Page 1

®

724/725/726

Calibrators

Calibration Manual

PN 667581

September 1999 Rev. 2, 2/06

© 1999, 2000, 2006 Fluke Corporation. All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is three years and begins on the date of shipment. Parts, product repairs, and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of

a Fluke authorized reseller, and does not apply to fuses, disposable batteries, or to any product which, in

Fluke's opinion, has been misused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke warrants that software will operate substantially in accordance with

its functional specifications for 90 days and that it has been properly recorded on non-defective media. Fluke

does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers

only but have no authority to extend a greater or different warranty on behalf of Fluke. Warranty support is

available only if product is purchased through a Fluke authorized sales outlet or Buyer has paid the

applicable international price. Fluke reserves the right to invoice Buyer for importation costs of

repair/replacement parts when product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair,

or replacement of a defective product which is returned to a Fluke authorized service center within the

warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the difficulty,

postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following

warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke

determines that failure was caused by neglect, misuse, contamination, alteration, accident, or abnormal

condition of operation or handling, including overvoltage failures caused by use outside the product’s

specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not

apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court or other

decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction........................................................................................................ 1

Contacting Fluke................................................................................................ 1

Read First – Safety Information......................................................................... 2

International Symbols ........................................................................................ 3

Specifications..................................................................................................... 4

DC Voltage Measurement (724 and 725)...................................................... 4

DC Voltage Measurement and Source (726)................................................. 4

DC Voltage Source (724 and 725) ................................................................ 4

DC mA Measurement and Source (724 and 725)

(Measurement only for 724)....................................................................... 4

DC mA Measurement and Source (726) ....................................................... 5

Ohms Measurement (724 and 725) ............................................................... 5

Ohms Measurement (726) ............................................................................. 5

Ohms Source (724 and 725) .......................................................................... 5

Ohms Source (726)........................................................................................ 6

Frequency Measurement (725)...................................................................... 6

Frequency Measurement (726)...................................................................... 6

Frequency Source (725) ................................................................................ 6

Frequency Source (726) ................................................................................ 7

Millivolt Measurement and Source (724 and 725)........................................ 7

Temperature, Thermocouples (724 and 725)................................................. 7

Temperature, Thermocouples (726) .............................................................. 8

Temperature, RTD Ranges, and Accuracies (724 and 725) .......................... 9

RTD Accuracy (Read and Source) (ITS-90) (726)........................................ 10

Loop Power Supply ....................................................................................... 11

Pressure Measurement (725 and 726) ........................................................... 11

Pulse Read and Pulse Source (726) ............................................................... 11

Pressure Units Availability (725) .................................................................. 11

General Specifications................................................................................... 12

Cleaning the Calibrator...................................................................................... 12

Replacing the Batteries ...................................................................................... 12

Fuses .................................................................................................................. 13

Remote Control Interface (725 and 726) ........................................................... 14

Serial Command List (726)................................................................................ 17

Required Equipment .......................................................................................... 22

Performance Tests.............................................................................................. 24

Preparing for the Performance Tests ............................................................. 24

Upper Display Voltage Measurement Tests .................................................. 25

Lower Display mV/TC Measurement Tests .................................................. 26

Lower Display Voltage Measurement Tests.................................................. 27

i

Page 4

724/725/726

Calibration Manual

Upper Display mA Measurement Tests......................................................... 28

Lower Display mA Measurement Tests (725 and 726)................................. 29

Lower Display Frequency Measurement Test (725 and 726) ....................... 30

Lower Display Frequency Source Test (725 and 726) .................................. 31

Lower Display 4-Wire Resistance Measurement Tests................................. 32

Lower Display 3-Wire RTD Measurement ................................................... 33

Lower Display Thermocouple Measurement Tests....................................... 34

Lower Display Thermocouple Source Test ................................................... 35

Lower Display mA Source Tests (725 and 726) ........................................... 36

Lower Display mV Source Tests................................................................... 37

Lower Display Voltage Source Tests ............................................................ 37

Lower Display Ohms Source Tests ............................................................... 38

Pressure Module Input (725/726).................................................................. 39

Calibration Adjustment...................................................................................... 39

Setup.............................................................................................................. 39

Initiating Communication (724 and 725) ...................................................... 40

Calibration Adjustment Procedures (724 and 725) ....................................... 41

Cal Volts Input .......................................................................................... 41

Cal Volts Output ....................................................................................... 42

Cal mA Input (Fluke 725 Only) ................................................................ 43

Cal mA Output (725 Only) ....................................................................... 44

Cal mV Input............................................................................................. 45

Cal mV Output .......................................................................................... 46

Cal Thermocouples ................................................................................... 47

Cal Ohms Hi Source.................................................................................. 48

Cal Ohms Low Source .............................................................................. 49

Cal RTD Low Range................................................................................. 50

Cal RTD Hi Range .................................................................................... 51

Cal ISO Volts ............................................................................................ 52

Cal ISO mA............................................................................................... 53

Calibration Adjustment Procedures (726) ..................................................... 54

Initiating Communication ......................................................................... 54

Calibrating Isolated mA Input................................................................... 55

Calibrating Isolated Voltage Input ............................................................ 56

Calibrating mA Input ................................................................................ 57

Calibrating mA Output.............................................................................. 58

Calibrating Voltage Input.......................................................................... 59

Calibrating Voltage Output ....................................................................... 60

Calibrating Low Ohms Source.................................................................. 61

Calibrating High Ohms Source ................................................................. 62

Calibrating Ohms Measure........................................................................ 63

Calibrating Thermocouple mV Output ..................................................... 64

Calibrating Thermocouple mV Input ........................................................ 65

Calibrating Thermocouple CJC:................................................................ 66

Replaceable Parts............................................................................................... 67

ii

Page 5

List of Tables

Table Title Page

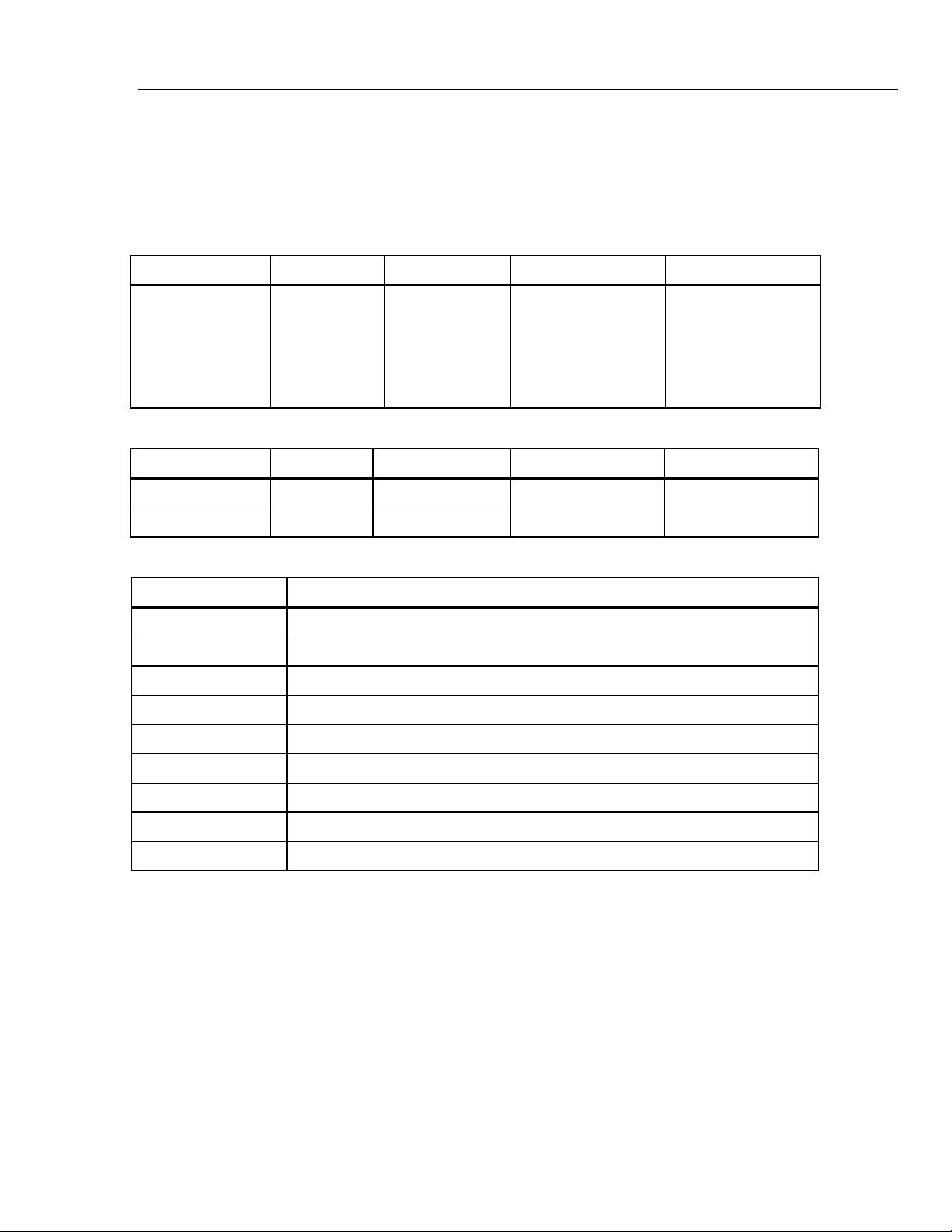

1. International Symbols ............................................................................................ 3

2. Upper Display Remote Commands (725) .............................................................. 14

3. Lower Display Remote Commands (725).............................................................. 15

4. Remote Commands for Sensor Selection (725) ..................................................... 16

5. Serial Command List-726 ...................................................................................... 17

6. Required Equipment and Software ........................................................................ 23

7. Upper Display Voltage Readings........................................................................... 25

8. Lower Display mV Readings ................................................................................. 26

9. Lower Display Voltage Readings .......................................................................... 27

10. Upper Display mA Readings.................................................................................. 28

11. Lower Display mA Readings ................................................................................. 29

12. Lower Display 4-Wire Resistance Readings.......................................................... 32

13. Type J Thermocouple Readings............................................................................. 34

14. Lower Display Thermocouple Source Readings.................................................... 35

15. Lower Display mA Source Readings ..................................................................... 36

16. Lower Display mV Source Readings ..................................................................... 37

17. Lower Display Voltage Source Readings .............................................................. 37

18. Lower Display Ohms Source Readings.................................................................. 38

19. Replacement Parts.................................................................................................. 67

iii

Page 6

724/725/726

Calibration Manual

iv

Page 7

List of Figures

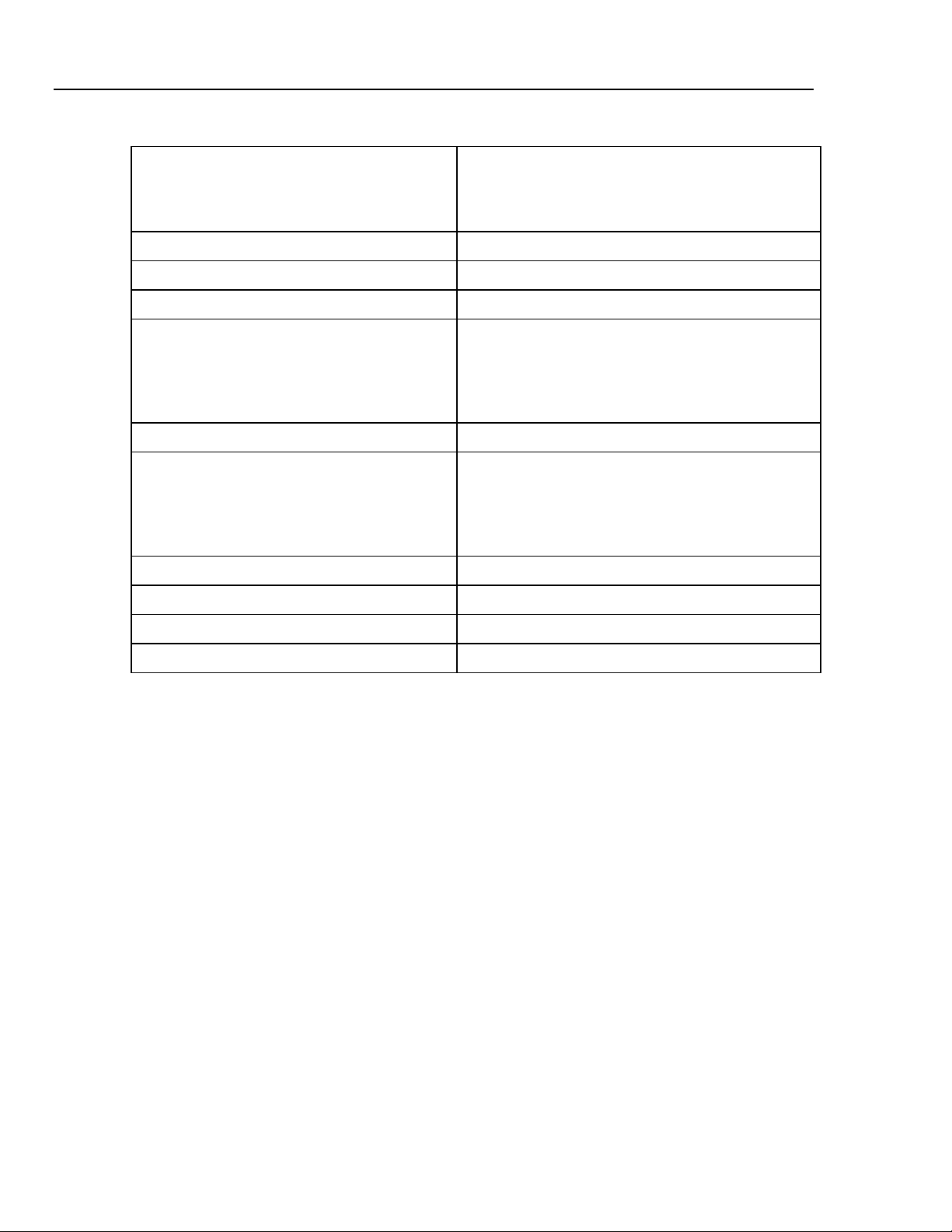

Figure Title Page

1. Replacing the Batteries and Replaceable Fuses ..................................................... 13

2. Upper Display Voltage Test Connections.............................................................. 25

3. Lower Display mV and Voltage Test Connections................................................ 26

4. Upper Display mA Test Connections..................................................................... 28

5. Lower Display mA Test Connections .................................................................... 29

6. Lower Display Frequency Test Connections ......................................................... 30

7. Lower Display Frequency Source Test Connections ............................................. 31

8. Lower Display 4-Wire Resistance Test Connections............................................. 32

9. Lower Display 3-Wire Resistance Test Connections............................................. 33

10. Lower Display Thermocouple Test Connections................................................... 34

11. Lower Display mA Source Test ............................................................................. 36

12. Lower Display Ohms Source Test Connections.................................................... 38

13. Volts Input Calibration Connections...................................................................... 41

14. Volts Output Calibration Connections ................................................................... 42

15. mA Input Calibration Connections ........................................................................ 43

