Page 1

810

Vibration Tester

Users Manual

January 2010, Rev.1, 3/10

© 2010 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Page 2

Your Fluke Vibration Tester is warranted to be free from defects in material and workmanship under normal use and service for three years

from the date of shipment to you. The same warranty applies to the Tachometer and the Sensor but for one year from the date of shipment.

Parts, product repairs, and services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of a

Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in Fluke's opinion, has been misused,

altered, neglected, contaminated, or damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software will

operate substantially in accordance with its functional specifications for 90 days and that it has been properly recorded on non-defective

media. Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to

extend a greater or different warranty on behalf of Fluke. Warranty support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a defective

product which is returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return authorization information, then send the

product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk

for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition of operation or handling,

including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components,

Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the product will be

returned to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held

invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability

of any other provision.

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Page 3

Table of Contents

Chapter Title Page

1 Overview ....................................................................................................................... 1-1

Introduction .................................................................................................................... 1-3

Features ......................................................................................................................... 1-3

How to Contact Fluke..................................................................................................... 1-4

Safety ............................................................................................................................. 1-4

Rotating Equipment ................................................................................................... 1-4

Tachometer ............................................................................................................... 1-5

Heat Sink................................................................................................................... 1-5

Symbols ......................................................................................................................... 1-5

Unpack and Inspect........................................................................................................ 1-6

Storage........................................................................................................................... 1-8

Battery............................................................................................................................ 1-8

Accessories.................................................................................................................... 1-10

i

Page 4

810

Users Manual

2 Specifications .............................................................................................................. 2-1

810 Vibration Tester Specifications ............................................................................... 2-3

Diagnostic Specifications .......................................................................................... 2-3

Electrical Specifications ............................................................................................ 2-3

General Specifications .............................................................................................. 2-4

Sensor Specifications .................................................................................................... 2-5

Tachometer Specifications ............................................................................................ 2-6

Viewer Software Requirements ..................................................................................... 2-6

3 Getting Started............................................................................................................. 3-1

Introduction.................................................................................................................... 3-3

Navigation and User Interface ....................................................................................... 3-3

How to Use the Dial .................................................................................................. 3-4

How to Use the Function Softkeys ............................................................................ 3-4

Accessory Connectors................................................................................................... 3-5

Start the Tester.............................................................................................................. 3-6

Sensor Setup................................................................................................................. 3-7

Compatible Sensors.................................................................................................. 3-7

How to Connect the Fluke Sensor ............................................................................ 3-7

Sensor Care and Handling........................................................................................ 3-8

Tachometer Setup ......................................................................................................... 3-9

How to Measure RPM with the Tachometer ............................................................. 3-9

Laser Safety Precautions.......................................................................................... 3-10

How to Access Help....................................................................................................... 3-11

Instrument Setup ........................................................................................................... 3-11

Self Test.................................................................................................................... 3-12

Settings..................................................................................................................... 3-12

Clear Memory ........................................................................................................... 3-15

ii

Page 5

Contents (continued)

4 Operation ...................................................................................................................... 4-1

Start the Tester .............................................................................................................. 4-3

Create a New Machine Setup ........................................................................................ 4-4

Machine Setup ............................................................................................................... 4-5

Motor Input (Driver) Information................................................................................. 4-6

RPM Entry ................................................................................................................. 4-8

Coupling Information ................................................................................................. 4-8

Transmission with Closed Coupling...................................................................... 4-9

Transmission without Closed Coupling................................................................. 4-10

Driven Component..................................................................................................... 4-11

Pump .................................................................................................................... 4-11

Fan ....................................................................................................................... 4-12

Compressor .......................................................................................................... 4-13

Blower................................................................................................................... 4-14

Spindle.................................................................................................................. 4-14

Transmission Component.......................................................................................... 4-14

Gearbox................................................................................................................ 4-14

Belt Drive .............................................................................................................. 4-17

Copy an Existing Machine Setup............................................................................... 4-19

Edit the Saved Machine Setup .................................................................................. 4-22

Before You Measure ...................................................................................................... 4-24

Select Measurement Locations ................................................................................. 4-24

Total Number of Measurement Locations.................................................................. 4-25

Sensor Orientation..................................................................................................... 4-26

Sensor Mounting ....................................................................................................... 4-27

How to Measure Vibration .............................................................................................. 4-29

How to Diagnose............................................................................................................ 4-38

Fault Types................................................................................................................ 4-38

iii

Page 6

810

Users Manual

Severity Scale........................................................................................................... 4-40

Fault Details and Vibration Spectrum........................................................................ 4-42

How to Access the Memory ........................................................................................... 4-45

View by Machine Setup ............................................................................................ 4-45

View by Measurement Date...................................................................................... 4-46

View by Last Diagnosis............................................................................................. 4-48

5 Viewer Software ........................................................................................................... 5-1

Introduction.................................................................................................................... 5-3

System Requirements ................................................................................................... 5-3

PC Connections............................................................................................................. 5-3

Install the Viewer Software ............................................................................................ 5-5

Microsoft .Net Framework 2.0................................................................................... 5-5

Microsoft .Net Framework 3.5 SP1 ........................................................................... 5-5

Microsoft SQL Server 2005 Express......................................................................... 5-6

Microsoft ActiveSync 4.5........................................................................................... 5-6

Microsoft SQL Server Compact 3.5 SP1................................................................... 5-6

Microsoft SQL Server Compact 3.5 SP1 for Devices................................................ 5-6

Viewer Software........................................................................................................ 5-7

Uninstall the Viewer Software........................................................................................ 5-8

Navigation...................................................................................................................... 5-9

Preferences ................................................................................................................... 5-11

Application Settings .................................................................................................. 5-11

Upgrades .................................................................................................................. 5-12

Data Transfer............................................................................................................ 5-12

Import Machine Setup .......................................................................................... 5-14

Export Machine Setup.......................................................................................... 5-15

Import Diagnostic Data......................................................................................... 5-18

Export Diagnostic Data ........................................................................................ 5-19

iv

Page 7

Contents (continued)

Export Faults Data ................................................................................................ 5-22

Machine Setup ............................................................................................................... 5-24

Set Up a New Machine.............................................................................................. 5-26

View Machine Setups ................................................................................................ 5-28

View Diagnosis............................................................................................................... 5-31

View Other Data Files................................................................................................ 5-34

Time Waveform ......................................................................................................... 5-34

Spectra ...................................................................................................................... 5-36

6 Maintenance ................................................................................................................. 6-1

Introduction .................................................................................................................... 6-3

How to Clean.................................................................................................................. 6-3

Sensor Care ................................................................................................................... 6-3

Battery Replacement...................................................................................................... 6-3

External SD Memory Card Installation ........................................................................... 6-5

Vibration Tester Upgrades ............................................................................................. 6-7

How to Troubleshoot ...................................................................................................... 6-8

Appendices

A Frequently Asked Questions ................................................................................... A-1

B Warning and Error Messages ................................................................................. B-1

C Glossary.................................................................................................................. C-1

v

Page 8

810

Users Manual

vi

Page 9

List of Tables

Table Title Page

1-1. Symbols................................................................................................................................. 1-5

1-2. Accessories ........................................................................................................................... 1-10

3-1. Front Panel............................................................................................................................ 3-4

3-2. Navigation Softkey Functions................................................................................................ 3-5

3-3. Accessory Connectors .......................................................................................................... 3-6

3-4. Tester Settings ...................................................................................................................... 3-14

4-1. New Machine Setup Functions.............................................................................................. 4-5

4-2. Motor Input Options............................................................................................................... 4-7

4-3. Closed Coupling Transmission Options ................................................................................ 4-9

4-4. Transmission without Closed Coupling Options .................................................................... 4-10

4-5. Pump Options for Driven Components .................................................................................. 4-11

4-6. Fan Options for Driven Components ..................................................................................... 4-12

4-7. Compressor Options for Driven Components........................................................................ 4-13

