Page 1

molbox™ RFM™

Reference

Flow Monitor

(Ver 1.20 and Higher)

Operation and Maintenance Manual

© 2010 Fluke Calibration

Page 2

Warning

High pressure liquids and gases are potentially hazardous. Energy stored in these

liquids and gases can be released unexpectedly and with extreme force. High

pressure systems should be assembled and operated only by personnel who have

© 2010 Fluke Calibration All rights reserved.

Information in this document i s subject to change without not i ce. No part of this docum ent may be reproduced or transmit ted in any

form or by any means, elect ronic or mechanical, for any purpose, without the express writt en permission of Fluke Calibration,

4765 East Beautiful Lane, Phoenix, Arizona 85044-5318 USA.

Fluke Calibration makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. Fl uke Calibration disclaims any respons ibility or liability for any direct or indirect damages

resulting from the use of the inform ation in this manual or products described in it. Mention of any product or brand does not

constitute an endorsem ent by Fluke Calibration of that product or brand. This manual was original ly composed in English and

was subsequently translated into ot her languages. The fi delit y of the t ransl ation c annot be guarant eed. I n cas e of confl ict between

the English version and other language versions, the English version predom i nates.

Products described in thi s manual are manufactured under int ernational patents and one or more of the f ollowing U.S. patents:

5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

been instructed in proper safety practices.

Fluke Calibration, FCAL, DH, DHI, molbox, molbox RFM , molbox1, molbox1+, molbloc, molbloc-L, molbloc-S, molstic,

COMPASS, CalTool are tradem ark s, registered and otherwise, of Fluke Corporation.

LabVIEW is registered trademark of National Ins truments Corporation.

Swagelok is a regis t ered trademark of the Swagelok Com pany.

Document No. 3152156

101115

Printed in the USA.

© 2010 Fluke Calibration Page II

Page 3

Table Of Contents

Table Of Contents ................................................................ III

Tables ................................................................................ VII

Figures ................................................................................ IX

About This Manual ................................................................ XI

1. Introduction ..................................................................... 1

1.1 Product Overview ................................................................................................................................... 1

1.1.1 molbloc Flow Elements ........................................................................................................................... 1

1.1.1.1 molbloc-L Flow Element ......................................................................................................................... 1

1.1.1.2 molbloc-S Flow Element ........................................................................................................................ 2

1.2 Specifications ......................................................................................................................................... 2

1.2.1 General Specifications ............................................................................................................................ 2

1.2.2 Reference Pressure Transducer (RPT) Specifications .......................................................................... 3

1.2.2.1 Upstream and Downstream RPT s .......................................................................................................... 3

1.2.2.2 Differential RPT (Microrange Option) ..................................................................................................... 3

1.2.3 Temperature Measurement Speci fi cations ............................................................................................. 4

1.2.4 Flow Measurement Specifications .......................................................................................................... 4

1.2.4.1 molbloc-L Flow Measurement Spec i fications, Model Ranges 1E1-L t hru 3E 4-L .................................... 4

1.2.4.1.1 molbloc-L FLOW MEASUREMENT SPECIFICATIONS, MICRORANGE OPTION ............................ 5

1.2.4.1.2 molbloc-L Pressure Dependent Cali bration Types .............................................................................. 6

1.2.4.1.3 molbloc-L Ranges with Low Pressure Calibrati ons ............................................................................. 7

1.2.4.1.4 molbloc-L Ranges with High Press ure Cali brations ............................................................................ 8

1.2.4.1.5 molbloc-L DIMENSI ONS .................................................................................................................... 9

1.2.4.2 molbloc-S ............................................................................................................................................. 10

1.2.4.2.1 molbloc-S Pressure Dependent Calibration Types ........................................................................... 10

1.2.4.2.2 molbloc-S Ranges ............................................................................................................................ 11

1.2.4.2.3 molbloc-S Dimens i ons ..................................................................................................................... 22

1.2.5 Front and Rear Panels ........................................................................................................................... 24

1.2.5.1 Front Panel .......................................................................................................................................... 24

1.2.5.2 Rear Panel ........................................................................................................................................... 24

2. Installation ..................................................................... 25

2.1 UNPACKING AND INSPECTION .......................................................................................................... 25

2.1.1 Removing From Packaging ................................................................................................................... 25

2.1.2 Inspecting Contents ............................................................................................................................... 25

2.2 Site Requirements ................................................................................................................................ 25

2.3 Initial setup ........................................................................................................................................... 26

2.3.1 Preparing for Operation ......................................................................................................................... 26

2.3.2 Power Connection ................................................................................................................................. 26

2.3.3 molbox RFM to molbloc Connection .................................................................................................... 27

2.3.4 GAS Supply And Flowpath Connections .............................................................................................. 27

2.3.5 Vacuum Supply (molbloc-S only) .......................................................................................................... 28

2.3.6 Communications Connections.............................................................................................................. 28

2.4 Power UP and Verification ................................................................................................................... 29

2.4.1 Power UP ................................................................................................................................................ 29

2.4.2 Check Proper Pressure Measurem en t Op er ati o n ................................................................................ 29

2.4.3 Check Proper Temperature Measurem ent O peration .......................................................................... 29

2.4.4 Leak Check ............................................................................................................................................. 30

2.4.5 Check/Set Security Level ....................................................................................................................... 30

2.5 Additional Precautions to Take Before Making Flow Measurements .............................................. 30

2.6 Short Term Storage .............................................................................................................................. 31

Page III © 2010 Fluke Calibration

Page 4

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

3. Operation ....................................................................... 33

3.1 General Operating Principles .............................................................................................................. 33

3.1.1 molbloc-L and molbloc-S operation ..................................................................................................... 33

3.1.2 molbloc-S BPR Limits............................................................................................................................ 33

3.1.3 Flow Ready/Not Ready Indication ......................................................................................................... 34

3.1.3.1 molbloc-L Operation ............................................................................................................................. 35

3.1.3.2 molbloc-S Operation ............................................................................................................................ 35

3.1.4 Soft [On/Off] Key .................................................................................................................................... 35

3.1.5 Microrange option (Optional) ................................................................................................................ 36

3.1.6 Reference pressure transducer (RPT) overpressure ........................................................................... 37

3.1.6.1 Upstream and Downstream Abs ol ut e RP T S ........................................................................................ 37

3.1.6.2 Differential RPT, Microrange Opt i on ..................................................................................................... 37

3.2 Main Run Screen .................................................................................................................................. 37

3.2.1 molbloc-L Operation .............................................................................................................................. 38

3.2.2 molbloc-S Operation .............................................................................................................................. 39

3.3 Manual Operation ................................................................................................................................. 40

3.3.1 Keypad Layout and Protocol ................................................................................................................. 40

3.3.2 Sounds.................................................................................................................................................... 41

3.3.3 Soft [On/Off] Key .................................................................................................................................... 41

3.3.4 Direct Function Keys Summary ............................................................................................................ 41

3.4 Direct Function Keys ............................................................................................................................ 42

3.4.1 [K] ............................................................................................................................................................ 42

3.4.2 [GAS] ....................................................................................................................................................... 44

3.4.2.1 molbloc-L Operation ............................................................................................................................. 45

3.4.2.2 molbloc-S Operation ............................................................................................................................ 46

3.4.3 [UNIT] ...................................................................................................................................................... 48

3.4.3.1 Mass Flow vs. Volume Flow ................................................................................................................. 49

3.4.3.2 Volumetrically B ased Mass Flow Units ................................................................................................. 50

3.4.3.3 Volumetrically Based Mass Flow Units at Various Reference Temperatures (UXXX) ........................... 51

3.4.3.4 Volume Flow Units (vlm) ...................................................................................................................... 51

