Follett 25C1400A, 25CI400W Service Manual

Ice and Water Dispensers

25CI400A/W, 25HI400A, 50CI400A/W, 50HI400A

Order parts online

www.follettice.com

Installation, Operation and Service Manual

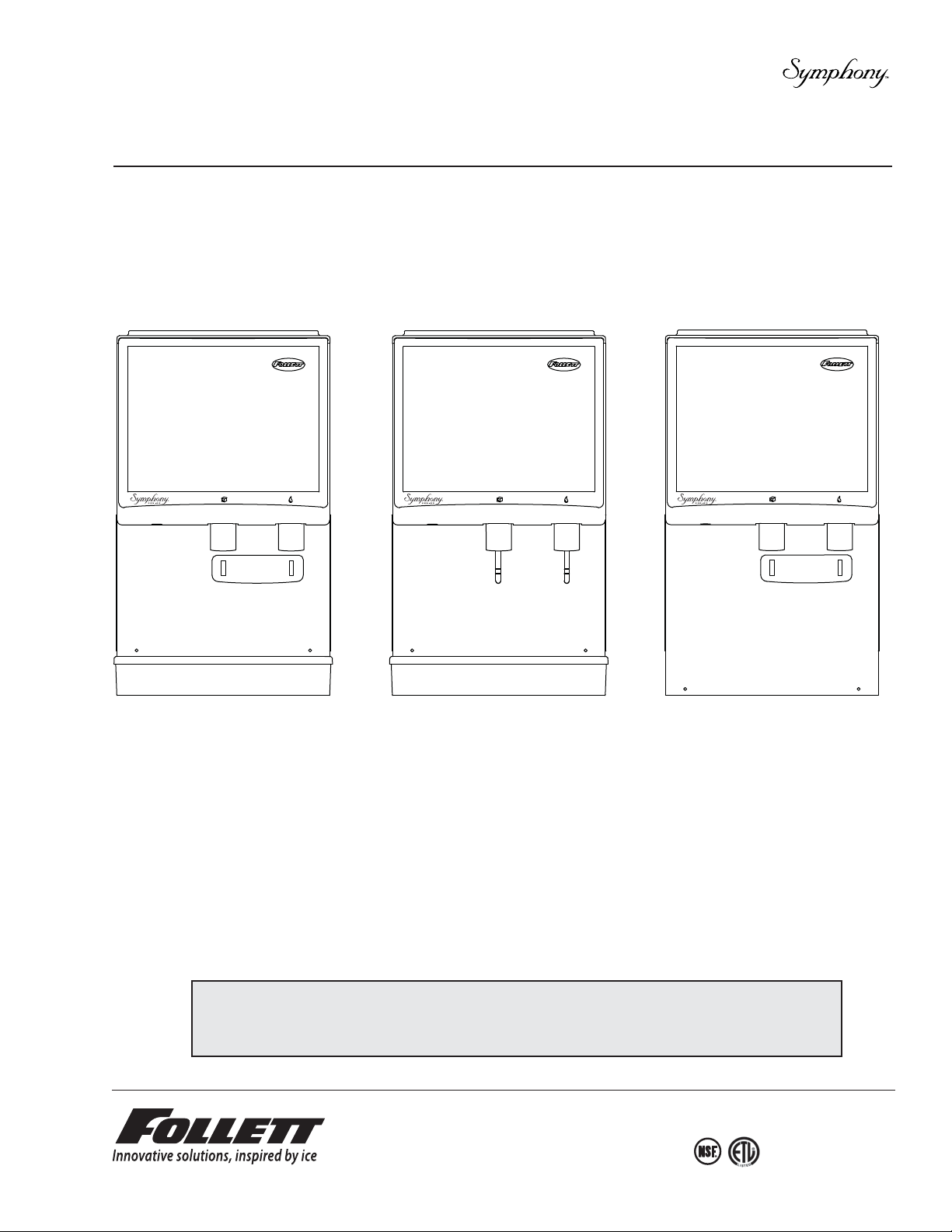

25CI400A Countertop Dispenser

with SensorSAFE™ option

Following installation, please forward this manual

25HI400A Wall Mount Dispenser25CI400A/W Lever

Countertop Dispenser

to the appropriate operations person.

801 Church Lane • Easton, PA 18040, USA

Toll free (800) 523-9361 • (610) 252-7301

Fax (610) 250-0696 • www.follettice.com

© Follett Corporation

00187153R01

Contents

Welcome to Follett . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Speci cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ambient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ventilation and service clearances . . . . . . . . . . . . . . . . . 5

Uncrated weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing countertop dispensers with

rear exiting utilities (no legs) . . . . . . . . . . . . . . . . . . . . . . 6

Installing countertop dispensers with

bottom exiting utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing wall mount dispensers . . . . . . . . . . . . . . . . . . . 8

Icemaker cleaning & sanitizing . . . . . . . . . . . . . . . . . . . . . . . .10

Quarterly air lter cleaning . . . . . . . . . . . . . . . . . . . . . . . .10

Semi-annual icemaker cleaning & sanitizing . . . . . . . . . .10

Cleaning solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sanitizing solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Start-up following cleaning . . . . . . . . . . . . . . . . . . . . . . . .11

Dispenser cleaning & sanitizing . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Sanitizing solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Daily cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Weekly cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning SensorSAFE lens . . . . . . . . . . . . . . . . . . . . . . .12

Semi-annual cleaning and sanitizing

of dispenser hopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Icemaker operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

The icemaking process . . . . . . . . . . . . . . . . . . . . . .13

Ice harvest system diagram . . . . . . . . . . . . . . . . . . .13

Disassembly and replacement instructions . . . . . . . . . . .14

Dispense wheel removal and installation . . . . . . . . .14

Drive bar removal . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Wheel motor assembly removal . . . . . . . . . . . . . . . .14

Ice transport tube replacement . . . . . . . . . . . . . . . .14

Icemaker removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Evaporator disassembly . . . . . . . . . . . . . . . . . . . . . .18

Evaporator reassembly . . . . . . . . . . . . . . . . . . . . . . .18

Gearmotor replacement . . . . . . . . . . . . . . . . . . . . . .19

Fan removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Electrical systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Electrical component locations . . . . . . . . . . . . . . . . . . . 20

Wiring diagram - lever dispense model . . . . . . . . . . . . . 21

Wiring diagram - SensorSAFE model . . . . . . . . . . . . . . 22

Icemaker operational and diagnostic sequences . . . . . . . . . 23

Circuitry notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Normal operation – Stage 1 . . . . . . . . . . . . . . . . . . 24

Normal operation – Stage 2 . . . . . . . . . . . . . . . . . . 24

Normal operation – Stage 3 . . . . . . . . . . . . . . . . . . 25

Normal operation – Stage 4 . . . . . . . . . . . . . . . . . . 25

Normal operation – Stage 5 . . . . . . . . . . . . . . . . . . 26

Normal operation – Stage 6 . . . . . . . . . . . . . . . . . . 26

Diagnostic sequence – Stage 7 . . . . . . . . . . . . . . . 27

Diagnostic sequence – Stage 8 . . . . . . . . . . . . . . . 27

Diagnostic sequence – Stage 9 . . . . . . . . . . . . . . . 28

Diagnostic sequence – Stage 10 . . . . . . . . . . . . . . 28

Refrigeration cycle . . . . . . . . . . . . . . . . . . . . . . . . . 29

Refrigeration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ice production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ice capacity test . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Compressor current draw . . . . . . . . . . . . . . . . . . . . 30

Gearmotor data . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Refrigeration system . . . . . . . . . . . . . . . . . . . . . . . . 30

Icemaker charge speci cations . . . . . . . . . . . . . . . 30

Refrigerant replacement requirements . . . . . . . . . . 30

Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ambients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dispenser troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Before calling for service . . . . . . . . . . . . . . . . . . . . . . . . 31

Lever model troubleshooting guide . . . . . . . . . . . . . . . . 31

SensorSAFE model troubleshooting guide . . . . . . . . . . 31

Board guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Lens/sensor troubleshooting . . . . . . . . . . . . . . . . . 31

Icemaker troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dispenser replacement parts . . . . . . . . . . . . . . . . . . . . . . . . 34

Dispenser exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dispense chute and splash panel areas –

lever models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Dispenser electrical box – lever models . . . . . . . . . . . . 36

Dispense chute and splash panel areas –

SensorSAFE models . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Dispenser electrical box – SensorSAFE models . . . . . . 38

Wheel motor and drive system . . . . . . . . . . . . . . . . . . . 39

Water and drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Icemaker replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . 41

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Air-cooled icemakers . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Water-cooled icemakers . . . . . . . . . . . . . . . . . . . . . . . . . 44

Icemaker electrical components . . . . . . . . . . . . . . . . . . 46

Follett Corporation Equipment Return Policy

Follett equipment may be returned for credit under the following conditions:

1. The equipment is new and unused.

2. A return authorization number has been issued by customer service within 30 days after shipment.

3. Follett receives the equipment at the factory in Easton, PA within 30 days after issuance of the return authorization number.

