Page 1

Fluke 750P

Series Pressure

Modules

Precision pressure measurement for

75X and 720 series calibrators

The 750P Series Pressure Modules are the ideal pressure

modules to enable gage, differential and absolute pressure

measurement with Fluke 750 and 740 series DPCs and 725,

726 MPCs to measure pressure.

• 0.025 % reference uncertainty

• 6-month and 1-year specifications

• Temperature compensated 0 °C to 50 °C

• Digital communication to calibrators, no analog

losses or errors

• Broad selection of ranges

• Gage, differential, dual range, absolute and vacuum

measurement models

A complete family of pressure modules

A family of 48 pressure modules covers pressure

calibrations from 0 to 1 in H

to 690 bar).

Gage pressure modules have one pressure fitting

and measure the pressure with respect to atmospheric

pressure. Differential pressure modules have two pressure fittings and measure the difference between the

applied pressure on the high fitting versus the low

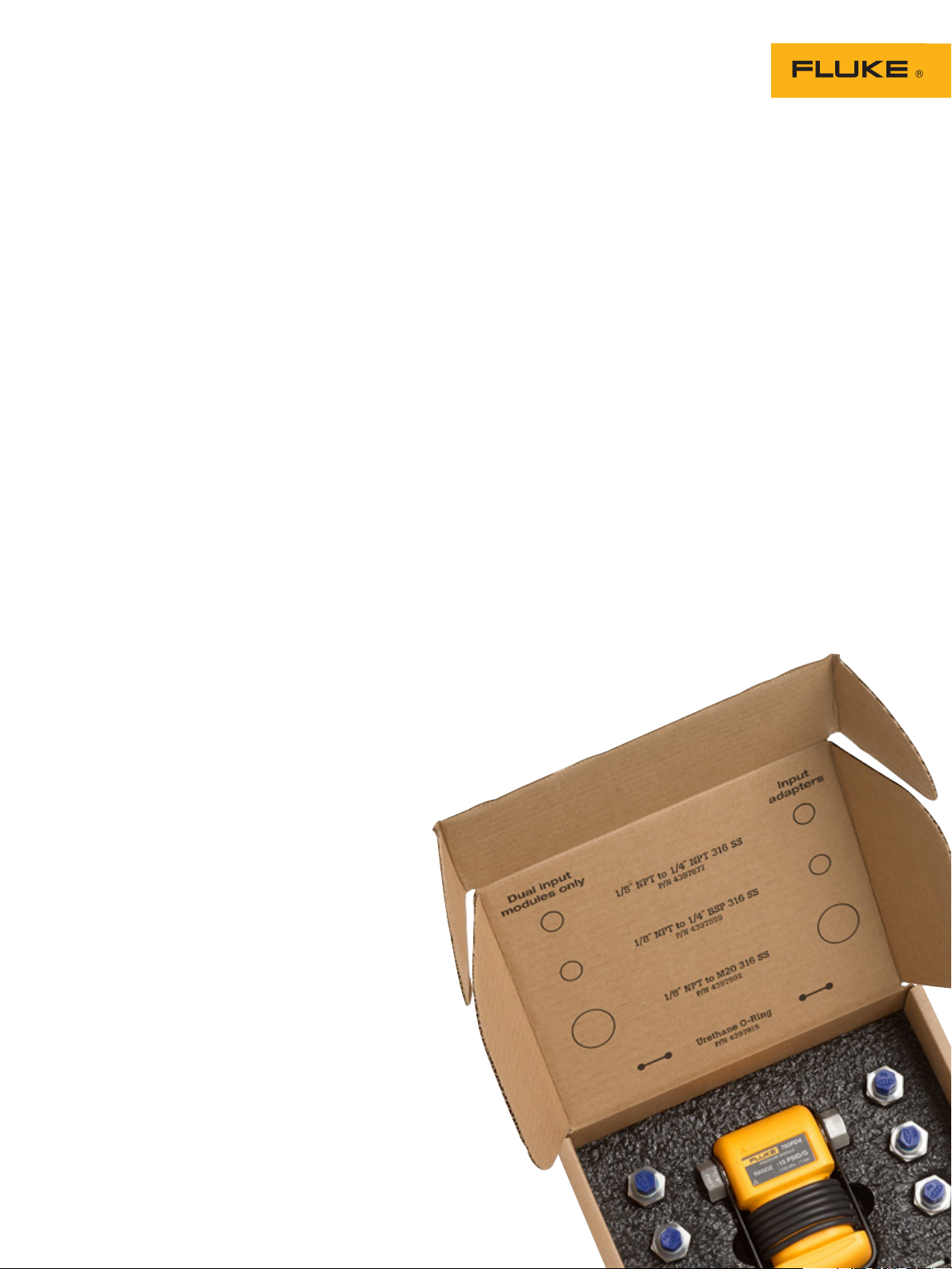

fitting. Each module is clearly labeled for range, overpressure and media compatibility. All modules include

NPT, metric (BSP) and M20 adapters.

Quick and easy measurements

Fluke 750P Series Pressure Modules are easy to use.

To measure pressure, connect the pressure module to

a pressure source or hand pump and then connect the

pressure module cable to the calibrator. Apply pressure

from the pressure source and it is displayed digitally

on the calibrator. At the touch of a button, the pressure

may be displayed in up to 11 different engineering

units. When used with the 750 Series Documenting

Process Calibrators, pressure readings can be date/time

stamped and stored electronically for later retrieval.

This saves time, eliminates errors, and supports compliance with quality standards and regulations.

85

0 to 10000 psi (2.5 mBar

2

Technical Data

Page 2

Pressure module performance

and technology

Fluke 750P Series pressure modules are highly

accurate, with specifications that apply from 0 °C to

50 °C (32 °F to 122 °F), a feature that sets them apart

from other pressure calibrators. Many ranges have

total uncertainties of 0.04

uncertainties of 0.01

table).

This performance is possible through the innovative application of mathematics and micro-processor