3.4.3.5 Customizing FLOW Units Available Under The UNIT Function ............................................................ 52

3.4.4 [TARE] ..................................................................................................................................................... 53

3.4.4.1 <1Tare> ............................................................................................................................................... 54

3.4.4.1.1 molbloc-L OPERATION ................................................................................................................... 54

3.4.4.1.2 molbloc-S Operation ........................................................................................................................ 57

3.4.4.2 <2Purge> ............................................................................................................................................. 58

3.4.4.3 <3Leak Check> .................................................................................................................................... 60

3.4.4.3.1 Leak Check molbox .......................................................................................................................... 61

3.4.4.3.2 Leak Check System ......................................................................................................................... 63

3.4.4.4 <4AutoZ> ............................................................................................................................................. 67

3.4.4.4.1 Edit AutoZ ........................................................................................................................................ 69

3.4.4.4.2 Run AutoZ ........................................................................................................................................ 70

3.4.4.5 <5BPR> (molbloc-S Operati on onl y) .................................................................................................... 72

3.4.5 [P&T] (Pressure and Temperature) ....................................................................................................... 73

3.4.6 [DISPLAY] ............................................................................................................................................... 75

3.4.6.1 <1Rate> ............................................................................................................................................... 76

3.4.6.2 <2AVG> (AVERAGE) ........................................................................................................................... 77

3.4.6.3 <3 Hi/Lo> ............................................................................................................................................. 78

3.4.6.4 <4TOTAL> (TOTALIZER) .................................................................................................................... 78

3.4.6.5 <5UNIT> .............................................................................................................................................. 80

3.4.6.6 <6DEV> ............................................................................................................................................... 81

3.4.6.7 <7FREEZE>......................................................................................................................................... 82

3.4.6.8 <8CLEAN> ........................................................................................................................................... 82

3.4.7 [MICRO] (Optional) ................................................................................................................................. 83

3.4.8 [molbloc] ................................................................................................................................................. 84

3.4.8.1 molbloc-L and molbloc-S size and Range Designations ....................................................................... 85

3.4.9 [RES] ....................................................................................................................................................... 86

3.5 [SETUP] ................................................................................................................................................. 86

3.5.1 <1FLOWU> ............................................................................................................................................. 87

3.5.2 <2PRESU> .............................................................................................................................................. 87

3.5.3 <3TEMPU> .............................................................................................................................................. 88

3.5.4 <4molbloc> ............................................................................................................................................. 88

3.5.5 <5stab> ................................................................................................................................................... 89

3.5.6 <6ADJ> .................................................................................................................................................... 90

© 2010 Fluke Calibration Page IV

Page 5

TABLE OF CONTENTS

3.6 [SPECIAL] ............................................................................................................................................. 91

3.6.1 <1reset> .................................................................................................................................................. 92

3.6.1.1 <1sets> ................................................................................................................................................ 92

3.6.1.2 <2units> ............................................................................................................................................... 93

3.6.1.3 <3com> ................................................................................................................................................ 93

3.6.1.4 <4cal> .................................................................................................................................................. 93

3.6.1.5 <5all> ................................................................................................................................................... 94

3.6.2 <2level> ................................................................................................................................................... 94

3.6.2.1 Security Levels ..................................................................................................................................... 95

3.6.3 <3UL> ...................................................................................................................................................... 98

3.6.3.1 Upper Limit Alarm and S equence......................................................................................................... 99

3.6.4 <4cal>...................................................................................................................................................... 99

3.6.5 <5prefs> .................................................................................................................................................. 99

3.6.5.1 <1ScrSVR> .........................................................................................................................................100

3.6.5.2 <2Sound> ...........................................................................................................................................100

3.6.5.3 <3Time> ..............................................................................................................................................100

3.6.5.4 <4ID> ..................................................................................................................................................101

3.6.5.5 <5log> .................................................................................................................................................102

3.6.6 <6remote> ..............................................................................................................................................102

3.6.6.1 COM1 and COM2 ...............................................................................................................................103

3.6.6.2 IEEE-488 ............................................................................................................................................103

3.6.6.3 RS232 Self-Test ..................................................................................................................................103

3.6.7 <7Micro> ................................................................................................................................................104

3.6.8 <8Head> .................................................................................................................................................105

3.6.9 <9BPR> ..................................................................................................................................................106

4. Remote Operation ......................................................... 111

4.1 Overview ............................................................................................................................................. 111

4.2 Interfacing ........................................................................................................................................... 111

4.2.1 RS232 Interface .....................................................................................................................................111

4.2.1.1 COM1 .................................................................................................................................................112

4.2.1.2 COM2 .................................................................................................................................................112

4.2.2 IEEE-488 (GPIB) ....................................................................................................................................113

4.3 Commands .......................................................................................................................................... 113

4.3.1 Command Syntax ..................................................................................................................................113

4.3.2 COMMAND summary ............................................................................................................................114

4.3.3 Error Messages .....................................................................................................................................116

4.3.4 Command Descriptions ........................................................................................................................117

4.3.4.1 IEEE Std. 488.2 Common and Status Commands ..............................................................................117

4.3.4.2 MOLBOX rfm commands ....................................................................................................................121

4.4 Status System ..................................................................................................................................... 147

4.4.1 Status Reporting System ......................................................................................................................147

4.4.1.1 Status Byte Register ...........................................................................................................................147

4.4.1.2 Standard Event Register .....................................................................................................................149

5. Maintenance, Adjustments And Calibration ..................... 151

5.1 Product Overview ............................................................................................................................... 151

5.2 Calibration of Reference Pressure Transducers (RPTs) ................................................................ 152

5.2.1 Principle.................................................................................................................................................152

5.2.1.1 PA and PM Coefficients ......................................................................................................................153

5.2.2 Equipment Required .............................................................................................................................153

5.2.2.1 upstream and downstream AB solute RPTs .........................................................................................153

5.2.2.2 Differential (microrange) RP T ..............................................................................................................154

5.2.3 Set-Up and Preparation ........................................................................................................................154

5.2.3.1 UPSTREAM AND DOWNSTREAm Absolute RPTS ...........................................................................154

5.2.3.2 MICRORANGE Differential RP T .........................................................................................................155

5.2.4 Viewing and editing RPT READINGS AND Calibration Information...................................................155

5.2.4.1 Viewing RPT outputs ...........................................................................................................................156

5.2.4.2 Viewing and Editing rpt PA, PM and Calibration dat e ..........................................................................158

5.2.5 RPT Calibration/Adjustment Procedure Without Using CALTOOL for RPTS Software ....................159

5.3 OHMIC Measurement System Verification ....................................................................................... 160

5.3.1 OHMIC Measurement S ystem Calibration /Adjustment Procedure .....................................................162

Page V © 2010 Fluke Calibration

Page 6

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

5.4 Reloading Embedded Software Into molbox RFM Flash Memory ................................................. 163

5.5 RELOADING MOLBLOC EEPROM FILE ............................................................................................ 163

5.6 Overhaul .............................................................................................................................................. 163

5.6.1 Internal View ..........................................................................................................................................164

5.6.1.1 Upstream absolute RPT ......................................................................................................................165

5.6.1.2 Downstream absolute RPT .................................................................................................................165

5.6.1.3 Differential mic rorange RPT (opt i onal ) ................................................................................................165

5.6.1.4 Display ................................................................................................................................................165

5.6.1.5 Power Supply ......................................................................................................................................165

5.6.1.6 Micro Board .........................................................................................................................................165

5.6.1.7 Valving Module....................................................................................................................................165

5.6.1.8 Main Board ..........................................................................................................................................166

5.6.1.9 Cooling fan ..........................................................................................................................................166

6. Troubleshooting ........................................................... 167

6.1 OVERVIEW .......................................................................................................................................... 167