4. The equipment must be returned in Follett packaging. If the packaging has been damaged or discarded, Follett will forward, at the customer’s expense, new

packaging.

Note: Return freight charges are the responsibility of the customer. If equipment is returned and is damaged because of improper packaging, Follett Corporation

will not be held responsible.

Credit will be issued when: The equipment has been inspected by Follett and deemed suitable to be returned to stock.

Note: A 15% restocking charge will be deducted from the credit. If the cost to return the product to stock exceeds 15%, the actual cost will be deducted.

2 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

Welcome to Follett

Follett equipment enjoys a well-deserved reputation for excellent performance, long-term reliability and outstanding

after-the-sale support. To ensure that this equipment delivers that same degree of service, we ask that you take a

moment to review the installation portion of this manual before beginning to install the unit. Our installation instructions

are designed to help you achieve a trouble-free installation. Should you have any questions or require technical help at

any point, please call our technical service group at (800) 523-9361 or (610) 252-7301.

Note: To expedite assistance, all correspondence or communication MUST include the model number, serial number

and complete and detailed explanation of the problem

Before you begin

After uncrating and removing all packing material, inspect the equipment for concealed shipping damage. If damage

is found, notify the shipper immediately and contact Follett Corporation so that we can help in the ling of a claim, if

necessary.

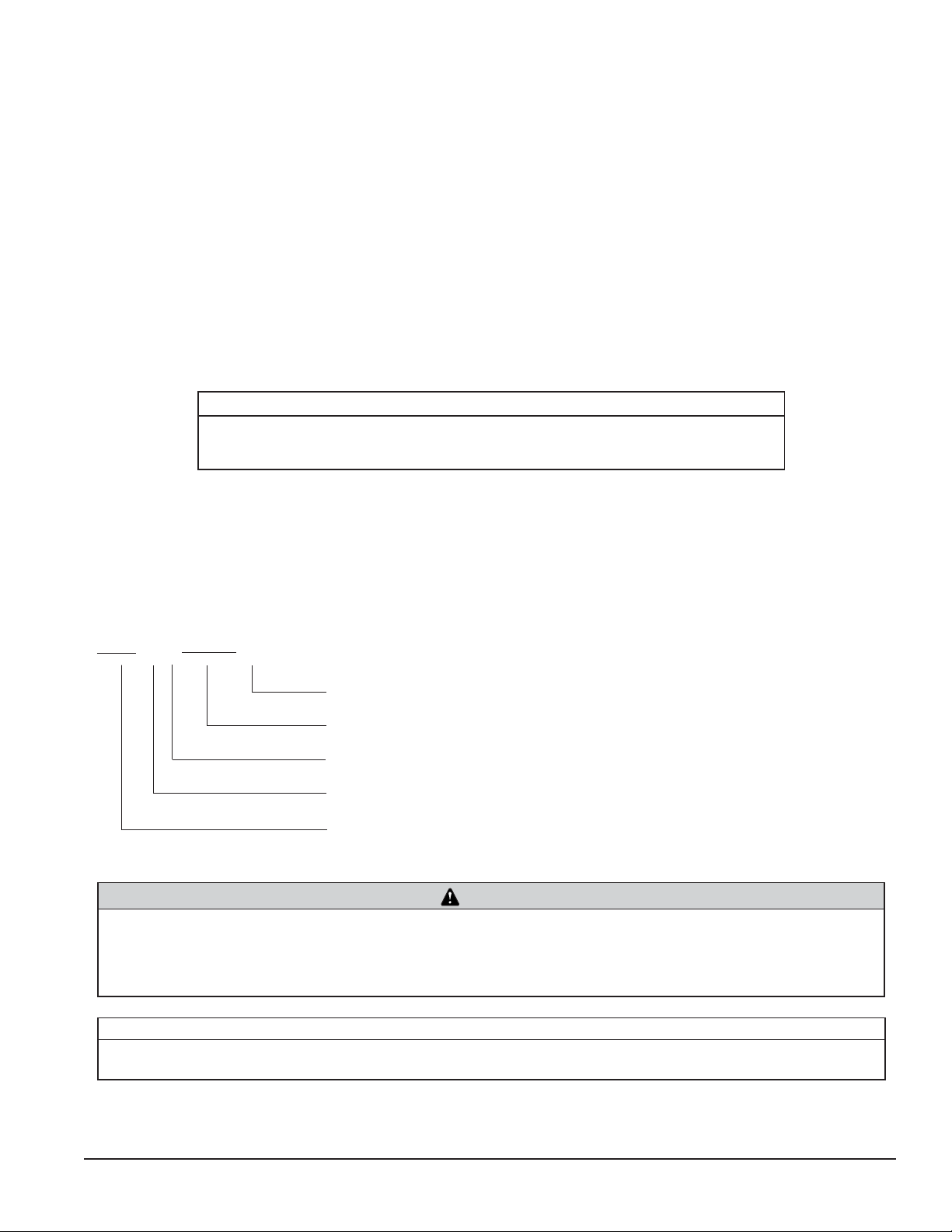

Check your paperwork to determine which model you have. Follett model numbers are designed to provide information

about the type and capacity of Follett ice dispensing equipment. Following is an explanation of the different model

numbers.

IMPORTANT

• Only quali ed technicians should attempt to service or maintain this ice and water dispenser

• No service or maintenance should be undertaken until the technician has thoroughly read this

service manual

Contact Information

FOLLETT CORPORATION, 801 Church Lane, Easton, PA 18040 USA

Phone: 800-523-9361

Fax: 610-250-0696

Web site: www.follettice.com

25CI400A

Condenser type, A = air-cooled, W= water-cooled

Icemaker capacity in lbs per day

Icemaker location, I = integral (behind front splash panel)

Dispenser con guration, C = countertop, H = wall mount

Approximate storage capacity in lbs (25 or 50)

CAUTION

• Do not tilt any unit further than 30° off vertical during uncrating or installation

• Dispenser bin area contains mechanical, moving parts. Keep hands and arms clear of this area at all times. If access to this area

is required, power to unit must be disconnected rst.

• Ice is slippery. Be sure counters and oors around dispenser are clean, dry and free of ice.

• Do not block left side air intake or right side air exhaust

IMPORTANT NOTICE

• Follett recommends a Follett QC4-FL4S water lter system (item# 00130229) be installed in the icemaker inlet water line

• Prior to operation clean and sanitize the dispenser in accordance with instructions found in this manual

