Page 1

molbox™ RFM™

(Ver 1.10 and Higher)

Reference Flow Monitor

Operation and Maintenance Manual

© 1998-2007 DH Instruments, a Fluke Company

Page 2

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled

and operated only by personnel who have been instructed in proper safety practices.

© 1998 - 2007 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its’ published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product does not constitute an

endorsement by DH Instruments of that product. This manual was originally composed in English and was subsequently translated

into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English version and other

language versions, the English version predominates.

Products described in this manual are manufactured under international patents and one or more of the following U.S. patents:

5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

DH Instruments, DH, DHI, molbox, molbox RFM, molbloc, molbloc-L, molbloc-S and CalTool are trademarks, registered and

otherwise, of DH Instruments, a Fluke Company.

LabVIEW is registered trademark of National Instruments Corporation.

Swagelok is a registered trademark of the Swagelok Company.

Document No. 550107f

050512

Printed in the USA.

© 1998-2007 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE

T

O

O

FF

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES.................................................................................. V

FIGURES................................................................................VI

ABOUT THIS MANUAL............................................................ VII

1. INTRODUCTION ................................................................. 1

1.1 PRODUCT OVERVIEW.................................................................................................................................................................1

1.1.1 MOLBLOC FLOW ELEMENTS ........................................................................................................................................................... 1

1.1.1.1 MOLBLOC-L FLOW ELEMENT....................................................................................................................................................... 1

1.1.1.2 MOLBLOC-S FLOW ELEMENT...................................................................................................................................................... 1

1.2 SPECIFICATIONS.........................................................................................................................................................................2

1.2.1 GENERAL SPECIFICATIONS ............................................................................................................................................................. 2

1.2.2 REFERENCE PRESSURE TRANSDUCER (RPT) SPECIFICATIONS .............................................................................................. 2

1.2.2.1 UPSTREAM AND DOWNSTREAM RPTS...................................................................................................................................... 2

1.2.2.2 DIFFERENTIAL RPT (MICRORANGE OPTION)............................................................................................................................3

1.2.3 TEMPERATURE MEASUREMENT SPECIFICATIONS......................................................................................................................3

1.2.4 FLOW MEASUREMENT SPECIFICATIONS.......................................................................................................................................3

1.2.4.1 MOLBLOC-L .................................................................................................................................................................................... 3

1.2.4.1.1 MOLBLOC-L FLOW MEASUREMENT SPECIFICATIONS, MICRORANGE OPTION............................................................. 4

1.2.4.1.2 MOLBLOC-L PRESSURE DEPENDENT CALIBRATION TYPES............................................................................................. 4

1.2.4.1.3 MOLBLOC-L RANGES WITH LOW PRESSURE CALIBRATIONS........................................................................................... 6

1.2.4.1.4 MOLBLOC-L RANGES WITH HIGH PRESSURE CALIBRATIONS..........................................................................................7

1.2.4.1.5 MOLBLOC-L DIMENSIONS....................................................................................................................................................... 8

1.2.4.2 MOLBLOC-S.................................................................................................................................................................................... 9

1.2.4.2.1 MOLBLOC-S RANGES............................................................................................................................................................... 9

1.2.4.2.2 MOLBLOC-S PRESSURE DEPENDENT CALIBRATION TYPES.......................................................................................... 11

1.2.4.2.3 MOLBLOC-S DIMENSIONS.....................................................................................................................................................12

1.2.5 FRONT AND REAR PANELS............................................................................................................................................................ 13

1.2.5.1 FRONT PANEL..............................................................................................................................................................................13

1.2.5.2 REAR PANEL................................................................................................................................................................................ 14

2. INSTALLATION ................................................................ 15

2.1 UNPACKING AND INSPECTION ...............................................................................................................................................15

2.1.1 REMOVING FROM PACKAGING...................................................................................................................................................... 15

2.1.2 INSPECTING CONTENTS ................................................................................................................................................................. 15

2.2 SITE REQUIREMENTS............................................................................................................................................................... 15

2.3 INITIAL SETUP............................................................................................................................................................................ 16

2.3.1 PREPARING FOR OPERATION ....................................................................................................................................................... 16

2.3.2 POWER CONNECTION ..................................................................................................................................................................... 16

2.3.3 MOLBOX RFM TO MOLBLOC CONNECTION.................................................................................................................................16

2.3.4 GAS SUPPLY AND FLOWPATH CONNECTIONS........................................................................................................................... 17

2.3.5 VACUUM SUPPLY (MOLBLOC-S ONLY) ........................................................................................................................................ 18

2.3.6 COMMUNICATIONS CONNECTIONS .............................................................................................................................................. 18

2.4 POWER UP AND VERIFICATION.............................................................................................................................................. 18

2.4.1 POWER UP.........................................................................................................................................................................................18

2.4.2 CH E CK P ROPER PRESS URE MEASU REMEN T OP ERATI O N .......................................................................................... 19

2.4.3 CHECK PROPER TEMPERATU R E M EASUR E M ENT OPERATIO N..........................................................................................19

2.4.4 LEAK CHECK.....................................................................................................................................................................................19

2.4.5 CHECK/SET SECURITY LEVEL ....................................................................................................................................................... 20

2.5 ADDITIONAL PRECAUTIONS TO TAKE BEFORE MAKING FLOW MEASUREMENTS .......................................................20

2.6 SHORT TERM STORAGE...........................................................................................................................................................20

Page I © 1998-2007 DH Instruments, a Fluke Company

Page 4

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

3. OPERATION..................................................................... 21

3.1 GENERAL OPERATING PRINCIPLES ......................................................................................................................................21

3.1.1 MOLBLOC-L AND MOLBLOC-S OPERATION................................................................................................................................ 21

3.1.2 MOLBLOC-S BPR LIMITS................................................................................................................................................................. 21

3.1.3 FLOW READY/NOT READY INDICATION ....................................................................................................................................... 22

3.1.3.1 MOLBLOC-L OPERATION............................................................................................................................................................22

3.1.3.2 MOLBLOC-S OPERATION............................................................................................................................................................ 22

3.1.4 SOFT [ON/OFF] KEY ......................................................................................................................................................................... 23

3.1.5 MICRORANGE OPTION (OPTIONAL).............................................................................................................................................. 23

3.1.6 REFERENCE PRESSURE TRANSDUCER (RPT) OVERPRESSURE ............................................................................................ 24

3.1.6.1 UPSTREAM AND DOWNSTREAM ABSOLUTE RPTS................................................................................................................ 24

3.1.6.2 DIFFERENTIAL RPT, MICRORANGE OPTION........................................................................................................................... 24

3.2 MAIN RUN SCREEN................................................................................................................................................................... 25

3.2.1 MOLBLOC-L OPERATION................................................................................................................................................................ 25

3.2.2 MOLBLOC-S OPERATION................................................................................................................................................................ 26

3.3 MANUAL OPERATION............................................................................................................................................................... 27

3.3.1 KEYPAD LAYOUT AND PROTOCOL............................................................................................................................................... 27

3.3.2 SOUNDS............................................................................................................................................................................................. 28

3.3.3 SOFT [ON/OFF] KEY ......................................................................................................................................................................... 28

3.3.4 DIRECT FUNCTION KEYS SUMMARY ............................................................................................................................................ 28

3.4 DIRECT FUNCTION KEYS.........................................................................................................................................................29

3.4.1 [K] ....................................................................................................................................................................................................... 29

3.4.2 [GAS] .................................................................................................................................................................................................. 31

3.4.2.1 MOLBLOC-L OPERATION............................................................................................................................................................32

3.4.2.2 MOLBLOC-S OPERATION............................................................................................................................................................ 33

3.4.3 [UNIT]..................................................................................................................................................................................................34

3.4.3.1 MASS FLOW VS. VOLUME FLOW...............................................................................................................................................35

3.4.3.2 VOLUMETRICALLY BASED MASS FLOW UNITS....................................................................................................................... 36

3.4.3.3 VOLUMETRICALLY BASED MASS FLOW UNITS AT VARIOUS REFERENCE TEMPERATURES (UXXX) ........................... 37

3.4.3.4 VOLUME FLOW UNITS (VLM)......................................................................................................................................................37

3.4.3.5 CUSTOMIZING FLOW UNITS AVAILABLE UNDER THE UNIT FUNCTION.............................................................................. 38

3.4.4 [TARE] ................................................................................................................................................................................................ 39

3.4.4.1 <1TARE> ....................................................................................................................................................................................... 40

3.4.4.1.1 MOLBLOC-L OPERATION.......................................................................................................................................................40

3.4.4.1.2 MOLBLOC-S OPERATION....................................................................................................................................................... 43

3.4.4.2 <2PURGE>.................................................................................................................................................................................... 44

3.4.4.3 <3LEAK CHECK>.......................................................................................................................................................................... 46

3.4.4.3.1 LEAK CHECK MOLBOX........................................................................................................................................................... 47

3.4.4.3.2 LEAK CHECK SYSTEM........................................................................................................................................................... 49

3.4.4.4 <4AUTOZ>.....................................................................................................................................................................................53

3.4.4.4.1 EDIT AUTOZ.............................................................................................................................................................................55

3.4.4.4.2 RUN AUTOZ............................................................................................................................................................................. 56

3.4.4.5 <5BPR> (MOLBLOC-S OPERATION ONLY) ...............................................................................................................................58

3.4.5 [P&T] (PRESSURE AND TEMPERATURE)......................................................................................................................................59

3.4.6 [DISPLAY] .......................................................................................................................................................................................... 61

3.4.6.1 <1RATE> ....................................................................................................................................................................................... 62

3.4.6.2 <2AVG> (AVERAGE) .................................................................................................................................................................... 63

3.4.6.3 <3 HI/LO>....................................................................................................................................................................................... 64

3.4.6.4 <4TOTAL> (TOTALIZER).............................................................................................................................................................. 64

3.4.6.5 <5UNIT>......................................................................................................................................................................................... 66

3.4.6.6 <6DEV>.......................................................................................................................................................................................... 66

3.4.6.7 <7FREEZE>................................................................................................................................................................................... 67

3.4.6.8 <8CLEAN>..................................................................................................................................................................................... 68

3.4.7 [MICRO] (OPTIONAL)........................................................................................................................................................................ 68

3.4.8 [MOLBLOC]........................................................................................................................................................................................70

3.4.8.1 MOLBLOC-L AND MOLBLOC-S SIZE AND RANGE DESIGNATIONS.......................................................................................70

3.4.9 [RES]...................................................................................................................................................................................................71

3.5 [SETUP].......................................................................................................................................................................................72

3.5.1 <1FLOWU>......................................................................................................................................................................................... 72

3.5.2 <2PRESU>..........................................................................................................................................................................................73

3.5.3 <3TEMPU> ......................................................................................................................................................................................... 73

3.5.4 <4MOLBLOC>.................................................................................................................................................................................... 74

3.5.5 <5STAB> ............................................................................................................................................................................................ 74

3.5.6 <6ADJ>............................................................................................................................................................................................... 75

© 1998-2007 DH Instruments, a Fluke Company Page II

Page 5

TABLE OF CONTENTS

3.6 [SPECIAL]................................................................................................................................................................................... 76

3.6.1 <1RESET>.......................................................................................................................................................................................... 77

3.6.1.1 <1SETS>........................................................................................................................................................................................ 78

3.6.1.2 <2UNITS>...................................................................................................................................................................................... 78