4-8. Blower Options for Driven Components ................................................................................ 4-14

vii

Page 10

810

Users Manual

4-9. Gearbox Options for the Transmission ................................................................................. 4-15

4-10. Driven Component Options................................................................................................... 4-16

4-11. Drive Options for the Transmission....................................................................................... 4-17

4-12. Change Machine Name ........................................................................................................ 4-18

4-13. Saved Machine Setup Functions .......................................................................................... 4-19

4-14. Copy Machine Setup Functions ............................................................................................ 4-21

4-15. Change Machine Name Functions........................................................................................ 4-23

4-16. Sensor Placement Functions ................................................................................................ 4-32

4-17. Measurement Functions ....................................................................................................... 4-34

4-18. Measurement Complete Functions ....................................................................................... 4-35

4-19. Sensor Placement Functions ................................................................................................ 4-37

4-20. Diagnosis Faults ................................................................................................................... 4-39

4-21. Cited Peak Details ................................................................................................................ 4-43

4-22. Diagnosis Spectra Functions ................................................................................................ 4-44

4-23. Existing Machine Setup Functions........................................................................................ 4-46

4-24. Measurement Date Functions............................................................................................... 4-46

4-25. View by Measurement Date Functions ................................................................................. 4-47

5-1. Viewer Software Navigation Menus...................................................................................... 5-10

5-2. Application Settings .............................................................................................................. 5-12

5-3. View Machine Setup Utilities................................................................................................. 5-30

6-1. Troubleshooting .................................................................................................................... 6-8

viii

Page 11

List of Figures

Figure Title Page

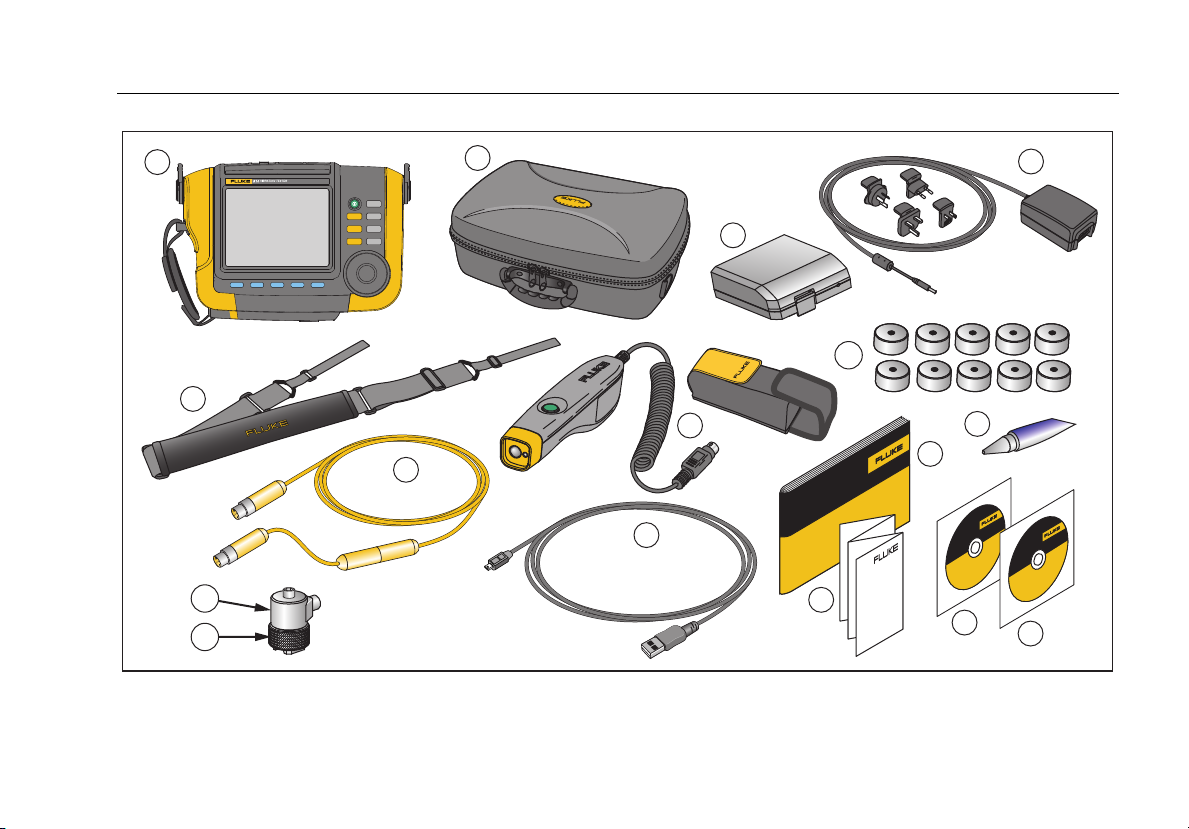

1-1. Items Included with the Tester............................................................................................... 1-7

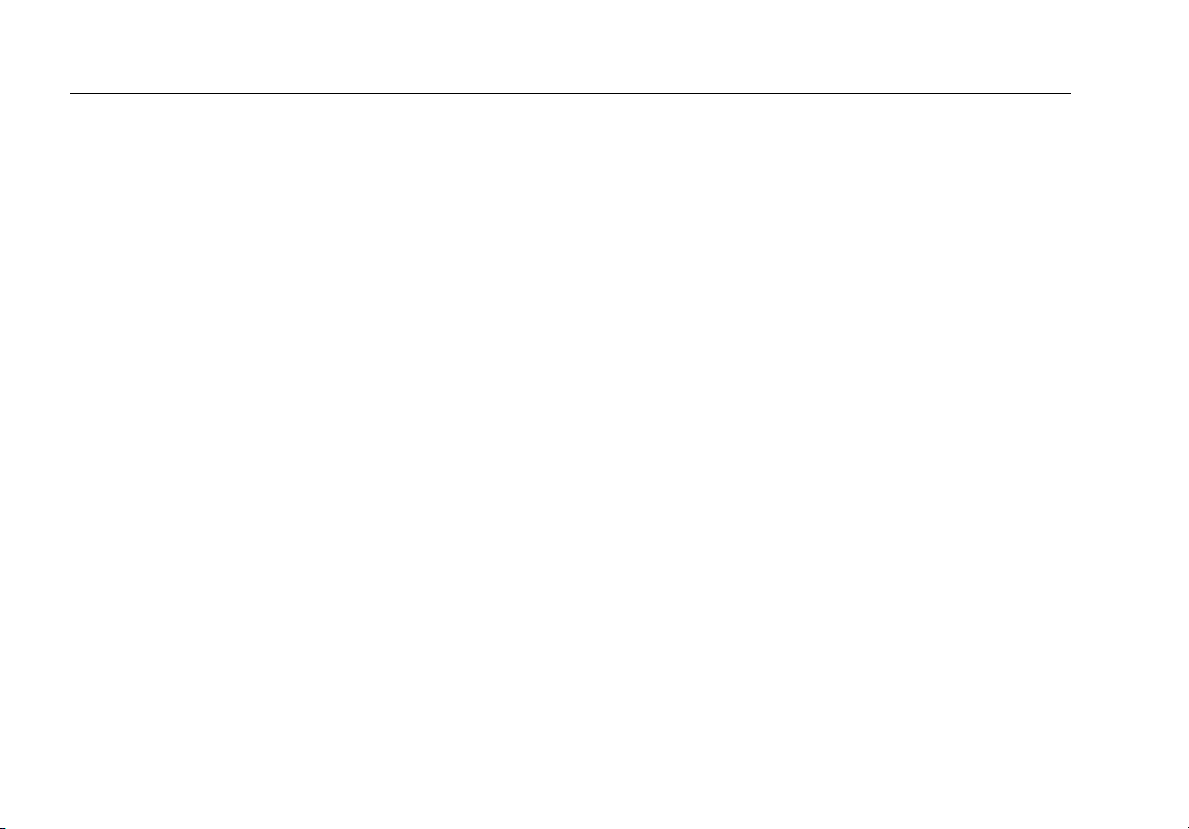

1-2. How to Charge the Battery .................................................................................................... 1-9