power. Fluke pressure modules have silicon piezoresistor sensors which consist of a resistive bridge

fabricated in a silicon diaphragm. Pressure applied to

the diaphragm causes a change in the balance of the

bridge which is proportional to the applied pressure.

The bridge balance change is not linear and is very

sensitive to temperature. However, since these effects

are quite stable with time and with repetitive changes

of condition, the sensors are carefully characterized.

During manufacture, Fluke pressure module sensors

are characterized by reading temperature and pressure

at multiple points. A least-squares regression is used

to calculate the coefficients of a polynomial expression

for pressure. The coefficients, unique to that pressure

module, are stored in the module’s memory.

Each module has its own microprocessor, allowing

it to run the measurement circuitry and to communicate digitally with a calibrator. When connected to

the calibrator, the modules coefficients are uploaded

from the pressure module to the calibrator. Then, as

pressure measurements are made, raw sensor values

for pressure and temperature are digitally loaded to

the calibrator, where the raw sensor values and coefficients are manipulated to derive and display the

pressure reading.

This innovative technique provides several benefits:

1. Digital communication eliminates errors due to poor

connections and electrical interference.

2. The modules are inherently temperature-

compensated from 0 °C to 50 °C (32 °F to 122 °F).

% of full scale and reference

% of full scale (see specification

3. The modules are fully interchangeable because

all measurements are completed in the pressure module itself and then communicated to the

calibrator in digitized form. Modules are calibrated

independently of the calibrator, and can be used

with any 740, 750 or compatible 720 or 710 series

calibrator. Each module has its own serial number

to maintain independent traceability.

Sensor protection in isolated modules

Many of these modules (see table) incorporate a stainless steel diaphragm to isolate the sensor. With these

modules, any medium that is compatible with stainless

steel can be used on the high side of the module.