3.6.1.3 <3COM>......................................................................................................................................................................................... 79

3.6.1.4 <4CAL>.......................................................................................................................................................................................... 79

3.6.1.5 <5ALL>........................................................................................................................................................................................... 79

3.6.2 <2LEVEL> .......................................................................................................................................................................................... 80

3.6.2.1 SECURITY LEVELS...................................................................................................................................................................... 80

3.6.3 <3UL> ................................................................................................................................................................................................. 83

3.6.3.1 UPPER LIMIT ALARM AND SEQUENCE.....................................................................................................................................84

3.6.4 <4CAL>............................................................................................................................................................................................... 84

3.6.5 <5PREFS>.......................................................................................................................................................................................... 84

3.6.5.1 <1SCRSVR>..................................................................................................................................................................................85

3.6.5.2 <2SOUND>....................................................................................................................................................................................85

3.6.5.3 <3TIME>......................................................................................................................................................................................... 86

3.6.5.4 <4ID>.............................................................................................................................................................................................. 86

3.6.5.5 <5LOG>.......................................................................................................................................................................................... 87

3.6.6 <6REMOTE>.......................................................................................................................................................................................87

3.6.6.1 COM1 AND COM2......................................................................................................................................................................... 88

3.6.6.2 IEEE-488........................................................................................................................................................................................88

3.6.6.3 RS232 SELF-TEST........................................................................................................................................................................ 88

3.6.7 <7MICRO>.......................................................................................................................................................................................... 89

3.6.8 <8HEAD>............................................................................................................................................................................................ 90

3.6.9 <9BPR>............................................................................................................................................................................................... 91

4. REMOTE OPERATION ....................................................... 95

4.1 OVERVIEW..................................................................................................................................................................................95

4.2 INTERFACING.............................................................................................................................................................................95

4.2.1 RS232 INTERFACE ........................................................................................................................................................................... 96

4.2.1.1 COM1.............................................................................................................................................................................................96

4.2.1.2 COM2.............................................................................................................................................................................................96

4.2.2 IEEE-488 (GPIB).................................................................................................................................................................................97

4.3 COMMANDS................................................................................................................................................................................ 97

4.3.1 COMMAND SYNTAX ......................................................................................................................................................................... 97

4.3.2 COMMAND SUMMARY ..................................................................................................................................................................... 98

4.3.3 ERROR MESSAGES..........................................................................................................................................................................99

4.3.4 COMMAND DESCRIPTIONS...........................................................................................................................................................101

4.3.4.1 IEEE STD. 488.2 COMMON AND STATUS COMMANDS.........................................................................................................101

4.3.4.2 MOLBOX RFM COMMANDS...................................................................................................................................................... 104

4.4 STATUS SYSTEM.....................................................................................................................................................................129

4.4.1 STATUS REPORTING SYSTEM ..................................................................................................................................................... 129

4.4.1.1 STATUS BYTE REGISTER.........................................................................................................................................................129

4.4.1.2 STANDARD EVENT REGISTER................................................................................................................................................. 131

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION ...........133

5.1 PRODUCT OVERVIEW.............................................................................................................................................................133

5.2 CALIBRATION OF REFERENCE PRESSURE TRANSDUCERS (RPTS)..............................................................................134

5.2.1 PRINCIPLE....................................................................................................................................................................................... 134

5.2.1.1 PA AND PM COEFFICIENTS...................................................................................................................................................... 135

5.2.2 EQUIPMENT REQUIRED.................................................................................................................................................................135

5.2.2.1 UPSTREAM AND DOWNSTREAM ABSOLUTE RPTS.............................................................................................................. 135

5.2.2.2 DIFFERENTIAL (MICRORANGE) RPT....................................................................................................................................... 136

5.2.3 SET-UP AND PREPARATION.........................................................................................................................................................136

5.2.3.1 UPSTREAM AND DOWNSTREAM ABSOLUTE RPTS.............................................................................................................. 136

5.2.3.2 MICRORANGE DIFFERENTIAL RPT......................................................................................................................................... 136

5.2.4 VIEWING AND EDITING RPT READINGS AND CALIBRATION INFORMATION........................................................................ 137

5.2.4.1 VIEWING RPT OUTPUTS...........................................................................................................................................................138

5.2.4.2 VIEWING AND EDITING RPT PA, PM AND CALIBRATION DATE...........................................................................................140

5.2.5 RPT CALIBRATION/ADJUSTMENT PROCEDURE WITHOUT USING CALTOOL FOR RPTS SOFTWARE ............................ 141

5.3 OHMIC MEASUREMENT SYSTEM VERIFICATION................................................................................................................142

5.4 RELOADING EMBEDDED SOFTWARE INTO MOLBOX RFM FLASH MEMORY.................................................................143

5.5 RELOADING MOLBLOC EEPROM FILE.................................................................................................................................144

Page III © 1998-2007 DH Instruments, a Fluke Company

Page 6

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

5.6 OVERHAUL...............................................................................................................................................................................144

5.6.1 INTERNAL VIEW..............................................................................................................................................................................145

5.6.1.1 UPSTREAM ABSOLUTE RPT ....................................................................................................................................................146

5.6.1.2 DOWNSTREAM ABSOLUTE RPT..............................................................................................................................................146

5.6.1.3 DIFFERENTIAL MICRORANGE RPT (OPTIONAL)................................................................................................................... 146

5.6.1.4 DISPLAY......................................................................................................................................................................................146

5.6.1.5 POWER SUPPLY........................................................................................................................................................................ 146

5.6.1.6 MICRO BOARD........................................................................................................................................................................... 146

5.6.1.7 VALVING MODULE..................................................................................................................................................................... 146

5.6.1.8 MAIN BOARD ..............................................................................................................................................................................147

5.6.1.9 COOLING FAN ............................................................................................................................................................................147

6. TROUBLESHOOTING .......................................................149

6.1 OVERVIEW................................................................................................................................................................................149

7. APPENDIX ......................................................................155

7.1 CONVERSION OF NUMERICAL VALUES...............................................................................................................................155

7.1.1 PRESSURE ...................................................................................................................................................................................... 155

7.1.2 TEMPERATURE...............................................................................................................................................................................155

7.1.3 FLOW................................................................................................................................................................................................ 156

7.2 WARRANTY STATEMENT....................................................................................................................................................... 159

8. GLOSSARY .....................................................................161

© 1998-2007 DH Instruments, a Fluke Company Page IV

Page 7

TABLES & FIGURES

T

AABBLLEES

T

Table 1. molbloc-L Pressure Dependent Calibration Types........................................................................5

Table 2. molbloc-L Ranges with Low Pressure Calibrations.......................................................................6

Table 3. molbloc-L Ranges with High Pressure Calibrations ...................................................................... 7

Table 4. molbloc-S Flow at Various molbloc Upstream Pressures ...........................................................10

Table 5. Minimum molbloc-S Critical Flow (slm) at Various molbloc-S Downstream Pressures ..............10

Table 6. molbloc-S Calibration Types........................................................................................................11

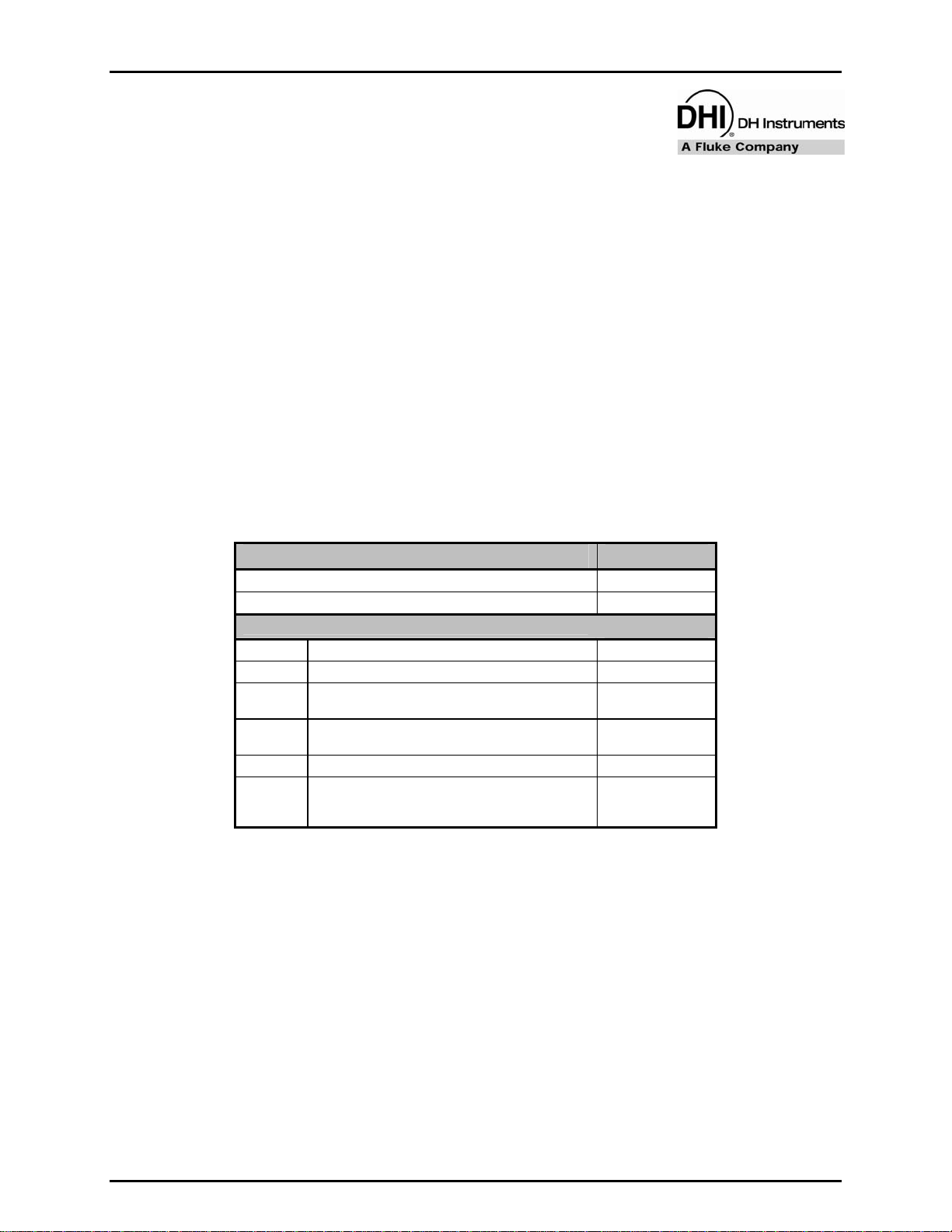

Table 7. molbox RFM Parts List.................................................................................................................15

Table 8. Summary of molbox RFM Direct Function Key Operations.........................................................29

Table 9. Available molbloc-L Gases .......................................................................................................... 32

Table 10. Available molbloc-S Gases........................................................................................................33

Table 11. Available Flow Units...................................................................................................................39

Table 12. Flow Units and Corresponding Total Mass or Volume Units.....................................................65

Table 13. molbloc-L Size and Nominal Range Designations .................................................................... 71

Table 14. molbloc-S Size Designation and Pressure to Flow Conversion Ratio (KF)................................71

Table 15. Pressure Units of Measure Available.........................................................................................73

Table 16. Security Levels - Functions NOT Executed Per Function/Level................................................81

Table 17. Security Levels - Functions NOT Executed Per Function/Level (Continued)............................82

