Page 1

TM

INCU

Incubator Analyzer

Operators Manual

PN 2206965

April 2005

© 2005 Fluke Corporation

All product names are trademarks of their respective companies.

All rights reserved. Printed in USA

Page 2

INCU

Operators Manual

Notices

Fluke Biomedical

6920 Seaway Blvd.

Everett, WA 98203

USA

Customer Service and Sales

USA and Canada: 800.648.7952

Outside the USA: 775.883.3400

Sales Fax: 775.883.9541

Sales E-Mail: sales@flukebiomedical.com

Service: 888.993.5853

Service Fax: 775.886.6320

Service E-mail: techservices@flukebiomedical.com

Internet: www.flukebiomedical.com

For additional sales or service information, contact your local Fluke Biomedical Distributor or Fluke

Electronics office.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke

Biomedical. Changes made to the information in this document will be incorporated in new editions of

the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of software

or equipment that is not supplied by Fluke Biomedical or its affiliated dealers.

All Rights Reserved

Copyright 2005, Fluke Biomedical. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language without the written

permission of Fluke Biomedical.

ii

Page 3

Incubator Analyzer

Notices, Warranty and Contents

Safety Considerations

Warnings and Cautions

Use of this instrument is restricted to qualified personnel who recognize shock hazards and are

familiar with safety precautions used when operating electrical equipment. Read the manual carefully

before operating the INCU.

☛ The following warning and informational symbols may be found on the INCU.

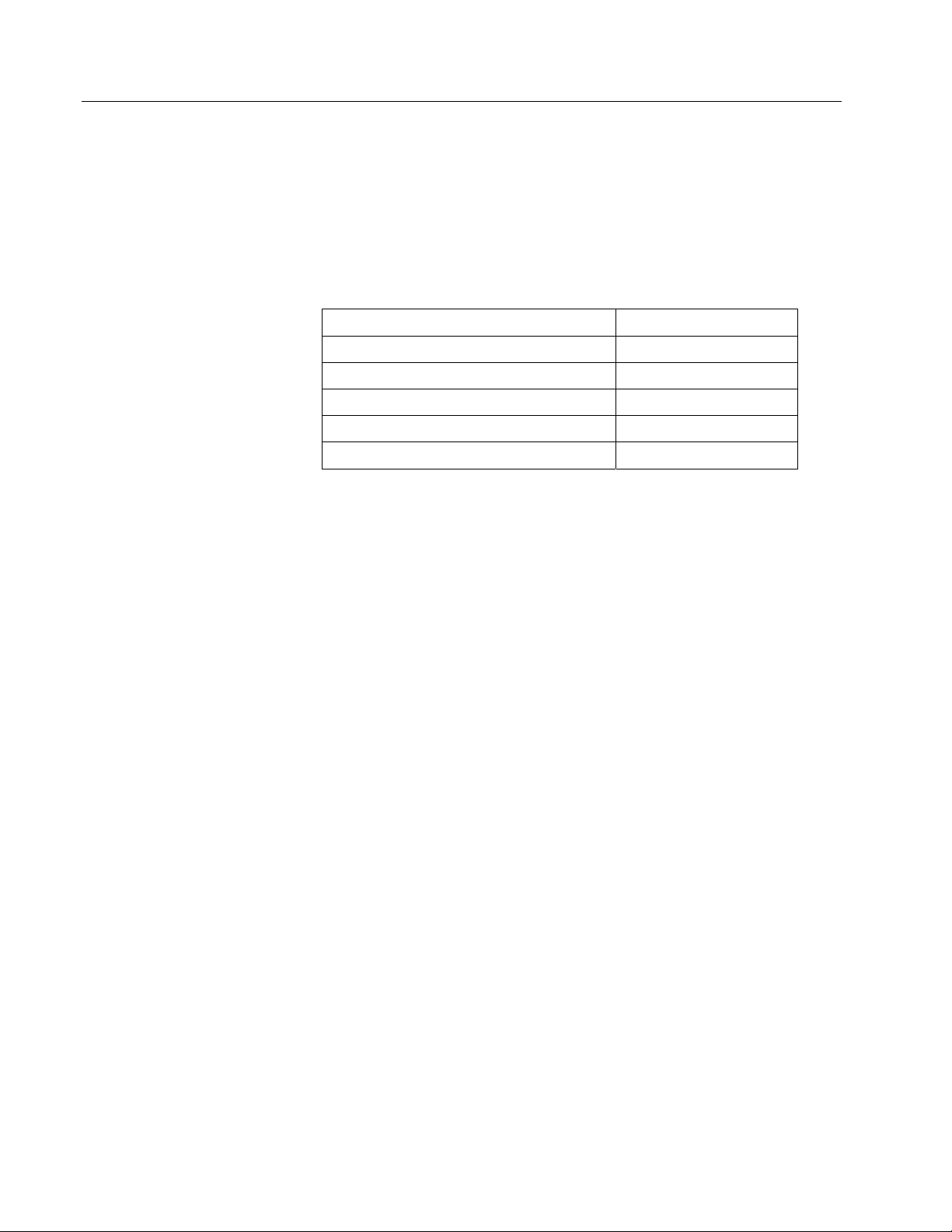

Symbol Description

I P 30

Alternating Current

Caution: Refer to accompanying

documentation

Master ON/OFF,switch. Push for OFF or ON

Direct / Alternating Current

Direct Current

Enclosure with double insulation or reinforced

insolution

Fuse

Class of protection see Appendix A

iii

Page 4

INCU

Operators Manual

Hazard Warnings

☛ Warning! Power Rating. The INCU mains power input must be connected using an

☛ Warning! Internal Voltage. Always turn off the power switch and unplug the power

☛ Warning! Liquids. Avoid spilling liquids on the analyzer; fluid seepage into internal

☛ Warning! “Do not use in the presence of oxygen”. The Air Flow sensor is hot wire

☛ Warning! “Use only approved battery charger." The INCU contains a lead-acid

Precautions

The following precautions are provided to help you avoid damaging the system:

☛ Caution: Service. Authorized service personnel should service the INCU. Only

☛ Caution: Environmental Conditions. Do not expose the system to temperature

☛ Caution: Do NOT Immerse. Clean only with a mild detergent, and gently wipe down

☛ Caution: Electromagnetic radiation may affect the noise measurement.

external power supply that provides voltage and current within the specified rating for

the system.

cord before cleaning the outer surface of the INCU.

components creates a potential shock hazard. Do not operate the instrument if

internal components are exposed to fluid.

technology and is a source of combustion if used in the presence of oxygen within

the incubator. Use the INCU only in ambient oxygen conditions.

rechargeable battery. Use only the approved charger with proper voltage and current

ratings; otherwise, damage to the unit may result.

qualified technical personnel should perform troubleshooting and service procedures

on internal components.

extremes. Ambient temperatures should remain between 18°C to 40°C. System

performance may be adversely affected if temperatures fluctuate above or below this

range.

with a clean, lint-free cloth.

iv

Page 5

Incubator Analyzer

Notices, Warranty and Contents

Applicable Testing Standards

The INCU has been tested by an independent laboratory and meets the requirements listed here.

Safety Requirements

EC Directive

73/23/EEC

IEC 1010-1, Safety requirement for electrical equipment for

measurement, control and laboratory use, Part 1: General

Requirements.

North America

Battery Charger is UL marked.

Electromagnetic Interference and Susceptibility

The system meets the requirements of EC Directive 89/336/EEC Electromagnetic Compatibility (see

page viii).

☛ USA FCC Class A

Warning: Changes or modifications to this unit not expressly approved by the manufacturer could

void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. Like all similar equipment, this equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause interference, in which case the user will be

required to correct the interference at his/her own expense.

☛ Canadian Department of Communications Class A

This digital apparatus does not exceed Class A limits for radio emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'met pas du bruits radioelectriques depassant les limites applicables

aux appareils numerique de la Class A prescrites dans le Reglement sur le brouillage radioelectrique

edicte par le ministere des Communications du Canada.

v

Page 6

INCU

Operators Manual

EC Directive 89/336/EEC Electromagnetic Compatibility

☛ Emissions - Class B

NFEN 55022 Class B (12/94) Radio disturbance

Immunity

☛

The system has been type tested by an independent, accredited testing laboratory and found to meet

the requirements for Immunity. Verification of compliance was conducted to the limits and methods of

the following:

EN 61000-4-2 (1995) Electrostatic Discharge

EN 61000-4-3 (1984) Radiated EM Fields (electromagnetic radiation may affect the noise

measurement)

EN 61000-4-4 (1995) Electrical Fast Transient/Burst

Based on the testing standards below,

this device bears the

mark.

EN 61000-4-5 (1995) Surge Immunity

EN 61000-4-6 (1996) Conducted Disturbances

EN 61000-4-11 (1994) Voltage Dips, Short Interruptions and Variations (N/A; Battery buffers

transients)

EC Directive 73/23/EEC Low Voltage (User Safety)

The system has been type tested by an independent testing laboratory and found to meet the

requirements of EC Directive 73/23/EEC for Low Voltage. Verification of compliance was conducted

to the limits and methods of the following:

IEC 1010-1 1990 and Amendments 1 1992 and Amendments 2 1995

“Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use,

Part 1: General requirements” (including amendments 1 and 2).

vi

Page 7

Incubator Analyzer

Notices, Warranty and Contents

Warranty

This Warranty is limited and applies only to new products, except for computer-based software, which

is covered under a separate Warranty Policy, manufactured by Fluke Biomedical. Fluke Biomedical

makes no warranty whatsoever regarding the condition of used products.

