Page 1

Instruction Sheet

i400

AC Current Clamp

Introduction

The Model i400 (hereafter called “the Current Clamp”) is an ac

current clamp that outputs 1 mA/A via safety-shrouded banana

plugs; it is designed to extend the measuring capability of an

ac current meter to 400 A.

Safety Information

XW Read First: Safety Information

To ensure safe operation and service of the Current

Clamp, follow these instructions:

• Read the operating instructions before use and

follow all safety instructions.

• Use the Current Clamp only as specified in the

operating instructions, otherwise the clamp’s safety

features may not protect you.

• Adhere to local and national safety codes.

Individual protective equipment must be used to

prevent shock and arc blast injury where hazardous

live conductors are exposed.

• Do not hold the Current Clamp anywhere beyond

the tactile barrier, see Figure 1.

• Before each use, inspect the Current Clamp. Look

for cracks or missing portions of the clamp housing

or output cable insulation. Also look for loose or

weakened components. Pay particular attention to

the insulation surrounding the jaws.

• Never use the clamp on a circuit with voltages

higher than 1000 V CAT III or 600 V CAT IV.

• CAT III equipment is designed to protect

against transients in equipment in fixedequipment installations, such as distribution

panels, feeders and short branch circuits, and

lighting systems in large buildings.

• CAT IV equipment is designed to protect

against transients from the primary supply

level, such as an electricity meter or an

overhead or underground utility service.

• Use extreme caution when working around bare

conductors or bus bars. Contact with the conductor

could result in electric shock.

• Use caution when working with voltages above 60 V

dc or 30 V ac. Such voltages pose a shock hazard.

Symbols

Application around and removal from hazardous live

,

conductors is permitted.

T Product is protected by double insulation.

W Risk of Danger. Important information. See Instruction Sheet.

X Hazardous voltage.

Conforms to relevant Canadian Standards Association

)

directives.

P Conforms to relevant European Union directives.

PN 2282667

December 2004

© 2004 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

®

Electrical Specifications

Reference Conditions: 23 ± 5 °C, 20 to 75 % RH; conductor

centered in jaw opening; no dc component; no adjacent

conductor

Measurement Range: 1 A to 400 A ac rms

Output: 1 mA/A

Accuracy: 2 % + 0.06 A, 45 Hz to 400 Hz

Typical Bandwidth: 5 Hz to 20 kHz

Working Voltage: 1000 V ac rms, in compliance with

EN61010

Common Mode Voltage: 1000 V ac rms from earth ground, in

compliance with EN61010

Load Impedance: < 10 Ω

Maximum Non-destructive Current: 1000 A

Duty Cycle: 1 A to 400 A continuous

Influence of Adjacent Conductor: < 7.5 mA/A

Influence of Conductor Position in Jaw Opening: ± 1.0 % of

reading + 0.05 A

Safety Specifications

Category Rating: CAT III 1000 V and CAT IV 600 V per

EN61010-1, Pollution Degree 2 IEC 61010-02-032

EMC: EN 61326-1, FCC for emission and immunity

): Tested to US and Canadian standards for compliance to

UL61010-1 and CAN/CSA C22.2 No. 101.1:2004

P: IEC 61010-1 2

nd

Edition

General Specifications

Output Cable Length: 1.5 m

Maximum Conductor Size: 32 mm

Storage Temperature: -20 °C to 60 °C

Operating Temperature: 0 °C to 50 °C

Relative Humidity: 10 °C to 30 °C: 95 %

30 °C to 40 °C: 75 %

40 °C to 50 °C: 45 %

Temperature Coefficient: 0.01 X (specified accuracy)/ °C

(< 18 °C or > 28 °C)

Altitude: Operating: 2000 m; Non-operating: 12000 m

Dimensions: 150 x 70 x 30 mm

Weight: 114 g

Instrument Compatibility

The i400 is compatible with any Fluke Multimeter or any other

current measurement device that has the following features:

• 20 mA ac or greater current range

• Banana inputs

• Input accuracy of 2 % or better to take full advantage of

the accuracy of the Current Clamp.

• Input impedance of < 10 Ω

Measurement Considerations

Observe the following guidelines for positioning the Current

Clamp jaws:

• Center the conductor inside the Current Clamp jaw.

• Make sure the clamp is perpendicular to the conductor.

