Fluke 8508A User Manual

8508A Reference Multimeter

Extended Specifications

Interpreting and applying

the specifications

Introduction

The Fluke 8508A has been designed specifically

for metrologists. Not only does it provide the

performance metrologists need, but it is specified

in a way to allow users to really understand the

uncertainties of the measurements, and easily

make allowance for those uncertainty contributions when performing measurement uncertainty

analyses and compiling uncertainty budgets.

Contemporary metrology practices, including

ISO 17025 based laboratory accreditation

schemes, require uncertainty analysis to be

performed in accordance with the statistically

based techniques described in the ISO Guide to

the Expression of Uncertainty in Measurement

(often referred to as the 'GUM'). For convenience,

the 8508A specifications are quoted at a coverage

factor of k=2, equivalent to a confidence level of

approximately 95 %, as required by these

methods. Specifications are also provided at a

confidence level of 99 %.

Performance specifications for the 8508A

consist of two elements; the first is a contribution

expressed as parts-per-million of the Reading,

and the second contribution is expressed as

parts-per-million of the Range. These must be

evaluated and combined for the relevant reading

and range values applicable to the measurement

being made, ensuring that both elements are

evaluated on the same basis, such as parts per

million of the measured value or in absolute

terms (volts, amps, ohms, etc). The two elements

are combined by adding algebraically. For

example, measuring 10 V on the 20 VDC range

and applying the 365 day ±1 °C specifications:

First, expressing the contributions in terms of

parts-per-million of the measured value.

Second, expressing the contributions in volts:

To realize the full potential of the 8508A performance, accepted metrology practices should

be employed, such as performing a zeroing or

null operation to remove any offsets present in

the measurement setup when making DC measurements. The 8508A specifications assume that

these methods are employed.

Absolute and Relative specifications

The Relative to Calibration Standards specifications describe the performance of the 8508A

itself for the time periods and temperature range

listed, excluding the uncertainty of the standards

used to perform calibration of the 8508A during

manufacture. The Absolute specifications

include the uncertainty of the standards used to

perform calibration of the 8508A at manufacture

and may be used to determine the uncertainty

of measurements made with the 8508A for

periods up to 1 year and over a temperature

range of ±5 °C from calibration. If the user has

their 8508A calibrated with different uncertainties,

the Relative specifications can be combined

with the uncertainties applicable to that

calibration to determine the effective absolute

uncertainty following that calibration.

Applying user’s calibration uncertainties

When the 8508A is calibrated by another

laboratory, the uncertainties of the calibration

standards used may be applied by combining

those uncertainties with the 8508A's Relative to

Standards specifications. The applicable

calibration uncertainties and the 8508A relative

specifications must both be expressed at the

same confidence level, and be combined in an

RSS (Root Sum Square) summation. Accepted

metrology practice mandates that calibration

uncertainties are stated at 95 %. Check the

applicable calibration uncertainties are stated at

95 % and then combine them with the 8508A

95 % Relative specifications. For example, if the

8508A is calibrated at 10 VDC with an

uncertainty of 1.5 ppm at 95 % the absolute

uncertainty at 10 V for a period of 90 days and

±1 °C from calibration is:

The 8508A is designed to provide accuracy

and stability without the need for internal auto

or self calibration routines which may otherwise

compromise the continuity and traceability of

measurement performance history.