Fluke Biomedical warrants the instrument (hereinafter collectively referred to as “Products” or

“Product”) for a period of one (1) year from the original purchase date against defective materials or

workmanship. This Warranty is limited to the original purchaser (the “Purchaser”) and cannot be

assigned or transferred. All claims under this Limited Warranty must be made in writing to Fluke

Biomedical, Attention: Service Department. Purchaser must ship the Product to Fluke Biomedical,

postage pre-paid. Fluke Biomedical shall either repair or replace with new or like new, at its option

and without cost to the Purchaser, any Product which in Fluke Biomedical’s sole judgment is

defective by reason of defects in the materials or workmanship.

This Warranty is VOID if the Product has been damaged by accident or misuse, or has been

damaged by abuse or negligence in the operation or maintenance of the Product, including without

limitation unsafe operation, operation by untrained personnel, and failure to perform routine

maintenance. This Warranty is VOID if the Product has been repaired or altered by persons not

authorized by Fluke Biomedical, or if the Product has had the serial number altered, effaced, or

removed. This Warranty is VOID if any of the Products has not been connected, installed or adjusted

strictly in accordance with written directions furnished by Fluke Biomedical. Batteries, fuses, light

bulbs, and other “consumable” items used in any of the Products are not covered by this Warranty.

Software utilized in conjunction with any of the Products is not covered by the terms of this Warranty

but may be covered under a separate Fluke Biomedical software warranty.

We will continue to stock parts for a maximum period of five (5) years after the manufacture of any

equipment has been discontinued. Parts shall include all materials, charts, instructions, diagrams,

and accessories that were furnished with the standard models.

THIS WARRANTY CONTAINS THE ENTIRE OBLIGATION OF FLUKE BIOMEDICAL, AND NO

OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY ARE GIVEN. PURCHASER

AGREES TO ASSUME ALL LIABILITY FOR ANY DAMAGES AND/OR BODILY INJURY OR DEATH

THAT MAY RESULT FROM THE USE OR MISUSE OF ANY EQUIPMENT OR INSTRUMENT BY

THE PURCHASER, HIS EMPLOYEES, AGENTS, OR CUSTOMERS, OTHER THAN THE EXPRESS

WARRANTY CONTAINED HEREIN. WE SHALL NOT BE RESPONSIBLE FOR ANY DIRECT OR

CONSEQUENTIAL DAMAGES OF ANY KIND. THIS WARRANTY SHALL NOT BE CHANGED OR

MODIFIED IN ANY WAY WITHOUT THE EXPRESS WRITTEN PERMISSION OF AN OFFICER OF

FLUKE BIOMEDICAL.

THIS WARRANTY IS VOID UNLESS THE PURCHASE REGISTRATION CARD HAS BEEN

COMPLETED AND MAILED TO US WITHIN TEN (10) DAYS OF PURCHASE.

vii

Page 8

INCU

Operators Manual

About This Manual

This manual provides a complete description of the INCU Incubator Analyzer and its applications.

The manual is organized as follows:

Chapter 1, Overview: An introduction to the INCU and optional accessories

•

•

Chapter 2, Installation: How to connect the INCU and install the PC software

•

Chapter 3, General Operation: INCU keypad functions, setup, and stand-alone operation

•

Chapter 4, PC Software Operation: PC software operation

• Chapter 5, Safety, Displayed Messages, Troubleshooting, and Support

• Appendix A, INCU Specifications

• Appendix B, INCU Report Examples

• Appendix C, DAT File Format

viii

Page 9

Incubator Analyzer

Notices, Warranty and Contents

Contents

Notices ................................................................................................................... ii

Restrictions and Liabilities ........................................................................ ii

All Rights Reserved................................................................................... ii

Safety Considerations............................................................................................iii

Warnings and Cautions............................................................................ iv

Hazard Warnings............................................................................... iv

Precautions........................................................................................ iv

Applicable Testing Standards ................................................................................ v

Safety Requirements ................................................................................ v

Electromagnetic Interference and Susceptibility....................................... v

EC Directive 89/336/EEC Electromagnetic Compatibility................... vi

Emissions............................................................................................ vi

Immunity ............................................................................................. vi

EC Directive 73/23/EEC Low Voltage (User Safety) ............................... vi

Warranty............................................................................................................. vivii

About This Manual ...............................................................................................viii

Chapter 1: Overview ................................................................................ 1-1

Introducing the INCU™.......................................................................................1-2

INCU Measurements...........................................................................................1-3

Getting to Know the INCU................................................................................... 1-4

AAMI/IEC Standards...........................................................................................1-6

INCU Applications ..................................................................................1-6

Accessories.........................................................................................................1-8

Chapter 2: Installation ............................................................................. 2-1

Unpacking and Inspection................................................................................... 2-2

Connecting INCU ................................................................................................2-3

AC-DC Battery Charger Connection ......................................................2-3

Internal Battery.......................................................................................2-3

RS-232 Port ...........................................................................................2-3

Air Flow Sensor......................................................................................2-4

Radiant Baby Assembly.........................................................................2-4

PC Software System Requirements ...................................................................2-5

Installing the PC Software................................................................................... 2-6

Installing the Software............................................................................ 2-6

ix

Page 10

INCU

Operators Manual

Chapter 3: General Operation................................................................. 3-1

INCU Keypad Functions ..................................................................................... 3-2

Key Details............................................................................................. 3-3

INCU Setup......................................................................................................... 3-5

Placement of the INCU in the Incubator................................................ 3-5

Infant Radiant Warmers......................................................................... 3-9

INCU Operation ................................................................................... 3-10

Chapter 4: INCU PC Software Operation ............................................... 4-1

Introduction ......................................................................................................... 4-2

Configuring the INCU for Data Acquisition ......................................................... 4-2

Data Acquisition.................................................................................................. 4-4

Transferring Data to the PC Software ................................................................ 4-5

Graphs ................................................................................................................ 4-7

Software Options ................................................................................................ 4-8

Open Files ............................................................................................. 4-8

Save Files .............................................................................................. 4-8

Printer Configuration.............................................................................. 4-8

Print Folder ............................................................................................ 4-8

Cascade................................................................................................. 4-9

Heading ............................................................................................... 4-10

Graph Colors ....................................................................................... 4-11

Com Port.............................................................................................. 4-12

Language............................................................................................. 4-12

Zoom.................................................................................................... 4-13

Chapter 5: Safety, Displayed Messages, Troubleshooting,

and Support........................................................................... 5-1

Electrical Safety .................................................................................................. 5-2

Cleaning................................................................................................. 5-2

Air Flow Sensor ..................................................................................... 5-2

Displayed Messages .......................................................................................... 5-3

Troubleshooting.................................................................................................. 5-4

Support ............................................................................................................... 5-6

Appendix A: Specifications ....................................................................A-1

Appendix B: Report Examples ...............................................................B-1

Appendix C: DAT File Format.................................................................C-1

x

Page 11

Incubator Analyzer

Notices, Warranty and Contents

List of Illustrations

Figure 1-1. Closed Incubator With Forced Convection.......................................1-3

Figure 1-2. Infant Warmer...................................................................................1-3

Figure 1-3. Descriptions and Locations of INCU Sensors .................................. 1-4

Figure 1-4. View of Right Side of INCU ..............................................................1-5

Figure 1-5.

Figure 2-1. Radiant Baby Assembly ...................................................................2-4

Figure 2-2. INCU Setup Screen .......................................................................... 2-6

Figure 3-1. The INCU Front Panel ...................................................................... 3-2

Figure 3-2. INCU Keypad Display.......................................................................3-3

Figure 3-3. INCU Inside a Closed Incubator.......................................................3-5

Figure 3-4. Placement of Temperature Sensors T1-T3 ...................................... 3-6

Figure 3-5. Placement of Air Flow Sensor ..........................................................3-7

Figure 3-6. Placement of Temperature Sensor T4 .............................................3-8

Figure 3-7. Placement of an INCU Inside an Infant Warmer ..............................3-9

Figure 3-8. Placement of a Radiant Baby Adapter on Top of the INCU .............3-9

Figure 3-9. Data Acquisition Mode Screen .......................................................3-11

Figure 4-1. PC Interconnected With the INCU....................................................4-2

Figure 4-2. Using the Config Menu ..................................................................... 4-3

Figure 4-3. INCU Keypad Display.......................................................................4-4

Figure 4-4. INCU File Transfer Menu..................................................................4-5

Figure 4-5. INCU Comments Entry Window ....................................................... 4-6

Figure 4-6. INCU Parameter Options Menu........................................................4-7

Figure 4-7. INCU Parameter Screen...................................................................4-7

Figure 4-8. INCU File Menu Screen....................................................................4-8

Figure 4-9. INCU Window Menu Screen.............................................................4-9

Figure 4-10. INCU Parameters Menu Screen..................................................... 4-9

Figure 4-11. INCU Heading Screen ..................................................................4-10

Figure 4-12. INCU Graph Colors Screen..........................................................4-11

Figure 4-13. INCU Communication Menu Screen ............................................4-12

Figure 4-14. INCU Language Menu Screen .....................................................4-12

Figure 4-15. INCU Zoom Menu Screen ............................................................4-13

Figure 4-16. INCU Zoom on Window Screen ...................................................4-13

Figure B-1. Sample Monitoring Sheet................................................................ B-3

Figure B-2. Sample History Graph Sheet .......................................................... B-4

Figure B-3. Sample Parameter Numerical List .................................................. B-5

