Page 1

750PEx

Pressure Modules

Instruction Sheet

Introduction

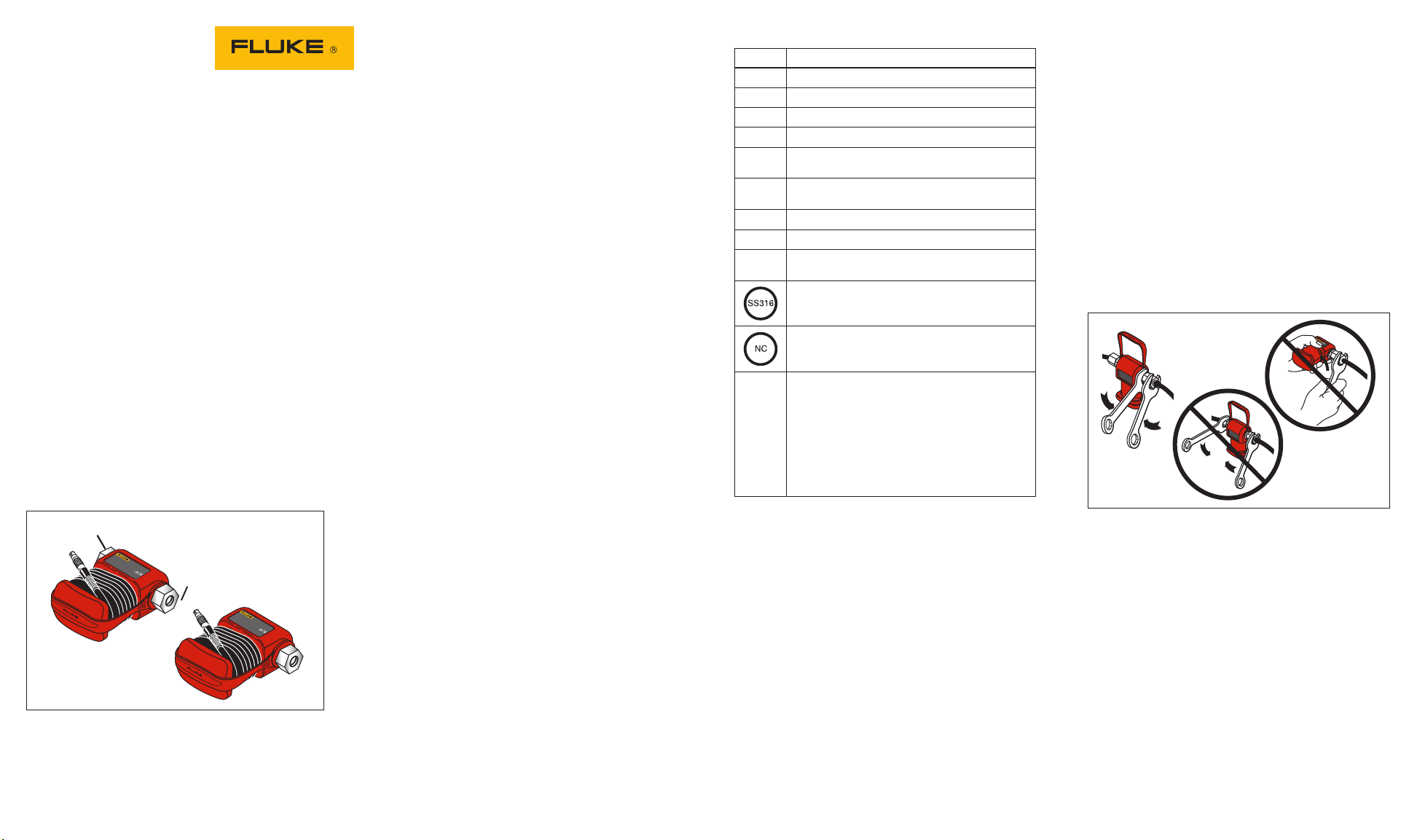

The Fluke 750PEx Series Pressure Modules (the Product)

are to be used with Fluke intrinsically safe calibrators such as

the 718Ex.

The Product measures pressure with an internal

microprocessor compensated sensor. It receives power from

and sends digital information to the Fluke calibrator.

Gage pressure modules have one pressure tting and

measure pressure with respect to atmospheric pressure.