3-1. Front Panel............................................................................................................................ 3-3

3-2. Accessory Connectors .......................................................................................................... 3-5

3-3. Sensor Setup and Connection............................................................................................... 3-8

3-4. Tachometer Setup and Connection....................................................................................... 3-9

4-1. Sensor Location .................................................................................................................... 4-25

4-2. Axes Orientation.................................................................................................................... 4-26

4-3. Sensor Mounting Options ...................................................................................................... 4-27

5-1. Tester to PC Connections ..................................................................................................... 5-4

6-1. Battery Replacement............................................................................................................. 6-4

6-2. Memory Card Installation....................................................................................................... 6-6

ix

Page 12

810

Users Manual

x

Page 13

Chapter 1

Overview

Title Page

Introduction ................................................................................................................. 1-3

Features ...................................................................................................................... 1-3

How to Contact Fluke .................................................................................................. 1-4

Safety .......................................................................................................................... 1-4

Rotating Equipment ................................................................................................ 1-4

Tachometer ............................................................................................................ 1-5

Heat Sink................................................................................................................ 1-5

Symbols ...................................................................................................................... 1-5

Unpack and Inspect..................................................................................................... 1-6

Storage........................................................................................................................ 1-8

Battery......................................................................................................................... 1-8

Accessories................................................................................................................. 1-10

1-1

Page 14

810

Users Manual

1-2

Page 15

Overview

Introduction

1

Introduction

The Fluke 810 Vibration Tester with diagnostic technology

(the Tester) helps you quickly identify and prioritize

mechanical problems. With the Tester, you can make

decisions about mechanical maintenance and use it as a

supplement to your own judgment based on machine

knowledge. The expertise of a trained vibration analyst is

in your hands.

The Fluke 810 uses a simple step-by-step process to

report on machine faults the first time measurements are

taken without prior measurement history. The diagnostic

technology analyzes your machinery and provides textbased diagnoses, severity levels and possible repair

recommendations. Faults are identified by comparing

vibration data gathered by the Fluke 810 to an extensive

set of rules gathered over years of field experience.

Primarily used for troubleshooting problem equipment, the

Tester can also be used to survey equipment before or

after planned maintenance. The combination of

diagnoses, severity and possible repair recommendations

help you make more informed maintenance decisions and

address critical problems first.

XW Warning

Read “Safety Information” before using this

Tester.

Features

• On-board diagnosis and location of the four most

common standard mechanical faults: bearings,

looseness, misalignment, unbalance and other (nonstandard faults)

• Fault severity scale with four severity levels: Slight,

Moderate, Serious, and Extreme

• Prioritized repair recommendations

• Diagnostic details include cited peaks and vibration

spectra

• Context Sensitive Help

• 2 GB expandable on-board memory

• Data export (via USB connection) for more detailed

analysis

• Self-test function

• Laser tachometer for accurate machine running speed

• 100 mV/g TEDS triaxial accelerometer

• Data storage and tracking with included Viewer

Software

• Color LCD display

• Languages: English, French, German, Italian,

Portuguese, Spanish, Japanese, Simplified Chinese

1-3

Page 16

810

Users Manual

How to Contact Fluke

To contact Fluke, call one of the following telephone

numbers:

• Technical Support USA: 1-800-44-FLUKE (1-800-

443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-

993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-3434-0181

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your product, visit http://register.fluke.com

To view, print, or download the latest manual supplement,

visit http://us.fluke.com/usen/support/manuals

.

.

.

Safety

The Tester complies with:

) P ;

In this manual, a Warning identifies hazardous conditions

and actions that could cause bodily harm or death. A

Caution identifies conditions and actions that could

damage the Tester, the equipment under test, or cause

permanent loss of data.

W Warning

To avoid personal injury, follow these

guidelines for the Tester:

• Use only as specified in this manual or

the protection provided by the Tester

might be impaired.

• Do not use if damaged. Before you use

the Tester, inspect the case. Look for

cracks or missing plastic.

• Make sure the battery is securely in

place before operation.

• Do not operate around explosive gas,

vapor, or dust.

• Use proper protective equipment, as

required by local or national authorities,

when working in hazardous areas.

• Comply with local and national safety

requirements when working in

hazardous locations.

Rotating Equipment

W Warning

To avoid personal injury:

• Use caution around rotating equipment.

• Keep cords and straps contained.

1-4

Page 17

Overview

Symbols

1

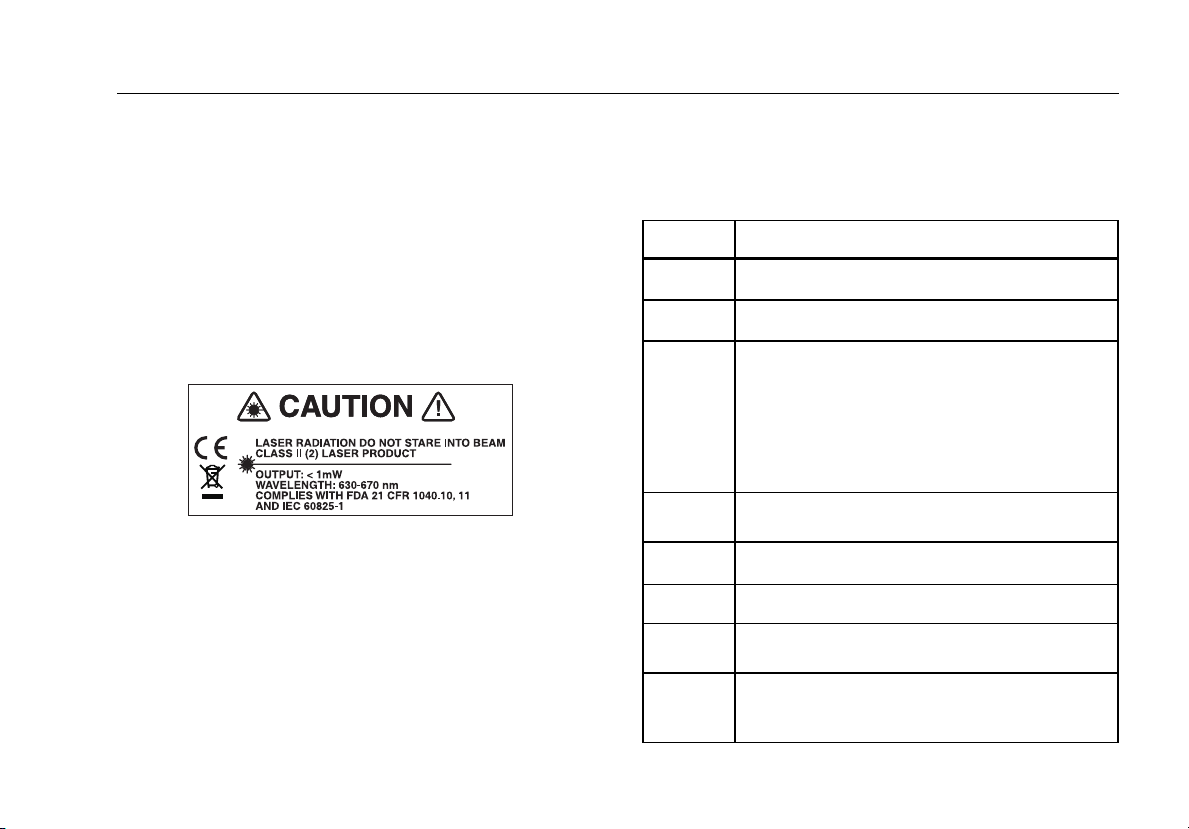

Tachometer

*W Warning

To avoid personal injury or damage to the

Tachometer:

• Do not point laser beam directly at eyes.

• Do not operate around explosive gas,

vapor or dust.

• Do not open. The Tachometer does not

contain any user-serviceable parts.

• When not in use, always place in

protective cover.

