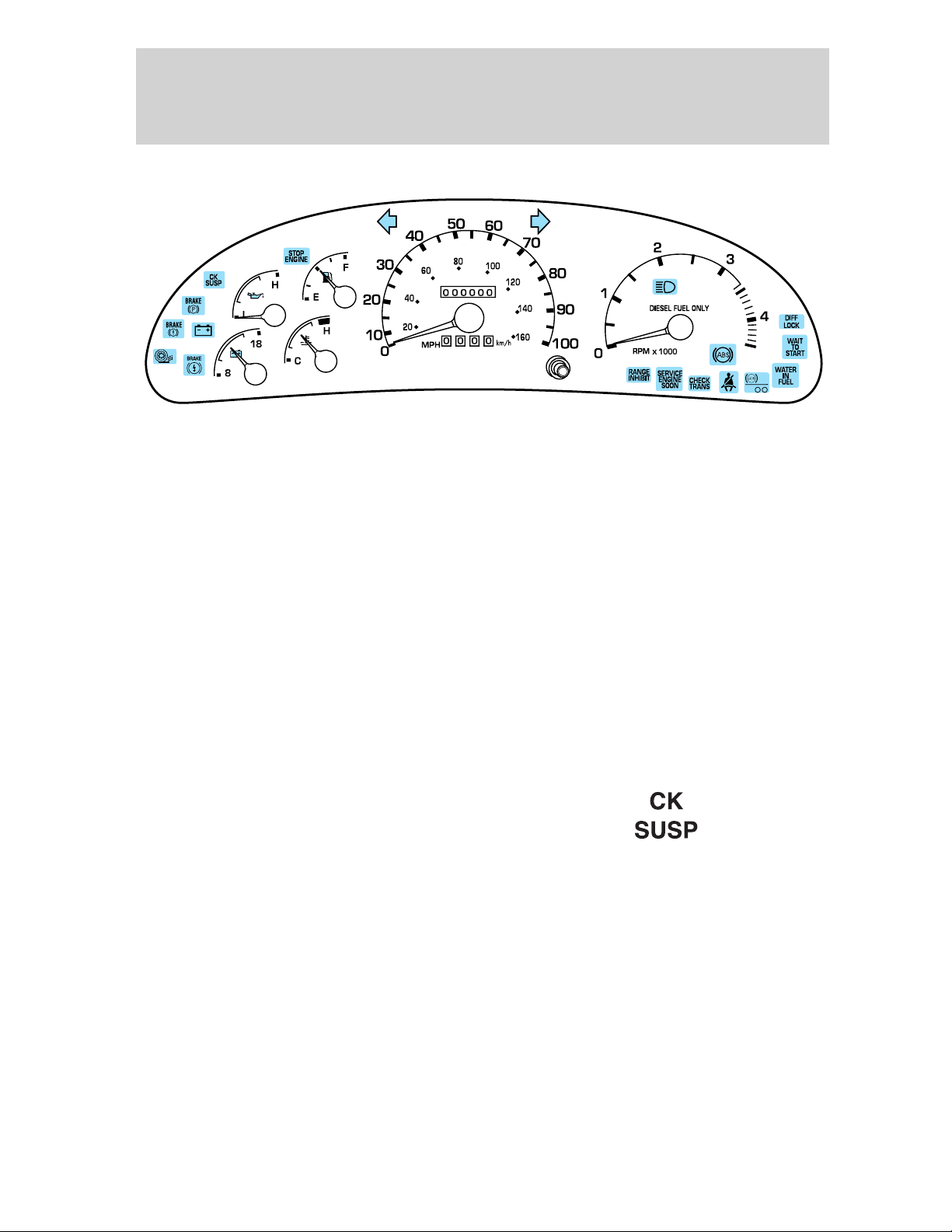

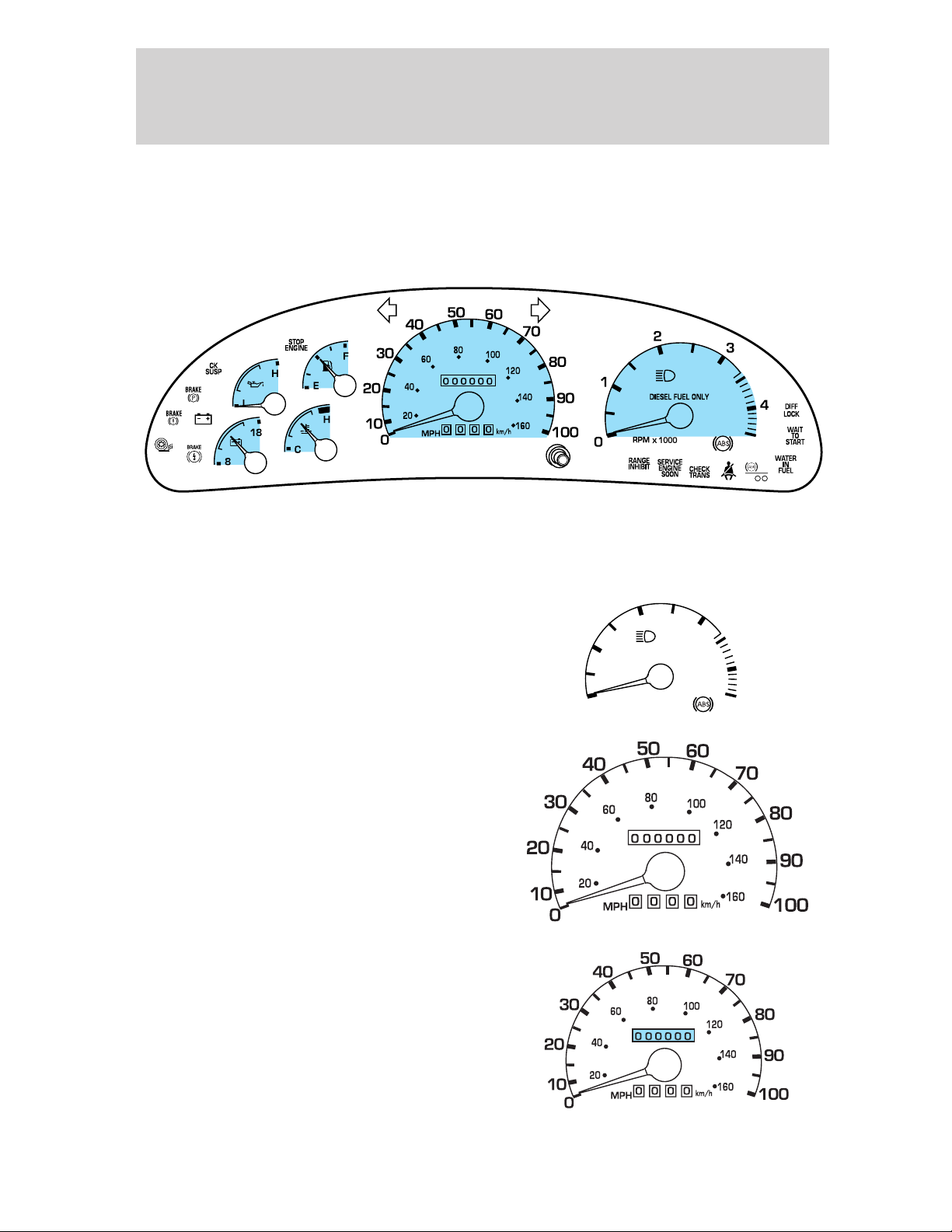

Instrument Cluster

WARNING LIGHTS AND CHIMES

Warning lights and gauges can alert you to a vehicle condition that may

become serious enough to cause expensive repairs. A warning light may

illuminate when a problem exists with one of your vehicle’s functions.

