Fluke 8508A Service Manual

®

8508A

Reference Multimeter

Service Manual

September 2004 Rev. 1, 8/08

© 2004, 2008 Fluke Corporation, All rights reserved. Specifications are subject to change without notice

All product names are trademarks of their respective companies.

Warranty

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance

with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

To register your product online, visit register.fluke.com

Table of Contents

Chapter Title Page

1 Introduction and Specifications......................................................... 1-1

Introduction........................................................................................................ 1-3

Safety Considerations ........................................................................................ 1-3

Symbols ......................................................................................................... 1-5

Service Information ........................................................................................... 1-6

How to Contact fluke......................................................................................... 1-6

Specifications..................................................................................................... 1-6

General Specifications................................................................................... 1-7

Maximum Voltage and Current Inputs.......................................................... 1-8

DC and AC Voltage .................................................................................. 1-8

DC and AC Current................................................................................... 1-8

Resistance and Temperature ..................................................................... 1-8

DC Voltage.................................................................................................... 1-9

DC Current .................................................................................................... 1-10

AC Voltage.................................................................................................... 1-11

AC Current .................................................................................................... 1-13

Resistance...................................................................................................... 1-15

Temperature................................................................................................... 1-17

Read Rate and Additional Uncertainty.......................................................... 1-18

Applying the Specifications............................................................................... 1-19

Introduction ................................................................................................... 1-19

Absolute and Relative Specifications ............................................................ 1-19

Applying User’s Calibration Uncertainties ................................................... 1-20

Operating and Calibration Temperature Ranges ........................................... 1-20

Applying Temperature Coefficient Specifications ........................................ 1-20

Ratio Measurements ...................................................................................... 1-21

Additional Errors........................................................................................... 1-21

2 Theory of Operation ............................................................................ 2-1

Introduction........................................................................................................ 2-3

Overall Functional Description.......................................................................... 2-3

Main Assemblies ........................................................................................... 2-3

Power Supplies .............................................................................................. 2-6

i

8508A

Service Manual

3 Calibration and Verification................................................................ 3-1

Introduction........................................................................................................ 3-3

Calibration Overview......................................................................................... 3-3

Calibration Interval and Performance................................................................ 3-3

Calibration Points .............................................................................................. 3-3

Non-Nominal Values..................................................................................... 3-4

Enabling Access to Calibration Mode ............................................................... 3-4

Calibration Menus.............................................................................................. 3-4

Accessing the Calibration Menus and Calibration Mode .............................. 3-4

Calibration Menu........................................................................................... 3-4

SET VALUE Menu ....................................................................................... 3-5

SPOT CAL Menu .......................................................................................... 3-6

SPOT (1 to 6) RMS Menus ........................................................................... 3-6

SPOT FREQUENCY (1 to 6) Menu ............................................................. 3-6

Special Calibration ........................................................................................ 3-7

SPCL Menu ................................................................................................... 3-7

SER # = Menu ............................................................................................... 3-7

Hvlin Menu.................................................................................................... 3-8

Non-volatile input offset compensation............................................................. 3-8

Routine Calibration............................................................................................ 3-9

Equipment Required for Calibration ............................................................. 3-10

Preparing for Calibration............................................................................... 3-10

Interconnections ............................................................................................ 3-11

ADC Calibration............................................................................................ 3-14

DC Voltage Calibration................................................................................. 3-14

AC Voltage Calibration................................................................................. 3-16

Resistance Calibration ................................................................................... 3-18

DC Current Calibration ................................................................................. 3-25

AC Current Calibration ................................................................................. 3-27

Frequency Calibration ................................................................................... 3-28

Exit From Calibration Mode and Non-Volatile Input Offset Adjustment..... 3-29

Cal Due Date Entry and Calibration Mode Disable ...................................... 3-30

ACV Spot Frequency Calibration...................................................................... 3-30

Performance Verification................................................................................... 3-31

Equipment Requirements .............................................................................. 3-32

Interconnections ............................................................................................ 3-32

Applicable Verification Tolerance and Conditions ....................................... 3-32

Preparation..................................................................................................... 3-33

DC Voltage Checks ....................................................................................... 3-33

AC Voltage Checks ....................................................................................... 3-35

Resistance Checks ......................................................................................... 3-37

DC Current Checks........................................................................................ 3-40

AC Current Checks........................................................................................ 3-41

Frequency Checks ......................................................................................... 3-43

4 Maintenance......................................................................................... 4-1

Introduction........................................................................................................ 4-3

Access Procedures ............................................................................................. 4-3

Before You Start............................................................................................ 4-3

Cabling and Wiring Connections .................................................................. 4-4

Removing the A1 DC PCA ........................................................................... 4-5

Removing the A2 AC PCA ........................................................................... 4-6

Removing the A3 Ohms PCA ....................................................................... 4-7

Removing the A4 Digital PCA...................................................................... 4-8

ii

Contents (continued)

Removing the A5 Bezel Assembly................................................................ 4-9

Removing the A5A1 Display PCA................................................................ 4-10

Removing the A6 Rear Input Assembly........................................................ 4-11

Fuse Replacement and Line-Voltage Selection ................................................. 4-12

Line-Power Fuse F1 and Voltage Selection .................................................. 4-12

Rear-Input Current Fuse F2 (Rear Inputs Option)......................................... 4-13

Self Test ............................................................................................................. 4-13

Self-Test Errors ............................................................................................. 4-13

Fatal Errors .................................................................................................... 4-16

Execution Errors............................................................................................ 4-18

Device Dependant Errors .............................................................................. 4-19

5 List of Replaceable Parts.................................................................... 5-1

Introduction........................................................................................................ 5-3

How to Obtain Parts........................................................................................... 5-3

How to Contact Fluke ........................................................................................ 5-3

Parts Lists........................................................................................................... 5-4

iii

8508A

Service Manual

iv

List of Tables

Table Title Page

3-1. Required Equipment for Calibration and Performance Verification...................... 3-10

3-2. Calibration Sequence ............................................................................................. 3-11

3-3. DC Voltage Calibration Points and Sequence........................................................ 3-15

3-4. AC Voltage Calibration Points and Sequence........................................................ 3-17

3-5. Resistance Calibration Points and Sequence.......................................................... 3-18

3-6. DC Current Calibration Points and Sequence ........................................................ 3-26

3-7. AC Current Calibration Points and Sequence ........................................................ 3-28

3-8. DC Voltage Verification Points and Sequence ...................................................... 3-34

3-9. AC Voltage Verification Points and Sequence ...................................................... 3-36

3-10. Resistance Verification Points and Sequence ........................................................ 3-39

3-11. DC Current Verification Points and Sequence....................................................... 3-41

3-12. AC Current Verification Points and Sequence....................................................... 3-42

4-1. Power Input Fuse 1................................................................................................. 4-12

4-2. Current Function Rear Input Fuse 2....................................................................... 4-13

4-3. Self-Test Errors ...................................................................................................... 4-13

4-4. 9000 System Kernel Fault Errors........................................................................... 4-16

4-5. Unexpected Exception Errors................................................................................. 4-16

4-6. Serial Interface Errors ............................................................................................ 4-17

4-7. Serial Loop Mismatch Errors ................................................................................. 4-18

4-8. Execution Errors..................................................................................................... 4-19

4-9. Device Dependent Errors ....................................................................................... 4-20

5-1. 8508A Final Assembly........................................................................................... 5-4

5-2. 8508A Chassis Assembly....................................................................................... 5-6

5-2. Bezel (front panel) Assembly................................................................................. 5-7

5-4. A6Rear Input Assembly (optional) ........................................................................ 5-12

v

8508A

Service Manual

vi

List of Figures

Figure Title Page

1-1. 8508A Dimentional Outline Drawing .................................................................... 1-6

2-1. 8508A Functional Block Diagram ......................................................................... 2-4

2-2. Power Supplies - Simplified Block Diagram ......................................................... 2-7

3-1. Equipment Connections Required for Calibration ................................................. 3-13

4-1. Internal Wiring and Cabling Diagram.................................................................... 4-4

4-3. Removing the A2 AC PCA .................................................................................... 4-6

4-4. Removing the A3 Ohms PCA ................................................................................ 4-7

4-5. Removing the A4 Digital PCA............................................................................... 4-8

4-6. Removing the A5 Bezel Assembly ........................................................................ 4-9

4-7. Removing the A5A1 Display PCA ........................................................................ 4-10

4-8. Removing the A6 Rear Input Assembly ................................................................ 4-11

4-9. Rear Panel - Power Input Fuse and line Power Locations ..................................... 4-12

5-1. 8508A Final Assembly........................................................................................... 5-5

5-2. 8508A Chassis Assembly....................................................................................... 5-7

5-3. A5 Bezel (front panel) Assembly........................................................................... 5-11

5-4. Rear Input Assembly (optional) ............................................................................. 5-14

vii

8508A

Service Manual

viii

Chapter 1

Introduction and Specifications

Title Page

Introduction.......................................................................................................... 1-3

Safety Considerations .......................................................................................... 1-3

Symbols ........................................................................................................... 1-5

Service Information ............................................................................................. 1-6

How to Contact fluke........................................................................................... 1-6

Specifications....................................................................................................... 1-6

General Specifications..................................................................................... 1-7

Maximum Voltage and Current Inputs............................................................ 1-8

DC and AC Voltage .................................................................................... 1-8

DC and AC Current..................................................................................... 1-8

Resistance and Temperature ....................................................................... 1-8

DC Voltage...................................................................................................... 1-9

DC Current ...................................................................................................... 1-10

AC Voltage...................................................................................................... 1-11

AC Current ...................................................................................................... 1-13

Resistance........................................................................................................ 1-15

Temperature..................................................................................................... 1-17

Read Rate and Additional Uncertainty............................................................ 1-18

Applying the Specifications................................................................................. 1-19

Introduction ..................................................................................................... 1-19

Absolute and Relative Specifications .............................................................. 1-19

Applying User’s Calibration Uncertainties ..................................................... 1-20

Operating and Calibration Temperature Ranges ............................................. 1-20

Applying Temperature Coefficient Specifications .......................................... 1-20

Ratio Measurements ........................................................................................ 1-21

Additional Errors............................................................................................. 1-21

1-1

8508A

Service Manual

1-2

Introduction and Specifications

Introduction 1

Introduction

The Fluke 8508A Reference Multimeter (hereafter "the Multimeter") is designed for the

most demanding measurement applications and provides extremely high measurement

precision in both stand-alone and systems applications.

This Service Manual provides the information necessary to maintain the Multimeter at a

module (or board) level. A brief description of the information contained in the various

chapters follows:

Chapter 1 Introduction and Specification provides a brief description of the product,

safety information regarding the product and its use, and a complete set of detailed

specifications.

Chapter 2 Theory of Operation provides an overall functional description of the internal

workings of the Multimeter. The intent of the theory is to aid in locating and isolating a

faulty PCA.

Chapter 3 Calibration and Verification provides a thorough and complete description of

both the Verification and the Calibration procedures for the Multimeter.

Chapter 4 Maintenance provides detailed descriptions of how to disassemble the

Multimeter to the PCA level. The purpose of the descriptions is to assist with equipment

repairs at the PCA level.

Chapter 5 List of Replaceable Parts provides all of the information required to identify

and order replacement parts for repairing the Multimenter at the PCA level.

To avoid electric shock, personal injury, or death, carefully read

the information under Safety Considerations before attempting

to install, use, or service the Multimeter.

Safety Considerations

This instrument has been designed and tested in accordance with the European standard

publication EN61010-1: 2001 and U.S. / Canadian standard publications UL 61010-1A1

and CAN/CSA-C22.2 No.61010.1. The instrument has been supplied in a safe condition.

This manual contains information and warnings that must be observed to keep the

instrument in a safe condition and ensure safe operation.

Using or servicing this Multimeter in conditions other than as specified in the Service

Manual could compromise your safety.

To use the Multimeter correctly and safely, read and adhere to the precautions on the

Safety Page and follow all the safety instructions or warnings given throughout this

manual and the Users Manual that relate to specific measurement functions. In addition,

follow all generally accepted safety practices and procedures required when working with

and around electricity.

XW Warning

1-3

8508A

Service Manual

Warning: To avoid possible electric shock, personal injury, or death, read the following

before using the Multimeter:

⇒ Use the Multimeter only as specified in this manual, or the protection provided by

⇒ Do not use the Multimeter in wet environments.

⇒ The Multimer can output lethal voltages. Use it only as described in this manual.

⇒ Inspect the Multimeter before using it. Do not use the Multimeter if it appears

⇒ Inspect the test leads before use. Do not use them if insulation is damaged or metal

⇒ Verify the Multimeter's operation by measuring a known voltage before and after

⇒ Whenever it is likely that safety protection has been impaired, make the Multimeter

⇒ Have the Multimeter serviced only by qualified service personnel.

⇒ Do not apply more than the rated voltage, as marked on the Multimeter, between

⇒ Always use the power cord and connector appropriate for the voltage and outlet of

⇒ Remove test leads from the Multimeter before opening the case.

⇒ Never remove the cover or open the case of an instrument without first removing

⇒ Never operate the Multimeter with the cover removed or the case open.

⇒ Use caution when working with voltages above 30 V ac rms, 42 V ac peak, or 42 V

⇒ Use only the replacement fuse(s) specified by the manual.

⇒ Use the proper terminals, function, and range for your measurements.

⇒ Do not operate the Multimeter around explosive gas, vapor, or dust.

⇒ When using probes, keep your fingers behind the finger guards.

⇒ When making electrical connections, connect the common test lead before

⇒ Disconnect circuit power and discharge all high-voltage capacitors before testing

⇒ Before measuring current, check the Multimeter's fuses and turn OFF power to the

⇒ When servicing the Multimeter, use only specified replacement parts.