Heat Sink

: W Caution

• The heat sink may feel warm to the

touch, this is normal.

• To avoid overheating, do not cover the

heat sink while the Tester is on.

gbk15.eps

Symbols

Table 1-1 lists and describes the symbols used on the

Tester and in this manual.

Table 1-1. Symbols

Symbol Description

W

U

´

)

;

P

*

~

Important Information; refer to manual

Battery condition

This product contains a Lithium-ion battery.

Do not mix with the solid waste stream.

Spent batteries should be disposed of by a

qualified recycler or hazardous materials

handler per local regulations. Contact your

authorized Fluke Service Center for recycling

information.

Conforms to relevant Canadian and US

standards

Conforms to relevant Australian standards

Conforms to European Union directives

Warning. Class 2 Laser Product. Laser

radiation. Do not stare into beam.

Do not dispose of this product as unsorted

municipal waste. Go to Fluke’s website for

recycling information.

1-5

Page 18

810

Users Manual

Unpack and Inspect

Carefully unpack and inspect all the items in Figure 1-1.

The items that follow are included in your purchase of the

Tester:

Fluke 810 Vibration Tester

Storage Case

Smart Battery Pack

Smart Battery Pack Charger and Adapters

Shoulder Strap

Tachometer and Pouch

Sensor

Sensor Magnet Mount

Sensor Quick Disconnect Cable

Sensor Mounting Pads (10-pack)

Adhesive

Mini USB to USB Cable

Getting Started Guide

Quick Reference Guide

User Documentation / Viewer Software CD-ROM

Training DVD

1-6

Page 19

Overview

Unpack and Inspect

1

1

SAVE

SETUP

MEMORY

INFO

MEASURE

INSTRUMENT

DIAGNOSE

SETUP

F1 F2 F3 F4 F5

ENTER

2

3

4

10

5

6

9

11

13

12

7

8

14

15

16

gbk10.eps

Figure 1-1. Items Included with the Tester

1-7

Page 20

810

Users Manual

Storage

When not in use, keep the Tester in the protective

storage case. The case has sufficient space for the

Tester and all accessories.

Battery

The Tester operates on an internal rechargeable

Lithium-ion battery. After you unpack and inspect the

Tester, fully charge the battery before the first use.

Afterwards, charge the battery when the battery icon on

the screen indicates that power is low. To charge the

battery with the battery in place on the Tester:

1. Connect the ac adapter to the ac input socket on the

Tester.

2. Connect the adapter to a power source.

Or, to charge the battery outside the Tester:

1. Remove the battery from the Tester, see Figure 1-2.

2. Connect the ac adapter to the ac input socket of the

battery.

3. Connect the adapter to a power source.

Note

Three hours are necessary for a full battery

charge.

The color of the battery status LED shows:

Red - battery is connected to the power source and

charging.

Green - battery is connected to the power source and is

fully charged.

W Caution

To prevent damage to the Tester:

• Use only the ac adapter that is included with

the Tester.

• Make sure that the external power

source is correctly rated for the Tester.

• Do not leave batteries unused for

extended periods of time, either in the

product or in storage.

• When a battery has not been used for six

months, check the charge status and

charge or dispose of the battery as

appropriate.

1-8

Page 21

Overview

Battery 1

gbk03.eps

Figure 1-2. How to Charge the Battery

1-9

Page 22

810

Users Manual

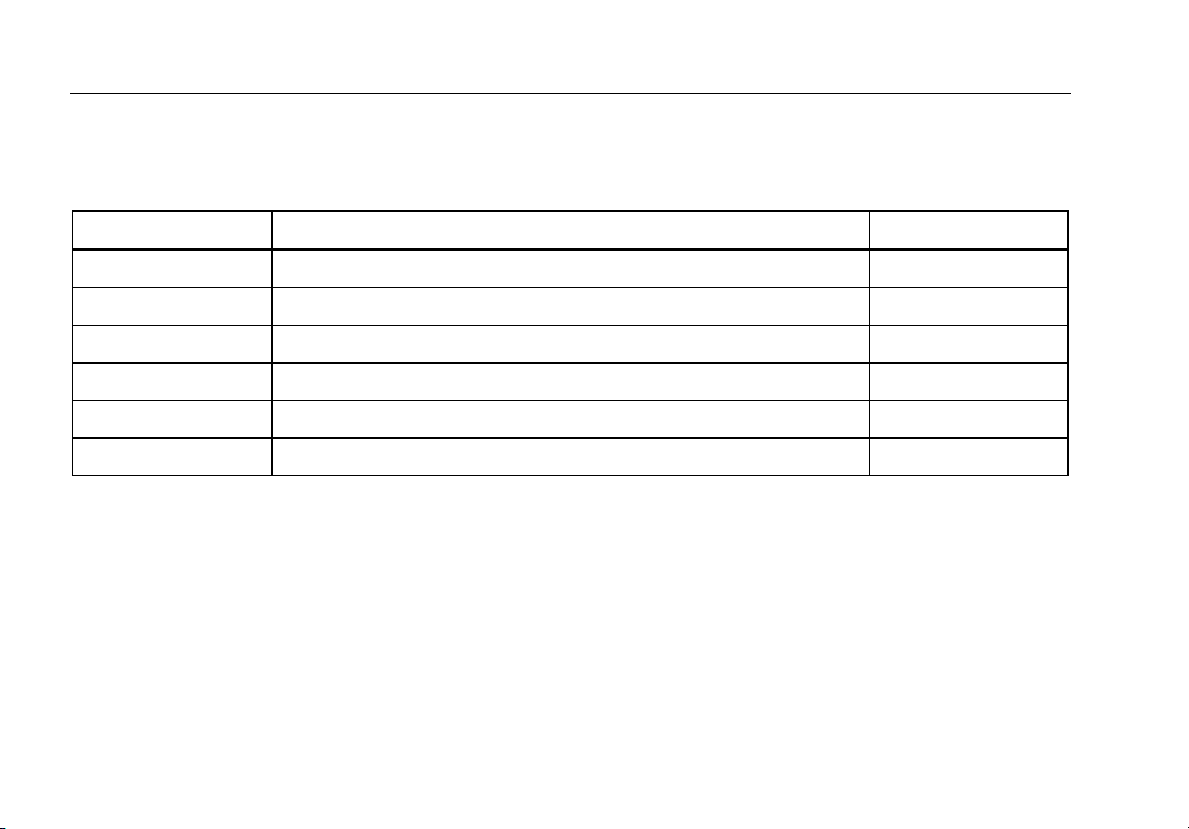

Accessories

Table 1-2 lists the accessories that are available and sold separately for the Tester.

Table 1-2. Accessories

Model Description Part Number

810T Tachometer 3530819

810S Sensor 3530828

810QDC Quick Disconnect Cable 3530837

SBP810 Smart Battery Pack 3530843

810SMM Sensor Magnet Mount 3530862

810SMP Sensor Mounting Pads 3530855

1-10

Page 23

Chapter 2

Specifications

Title Page

810 Vibration Tester Specifications ............................................................................. 2-3

Diagnostic Specifications........................................................................................ 2-3

Electrical Specifications.......................................................................................... 2-3

General Specifications............................................................................................ 2-4

Sensor Specifications.................................................................................................. 2-5

Tachometer Specifications .......................................................................................... 2-6

Viewer Software Requirements................................................................................... 2-6

2-1

Page 24

810

Users Manual

2-2

Page 25

Specifications

810 Vibration Tester Specifications 2

810 Vibration Tester Specifications

Specifications are subject to change without notice.