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 3

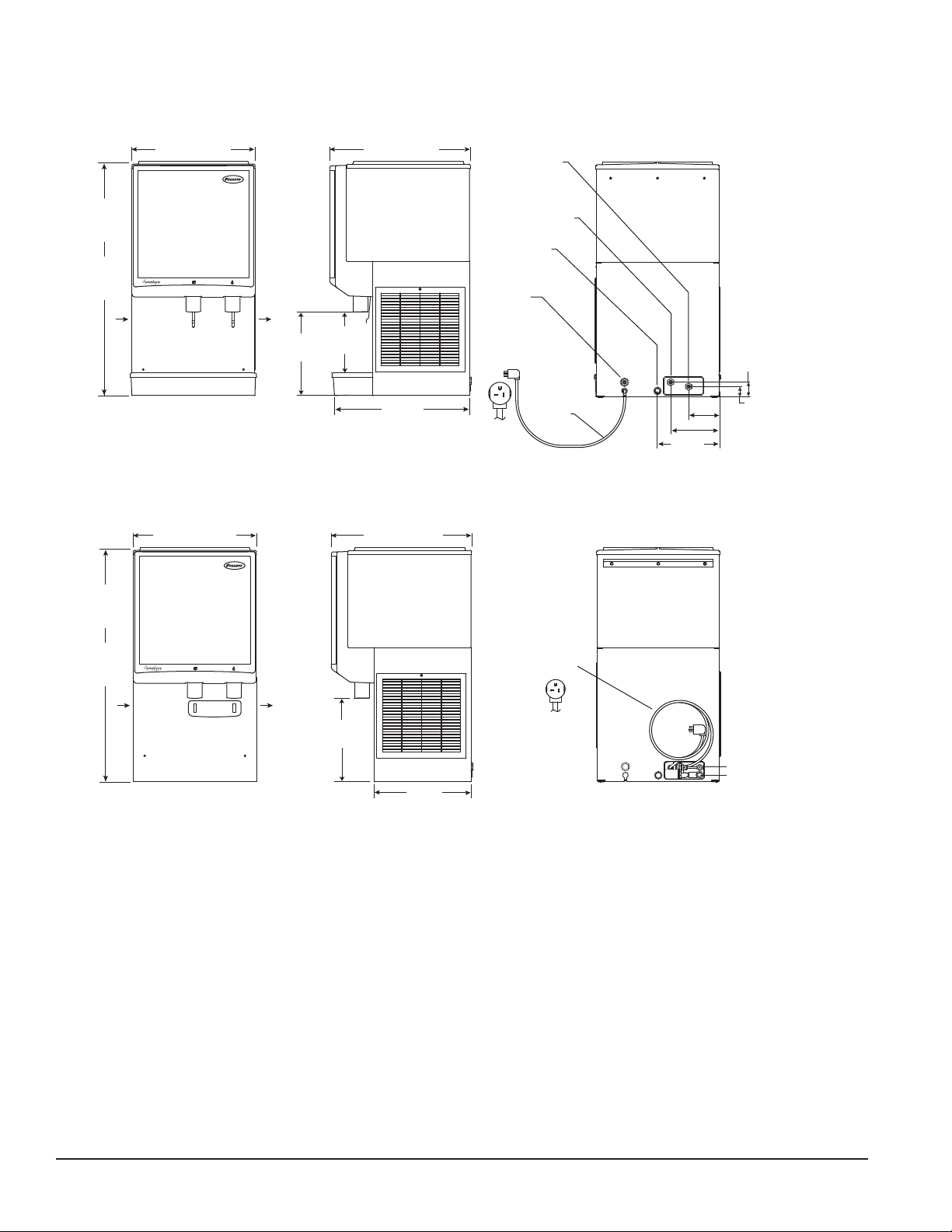

Speci cations

Countertop

25CI400A/W

36"

(915mm)

50CI400A/W

40"

(1016mm)

Wall mount

Front View

21" (534mm) 24" (610mm)

14.25"

(362mm)

AIR INTAKE

AIR EXHAUST

Right Side View Rear View

3/8" FPT

condenser

inlet (watercooled only)

3/8" FPT

condenser

outlet (watercooled only)

3/4" FPT

drain

3/8" water

inlet

10.5"

(267mm)

7' (2.1m)

power cord

w/5-20 90°

23"

(585mm)

hospital-grade

plug

Front View Right Side View Rear View

21.5" (546mm) 24.5" (622mm)

10.5"

(267mm)

2.50"

(64mm)

1.75" (45mm)

5.18" (132mm)

8.25" (210mm)

25HI400A/W

36.5"

(927mm)

50HI400A/W

40.5"

(1029mm)

AIR INTAKE

7' (2.1m)

power cord

w/5-20 90°

hospital-grade

plug

14.25"

(362mm)

AIR EXHAUST

17"

(432mm)

3/8" water inlet

3/4" FPT drain

4 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

Electrical

115V, 60Hz, 1 phase, 14.0 amps. Connect to dedicated 20 amp circuit, fuse or breaker.

Note: It is preferred that circuit be protected by a GFCI.

Furnished with 7 ft (2m) power cord with a 90° NEMA hospital grade 5-20 plug.

Ambient

Maximum Minimum

Air temp 100 F/38 C (Best performance below 80 F/27 C) 50 F/10 C

Water temp 90 F/32 C (Best performance below 70 F/21 C) 40 F/4 C

Water pressure 70 P.S.I. 10 P.S.I.

Plumbing

Connections – 25/50CI400A/W Rough-ins – 25/50HI400A/

Dispenser drain All – 3/4" FNPT Air-cooled – 3/4" FNPT

Water inlet All – 3/8" FNPT All – 1/2" FNPT

Condenser inlet Water-cooled – 3/8" FNPT N/A

Condenser outlet Water-cooled – 3/8" FNPT N/A

Note: Water shut-off recommended within 10 feet (3m) of dispenser. Drain to be hard-piped

and insulated. Maintain at least 1/4" per foot (20mm per 1m run) of slope on horizontal runs.

CAUTION

• Do not block left side air intake or right side air exhaust

Ventilation and service clearances

Air-cooled Water-cooled

Required for ventilation 3" (77mm) each side N/A

Suggested for service 12" (305mm) top,

6"(153mm) left side

Uncrated weight

25/50CI400A/W (countertop) 215 lbs (98kg)

25/50HI400A (wall mount) 230 lbs (105kg)

12" (305mm) top

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 5

Installation

Before you begin

Level dispenser in both directions to ensure proper

operation.

Provide clearances noted in clearances table on page 5.

Countertop models provide the option of taking utilities

out bottom or back of dispenser.

Wall mount model utilities exit through back of

dispenser only.

Directions for each installation follow.

WARNING

• DO NOT LIFT UNIT AT THESE POINTS.

Panels will not support weight of unit

• Failure to follow warning may result in

equipment damage or personal injury

Installing countertop dispensers with rear

exiting utilities (no legs)

Fig. 1

Countertop anchoring locations

1.56"

(40mm)

4X

12.50"

(318mm)

.50"

(13mm)

Ø.375"

(10mm)

hole

20" (508mm)

Fig. 2

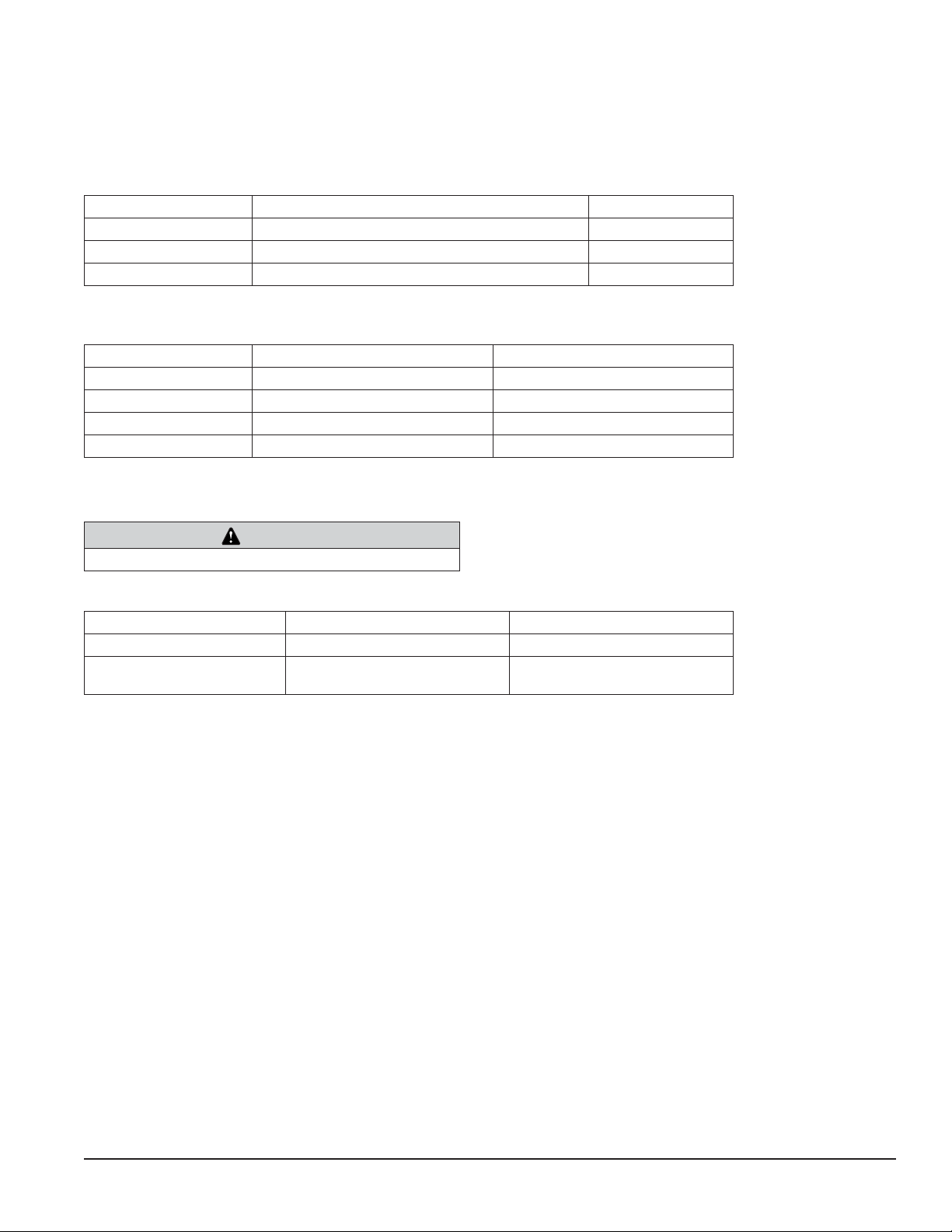

Utility connections as vie

wed

from top for countertop back access

condenser outlet

3/8" FNPT

condenser inlet

3/8" FNPT

drain plug

drain

3/4" FNPT

potable water

3/8" FNPT

3/8"

diameter cord

7. Make utility connections (Fig. 2).

CAUTION

• Do not connect water-cooled condenser outlet line to

the dispenser drain line.