7. Appendix ...................................................................... 173

7.1 CONVERSION OF NUMERICAL VALUES.......................................................................................... 173

7.1.1 PRESSURE ............................................................................................................................................173

7.1.2 Temperature ..........................................................................................................................................173

7.1.3 Flow .......................................................................................................................................................174

7.2 Limited Warranty and Limitation of Liability .................................................................................... 177

8. Glossary ...................................................................... 179

© 2010 Fluke Calibration Page VI

Page 7

Tables

Table 1. molbloc-L Pressure Dependent Calibration Types ......................................................................... 6

Table 2. molbloc-L Ranges with Low Pressure and Downstream Calibrations ............................................ 7

Table 3. molbloc-L Ranges with High Pressure Calibrations ....................................................................... 8

Table 4: molbloc-S Calibration Types ......................................................................................................... 11

Table 5: N2. molbloc-S Flow in Nitrogen at Various molbloc Upstream Pressures ................................... 12

Table 6: Ar. molbloc-S Flow in Argon at Various molbloc Upstream Pressures ........................................ 12

Table 7: He. molbloc-S Flow in Helium at Various molbloc Upstream Pressures ..................................... 13

Table 8: SF6. molbloc-S Flow in Sulfur Hexafluoride at Various molbloc Upstream Pressures ................ 13

Table 9: Xe. molbloc-S Flow in Xenon at Various molbloc Upstream Pressures ...................................... 14

Table 10: C4H10. molbloc-S Flow in Butane at Various molbloc Upstream Pressures ............................. 14

Table 11: C2H6. molbloc-S Flow in Ethane at Various molbloc Upstream Pressures ............................... 15

Table 12: C2H4. molbloc-S Flow in Ethylene at Various molbloc Upstream Pressures ............................ 15

Table 13: H2. molbloc-S Flow in Hydrogen at Various molbloc Upstream Pressures ............................... 16

Table 14: CH4. molbloc-S Flow in Methane at Various molbloc Upstream Pressures .............................. 16

Table 15: C3H8. molbloc-S Flow in Propane at Various molbloc Upstream Pressures ............................ 17

Table 16: CF4. molbloc-S Flow in Carbon Tetrafluoride at Various molbloc Upstream Pressures ........... 17

Table 17: C2F6. molbloc-S Flow in Hexafluoroethene at Various molbloc Upstream Pressures .............. 18

Table 18: CHF3. molbloc-S Flow in Trifluoromethane at Various molbloc Upstream Pressures .............. 18

Table 19: Air. molbloc-S Flow in Air at Various molbloc Upstream Pressures .......................................... 19

Table 20: CO2. molbloc-S Flow in Carbon Dioxide at Various molbloc Upstream Pressures ................... 19

Table 21: CO. molbloc-S Flow in Carbon Monoxide at Various molbloc Upstream Pressures ................. 20

Table 22: N2O. molbloc-S Flow in Nitrous Oxide at Various molbloc Upstream Pressures ...................... 20

Table 23: C4F8. molbloc-S Flow in Octafluorocyclobutane1 at Various molbloc Upstream Pressures ..... 21

Table 24: O2. molbloc-S Flow in Oxygen at Various molbloc Upstream Pressures .................................. 21

Table 25. molbox RFM Parts List ............................................................................................................... 25

Table 26: Minimum molbloc-S Critical Flow (slm) in Nitrogen at Various

molbloc-S Downstream Pressures .......................................................................................... 34

Table 27. Summary of molbox RFM Direct Function Key Operations ....................................................... 42

Table 28. Available molbloc-L Gases ......................................................................................................... 45

Table 29. Available Flow Units ................................................................................................................... 52

Table 30. Flow Units and Corresponding Total Mass or Volume Units ...................................................... 80

Table 31. molbloc-L Size and Nominal Range Designations ..................................................................... 85

Table 32. molbloc-S Size Designation and Pressure to Flow Conversion Ratio (KF) ................................. 86

Table 33. Pressure Units of Measure Available ......................................................................................... 88

Table 34. Security Levels - Functions NOT Executed Per Function/Level ................................................ 96

Table 35. Security Levels - Functions NOT Executed Per Function/Level (Continued) ............................. 97

Table 36. COM1 and COM2 Available Settings ....................................................................................... 103

Table 37. COM1 DB-9F Pin Designation ................................................................................................. 112

Table 38. COM2 DB-9M Pin Designation ................................................................................................. 113

Table 39. Command Summary ................................................................................................................ 114

Table 40. Error Messages ........................................................................................................................ 116

Table 41. Status Byte Register ................................................................................................................. 147

Table 42. Standard Event Register .......................................................................................................... 149

Table 43. Troubleshooting Checklist ........................................................................................................ 167

Page VII © 2010 Fluke Calibration

Page 8

ABOUT THIS MANUAL

Table 44. Pressure Unit Conversions ...................................................................................................... 173

Table 45. Temperature Unit Conversion .................................................................................................. 173

Table 46. Conversions From kg/s To sccm At 0 °C For Various Gases .................................................. 174

Table 47. Conversions From sccm At 0 °C To Other Volumetrically Based Flow Units .......................... 174

Table 48. Conversions From Volumetrically Based Flow Units At 0 °C To Corresponding Units

At Another Temperature (uxxx) ............................................................................................. 175

Table 49. Conversions From kg/s To mole/s For Various Gases ............................................................ 175

Table 50. Conversion From mole/s To pccm ........................................................................................... 176

Table 51. Conversion From sccm At 0 °C to Volume Flow Units At Another Pressure

And Temperature ................................................................................................................... 176

Table 52. Fluke Calibration Authorized Service Providers ....................................................................... 178

© 2010 Fluke Calibration Page VIII

Page 9

Figures

Figure 1. molbloc-L Upstream End Flange with Integrated Filter ................................................................. 2

Figure 2. molbox RFM Front Panel ............................................................................................................ 24

Figure 3. molbox RFM Rear Panel ............................................................................................................. 24

Figure 4. molbox RFM Internal Pneumatic Schematic – ............................................................................ 36

Figure 5. Keypad Layout ............................................................................................................................ 40

Figure 6. molbox RFM Internal Pneumatic Schematic – TARING,

UPSTREAM molbloc-L OPERATION ...................................................................................... 55

Figure 7. molbox RFM Internal Pneumatic Schematic – TARING molbloc-S OPERATION ...................... 58

Figure 8. molbox RFM Internal Pneumatic Schematic – PURGING .......................................................... 59

Figure 9. molbox RFM Internal Pneumatic Schematic – LEAK CHECK molbox ....................................... 62

Figure 10. molbox RFM Internal Pneumatic Schematic – SYSTEM LEAK CHECK –

CHECKING OFFSET AND STABILITY molbloc-L operation .................................................. 64

Figure 11. molbox RFM Internal Pneumatic Schematic – SYSTEM LEAK CHECK –

CHECKING OFFSET AND STABILITY molbloc-S operation .................................................. 66

Figure 12. molbox RFM Internal Pneumatic Schematic – molbloc-S OPERATION, BPR ON ................ 107

Figure 13. molbox RFM Internal Pneumatic Schematic – molbloc-S OPERATION, BPR OFF ............... 107

Figure 14. Status Byte Register ............................................................................................................... 148

Figure 15. molbox RFM Internal Pneumatic Schematic – RUN UPSTREAM OR DOWNSTREAM

ABSOLUTE RPT CALIBRATION .......................................................................................... 157

Figure 16. molbox RFM Internal Pneumatic Schematic – RUN MICRORANGE DIFFERENTIAL

RPT CALIBRATION............................................................................................................... 158

Figure 17. molbox RFM Internal View ...................................................................................................... 164

Figure 18. molbox RFM Valving Assembly Schematic ............................................................................ 166

Page IX © 2010 Fluke Calibration

Page 10

ABOUT THIS MANUAL

Notes

© 2010 Fluke Calibration Page X

Page 11

About This Manual

This manual provides the user with the infor mation necessary to operate a molbox RFM, Referenc e Flow

Monitor. It also includes a great deal of additional information provided to help you optimize molbox RFM use

and take full advantage of its many features and functions.