• For optimal reading, make sure the conductor is positioned

between the alignment marks on the jaw of the Current

Clamp.

Observe the following guidelines when making measurements:

• Avoid taking measurements close to other current-carrying

conductors.

• The Current Clamp displays current readings at 1/1000 of

the actual current on the conductor. For example, a

5 A input current will be transformed into a 5 mA output

current.

Low-Level Current Measurements

The Current Clamp is specified to measure currents of 1 A or

greater. Measurement accuracy of currents less than 1 A is

unspecified.

Operation

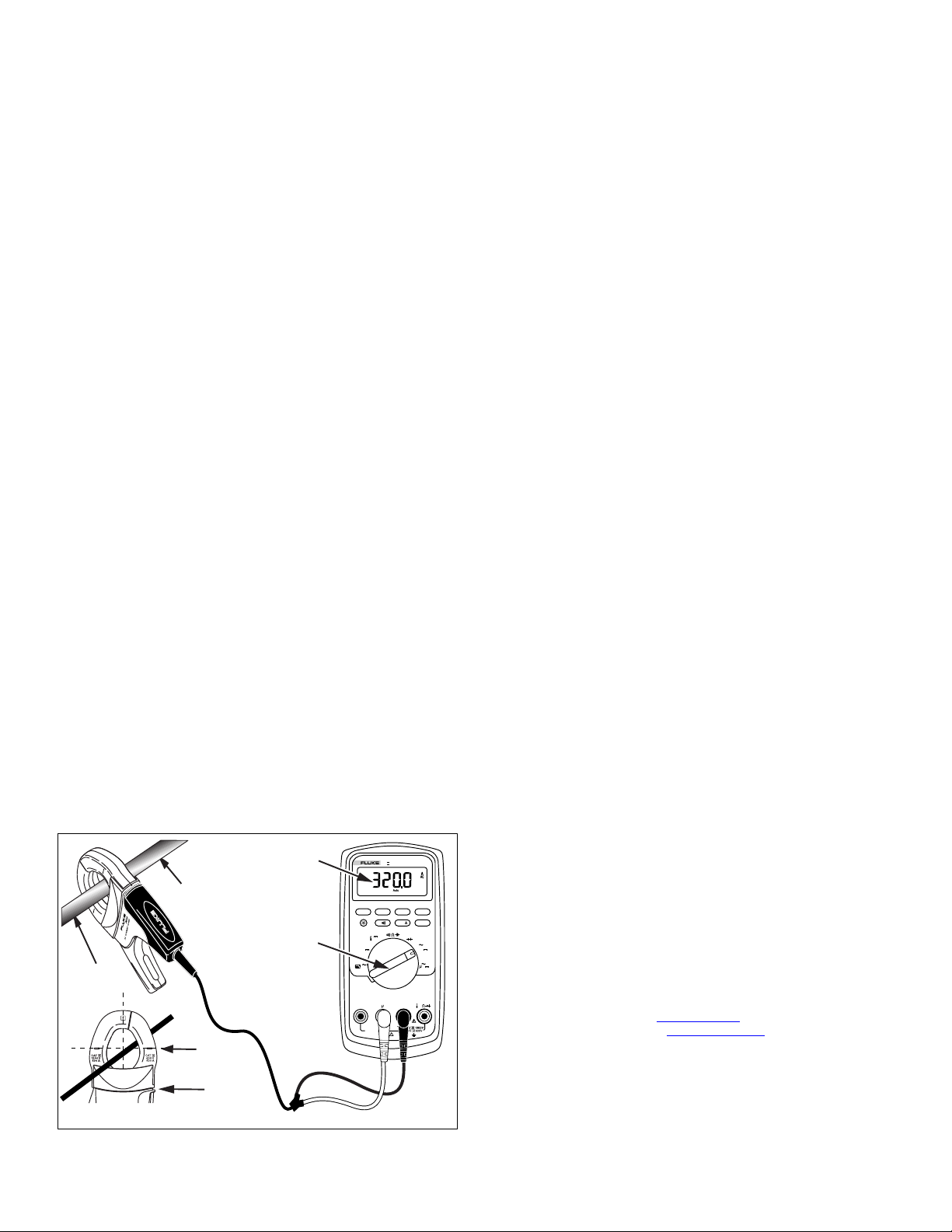

To use the i400, (refer to Figure 1):

Page 2

1. Insert the banana plug into the common and current

inputs of a Multimeter and switch the Meter on.