Table 18. COM1 and COM2 Available Settings ........................................................................................88

Table 19. COM1 DB-9F Pin Designation...................................................................................................96

Table 20. COM2 DB-9M Pin Designation..................................................................................................97

Table 21. Command Summary..................................................................................................................98

Table 22. Error Messages........................................................................................................................100

Table 23. Status Byte Register ................................................................................................................129

Table 24. Standard Event Register..........................................................................................................131

Table 25. Troubleshooting Checklist .......................................................................................................149

Table 26. Pressure Unit Conversions......................................................................................................155

Table 27. Temperature Unit Conversion..................................................................................................155

Table 28. Conversions From kg/s To sccm At 0 °C For Various Gases .................................................156

Table 29. Conversions From sccm At 0 °C To Other Volumetrically Based Flow Units .........................156

Table 30. Conversions From Volumetrically Based Flow Units At 0 °C To

Table 31. Conversions From kg/s To mole/s For Various Gases............................................................157

Table 32. Conversion From mole/s To pccm...........................................................................................158

Table 33. Conversion From sccm At 0 °C to Volume Flow Units At Another Pressure

Table 34. Authorized Service Providers ..................................................................................................159

S

Corresponding Units At Another Temperature (uxxx)...........................................................157

And Temperature...................................................................................................................158

Page V © 1998-2007 DH Instruments, a Fluke Company

Page 8

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

F

IIGGUURREES

F

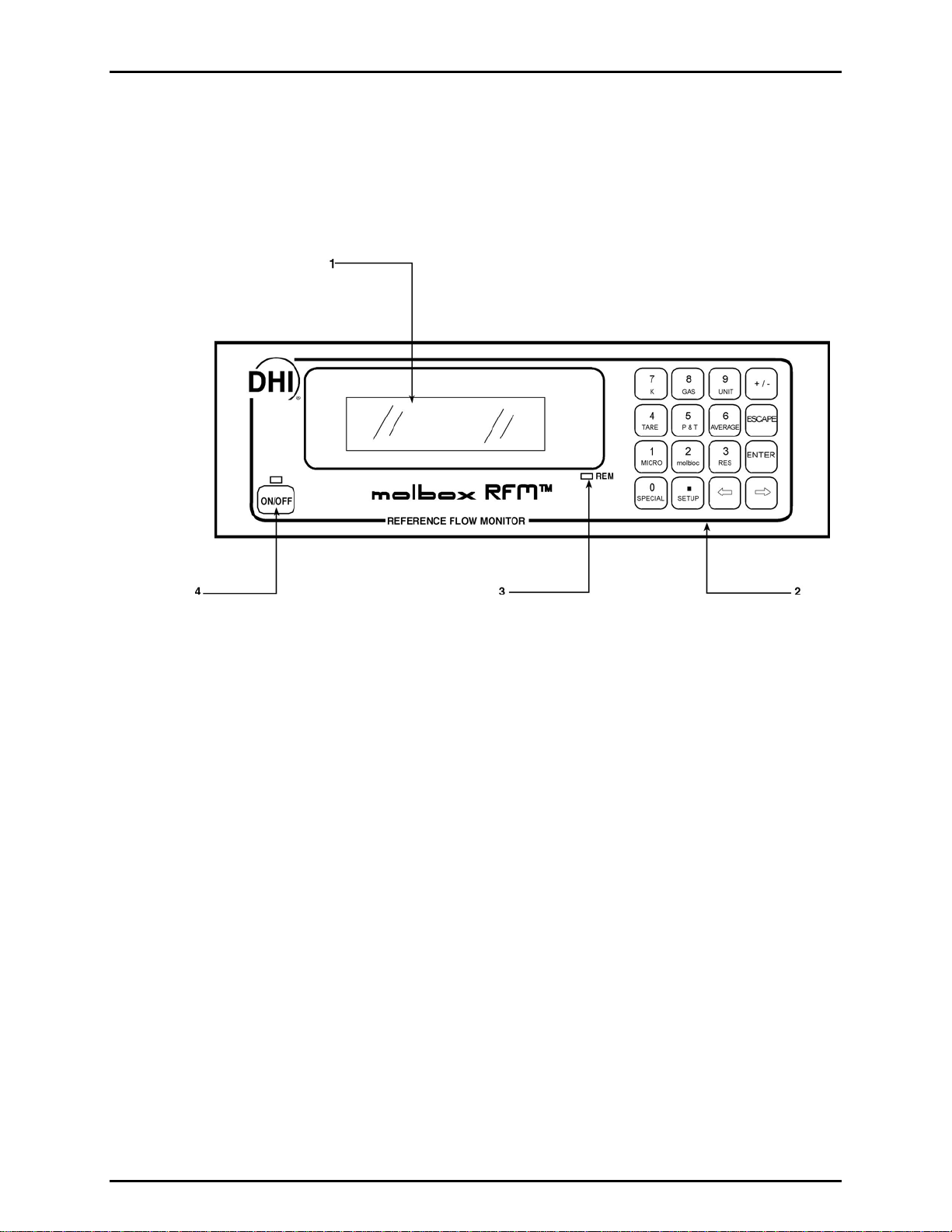

Figure 1. molbox RFM Front Panel............................................................................................................13

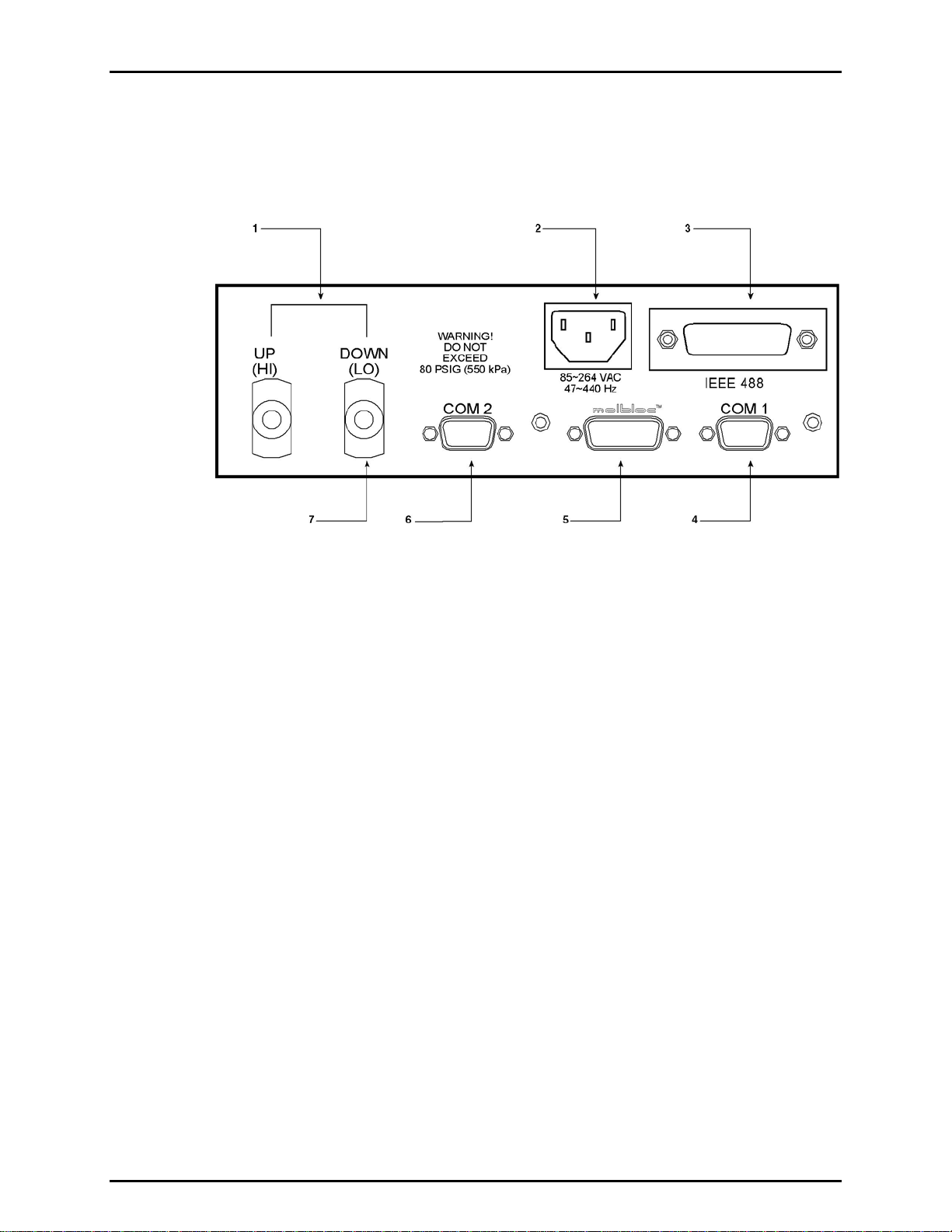

Figure 2. molbox RFM Rear Panel ............................................................................................................ 14

Figure 3. molbox RFM Internal Pneumatic Schematic – MICRORANGE OPTION RPT

Figure 4. Keypad Layout............................................................................................................................27

Figure 5. molbox RFM Internal Pneumatic Schematic – TARING, UPSTREAM

Figure 6. molbox RFM Internal Pneumatic Schematic – TARING molbloc-S OPERATION..................... 44

Figure 7. molbox RFM Internal Pneumatic Schematic – PURGING ......................................................... 45

Figure 8. molbox RFM Internal Pneumatic Schematic – LEAK CHECK molbox.......................................48

Figure 9. molbox RFM Internal Pneumatic Schematic – SYSTEM LEAK CHECK –

Figure 10. molbox RFM Internal Pneumatic Schematic – SYSTEM LEAK CHECK –

Figure 11. molbox RFM Internal Pneumatic Schematic – molbloc-S OPERATION, BPR ON..................92

Figure 12. molbox RFM Internal Pneumatic Schematic – molbloc-S OPERATION, BPR OFF................ 92

Figure 13. Status Byte Register...............................................................................................................130

Figure 14. molbox RFM Internal Pneumatic Schematic – RUN UPSTREAM OR DOWNSTREAM

Figure 15. molbox RFM Internal Pneumatic Schematic – RUN MICRORANGE DIFFERENTIAL

Figure 16. molbox RFM Internal View......................................................................................................145

Figure 17. molbox RFM Valving Assembly Schematic............................................................................147

S

ACTIVE/INACTIVE..................................................................................................................23

molbloc-L OPERATION...........................................................................................................41

CHECKING OFFSET AND STABILITY molbloc-L operation..................................................50

CHECKING OFFSET AND STABILITY molbloc-S operation .................................................52

ABSOLUTE RPT CALIBRATION..........................................................................................139

RPT CALIBRATION ..............................................................................................................139

© 1998-2007 DH Instruments, a Fluke Company Page VI

Page 9

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the user with the information necessary to operate a molbox RFM, Reference Flow

Monitor. It also includes a great deal of additional information provided to help you optimize molbox RFM

use and take full advantage of its many features and functions.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure: All first

time molbox RFM users should read Section

molbox RFM operating principles. Section 4 is for

provides maintenance and calibration information. Section 6 is a quick troubleshooting guide. Use

troubleshoot unexpected molbox RFM behavior based on the symptoms of that behavior.

Certain words and expressions have specific meaning as they pertain to molbox RFM. Section 8 is useful as

a quick reference for exact definition of specific words and expressions as they are used in this manual.

