Fluke 863, 867B Service Manual

867B,863

®

Graphical Multimeters

Service Manual

PN 689312

December 1997

© 1997 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Table of Contents

Chapter Title Page

1 Introduction and Specifications .......................................................................................... 1-1

1-1.. Introduction ............................................................................................................. 1-3

1-2. Description .............................................................................................................. 1-3

1-3. Power Requirements ............................................................................................... 1-3

1-4. Options, Accessories and Related Equipment ....................................................... 1-4

1-5. Operating Instructions ............................................................................................ 1-4

1-6. Obtaining Service ................................................................................................... 1-4

1-7. Conventions Used in This Manual ......................................................................... 1-5

1-8. Chapter Contents .................................................................................................... 1-5

1-9. Specifications .......................................................................................................... 1-6

2 Theory of Operation............................................................................................................. 2-1

2-1. Introduction ............................................................................................................. 2-3

2-2. Start-Up Sequence .................................................................................................. 2-3

2-3. Function Selection .................................................................................................. 2-3

2-4. Power Supply .......................................................................................................... 2-4

2-5. Power Supply Input Voltages ................................................................................. 2-4

2-6. Power Supply Output Voltages and Currents ........................................................ 2-6

2-7. Power Supply Signals ............................................................................................ 2-7

2-8. Power ON/OFF Requirements ............................................................................... 2-8

2-9. NiCd Charging Requirements ................................................................................ 2-8

2-10. Battery and Line Level Detection .......................................................................... 2-8

2-11. Power Supply Functional Blocks ........................................................................... 2-9

2-12. Input Power Selector (A) ........................................................................................ 2-9

2-13. Boost Preregulator (B) ............................................................................................ 2-10

2-14. Battery Charger (C) ................................................................................................ 2-10

2-15. DC-DC Converter (D) ............................................................................................ 2-12

2-16. Backlight Current Sink (E) ..................................................................................... 2-12

2-17. Power Switch Circuitry (F) .................................................................................... 2-12

2-18. LCD Contrast Control (G) ...................................................................................... 2-12

2-19. Power-On Reset Circuit (H) ................................................................................... 2-12

2-20. Linear Post Regulators (I) ....................................................................................... 2-13

2-21. Input Overload Protection ...................................................................................... 2-13

i

Contents (continued)

2-22. Volt/Ohms Input Protection ................................................................................... 2-13

2-23. External Trigger and Logic Activity Input Protection ........................................... 2-14

2-24. Amps / mA / µA Input Protection .......................................................................... 2-14

2-25. Input Signal Conditioning ...................................................................................... 2-14

2-26. AC Volts ................................................................................................................. 2-14

2-27. DC Volts ................................................................................................................. 2-16

2-28. mV DC .................................................................................................................... 2-16

2-29. Ohms ....................................................................................................................... 2-17

2-30. Diode Test ............................................................................................................... 2-17

2-31. Capacitance ............................................................................................................. 2-17

2-32. mA/µA .................................................................................................................... 2-18

2-33. Amps ....................................................................................................................... 2-18

2-34. Waveform Processing ............................................................................................. 2-19

2-35. Overview ................................................................................................................. 2-19

2-36. Detailed Description ............................................................................................... 2-19

2-37. Waveform Triggering ............................................................................................. 2-20

2-38. Overview ................................................................................................................. 2-20

2-39. Dual Trigger ............................................................................................................ 2-20

2-40. Single Trigger ......................................................................................................... 2-21

2-41. External Trigger ...................................................................................................... 2-21

2-42. Glitch Capture ......................................................................................................... 2-22

2-43. Single Shot .............................................................................................................. 2-22

2-44. Frequency Trigger .................................................................................................. 2-22

2-45. Logic Activity Trigger ............................................................................................ 2-22

2-46. Peak Hold ................................................................................................................ 2-22

2-47. Auto Diode .............................................................................................................. 2-22

2-48. Component Test ...................................................................................................... 2-23

2-49. Digital Circuitry ...................................................................................................... 2-24

2-50. RS-232 Serial Port .................................................................................................. 2-24

3 Maintenance .......................................................................................................................... 3-1

3-1. Introduction ............................................................................................................. 3-3

3-2. Warranty Repairs and Shipping Information ......................................................... 3-3

3-3. Static-Safe Handling ............................................................................................... 3-3

3-4. Cleaning .................................................................................................................. 3-4

3-5. Disassembly ............................................................................................................ 3-4

3-6. Reasssembly ............................................................................................................ 3-7

3-7. Replacing the 440 mA Fuse ................................................................................... 3-9

3-8. Replacing the 11A (High Energy) Fuse ................................................................. 3-9

4 Perfomance Testing and Calibration ................................................................................. 4-1

4-1. Introduction ............................................................................................................. 4-3

4-2. Required Test Equipment ....................................................................................... 4-3

4-3. Alternative Test Equipment (Fluke 5500A) ........................................................... 4-3

4-4. Performance Tests .................................................................................................. 4-4

4-5. mV DC Test ............................................................................................................ 4-4

4-6. DC Volts Test ......................................................................................................... 4-6

4-7. Diode Test ............................................................................................................... 4-7

4-8. AC Volts Test ......................................................................................................... 4-8

4-9. Ohms and Conductance Tests ................................................................................ 4-10

4-10. Capacitance Test ..................................................................................................... 4-11

4-11. Frequency Test ........................................................................................................ 4-12

4-12. Duty Cycle Test ...................................................................................................... 4-14

4-13. Logic Test (867B Only) .......................................................................................... 4-15

ii

Contents (continued)

4-14. Amps Tests ............................................................................................................. 4-16

4-15. Peak Hold Test ........................................................................................................ 4-19

4-16. Component Test (867B Only) ................................................................................ 4-19

4-17. Rel Test/Touch Hold Test ...................................................................................... 4-20

4-18. Glitch Capture Test ................................................................................................. 4-21

4-19. External Trigger Test .............................................................................................. 4-21

4-20. Calibration ...............................................................................................................4-22

4-21. Measuring the System Resistance .......................................................................... 4-22

4-22. Starting Calibration Mode on the GMM ................................................................ 4-22

4-23. mV DC Calibration ................................................................................................. 4-23

4-24. DC Volts Calibration .............................................................................................. 4-24

4-25. DC mAuA Calibration ............................................................................................ 4-24

4-26. DC Amps Calibration ............................................................................................. 4-24

4-27. Ohms/nS Calibration .............................................................................................. 4-25

4-28. Modifying the Displayed Value ............................................................................. 4-25

4-29. Ohms Calibration .................................................................................................... 4-26

4-30. AC Volts Calibration .............................................................................................. 4-27

4-31. AC mA(A Calibration ............................................................................................ 4-27

4-32. AC Amps Calibration ............................................................................................. 4-27

4-33. Internal Constants Calibration ................................................................................ 4-28

4-34. Setting LCD Voltage .............................................................................................. 4-28

5 List of Replaceable Parts ..................................................................................................... 5-1

5-1. Introduction ............................................................................................................. 5-3

5-2. How To Obtain Parts .............................................................................................. 5-3

5-3. Manual Status Information ..................................................................................... 5-3

5-4. Newer Instruments .................................................................................................. 5-3

5-5. Service Centers ....................................................................................................... 5-4

5-6. Parts ......................................................................................................................... 5-4

6 Schematic Diagrams.............................................................................................................6-1

iii

List of Tables

Table Title Page

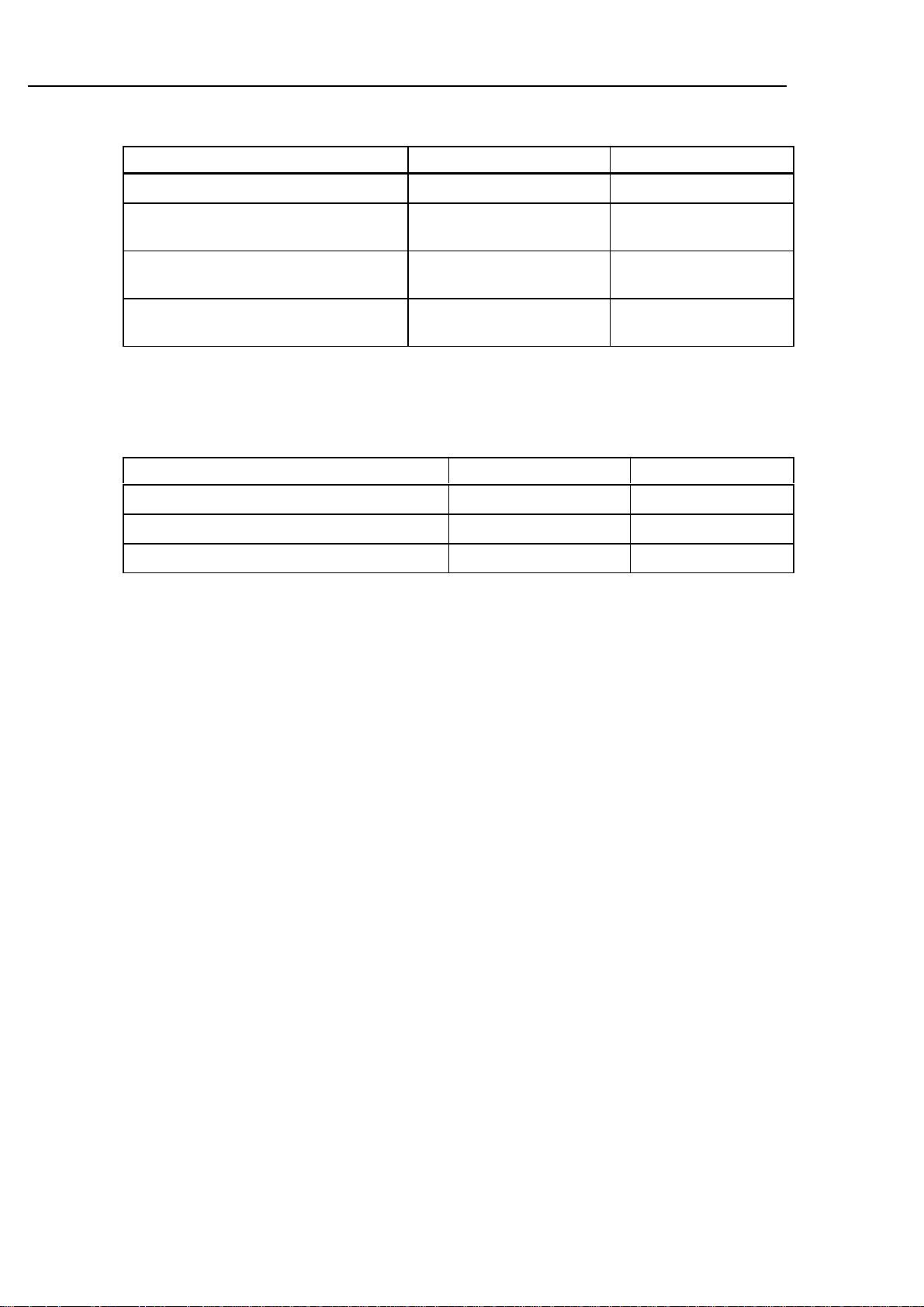

1-1. Power Sources ......................................................................................................... 1-4

1-2. Accessories Included with Each GMM ................................................................... 1-4