2. Select a 20 mA ac or greater current range.

3. Clamp the i400 around the current-carrying conductor

to be measured. Make sure the jaws are tightly closed

around the conductor. The Current Clamp is designed

for highest accuracy when the conductor is centered on

the jaw’s alignment marks, see Figure 1.

XW Warning

To avoid shock or personal injury, keep fingers

behind the tactile barrier, see Figure 1.

4. Multimeter readings displayed in milliamps (mA) can be

read directly as amperes of input current. Readings

displayed in amperes (A) must be multiplied times

1000 to obtain the amperes of input current.

Maintenance

XW Warning

To avoid possible electric shock or personal

injury:

• Before each use, inspect the Current Clamp.

Look for cracks or missing portions of the

clamp housing and output cable insulating

cover and for loose or weakened

components. Pay particular attention to the

insulation surrounding the clamp jaws.

• Do not use a damaged Current Clamp. If a

clamp is damaged, tape it shut to prevent

unintended operation. A damaged clamp

under warranty will be promptly repaired or

replaced (at Fluke’s discretion) and returned

at no extra charge.

If the Current Clamp does not work or perform properly, use

the following steps to help isolate the problem:

1. Inspect the jaw mating surface for cleanliness. If any

foreign material is present, the jaw will not close properly

and measurement errors will result.

2. Verify that the function selection and range on the

Multimeter are correct and adjusted to the sensitivity of the

Current Clamp.

3. Verify the DMM current fuse. If the current fuse is open,

the clamp may not function properly.

Cleaning

Periodically wipe the case with a damp cloth and mild

detergent.

W Caution

To avoid damaging the Current Clamp, do not use

abrasives or solvents to clean the clamp.

Open the jaws and wipe the magnetic pole pieces with a lightly

oiled cloth. Do not allow rust or corrosion to form on the

magnetic core ends.

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and

workmanship under normal use and service. The warranty period is

one year and begins on the date of shipment. Parts, product repairs,

and services are warranted for 90 days. This warranty extends only to

the original buyer or end-user customer of a Fluke authorized reseller,

and does not apply to fuses, disposable batteries, or to any product

which, in Fluke's opinion, has been misused, altered, neglected,

contaminated, or damaged by accident or abnormal conditions of

operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days

and that it has been properly recorded on non-defective media. Fluke

does not warrant that software will be error free or operate without

interruption.

Fluke authorized resellers shall extend this warranty on new and

unused products to end-user customers only but have no authority to

extend a greater or different warranty on behalf of Fluke. Warranty

support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international

price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is

submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the

purchase price, free of charge repair, or replacement of a defective

product which is returned to a Fluke authorized service center within

the warranty period.

To obtain warranty service, contact your nearest Fluke authorized

service center to obtain return authorization information, then send the

product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no

risk for damage in transit. Following warranty repair, the product will be

returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination,

alteration, accident, or abnormal condition of operation or handling,

including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components,

Fluke will provide an estimate of repair costs and obtain authorization

before commencing the work. Following repair, the product will be

returned to the Buyer transportation prepaid and the Buyer will be

billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING

FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an

implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty

may not apply to every buyer. If any provision of this Warranty is held

invalid or unenforceable by a court or other decision-maker of

competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Single Current

Carrying Conductor

320 mA

320 A

AC Current

Function

Alignment

Marks

Tactile

Barrier

Figure 1. i400 Setup

4½ DIGITS

1 Second

LOLO

TRUE RMS MULTIMETER

87

V

11/99

F

˚C/˚

AutoHOLD

RANGE

MIN MAX

Peak MIN MAX

Hz %

REL

mV

mA

V

V

OFF

A

10A MAX

FUSED

A

A

COM

V

mA

A

400mA

FUSED

To contact Fluke, call one of the following telephone numbers:

USA: 1-888-44-FLUKE (1-888-443-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

USA Service: 1-888-99-FLUKE (1-888-993-5853)

Or, visit Fluke's Web site at www.fluke.com

To register your product, visit register.fluke.com

.

aym02f.eps

Loading...

Loading...