Many lights will illuminate when you start your vehicle to make sure the

bulb works. If any light remains on after starting the vehicle, have the

respective system inspected immediately.

Some of the warning lights shown are optional based on vehicle

equipment; your vehicle may not have some of the warning lights shown

in this section.

Service engine soon: If this light

illuminates while driving, it is a

possible indication that one of the

engine’s emission control systems

has failed.

Check suspension: Illuminates

when there is a fault in the

electronic subsystem of the air

suspension.

SERVICE

ENGINE

SOON

23

Instrument Cluster

Stop engine: This light is used in

conjunction with the electronic

engine control.

Refer to the Engine Operator’s Manual for specific information regarding

this feature.

If the engine shuts down, it can be restarted and operated for 30

seconds at a time or until the problem is corrected. Refer to Engine

shutdown system in the Driving chapter.

Drivers of electronically controlled engines should know the

extent of warning engine shutdown system before operating the

vehicle. This information can be obtained from your dealer.

Brake reserve system warning:

Illuminates to indicate normal

Hydromax booster reserve system

activation when the engine is OFF

and the service brake pedal is

applied.

This light may also illuminate momentarily if the engine is running and

the driver turns the steering wheel fully in one direction while braking.

If the light remains on while the engine is running, this indicates

inadequate hydraulic booster pressure or reserve pump system failure.

Stop the vehicle safely as soon as possible and seek service immediately.

STOP

ENGINE

BRAKE

Brake system warning light: To

confirm the brake system warning

light is functional, this light will

momentarily illuminate when the

ignition is turned to the ON position when the engine is not running. If

the brake system warning light does not illuminate at this time, seek

service immediately from your dealership. Illumination after starting the

vehicle indicates a pressure differential in the master cylinder and the

brake system should be inspected immediately by your dealership.

If equipped with an air brake system, the warning light stays on until the

air pressure builds up to 60 psi (414 kPa). If the air pressure drops

below 60 psi (414 kPa) during operation, the remaining brake system is

still operational but the stopping distance will be greater.

Driving a vehicle with the brake system warning light on is

dangerous. A significant decrease in braking performance may

occur. It will take you longer to stop the vehicle. Have the vehicle

checked by your dealer immediately.

24

Instrument Cluster

Wait to start: Indicates the air

WAIT

TO

START

intake heater is in operation and special starting procedures are

required. Refer to the Driving chapter.

If equipped with an air intake heater, DO NOT use ether or any

other starting fluids. The use of starting fluids (ether) in an

engine equipped with an air intake heater could result in damage

and/or personal injury.

Water in fuel: During refueling, it

is possible for water-contaminated

diesel fuel to be pumped into your

tank. Your vehicle fuel system is

equipped with a fuel filter/water

separator to remove water from the fuel. The WATER IN FUEL light will

illuminate when the fuel filter/water separator has a significant quantity

of water in it.

WATER

IN

FUEL

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the fuel

filter/water separator. Refer to Fuel filter/water separator in the

Maintenance and Specifications section for the drain procedure.

Allowing water to stay in the system could result in extensive damage to,

or failure of, the fuel injection system.

Do not drain water separator while engine is running. Fuel may

ignite if separator is drained while engine is running or vehicle is

moving.

Traction control: Illuminates when

the traction control system is turned

off.

25

Instrument Cluster

Differential lock: Illuminates when

the main differential is locked

(engaged).

Parking brake warning:

Momentarily illuminates when the

ignition is turned to the ON position

and the engine is off. Also

illuminates when the parking brake

is engaged. If the brake warning

lamp does not illuminate at these

times, seek service immediately.

Vehicles equipped with the Power Park (air-operated parking

brake) option: If after setting the parking brake on your vehicle the

park brake warning lamp begins to blink, this may indicate a failure in

the parking brake system. Seek service from your dealer immediately.