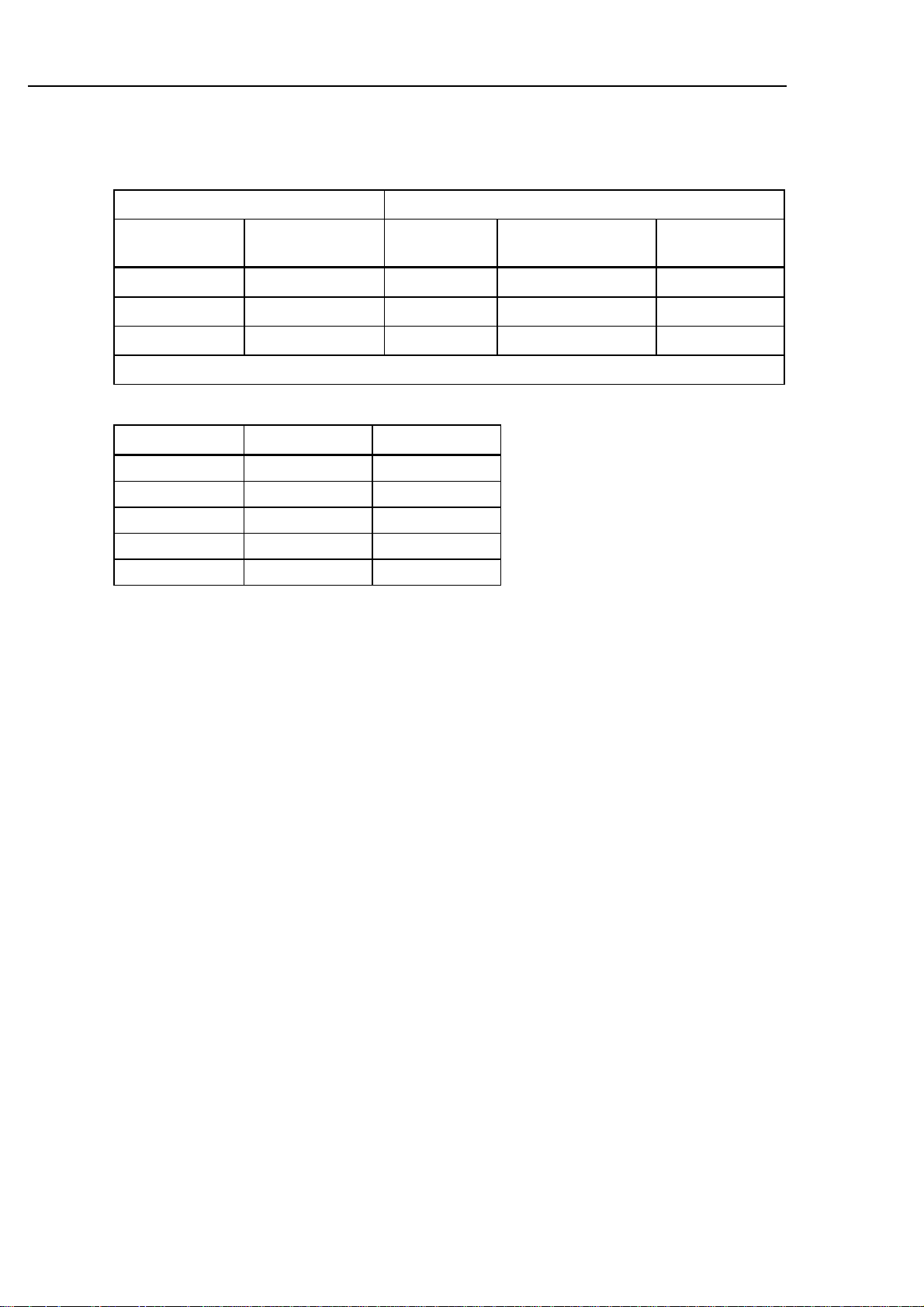

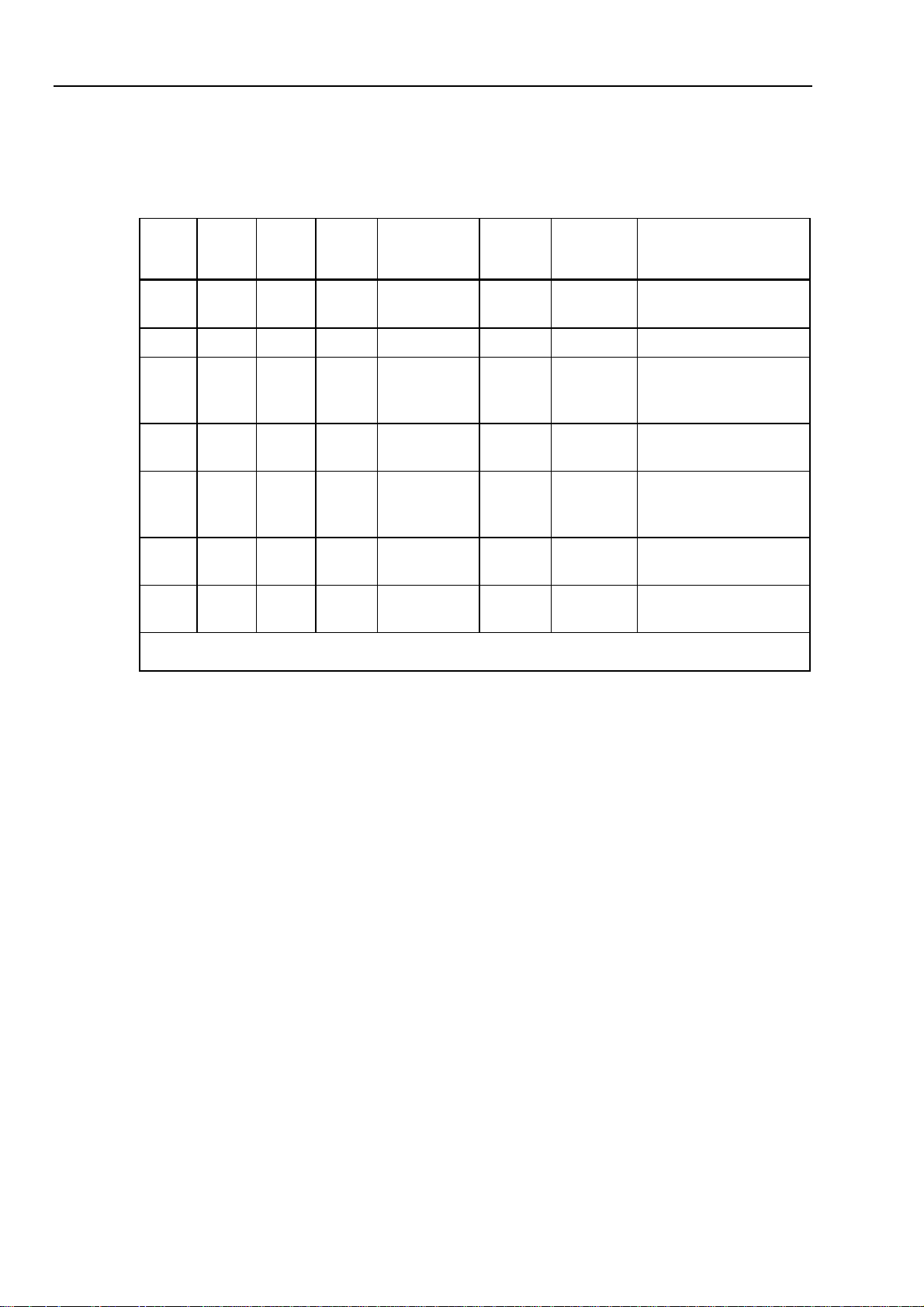

2-1. Power Supply Inputs................................................................................................ 2-4

2-3. Power Supply Signals.............................................................................................. 2-7

2-4. Power Source Detection .......................................................................................... 2-9

2-5. Average Converter................................................................................................... 2-15

2-6. RMS Converter (U3) ............................................................................................... 2-16

2-7. Test Point Voltages.................................................................................................. 2-16

2-8. Ohms Ratiometric Measurements ........................................................................... 2-17

2-9. Amps Measurement Paths....................................................................................... 2-18

4-1. Recommended Test Equipment............................................................................... 4-4

4-2. mV DC Performance Test ....................................................................................... 4-4

4-3. DC Volts Performance Test..................................................................................... 4-6

4-4. Diode Test Performance Test .................................................................................. 4-7

4-5. AC Volts RMS Performance Test ........................................................................... 4-8

4-6. AC Volts Average Performance Test...................................................................... 4-8

4-7. Ohms Performance Test .......................................................................................... 4-10

4-8. Conductance Performance Test............................................................................... 4-10

4-9. Capacitance Performance Test ................................................................................ 4-11

4-10. Frequency (AC Volts) Performance Test ................................................................ 4-12

4-11. Frequency (mAuA) Performance Test .................................................................... 4-12

4-12. Duty Cycle Performance Test.................................................................................. 4-14

4-13. Logic Performance Test .......................................................................................... 4-15

4-14. DC Amps Performance Test.................................................................................... 4-16

4-15. AC Amps RMS Performance Test .......................................................................... 4-16

4-16. AC Amps Average Performance Test ..................................................................... 4-17

4-17. Peak Hold Performance Test................................................................................... 4-19

4-18. Component Test Performance Test ......................................................................... 4-19

4-19. Rel Performance Test .............................................................................................. 4-20

4-20. Touch Hold Performance Test................................................................................. 4-20

4-21. Glitch Capture Performance Test ............................................................................ 4-21

4-22. External Trigger Performance Test ......................................................................... 4-21

5-1. 860 Series Final Assembly ...................................................................................... 5-5

5-2. A1 Main PCA.......................................................................................................... 5-8

iv

List of Figures

Figure Title Page

1-1. Temperature and Humidity...................................................................................... 1-7

2-1. Block Diagram......................................................................................................... 2-5

2-2. Power Supply Blocks .............................................................................................. 2-11

2-3. Keypad Connections................................................................................................ 2-25

3-1. Disassembly............................................................................................................. 3-5

3-2. Reassembly.............................................................................................................. 3-8

3-3. Replacing the 400 mA Fuse..................................................................................... 3-9

4-1. Configuration 1 (mV DC) ....................................................................................... 4-5

4-2. Configuration 2 (DC Volts)..................................................................................... 4-6

4-3. Configuration 6 (AC Volts)..................................................................................... 4-9

4-4. Configuration 5 (Ohms) .......................................................................................... 4-11

4-5. Configuration 7 (PM5139) ...................................................................................... 4-13

4-6. Configuration 7 (PM5139) ...................................................................................... 4-14

4-7. Configuration 9 (PM5139) ...................................................................................... 4-16

4-8. Configuration 3 (mAuA, DC and AC) .................................................................... 4-17

4-9. Configuration 4 (Amps, DC and AC)...................................................................... 4-18

4-10. Configuration 8 (Component Test).......................................................................... 4-19

4-11. Initiating Calibration ............................................................................................... 4-22

4-12. Entering Calibration Mode...................................................................................... 4-23

4-13. Modifying the Displayed Value .............................................................................. 4-25

4-14. Ohms Calibration..................................................................................................... 4-26

5-1. 860 Series Final Assembly ..................................................................................... 5-7

5-2. A1 Main PCA.......................................................................................................... 5-16

v

Chapter 1

Introduction and Specifications

Title Page

1-1. Introduction............................................................................................. 1-3

1-2. Description.............................................................................................. 1-3

1-3. Power Requirements ............................................................................... 1-3

1-4. Options, Accessories and Related Equipment......................................... 1-4

1-5. Operating Instructions............................................................................. 1-4

1-6. Obtaining Service.................................................................................... 1-4

1-7. Conventions Used in This Manual.......................................................... 1-5

1-8. Chapter Contents..................................................................................... 1-5

1-9. Specifications.......................................................................................... 1-6

1-1

Introduction and Specifications

Introduction

Introduction 1-1.

This manual includes the following information:

• Specifications (Chapter 1):

• Theory of Operation (Chapter 2):

• General Maintenance (Chapter 3):

• Performance Testing and Calibration procedures (Chapter 4):

• List of Replaceable Parts (Chapter 5):

• Schematic Diagrams and component locators (Chapter 6):

The information in this manual is applicable to both the 867B and 863 models unless

otherwise indicated.

Description 1-2.

The Fluke 867B and 863 Graphical Multimeters (GMMs) provide full digital multimeter

(DMM) capabilities along with graphical waveform displays and trend plotting. Model

867B also provides component testing and logic activity testing.

1

Power Requirements 1-3.

The GMM can be powered with the Battery Eliminator or with 6 “AA” (ANSI/NEDAL40) alkaline cells. New alkaline batteries provide a minimum of 6 hours of continuous

operation. You can also use the NiCd battery pack. Depending on battery condition, a

fully charged NiCd battery pack provides 8 hours (typical) or less of continuous

operation. Internal charging is available on Model 867B.

1-3

867B,863

Service Manual

Battery Eliminator Operation

Alkaline Battery Operation (6 AA,

ANSI/NEDA-L40)

Table 1-1. Power Sources

Model 867B Model 863

••

••

NiCd Battery Pack Operation (with

internal charging)

NiCd Battery Pack Operation (with

external charging)

•

•

Options, Accessories and Related Equipment 1-4.

Accessories supplied with Fluke 867B and 863 GMMs are listed in Table 1-2.

Table 1-2. Accessories Included with Each GMM

Model 867B Model 863

TL70A Test Leads (2)

Battery Eliminator

NiCd Battery Pack

••

•

•

Operating Instructions 1-5.

Operating instructions for the Fluke 867B and 863 Graphical Multimeters can be found in

the Users Manual. For ordering information, see “How to Obtain Parts” in Chapter 5.

Obtaining Service 1-6.

A GMM under warranty will be promptly repaired or replaced (at Fluke’s option) and

returned at no charge. See the registration card for warranty terms. If the warranty has

expired, the GMM will be repaired and returned for a fixed fee. Contact the nearest

Service Center for information and prices. A list of U.S. and International Service

Centers is available on the World Wide Web at www.fluke.com. Refer to Chapter 3 for a

list of Fluke telephone numbers.

1-4

Introduction and Specifications

Conventions Used in This Manual

Conventions Used in This Manual 1-7.

The following conventions are used in this manual:

• “GMM” refers to all Graphical Multimeter models in the 860 Series.

• “863” and “867B” are specifically mentioned where a description does not apply to

all models in the 860 Series.

• A “pca” is a printed circuit board and its attached parts.

• A pin or connection on a component is specified by the component reference

designator, a dash (-), and a pin number. For example, component U30, pin 92 would

be U30-92.

Chapter Contents 1-8.

The chapters in this manual document service for the GMM as follows:

• Chapter 1. Introduction and Specifications describes the Service Manual, explains

special terminology and conventions, and provides complete GMM specifications.

• Chapter 2. Theory of Operation describes the GMM’s circuitry in terms of functional

blocks, with a description of each block’s role in overall operation. A detailed circuit

description is then given for each block.

1

• Chapter 3. General Maintenance provides information on general maintenance,

handling precautions and disassembly instructions. Instructions covering warranty

repairs and shipping the instrument to a service center are also contained in this

chapter.

• Chapter 4. Performance Testing and Calibration contains information on required test

equipment, performance test procedures and calibration of the GMM.

• Chapter 5. List of Replaceable Parts describes parts used in the GMM along with

ordering information.

• Chapter 6. Schematic Diagrams contains a full set of schematic diagrams and

component locators.

1-5

867B,863

Service Manual

Specifications 1-9.

