Page 1

i310s

AC/DC Current Clamp

Instruction Sheet

Introduction

The i310s Current Clamp (“Clamp”) has been designed for use

with oscilloscopes and digital multimeters for accurate nonintrusive measurement of ac, dc and complex waveform currents.

Using advanced Hall Effect technology, the Clamp can

accurately measure currents up to 450 A peak over the

frequency range of dc to 20 kHz. These features make it a

powerful tool for use in inverters, switch mode power supplies,

industrial controllers, automotive diagnostics, and other

applications requiring current measurements and/or waveform

analysis.

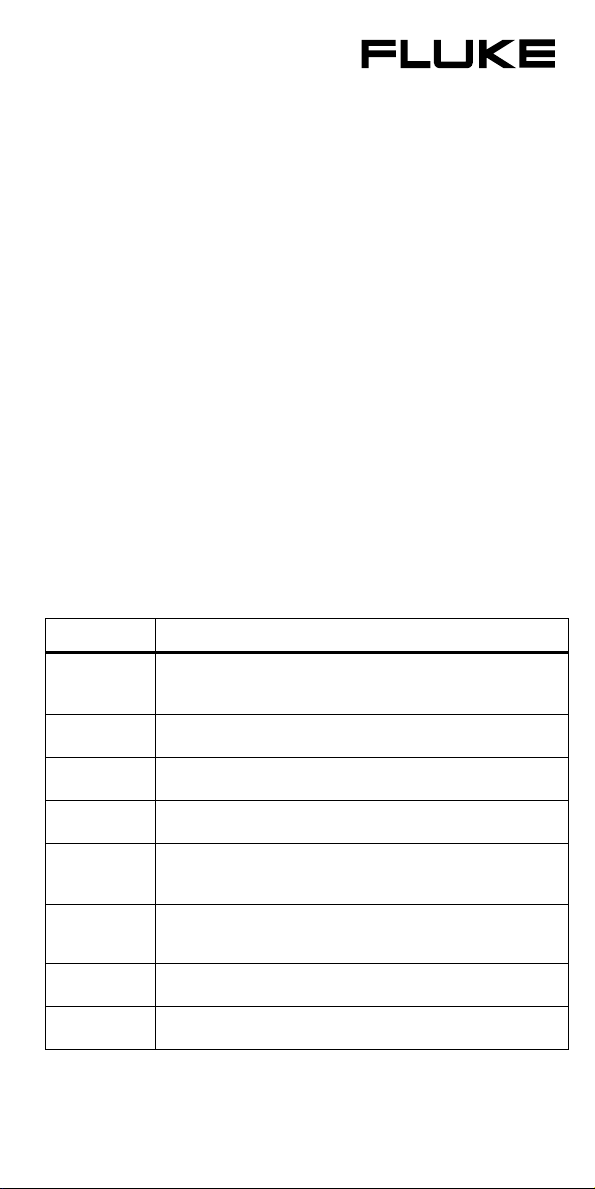

Symbols

The table below lists the symbols used on the Clamp and/or in

this manual.

Symbol Description

®

~

W

X

T

,

)

P

;

PN 2842344

June 2007

©2007 Fluke Corporation. All rights reserved. Printed in China.

Do not dispose of this product as unsorted municipal

waste. Go to Fluke’s website for recycling information.

Important Information. See manual.

Hazardous Voltage. Risk of electric shock.

Double insulation.

Application around and removal from HAZARDOUS

LIVE conductors is permissible.

Conforms to Canadian Standards Association.

Complies with the relevant European standards.

Conforms to Australian standards.

Page 2

Safety Instructions

Please read this section carefully. It will make you familiar with

the most important safety instructions for handling your product.

In this instruction sheet, a Warning identifies conditions and

actions that pose hazard(s) to the user. A Caution identifies

conditions and actions that may damage the calibrator or the test

instruments.

WX Warning

The Clamp may only be used and handled by

qualified personnel. To avoid personal injury, follow

these precautions:

• To avoid electric shock, use caution during

installation and use of this product; high

voltages and currents may be present in circuit

under test.

• Do not use the Clamp if damaged. Always

connect to display device before it is installed

around the conductor.

• Always ensure the Clamp is removed from any

live electric circuit, and leads are disconnected

before removing the battery cover.

• Use the Clamp only as specified in the

operating instructions; otherwise the safety

features may not protect you.

• Adhere to local and national safety codes.