8. Turn on water supply and check for leaks.

9. Clean and sanitize dispenser and icemaker before

putting into service.

10. Turn power on and allow icemaker to produce ice.

Installing countertop dispensers with

bottom exiting utilities

WARNING

• A sturdy work surface capable of supporting the entire

dispenser must be used

• The work surface must be large enough to accommodate

height of dispenser

• Failure to provide proper support may result in personal

injury

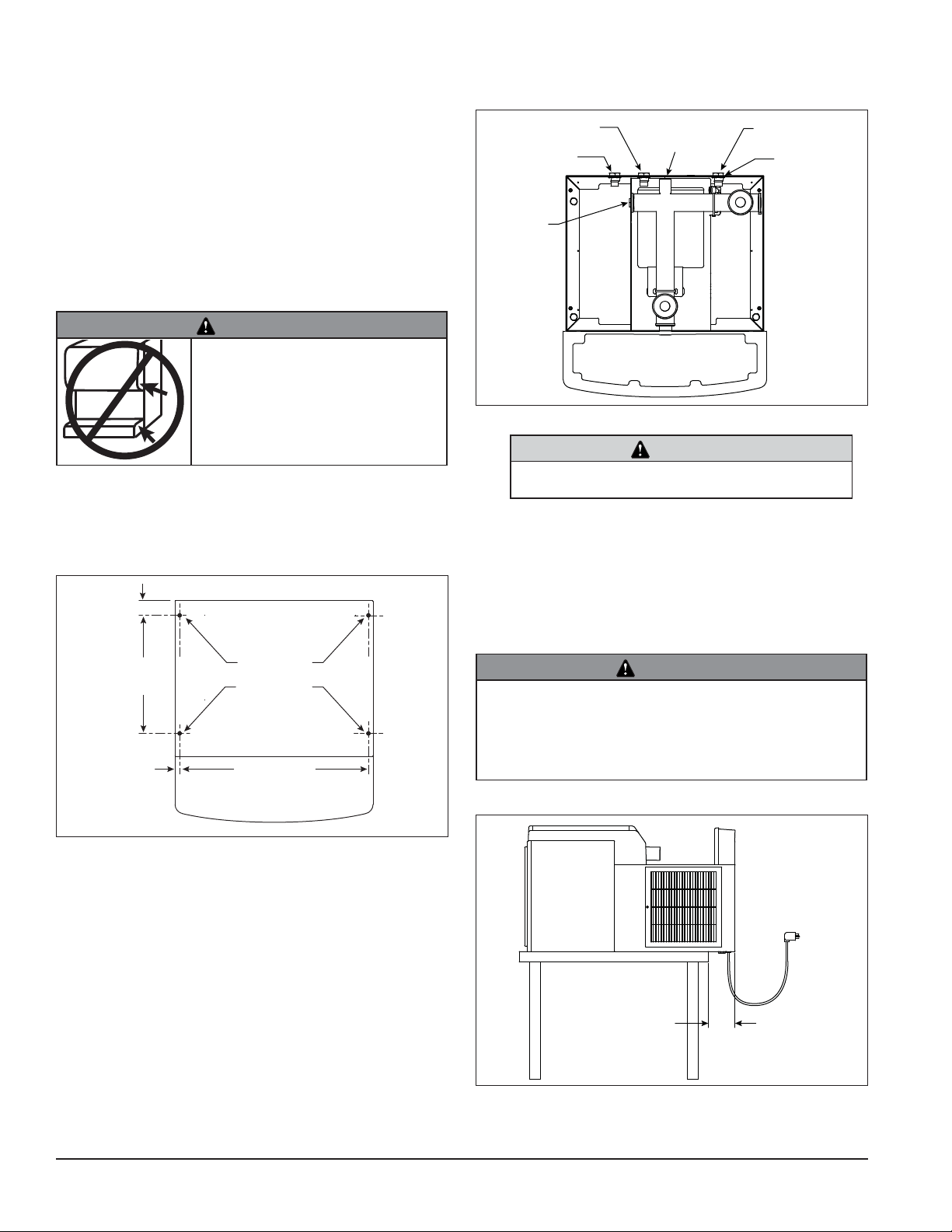

Fig. 3

1. Position dispenser in desired location.

2. Mark dispenser outline on counter and remove

dispenser.

3. Drill four 7/16" holes in counter to anchor dispenser

to counter (Fig. 1).

4. Apply a thick bead approximately 1/4" (7mm)

diameter of NSF listed silicone sealant (Dow

Corning*1 RTV-732 or equivalent) 1/4" (7mm) inside

marked outline of dispenser.

5. Reposition dispenser on counter and secure to

counter with four 3/8"-16NC bolts.

5.00"

(127mm)

min.

6. Smooth excess sealant around outside of dispenser.

1. Position dispenser with dispense chutes facing

upward on sturdy work surface (Fig. 3).

* Dow Corning is a register trademark of Dow Corning Corporation in the United

States and other countries

6 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

Fig. 4

4.2

4.1

4.4

12. Raise the dispenser upright and position in desired

location.

13. Mark dispenser outline on counter and remove

dispenser.

Fig. 6

Countertop cutout viewed from top

3.13"

(80mm)

1.56"

(40mm)

16.00"

(407mm)

Fig. 5

5.3

5.4

4.3

5.1

5.2

12.50"

(318mm)

14"

(356mm)

.50"

(13mm)

Cutout

connections

through

bottom

20"

(508mm)

4X

Ø.375"

(10mm)

hole

14. Cut countertop utility opening and drill four 7/16"

holes to anchor dispenser to counter (Fig. 6).

15. Apply a thick bead approximately 1/4" (7mm)

diameter of NSF listed silicone sealant (Dow

Corning* RTV-732 or equivalent) 1/4" (7mm) inside

marked outline of dispenser.

16. Reposition dispenser on counter and secure to

counter with four 3/8"-16NC bolts.

17. Smooth excess sealant around outside of dispenser.

18. Make utility connections through countertop cutout.

CAUTION

• Do not connect water-cooled condenser outlet line to

the dispenser drain line.

2. Disconnect the internal water line from the potable

water connection tting.

3. Remove tting from the back wall of the dispenser

(Fig. 4.1).

20. Clean and sanitize dispenser and ice machine

before putting into service.

21. Turn power on and allow icemaker to produce ice.

4. Relocate tting to internal bulkhead and reconnect

(Fig. 5.1).

6. Remove power cord strain relief (Fig. 4.2).

7. Relocate the cord and strain relief to the internal

bulkhead and reconnect (Fig. 5.2).

8. Water-cooled only. Disconnect internal condenser

water inlet and outlet ttings (Fig. 4.3).

9. Water-cooled only. Relocate water inlet and outlet

ttings and reconnect (Fig. 5.3). Note: The water

inlet is connected to the condenser; the outlet line is

connected to the water regulating valve.

10. Remove the drain plug from the internal drain line

connection point (Fig. 5.4).

11. Relocate to back of dispenser and reconnect

(Fig. 4.4).

