Page 1

GFS2102™

Gravimetric Flow Standard

Operation and Maintenance Manual

© 2007 DH Instruments, a Fluke Company

Page 2

GFS2102™ OPERATION AND MAINTENANCE MANUAL

Pressurized gases are potentially hazardous. Energy stored in these gases can be released unexpectedly

and with extreme force. Pressurized systems should be assembled and operated only by personnel who have

been instructed in proper safety practices.

© 2007 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix Arizona 85044-5318 USA.

DH Instruments makes sincere efforts to ensure the accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages

resulting from the use of the information in this manual or products described in it. Mention of any product or brand does not

constitute an endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was

subsequently translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the

English version and other language versions, the English version predominates.

DH Instruments, DH, DHI, GFS2102, GFS Tools, AMH, LCM, MFC-CB, molbloc and molbox are trademarks, registered and

otherwise, of DH Instruments, a Fluke Company

Swagelok and Nupro are registered trademarks of the Swagelok Company.

Krytox is a registered trademark of the Dupont de Nemours Company.

Windows, Excel, Word are registered trademarks of the Microsoft Corporation.

Products described in this manual are manufactured under international patents and one or more of the following U.S.

patents: 6,701,791, 5,142,483, 5,257,640, 5,331,838, 5,445,035. Other U.S. and international patents pending.

Document No. 550149a

071129

Printed in the USA

© 2007 DH Instruments, a Fluke Company

Page 3

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

C

OONNTTEENNTTS

C

S

TABLE OF CONTENTS ...............................................................I

TABLES................................................................................ VII

FIGURES................................................................................IX

ABOUT THIS MANUAL........................................................... XIII

1. INTRODUCTION ................................................................. 1

1.1 SPECIFICATIONS ...................................................................................................................................1

1.1.1 GFS2102 GENERAL SPECIFICATIONS.......................................................................................................1

1.1.2 GFS2102 MASS BALANCE SPECIFICATIONS ...........................................................................................2

1.1.3 LCM AMBIENT CONDITIONS MEASUREMENT SPECIFICATIONS...........................................................2

1.1.3.1 PRT BALANCE AMBIENT TEMPERATURE MEASUREMENT ................................................................2

1.1.3.2 TH PROBE REFERENCE GAS CYLINDER SURROUNDINGS AMBIENT CONDITION

1.1.3.3 INFRARED PROBE REFERENCE GAS CYLINDER SURFACE TEMPERATURE MEASUREMENT.....2

1.1.3.4 AMBIENT CONDITIONS MEASUREMENT...............................................................................................2

1.1.3.5 BALANCE READING TIME MEASUREMENT...........................................................................................2

1.1.4 MFC-CB SPECIFICATIONS..........................................................................................................................3

1.1.5 FLOW MEASUREMENT SPECIFICATIONS.................................................................................................3

MEASUREMENT .......................................................................................................................................2

2. SYSTEM OVERVIEW ........................................................... 5

2.1 BALANCE AND AMH-GFS2102..............................................................................................................6

2.2 REFERENCE GAS CYLINDER ASSEMBLY...........................................................................................8

2.2.1 REFERENCE GAS CYLINDER.....................................................................................................................8

2.2.2 CYLINDER SUPPORT...................................................................................................................................9

2.2.3 REFERENCE GAS CYLINDER CONNECTOR...........................................................................................10

2.2.4 REGULATOR ASSEMBLY..........................................................................................................................11

2.2.5 REFERENCE GAS CYLINDER CASE........................................................................................................11

2.3 GFS DRAFT ENCLOSURE AND VIBRATION ISOLATION TABLE.....................................................12

2.4 LABORATORY CONDITIONS MONITOR (LCM)..................................................................................13

2.5 MFC-CB .................................................................................................................................................13

2.6 GFS TOOLS...........................................................................................................................................14

2.7 HEAT EXCHANGER..............................................................................................................................14

2.8 GFS-FS REFERENCE GAS CYLINDER FILL STATION......................................................................14

2.9 MASS FLOW CONTROLLERS .............................................................................................................14

2.10 MOLBLOC MOLSTICS (OPTIONAL)....................................................................................................15

2.11 MASS SET (OPTIONAL).......................................................................................................................15

3. INSTALLATION ................................................................ 17

3.1 UNPACKING AND INSPECTION ..........................................................................................................17

3.1.1 GRANITE VIBRATION ISOLATION TABLE AND STAND..........................................................................17

3.1.2 GFS DRAFT ENCLOSURE AND SYSTEM ACCESSORIES......................................................................18

3.1.3 LABORATORY CONDITIONS MONITOR...................................................................................................19

3.1.4 MFC-CB .......................................................................................................................................................19

3.1.5 GFS-FS REFERENCE GAS CYLINDER FILL STATION............................................................................19

3.1.6 GFS MASS BALANCE.................................................................................................................................20

3.1.7 AMH-GFS2102.............................................................................................................................................20

3.1.8 REFERENCE GAS CYLINDER ASSEMBLIES...........................................................................................21

3.1.9 SYSTEM CONTROLLER.............................................................................................................................22

Page I © 2007 DH Instruments, a Fluke Company

Page 4

GFS2102™ OPERATION AND MAINTENANCE MANUAL

3.1.10 MS-2102-0.7 MASS SET OR MS-2102-CAR MASS CARRIER..................................................................23

3.1.11 MOLSTICS...................................................................................................................................................23

3.2 SITE REQUIREMENTS..........................................................................................................................23

3.2.1 GFS2102 SYSTEM ......................................................................................................................................23

3.2.2 GFS-FS REFERENCE GAS CYLINDER FILL STATION............................................................................25

3.3 SETUP ...................................................................................................................................................26

3.3.1 POSITION THE VIBRATION ISOLATION TABLE......................................................................................26

3.3.2 INSTALL DRAFT ENCLOSURE ON VIBRATION ISOLATION TABLE......................................................27

3.3.3 SETUP LCM.................................................................................................................................................28

3.3.4 SETUP MFC-CB ..........................................................................................................................................29

3.3.5 SET UP THE SYSTEM CONTROLLER (PC) ..............................................................................................29

3.3.6 VERIFY GFS CALIBRATION DATA............................................................................................................29

3.3.7 ASSEMBLE REFERENCE GAS CYLINDER(S)..........................................................................................30

3.3.8 ENTER REFERENCE GAS CYLINDER DATA...........................................................................................32

3.3.9 INSTALLATION OF REFERENCE MASS ON MASS PLATE.....................................................................32

3.3.10 INITIAL BALANCE AND AMH BASE SETUP.............................................................................................34

3.3.11 SETUP BALANCE LOCATION....................................................................................................................35

3.3.12 AMH POSITION FINE ADJUSTMENT.........................................................................................................36

3.3.13 SETUP PROBE LOCATIONS......................................................................................................................38

3.3.14 PREPARE THE HEAT EXCHANGER..........................................................................................................39

3.3.15 CONNECT THE DUT FLOW PATH.............................................................................................................40

3.3.16 CONNECT GAS CONVEYANCE LOOP......................................................................................................41

4. OPERATION..................................................................... 43

4.1 GENERAL OPERATING PRINCIPLES .................................................................................................43

4.1.1 GFS2102 MEASUREMENT PRINCIPLE.....................................................................................................43

4.1.2 GAS DEPENDENT MASS RANGES AND CYLINDER SIZE SELECTION ................................................44

4.1.3 AUTOZERO..................................................................................................................................................46

4.1.4 GFS2102 DATA COLLECTION METHODS AND CONVENTIONS............................................................46

4.1.4.1 ACCUMULATIONS ..................................................................................................................................46

4.1.4.2 SAMPLES ................................................................................................................................................46

4.1.4.3 AVERAGES AND BEST FITS..................................................................................................................47

4.1.5 SETTINGS FOR FLOW SAMPLING............................................................................................................47

4.1.5.1 SETTING UP STARTING AND ENDING SAMPLE TOLERANCE...........................................................48

4.2 MANUAL GFS TOOLS OPERATION....................................................................................................48

4.2.1 READING THE BALANCE...........................................................................................................................48

4.2.2 AMH OPERATION.......................................................................................................................................49