Before using the m anual, tak e a m om ent to f am iliarize yourself with the Table of Contents str ucture: All f irst

time molbox RFM user s should read Section 2. Section 3 provides a comprehensive description of gener al

molbox RFM operating principles. Section 4 is for remote operation from an ex ternal computer. Section 5

provides maintenance and calibration information. Section 6 is a quick troubleshooting guide. Use it to

troubleshoot unexpected molbox RFM behavior based on the symptoms of that behavior.

Certain words and expres s ions have s pecif ic meaning as they pertain to molbox RFM. Section 8 is useful as

a quick reference for exact definition of specific words and expressions as they are used in this manual.

Note

For those of you who “don’t read manuals”, go directly to section 2.3, initial setup,

to set up your molbox RFM. Then go to section 2.4, power up and verification.

This will get you running quickly with minimal risk of causing damage to yourself

or your molbox RFM. THEN… when you have questions or start to wonder about

all the great features you might be missing, get into the manual!

Manual Conventions

Caution

“Caution” is used in throughout the manual to identify conditions or actions that

could cause harm to the molbox RFM or to the devices that are connected to the

molbox RFM.

Warning

“Warning” is used in throughout the manual to identify actions that could pose a

hazard to the user of the molbox RFM.

Note

“Note” is used throughout the manual to identify operating and applications advice

[ ] Indicates direct function keys (e.g., [RANGE]).

< > Indicates molbox1+ screen displays (e.g., <1yes>).

and additional explanations.

Page XI © 2010 Fluke Cali brat i on

Page 12

ABOUT THIS MANUAL

Notes

© 2010 Fluke Calibration Page XII

Page 13

1. Introduction

1.1 Product Overview

molbox RFM is a support unit for making low mass flow measurements using molbloc mass

flow elements. molbox RFM reads calibration data off the molbloc EEPROM and measures molbloc

upstream and downstream pressure using built-in high accuracy Reference Pressure

Transducers (RPTs). An ohmic measurement system reads the resistance of the molbloc platinum

resistance thermometers from which molbloc temperature is calculated. Using the molbloc calibration

data, pressures, temperature and gas properties stored in memory, the flow rate of the gas flowing

through the molbloc is calculated. For molbloc-L laminar flow element model ranges 1E1-L to 3E4-L a

microrange option is available to increa se resoluti on and accuracy be low 10 % FS of the flow ra nge. For

the molbloc-L model range 1E5-L the microrange option is required to achieve the stated uncertainty due

to the very low differential pressure of this range. The microrange option has no function in relation to

the molbloc-S sonic flow elements.

Internal molbox RFM valving supports on-boar d PRESSURE TRANSDUCER TARING , LEAK TESTING

and SELF PROTECTION functions as well as a gas purge routine.

molbox RFM provides a loc al user interface via a fr ont panel key pad and display and includes advanced

on-board functions. Remote communication capability is supported with RS232 and IEEE-488 interfaces.

molbox RFM is intended for applications in which a highly compact presentation, high range ability and

lower cost are the prim ary considerations. A second m odel, m olbox 1+, is available for applications where

higher accuracy is the most important requirement.

1.1.1 molbloc Flow Elements

Two different types of molblocs may be used with molbox RFM; molbloc-L (laminar) and

molbloc-S (sonic). The molbox RFM version 1.20 or later maintains support for older

molblocs but also supports operation with new or upgraded molblocs that have the updated

data structure to take advantage of molbox1+ features.

1.1.1.1 molbloc-L Flow Eleme nt

molbloc-L is the original molbloc laminar flow element. molbloc-L covers the

lower portion of the molbloc/molbox system flow range. The key molbloc-L

measurement is the differential pressure across the element, which is roughly

proportional to the m ass flow rate through it. molbloc -L elements are calibrated

to be used at an absolute pressure that remains nearly constant, while the

differential pressure varies with flow rate. Different operating pressure options

and their effect on molbloc flow range are described in Section 1.2.4.1.2.

Page 1 © 2010 Fluke Cal i brat i on

Page 14

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

In addition to the new data structure and modelization methods that became

available for molblocs with the introduction of molbox1+, all molbloc-L elements

of range 1E1-L to 3E4-L produced or upgraded af ter the r elease of m olbox1+ are

equipped standard with an upstream ¼” VCR flange, or f lowpath connection, that

has an integrated sintered metal filter. T his filter is intended to be a last defense

against particulate contamination of the molbloc-L internal flowpath which can

affect molbloc-L m easurem ents. Every eff ort should still be m ade to supply clean

dry gas to the molbloc to ensure its measurement performance and long-term

stability. molblocs that have the integrated upstream filter are recognizable by the

visible filter element as shown below.

Figure 1. molbloc-L Upstream End Flange with Integrated Filter

New molbloc-L elements produced with molbox1+ calibration data structure,

premium calibration options, and integrated filter hardware can be identified by

having a serial number of 6000 or higher. Most older molbloc-L elements are

eligible for upgrade to this hardware/version by Fluke Calibration.

1.1.1.2 molbloc-S Flow Eleme nt

molbloc-S elements us e critical (s onic) f low venturi nozzle technology to measure

flows, which overlap with the higher molbloc-L ranges and ex tend the high end of

the molbloc/molbox RFM system flow range. The mass flow rate through a

molbloc-S element is roughly proportional to the upstream absolute pressure

when the flow is “choked”, so the molbloc-S operating pres sure can vary widely

as the mass flow rate is changed throughout the flow range. The limits of

molbloc-S operating pressure and flow ranges are defined by the molbloc-S

calibration type, described in Section 1.2.4.2.2.

New calibration data structure and premium calibration options for molbloc-S

were also introduced along with molbox1+. molbloc-S elements produced with

this support will have serial num ber of 4000 or higher. O lder molbloc-S elem ents

are eligible for upgrade to this version format by Fluke Calibration.

1.2 Specifications

1.2.1 General Specifications

Power Requirements

Fuse

Operating Temperature Range

Storage Temperature Range

Vibration

Weight

Dimensions

© 2010 Fluke Calibration Page 2

85 to 264 VAC, 47 to 440 Hz, 18 VA m ax. c onsumption

1A/250V, slow blow, 5x20mm, NSN: 5920008930491

15 to 35 °C

-20 to 70 °C

Meets MIL-T-28800D

2.55 kg (5.6 lb) max.

8 cm H x 22.5 cm W x 20 cm D

(3.1 in. x 8.9 in. x 7.9 in.) approx.

Page 15

1. INTRODUCTION

Microprocessor

Communication Ports

Reference Pressure Transducers

(RPTs)

Ohmic Measurement System

Gases Supported

Pressure Connections

Pressure Limits

Flow Ranges

CE Conformance

Motorola 68302, 16 MHz

RS232 (COM1), RS232 (COM2), IEEE-488

Standard: 2 x 600 kPa (87 psia) calibrated range piezores i s tive silicon

Microrange option: 12.5 kPa (1.8 psi d) pi ezores i stive silicon

Resolution: 0.004 Ω

Accuracy: ± 0.04 Ω

Accuracy of 100 and 110 Ω ref erence resistors: ± 0.01 %

Stability of 100 and 110 Ω reference resistors: ± 0.005 % per three years

molbloc-L and molbloc -S

Nitrogen (N2), dry Air, humid Air (molbloc-S only) , Argon (Ar), B utane

(Butn), Carbon Monoxide (CO), Helium (He), Oxygen (O2), Carbon

Dioxide (CO2), Carbon Tetrafluoride (CF4), Octofluorocyclobutane

(C4F8), Ethane (C2H6), Ethylene (C2H4), Fluoroform (CHF3),

Hexafluoroethane (C2F6), Hydrogen (H2), Methane (CH4), Nitrous

Oxide (N2O), Propane (C3H8), Sulfur Hexafluoride (SF6), Xenon (Xe)

Quick connectors equivalent to Swagelok QM Series (-QM2-B200)

Maximum working pressure 600 kPa absolute (87 psi a)

Maximum pressure without damage 800 kPa absolute (115 psia)

NOTE: The microrange option includes a 12. 5 kPa (1.8 psi) differenti al

RPT which may be damaged by differenti al pressure greater than 100

kPa (15 psi).

