Page 1

20102010

ESCAPE HYBRID

MARINER HYBRID

MODIFIERS GUIDE

FCS-15101-10

Page 2

2 Electrical

3 Mounting

4 Reference

INTRODUCTION

All rights reserved. Reproduction by any means, elec tron ic or me chan i cal, in clud ing pho to copy ing,

SECTIONS

TABLE

OF

CONTENTS

Page 3

SECTION 0

Introduction.......................................................................................0-1

Genuine Ford Accessories For Your Vehicle ..............................0-1

Introduction

Contents

Considerations When Using or Installing Accessories ............0-2

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 4

Introduction 0-1

Introduction

Note: The descriptions and specifications contained in this manual were in effect at the time this

manual was approved for printing. Ford Motor Company reserves the right to discontinue

models at any time, or change specifications or design without notice and without incurring

any obligation. All rights reserved. Reproduction by any means, electronic or mechanical,

including photocopying, recording or by any information storage and retrieval system or

translation in whole or part is not permitted without written authorization from Ford Motor

Company.

Ford Motor Company has assembled this Escape/Mariner Hybrid Modifier Guide to assist vehicle

modifiers in producing safe and quality products. Ford believes that safety and quality come first.

To achieve customer satisfaction, we want to assist modifiers in achieving the highest standards of

safety and quality in their products.

This book is divided into topics pertinent to modifiers of vehicles. Reference is made to the current

Escape/Mariner Hybrid Workshop Manual for appropriate service procedures, torque specifications,

component separation clearances and other standard information which is common with the

unmodified vehicle. Specifications which are unique to the guide are designated.

This modifier guide is not a ‘‘how-to’’ book, it should be used as a checklist to help make sure that

certain important steps in the modification process are considered. While Ford is providing this

information to assist modifiers, it does not warrant the products, methods, materials or the

workmanship of the modifier. Nor does it warrant against failures that result from the modification

of a vehicle.

Following the guidelines contained in this guide does not assure individual modifiers that the

products they modify comply with U.S. Federal or Canadian Motor Vehicle Safety Standards in

effect at the time of the modification. The guidelines set forth are based on engineering analysis of

typical vehicles. If followed, the modifier’s efforts in certifying vehicles to applicable standards

should be aided. Compliance testing that may be required for certification of specific vehicle

configurations or construction is, however, the sole responsibility of the individual modifier.

Genuine Ford Accessories For Your Vehicle

A wide selection of Genuine Ford Accessories are available for your vehicle through your local

authorized Ford or Ford of Canada dealer. These quality accessories have been specifically

engineered to fulfill your automotive needs; they are custom designed to complement the style and

aerodynamic appearance of your vehicle. In addition, each accessory is made from high quality

materials and meets or exceeds Ford’s rigorous engineering and safety specifications. Ford Motor

Company will repair or replace any properly dealer-installed Genuine Ford Accessory found to be

defective in factory-supplied materials or workmanship during the warranty period, as well as any

component damaged by the defective accessory. The accessory will be warranted for whichever

provides you the greatest benefit:

• 12 months or 12,000 miles (20,000 km) (whichever occurs first), or

• the remainder of your new vehicle limited warranty.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 5

0-2 Introduction

Introduction

This means that Genuine Ford Accessories purchased along with your new vehicle and installed

by the dealer are covered for the full length of your New Vehicle’s Limited Warranty — 3 years or

36,000 miles (60,000 km) (whichever occurs first). Contact your dealer for details and a copy of

the warranty.

Considerations When Using or Installing Accessories

For maximum vehicle performance, keep the following information in mind when adding

accessories or equipment to your vehicle:

• When adding accessories, equipment, passengers and luggage to your vehicle, do not exceed

the total weight capacity of the vehicle or of the front or rear axle (GVWR or GAWR as indicated

on the Safety Compliance Certification label). Consult your dealer for specific weight information.

• The Federal Communications Commission (FCC) and Canadian Radio Telecommunications

Commission (CRTC) regulate the use of mobile communications systems — such as 2-way

radios, telephones and theft alarms that are equipped with radio transmitters. Any such

equipment installed in your vehicle should comply with FCC or CRTC regulations and should be

installed only by a qualified service technician.

• Mobile communications systems may harm the operation of your vehicle, particularly if they are

not properly designed for automotive use.

• To avoid interference with other vehicle functions, such as anti-lock braking systems, amateur

radio users who install radios and antennas onto their vehicle should not locate the Amateur

Radio Antennas in the area of the driver’s side hood.

• Electrical or electronic accessories or components that are added to the vehicle by the dealer or

the owner may adversely affect battery performance and durability.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 6

SECTION 1

Section 1: General Information........................................................1-1

Important Safety Notice................................................................1-1

General Information

Contents

Notes, Notices and Warnings...................................................1-2

Making Safety Devices and Elements Inoperative...................1-3

Good Practices .............................................................................1-3

Process and Quality Assurance Systems ................................1-3

Quality Assurance.....................................................................1-4

Minimum and Maximum Screw Sizes ......................................1-4

Tires and Loading.........................................................................1-4

Tire Replacement Requirements ..............................................1-4

Using Snow Tires and Traction Devices ..................................1-5

Vehicle Loading ........................................................................1-5

Vehicle Storage ............................................................................1-6

Vehicle Storage — General......................................................1-6

Vehicle Storage — Electrical....................................................1-6

Vehicle Storage — Body ..........................................................1-7

Vehicle Storage — Engine .......................................................1-7

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 7

SECTION 1

Contents (Continued)

Vehicle Storage — Fuel System ..............................................1-7

Vehicle Storage — Tires...........................................................1-7

General Information

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 8

General Information 1-1

Section 1: General Information

Important Safety Notice

Note: The descriptions and specifications contained in this guide were in effect at the time this

manual was approved for printing. Ford Motor Company reserves the right to discontinue

models at any time, or change specifications or design without notice and without incurring

obligation.

Appropriate repair methods and procedures are essential for the safe, reliable operation of all

motor vehicles as well as the personal safety of the individual doing the work. This manual

provides general directions and guidelines for performing modifications to the Escape/Mariner

Hybrid. Following them will help assure reliability.

There are numerous variations in procedures, techniques, tools and parts for modifying vehicles,

as well as in the skill of the individual doing the work. This manual cannot possibly anticipate all

such variations and provide advice or cautions as to each. Accordingly, anyone who departs from

the instructions provided in this manual must first establish that he compromises neither his

personal safety nor the vehicle integrity by his choice of methods, tools or parts.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 9

1-2 General Information

Section 1: General Information

Notes, Notices and Warnings

As you read through this guide, you will come across NOTES, NOTICES and WARNINGS. Each

one is there for a specific purpose. NOTES give you added information that will help you to

complete a particular procedure. NOTICES are given to prevent you from making an error that

could damage the vehicle. WARNINGS remind you to be especially careful in those areas where

carelessness can cause you personal injury. The following list contains some general warnings

that you should follow when you work on a vehicle.

WARNING:

• Before carrying out any vehicle modifications, the high-voltage traction battery (HVTB)

must be depowered. Failure to follow these instructions may result in severe personal

injury or death.

• The nominal HVTB voltage is 330 volts DC. A buffer zone must be set up and high-voltage

insulated safety gloves and a face shield must be worn when modifying the vehicle in

close proximity to the high-voltage system. Failure to follow these instructions may result

in severe injury or death.

• The HVTB and charging system contain high-voltage components and wiring.

High-voltage cables and wiring are orange in color. High-voltage insulated safety gloves

and a face shield must be worn when modifying the vehicle in close proximity to the

high-voltage system. Failure to follow these instructions may result in severe personal

injury or death.

• The high-voltage insulated safety rubber insulating gloves that are to be worn when

modifying the vehicle in close proximity to the high-voltage system should be of the

appropriate safety and protection rating for use on the high-voltage system. They must be

inspected before use and must always be worn in conjunction with the leather outer

gloves. Any hole in the rubber insulating glove is a potential entry point for high voltage.