4.2.3 BALANCE ZERO AND SPAN ADJUSTMENT............................................................................................49

4.3 REFERENCE GAS CYLINDER FILLING ..............................................................................................49

4.3.1 TRANSPORTING THE REFERENCE GAS CYLINDER ASSEMBLY.........................................................49

4.3.2 EVACUATING AND RINSING .....................................................................................................................50

4.3.3 CONNECTING TO GFS-FS .........................................................................................................................50

4.3.4 FILLING THE CYLINDER............................................................................................................................51

4.4 CONSIDERATIONS FOR MAKING RELIABLE MEASUREMENTS.....................................................53

4.4.1 COOLING AND CONDENSATION AT HIGH FLOW...................................................................................53

4.4.2 STABILITY OF AMBIENT CONDITIONS....................................................................................................53

4.4.3 COMPARING REFERENCE AND DUT MEASUREMENTS USING FLOW VS. MASS CALCULATIONS 54

4.4.4 LEAKS .........................................................................................................................................................54

4.4.4.1 LEAK TEST OPTION IN A TEST DEFINITION........................................................................................55

4.4.4.2 SEMI-AUTOMATED LEAK TEST.............................................................................................................55

4.4.4.3 SEMI-AUTOMATED LEAK TEST TO MANUAL ISOLATION POINT ......................................................55

4.4.5 FLOW CONTROL AND STABILITY............................................................................................................56

© 2007 DH Instruments, a Fluke Company Page II

Page 5

TABLE OF CONTENTS

5. GFS TOOLS SOFTWARE ................................................... 57

5.1 MAIN DISPLAY AND FEATURES.........................................................................................................57

5.1.1 OVERVIEW..................................................................................................................................................57

5.1.2 MAIN MENU BAR........................................................................................................................................57

5.1.2.1 [RUN]........................................................................................................................................................57

5.1.2.2 [SETUP] ...................................................................................................................................................58

5.1.2.3 [TOOLS] ...................................................................................................................................................58

5.1.2.4 [DATA]......................................................................................................................................................58

5.1.2.5 [WINDOW]................................................................................................................................................59

5.1.2.6 [HELP]......................................................................................................................................................59

5.1.3 STATUS BAR...............................................................................................................................................59

5.1.4 MAIN TOOLBAR..........................................................................................................................................60

5.1.4.1 RUN TEST TOOLS ..................................................................................................................................60

5.1.4.2 RUN DISPLAY TOOLS ............................................................................................................................60

5.1.4.3 DATA ACQUISITION TOOLS ..................................................................................................................61

5.1.5 RUN SCREENS ...........................................................................................................................................63

5.1.5.1 OVERVIEW..............................................................................................................................................63

5.1.5.2 GFS RUN SCREEN .................................................................................................................................64

5.1.5.3 GFS DIAGNOSTICS RUN SCREEN........................................................................................................68

5.1.5.4 BALANCE OUTPUT RUN SCREEN........................................................................................................70

5.1.5.5 AMBIENT CONDITIONS RUN SCREEN.................................................................................................71

5.1.5.6 DUT/REFERENCE COMPARISON RUN SCREEN.................................................................................72

5.1.5.7 DEVICE OUTPUT RUN SCREEN............................................................................................................73

5.1.5.8 SPY WINDOWS.......................................................................................................................................74

5.1.5.9 MOLBOX OUTPUT RUN SCREEN..........................................................................................................75

5.1.5.10 TARE MOLBOX........................................................................................................................................77

5.1.5.11 MFC-CB RUN SCREEN...........................................................................................................................78

5.1.5.12 DATA GRID RUN SCREEN.....................................................................................................................79

5.1.5.13 DATA PLOT RUN SCREEN.....................................................................................................................79

5.2 [TOOLS] MENU.....................................................................................................................................80

5.2.1 OVERVIEW..................................................................................................................................................80

5.2.2 [OPTIONS]...................................................................................................................................................80

5.2.2.1 [RUN TEST] TAB......................................................................................................................................80

5.2.2.2 [INITIALIZE TEST] TAB............................................................................................................................83

5.2.2.3 [END TEST] TAB......................................................................................................................................84

5.2.2.4 [DATA FILE] TAB .....................................................................................................................................85

5.2.2.5 [DATA GRID] TAB....................................................................................................................................87

5.2.3 [UNIT OF MEASURE CONVERTER] ..........................................................................................................89

5.2.4 [REMOTE COMMUNICATIONS].................................................................................................................89

5.2.5 [PROCESS GAS EDITOR]..........................................................................................................................90

5.2.6 [CHANGE GFS AMH STATE]......................................................................................................................91

5.2.7 [PC TIMER CALIBRATION] ........................................................................................................................91

5.3 [DATA] MENU........................................................................................................................................91

5.3.1 OVERVIEW..................................................................................................................................................91

5.3.2 [VIEW DATA FILE]......................................................................................................................................91

5.3.3 [PLOT DATA]...............................................................................................................................................93

5.3.3.1 PLOT TOOLBAR......................................................................................................................................93

5.3.3.2 PLOT OPTIONS MENU ...........................................................................................................................94

5.3.3.3 CREATE/EDIT PLOTS.............................................................................................................................94

5.3.3.4 PLOT POINTS..........................................................................................................................................96

5.3.4 [REPORT DATA].........................................................................................................................................98

5.4 DATA FILES ..........................................................................................................................................99

5.4.1 OVERVIEW..................................................................................................................................................99

5.4.2 DATA FILE CREATION ...............................................................................................................................99

5.4.3 NAMING AND STORING DATA FILES.......................................................................................................99

5.4.4 DATA FILE STRUCTURE..........................................................................................................................100

5.5 [SETUP] MENU ...................................................................................................................................102

5.5.1 OVERVIEW................................................................................................................................................102

5.5.1.1 SETUP SELECTOR...............................................................................................................................102

5.5.1.2 EDITOR TOOLBAR................................................................................................................................102

5.5.2 [SETUP], [TEST]........................................................................................................................................104

5.5.2.1 CREATING TEST DEFINITIONS...........................................................................................................104

5.5.2.2 EDITING TEST DEFINITIONS...............................................................................................................105

5.5.2.3 TEST POINT SEQUENCE.....................................................................................................................105

5.5.2.4 [PRE-TEST] TAB....................................................................................................................................105

5.5.2.5 [CONTROL]............................................................................................................................................107

5.5.2.6 [DATA]....................................................................................................................................................108

5.5.2.7 [AUTOZERO]..........................................................................................................................................110

Page III © 2007 DH Instruments, a Fluke Company

Page 6

GFS2102™ OPERATION AND MAINTENANCE MANUAL

5.5.2.8 [OPTIONS] .............................................................................................................................................111

5.5.2.9 [COMMENT]...........................................................................................................................................112

5.5.3 [DUT ].........................................................................................................................................................113

5.5.3.1 [HEADER] TAB ......................................................................................................................................114

5.5.3.2 [CALIBRATION] TAB..............................................................................................................................116

5.5.3.3 [COMMUNICATIONS] TAB....................................................................................................................117

5.5.3.4 REMOTE COMMAND EDITOR..............................................................................................................120

5.5.3.5 [OUTPUT] TAB.......................................................................................................................................125

5.5.3.6 [COMMENT] TAB...................................................................................................................................128

5.5.4 [SUPPORT HARDWARE]..........................................................................................................................129

5.5.5 [REFERENCE GAS CYLINDER]...............................................................................................................129

5.5.6 [CONFIGURATION]...................................................................................................................................131

5.5.6.1 [SYSTEM]...............................................................................................................................................131

5.5.6.2 GFS AMH...............................................................................................................................................133

5.5.6.3 [LIMITS]..................................................................................................................................................134

5.5.6.4 [LCM]......................................................................................................................................................135

5.5.6.5 [BALANCE].............................................................................................................................................136

5.5.6.6 [INTERFACE].........................................................................................................................................137

5.5.7 [CALIBRATION].........................................................................................................................................138

5.5.7.1 [TIME/MASS]..........................................................................................................................................138

5.5.7.2 [AMBIENT] .............................................................................................................................................139