See Sections 1.2.4. 1. 3, 1.2.4.1.4and 1.2.4.2. 1

Available. Must be specif i ed.

1.2.2 Reference Pressure Transducer (RPT) Specifications

1.2.2.1 Upstream and Downstream RPTs

Piezoresistive silicon

Type

Range

Resolution

Repeatability

Accuracy

1.2.2.2 Differential RPT (Microrange Option)

Range

Resolution

Repeatability

Accuracy

0 to 600 kPa absolute (0 to 87 psia)

6.0 Pa (0.0009 psi)

± 0.01 % FS

Absolute measurements: ± 0.06 % FS f or one year

Differential measurements: ± (20 Pa + 0.05 % ∆Ρ). T ari ng sequence eliminates zero

error on measurement of dif ference between the two RPTs.

Piezoresistive silicon

Type

0 to 12.5 kPa differenti al (0 t o 1.8 psid)

0.14 Pa (0.00002 psi)

± 0.01 % FS

± (0.14% of reading + 0.01% F.S .) for one year.

Taring sequence eliminates zero error.

Page 3 © 2010 Fluke Calibration

Page 16

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

1.2.3 Temperature Measurement Specifications

Specifications are for m olbloc mounted Platinum Resistance T hermom eters (PRT ) combined

with molbox RFM resistance measurement system and temperature calculation.

Range

Accuracy

Resolution

0 to 40 °C

± 0.05 °C

0.01 °C

The molbox RFM internal res istance measurement system is autom atically calibrated using

reference 100 and 110 Ω (± 0.01 %) resistors (see Section 5.3).

1.2.4 Flow Measurement Specif i cations

molbox RFM meas ures the f low through molbloc flow elements. Ther e are two different types

of molblocs, molbloc-L (laminar) (see Section 1.1.1.1) and molbloc-S (sonic) (see Section

1.1.1.2). Flow measurement specifications, calibration types, ranges and dimensions are

detailed separately for each molbloc type in Section 1.2.4.1 and 1.2.4.2.

All flow measurem ent uncertainties are valid only for measurem ents in a gas for which the

molbloc is calibrated, and within the range of pressures for which the calibration is specified.

1.2.4.1 molbloc-L Flow Measurement Specifications, Model Ranges 1E1-L thru 3E4-L

The flow range, useable operating pressure and absolute and differential

pressure associated with molbloc -L operation depend on the molbloc used and its

pressure-dependent calibration options (s ee Section 1.2.4.1.2). Use of mobloc-L

model range 1E5-L is only recomm ended for us e with the mic rorange option (s ee

Section 1.2.4.1.1).

Measurement Update Rate

Range

Resolution

Linearity

Repeatability

Precision

Stability

(1 year)

Measurement Uncertainty

(1 year, N2 and any molbox RFM

supported gas for which the molbl oc

1 Precision: Combined linearity, hysteresis, repeatability.

2 Stability: Maximum change in zero and span over specified time period for typical molbox RFM and molbloc used

under typical conditions. As stability can only be predicted, stability for a specific molbox RFM should be

established from experience.

3 Measurement Uncertainty: Maximum deviation of the molbox RFM flow indication from the true value of the flow

through the molbloc including precision, stability and Fluke calibration standard uncertainty. Measurement

uncertainty specifications for molblocs are valid only for gases with which the molbloc has been calibrated. All

molblocs are calibrated for N

maintained at all times for all gases on all molbloc designations. Check for availability before ordering.

in use is calibrated)

2. Calibrations with other gases are optional. Fluke calibration capability is not

1 second

0 to molbloc full s cale depending on gas and molbloc

pressure dependent calibration type

(see Section 1.2.4.1.2).

0.01 % FS

± 0.23 % of reading from 10 t o 100 % F S,

± 0.023 % FS under 10 % FS

± 0.1 of reading from 10 to 100 % F S,

± 0.01 % FS under 10 % FS

1

± 0.25 % of reading from 10 t o 100 % FS,

± 0.025 % FS under 10 % FS

2

± 0.15 % of reading from 10 t o 100 % F S,

± 0.015 % FS under 10 % FS

3

± 0.5 % of reading from 10 t o 100 % F S,

± 0.05 % FS under 10 % FS

© 2010 Fluke Calibration Page 4

Page 17

1. INTRODUCTION

1.2.4.1.1 molbloc-L FLOW MEASUREMENT

SPECIFICATIONS, MICRORANGE OPTION

The microrange option (see Section 1.2.2.2) improves molbloc-L flow

measurement s pecifications below 10 % FS of the molbloc model ranges 1E1-L

thru 3E4-L, and is required to achieve the measurement specification of molbloc

model range 1E5-L. With the microrange option, the affected measurement

specifications become:

Molbloc-L (Ranges 1E1-L Thru 3E4-L)

Update Rate

Range

Resolution

Linearity

Repeatability

Precision

Stability

(1 year)

Measurement Uncertainty

molbloc-L (Ranges 1E5-L Only)

Update Rate

Range

Resolution

Linearity

Repeatability

Precision

Stability

(1 year)

Measurement Uncertainty

1 Precision: Combined linearity, hysteresis, repeatability.

2 Stability: Maximum change in zero and span over specified time period for typical molbox RFM and molbloc used

under typical conditions. As stability can only be predicted, stability for a specific molbox RFM should be

established from experience.

3 Measurement Uncertainty: Maximum deviation of the molbox RFM flow indication from the true value of the

flow through the molbloc including precision, stability and Fluke calibration standard uncertainty. Measurement

uncertainty specifications for molblocs are valid only for gases with which the molbloc has been calibrated. All

molblocs are calibrated for N

maintained at all times for all gases on all molbloc designations. Check for availability before ordering.

2. Calibrations with other gases are optional. Fluke calibration capability is not

1 second

0 to molbloc full s cale depending on gas and molbloc

pressure dependent calibration type (s ee molbloc-L tables)

0.01% FS, 0.001% FS under 10% FS

±0.23% of reading from 1 to 100% FS,

±0.0023% FS under 1% FS

±0.1% of reading from 1 to 100% FS,

±0.001% FS under 1% FS

1

±0.25% of reading from 1 to 100% FS,

±0.0025% FS under 1% FS

2

±0.15% of reading from 1 to 100% FS,

±0.0015% FS under 1% FS

3

±0.5% of reading from 1 to 100% FS,

±0.005% FS under 1% FS

1 second

0 to molbloc full scale depending on gas and molbloc

pressure dependent calibration type (s ee molbloc-L tables)

0.01% FS

± 0.25% of reading from 5 to 100% FS,

± 0.0125% FS under 5% FS

± 0.2% of reading from 5 t o 100% F S,

± 0.01% FS under 5% FS

1

± 0.32% of reading from 5 to 100% FS,

± 0.016% FS under 5% FS

2

± 0.2% of reading from 5 to 100% FS,

± 0.01% FS under 5% FS

3

± 0.5% of reading from 5 to 100% FS,

± 0.025% FS under 5% FS

Page 5 © 2010 Fluke Calibration

Page 18

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

PRESSURE AT MAX. FLOW

MOLBLOC

MOLBLOCS

1.2.4.1.2 molbloc-L Pressure Dependent Calibration Types

See your molbloc’s Calibration Report to determine the

calibration type of the molbloc you are using.