View of Left Side of INCU.................................................................1-5

xi

Page 12

INCU

Operators Manual

xii

Page 13

Chapter 1: Overview

1

Inside This Chapter

• Introducing INCUTM

TM

• INCU

• Getting to Know INCU

• AAMI/IEC Standards

• Accessories

Measurements

TM

1-1

Page 14

INCU

Operators Manual

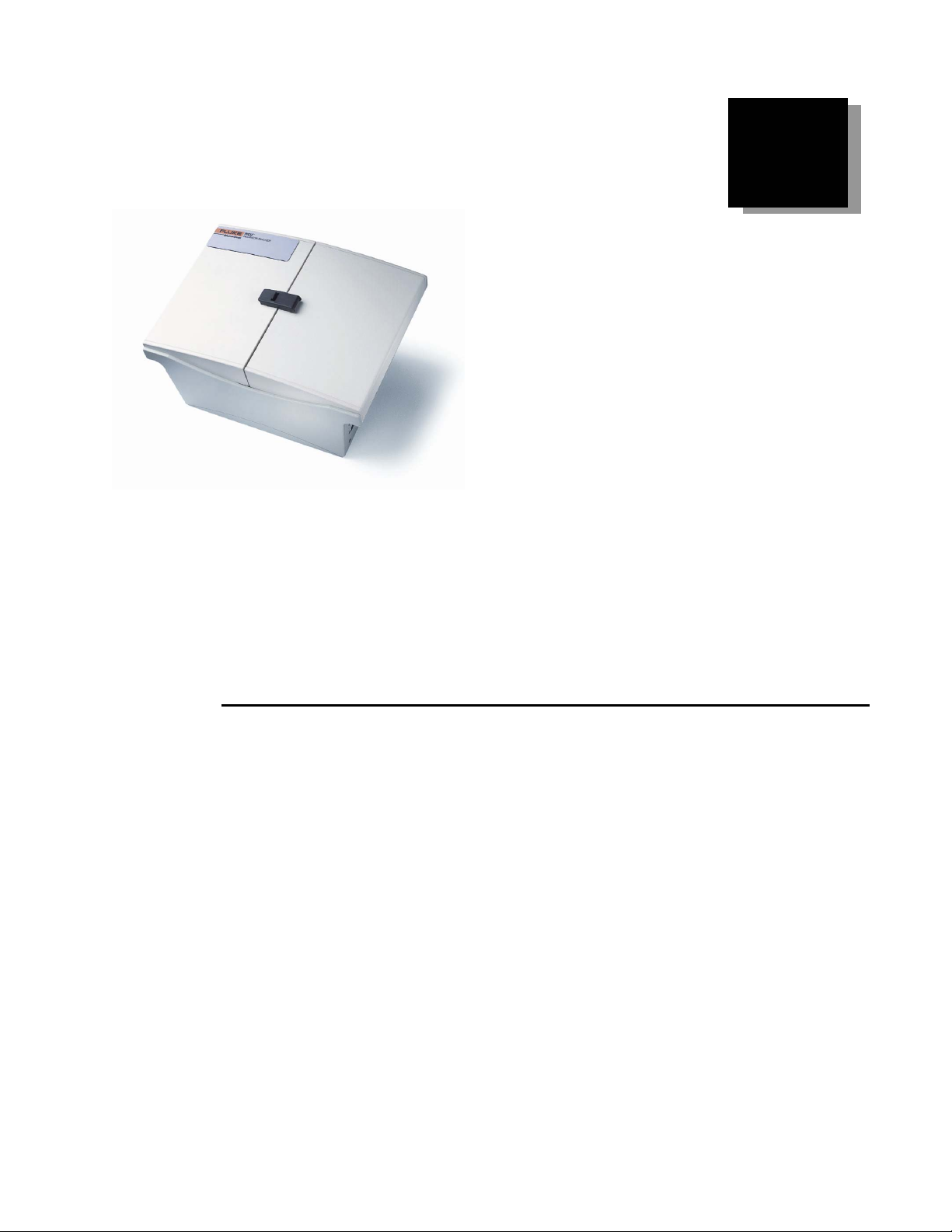

Introducing INCUTM

The INCU Incubator Analyzer is a portable device designed to verify the

proper operation and environment of infant incubators. This unit records

parameters important to the care of infants over time, such as airflow, sound

level, temperature (four individual measurement probes), and relative

humidity. Event markers can be placed on the recording to identify certain

activities or periods. The rechargeable battery allows the unit to be placed

within the incubator chamber for up to 24 hours without compromising the

integrity of the environment.

The INCU can operate stand-alone or with the use of a personal computer.

With a PC, the user selects the desired record time/interval via the software,

and then initiates the start of the test from the INCU. After completion of the

test, the user uploads the data collected by INCU into the PC software for

display and analysis. The user may store the recorded data in a file or print

the data to a report. In stand-alone mode, the unit displays all measured

parameters repeatedly in cycle fashion, and no data is recorded.

Features on the INCU include:

Portability: Sits in place of the infant within the incubator.

•

Multiple Sensors: Measures and documents multiple key infant

•

incubator parameters simultaneously.

Compliance: Measures most parameters according to IEC and

•

AAMI standards.

Efficient: Saves time in testing critical infant incubators.

•

•

Data Collection: Uses Microsoft

®

Windows® software for

evaluation and documentation.

•

Reporting: Allows printing of numerical and graphical reports.

Recording Flexibility: Provides adjustable measurement intervals.

•

Two Modes of Operation: Operates stand-alone or fully

•

functioning, requiring a computer.

1-2

Page 15

Incubator Analyzer

Getting to Know the INCU

INCU is to be used by service personnel or Biomedical institutions to verify

and test infant incubators. INCU is designed to support testing of two types

of incubators, as shown in Figures 1-1 and 1-2.

Figure 1-1. Closed incubator with forced convection

INCU Measurements

INCU is an autonomous acquisition system that is used to measure and save

the operational parameters of an empty incubator, and then transmit data via

a serial communications port. INCU

measurement systems that allow you to record the multiple parameters

simultaneously.

The following measurement parameters are recorded:

Temperature – 4 Sensors T1-T4

Relative Humidity – 1 Sensor

Air Flow – 1 Sensor

Sound – 1 Sensor

See Appendix A, Specifications for performance specifications.

Figure 1-2. Infant warmer

provides, in a single unit, the

1-3

Page 16

INCU

Fig

Operators Manual

Getting to Know the INCU

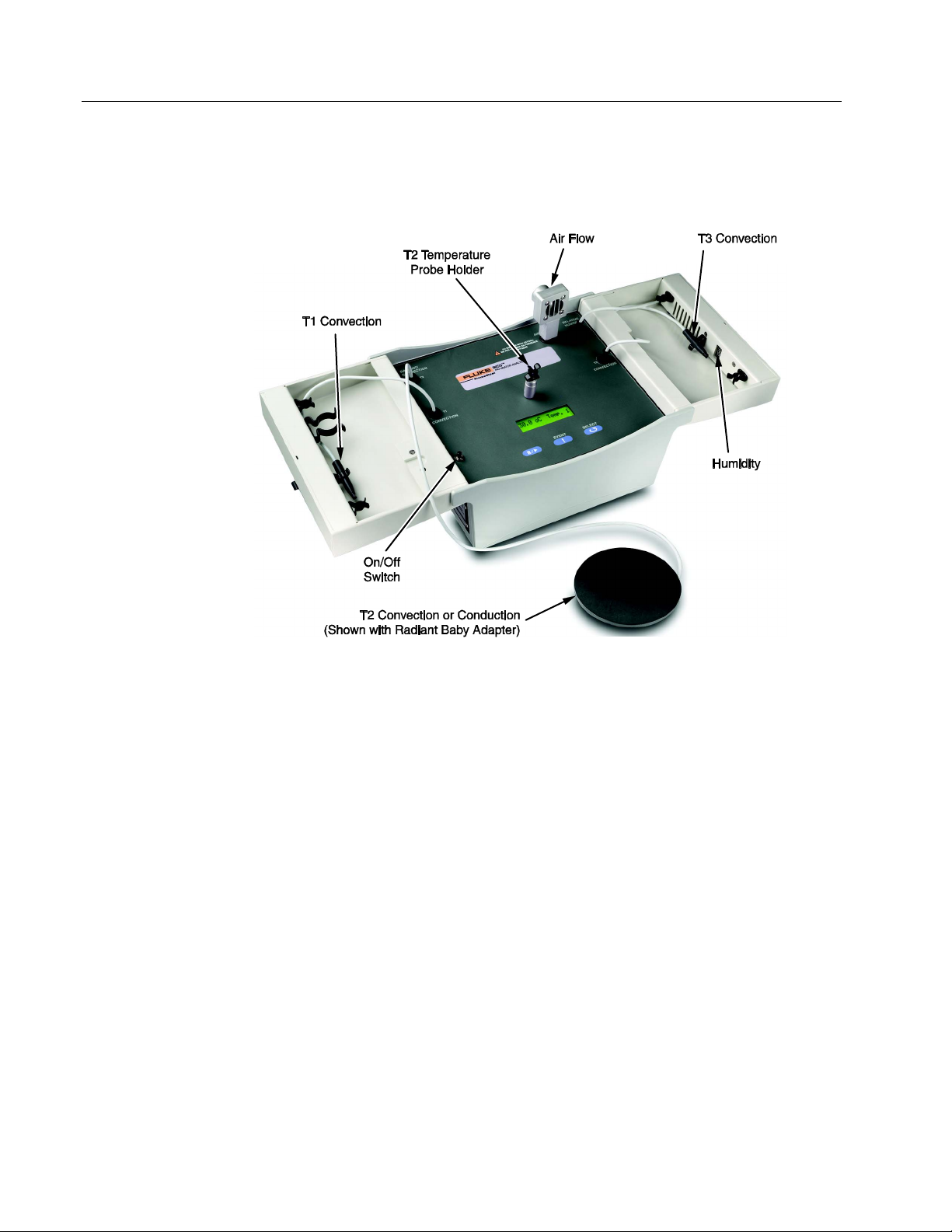

Sensors are integrated and stored within INCU. Open INCU by releasing the

latch on the top cover. Fold the covers open to expose the sensors when

taking measurements. Figure 1-3 shows the location of each sensor.

ure 1-3. INCU sensors

• Temperature Sensor T1: Used for Convection measurements.

Temperature Sensor T2: Used for Convection or Radiant

•

measurements; used with radiant baby adapter supplied with INCU.

Temperature Sensor T3: Used for Convection measurements.