5.5.7.3 [TH PROBE #2]......................................................................................................................................140

5.5.7.4 [TH PROBE #3]......................................................................................................................................141

5.5.7.5 [EXTERNAL PRT] ..................................................................................................................................141

5.5.7.6 [IR PROBE] ............................................................................................................................................142

5.6 [RUN] MODES.....................................................................................................................................142

5.6.1 RUN TEST..................................................................................................................................................143

5.6.2 RUN MANUAL TEST.................................................................................................................................147

5.6.3 RUN DIAGNOSTIC TEST..........................................................................................................................149

5.7 CALCULATIONS .................................................................................................................................149

5.7.1 OVERVIEW................................................................................................................................................149

5.7.2 ERRORS....................................................................................................................................................149

5.7.3 TOLERANCE.............................................................................................................................................150

5.7.4 AUTOZERO CORRECTION ......................................................................................................................150

5.7.5 REFERENCE CYLINDER BUOYANCY.....................................................................................................151

5.7.6 FULLY COMPENSATED MASS................................................................................................................153

5.7.7 AVERAGE FLOW......................................................................................................................................154

5.7.8 BEST FIT FLOW........................................................................................................................................154

5.7.9 INTEGRATED MASS.................................................................................................................................155

5.7.10 %READING GFS TOLERANCE................................................................................................................155

5.7.11 SAMPLE RATE..........................................................................................................................................157

6. GENERAL MAINTENANCE, ADJUSTMENTS, AND STORAGE .159

6.1 SUMMARY...........................................................................................................................................159

6.2 AMH-GFS2102 PLATE POSITIONING POSTS LUBRICATION.........................................................159

6.3 REFERENCE GAS CYLINDER ALIGNMENT.....................................................................................160

6.3.1 CHECK REFERENCE GAS CYLINDER ALIGNMENT.............................................................................160

6.3.2 ALIGNMENT OF THE REFERENCE GAS CYLINDER.............................................................................161

6.4 PREPARING THE REFERENCE GAS CYLINDER ASSEMBLY FOR SHIPMENT OR LONG TERM

STORAGE............................................................................................................................................162

6.5 REFERENCE GAS CYLINDER HYDROSTATIC TESTING................................................................163

6.6 REMOVING OR REASSEMBLING THE CYLINDER CARRIER.........................................................163

6.6.1 REMOVING THE CYLINDER CARRIER...................................................................................................164

6.6.2 REASSMBLING THE CARRIER TO THE CYLINDER..............................................................................164

6.7 CHECK/CHANGE FLUID IN HEAT EXCHANGER..............................................................................165

6.8 RELEVEL SYSTEM SURFACES.........................................................................................................165

6.9 LEAK CHECK THE FLOW PATH........................................................................................................165

© 2007 DH Instruments, a Fluke Company Page IV

Page 7

TABLE OF CONTENTS

7. MAINTENANCE OF TRACEABILITY AND RECALIBRATION ...167

7.1 PRINCIPLES OF GFS2102 TRACEABILITY MAINTENANCE...........................................................167

7.2 [PC TIMER CALIBRATION] ................................................................................................................167

7.3 MOLBOX AUTOZ AND TARE OPERATIONS.....................................................................................167

7.4 REFERENCE MASS RECALIBRATION..............................................................................................167

7.5 LABORATORY CONDITIONS MONITOR (LCM) RECALIBRATION.................................................168

7.5.1 OVERVIEW................................................................................................................................................168

7.5.2 AS RECEIVED DATA REVIEW .................................................................................................................169

7.5.3 LCM TIME VERIFICATION OR ADJUSTMENT........................................................................................169

7.5.3.1 PRINCIPLE ............................................................................................................................................169

7.5.3.2 LCM TIME VERIFICATION....................................................................................................................169

7.5.3.3 LCM TIME ADJUSTMENT.....................................................................................................................170

7.5.3.4 EQUIPMENT REQUIRED.................................................................................................................170

7.5.3.5 OPERATION.....................................................................................................................................170

7.5.4 AMBIENT P, T, H SENSOR ADJUSTMENT.............................................................................................171

7.5.4.1 PRINCIPLE ............................................................................................................................................171

7.5.4.2 ENCLOSURE PRESSURE SENSOR....................................................................................................172

7.5.4.3 AMBIENT TEMPERATURE SENSOR...................................................................................................173

7.5.4.4 RELATIVE HUMIDITY SENSOR............................................................................................................174

7.5.5 TH PROBE ADJUSTMENT........................................................................................................................175

7.5.5.1 TH PROBE TEMPERATURE SENSOR.................................................................................................175

7.5.5.2 TH PROBE RELATIVE HUMIDITY SENSOR........................................................................................176

7.5.6 EXTERNAL PRT TEMPERATURE ADJUSTMENT ..................................................................................177

7.5.7 INFRARED (IR) CYLINDER TEMPERATURE ADJUSTMENT.................................................................178

7.5.8 LCM OHMIC MEASUREMENT SYSTEM VERIFICATION........................................................................179

7.5.9 STANDARD RESISTOR MEASUREMENT AND ADJUSTMENT.............................................................181

7.5.10 LCM REMOTE COMMAND FOR AUTOMATION......................................................................................182

7.6 MOLBOX RECALIBRATION...............................................................................................................183

7.7 MFC-CB RECALIBRATION.................................................................................................................183

7.8 BALANCE RECALIBRATION..............................................................................................................183

7.8.1 INTERNAL BALANCE CALIBRATION......................................................................................................183

7.8.2 GFS TOOLS ZERO AND SPAN CALIBRATION.......................................................................................183

7.8.3 VERIFICATION BY MASS CARRIER........................................................................................................184

8. TROUBLESHOOTING .......................................................185

8.1 OVERVIEW..........................................................................................................................................185

9. APPENDIX ......................................................................187

9.1 GLOSSARY .........................................................................................................................................187

9.2 TYPICAL TEST SETUPS.....................................................................................................................188

9.3 WARRANTY STATEMENT..................................................................................................................189

Page V © 2007 DH Instruments, a Fluke Company

Page 8

GFS2102™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page VI

Page 9

TABLES & FIGURES

T

AABBLLEES

T

Table 1. GFS2102 packing list...................................................................................................................17

Table 2. Draft enclosure and system accessories list ...............................................................................18

Table 3. LCM parts list................................................................................................................................19

Table 4. MFC-CB parts list..........................................................................................................................19

Table 5. GFS-FS fill station parts list ..........................................................................................................20

Table 6. GFS mass balance parts list........................................................................................................20

Table 7. AMH-GFS2102 parts list...............................................................................................................21

Table 8. Reference gas cylinder assemblies’ parts lists............................................................................22

Table 9. MS-2102-0.7 mass set parts list..................................................................................................23

Table 10. MS-2102-CAR mass carrier parts list........................................................................................23

Table 11: Maximum mass available for flow testing for various GFS2102 supported gases.....................45

Table 12. Main Toolbar, Run Test Tools ...................................................................................................60

Table 13. Main Toolbar, Run Display Tools...............................................................................................61

Table 14. <Control> Toolbar, Data Acquisition Options ............................................................................ 62

Table 15. GFS Control Panel Fields..........................................................................................................65

Table 16. GFS System Display Fields.......................................................................................................67

Table 17. GFS Control Toolbar icons .........................................................................................................67

Table 18. GFS Diagnostics Fields .............................................................................................................69

Table 19. Balance Output Run Screen Fields ..........................................................................................70

Table 20. GFS Ambient Conditions Run Screen Fields ...........................................................................71

Table 21. DUT/Reference Comparison Run Screen Fields......................................................................73

Table 22. Spy Window Information............................................................................................................75

Table 23. <molbox Output> Run Screen Fields.........................................................................................76

Table 24. Tare molbox Fields ....................................................................................................................78

Table 25. MFC CB Fields...........................................................................................................................79

Table 26. Options, [Run Test] Tab Fields..................................................................................................81

Table 27. Options, [Initialize Test] Tab Fields............................................................................................83

Table 28. Options, [End Test] Tab Fields ..................................................................................................85

Table 29. Options, [Data File] Tab Fields ..................................................................................................86