Differential pressure modules have two pressure ttings and

measure the difference between the applied pressure on the

high tting versus the low tting. A differential pressure module

functions like a gage module when the low tting is open. The

absolute pressure modules measure pressure with respect to

an absolute vacuum. The vacuum pressure modules measure

negative pressure.

See the Users Manual for your specic Fluke calibrator for

operation instructions. Differential and Gage models are

shown in Figure 1.

Low

Differential

RA

N

Cl

GE

as

AE

s I

D

x

750P

1

E

i

0

D

a

K

2.

i

RA

i

II

v

n

CT4

1

5

.H

04

G

k

01Ex

r

Pa

G

oup

A

2

0

TE

a

II

A

X 1

2

P

-

1

5

D

R

M

1

E

G

m

02X

ODUL

S

Ex

ba

S

URE

T=0º

i

r

a

a

E

I

I

C

T

C..

4

.

Ga

+5

0º

C

Figure 1. Differential and Gage Pressure Modules

High

Gage

RAN

Cl

GE

as

AE

s I

D

x

750P0

1

E

i

0

D

a

K

2.

i

R

i

II

v

n

CT4

1

A

5

.H

04

G

k

r

Pa

A

Ga

1

oup

2

0

T

Ex

E

A

X

II

2

P

-

1

1

5

D

R

M

1

E

G

m

02

ODUL

S

E

ba

S

X

x

URE

T

i

r

a

a

E

=

I

I

0º

C

T

C.

4 Ga

.

.

+5

0

ºC

hhb001.jpg

Safety Information

A Warning identies conditions and procedures that are

dangerous to the user. A Caution identies conditions and

procedures that can cause damage to the Product or the

equipment under test.

Warning

To avoid injury due to the release of high-pressure uid:

● Use only adapters and ttings rated to withstand the

appropriate pressure. Ensure that all adapters and

ttings are securely connected.

● Never exceed the specied BURST PRESSURE for the

Product.

● To avoid a violent release of pressure in a pressurized

system, shut off the isolation valve and slowly bleed

off the pressure before you attach or remove the

pressure module from the pressure line.

● Do not alter the Product and use only as specied,

or the protection supplied by the Product can be

compromised.

Ex-Hazardous Areas

The Product has been designed for use in Ex-Hazardous

Areas. These are areas where potentially ammable or

explosive vapors may occur. These areas are referred to

as hazardous (classied) locations in the United States, as

Hazardous Locations in Canada, as Potentially Explosive

Atmospheres in Europe and as Explosive Gas Atmospheres

by most of the rest of the world. The Product is designed as

intrinsically safe. This means that connecting the Product to

equipment that is used within intrinsically-safe circuits will not

cause an ignition-capable arc as long as the entity parameters

are suitably matched.

Warning

To prevent re, explosion, or personal injury:

● Check entity parameters before making any

connections to this device.

● Use only specied replacement parts or Intrinsic

Safety can be impaired.

● Precautions are required to ensure that a chargegenerating mechanism is unlikely to be present,

and/or discharge to earthed metal is improbable.

The exposed metal parts are not earthed and have

a capacitance of more than 3 pF with respect to an

earthed conductor. If a charge-generating mechanism

is present, an incendive level of charge could migrate

to these metal parts and subsequently discharge to

earthed metal.

Table 1. Symbols

Symbol Meaning

WARNING. RISK OF DANGER.

Direct Current

Consult user documentation.

Conforms to European Union directives.

Conforms to relevant South Korean EMC

Standards.

Certied by CSA Group to North American safety

standards.

Pressure (found on Fluke calibrators)

f

Conforms to relevant Australian EMC standards.

Conforms to the European Explosive

(

Atmospheres (ATEX) directive.

Medium compatibility: 316 Stainless Steel,

Medium compatibility: noncorrosive gasses.

This product complies with the WEEE Directive

(2002/96/EC) marking requirements. The

afxed label indicates that you must not

discard this electrical/electronic product in

domestic household waste. Product Category:

With reference to the equipment types in

the WEEE Directive Annex I, this product is

classed as category 9 “Monitoring and Control

Instrumentation” product. Do not dispose of this

product as unsorted municipal waste.