For those of you who “don’t read manuals”, go directly to section 2.3, initial setup, to set up your

molbox RFM. Then go to section 2.4, power up and verification. This will get you running quickly with

minimal risk of causing damage to yourself or your molbox RFM. THEN… when you have questions or

start to wonder about all the great features you might be missing, get into the manual!

T

T

HHIISS

M

AANNUUAAL

M

L

2. Section 3 provides a comprehensive description of general

remote operation from an external computer. Section 5

Manual Conventions

it to

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates molbox RFM screen displays (e.g., <1yes>).

Page VII © 1998-2007 DH Instruments, a Fluke Company

Page 10

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 1998-2007 DH Instruments, a Fluke Company Page VIII

Page 11

1. INTRODUCTION

.

11.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

molbox RFM is a support unit for making low mass flow measurements using molbloc mass

flow elements. molbox RFM reads calibration data off the molbloc EEPROM and measures molbloc

upstream and downstream pressure using built-in high accuracy Reference Pressure

Transducers (RPTs). An ohmic measurement system reads the resistance of the molbloc platinum

resistance thermometers from which molbloc temperature is calculated. Using the molbloc calibration

data, pressures, temperature and gas properties stored in memory, the flow rate of the gas flowing

through the molbloc is calculated. A microrange option is available to increase resolution and accuracy

below 10 % FS of the molbloc-L flow range.

Internal molbox RFM valving supports on-board PRESSURE TRANSDUCER TARING, LEAK TESTING

and SELF PROTECTION functions as well as a gas purge routine.

molbox RFM provides a local user interface via a front panel key pad and display and includes advanced

on-board functions. Remote communication capability is supported with RS232 and IEEE-488 interfaces.

molbox RFM is intended for applications in which a highly compact presentation, high range ability and

lower cost are the primary considerations. A second model, molbox1, is available for applications where

higher accuracy is the most important requirement.

1.1.1 MOLBLOC FLOW ELEMENTS

Two different types of molblocs may be used with molbox RFM; molbloc-L (laminar) and

molbloc-S (sonic).

1.1.1.1 MOLBLOC-L FLOW ELEMENT

molbloc-L is the original molbloc laminar flow element. molbloc-L covers the

lower portion of the molbloc/molbox system flow range. The key molbloc-L

measurement is the differential pressure across the element, which is roughly

proportional to the mass flow rate through it. molbloc-L elements are calibrated

to be used at an absolute pressure that remains nearly constant, while the

differential pressure varies with flow rate. Different operating pressure options

and their effect on molbloc flow range are described in Section 1.2.4.1.2.

1.1.1.2 MOLBLOC-S FLOW ELEMENT

molbloc-S elements use critical (sonic) flow venturi nozzle technology to

measure flows, which overlap with the higher molbloc-L ranges and extend the

high end of the molbloc/molbox RFM system flow range. The mass flow rate

through a molbloc-S element is roughly proportional to the upstream absolute

pressure when the flow is “choked”, so the molbloc-S operating pressure can

vary widely as the mass flow rate is changed throughout the flow range. The

limits of molbloc-S operating pressure and flow ranges are defined by the

molbloc-S calibration type, described in Section 1.2.4.2.2.

Page 1 © 1998-2007 DH Instruments, a Fluke Company

Page 12

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

1.2 SPECIFICATIONS

1.2.1 GENERAL SPECIFICATIONS

Power Requirements

Fuse

Operating Temperature Range

Storage Temperature Range

Vibration

Weight

Dimensions

Microprocessor

Communication Ports

Reference Pressure Transducers

(RPTs)

Ohmic Measurement System

Gases Supported

Pressure Connections

Pressure Limits

Flow Ranges

CE Conformance

85 to 264 VAC, 47 to 440 Hz, 18 VA max. consumption

1A/250V, slow blow, 5x20mm, NSN: 5920008930491

15 to 35 °C

-20 to 70 °C

Meets MIL-T-28800D

2.55 kg (5.6 lb) max.

8 cm H x 22.5 cm W x 20 cm D

(3.1 in. x 8.9 in. x 7.9 in.) approx.

Motorola 68302, 16 MHz

RS232 (COM1), RS232 (COM2), IEEE-488

Standard: 2 x 600 kPa (87 psia) calibrated range piezoresistive silicon

Microrange option: 12.5 kPa (1.8 psid) piezoresistive silicon

Resolution: 0.004 Ω

Accuracy: ± 0.02 % of reading

Accuracy of 100 and 110 Ω reference resistors: ± 0.01 %

Stability of 100 and 110 Ω reference resistors: ± 0.005 % per three years

With molbloc-L Nitrogen (N2), Air, Argon (Ar), Butane (Butn), Carbon

Monoxide (CO), Helium (He), Oxygen (O2), Carbon Dioxide (CO2),

Carbon Tetrafluoride (CF4), Octofluorocyclobutane (C4F8), Ethane

(C2H6), Ethylene (C2H4), Fluoroform (CHF3), Hexafluoroethane (C2F6),

Hydrogen (H2), Methane (CH4), Nitrous Oxide (N2O), Propane (C3H8),

Sulfur Hexafluoride (SF6), Xenon (Xe)

With molbloc-S Nitrogen (N2), Air (dry and humid)

Quick connectors equivalent to Swagelok QM Series (-QM2-B200)

Maximum working pressure 600 kPa absolute (87 psia)

Maximum pressure without damage 800 kPa absolute (115 psia)

NOTE: The microrange option includes a 12.5 kPa (1.8 psi) differential

RPT which may be damaged by differential pressure greater than 100

kPa (15 psi).

See Sections 1.2.4.1.3, 1.2.4.1.4and 1.2.4.2.1

Available. Must be specified.

1.2.2 REFERENCE PRESSURE TRANSDUCER (RPT) SPECIFICATIONS

1.2.2.1 UPSTREAM AND DOWNSTREAM RPTS

Type

Range

Resolution

Repeatability

Accuracy

© 1998-2007 DH Instruments, a Fluke Company Page 2

Piezoresistive silicon

0 to 600 kPa absolute (0 to 87 psia)

6.0 Pa (0.0009 psi)

± 0.01 % FS

Absolute measurements: ± 0.05 % FS for one year

Differential measurements: ± (20 Pa + 0.05 % ΔΡ). Taring sequence eliminates zero

error on measurement of difference between the two RPTs.

Page 13

1. INTRODUCTION

1.2.2.2 DIFFERENTIAL RPT (MICRORANGE OPTION)

Type

Range

Resolution

Repeatability

Accuracy

Piezoresistive silicon

0 to 12.5 kPa differential (0 to 1.8 psid)

0.14 Pa (0.00002 psi)

± 0.01 % FS

± 0.05 % FS for one year. Taring sequence eliminates zero error.

1.2.3 TEMPERATURE MEASUREMENT SPECIFICATIONS

Specifications are for molbloc mounted Platinum Resistance Thermometers (PRT) combined

with molbox RFM resistance measurement system and temperature calculation.

Range

Accuracy

Resolution

0 to 40 °C

± 0.05 °C

0.01 °C

The molbox RFM internal resistance measurement system is automatically calibrated using

reference 100 and 110 Ω (± 0.01 %) resistors (see Section

5.3).

1.2.4 FLOW MEASUREMENT SPECIFICATIONS

molbox RFM measures the flow through molbloc flow elements. There are two different

types of molblocs, molbloc-L (laminar) (see Section 1.1.1.1) and molbloc-S (sonic) (see

Section 1.1.1.2). Flow measurement specifications, calibration types, ranges and dimensions

are detailed separately for each molbloc type in Section 1.2.4.1 and 1.2.4.2.

1.2.4.1 molbloc-L

The flow range, useable operating pressure and absolute and differential

pressure associated with molbloc-L operation depend on the molbloc used and

its pressure-dependent calibration options (see Section

Measurement Update Rate

Range

Resolution

Linearity

Repeatability

Precision

Stability

(1 year)

Measurement Uncertainty

(1 year, N2 and any molbox RFM

supported gas for which the molbloc

1 Precision: Combined linearity, hysteresis, repeatability.

2 Stability: aximum change in zero and span over specified time period for typical molbox RFM and

molbloc used under typical conditions. As stability can only be predicted, stability for a specific

molbox RFM should be established from experience.

3 Measurement Uncertainty (Accuracy): Maximum deviation of the molbox RFM flow indication from

the true value of the flow through the molbloc including precision, stability and DHI calibration

standard measurement uncertainty.

in use is calibrated)

1 second

0 to molbloc full scale depending on gas and molbloc

pressure dependent calibration type

(see Section 1.2.4.1.2).

0.01 % FS

± 0.23 % of reading from 10 to 100 % FS,

± 0.023 % FS under 10 % FS

± 0.1 of reading from 10 to 100 % FS,

± 0.01 % FS under 10 % FS

1

± 0.25 % of reading from 10 to 100 % FS,

± 0.025 % FS under 10 % FS

2

± 0.15 % of reading from 10 to 100 % FS,

± 0.015 % FS under 10 % FS

3

± 0.5 % of reading from 10 to 100 % FS,

± 0.05 % FS under 10 % FS

1.2.4.1.2).

Page 3 © 1998-2007 DH Instruments, a Fluke Company

Page 14

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

1.2.4.1.1 molbloc-L FLOW MEASUREMENT

SPECIFICATIONS, MICRORANGE OPTION

The microrange option (see Section 1.2.2.2) improves molbloc-L flow

measurement specifications below 10 % FS of the molbloc range. With the

microrange option, the affected measurement specifications below 10 % FS

become:

Resolution

Linearity

Repeatability

Precision1

Stability

(1 year)

Measurement Uncertainty

(1 year, N2 and any molbox RFM

supported gas for which the molbloc in

use is calibrated)

1 Precision: Combined linearity, hysteresis, repeatability.

2 Stability: Maximum change in zero and span over specified time period for typical molbox RFM and

molbloc used under typical conditions. As stability can only be predicted, stability for a specific

molbox RFM should be established from experience.

3 Measurement Uncertainty (Accuracy): Maximum deviation of the molbox RFM flow indication from

the true value of the flow through the molbloc including precision, stability and DHI calibration

standard measurement uncertainty.

0.01 % of 10 % FS (0.001 % FS)

± 0.23 % of reading from 1 to 10 % FS

± 0.1 % of reading from 1 to 10 % FS

± 0.25 % of reading from 1 to 10 % FS

2

± 0.15 % of reading from 1 to 10 % FS

3

± 0.5 % of reading from 1 to 10 % FS

1.2.4.1.2 molbloc-L PRESSURE DEPENDENT CALIBRATION

TYPES

See your molbloc’s Calibration Report to determine the calibration type of

the molbloc you are using.

Different pressure dependent calibration options for molbloc-L elements determine

the range of operating pressures over which a molbloc can be used within its

mass flow measurement specifications. The calibration option also affects the

molbloc flow range and the differential pressure associated with the flow range.

Measurement uncertainty (accuracy) specifications for molbloc-L are valid only

for gases with which the molbloc has been calibrated. All molbloc-L elements

are calibrated for N2. Calibrations with other gases are optional. DHI calibration

capability is not maintained at all times for all gases on all molbloc designations.

Check for availability before ordering calibrations.