Table 30. Options, [Data Grid] Tab Selections..........................................................................................89

Table 31. Data File Viewer Options...........................................................................................................92

Table 32. Data Plot Toolbar.......................................................................................................................93

Table 33. Custom Plot Editor Fields ..........................................................................................................95

Table 34. Plot Points General Tab Fields..................................................................................................97

Table 35. Plot Points Best Fit Tab Fields...................................................................................................98

Table 36. Data Files Types........................................................................................................................99

Table 37. Data File Data Field Optional Selections.................................................................................100

Table 38. Data File Structure...................................................................................................................101

Table 39. Editor Toolbar Features...........................................................................................................103

Table 40. Test Editor, [Pre-Test] Tab, <Leak Test> Fields......................................................................106

Table 41. Test Definition Editor, Point Sequence Tab, [General] Child Tab Fields.................................107

Table 42. Test Definition Editor [Data] Tab Fields...................................................................................109

Table 43. Test Definition Editor [AutoZero] Tab Fields............................................................................111

Table 44. Test Definition Editor [Options] Tab Fields..............................................................................112

Table 45. DUT Editor, [Header] Tab Fields .............................................................................................114

S

Page VII © 2007 DH Instruments, a Fluke Company

Page 10

GFS2102™ OPERATION AND MAINTENANCE MANUAL

Table 46. Device Editor, [Calibration] Tab Fields ....................................................................................117

Table 47. Device Editor, [Communications] Tab Fields..........................................................................119

Table 48. Remote Command Editor, [Command] Tab Fields..................................................................123

Table 49. Remote Command Editor, [Global Settings] Tab Options.......................................................124

Table 50. DUT Editor, [Output] Tab Fields ..............................................................................................126

Table 51. Tolerance Type Choices..........................................................................................................127

Table 52. Device Type Options................................................................................................................129

Table 53. Reference Cylinder Editor Fields.............................................................................................130

Table 54. GFS Configuration Editor [System] Tab Fields........................................................................132

Table 55. GFS Configuration Editor [GFS AMH] Tab Fields ...................................................................133

Table 56. GFS Configuration Editor [Limits] Tab Fields .......................................................................... 134

Table 57. GFS Configuration Editor [LCM] Tab Fields............................................................................135

Table 58. GFS Configuration Editor [Balance] Tab .................................................................................136

Table 59. GFS Configuration Editor [Interface] Tab Fields......................................................................137

Table 60. Calibration Editor [Time/Mass] Tab Fields...............................................................................138

Table 61. Calibration Editor [Ambient] Tab Fields...................................................................................139

Table 62. Calibration Editor [TH Probe #2] and [TH Probe #3] Tab Fields .............................................140

Table 63. Calibration Editor [External PRT] Tab Fields...........................................................................142

Table 64. Calibration Editor [IR Probe] Tab Fields..................................................................................142

Table 65. Mechanical maintenance procedures......................................................................................159

Table 66. Troubleshooting checklist ........................................................................................................185

Table 67. DHI Authorized Service Providers ...........................................................................................189

© 2007 DH Instruments, a Fluke Company Page VIII

Page 11

TABLES & FIGURES

F

IIGGUURREES

F

Figure 1. GFS2102 system.......................................................................................................................... 5

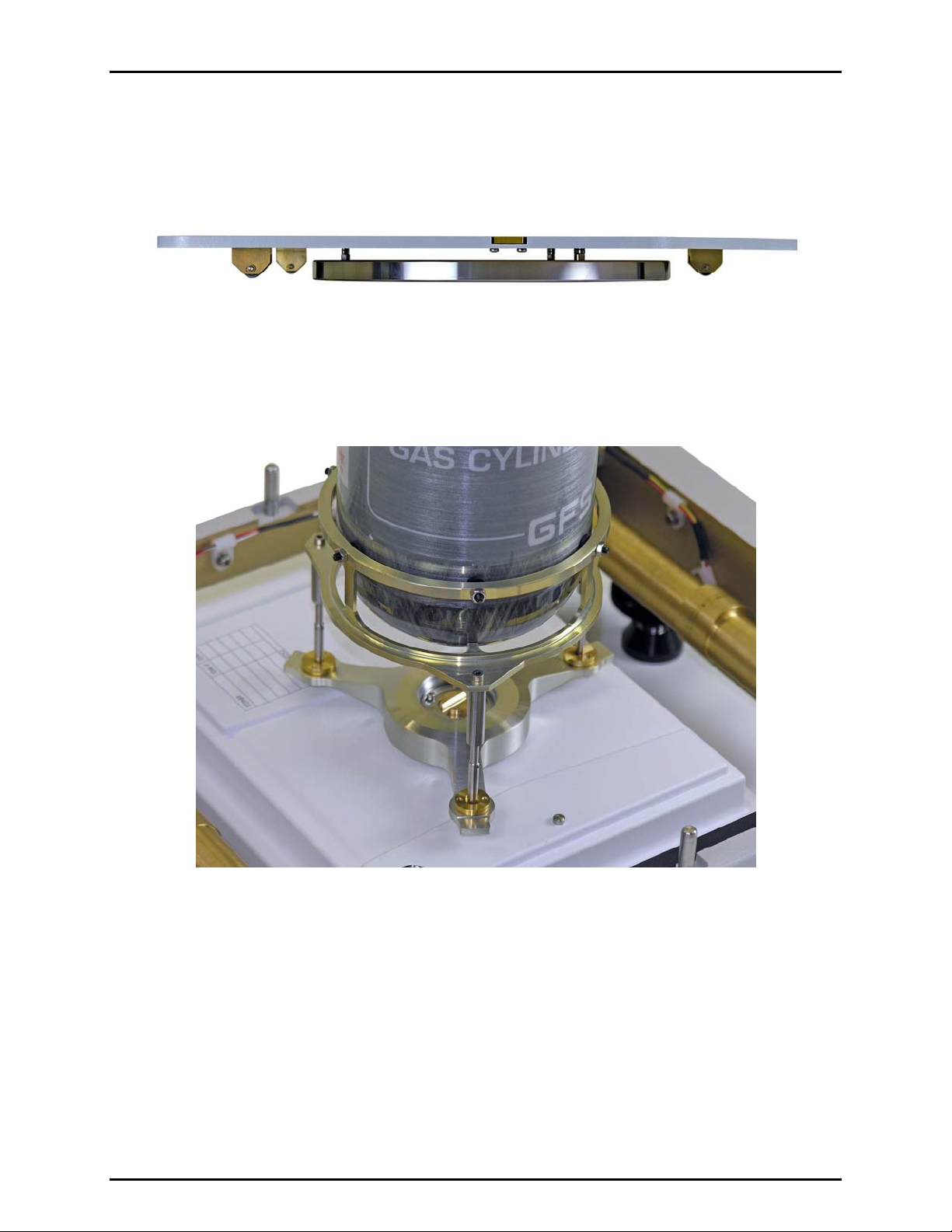

Figure 2. Reference gas cylinder resting on GFS balance and AMH-GFS2102.........................................6

Figure 3. AMH reference mass plate...........................................................................................................7

Figure 4. Balance mass tray supporting the reference gas cylinder ...........................................................7