Diagnostic Specifications

Standard Fault Detection......................................Unbalance, Looseness, Misalignment and Bearing Failures

Analysis for ............................................................ Motors, Fans, Blowers, Belts and Chain Drives, Gearboxes, Couplings, Centrifugal

Machine Rotational Speed Range.......................... 200 RPM to 12,000 RPM

Diagnosis Details ..................................................Fault Severity (Slight, Moderate, Serious, Extreme), Repair Details, Cited Peaks, Spectra

Electrical Specifications

Ranging .................................................................. Automatic

A/D Converter ........................................................4 channel, 24 bit

Usable Bandwidth ...............................................2 Hz to 20 kHz

Sampling .............................................................51.2 Hz

Digital Signal Processing Functions ................... Automatically-configured anti-alias filter, High-pass filter, Decimation, Overlapping,

Sampling Rate .......................................................2.5 kHz to 50 kHz

Dynamic Range .....................................................128 dB

Signal-to-Noise Ratio ............................................ 100 dB

FFT Resolution ......................................................800

Spectral Windows .................................................Hanning

Frequency Units ....................................................Hz, orders, cpm

Amplitude Units.....................................................in/sec, mm/sec, VdB (US), VdB* (Europe)

Non-Volatile Memory.............................................SD micro memory card, 2 GB internal + user-accessible slot for additional storage

Pumps, Piston Pumps, Sliding Vane Pumps, Propeller Pumps, Screw Pumps, Rotary

Thread/Gear/Lobe Pumps, Piston Compressors, Centrifugal Compressors, Screw

Compressors, Closed Coupled Machines, Spindles

Windowing, FFT and Averaging

2-3

Page 26

810

Users Manual

General Specifications

Size......................................................................... 7.30 in × 2.76 in × 10.52 in (18.56 cm x 7.00 cm x 26.72 cm)

Weight (with battery) ............................................ 4.2 lbs (1.9 kg)

Display ...................................................................¼ VGA, 320 × 240 Color (5.7 inch diagonal) TFT LCD with LED backlight

Input/Output Connections

Triaxial sensor connection .................................. 4 pin M12 Connector

Single axis sensor connection ............................BNC Connector

Tachometer connection ......................................Mini DIN 6 pin Connector

PC connection .................................................... Mini ‘B’ USB (2.0) Connector

Battery

Battery type......................................................... Lithium-ion, 14.8 V, 2.55 Ah

Battery charging time.......................................... 3 hr

Battery discharge time ........................................ 8 hr (under normal conditions)

AC Adapter

Input voltage .......................................................100 Vac to 240 Vac

Input frequency ................................................... 50/60 Hz

Operating System .................................................WinCE 6.0 Core

Operating Temperature ........................................32 °F to 122 °F (0 °C to 50 °C)

Storage Temperature ............................................ -4 °F to 140 °F (-20 °C to 60 °C)

Operating Humidity............................................... 10 % to 95 % RH (non-condensing)

Altitude................................................................... 2000 m

IP Rating ................................................................ 54

Agency Approvals

CSA .................................................................... CAN/CSA-C22.2 No 61010-1-04, Pollution Degree 2

CE (Conformite Europeene) ...............................EN 61010-1:2001, EN 60825-1:2007

Australian Mark................................................... Conforms to relevant Australian standards.

Electromagnetic Compatibility ............................EN 61326-1:2006

Recommended Calibration Interval..................... 2 years

2-4

Page 27

Specifications

Sensor Specifications 2

Sensor Specifications

Sensor Type........................................................... Accelerometer

Sensitivity, ±5 %, 25 °C .........................................100 mV/g

Acceleration Range...............................................80 g peak

Amplitude Nonlinearity .........................................1 %

Frequency Response

Z, ±3 dB............................................................... 2 - 7,000 Hz

X, Y, ±3 dB ..........................................................2 - 5,000 Hz

Power Requirement (IEPE) ...................................18-30 VDC, 2-10 mA

Bias Output Voltage ..............................................12 VDC

Grounding .............................................................. Case grounded

Sensing Element Design ......................................PZT ceramic / shear

Case Material .........................................................316L stainless steel

Mounting ................................................................10-32 capacitive socket head screw, 2-pole rare earth magnet (48 lb pull strength)

Output Connector..................................................4-Pin, M12

Mating Connector..................................................M12 - F4D

Non-Volatile Memory.............................................TEDS 1451.4 compatible

Vibration Limit .......................................................500 g peak

Shock Limit ............................................................5000 g peak

Electromagnetic Sensitivity, Equivalent g .......... 100 μg/gauss

Sealing....................................................................Hermetic

Temperature Range...............................................-58 °F to 248 °F (-50 °C to 120 °C) ±7 %

2-5

Page 28

810

Users Manual

Tachometer Specifications

Dimensions............................................................ 1.125 in x 4.80 in (2.86 cm x 12.19 cm)

Weight .................................................................... 3.4 oz (96 gr) with cable

Power .....................................................................Powered by 810 Vibration Tester

Detection................................................................ Laser Diode Class 2

Range ..................................................................... 6.0 to 99,999 RPM

Accuracy

6.0 to 5999.9 RPM .............................................. ±0.01 % and ±1 digit

5999.9 to 99999 RPM ......................................... ±0.05 % and ±1 digit

Resolution ............................................................. 0.1 RPM

Effective Range ..................................................... 0.4 in to 39.27 in (1 cm to 100 cm)

Response Time ..................................................... 1 second (>60 RPM)

Controls .................................................................Measure on/off transparent button

Interface ................................................................. 6 Pin Mini DIN

Cable Length .........................................................19.586 in (50 cm)

Tachometer Accessories

Reflective tape .................................................... 0.59 in × 20.67 in (1.5 cm x 52.5 cm)

Viewer Software Requirements

Minimum Hardware............................................... 1 GB RAM

Operating System .................................................Windows XP, Vista, Windows 7

2-6

Page 29

Chapter 3

Getting Started

Title Page

Introduction ................................................................................................................. 3-3

Navigation and User Interface..................................................................................... 3-3

How to Use the Dial................................................................................................ 3-4

How to Use the Function Softkeys.......................................................................... 3-4

Accessory Connectors ................................................................................................ 3-5

Start the Tester ........................................................................................................... 3-6

Sensor Setup .............................................................................................................. 3-7

Compatible Sensors ............................................................................................... 3-7

How to Connect the Fluke Sensor .......................................................................... 3-7

Sensor Care and Handling ..................................................................................... 3-8

Tachometer Setup....................................................................................................... 3-9

How to Measure RPM with the Tachometer ........................................................... 3-9

Laser Safety Precautions ....................................................................................... 3-10

How to Access Help .................................................................................................... 3-11

Instrument Setup......................................................................................................... 3-11

Self Test ................................................................................................................. 3-12

Settings .................................................................................................................. 3-12

Clear Memory......................................................................................................... 3-15

3-1

Page 30

810

Users Manual

3-2

Page 31

Getting Started

Introduction

3

Introduction

This chapter helps you to understand and become

familiar with the user interface, connections, and

accessories.

Navigation and User Interface

Figure 3-1 shows the front panel of the Vibration Tester.

Table 3-1 lists the front-panel controls and their functions.

1

2

SETUP

3

MEASURE

4

DIAGNOSE

F1 F2 F3 F4 F5

10

Figure 3-1. Front Panel

SAVE

MEMORY

INFO

INSTRUMENT

SETUP

SETUP

MEASURE

DIAGNOSE

ENTER

SAVE

MEMORY

INFO

INSTRUMENT

SETUP

5

6

7

8

9

gbk02.eps

3-3

Page 32

810

Users Manual

Table 3-1. Front Panel

Item Control Description

D

Turns the Tester on or off.

Shows the Machine Setup options:

Set up new Machine, Copy Machine

Setup, Change a Machine Setup

Shows the Machine Setups

available for measurement. After the

selection of a Machine Setup,

continue with the measurement

screens.

Shows the completed Machine

Setups with measurements that are

available for diagnosis. After a

measurement, push to see the

diagnosis screen.

Saves the parameters for the Tester

settings and Machine Setups.

Shows the Machine Setups and

diagnoses in Tester memory.

From the Startup screen, shows the

Help menu. For other screens,

shows Help for the current screen.

Dial

Softkeys

Shows the Self Test, Settings, and

Clear Memory functions.

Turn the Dial to move the cursor

highlight on the screen. Push the

center of the Dial (Enter) to make

the selection.