General

Display: LCD - Dot Matrix, 240 X 200 pixels

Fluke 867B: Transmissive, Backlit

Fluke 863: Reflective

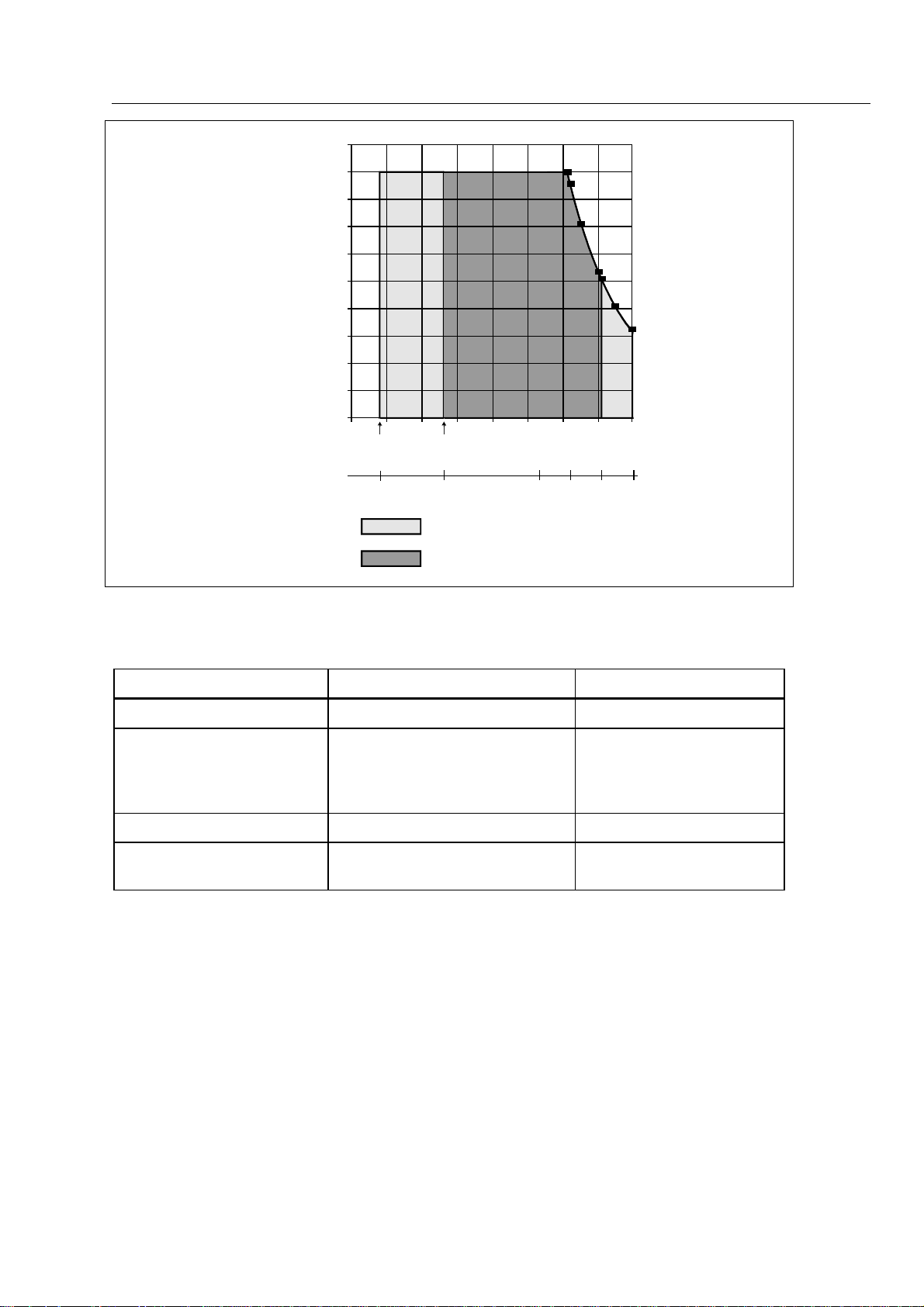

Temperature Operating: 0°C to 50°C (See Figure 1-1.)

Storage: -20°C to 60°C (Batteries Removed)

Charging: 0 to 45°C

Temperature Coefficient: (0.1 X % Accuracy) per °C (0°C to 18°C and 28°C to 59°C)

Relative Humidity: 0% to 90% non-condensing

Altitude Operating/Non-operating: 6,562 ft. (2,000 meters)/ 40,000 ft. (12,200 meters)

Input Impedance: 10 MΩ

Shock and Vibration: per MIL-T-28800, class 3, sinusoidal, non-operating

Dimensions: 5.4 x 9.7 x 2.7 in. (137 x 246 x 68 mm)

Weight: 3 lbs (1.35 kg)

Battery Operating Time (backlight off or low)

Alkaline: 8 hours typical

NiCd:

863: 10 hours typical

867B: 8 hours typical

Battery Recharge Time: 16 hours minimum from full discharge

Drip Proof Case: per IEC 529; IP 52, Drip Proof

Safety: Designed to meet IEC 1010-1 Category III, UL3111, CSA-C22.2. 1010-1-92, CE and TUV

requirements

Certification:

Electromagnetic Interference

RF Emissions EN-50081-1 Commercial Limits

VFG 243-1991

FCC Part 15 Class B,

RF Susceptibility: EN 50082-1 Industrial Limits

1-6

%RH

Introduction and Specifications

100

90

80

70

60

50

40

30

20

10

0

-20 0 20 40 60 80 100 120 140

-4

32

Temperature ( F)

°

Specifications

1

-20

Figure 1-1. Temperature and Humidity

0

Temperature ( C)

= Storage (-20 C —° 60 C)

= Normal Operation (0 C —

30 40 50 60

°

°

°

50 C)

°

Power

Fluke 867B Fluke 863

Battery Eliminator/Charger Yes Optional Eliminator only

NiCd Battery Pack Yes

Alkaline Batteries 6 AA Cells Optional Customer Supplied Yes

Battery Life: NiCad

Alkaline

≥8 hrs (supplied)

≥8 hrs (optional)

Optional BP7217 Battery

Pack

Optional BC7210 Ext.

Charger

≥10 hrs (optional)

≥8 hrs (supplied)

os1f.eps

1-7

867B,863

3

Service Manual

Resolution and Accuracy

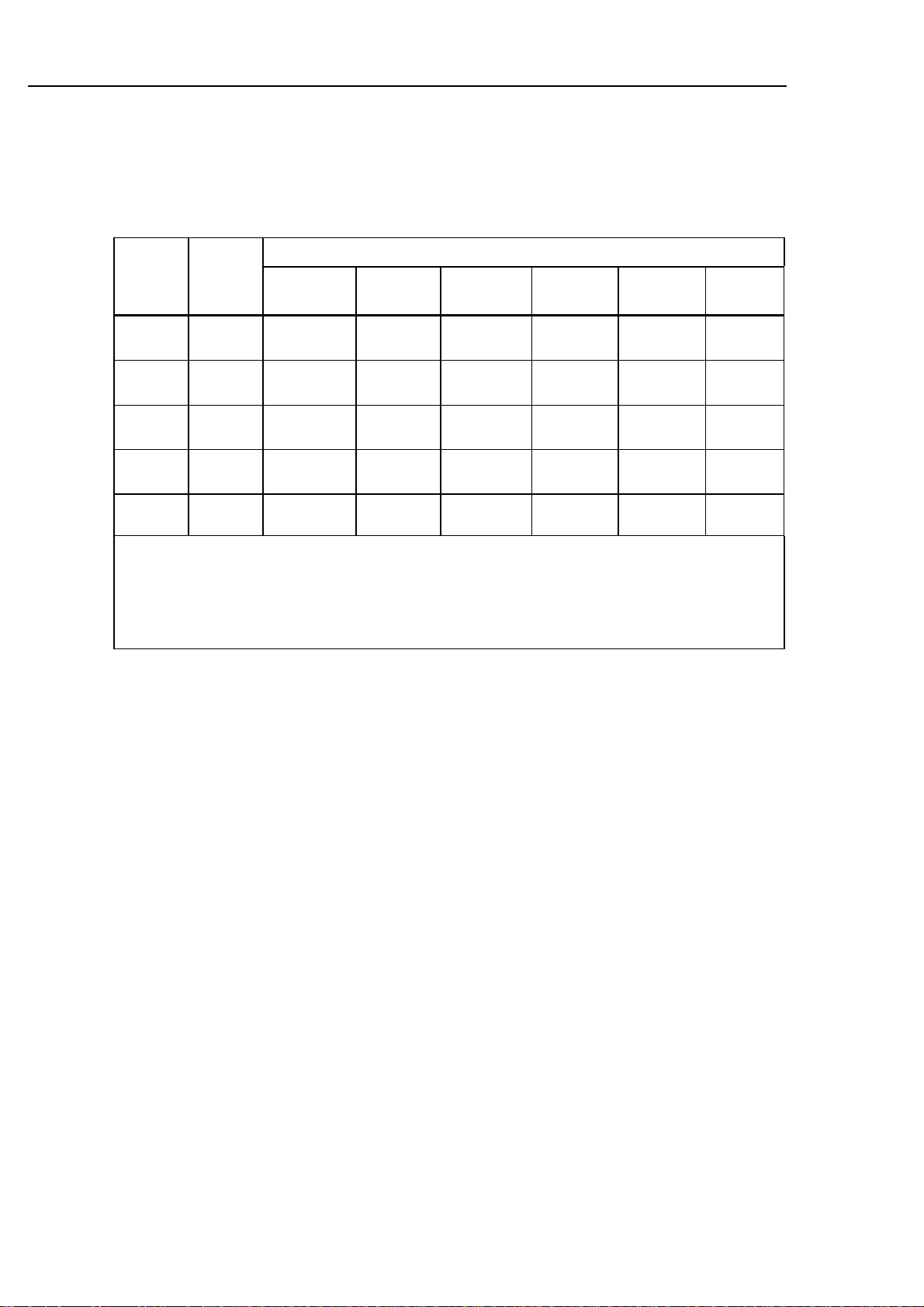

AC Volts (True RMS, AC-Coupled) [±(percent of reading + counts)]

The following specifications apply within 1 year of calibration when operating in a temperature range of

18°C (64°F) to 28°C (82°F).

Frequency

Range Res.

20 -

50 Hz

50 -

1 kHz

1 kHz 30 kHz

30 kHz-

100 kHz

100kHz-

200kHz

200 kHz-

300 kHz

00.00 mV 0.01 mV 1.5% + 10

0.19 dB

3.0000V 0.1 mV

30.000V 1 mV 1.5% + 10

300.00V 10 mV 1.5% + 10

1000.0V 100 mV

300 mV - 300V ranges ≥3:1, 1000V range ≥3:1 decreasing to ≥1.41:1 as input voltage increases to 1000V (peak

voltage not to exceed 1414V).

Measurement Range: 300 mV range from 10% to 100% of range.

1.5% + 10

0.19 dB

0.19 dB

0.19 dB

1.5% + 10

0.19 dB

3V - 1000V ranges from 5% to 100% of range.

For frequencies > 100 kHz 30% to 100% of range (all ranges).

0.5% + 10

0.10 dB

0.5% + 10

0.10 dB

0.5% + 10

0.10 dB

0.5% + 10

0.10 dB

1.5% + 10

0.19 dB

0.5% + 10

0.10 dB

0.5% + 10

0.10 dB

0.5% + 10

0.10 dB

0.5% + 10

0.10 dB

NA NA NA NA

4% + 200

1.39 dB

4% + 200

1.39 dB

4% + 200

1.39 dB

4% + 200

1.39 dB

8% + 200

1.68 dB

8% + 200

1.68 dB

8% + 200

1.68 dB

8% + 200

1.68 dB

10%+ 200

1.82 dB

10%+ 200

1.82 dB

10%+ 200

1.82 dB

10%+ 200

1.82 dB

1-8

Introduction and Specifications

AC Volts - Average Responding AC Coupled [±(percent of reading + counts)]

Frequency

Range Res.