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 7

19. Turn on water supply and check for leaks.

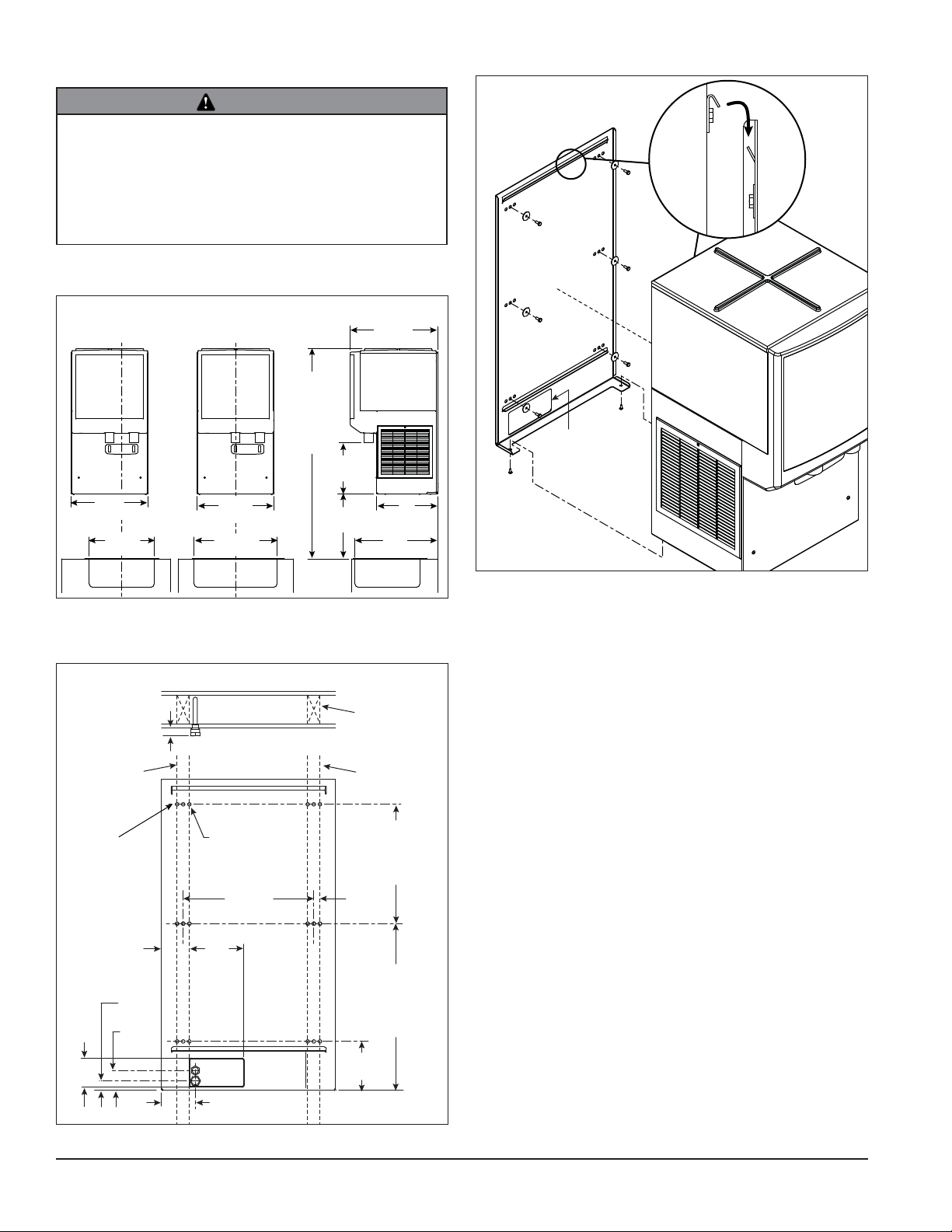

Installing wall mount dispensers

WARNING

• Wall mount dispensers are intended to be mounted above a

sink, eliminating the need for a drain pan.

• Before beginning installation verify that the sink size and

location meet the requirements shown in Fig. 7.

• If requirements are not met, a drain pan must be used to

prevent ice and water from falling on counter or oor.

• FAILURE TO TAKE THESE PRECAUTIONS COULD RESULT IN

SLIPS AND FALLS ON WET FLOORS

Fig. 7

Minimum sink requirements (without drain pan)

Fig. 9

9.3

9.1

Front View

Sink centered

below chutes

21.5"

(547mm)

14.25"

(362mm) min.

Front View

Sink centered

below dispenser

21.5"

(547mm)

23"

(585mm) min.

Fig. 8

Wall bracket location guide

Top view

1"

(26mm)

Front view

(anchor

points)

3.4"

(87mm)

1"

(26mm)

2.44"

(62mm)

3.50"

89mm)

0.438" (11mm)

clearance

16.00"

(406 mm)

7"

(178mm)

4.12"

(105mm)

Utility

cut-out

25HI

54.5"

(1385mm)

50HI

58.5"

(1486mm)

14.25"

(362mm)

18"

(458mm)

(20mm)

(153mm)

Side View

24.5"

(623mm)

17"

(432mm)

23"

(585mm) min.

Wall stud

Wall studWall stud

25HI400A

13" (330mm)

50HI400A

15" (381mm)

.75"

25HI400A

19" (483mm)

50HI400A

21" (483mm)

6"

9.2

9.4

1. Using Fig. 8 as a guide, locate wall bracket

mounting position relative to wall studs.

2. Install the supplied wall bracket with six 3/8"

diameter fasteners (Fig. 9.1).

Note: Three holes are available at each fastening

site to allow capture of studs or supports within the

wall.

2. Locate and cut utility hole in wall using Fig. 8

dimensions (9.2).

3. Rough in utilities. Wall mount bracket dimensions

(Fig. 8) can be used as a template.

Water: 1/2" FNPT

Drain: 3/4" FNPT

4. Lift dispenser onto wall bracket positioning unit so

that hook on back of dispenser is captured by wall

bracket support angle (Fig. 9.3).

5. Install two 1/4" X 20 screws through bottom of wall

bracket into bottom of dispenser to secure dispenser

to wall bracket (Fig. 9.4).

6. Install supplied 1/2" MPT X 3/8" push-in adapter

onto 1/2" FNPT water supply.

8 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

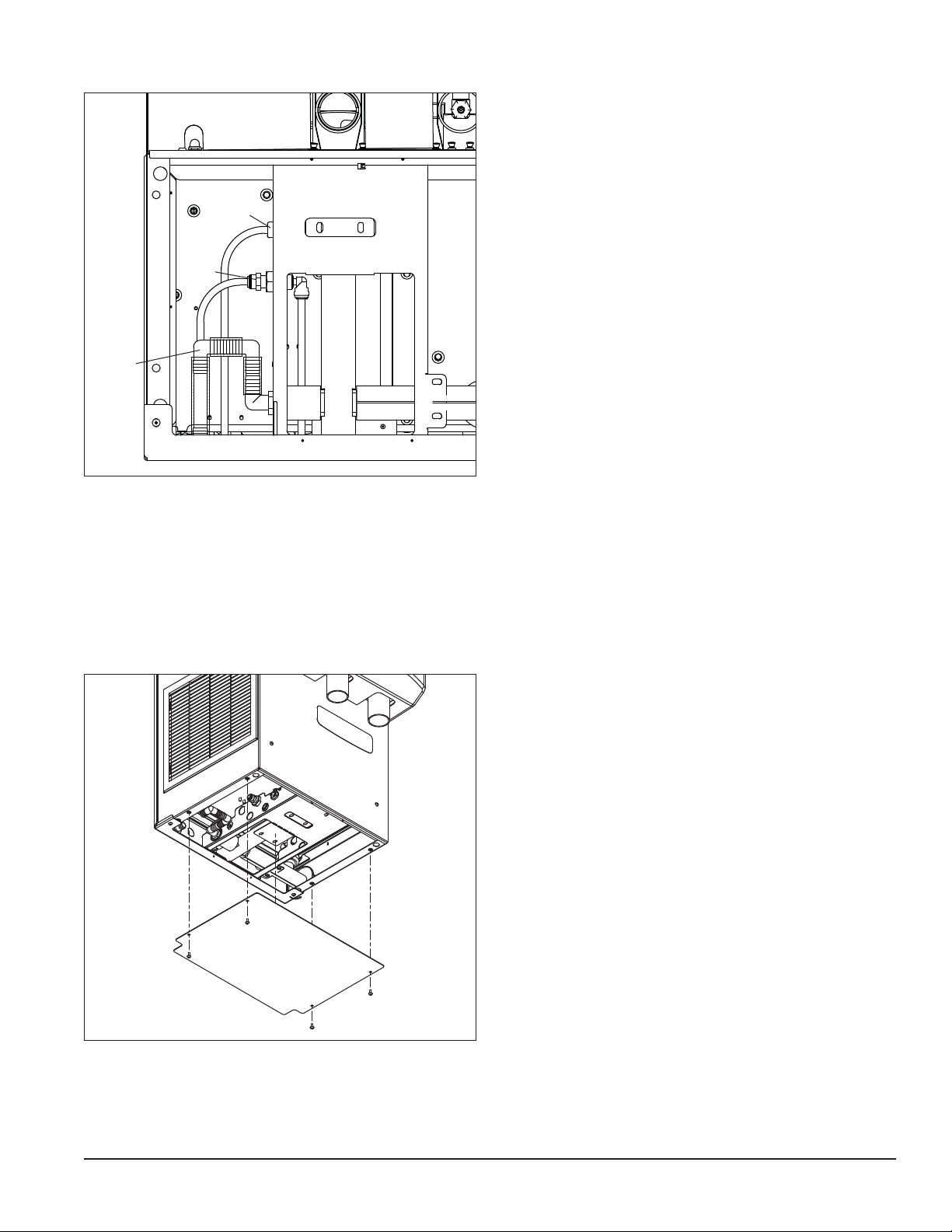

Fig. 10

Dispenser bot

10.2

7. Connect supplied 3/8" water line between water

supply and water inlet fitting (Fig. 10.1).