© 1998-2007 DH Instruments, a Fluke Company Page 4

Page 15

1. INTRODUCTION

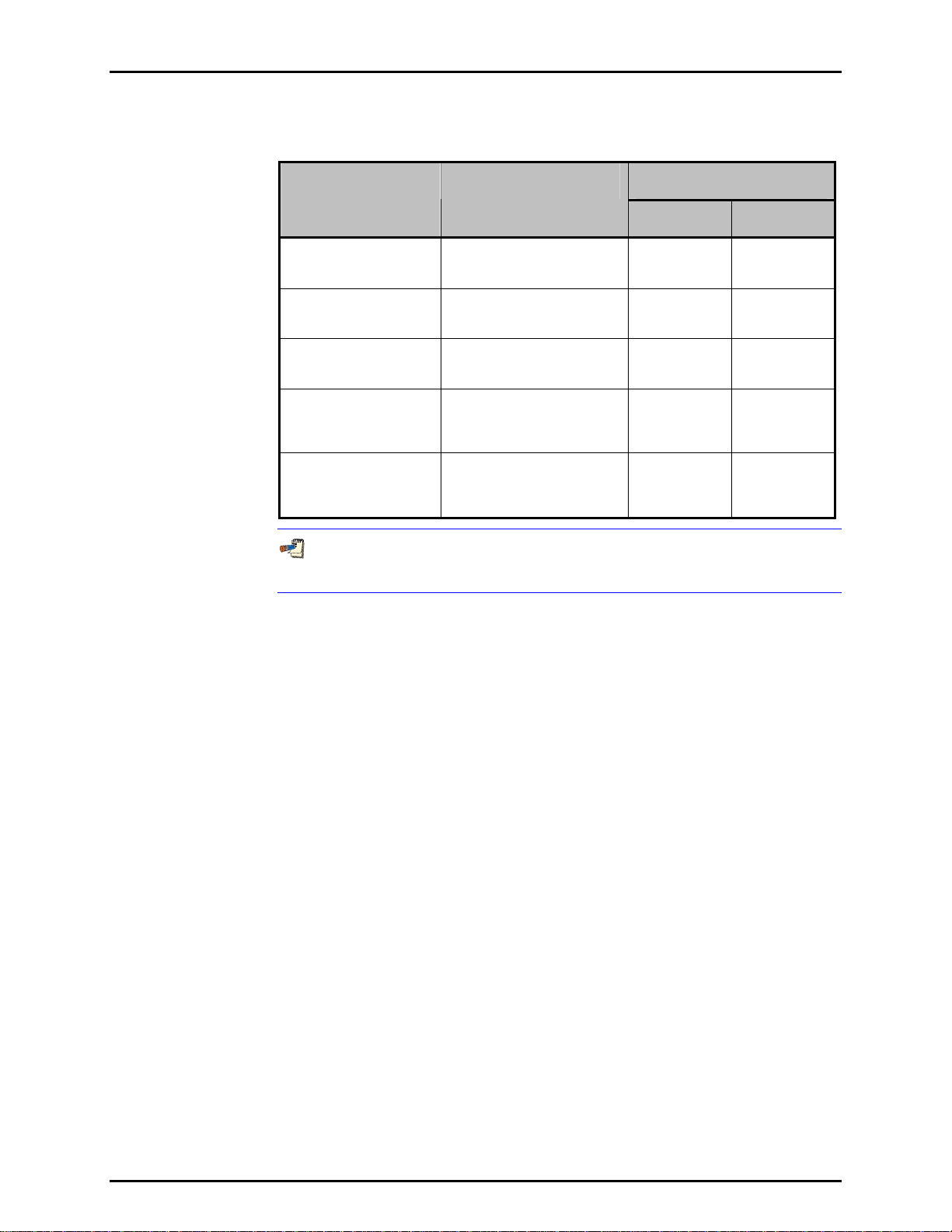

The molbloc-L pressure dependent calibration types are summarized in Table 1.

Table 1. molbloc-L Pressure Dependent Calibration Types

CALIBRATION TYPE

Full mod,

low pressure

Full mod,

high pressure

Downstream

Single P,

low pressure

(non-N2 gases only )

Single P,

high pressure

(non-N2 gases only )

OPERATING PRESSURE

200 to 325 kPa absolute

(29 to 48 psia)

upstream of molbloc

325 to 525 kPa absolute

(48 to 76 psia)

upstream of molbloc

Atmospheric pressure (95 to

105 kPa, 13.8 to 15.2 psia)

downstream of molbloc

Any specified single molbloc

upstream pressure between

200 and 325 kPa absolute (29

to 48 psia)

Any specified single molbloc

upstream pressure between

325 and 525 kPa absolute (48

to 76 psia)

NOMINAL DIFFERENTIAL

PRESSURE AT MAX. FLOW

1E5

MOLBLOC

5 kPa

(.725 psi)

Not available 50 kPa

12.5 kPa

(1.8 psi)

5 kPa

(.725 psi)

Not available 50 kPa

ALL OTHER

MOLBLOCS

50 kPa

(7.5 psi)

(7.5 psi)

80 kPa

(12 psi)

50 kPa

(7.5 psi)

(7.5 psi)

Differential pressure values are nominal and may vary by up to 15 % with the

actual molbloc used.