Individual protective equipment must be used

to prevent the shock and arc blast injury where

hazardous live conductors are exposed.

• Do not hold the Clamp anywhere beyond the

tactile barrier.

• Before each use, inspect the Clamp. Look for

cracks or missing portions of the housing or

output cable insulation. Also look for loose or

weakened components. Pay particular attention

to the insulation surrounding the jaws.

• Use caution when working with voltages above

60 V dc, 30 V ac rms or 42 V ac peak. Such

voltages pose a shock hazard.

• Use of this equipment is designed to protect

against transients in equipment in fixed

equipment installations, such as distribution

panels, feeders and short branch circuits, and

lighting systems in large buildings.

Page 3

• CAT III equipment is designed to protect against

the transients in the equipment in fixed

equipment installations, such as distribution

panels, feeders and short branch circuits, and

the lighting systems in large buildings.

• Do not use Clamp in wet environments or in

locations that hazardous gases exist.

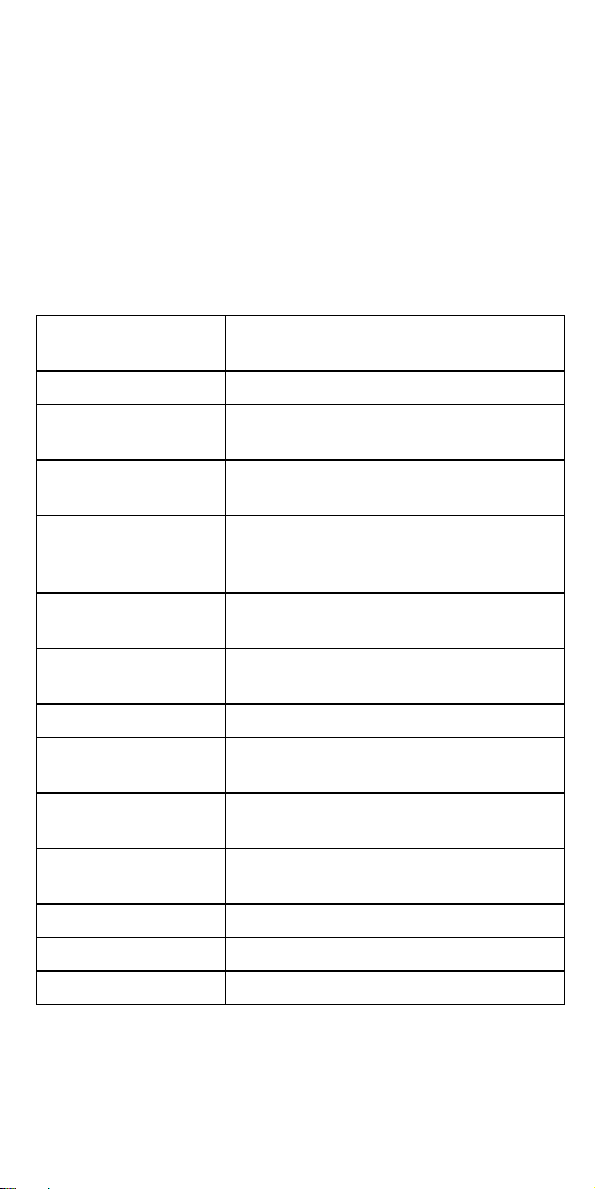

Specifications

Electrical Characteristics

All accuracies stated at 23°C ± 1°C (73.4 °F ± 33.8 °F)

Current Range

Inrush Current 600 A ac rms Max

Output Sensitivity

Accuracy

Bandwidth to Meet

Accuracy

Specification

Phase Shift below 1

kHz

Resolution

Load impedance > 10 k Ω and ≤ 100 pF

Conductor Position

Sensitivity

Frequency Range

(small signal)

Temperature

Coefficient

Power Supply 9 V Alkaline, NEDA 1604/PP3 IEC 6LR61

Working Voltage 300 V ac rms or dc

Battery Life 30 hours, low battery indicator

30 A and 300 A ac rms or

± 45 A and 450 A dc

10 mV/A (30 A)

1 mV/A (300 A)

(30 A range) ± 1 % of reading ± 50 mA

(300 A range) ± 1 % of reading ± 300 mA

@25 °C, Bandwidth dc to 1 kHz

1 kHz

< 2 degrees

± 50 mA (30 A)

± 100 mA (300 A)

± 1.5 % relative to center reading

DC to 20 kHz (-3 dB)