XW Safety – Read First

the Multimeter might be impaired.

damaged. Pay particular attention to the insulation around the connectors.

is exposed. Check the test leads for continuity. Replace damaged test leads before

using the Multimeter.

using it. Do not use the Multimeter if it operates abnormally. Protection may be

impaired. If in doubt, have the Multimeter serviced.

inoperative and secure it against any unintended operation.

the terminals or between any terminal and earth ground.

the country or location in which you are working.

the power source.

dc. These voltages pose a shock hazard.

connecting the live test lead; when disconnecting, disconnect the live test lead

before disconnecting the common test lead.

resistance, continuity, diodes, or capacitance.

circuit before connecting the Multimeter to the circuit.

1-4

Introduction and Specifications

Symbols

The following safety and electrical symbols may be used on the Multimeter or in this

manual.

Safety Considerations 1

W

X

B

F

D

or

C

H

Y

Risk of danger.

Important information. See manual.

Hazardous voltage. Voltage > 30 V dc or

ac peak might be present

AC (Alternating Current).

DC (Direct Current).

AC or DC (Alternating or Direct Current)

Digital signal.

Potentially hazardous voltage.

Power ON / OFF

+

Earth ground.

J

CAT IEC 61010 Overvoltage (installation or

I

~

<

T

measurement) Category .

Fuse.

Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for

recycling information.

Recycle.

Double insulated.

1-5

8508A

Service Manual

Service Information

How to Contact fluke

In case of difficulty within the 1-year Warranty period, return the Multimeter to a Fluke

Service Center for Warranty repair. For out of Warranty repair, contact a Fluke Service

Center for a cost estimate.

This service manual provides instructions for verification of performance, calibration,

and maintenance. If you choose to repair a malfunction, information in this manual can

help you to determine which module (PCA) has a fault. See Chapter 5 for cautions about

handling the internal components.

To contact Fluke, call one of the following telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com.

To register your product, visit register.fluke.com

Specifications

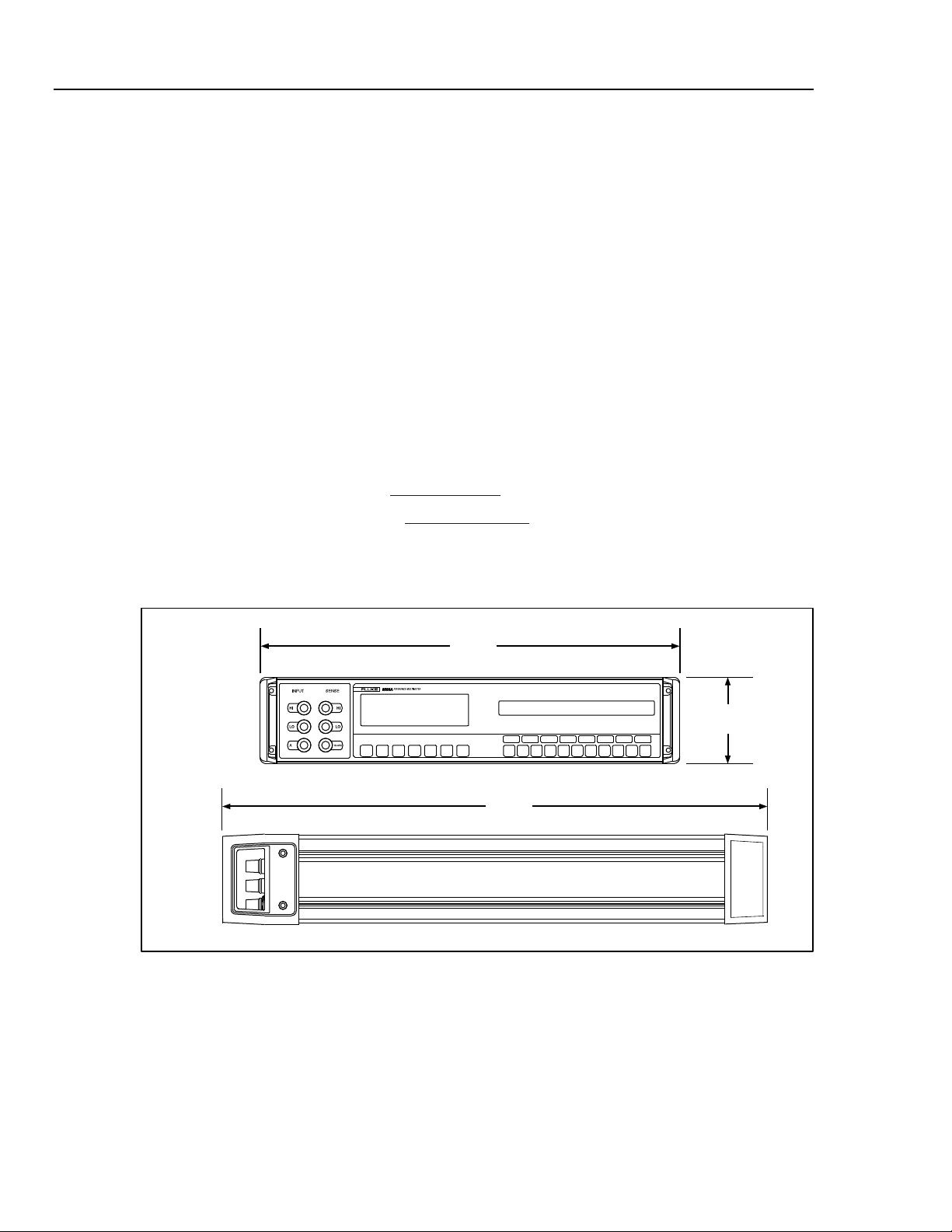

Figure 1-1 shows the overall dimensions of the 8505A Reference Multimeter.

427 mm

(16.8 in)

487 mm

(19.2 in)

Figure 1-1. 8508A Dimentional Outline Drawing

8.8 mm

(3.5 in)

avw001f.eps

1-6

Introduction and Specifications

Specifications 1

General Specifications

Power

Voltage

115 V Setting ..................................................... 100 V to 120 V rms ±10 %

230 V Setting ..................................................... 200 V to 240 V rms ±10 %

Frequency ............................................................... 47 Hz to 63 Hz

Consumption........................................................... < 80 VA

Dimensions

Height...................................................................... 88 mm (3.5 inches)

Width....................................................................... 427 mm (16.8 inches)

Depth ...................................................................... 487 mm (19.2 inches)

Weight..................................................................... 11.5 kg (25.5 lbs)

Environment

Temperature

Operating............................................................ 0 °C to 50 °C

Specified Operation ............................................ 5 °C to 40 °C

Calibration (TCal)................................................ 20 °C to 25 °C

Factory Cal Temp ...............................................23 °C

Storage ............................................................... -20 °C to 70 °C

Warm Up............................................................. 4 hours to full uncertainty specification.

Relative Humidity (non- condensing)

Operating ........................................................... 5 °C to 40 °C < 90 %

Storage .............................................................. 0 °C to 70 °C < 95 %

Altitude

Operating............................................................ < 2000 meters

Storage ............................................................... < 12000 meters

Vibration and Shock................................................ Complies with MIL-PRF-28800F Class 3.

Safety ..................................................................... Designed and tested to EN61010-1: 2001, UL 61010-1A1,

EMC ........................................................................ EN50081-1 Class B, EN55011/22, EN61326-1:1998,

Measurement Isolation

Guard to Safety Ground ......................................... < 3300 pF, > 10 GΩ.

Lo to Guard

In Remote Guard ................................................ < 2800 pF, > 10 GΩ (Not in Resistance function).

In Local Guard .................................................... Lo and Guard terminals are internally shorted

Autorange

Range Up................................................................ 100 % of range.

Range Down ........................................................... 9 % of range (18 % on 1000 V range).

Remote Interface................................................... IEEE 488.2

Warranty ................................................................ 1 Year

CAN/CSA-C22.2 No.61010.1, CE and ETL marked.

Pollution Degree 2.

Installation Category II.

Equipment Class I (single insulation / Earthed metal case).

Protection against water ingress IP4X (general indoor conditions).

Input circuitry and connections (creepage and clearances) designed to

interface at Installation or Measurement Category I.

EN50082-1, EN55011 1991 Class B,

EN61000-6-1:2001, FCC Rules part 15 sub part J class B,

CETL and CE marked.

(in Resistance < 2800 pF, > 10 GΩ).