Trailer ABS brake system:

Illuminates briefly when the engine

is powered-up and only when a PLC

trailer or a PLC diagnostic tool is

connected. If the light remains on

after the vehicle is started, continues to flash or fails to illuminate, have

the system serviced immediately.

BRAKE

P

Anti-lock brake system: If the

ABS light stays illuminated or

continues to flash, a malfunction has

been detected, have the system

serviced immediately. Normal

braking is still functional unless the brake warning light also is

illuminated.

26

ABS

Instrument Cluster

Check trans (Allison automatic

transmission only): The lamp will

illuminate for several seconds after

the ignition is turned to the ON

position. Illumination of this light indicates that a problem has been

detected and shifting may be restricted. Depending upon the severity of

the problem, the read-out digit on the shifter display may be blank.

Operation may continue in order to reach service assistance. The ECU

may not respond to shift selector requests, since operating limitations

are being placed on the transmission, i.e. upshifts and downshifts may be

restricted. Direction changes will not occur.

Refer to the Transmission Operator’s Manual for more information.

Safety belt: Reminds you to fasten

your safety belt.

Range inhibit: Illuminates when

the transmission is not engaged in

the selected gear. The warning light

will go off when the gearshift lever

is adjusted in to the appropriate gear.

CHECK

TRANS

RANGE

INHIBIT

Refer to the Transmission Operator’s Manual for more information.

Charging system: Illuminates when

the battery is not charging properly.

Turn signal: Illuminates when the

left or right turn signal or the

hazard lights are turned on. If the

indicators stay on or flash faster, check for a burned out bulb.

High beams: Illuminates when the

high beam headlamps are turned on.

Safety belt warning chime: Sounds when the key is in the ignition and

the driver’s safety belt is not fastened.

Key-in-ignition warning chime: Sounds when the key is left in the

ignition in the OFF/LOCK or ACC position and the driver’s door is

opened.

27

Instrument Cluster

Headlamps on warning chime: Sounds when the headlamps or parking

lamps are on, the ignition is off (and the key is not in the ignition) and

the driver’s door is opened.

GAUGES

Some of the gauges shown are optional based on vehicle equipment; your

vehicle may not have some of the gauges shown in this section.

Tachometer: Indicates the engine

speed in revolutions per minute.

Driving with your tachometer

pointer continuously at the top of

the scale may damage the engine.

Speedometer: Indicates the

current vehicle speed.

Odometer: Registers the total miles

(kilometers) of the vehicle.