2 Fluke Corporation 8508A Extended Specifications

Applying the specifications

Operating and calibration

temperature ranges

As a metrology tool, the 8508A will commonly

be used in a calibration laboratory where the

temperature would be controlled to ±1 °C, and

the 8508A ±1 °C specifications are applicable to

those situations. The majority of electrical

calibration laboratories operate at a nominal

temperature of 23 °C, the temperature at which

the 8508A is calibrated by Fluke during manufacture and service. The 8508A is also capable

of being calibrated at any temperature between

20 °C and 25 °C and the ±1 °C specifications will

apply to operation within ±1 °C of that calibration temperature. In the 8508A specification

tables, the temperature of calibration is referred

to as TCal. Specifications for ±5 °C are provided

for situations where the 8508A is operated in

environments with wider temperature variations

up to ±5 °C. For applications where the knowledge

of the effect of temperature on 8508A performance is important, temperature coefficients are

listed in the 8508A specifications. If the operating

temperature is within the range 15 °C to 30 °C,

the 15 °C to 30 °C temperature coefficient

specifications are applicable; otherwise use the

5 °C to 15 °C/30 °C to 40 °C figures, provided

the temperature lies within that range. The

8508A may be operated at temperatures

between 0 °C and 50 °C, but performance is not

specified outside the range 5 °C to 40 °C.

Applying temperature coefficient

specifications

The 8508A specification tables include

information for the typical operating conditions

of ±1 °C for calibration laboratories with tight

temperature control, and ±5 °C for calibration

laboratories with looser temperature control or

uncontrolled environments within that temperature range. For the majority of applications,

choosing the Absolute specifications for the most

appropriate operating temperature range will be

adequate. However performance at other

temperatures may be determined by including

an allowance for temperature coefficient over

the additional temperature range. Care should

be taken when making this calculation, as an

amount of temperature coefficient is already

included in the 8508A specifications, and those

specifications are themselves based on combining

contributions using techniques similar to those

employed in uncertainty analysis. For example,

consider operating at 33 °C, 10 °C from the 23 °C

calibration temperature. The ±5 °C specifications

already include a contribution for 5 °C of temperature difference, so this amount of temperature

effect must be removed before the effect of the

10 °C difference is added. Consider 10 V on the

20 VDC range: 365 day absolute specification

(95 %) at 33 °C expressed in parts-per-million of

10 V is:

The Fluke 8508A and 8508A-SPRT Standard

Platinum Resistance Thermometer

Fluke Corporation 8508A Extended Specifications 3

Applying the specifications

Ratio measurements

The 8508A Ratio mode will automatically take

measurements of inputs applied to the front and

rear terminals and display the result as a ratio in

the voltage and resistance functions. The

measurements can be made on the same range

or different ranges. When making measurements

on different ranges, the error in each measurement is evaluated by applying the relevant

specification for each range and combining the

two specifications in an RSS summation,

expressing the contributions in parts-per-million

of the measured values. For example, making

measurements of the ratio of 100 mV on the

200 mVDC range and 100 V on the 200 VDC

range, applying the 365 day ±1 °C Absolute

specifications:

Making measurements on the same range

will eliminate range-to-range errors, such as

drift since the time of calibration, and improve

the result. When making measurements on the

same range, these errors will affect both measurements and effectively cancel, leaving short

term noise and linearity as the dominant errors.

The 20 minute Transfer Uncertainty specifications are provided to describe the performance

obtained when making ratio measurements on

the same range. The error in each measurement

is evaluated by applying the relevant 20 minute

Transfer Uncertainty Specification for each value

and combining the two specifications in an RSS

summation, expressing the contributions in

parts-per-million of the measured values. If the

measurements are made within the same range,

but independently (not using the ratio mode)

with an elapsed time greater than 20 minutes

but less than 24 hours between the measurements,

then the 24 hour specifications should be

applied instead.

For example, making measurements of the

ratio of 5 V and 10 V on the 20 VDC range,

applying the 20 minute Transfer Uncertainty

Specifications:

Additional errors

The 8508A specifications are listed for the

maximum resolution in each function, using the

Normal reading mode. For measurements taken

in other resolutions or the Fast read mode

additional error contributions listed in the Read

Rate and Additional Uncertainty table must be

included. These additional contributions must be

added algebraically to the relevant specifications. For example, measuring 10 V on the

20 VDC range at 5 digit resolution in Fast mode

and applying the 365 day ±1 °C Absolute

specifications:

Other additional contributions apply in certain

situations and are also to be added algebraically

to the relevant specifications. These additional

contributions include the DC Accuracy specification to be applied when making DC measurements on the AC Voltage function when DC

coupled, and the High Voltage Adder when

making measurements above 300 V on the AC

function.