20 - 50 Hz 50 - 1 kHz 1 kHz - 30 kHz 30 kH - 50 kHz

Specifications

1

300.0 mV 0.1 mV 1.5% + 4

0.25 dB

3.000V 1 mV 1.5% + 4

0.25 dB

30.00V 10 mV 1.5% + 4

0.25 dB

300.0V 100 mV 1.5% + 4

0.25 dB

1000V 1 V 1.5% + 4

0.25 dB

Input Impedance: 1.11 MΩ ±1% in series with 0.1 µF

Volts-Hertz Product: 2 x 10

Common Mode Rejection: >60 dB at 50 Hz and 60 Hz (1 kΩ unbalance)

Common Mode Volts-Hertz Product: 1 x 10

dBm Reference: 2, 4, 8, 16, 50, 75, 93, 110, 125, 135, 150, 300, 600, 900, 1000, and 1200Ω

Overload Protection: 1000V rms

7

0.5% + 4

0.16 dB

0.5% + 4

0.16 dB

0.5% + 4

0.16 dB

0.5% + 4

0.16 dB

1.5% + 4

0.25 dB

7

0.5% + 4

0.16 dB

0.5% + 4

0.16 dB

0.5% + 4

0.16 dB

0.5% + 4

0.16 dB

NA NA

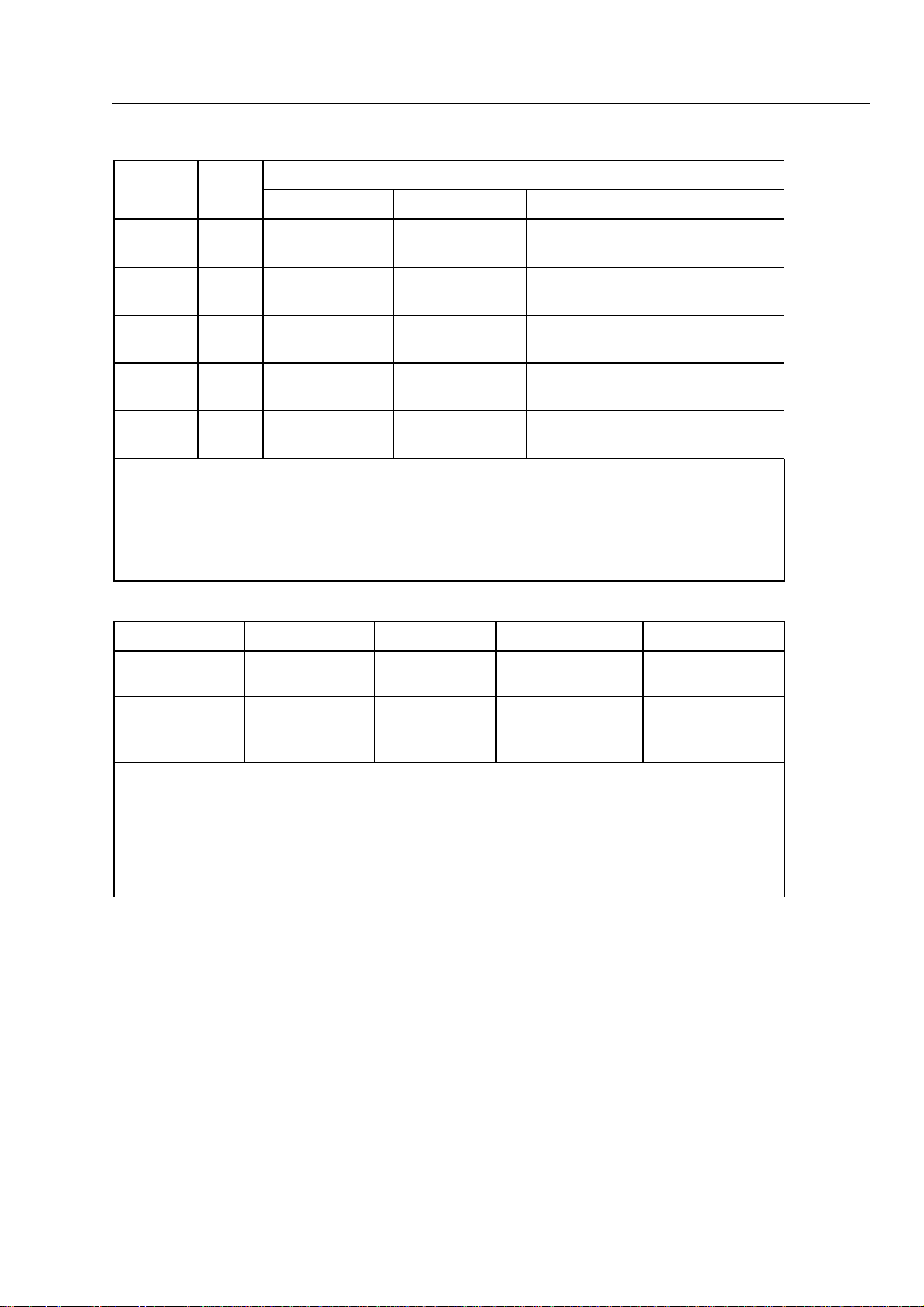

DC Volts [±(percent of reading + counts)]

Function Range Res. Fluke 867B Fluke 863

mV DC

V DC 300.00V 0.01 V 0.025% + 2 0.04% + 2

Input Impedance: V DC-10 MΩ, mV DC-10 MΩ, mV DC Hi-Z ->1000 MΩ

Normal Mode Rejection: >60 dB at 50 Hz or 60 Hz

Common Mode Rejection: >120 dB a dc, >90 dB at 50 Hz and 60 Hz (1 kΩ unbalance)

Overload Protection: 1000 V rms

Maximum Allowable Peak AC + DC Voltage (without causing a reading error)

300 mV, 3000 mV ranges: 15V

30V range: 1000V; 300V, 1000V ranges: 1414V

300.00 mV 0.01 mV 0.025% + 2 0.04% + 2

3000.0 mV 0.1 mV 0.025% + 2 0.04% + 2

30.000V 0.001 V 0.025% + 2 0.04% + 2

1000.0V 0.1 V 0.025% + 2 0.04% + 2

2% + 4

0.25 dB

2% + 4

0.25 dB

2% + 4

0.25 dB

2% + 4

0.25 dB

1-9

867B,863

Service Manual

Diode Test (Manual)

Diode Test (Auto)

Current Ranges

Range: 3V

Resolution: 0.0001V

Accuracy: ±0.05% of reading + 2 digits

Open Circuit Voltage: 3.1V

Accuracy: 20%

Ranges for True

RMS AC Current

and DC Current

300.00 µA

3000.0 µA

1

1

True RMS

Measurement Range

(% Range to % Full

Scale)

Ranges for Average

Responding AC

Current

Maximum

Burden

Voltage

5% - 100% 300.0 µA 0.03V 440 mA @

5% - 100% 3000 µA 0.3V 440 mA @

Fuse

Protection

1000V

1000V

30.000 mA 5% - 100% 30.00 mA 0.03V 440 mA @

1000V

300.00 mA 5% - 100% 300.0 mA 0.3V 440 mA @

1000V

3.0000A 5% - 100% 3.000A 0.1V 11A @

1000V

10.000A 5% - 100% 10.00A 0.3V 11A @

1000V

1. DC ranges available on the Fluke 867B only.

DC Current Accuracy [±(percent of reading + counts)]

Range Resolution Accuracy

1

300 µA

3000 µA

30 mA

1

2

0.01 µA0.1% + 15

0.1 µA0.1% + 2

1 µA 0.05% + 15

300 mA 10 µA0.1% + 2

3A 100 µA0.2% + 15

10A 1 mA 0.2% + 2

1. Ranges available on the Fluke 867B only.

2. Fluke 863 30 mA DC range accuracy 0.1% + 15.

AC Current Accuracy [±(percent of reading + counts)]

Range Resolution True RMS AC Current Accuracy (Average AC counts)

True RMS Avg. 20 Hz to

50 Hz

50 Hz to

3 kHz

3 kHz to

10 kHz

300 µA10.01 µA0.1 µA1% + 10 (4) 0.75% + 10 (4) 2% + 20 (4) 2% + 40 (4)

3000 µA10.1 µA1 µA1% + 10 (4) 0.75% + 10 (4) 2% + 20 (4) 2% + 40 (4)

30 mA 1 µA 10 µA1% + 10 (4) 0.75% + 10 (4) 2% + 20 (4) 2% + 40 (4)

300 mA 10 µA 100 µA1% + 10 (4) 0.75% + 10 (4) 2% + 20 (4) NA

3A 100 µA1 mA1% + 10 (4) 0.75% + 10 (4) NA NA

10A 1 mA 10 mA 1% + 10 (4) 0.75% + 10 (4) NA NA

1. Ranges available on the Fluke 867B only.

2. Replace counts with Average AC counts for Average Responding AC measurements. In 300 µA

range, floor count increases to 20 with battery eliminator.

2

10 kHz to

30 kHz

1-10

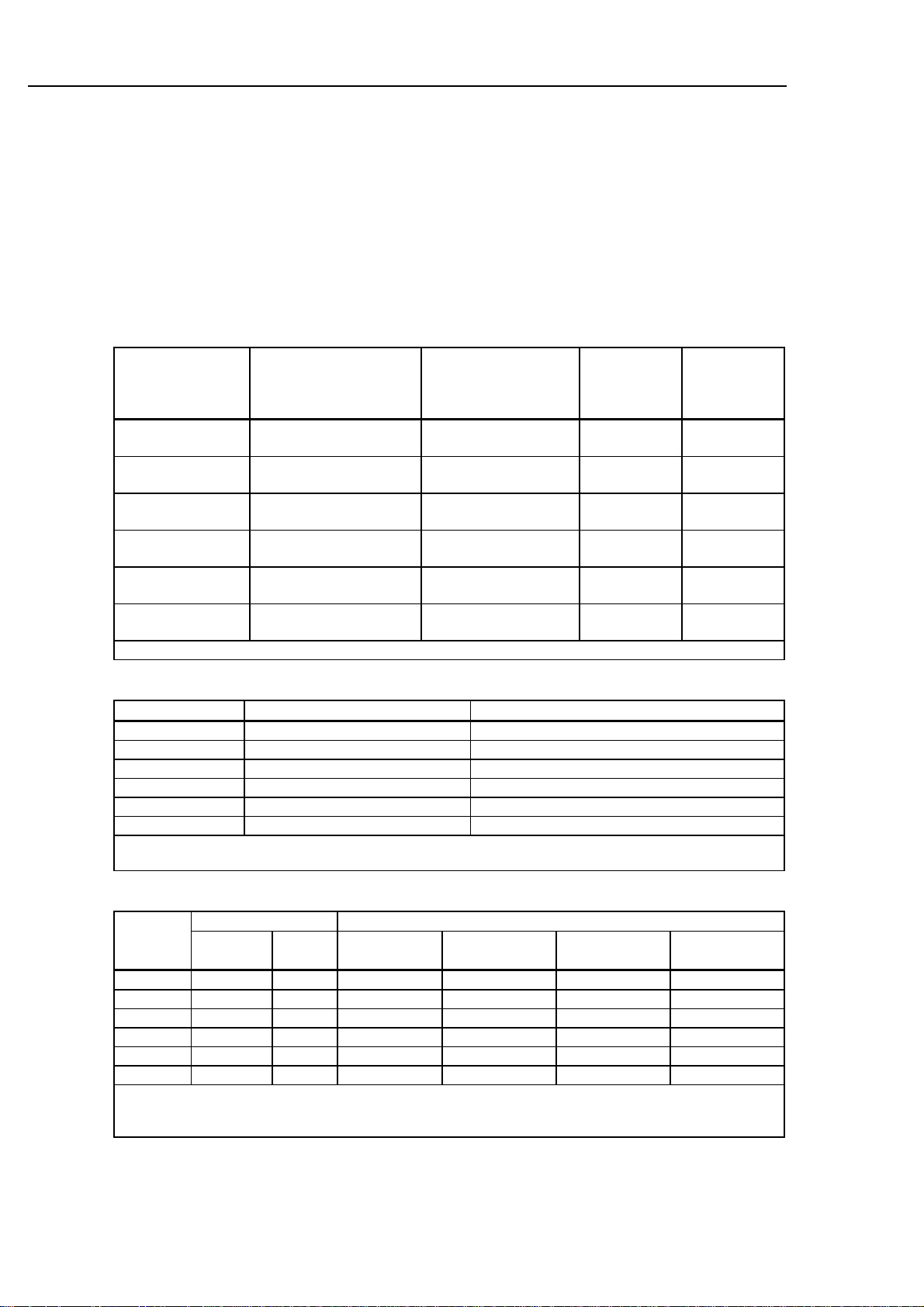

Conductance [±(percent of reading + counts)]

Range Resolution Accuracy

300.00 nS 0.01 nS 0.5% + 20 3.2V

3000.0 nS 0.1 nS 0.5% + 20 3.2V

Overload Protection: 1000V rms

Open Circuit

Capacitance [±(percent of reading + counts)]

Range Resolution Accuracy

10000 pF

.1000 µF 100 pF 1.9% + 2

1.000 µF 1 nF 1.9% + 2

10.00 µF 0.01 µF1.9% + 2

100.0 µF0.1 µF1.9% + 2

1000 µF1 µF1.9% + 2

10000 µF

Overload Protection: 1000V rms

1. 10,000 pF range last digit reads zero.

2. 10,000 µF range last two digits read zero.

3. Using REL to zero internal offset.

1

2, 3

10 pF 1.9% + 20

100 µF 10% + 900

Voltage

Introduction and Specifications

Specifications

1

Continuity Beeper Values

Range Beeper On Beeper Off

300Ω 32Ω 136Ω

3 kΩ 212Ω 725Ω

30 kΩ 1586Ω 4799Ω

300 k Ω 15.3 kΩ 45.5 kΩ

3 MΩ 152.7 kΩ 459.1 kΩ

30 MΩ 66 kΩ 194 kΩ

Resistance [±(percent of reading + counts)]

Range Resolution Accuracy Maximum

Current

300.00Ω 0.01 Ω 0.07% + 10 1 mA 3.2V

3.0000 kΩ 0.1 Ω 0.07% + 2 120 µA1.5V

30.000 kΩ 1 Ω 0.07% + 2 14 µA1.5V

300.00 kΩ 10 Ω 0.07% + 2 1.5 µA1.5V

3.0000 MΩ 100 Ω 0.15% + 2 150 nA 1.5V

30.000 MΩ 1 kΩ 0.2% + 3 320 nA 3.2V

Open Circuit

Voltage

1-11

867B,863

Service Manual

Frequency

AC Sensitivity

AC Volts AC Current

Frequency Sine Wave

Level

2 Hz - 500 kHz 60 mV rms 5 Hz - 30 kHz 300 µA - 300 mA 20% of range

500 kHz - 1 MHz 100 mV rms 5 Hz - 2 kHz 3A 300 mA

1 MHz - 2 MHz* 1V rms 5 Hz - 2 kHz 10A 3A

* Use single trigger mode for inputs above 1 MHz.