2

1

0

DIESEL FUEL ONLY

RPM

1000

X

3

4

28

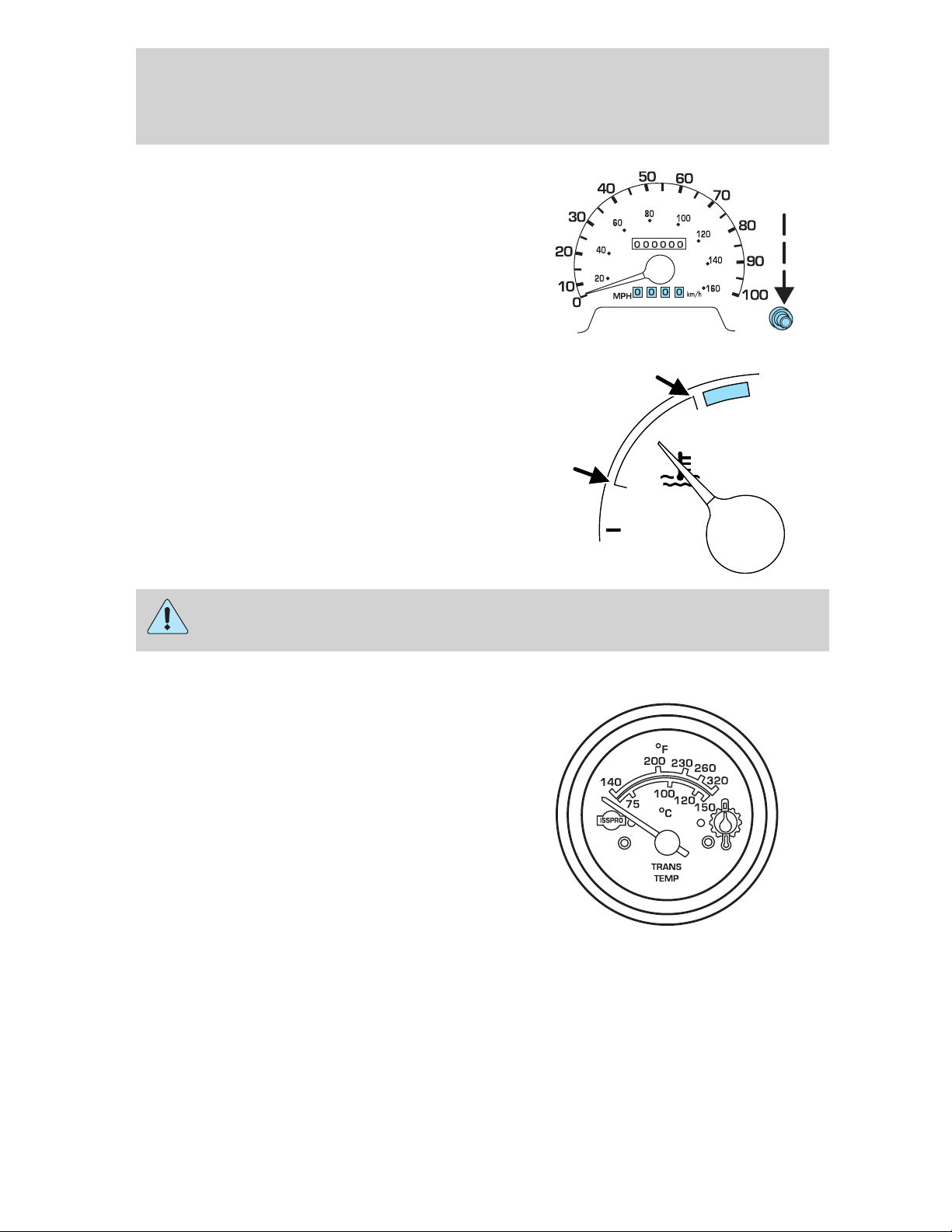

Trip odometer: Registers the miles

(kilometers) of individual journeys.

To reset, depress the control.

Engine coolant temperature

gauge: Indicates engine coolant

temperature. At normal operating

temperature, the needle will be in

the normal range (between “H” and

“C”). If it enters the red section,

the engine is overheating. Stop

the vehicle as soon as safely

possible, switch off the engine

and let the engine cool.

Instrument Cluster

H

C

Never remove the coolant reservoir cap while the engine is

running or hot.

Transmission temperature gauge

(if equipped, automatic

transmission only):

Indicates the temperature of the

transmission fluid. The normal

temperature range is 150°–230°F

(65°–110°C). Readings of

230°–250°F (110°–121°C) are

satisfactory for intermittent

operation and are not cause for

alarm. Operation above 250°F

(121°C) can cause the fluid to break down and will result in component

damage.