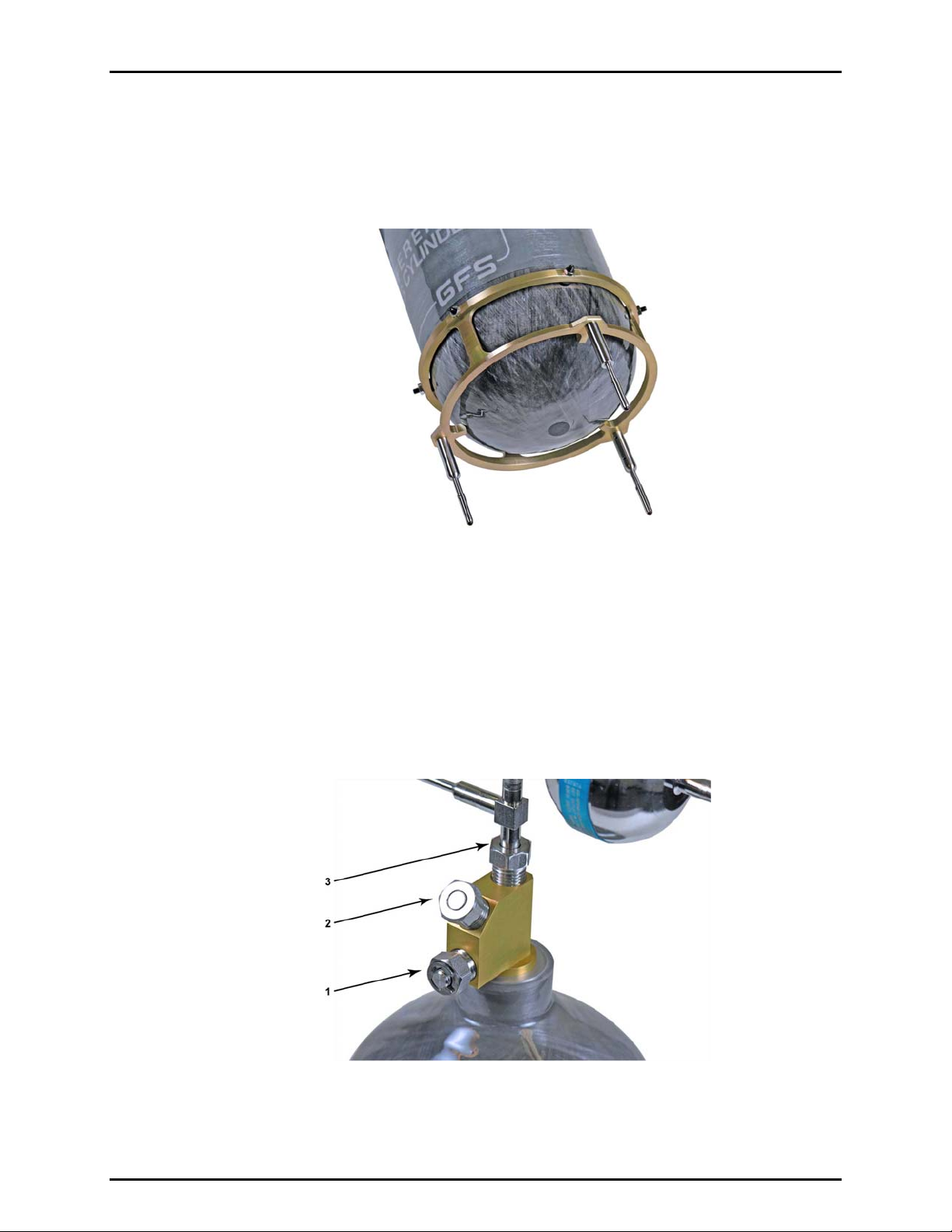

Figure 5. Reference gas cylinder assembly...................................................................................................8

Figure 6. 1.5 liter and 1.1 liter reference gas cylinder assemblies .............................................................. 9

Figure 7. Reference gas cylinder support..................................................................................................10

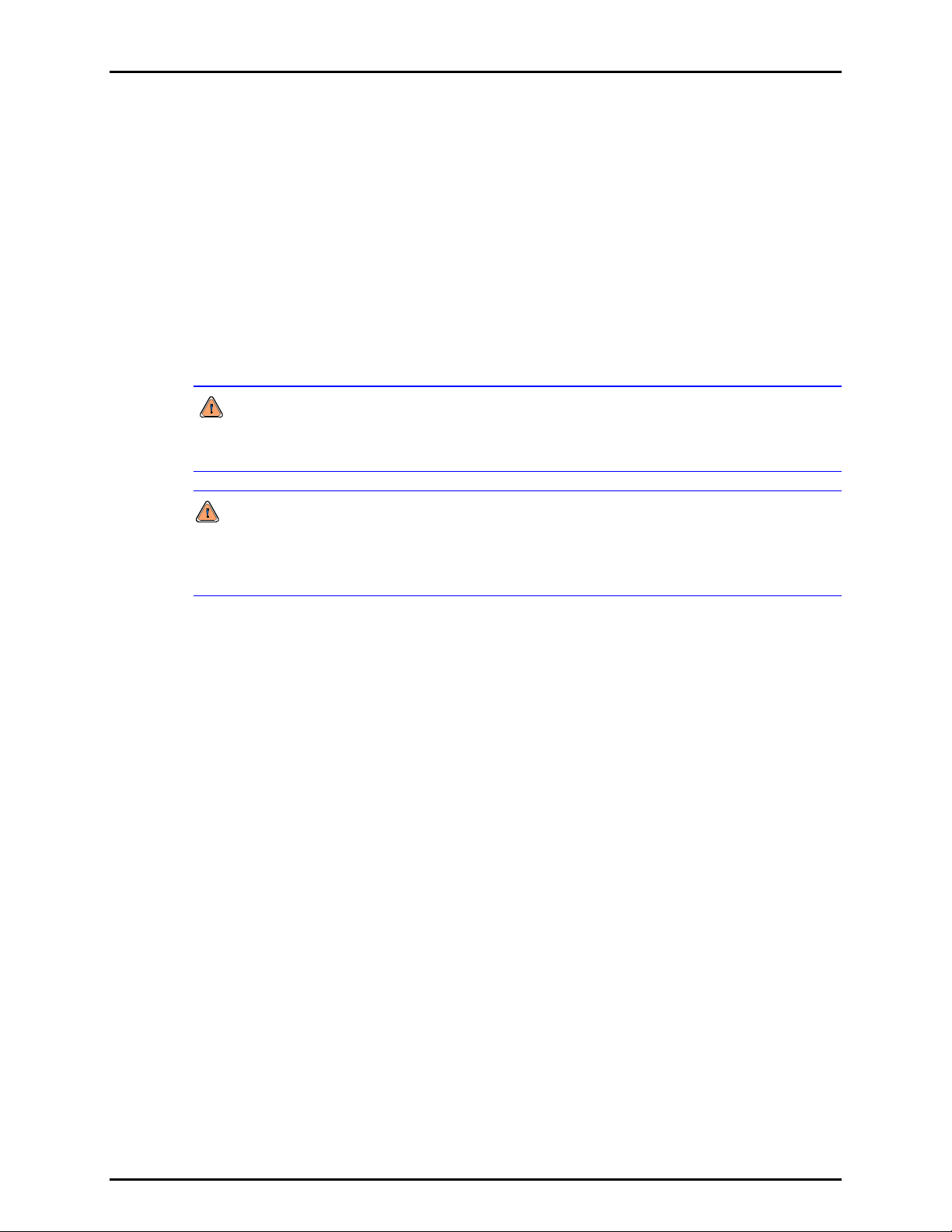

Figure 8. Reference gas cylinder connector..............................................................................................10