1-7

8508A

Service Manual

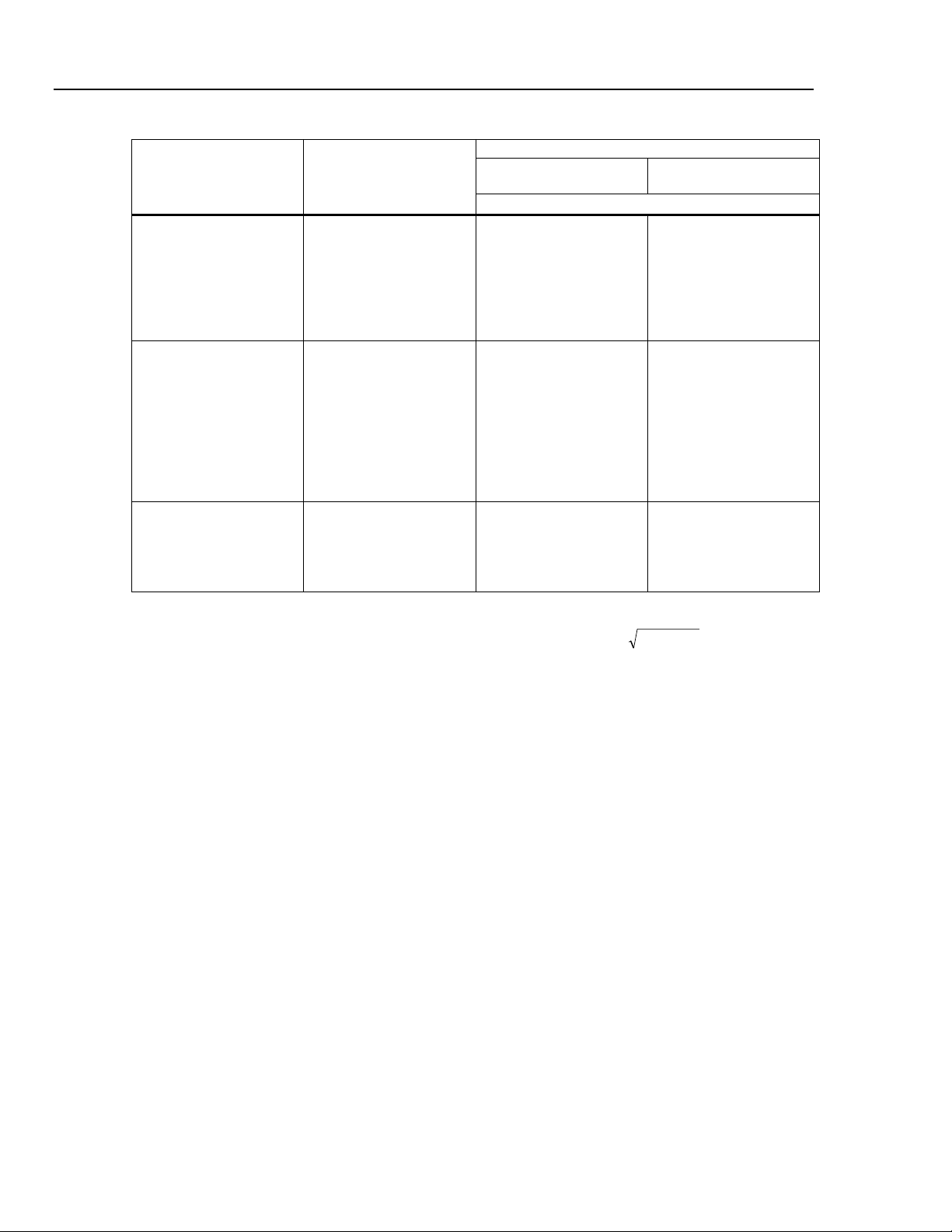

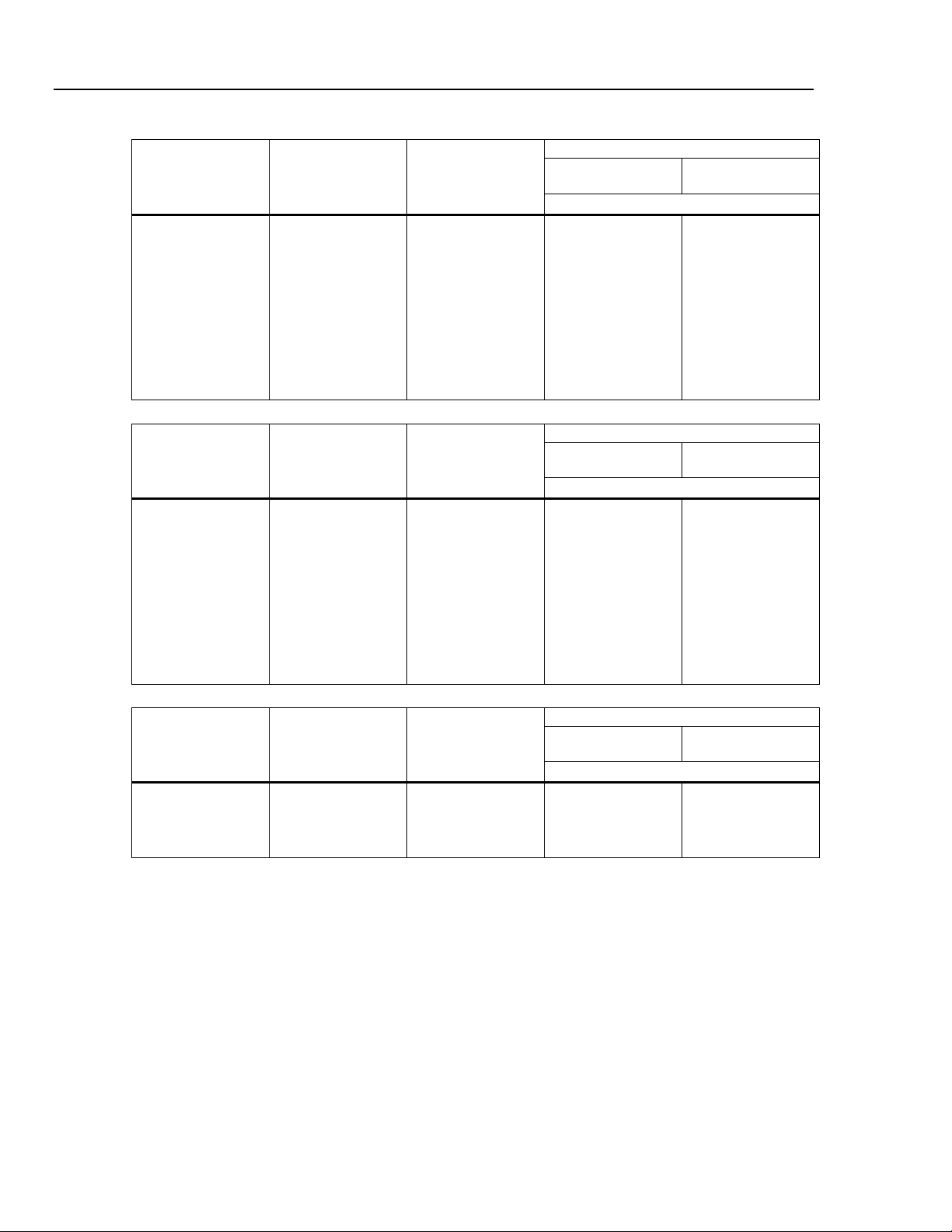

Maximum Voltage and Current Inputs

Notes to maximum voltage and current input specifications

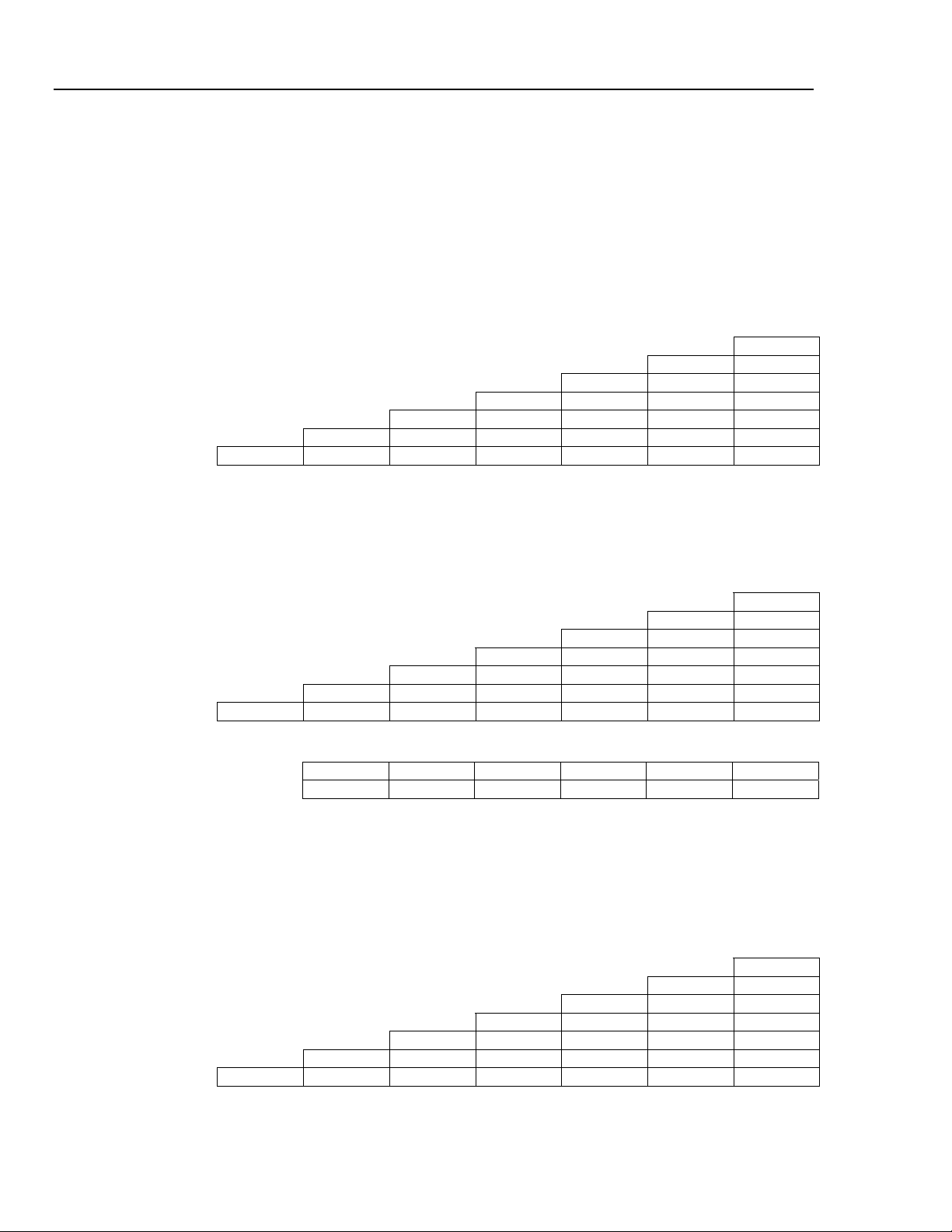

DC and AC Voltage

Sense Hi

Hi 250 V

Sense Lo 1000 V 1000 V

Lo 250 V 1000 V 1000 V

A 1000 V 1000 V 1000 V 1000 V

Guard 1000 V 250 V 250 V 1000 V 1000 V

DigGnd 650 V 650 V 650 V 650 V 1000 V 1000 V

Ground 0 V 650 V 650 V 650 V 650 V 1000 V 1000 V

Notes

DC and AC Current

• Maximum DC input equal to maximum rms input. Maximum peak input is rms x 1.414

• Specifications apply equally to front and rear input terminals except where noted below.

• Front to rear isolation allows opposing polarity of maximum terminal voltage on each input.

• Digital I/O Ground (DigGnd) is internally connected to Safety Ground (Ground).

Maximum rms terminal voltages

• The A terminal is open circuit in these functions.

• In 4wV mode Sense Hi is internally connected to Hi and Sense Lo is internally connected to Lo.

Maximum rms terminal voltages

Sense Hi

Hi 250 V

Sense Lo 1000 V 1000 V

Lo 250 V 1000 V 1000 V

A 5 V 250 V 1000 V 1000 V

Guard 250 V 250 V 250 V 1000 V 1000 V

DigGnd 650 V 650 V 650 V 650 V 1000 V 1000 V

Ground 0 V 650 V 650 V 650 V 650 V 1000 V 1000 V

Maximum rms terminal currents

Guard A Lo Sense Lo Hi Sense Hi

Front Input n.a 20 A 20 A n.a n.a n.a

Rear input n.a 2 A 2 A n.a n.a n.a

Notes

• The Sense Lo, Sense Hi, and Hi Terminals are open circuit in these functions.

• The front input A terminal protection is automatic and self-resetting, and does not interrupt current flow. Damage is likely to

occur if more than 20 A is applied.

• The rear input A terminal is protected by a fuse mounted on the rear panel.

Resistance and Temperature

Maximum rms terminal voltages

Sense Hi

Hi 250 V

Sense Lo 250 V 250 V

Lo 250 V 250 V 250 V

A 250 V 250 V 250 V 250 V

Guard 250 V 250 V 250 V 250 V 250 V

DigGnd 650 V 650 V 650 V 650 V 1000 V 1000 V

Ground 0 V 650 V 650 V 650 V 650 V 1000 V 1000 V

Note

1-8

• The A terminal is open circuit in these functions.

Introduction and Specifications

Specifications 1

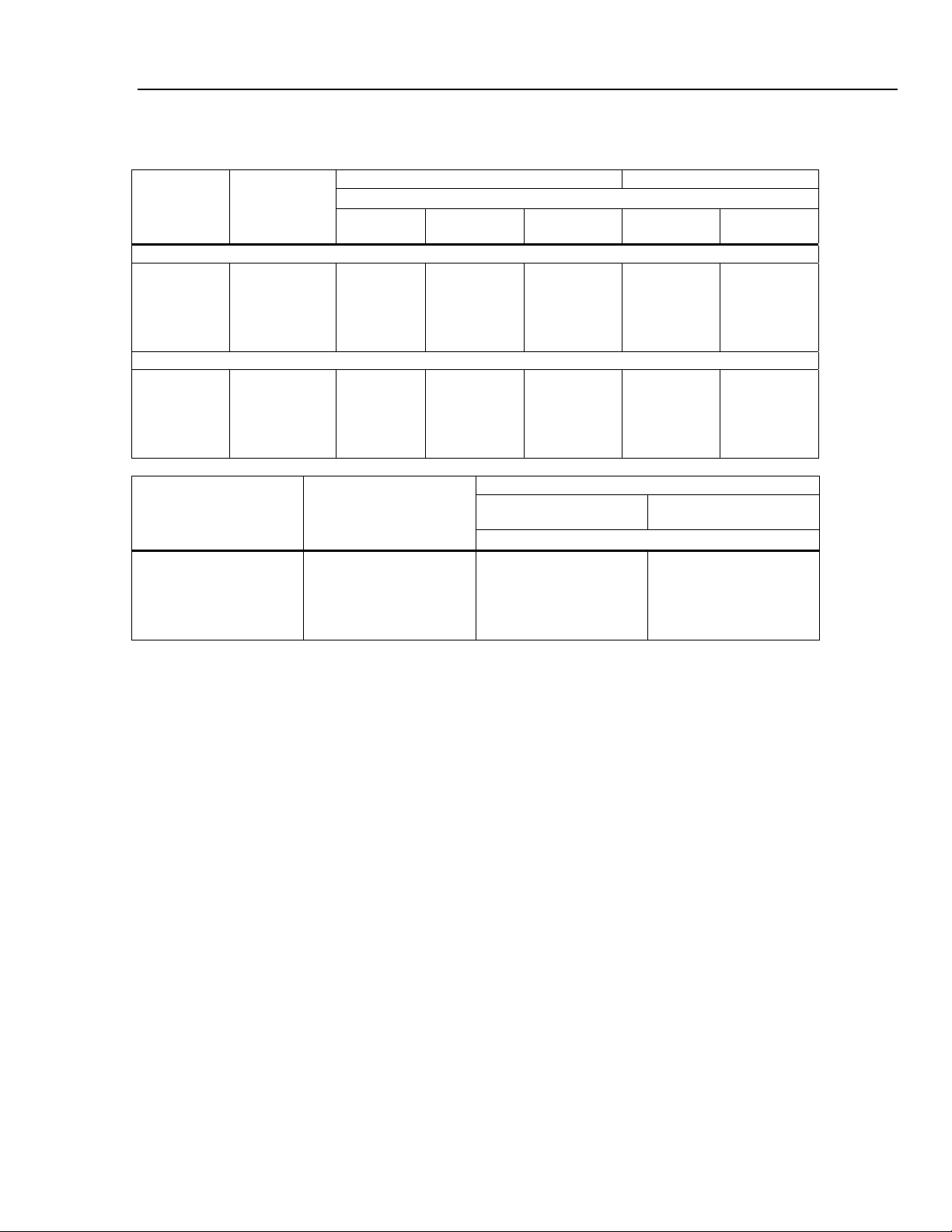

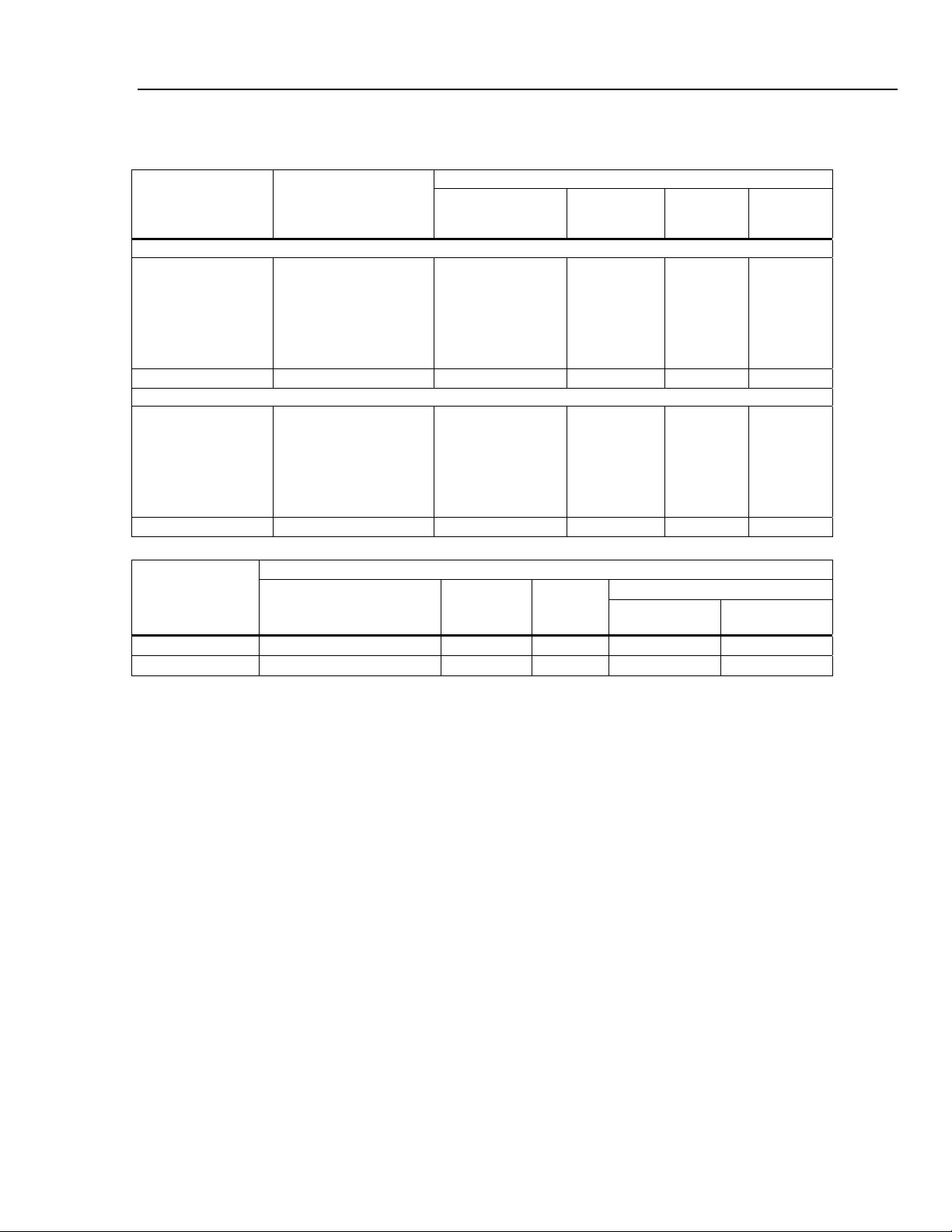

DC Voltage

DC Voltage

Uncertainty Relative to Cal Stds Absolute Uncertainties

Range Full Scale

[15]