16. mA Output Calibration Connections...................................................................... 44

17. mV Input Calibration Connections ........................................................................ 45

18. mV Output Calibration Connections...................................................................... 46

19. Thermocouples Calibration Connections ............................................................... 47

20. Ohms Hi Source Calibration Connections ............................................................. 48

21. RTD Low Range Calibration Connections ............................................................ 50

22. ISO Volts Calibration Connections........................................................................ 52

23. ISO mA Calibration Connections .......................................................................... 53

24. Isolated mA Input Calibration Connections........................................................... 55

25. Isolated Voltage Input Calibration Connections .................................................... 56

26. mA Input Calibration Connections ........................................................................ 57

27. mA Output Calibration Connections...................................................................... 58

28. Voltage Input Calibration Connections.................................................................. 59

29. Voltage Output Calibration Connections ............................................................... 60

30. Low Ohms Source Calibration Connections.......................................................... 61

31. High Ohms Source Calibration Connections ......................................................... 62

32. Ohms Measure Calibration Connections................................................................ 63

33. Thermocouple mV Output Calibration Connections.............................................. 64

34. Thermocouple mV Input Calibration Connections ................................................ 65

35. Thermocouple CJC Calibration Connections......................................................... 66

36. Replacement Parts.................................................................................................. 68

v

Page 8

724/725/726

Calibration Manual

vi

Page 9

Introduction

The information provided in this manual is for the use of qualified

personnel only. Do not perform the verification tests or calibration

procedures described in this manual unless you are qualified to do

so.

This Calibration Manual provides the following information for the Fluke 724

Temperature Calibrator and the Fluke 725 and 726 Multifunction Process Calibrators

(also referred to as "the Calibrator" and/or “the UUT”):

• Precautions and safety information

• Equipment required for performance tests and calibration

• Specifications

• Basic maintenance (cleaning, batteries, and fuses)

• Instructions for using the remote control interface

• Performance test procedures

• Calibration procedures

• List of replaceable parts

For complete operating instructions, refer to the appropriate Users Manual (located on

the CD-ROM shipped with the instrument).

The Calibrator contains parts that can be damaged by static

discharge. No procedure in this document requires the case to be

opened. If you do so, follow the standard practices for handling static

sensitive devices.

XWWarning

Caution

Contacting Fluke

To locate an authorized service center, visit us on the World Wide Web at

www.fluke.com or call Fluke using any of the following numbers:

• USA: 1-888-44-FLUKE (1-888-443-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-3434-0181

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

1

Page 10

724/725/726

Calibration Manual

Read First – Safety Information

In this calibration manual, a Warning identifies conditions and actions that pose

hazard(s) to the user. A Caution identifies conditions and actions that may damage the

Calibrator or the test instruments.

XWWarnings

To avoid possible electric shock or personal injury:

•

DO NOT use the Calibrator if it looks damaged.

•

Follow all safety procedures for the test and calibration equipment you

use.

•

Examine the Calibrator before use. Look for cracks in the case, missing plastic,

or damaged insulation around the connectors.

• Inspect the test leads for damaged insulation or exposed metal. Check for

test lead continuity. Replace damaged test leads as necessary.

• Do not use the Calibrator if it operates abnormally. Protection may be

impaired. When in doubt, have the instrument serviced.

• Do not apply more than the rated voltage, as marked on the Calibrator,

between terminals or between any terminal and earth ground.

• Never touch the probes to a voltage source when the test leads are plugged

into the current terminals.

• Select the proper function and range for each measurement.

• Disconnect the test leads before changing to another measure or source

function.

• When using probes, keep fingers behind the finger guards on the probes.

• Use caution when working above 30 V ac rms, 42 V ac peak, or 60 V dc.

Such voltages pose a shock hazard.

• Connect the common lead (COM) before connecting the live test lead. When

disconnecting test leads, disconnect the live test lead first.

• Always place the 5520A calibrator in Standby (STBY) mode between tests

and before handling the test connections or cables.

• Remove test leads from the Calibrator before opening the battery door.

• Do not operate the Calibrator around explosive gas, vapor, or dust.

• During normal operation, only use four properly installed AA batteries to

power the Calibrator.

• Make sure the battery door is closed and latched before you operate the

Calibrator.

2

• During calibration, use only specified calibration equipment listed in

Table 6.

(Continued on the next page)

Page 11

Calibrators

International Symbols

XWWarnings (cont)

• When servicing the Calibrator, use only specified replacement parts.

• To avoid false readings, which can lead to possible electric shock or personal

injury, replace the batteries as soon as the low battery indicator (

Caution

To avoid possible damage to the Calibrator or to the test instruments:

• Disconnect the power and discharge all high voltage capacitors before

testing resistance, diodes, or continuity.

• Use the proper jacks, function, and range for each measurement or

sourcing application.

B) appears.

International Symbols

International symbols used on the Calibrator and in this manual are explained in Table 1.

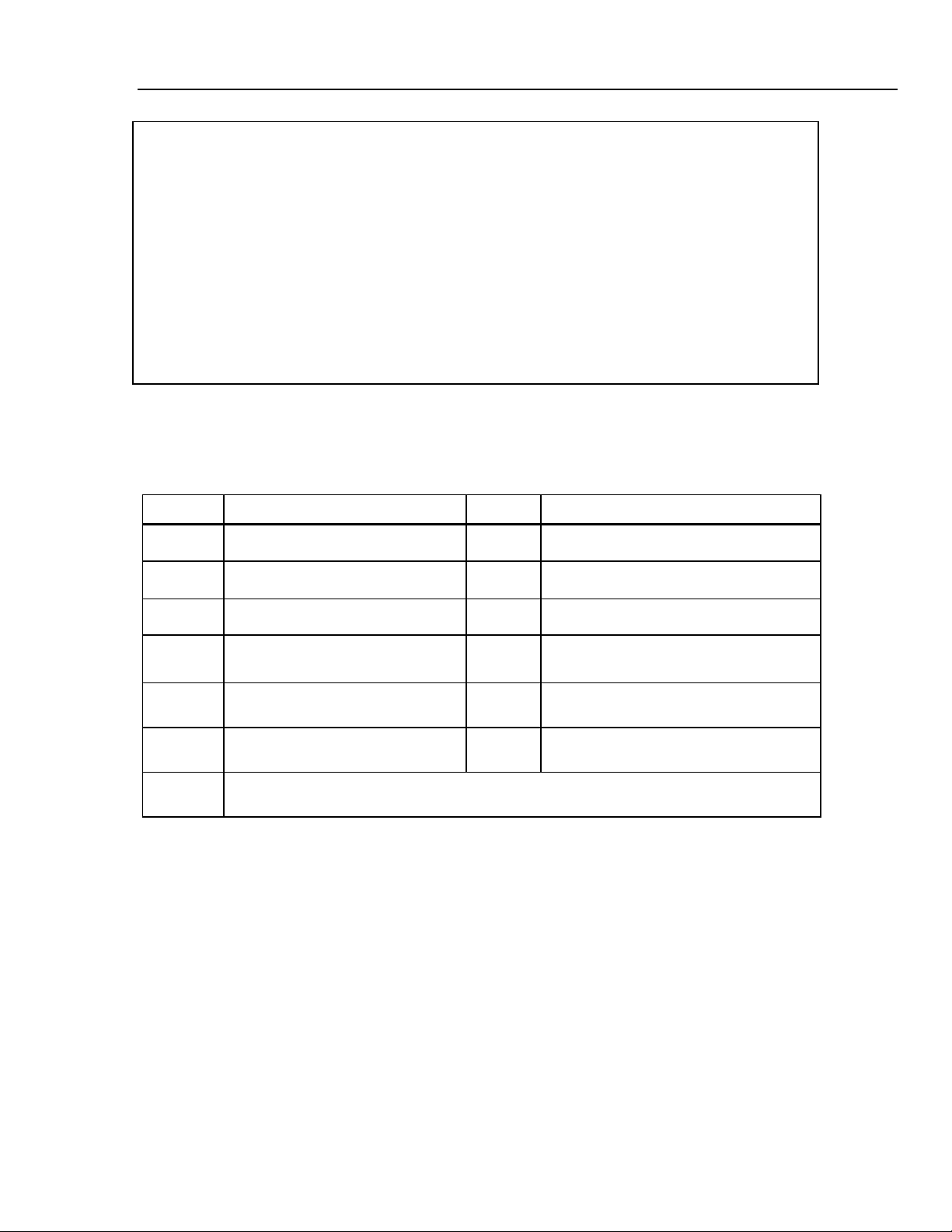

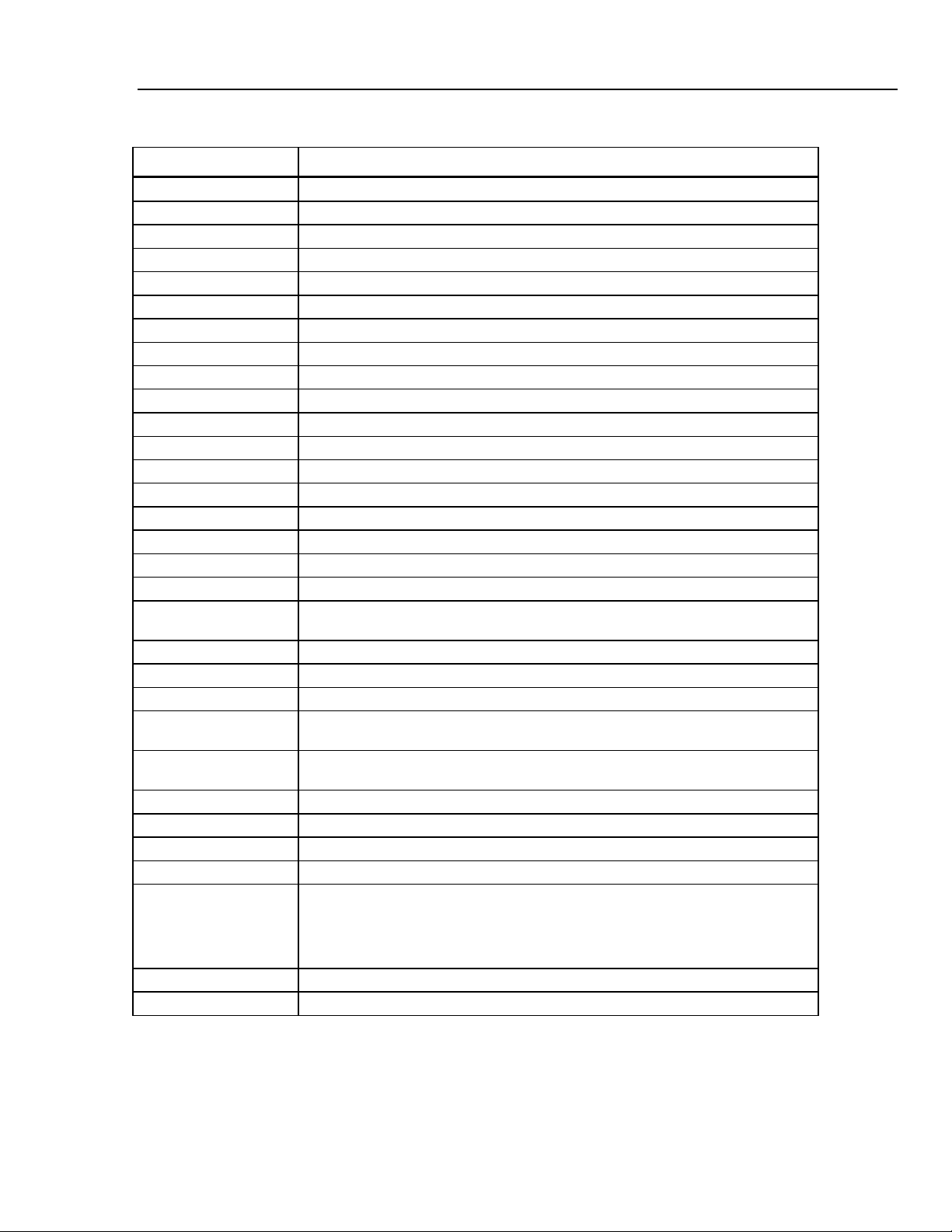

Table 1. International Symbols

Symbol Meaning Symbol Meaning

B

F

D

f

W

X

~

Alternating current

Direct current

Alternating or direct current

Pressure

Refer to the manual.

Important information.

Take appropriate precautions.

Hazardous voltage may be present.

Do not dispose of this product as unsorted municipal waste. Contact Fluke or a qualified

recycler for disposal.