•

•

Relative Humidity: Located in right top cover (cover must be open

for proper measurements).

Air Flow: Detachable for storage.

•

ON/OFF Switch: Top cover engages this switch to turn power off to

•

INCU automatically, if the master On/Off switch is left in the ON

position and the top covers are closed (master switch is on the left

side of the exterior).

Temperature Probe Holder: Used to hold temperature probe T2

•

when taking convection measurements. This is a mechanical

connection only; there is no electrical connection.

1-4

Page 17

Incubator Analyzer

Fig

Fig

AAMI/IEC Standards

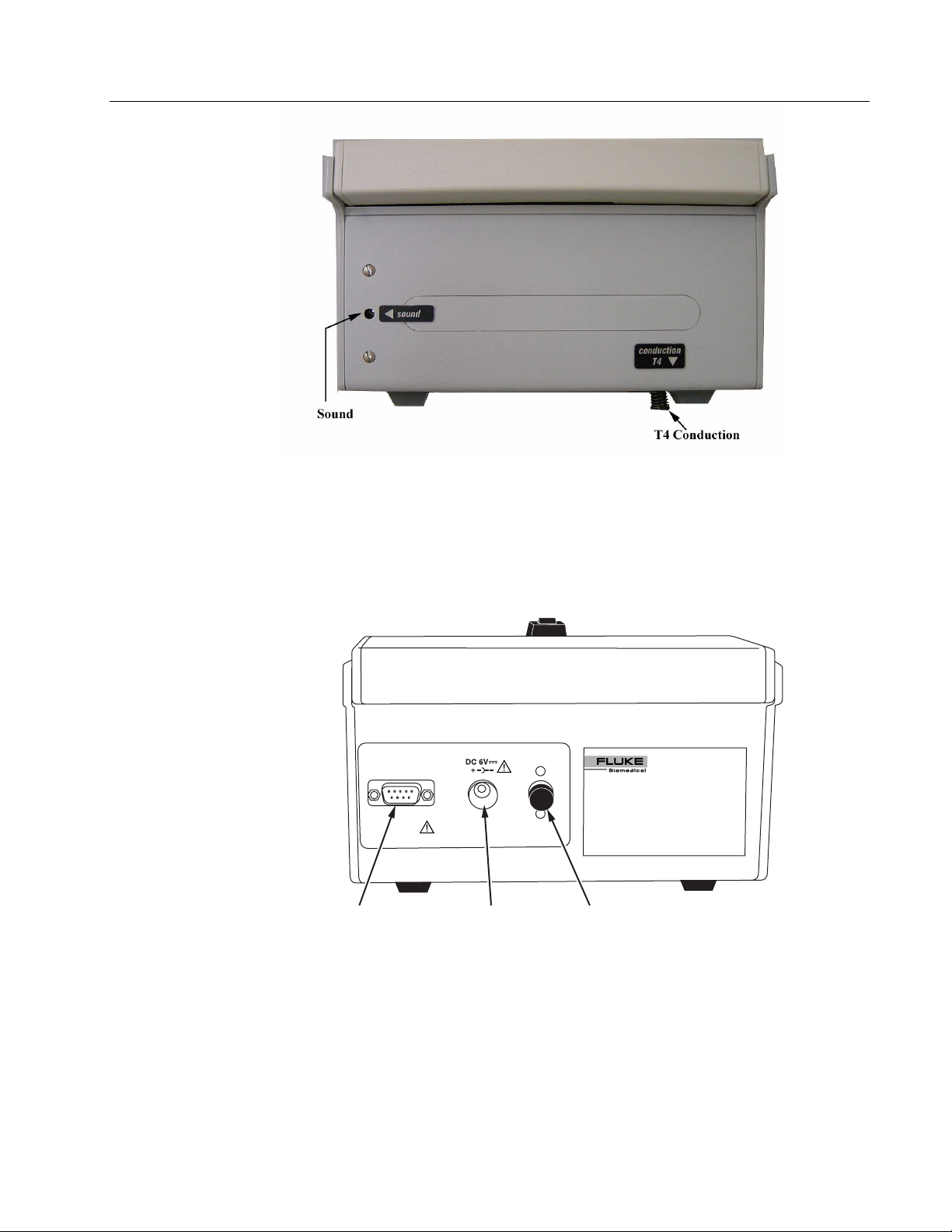

ure 1-4. View of right side of INCU

• Sound Sensor: Internal Microphone used for sound measurements.

Temperature Sensor T4: Used for Mattress Temperature

•

Measurements, made by conduction.

INCU

INCUBATOR ANALYZER

RS 232

Port

RS 232

DO NOT USE WITH OXYGEN

NE PAS UTILISER EN PRESENCE

D'OXYGENE

Power

DC in Jack

On/Off Switch

ure 1-5. View of left side of INCU

• RS-232 Port: 9 Pin D Sub type Male Connector.

•

Power DC IN Jack: Use only the specified charger. AC-DC 6V

600 mA.

Master On/Off Switch: Push for OFF or ON.

•

1-5

Page 18

INCU

Operators Manual

AAMI/IEC Standards

The AAMI and IEC standards specify sound levels, CO2 concentration, and

thermal characteristics for incubators. The standards are used by

manufacturers when designing and manufacturing incubators. INCU was

designed with consideration of the standards, and can perform testing to

satisfy many testing requirements.

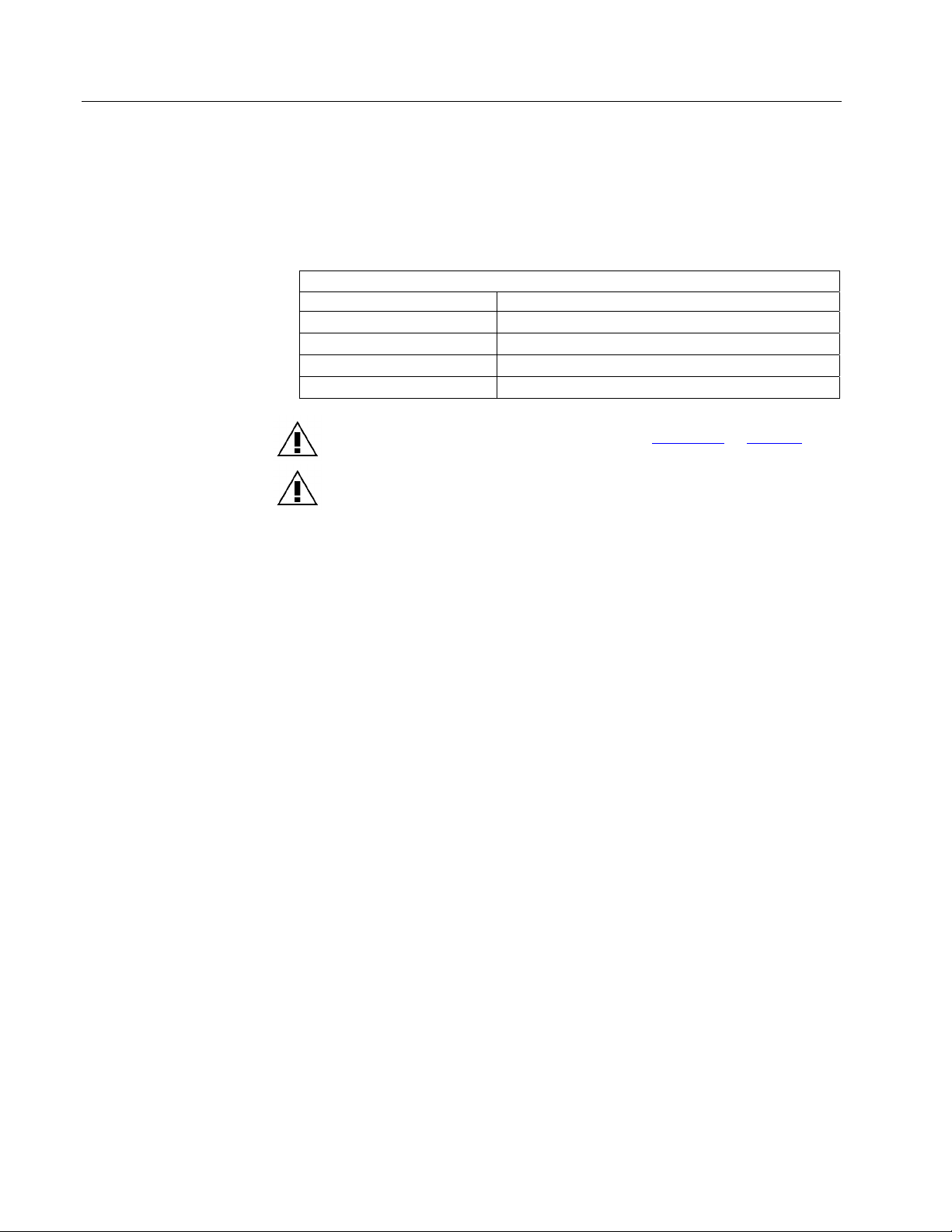

Incubator Standards

Standard# Description

IEC 601-2-19 Infant Incubator Tester Safety Requirements

IEC 601-2-20 Safety Requirements for Transport Incubators

IEC 601-2-21 Infant Radiant Warmer Standard

ANSI/AAMI 1136-1997 Infant Incubators

Note:

Note:

For up-to-date standards, please visit AAMI.org or IEC.org.

The following are examples of standards for description

proposed. Please reference the current application to determine

your testing protocol.

INCU Applications

The following section provides information describing how INCU

can be

used to perform testing in consideration of the standards.

Temperature – Standard: During steady state condition, the

1.

INCUBATOR TEMPERATURE shall not differ from the AVERAGE

INCUBATOR TEMPERATURE by more than 0.5°C (1°C transportable)

during at least 1 hour at the control temperatures of 32°C and 36°C.

INCU: The user shall check the oscillation from min to max in steady

state.