24 hour

TCal ±1 °C

TCal ±1 °C

95 % Confidence Level

200 mV 199.990 000 0.7 + 0.5 1.4 + 0.5 2.7 + 0.5 4.5 + 0.5 5.0 + 0.5

2 V 1.999 900 00 0.5 + 0.2 1.4 + 0.2 2.7 + 0.2 3.0 + 0.2 3.5 + 0.2

20 V 19.999 000 0 0.5 + 0.2 1.4 + 0.2 2.7 + 0.2 3.0 + 0.2 3.5 + 0.2

200 V 199.990 000 1.0 + 0.2 2.6 + 0.2 4.0 + 0.2 4.5 + 0.2 5.5 + 0.2

1000 V 1050.000 00 1.0 + 0.5 2.6 + 0.5 4.0 + 0.5 4.5 + 0.5 5.5 + 0.5

99 % Confidence Level

200 mV 199.990 000 0.8 + 0.6 2.0 + 0.6 3.5 + 0.6 6.0 + 0.6 6.5 + 0.6

2 V 1.999 900 00 0.6 + 0.25 1.8 + 0.25 3.5 + 0.25 4.0 + 0.25 4.5 + 0.25

20 V 19.999 000 0 0.6 + 0.25 1.8 + 0.25 3.5 + 0.25 4.0 + 0.25 4.5 + 0.25

200 V 199.990 000 1.2 + 0.25 3.5 + 0.25 5.2 + 0.25 6.0 + 0.25 7.0 + 0.25

1000 V 1050.000 00 1.2 + 0.6 3.5 + 0.6 5.2 + 0.6 6.0 + 0.6 7.0 + 0.6

DC Voltage (Secondary Specifications)

Transfer Uncertainty

Range

20 mins ±1 °C ± (ppm

Reading+ ppm Range)

200 mV 0.4 + 0.3 0.4 0.6

2 V 0.12 + 0.1 0.3 0.5

20 V 0.12 + 0.1 0.3 0.5

200 V 0.4 + 0.1 0.7 1.0

1000 V 0.4 + 0.3 0.7 1.0

Type ....................................................................... Multi-slope, multi-cycle A-D Converter

CMRR (1 kΩ unbalance)

[5]

NMRR

Filter Out ................................................................. 60 dB at 50/60 Hz ±0.09 %

Filter In .................................................................... 110 dB at 50/60 Hz ±0.09 %

Protection (All ranges)........................................... 1 kV rms

Input Impedance

200 mV to 20 V Ranges.......................................... > 10 GΩ

200 V & 1000 V Ranges ......................................... 10.1 MΩ ± 1 %

Max Input Current .................................................50 pA

Ratio Accuracy

Range to Range...................................................... ±(Net Front Input Accuracy + Net Rear Input Accuracy)

Within Range .......................................................... Apply 24 hour or 20 minute Transfer Uncertainty specifications

Settling Time (to 10 ppm step size)

Filter Out ................................................................. < 50 ms

Filter In .................................................................... < 1 s

[5]

.................................... 140 dB at DC and 1 - 60 Hz

[1] [2] [3]

± (ppm Reading + ppm Range)

90 day

365 day

TCal ±1 °C

[1] [2] [3]

Temperature Coefficient

15 °C - 30 °C

± ppm Reading/°C

TCal ±1 °C

[4]

365 day

365 day TCal

±5 °C

5 °C - 15 °C

30 °C - 40 °C

1-9

8508A

Service Manual

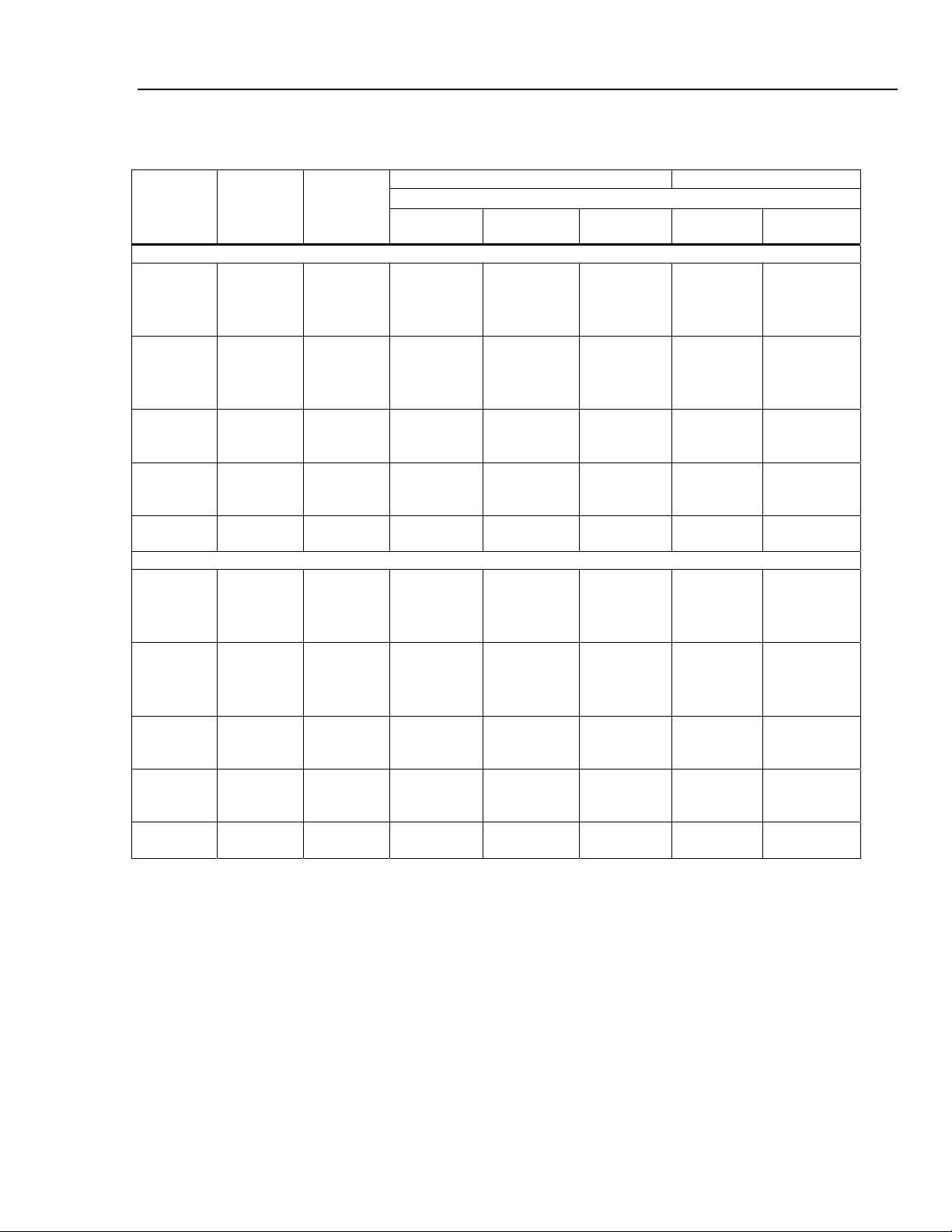

DC Current

95 % Confidence Level

200 μA 199.990 00 5.5 + 2.0 6.0 + 2.0 6.5 + 2.0 12 + 2.0 12 + 2.0

2 mA 1.999 900 0 5.5 + 2.0 6.0 + 2.0 6.5 + 2.0 12 + 2.0 12 + 2.0

20 mA 19.999 000 6.5 + 2.0 7.0 + 2.0 8.0 + 2.0 13 + 2.0 14 + 2.0

200 mA 199.990 00 28 + 4.0 30 + 4.0 33 + 4.0 36 + 4.0 48 + 4.0

2 A 1.999 900 0 80 + 8.0 125 + 8.0 170 + 8.0 170 + 8.0 185 + 8.0

20 A 19.999 000 200 + 20 290 + 20 380 + 20 380 + 20 400 + 20

99 % Confidence Level

200 μA 199.990 00 7.0 + 2.0 7.5 + 2.0 8.0 + 2.0 15 + 2.0 16 + 2.0

2 mA 1.999 900 0 7.0 + 2.0 7.5 + 2.0 8.0 + 2.0 15 + 2.0 16 + 2.0

20 mA 19.999 000 8.0 + 2.0 9.0 + 2.0 10 + 2.0 16 + 2.0 18 + 2.0

200 mA 199.990 00 35 + 4.0 37 + 4.0 40 + 4.0 45 + 4.0 60 + 4.0

2 A 1.999 900 0 100 + 8.0 150 + 8.0 205 + 8.0 210 + 8.0 225 + 8.0

20 A 19.999 000 250 + 20 350 + 20 450 + 20 455 + 20 500 + 20

200 μA

2 mA 15.2 15.2 0.4 0.6

20 mA 1.8 1.9 1.2 1.8

200 mA 1.2 1.3 6. 0 9.0

2 A 0.3 0.4 8.0 12

20 A 0.04 - 15 20

Type........................................................................ Multi-slope, multi-cycle A-D Converter

Protection

Front Input............................................................... 20 A rms

Rear Input ............................................................... 2 A rms, Rear Panel Fuse

Settling Time

200 μA to 200 mA Ranges, to 10 ppm step size .... Filter Out < 50 ms, Filter In < 1 s

2 A Range

to 100 ppm step size........................................... < 1 s

to 75 ppm step size............................................. < 30 s

to 30 ppm step size............................................. < 5 minutes

20 A Range (at 10 A)

to 300 ppm step size........................................... < 1 s

to 250 ppm step size........................................... < 30 s

to 100 ppm step size........................................... < 5 minutes

Range Full Scale

Range

DC Current

[1] [2] [3]

Uncertainty Relative to Cal Stds Absolute Uncertainties

365 day

TCal ±1 °C

[4]

[15]

24 hour

TCal ±1 °C

± (ppm Reading + ppm Range)

90 day

TCal ±1 °C

DC Current (Secondary Specifications)

365 day

TCal ±1 °C

[1] [2] [3]

Temperature Coefficient

Input Impedance (Ω)

Front Rear

150 150 0.4 0.6

15 °C - 30 °C

± ppm Reading/°C

365 day

TCal ±5 °C

5 °C - 15 °C

30 °C - 40 °C

1-10

Introduction and Specifications

Specifications 1

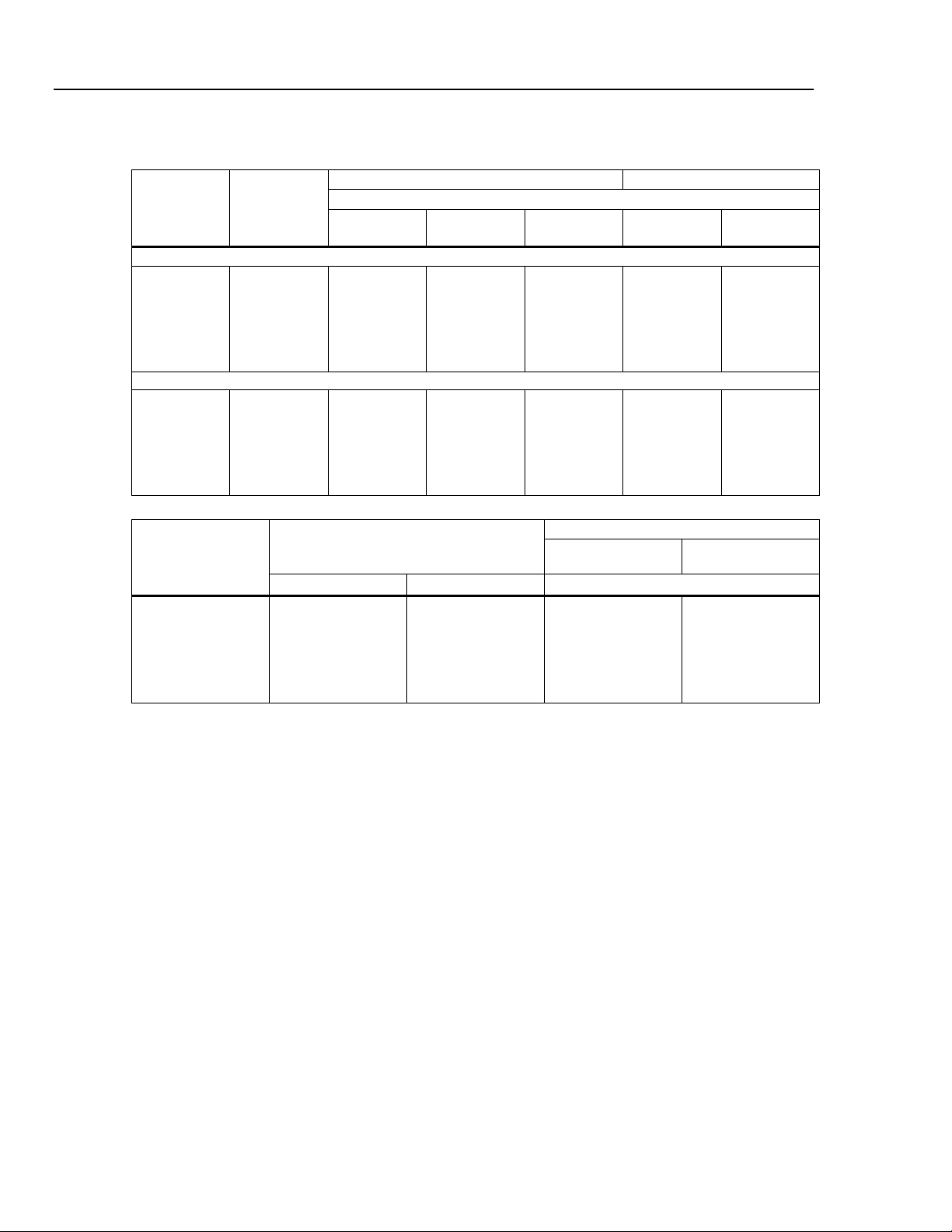

AC Voltage

AC Voltage

Uncertainty Relative to Cal Stds Absolute Uncertainties

Range Full Scale

95% Confidence Level

200 mV 199.990 0 1 - 10 80 + 70 120 + 70 120 + 70 160 + 70 165 + 70

2 V, 20 V &

200 V

1.999 900 1 - 10 70 + 60 100 + 60 100 + 60 140 + 60 150 + 60

19.999 00 10 - 40 70 + 10 100 + 10 100 + 10 105 + 10 115 + 10

199.990 0 40 - 100 50 + 10 80 + 10 80 + 10 85 + 10 90 + 10

[8]