J

O

P

B

)

T

Earth ground

ON/OFF

Conforms to European Union directives

Battery

Conforms to relevant Canadian

Standards Association directives

Double insulated

3

Page 12

724/725/726

Calibration Manual

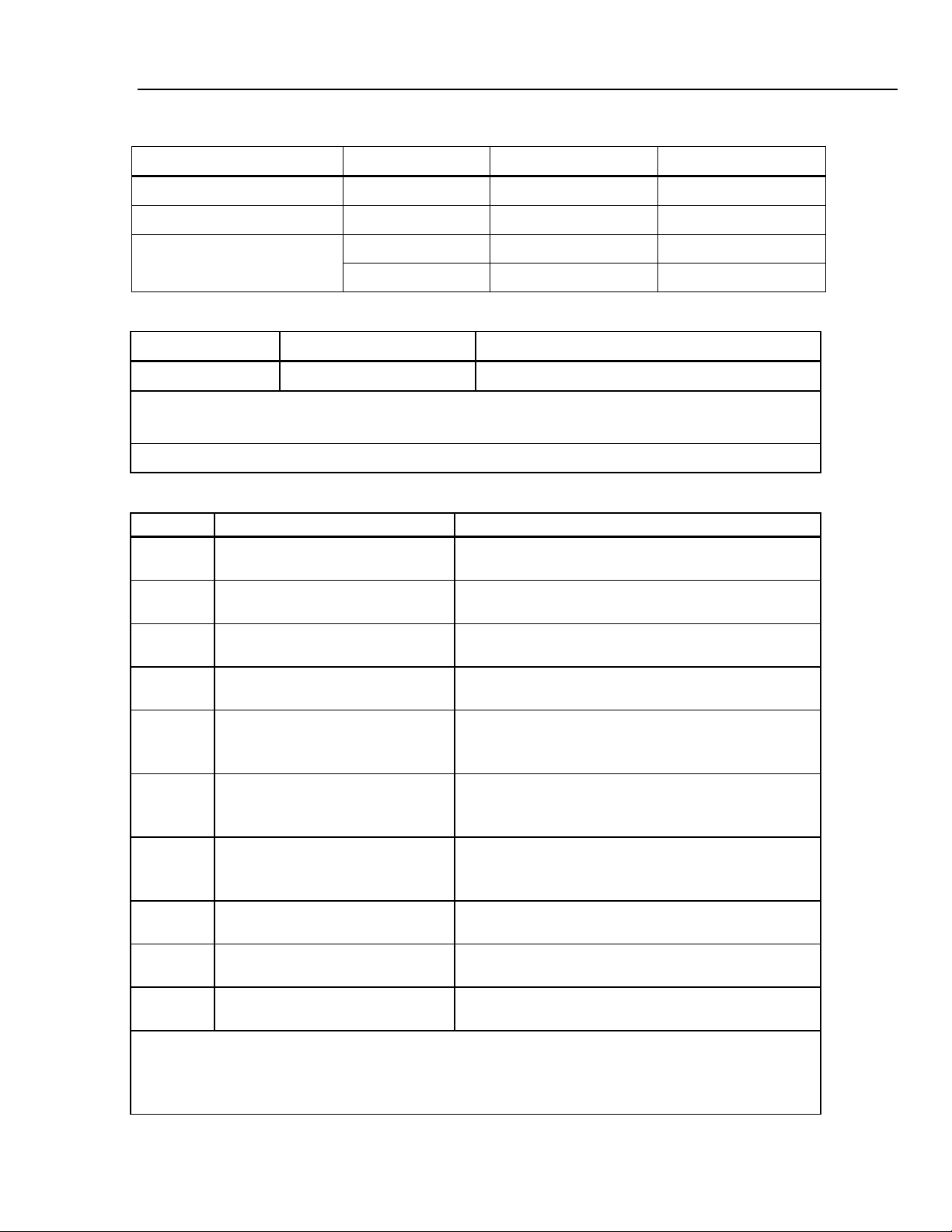

Specifications

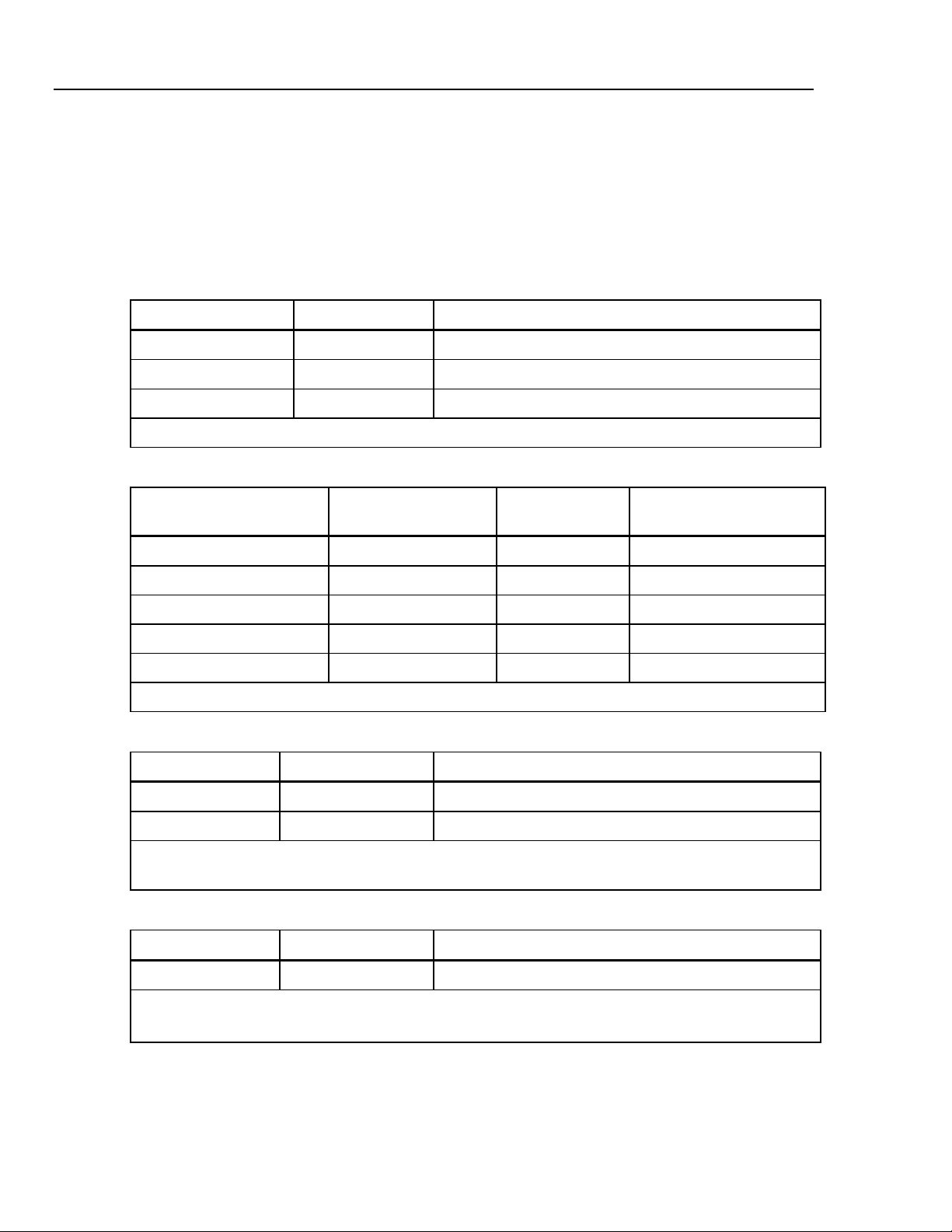

DC Voltage Measurement (724 and 725)

30 V (upper display) 0.001 V 0.02 % + 2

20 V (lower display) 0.001 V 0.02 % + 2

90 mV (lower display) 0.01 mV 0.02 % + 2

Temperature coefficient -10 °C to +18 °C, 28 °C to 55 °C: ±0.005 % of range per °C

DC Voltage Measurement and Source (726)

Performance and accuracy are specified for one year after calibration, at operating

temperatures of +18 °C to +28 °C (64 °F to 82 °F), in relative humidity to 90 %, after a

5 minute warm up period.

Note

A “count” is the amount by which the least significant digit can vary.

Range Resolution Accuracy (% of Reading + Counts)

Range Minimum Maximum

30 V (upper display) 0.000 V 30.000 V 0.010 % + 2 mV

20 V (lower display) 0.000 V 20.000 V 0.010 % + 2 mV

20 V (Source) 0.000 V 20.000 V 0.010 % + 2 mV

100 mV (Source) 0.000 V 100.000 mV 0.010 % + 10 µV

90 mV (Read) 0.000 V 90.000 mV 0.010 % + 10 µV

Maximum current output in voltage ranges is 1 mA with an output impedance of ≤ 1 Ω

Accuracy,

(% of Reading + Floor)

DC Voltage Source (724 and 725)

Range Resolution Accuracy (% of Reading + Counts)

100 mV 0.01 mV 0.02 % + 2

10 V 0.001 V 0.02 % + 2

Temperature coefficient -10 °C to +18 °C, 28 °C to 55 °C: ±0.005 % of range per °C

Maximum load: 1 mA

DC mA Measurement and Source (724 and 725) (Measurement only for 724)

Range Resolution Accuracy ( % of Reading + Counts)

4

24 mA 0.001 mA 0.02 % + 2

Temperature coefficient -10 °C to +18 °C, +28 °C to 55 °C: ±0.005 % of range per °C

Drive capability: 1000 Ω at 20 mA

Page 13

Calibrators

Specifications

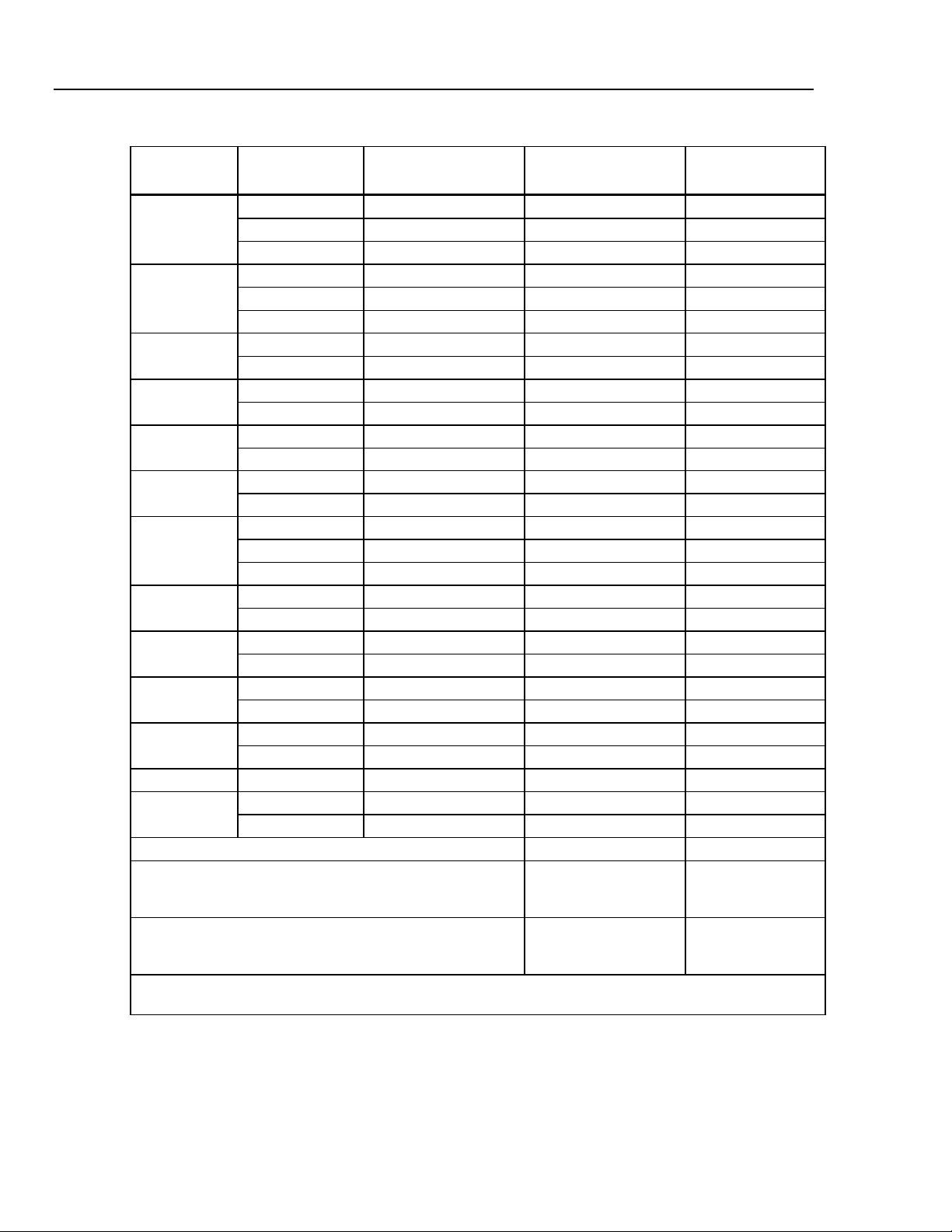

DC mA Measurement and Source (726)

Accuracy,

Range Minimum Maximum

mA Read (Upper Display) 0.000 24.000 0.010 % + 2 µA

mA Read (Lower Display) 0.000 24.000 0.010 % + 2 µA

mA Source 0.000 24.000 0.010 % + 2 µA

Maximum load on, mA source is 1 kΩ. With the HART resistor on, maximum load is 750 Ω.

Voltage input range on simulate mode is 5 to 30 V

(% of Reading +

Floor)

Ohms Measurement (724 and 725)

Ohms Range Accuracy, 4-Wire Accuracy*, 2-Wire, or 3-Wire

0 Ω to 400 Ω** ±0.1 Ω ±0.15 Ω

400 Ω to 1.5 kΩ ±0.5 Ω ±1.0 Ω

1.5 Ω to 3.2 kΩ ±1 Ω ±1.5 Ω

Excitation Current: 0.2 mA

Maximum input voltage: 30 V

Temperature coefficient -10 °C to +18 °C, +28 °C to 55 °C: ±0.005 % of range per °C

* 2-wire: Does not include lead resistance.

