Page 1

80T-IR/E

Infrared Temperature Probe

Calibration Procedure

®

Introduction

This procedure covers the following topics relating to

the calibration of the Fluke 80T-IR/E Infrared

Temperature Probe, hereafter referred to as the UUT

(Unit Under Test):

• Service Information

• Required Test Equipment

• Calibration Verification

Service

To obtain Service Information in the U.S.A. call 1888-893-5853. Outside the U.S.A., contact your

nearest Fluke Service Center.

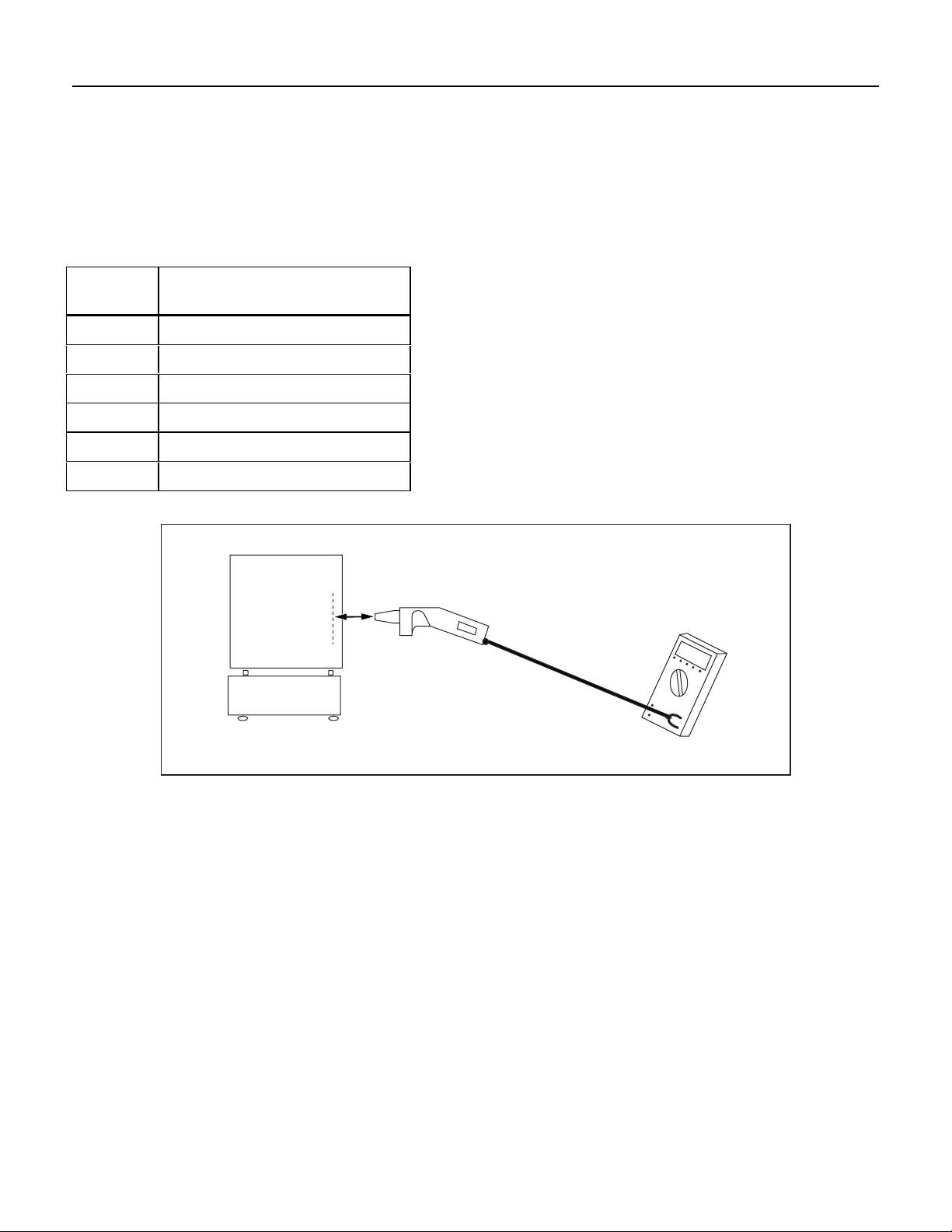

Recommended Equipment

Table 1 lists the equipment required to perform the

calibration verification procedure. Refer to Figure 1

for equipment configuration.

Table 1. Calibration Equipment

Instrument Type Recommended

Model

Blackbody (-20 – 150 °C)

Required Accuracy = +/- 0.75 %

W/Cert. @ 0.95 Emissivity

Blackbody (100-650°C)

Required Accuracy = +/- 0.75 %

W/Cert. @ 0.95 Emissivity

DMM 0.1% Basic Accuracy

1. May substitute less accurate blackbody if using in

conjunction with transfer standard of equivalent

accuracy, i.e.; Raytek PM3-DCI

1

1

Mikron M340

Mikron M305X

Fluke 87

Initial Setup

Each of the measurements listed in the following

procedure assumes that the temperature of the UUT

has stabilized in a test environment with an ambient

temperature of 18 - 28°C and relative humidity of less

than 95%. Accuracy figures are valid for a period of

one year.

1. With the UUT powered on, check that the battery

voltage is at least 7.0 V. Replace the battery if

necessary.

2. Verify that the UUT is in the °F mode.

3. Power up the UUT and allow it to stabilize for

five minutes.

4. Connect the output of the UUT to the VΩ

and

COM input of the DMM.

Calibration Verification

To verify calibration of the 80T-IR/E, complete the

following performance test. If your ins trum ent fa il s to

pass any performance specifications, return it to the

Fluke Factory or Service Center for repair.

1. Adjust the setpoint of the Blackbody to output

each of the temperatures in Table 2 at 0.95

emissivity.

2. Set the DMM to the 3.000 V dc range.

Note

To avoid inaccuracy, only expose the UUT to the heat

source long enough to complete the measurement

(<10 sec). In between measurements move the UUT to

an environment not affected by the heat source.

3. Place the UUT aperature three inches from the

center and perpendicular to both axes of the

Blackbody plate.

4. Record the reading displayed on the DMM.

5. The reading in step 4 must be within 3% or 5° F

(whichever is greater) of the Blackbody output or

transfer standard measurement at 0.95 emissivity

in step 1.

6. Repeat steps 1 through 5 for the remaining

verification points called out in Table 2.

PN 650900

April 2000

©1998 Fluke Corporation. All rights reserved. Printed in U.S.A. 1

Page 2

80T-IR/E

Calibration Procedure

Note

The UUT will shift into sleep mode after 10 minutes.

Reactivate by switching the UUT off and on again.

This completes calibration verification for the

80T-IR/E.

Table 2. Verification Points

Model Blackbody Temperature

at 0.95 Emissivity

M340 77 °F

M340 175 °F

M340 275 °F

M305X 375 °F

M305X 575 °F

M305X 975 °F

Blackbody

3"

Figure 1.

UUT

Test DMM

2

Loading...

Loading...