Different pressure dependent calibration options for molbloc-L elements determine

the range of operating pressures over which a molbloc can be used within its

mass flow measurement specifications. The calibration option also affects the

molbloc flow range and the differential pressure associated with the flow range.

Measurement uncertainty (accuracy) specifications for molbloc-L are valid only for

gases with which the molbloc has been calibrated. All m olbloc-L elements are

calibrated for N2. Calibrations with other gases are optional. Fluke calibration

capability is not maintained at all times for all gases on all molbloc designations.

Check for availability before ordering calibrations.

The molbloc-L pressure dependent calibration types are summarized in Table 1.

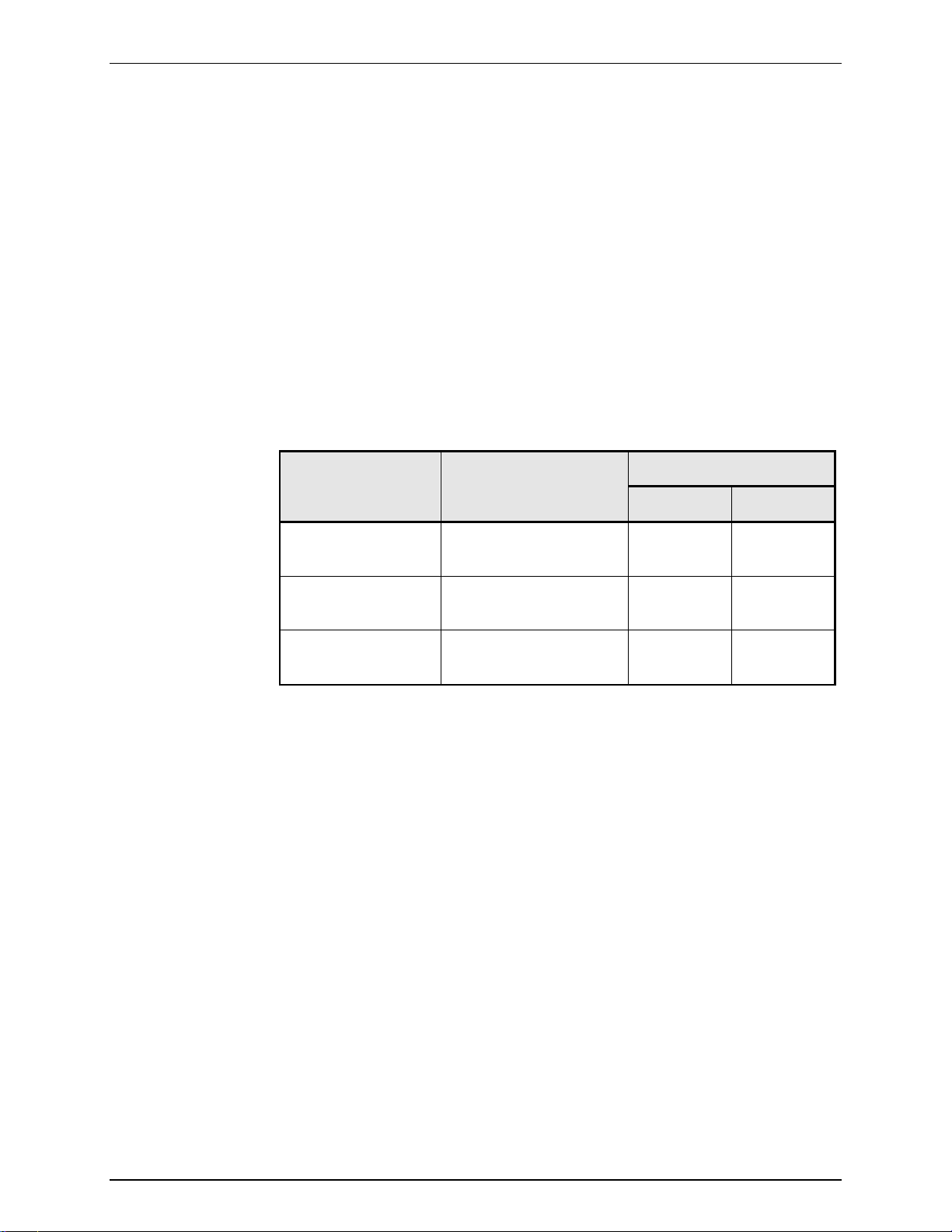

Table 1. molbloc-L Pressure Dependent Calibration Types

Note

CALIBRATION TYPE

(CALIBRATION NAME)

Low pressure

(LOP)

High pressure

(HIP)

Downstream

(DOWN)

OPERATING PRESSURE

200 to 325 kPa absolute

(29 to 48 psia)

upstream of molbloc

325 to 525 kPa absolute

(48 to 76 psia)

upstream of molbloc

Atmospheric pressure

downstream of m ol bl oc. 85 to

105 kPa (12 to15 psia).

NOMINAL DIFFERENTIAL

1E5

5 kPa

(.725 psi)

Not available 50 kPa

12.5 kPa

(1.8 psi)

ALL OTHER

50 kPa

(7.5 psi)

(7.5 psi)

80 kPa (12 psi)

Note

Differential pressure values are nominal and may vary by up to

15 % with the actual molbloc used.

© 2010 Fluke Calibration Page 6

Page 19

1. INTRODUCTION

2

CARBONS

1.2.4.1.3 molbloc-L Ranges with Low Pressure Calibrations

Table 2. molbloc-L Ranges with Low Pressure and Downstream Calibrations

SIZE

Nitrogen

GASES

N

SIZE

1E1

5E1

10 50 100 200 500 1,000 5,000 10,000 30,000 100,000

Argon Ar 10 50 100 200 500 1,000 5,000 10,000 30,000 80,000

Helium He 10 50 100 200 500 1,000 5,000 10,000 30,000 100,000

Sulfur Hexafluoride

INERT

SF

10 50 100 200 500 1,000 2,000

6

Xenon XE 10 40 80 150 400 800 3,500

Butane

Ethane

Ethylene

Hydrogen

FLAMMABLE

Methane

Propane

Carbon

Tetrafluoride

Hexafluorethene

Trifluoromethane

FLUORO-

C

4H1

0

C

2H6

C

2H4

H

2

CH

C

3H8

CF

C

2F6

CHF

20 100 130

20 100 200 400 1,000 2,000 6,000

16 80 160 320 800 1 600 7,000

20 100 200 400 1,000 2,000 10,000 20,000 60,000 200,000

16 80 160 320 800 1 600 8,000 16,000 40,000

4

20 100 200 400 1,000 2,000 3,000

10 50 100 200 500 1,000 4,000

4

10 50 100 200 500 1,000 2,000

10 50 100 200 500 1,000 4,000

3

Air Air 10 50 100 200 500 1,000 5,000 10,000 30,000 100,000

Carbon Dioxide

CO

10 50 100 200 500 1,000 5,000 10,000 20,000

2

Carbon Monoxide CO 10 50 100 200 500 1,000 5,000 10,000 30,000 100,000

Nitrous Oxide

N

2

10 50 100 200 500 1,000 5,000 10,000 20,000

O

OTHER

C

Octafluorocyclobutane1

Oxygen

15 60 9 65

4F8

O

2

10 50 100 200 500 1,000 5,000 10,000 30,000 80,000

See Table 3 for footnotes.