Failure to follow these instructions may result in severe personal injury or death.

• Exposure to high voltage may result in severe personal injury or death. High-voltage

components must be serviced by a trained service technician.

• Always wear safety glasses for eye protection.

• Use safety stands whenever a procedure requires you to be under the vehicle.

• Make sure that the ignition switch is always in the OFF position, unless otherwise

required by the procedure.

• Set the parking brake when working on the vehicle. The gear selector should be set in

PARK unless instructed otherwise for a specific operation. Place wood blocks (4 inch x 4

inch or larger) against the front and rear surfaces of the tires to help prevent the vehicle

from moving.

• Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide

poisoning.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 10

General Information 1-3

Section 1: General Information

• Keep yourself and your clothing away from moving parts when the engine is running,

especially the drive belts.

• To reduce the risk of serious burns, avoid contact with hot metal parts such as the

radiator, exhaust manifold, tailpipe, catalytic converter and muffler.

• Do not smoke while working on a vehicle.

• To reduce the risk of injury, always remove rings, watches, loose hanging jewelry and

loose clothing before beginning to work on a vehicle.

• When it is necessary to work under the hood, keep hands and other objects clear of the

radiator fan blades.

• Failure to follow these instructions may result in personal injury.

NOTICE:

• Do not disable the A/C system. The high voltage traction battery (HVTB) cooling system

uses the cabin air to cool the HVTB.

• Before placing the vehicle in a paint booth, make sure that the high-voltage traction

battery (HVTB) is not installed in the vehicle. High paint booth temperatures may damage

the HVTB.

• Place the service disconnect plug into the SERVICING SHIPPING position while carrying

out any vehicle modifications. If the service disconnect plug is left out and placed on the

bench or toolbox, dirt or other contaminants may enter the HVTB, which can cause

damage.

Making Safety Devices and Elements Inoperative

The vehicle contains many safety features required by Federal or Canadian Motor Vehicle Safety

Standards. These features, which include the key-in-ignition chime and brake lights, should never

be disabled or modified.

CFR 49 Section 30122 states that ‘‘A manufacturer, distributor, dealer or motor vehicle repair

business may not knowingly make inoperative any part of a device or element of design installed

on or in a motor vehicle or motor vehicle equipment in compliance with an applicable motor vehicle

safety standard prescribed under this chapter unless the manufacturer, distributor, dealer or repair

business reasonably believes the vehicle or equipment will not be used (except for testing or a

similar purpose during maintenance or repair) when the device or element is inoperative.’’

Good Practices

Process and Quality Assurance Systems

A formalized Process and Quality Assurance Systems check may be helpful in consistently

producing high quality products. An overview of some of the key items for such a system are

outlined in this section.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 11

1-4 General Information

Section 1: General Information

Quality Assurance

Completed unit sign-off: All control items should be inspected with a written sign-off. All labels

should be inspected and signed off, including verification that the information on the labels is

correct. All appropriate systems should be checked for leaks. A road test should be performed to

verify that all systems are operating correctly. All systems and functions that were provided by

Ford should be checked to make sure that they function correctly after the build process.

The modifier’s Process and Quality Assurance Systems should also make sure that appropriate

training is provided to the employees.

Minimum and Maximum Screw Sizes

When installing aftermarket equipment, avoid using fasteners that are too long for the application

or are in an area which might damage vehicle components, including wiring, brake lines, fuel tank

and lines, powertrain components, exhaust system and suspension.

Tires and Loading

Tire Replacement Requirements

WARNING: Only use replacement tires and wheels that are the same size and type

(such as P-metric versus LT-metric or all-season versus all-terrain) as those originally

provided by Ford. Use of any tire or wheel not recommended by Ford can affect the safety

and performance of your vehicle, which could result in an increased risk of loss of vehicle

control, vehicle rollover, personal injury and death. Additionally the use of

non-recommended tires and wheels could cause steering, suspension, axle or transfer

case/power transfer unit failure. If you have questions regarding tire replacement, see an

authorized Ford or Lincoln Mercury dealer.

WARNING: Do not install an offroad, aggressive tread or incorrectly sized tire. Any of

these may cause elevated stress to the steering system. This can cause the power steering

system to overheat and shut off the power assist, which can affect the safety and

performance of your vehicle.

Note: The Escape/Mariner Hybrid vehicle is equipped with a reduced rolling resistance tire

design. The use of a different tire can effect the fuel economy of your vehicle.

Make sure all tires and wheels on the vehicle are of the same size, type, tread design, brand,

load-carrying capacity and speed rating because it can affect the safety and performance of your

vehicle, which could result in an increased risk of loss of vehicle control, vehicle rollover, personal

injury and death.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 12

General Information 1-5

Section 1: General Information

Using Snow Tires and Traction Devices

Note: Snow tires must be the same size and grade as originally equipped on your vehicle.

The tires on your vehicle have all-weather treads to provide traction in rain and snow. However, in

some climates, using snow tires or traction devices may be necessary.

Follow these guidelines when using snow tires and traction devices:

• SAE Class ‘‘S’’ cables should ONLY be used on the front axle tires.

• Install cables or chains securely, verifying that the cables or chains do not touch any wiring,

brake lines or fuel lines.

• Drive cautiously. If you hear the cables or chains rub or bang against the vehicle, stop and

retighten them. If this does not work, remove the cables or chains to prevent vehicle damage.

• Avoid overloading your vehicle.

• Remove the cables or chains when they are no longer needed.

• Do not use cables or chains on dry roads.

• Do not exceed 48 km/h (30 mph) with tire cables or chains on your vehicle.

Consult your dealer for information on other Ford approved methods of traction control.

Vehicle Loading

WARNING: The appropriate loading capacity of your vehicle can be limited either by

volume capacity (how much space is available) or by payload capacity (how much weight

the vehicle should carry). Once you have reached the maximum payload of your vehicle, do

not add more cargo, even if there is space available. Overloading or improperly loading

your vehicle can contribute to loss of vehicle control and vehicle rollover.

WARNING: Exceeding the Safety Compliance Certification Label axle and/or vehicle

weight rating limits could result in substandard vehicle handling or performance, engine,

transmission and/or structural damage, serious damage to the vehicle, loss of control and

personal injury.

Gross Vehicle Weight Rating (GVWR) — is the maximum allowable weight of the fully loaded

vehicle (including all options, equipment, passengers and cargo). The GVWR is shown on the

Safety Compliance Certification Label located on the B-pillar or the edge of the driver’s door.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 13

1-6 General Information

Section 1: General Information

Gross Axle Weight Rating (GAWR) — is the maximum allowable weight that can be carried by a

single axle (front or rear). These numbers are shown on the Safety Compliance Certification Label

located on the B-pillar or the edge of the driver’s door. The total load on each axle must never

exceed its GAWR.

WARNING: Do not use replacement tires with lower load carrying capacities than the

original tires because they may lower the vehicle’s Gross Vehicle Weight Rating (GVWR)

and Gross Axle Weight Rating (GAWR) limitations. Replacement tires with a higher limit

than the originals do not increase the GVWR and GAWR limitations.

Steps for determining the correct load limit:

• Locate the statement ‘‘The combined weight of occupants and cargo should never exceed XXX

kg or XXX lb’’ on your vehicle’s placard.

• Determine the combined weight of the driver and passengers that will be riding in your vehicle.

• Subtract the combined weight of the driver and passengers from XXX kg or XXX lb.

• The resulting figure equals the available amount of cargo and luggage load capacity. For

example, if the ‘‘XXX’’ amount equals 1,400 lb and there will be five 150 lb passengers in your

vehicle, the amount of available cargo and luggage load capacity is 650 lb (1400 - 750 (5 x 150)

= 650 lb). In metric units (635 - 340 (5 x 68) = 295 kg).

• Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight

may not safely exceed the available cargo and luggage load capacity calculated in the step

above.

Vehicle Storage

Vehicle Storage — General

• Vehicles should be stored in a dry, ventilated place and protected from sunlight, if possible.

• If vehicles are stored outside, maintenance against rust and damage, as described below, is

recommended.

NOTICE: Keep all rubber parts free from oil and solvents.

Vehicle Storage — Electrical

Note: Extended storage times which result in the discharge of the low- or high-voltage batteries

may result in the setting of DTCs and/or a no start condition.

Your vehicle must be started and run for a minimum of 10 minutes once a month in order to

maintain the high-voltage battery charge. This will maintain the high-voltage battery but it is not

enough to maintain the low-voltage (underhood) battery and additional low-voltage (underhood)

battery charging may be required after 60 days.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 14

General Information 1-7

Section 1: General Information

If your vehicle is to be stored for 30 days or longer, the low-voltage (underhood) battery negative

terminal must be disconnected. Failure to do this could damage your vehicle’s battery systems.

Vehicle Storage — Body

• Wash vehicle thoroughly to remove dirt, grease, oil, tar or mud from exterior surfaces and

underside of front fender.

• Periodically wash vehicles stored in exposed locations.

• Touch up exposed raw or primed metal to provide rust protection.

• Cover chrome and stainless steel parts with a thick coat of auto wax to prevent discoloration.

Rewax as necessary when the vehicle is washed.

• Lubricate all hood, door hinges and latches with a light grade oil.

• Cover the interior soft trim to prevent fading.

Vehicle Storage — Engine

• Start the engine every month. Run it at fast idle until it reaches normal operating temperature.

• With foot on brake pedal (and brake applied), shift the transmission into all gears while the

engine is running.

Vehicle Storage — Fuel System

• Regularly move vehicles short distances to mix fuel anti-oxidation agents.

Note: During extended periods of vehicle storage (60 days or more), gasoline may deteriorate

due to oxidation. This can damage rubber and other polymers in the fuel system and may

clog small orifices. A commercially available gasoline fuel stabilizer (Sta-Bil or equivalent)

should be added to gasoline-powered vehicles whenever actual or expected storage

periods exceed 60 days. The manufacturer’s instructions packaged with the product should

be followed. The vehicle should then be operated at an idle speed to circulate the additive

throughout the fuel system.

Vehicle Storage — Tires

Most high performance tires are made with nylon overlay.

As such, the following steps should be taken to avoid flat spotting when the vehicles are not used

for a period of time.

• Store the vehicles with 303 kPa (44 psi) in the tires. If the cars are to be driven, the air pressure

should be reduced to recommended operating pressure and then increased back up to 303 kPa

(44 psi) when returned to storage.

• If the vehicle is stored for periods longer than 30 days, it should be moved several feet at least

once during each 30-day period, so that a different portion of the tread contacts the ground.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 15

SECTION 2

Section 2: Electrical .........................................................................2-1

Electrical Basics ...........................................................................2-1

Electrical

Contents

Electrical Terms ........................................................................2-1

Control Modules — Red Area......................................................2-2

Controller Area Network (CAN) Bus ............................................2-2

General Electrical Considerations ................................................2-2

Communication Equipment.......................................................2-2

Vehicle Speed Signal................................................................2-2

Disabling Brake Lights ..............................................................2-2

High- and Low-Voltage Systems..................................................2-2

12-Volt Battery ..........................................................................2-3

High-Voltage Traction Battery (HVTB) .....................................2-3

DC/DC Converter......................................................................2-4

DC/AC Inverter and AC Power Point .......................................2-4

Auxiliary Power Point — 12V ...................................................2-5

Buffer Zone...................................................................................2-5

Rubber Insulating Gloves Testing................................................2-6

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 16

SECTION 2

Contents (Continued)

High-Voltage Traction Battery (HVTB) Systems

Depowering.................................................................................2-7

Electrical Systems Management ..................................................2-9

Electrical

Generator Output..........................................................................2-9

Vehicle Component Electrical Loads ...........................................2-9

Typical Police/Taxi Equipment................................................2-10

General Guidelines.....................................................................2-11

Keep-Alive Memory Power .....................................................2-12

Equipment Grounding Guidelines...........................................2-12

Wire Insulation ........................................................................2-12

Terminals and Connectors......................................................2-12

Circuit Protection and Electrical Load ....................................2-13

Wire Protection Requirements................................................2-14

Grommets and Sealing Requirements ...................................2-16

Wire Routing ...........................................................................2-16

Wire Retention and Routing ...................................................2-18

Splices and Repairs ...................................................................2-20

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 17

SECTION 2

Contents (Continued)

Recommended Splicing Method — Solder (For 16

AWG and Smaller Diameter Wire Only)...............................2-20

Heat Shrinkable Tubing (Heat Shrink) (Ford

Specification ESB-M99D56-A2) ............................................2-23

Electrical

Recommended Splicing Method — Crimp (For 10 -

22 AWG Diameter Wire to Like Wire Diameter) ..................2-23

Wiring Reference Information.....................................................2-26

Wiring Diagrams .....................................................................2-26

Connector End Views .............................................................2-29

Connector and Ground Locator..............................................2-31

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 18

Electrical 2-1

Section 2: Electrical

Electrical Basics

Inside a vehicle, electricity is supplied through ‘‘hot’’ wires, comparable to the pressurized supply

pipes of a plumbing system. At various points along the wires are outlets in the form of lights,

switches and receptacles. Turning on a light switch is somewhat like opening a faucet to let water

run, an electric current flows through the hot wire to make the light glow. Once the electricity has

done its work, its potential drops to zero, just as water loses pressure after flowing through a sink

or laundry tub. The electrical system has ‘‘drains’’, which are the ground wires that return the

current to its source, just as a plumbing system has drain pipes through which water runs into the

sewer mains or the ground.

The light or equipment powered by the current, technically called the load, can be compared to a

water wheel that remains motionless until a stream of water causes it to turn. A load may be one

of 2 kinds. The first consists of a resistance, a material that permits the passage of electric

current, but only with difficulty and thereby creates heat. The tungsten filament of an incandescent

bulb is resistance; so is the heating element of an electric heater of a coffee pot. A load may also

be an inductance, typically a motor with windings of copper wire, in which the magnetic fields

generated by the current create motion. At any moment, the demand on an electrical system

depends on the number of loads in operation and their consumption of energy, just as demand on

a water system depends on how many faucets are opened and how wide they are opened.

The mechanics and physical fittings of the system are simple. Current moves throughout the

vehicle in wires of different sizes, according to the current a circuit may have to carry. Power is

supplied directly to equipment through connectors.

Electrical Terms

VOLT is the unit of electrical potential, equal to the difference of electrical potential between 2

points on a circuit.

AMPERE is the unit used to measure the amount of current, that is, the number of electrically

charged particles called electrons, that flows past a given point on a circuit each second. It is

similar to measuring the amount of water flowing through a pipe at any given point. The larger the

pipe is, the more water that can flow past the point per second. Similarly, the bigger the wire is,

the more current that can flow through it at any given point. Current that has lost its voltage still

has amperage as it completes the circuit and returns to the battery.

WATT is the unit of power. It indicates that rate at which a device converts electric current to

another form of energy, either heat or motion, or to put it another way, the rate at which a device

consumes energy.

The relationship of volts, amperes and watts to one another is expressed in a simple equation that

enables you to make any calculations you may need for proper and safe electrical modifications to

the vehicle. Volts x amperes = watts. If the current is at 12 volts and a device requires 4 amperes

of current, the equation will read 12 volts x 4 amperes = 48 watts.