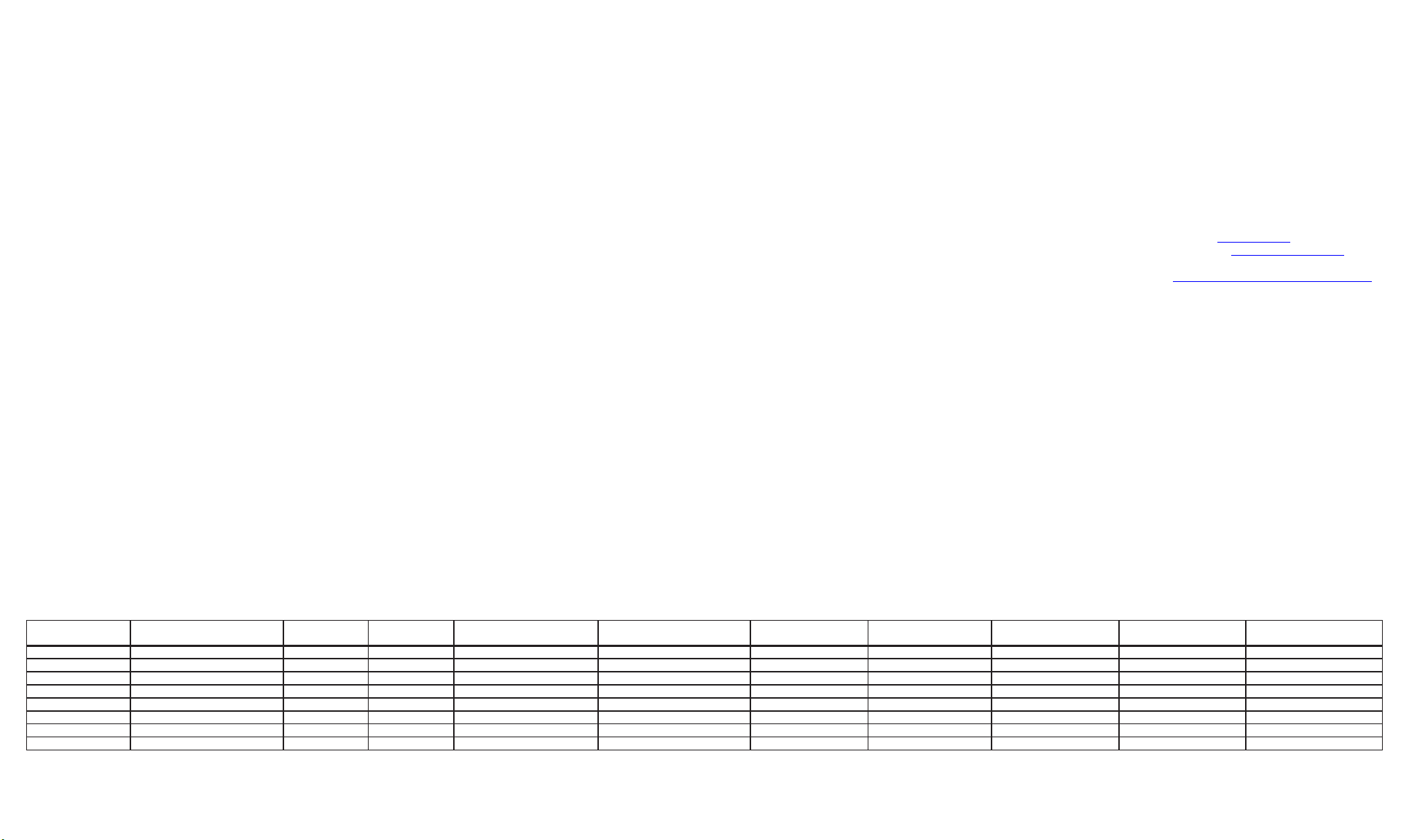

Mechanical Damage Prevention

Caution

To avoid Product damage, never apply more than 10 lb-ft

of torque between the pressure module ttings or

between the ttings and the body of the module. Always

apply appropriate torque between the pressure module

tting and connecting ttings or adapters.

Over Pressure Damage Prevention

Caution

To avoid Product damage:

● Use the Product only with specied media as shown

on the Product label to avoid Product damage from

corrosion.

● To avoid product damage do not apply pressure in

excess of 120 % of the specied upper limit.

Figure 2 shows correct and incorrect ways to use a wrench to

apply torque to the pressure module tting.

RANGE

10

0

k

P

a

hhb002.eps

Figure 2. Applying Torque

Recommended Measurement

Technique

For best results, before you zero the Product or take

measurements, pressurize the Product to full scale and then

vent to zero pressure (atmosphere).