Frequency Ranges Sine Wave

Level

Accuracy [±(percent of reading + counts)]

Range Resolution Accuracy

1000.00 Hz 0.01 Hz 0.05% + 2

10.0000 kHz 0.1 Hz 0.05% + 1

100.000 kHz 1 Hz 0.05% + 1

1.00000 MHz 10 Hz 0.05% + 1

2.0000 MHz 100 Hz 0.05% + 1

Duty Cycle

Range: 0.1% to 99.9%

Accuracy: ±(5.2% divided by the pulse width in microseconds + 2 counts) (1 ms = 1000 microseconds).

Period

Ranges: 999.99 µs, 9.999 ms, 99.99 ms, and 999 ms

Accuracy: ±(0.05% of reading + 2 counts)

Pulse Width

Ranges: 999.99 µs, 9.999 ms, 99.99 ms, and 999 ms

Accuracy: ±(5.2% divided by the pulse width in microseconds + 2 counts) (1 ms = 1000 microseconds).

1-12

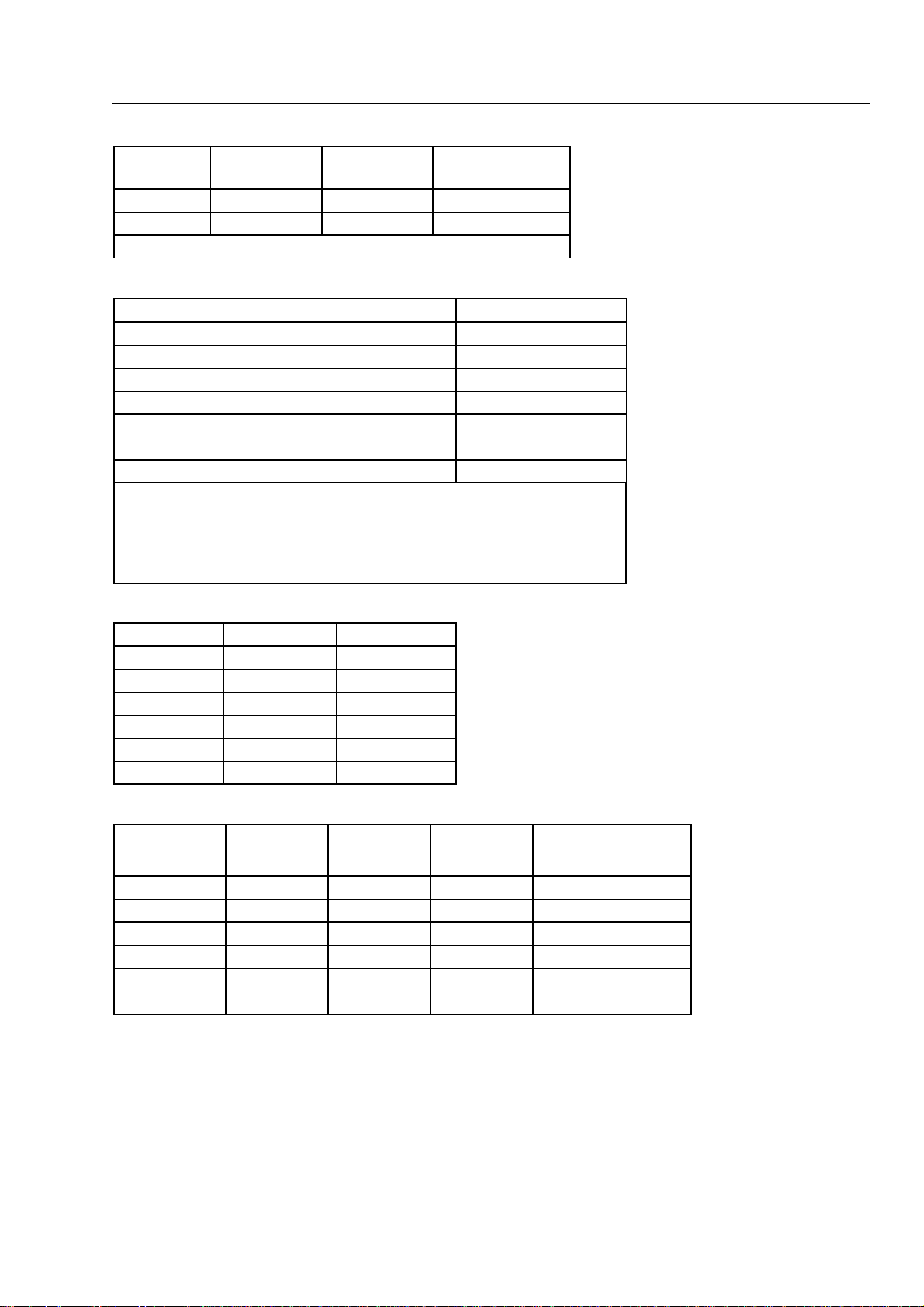

Logic (Fluke 867B Only)

Trigger Levels

Logic Family Low High

3V CMOS 1.4V 1.7V

5V CMOS 2.6V 2.8V

TTL 1.7V 1.9V

1. Frequency measurements will trigger on the

logic family high levels. All measurements are

made using the Logic/Ext. Trig. input jack.

2. For frequency > 1 MHz use full logic level.

Frequency Measurements

Frequency Resolution Accuracy

1

Introduction and Specifications

Specifications

1

1000.00 Hz

10.0000 kHz

100.000 kHz

1.00000 MHz

2.0000 MHz

10.0000 MHz 100 Hz 0.05% + 1

0.01 Hz

0.1 Hz

1 Hz

10 Hz

100 Hz

0.05% + 2

0.05% + 1

0.05% + 1

0.05% + 1

0.05% + 1

1-13

867B,863

Service Manual

Component Test

Peak Hold

MIN/MAX/AVG

View Mode Specifications

Frequency Capacitance

2 Hz 0.72 µF to 72 µF

20 Hz 0.072 µF to 7.2 µF

200 Hz 7200 pF to 0.72 µF

2 kHz 720 pF to 0.072 µF

18.75 kHz 77 pF to 7700 pF

Captures peak minimums and maximums of signals ≥10 µs.

Accuracy: ±(5% of reading + 30 counts)

Accuracy: add 8 counts to the number of counts in the accuracy table of the selected function.

Horizontal Specifications

Sample Rate: 4.8 Megasamples per second

Sample per Division: 20 per horizontal division

Samples Captured: 512 in Single Shot and Glitch Capture; 256 all other modes

Update Rate: 4 times per second

Time Base

Modes: Single Shot and Recurrent

Ranges: From 4.2 µs per division to 5 seconds per division

Trigger

Types: Internal and External

Coupling: AC, DC and Glitch Capture

External Trigger Impedance: 1 MΩ in parallel with ≤75 pF

External Trigger Input: Logic/External Trigger Terminal

External Trigger Level: ±5V adjustable in ±10 steps

Amplitude Specifications

Amplitude Resolution: 8 bits

Frequency Response (-3 dB)

Volts DC Coupled: DC to 1 MHz

Volts AC Coupled: 3 Hz to 1 MHz

1-14

Input Impedance

Refer to the meter mode specifications

Glitch Capture

Glitch Trigger Level: 20% of range 300 mV - 300V

6% of range 1000V

Minimum Glitch Time: 1 µs

Chapter 2

Theory of Operation

Title Page

2-1. Introduction............................................................................................. 2-3

2-2. Start-Up Sequence .............................................................................. 2-3

2-3. Function Selection .............................................................................. 2-3

2-4. Power Supply .......................................................................................... 2-4

2-5. Power Supply Input Voltages ............................................................. 2-4

2-6. Power Supply Output Voltages and Currents..................................... 2-6

2-7. Power Supply Signals ......................................................................... 2-7

2-8. Power ON/OFF Requirements............................................................ 2-8

2-9. NiCd Charging Requirements............................................................. 2-8

2-10. Battery and Line Level Detection....................................................... 2-8

2-11. Power Supply Functional Blocks............................................................ 2-9

2-12. Input Power Selector (A) .................................................................... 2-9

2-13. Boost Preregulator (B)........................................................................ 2-10

2-14. Battery Charger (C) ............................................................................ 2-10

2-15. DC-DC Converter (D) ........................................................................ 2-12

2-16. Backlight Current Sink (E) ................................................................. 2-12

2-17. Power Switch Circuitry (F)................................................................. 2-12

2-18. LCD Contrast Control (G) .................................................................. 2-12

2-19. Power-On Reset Circuit (H) ............................................................... 2-12

2-20. Linear Post Regulators (I)................................................................... 2-13

2-21. Input Overload Protection....................................................................... 2-13

2-22. Volt/Ohms Input Protection................................................................ 2-13

2-23. External Trigger and Logic Activity Input Protection........................ 2-14

2-24. Amps / mA / µA Input Protection....................................................... 2-14

2-25. Input Signal Conditioning....................................................................... 2-14

2-26. AC Volts ............................................................................................. 2-14

2-27. DC Volts ............................................................................................. 2-16

2-28. mV DC................................................................................................ 2-16

2-29. Ohms................................................................................................... 2-17

2-30. Diode Test........................................................................................... 2-17

2-31. Capacitance......................................................................................... 2-17

2-32. mA/µA ................................................................................................ 2-18

2-33. Amps................................................................................................... 2-18

2-34. Waveform Processing ............................................................................. 2-19

2-35. Overview............................................................................................. 2-19

2-36. Detailed Description ........................................................................... 2-19

2-1

867B,863

Service Manual

2-37. Waveform Triggering.............................................................................. 2-20

2-38. Overview............................................................................................. 2-20

2-39. Dual Trigger........................................................................................ 2-20

2-40. Single Trigger ..................................................................................... 2-21

2-41. External Trigger.................................................................................. 2-21

2-42. Glitch Capture..................................................................................... 2-22

2-43. Single Shot.......................................................................................... 2-22

2-44. Frequency Trigger .............................................................................. 2-22

2-45. Logic Activity Trigger........................................................................ 2-22

2-46. Peak Hold................................................................................................ 2-22

2-47. Auto Diode.............................................................................................. 2-22

2-48. Component Test ...................................................................................... 2-23

2-49. Digital Circuitry...................................................................................... 2-24

2-50. RS-232 Serial Port .................................................................................. 2-24

2-2

Theory of Operation

Introduction

Introduction 2-1.

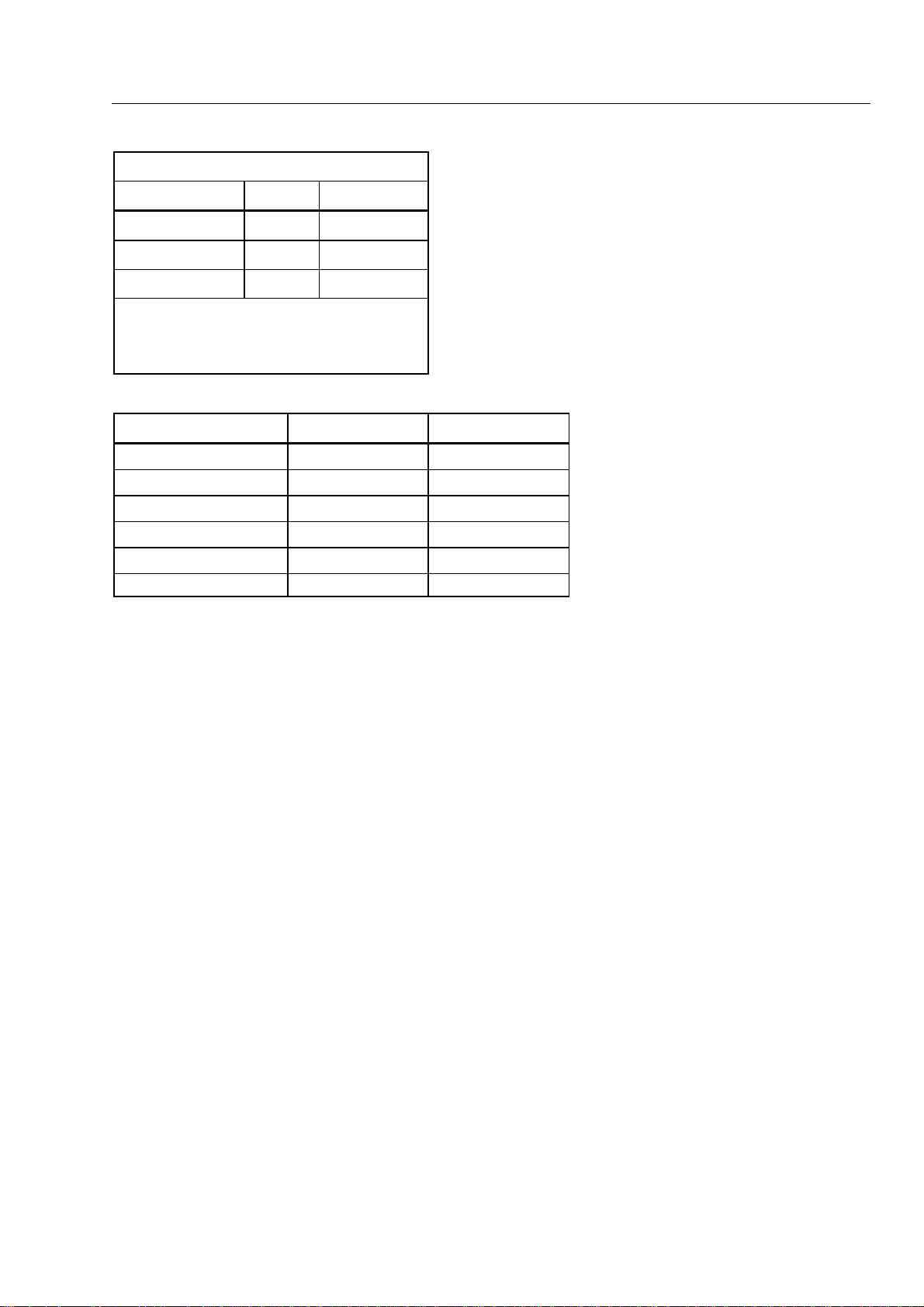

This chapter describes the functional blocks shown in Figure 2-1. Overall descriptions

are broken down into Power Supply, Analog Circuitry, and Digital Circuitry.