8. Using supplied 3/4" drain tubing and barbed fittings,

connect 3/4" barbed drain elbow tting on dispenser

to 3/4" FNPT drain (Fig. 10.2).

9. Route power cord through utility access hole to

power supply (Fig. 10.3).

10. Turn on water supply and check for leaks.

tom view

10.3

10.1

Fig. 11

11. Install bottom panel (Fig. 11).

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 9

Icemaker cleaning & sanitizing

Periodic cleaning of Follett’s icemaker system is required

to ensure peak performance and delivery of clean,

sanitary ice. The following cleaning procedures should be

performed at least as frequently as recommended, and

more often if environmental conditions dictate.

WARNING

• To reduce risk of electrical shock disconnect

power before servicing

• Wear rubber gloves and safety goggles (and/

or face shield) when handling ice machine

cleaner or sanitizer mixtures

CAUTION

• Use only Follett approved cleaners (see procedure below)

• It is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling

• Read and understand all packaging instructions before use

• Do not use solvents, abrasive cleaners, metal scrapers or

sharp objects to clean any part of the dispenser

Quarterly air lter cleaning

1. Remove screw at top of louvered panel on left side

of unit.

2. Slide panel toward back of dispenser and lift.

3. Remove the air lter located under the louver.

4. Clean with soap and water.

5. Rinse, and replace when completely dry.

Semi-annual icemaker cleaning & sanitizing

Note: If icemaker and dispenser are cleaned and

sanitized at the same time, icemaker should be cleaned

and sanitized rst.

Cleaning solution

Solution A: Ice machine cleaner: Prepare one gallon

(3.8L) of Follett SafeCLEAN™ Ice Machine cleaner (one

7 oz packet) or equivalent. Solution temperature must be

at least 120 F (49 C).

Warning: Most ice machine cleaners contain citric or

phosphoric acid that can cause skin irritation. Read

caution label on product and follow instructions carefully.

Sanitizing solution

Solution B: Prepare sanitizing solution (50 ppm of

available chlorine content) of Ecolab Mikro-chlor Cleaner

or equal chlorinated detergent. Solution temperature

must be 75 F – 125 F (24 C – 52 C).

Note: Before cleaning SensorSAFE units, deactivate

dispenser by depressing and releasing clean switch

located on left side of unit under top front cover. When

cleaning is complete, reactivate by depressing and

releasing clean switch a second time. Dispenser will

automatically reactivate after two minutes.

1. Remove the upper front cover.

2. Remove splash panel and lower drain pan protector.

3. Turn compressor switch on electrical box of

icemaker to OFF position.

4. Remove water reservoir cover and close water

supply valve.

5. Drain water from reservoir by releasing evaporator

drain line from oat reservoir bracket and removing

plug from drain line.

6. Following manufacturer’s instructions, prepare one

gallon (3.8L) cleaning solution A or equivalent.

Solution temperature must be at least 120 F (49 C).

WARNING: Most ice machine cleaners contain

citric or phosphoric acid that can cause skin

irritation. Read caution label on product and follow

instructions carefully.

7. Plug drain hose, replace drain line in reservoir

bracket and pour part of cleaning solution into

reservoir, lling it almost to over owing.

8. Remove stainless steel compression nozzle and

drain lines and submerge in a cup of cleaning

solution while cleaning rest of system.

CAUTION: To avoid potential pitting, do not soak

parts in SafeCLEAN for more than 45 minutes.

9. Restore power to icemaker (gearmotor will run;

compressor and fan will not).

10. After 15 minutes, turn power OFF;

drain solution from reservoir and evaporator.

11. Fill reservoir almost to over owing with clean,

120 F (49 C) water, and drain. Repeat three times.

12. Following manufacturer’s instructions, prepare

1 gallon (3.8L) sanitizing solution B. Solution

temperature must be at least 120 F (49 C).

13. Rinse compression nozzle in clean water and

submerge in a cup of sanitizing solution while

following steps 14-19.

14. Connect ice transport tube directly onto evaporator

outlet port without compression nozzle.

Note: If bin will not be cleaned at this time, place a

large pan in bin storage area to catch ice or connect

a separate ice transport tube to evaporator and

divert ice into separate container.

15. Fill reservoir almost to over owing with sanitizing

solution.

16. Restore power to icemaker (gearmotor will run;

compressor and fan will not).

17. After 10 minutes, turn compressor switch to ON

position.

18. As unit starts to make ice, continue to pour

sanitizing solution into reservoir, maintaining level

just below reservoir over ow.

19. Continue to make ice with sanitizing solution for

20 minutes.

10 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

20. Turn power to icemaker OFF.

21. Disconnect transport tube from evaporator outlet

port. Rinse compression nozzle in clean water and

reinstall on evaporator outlet. Reconnect transport

tube to compression nozzle.

22. Drain any remaining sanitizing solution from

evaporator.

23. Fill reservoir almost to over owing with clean,

120 F (49 C) water, and drain. Repeat three times.

24. Open water supply valve and replace reservoir

cover. Restore power to icemaker and ensure

compressor switch is in ON position. Make ice for

at least 15 minutes to ush any remaining solution

from system. Discard this and all ice made during

sanitizing.

25. Inspect evaporator drain pan and drain line and

remove any accumulated scale build up.

26. Replace any panels removed prior to cleaning.

Start-up following cleaning

1. Clean and sanitize ice storage area of dispenser in

accordance with instructions before making ice.

2. Turn icemaker on and begin to make ice. Icemaker

should start immediately with power and bin signal

supplied.

3. After approximately 30 minutes, test dispenser for

proper dispensing.

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 11

Dispenser cleaning & sanitizing

Periodic cleaning of Follett’s ice and water dispenser

system is required to ensure peak performance and

delivery of clean, sanitary ice. The following cleaning

procedures should be performed at least as frequently

as recommended, and more often if environmental

conditions dictate.

WARNING

• To reduce risk of electrical shock disconnect

power before servicing

• Wear rubber gloves and safety goggles (and/

or face shield) when handling ice machine

cleaner or sanitizer mixtures

CAUTION

• Use only Follett approved cleaners (see procedure below).

• It is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling

• Read and understand all packaging instructions before use

• Do not use solvents, abrasive cleaners, metal scrapers or

sharp objects to clean any part of the dispenser

Cleaning solution

Solution A: Prepare cleaning solution (200 ppm of

available chlorine content) of Ecolab Mikro-chlor Cleaner

or equal chlorinated detergent. Solution temperature

must be 75 F – 125 F (24 C – 52 C).

Sanitizing solution

Solution B: Prepare sanitizing solution (50 ppm of

available chlorine content) of Ecolab Mikro-chlor Cleaner

or equal chlorinated detergent. Solution temperature

must be 75 F – 125 F (24 C – 52 C).

Note: Before cleaning SensorSAFE units, deactivate

dispenser by depressing and releasing clean switch

located on left side of unit under top front cover. When

cleaning is complete, reactivate by depressing and

releasing clean switch a second time. Dispenser will

automatically reactivate after two minutes.

Cleaning SensorSAFE lens

1 Deactivate dispenser by depressing and releasing

clean switch located on left side of unit under top

front cover.

2. Clean lens using soft cloth and mild, non-abrasive

cleaner.

3. Reactivate by dispenser depressing and releasing

clean switch a second time. Dispenser will

automatically reactivate after two minutes.

Semi-annual cleaning and sanitizing of

dispenser hopper

Note: If icemaker and dispenser are cleaned and

sanitized at the same time, icemaker should be cleaned

and sanitized rst.

1. Remove ice from dispenser. Disconnect power.

2. Working inside storage area, remove center

thumbscrew from dispense wheel, tilt wheel up

toward back to clear baffle and disengage wheel

from motor shaft.

3. Remove front cover, chute cover and clear plastic

chute.

4. Wipe lid, wheel, baffle and clear plastic chute with a

clean damp cloth wrung out in cleaning solution A.

5. Rinse all above items with damp cloth wrung out in

clean water.