1000 V

1050.000 1 - 10 70 + 70 100 + 70 100 + 70 140 + 70 150 + 70

99% Confidence Level

200 mV 199.990 0 1 - 10 90 + 80 140 + 80 140 + 80 200 + 80 210 + 80

2 V, 20 V &

200 V

1000 V

1.999 900 1 - 10 80 + 70 115 + 70 115 + 70 180 + 70 190 + 70

19.999 00 10 - 40 80 + 12 115 + 12 115 + 12 120 + 12 135 + 12

199.990 0 40 - 100 60 + 12 90 + 12 90 + 12 95 + 12 110 + 12

[8]

1050.000 1 - 10 80 + 80 115 + 80 115 + 80 180 + 80 190 + 80

[15]

Frequency (Hz)

100 k - 300 k 0.15 % + 0.1 % 0.3 % + 0.1 % 0.3 % + 0.1 % 0.3 % + 0.1 % 0.3 % + 0.1 %

100 k - 300 k 0.15 %+0.12 % 0.3 %+0.12 % 0.3 % + 0.12 % 0.3 % + 0.12 % 0.3 % + 0.12 %

24 hour

TCal ±1 °C

10 - 40 80 + 20 120 + 20 120 + 20 130 + 20 140 + 20

40 - 100 60 + 20 100 + 20 100 + 20 110 + 20 115 + 20

100 - 2 k 40 + 10 100 + 10 100 + 10 105 + 10 110 + 10

2k - 10 k 60 + 20 100 + 20 100 + 20 105 + 20 135 + 20

10k - 30 k 250 + 30 300 + 40 300 + 40 305 + 40 340 + 40

30k - 100 k 400 + 100 700 + 100 700 + 100 705 + 100 765 + 100

100 - 2 k 30 + 10 60 + 10 60 + 10 65 + 10 75 + 10

2 k - 10 k 50 + 10 80 + 10 80 + 10 85 + 10 110 + 10

10 k - 30 k 100 + 20 200 + 20 200 + 20 205 + 20 220 + 20

30 k - 100 k 250 + 100 500 +100 500 +100 505 + 100 570 + 100

300 k - 1 M 1 % + 0.5 % 1 % + 1 % 1 % + 1 % 1 % + 1 % 1 % + 1 %

10 - 40 70 + 20 100 + 20 100 + 20 110 + 20 120 + 20

40 - 10 k 50 + 20 80 + 20 80 + 20 95 + 20 115 + 20

10 k - 30 k 100 + 40 200 + 40 200 + 40 205 + 40 225 + 40

30 k - 100 k 250 + 200 500 + 200 500 + 200 510 + 200 580 + 200

10 - 40 90 + 25 140 + 25 140 + 25 145 + 25 160 + 25

40 - 100 70 + 25 115 + 25 115 + 25 125 + 25 135 + 25

100 - 2 k 45 + 12 115 + 12 115 + 12 125 + 12 135 + 12

2 k - 10 k 70 + 25 115 + 25 115 + 25 125 + 25 165 + 25

10 k - 30 k 270 + 35 340 + 50 340 + 50 345 + 50 395 + 50

30 k - 100 k 450 + 120 750 + 120 750 + 120 755 + 120 855 + 120

100 - 2 k 35 + 12 70 + 12 70 + 12 75 + 12 90 + 12

2 k - 10 k 60 + 12 90 + 12 90 + 12 95 + 12 135 + 12

10 k - 30 k 115 + 25 240 + 25 240 + 25 245 + 25 260 + 25

30 k - 100 k 270 + 120 550 + 120 550 +120 555 + 120 650 + 120

300 k - 1 M 1 % + 0.6 % 1 % + 1.2 % 1 % + 1.2 % 1 % + 1.2 % 1 % + 1.2 %

10 - 40 80 + 25 115 + 25 115 + 25 135 + 25 145 + 25

40 - 10 k 60 + 25 90 + 25 90 + 25 110 + 25 140 + 25

10 k - 30 k 115 + 50 240 + 50 240 + 50 250 + 50 265 + 50

30 k - 100 k 270 + 250 600 + 250 600 + 250 615 + 250 700 + 250

[1] [2] [6] [7]

± (ppm Reading + ppm Range)

90 day

TCal ±1 °C

365 day

TCal ±1 °C

[4]

365 day

TCal ±1 °C

[9]

365 day

TCal ±5 °C

1-11

8508A

Service Manual

AC Voltage (Secondary Specifications)

Range Frequency (Hz)

200 mV 1 - 10 5 10

2 V 1 - 10 5 10

20 V 10 - 40 5 10

200 V 40 - 100 5 10

1000 V 1 - 10 5 10

10 - 40 5 10

40 - 100 5 10

100 - 2 k 5 10

2 k - 10 k 12 20

10 k - 30 k 15 20

30 k - 100 k 40 60

100 - 2 k 5 10

2 k - 10 k 10 15

10 k - 30 k 12 20

30 k - 100 k 40 60

100 k - 300 k 60 90

300 k - 1 M 80 120

10 - 40 5 10

40 - 10 k 10 15

10 k - 30 k 12 20

30 k - 100 k 40 60

15 °C - 30 °C

[1] [2]

Temperature Coefficient

5 °C - 15 °C

30 °C - 40 °C

± ppm Reading/°C

Type ....................................................................... True rms, AC coupled measures AC component with up to 1000 V DC

bias on any range. DC coupled gives

CMRR (1 kΩ unbalance)

Crest Factor

200 mV to 200 V ranges ........................................ 10:1 at 12 % range, 5:1 at 50 % range, 2.5:1 at full range

1000 V range ......................................................... 10:1 at 25 % range, 5:1 at full range

Protection (All ranges)........................................... 1 kV rms

Input Impedance ................................................... 1 MΩ in parallel with 150 pF

DC Accuracy (DC Coupled)................................... Add ±(50 ppm Reading + 50 ppm Range + 20 μV)

Ratio Accuracy

Range to Range...................................................... ±(Net Front Input Accuracy + Net Rear Input Accuracy)

Within Range ......................................................... Apply 24 hour or 20 minute Transfer Uncertainty specifications

Settling Time (to 100 ppm step size)

100 Hz filter............................................................. < 0.5 s

40 Hz filter............................................................... < 1.25 s

10 Hz filter............................................................... < 5 s

1 Hz filter................................................................. < 50 s

Frequency Measurement

Signal Amplitude Range ......................................... 5 % of range to limit set by maximum V

Gate Mode Normal Fast

Resolution......................................................... 6.5 digits 4.5 digits

Frequency Range ............................................. 10 Hz - 1 MHz 200 Hz - 1 MHz

Accuracy (1 year, 13 °C - 33 °C) ..................... ± (10 ppm of Reading + 2 digits) ± 2 digits

Sample Interval................................................. 1 s 50 ms

[5]

..................................... > 90 dB DC - 60 Hz

.

Hz

)dc(ac22+

1-12

Introduction and Specifications

Specifications 1

AC Current

AC Current

Uncertainty Relative to Cal Stds Absolute Uncertainties

Frequency

Range Full Scale

95% Confidence Level

200 μA

2 mA &

20 mA

200 mA 199.990 0 1 - 10 200 + 100 250 + 100 250 + 100 290 + 100 310 + 100

10 -10 k 200 + 100 250 + 100 250 + 100 250 + 100 290 + 100

10 k - 30 k 500 + 100 600 + 100 600 + 100 600 + 100 625 + 100

2 A 1.999 900 10 - 2 k 500 + 100 600 + 100 600 + 100 600 + 100 620 + 100

2 k - 10 k 600 + 100 700 + 100 700 + 100 710 + 100 735 + 100

10 k - 30 k 0.25 % + 100 0.3 % + 100 0.3 % + 100 0.3 % + 100 0.3 % + 100

20 A 19.999 00 10 - 2 k 700 + 100 800 + 100 800 + 100 800 + 100 820 + 100

2 k - 10 k 0.2 % + 100 0.25 % + 100 0.25 % + 100 0.25 % + 100 0.25 % + 100

99% Confidence Level

200 μA

2 mA &

20 mA

200 mA 199.990 0 1 - 10 250 + 120 300 + 120 300 + 120 380 + 120 400 + 120

10 - 10 k 250 + 120 300 + 120 300 + 120 305 + 120 360 + 120

10 k - 30 k 600 + 120 700 + 120 700 + 120 700 + 120 740 + 120

2 A 1.999 900 10 - 2 k 600 + 120 700 + 120 700 + 120 705 + 120 725 + 120

2 k - 10 k 700 + 120 800 + 120 800 + 120 815 + 120 860 + 120

10 k - 30 k 0.25 % + 120 0.3 % + 120 0.3 % + 120 0.3 % + 120 0.3 % + 120

20 A 19.999 00 10 - 2 k 800 + 120 900 + 120 900 + 120 900 + 120 920 + 120

2 k - 10 k 0.2 % + 120 0.25 % + 120 0.25 % + 120 0.25 % + 120 0.25 % + 120

199.990 0 1 - 10 200 + 100 250 + 100 250 + 100 475 + 100 500 + 100

10 - 10 k 200 + 100 250 + 100 250 + 100 475 + 100 500 + 100

10 k - 30 k 500 + 100 600 + 100 600 + 100 650 + 100 710 + 100

30 k - 100 k 0.35 % + 100 0.4 % + 100 0.4 % + 100 0.4 % + 100 0.4 % + 100

1.999 900

19.9990 00

199.990 0 1 - 10 250 + 120 300 + 120 300 + 120 590 + 120 620 + 120

10 - 10 k 250 + 120 300 + 120 300 + 120 590 + 120 620 + 120

10 k - 30 k 600 + 120 700 + 120 700 + 120 775 + 120 800 + 120

30 k - 100 k 0.35 % + 120 0.4 % + 120 0.4 % + 120 0.4 % + 120 0.4 % + 120

1.999 900

19.999 00

[15]

(Hz)

1 - 10 200 + 100 250 + 100 250 + 100 290 + 100 310+ 100

10 - 10 k 200 + 100 250 + 100 250 + 100 280 + 100 300 + 100

10 k - 30 k 500 + 100 600 + 100 600 + 100 650 + 100 710 + 100

30 k - 100 k 0.35 % + 100 0.4 % + 100 0.4 % + 100 0.4 % + 100 0.4 % + 100

1 - 10 250 + 120 300 + 120 300 + 120 380 + 120 400 + 120

10 - 10 k 250 + 120 300 + 120 300 + 120 340 + 120 370 + 120

10 k - 30 k 600+ 120 700 + 120 700 + 120 775 + 120 800 + 120

30 k - 100 k 0.35 % + 120 0.4 % + 120 0.4 % + 120 0.4 % + 120 0.4 % + 120

24 hour

TCal ±1 °C

[1] [2] [6] [9]

± (ppm Reading + ppm Range)

90 day

TCal ±1 °C

365 day

TCal ±1 °C

[4]

365 day

TCal ±1 °C

[9]

365 day

TCal ±5 °C

1-13

8508A

Service Manual

200 μA

[1] [2] [6] [9]

Input Impedance (Ω)

150 150

22

)dc(ac

+

AC Current (Secondary Specifications)

Temperature Coefficient

Range Frequency (Hz)

200 μA, 2 mA &

20 mA

200 mA 1 - 10 10 15 1.2 1.3

10 - 10 k 15 20

10 k - 30 k 15 20

2 A 10 - 2 k 10 15 0.3 0.4

2 k - 10 k 15 20

10 k - 30 k 20 30

20 A 10 - 2 k 20 25 0.04 2 k - 10 k 25 30

Type........................................................................ True rms, AC coupled. DC coupled gives

Crest Factor........................................................... 3:1 at 50 % range, 1.5:1 at full range

Protection

Front Input............................................................... 20 A rms

Rear Input ............................................................... 2 A rms, Rear Panel Fuse