Rugged construction

A urethane overmolding protects against shock if a

module is accidentally dropped and also seals against

dirt, dust, and moisture. Pressure connections are

1

” NPT female connection. A ¼” NPT Male, ¼” BSP/

/

8

ISO and M20 male adapter are also provided with each

pressure module.

Convenient setup

A one-meter cable between the pressure module and

calibrator reduces the length of connecting tubing to

the pressure source. The remote pressure head also

provides an extra margin of safety and convenience

by removing the calibrator and operator from the

pressure source in the event or need for semi-remote

measurements.

2 Fluke Corporation Fluke 750P Series Pressure Modules

Page 3

Pressure accessories

Image Description Application

Fluke 700PTP-1 Pneumatic Test Pump

The Fluke 700PTP-1 is a handheld pressure

pump designed to generate either vacuum

to -13 psi/-0.9 bar or pressure to

600 psi/40 bar

The Fluke 700PTP-1 has two pressure ports:

• ¼” NPT female parallel thread fitting for

the reference gauge or pressure module

• ¼” NPT female parallel thread fitting for

the unit under test

Fluke 700HTP-2Hydraulic Test Pump

The Fluke 700HTP-1 is designed to generate

pressures up to 10000 psi/700 bar. The

Fluke 700HTP-1 has two pressure ports:

• ¼” NPT female parallel thread fitting for

the reference gauge or pressure module

• ¼” NPT female parallel thread fitting for

the unit under test

Note: The user must provide a hose with appropriate end

fittings from this port to the unit under test.

Fluke 700LTP-1 Low-Presure Test Pump

The Fluke 700LTP-1 is a hand operated

pressure pump designed to generate either

vacuum to -12 psi/-.85 bar or pressures to

100 psi/6.9 bar. The Fluke 700LTP-1 has

two pressure ports with push fit connectors. These push fit connectors, one for the

reference port for connection to a Fluke 700

Series Pressure Module and one to connect

to a unit under test, connect to the supplied

test hoses.

Fluke 700HTH-1 Hydraulic Test Hose

The Fluke 700HTH-1 Hydraulic Test Hose

is a 10000 psi, 700 bar working pressure

test hose. The hose uses self-sealing fittings

with easy finger tight connections.

The Fluke 700PTP-1 features an integral pressure adjustment vernier

which varies the pressurized volume by 2.0 cc over approximately

eleven turns of the vernier knob. The pressure variation achievable with

the vernier will depend on the nominal pressure and total pressurized

volume, but with a minimum volume and maximum pressure, the vernier

provided 600 ± 20 psi adjustment range. With a minimum volume and

no pressure applied, the vernier can also be used to provide a 0 to 70˝

H2O range. Larger volumes will provide a smaller range of adjustment,

but greater resolution. The length of the stroke can be adjusted to limit

the maximum output pressure. Maximum output pressure is adjustable

from 2.5 psi to 600 psi.

For use with: Fluke 700 and 750P Series Pressure Modules and the

Fluke 710 and 720 Series Pressure Calibrators

This pump can provide up to 10000 psi using distilled water or mineralbased hydraulic oil. The pump is operated by pumping several strokes

to prime the system, then switching to high pressure mode when the

resistance increases. An integral pressure adjustment vernier knob varies

the pressurized volume by 0.6 cc. The pressure variation achievable with

the vernier will depend on the nominal pressure and total pressurized

volume, but with a minimum volume, the vernier provided 150 psi to

3000 psi (at 150 psi nominal) and 3000 psi to10000 psi (at 3000 psi

nominal) adjustment ranges. With a minimum volume and no pressure

applied, the vernier can also be used to provide a 0 to 1.7 psi range.

Larger volumes will provide a smaller range of adjustment, but greater

resolution.

For use with: Fluke 700 and 750P Series Pressure Modules and the

Fluke 710 and 720 Series Pressure Calibrators

The Fluke 700LTP-1 is primarily intended for low pressure applications.