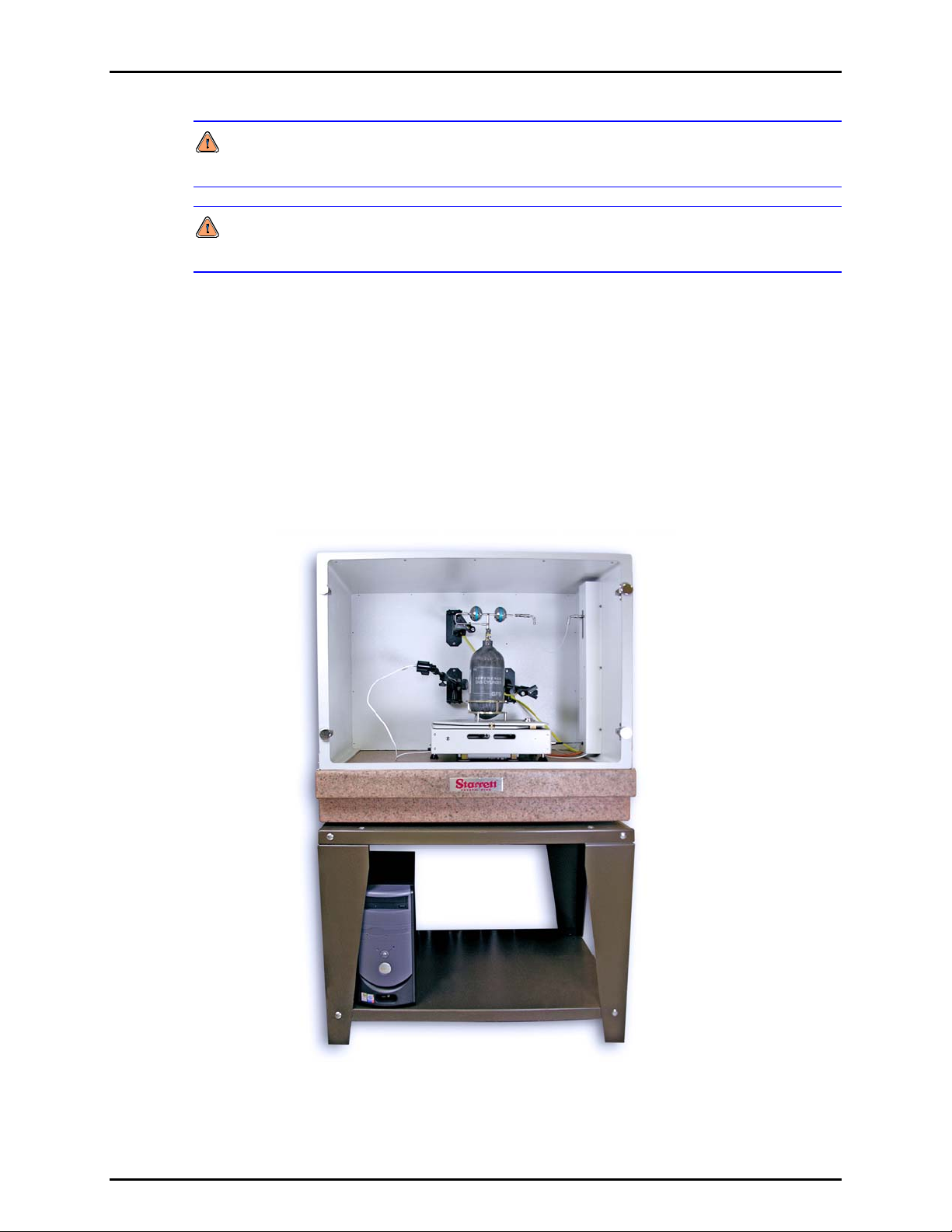

Figure 9. GFS draft enclosure on vibration isolation table......................................................................... 12

Figure 10. Laboratory Conditions Monitor .................................................................................................13

Figure 11. GFS-FS Reference gas cylinder fill station ..............................................................................14

Figure 12. Typical layout of overall GFS2102 system at site of use..........................................................25

Figure 13. Installation of draft enclosure doors..........................................................................................28

Figure 14. LCM rear panel connections.....................................................................................................28

Figure 15. Reference gas cylinder assembly...............................................................................................30

Figure 16. Reference gas cylinder connector............................................................................................31

Figure 17. Regulator assembly position before and after tightening.........................................................32

Figure 18. Reference Mass Legs (Spherical (x 2) and Flat)......................................................................32

Figure 19. Location of balance positioning bracket mounting holes..........................................................34

Figure 20. GFS balance rear panel connections.......................................................................................34

Figure 21. GFS balance inside AMH with mass tray installed..................................................................35

Figure 22. Checking height and level of gas conveyance loop connections using loop alignment tool....36

Figure 23. Reference Gas Cylinder resting on balance. AMH top plate installed; reference

Figu r e 2 4 . View of cylinder support legs through AMH top plate. ...........................................................37

Figu r e 25 . Temperature probe positions around reference gas cylinder. .................................................39

Figure 26: Heat Exchanger, Low ................................................................................................................39

Figure 27: Heat Exchanger unassembled ..................................................................................................40

Figure 28: Single, Low flow molstic.............................................................................................................40

Figu r e 2 9 . GFS-FS reference gas cylinder fill station connections............................................................50

Figure 30. Reference gas cylinder connector..............................................................................................51

Figure 31. <Status Bar>.............................................................................................................................59

Figure 32. Test Status................................................................................................................................59

Figure 33. Progress Indicator.....................................................................................................................59

Figure 34. Main Toolbar - Display while idle..............................................................................................60

Figure 35. Manual Averaging Options .......................................................................................................62

Figure 36. <Average Setup>......................................................................................................................63

Figure 37. GFS Run Screen ......................................................................................................................64

Figure 38: GFS Control Panel section of GFS Run Screen .......................................................................65

Figure 39: GFS System Display section of GFS Run Screen ....................................................................66

Figure 40. GFS Control Toolbar section of GFS Run Screen ...................................................................67

Figure 41. GFS Diagnostics Run Screen...................................................................................................69

Figure 42. Balance Output Run Screen....................................................................................................70

Figure 43. GFS Ambient Conditions Run Screen.....................................................................................71

Figure 44. DUT/Reference Comparison Run Screen...............................................................................72

S

mass plate uninstalled.............................................................................................................37

Page IX © 2007 DH Instruments, a Fluke Company

Page 12

GFS2102™ OPERATION AND MAINTENANCE MANUAL

Figure 45. Device Output Run Screen.......................................................................................................74

Figure 46. Spy Window Screen .................................................................................................................74

Figure 47. <molbox Output> Run Screen..................................................................................................75

Figure 48. molbox Output Run Screen in Tare Mode................................................................................77

Figure 49. MFC-CB Run Screen................................................................................................................78

Figure 50. Data Grid Run Screen ..............................................................................................................79

Figure 51. Data Plot Run Screen...............................................................................................................80

Figure 52. Options, [Run Test] Tab............................................................................................................81

Figure 53. Options, [Initialize Test] Tab.....................................................................................................83

Figure 54. Options, [End Test] Tab............................................................................................................84

Figure 55. Options, [Data File] Tab............................................................................................................86

Figure 56. Options, [Data Grid] Tab...........................................................................................................88

Figure 57. Direct Remote Communication.................................................................................................90

Figure 58. Change GFS AMH State ..........................................................................................................91

Figure 59. Data File Viewer .......................................................................................................................92

Figure 60. [Data], [Plot Data File] Screen..................................................................................................93

Figure 61. Custom Plot Editor....................................................................................................................95

Figure 62. Plot Points display ....................................................................................................................97

Figure 63. Plot Points Best Fit Tab............................................................................................................98

Figure 64. Setup Selector ........................................................................................................................102

Figure 65. Editor Toolbar .........................................................................................................................103

Figure 66. Test Definition Editor, Point Sequence...................................................................................105

Figure 67. Test Definition Editor [Control] Tab ........................................................................................107

Figure 68. Test Definition Editor [Data] Tab ............................................................................................109

Figure 69. Test Definition Editor [AutoZero] Tab.....................................................................................110

Figure 70. Test Definition Editor [Options] Tab........................................................................................111

Figure 71. Test Definition Editor, [Comment] Tab ...................................................................................113

Figure 72. DUT Editor, [Header] Tab.......................................................................................................114

Figure 73. DUT Editor, [Calibration] Tab .................................................................................................116

Figure 74. Date Selection ........................................................................................................................117

Figure 75. DUT Definition Editor [Communications] Tab.........................................................................118

Figure 76. Remote Command Editor.......................................................................................................121

Figure 77. DUT Device Edit [Output] Tab................................................................................................125

Figure 78. %Reading Tolerance..............................................................................................................127

Figure 79. %Span Tolerance...................................................................................................................127

Figure 80. %Span or %Reading (Greater of)...........................................................................................128

Figure 81. %Span + %Reading ...............................................................................................................128

Figure 82. DUT Device Edit [Comment] Tab ...........................................................................................129

Figure 83. Reference Cylinder Editor ......................................................................................................130

Figure 84. GFS Configuration [System] Tab............................................................................................131

Figure 85. GFS Configuration [GFS AMH] Tab.......................................................................................133

Figure 86. GFS Configuration [Limits] Tab ..............................................................................................134

Figure 87. GFS Configuration [LCM] Tab................................................................................................135

Figure 88: Remote interface settings window...........................................................................................136