** For Firmware V1.7 or lower, the lowest range is 15 Ω to 400 Ω.

3-wire: Assumes matched leads with a total resistance not exceeding 100 Ω.

Ohms Measurement (726)

Ohms Range Minimum Maximum

Ohms Read (low) 0.00 400.00 0.015 % + 0.05 Ω

Ohms Read (high) 400.0 4000.0 0.015 % + 0.5 Ω

Accuracy

(% of Reading + Floor)

Ohms Source (724 and 725)

Ohms Range Excitation Current from Measurement Device

15 Ω to 400 Ω 0.15 mA to 0.5 mA ±0.15 Ω

15 Ω to 400 Ω 0.5 mA to 2 mA ±0.1 Ω

400 Ω to 1.5 kΩ 0.05 mA to 0.8 mA ±0.5 Ω

1.5 Ω to 3.2 kΩ 0.05 mA to 0.4 mA ±1 Ω

Accuracy

Temperature coefficient -10 °C to +18 °C, 28 °C to 55 °C: ±0.005 % of resistance range per °C

Resolution

15 to 400 Ω 0.1 Ω

400 to 3.2 kΩ 1 Ω

5

Page 14

724/725/726

Calibration Manual

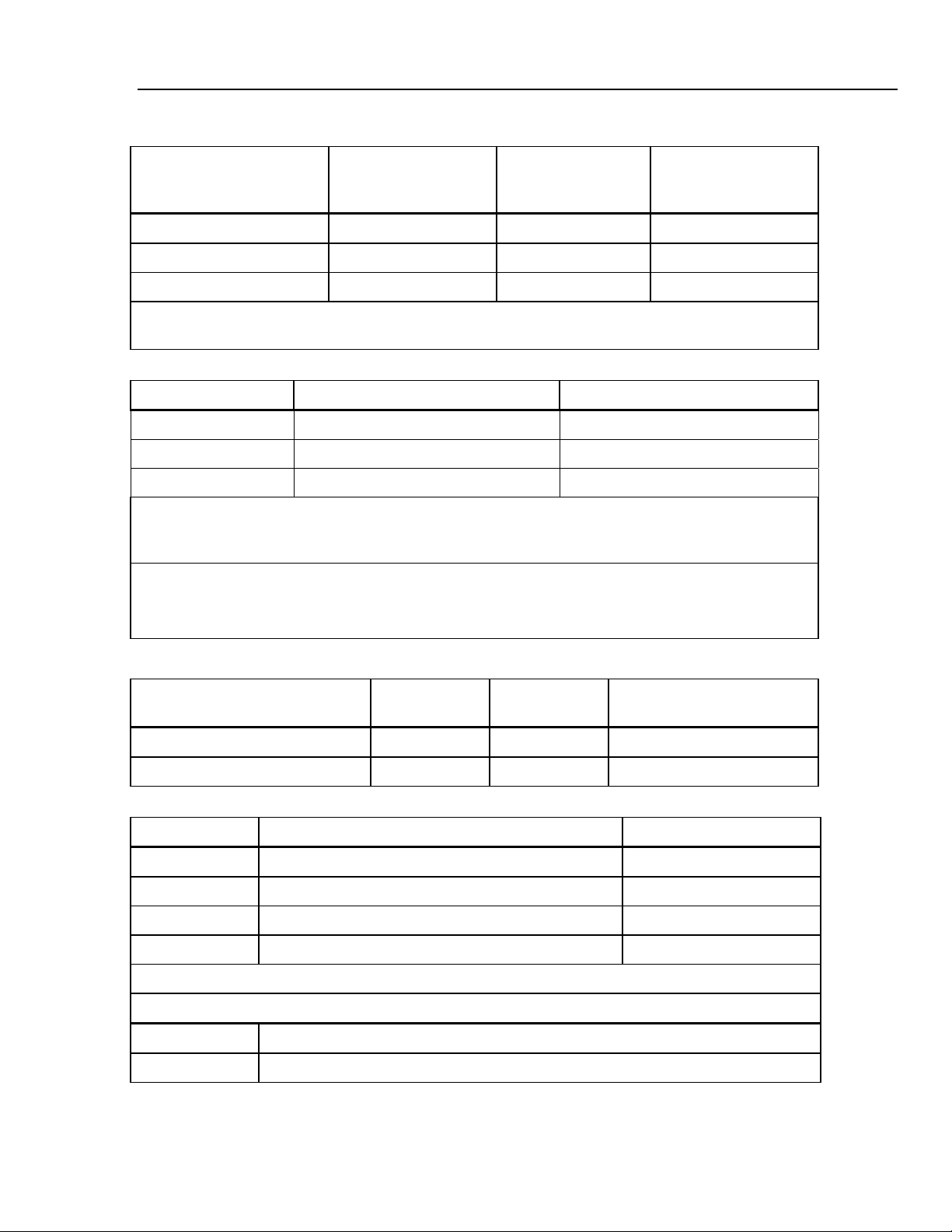

Ohms Source (726)

Ohms Range Minimum Maximum

Ohms Source (low)

Ohms Source (high)

Unit is compatible with smart transmitters and PLCs.

Frequency response is ≤ 5 mS

5.0 400.0 0.1 to 0.5 mA

5.0 400.0 0.5 to 3 mA

400 1500 0.05 to 0.8 mA

1500 4000 0.05 to 0.4 mA

Excitation Current from

Measurement Device

(% of Reading +

0.015 % + 0.1 Ω

0.015 % + 0.05 Ω

0.015 % + 0.5 Ω

0.015 % + 0.5 Ω

Frequency Measurement (725)

Range Resolution Accuracy

2.0 to 1000.0 CPM 0.1 CPM ± (0.05 % + 1 count)

1 to 1000 Hz 0.1 Hz ± (0.05 % + 1 count)

1.0 to 10.0 kHz 0.01 kHz ± (0.05 % + 1 count)

Sensitivity: 1 V peak-to-peak minimum

Waveform: Squarewave

Frequency Measurement (726)

Accuracy

Floor)

Accuracy

Range Minimum Maximum

CPM Read 2.0 1000.0 0.05 % + 0.1 CPM

Hz Read 1.0 1000.0 0.05 % + 0.1 Hz

KHz Read 1.00 15.00 0.05 % + 0.01 KHz

(% of Reading +

Floor)

Frequency Source (725)

Range Resolution Accuracy (% of output frequency)

2.0 to 1000.0 CPM 0.1 CPM ± 0.05 %

1 to 1100 Hz 1 Hz ± 0.05 %

1.0 to 10.0 kHz 0.1 kHz ± 0.25 %

Waveform: 5 V p-p squarewave, -0.1 V offset

6

Page 15

Calibrators

Specifications

Frequency Source (726)

Range Minimum Maximum Accuracy

CPM Source 2.0 1000 0.05 %

Hz Source 1.0 1000.0 0.05 %

KHz Source

1.0 10.00 0.25 %

10.00 15.00 0.50 %

Millivolt Measurement and Source (724 and 725)

Range* Resolution Accuracy

-10 mV to +75 mV 0.01 mV ±(0.025 % + 1 count)

Maximum input voltage: 30 V

Temperature coefficient -10 °C to +18 °C, 28 °C to 55 °C: ±0.005 % of range per °C

*Select this function by pressing T. The signal is available at the thermocouple miniplug connector.

Temperature, Thermocouples (724 and 725)

Type Range (°C) Measure and Source Accuracies (°C)

J

K

T

E

R

S

B

L

U

N*

Resolution:

J, K, T, E, L, N, U: 0.1 °C, 0.1 °F

B, R, S: 1 °C, 1 °F

* For Firmware V1.7 or lower, the type N TC has 400 °C as the upper limit.

-200 to 0

0 to 1200

-200 to 0

0 to 1370

-200 to 0

0 to 400

-200 to 0

0 to 950

-20 to 0

0 to 500

500 to 1750

-20 to 0

0 to 500

500 to 1750

600 to 800

800 to 1000

1000 to 1800

-200 to 0

0 to 900

-200 to 0

0 to 400

-200 to 0

0 to 1300

1.0

0.7

1.2

0.8

1.2

0.8

0.9

0.7

2.5

1.8

1.4

2.5

1.8

1.5

2.2

1.8

1.4

0.85

0.7

1.1

0.75

1.5

0.9

7

Page 16

724/725/726

Calibration Manual

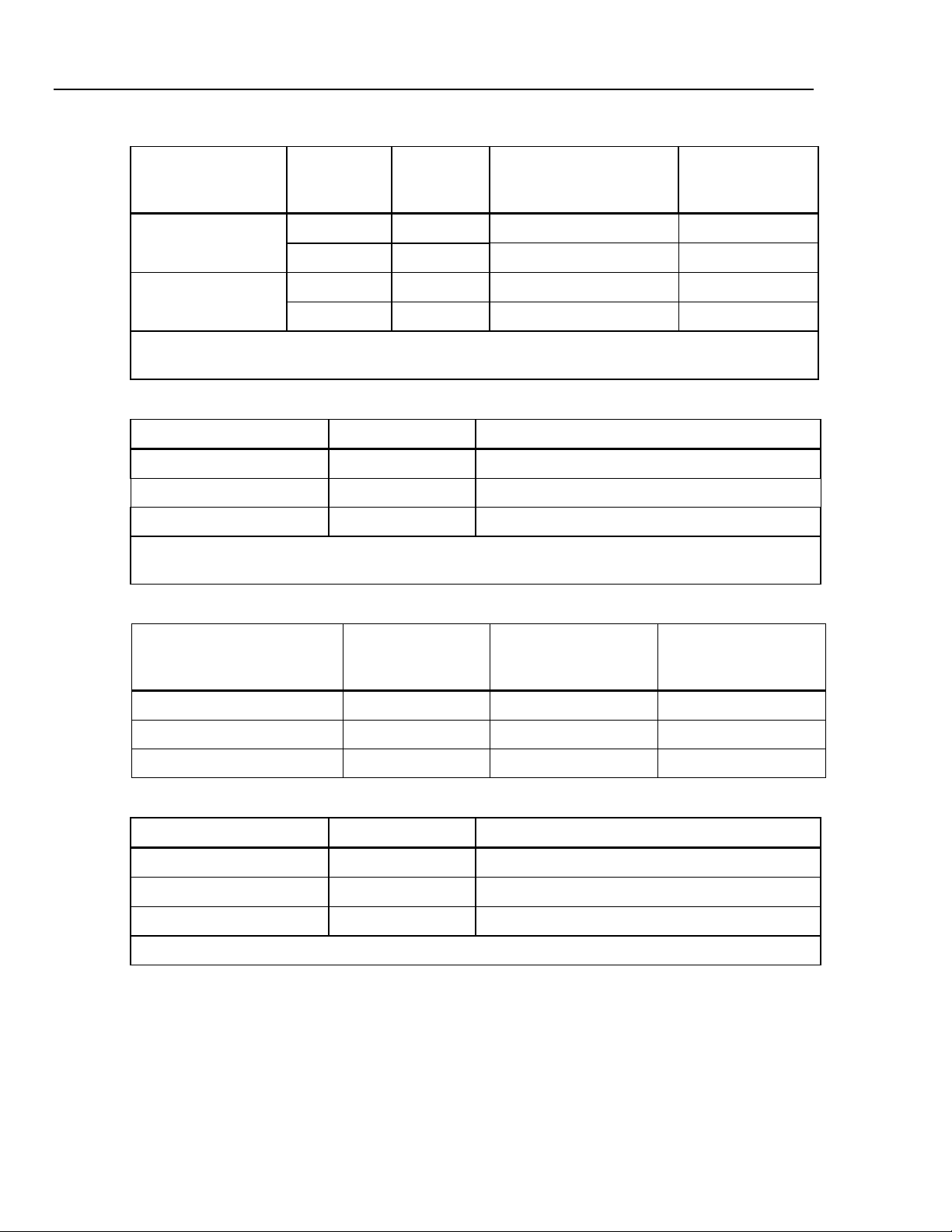

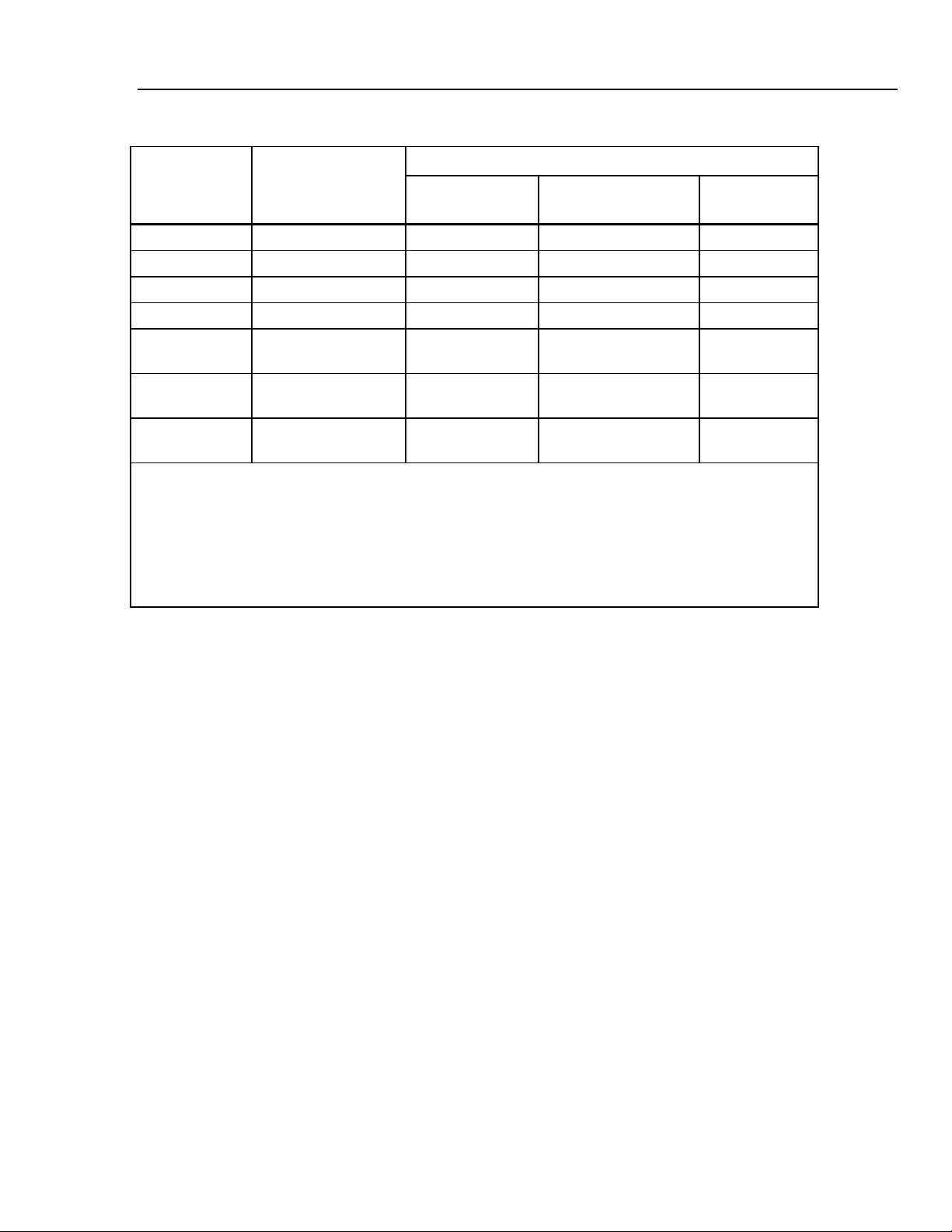

Temperature, Thermocouples (726)