Softkeys through

make the selections that show on

the screen above each softkey.

How to Use the Dial

The Dial has multiple functions. Turn the Dial clockwise or

counterclockwise to move the cursor or highlight. Push

the Dial to make a selection.

How to Use the Function Softkeys

Along the bottom of the display, a row of labels shows the

available functions. Push a softkey, through

, below the display label to start that function.

Table 3-2 lists the navigation softkeys and their function.

3-4

Page 33

Getting Started

Accessory Connectors

3

Table 3-2. Navigation Softkey Functions

Softkey Function

Previous Page

/ Next Page

Enter

Back

Move Cursor

Delete

Character

Exit

Save

Done

Also, you can use the front-panel buttons, along the right

side of the Tester, to go directly to a top-level menu.

When the beeper is on, a short beep sounds for

a valid button push. A long beep sounds for an

invalid button push.

View the previous/next screen.

Select the highlighted function. Or,

push the Dial to select the same

function.

Go to the previous field or screen.

Move the cursor one space to the left.

Delete a character.

Exit from current display.

Save settings in current display.

Save keyboard entries.

Note

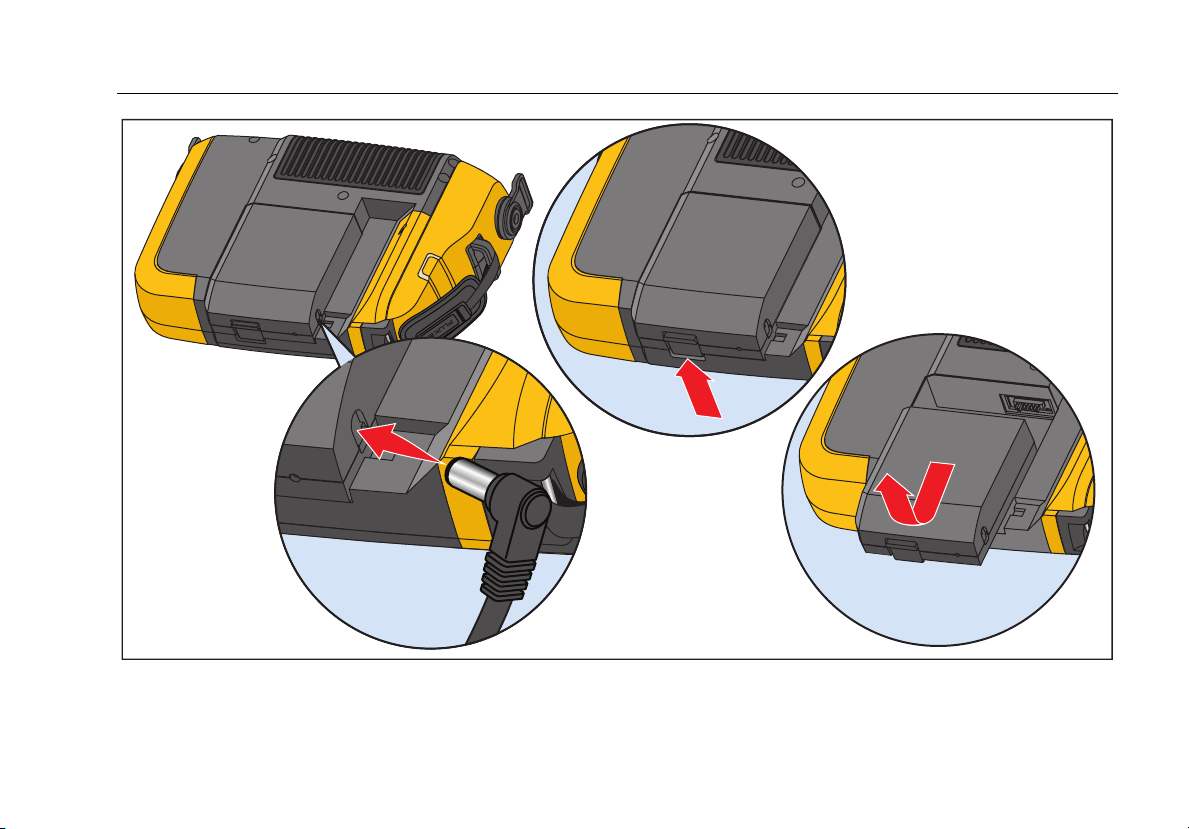

Accessory Connectors

Figure 3-2 shows the connector panel of the Tester.

Table 3-3 is a list of descriptions for each connector on

the Tester.

1

2

3

4

gbk01.eps

Figure 3-2. Accessory Connectors

3-5

Page 34

810

Users Manual

Table 3-3. Accessory Connectors

Item Connector Description

Tachometer Connects the Tachometer

USB

Sensor

Connects the Tester to the PC

using a USB cable

Optional connector for single

axis Sensor

Sensor Connects the triaxial Sensor

Start the Tester

Note

• Before using the Tester for the first time,

charge the battery for at least three hours.

For charging procedure, see “Battery.”

• Before using the Tester, make sure that

there is sufficient battery charge and free

memory.

Push to turn on the Tester. At power up, the Tester

displays the remaining memory and the battery status.

Push and hold two seconds to turn off the Tester

The battery status icon U and the set date and time

appear at the top of the display.

gbk21.bmp

3-6

Page 35

Getting Started

Sensor Setup

3

Note

The first time you turn the Tester on, it displays

the Settings screen. It is important to enter the

correct information into the setup fields before

you start a test, especially the power line

frequency. For more information, see

“Instrument Setup” section.

gbk40.bmp

Sensor Setup

The Tester includes a triaxial Sensor with TEDS

technology (Transducer Electronic Data Sheets). With

this technology, your Tester can identify and

automatically read the Sensor configuration. This

technology provides:

• Improved results from detailed calibration information

• Reduced configuration time without manual data

entry

• Sensor calibration tracking with the last calibration

date stored electronically

Compatible Sensors

• It is highly recommended to use a Fluke Triaxial

Sensor with the Tester. Using a Sensor other than a

Fluke Triaxial Sensor will result in misleading

diagnoses. The Tester is compatible with single axis

Sensors.

W Caution

Non-Fluke triaxial Sensors are not

compatible with the Tester.

How to Connect the Fluke Sensor

To connect and set up a triaxial Sensor:

1. Attach the cable to the Sensor and tighten the

threaded cable sleeve. See Figure 3-3.

2. Connect the cable to the Tester and tighten the

threaded cable sleeve.

3-7

Page 36

810

Users Manual

Figure 3-3. Sensor Setup and Connection

gbk07.eps

Sensor Care and Handling

W Caution

• To prevent damage to the piezoelectric

element inside the Sensor, do not drop.

A faulty Sensor significantly affects the

diagnostic quality.

• Do not pull or force the cable while

attaching or removing the Sensor.

• Allow the Sensor 10 seconds to warm-up

before data collection.

• Make sure that all cables are free from

any rotating parts of the machine.

• Always disconnect the Sensor cable

from the Tester when not in use.

• Always place the Sensor in the softcase

pouch when not in use.

3-8

Page 37

Getting Started

Tachometer Setup

Tachometer Setup

During the Machine Setup procedure, you have to enter

the speed/RPM (revolutions/minute) of the rotating

machine under test. If the RPM is unknown, you can use

the non-contact type laser Tachometer to measure the

RPM.

Note

Fluke recommends the use of a Tachometer for

variable-frequency drives (VFD) to determine the

running speed under varying load conditions.

How to Measure RPM with the Tachometer

To make a Tachometer measurement:

1. Attach the Tachometer to the 6-pin DIN connector on

the Tester. See Figure 3-4.

W Warning

To avoid injury when attaching reflective

tape to the machine, stop the rotating

machine. Attach a piece of reflective tape

onto the shaft or other rotating part of the

machine. Restart the machine and wait until

it reaches its normal operating conditions.

2. Aim the laser beam towards the attached reflective

tape.