Settling Time 200 μA to 200 mA Ranges 2 A Range 20 A Range (at 10 A)

to 100 ppm of step to 100 ppm of step to 300 ppm of step

100 Hz filter............................................................. < 0.5 s < 1 s < 1 s

40 Hz filter............................................................... < 1.25 s < 2 s < 2 s

10 Hz filter............................................................... < 5 s < 10 s < 10 s

1 Hz filter................................................................. < 50 s < 50 s < 50 s

1 - 10 10 15

10 - 10 k 10 15 2 mA 15.2 15.2

10 k - 30 k 12 20 20 mA 1.8 1.9

30 k - 100 k 40 60

15 °C - 30 °C

± ppm Reading/°C Range Front Rear

5 °C - 15 °C

30 °C - 40 °C

1-14

Introduction and Specifications

Specifications 1

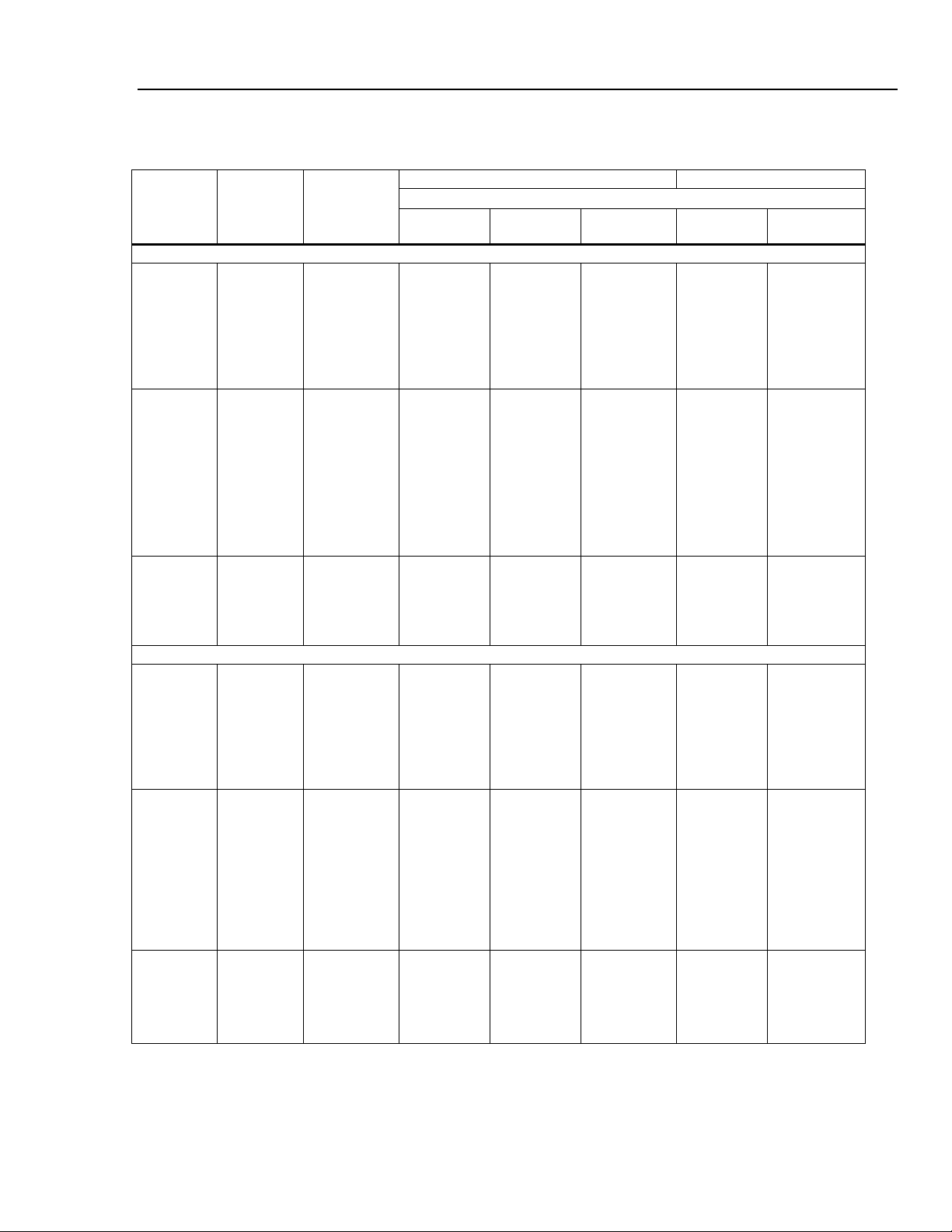

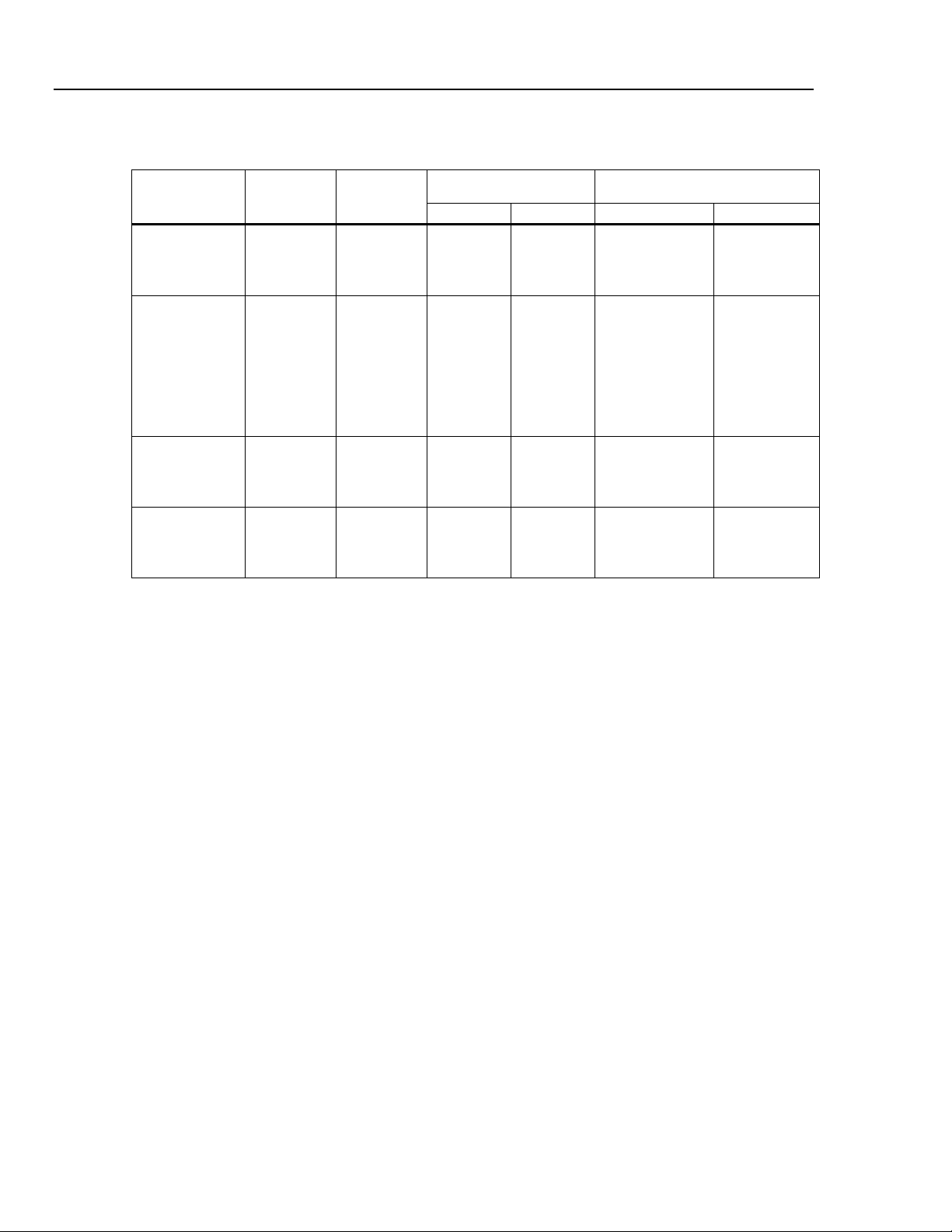

Resistance

Resistance

Uncertainty Relative to Cal Stds Absolute Uncertainties

Range Full Scale

95% Confidence Level

2 Ω 1.999 900 00 Normal 5.0 + 2.0 8.0 + 2.0 10 + 2.0 15 + 2.0 17 + 2.0

20 Ω 19.999 000 0 Normal 2.5 + 0.7 4.5 + 0.7 7.0 + 0.7 9.0 + 0.7 9.5 + 0.7

200 Ω 199.990 000 Normal 1.5 + 0.25 4.0 + 0.25 7.0 + 0.25 7.5 + 0.25 8.0 + 0.25

2 kΩ 1.999 900 00 Normal 1.0 + 0.25 3.5 + 0.25 7.0 + 0.25 7.5 + 0.25 8.0 + 0.25

20 kΩ 19.999 000 0 Normal 1.0 + 0.25 3.5 + 0.25 7.0 + 0.25 7.5 + 0.25 8.0 + 0.25

200 kΩ 199.990 000 Normal 1.0 + 0.25 3.5 + 0.25 7.0 + 0.25 7.5 + 0.25 8.0 + 0.25

2 MΩ 1.999 900 00 Normal 2.0 + 0.5 4.0 + 0.5 7.0 + 0.5 8.5 + 0.5 9.0 + 0.5

20 MΩ 19.999 000 0 Normal 3.5 + 5.0 6.0 + 5.0 9.0 + 5.0 15 + 5.0 20 + 5.0

200 MΩ 199.990 000 Normal 20 + 50 25 + 50 30 + 50 60 + 50 120 + 50

2 GΩ 1.999 900 00 Normal 250 + 500 350 + 500 500 + 500 525 + 500 1510 + 500

2 Ω 1.999 900 00 Lo Current 5.0 + 2.0 8.0 + 2.0 10 + 2.0 15 + 2.0 17 + 2.0

20 Ω 19.999 000 0 Lo Current 2.5 + 0.7 4.5 + 0.7 7.0 + 0.7 9.0 + 0.7 9.5 + 0.7

200 Ω 199.990 000 Lo Current 2.5 + 0.7 5.0 + 0.7 7.0 + 0.7 7.5 + 0.7 8.0 + 0.7

2 kΩ 1.999 900 00 Lo Current 2.5 + 0.7 5.0 + 0.7 7.0 + 0.7 7.5 + 0.7 8.0 + 0.7

20 kΩ 19.999 000 0 Lo Current 2.5 + 0.7 5.0 + 0.7 7.0 + 0.7 7.5 + 0.7 8.0 + 0.7

200 kΩ 199.990 000 Lo Current 5.0 + 0.5 6.5 + 0.5 7.0 + 0.5 7.5 + 0.5 8.0 + 0.5

2 MΩ 1.999 900 00 Lo Current 7.0 + 0.5 8.0 + 0.5 9.0 + 0.5 10 + 0.5 15 + 0.5

20 MΩ 19.999 000 0 Lo Current 20 + 5.0 20 + 5.0 25 + 5.0 35 + 5.0 90 + 5.0

200 MΩ 199.990 000 Lo Current 250 + 500 350 + 500 500 + 500 515 + 500 1505 + 500

2 GΩ 1.999 900 00 Lo Current 250 + 500 350 + 500 500 + 500 525 + 500 1510 + 500

20 MΩ 19.999 000 0 High Voltage 2.0 + 0.5 4.0 + 0.5 7.0 + 0.5 15 + 0.5 17 + 0.5

200 MΩ 199.990 000 High Voltage 3.5 + 5.0 6.0 + 5.0 9.0 + 5.0 60 + 5.0 65 + 5.0

2 GΩ 1.999 900 00 High Voltage 20 + 50 25 + 50 30 + 50 150 + 50 180 + 50

20 GΩ 19.999 000 0 High Voltage 250 + 500 350 + 500 500 + 500 525 + 500 1510 + 500

99% Confidence Level

2 Ω 1.999 900 00 Normal 6.0 + 2.5 10 + 2.5 12 + 2.5 19 + 2.5 22 + 2.5

20 Ω 19.999 000 0 Normal 3.0 + 0.9 5.5 + 0.9 8.5 + 0.9 11.5 + 0.9 12.0 + 0.9

200 Ω 199.990 000 Normal 1.8 + 0.3 5.0 + 0.3 8.5 + 0.3 9.5 + 0.3 10 + 0.3

2 kΩ 1.999 900 00 Normal 1.2 + 0.3 4.5 + 0.3 8.5 + 0.3 9.5 + 0.3 10 + 0.3

20 kΩ 19.999 000 0 Normal 1.2 + 0.3 4.5 + 0.3 8.5 + 0.3 9.5 + 0.3 10 + 0.3

200 kΩ 199.990 000 Normal 1.2 + 0.3 4.5 + 0.3 8.5 + 0.3 9.5 + 0.3 10 + 0.3

2 MΩ 1.999 900 00 Normal 2.5 + 0.6 5.0 + 0.6 8.5 + 0.6 10.5 + 0.6 12 + 0.6

20 MΩ 19.999 000 0 Normal 4.5 + 6.0 7.5 + 6.0 12 + 6.0 20 + 6.0 25 + 6.0

200 MΩ 199.990 000 Normal 25 + 60 30 + 60 35 + 60 75 + 60 150 + 60

2 GΩ 1.999 900 00 Normal 325 + 600 450 + 600 650 + 600 675 + 600 1810 + 600

2 Ω 1.999 900 00 Lo Current 6.0 + 2.5 10 + 2.5 12 + 2.5 19 + 2.5 22 + 2.5

20 Ω 19.999 000 0 Lo Current 3.0 + 0.9 5.5 + 0.9 8.5 + 0.9 11.5 + 0.9 12.0 + 0.9

200 Ω 199.990 000 Lo Current 3.0 + 0.9 6.5 + 0.9 8.5 + 0.9 9.5 + 0.9 10.0 + 0.9

2 kΩ 1.999 900 00 Lo Current 3.0 + 0.9 6.5 + 0.9 8.5 + 0.9 9.5 + 0.9 10.0 + 0.9

20 kΩ 19.999 000 0 Lo Current 3.0 + 0.9 6.5 + 0.9 8.5 + 0.9 9.5 + 0.9 10.0 + 0.9

200 kΩ 199.990 000 Lo Current 6.0 + 0.6 8.0 + 0.6 9.0 + 0.6 9.5 + 0.6 10.0 + 0.6

2 MΩ 1.999 900 00 Lo Current 8.0 + 0.6 10.0 + 0.6 12.0 + 0.6 13.0 + 0.6 17.0 + 0.6

20 MΩ 19.999 000 0 Lo Current 25 + 6.0 25 + 6.0 30 + 6.0 45 + 6.0 110 + 6.0

200 MΩ 199.990 000 Lo Current 325 + 600 450 + 600 650 + 600 670 + 600 1810 + 600

2 GΩ 1.999 900 00 Lo Current 325 + 600 450 + 600 650 + 600 675 + 600 1810 + 600

20 MΩ 19.999 000 0 High Voltage 2.5 + 0.6 5.0 + 0.6 8.5 + 0.6 19 + 0.6 20 + 0.6

200 MΩ 199.990 000 High Voltage 4.5 + 6.0 7.5 + 6.0 12 + 6.0 75 + 6.0 80 + 6.0

2 GΩ 1.999 900 00 High Voltage 25 + 60 30 + 60 35 + 60 195 + 60 230 + 60

20 GΩ 19.999 000 0 High Voltage 325 + 600 450 + 600 650 + 600 675 + 600 1810 + 600

[15]