Type Minimum Maximum

-210 0.0 0.6 0.4

J

K

T

E

R

S

B

C

L

U

N

XK -200 800 0.4 0.2

BP

Thermocouple in mV read -10 mV to 75 mV

Thermocouple in mV source -10 mV to 75 mV

Maximum current output in voltage ranges is 1 mA with an output impedance of ≤ 1 Ω

CJC error outside of 23 ± 5 °C is 0.05 °C / °C

0.0 800 0.4 0.2

800 1200 0.5 0.3

-200 0.0 0.8 0.6

0.0 1000 0.5 0.3

1000 1372 0.7 0.5

-250 0.0 0.8 0.6

0.0 400 0.4 0.2

-250 -100 0.8 0.6

-100 1000 0.4 0.4

-20 0.0 2.0 1.8

0.0 1767 1.4 1.2

-20 0.0 2.0 1.8

0.0 1767 1.4 1.2

600 800 1.4 1.2

800 1000 1.5 1.3

1000 1820 1.7 1.5

0.0 1000 0.8 0.6

1000 2316 2.5 2.3

-200 0.0 0.45 0.25

0.0 900 0.4 0.2

-200 0.0 0.7 0.5

0.0 600 0.45 0.25

-200 0.0 1.0 0.8

0.0 1300 0.6 0.4

0.0 800 1.1 0.9

800 2500 2.3 2.1

Range Accuracy

CJC ON

Accuracy

CJC OFF

Accuracy

0.015 % + 10 µV

(% of Reading +

Floor)

0.015 % + 10 µV

(% of Reading +

Floor)

8

Page 17

Calibrators

Specifications

Temperature, RTD Ranges, and Accuracies (724 and 725)

Type

Ni120 -80 to 260 0.2 0.3 0.2

Pt100-385 - 200 to 800 0.33 0.5 0.33

Pt100-392 -200 to 630 0.3 0.5 0.3

Pt100-JIS -200 to 630 0.3 0.5 0.3

Pt200-385

Pt500-385

Pt1000-385

Resolution: 0.1 °C, 0.1 °F

Allowable excitation current (source): Ni120, Pt100-385, Pt100-392, Pt100-JIS,

Pt200-385: .05 to .80 mA,Pt500-385: 0.05 to 0.80 mA; Pt1000-385: 0.05 to 0.40 mA

RTD Source: Addresses pulsed transmitters and PLCs with pulses as short as 5 ms. SN < 7624001 may

need modification for pulses less than 15 ms.

*2-wire: Does not include lead resistance.

3-wire: Assumes matched leads with a total resistance not exceeding 100 Ω.

Range (°C)

-200 to 250

250 to 630

-200 to 500

500 to 630

-200 to 100

100 to 630

Measure

4-wire (°C)

0.2

0.8

0.3

0.4

0.2

0.2

Accuracy

Measure*

2- and 3-wire (°C)

0.3

1.6

0.6

0.9

0.4

0.5

Source (°C)

0.2

0.8

0.3

0.4

0.2

0.2

9

Page 18

724/725/726

Calibration Manual

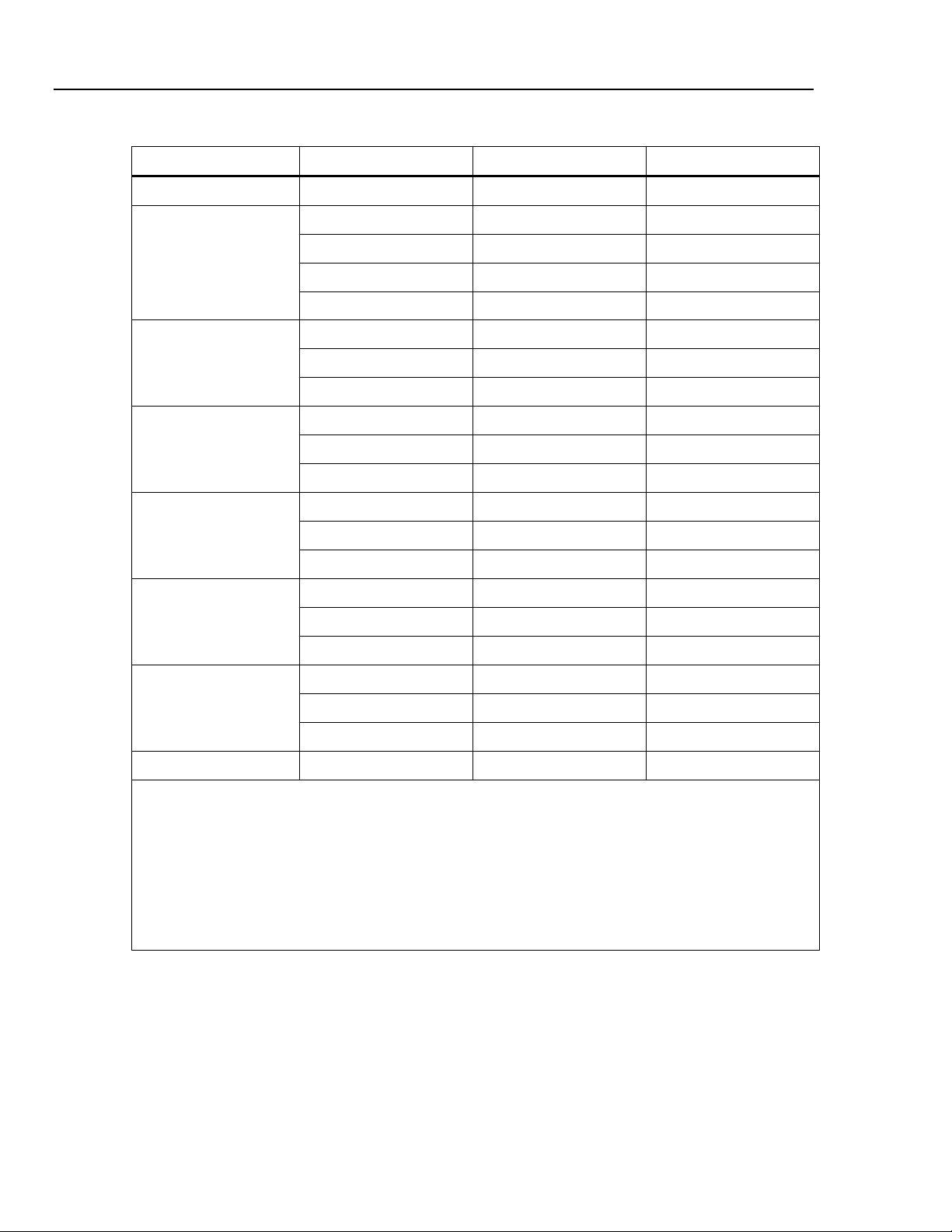

RTD Accuracy (Read and Source) (ITS-90) (726)

Ni120 (672) -80.00 260.00 0.15

Range Minimum Maximum Accuracy

-200.00 100.00 0.15

Pt100 (385)

Pt100 (3926)

Pt100 (3916)

Pt200 (385)

Pt500 (385)

100.00 300.00 0.25

300.00 600.00 0.35

600.00 800.00 0.45

-200.00 100.00 0.15

100.00 300.00 0.25

300.00 630.00 0.35

-200.00 100.00 0.15

100.00 300.00 0.25

300.00 630.00 0.35

-200.00 100.00 0.75

100.00 300.00 0.85

300.00 630.00 0.95

-200.00 100.00 0.35

100.00 300.00 0.45

300.00 630.00 0.55

-200.00 100.00 0.15

Pt1000 (385)

CU10 -10.00 250.00 1.8

Notes: Read Accuracy is based on 4-wire input. For 3-wire input, add ± 0.05 Ω assuming all three RTD

leads are matched.

Source Accuracy is based on 0.5 to 3.0 mA excitation current (0.1 mA for pt1000 range)

Resolution: 0.1 °C, 0.1 °F

Allowable excitation current (source): Ni120, Pt100-385, Pt100-392, Pt100-JIS,

Pt200-385: .05 to .80 mA,Pt500-385: 0.05 to 0.80 mA; Pt1000-385: 0.05 to 0.40 mA

RTD Source: Addresses pulsed transmitters and PLCs with pulses as short as 5 ms. SN < 7624001 may

need modification for pulses less than 15 ms.

100.00 300.00 0.25

300.00 630.00 0.35

10

Page 19

Calibrators

Specifications

Loop Power Supply

Voltage: 24 V

Maximum current: 22 mA

Short circuit protected

Pressure Measurement (725 and 726)

Range Resolution Accuracy Units Mode (726 Only)

Determined by

pressure module

5 digits

Determined by

pressure module

psi, inH

inH

cmH

cmH

mbar, kg/cm

inHg

O@4 °C,

2

O@20 °C, kPa,

2

O@4 °C,

2

O@20 °C, bar,

2

, mmHg,

2

Pushing A for 3

seconds stores

present pressure

value as an offset and

subtracts it from the

displayed value.

Pulse Read and Pulse Source (726)

Pulse Min Max Accuracy Frequency

Source 10,000

Read

1

100,000

1 Count 2 CPM to 10 kHz

Pressure Units Availability (725)

Unit Availability

psi Available on all pressure ranges

inH2O All ranges through 3000 psi

cmH2O All ranges through 1000 psi

bar 15 psi and above

mbar All ranges through 1000 psi

kPa Available on all pressure ranges

inHg Available on all pressure ranges

mmHg All ranges through 1000 psi

kg/cm2 15 psi and above

11

Page 20

724/725/726

Calibration Manual

General Specifications

Operating temperature

724 and 725

726

Storage temperature - 20 °C to 70 °C

Stability ± 0.005 % of range/°C outside of 23 ± 5 °C

Operating altitude 3000 meters above mean sea level

Relative Humidity (% RH operating without

condensation)

Vibration Random, 2 g, 5 Hz to 500 Hz

Safety

724 and 725

726

Power requirements 4 AA alkaline batteries

Protection Class Pollution Degree II

-10 °C to 55 °C

-10 °C to 50 °C

90 % (10 to 30 °C)

75 % (30 to 40 °C)

45 % (40 to 50 °C)

35 % (50 to 55 °C)

uncontrolled < 10 °C

EN 61010-1:1993, ANSI/ISA S82.01-1994; CAN/CSA

C22.2 No 1010.1:1992

EN50082-1:1992 and EN55022: 1994 Class B Criteria

A or B CSA C22.2 No 1010.1:1992

Size 96 x 200 x 47 mm (3.75 x 7.9 x 1.86 in)

Weight 650 gm (1 lb, 7 oz)

Cleaning the Calibrator

XWWarning

To avoid electric shock or damage to the Calibrator, never allow water

inside the Calibrator’s case.

If the Calibrator requires cleaning, wipe it down with a cloth that is lightly dampened

with water or a mild detergent.

Do not use aromatic hydrocarbons, chlorinated solvents, or methanol-based fluids when

cleaning the Calibrator. To avoid damaging the case, never apply solvents to the

Calibrator.

Replacing the Batteries

XWWarning

To avoid electric shock, remove the test leads from the Calibrator

before opening the battery door. Close and latch the battery door

before using the Calibrator.

To avoid false readings, which can lead to possible electric shock or

personal injury, replace the batteries as soon as the low battery

indicator (

B) appears.

12

When replacing the batteries, always use four new AA batteries. Never

mix new and used batteries in the Calibrator.