3. Hold the Tachometer firmly and steady.

Figure 3-4. Tachometer Setup and Connection

4. When the RPM entry screen appears on the display,

the power button on the Tachometer lights to indicate

that the Tester is ready for RPM measurement.

3

gbk06.eps

3-9

Page 38

810

Users Manual

5. Push and hold the trigger button of the Tachometer

to start measuring.

6. Hold the trigger button until the RPM value settles

and displays on the Tester.

7. Release the power button to stop measurement.

8. Wait for the short beep that verifies the RPM value

has been acquired.

The Tester automatically turns off the Tachometer.

gbk20.bmp

Laser Safety Precautions

*W Warning

• The Tachometer contains a Class 2 laser

pointer.

• To avoid eye damage, do not point laser

directly at eye or indirectly off reflective

surfaces.

• Use, other than those specified here,

may result in hazardous laser radiation

exposure.

• Do not use Tachometer in a manner not

specified in this document or the

protection provided by the equipment

may be impaired.

• Do not aim the laser beam at people or

animals.

W Caution

• Keep the Tachometer out of the reach of

children.

• Do not open the Tachometer. The

Tachometer has no user serviceable

parts.

• When not in use, always place the

Tachometer in its protective cover.

3-10

Page 39

Getting Started

How to Access Help

3

How to Access Help

The Tester has context sensitive Help. With the Help

feature you can quickly find additional information while

you set up the Tester and make measurements. The Help

content that shows depends on the current task selection.

Push at anytime to view specific Help for the

current task. The Help for the Tester includes pages for

frequently asked questions (FAQ), a glossary, and

troubleshooting.

gbk23.bmp

Instrument Setup

Push or the Instrument Setup softkey to display

the Self test, Settings, and Clear memory options.

gbk25.bmp

Use the Dial to highlight an option. Push the Dial or Enter

(F3) softkey to select that option.

3-11

Page 40

810

Users Manual

Self Test

The Self test option tests the internal modules of the

Tester. When you select the Self test option, the Tester

runs a test module and then displays the self test results

as pass or fail.

gbk26.bmp

Push the Done softkey to go back to Instrument Setup.

Note

If the self-test fails, contact Fluke Service.

Settings

To edit the Tester settings in Table 3-4, select the

Settings option. Three pages of settings are available.

gbk28.bmp

Note

Before you take a measurement, make sure the

power line frequency is set correctly.

3-12

Page 41

Getting Started

Instrument Setup

3

Push the Next Page softkey to move down the screen

and edit the additional settings for the beeper, backlight,

power save, time waveform capture, and measurement

units.

gbk29.bmp

Push the Next Page softkey to move down the screen

and edit the additional settings. The last screen also

displays the Tester’s serial number, software version,

Sensor calibration due date, and Memory remaining.

3-13

Page 42

810

Users Manual

Table 3-4. Tester Settings

Option Description

Power line freq

Date format Set the Date format as d/m/y or m/d/y

Date Scroll and set the Day, Month, and Year fields

Time format Set the Time format as 12Hr or 24Hr

Time Scroll and set the Hour, Minute, and AM or PM fields

Beeper Set the Beeper as ON or OFF

Backlight brightness Set the display brightness as High or Low

Power save

Backlight duration

Time waveform

capture

Units

Language Scroll and select a language.

Set the ac power line frequency to 60Hz or 50Hz. The diagnostic quality of a test depends on the

correct selection of the ac power line frequency.

Scroll and select to set the delay time for the Sleep Mode. If no key is pushed during the set time, the

Tester goes into the sleep mode to save battery power. Any key push cancels the sleep mode and

resumes normal operation.

Scroll and select to set the delay time for the display backlight. If no key is pushed during the set

time, the backlight turns off to save battery power. The backlight turns on when any key is pushed.

Scroll and select the number of measurements where the time waveform is to be captured. The

Tester captures and stores the time waveform data for the selected number of measurements.

Note

Capture and review of time waveform data is useful in advanced vibration analysis, but keep in mind

that data capture uses a significant amount of memory. Captured time waveforms can only be

viewed in the Viewer Software, not the Tester.

Scroll and select a unit of measurement as US or metric. Also select the units for the vibration

amplitude. VdB and in/sec for US. VdB* indicates VdB Europe and mm/sec for Metric.

3-14

Page 43

Getting Started

Instrument Setup

Clear Memory

Select the Clear Memory option on the Instrument Setup

screen to erase all measurement and diagnosis data. A

sequence of confirmation messages display:

gbk31.bmp

If you select Yes, another confirmation message displays:

3

gbk32.bmp

Select Yes to clear the memory. This action erases all

stored measurement and diagnosis data.

3-15

Page 44

810

Users Manual

3-16

Page 45

Chapter 4

Operation

Title Page

Start the Tester ........................................................................................................... 4-3

Create a New Machine Setup ..................................................................................... 4-4

Machine Setup ............................................................................................................ 4-5

Motor Input (Driver) Information.............................................................................. 4-6

RPM Entry .............................................................................................................. 4-8

Coupling Information .............................................................................................. 4-8

Transmission with Closed Coupling................................................................... 4-9

Transmission without Closed Coupling.............................................................. 4-10

Driven Component.................................................................................................. 4-11

Pump ................................................................................................................. 4-11

Fan .................................................................................................................... 4-12

Compressor ....................................................................................................... 4-13

Blower................................................................................................................ 4-14

Spindle............................................................................................................... 4-14

Transmission Component....................................................................................... 4-14

Gearbox............................................................................................................. 4-14

Belt Drive ........................................................................................................... 4-17

4-1

Page 46

810

Users Manual

Copy an Existing Machine Setup ............................................................................ 4-19

Edit the Saved Machine Setup................................................................................ 4-22

Before You Measure.................................................................................................... 4-24

Select Measurement Locations............................................................................... 4-24

Total Number of Measurement Locations ............................................................... 4-25

Sensor Orientation .................................................................................................. 4-26

Sensor Mounting..................................................................................................... 4-27

How to Measure Vibration ........................................................................................... 4-29

How to Diagnose ......................................................................................................... 4-38

Fault Types ............................................................................................................. 4-38

Severity Scale......................................................................................................... 4-40

Fault Details and Vibration Spectrum...................................................................... 4-42

How to Access the Memory ......................................................................................... 4-45

View by Machine Setup .......................................................................................... 4-45

View by Measurement Date.................................................................................... 4-46

View by Last Diagnosis........................................................................................... 4-48

4-2

Page 47

Operation

Start the Tester

4

Start the Tester

Note

• Before using the Tester for the first time,

charge the battery for at least 3 hours. For

charging procedure, see “Battery.”

• Before using the Tester, make sure that

there is sufficient battery charge and free

memory.

Push to turn on the Tester. At power up, the Tester

displays:

gbk21.bmp

Note

The first time you turn the Tester on, it displays

the Settings screen. It is important to enter the

correct information into the setup fields before

you start a test, especially the power line

frequency. For more information, see

“Instrument Setup” section.

gbk40.bmp

4-3

Page 48

810

Users Manual

Create a New Machine Setup

Before recording data, create a Machine Setup name for

the machine under test. To create a new Machine Setup

name:

1. Push New Machine on the startup screen. Or

push .

gbk22.bmp

2. Select Set up new machine. An alphanumeric

keyboard appears.

3. Use the Dial to highlight characters.

4. Push the Dial to select a character. A maximum

of 15 characters is allowable.

gbk41.bmp

5. Push Move Cursor to move the cursor in the

text box one space to the left.

6. Push Delete Character to remove the last

character entered in the text box.

7. After you enter the name, push Done. The new

Machine Setup name appears in the name field.

4-4

Page 49

Operation

Machine Setup

Machine Setup

For the best machine analysis and diagnosis, the Tester

has to understand the layout and components of the

machine. The Machine Setup wizard guides you through

several questions about the profile of the machine. These

machine setup values must be correct for valid diagnostic

results.