To figure the current needed for a device rated in watts, turn the equation around: Watts/volts =

amperes. For example, if you have a piece of equipment, such as a communications radio, that

uses 120 watts: 120 watts/12 volts = 10 amperes.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 19

2-2 Electrical

Section 2: Electrical

Control Modules — Red Area

Do not install any components into the control modules or module harness. Connecting into this

system may affect control module operation. As an example: connection of aftermarket electrical

equipment into the brake light circuit or any other circuit which is connected to the PCM, anti-lock

brake computer, air bag system or any other vehicle system will cause vehicle malfunction.

Controller Area Network (CAN) Bus

NOTICE: Wiring faults in the controller area network (CAN) bus may shut down the vehicle

and prevent further operation.

Do not splice or connect any equipment to the controller area network (CAN) bus wiring.

General Electrical Considerations

Communication Equipment

Mobile communication systems may harm the operation of the vehicle, particularly if they are not

properly designed for automotive use or are not properly installed. For example, when operated,

such systems may cause the engine to stumble or stall. Citizen band (CB) transceivers, garage

door openers and other transmitters whose power output is 5 watts or less will not ordinarily affect

the operation of the vehicle.

Vehicle Speed Signal

The vehicle speed signal is sent from the PCM to other vehicle modules through the CAN bus.

There is no specific wire or circuit that carries the vehicle speed signal pulses.

Disabling Brake Lights

Do not disable the brake light circuits for any reason.

Disabling the A/C System

Do not disable the A/C system. The cabin air is used to cool the high voltage traction battery

(HVTB).

High- and Low-Voltage Systems

NOTICE: Do not splice the high-voltage system. Voltage in the system is in the range of 216

to 397 volts. Damage may occur to equipment added to the system.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 20

Electrical 2-3

Section 2: Electrical

The high-voltage system has a floating ground. When the engine is operating or the vehicle is

moving, the high-voltage generator begins to generate high voltage, AC electricity. High-voltage

AC electricity can be consumed or generated by the motor generator, the traction motor or a

combination of both motors. Excess high-voltage current is converted from high-voltage AC to

high-voltage DC electrical power inside the motor generator unit and transmitted through the

high-voltage cables. The high-voltage DC electrical power is converted to low-voltage DC electrical

power through the DC/DC converter. This low-voltage DC electrical power is then supplied to the

12-volt battery through the low-voltage battery cables.

12-Volt Battery

The 12-volt battery is a standard automotive battery. It is a DC source connected in a negative

ground system. The battery case is sealed, with 2 vent holes to release gases. The battery has 3

major functions:

• Storage of electricity for later use

• Voltage stabilizer for the electrical system

• Temporary power source when electrical loads exceed the DC/DC converter output current

High-Voltage Traction Battery (HVTB)

NOTICE: Do not splice the high-voltage wiring. Voltage in the system is in the range of 216

to 397 volts. Damage may occur to equipment added to the system.

The high-voltage traction battery (HVTB) is a 216-397 volt DC source connected in a floating

ground system. The battery receives, stores and delivers high-voltage electrical power when

required. It contains the traction battery control module (TBCM), which controls the higher

functions of the battery. The TBCM also estimates the state of charge, estimates the power

available, estimates the power it can absorb and controls the battery temperature. The TBCM

controls the battery temperature by activating or deactivating the fans contained within the HVTB.

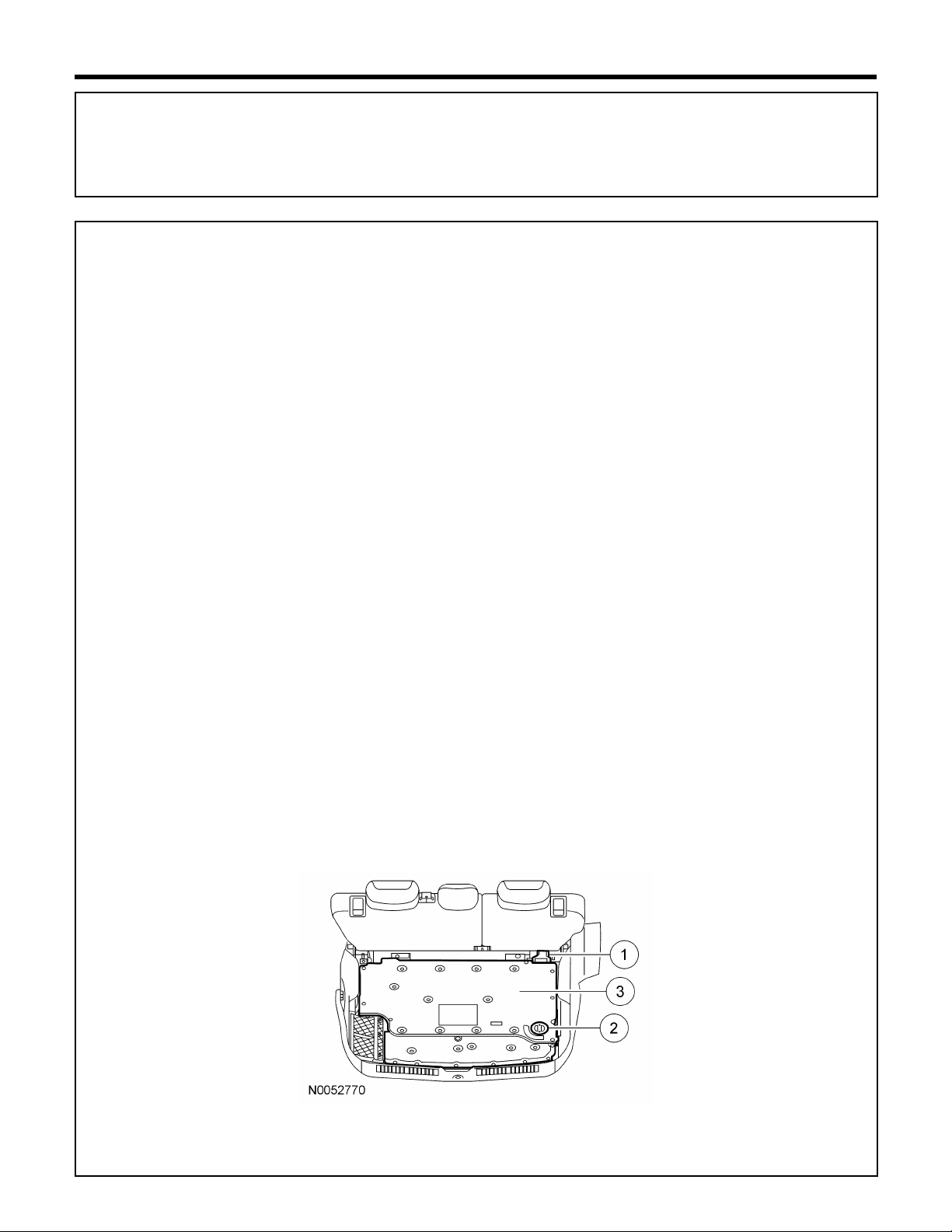

Figure 1.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 21

2-4 Electrical

Section 2: Electrical

1. High-voltage connector shield

2. Service disconnect

3. High-voltage battery case

DC/DC Converter

The DC/DC converter is a liquid-cooled component that converts high-voltage (216-397 volts) DC

power to low-voltage (12 volts) DC power while maintaining electrical isolation between the 2 DC

power systems. The converter steps down the high voltage to 12 volts, providing power to the

vehicle low-voltage battery systems. The PCM controls the operation of the DC/DC converter

through an enable input from the PCM to the DC/DC converter.

DC/AC Inverter and AC Power Point

Note: Do not keep electrical devices plugged in the power point whenever the device is not in

use. It is not recommended to use any extension cord with the 110 VAC power point, since

it will defeat the safety protection design provided by the cap and twist tab. It will also

cause the power point to overload due to powering multiple devices that can reach beyond

the 150 watt load limit.