± 0.01 % of reading / °C

Page 4

General Characteristics

Maximum Conductor

Size

Output Cable and

Connections

Output Zero Manual adjust via thumbwheel

Cable Length 2 meters

Operating Temperature

Range

Storage Temperature

Range (with battery

removed)

Operating Humidity 15 % to 85 % (non-condensing)

Weight 250 g (8.812 oz)

19 mm (0.748 in) diameter

Safety BNC connector supplied

with safety 4 mm adapter

-10 to +50 °C (14 to +122 °F)

-20 to +85 °C (-4 to +185 °F)

Safety Standards

EN 61010-1: 2001

EN 61010-2-032: 2002

EN 61010-031: 2002

300 V rms Category III, Pollution Degree 2

Use of the Clamp on non-insulated conductors is limited to 300

V ac rms or dc and frequencies below 1 kHz.

EMC Standards

EN 61236 :1998 +A1, A2, & A3

Page 5

Typical Performance Plots

Amps

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

% Error of Reading

Typical Accuracy i310s 30A range

Amps

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

% Error of Reading

Typical Accuracy i310s 300A range

300A Range

Gain in dB

30A Range

Typical Frequency Response i310s

Frequency in Hz

evy01_4.eps

Typical Frequency Response

evy02.eps

Typical Frequency Response

Typical Accuracy Curve

evy03.eps

Page 6

Operating Instructions

6 7

3

2

1

5

4

Figure 1. i310s AC/DC Current Clamp

1 LED

2 Zero Adjust

3 Battery Cover

4 ON/OFF Range Switch

5 Tactile Barrier

6 Jaws

7 Battery Cover

Screw (Captive)

evy04.eps

WX Warning

To avoid injury, when using the Clamp, ensure that

your fingers are behind the protective barrier as

shown in Figure 1.

Do not use the Clamp if any part, including the lead

and connector(s), appears to be damaged or if a

malfunction of the instrument is suspected.

Switch On

Switch the Clamp to the required current range, and check that

the LED is lit. The LED starts flashing when the battery voltage is

too low for normal operation and warns the user that it requires

changing. This procedure is described below.

Zero Adjustment

The output zero offset voltage of the Clamp may change due to

thermal shifts and other environmental conditions. To adjust the

output voltage to zero, depress the thumbwheel and rotate.

Ensure that the Clamp is away from the current carrying

conductor whilst the adjustment is made.

Page 7

Current Measurement

1. Switch on the Clamp to the required current range and

check that the LED is lit.

2. Connect the output lead to an oscilloscope, multimeter,

or other measuring equipment.

3. If necessary, adjust the Clamp output voltage to zero as

described in section Zero Adjustment.

4. Clamp the jaw around the conductor ensuring a good

contact between the closing faces of the jaws.

5. Observe and take measurements as required. Positive

output indicates that the current flow is in the direction

shown by the arrow on the Clamp.

Maintenance

Cleaning

Clean the case periodically by wiping it with a damp cloth and

detergent. Do not use abrasive cleaners or solvents. Do not

immerse the Clamp in liquids.

Battery Replacement

WX Warning

To avoid personal injury, always ensure the Clamp

is removed from any live electric circuit, and leads

are disconnected before removing the battery cover.

Never operate the Clamp without the battery cover

fitted.

The red LED will flash when the minimum operating voltage is

approached. Refer to Figure 1. Use the following procedure:

1. Unclamp from the conductor, turn it off using the On –

Off switch and disconnect the output leads, from

external equipment.

2. Loosen the captive screw that secures the battery

cover. Lift the cover through 30° and pull it clear of the

Clamp body as shown in Figure 1. The battery is then

accessible. Replace the battery and re-fit the battery

cover and fasten the screw.

Note

Replacement with other than the specified type of

battery will invalidate the warranty.

Fit only the type 9 V PP3 Alkaline (MN 1604).

Page 8

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and

workmanship for one year from the date of purchase. This

warranty does not cover fuses, disposable batteries, or damage

from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not

authorized to extend any other warranty on Fluke’s behalf. To

obtain service during the warranty period, contact your nearest

Fluke authorized service center to obtain return authorization

information, then send the product to that Service Center with a

description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM

ANY CAUSE OR THEORY. Since some states or countries do

not allow the exclusion or limitation of an implied warranty or of

incidental or consequential damages, this limitation of liability

may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Loading...

Loading...