molbloc-L SIZE AND FULL SCALE FLOW (sccm @ 0 ºC)

SIZE

1E2

SIZE

2E2

SIZE

5E2

SIZE

1E3

SIZE

5E3

500

500

270

30

50

670

140

2,300 2,200

1,400

18,000

1,000

16,000 20,000

1,000

10,000

1,000

10,000 12,000

600

600

10,000 12,000

600

130

17

34

330

85

1,100

175

1,050

840

SIZE

1E4

6,000

1,000

SIZE

3E4

6,000

4,000

8,000 11,000

3,000

7,000

3,000

---

---

18,000

2,000

6,000

5,000

5,000

10,000

2,000

7,000

3,000

6,000

1,200

6,000

4,000

4,000

4,000

4,000

3,400

--- ---

1,700

SIZE

1E5

---

---

30,000

20,000

---

---

60,000

50,000

70,000

40,000

120,000

40,000

---

---

36,000

25,000

---

---

38,000

30,000

60,000

30,000

60,000

30,000

Page 7 © 2010 Fluke Calibration

Page 20

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

CARBONS

1.2.4.1.4 molbloc-L Ranges with High Pressure Calibrations

Table 3. molbloc-L Ranges with High Pressure Calibrations

GASES

Nitrogen

SIZE

SIZE

1E1

5E1

N

2

20 100 200 400 1,000 2,000 10,000 20,000 40,000

molbloc-L SIZE AND FULL SCALE FLOW (sccm @ 0 ºC)

SIZE

SIZE

1E2

2E2

SIZE

5E2

SIZE

1E3

SIZE

5E3

SIZE

1E4

SIZE

3E4

7,500

Argon Ar 20 100 200 400 1,000 2,000 10,000 17,000 35,000

6,000

Helium He 20 100 200 400 1,000 2,000 10,000 20,000 65,000 N/A

INERT

Sulfur Hexafluoride

SF

6

Xenon XE 20 100 150 350 650 1,700 3,350

Butane

Ethane

Ethylene

Hydrogen

Methane

FLAMMABLE

Propane

Carbon

Tetrafluoride

Hexafluorethene

FLUORO-

Trifluoromethane

C

4H10

C

2H6

C

2H4

H

2

CH

C

3H8

CF

C

2F6

CHF

4

25 100

15

120

30

250

50

600

150

2,000

300

2,000

1,400

6,200

2,800

11,000

950

1,900

N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

40 200 350

40 200 350 700 2,000 4,000 7,000

50

700

100

1,800

200

4,000 6,000

2 300

2,000

20,000

4,500

22,000

4,000

40 200 400 900 2,000 4,500 22,000 45,000 130,000 N/A

35 175 350 700 1,700 3,500 13,000

4

50 200

20 100 200 400 1,000 2,000 3,700

25 100

25 125 240

3

25

15

200

50

120

30

30

400

100

250

50

450

60

1,000

250

600

150

1,200

150

2,000

3,500

500

3,500

2,600

1,200

2,000

300

1,800

1,500

2,500 4,000

1,500

33,000 42,000

11,000

5,400

12,000

2,400

6,000

3,000

12,000

3,000

--

--

11,000

5,700

20,000

13,000

22,000

12,700

12,000

--

--

12,000

7,300

--

--

12,000

8,800

Air Air 20 100 200 400 1,000 2,000 10,000 20,000 40,000

7,200

Carbon Dioxide

CO

25 125 250 500 1,250 2,500 6,600

2

1,400

20,000

2,500

20,000

8,800

Carbon Monoxide CO 20 100 200 400 1,000 2,000 10,000 20,000 40,000

7,500

Nitrous Oxide

OTHER

Octafluorocyclobutane2

Oxygen

N

O

2

C

4F8

O

2

25 125 250 500 1,250 2,500 11,000

1,500

20,000

3,000

20,000

9,000

N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

20 100 200 400 1,000 2,000 10,000 20,000 40,000

6,500

SIZE

1E5

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

A bold value indicates that the maximum flow is li mited by the maximum Reynolds number value of 1 200 which is reached

before the normal differenti al pressure range is reached. In that c ase, the second value gives the minimum flow for which

measurement uncert ai nt y (ac curacy) is equal to the nominal uncertainty specific at i on. Divide the second value by 10 when

using molbox RFM microrange option.

Where there is no value in t he field (–), this indicates that the maximum Reynolds number is reached before the di fferential

pressure reaches 5 kPa (1 kPa i n the case of the 1E5 molbl oc), therefore calibration with that gas is not useful.

1

Due to low vapor pressure, only downstream calibrati on type is available.

2

The operating pressure range is greater than t he vapor pressure value for this gas.

© 2010 Fluke Calibration Page 8

Page 21

1. INTRODUCTION

1.2.4.1.5 molbloc-L DIMENSIONS

5E3 AND LOWER 1E4, 3E4 1E5

58.50 (2.303) 74.50 (2.933) 74.50 (2.933)

A

16.00 (0.630) 24.00 (0.945) 24.00 (0.945)

B

32.00 (1.260) SQ 48.00 (1.890) SQ 48.00 (1.890) SQ

C

68.84 (2.750) 80.00 (3.150) 80.00 (3.150)

D

19.06 (0.750) 28.00 (1.102) 28.00 (1.102)

E

124.00 (4.881) 157.00 (6.181) 164.00 (6.458)

F

1/4 in. VCR M 1/4 in. VCR M 1/2 in. VCR M

G

molbloc-L SIZES [mm(in.)]

Page 9 © 2010 Fluke Calibration

Page 22

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

calibration

1.2.4.2 molbloc-S

The flow range and operating pressure associated with molbloc-S operation

depend on the molbloc used and its calibration options (see Section 1.2.4.2.2)

Measurement Update

Range

Resolution

Linearity

Repeatability

Precision

Predicted Stability

(1 year)

Measurement

Uncertainty

With SP molbloc-S

calibration

Measurement

Uncertainty

With LP molbloc-S

calibration

Measurement

Uncertainty

With HP molbloc-S

1 Precision: Combined linearity, hysteresis, repeatability.

2. Stability: Maximum change in zero and span over specified time period for typical molbox RFM and molbloc

used under typical conditions. As stability can only be predicted, stability for a specific molbloc and molbox

RFM should be established from experience.

3. Measurement uncertainty (accuracy): Maximum deviation of the molbox RFM flow indication from the true value

of the flow through the molbloc including precision, stability and Fluke calibration standard measurement

uncertainty.

1 second

Rate

Depends on molbloc-S pressure dependent calibration type

(see Section 1.2.4.2. 2)

0.01 % of FS

± 0.25 % of reading

± 0.10 % of reading

1

± 0.30 % of reading

2

± 0.2 % of reading

± 0.5 % of reading from 50 to 500 kPa

3

± 0.5 % of reading from 50 t o 200 kPa

3

± 0.5 % of 50 kPa flow from 20 to 50 kPa

± 0.5 % of reading from 200 to 600 kPa

3

1.2.4.2.1 molbloc-S Pressure Dependent Calibration Types

See your molbloc’s Calibration Report to determine the

calibration type of the molbloc you are using.

Measurement uncertainty (accuracy) specificat ions for molbloc s are valid only for

gases with which the m olbloc has been calibrated. All molbloc-S elements are

calibrated in one standard gas, either air or N2, and m ay be calibrated in other

gases. Calibrations with other gases are optional. The list of gases which can be

measured by molbloc-S is the sam e as molbloc-L. FLUKE calibration capability

is not maintained at all times for all gases on all molbloc designations. Check for

availability before ordering calibrations.

molbloc-S calibrations are performed over flow ranges corres ponding to one of

three pressure ranges, summarized in Table 4.