The DC/AC inverter converts 12-volt DC to 110-volt AC to power a device that uses AC current

with a rating of less than 150 watts. The power point will automatically shut off if the load exceeds

150 watts. This prevents damage to the inverter or load. The inverter supplies 110-volt AC power

only when the key is in the ON/START position. This reduces the draw on the 12-volt system

when the vehicle is not running. The DC/AC inverter outlet (AC power point) is equipped with a

green LED that indicates the system integrity. The green LED illuminates continuously when the

key is in the ON/START position and the system is operating normally. The green LED flashes

constantly if the key is in the ON/START position and a fault is detected. Short circuits, overloads

or overheating of the inverter will cause the green LED to flash and the power to be cut off to the

outlet. If the LED is flashing, the problem must be corrected (that is, short circuit or excessive

load). If the inverter is overheated, it must be allowed time to cool off (without the load connected).

The power outlet is not designed for the following electric appliances; they may not work properly:

• Cathode ray tube-type televisions

• Motor loads, such as vacuum cleaners, electric saws and other electric power tools,

compressor-driven refrigerators

• Measuring devices, which process precise data, such as medical equipment, measuring

equipment

• Other appliances requiring an extremely stable power supply: microcomputer-controlled electric

blankets, touch sensor lamps

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 22

Electrical 2-5

Section 2: Electrical

Auxiliary Power Point — 12V

NOTICE: Power outlets are designed for accessory plugs only. Do not insert any other

object in the power outlet as this will damage the outlet and blow the fuse. Do not hang any

type of accessory or accessory bracket from the plug. Improper use of the power outlet can

cause damage not covered by your warranty.

Note: Do not use the power point for operating the cigarette lighter element (if equipped).

To prevent the fuse from being blown, do not use the power point(s) over the vehicle capacity of

12-VDC/180W.

To prevent the battery from being discharged, do not use the power point longer than necessary

when the engine is not running.

Buffer Zone

WARNING: The nominal high-voltage traction battery (HVTB) voltage is 330 volt DC. A

buffer zone must be set up and high-voltage insulated safety gloves and a face shield must

be worn when modifying the vehicle in close proximity to the high-voltage system. Failure

to follow these instructions may result in severe injury or death.

WARNING: The high-voltage traction battery (HVTB) and charging system contains

high-voltage components and wiring. High-voltage cables and wiring are orange in color.

High-voltage insulated safety gloves and a face shield must be worn when carrying out any

modifications on this vehicle. Failure to follow these instructions may result in severe

personal injury or death.

WARNING: Before carrying out any vehicle modifications, the high-voltage traction

battery (HVTB) must be depowered. Failure to follow these instructions may result in severe

personal injury or death.

WARNING: The high-voltage insulated safety rubber insulating gloves that are to be

worn while working on the high-voltage system should be of the appropriate safety and

protection rating for use on the high-voltage system. They must be inspected before use

and must always be worn in conjunction with the leather outer gloves. Any hole in the

rubber insulating glove is a potential entry point for high voltage. Failure to follow these

instructions may result in severe personal injury or death.

1. Position the vehicle in the repair bay.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 23

2-6 Electrical

Section 2: Electrical

2. Position 4 orange cones around the corners of the vehicle to mark off a 1 m (3 ft) perimeter

around the vehicle.

3. Do not allow any unauthorized personnel into the buffer zone during repairs involving the

high-voltage system. Only personnel trained for repair on the high-voltage system are to be

permitted in the buffer zone.

Rubber Insulating Gloves Testing

WARNING: The high-voltage insulated safety rubber insulating gloves that are to be

worn when modifying the vehicle in close proximity to the high-voltage system, should be

of the appropriate safety and protection rating for use on the high-voltage system. They

must be inspected before use and must always be worn in conjunction with the leather

outer gloves. Any hole in the rubber insulating glove is a potential entry point for high

voltage. Failure to follow these instructions may result in severe personal injury or death.

Note: The high-voltage insulated safety gloves must be re-certified every 6 months to remain

within OSHA guidelines.

1. Roll the glove up from the open end until the lower portion of the glove begins to balloon from

the resulting air pressure. If the glove leaks any air, it must not be used.

2. The gloves should not be used if they show any signs of wear and tear.

3. The leather gloves must always be worn over the rubber insulating gloves in order to protect

them.

4. The rubber insulating gloves must be class ‘‘00’’ and meet all of the American Society for

Testing and Materials (ASTM) standards.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 24

Electrical 2-7

Section 2: Electrical

High-Voltage Traction Battery (HVTB) Systems Depowering

WARNING: The nominal high-voltage traction battery (HVTB) voltage is 330 volt DC. A

buffer zone must be set up and high-voltage insulated safety gloves and a face shield must

be worn when modifying the vehicle in close proximity to the high-voltage system. Failure

to follow these instructions may result in severe injury or death.

WARNING: The high-voltage traction battery (HVTB) and charging system contains

high-voltage components and wiring. High-voltage cables and wiring are orange in color.

High-voltage insulated safety gloves and a face shield must be worn when modifying the

vehicle in close proximity to the high-voltage system. Failure to follow these instructions

may result in severe personal injury or death.

WARNING: Before carrying out any vehicle modifications, the high-voltage traction

battery (HVTB) must be depowered. Failure to follow these instructions may result in severe

personal injury or death.

WARNING: The high-voltage insulated safety rubber insulating gloves that are to be

worn when modifying the vehicle in close proximity to the high-voltage system, should be

of the appropriate safety and protection rating for use on the high-voltage system. They

must be inspected before use and must always be worn in conjunction with the leather

outer gloves. Any hole in the rubber insulating glove is a potential entry point for high

voltage. Failure to follow these instructions may result in severe personal injury or death.

WARNING: A buffer zone is required when modifying the vehicle in close proximity to

the high voltage system. Failure to follow this instruction may result in severe personal

injury or death.

1. Set up the buffer zone around the vehicle. For additional information, refer to Buffer Zone in

this section.

2. Turn the ignition to the OFF position.

3. Disconnect the 12-volt battery.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 25

2-8 Electrical

Section 2: Electrical

4. Remove the service disconnect plug.

a. Rotate the service disconnect plug from the LOCK (1) position to the UNLOCK (2) position.

b. Remove the service disconnect plug and place in the SERVICE SHIPPING (3) position.

5. NOTICE: Place the service disconnect plug into the SERVICE SHIPPING position while

carrying out any vehicle modifications. If the service disconnect plug is left out and

placed on the bench or toolbox, dirt or other contaminants may enter the high voltage

traction battery (HVTB), which can cause damage.

Insert the service disconnect plug into the SERVICE SHIPPING position. This disconnects the

HVTB.

6. To connect, reverse the disconnect procedure.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 26

Electrical 2-9

Section 2: Electrical

Electrical Systems Management

Care must be given in deciding what equipment should be installed into a vehicle given the power

demands of the equipment and the power available from the vehicle. A power load strategy should

be developed to minimize the risk of running out of power. Examine the proposed equipment for

vehicle installation. Add up the current requirements. If the current requirements exceed what the

vehicle can reasonably be expected to be able to provide, the battery will begin discharging to

provide the power to the equipment that the generator is unable to provide. After some period of

time, the vehicle will shut off as the battery voltage decreases to a level that cannot sustain

vehicle operation.

There are alternatives that can be considered to minimize system electrical overload. Consider

the current requirements of equipment before it is purchased and installed. Modern light bars and

radios use a fraction of the current than units made as recently as 1996. As the light bar is the

most power intensive unit installed on most vehicles, considerable attention should be given to its

current requirements. Changes in driver habits can make a difference as well. When a vehicle is

sitting and no one is in the car, the air conditioner can be turned off until the driver is ready to get

back into the vehicle. The air conditioner is among the largest current user of OEM equipment.

As such, it can impact available power for other uses as well.