4 Fluke Corporation 8508A Extended Specifications

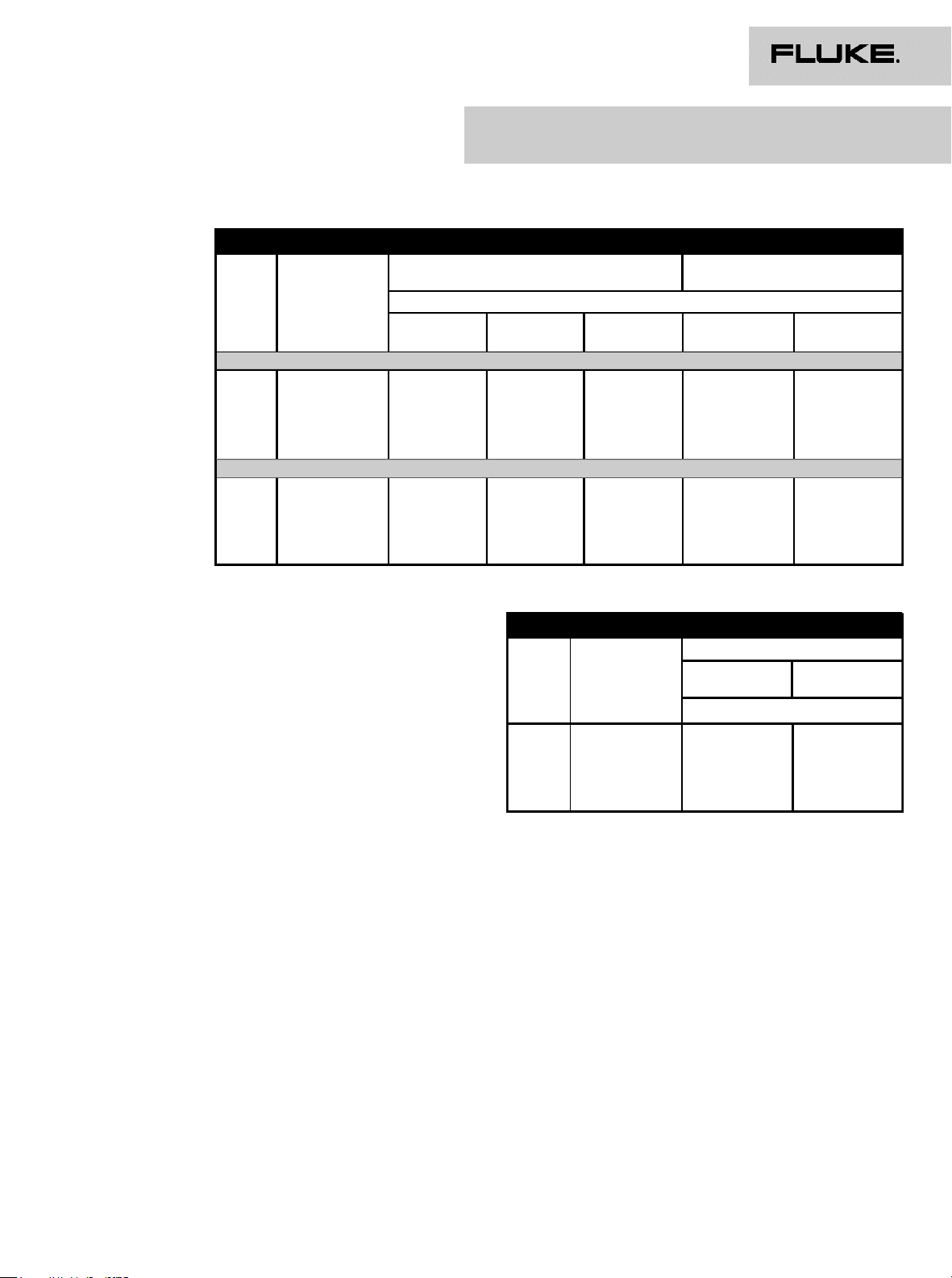

DC Voltage specifications

DC Voltage

Range

[1] [2] [3]