Temperature - Standard: The AVERAGE TEMPERATURE in each

2.

point A,B,C,D,E, shall not differ from the AVERAGE INCUBATOR

TEMPERATURE (test at a set T of 32°C - 36°C) by more than ±0.8°C

(±1.5°C transportable).

1-6

INCU: In any position of the tilted mattress, it shall not differ by more

than

±

1.0°C (±2.0°C transportable). Calculate manually the difference

between the mean value at the center and the other sensors readings.

3.

Temperature - Standard: The TEMPERATURE as measured by the

skin temperature sensor shall not differ from a reference sensor

temperature by more than 0.3°C in steady temperature condition.

INCU: Check the difference between the value given by the T2 sensor

and the value displayed by the skin sensor when placed in close

proximity to the T2 sensor.

Page 19

Incubator Analyzer

AAMI/IEC Standards

4. Temperature - Standard: The INCUBATOR shall be provided with an

indicator of the internal temperature. The mean value of the reading of

this device shall not differ from the average incubator temperature

measured by a standard thermometer by more than ±0.8°C (±1°C

transportable), less the standard thermometer

error. The standard

thermometer shall be accurate within ±0.05°C.

INCU: Check the difference between the value of the mean value at the

center and the one displayed by the indicator.

Temperature - Standard: Working as an air-controlled INCUBATOR,

5.

the average INCUBATOR TEMPERATURE shall not differ from the

control temperature by more than ±1.5°C (±2°C transportable).

INCU: Check the difference between the value of the mean value at the

center and the set value.

Temperature - Standard: The warm-up time of the equipment shall not

6.

differ by more than 20% from the warm-up time specified in the

instructions for use.

INCU: Check the difference between the time stated by the manufacturer

and the time to raise the temperature by 11 C, starting at the

environmental conditions with a setting temperature 12°C above the

ambient.

Temperature - Standard: After adjusting the temperature from 30°C to

7.

34°C or Transit 32°C to 36°C, the overshoot in the incubator temperature

shall not exceed 2°C.

INCU: Calculate the overshoot manually.

Standard: Any indicated value of relative humidity shall have an

8.

accuracy of ±10% (±15% transportable) of the actual measured value.

INCU: Read the value and compare it with the set value.

Sound Pressure - Standard: In normal use, the sound level within the

9.

baby compartment shall not exceed 60 dB except as specified in 102.2.

INCU: Read the value and compare it with the threshold.

Sound Pressure - Standard: When any incubator alarm is sounding,

10.

the sound level within the baby compartment shall not exceed 80 dB.

INCU: Activate an alarm, read the value, and compare it with the

threshold.

Sound Pressure - Standard: Audible alarms shall have a sound level of

11.

at least 80 dB at a distance of 3 m perpendicular to the front of the

control unit.

INCU: Activate an alarm, move the INCU

outside, read the value, and

compare it with the threshold.

1-7

Page 20

INCU

Operators Manual

Accessories

12. Air Flow – Standard: In normal use, air velocity over the mattress shall

not exceed 0.35 m/s.

INCU: Read the value and compare it with the threshold.

The following accessories are available for your INCU Incubator Analyzer.

Description Part No.

DB9 Serial Cable 2238834

Transport Bag 2248900

Radiant Baby Assembly 2239002

Outside Temperature Probe Holder 2213928

Service Manual 2206983

1-8

Page 21

Chapter 2: Installation

2

Inside This Chapter

• Unpacking and Inspection

TM

• Connecting INCU

• PC Software System Requirements

• Installing the PC Software

2-1

Page 22

INCU

Operators Manual

Unpacking and Inspection

Before unpacking the INCU, visually inspect the shipping box for damage.

If no damage is evident, unpack the INCU and use the checklist below to

ensure that you have received the instrument accessories. Save the foam

inserts and shipping box. You must use the original packing materials when

shipping the INCU for service or re-calibration. If the original shipping

carton and packing materials are not available, call a Fluke service

representative for assistance.

If the shipping box is damaged, unpack the analyzer and inspect it for visible

defects.

If the instrument is damaged, notify the carrier and your local dealer or

service center. Keep the shipping cartons and packing materials for the

carrier's inspection. Call a Fluke service representative to arrange for repair

or replacement of your instrument without waiting for the claim against the

carrier to be settled.

After unpacking the INCU, use the following checklist to ensure that you

have received everything. In addition to the analyzer and this manual

(P/N 3901000), you should have the following:

• A Transport Bag, P/N 2248900

• An Air Flow Sensor, P/N 2239025

• PC Software CD ROM, P/N 2213919

• AC Battery Charger with Country Adapters for the USA, Europe,

Australia, or the UK, P/N 2213937

• 9-Pin to 9-Pin Serial Cable, P/N 2238834

• Temperature Probe Holder, P/N 2213928

• Radiant Baby Assembly, P/N 2239002

• Certificate of Calibration

• Declaration of Conformity

• Fluke Biomedical Warranty Card Information

2-2

Page 23

Incubator Analyzer

Connecting INCU

Connecting INCU

AC-DC Battery Charger Connection

The INCU can operate either on its internal battery or with AC power.

Connect the specified adapter to the INCU

Plug the opposite end into the AC power source. The universal charger can

be plugged into AC power sources ranging from 90 VAC to 240 VAC,

50/60 Hz. Use the charger to recharge the internal batteries when a “low

battery” warning is displayed. Regular charging of the battery will increase

its life.

DC jack on the side of the unit.

Internal Battery

RS-232 Port

Warning:

To reduce the risk of damage to the battery and to the INCU,

only use the specified Fluke Biomedical Charger, P/N 2213937,

AC-DC 8V 800 mA. Failure to do so will void the warranty.

The system is equipped with a lead-acid battery, giving a maximum of 24

hours of operation. Use the AC Charger if recording parameters for longer

than 24-hour periods.

Connect the INCU RS 232 port to an available COM port on the PC using

the supplied 9-pin to 9-pin serial cable.

2-3

Page 24

INCU

Operators Manual

Air Flow Sensor

Plug the Air Flow Sensor into the jack on top of the INCU where it is labeled

"Air Flow." Ensure that the Air Flow Sensor is installed before attempting to

use the INCU. Otherwise, a “Sensor Fault” condition will result, indicating

the absence of this sensor. To bypass the “ Fault sensor : 6” message, press

any key. INCU operation will continue with normal operation with the

exception of recording Air Flow parameters. Results will be displayed as

9.99 m/s.

The Air Flow Sensor is calibrated for each INCU unit. If the Air Flow Sensor

is lost or damaged, the unit must be returned for service. See "Support" in

Chapter 5, Safety, Displayed Messages, Troubleshooting, and Support.

Warning! Do not use in the presence of oxygen!

uses a hot-wire technology that can be a source of ignition if

used in oxygen-enriched environments. INCU should not be

The Air Flow Sensor

used in conditions where oxygen levels are greater than

ambient.

Radiant Baby Assembly

Figure 2-1 shows the radiant baby assembly.

2-4

Figure 2-1. Radiant baby assembly

Page 25

Incubator Analyzer

Installing the PC Software

PC Software System Requirements

To utilize the full capabilities of your INCU program, the following

minimum environment is required:

A PC or portable computer equipped with:

• Pentium 133 MHz microprocessor

• 16 MB free hard disk space

• SVGA color monitor

• Serial port COM 1-4 (one com port available)

• Mouse compatible with Microsoft® operating system

• 1 CD ROM disk drive

• Microsoft® Windows® 95B, Windows® 98, Windows NT® 4.0, or

Windows® 2000 operating system

• A laser or inkjet printer

Note: Microsoft® Windows® 3.0 and Windows® 3.1 for Workgroup

3.11 are not supported by this application.

Note: Certain portable computers are equipped with an infrared serial

communications port. The presence of such a port, typically

COM 2, may create operating difficulties on the COM 1 serial

port. In this case, delete the infrared COM 2 port from the

peripheral driver.

2-5

Page 26

INCU

Operators Manual

Installing the PC Software

Installing the Software

The INCU PC Software is provided with both French and English

installation instructions. If desired, the language for the PC Software may be

selected after installation.

1. Insert the INCU PC Software for Windows CD ROM into the CD

ROM drive on your PC. Under Microsoft Windows 95/98/NT, select

Run from the Start menu.

For English, when the

d:\incugb\setup.exe. If your disk drive is not "D", then substitute the

correct drive letter. Click

For French, when the

d:\incufr\setup.exe. If your disk drive is not “D”, then substitute the

correct drive letter. Click

Run dialog box is displayed, type in

OK.

Run dialog box is displayed, type in

OK.

2-6

Figure 2-2. INCU setup screen

2. To exit the installation program, click on

3. As shown in Figure 2-2, click on

Change Directory to select a location

Exit Setup.

on your computer in which the program will be installed.

4. Simply follow the instructions given by the installation program. If no

changes are made to the default installation options, INCU PC Software

will be installed to

C:\Program Files\INCU, and the shortcuts to the

program will be in the INCU group.

5. To start the program, double-click on the INCU icon.

Page 27

Chapter 3: General Operation

3

Inside This Chapter

• INCU Keypad Functions

• INCU Setup

• INCU Operation

3-1

Page 28

INCU

Operators Manual

INCU Keypad Functions

Figure 3-1 illustrates the INCU keypad. The keys and their functions are

described on the following pages.

RADIANT/

CONVECTION

T2

T1

CONVECTION

DO NOT USE WITH OXYGEN

NE PAS UTILISER EN PRESENCE

D'OXYGENE

INCU

INCUBATOR ANALYZER

EVENT SELECT

AIR FLOW

RELATIVE

HUMIDITY

T3

CONVECTION

!

Figure 3-1. The INCU front panel

3-2

Page 29

Incubator Analyzer

INCU Keypad Functions

Key Details

Start/Pause Key

1. Press this key for approximately 1 second to

begin recording. This function is only active

once the INCU has been connected to a PC and

a measurement cycle has been initialized.