Figure 89. GFS Configuration [Balance] Tab...........................................................................................136

Figure 90. GFS Configuration [Interface] Tab..........................................................................................137

Figure 91. Calibration [Time/Mass] Tab...................................................................................................138

Figure 92. Calibration [Ambient] Tab.......................................................................................................139

Figure 93. Calibration [TH Probe #2] Tab................................................................................................140

Figure 94. Calibration [TH Probe #3] Tab................................................................................................141

© 2007 DH Instruments, a Fluke Company Page X

Page 13

TABLES & FIGURES

Figure 95. Calibration [External PRT] Tab...............................................................................................141

Figure 96. Calibration [IR Probe] Tab......................................................................................................142

Figure 97: Run Test - Setup Test Definition window ................................................................................143

Figure 98: Run Test - Select Test Definition Window...............................................................................144

Figure 99: Run Test - Select DUTs window..............................................................................................144

Figure 100: Run Test - Configure DUT Device window............................................................................145

Figure 101: Run Test - Setup Flow Controller window.............................................................................145

Figure 102: Run Test - Configure MFC Device window...........................................................................146

Figure 103: Run Test - Initializing Test Instruments window....................................................................146

Figure 104: Run Manual Test - Setup Manual Test window.....................................................................147

Figure 105: Accumulation Sample Setup window .................................................................................... 148

Figure 106: US-DOT and European Reference Gas Cylinder labels....................................................... 163

Figure 107. Reference gas cylinder carrier..............................................................................................164

Figure 108. Time Calibration window .......................................................................................................170

Figure 109. Calibration Time/Mass tab.....................................................................................................171

Figure 110: LCM default front panel display.............................................................................................172

Figure 111. Ambient sensors adjustment tab...........................................................................................173

Figure 112: LCM TH probe front panel display.........................................................................................175

Figure 113. TH Probe #2 adjustment tab..................................................................................................176

Figure 114. External PRT adjustment tab.................................................................................................178

Figure 115. LCM IR probe front panel display..........................................................................................179

Figure 116. IR Probe adjustment tab........................................................................................................179

Figure 117. View of main board socket J19 or top view of calibration cable...........................................182

Page XI © 2007 DH Instruments, a Fluke Company

Page 14

GFS2102™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page XII

Page 15

ABOUT THIS MANUAL

A

BBOOUUTT

A

This manual provides the information necessary to operate a GFS2102 gravimetric mass flow calibration

standard to make gas mass flow measurements. It also provides additional recommendations and

information to help you optimize use of the GFS2102 system and take full advantage of it’s many features

and functions.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure. Set

up of a GFS2102 system should not be attempted without using Section 3. All first time GFS2102 users

should read Section 4. There is a glossary of common terms in Section 9.1, a troubleshooting guide in

Section 1, and a chart of typical test settings in Section

(CAUTION) is used throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys or objects (e.g., [RANGE]) on an instrument front panel keypad or in a

software user interface.

T

T

HHIISS

M

AANNUUAAL

M

L

Manual Conventions

< > indicates instrument front panel screen displays or labels in a software user interface (e.g., <1yes>)

Page XIII © 2007 DH Instruments, a Fluke Company

Page 16

GFS2102™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page XIV

Page 17

1. INTRODUCTION

.

11.

GFS2102 is a primary gravimetric gas flow measurement standard. It is intended for use in calibrating

gas flow transfer standards or other flow devices requiring a very low uncertainty reference. GFS2102 is

recommended when low uncertainty is the primary requirement of a flow measurement or the ability to

internally maintain traceability of mass flow measurements is desired. GFS2102 covers the range of

10 sccm to 10 slm in most gases.

GFS2102 measures gas mass flow by measuring the loss of mass from a reference gas cylinder over a

measured period of time. The reference gas cylinder assembly rests on the GFS mass balance and flow is

transmitted from the cylinder through a flow path designed to have minimal effect on the balance mass

measurement. Balance mass and time measurements and a number of ambient conditions are all read using

a component of the GFS2102 system called LCM, the Laboratory Conditions Monitor. Since test times may

be long, a special automated mass handling platform is used to load a fixed reference mass on the GFS

balance at intervals thoughout the test to quantify and remove any effects from balance drift over time.

All measurement functions of the GFS2102 system are operated by a system controller (personal

computer) running GFS Tools software. The system is made up of several individual components

working together and controlled by GFS Tools.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 SPECIFICATIONS

1.1.1 GFS2102 GENERAL SPECIFICATIONS

Power Requirements

Operating Temperature Range

Humidity Range

Weight

Granite table and stand

Rest of system

Dimensions

Enclusure on Granite Table w/ stand

Supported Gases

Flow Measurement Range

All other gases

Pressure Connections

outlet flow path from enclosure

Reference Gas Cylinder Pressure Limit

CE Conformance

Balance

LCM

MFC-CB

LCM

MFC-CB

GFS-FS

He, H2

100 to 240 VAC, 50 to 60 Hz, 27 W max. consumption

100 to 240 VAC, 50 to 60 Hz, 40 W max. consumption

85 to 264 VAC, 50 to 60 Hz, 36 W max. consumption

15 to 25 °C

5 to 70% RH, non-condensing

320 kg (700 lb) approx.

70 kg (150 lb) approx.

150 cm H x 90 cm W x 60 cm D (58 in. x 36 in. x 24 in.)

8 cm H x 22.5 cm W x 20 cm D (3.1 in. x 8.9 in. x 7.9 in.)

8 cm H x 22.5 cm W x 20 cm D (3.1 in. x 8.9 in. x 7.9 in.)

20 cm H x 41.4 cm W x 20 cm D (7.9 in. x 16.3 in. x 7.9 in.)

Nitrogen (N2), Air, Argon (Ar), Carbon Monoxide (CO), Helium (He),

Oxygen (O2), Carbon Dioxide (CO2), Carbon Tetrafluoride (CF4),

Ethane (C2H6), Ethylene (C2H4), Fluoroform (CHF3),

Hexafluoroethane (C2F6), Hydrogen (H2), Methane (CH4), Nitrous

Oxide (N2O), Sulfur Hexafluoride (SF6), Xenon (Xe)

at least:

100 sccm to 10 slm

10 sccm to 10 slm

1/8” Swagelok tube fitting or equivalent, with adaptor to

1/4” Swagelok tube fitting or equivalent

20 MPa (3000 psi)

Available, must be specified.

Page 1 © 2007 DH Instruments, a Fluke Company

Page 18

GFS2102™ OPERATION AND MAINTENANCE MANUAL

1.1.2 GFS2102 MASS BALANCE SPECIFICATIONS

Operating temperature range

Operating humidity (maximum)

Resolution

Mass Uncertainty

15 to 30 °C

70% RH, non-condensing

0.1 mg

10 ppm of span or better

1.1.3 LCM AMBIENT CONDITIONS MEASUREMENT SPECIFICATIONS

1.1.3.1 PRT BALANCE AMBIENT TEMPERATURE MEASUREMENT

Temperature:

Range

Uncertainty

1.1.3.2 TH PROBE REFERENCE GAS CYLINDER SURROUNDINGS

AMBIENT CONDITION MEASUREMENT

Temperature:

Range

Uncertainty

Relative Humidity:

Range

Uncertainty

[°C]

15 to 30

± 0.1

[°C]

15 to 30

± 0.2

5 to 95 %RH

± 10 %RH

1.1.3.3 INFRARED PROBE REFERENCE GAS CYLINDER SURFACE

TEMPERATURE MEASUREMENT

Temperature:

Range

Uncertainty

[°C]

0 to 30

± 2.2

1.1.3.4 AMBIENT CONDITIONS MEASUREMENT

Pressure:

Range

Uncertainty

Temperature:

Range

Uncertainty

Relative Humidity:

Range

Accuracy

[kPa]

70 to 110

± 0.2

[°C]

15 to 30

± 1.0

5 to 95 %RH

± 10 %RH

1.1.3.5 BALANCE READING TIME MEASUREMENT

Time:

32 ppm

© 2007 DH Instruments, a Fluke Company Page 2

Page 19

1. INTRODUCTION

1.1.4 MFC-CB SPECIFICATIONS

ANALOG OUTPUT

Voltage Range

Voltage Accuracy

Voltage Resolution

Current Range

Current Accuracy

Current Resolution

0 to 6.000 VDC

± 0.015 % FS

0.1 mVDC

4 to 20 mA

± 0.025 % FS

0.4 μA

ANALOG INPUT

Voltage Range

Min/Max Measurable Voltage

Voltage Accuracy

Voltage Resolution

Current Range

0 to 6.000 VDC

- 0.25/6.00 VDC

± 0.015 % FS

1 mVDC

4 to 20 mA

1.1.5 FLOW MEASUREMENT SPECIFICATIONS

Repeatability

Measurement Uncertainty

less than ± 0.05% of reading

less than ± 0.1% of reading

Page 3 © 2007 DH Instruments, a Fluke Company

Page 20

GFS2102™ OPERATION AND MAINTENANCE MANUAL

N

N

OOTTEES

S

© 2007 DH Instruments, a Fluke Company Page 4

Page 21

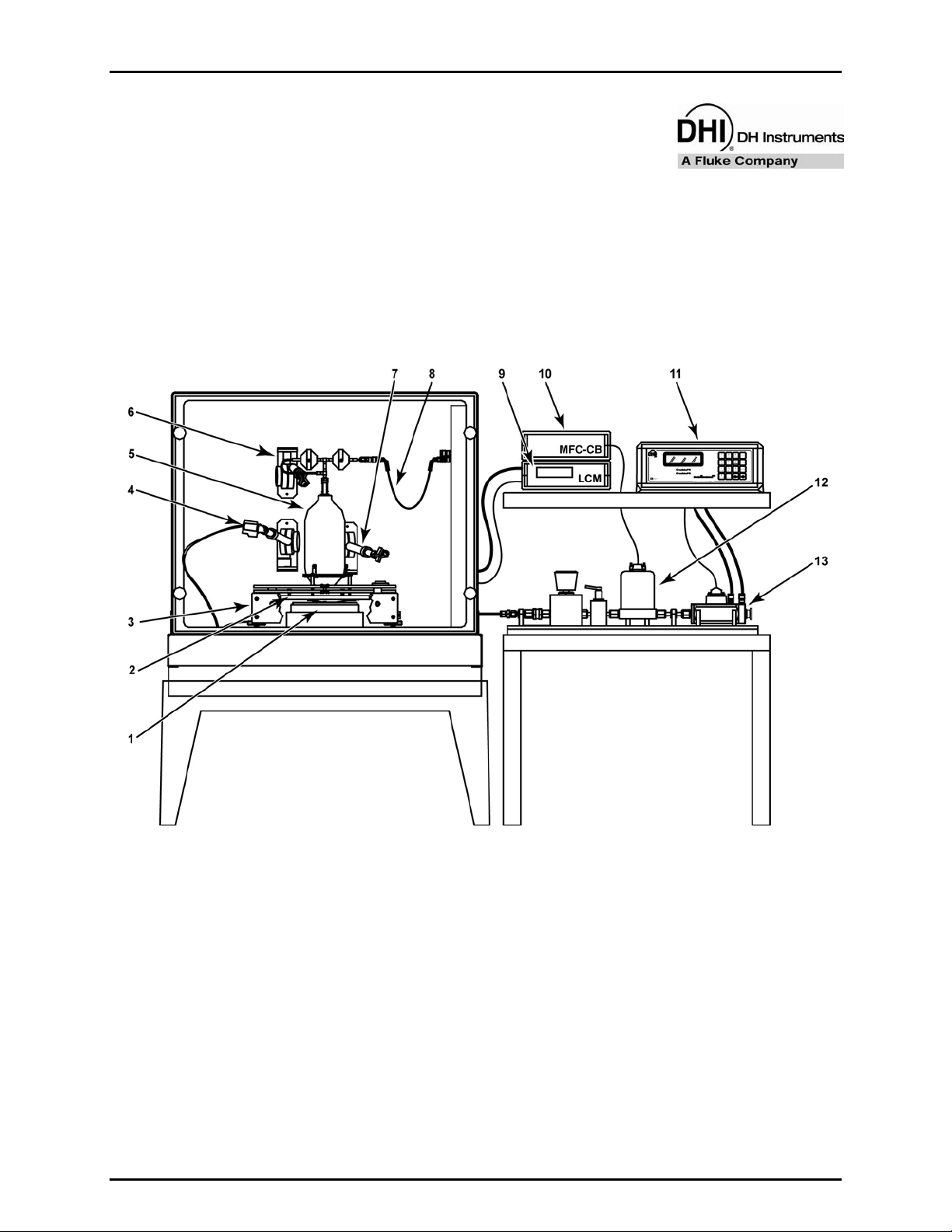

2. SYSTEM OVERVIEW

.

22.

GFS2102 is a primary gravimetric gas flow measurement standard. It is intended for use in calibrating gas flow

transfer standards or other flow devices requiring a very low uncertainty reference. GFS2102 is recommended

when low uncertainty is the primary requirement of a flow measurement. GFS2102 covers the range of 10 sccm

to 10 slm in most gases. All measurement functions of the GFS2102 system are managed by a system controller

(personal computer) running GFS Tools software. The system is made up of several individual components

working together and controlled by GFS Tools, which is the user interface for the GFS2102 instrument.

S

YYSSTTEEMM

S

O

VVEERRVVIIEEW

O

W

Figure 1. GFS2102 system

1. Precision mass balance 8. Catenary gas conveyance loop

2. Reference mass 9. Laboratory conditions monitor

3. AMH-GFS2102 automated mass handler 10. MFC control box

4. IR probe 11. Flow terminal (for device under test)

5. Reference gas cylinder 12. Mass flow controller

6. Ambient conditions probe 13. Device under test

7. Ambient conditions probe

GFS2102 measures gas mass flow by measuring the loss of mass from a reference gas cylinder over a

measured period of time. The reference gas cylinder assembly rests on the GFS mass balance that is placed on

a vibration isolation table and inside an insulated draft enclosure. Flow is transmitted from the cylinder and out

through the enclosure wall in a flow path designed to cause minimal effect on the balance mass measurement.

Page 5 © 2007 DH Instruments, a Fluke Company

Page 22

GFS2102™ OPERATION AND MAINTENANCE MANUAL

In order to mitigate mass measurement errors due to balance drift over time, the balance sits inside an

automated mass handling platform assembly, AMH-GFS2102, that allows the cylinder assembly to be lifted off

the balance, and a reference mass to be loaded on the balance, without interrupting the flow measurement.

The Laboratory Conditions Monitor (LCM) is a central piece of hardware for GFS system operation. It performs

several different functions for the system. These include measurement of temperature under the AMH platform,

measuring temperature and humidity surrounding the reference gas cylinder, measuring the temperature of the

reference gas cylinder, actuating the AMH platform movement, measuring ambient pressure and recording the

precise time at which each balance reading is taken. Another piece of support hardware, MFC-CB is used for

sending flow command signals to the flow controllers, and possibly reading the device under test if the device

has a voltage output.

2.1 BALANCE AND AMH-GFS2102

GFS2102 measures the changing reference gas cylinder mass using a high precision 2.3 kg range mass

balance. It is a mass comparator type balance, so there is no significant deflection of the mass tray while

the mass load is placed on it. The balance has a digital serial output which is read by the LCM.

In a typical mass measurement, the balance can be zeroed, or tared, immediately before placement of the

mass, and the measurement can be made relatively quickly after zeroing. Since gravimetric gas flow

measurements can require up to several hours or days for some gases and flow ranges, the balance’s

stability over time and level of influence from surrounding conditions becomes very significant to GFS2101

measurements.

A key to reaching the desired level of uncertainty using GFS2101 is to eliminate or minimize the uncertainty

due to drift of the mass balance over time. In order to quantify and correct for the balance drift, a specialized

automated mass handling platform called AMH-GFS2102 has been developed to allow the GFS balance to

be AutoZeroed at selected intervals during a flow measurement. The AMH alternately lifts the reference gas

cylinder assembly off the balance, loads a fixed reference mass in its place for measurement, and returns the