6. Wipe all bin surfaces (including the area under

dispense wheel) with a damp cloth wrung out in

cleaning solution A.

7. Rinse all bin surfaces thoroughly with damp cloth

wrung out in clean water.

Caution: Do not rinse by pouring water into the

storage bin. Damage to the dispense motor can

result.

8. Sanitize lid, wheel, baffle, clear plastic chute and all

bin surfaces by wiping with a damp cloth wrung out

in sanitizing solution B. DO NOT RINSE.

9. Reinstall dispense wheel and other components.

Daily cleaning

1. Remove all debris from drain pan.

2. Slowly pour 1 gallon (3.8L) hot water into drain pan

to keep drain lines clear.

Weekly cleaning

1. Wash drain pan and grille with cleaning solution A.

Rinse thoroughly with clean water.

2. Slowly pour solution of one cup (8oz/237ml)

household bleach mixed with one gallon (3.8L) hot

water into drain pan to help prevent algae growth in

drain lines.

12 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

Service

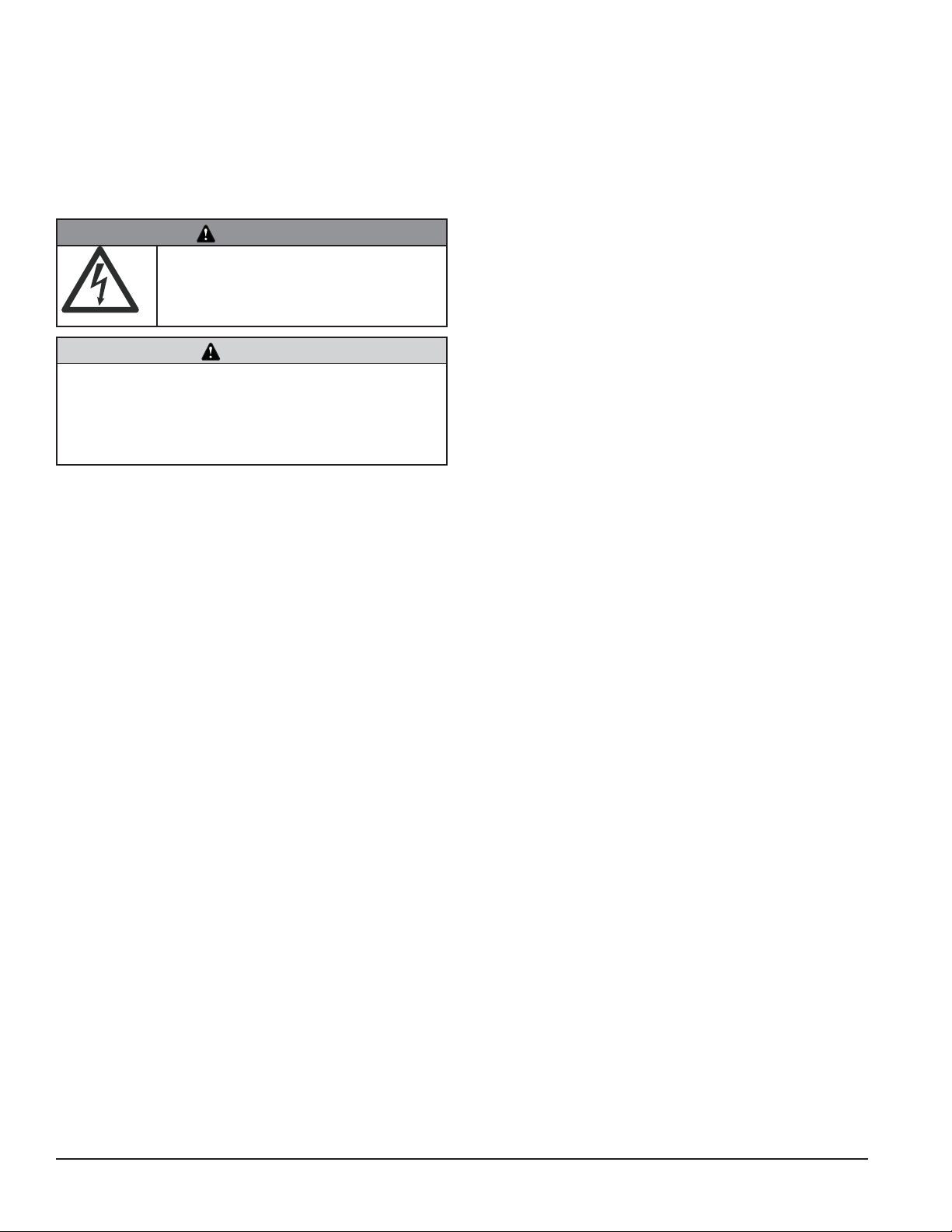

water

inlet

auger

compression nozzle

ice transport tube

discharge

port

Icemaker operation

Follett’s icemaker consists of four distinct functional systems:

• Refrigeration system

• Water system

• Harvesting system

• Electrical control system

These four systems work together to accomplish the production and harvesting of ice. A problem in any one of these

systems will result in improper operation of the entire ice production cycle. When troubleshooting the icemaker, it is

important to analyze the entire system operation to determine which system is not functioning properly, then pinpoint

the component within that system that is malfunctioning. Determine what corrective action must be taken before

making any adjustments or replacing any components.

The icemaking process

The Follett icemaker uses a stainless steel jacketed evaporator and operates on a continuous freezing cycle.

Water is supplied to the evaporator from the water reservoir where the water level is controlled by a oat valve.

This valve also shuts off the water supply when the icemaker is not running.

When the icemaker is running, a layer of ice

forms on the interior surface of the evaporator.

This ice is continuously removed by a slowly

rotating (12 RPM) auger.

Ice harvest system diagram

The auger carries the ice upward into the cavity

formed by the top bearing housing and the

compression loop, where it is compressed to

remove excess water.

When the ice reaches the desired hardness it

rotates within the cavity and is forced through

a discharge port and compression nozzle and

into the ice transport tube. The discharge tube

and compression nozzle are slightly restricted

to further compress the ice and produce the

desired hardness. As the formation of ice

continues, ice in the transport tube is pushed

through the tube to the storage compartment in

the ice dispenser.

A solid state control board, located in the

electrical box of the icemaker, controls the

normal operation of the icemaker and monitors

gearmotor torque. This control board will shut

down the icemaker should an over-torque

condition occur. It is very important that

you familiarize yourself with the operational

sequences detailed in this manual before

attempting to service the icemaker.

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 13

Disassembly and replacement instructions

Dispense wheel removal and installation

1. Remove all ice from storage area of dispenser.

2. Remove center thumb nut from dispense wheel.

3. Remove thumb nuts holding baffle inside bin and

remove baffle.

4. Tilt rear of wheel up and lift off motor drive shaft.

5. After reinstalling wheel, secure baffle loosely with

thumb nuts, but do not tighten.