2. A second display line appears (see Figure 3-2)

with the following information:

• Measurements that have already elapsed

• Total measurements

• The number of events recorded

(maximum 5).

20.4 C Temp. 1

º

1:210 Evt. 0

event select

Figure 3-2. INCU keypad display

3. The sensor number that is displayed flashes

to indicate that the measured values have

been recorded.

4. Press this key a second time to pause (to

allow time for adjustment, for example).

During this pause phase, the channel

number stops flashing.

5. Press this key a third time to resume

recording. There is no limit to the number

of interruptions possible.

3-3

Page 30

INCU

Operators Manual

event

!

Event Key

Press this key for approximately 1 second to mark a

particular value or a pause in the recording sequence.

As a result, the action is recorded and then displayed

on the History Graph Sheet and Parameter Numerical

List (see Appendix B, Report Examples).

For an explanation of the significance of each marker,

see "Transfer Data to the PC Software" in Chapter 4,

INCU PC Software Operation.

Note: It is possible to store 5 events. The stored

events cannot be deleted.

select

Sensor Key

1. First mode:

• Each time this key is pressed for

approximately 1 second, the next

sensor is displayed (one of the 7

currently active sensors, in order).

2. Second mode:

• Pressing this key two times quickly

allows you to scroll through the

channels. Press the key a third time to

freeze the display.

3-4

Page 31

Incubator Analyzer

INCU Setup

INCU Setup

Placement of the INCU in the Incubator

With both covers open and fully extended, the INCU has dimensions (length

and width) similar to those of a typical infant (non-preemie). The INCU

should therefore be placed in an isolette (incubator), or infant warmer in the

same manner as an infant would be positioned for normal operation; i.e.,

centered on the mattress ensuring that air circulation vents, temperature

probes, etc. are not blocked or impinged. Figure 3-3 shows the INCU inside

a closed incubator.

Closed Incubators

Figure 3-3. INCU inside a closed incubator

3-5

Page 32

INCU

Operators Manual

T1, T2, and T3 Convection Sensors: Figure 3-4 shows the recommended

placement for temperature sensors T1-T3 for closed incubators utilizing

forced convection. With the sensors mounted to the provided clips,

temperature accuracy, response, and uniformity can be monitored throughout

the area occupied by the infant at the height of approximately 10 cm above

the mattress as specified by standards. In this case, T2 is being utilized as a

convection temperature sensor.

Humidity Sensor (Fixed): The humidity sensor is fixed and is located on the

inside of the right-hand cover as shown in Figure 3-4.

T1 Convection

CONVECTION

T2 Convection

or Conduction

R

A

D

IA

N

T

/

C

O

N

V

E

C

T

IO

N

T

2

T1

EVENT

Air Flow

D

O

N

O

T

U

N

S

E

E

P

W

A

S

I

T

U

A

H

T

O

IR

IL

X

I

F

Y

S

G

E

L

R

E

O

E

N

W

N

P

D

R

'O

E

X

S

Y

INCU

IN

CU

B

AT

O

R

!

SELECT

E

G

N

E

C

N

E

E

A

N

A

LYZ

ER

R

E

L

A

T

IV

E

H

U

M

ID

IT

Y

T3

CO

NVECTIO

N

On/Off Switch

Temperature

Probe Holder

T3 Convection

Humidity

Figure 3-4. Placement of temperature sensors T1-T3

Note: To achieve a better temperature slew rate, for T1, T2, it

is preferable to clip on the sensor cable instead of the

body sensor.

3-6

Page 33

Incubator Analyzer

INCU Setup

Air Flow Sensor: The Air Flow Sensor is detachable; however, it must be

inserted to perform measurements. An error "fault sensor" will be displaced

if not inserted or if the Hot Wire is broken in the sensor. The INCU will not

perform airflow measurements in this condition.

The Air Flow Sensor (Figure 3-5) rotates 360 degrees. For best results,

position the Air Flow Sensor perpendicular to the airflow within the

incubator. Incubators utilize different airflow patterns; thus, the user needs to

be familiar with the particular airflow pattern utilized by the incubator under

test to properly position the Air Flow Sensor.

Figure 3-5. Placement of Air Flow Sensor

Warning! Do not use in the presence of oxygen! The Air

Flow Sensor should

environment. The Air Flow Sensor utilizes a hot-wire technique,

which can be a source of ignition.

not be used in an oxygen-enriched

3-7

Page 34

INCU

Operators Manual

T4 Conduction Sensor: As shown in Figure 3-6, the T4 conduction sensor

is fixed and is located on the bottom of the INCU. T4 provides the

temperature of the mattress.

Sound Sensor (Fixed): The sound sensor is fixed and is located on the right

side of the INCU.

Figure 3-6. Placement of temperature sensor T4

3-8

Page 35

Incubator Analyzer

INCU Operation

Infant Radiant Warmers

INCU sensor placement for testing infant radiant warmers is treated in the

same manner as closed incubators utilizing forced convection, with the

exception of T2. As discussed above, T2 is used as a third convection

temperature sensor for testing closed incubators with forced convection. In

contrast, when testing infant radiant warmers, T2 is utilized as a radiant

temperature sensor.

For testing infant radiant warmers, T2 is clipped to the underside of the

radiant baby adapter that is provided. The radiant baby adapter is a stand-

alone circular-shaped piece that simulates the absorption properties of an

infant. This adapter must be placed on top of the INCU when testing. Align

the adapter with the heater in the warmer.

Other temperature sensors (T1, T3) may be used to monitor ambient

temperature conditions.

Figure 3-7 shows the placement of the INCU in an infant warmer.

Figure 3-8 shows the placement of a radiant baby adapter on top of the

INCU.

Figure 3-7. Placement of an INCU inside

an infant warmer

3-9

Figure 3-8. Placement of a radiant baby adapter

on top of the INCU

Page 36

INCU

Operators Manual

INCU Operation

1. Place the INCU into position within the incubator or infant warmer.

Refer to Figures 3-3 and 3-7 for placement of the INCU.

2. Place the sensors into position.

Place temperature sensors T1, T2, and T3 into position, and connect the

Air Flow Sensor.

To conduct a test on an infant warmer, clip the end of probe T2 under the

radiant baby adapter as shown in Figure 2-1.

3. Turn on the power.

If acquiring data for periods longer than 24 hours, use the AC Charger.

Open both covers to expose the INCU panel and display. Push the

On/Off switch located on the left-hand-side panel of INCU to turn on the

INCU.

Note: The INCU is equipped with a secondary On/Off switch on the

top panel. This is a safety switch used to prevent INCU power

from remaining on when the covers are closed.

Caution: Pressing the On/Off switch located on the top panel during

data acquisition will initialize the INCU and stop the data

acquisition session.

The unit will display the following:

Line 1: INCU. ANALYZER

Line 2:

Ver : 3.00

followed by:

Line 1:

Self Testing

If error conditions are present, the unit will display an error.

For detailed error condition information, refer to Chapter 5, Safety,

Displayed Messages, Troubleshooting, and Support.

3-10

Page 37

Incubator Analyzer

INCU Operation

4. Obtain Readings

The unit is now ready either to be used as a measuring device in manual

mode, or in an automated data acquisition mode as configured by the PC

software. For further information on configuring INCU for data

acquisition, refer to Chapter 4, INCU PC Software Operation.

5. Observe Readings – Manual Mode

Sensor data is displayed on the first line. To manually cycle through the

available sensors, press the

quickly and then released, the INCU will cycle through and display each

of the available sensor channels automatically. To revert to manual

mode, press the

Select key again. No data is stored within the INCU in

this mode. The INCU must be configured for using the PC software prior

to starting any automated data acquisition.

6. Data Acquisition Mode Using the PC Software

After being configured for data acquisition, the INCU will display

Ready. Press the Pause/Play key to begin data acquisition.

The second line of the display shows the following (Figure 3-9):

Select key. If the Select key is pressed too

• Measurement samples already recorded

• Total samples

• The number of events memorized (maximum 5)

20.4 C Temp. 1

º

1:210 Evt. 0

event select

Figure 3-9. Data acquisition mode screen

The sensor channel number on the display flashes, indicating that the

measured values have been stored.

Press the

Pause/Play key a second time to pause data acquisition (to allow

time for adjustment, for example). During this pause phase, the channel

number stops flashing.

To resume data acquisition, press the

Pause/Play key again. There is no

limit to the number of interruptions possible.

3-11

Page 38

INCU

Operators Manual

3-12

Page 39

Chapter 4: INCU PC Software Operation

4

Inside This Chapter

• Introduction

• Configuring the INCU for Data Acquisition

• INCU Data Acquisition

• Transferring Data to the PC Software

• Graphs

• Software Options

4-1

Page 40

INCU

Operators Manual

Introduction

The full capability of the INCU is realized when used in conjunction with the

provided PC application.

The provided PC software for INCU is used to:

• Select the measurement interval (1-10) minutes

• Select the total recording period (35 hours max)

• Display recorded data in graphical form

• Print a provisional monitoring sheet

• Create backup files that can be used by a spreadsheet program such

as Microsoft® Excel.

Configuring the INCU for Data Acquisition

1. Connect all sensors

2. Press the On/Off button for approximately one second.

3. Wait until the INCU has completed the initialization sequence.

4. Using the supplied RS-232 cable, connect the INCU to a PC that is

loaded with the INCU PC software as shown below.

5. Double-click on the installed icon to start the INCU PC software.

Figure 4-1 shows an example of a PC interconnected with an INCU.

COM PORT

4-2

Figure 4-1. PC interconnected with the INCU

Page 41

Incubator Analyzer

Data Acquisition

6. Once the PC program is up and running, select the

command and then

Config.