It features a fine adjust vernier with .00145 psi resolution at low pressures. The pressure variation achievable with the vernier will depend on

the nominal pressure and total pressurized volume, but with minimum

volume and maximum pressure the vernier provides 30 psi ± 6 psi. The

adjustable pressure relief valve features a slow-bleed capability that

allows the user to slowly release pressure at a controlled rate to achieve

a desired pressure.

The Fluke 700HTH-1 allows connections to a unit under test from a

Fluke 700HTP-1 hydraulic test pump in use with the Fluke 700 and

750P Series Pressure Modules. The 700HTH-1 is compatible with water

and non-corrosive oil.

Fluke 71X Hose Kit

The Fluke 71X hose kit includes (2) quick

disconnect fittings to connect to the 718 or

719, (3) 1-meter translucent hoses and one

BSP adapter.

Fluke 700PRV-1 Pressure Relief Valve Kit

The Fluke 700PRV-1 consists of two relief

valves (1360 and 5450 psi) to be used with

the 700HTP-1 Hydraulic Test Pump. These

relief valves will protect the Fluke pressure

modules from damage due to over-pressurization. 1/4 BSP male parallel thread to fit

Fluke 700HTP-1.

Fluke 700 PMP Pressure Pump

The Fluke 700PMP is a hand-operated pressure pump to provide pressures up to

150 psi/1000 kPa. Output fitting is 1/8

FNPT.

3 Fluke Corporation Fluke 750P Series Pressure Modules

For use with: Fluke 718 and 719 Pressure Calibrators

Repeatability ± 10 % of nominal setting. Multiturn adjustment screw to

set preload on internal disc springs.

For use with: Fluke 700HTP-1 Hydraulic Test Pump.

Linear stroke of 1.6 in (4 cm). Multi-turn vernier for fine adjustment of

pressure. Includes controlled pressure bleed valve.

For use with: Fluke 700 and 750P Series Pressure Modules and the

Fluke 710 and 720 Series Pressure Calibrators.

Page 4

General specifications

Model Parameter/

Range

Differential

750P00 0 to 1 in H2O

(0 to 2.5 mBar)

750P01 0 to 10 in H2O

(0 to 25 mBar)

750P02 0 to 1 psi

(0 to 70 mBar)

750P22 0 to 1 psi

(0 to 70 mBar)

750P03 0 to 5 psi

(0 to 350 mBar)

750P23 0 to 5 psi

(0 to 350 mBar)

750P04 0 to 15 psi

(0 to 1 bar)

750P24 0 to 15 psi

(0 to 1 bar)

Gage

750P05 0 to 30 psi

(0 to 2 bar)

750P06 0 to 100 psi

(0 to 7 bar)

750P27 0 to 300 psi

(0 to 20 bar)

750P07 0 to 500 psi

(0 to 35 bar)

750P08 0 to 1000 psi

(0 to 70 bar)

750P09 0 to 1500 psi

(0 to 100 bar)

750P2000 0 to 2000 psi

(0 to 140 bar)

High

750P29 0 to 3000 psi

(0 to 200 bar)

750P30 0 to 5000 psi

(0 to 340 bar)

750P31 0 to 10000 psi

(0 to 700 bar)

Absolute

750PA3 0 to 5 psia

(0 to 350 mBar)

750PA4 0 to 15 psia

(0 to 1 bar)

750PA5 0 to 30 psia

(0 to 2 bar)

750PA6 0 to 100 psia

(0 to 7 bar)

750PA27 0 to 300 psia

(0 to 20 bar)

750PA7 0 to 500 psia (0

to 35 bar)

750PA8 0 to 1000 psia

(0 to 70 bar)

750PA9 0 to 1500 psia

(0 to 100 bar)