Note

All questions in the Machine Setup Wizard are

required to generate a diagnosis unless

gbk42.bmp

Table 4-1 describes the softkey functions for the New

Machine Setup screen.

Table 4-1. New Machine Setup Functions

Softkey Function

Edit Name Edit the Machine Setup name

Next Go to the first Machine Setup screen

Exit Exit to the Startup screen.

otherwise labeled “optional.” Including optional

information will improve the results of the final

machine diagnosis.

Once you create a Machine Name, the Tester starts the

Machine Setup wizard and you enter the parameters of

the machine under test. The Machine Setup wizard

displays the options sequentially based on the input you

give and organizes the options into these categories:

• Motor Input (Driver)

• Coupling and Transmission

• Driven Components

4

4-5

Page 50

810

Users Manual

Note

• Push to access the on-board help for

any Machine Setup option.

• As you select the options, the Tester

displays a corresponding drivetrain image

template at the top of the display.

The Machine Setup Wizard uses combo boxes. A combo

box is a combination of a drop-down list or list box. You

can choose from the list of existing options. To make a

selection:

1. Push Enter to activate the combo box.

2. Rotate the Dial to highlight different options in

the combo box.

3. Push Enter to confirm the selection. Depending

on the component you select, the options appear

for the details of the component.

gbk115.bmp

Motor Input (Driver) Information

Entering an accurate running speed (RPM) is critical to

receiving a proper diagnosis. An accurate running speed

helps the diagnostic engine in the Tester discern different

fault conditions. The motor nameplate or manual also lists

the running speed.

If an ac motor uses a variable frequency drive (VFD), it

operates under a varying load that influences the

vibration signal. It is important to obtain the correct RPM

using a tachometer. Or, refer to the frequency on the

motor controller label. For consistent diagnoses over

time, it may be necessary to reduce or increase the load

on the motor to match the load from previous

measurements.

Measuring VFDs requires entering RPM at the time of

measurement (instead of relying on RPM values in the

Machine Setup) due to variable loads. To obtain an

accurate RPM value, use the Tachometer provided with

the Tester or obtain the frequency value from the drive

controller itself. To convert the frequency value to RPM,

calculate:

Hz * 60 = RPM

Horsepower (HP) or kilowatt (kW) input is required for the

diagnostic system to identify the number of measurement

locations.

4-6

Page 51

Operation

Machine Setup

Table 4-2 is a list of the options for the motor input.

Table 4-2. Motor Input Options

Selection Option Description

4

Select motor type

AC motor with VFD

Enter Speed in RPM RPM Entry screen

Enter nominal HP (US)

or

Enter nominal kW (metric)

Motor mounted

Motor bearing type

Motor is detached from

drivetrain

[1] The Tester cannot analyze drive trains with beveled gears where the shaft changes direction at a 90

AC

DC

Yes

No

Numeric keyboard

entry

Horiz (Horizontal)

Vert (Vertical)

Roller

Journal

Yes

No

[1]

Select the motor type of the machine under test.

For ac motor type, identify the motor as VFD (variable-frequency

drive) or not.

RPM Entry screen appears. Use the Tachometer to get the RPM.

Or, if you know the RPM, enter the value manually. See “RPM

Entry.”

Push Keyboard to access the numeric keyboard. Enter the HP

(Horsepower) or the kW of the motor.

[1]

Identify the motor mounting as horizontal or vertical

to enter the motor mounting as it affects Sensor orientation.

Select the bearing type in the motor. Different bearing types have

distinct vibration signatures.

Are you testing the motor only. If the motor is detached from the

drivetrain, select Yes.

[1]

. It is important

°

angle between components.

4-7

Page 52

810

Users Manual

RPM Entry

When an RPM value has to be entered, the RPM entry

screen opens.

gbk20.bmp

1. Use the Tachometer to measure the RPM. See

“Tachometer Setup” to set up the Tachometer

and measure the RPM. After you set the RPM

value, the Tester goes back to the Machine

Setup wizard.

Or, you can manually enter the RPM value as

follows:

2. Push Manual Entry. The Tester displays a

numeric keyboard.

gbk43.bmp

3. To select a character, use the Dial to highlight

the value. Or, use Move Cursor to highlight the

value.

4. Push the Dial to select the value.

5. To delete a character, use Delete Character.

6. Push Done to go back to the Machine Setup

wizard.

Coupling Information

If the machine consists of a driven component coupled

with a motor, select No to the previous option. Options for

the closed coupled machine appear based on the

selection you make.

4-8

Page 53

Operation

Machine Setup

4

Transmission with Closed Coupling

Table 4-3 is a list of the options for a transmission with a

closed coupling.

Table 4-3. Closed Coupling Transmission Options

Selection Option Action Option Action Description

Centrifugal

pump

Gear pump

Motor

directly

bolted to:

Note: Vanes, gear teeth, screw teeth, pistons and fan blades generate distinct vibration signatures. Enter the correct number for proper

diagnosis.

Fan

Centrifugal

compressor

(Cntfgl Comp)

Screw/lobe

pump

Scroll and select

the driven

component that

connects to the

motor (driver)

Number of vanes

(optional)

Number of gear or

screw teeth (optional)

Number of blades

(optional)

Number of compressor

vanes (optional)

Number of teeth/lobes

(optional)

This is optional information.

Numeric

keyboard

entry

Push Keyboard to access

the numeric keyboard. Enter

the appropriate number for

the option.

4-9

Page 54

810

Users Manual

Transmission without Closed Coupling

The Tester cannot analyze drive trains with beveled gears

where the shaft changes direction at a 90 ° angle

between components. Table 4-4 is a list of the options for

a transmission without a closed coupling.

Table 4-4. Transmission without Closed Coupling Options

Selection Option Description

Coupling between motor

and next component

Yes

No

Is there a coupling between motor (driver) and the next component in

the drivetrain? Select Yes or No accordingly.

Pump

Fan

Compressor

Next component

Notes

[1]

If you select Gearbox, Belt drive, or Chain drive, the options for the details of the transmission drive appear. See “Transmission

Component” for related options.

[2]

These selections are unavailable if there is a flexible coupling between the motor and the next component.

Blower

Spindle

Gearbox

Belt drive

[1]

[1] [2]

Chain drive

[1] [2]

Scroll and select the next component in the drivetrain from the list.

4-10

Page 55

Operation

Machine Setup

4

Driven Component

Depending on the component selection, the options for

the details of the driven component appear.

Pump

Table 4-5 is a list of the pump options.

Table 4-5. Pump Options for Driven Components

Selection Option Action Option Action Description

Bearing

type

Pump

type

Roller --- --- ---

Journal --- --- ---

Impeller is supported

Centrifugal

Propeller

Sliding

vanes

Screw/lobe

Piston

Scroll and

select the

pump type

by

Number of vanes

(optional)

Number of vanes

(optional)

Number of vanes

(optional)

Number of

teeth/lobes (optional)

Number of pistons

(optional)

Two bearings

Overhung

Input value between 2

and 20 with keyboard.

Input value between 2

and 20 with keyboard.

Input value between 2

and 20 with keyboard.

Select 2 through 12

Select 2 through 13

Select the bearing type in the

pump.

Scroll and identify the

impeller support.

This is optional information.

Push Keyboard to access

the numeric keyboard. Enter

the number for the option.

This is optional information.

Scroll and select the number.

4-11

Page 56

810

Users Manual

Fan

Table 4-6 is a list of the fan options.

Option Selection Description

Table 4-6. Fan Options for Driven Components

Driven component

bearing type

Fan is supported by

Number of fan blades

(optional)

4-12

Roller

Journal

Two bearings

Overhung

Numeric keyboard entry

Select the bearing type in the fan.

Scroll to identify the fan support.

This is optional information. Push Keyboard to access the

numeric keyboard. Enter the number of fan blades.

Page 57

Operation

Machine Setup

4

Compressor

Table 4-7 is a list of the compressor options. Different

setup options are available based on the compressor

selection.

Table 4-7. Compressor Options for Driven Components

Selection Option Action Option Action Description