Page 1

80PK-8

Type K Thermocouple Pipe Clamp Temperature Probe

Instruction Sheet

Introduction

XWWarning

To avoid electric shock, do not

use this probe when voltages

exceeding 24 V ac or 60 V dc are

present. The probe is electrically

connected to the output terminals.

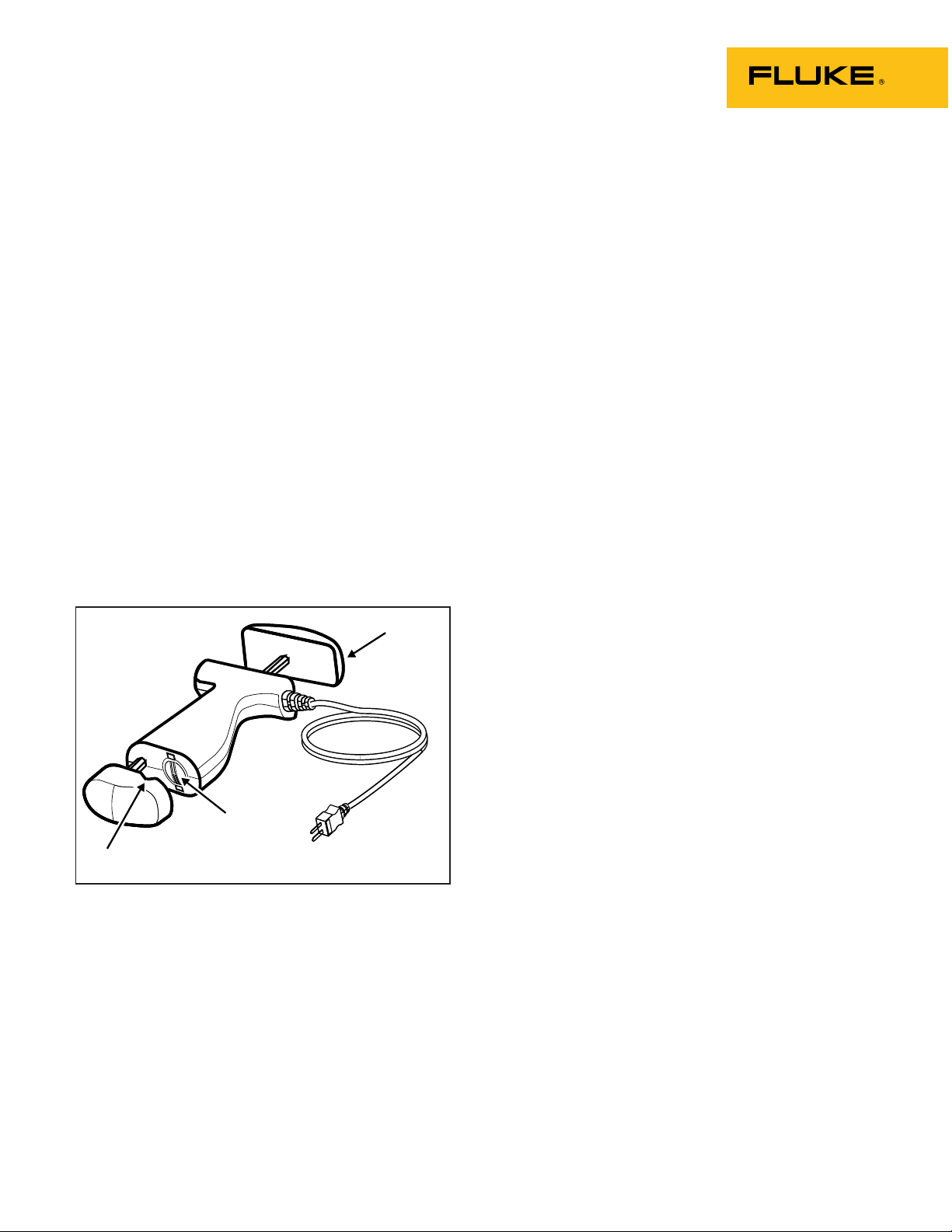

The 80PK-8 Type K Thermocouple Pipe Clamp

Temperature Probe (Figure 1) is designed to reliably

measure the temperature of pipes ¼-inch (6 mm) to 1

3/8-inch (35 mm) in diameter, at temperatures

between -29 °C and 149 °C (-20 °F and 300 °F),

while retaining a long service life.

Plunger

Specifications

Measurement Range: -29 °C to 149 °C (-20 °F to

300 °F)

Accuracy: ±1.9 °C (±.3.4 °F). Surface measurement

accuracy of ±1.9 °C includes ±1.1°C variation in alloy

plus probe contact and shunting uncertainty of

±0.8 °C.