Burst

Rating

30X Dry Air Dry Air ±0.15 % ± 0.3 % ± 0.35 % ± 0.25 % ± 0.30 %

3X Dry Air Dry Air ±0.1 % ± 0.2 % ± 0.3 % ± 0.15 % ± 0.25 %

3X Dry Air Dry Air ±0.050 % ± 0.1 % ± 0.15 % ± 0.075 % ± 0.125 %

3X 316 SS Dry Air ±0.050 % ± 0.1 % ± 0.15 % ± 0.075 % ± 0.125 %

3X Dry Air Dry Air ±0.02 % ± 0.04 % ± 0.05 % ± 0.035 % ± 0.04 %

4X 316 SS Dry Air ±0.02 % ± 0.04 % ± 0.05 % ± 0.035 % ± 0.04 %

3X Dry Air Dry Air ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

4X 316 SS Dry Air ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

4X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

4X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

4X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

4X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

3X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

3X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

3X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

3X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

3X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

2X 316 SS N/A ±0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

4X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

4X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

4X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

4X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

4X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

4X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

3X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

3X 316 SS N/A ±0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

Hi Side

6

Media

Lo Side

2

Media

Reference

2

Uncertainty

Total

4

Uncertainty

1-year

(15-35 �C)

Total

Uncertainty

1

1-year

Total

Uncertainty

6-month

(15-35 �C)

Total

Uncertainty

6-month

1

4 Fluke Corporation Fluke 750P Series Pressure Modules

Page 5

General specifications (continued)

Model Parameter/

Range

Burst

Rating

Hi Side

6

Media

Lo Side

2

Media

Reference

2

Uncertainty

Total

4

Uncertainty

1-year

(15 �C to 35 �C)

Total

Uncertainty

1

1-year

Total

Uncertainty

6-month

(15 �C to 35 �C)

Total

Uncertainty

6-month

1

Vacuum

750PV3 -5 psi

4X 316 SS Dry Air ± 0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

(-350 mBar)

750PV4 -15 psi

4X 316 SS Dry Air ± 0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

(-1 bar)

Dual

750PD2 -1 to 1 psi

4X 316 SS Dry Air ± 0.05 % ± 0.1 % ± 0.15 % ± 0.075 % ± 0.125 %

(-70 to 70 mBar)

750PD3 -5 to 5 psi

4X 316 SS Dry Air ± 0.03 % ± 0.06 % ± 0.07 % ± 0.05 % ± 0.06 %

(-350 to

350 mBar)

750PD10 -10 to 10 psi

4X 316 SS Dry Air ± 0.025 % ± 0.05 % ± 0.07 % ± 0.04 % ± 0.06 %

(-700 to

700 mBar)

750PD4 -15 to 15 psi

4X 316 SS Dry Air ± 0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

(-1 to 1 bar)

750PD5 -15 to 30 psi

4X 316 SS — ± 0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

(-1 to 2 bar)

750PD50 -15 to 50 psi

4X 316 SS — ± 0.0175

% ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

(-1 to 3.5 bar)

750PD6 -15 to 100 psi

4X 316 SS — ± 0.0175

% ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

(-1 to 7 bar)

750PD7 -15 to 200 psi

4X 316 SS — ± 0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

(-1 to 14 bar)

750PD27 -15 to 300 psi

4X 316 SS — ± 0.0175 % ± 0.035 % ± 0.045 % ± 0.03 % ± 0.04 %

(-1 to 20 bar)

Reference

750R0450 to 15 psi

3X Dry Air Dry Air ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 1 bar)

750R0650 to 100 psi

4X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 7 bar)

750R27 0 to 300 psi

4X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 20 bar)

750R07 0 to 500 psi

4X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 35 bar)

750R0850 to 1000 psi

3X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 70 bar)

750R29 0 to 3000 psi

3X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 200 bar)

750R30 0 to 5000 psi

3X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 340 bar)

750R3150 to 10000 psi

2X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(0 to 700 bar)

750RD5 -15 to 30 psi

4X Dry Air — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(-1 to 2 bar)

750RD65-12 to 100 psi

4X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(-1 to 7 bar)

750RD27 -12 to 300 psi

4X 316 SS — ± 0.01 % of FS ± 0.02 % of FS ± 0.04 % of FS ± 0.015 % of FS ± 0.035 % of FS

(-0.8 to 20 bar)

1. Total uncertainty, % of full span for temperature range 0 °C to +50 °C, one year interval. Total uncertainty, 1.0% of full span for temperature range -10 °C to 0 °C, one year interval. No 6

month specification available for range -10 °C to 0 °C.