For all measurements, inputs (e.g., Ë and â) are applied through overvoltage

(and overcurrent) protection circuits, switched to an appropriate range, and branched into

two signal paths. One path leads first to a Fast A/D Converter (8-bit, 4.8-MHz sample

rate) that digitizes the data, then to a digital gate array that stores and processes the data.

The other path leads to a Slow A/D Converter (high accuracy, dual slope) in the U30

custom IC. The microprocessor takes data from both the Slow A/D Converter (U30) and

the custom digital IC (U24) storage to simultaneously display a waveform and a 4-1/2

digit meter reading. Power supplies include 5.2V dc and -5.2V dc for analog circuitry,

3.3V dc for digital circuits, and VEE (nominally -23V dc) for the LCD module.

Start-Up Sequence 2-2.

The GMM sequences through the following steps when power is applied:

• The 3.3V power supply comes up.

• The reset pin on the microprocessor (U25-1) goes high.

2

• The microprocessor (U25) begins executing the program stored in EEPROMs U11

and U19.

• LCD controller (U13) data is initialized.

• VEE is turned on (-20V dc), and the display comes on.

Function Selection 2-3.

When the selector is turned to a new function, a rotary switch wiper sets up a resistor

divider by grounding the selected resistor in series with R170. The resulting voltage is

read by the microprocessor (U25-83).

2-3

867B,863

Service Manual

Power Supply 2-4.

The GMM can be powered with a Fluke BP7217 rechargeable battery pack (6 - 4/3A

NiCd cells), 6 AA alkaline batteries, or a battery eliminator. The GMM automatically

detects power by source (NiCd battery pack, AA alkaline batteries, or battery

eliminator.) Diodes provide reverse polarity protection for the batteries.

The NiCd battery pack recharges in a minimum of 16 hours when the GMM is not

operating or at a trickle rate while the GMM is operating. Only cells in the Fluke BP7217

battery pack can be charged internally. Internal charging is not available with Model 863.

Caution

Do not attempt to place other batteries in the BP7217 battery

pack; damage to the batteries could result.

A low battery indicator ( ) comes on when battery voltage drops below a preset

++++

voltage level. This level is the same for all types of batteries: remaining battery life can

vary from minutes to hours, depending on battery type, ambient temperature, and battery

history. A low-battery power down can also occur. (No automatic power down occurs

when the GMM is powered by the battery eliminator.)

Refer to Chapter 1 for battery and battery eliminator specifications.

Power Supply Input Voltages 2-5.

Refer to Table 2-1.

Table 2-1. Power Supply Inputs

Input Source Voltage Lifetime (w/o Backlight)

Line 12 ±5% volts --

NiCd Battery Pack (Fluke BP7217) 6-10 volts 867B : ≥ 8 hrs typical

863: ≥ 10 hrs typical

Alkaline (6-AA) 5.5-10 volts ≥ 8 hrs typical

2-4

Theory of Operation

Power Supply

2

Adjust

LCD

Contrast

RS-232

To /F ro m

240 x200, Backlight

LCD Module - Drivers,

4 1/2 Digit

To/From uProcessor

ADControl

U21

U13

RIC

To /F r o m

LCD Controller

1335

I/O

Dsiplay

SRAM

32 x 8

A/D

(25 bits)

2 Frequency

Counters

Multiplexer

H8

I/O

INT1

Module

Keyboard

(25 bits)

Reference

Counter

CLK

MICROPROCESSOR

U25

Data

Addr

EEPROM

Status and

Control R egs

Circuitry

Divide by

U11, U19

Acquisition Cnt.

Min

ROM

(Trigger) Circuit

4.8 MHz

2 128 x 8

Addr

CompareCompare

U10

Flash A/D

U20

SRAM

32k x 8

System

Acq.

Ram

512 x 8

Data

RIC Function Blocks - U30

DIC Function Blocks - U24

Max

DAC1

8 bit/10 Mhz

DAC2

SWCrtl13

Circuitry

UART

SWCtrl3

SWControl

Ohms/

SWCrtl10

U11

10Bit DAC

Component

DACData

DC Filter

ADControl

DC Input

Capacitance

Source

Test Source

Protection

Volts/ohms

SWCrtl1

SWCrtl0

Attenuation

-5.2 volts

5.2 volts

AC Input

BATTELIM

Voltage VEE

LCD

3.27 volts

Dual

U3 RMS

Converter

Attenuation

& x10 gain

BATTLVL

BATTTYPE

To uProcessor A/D

To u P r o ce s s o r A/ D

Power Supply

Trigger

Comparators

Te st

DC Level

DAC)

DACL1

DACL2

ACR1-4

To uProcessor A/D

POWER_DOWN*

(Comp.

From uProcessor

Filter

Circuit

x1/10,x1,x10

Combination/

Multiplexer

Attenuation

Logic Activity/

External Trigger

Trigger

External

Logic Activity/

DACL2

DACL1

IR1

mA/A

uA

Wakeup* to Power Supply

To uProcessor A/D

Rotary

Switch

SWCtrl6

Voltage

Tes t

Component

Current to

SHUNTS

Switching

Current

AMPS

mA/uA

Volts/Ohms/Current

Component Test

COM

Figure 2-1. Block Diagram

os2f..eps

2-5

867B,863

Service Manual

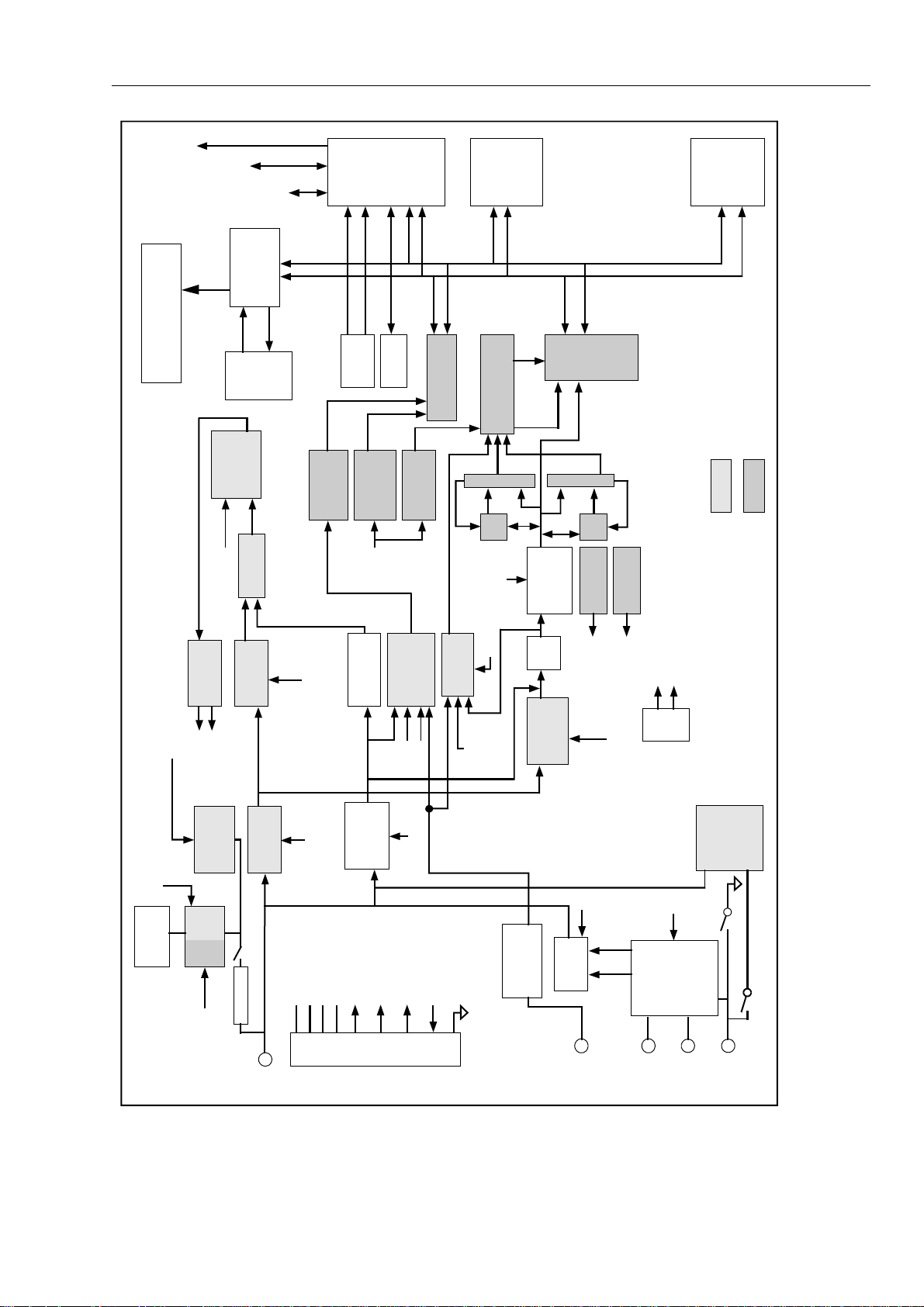

Power Supply Output Voltages and Currents 2-6.

Refer to Table 2-2.

Table 2-2. Power Supply Outputs

Name Voltage

VDD 5.2V 0.26 5.0% 50 mV rms** 43 mA 224 mW 0.2V p-p maximum noise

VAD 3.27V 0.07 2.0% 50 mV rms** 12 mA 40 mW ±0.02%/C max

VCC 3.27V 0.07 2.0% 50 mV rms** 82 mA 271 mW VAD and VCC are tied

VSS -5.2V 0.26 5.0% 50 mV rms** 32 mA 166 mW 0.2V p-p maximum noise

VEE -20V na 5 mA 115 mW TC = -38 mV/°C, center

IBL+ * 4V ±15% na 80 mA 264 mW current for backlight

IBL- na Current Return for IBL+,

* IBL is controlled by a linear current source taken from unregulated DC.

** Measured with an 8842A in AC rms mode.

Tol ±±±± V Tol ±±±±%

Ripple

(peak to

peak)

mA Power Notes

to 1 MHz BW

together, unregulated

DC used for IBL+

to 1 MHz BW

value adjusted and

stored at test

LED, ±15%

max 1.5V burden voltage

2-6

Theory of Operation

Power Supply

Power Supply Signals 2-7.

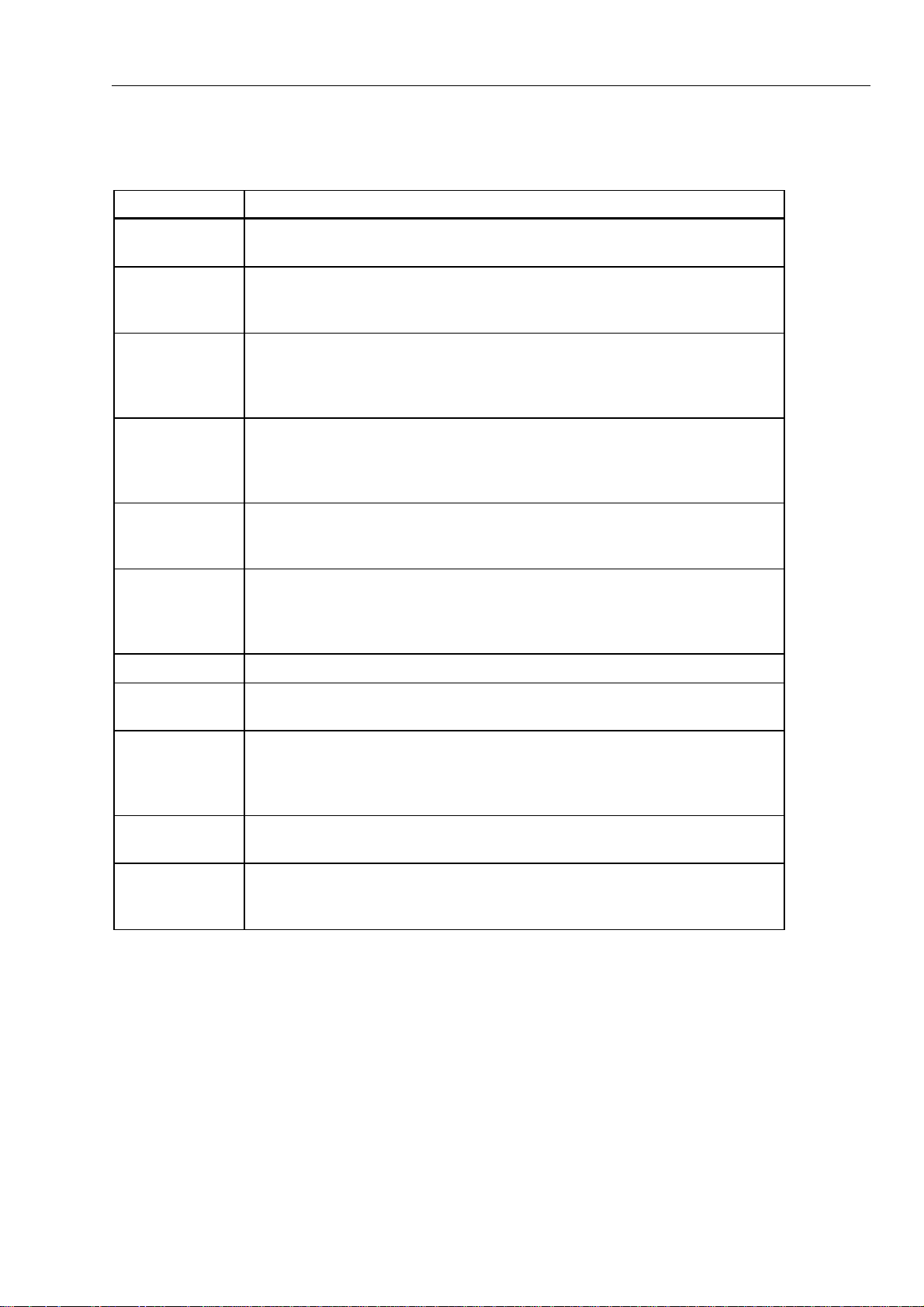

Table 2-3. Power Supply Signals

Signal Name Description

BACKLIGHT_ON* Control signal generated by U25. In Model 867B, this signal toggles the backlight

power levels.