Page 5 © 1998-2007 DH Instruments, a Fluke Company

Page 16

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

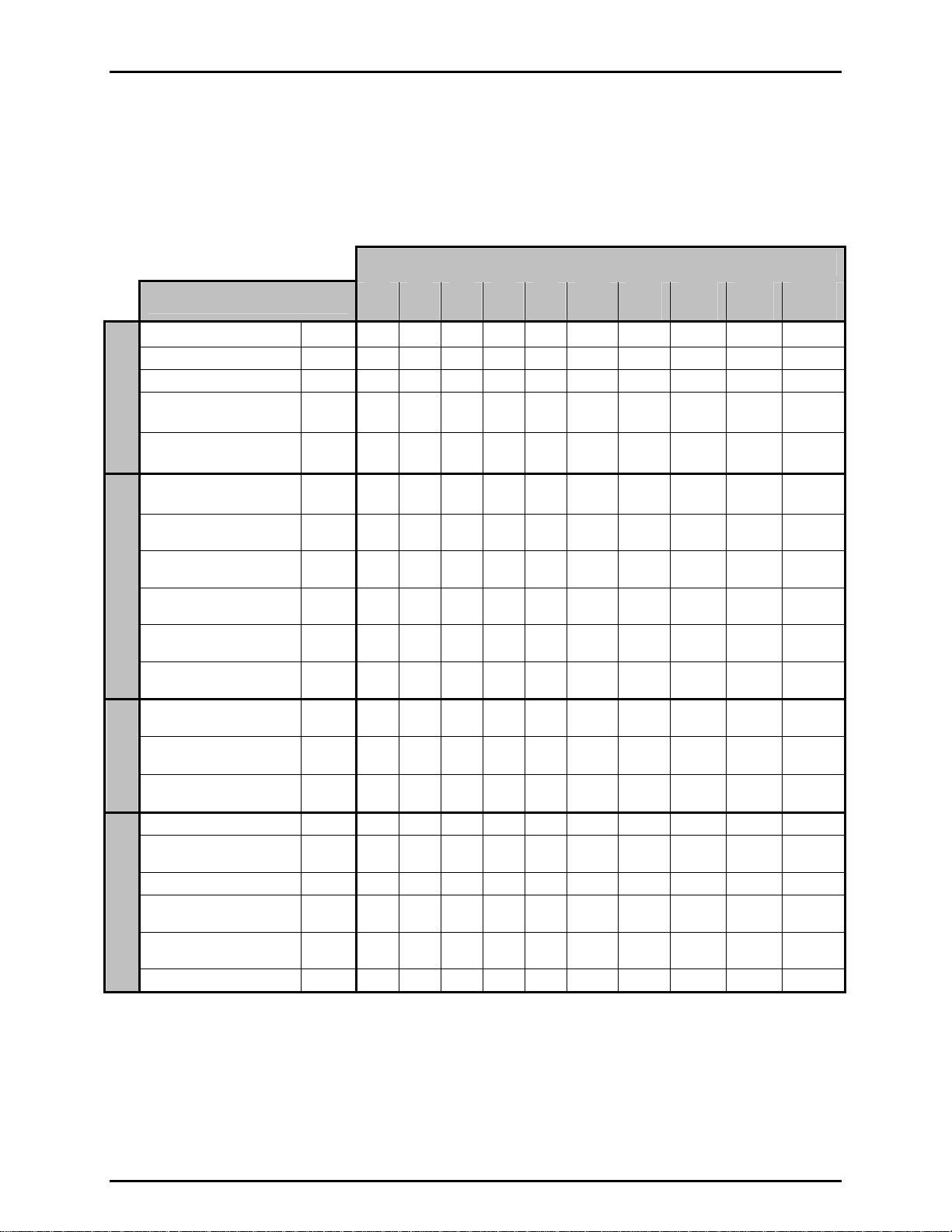

1.2.4.1.3 molbloc-L Ranges with Low Pressure Calibrations

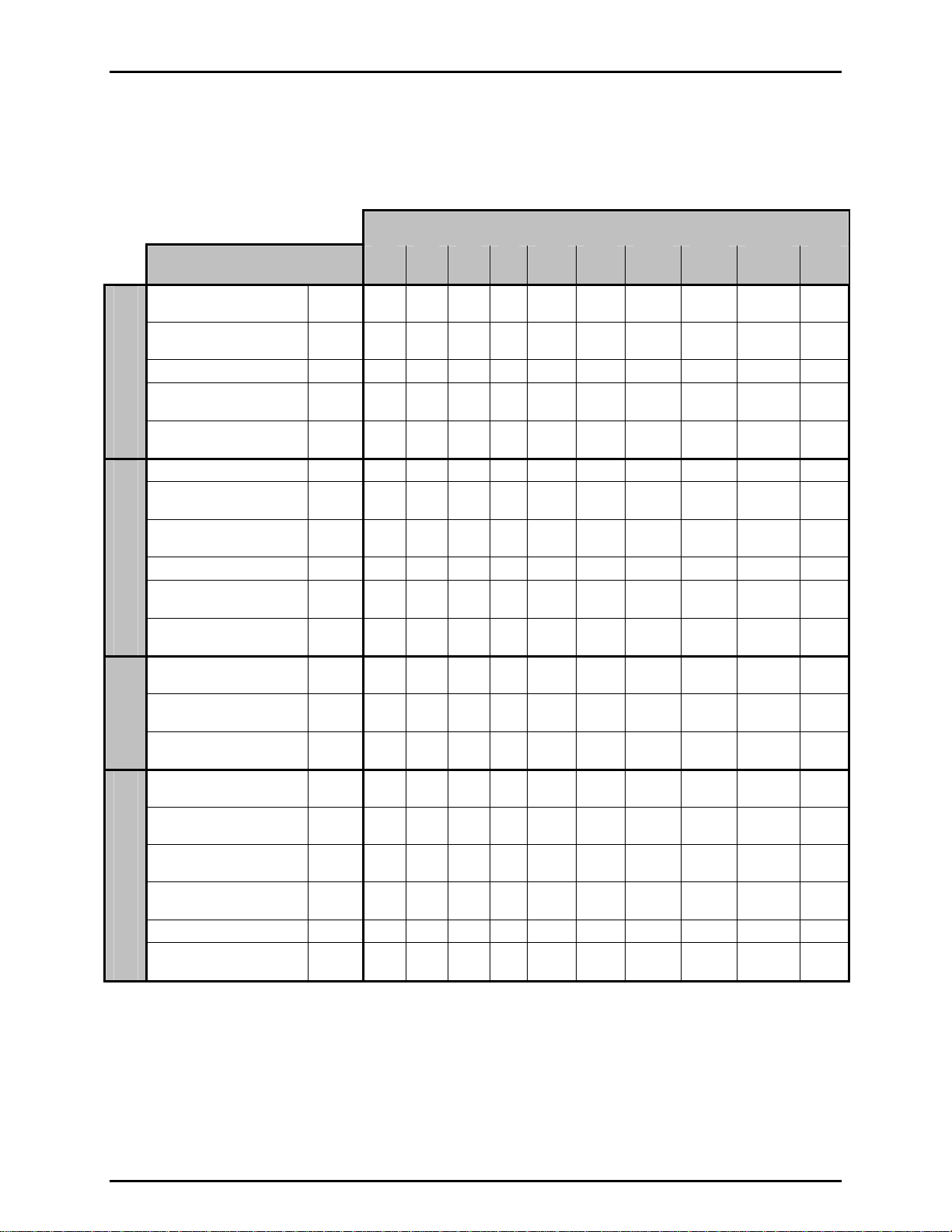

Table 2. molbloc-L Ranges with Low Pressure Calibrations

- full mod, low pressure

- full mod, downstream

- single P, low pressure

SIZE

Nitrogen N2

Argon Ar

Helium He

Sulfur Hexafluoride SF6

INERT

Xenon XE

Butane C4H10

Ethane C2H6

Ethylene C2H4

Hydrogen H2

FLAMMABLE

Methane CH4

Propane C3H8

Carbon

Tetrafluoride

Hexafluorethene C2F6

FLUORO-

CARBONS

Trifluoromethane CHF3

Air Air

Carbon Dioxide CO2

Carbon Monoxide CO

Nitrous Oxide N2O

OTHER

Octafluorocyclobutane

Oxygen O2

A bold value indicates that the maximum flow is limited by the maximum Reynolds number value of 1 200 which is reached

before the normal differential pressure range is reached. In that case, the second value gives the minimum flow for which

relative accuracy is ± 0.5 % of the measured value. With the microrange option, this value is divided by 10 (see Section

1.2.2.2).

Where there is no value in the field (--), this indicates that the maximum Reynolds number is reached before the differential

pressure reaches 5 kPa (1 kPa in the case of the 1E5 molbloc), therefore calibration with that gas is not useful.

[1] Due to low vapor pressure, only downstream calibration type is available.

GASES

[1]

C4F8

CF4

SIZE

1E1

5E1

10 50 100 200 500 1 000 5 000 10 000 30 000 100 000

10 50 100 200 500 1 000 5 000 10 000 25 000 80 000

10 50 100 200 500 1 000 5 000 10 000 30 000 100 000

10 50 100 200 500 1 000

10 40 80 150 400 800

20 100

20 100 200 400 1

16 80 160 320 800 1 600

20 100 200 400 1

16 80 160 320 800 1 600 8 000 16 000

20 100 200 400 1

10 50 100 200 500 1 000

10 50 100 200 500 1 000

10 50 100 200 500 1 000

10 50 100 200 500 1 000 5 000 10 000 30 000 100 000

10 50 100 200 500 1 000 5 000 10 000

10 50 100 200 500 1 000 5 000 10 000 30 000 100 000

10 50 100 200 500 1 000 5 000 10 000

15

10 50 100 200 500 1 000 5 000 10 000 30 000 80 000

molbloc-L SIZE AND FULL SCALE FLOW (sccm)

SIZE

SIZE

1E2

130

30

609 65

17

SIZE

2E2

270

50

130

34

5E2

670

140

000

000

000

330

85

SIZE

1E3

2 300

2 000

2 000 10

2 000

1 100

175

SIZE

5E3

2 000

500

3 500

500

2 200

1 400

6 000

1 000

7 000

1 000

000

3 000

1 000

4 000

600

2 000

600

4 000

600

1 050

840

SIZE

1E4

6 000

1 000

8 000

7 000

3 000

18 000

2 000

16 000

20 000 60 000 200 000

10 000

2 000

10 000

6 000

1 200

10 000

3 400

1 700

6 000

4 000

11 000

18 000

20 000

40 000

10 000

12 000

12 000

20 000

20 000

SIZE

3E4

3 000

---

---

6 000

5 000

5 000

7 000

3 000

6 000

4 000

4 000

4 000

4 000

--- ---

SIZE

1E5

---

---

30 000

20 000

---

---

60 000

50 000

70 000

40 000

120 000

40 000

---

---

36 000

25 000

---

---

38 000

30 000

60 000

30 000

60 000

30 000

© 1998-2007 DH Instruments, a Fluke Company Page 6

Page 17

1. INTRODUCTION

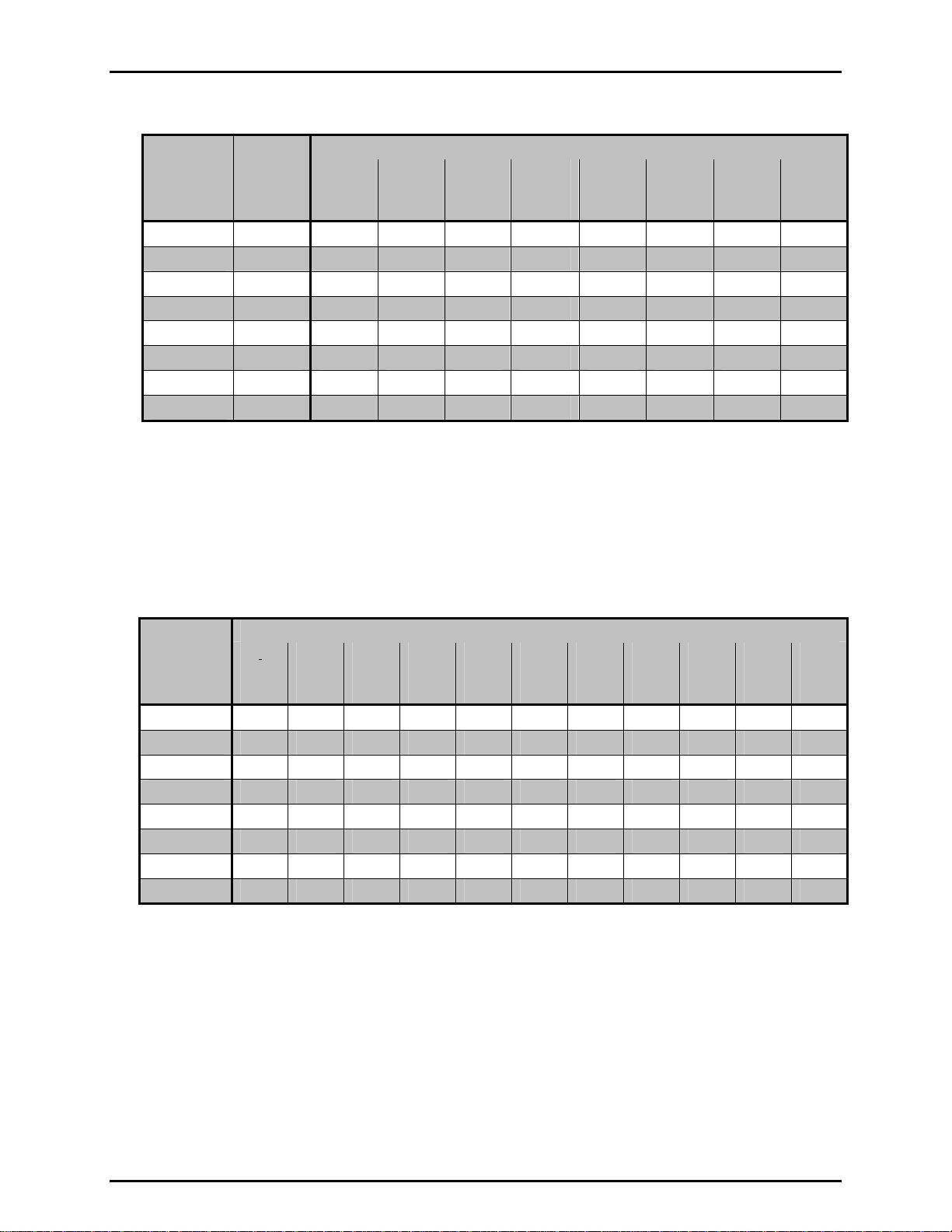

1.2.4.1.4 molbloc-L Ranges with High Pressure Calibrations

Table 3. molbloc-L Ranges with High Pressure Calibrations

- full mod, high pressure

- single P, high pressure

SIZE

GASES

Nitrogen N2

SIZE

1E1

5E1

20 100 200 400 1 000 2 000 10 000 20 000

molbloc-L SIZE AND FULL SCALE FLOW (sccm)

SIZE

SIZE

1E2

2E2

SIZE

5E2

SIZE

1E3

SIZE

5E3

SIZE

1E4

SIZE

3E4

40 000

SIZE

1E5

N/A

7 500

Argon Ar

20 100 200 400 1 000 2 000 10 000 17 000

35 000

N/A

6 000

Helium He

INERT

Sulfur Hexafluoride SF6

Xenon XE

[2]

Butane

C

4H10

Ethane C2H6

Ethylene C2H4

Hydrogen H2

Methane CH4

FLAMMABLE

Propane C3H8

Carbon

CF4

Tetrafluoride

Hexafluorethene C2F6

FLUORO-

CARBONS

Trifluoromethane CHF3

Air Air

20 100 200 400 1 000 2 000 10 000 20 000 65 000 N/A

25

100

120

15

30

20 100 150 350 650 1 700

250

* * * * * * * * * N/A

40 200

350

50

700

100

40 200 350 700 2 000 4 000

50

600

150

1 800

200

2 000

300

4 000

2 000

1 400

3 350

950

6 000

2 300

7 000

2 000

6 200

2 800

11 000

1 900

20 000

4 500

22 000

4 000

--

--

11 000

5 700

20 000

13 000

22 000

12 700

40 200 400 900 2 000 4 500 22 000 45 000 130 000 N/A

35 175 350 700 1 700 3 500

13 000

2 000

50 200

20 100 200 400 1 000 2 000

25

200

50

400

100

1 000

250

3 500

500

3 500

2 600

3 700

1 200

25

100

120

15

25 125

30

240

30

250

450

50

60

600

150

1 200

150

2 000

300

2 500

1 800

1 500

4 000

1 500

20 100 200 400 1 000 2 000 10 000 20 000

33 000 42 000

12 000

11 000

5 400

12 000

2 400

6 000

3 000

12 000

3 000

--

--

12 000

7 300

--

--

12 000

8 800

40 000

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

7 200

Carbon Dioxide CO2

Carbon Monoxide CO

25 125 250 500 1 250 2 500

6 600

1 400

20 000

2 500

20 000

8 800

20 100 200 400 1 000 2 000 10 000 20 000 40 000

N/A

N/A

7 500

OTHER

Oxygen O2

20 100 200 400 1 000 2 000 10 000 20 000

40 000

N/A

6 500

Octafluorocyclobutane

[2]

C4F8

Nitrous Oxide N2O

A bold value indicates that the maximum flow is limited by the maximum Reynolds number value of 1 200 which is reached before

the normal differential pressure range is reached. In that case, the second value gives the minimum flow for which relative accuracy

is ± 0.5 % of the measured value. With the microrange option, this value is divided by 10 (see Section 1.2.2.2).