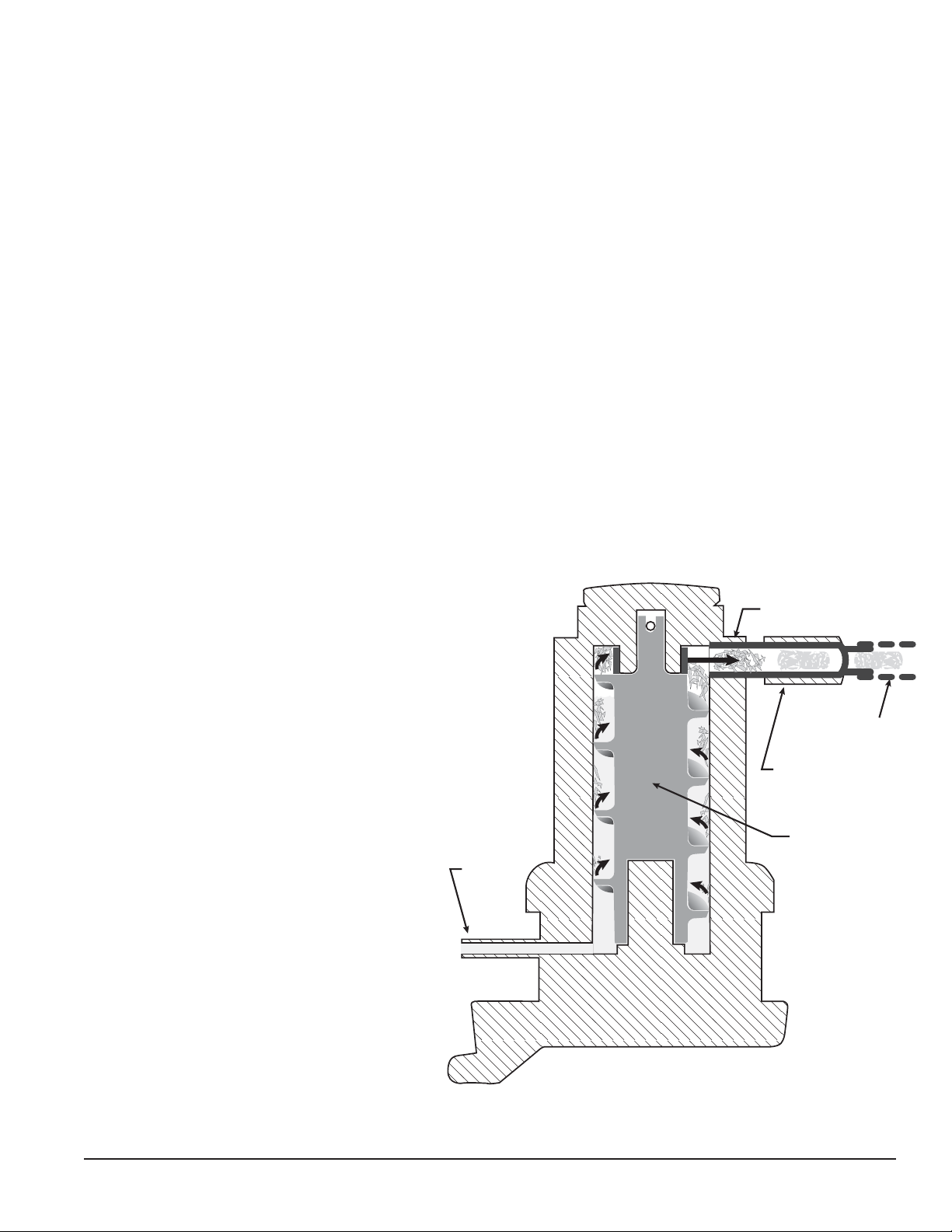

Fig. 12

baffle

dispenser

front

1/16" (2mm)

spacer

3. Disconnect e

xisting ice tube from engaging pin on

transport tube bracket in ice storage bin and pull

tube up through dispenser chase.

Fig. 13

ice level control stat

capillary tube

ice tube mounting bracket

3/16" (5mm) ice tube hole

1"

(26mm)

engaging pin

ice tube

4. Run the new ice transport tube down through chase

making sure that the end with the 3/16" (5mm) hole

is in the bin (Fig. 13).

side view wheel section

6. Place a 1/16" (2mm) spacer against wheel and

allow baffle to drop until it touches spacer (Fig. 12).

7. Tighten thumb nuts and remove spacer.

Drive bar removal

1. Remove dispense wheel from dispenser

(see above).

2. Pull drive bar out of its channel in bottom of wheel.

Wheel motor assembly removal

1. Disconnect power.

2. Remove top cover and dispense wheel.

3. Slide icemaker out of dispenser as described on

page 16, icemaker removal. Icemaker does not

need to be removed completely if there is sufficient

clearance to access the dispenser motor through

the right louvered panel.

4. Disconnect wires on motor.

5. Remove four bolts (7/16" socket) holding motor

assembly to bottom of dispenser.

6. Remove motor assembly.

Ice transport tube replacement

CAUTION

• Tubing must be supplied by Follett Corporation

1. Disconnect power. Remove top and partially slide

icemaker out of dispenser as described on page 16.

2. Disconnect end of tube from icemaker.

Fig. 14

.3/16" (5mm)

dia. hole

Section A – A

1"

(26mm)

A

A

5. Push the 3/16" (5mm) hole near end of tube into pin

on ice tube bracket (Fig. 14).

6. Reinstall insulation

Fig. 15

7. Heat end of transport tube in cup of 160 F (71 C)

hot water to soften (Fig. 15).

8. Slip supplied hose clamp onto tube and push

tube onto compression nozzle on exit port of

evaporator. Do not twist tubing when securing to

evaporator.

9. Secure tube on port with hose clamp, being sure

that clamp is positioned on evaporator side of

nozzle ange.

14 25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A

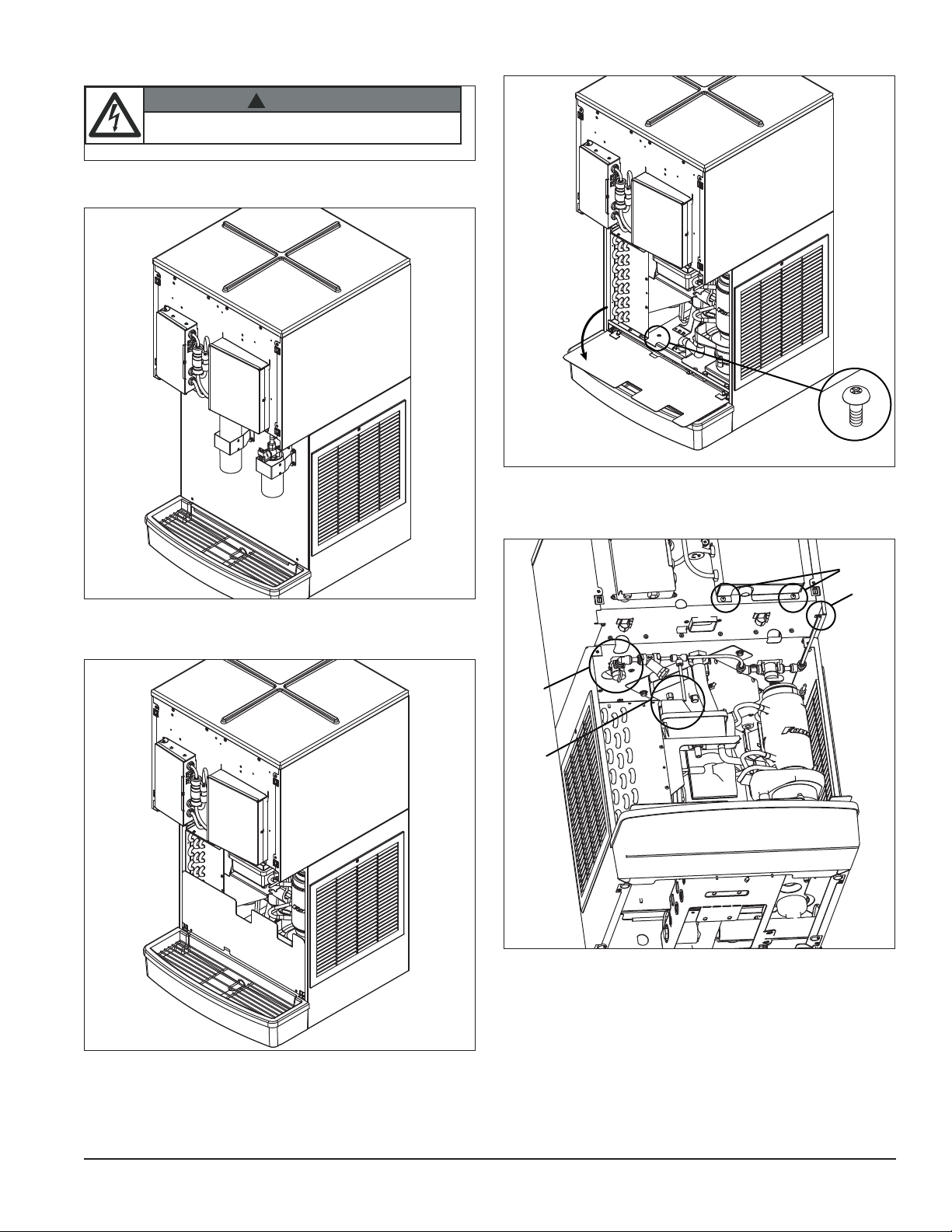

Icemaker removal

To reduce risk of shock disconnect power before

servicing.

Fig. 16– All models

!

WARNING

Fig. 18 – All models

18.1

18.2

3. Lower drain pan protector (Fig. 18.1). Remove and

discard shipping screw (Fig. 18.2).

1. Remove front cover (Fig. 16).

Fig. 17 – All models

2. Remove splash panel (Fig. 17).

Fig. 19 – All models

19.4

19.3

19.1

19.2

4. Close main water shut off valve (Fig. 19.1).

5. Disconnect water line to oat valve (Fig. 19.2).

6. Disconnect water line to solenoid (Fig. 19.3).

7. Remove screws securing bottom of icemaker

electrical box (Fig. 19.4).

25CI400A/W • 25HI400A • 50CI400A/W • 50HI400A 15

Loading...

Loading...