The

Config command is used to select the measurement interval and

total recording period, and to document the serial number of the

incubator under test as shown in Figure 4-2.

Figure 4-2. Using the Config menu

Connect

7. To select the measurement interval, click on the scrolling arrows

located next to

Sampling interval. You can choose from 1 minute

up to 10 minutes in one-minute intervals.

The measurement interval specifies how often the sensors are

sampled for data. That is, if the measurement interval is one minute,

all seven INCU sensors are then polled every minute and the results

are recorded.

8. To select the recording period, click on the scrolling arrows located

next to

Total measurement time. You can choose up to 35 hours for

the recording period (with a 10-minute sampling period).

The recording period specifies the duration of the test. That is, if the

measurement interval is one minute and the recording period is set

for one hour, the test will last for one hour, and during that time, 60

measurements for each sensor will be recorded. The maximum

measurement capacity of the INCU is 1470 (210 records x 7

parameters).

9. Enter the serial number for the incubator under test in the field next

to

Incubator serial no.

Note: You must enter a serial number in this field to proceed.

10. From the

File menu, choose Print to print out a monitoring sheet

(see Figure B-1 in Appendix B, Report Examples). This sheet

contains the INCU configuration information along with fields for

manufacturer, type, department, etc. Use the

monitoring sheet to

record events that occur during the incubator-testing phase.

4-3

Page 42

INCU

Operators Manual

Data Acquisition

After the INCU is configured for data acquisition, Ready will be displayed.

Disconnect the INCU from the PC and place it into an incubator or infant

radiant warmer under test as described in Chapter 3. When properly

configured and positioned, the INCU is ready for data acquisition.

Start/Pause Key

1. Press this key for approximately 1 second to begin

recording. This function is only active once the

INCU has been connected to a PC and a

measurement cycle has been initialized.

2. A second display line appears (see Figure 4-3)

with the following information:

• Measurements that have already elapsed

• Total measurements

• The number of events recorded

(maximum 5).

20.4 C Temp. 1

º

1:210 Evt. 0

event select

Figure 4-3. INCU keypad display

3. The sensor number that is displayed flashes to

indicate that the measured values have been

recorded.

4. Press this key a second time to pause (to allow

time for adjustment, for example). During this

pause phase, the channel number stops

flashing.

5. Press this key a third time to resume

recording. There is no limit to the number of

interruptions possible.

4-4

Page 43

Incubator Analyzer

Transferring Data to the PC Software

Transferring Data to the PC Software

After data acquisition is complete, data transfer can be executed. Data

transfer is the act of transferring the data in the INCU from the previous

acquisition to a PC running INCU PC software. When data is transferred to a

PC, it can be displayed in graphical or numerical form, and/or saved as a file

for future reference (see Appendix B for examples of graphs and numerical

data). Numerical data can be entered into Microsoft® Excel or some other

spreadsheet program to customize your own graphs.

6. Press the

1 second to mark a particular value or a pause

in the recording sequence. As a result, the

action is recorded and then displayed on the

History Graph Sheet and Parameter Numerical

List (see Figures B-2 and B-3 in Appendix B,

Report Examples).

7. Describe these events on the

sheet

acquisition. It is possible to record up to five

events.

When the acquisition phase is complete,

measurements

Events key for approximately

monitoring

if one was printed before data

will be displayed.

end of

To initiate a data transfer from the INCU, connect the INCU to a PC running

the INCU PC software via the RS-232 port utilizing the supplied RS-232

cable. Click on connect and transfer as shown in Figure 4-4 to initiate data

transfer. During the transfer phase, the mouse pointer indicates the progress

of data transfer.

Figure 4-4. INCU file transfer menu

4-5

Page 44

INCU

Operators Manual

At the end of transmission, the comments entry window appears as shown

below. This window allows you to enter comments for or update

monitoring sheet.

the

Figure 4-5. INCU comments entry window

At download the user can enter either the start or end of time of the

acquisition by clicking on the checkbox. Use the two scrollbars to specify the

hour and the minutes. If

PC software defaults to

The PC software will calculate the

selected and the

end of acquisition time entry.

Start time of the acquisition: is not checked, the

end of acquisition time.

start time based on the sample interval

4-6

Page 45

Incubator Analyzer

Graphs

Graphs

This menu is accessible after the recorded data has been loaded. When the

graph menu option is selected, four parameters are displayed.

Figure 4-6. INCU parameter options menu

When a parameter is selected, a window is displayed presenting data in

graphical form (see Appendix B for examples of graphs). The upper section

of the window is shown in Figure 4-7.

Figure 4-7. INCU parameter screen

First Scrolling Bar: Selects the specific time during the acquisition period in

1

hours and minutes. The associated dialogue box shows the value of the data

item for the time selected.

Second Scrolling Bar: Selects the time interval for calculating an average

2

for the data item. The average is based on the time specified by the first

scrolling bar and is updated when the first scroll bar is adjusted (rolling

average).

Print Key: Prints the graph displayed on a single page.

3

INFO/Marker Key: Loads the Comments Window associated with an event

when an event marker is encountered by moving the

key is only active when an event is encountered.

first scrolling bar. The

4-7

This box shows the value of the data item selected by the mouse pointer.

5

Page 46

INCU

Operators Manual

Software Options

Open Files

INCU PC File menu features shown in Figure 4-8 are described below.

Figure 4-8. INCU File menu screen

To open a document:

Save Files

Printer Configuration

1. In the

2. In the area listing the folders and files, double-click on the name of

3. Double-click on each sub-folder in turn until you reach the sub-

To save a file:

1. In the

2. If you have not yet saved your file, type the name you wish to give it

This window enables you to access the different parameters of your printer.

These functions are variable and depend on the type of printer used.

File name field, click on the drive containing the document.

the folder in which the document is stored

folder containing the document.

File menu of the program you are working in, click on Save.

File name field.

in the

4-8

Print Folder

Click on

sheet

Appendix B.

Print Folder to print the recorded data including the monitoring

, the history graph sheet, and the parameter numerical list shown in

Page 47

Incubator Analyzer

Software Options

Cascade

INCU PC

Vertical tile, are shown in Figure 4-9 and are described below.

Window menu features, including Cascade, Horizontal tile, and

Figure 4-9. INCU Window menu screen

To organize windows so that they overlap each other, click on the menu

Window, then on Cascade. To position windows side by side without any

overlap, click on the

position windows from top to bottom without any overlap, click on the

Window menu, and then click on Horizontal Tile.

Window menu, and then click on Vertical tile. To

Figures 4-10 through 4-14 show the INCU PC Parameters menu features,

described below.

Figure 4-10. INCU Parameters menu screen

4-9

Page 48

INCU

Operators Manual

Heading

Figure 4-11. INCU Heading screen

This menu is used to customize the monitoring sheet. All fields shown in

red must be completed when you enter this menu.

• Site name

• Address

• Department name

• Operator name

The only exception is the

the

Comments heading in the Comments entry window.

Information field, intended for customization of

4-10

Page 49

Incubator Analyzer

Software Options

Graph Colors

Figure 4-12. INCU Graph colors screen

Use this menu to apply the color of each graph from 15 available colors. The

Desk key allows you to set the background color of the INCU window.

When you exit the INCU program, your choices are automatically saved in

the file

setup.cfg.

4-11

Page 50

INCU

Operators Manual

Com Port

Figure 4-13. INCU Communication menu screen

This menu allows you to select the serial communications port

(Com). Com2 port is the default. Select the Com1, 3,or 4 port as

shown in Figure 4-13. When you exit the INCU program, your

choices are saved in the file

setup.cfg.

Language

Figure 4-14. INCU Language menu screen

This menu allows you to select the language by clicking on French or

English text.

4-12

Page 51

Incubator Analyzer

Software Options

Zoom

The

Zoom menu screen is shown in Figures 4-15 and 4-16. The Zoom

command is only applicable when a graph is displayed.

Figure 4-15. INCU Zoom menu screen

The Zoom menu applies only to the last graph activated. It consists of two

elements:

1. Zoom X for the horizontal axis (x-coordinate: real-time scale on

graphs)

2. Zoom Y for the vertical axis (y-coordinate).

Zoom X

Figure 4-16. INCU Zoom on window screen

This command is active when a graph is displayed. It allows for inspection of

a small interval of the total acquisition time. Maximum zoom is equal to 30

times the sample interval. When you close a graph, the zoom x menu

becomes inactive.

Zoom Y

This is an optional command. It is used to define the Y-axis of the graph

between the minimum value and the maximum value of the parameter at the

time under observation.

If you wish to use the

again through the Graph menu.

4-13

Zoom feature on an inactive graph, open the graph

Page 52

INCU

Operators Manual

4-14

Page 53

Chapter 5: Safety, Displayed Messages,

Troubleshooting, and Support

5

Inside This Chapter

• Electrical Safety and Maintenance

• Displayed Messages

• Troubleshooting

• Support

5-1

Page 54

INCU

Operators Manual

Electrical Safety

Cleaning

Air Flow Sensor

Warning:

For safe operation, use only the specified AC Charger with the

INCU. Use of any charger other than that specified may result

in a hazardous condition.

The system is to be cleaned with a damp cloth on the exterior only. A

solution of 70% isopropyl alcohol may be used to remove stains and clean

the system. No other solvents are recommended.

The Air Flow Sensor has been calibrated for use with each INCU. If an Air

Flow Sensor is lost or misplaced, the unit must be returned to the factory or

to a certified service center for recalibration. Failure to do so will result in

invalid Air Flow readings.

Preventive Maintenance

Only authorized, qualified technicians should perform annual verification

and calibration of the INCU unit according to the manufacturer's

recommended procedures.

5-2

Page 55

Incubator Analyzer

Troubleshooting

Displayed Messages

Possible INCU displayed messages are described below.