Generator Output

The Escape/Mariner Hybrid generator is different from that used on the standard Escape/Mariner.

The Escape/Mariner Hybrid has a 110-amp generator.

Vehicle Component Electrical Loads

Vehicle component electrical loads are shown in the table below. Not all features are powered all

the time, so actual vehicle loads on the power supply system will vary.

Note: Smart junction box (SJB) fuse 1 (30A), circuit SBP04 (GN/RD) for the DC/AC power

inverter is at maximum available current limit when the power inverter is installed and used.

Do not splice into this fused circuit when the DC/AC power inverter is installed and used.

Note: SJB fuse 18 (20A), circuit SBP18 (YE/RD) for the heated seats is at maximum available

current limit when the heated seats option is installed and used. Do not splice into this

fused circuit when the heated seats option is installed and used.

Note: If the heated seat connectors are disconnected, DTCs will set in the electronic automatic

temperature control (EATC) module.

Component Amps

Base

Miscellaneous Base Loads 36.1

Cooling

Cooling Fan (variable speed) 24.0

Climate Control

(Continued)

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 27

2-10 Electrical

Section 2: Electrical

Component Amps

A/C Clutch 3.7

A/C Fan to Face — High Speed 21.7

(recirculating air)

A/C Fan to Face — M/H Speed 11.9

(recirculating air)

Heater Fan to Foot — M/H Speed 10.7

(fresh air)

Lighting

Exterior and IP Lamps 4.5

(non-dimmable)

Headlamps — Low Beam 10.0

Fog Lamps 8.0

Brake Lights (with CHMSL) 7.5

Heated Features

Heated Rear Window (includes 14.0

heated mirrors)

Heated Front Seat — LH 6.5

Heated Front Seat — RH 6.5

Other

Radio 1.9

DC/AC Inverter 10.7

Speed Control 1.8

Typical Vehicle Load = 95-110 Amps

Typical Police/Taxi Equipment

Loads for equipment commonly found on police vehicles are shown in the table below. Not all

equipment will be operating at the same time, so actual loads on the power supply system will

vary.

Component Amps

Communications Radio 5.0-20.0

Light Bar 28.0-43.0

LED Light Bar 6.0

Siren 15.0-30.0

Headlamp Flasher 1.0-1.5

LED Deck Bars/Led Visor 2.0

Lights

Radar 0.8

Taximeter 3.3

Receipt Printer 3.0

Spot Lights (each) 7.8

Alley Lights (each) 1.0

Camcorder 2.0

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 28

Electrical 2-11

Section 2: Electrical

General Guidelines

• Provide circuit protection (fuses) for all wiring. The fuse rating should not exceed either the rated

wiring current capacity or the total current requirements for all the add-on components on the

circuit. Install fuses as close to the point of tapped power as possible.

• Document all revisions to the electrical system and place with the vehicle Owner’s Literature.

Color code and/or label all revisions or additions to wiring.

• Provide protective covering in all areas that could be damaged during normal equipment

installations.

• Disconnect the negative battery cable of vehicles stored on site to reduce the possibility of

draining the battery by lights or other equipment.

• Do not allow control panels attached to the instrument panel to protrude into the driver and

passenger air bag deployment zones. For additional information, refer to Section 4: Reference in

this guide.

• Do not install switches and gauges in the driver or passenger knee impact areas.

• Inspect all Ford gauges, lights and switches for correct operation after instrument panel work is

performed.

• Properly secure all wiring relocated or removed while working behind the instrument panel to

prevent chafing, squeaks and rattles.

• Provide adequate retention for wiring harnesses so that they are clear of bolts, corners or edges

which could abrade the wires during normal vehicle operation.

• Anticipate misrouted wiring situations and protect all wiring from penetration by screws and raw

edges.

• Weather-seal all electrical connectors exposed to the elements.

• Do not use quick splice connectors or wire nuts.

• Install the fuse panel so fuses are readily accessible.

• Make sure that connections are easily accessible for assembly and service.

• Make sure submersible connectors do not lose their seals under extreme assembly conditions

such as bending wires 90 degrees immediately after the connector.

• Whenever using connectors, use a socket (female) connector on the electrical source side and a

plug (male) connector on the electrical load side to reduce the possibility of a short circuit when

disconnected.

• Air bag restraint systems must remain intact as received from Ford Motor Company. Before

modifications are done to the vehicle, the system must be disarmed by following the instructions

provided in the current Escape/Mariner Hybrid Workshop Manual.

• Adherence to the above guidelines is not to be construed as approval by Ford Motor Company

of any specific revisions or additions to the vehicle’s original electrical system.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 29

2-12 Electrical

Section 2: Electrical

Keep-Alive Memory Power

The electronic engine and transmission control modules require battery power to be supplied at all

times to maintain the keep-alive memory. Keep this in mind when installing load disconnect

switches or solenoids.

Equipment Grounding Guidelines

• Do not ground the body to the transmission or transmission crossmember. Ground accessories

to the chassis or the vehicle battery.

• Splicing into circuitry relating to the electronic engine and/or transmission control systems is not

acceptable because of the adverse effect on the electronic system operation.

• Adequately protect electrical connections exposed to the elements.

Wire Insulation

• Polyvinyl Chloride (PVC) rated at 90°C (194°F) is the standard wire insulation that is acceptable

for inside body use but is not acceptable for underhood/underbody wiring.

• Hypalon insulation should be used on links only (Ford Specification ESB-M1L54-A).

• Cross-linked Polyethylene (XPLPE or SXL) rated at 125°C (257°F) is the required insulation for

underhood/underbody applications (Ford Specification ESB-M1L123-A).

• GXL can be used as an alternate wire (Ford Specification ESB-M7L85B) as long as the

concentricity specifications are met. To provide a water-resistant seal in conjunction with crimp

connectors, a Duraseal crimp connector is recommended since it is designed to account for

outside wire diameter that is smaller than the present SXL wire.

Terminals and Connectors

Connector Types:

• Submersible (sealed) — A connector that is capable of being immersed in water.

• Weather-resistant — A connector that will retain its sealing and connection qualities while being

exposed to adverse weather conditions.

• Duraseal crimp — A supplier trade name for a sealed wiring repair or splice.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 30

Electrical 2-13

Section 2: Electrical

When a connection is not defined (typical situation — harness-to-harness connectors), the

following suggestions should be implemented:

• Determine the connector type. If it will be located in a hostile environment, use a sealed

connector; if not, use an open connector. A hostile environment is defined as being exposed to

water and/or salt accumulation and/or high temperatures (that is; underhood, exterior panels and

footwells). Use in-line connectors with secondary locks to prevent the terminal from being

pushed out.

— Do not use single wires smaller than 14 gauge in a 2-way or larger weather-resistant

connector (the very large style), since the wire may break during disengagement.

— Use Hypalon, XLPE or Elexar insulation in submersible connectors to maintain sealing

integrity. PVC is not acceptable because it cold flows and allows setting in a deformed

pattern, therefore compromising the integrity of the seal.

• Determine the terminal type. Base your decision on wire gauge, current carrying capacity,

connector type and insulation type.

— Use non-detent low insertion force terminals whenever possible.

— Do not use low insertion force female terminals in weather-resistant connectors.

— Analyze circuit requirements (signal levels, current, voltage) to determine the proper plating

material (such as gold). Use of non-plated terminals is not recommended.

— Do not use plugs to seal holes in micropin connector grommets. It is very easy to forget to

insert them during manufacturing and ruin the seal. Use a grommet with only the necessary

number of holes or use dummy wires at least 600 mm (24 in) long.

— Fully align connectors prior to terminal connection — terminal cavities should have minimum

tolerance to prevent terminals from floating, bending or pin push-out during

mating/engagement.

— Make sure connectors of similar type and color are identifiable to the operator to eliminate

crossed connections and minimize assembly time. Avoid using similar types and colors of

connectors close together.