Where there is no value in the field (--), this indicates that the maximum Reynolds number is reached before the differential pressure

reaches 5 kPa (1 kPa in the case of the 1E5 molbloc), therefore calibration with that gas is not useful.

* * * * * * * * * N/A

25 125 250 500 1 250 2 500

11 000

1 500

20 000

3 000

20 000

9 000

N/A

[2] The operating pressure range is greater than the vapor pressure value for the gas.

Page 7 © 1998-2007 DH Instruments, a Fluke Company

Page 18

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

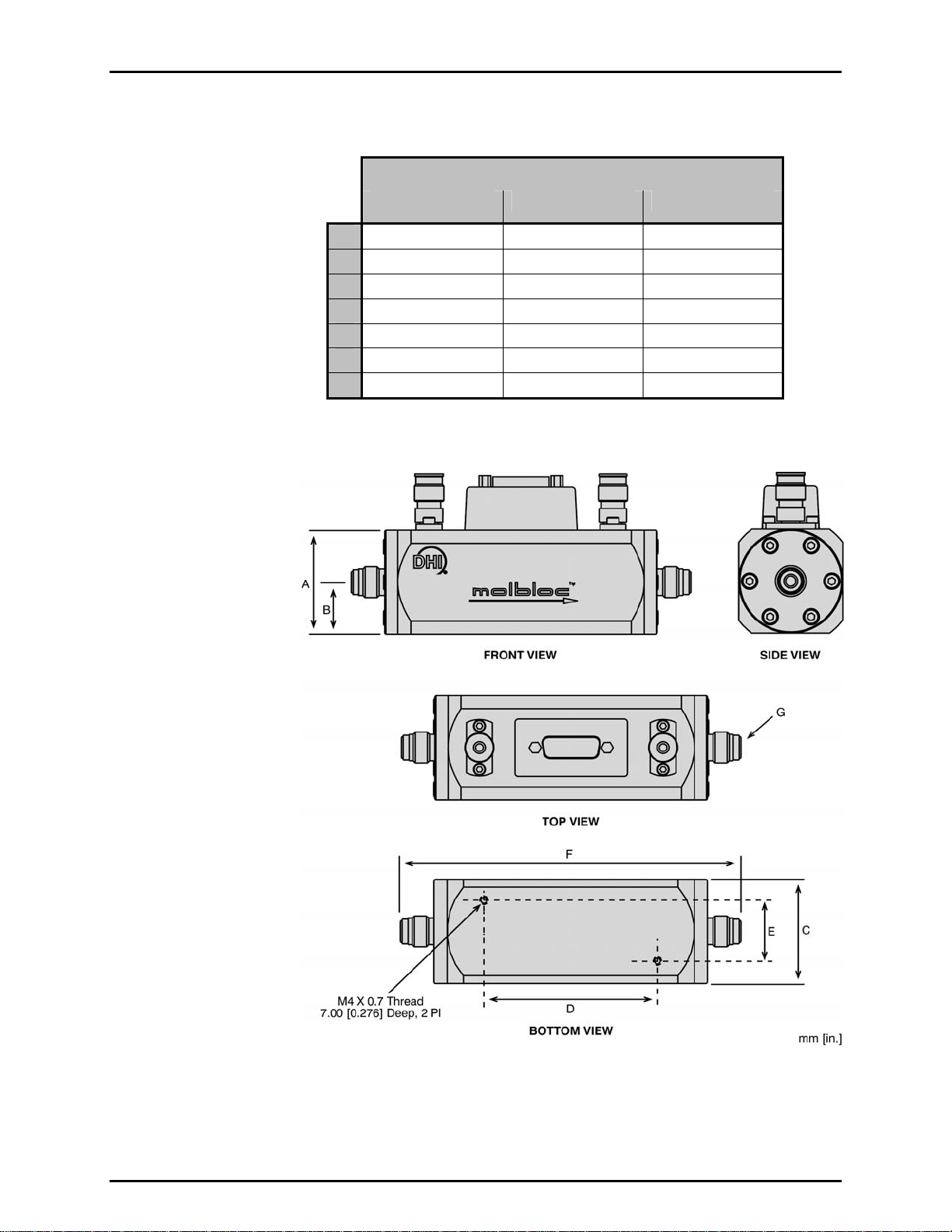

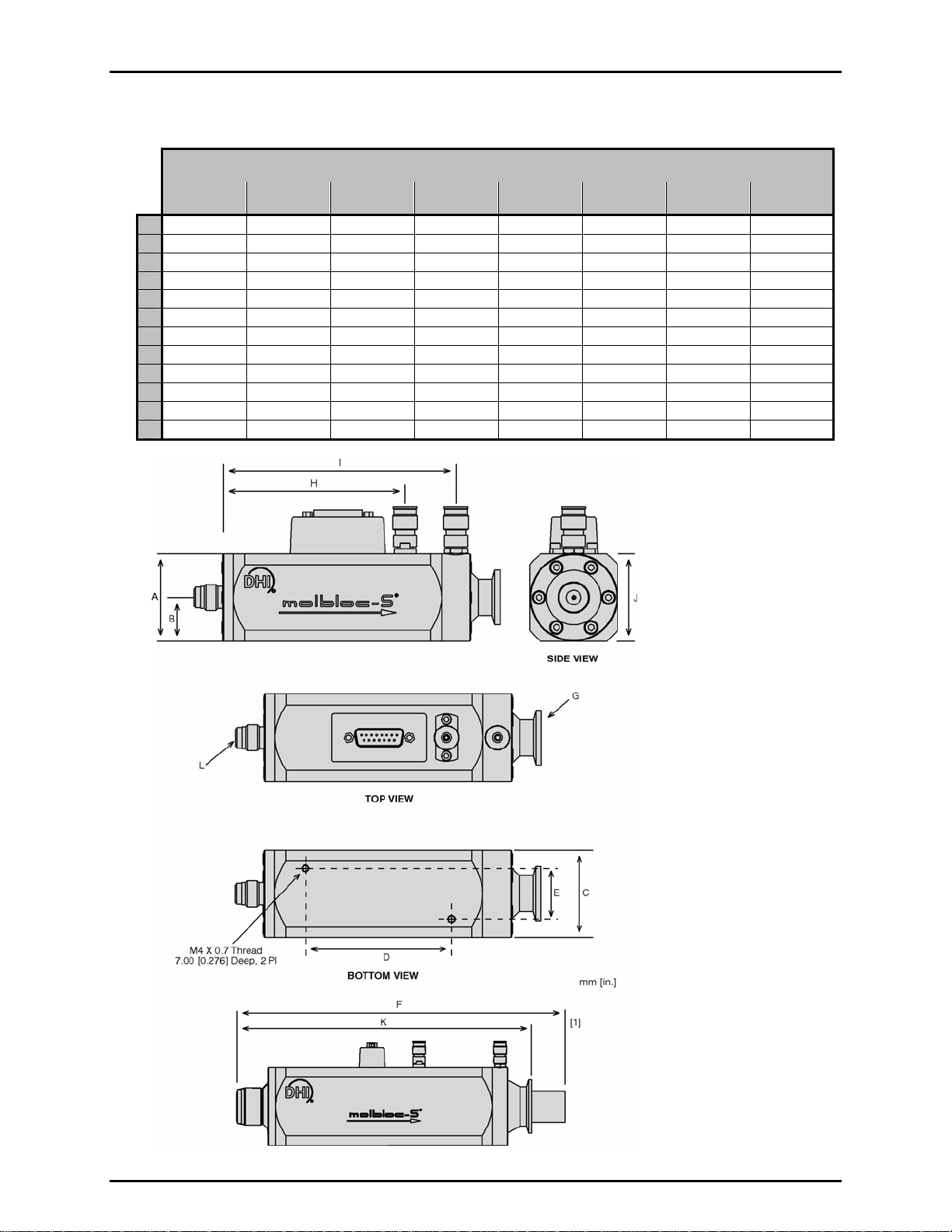

1.2.4.1.5 molbloc-L DIMENSIONS

5E3 AND LOWER 1E4, 3E4 1E5

58.50 (2.303) 74.50 (2.933) 74.50 (2.933)

A

16.00 (0.630) 24.00 (0.945) 24.00 (0.945)

B

32.00 (1.260) SQ 48.00 (1.890) SQ 48.00 (1.890) SQ

C

68.84 (2.750) 80.00 (3.150) 80.00 (3.150)

D

19.06 (0.750) 28.00 (1.102) 28.00 (1.102)

E

124.00 (4.881) 157.00 (6.181) 164.00 (6.458)

F

1/4 in. VCR M 1/4 in. VCR M 1/2 in. VCR M

G

molbloc-L SIZES [mm(in.)]

© 1998-2007 DH Instruments, a Fluke Company Page 8

Page 19

1. INTRODUCTION

1.2.4.2 molbloc-S

The flow range and operating pressure associated with molbloc-S operation

depend on the molbloc used and its calibration options (see Section 1.2.4.2.2)

Measurement Update

Range

Resolution

Linearity

Repeatability

Precision

Predicted Stability

(1 year)

Measurement

Uncertainty

With SP molbloc-S

calibration

Measurement

Uncertainty

With LP molbloc-S

calibration

1 Precision: Combined linearity, hysteresis, repeatability.

2. Stability: Maximum change in zero and span over specified time period for typical molbox RFM

and molbloc used under typical conditions. As stability can only be predicted, stability for a

specific molbloc and molbox RFM should be established from experience.

3. Measurement uncertainty (accuracy): Maximum deviation of the molbox RFM flow indication

from the true value of the flow through the molbloc including precision, stability and DHI

calibration standard measurement uncertainty.

1 second

Rate

Depends on molbloc-S pressure dependent calibration type

(see Section 1.2.4.2.2)

0.01 % of FS

± 0.25 % of reading

± 0.10 % of reading

1

± 0.30 % of reading

2

± 0.2 % of reading

± 0.5 % of reading from 50 to 500 kPa

3

± 0.5 % of reading from 50 to 200 kPa

3

± 0.5 % of 50 kPa flow from 20 to 50 kPa

1.2.4.2.1 molbloc-S RANGES

molbloc-S flow ranges are defined by the molbloc’s Pressure to Flow Conversion

Ratio, K

downstream pressure and the acceptable back pressure ratio (see Section

3.1.2). K

between mass flow and the absolute upstream pressure delivered to the

molbloc-S. molbloc-S sizes are defined by the nominal K

nozzle, using scientific notation, for example a 1E3 molbloc-S has a K

sccm/kPa. To differentiate from molbloc-L size designations, this molbloc size is

designated 1E3-S.

The molbox RFM pressure range, the molbloc-S calibration type (see Section

1.2.4.2.2) and the back pressure ratio (BPR) requirements (see Section 3.1.2)

limit the pressures, and flows, over which a molbloc-S can be used within known

measurement uncertainty limits. In practice, the usable range of a molbloc-S in a

given application also may depend on the available gas supply pressure, the presence

and flow capacity of a vacuum pump downstream or the allowable back pressure

on an upstream DUT.

The flow ranges for each molbloc-S size at various typical operating pressures

are summarized in Table 4 and the BPR limits are in Table 5.