BATT_LVL Monitors an attenuated (0 to 5V) version of the raw battery voltage. This signal is

monitored by the U25 microprocessor A/D Converter. The attenuation factor is

0.0909:1 with an output impedance of approximately 91 kΩ.

BATT_TYPE Monitors an attenuation level of the battery charging voltage. The attenuation ratio is

0.0901:1 with an output impedance of approximately 91 kΩ.=If the measured voltage

is greater than 11 volts, the battery is assumed to be an alkaline cell. Voltages 10.5

volts and below indicate that a Fluke BP7217 battery pack has been installed.

BATT_ELIM This is a contact on the battery eliminator input receptacle. It is pulled to LINE with 5

kΩ and tied to GND4 through=475Ω,=forming a 10.51:1 divider. If open (voltage

>1.0V), a line-powered battery eliminator has been installed. If closed (shorted to

ground), the battery eliminator is not plugged-in or is not powered.

2

CONTRAST PWM signal from U25. The frequency is set at U25_SYSCLK/(CLOCK_DIVIDER x

COUNTER_LIMIT), yielding 4.8 MHz/(4 x 4096), equaling 293 Hz. The PWM signal

has 12-bit resolution, which can vary the duty cycle from 0 to 100%.

IBL+ Current source generated by power supply used to run the LCD backlight. Current

source is controlled by the BACKLIGHT_ON* control signal. Typical current level is

80 mA. This is the sourcing node derived from unregulated DC, typically +6.0V

(5.8V minimum.)

IBL- Current return for IBL+, with approximately 1V burden.

POWER_DOWN Powers down the GMM. Signal is generated by U25. This signal shuts the GMM off

completely. Pulled-down to GND with 20 kΩ.

PWR_RESET* Signal generated by the power supply when the VCC power supply drops below 3.0

volts. The reset lasts 100 milliseconds minimum. If the selector is left in the OFF

position or the GMM is powered down, the PWR-RESET* signal restarts the 100 ms

time-out period. This signal is pulled up to VCC by 10 kΩ .

VEE_ON Control signal generated by U25. Turns the VEE power supply on and off. Pulled

down to ground by 100 kΩ .

WAKEUP* This signal is generated by both the rotary selector switch and the WAKEUP button.

Upon going LOW, followed by a return to HIGH, the GMM powers up. In the OFF

position, this feature is overridden by the OFF switch.

2-7

867B,863

Service Manual

Power ON/OFF Requirements 2-8.

NiCd Charging Requirements 2-9.

The GMM is turned off when the selector is rotated to OFF. If the selector is

immediately rotated beyond OFF, the GMM does not turn off. If the selector remains in

OFF for 125 ms, GMM software recognizes a valid OFF signal. If the selector remains in

the OFF position for more than 250 ms and an OFF signal is not generated, a hardware

timeout occurs and the GMM powers off.

The signal PWR_RESET* goes true (LOW) immediately when a software OFF signal or

hardware timeout is generated. This action forces a complete restart sequence, with

PWR_RESET* remaining low for at least 100 ms.

After a software OFF signal has occurred, turn the GMM on by rotating the selector to

any function or by pressing (the WAKEUP button.). If a hardware timeout has

occurred, pressing does not turn the GMM on; the selector must be rotated to a new

function.

Models 867B use an internal two-state charger. The initial charge state is at

approximately 170 mA (±30 mA) to allow for full overnight charging (16 hours

minimum). The second charge state is at approximately 40 mA (±15 mA) to allow for

battery charge maintenance without full charging from a discharged condition.

A timer (reset each time the battery eliminator is plugged in) controls the charge state.

The rate shifts to 40 mA after approximately 16 hours of accumulated charge time.

The 40-mA rate is used with batteries below approximately 6 volts to limit the amount of

power dissipated when a completely dead battery pack is used. After this 6-volt cutoff

point has been reached, the GMM starts charging at 170 mA.

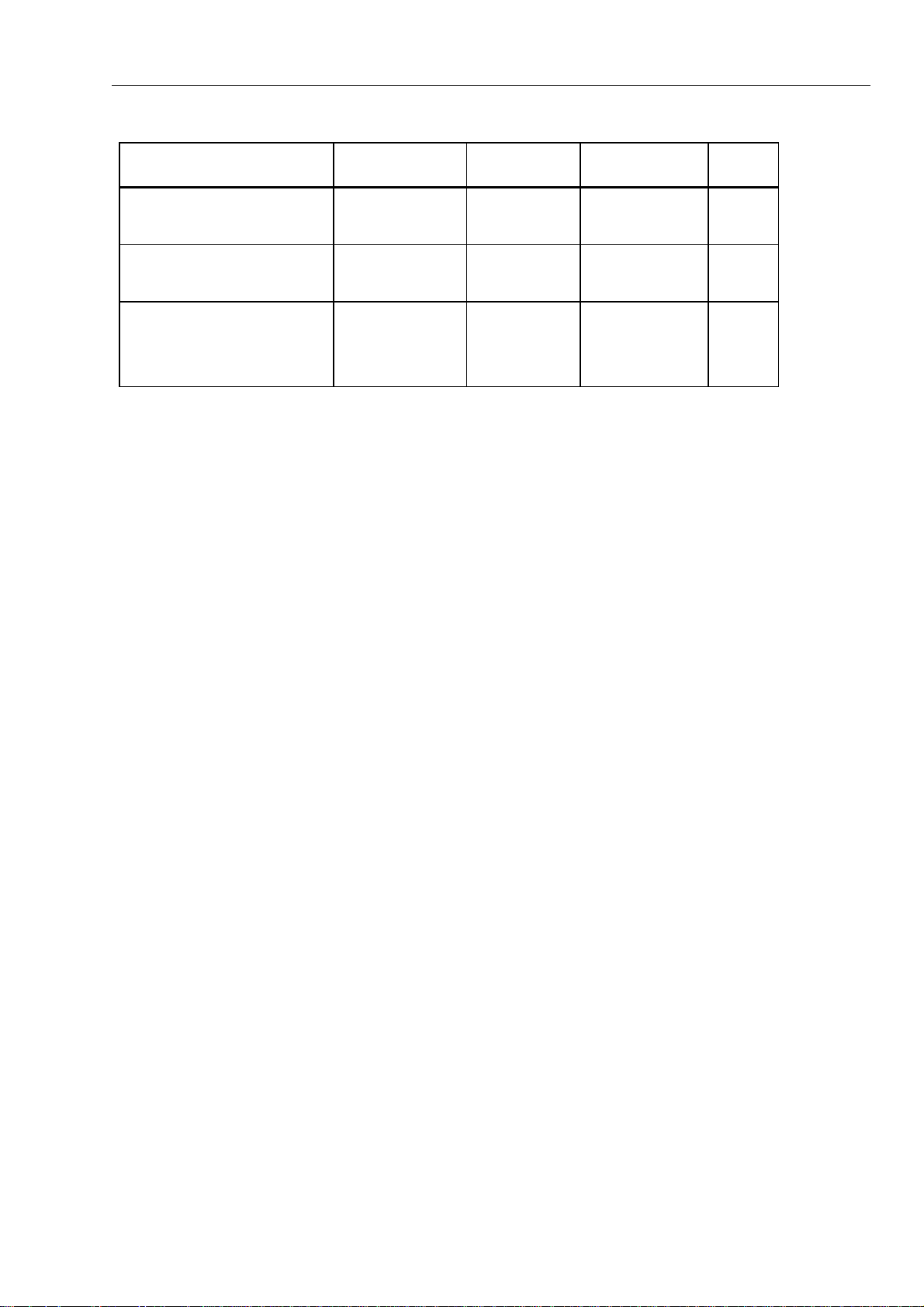

Battery and Line Level Detection 2-10.

The BATT_LVL signal is an attenuated version of the battery and charging voltages.

Table 2-4 summarizes the values to be used by the software to control LOW BATTERY

detection and SOFT SHUTDOWN. After LOW BATTERY is detected, the backlight is

turned off and backlight control is disabled.