Mode

[10]

24 hour

TCal ±1 °C

[1] [2] [3] [9]

± (ppm Reading + ppm Range)

90 day

TCal ±1 °C

365 day

TCal ±1 °C

[4]

365 day

TCal ±1 °C

365 day

TCal ±5 °C

1-15

8508A

Service Manual

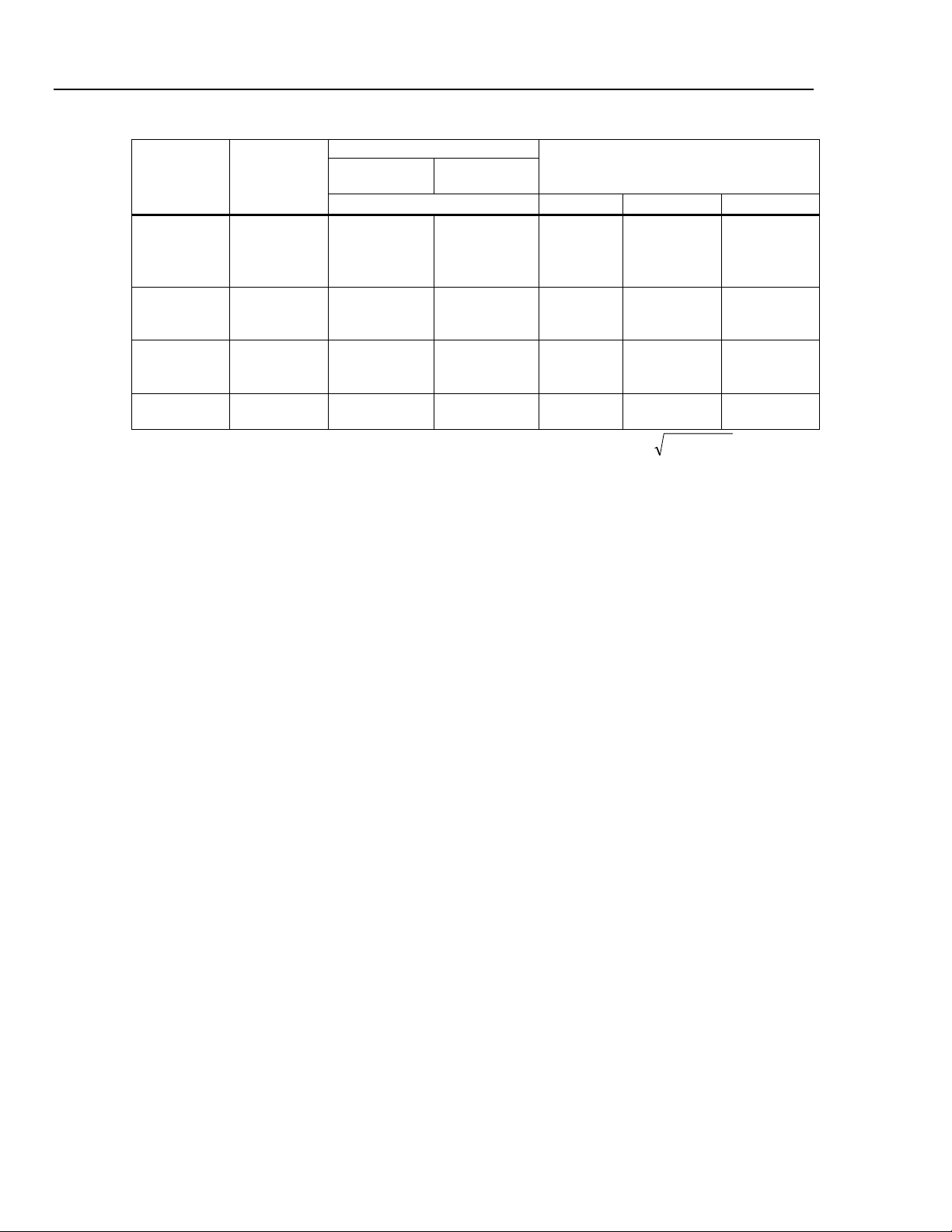

Resistance - Normal Mode (Secondary Specifications)

Range Measurement Current

2 Ω

20 Ω

200 Ω

2 kΩ

100 mA 2.0 + 2.0 1.5 2.5

10 mA 0.8 + 0.7 0.6 1.0

10 mA 0.2 + 0.15 0.5 0.8

1 mA 0.2 + 0.15 0.5 0.8

20 kΩ 100 μA

200 kΩ 100 μA

2 MΩ 10 μA

20 MΩ 1 μA

200 MΩ

2 GΩ

100 nA 15 + 50 20 30

10 nA 200 + 500 200 300

Resistance - Lo Current Mode (Secondary Specifications)

Range Measurement Current

2 Ω

20 Ω

200 Ω

100 mA 2.0 + 2.0 1.5 2.5

10 mA 0.8 + 0.7 0.6 1.0

1 mA 0.8 + 0.7 0.6 1.0

2 kΩ 100 μA

20 kΩ 10 μA

200 kΩ 10 μA

2 MΩ 1 μA

20 MΩ

200 MΩ

2 GΩ

100 nA 15 + 5 20 30

10 nA 200 + 500 200 300

10 nA 200 + 500 200 300

Resistance - High Voltage Mode (Secondary Specifications)

[9]

Range

Measurement Current

20 MΩ 10 μA

200 MΩ 1 μA

2 GΩ

20 GΩ

100 nA 15 + 50 20 30

10 nA 200 + 500 200 300

Transfer Uncertainty

20 mins ±1 °C

± (ppm Reading

15 °C - 30 °C

+ ppm Range)

0.2 + 0.15 0.5 0.8

0.2 + 0.15 0.5 0.8

0.5 + 0.5 0.6 1.0

2.5 + 5 2 3

Transfer Uncertainty

20 mins ±1 °C

± (ppm Reading

15 °C - 30 °C

+ ppm Range)

0.8 + 0.7 0.6 1.0

0.8 + 0.7 0.6 1.0

0.5 + 0.5 0.6 1.0

2.0 + 0.5 2 3

Transfer Uncertainty

20 mins ±1 °C

± (ppm Reading

15 °C - 30 °C

+ ppm Range)

0.5 + 0.5 0.6 1.0

2.0 + 0.5 2.0 3

[1] [2] [3] [10]

Temperature Coefficient

5 °C - 15 °C

30 °C - 40 °C

± ppm Reading/°C

[1] [2] [3] [10]

Temperature Coefficient

5 °C - 15 °C

30 °C - 40 °C

± ppm Reading/°C

[1] [2] [3]

Temperature Coefficient

5 °C - 15 °C

30 °C - 40 °C

± ppm Reading/°C

Type........................................................................ True 4-wire with Ohms guard. 2-wire selectable.

Max Lead Resistance............................................ 10 Ω in any or all leads, 1 Ω on 2 Ω range

Full Scale Measurement Voltage

Normal Mode .......................................................... 200 mV/2 V/20 V

Lo Current Mode ..................................................... 200 mV/2 V

High Voltage Mode ................................................. 200 V

Protection (All ranges) .......................................... 250 V rms, 360 V pk

Ratio Accuracy

Range to Range...................................................... ±(Net Front Input Accuracy + Net Rear Input Accuracy)

Within Range .......................................................... Apply 24 hour or 20 minute Transfer Uncertainty specifications

Settling Time ......................................................... Up to 200 kΩ range generally the same as DC Voltage Filter In but

depends on external connections

1-16

Introduction and Specifications

Specifications 1

Temperature

Temperature Readout

Typical Equivalent Temperature Measurement Uncertainty

[11]

Probe Type

25 Ω PRT/SPRT

25 Ω PRT/SPRT

25 Ω PRT/SPRT

100 Ω PRT/SPRT

100 Ω PRT/SPRT

100 Ω PRT/SPRT

100 Ω PRT/SPRT

25 Ω PRT/SPRT

25 Ω PRT/SPRT

25 Ω PRT/SPRT

100 Ω PRT/SPRT

100 Ω PRT/SPRT

100 Ω PRT/SPRT

100 Ω PRT/SPRT

Resistance Range

95% Confidence Level

0 - 199.990 000 Ω

200 - 1999.900 00 Ω

99% Confidence Level

0 - 199.990 000 Ω

200 - 1999.900 00 Ω

Absolute Resistance

Measurement Uncertainty

365 day Tcal ±1 °C

[4]

±(ppm Reading + mΩ)

7.5 + 0.14

7.5 + 0.5

9.5 + 0.18

9.5 + 0.6

Temperature Readout (Secondary Specifications)

Resistance Measurement Uncertainty

Resistance Range

0 - 199.990 000 Ω

200 - 1999.900 00 Ω

Transfer Uncertainty

20 Minute ±1 °C

±(ppm Reading + mΩ)

[11]

0.8 + 0.14 0.1 0.005 0.6 1.0

0.2 + 0.5 0.1 0.005 0.5 0.8

2-Wire

Adder

(Ω)

Type ....................................................................... 4-wire current reversal resistance measurement with readout of

Temperature Range ..............................................-200 °C to 660 °C, readout also available in °F or K.

Linearization ......................................................... ITS-90 or Callendar van Dusen. Entry and storage of coefficients and

Current Source ..................................................... 1 mA

equivalent temperature. 2-wire and 3-wire selectable without current

reversal. Refer to Resistance specifications for additional details.

nominal resistance for up to 100 probes.

[1] [2] [3]

3-Wire

Adder

Nominal

Temperature

(°C)

-200 5 0.0085

0 25 0.0035

660 84 0.0025

-200 20 0.0035

0 100 0.0025

232 185 0.0020

400 250 0.0025

-200 5 0.0010

0 25 0.0040

660 84 0.0025

-200 20 0.0040

0 100 0.0025

232 185 0.0020

400 250 0.0025

(Ω)

Resistance

(Ω)

[1] [2] [3]

Temp Coeff. ± ppm Reading/°C

15 °C - 30 °C

[12]

Accuracy

± (°C)

5 °C - 15 °C

30 °C - 40 °C

1-17

8508A

Service Manual

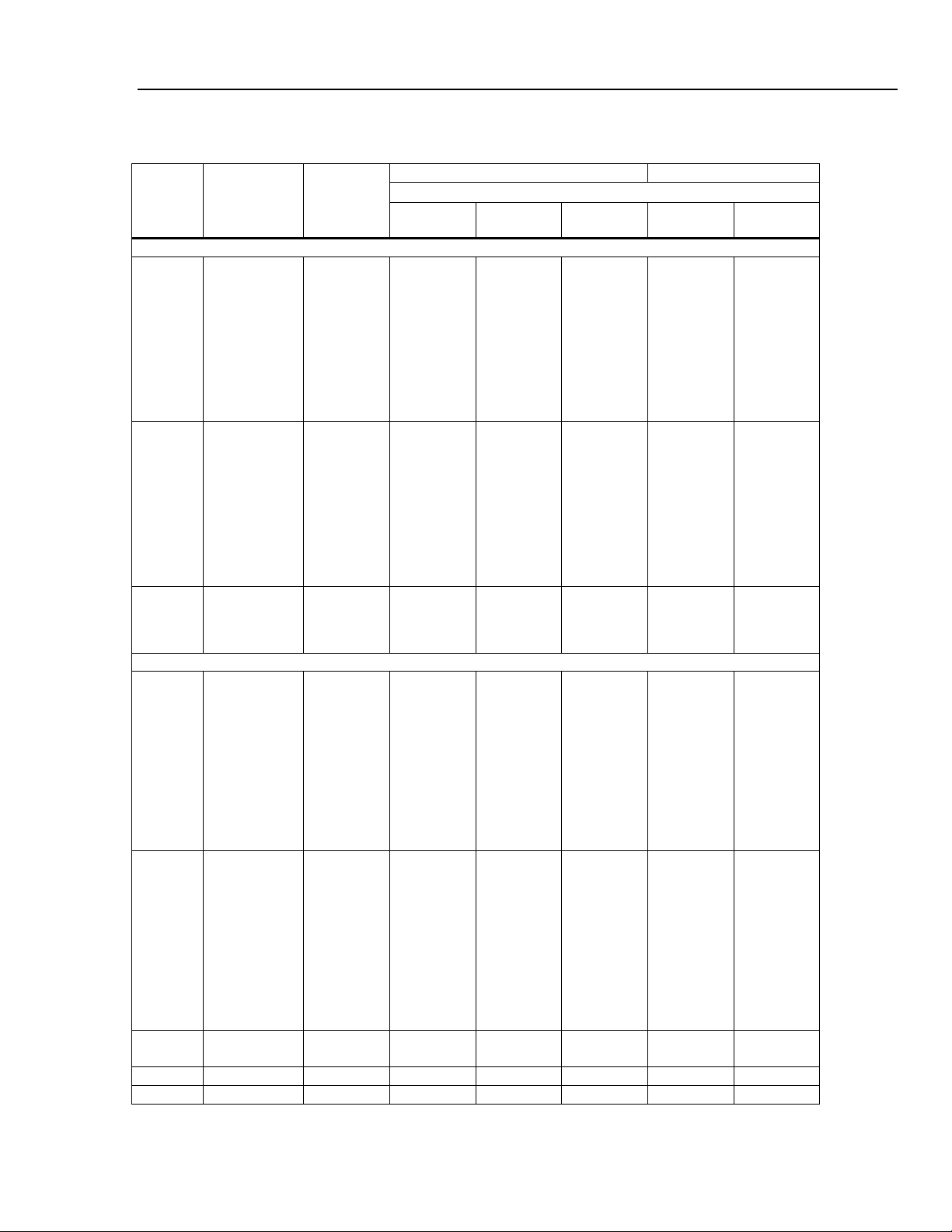

Read Rate and Additional Uncertainty

Function Resolution

DCV, DCI & Ohms

[10]