Page 21

Calibrators

Fuses

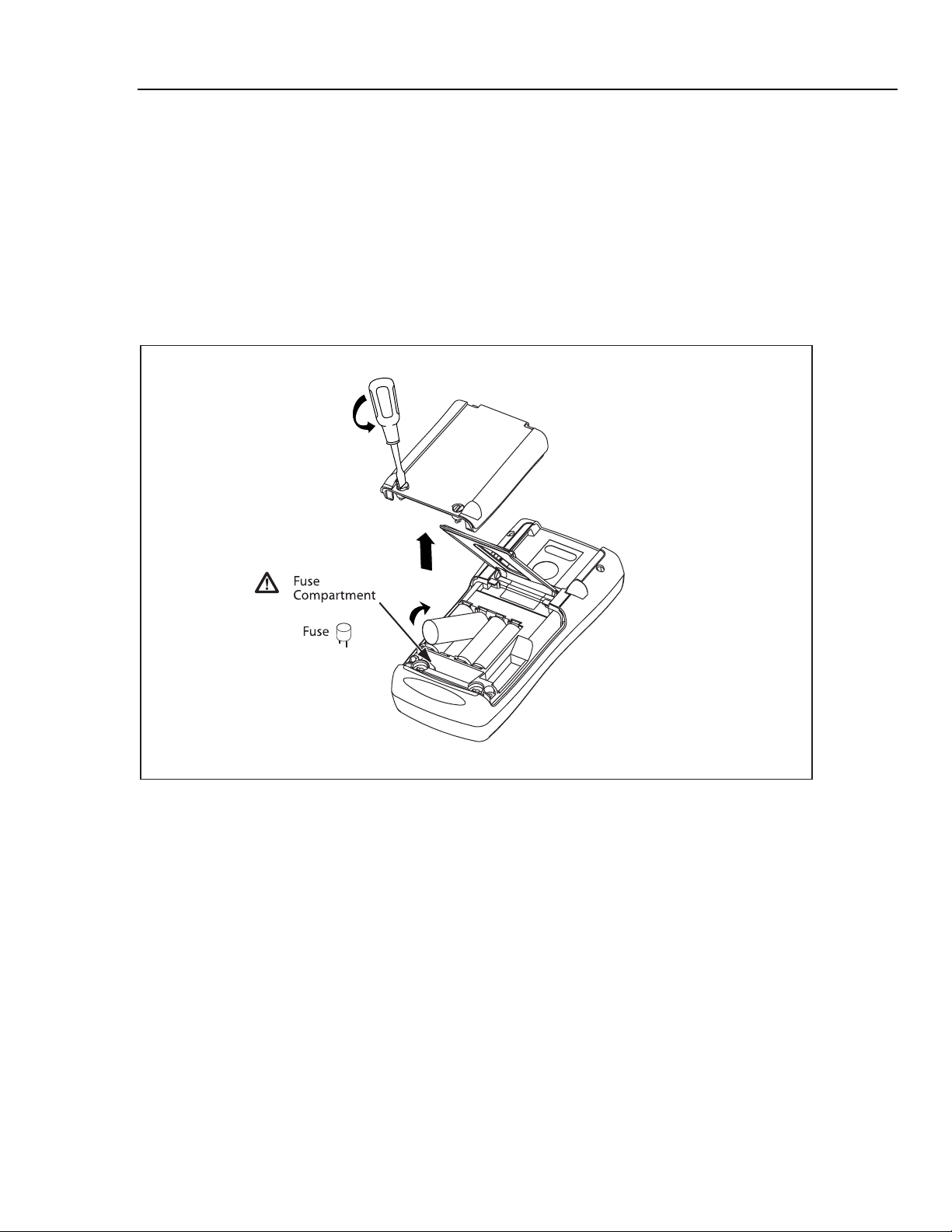

Four AA alkaline batteries (ANSI/NEDA 15A or IEC LR6) are used to power the

Calibrator. To replace the batteries, refer to Figure 1 and do the following:

1. Turn the Calibrator off, remove the test leads from the terminals, and hold the

Calibrator face down.

2. Using a flat-blade screwdriver, turn the battery door screws 1/4-turn

counterclockwise and remove the battery door.

3. Remove the batteries, then install new batteries. Be sure to follow the polarity

markings shown in the battery compartment.

4. Replace the battery door and secure it by turning the screws 1/4-turn clockwise.

Fuses

Over time, the input protection has been modified to increase reliability. There will either

be self-resetting fuses, or replaceable fuses in sockets. The self-resetting fuses open when

heated by a current overload, and close when they cool down. When an input’s fuse is

open, the input’s functions will not work.

Figure 1. Replacing the Batteries and Replaceable Fuses

XWWarning

To avoid electrical shock:

• Remove the test leads from the calibrator before opening the

battery door. Close and latch the battery door before using the

calibrator.

• Use only the specified replacement fuses listed under

“Replaceable Parts”.

• Do not allow water into the case.

13

aal01f.eps

Page 22

724/725/726

Calibration Manual

The time required for a self-resetting fuse to reset depends on the magnitude of the

overload. If a self-resetting fuse does not reset, return the Calibrator to an authorized

service center for repair.

If a replaceable fuse has been damaged, it needs to be replaced. The fuses can be

removed and checked for resistance. A value of < 10 Ω is good.

The calibrator comes equiped with three 0.2 A 250 V socketed fuses.

• Problems while measuring with the right jacks indicate that F3 may have opened.

• Problems while measuring

or sourcing with the center jacks or the TC jacks

indicate that F2 may have opened.

• If you can’t measure or source current with the left jacks, F4 may have opened.

To access the fuses, refer to instructions under “Replacing the Batteries”. The fuse

compartment is located below the battery compartment. Use needle-nosed pliers to

remove them and test them with a multimeter. Replace the fuse with the proper

replacement fuse and follow the directions for reassembling the Calibrator. Refer to

Figure 1.

Remote Control Interface (725 and 726)

The Calibrator’s serial interface and remote control commands let you use a PC to

remotely select Calibrator functions and read the Calibrator’s display. This remote

interface is especially useful if you want to write your own calibration software.

The 726 remote control interface is always active.

To activate the 725 remote control interface, proceed as follows:

1. Turn off the UUT; then use the Fluke 700SC serial interface cable to connect the

UUT to a serial port on the PC.

2. Start the terminal communication software on the PC. Create a new connection with

the following properties:

• Bits per second: 9600

14

• Data bits: 8

• Parity: None

• Stop bits: 1

• Flow control: None

• Local echo on

3. Hold down the Calibrator’s M button while turning the Calibrator on.

4. Use the commands given in Tables 2 through 4 to remotely control the Calibrator.

Table 2. Upper Display Remote Commands (725)

Remote Command Description

i mA measurement

L mA Loop Power

E Voltage measurement

B Single broadcast of the most recent upper display value and units

( Single broadcast of most recent upper display value without header or units

Page 23

Calibrators

Table 3. Lower Display Remote Commands (725)

Remote Command Description

A mA measurement

a mA source

I mA 2W Sim

V Voltage measurement

v Voltage source

M mV measurement

m mV source

K kHz measurement

k kHz source

H Hz measurement

h Hz source

P CPM measurement

p CPM source

O Ohms measurement (default 2W)

o Select Ohms source

W 2-wire measurement (Ohms and RTDs)

X 3-wire measurement (Ohms and RTDs)

Y 4-wire measurement (Ohms and RTDs)

T Thermocouple measurement (default Type J). Use “S” command to select a

sensor type.

t Thermocouple source (default Type J). Use “S” command to select a sensor type

C Selects Centigrade ( T/C-RTD)

F Selects Fahrenheit ( T/C-RTD)

R RTD measurement mode (default Pt100 385). Use “S” command to select a

sensor type

r RTD measurement mode (default Pt100 385). Use “S” command to select sensor

type.

u Increment display source value

d Decrement display source value

< The < arrow key PC keyboard selects left arrow on 725

> The > arrow key PC keyboard selects right arrow on 725

0-9 Enter a source value using ASCII characters 0,1,2,...9,-,.terminated by <CR>

(carriage return)

-,. The 725 can receive a maximum of 10 characters prior to the carriage return.

<CR>

b Single Broadcast of most recent lower display value and units

) Single broadcast of most recent lower display value without header or units.

Remote Control Interface (725 and 726)

15

Page 24

724/725/726

Calibration Manual

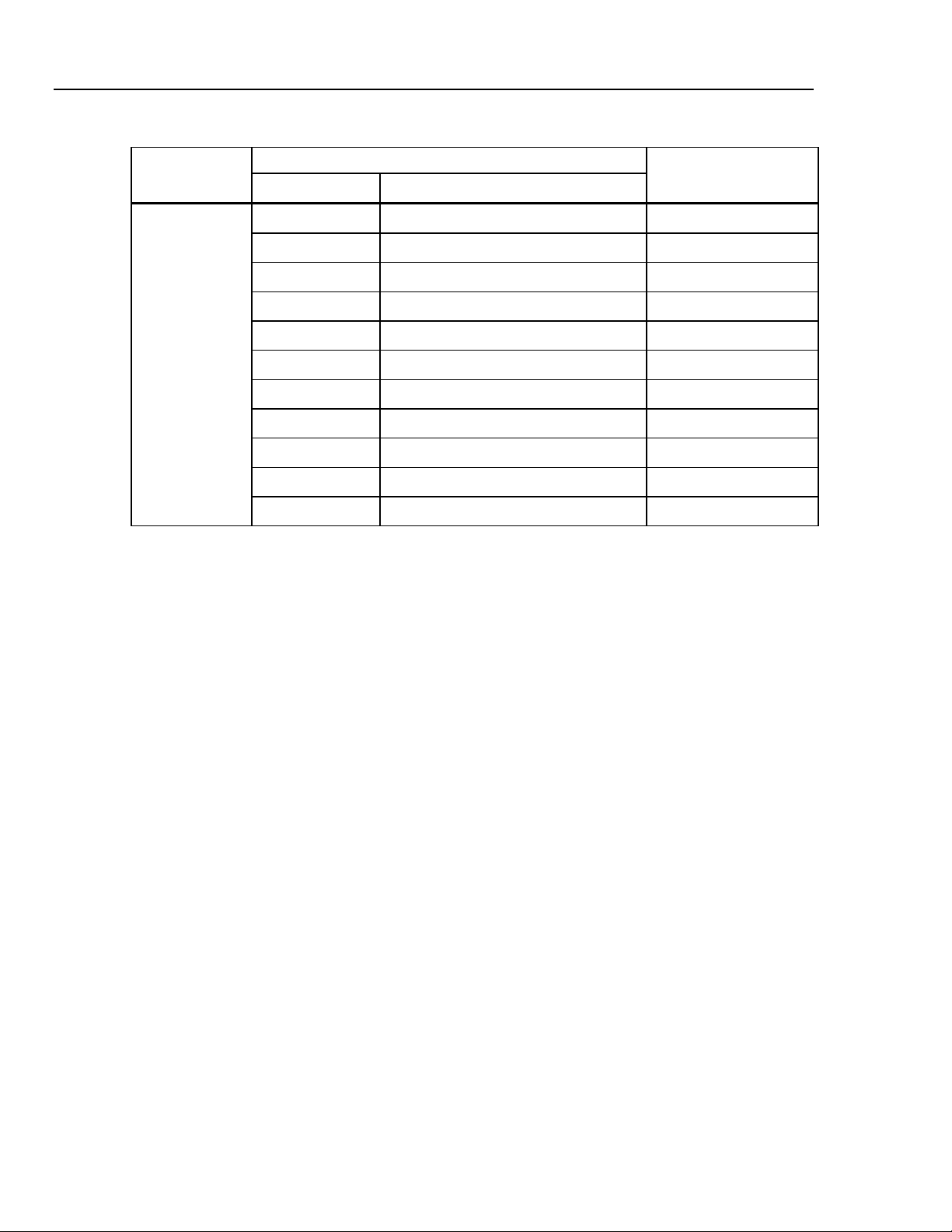

Serial Input No. Thermocouple Type RTD Type

2 K Pt100 (385)

3 T Pt100 (3916)

4 E Pt200 (385)

5 R Pt500 (385)

6 S Pt1000 (385)

7 B Ni120

8 L -

9 U -

A N -

Table 4. Remote Commands for Sensor Selection (725)

Selection Entry

S 1 J Pt100 (3926)

B mV -

16

Page 25

Calibrators

Serial Command List (726)

Serial Command List (726)

Table 5 lists the serial commands for the 726 Calibrator. Refer to “Remote Control

Interface (725 and 726)” for activation steps.

Table 5. Serial Command List-726

Command Response/Actions

*IDN? Returns the ID string

“FLUKE,726,0,{sw_rev}” where

sw_revision is the firmware

revision

FUNC? Returns {Upper},{Lower}

{Upper} responses

(Channel 1)

DCI, DCI_LOOP, DCV,

DCI_ERROR,

DCI_ERROR_LOOP

{Lower} responses

DCI, DCMV, DCV, DCI_SIM, TC,

RTD, FREQUENCY,

PULSE_TRAIN

VAL? Returns the measured value with

base units for the upper and lower

display

{upper_val},{upper_units},{lower_

val},{lower _units},

upper_units: V, A, PERCENT

lower _units: V, CEL, FAR, A,

OHM, CPM, HZ, COUNT

Command

Arguments

Verify model

Answers with

Comment Ch 1 Ch 2

number and

firmware

revision

the configured

function for the

upper and

lower display

X X

X X

X X

UPPER_MEAS 1 argument, valid

settings: DCI,

DCI_LOOP, DCV,

DCI_ERROR,

DCI_ERROR_LOOP

17

Set upper

channel

measure mode X

Page 26

724/725/726

Calibration Manual

Table 5. Serial Command List-726 (cont.)

Command Response/Actions

Command

Arguments

OUT Arguments:

{value} {units}

Multipliers:

u for micro, m for

milli, and k for kilo

are accepted.

Units:

-V used for mV and

Volts, the V_range

command can be

used to switch

ranges

-CEL used for RTD,

TC AND TC mV

-FAR used for RTD

and TC

-A used for mA (see

SIM for mA SIM)

-OHM used for RTD

ohms, RTD_TYPE

must be set to ohms

-CPM used for

frequency

-HZ used for HZ and

KHZ frequency (unit

will auto range)

-COUNT used for

pulse

Comment Ch 1 Ch 2

Configures

the output

source

function. If the

{value} and

{units} are

valid, this

command will

change

modes if

necessary

and set the

output value

to {value} and

{units} in that

mode.

X

18

OUT? Returns the output (source)

value with units or none.

FREQ_UNIT 1 argument: CPM,

Verify the

output

function and

units

Set the output

HZ or KHZ

frequency

range

FREQ_UNIT? Returns CPM, HZ, KHZ Verify the

frequency

range

X

X

X

Page 27

Calibrators

Table 5. Serial Command List-726 (cont.)