Full Scale Uncertainty Relative to Cal Stds

± (ppm Reading + ppm Range)

24 hour

TCal ±1 °C

90 day

TCal ±1 °C

365 day

TCal ±1 °C

Absolute Uncertainties

[4]

365 day

TCal ±1 °C

365 day

TCal ±5 °C

95 % Confidence Level

200 mV 199.999 999 0.7 + 0.5 1.4 + 0.5 2.7 + 0.5 4.5 + 0.5 5.0 + 0.5

2 V 1.999 999 99 0.5 + 0.2 1.4 + 0.2 2.7 + 0.2 3.0 + 0.2 3.5 + 0.2

20 V 19.999 999 9 0.5 + 0.2 1.4 + 0.2 2.7 + 0.2 3.0 + 0.2 3.5 + 0.2

200 V 199.999 999 1.0 + 0.2 2.6 + 0.2 4.0 + 0.2 4.5 + 0.2 5.5 + 0.2

1000 V 1050.000 00 1.0 + 0.5 2.6 + 0.5 4.0 + 0.5 4.5 + 0.5 5.5 + 0.5

99 % Confidence Level

200 mV 199.999 999 0.8 + 0.6 2.0 + 0.6 3.5 + 0.6 6.0 + 0.6 6.5 + 0.6

2 V 1.999 999 99 0.6+ 0.25 1.8 + 0.25 3.5 + 0.25 4.0 + 0.25 4.5 + 0.25

20 V 19.999 999 9 0.6 + 0.25 1.8 + 0.25 3.5 + 0.25 4.0 + 0.25 4.5 + 0.25

200 V 199.999 999 1.2 + 0.25 3.5 + 0.25 5.2 + 0.25 6.0 + 0.25 7.0 + 0.25

1000 V 1050.000 00 1.2 + 0.6 3.5 + 0.6 5.2 + 0.6 6.0 + 0.6 7.0 + 0.6

DC Voltage

Range

Transfer

Uncertainty

20 mins ±1 °C

± (ppm Reading

+ ppm Range)

(Secondary Specifications)

Temperature Coefficient

15 °C - 30 °C

± ppm Reading/°C

[1] [2] [3]

5 °C - 15 °C

30 °C - 40 °C

200 mV 0.4 + 0.3 0.4 0.6

2 V 0.12 + 0.1 0.3 0.5

20 V 0.12 + 0.1 0.3 0.5

200 V 0.4 + 0.1 0.7 1.0

1000 V 0.4 + 0.3 0.7 1.0

Type Multi-slope, multi-cycle A-D Converter

CMRR (1 kΩ unbalance)

[5]

NMRR

[5]

140 dB at DC and 1 - 60 Hz

Filter Out 60 dB at 50/60 Hz ±0.09 %

Filter In 110 dB at 50/60 Hz ±0.09 %

Protection (All ranges) 1 kV rms

Input Impedance

200 mV to 20 V Ranges >100 GΩ

200 V & 1000 V Ranges 10.1 MΩ ± 1 %

Max Input Current 50 pA

Ratio Accuracy

Range to Range ±(Net Front Input Accuracy + Net Rear Input Accuracy)

Within Range Apply 24 hour or 20 minute Transfer

Uncertainty specifications

Settling Time (to 10 ppm step size)

Filter Out <50 ms

Filter In <1 s

Fluke Corporation 8508A Extended Specifications 5

Loading...

Loading...