Note

Low-range pressure modules may be sensitive to gravity.

For best results, pressure modules 30 psi and below should

be held at the same physical orientation from the time they

are zeroed until the measurement is complete.

PN 4562480 September 2017

© 2017 Fluke Corporation. Product specications are subject to change

without notice. All rights reserved.

Page 2

Box Contents

The Product package should contain the listed items below. If

it does not, contact Fluke immediately. See “Contact Fluke”.

● Pressure module

● 1/8 NPT male to 1/4 NPT male adapter

● 1/8 NPT male to 1/4 BSP male adapter

● 1/8 NPT male to M20 male adapter

● O-RING,(-111) CAST URETHANE

● Certicate of calibration

● User documentation packet

Pressure Calibration Kit

The optional Fluke 700PCK (Pressure Calibration Kit)

accessory lets you calibrate the pressure modules at

your facility with your precision pressure standards. A

pressure calibrator or dead weight tester that is at least

4X more accurate than the pressure module under test is

recommended.

Performance Test

If you need to check that the pressure module meets its

accuracy specication, use a dead weight tester or suitable

pressure calibrator. The accuracy of the dead weight tester

or pressure calibrator should be signicantly better than the

Product pressure specication. Proceed as follows to verify

that a pressure module is operating within specication:

1. Read the pressure value with no externally applied

pressure to make sure the 0 % of scale is correct. When

reading the pressure, press the ZERO key to remove

any zero offset.

2. Connect the pressure module to a dead weight tester.

3. Set the dead weight tester to 20 % of the pressure

module’s full scale value.

4. Make sure the reading agrees with the dead weight

tester value within the specications.

5. Set the dead weight tester to 40, 60, 80, and 100 % of

full scale and compare the respective readings.

750 Model Number Parameter/Range

750P01Ex 0 inch to 10 inch H2O (0 to 25 mBar) 30 inH2O 3X NONCORROSIVE GASSES NONCORROSIVE GASSES ±0.1 % ±0.2 % ±0.3 % ±0.15 % ±0.25 %

750P24Ex 0 psi to 15 psi (0 to 1 Bar) 60 4X Stainless Steel SS-316 NONCORROSIVE GASSES ±0.0175 % ±0.035 % ±0.045 % ±0.03 % ±0.04 %

750P05Ex 0 psi to 30 psi (0 to 2 Bar) 120 4X Stainless Steel SS-316 N/A ±0.0175 % ±0.035 % ±0.045 % ±0.03 % ±0.04 %

750P06Ex 0 psi to 100 psi (0 to 7 Bar) 400 4X Stainless Steel SS-316 N/A ±0.0175 % ±0.035 % ±0.045 % ±0.03 % ±0.04 %

750P27Ex 0 psi to 300 psi (0 to 20 Bar) 1200 4X Stainless Steel SS-316 N/A ±0.0175 % ±0.035 % ±0.045 % ±0.03 % ±0.04 %

750P09Ex 0 psi to 1500 psi (0 to 100 Bar) 4500 3X Stainless Steel SS-316 N/A ±0.0175 % ±0.035 % ±0.045 % ±0.03 % ±0.04 %

750P29Ex 0 psi to 3000 psi (0 to 200 Bar) 9000 3X Stainless Steel SS-316 N/A ±0.0175 % ±0.035 % ±0.045 % ±0.03 % ±0.04 %

750PA4Ex 0 psia to 15 psia (0 to 1 Bar) 60 4X Stainless Steel SS-316 N/A ±0.03 % ±0.06 % ±0.07 % ±0.05 % ±0.06 %

1. Total uncertainty, % of full span for temperature range 0°C to +50°C, one year interval. Total uncertainty, 1.0% of full span for temperature range -10°C to 0°C, one

year interval. No 6 month specication available for range -10°C to 0°C.

2. “NONCORROSIVE GASSES” indicates dry air or non-corrosive gas as compatible media. “Stainless Steel 316-SS” indicates media compatible with Type 316

Stainless Steel.