2-8

Table 2-4. Power Source Detection

Theory of Operation

Power Supply Functional Blocks

2

POWER TYPE DETECTION

Battery Eliminator connected BATT_ELIM

≥ 1.0 Volts

NiCd Battery Pack installed BATT_TYPE

5 ≤ V ≤10.5 Volts

Alkaline (AA) Batteries installed BATT_TYPE

V ≤ 4.5 or

V ≥ 11 Volts

LOW BATTERY SOFT POWER-

OFF

na na 0.0951

6.2V 5.7V 0.0909

6.2V 4.8V 0.0909

SCALE

FACTOR

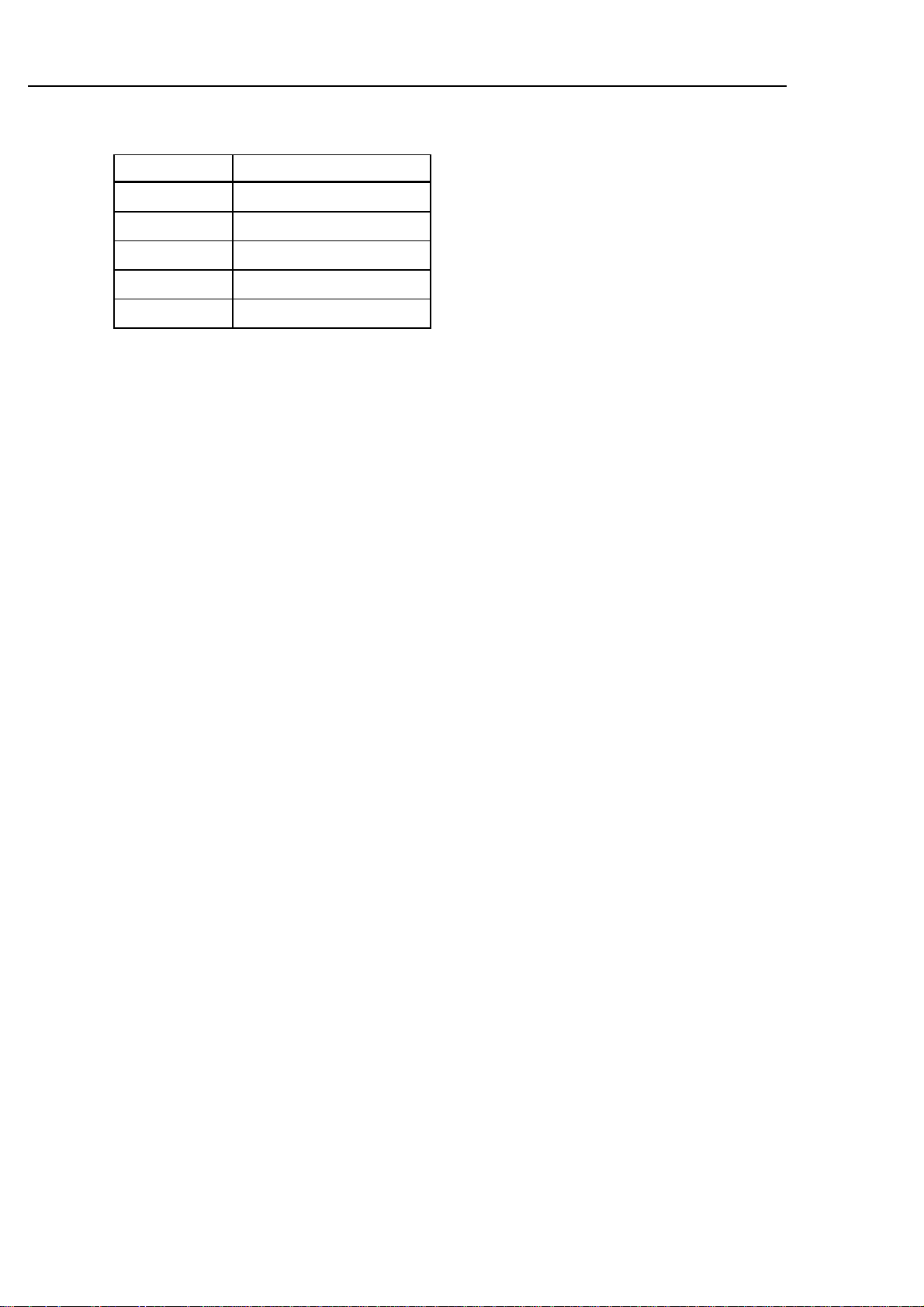

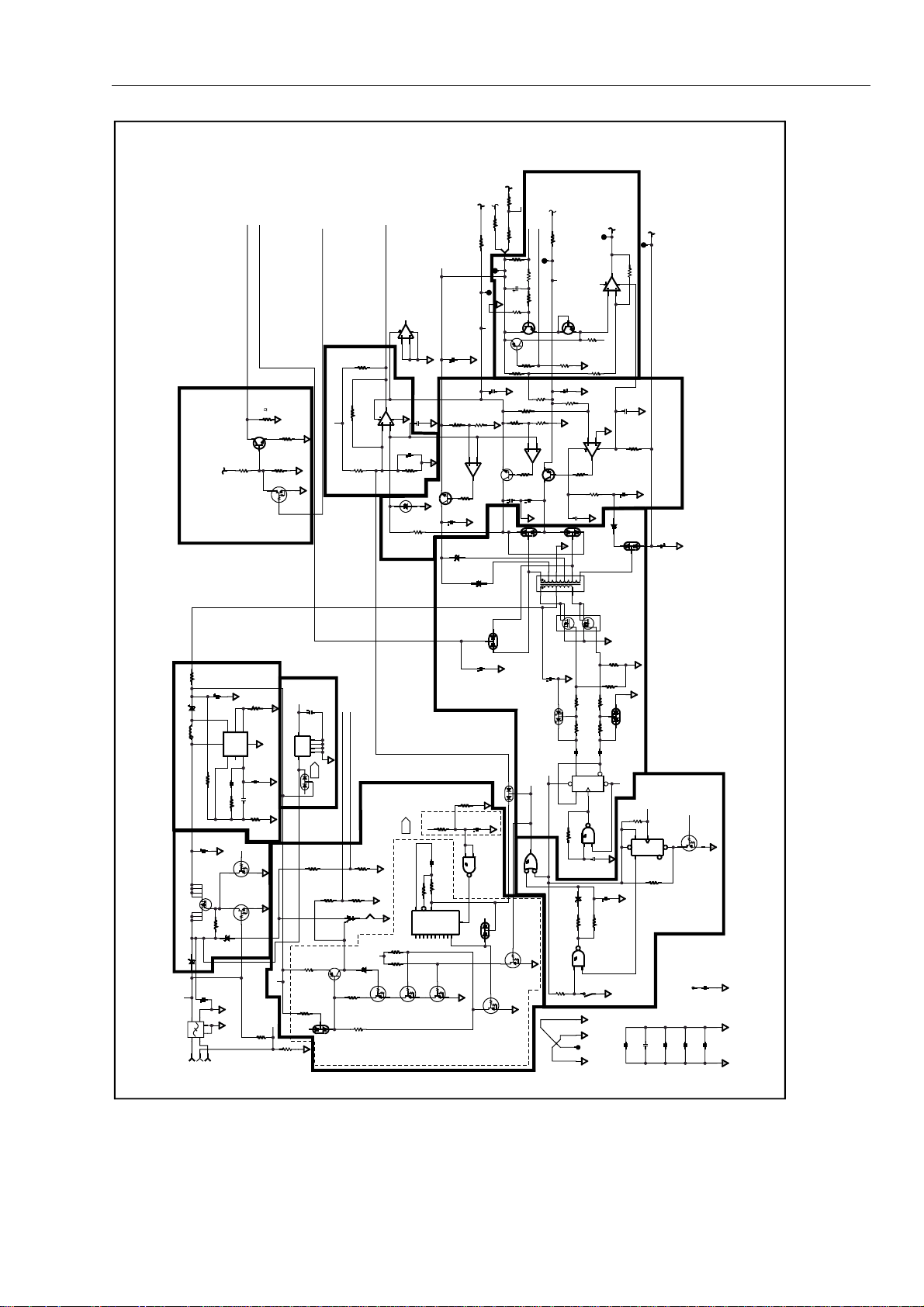

Power Supply Functional Blocks 2-11.

Refer to the Schematic Diagram in Chapter 7 during the following discussion. The power

supply consists of the circuit blocks listed below. Each block is identified with a letter

(A-J) keyed to Figure 2-2.

• Input power selector (A)

• Boost Preregulator (B)

• NiCd battery charger and timeout (C)

• DC-DC Converter (D)

• Backlight current sink (E)

• Power switch, wake-up and power down circuitry (F)

• LCD contrast control and temperature compensator (G)

• Power on reset (H)

• Linear post-regulators (I)

• +5 volt bias supply (J)

Input Power Selector (A) 2-12.

The input power selector automatically selects either battery eliminator power (line) or

battery. If a battery eliminator is connected to the GMM, +12 volts (±5%) is applied

through line filter FL1 to the anode of CR21. This 12 volts turns on Q13, which pulls

down the gate of Q14, turning it on. Current can then flow from the battery eliminator to

the boost circuit (B). Note that CR22 is back-biased.

If an eliminator is not connected, Q13 is off. Current is not allowed to flow through Q14

until Q12 is turned on. Q12 is turned on when enough voltage remains on the battery to

supply the bias regulator (J) and the power wake-up circuitry is enabled. When the GMM

is off (with no eliminator connected), Q14 is off and only the bias supply draws current.

The maximum off-state current draw is 100 µA.

CR21 and CR22 perform the power selection process.

2-9

867B,863

Service Manual

Boost Preregulator (B) 2-13.

Battery Charger (C) 2-14.

The boost preregulator outputs +15 volts from an input of +12 volts from the battery

eliminator or 5.5 to 10 volts from the battery.

U27 provides this boost in conjunction with L1, CR20, and C3. If U27 is not functioning,

the voltage at the positive of C3 is approximately 0.4 volts below the voltage on C90.

R114 provides peak current limiting to prevent rapid burnout of the boost circuit in the

event of an overload. Since R114 requires a functional U27, it does not provide complete

protection. R12 and R73 set the output voltage, while the other discrete components

provide timing and compensation for the regulator.

The output of this stage is delivered to the NiCd battery charger (C) and to the DC-DC

converter (D). R125 allows the charger and boost circuit to be tested independently of

the rest of the GMM. R125 is especially useful if a large load causes <15 volts at the

cathode of CR20.

The battery charger consists of the following two sections:

• Q22 and its associated components provide a linear current source of either 170 mA

or 40 mA to charge the NiCd battery. Transistors Q1, Q2, Q3, Q6, and Q11 provide

logic control of the charger state.

• The other part of the circuit is U32 and its associated components, which provide a

timeout of at least 16 hours to prevent continuous overcharging of the battery. This

circuit is reset each time a battery eliminator is plugged in (via U34, R141, R140

and C91).

A full charge of approximately 170 mA can only be provided to the battery if Q1, Q2,

and Q6 are turned on, Q3 is off, and Q11 is off. These states correspond to the GMM

being connected to line but turned off and U32 not being timed out. U32 is inhibited

from advancing by CR5 when power is on.

VR1 prevents Q2 from turning on until the battery voltage rises above about 5.8 volts.

This prevents excessive power dissipation in Q22 with a dead battery or shorted cells.

Note

The Fluke battery pack (BP7217) uses an extra wire to allow charging

current to flow. If individual batteries are installed, no connection is made,

and no charging current can flow.

2-10

Theory of Operation

Power Supply Functional Blocks

VCC

+3.3

0

VDD

VAD

RIC_VCC

R60

+5.2

IBL-

IBL+

BACKLIGHT_ON*

PWR_RESET*

INT_VCC

0

R87

0

R52

TP5

TP4

7

U22

LM393DT

RES

8

4

6

5

10.0K

R115

U22

R158

47

(867B only)

D

0

R16

Q21

4401

1

80 MA

BACKLIGHT

CURRENT SINK

3.24K

R106

VDD

E

0.2 (867B only)

D

3.24K

R11

D

D

10K

MUN2211

Q5

LM393DT

R124

3.32M

INT_VCC

8

3

6.34K

R69

H

D

1

RES

0.1UF

C58

25V

CER

D

4

D

2

10UF

C19

20%

16V

D

R81

31.6K

4401

+2.5V

U31

Q23

D

C9

LM4040-2.5

R119

10.0K

D

INT_VDD

1UF

C2

20V

D

1UF

C88

20V

3.24K

R128

R132

10.0K

D

6

5

4401

Q18

VCCDRIVE

7

MC33172

U2

475

R72

10UF

20%

16V

D

CR19

1N5817

CR18

1N5817

VSS

VEE_ON

CONTRAST

0

R62

R48

M2

TP1

10.0K

R35

R8

10.0K

10UF

C62

6V

R43

221K

221K

R41

6429

Q17

100K

R143

Q10

5087

R123

R116

1.82K

D

5.62K

10.0K

R19

10.0K

10.7K

R39

R89

3

2

U4

MC33172

VDDDRIVE

1

475

R133

1UF

C65

1UF

C61

20V

20V

D

CR16

MMBD7000

1

7

G

-5.2

VEE

-20

-24V

0

INT_VSS

Q19

4403

8

TP2

TP3

1

CONTRAST

CONTROL

LCD

Q20

6429

R142

100K

1UF

C12

20V

10.0K

R13

D

+REG

R46

0.22UF

C63

D

65432

9

8

7

5

R50

316K

MC33172

U2

VCCDRIVE

8

4

INT_VDD

3

2

R120

59.0K

INT_VSS

D

18.7K

R9

D

D

6

5

8

4

U4

7

475

MC33172

VDDDRIVE

475

R94

CER

D

VR2

CR17

MMBD7000

T1

RITA-6303

6

TPS ARE 40MIL PADS

0.22UF

C34

CER

-REG

D

I

475

R117

1UF

C1

35V

D

5240B

CR6

MMBD7000

1UF

C71

35V

D

2

1

3

2

4

Q16

CR12

BAV74

1UF

C21

20V

0

R125

D

R114

0.2

C3

25V

CR20

20%

220UF

1N5817

21

L1

330UH

8

VS

INM COL

1

140.0K

R12

2200PF

C59

BA

R122

D

C90

25V

20%

220UF

8765

SI9430DY

Q14

4

321

R137

100K

CR22

CR21

1N5817

10UF

C60

35V

LINE

CBB

D D

CBB

GND

FL1

PSG CG1

312

P3P3P3

D

765

LM3578AN

EMIT

CLIMOSC

4

D

GND

INP

3

2

680PF

C56

CER

CER

22PF

C23

CER

221K

D D

R73 U27

10.0K

POK-1

Q12

MUN2211

10K

D

Q13

MUN2211

D

10K

1N5817

+15

BATT_ELIM

4.99K

R7

J

+5B

16V

C85

10UF

20%

1

7632

BATT_LVL

BATT_TY PE

OUTIN

GND

U15

LM2936M

D

8

4

CR8

MMBD7000

C

100K

R141

LINE

5

1.00MEG

R14

12.1

R113

1/2W

1.82K

R74

D

R6

475

100K

R27

D

100K

R29

1.00MEG

R56

D

M4

D

BT1

6-4/3A

VR1

LINE

5231B

Q22

MJD32

10%

R15

6.49K

R55

10K

Q2

MUN2211

24.9K

R100

CR9

MMBD7000

10UF

16VAL20%

C84

R68

R44

1.00MEG

464K

111097

CKI

CKO

CKO*

+5B

U32

74HC4060DT

Q5Q6Q7Q8Q9

Q10

Q12

Q13

Q14

Q4

1

6

5

3

2

4

151413

100K

R28

100K

10K

10K

Q1

Q6

MUN2211

MUN2211

D

CR5

66.5K

R140

MMBD7000

D

1UF

C91

20V

D

5

4

+5B

U34

HC132

6

12

RESET

MMBD7000

CR15

D

10K

Q3

MUN2211

SI9955DY

1UF

C94

35V

D

CR14

BAT54S

+5B

POK-1

3

+5B

U34

HC132

1

2

10K

D

Q11

MUN2211

R126

D

M1

D

10.0K

R127

D

R23

22.1

R36

475

C57

CER

0.01UF

9

Q

U33

10

PR

HC74

D

11

12

11

U34

R10

10.0K

HC132

13

12

C22

CR25

BAT54

R138

100K

8

+5B

HC132

U34

9

10

S1

1.00MEG

3

5

1

TP6

D

D

10.0K

R131

D

R26

22.1

CR10

BAT54S

R17

475

CER

C24

0.01UF

8

Q

13

CL

+5B

POK-1

WAKEUP*

R57

100K

2

+5B

D

4

PR

HC74

Q

D

U33

5

CER

1%

470PF

1UF

C10

20V

D

R139

1.00MEG

D

OFF

C103

C104

CER

1000PF

MECCA CLIP TP

POWER_DOWN

3

10K

1

CL

+5B

Q

6

100K

R130

D

Q30

MUN2211

F

47PF

C117

5%

CER

D

WP1

PUT CAP AT

SHIELD SCREW

3

C105

C106

C107

CER

1000PF

CER

CER

CER

1000PF

1000PF

1000PF

D

Figure 2-2. Power Supply Blocks

os3f.eps

2-11

Loading...

Loading...