8 1/25 1/6 0 + 0 0 + 0.1

7 1/6 1/2 0 + 0.1 0 + 0.5

6 2 35 1.0 + 0.5 0 + 2.5

5 35 150 0 + 5 0 + 25

6 1 1/50 0 + 0

ACV & ACI

[6]

10 1/5 0 + 0

40 1/2 0 + 0

100 1 0 + 0

5 1 1/50 0 + 5

10 1/5 0 + 5

40 1/2 0 + 5

100 2 0 + 5

1 1/25 200 + 20

ACV Transfer Off

[6]

10 1/2.5 200 + 20

40 1 200 + 20

100 4 200 + 20

PRT & Tru Ohms

[14]

8 - 1/90 1/30 0 + 0

7 - 1/30 1/10 0 + 0.1

6 - 1/4 1/3 1.0 + 0.5

5 - 1/3 1/3 0 + 5

Read Rate and Additional Uncertainty

Filter

Frequency (Hz)

Read Rate

(readings/second)

Normal Fast Normal Fast

Additional Errors

[13]

± (ppm Reading + ppm Range)

Notes to Performance Specifications

Fluke guarantees 8508A performance verification using specifications stated to 99 % confidence level.

[1] Specifications apply for max resolution in each function, normal mode

[2] Assumes 4 hour warm-up period

[3] Input zero or offset null required whenever the temperature moves more than ±1 °C from the temperature at which the previous

null/zero was performed

[4] TCal = Ambient calibration temperature

[5] Integration time >1 Power Line cycle

[6] Valid for signals >1 % Full Scale, Transfer Mode On. Signals must be DC coupled <40 Hz. Readings invalid with Transfer Mode On

and 1Hz filter selected when using internal trigger mode

[7] Max Volt.Hertz 3 x 10

[8] >300 V, <10 kHz add: ±0.0004 x (Reading-300)

>300 V, 10 kHz - 30 kHz add: ± (0.0004 + (Frequency - 10000) x10

>300 V, >30 kHz add: ±0.0024 x (Reading-300)

[9] Typical below 10 Hz for ACV, below 10 Hz and above 10 kHz for ACI, and above 2 GΩ for Resistance

[10] Tru Ohms mode available on 2 Ω to 20 kΩ ranges. Read Rate reduced in Tru Ohms Mode. Specification for Tru Ohms same as

corresponding Normal or Lo Current range

[11] Valid for 4-wire sensor

[12] Not including sensor uncertainty

[13] Assume Range and Full Scale = 2000 V when calculating for 1000 V Range. For DCI, additional errors only apply in 5 digit

resolution

[14] Fast mode not available in PRT

[15] The maximum display value for the Analog to Digital converter is 199 990 000 counts. This sets the maximum value measurable on

each range to be a one followed by four nines. For example, the maximum measured values on the 2 V range on DC Voltage are

±1.999 900 00 V. However, the 1000 V ranges are limited to a maximum 1050 V.

7

2

ppm

2

ppm

-7

) x (Reading-300)2 ppm

1-18

Introduction and Specifications

(

)

Applying the Specifications 1

Applying the Specifications

Introduction

The Fluke 8508A has been designed specifically for metrologists. Not only does it

provide the performance metrologists need, but it is specified in a way to allow users to

really understand the uncertainties of the measurements, and easily make allowance for

those uncertainty contributions when performing measurement uncertainty analyses and

compiling uncertainty budgets. Contemporary metrology practices, including ISO17025

based laboratory accreditation schemes, require uncertainty analysis to be performed in

accordance with the statistically based techniques described in the ISO Guide to the

Expression of Uncertainty in Measurement (often referred to as the ‘GUM’). For

convenience, the 8508A specifications are quoted at a coverage factor of k=2, equivalent

to a confidence level of approximately 95 %, as required by these methods.

Specifications are also provided at a confidence level of 99 %.

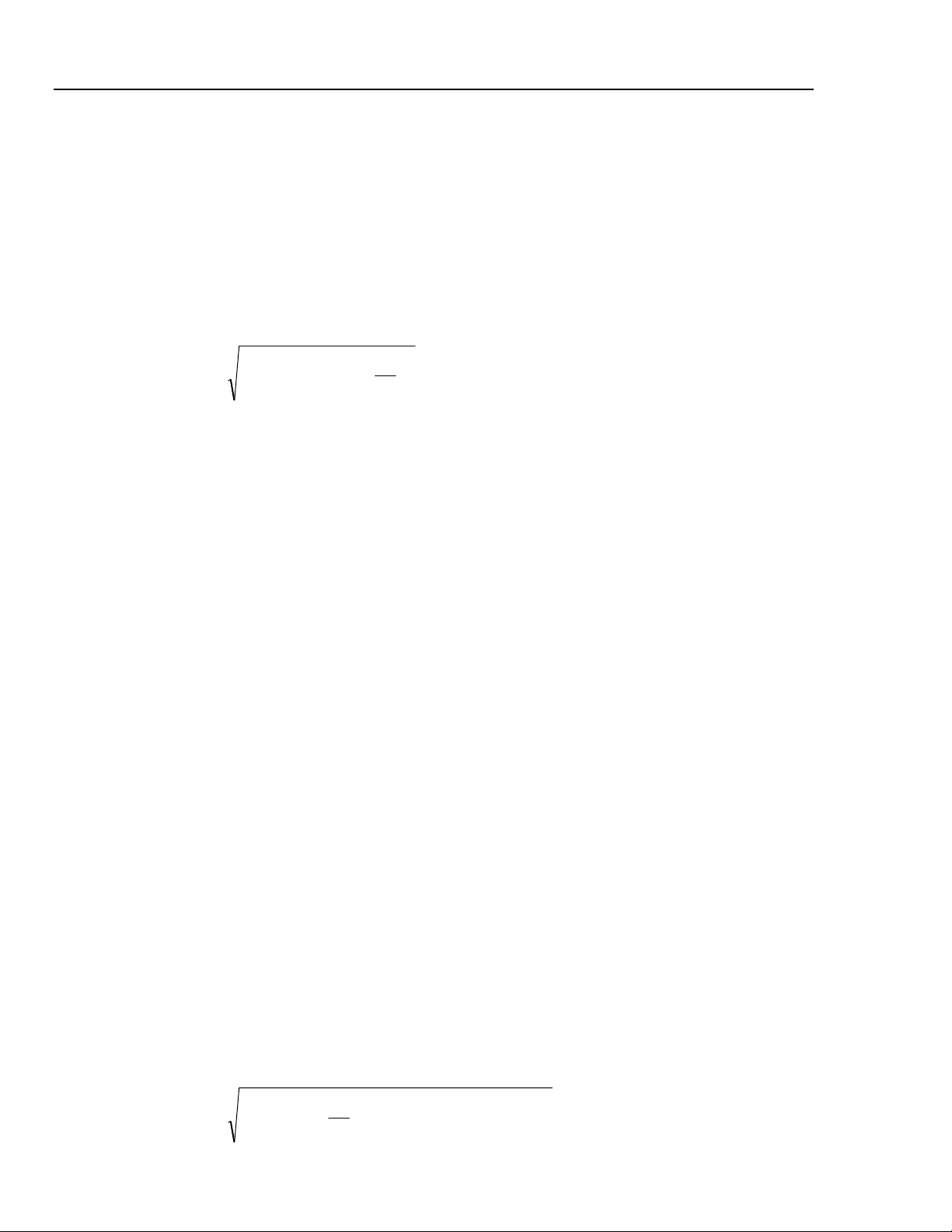

Performance specifications for the 8508A consist of two elements, the first is a

contribution expressed as parts-per-million of the Reading, and the second contribution is

expressed as parts-per-million of the Range. These must be evaluated and combined for

the relevant reading and range values applicable to the measurement being made,

ensuring that both elements are evaluated on the same basis, such as parts per million of

the measured value or in absolute terms (volts, amps, ohms, etc). The two elements are

combined by adding algebraically. For example measuring 10 V on the 20 VDC range

and applying the 365 day

±1 °C specifications:

First, expressing the contributions in terms of parts-per-million of the measured value:

⎛

+±=

⎜

⎝

Second, expressing the contributions in volts:

The 8508 is designed to provide accuracy and stability without the need for internal auto

or self calibration routines which may otherwise compromise the continuity and

traceability of measurement performance history. To realise the full potential of the

8508A performance accepted metrology practices should be employed, such as

performing a zeroing or null operation to remove any offsets present in the measurement

setup when making DC measurements. The 8508A specifications assume that these

methods are employed.

Absolute and Relative Specifications

The Relative to Calibration Standards specifications describe the performance of the

8508A itself for the time periods and temperature range listed excluding the uncertainty

of the standards used to perform calibration of the 8508A during manufacture. The

Absolute specifications include the uncertainty of the standards used to perform

calibration of the 8508A at manufacture and may be used to determine the uncertainty of

measurements made with the 8508A for periods up to 1 year and over a temperature

range of ±5 °C from calibration. If the user has their 8508A calibrated with different

uncertainties, the Relative specifications can be combined with the uncertainties

applicable to that calibration to determine the effective absolute uncertainty following

that calibration.

20

⎞

x2.00.3 ±=+±=

⎟

10

⎠

()

V 10ofppm4.34.00.3

566

−−−

μV3410x4.320x10x2.010x10x0.3

±=±=+±=

1-19

8508A

Service Manual

Applying User’s Calibration Uncertainties

Operating and Calibration Temperature Ranges

When the 8508A is calibrated by another laboratory the uncertainties of the calibration

standards used may be applied by combining those uncertainties with the 8508A’s

Relative to Standards specifications. The applicable calibration uncertainties and the

8508A relative specifications must both be expressed at the same confidence level, and

be combined in a RSS (Root Sum Square) summation. Accepted metrology practice

mandates that calibration uncertainties are stated at 95 %. Check the applicable

calibration uncertainties are stated at 95 % and then combine them with the 8508A 95 %

Relative specifications. For example, if the 8508A is calibrated at 10 V DC with an

uncertainty of 1.5 ppm at 95 %: The absolute uncertainty at 10 V for a period of 90 days

and ±1 °C from calibration is:

2

20

⎛

2

⎜

2.04.15.1

⎝

As a metrology tool, the 8508A will commonly be used in a calibration laboratory where

the temperature would be controlled to ±1 °C, and the 8508A ±1 °C specifications are

applicable to those situations. The majority of electrical calibration laboratories operate at

a nominal temperature of 23 °C, the temperature at which the 8508A is calibrated by

Fluke during manufacture and service. The 8508A is also capable of being calibrated at

any temperature between 20 °C and 25 °C and the ±1 °C specifications will apply to

operation within ±1 °C of that calibration temperature. In the 8508A specification tables

the temperature of calibration is referred to as TCal. Specifications for ±5 °C are

provided for situations where the 8508A is operated in environments with wider

temperature variations up to ±5 °C. For applications where the knowledge of the effect of

temperature on 8508A performance is important, temperature coefficients are listed in the

8508A specifications. If the operating temperature is within the range 15 °C to 30 °C the

15 °C to 30 °C temperature coefficient specifications are applicable otherwise use the

5 °C to 15 °C/30 °C to 40 °C figures, provided the temperature lies within that range. The

8508A may be operated at temperatures between 0 °C and 50 °C, but performance is not

specified outside the range 5 °C to 40 °C.

⎞

×++±=

10

±=

⎟

⎠

V 10ofppm3.2

1-20

Applying Temperature Coefficient Specifications

The 8508A specification tables include information for the typical operating conditions

of ±1 °C for calibration laboratories with tight temperature control, and ±5 °C for

calibration laboratories with looser temperature control or uncontrolled environments

within that temperature range. For the majority of applications choosing the Absolute

specifications for the most appropriate operating temperature range will be adequate.

However performance at other temperatures may be determined by including an

allowance for temperature coefficient over the additional temperature range. Care should

be taken when making this calculation as an amount of temperature coefficient is already

included in the 8508A specifications and those specifications are themselves based on

combining contributions using techniques similar to those employed in uncertainty

analysis. For example, consider operating at 33 °C, 10 °C from the 23 °C calibration

temperature. The ±5 °C specifications already include a contribution for 5 °C of

temperature difference, so this amount of temperature effect must be removed before the

effect of the 10 °C difference is added. Consider 10 V on the 20 VDC range: 365 day

absolute specification (95 %) at 33 °C expressed in parts-per-million of 10 V is:

2

20

⎛

⎜

2.05.3

⎝

⎞

×+±=

10

()( )

⎟

⎠

22

±=+−

V 10ofppm16.65.0x103.0x5

Loading...

Loading...