2. “NONCORROSIVE GASSES” indicates dry air or non-corrosive gas as compatible media. “Stainless Steel 316-SS” indicates media compatible with Type 316 Stainless Steel.

3. Specifications % of Full Span unless otherwise noted.

4. * Reference Uncertainty is the specification for as left data for 24 hours.

5. When reference class modules are used with fixed resolution products (717, 718, 719 series, 725 and 726) calibrators add ± 1 count to the overall accuracy specification.

6. Burst rating specification refers to the multiplier times full scale of the module for the rated burst pressure.

5 Fluke Corporation Fluke 750P Series Pressure Modules

Page 6

Ordering information

FLUKE-750P00

FLUKE-750P01

FLUKE-750P22 Pressure Module, 0 psi to 1 psi (0 to 70 mBar), (0 to 7 kPa)

FLUKE-750P23 Pressure Module, 0 psi to 5 psi (0 to 350 mBar), (0 to 35 kPa)

FLUKE-750P04 Pressure Module, 0 psi to 15 psi (0 to 1 bar), (0 to 100 kPa)

FLUKE-750P24 Pressure Module, 0 psi to 15 psi (0 to 1 bar), (0 to 100 kPa)

FLUKE-750P05 Pressure Module, 0 psi to 30 psi (0 to 2 bar), (0 to 200 kPa)

FLUKE-750P06 Pressure Module, 0 psi to 100 psi (0 to 7 bar), (0 to 700 kPa)

FLUKE-750P27 Pressure Module, 0 psi to 300 psi (0 to 20 bar), (0 to 2000 kPa)

FLUKE-750P07 Pressure Module, 0 psi to 500 psi (0 to 35 bar), (0 to 3500 kPa)

FLUKE-750P08 Pressure Module, 0 psi to 1000 psi (0 to 70 bar), (0 to 7000 kPa)

FLUKE-750P09 Pressure Module, 0 psi to 1500 psi (0 to 100 bar), (0 to 10 MPa)

FLUKE-750P2000 Pressure Module, 0 psi to 2000 psi (0 to 140 bar), (0 to 14 MPa)

FLUKE-750P29 Pressure Module, 0 psi to 3000 psi (0 to 200 bar), (0 to 20 MPa)

FLUKE-750P30 Pressure Module, 0 psi to 5000 psi (0 to 340 bar), (0 to 34 MPa)

FLUKE-750P31 Pressure Module, 0 psi to 10000 psi (0 to 700 bar), (0 to 70 MPa)

FLUKE-750PA3 Pressure Module, 0 psi to 5 psi (0 to 350 mBar), (0 to 35 kPa)

FLUKE-750PA4 Pressure Module, 0 psi to 15 psi (0 to 1 bar), (0 to 100 kPa)

FLUKE-750PA5 Pressure Module, 0 psi to 30 psi (0 to 2 bar), (0 to 200 kPa)

FLUKE-750PA6 Pressure Module, 0 psi to 100 psi (0 to 7 bar), (0 to 700 kPa)

FLUKE-750PA27 Pressure Module, 0 psi to 300 psi (0 to 20 bar), (0 to 2000 kPa)

FLUKE-750PA7 Pressure Module, 0 psi to 500 psi (0 to 35 bar), (0 to 3500 kPa)