© 2010 Fluke Calibration Page 10

Note

Page 23

Table 4: molbloc-S Calibration Types

1. INTRODUCTION

CALIBRATION TYPE

(CALIBRATION NAME)

Low pressure

(LP)

Standard pressure

(SP)

High pressure

(HP)

OPERATING PRESSURE

20 to 200 kPa absolute

(3 to 30 psia)

upstream of molbloc

50 to 500 kPa absolute

(7 to 70 psia)

upstream of molbloc

200 to 2000 kPa absolute

(29 to 290 psia)

upstream of molbloc

Note

molbloc-S flow measurements are valid only when the ratio of

pressure downstream to the pressur e ups tre am of th e nozzle is low

enough to assure a critical (choked) flow (see Section 3.1.5).

1.2.4.2.2 molbloc-S Ranges

molbloc-S flow ranges are defined by the molbloc’s Pres sure to Flow Conversion

Ratio, K

molbloc-S, the downstream pr ess ur e and the acceptable back pressure ratio (see

Section 3.1.5). K

between mass f low in nitrogen and the absolute upstream press ure delivered to

the molbloc-S. molbloc-S s izes are defined by the nominal K

nozzle, using scientific notation, for example a 1E3 molbloc -S has a K

sccm/k Pa. To differentiate from molbloc-L size designations, this molbloc s ize is

designated 1E3-S.

, the gas used, the absolute pressure that can be delivered upstream of

F

is expressed in units of s ccm/k Pa and defines the relationship

F

of the molbloc-S

F

of 1,000

F

The molbox RFM pressure range, the molbloc-S calibration type (see Section

1.2.5.2.2) and the back pressure ratio (BPR) requirements limit the pressures, and

flows, over which a molbloc-S can be used within known measurement

uncertainty limits. In practice, the usable range of a molbloc-S in a given

application also may depend on the available gas supply pressure, the presence and

flow capacity of a vacuum pump downstream or the allowable back pres sure on an

upstream DUT.

The mass f low range of a m olbloc-S element is dependent on the properties of the gas

used, so the range of a molbloc-S is diff erent f or each support ed gas. The f low ranges

for each molbloc-S size at various typical operating pressures are summarized

separately for each molbloc-S supported gas in the Tables below. For the common

application of using a molbloc-S with its downstream pressure at or near atmospher ic

pressure, it is helpful to know what minimum flow can be measured before violating back

pressure ratio requirements (see Section 3.1.5). In the tables below, this minimum flow

value is given in the “Minimum without vacuum” column.

FLUKE calibration capability may not be available for som e of the gas es listed, or

may be limited to less than the maxim um flow rate listed. Check for availability

before ordering calibrations.

The following notes apply to the ra nge table s below:

Ratio = Inverse square root density ratio of the current gas to Nitrogen

KF = Pressure to Flow Conversion Ratio, sccm/kPa

To estimate a f low in a given gas at a given pres s ure: F low(slm) = KF * Pressure

in kPa absolute / 1000 * Gas Ratio

Page 11 © 2010 Fluke Cali brat i on

Page 24

molbox™ RFM™ OPERATION AND MAINTENANCE MANUAL

Ratio = 1

DESIGNATOR

[sccm/ kPa]

(3 psia)

(7 psia)

(15 psia)

vacuum

(30 psia)

(70 psia)

(100 psia)

(174 psia)

(290 psia)

DESIGNATOR

[sccm/ kPa]

(3 psia)

(7 psia)

(15 psia)

vacuum

(30 psia)

(70 psia)

(100 psia)

(174 psia)

(290 psia)

Table 5: N2. molbloc-S Flow in Nitrogen at Various molbloc Upstream Pressures

Nitrogen

N2

KF

molbloc-S MASS FLOW RATE (slm @ 0 °C) WHEN molbloc-S UPSTREAM PRESSURE IS:[1][2]

20 kPa

50 kPa

100 kPa

Minimum

witout

(3)

200 kPa

500 kPa

700 kPa

1.2 MPa

2 MPa

1E1-S

2E1-S

5E1-S

1E2-S

2E2-S

5E2-S

1E3-S

2E3-S

5E3-S

1E4-S

Argon

Ratio = 0.837 Ar

100 2 5 10 15 20 50

200 4 10 20 28 40 100

500 10 25 50 67 100 250

1,000 20 50 100 129 200 500

2,000 40 100 200 248 400 1,000

5,000 100 250 500 596 1,000 2500

10,000 200 500 1,000 1,173 2,000 5,000

KF

10 0.2 0.5 1 2.0 2 5

20 0.4 1 2 3.5 4 10

50 1 2.5 5 7.7 10 25

[1] Flow values in table are valid only when critical flow is established.

[2] When volumetrically based mass flow units with reference temperatures other than 0°C are used, flow values will

generally be higher; the flow values for a given molbloc and upstream pressure are approximately 7% higher

when expressed in slm at 20°C. Flow values at a given pressure may vary by up to ± 2% due to flowpath

machining tolerances.

[3] Minimum upstream pressure to achieve critical flow with atmospheric pressure (approximately 100 kPa)

downstream of molbloc-S (no vacuum).

7

14

35

70

140

350

700

1,400

3,500

7,000

12 20

24 40

60 100

120 200

240 400

600 1,000

1,200 2,000

2,400 4,000

6,000 10,000

12,000 20,000

Table 6: Ar. molbloc-S Flow in Argon at Various molbloc Upstream Pressures

molbloc-S MASS FLOW RATE (slm @ 0 °C) WHEN molbloc-S UPSTREAM PRESSURE IS:[1][2]

20 kPa

50 kPa

100 kPa

Minimum

witout

(3)

200 kPa

500 kPa

700 kPa

1.2 MPa

2 MPa

1E1-S

2E1-S

5E1-S

1E2-S

2E2-S

5E2-S

1E3-S

2E3-S

5E3-S

10 0.2 0.4 0.8 1.7 1.7 4.2 5.9 10.0 16.7

20 0.3 0.8 1.7 3.0 3.3 8.4 11.7 20.1 33.5

50 0.8 2.1 4.2 6.5 8.4 20.9 29.3 50.2 83.7

100 1.7 4.2 8.4 12.9 16.7 41.9 58.6 100.5 167.4

200 3.3 8.4 16.7 23.3 33.5 83.7 117.2 200.9 334.9

500 8.4 20.9 41.9 57.1 83.7 209.3 293.0 502.3 837.2

1,000 16.7 41.9 83.7 107.8 167.4 418.6 586.0 1,004.6 1,674.4

2,000 33.5 83.7 167.4 207.6 334.9 837.2 1,172.1 2,009.3 3,348.8

5,000 83.7 209.3 418.6 498.2 837.2 2,093.0 2,930.2 5,023.2 8,372.0

10,046.4 16,744.

1E4-S

10,000 167.4 418.6 837.2 996.2 1,674.4 4,186.0 5,860.4

[1] Flow values in table are valid only when critical flow is established.

[2] When volumetrically based mass flow units with reference temperatures other than 0°C are used, flow values will

generally be higher; the flow values for a given molbloc and upstream pressure are approximately 7% higher

when expressed in slm at 20°C. Flow values at a given pressure may vary by up to ± 2% due to flowpath

machining tolerances.

[3] Minimum upstream pressure to achieve critical flow with atmospheric pressure (approximately 100 kPa)

downstream of molbloc-S (no vacuum).

0

© 2010 Fluke Calibration Page 12

Page 25

1. INTRODUCTION

DESIGNATOR

[sccm/ kPa]

(3 psia)

(7 psia)

(15 psia)

vacuum

(30 psia)

(70 psia)

(100 psia)

(174 psia)

(290 psia)

DESIGNATOR

[sccm/ kPa]

(3 psia)