3. Specications % of Full Span unless otherwise noted.

750 Burst

Pressure (psi)

Specications

Mechanical Specications

Size (H X W X L) .......45 mm X 94 mm X 110 mm

(1.77 in X 3.70 in X 4.33 in)

Weight . ..............292 g (10.3 oz)

Physical Interface.......Serial Connector, Pressure Port(s)

Environmental Specications

Operating Temperature...-10 °C to +50 °C (14 °F to 122 °F)

Storage Temperature ....-20 °C to +60 °C (-4 °F to 140 °C)

Operating Humidity......Non condensing (<10 °C) (<50 °F)

90 %RH (10 °C to 30 °C)

(50 °F to 86 °F)

75 %RH (30 °C to 40 °C)

(86 °F to 104 °F)

45 %RH (40 °C to 50 °C)

(104 °F to 122 °C)

Operating Altitude ......2000 m (6,561 ft)

Storage Altitude ........12 000 m (45 700 ft)

Ingress Protection.......IEC 60529: IP52 (not included in

the third party certication)

Compliance Markings

( II 1 G

SIRA 16ATEX2383X

IECEx SIR 16.0118X

Ex ia IIC T4 Ga

CIass I, Division 1, Groups A-D,T4

CIass I, Zone 0, AEx ia IIC T4 Ga

Ui 7.5V, Ii 200mA, Pi 0.375W, Ci 5.8 uF, Li 6.0 uH

Ex Certication by Fluke Corporation, Everett, WA USA

Burst Rating

0344

Hi Side Media Compatibility

Pressure Module Ranges

[2]

Lo Side Media Compatibility

Compliance

Safety ................IEC 60079-0, IEC 60079-11

IEC 61010-1: Pollution Degree 2

Electromagnetic Compatibility

International ...........IEC 61326-1: Basic

Electromagnetic Environment;

CISPR 11: Group 1, Class A

Group 1: Equipment has intentionally generated and/or

uses conductively-coupled radio frequency energy that is

necessary for the internal function of the equipment itself.

Class A: Equipment is suitable for use in all establishments

other than domestic and those directly connected to a

low-voltage power supply network that supplies buildings

used for domestic purposes. There may be potential

difculties in ensuring electromagnetic compatibility in other

environments due to conducted and radiated disturbances.

Caution: This equipment is not intended for use in

residential environments and may not provide adequate

How to Contact Fluke

To contact Fluke or locate a Service Center for parts, call one

of the following telephone numbers:

● Technical Support USA: 1-800-44-FLUKE

(1-800-443-5853)

● Calibration/Repair USA: 1-888-99-FLUKE

(1-888-993-5853)

● Canada: 1-800-36-FLUKE (1-800-363-5853)

● Europe: +31 402-675-200

● Japan: +81-3-6714-3114

● China: +86-400-921-0835

● Singapore: +65-6799-5566

● Anywhere in the world: +1-425-446-5500

Or, visit Fluke’s website at www.uke.com.

To register your product, visit http://register.uke.com.

To view, print, or download the latest manuals or manual

supplement, visit http://us.uke.com/usen/support/manuals.

protection to radio reception in such environments.

Korea (KCC) .......................................Class A Equipment

(Industrial Broadcasting & Communication Equipment)

Class A: Equipment meets requirements for industrial

electromagnetic wave equipment and the seller or user

should take notice of it. This equipment is intended for use

in business environments and not to be used in homes.

USA (FCC) .........................................47 CFR 15 subpart B.

This product is considered an exempt device per clause

15.103.

[3]

Reference Uncertainty

[2]

4. Reference Uncertainty is the specication for as left data for 24 hours.

5. Burst rating specication refers to the multiplier times full scale of the module for the rated burst pressure.

(23 ± 3 °C)

[4]

Total Uncertainty 1 year

(15-35 °C)

Total Uncertainty 1 year

(0-50 °C)

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and

workmanship for three years from the date of purchase.

This warranty does not cover fuses, disposable batteries,

or damage from accident, neglect, misuse, alteration,

contamination, or abnormal conditions of operation or

handling. Resellers are not authorized to extend any other

warranty on Fluke’s behalf. To obtain service during the

warranty period, contact your nearest Fluke authorized

service center to obtain return authorization information, then

send the product to that Service Center with a description of

the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER

WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS

NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL

OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING

FROM ANY CAUSE OR THEORY. Since some states or

countries do not allow the exclusion or limitation of an implied

warranty or of incidental or consequential damages, this

limitation of liability may not apply to you.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

11/99

[1]

Total Uncertainty 6 month

(15-35 °C)

Total Uncertainty 6 month

(0-50 °C)

[1]

Loading...

Loading...