29

Instrument Cluster

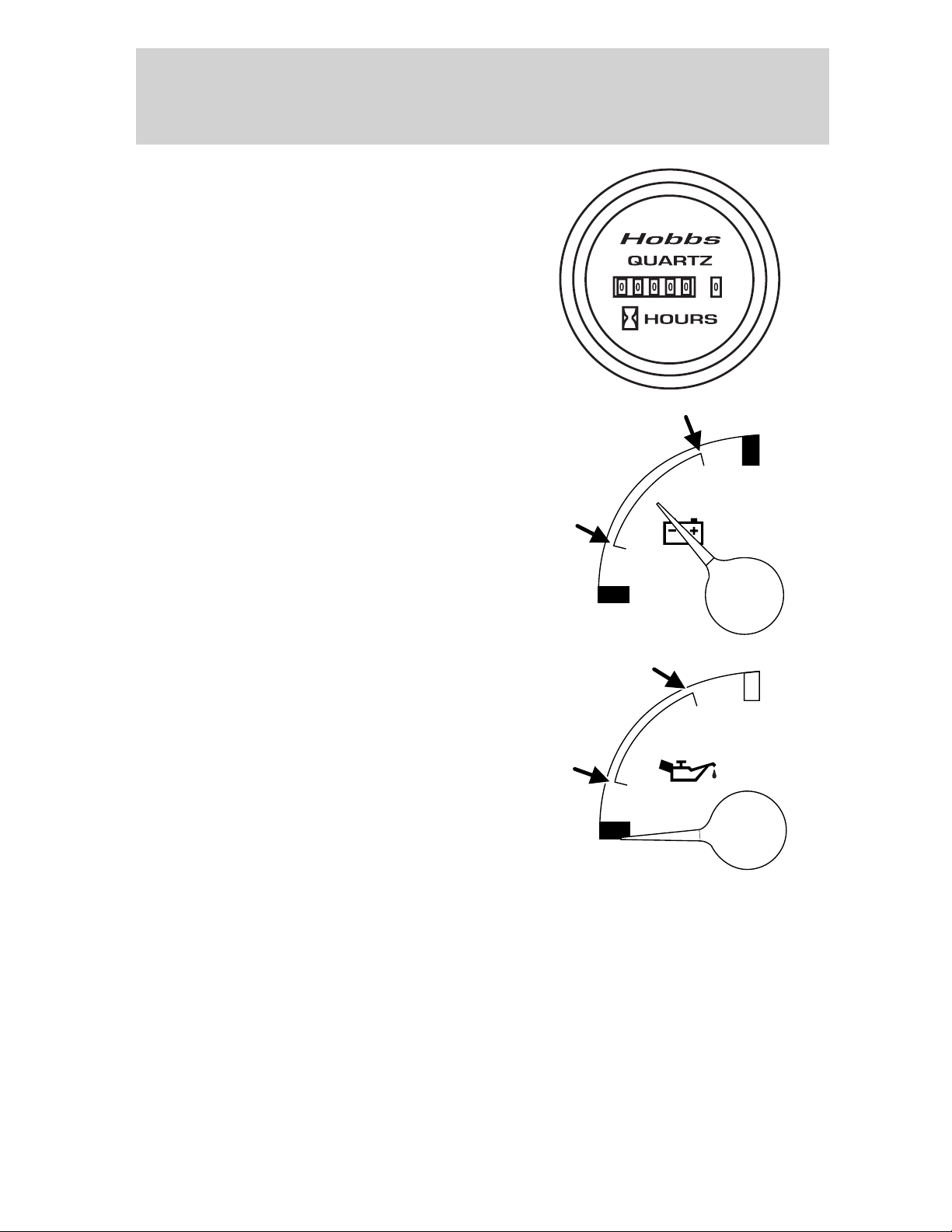

Hourmeter (if equipped):

Registers the hours the engine has

been operating.

Battery voltage gauge: Indicates

the battery voltage when the

ignition is in the ON position. If the

pointer moves and stays outside the

normal operating range (as

indicated by arrows), have the

vehicle’s electrical system checked

as soon as possible.

18

8

Engine oil pressure gauge:

Indicates engine oil pressure. The

needle should stay in the normal

operating range (as indicated by the

arrows). If the needle falls below

the normal range, stop the vehicle,

turn off the engine and check the

engine oil level. Add oil if needed. If

the oil level is correct, have your

vehicle checked at your dealership

or by a qualified technician.

H

L

30

Loading...

Loading...