Serial Command List (726)

Command Response/Actions

Command

Arguments

LOWER_MEAS 1 argument, Valid

Modes:

DCI, DCMV, DCV,

TC, RTD,

FREQUENCY,

PULSE_TRAIN

SIM 1 Argument {value}

Multipliers u for micro,

m for milli, and k for

kilo are accepted.

A is for amps

SIM? Returns the simulate value in

Amps with units or none

Verify the SIM

V_RANGE 1 Argument VOLTS or

MVOLTS

V_RANGE? Returns the voltage range VOLTS

or MVOLTS

Verify the

Comment Ch 1 Ch 2

Configures the

measurement

function. Sets

the specified

measure mode

If the value is

valid, this

command will

change modes

if necessary

and set the

output value to

{value} in that

mode.

output

Sets the

voltage range

voltage range

X

X

X

X

X

PULSE_FREQ 2 arguments

{number}{units}.

(units CPM ,Hz ,Khz)

PULSE_FREQ? Returns the pulse output

frequency with units.

Verify the pulse

FREQ_LEVEL 1 Argument, valid

values: 1-20V

FREQ_LEVEL? Returns the pulse output and

frequency output voltage 1-20V

TRIG Toggles the pulse mode and

totalize trigger for read and

source.

TRIG? Returns the state of the pulse

mode trigger, TRIGGERED,

UNTRIGGERED or NONE.

Verify the

Initialize

Verify TRIG

Sets the pulse

output

frequency and

range

frequency

Sets the pulse

output and

frequency

output voltage

frequency

voltage level

totalized pulse

measurement

or output

state X

X

X

X

X

X

19

Page 28

724/725/726

Calibration Manual

Table 5. Serial Command List-726 (cont.)

Command Response/Actions

Command

Arguments

TC_TYPE One argument, valid

settings: B, C, E, J, K,

L, N, R, S, T, U, BP,

XK, MV

TC_TYPE? Returns TC type

B, C, E, J, K, L, N, R, S, T, U,

BP, XK, MV

Verify TC type

TSENS_TYPE 1 argument TC or

RTD

TSENS_TYPE? Returns the sensor type TC or

RTD

Verify is set

CJC_STATE One argument ON

or OFF

CJC_STATE? Returns ON or OFF Verify CJC

RTD_TYPE 1 argument: NI120,

PT392_100,

PT385_100,

PTJIS_100,

PT385_200,

PT385_500,

PT385_1000,

CU_10, CUST1,

CUST2, CUST3,

OHMS

RTD_TYPE? Returns RTD type

NI120, PT392_100,

PT385_100, PTJIS_100,

PT385_200, PT385_500,

PT385_1000, CU_10, CUST1,

CUST2, CUST3, OHMS

Verify the

Comment Ch 1 Ch 2

Set TC type

X

X

Sets the

sensor type

TC or RTD

for RTD or TC

Thermocoupl

e cold

junction

compensation

state

Sets RTD

type

RTD type

setting

X

X

X

X

X

X

CPRT_R0 2 arguments

{number} OHM.

Sets the custom

CPRT R0.

CPRT_R0? Returns CPRT R0 with units

OHM.

CPRT_MIN_T 2 arguments

{number} CEL.

RTD_TYPE

must be either

CUST1,

CUST2 or

CUST3

CPRT_MIN_T? Returns {number} CEL.

X

X

X

X

20

CPRT_MAX_T 2 arguments

{number} CEL.

X

Page 29

Calibrators

Table 5. Serial Command List-726 (cont.)

Serial Command List (726)

Command Response/Actions

Command

Arguments

Comment Ch 1 Ch 2

CPRT_MAX_T? Returns {number} CEL. X

CPRT_COEFA 1 argument. Sets the

CPRT_COEFA? Returns the custom CPRT

Coefficient A.

custom CPRT

Coefficient A.

X

X

CPRT_COEFB 1 argument. Sets the

CPRT_COEFB? Returns the custom CPRT

Coefficient B.

custom CPRT

Coefficient B.

X

X

CPRT_COEFC 1 argument. Sets the

custom CPRT

Coefficient C.

CPRT_COEFC? Returns the custom CPRT

Coefficient C.

RTD_WIRE 1 argument, 2W, 3W or

4W. Sets RTD read

wire.

X

X

X

RTD_WIRE? Returns RTD read wire. Verify

connection

setting

TEMP_UNIT 1 argument. Sets

temperature units, CEL

or FAR

TEMP_UNIT? Returns temperature units, CEL or

FAR

CUST1_ALIAS 1 argument, sets

screen name for

CUST1 RTD.

CUST1_ALIAS? Returns screen name for CUST1

RTD

Verify RTD 1

CUST2_ALIAS 1 argument, sets

screen name for

CUST2 RTD.

CUST2_ALIAS? Returns screen name for CUST2

RTD.

Verify RTD 2

CUST3_ALIAS1 1 argument, sets

screen name for

CUST3 RTD.

CEL: Celsius

FAR: Fahrenheit

alias

alias

X

X

X

X

X

X

X

X

21

Page 30

724/725/726

Calibration Manual

Table 5. Serial Command List-726 (cont.)

Command Response/Actions

CUST3_ALIAS? Returns screen name for CUST3

RTD.

Command

Arguments

Verify RTD 3

HART_ON Turns HART mode on. Switches in 250

HART_OFF Turns HART mode off. Switches out

HART? Returns state of hart mode, ON or

OFF

Comment Ch 1 Ch 2

alias

Ω resistor

Ω resistor

250

X

X X

X X

X X

*CLS Clear the error queue X X

FAULT Returns error code FILO X X

ERROR CODES:

NONNUMERIC_ENRTY (100)

EBUFFER_OVERFLOW (101)

INVALID_UNITS_CODE (102)

ENTRY_OVER_RNG (103)

ENTRY_UNDER_RNG (104)

MISSING_PARM (105)

INVALID_UNIT_PARM (106)

INVALID_SENSOR_TYPE (108)

UNKNOWN_COMMAND (110)

BAD_PARM_VALUE (111)

INPUT_BUFF_OVERFLOW (112)

MSG_BUFF_OVERFLOW (113)

OUTPUT_BUFF_OVERFLOW

(114)

OUTPUT_OVERLOAD (115)

X

X

22

CAL_START

Initiates a password protected

calibration (password = 627)

Required Equipment

Equipment and software required to perform the procedures in this manual are identified

in Table 6. If the recommended equipment model is not available, other equipment can be

substituted if it meets the specifications indicated.

To avoid safety hazards and equipment damage during the calibration

procedures, use the specified calibration equipment listed in Table 6.

Using unspecified equipment can give unreliable results and pose

safety hazards.

XWWarning

X X

Page 31

Calibrators

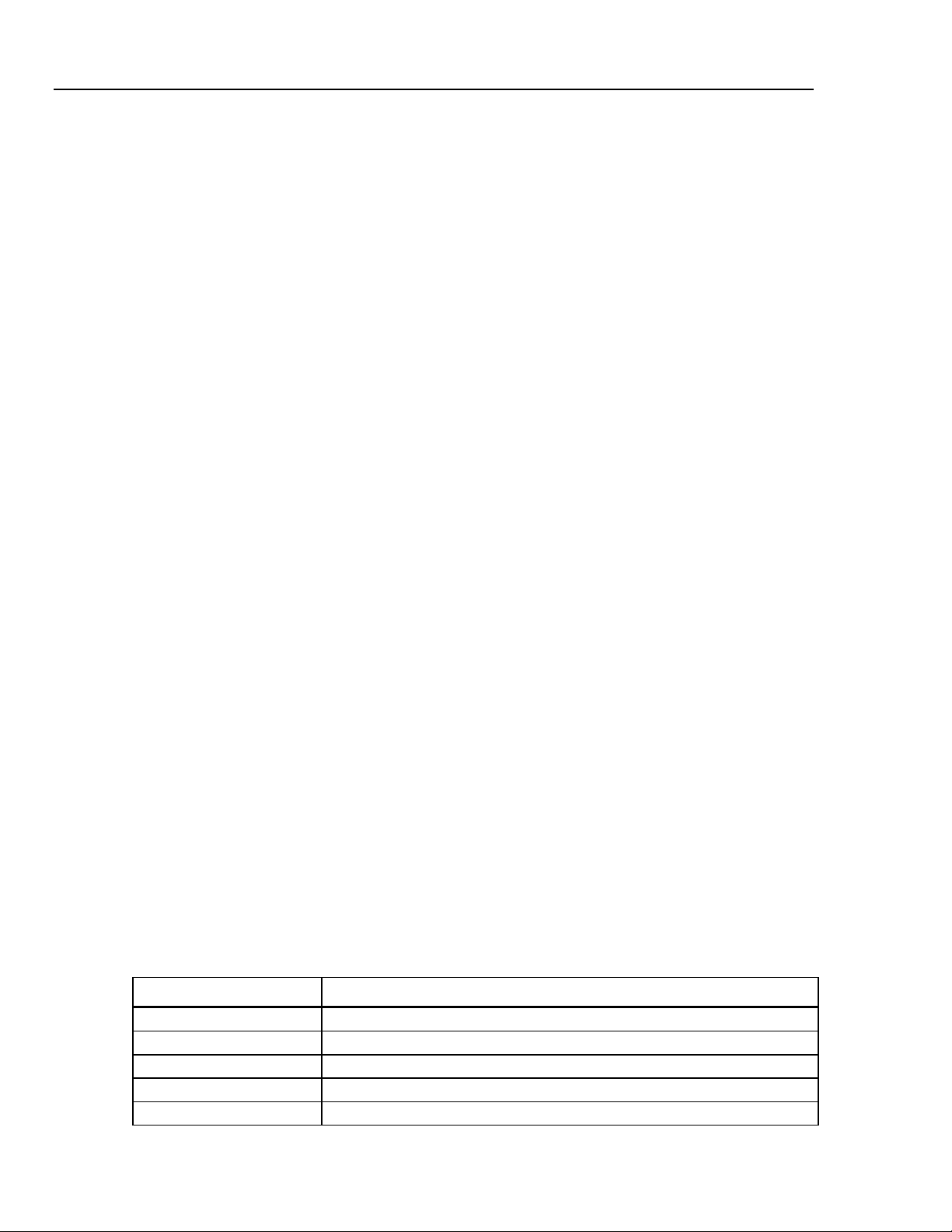

Equipment Minimum Specifications Recommended Model

Multi-Product Calibrator

MET/CAL® Metrology

Software

(see MET/CAL

Installation and Upgrade

Guide for minimum

hardware requirements)

Digital Multimeter

Table 6. Required Equipment and Software

DC voltage: 0 V to 30 V

Accuracy: ±0.005 %

DC current: 0 mA to 24 mA

Accuracy: ±0.005 %

Temperature: Type-J thermocouple

90 day accuracy: ±0.2 °C

Resistance accuracy: ±0.006 %

Frequency accuracy: ±0.01 %

Version 6.0 or later Contact Fluke for the latest version.

DC voltage: 0 V to 24 V

Accuracy: ±0.0013 %

DC voltage: 0 mA to 24 mA

Accuracy: ±0.005 %

Fluke Model 5520A Multi-Product

Calibrator only−no substitute

Fluke 8508A

Required Equipment

Pressure Module

(725 and 726)

Test Leads Two sets of stackable low thermal

Thermocouple Test

Lead

Personal computer Windows® 3.1 or later with terminal

PC interface cable

(725 and 726)

Calibration cable Fluke 724/725 Calibration Cable Fluke PN 1556747

Standard Thermometer 0.1 % accuracy

In working condition; for establishing

communication only

EMF banana test leads

2 Type-J male miniplugs with ~12”

(30.5 cm) of 20-gauge Type-J

thermocouple wire

communication software

Fluke 700SC serial interface cable

assembly (LEMO to DB-9 female)

Fluke 700PXX Series

2 red leads: Fluke PN 105809

2 black leads: Fluke PN 105806

Fluke Model 80CJ-M male miniplugs

(package of two)

20-gauge Type-J thermocouple wire

is available through an electronic

supply outlet

486 (or later) IBM-compatible

Fluke PN 667425

23

Page 32

724/725/726

Calibration Manual

Performance Tests

XXWarning

Some of the performance tests involve the use of high voltages and

should be performed by qualified personnel only.

To avoid electric shock, always set the calibration source (5520A) to

Standby (STBY) mode between tests and before handling the test

connections or test cables.

Performance tests confirm the complete operability of the Calibrator and check the

accuracy of each function against the Calibrator’s specifications.

Note

If the Calibrator fails any performance test, it needs calibration

adjustments. If the Calibrator continues to fail after calibration

adjustments, send it to an authorized Fluke Service Center for repair.

The Calibrator’s performance and accuracy are specified for one year after calibration at

operating temperatures of +18 °C to +28 °C (64 °F to 82 °F), in relative humidity to

90 %. The specifications assume the Calibrator has been warmed up for five minutes

before use.

It is not necessary to open the case for the performance tests; no mechanical adjustments

are necessary. Merely make the required connections, source the designated values, and

determine if the reading on the Calibrator or the multimeter falls within the acceptable

range indicated.

Preparing for the Performance Tests

Performance tests for the Calibrator can be performed manually, or they

can be computer-automated (using Fluke Metrology Software). The

Metrology Software automates all of the performance verification tasks,

except for connection of the standards to the Calibrator. This document

provides the procedures necessary for manual performance tests. Contact

Fluke for information on Metrology Software.

These performance tests assume that the person performing them knows

how to use the Calibrator and the required equipment.

Do not attempt to perform these tests unless you are qualified to do so.

Throughout the performance tests, “UUT” (unit under test) refers to the

Calibrator; the word “multimeter” is reserved for the digital multimeter

identified in the required equipment listed in Table 6.

Unless otherwise indicated, all connection diagrams for the verification

tests in this manual showing a calibrator or digital multimeter use a Fluke

5520A Calibrator or Fluke 8508A DMM. If you are using a different DMM,

make the connections appropriate for your instrument.