FLUKE-750PA8 Pressure Module, 0 psi to 1000 psi (0 to 70 bar), (0 to 7000 kPa)

FLUKE-750PA9 Pressure Module, 0 psi to 1500 psi (0 to 100 bar), (0 to 10 MPa)

FLUKE-750PV3 Pressure Module, -5 psi (-350 mBar), (-35 kPa)

FLUKE-750PV4 Pressure Module, -15 psi (-1 bar), (-100 kPa)

FLUKE-750PD2 Pressure Module, -1 psi to 1 psi (-70 to 70 mBar), (-7 to 7 kPa)

FLUKE-750PD3 Pressure Module, -5 psi to 5 psi (-350 to 350 mBar), (-35 to 35 kPa)

FLUKE-750PD10 Pressure Module, -10 psi to 10 psi (-0.7 to 0.7 bar), (-70 to 70 kPa)

FLUKE-750PD4 Pressure Module, -15 psi to 15 psi (-1 to 1 bar), (-100 to 100 kPa)

FLUKE-750PD5 Pressure Module, -15 psi to 30 psi (-1 to 2 bar), (-100 to 200 kPa)

FLUKE-750PD50 Pressure Module, -15 psi to 50 psi (-1 to 3.5 bar), (-100 to 350 kPa)

FLUKE-750PD6 Pressure Module, -15 psi to 100 psi (-1 to 7 bar), (-100 to 700 kPa)

FLUKE-750PD7 Pressure Module, -15 psi to 200 psi (-1 to 14 bar), (-100 to 1400 kPa)

FLUKE-750PD27 Pressure Module, -15 psi to 300 psi (-1 to 20 bar), (-100 to 2000 kPa)

FLUKE-750R04 Pressure Module, 0 psi to 15 psi (0 to 1 bar) (0 to 100 kPa)

FLUKE-750R06 Pressure Module, 0 psi to 100 psi (0 to 7 bar), (0 to 700 kPa)

FLUKE-750R27 Pressure Module, 0 psi to 300 psi (0 to 20 bar), (0 to 2000 kPa)

FLUKE-750R07 Pressure Module, 0 psi to 500 psi (0 to 35 bar), (0 to 3500 kPa)

FLUKE-750R08 Pressure Module, 0 psi to 1000 psi (0 to 70 bar), (0 to 7000 kPa)

FLUKE-750R29 Pressure Module, 0 psi to 3000 psi (0 to 200 bar), (0 to 20 MPa)

FLUKE-750R30 Pressure Module, 0 psi to 5000 psi (0 to 340 bar), (0 to 34 MPa)

FLUKE-750R31 Pressure Module, 0 psi to 10000 psi (0 to 700 bar), (0 to 700 MPa)

FLUKE-750RD5 Pressure Module, -15 psi to 30 psi (-1 to 2 bar), (-100 to 200 kPa)

FLUKE-750RD6 Pressure Module, -12 psi to 100 psi (-0.8 to 7 bar), (-80 to 700 kPa)

FLUKE-750RD27 Pressure Module, -12 psi to 300 psi (-0.8 to 20 bar), (-80 to 2000 kPa)

FLUKE-750P03 Pressure Module, 0 psi to 5 psi (0 to 350 mBar), (0 to 35 kPa)

FLUKE-750P02 Pressure Module, 0 psi to 1 psi (0 to 70 mBar), (0 to 7 kPa)

Pressure Module, 0 psi to 1 psi in H

Pressure Module, 0 psi to 10 psi in H2O (0 to 25 mBar),(0 to 2.5 kPa)

O (0 to 2.5 mBar), (0 to 0.25 kPa)

2

Included equipment

Manual, traceable calibration certificate, and adapters.

Fluke. The Most Trusted Tools

in the World.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2014 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 1/2014 6001669A_EN

Modification of this document is not permitted

without written permission from Fluke Corporation.

6 Fluke Corporation Fluke 750P Series Pressure Modules

Loading...

Loading...