Repeatability: ± 0.56 °C (±1 °F)

Output: @ 25 °C (77 °F) = 1.00 mV (Reference

junction at 0 °C)

Seebeck Coefficient:

@ 25 °C (77 °F) = 40.50 μV / °C

Measurement Time (Time Constant):

0.5 seconds (5 time constants = 1 complete step

change, i.e. 2.5 seconds)

Maximum Voltage Rating: 24 V ac rms, or 60 V

dc

Sensor Material: Chromel-Alumel

Cable Length: 40 inches (1 meter)

Cable Insulation: Material: PVC

Maximum Temperature: 105 °C (220 °F)

Sensor

V Notch

80PK8.eps

Figure 1. 80PK-8 Pipe Clamp Temperature Probe

February 1995, Rev. 2, 5/09

©1995 - 2009 Fluke Corporation. All rights reserved. Specifications subject to change without notice.

All product names are trademarks of their respective companies.

1

Minimum Temperature: -29 °C (20 °F)

Conductor: K Type AWG #24 stranded

Probe Body: PBT

Maximum Temperature: 149 °C (300 °F)

Minimum Temperature: -29 °C (20 °F)

Connector: Mini-thermocouple connector with

7.925 mm (0.312 in) pin spacing

Media Limitations: Must be compatible with

chromel, alumel, and PBT

Page 2

Type K Thermocouple Pipe Clamp Temperature Probe

Using the 80PK-8 to Measure Pipe Temperature

Using the 80PK-8 to Measure

Pipe Temperature

1. Using the miniature thermocouple connector,

connect the 80PK-8 to a compatible Type K

temperature measuring device.

2. Turn on the measuring instrument and select the

appropriate range and scale.

If you are using a temperature conversion module

(the 80TK, for example), insert the module into

the VΩ and COM inputs of the meter and select

the mV dc function.

3. Using your thumb or the palm of your hand, press

down on the plunger to open the jaws of the probe

wide enough to easily encompass the pipe.

Center the pipe on the “V” notch (see Figure 1)

on the jaw of the probe and relax pressure on the

plunger.

4. Read the temperature on the measuring

instrument. When no heat or cold is applied to the

sensor the measuring instrument should display

the ambient temperature. If the instrument does

not readout properly, refer to “Troubleshooting”.

Measurement Considerations

The 80PK-8 is designed to be compatible with any

temperature-measuring instrument that accepts

miniature Type K thermocouples with cold reference

junction compensation. The accuracy of the

temperature-measurement is a factor of the combined

accuracy of the temperature measuring instrument and

the 80PK-8.

A lowering of the temperature at the sensor contact

point is less likely (and response time is faster) on

clean, polished, thermally conductive surfaces, then

on surfaces with low thermal conductivity, such as

plastic or rough, greasy surfaces. To obtain the best

thermal contact and performance, the pipe must be

centered in the “V” notch of the probe jaw.

Troubleshooting

When no heat or cold is applied to the probe, the

measuring instrument should display the ambient

temperature. If the measuring instrument does not do

so, try the following:

1. Verify that the temperature measuring instrument

is designed to be used with Type K

thermocouples. The instrument should have a

yellow input connector and/or be marked with a

“K”.

2. Check for an open circuit indicator on the

measuring instrument. Some thermometers have a

built in circuit to indicate if the connected probe

is open. (All Fluke instruments have this feature.)

Refer to instruments owners’ manual to see if this

feature is available.

If you suspect a broken connection, use an

ohmmeter to check probe continuity from pin to

pin. If the ohmmeter reads ≤10 Ω, the probe is

good.

3. Short the two input connectors to the instrument

with a piece of wire. If the instrument is

functioning properly it should display the ambient

temperature.

Cleaning

W Caution

To prevent damage to the probe,

do not use solvents that may

deteriorate the handle and plunger

of the probe.

Using warm-soapy water, brush the sensor lightly

with a toothbrush. Excessive or abrasive brushing can

damage the sensor and void the warranty. If necessary

dip the brush (but not the sensor) in rubbing alcohol.

To get the most accurate temperature measurement,

adjust the connection between the sensor and the pipe

until you get the maximum or minimum temperature

reading.

W Caution

To prevent damage to the probe,

do not rotate the clamp when

measuring the temperature of a

rough surface.

2

Page 3

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The

warranty period is one year and begins on the date of shipment. Parts, product repairs, and services are warranted for 90 days.

This warranty extends only to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses,

disposable batteries, or to any product which, in Fluke's opinion, has been misused, altered, neglected, contaminated, or

damaged by accident or abnormal conditions of operation or handling. Fluke warrants that software will operate substantially in

accordance with its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke

does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no

authority to extend a greater or different warranty on behalf of Fluke. Warranty support is available only if product is purchased

through a Fluke authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice

Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for repair in another

country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a

defective product which is returned to a Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return authorization information, then

send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination).

Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation

prepaid (FOB Destination). If Fluke determines that failure was caused by neglect, misuse, contamination, alteration, accident, or

abnormal condition of operation or handling, including overvoltage failures caused by use outside the product’s specified rating,

or normal wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer transportation prepaid and the Buyer will be

billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this

Warranty is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect

the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

3

Loading...

Loading...