Displayed Message Description

Self Testing

Low Battery

INCU is performing internal self-checks to

determine proper operating condition before taking

measurements. Any errors encountered during this

test will be displayed on Line 1. Refer to Chapter 5

for an explanation of possible error conditions from

the INCU and possible cause and resolution.

The battery should be charged without delay.

When the battery voltage is less than 5.35 volts

DC, the message will be displayed. The battery

voltage is displayed on power-up during the selftest routine.

When the message appears, use the AC Charger

for normal operation and/or to recharge the internal

battery. When the internal battery voltage is greater

than 5.85 volts DC, the message will not be

present.

Note: Regular charging of the battery increases its

life considerably. The battery must never be

completely discharged.

Note: When this message appears, no data

transfer between the INCU and the PC is possible.

Use the AC charger. When the message

disappears, data transfer is possible.

End of Measurements

Data in Memory

Ready

Fault Sensor

Indicates that the data acquisition is complete.

Connect the INCU to the PC to transfer data

between the INCU and the PC.

Note: The recorded measurements can be

retrieved using the PC even if the cycle has been

interrupted before this message is displayed.

The data transfer has not been completed. Using

the PC Software, transfer the data to the PC. Data

must be transferred to the PC in order to take

further readings in memory.

Displayed after a new configuration has been sent

from the PC software and stored in the INCU unit.

There is an error with the subject sensor. Refer to

Chapter 5 to determine corrective action for each

respective sensor error.

5-3

Page 56

INCU

Operators Manual

Troubleshooting

Problem Possible Cause Corrective Action

INCU does not initialize

when the top covers are

opened.

INCU does not

communicate with the

computer

Incorrect cable Verify the cable used to

Correct COM port not

Operating system not

Internal Battery Low Recharge Battery or

Connect AC Charger for

operation.

Master ON/OFF switch

on side panel not turned

on.

RS-232 cable not

plugged in.

selected

supported.

Push switch to turn the

INCU on.

Verify that the INCU is

connected properly.

connect the RS-232 is a

straight-through cable. Null

modem cables will not

work properly.

Select the COM port used

via the PC Software –

Tools menu.

The INCU PC Software

requires 16550 UART.

This is not present in

earlier windows operating

systems Windows 3.0, 3.1,

and Workgroup for

Windows 3.11. These

operating systems are not

supported. More

information is available on

this issue from the

Microsoft website.

INCU not initialized Turn the analyzer off then

on to reinitialize the unit.

Fault sensor: 1 to 4

during starting sequence

The sensor temperature

Fault sensor: 2 Sensor is connected to

5-4

Problem with

Temperature sensor

is out of the range

(4°C to 70°C).

the radiant baby

assembly prior to

conducting the self-test.

Return the INCU for

service.

Allow the sensor to reach

ambient room

temperature, then

reinitialize the unit by

turning the power off then

back on.

Disconnect the T2 sensor

from the radiant baby

assembly. Allow the

sensor to reach ambient

room temperature, then,

reinitialize the unit by

turning the power off then

back on.

Page 57

Incubator Analyzer

Support

Troubleshooting (Cont.)

Problem Possible Cause Corrective Action

Fault sensor: 6 Air Flow Sensor not

plugged in.

Hot Wire broken in Air Flow

Sensor

INCU did not record all

the measurements that it

was configured for.

The stop key was

If the low battery

message appeared while

in the middle of data

collection, then the INCU

will stop the recording at

that time.

pressed prior to

completion of the desired

recording cycle.

Plug in Air Flow Sensor, or

press any key to bypass

the error condition. The

INCU will perform all other

measurements with the

exception of Air Flow. All

Air Flow readings will be

displayed and stored as

9.99 m/s.

Replace Air Flow Sensor; unit

must be sent back to Factory

for recalibration.

Recharge the battery, or

use the AC Charger. All

data is stored in the INCU

up to the point of the low

battery message. Transfer

the results to the PC using

the PC Software program.

All data is stored in the

INCU up to the point of the

low battery message.

Transfer the results to the

PC using the PC Software

program.

5-5

Page 58

INCU

Operators Manual

Support

Troubleshooting

If your new INCU

Department for assistance.

Service

Before returning the INCU

Department for further information.

Phone: 888.993. 5853

Fax: 425.446.5560

Internet:

Shipping Requirements

1. Pack the unit carefully. Enclose a completed Service Return Form.

2. Insure the unit for full retail value and ship to:

Fluke Biomedical

1420 – 75

Everett, WA 98203

USA

fails to operate successfully, call or e-mail Fluke's Service

for factory service, contact Fluke's Service

www.flukebiomedical.com

th

Sreet SW

5-6

Page 59

Appendix A: Performance Specifications

A

Inside This Appendix

• Performance Specifications

A-1

Page 60

INCU

Operators Manual

Performance Specifications

This appendix provides the device specifications for the INCU Incubator

Analyzer. For more information, please contact your Fluke Biomedical

Service representative.

Temperature Measurements

Conduction: 1 sensor in contact with mattress

Convection

(Inside the incubator): 3 sensors (T1, T3, T4)

Radiation: 1 sensor (T2) connected to the so-called “radiant

Convection

(Inside or outside the

incubator): 1 sensor T2

Measuring Range: 5°C to 70°C

(bottom of unit)

baby”

Resolution: 0.1°C

Accuracy: Reading Value ±0.5°C ± 1 LSB for the range

from 25°C to 40°C

Storage Temperature -20°C to 50°C

Operating Temperature: 10°C to 40°C

Dimensions

Relative Humidity

: 27 x 14 x 20 cm

Measuring Range: 0% RH to100% RH

Resolution: 0.1% RH

Accuracy: ±5% RH (for range 0 to 90% RH

@ 25°C to 40°C) or,

± 5.3 % RH (for range 0 to 100% RH

@ 25°C to 40°C)

Humidity must be without condensation.

Air Flow

Measuring Range: 0.1-0.7 m/s

Resolution: 0.01 m/s

Accuracy: From 0.1 m/s to 0.5 m/s reading

±0.1 m/s @ temperature 25°C to 40°C

and humidity 50% RH ± 15% RH

A-2

Page 61

Incubator Analyzer

Performance Specifications

Noise

Measuring Range: 30- 80 dbA

Resolution: 0.1 dbA

Accuracy: ±5 dbA @ 30-80 dbA

Display

2 x 16 Super Twist LCD

Measuring Interval

Via PC: Adjustable from 1 to 10 minutes

Internal Memory

Capacity: 1470 measurements

(210 records of 7 parameters)

Supply

Power Requirements: Maximum over-voltage: 264 VAC

Input voltage range: 100 to 240 VAC

Input frequency range: 47 to 63 Hz

Power consumption: < 60 Volt Amperes

Fuse rating: 2A Slow Blow

Battery: Rechargeable sealed lead-acid type

NP7-6 YUASA, 6V, 7 Ah

dimensions 151 x 34.x 101.0 mm

Operates for 24 hours continuously without the

low-battery warning

Charger 600 mA minimum, 8 VAC-DC

(Charger must be agency-approved, depending

on the country)

A-3

Page 62

INCU

Operators Manual

Protection Factor: IP 30

The first index digit -3 means that the unit is

protected from object access of solid foreign

matter larger than 2.5 mm in diameter.

The second index digit - 0 means no protection.

Weight: 3 kg

A-4

Page 63

Appendix B: Report Examples

B

Inside This Chapter

• Monitoring Sheet

• History Graph Sheet

• Parameter Numerical List

B-1

Page 64

INCU

Operators Manual

Report Examples

This appendix provides examples of reports (Figures B-1 through B-3) that

can be generated and/or printed from the INCU Incubator Analyzer. Refer to

Chapter 4, INCU PC Software Operation for details on how to print these

reports.

B-2

Page 65

Incubator Analyzer

Report Examples

Fluke Biomedical

Incubator Analyzer

Ver 2.05

Manufacturer :

Type :

Incubator serial no. : 1234

Marker 1: M1

Marker 2:

Marker 3:

Marker 4:

Marker 5:

Temperature order :

Sampling interval : 08 min

12/10/2001

Monitoring sheet

Hygrometry order :

Number of samples : 145

Start time of the acquisition : 08:24:00

Department name :

Procedure no. :

Information :

Check :

Operator name : Operator name

Signature :

Site name

Address

Ver 2.05

C:\Program Files\INCU\DEMO205.DAT

Successful [ ] Failed [ }

Page 1/9

Figure B-1. Sample monitoring sheet

B-3

Page 66

INCU

Operators Manual

Figure B-2. Sample history graph sheet

B-4

Page 67

Incubator Analyzer

Report Examples

Figure B-3. Sample parameter numerical list

B-5

Page 68

INCU

Operators Manual

B-6

Page 69

Appendix C: DAT File Format

C

Inside This Chapter

• DAT File Format

C-1

Page 70

INCU

Operators Manual

The DAT File is a text file that may be imported into popular spreadsheet programs for further processing

and/or analysis. The following is the format of the DAT file stored by the INCU PC Software.

File *.DAT

ASCII Hex Hex

Key word for INCU file identification LFCL 0D 0A

Incubator serial number 0123 0D 0A

Total measurement time 0145 0D 0A

Sampling interval 0010 0D 0A

Name of channel 1 Convection 1 (T1) 0D 0A

0187 0D 0A

Data sent by the sensor. Written in tenths. 0222 0D 0A

0258 0D 0A

Event markers indicated by an M preceding the value M295 0D 0A

Name of channel 2 Radiation/Ext. (T2) 0D 0A

0197 0D 0A

Data sent by the sensor, in tenths 0205 0D 0A

0224 0D 0A

0247 0D 0A

Name of channel 3 Convection 2 (T3) 0D 0A

0186 0D 0A

Data sent by the sensor, in tenths 0232 0D 0A

0271 0D 0A

0302 0D 0A

Name of channel 4 Conduction (T4) 0D 0A

0162 0D 0A

Data sent by the sensor, in tenths 0175 0D 0A