, the absolute pressure that can be delivered upstream of molbloc-S, the

F

is expressed in units of sccm/kPa and defines the relationship

F

of the molbloc-S

F

1 000

F

Page 9 © 1998-2007 DH Instruments, a Fluke Company

Page 20

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

Table 4. molbloc-S Flow at Various molbloc Upstream Pressures

[1][2]

250 kPa

(36 psia)

500 kPa

(70 psia)

molbloc-S

DESIGNATO

R

5E1-S

1E2-S

2E2-S

5E2-S

1E3-S

2E3-S

5E3-S

1E4-S

FLOW [slm @ 0°C] WHEN molbloc-S UPSTREAM PRESSURE IS:

KF

[sccm/kPa]

20 kPa

(3psia)

50 kPa

(7 psia)

100 kPa

(15 psia)

Minimum

without

vacuum

]

[3

150 kPa

(22 psia)

200 kPa

(30 psia)

50 1 2.5 5 7.7 7.5 10 12.5 25

100 2 5 10 15 15 20 25 50

200 4 10 20 28 30 40 50 100

500 10 25 50 67 75 100 125 250

1 000 20 50 100 129 150 200 250 500

2 000 40 100 200 248 300 400 500 1 000

5 000 100 250 500 596 750 1 000 1 250 2500

10 000 200 500 1 000 1 173 1 500 2 000 2 500 5 000

[1] When volumetrically based mass flow units with reference temperatures other than 0°C are used, flow values

will generally be higher; for example, the flow values for a given molbloc and upstream pressure are

approximately 7% higher when expressed in slm @ 20°C. Flow values at a given pressure may vary by up to

2% due to flowpath machining tolerances.

[2] Flow values in table are valid only when critical flow is established.

[3] Minimum upstream pressure to achieve critical flow with atmospheric pressure (approximately 100 kPa)

downstream of molbloc-S (no vacuum).

Table 5. Minimum molbloc-S Critical Flow (slm) at Various molbloc-S Downstream Pressures

molbloc-S

DESIGNATO

R

5E1-S

1E2-S

2E2-S

5E2-S

1E3-S

2E3-S

5E3-S

1E4-S

250

kPa

(36

psia)

[1]

300

kPa

(44

psia)

MINIMUM molbloc-S CRITICAL FLOW [SLM @ 0°C] WITH molbloc DOWNSTREAM PRESSURE OF:

≤ 5

kPa

(0.7

psia)

1

2

4

10

20

40

100

200

10

kPa

(1.5

psia)

[2]

1.7 3.4 4.7 7.7 8.4 9.4 11 14 17 20

[2]

3.4 5.9 8.4 15 16 18 21 27 33 38

[2]

5.9 9.8 16 28 31 34 40 51 63 74

[2]

12 20 37 67 72 80 95 122 149 179

[2]

20

[2]

40

[2]

100

[2]

200

25

kPa

(3.5

psia)

[2]

39 69 129 139 154 184 239 294 349

[2]

73 131 248 268 298 358 468 578 687

[2]

173 317 596 646 746 871 1 145 1 420 1 694

[2]

347 615 1 173 1 273 1 442 1 741 2 240 2 789 3 338

50

kPa

(7

psia)

100

kPa

(15

psia)

110

kPa

(16

psia)

125

kPa

(18

psia)

150

kPa

(22

psia)

200

kPa

(30

psia)

[1] When volumetrically based mass flow units with reference temperatures other than 0 °C are used, flow values

will generally be higher; for example, the flow values for a given molbloc and upstream pressure are

approximately 7 % higher when expressed in slm @ 20 °C. Flow values at a given pressure may vary by up to

2 % due to flowpath machining tolerances.

[2] Limited by 20 kPa minimum calibration pressure rather than back pressure ratio.

© 1998-2007 DH Instruments, a Fluke Company Page 10

Page 21

1. INTRODUCTION

1.2.4.2.2 molbloc-S PRESSURE DEPENDENT CALIBRATION

TYPES

See your molbloc’s Calibration Report to determine the calibration type of

the molbloc you are using.

Measurement uncertainty (accuracy) specifications for molblocs are valid only for

gases with which the molbloc has been calibrated. All molbloc-S elements are

calibrated in one standard gas, either air or N2, and may be calibrated in other

gases. Calibrations with other gases are optional. The set of gases which can

be measured by molbloc-S is separate from the list of molbloc-L gases, and may

be more limited. DHI calibration capability is not maintained at all times for all

gases on all molbloc sizes. Check for availability before ordering calibrations.

molbloc-S calibrations are performed over flow ranges corresponding to one of

two pressure ranges, summarized in Table 6.

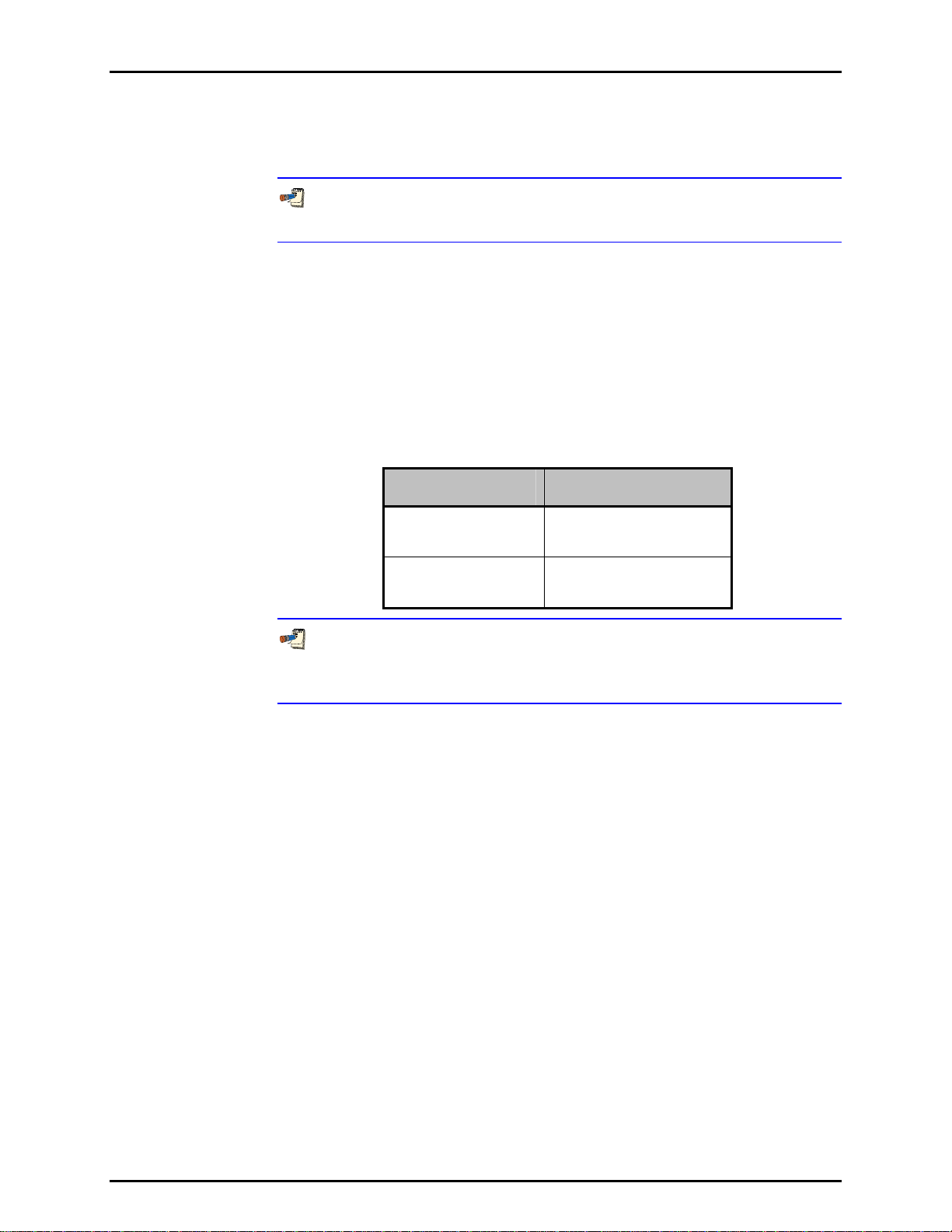

Table 6. molbloc-S Calibration Types

CALIBRATION TYPE

LP

low pressure

SP

standard pressure

OPERATING PRESSURE

20 to 200 kPa absolute (3 to

30 psia

upstream of molbloc

50 to 500 kPa absolute (7 to

70 psia)

upstream of molbloc

molbloc-S flow measurements are valid only when the ratio of pressure

downstream to pressure upstream of the nozzle is high enough to assure a

critical (choked) flow (see Section 3.1.2).

Page 11 © 1998-2007 DH Instruments, a Fluke Company

Page 22

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

1.2.4.2.3 molbloc-S Dimensions

5E1-S 1E2-S 2E2-S 5E2-S 1E3-S 2E3-S 5E3-S 1E4-S

48.0 (1.89) SQ 48.0 (1.89)SQ 48.0 (1.89) SQ 48.0 (1.89) SQ 48.0 (1.89) SQ 48.0 (1.89) SQ 80.0 (3.15) SQ 80.0 (3.15) SQ

A

24.0 (0.94) 24.0 (0.94) 24.0 (0.94) 24.0 (0.94) 24.0 (0.94) 24.0 (0.94) 40.0 (1.57) 40.0 (1.57)

B

48.0 (1.89) SQ 48.0 (1.89)SQ 48.0 (1.89) SQ 48.0 (1.89) SQ 48.0 (1.89) SQ 48.0 (1.89) SQ 80.0 (3.15) SQ 80.0 (3.15) SQ

C

80.0 (3.15) 80.0 (3.15) 80.0 (3.15) 80.0 (3.15) 80.0 (3.15) 80.0 (3.15) 176.0 (6.93) 176.0 (6.93)

D

28.0 (1.10) 28.0 (1.10) 28.0 (1.10) 28.0 (1.10) 28.0 (1.10) 28.0 (1.10) 44.0 (1.73) 44.0 (1.73)

E

167.5 (6.59) 167.5 (6.59) 171.0 (6.73) 171.0 (6.73) 171.0 (6.73) 175.0 (6.89)

F

KF16 FLANGE KF16 FLANGE KF16 FLANGE KF16 FLANGE KF16 FLANGE KF16 FLANGE KF40 FLANGE KF40 FLANGE

G

100.0 (3.94) 100.0 (3.94) 84.0 (3.31) 84.0 (3.31) 84.0 (3.31) 84.0 (3.31) 154.0 (6.06) 154.0 (6.06)

H

128.0 (5.04) 128.0 (5.04) 128.0 (5.35) 128.0 (5.35) 128.0 (5.35) 128.0 (5.35) 236.0 (9.29) 236.0 (9.29)

I

73.0 (2.87) 73.0 (2.87) 73.0 (2.87) 73.0 (2.87) 73.0 (2.87) 73.0 (2.87) 106.0 (4.17) 106.0 (4.17)

J

167.5 (6.59) 167.5 (6.59) 171.0 (6.73) 171.0 (6.73) 171.0 (6.73) 171.0 (6.73) 290.0 (11.42) 290.0 (11.42)

K

L

¼” VCR M

[2]

¼” VCR M

[2]

½” VCR M

molbloc-S SIZE [mm(in.)]

[2]

½” VCR M

[2]

½” VCR M

[2]

½” VCR M

[1]

299.7 (11.80)

[2]

1” NPT M

[1]

331.0 (13.03)

[2]

1” NPT M