— Be sure that connectors have positive locking devices that allow easy installation with a low

insertion force and easy removal. The connector snap should be easily felt and heard.

— Eliminate the use of edgeboard, tang-type and molded-over connectors. The use of

blade-type weather-resistant connectors is restricted to high current applications which cannot

be handled by submersible connectors.

Circuit Protection and Electrical Load

• Modification to existing vehicle wiring should be done only with caution and careful consideration

of effects on the completed vehicle’s electrical system. Anticipated circuitry should be studied to

determine the required circuit protection and to avoid feedback loops.

• Added circuitry must be protected either by a base vehicle fuse or circuit breaker, or by a similar

device supplied by the modifier.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 31

2-14 Electrical

Section 2: Electrical

• When adding loads to a base vehicle-protected circuit, make sure that the total electrical load

through the base vehicle fuse or circuit breaker is less than the device’s load rating.

• Use 80% of the fuse rating to determine maximum steady state load to reduce nuisance fuse

failures.

• Use 135% of the fuse rating when sizing wiring to protect the circuit in the event of an overload.

Fuses will last for one hour at 135% of their rating.

— Total current draw is the sum of the base vehicle’s circuit current requirement (measured with

an ammeter) and the anticipated add-on component current requirements.

— Never increase the rating of a factory installed fuse or circuit breaker.

— If the total electrical load including additional electrical components, on any circuit, is less

than the fuse protection rating or the capacity of some limiting component (switch, relay), the

items to be added can be connected directly to that circuit. The headlamp switch circuits

should never have additional lighting or electrical components directly connected.

— Added devices that exceed the current capabilities of the factory-installed system are best

controlled through the use of a relay or separate switch. The coil of the relay can be fed from

the circuit in the factory harness (now acting as a signal circuit) with added wiring providing

feeds to the added electrical device. The relay selection is important and depends on current

requirements, number of cycles expected in the relay lifetime, whether the relay is to be

operated intermittently or for long periods of time and whether the relay is exposed to

weather conditions or is installed in a protected area. When the current requirements of a

circuit exceed the capacity of an available relay, the load should be reduced or divided

through the use of additional relays.

Wire Protection Requirements

General Notes:

• Anticipate problems and design accordingly. Try to anticipate what could go wrong and modify

your designs to address any adverse impact.

• Review all connector applications and electrical systems to determine the need for solder,

grease, weather-resistant or sealed connectors. Make sure components and wire insulation are

compatible with greased connectors (important for long-term durability).

• Make sure that drip loops or other means are provided to prevent water leakage into the vehicle

through wiring assemblies that pass through the dash panel.

• Use greased or sealed connectors in floor pan troughs which are subject to moisture coming

through the carpeting.

• Use XLPE insulation for uncovered runs that exceed 305 mm (12 in).

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 32

Electrical 2-15

Section 2: Electrical

Electrical Protection

• Properly route wires away from noise-generating wires or components. However, if routing near

noisy wires or plugging into noisy components is unavoidable, additional protection must be

designed into the harness.

• Shielding — Electro Magnetic Interference (EMI) — Consider shielding if you must route close to

high-current or noisy circuits. Use shielded wire and ground one side. Seal all splices in wire

assemblies that use bare coaxial shielding (braid or tape) for EMI suppression, and insulate or

tape over all shielding ends that terminate near any open connectors. This prevents splice and

terminal shorts to the shielding. Minimize the length of conductors which extend beyond the

shield. Failure to do this reduces the effectiveness of the shield.

• Spike suppression, in general, is accomplished by connecting a diode or resistor-diode

combination across the terminals of the noisy component. The diode should be sufficiently close

to the component (both electrically and physically) so that inductive spikes are clamped off.

Make sure the diode is connected with the proper polarity.

Proper routing and retention will reduce the likelihood of chafing or pinching. When this ideal

routing is unattainable, the following additional protection is needed:

Mechanical/Environmental Protection

• Tape — Tape is the most basic means of protection. It contains the wires in a loose bundle and

provides limited environmental protection. It does not protect against chafing and pinching.

— Kendall Polyken Fiberglass Base Tape (Ford Specification ESB-M3G38-A) is used for engine

compartment applications. This durable tape provides protection against cut-through and

abrasion commonly found in underhood applications.

— Polyken 267 is a substitute tape that may be used in lower temperature areas of the engine

compartment (apron area).

• Convolute — Use convolute for all underhood/underbody applications or when increased

temperature, abrasion or pinch resistance is required. Convoluted tubing comes in different

diameters and materials to accommodate different temperature ranges and harness sizes.

— Use polyethylene convolute when abrasion is the only consideration; this convolute is

adequate up to 96°C (205°F) maximum. Use nylon convolute when underhood/underbody or

abrasion and temperature are considerations; nylon convolute is adequate up to 177°C

(350°F) maximum.

— On all engine-mounted wiring or bend points. Use vinyl tape on the outside of the convolute

to prevent wiring from looping out. This tape must be able to withstand temperatures 135°C

(275°F) or higher.

— Tape convolute junctions with abrasion-resistant tape (Polyken 267, fiberglass).

• Scroll — Similar to convolute, but without the ridges. Scroll is used where harness rigidity is

required, especially for maintaining critical locator dimensions. Use scroll for short lengths only,

as it is quite inflexible.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 33

2-16 Electrical

Section 2: Electrical

Note: This is not meant to be an all-inclusive list of methods for physically protecting the wires.

There are other means of protection available that are not listed.

Grommets and Sealing Requirements

Any additional wiring routed through sheet metal must pass through a grommet that both seals the

opening and locates the wire(s). Two-piece grommets (rubber with plastic inserts) are

recommended to facilitate installation and retention.

• Locate grommets so they are accessible for proper seating (achieved by pulling) in sheet metal

holes.

• Ramp grommets at the insertion end to facilitate installation and sealing.

• Be sure that the direction of the hole punch is in the direction of grommet seating and the hole is

burr-free.

• Make sure the grommet molding compound will adhere to the harness to prevent slippage.

• Make sure the grommet will withstand the environment (temperature, splash).

• Be sure that holes are large enough to allow the installation of the harness without causing

circuit damage.

• Use adhesive tape on main trunks or branches with at least a 50% overlap to prevent wicking

through grommets. Be certain to diaper-wrap the takeouts.

Wire Routing

WARNING: Do not place electrical component attachments or ground screws adjacent

to vehicle fuel tanks, fuel filler pipes, fuel lines, fuel vapor lines or carbon canisters. Failure

to follow these instructions may result in personal injury in the event of a collision.

Wire harness routing should conform to the following:

• Protect wires routed through holes in sheet metal or castings with a grommet whether or not

conduit is used (see figure below).

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 34

Electrical 2-17

Section 2: Electrical

• Route wires to avoid metal edges, screws, trim fasteners and abrasive surfaces. When such

routing is not possible, use protective devices (shields, caps) to protect the wires. Cover metal

edges with a protective shield and fasten the wiring within 76 mm (3 in) on each side of the

edge (see figure below).

• Route wires to provide at least 76 mm (3 in) of clearance to moving parts in their extreme

movement location, unless positively fastened and protected by a conduit.

• Avoid wire routing without conduit in areas where temperatures exceed 82°C (180°F). Minimum

clearance of 152 mm (6 in) should be maintained from exhaust system components. Heat

insulation and heat shields must be used on the wires routed in high temperature areas.

• Make certain that all underhood or underbody wiring is cross-linked polyethylene

high-temperature insulation wire 135°C (275°F) (minimum rating) consistent with SAE

specification J1128 Type SXL wire. Normal PVC wire must not be used in underhood or

underbody applications.

• Make sure all ground locations are readily accessible for installation, service and verification.

• Do not place ground attachments in high-splash areas.

• Do not route underbody wiring over the exhaust system.

• Underhood/underbody wiring must be routed in conduit for protection. Minimum conduit rating is

177°C (350°F).

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 35

2-18 Electrical

Section 2: Electrical

Wire Retention and Routing

Use the following criteria to determine the location of retainers:

• Size and weight of wire bundle.

• Holes with poor accessibility that prevent installation of locators.

• Movement of wires that can result in abrasion, squeaks and rattles.

• When wiring is routed between 2 members where relative motion can occur, the wiring should be

secured to each member with enough wire slack to allow flexing without damaging the wire.

• Wiring exposed to weather must provide a drip loop to prevent moisture from being conducted

into the device through the wire connection (see figure below).

• Avoid routing wires into areas exposed to wheel splash. When such routing cannot be avoided,

adequate clipping and/or protective shields are required to protect the wires from stone and ice

damage. Allow adequate slack in wiring between the engine and stationary components to

compensate for engine roll.

• Avoid routing wires under the frame side members or at points lower than the bottom frame

flange.

• Use plastic ‘‘zip’’ straps for ‘‘bundling’’ only (securing to other wires).

• The wire retainers and grommets installed by the assembly plant are usually designed to

accommodate only the Ford-installed wires. Additional wiring or tubing should be retained by

additional clips. When added wires or tubes are routed through sheet metal panels, new holes

with proper wire protection and sealing must be used.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 36

Electrical 2-19

Section 2: Electrical

For retainer screws, the following guidelines apply:

• Avoid using fasteners that are too long for the application or are in an area which might damage

vehicle components, including wiring, brake lines, fuel tank and lines, powertrain components,

exhaust system and suspension.

• Do not use pointed screws for attachments. Also check that screws used in the vicinity of the

wiring are blunt-ended.

• To minimize the potential for wiring shorts, do not use drill point screws. Trim components

(including wiring shields) should use pin-type attachments instead of screws.

• Always check areas that screws protrude into for verification that an interference condition to

other components does not exist.

• Make sure that retainers used are capable of withstanding the environment over the vehicle’s life

expectancy.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 37

2-20 Electrical

Section 2: Electrical

Splices and Repairs

For quality splicing and to reduce potential problems, the following guidelines are recommended:

• Stagger the splices within a harness to reduce increased harness diameter. Splice only on

straight areas as installed, not on bends.

• Strip wire ends making sure that individual conductor strands are not damaged.

• When soldering, make sure an adequate mechanical joint exists before applying solder. Use only

resin-core solder. Acid-core solder should not be used since it may result in corrosion.

• For crimp joints, use butt-type metal barrel fasteners and the proper tool at the appropriate

setting for the wire size (such as Motorcraft Crimp Tool S-9796) specifically designed for this

type of work.

• Make sure splice joints are adequately sealed and insulated. In an outside environment, use

Duraseal butt connectors or equivalent. A durable substitute splice joint can be achieved by

using a bare metal barrel, crimping, flow-soldering and covering with shrink tubing. Quality

electrical tape can be used inside the vehicle but is not recommended for an outside

environment.

• Be sure that the new wire is not a lesser gauge than its original mating wire.

Recommended Splicing Method — Solder (For 16 AWG and Smaller Diameter Wire Only)

1. Disconnect the battery ground cable.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 38

Electrical 2-21

Section 2: Electrical

2. Strip wires to appropriate length.

3. Install heat shrink tubing.

4. Twist the wires together.

5. Note: Use resin-core mildly-activated (RMA) solder. Do not use acid-core solder.

Solder wires together.

6. Note: Wait for solder to cool before moving wires.

Bend wire No. 1 back in a straight line.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 39

2-22 Electrical

Section 2: Electrical

7. Note: Overlap tubing on both wires.

Evenly position heat shrink tubing over wire repair.

8. Use a shielded heat gun to heat the repaired area until adhesive flows out of both ends of heat

shrink tubing.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 40

Electrical 2-23

Section 2: Electrical

9. Reconnect the battery ground cable.

Sealed Connectors

Ford Part Number Part Name Class

E6FZ-14488-A Butt Connector C

Gauge: 18-22, Color: Red

E6FZ-14488-B Butt Connector C

Gauge: 14-16, Color: Blue

E6FZ-14488-C Butt Connector C

Gauge: 10-12, Color: Yellow

Heat Shrinkable Tubing (Heat Shrink) (Ford Specification ESB-M99D56-A2)

Heat shrinkable tubing is available in various diameters for different splice sizes and

configurations. When shrunk, it forms a small, flexible hermetic seal.

Other methods (tape, PVC mold) do not provide a hermetic seal and are not recommended. Splice

balancing is critical with heat shrink insulation. If the splice is extremely unbalanced (more circuits

on one side than the other), heat shrink insulation will not provide a proper seal. Evaluate the use

of double terminals instead of splices where practical in these situations.

Recommended Splicing Method — Crimp (For 10 - 22 AWG Diameter Wire to Like Wire Diameter)

1. Disconnect the battery ground cable.

2. Strip wires to appropriate length.

3. Install heat shrink tubing.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 41

2-24 Electrical

Section 2: Electrical

4. Select the appropriate wire splice for the wires to be spliced from Rotunda Wire Splice Kit

164-R5903.

5. Note: Rotunda 164-R5901 Pro-Crimper supplied with the wire splice kit is the only tool that

can be used with these splices.

Identify the appropriate chamber on the Rotunda Pro-Crimper by matching the wire size on the

dies with the wire size stamped on the butt splice.

(1) Cavity

(2) Indenter

6. Crimp the connector.

(1) Center one end of the wire splice in the appropriate crimping chamber.

(2) Insert stripped wire into the barrel.

(3) Holding the wire in place, squeeze the tool handles until ratchet releases.

7. Repeating Step 6, crimp the other half of the splice.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 42

Electrical 2-25

Section 2: Electrical

8. Check for acceptable crimp.

(1) Crimp should be centered on each end of the butt splice.

(2) Wire insulation does not enter butt splice.

(3) Wire is visible through inspection hole of splices.

9. Evenly position supplied heat shrink tubing over wire repair.

10. Use shielded heat gun to heat the repaired area until adhesive flows out of both ends for the

heat shrink tubing.

11. Reconnect the battery ground cable.

Heat Shrinkable Tubing (Heat Shrink) (Ford Specification ESB-M99D56-A2)

Heat shrinkable tubing is available in various diameters for different splice sizes and

configurations. When shrunk, it forms a small, flexible hermetic seal.

Other methods (tape, PVC mold) do not provide a hermetic seal and are not recommended. Splice

balancing is critical with heat shrink insulation. If the splice is extremely unbalanced (more circuits

on one side than the other), heat shrink insulation will not provide a proper seal. Evaluate the use

of double terminals instead of splices where practical in these situations.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 43

2-26 Electrical

Section 2: Electrical

Wiring Reference Information

2009 Escape/Mariner Hybrid Wiring Diagram Excerpts

The following pages are from sections of the 2009 Escape/Mariner Hybrid Wiring Diagrams.

Ordering Information

To obtain information about ordering complete copies of Ford or Lincoln/Mercury publications, call

1-800-782-4356.

Available publications include Workshop Manuals, Wiring Diagrams, PC/ED Manuals and Owner’s

Literature.

In addition, a publications order form can be obtained by writing to: Ford Publications, C/O Helm

Inc., PO Box 07150, Detroit, MI 48207

Wiring Diagrams

Note: Smart junction box (SJB) fuse 18 (20A), circuit SBP18 (YE/RD) for the heated seats is at

maximum available current limit when the heated seats option is installed and used. Do not

splice into this fused circuit when the heated seats option is installed and used.

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 44

Electrical 2-27

Section 2: Electrical

2010 Escape Hybrid, Mariner Hybrid Modifiers Guide, 07/2009

Page 45

2-28 Electrical