Notes

24

To prepare the UUT for the performance tests, do the following:

1. Make sure that you have the required equipment available, see Table 6.

2. Make sure the UUT has fresh batteries. See “Replacing the Batteries” earlier in this

manual.

3. Warm up the multimeter as required by its specifications.

4. Remove all test leads from the front of the UUT.

5. Make sure that the UUT is in a stable ambient temperature between 18 °C and 28 °C

(64.4 °F and 82.4 °F) and that it has been warmed up for five minutes.

Page 33

Calibrators

Performance Tests

Upper Display Voltage Measurement Tests

1. Press RESET on the 5520A.

2. Press l on the UUT until V appears on the upper display.

3. Make the connections shown in Figure 2.

4. Set up the 5520A to output each of the voltages in Table 7 and verify that the UUT

readings are within the limits shown.

5. Press STBY on the 5520A.

Figure 2. Upper Display Voltage Test Connections

Table 7. Upper Display Voltage Readings

5520A Outputs 724/725 UUT Readings 726 UUT Readings

0.000 V -0.002 V to +0.002 V -0.002 V to +0.002 V

15.000 V 14.995 V to 15.005 V 14.996 V to 15.004 V

30.000 V 29.992 V to 30.008 V 29.995 V to 30.005 V

25

aal03f.eps

Page 34

724/725/726

Calibration Manual

Lower Display mV/TC Measurement Tests

1. Press RESET on the 5520A.

2. Press V on the UUT until MEASURE and mV appear on the lower display.

3. Make the connections shown in Figure 3.

4. Set up the 5520A to output each of the voltages in Table 8 and verify that the UUT

readings are within the limits shown.

5. Press STBY on the 5520A.

26

Figure 3. Lower Display mV and Voltage Test Connections

Table 8. Lower Display mV Readings

5520A Outputs 724/725 UUT Readings 726 UUT Readings

0.00 mV -0.02 mV to +0.02 mV -0.0100 mV to +0.010 mV

45.00 mV 44.97 mV to 45.03 mV 44.986 mV to 45.014 mV

90.00 mV 88.96 mV to 89.04 mV 88.981 mV to 89.019 mV

aal04f.eps

Page 35

Calibrators

Performance Tests

Lower Display Voltage Measurement Tests

1. Press RESET on the 5520A.

2. Press V on the UUT until MEASURE and V appear on the lower display.

3. Make the connections shown in Figure 3.

4. Set up the 5520A to output each of the voltages in Table 9 and verify that the UUT

readings are within the limits shown.

5. Press STBY on the 5520A.

Table 9. Lower Display Voltage Readings

5520A Outputs 724/725 UTT Readings 726 UTT Readings

0.000 V -0.002 V to +0.002 V -0.002 V to +0.002 V

10.000 V 9.996 V to 10.004 V 9.997 V to 10.003 V

20.000 V 19.994 V to 20.006 V 19.996 V to 20.004 V

27

Page 36

724/725/726

Calibration Manual

Upper Display mA Measurement Tests

1. Press RESET on the 5520A.

2. Press l on the UUT until MEASURE and mA appear on the upper display.

3. Make the connections shown in Figure 4.

4. Set up the 5520A to output each of the voltages in Table 10 and verify that the UUT

readings are within the limits shown.

5. Press STBY on the 5520A.

28

Figure 4. Upper Display mA Test Connections

Table 10. Upper Display mA Readings

5520A Settings 724/725 UUT Readings 726 UUT Readings

4.000 mA 3.997 mA to 4.003 mA 3.997 mA to 4.003 mA

12.000 mA 11.995 mA to 12.005 mA 11.997 mA to 12.003 mA

24.000 mA 23.993 mA to 24.007 mA 23.995 mA to 24.005 mA

aal05f.eps

Page 37

Calibrators

Performance Tests

Lower Display mA Measurement Tests (725 and 726)

1. Press RESET on the 5520A.

2. Press l on the UUT until MEASURE and mA appear on the lower display.

3. Make the connections shown in Figure 5.

4. Set up the 5520A to output each of the voltages shown in Table 11 and verify that the

UUT readings are within the limits shown.

5. Press STBY on the 5520A.

Figure 5. Lower Display mA Test Connections

Table 11. Lower Display mA Readings

5520A Outputs 724/725 UUT Readings 726 UUT Readings

4.000 mA 3.997 mA to 4.003 mA 3.997 mA to 4.003 mA

12.000 mA 11.995 mA to 12.005 mA 11.997 mA to 12.003 mA

24.000 mA 23.993 mA to 24.007 mA 23.995 mA to 24.005 mA

aal06f.eps

29

Page 38

724/725/726

Calibration Manual

Lower Display Frequency Measurement Test (725 and 726)

1. Set the 5520A to source a 10 kHz, 1 V peak-to-peak square wave (use the blue

softkey under the wave type to change the wave shape).

2. Press F on the UUT (Kfor 726) until MEASURE and kHz appear on the

lower display.

3. Make the connections shown in Figure 6.

4. Verify that the UUT frequency reads between 9.98 kHz and 10.02 kHz.

5. Press STBY on the 5520A.

30

Figure 6. Lower Display Frequency Test Connections

aal04f.eps

Page 39

Calibrators

Performance Tests

Lower Display Frequency Source Test (725 and 726)

1. Press M on the UUT until SOURCE appears on the lower display.

2. Press F on the UUT (Kfor 726) until Hz appears on the lower display.

3. Configure the Fluke 8508A to measure frequency; then make the connections shown

in Figure 7.

4. Use the arrow keys on the UUT to set the UUT output 10 kHz at 5 V and verify that

the Fluke 8508A readings are within the limits 9.975 Hz to 10.025 kHz.

5. Press M on the UUT to disable the sourcing function.

Figure 7. Lower Display Frequency Source Test Connections

31

aal08f.eps

Page 40

724/725/726

Calibration Manual

Lower Display 4-Wire Resistance Measurement Tests

1. Press F on the UUT (Ron 726) until Ω appears on the lower display. If

necessary, use M to get to the measure mode, and use X )to get to the 4W mode.

(MEASURE should also appear on the lower display).

2. Set the 5520A to 2-wire output with 2-wire compensation off; then make the

connections shown in Figure 8.

3. Set the 5520A to source the resistance values in Table 12 and verify that the UUT

resistance readings are within the limits shown.

4. Press STBY on the 5520A.

32

Figure 8. Lower Display 4-Wire Resistance Test Connections

Table 12. Lower Display 4-Wire Resistance Readings

5520A Outputs 724/725 UUT Readings 726 UUT Readings

15.00 Ω 14.90 Ω to 15.10 Ω 14.94 Ω to 15.06 Ω

350.00 Ω 349.90 Ω to 350.10 Ω 359.90 Ω to 350.10 Ω

500.00 Ω 499.5 Ω to 500.5 Ω 499.375 Ω to 500.625 Ω

1500.0 Ω 1499.5 Ω to 1500.5 Ω 1499.2 Ω to 1500.8 Ω

3200.0 Ω 3199.0 Ω to 3201.0 Ω -

3800.0 Ω - 3798.9 Ω to 3801.1 Ω

aal09f.eps

Page 41

Calibrators

Performance Tests

Lower Display 3-Wire RTD Measurement

1. Press F on the UUT (R on the 726) until Ω appears on the lower display. If

necessary, use M to select the measure mode, and use X (R on the 726) to get to

the 3W mode. (MEASURE should also appear on the lower display.)

2. Set the 5520A to 2-wire output with 2-wire compensation off; then make the

connections shown in Figure 9.

3. Set the 5520A to source 350 Ω and verify that the UUT resistance readings are within

the 349.80 to 350.2 Ω.

4. Press STBY on the 5520A.

Figure 9. Lower Display 3-Wire Resistance Test Connections

33

aal10f.eps

Page 42

724/725/726

Calibration Manual

Lower Display Thermocouple Measurement Tests

1. Remove the test leads from the UUT terminals; then connect a Type-J thermocouple

lead between the TC jack on the UUT and the TC jack on the 5520A, as shown in

Figure 10.

2. Press T on the UUT until J appears on the lower display. If necessary, press D

(use the configuration menu on the 726) so the temperature is displayed in °C.

3. Set the 5520A to output the Type-J thermocouple voltages shown in Table 13 and

verify the UUT temperature readings are within the limits shown (values use the ITS90 curves).

4. Press STBY on the 5520A.

34

Figure 10. Lower Display Thermocouple Test Connections

Table 13. Type-J Thermocouple Readings

5520A Settings

(referenced to 0 °C)

0.0 °C (0.000 mV) -0.7 °C to +0.7 °C -0.4 °C to +0.4 °C

724/725 UUT Readings 726 UUT Readings (CJC On)

aal11f.eps

Page 43

Calibrators

Performance Tests

Lower Display Thermocouple Source Test

1. Set the 5520A to measure Type-J thermocouple voltages.

2. Press M on the UUT until SOURCE appears on the lower display. If necessary,

press T on the UUT until J appears on the lower display and press D (use the

configuration menu on the 726) so the temperature is displayed in °C.

3. Use the arrow keys to set the UUT outputs to the temperatures in Table 14 and verify

that the 5520A temperature readings are within the limits shown.

4. Press STBY on the 5520A. Remove the TC lead from the 5520A and the UUT.

Table 14. Lower Display Thermocouple Source Readings

UUT Settings

0.0 °C -0.7 °C to +0.7 °C -0.4 °C to +0.4 °C

724/725

5520A Readings

(referenced to 0 °C)

726

Readings

35

Page 44

724/725/726

Calibration Manual

Lower Display mA Source Tests (725 and 726)

1. Press M on the UUT until SOURCE appears on the lower display; then press V

until mA appears on the lower display. If necessary, press M until SOURCE

appears on the lower display.

2. Set the Fluke 8508A to measure dc current.

3. Connect the UUT and the Fluke 8508A as shown in Figure 11.

4. Use the arrow keys on the UUT to set the UUT to the currents in Table 15 and verify

that the Fluke 8508A readings are within the limits shown.

36

Figure 11. Lower Display mA Source Connections

Table 15. Lower Display mA Source Readings

UUT Outputs

4.000 mA 3.9972 mA to 4.0028 mA 3.9976 mA to 4.0024 mA

12.000 mA 11.9956 mA to 12.0044 mA 11.9968 mA to 12.0032 mA

24.000 mA 23.9932 mA to 24.0068 mA 23.9956 mA to 24.0044 mA

Fluke 8508A Readings

724/725

Fluke 8508A Readings

726

aal12f.eps

Page 45

Calibrators

Performance Tests

Lower Display mV Source Tests

1. Press M on the UUT until SOURCE appears on the lower display; then press V

until mV appears on the lower display.

2. Set the Fluke 8508A to measure dc voltage in the 200 mV range.

3. Connect the UUT to the Fluke 8508A as shown in Figure 7.

4. Use the arrow keys on the UUT to set the UUT output to the current values in Table

16 and verify that the Fluke 8508A readings are within the limits shown.

5. Press Mon the UUT to disable the sourcing function.

Table 16. Lower Display mV Source Readings

UUT Outputs

0.00 mV -0.020 mV to +0.020 mV -0.010 mV to +0.010 mV

45.00 mV 44.970 mV to 45.030 mV 44.986 mV to 45.014 mV

100.00 mV 99.960 mV to 100.040 mV 99.980 mV to 100.020 mV

Fluke 8508A Readings

Lower Display Voltage Source Tests

1. Press M on the UUT until SOURCE appears on the lower display; then press V

until V appears on the lower display.

2. Set the Fluke 8508A to measure dc voltage in the 20 V range.

3. Connect the UUT to the Fluke 8508A as shown in Figure 7.

4. Use the arrow keys on the UUT to set the UUT outputs to the currents in Table 17

and verify that the Fluke 8508A readings are within the limits shown. You can use a

lower voltage range on the Fluke 8508A to verify the 0 V range.

Table 17. Lower Display Voltage Source Readings

UUT Outputs

0.000 V -0.002 V to +0.002 V -0.002 V to +0.002 V

Fluke 8508A Readings

724/725

724/725

726

Fluke 8508A Readings

726

Fluke 8508A Readings

5.000 V 4.9970 V to 5.0030 V -

10.000 V 9.9960 V to 10.0040 V 9.997 V to 10.003 V

19.000 V - 18.9961 V to 19.0039 V

37

Page 46

724/725/726

Calibration Manual

Lower Display Ohms Source Tests

1. Press F ( R on the 726) on the UUT until Ω appears on the lower display. If

necessary, press M until SOURCE appears on the lower display.

2. Set the Fluke 8508A to measure 4-wire resistance.

3. Set the Fluke 8508A to 2 k range for 72x resistance < 400 Ω, to 20 kΩ range for

400 Ω or more.

4. Make the connections shown in Figure 12.

5. Use the arrow keys on the UUT to set the UUT output to the resistance values in

Table 18 and verify that the Fluke 8508A readings are within the limits shown.

38

Figure 12. Lower Display Ohms Source Test Connections

Table 18. Lower Display Ohms Source Readings

UUT Settings

15.0 Ω 14.9 Ω to 15.1 Ω 14.94775 Ω to 15.05225 Ω 2 kΩ

360.0 Ω 359.9 Ω to 360.1 Ω 359.896 Ω to 360.104 Ω 2 kΩ

500 Ω 499.5 Ω to 500.5 Ω 499.375 Ω to 500.625 Ω 20 kΩ

1500 Ω 1499.5 Ω to 1500.5 Ω 1499.275 Ω to 1500.725 Ω 20 kΩ

3200 Ω 3199.0 Ω to 3201.0 Ω - 20 kΩ

3800 Ω - 3798.93 Ω to 3807.01 Ω 20 kΩ

Fluke 8508A Readings

724/725

Fluke 8508A Readings

726

Range

The performance tests for the 724 are now complete. Disconnect and secure all test

equipment.

aal13f.eps

Page 47

Calibrators

Pressure Module Input (725/726)

1. Connect a Fluke 700 Series Pressure Module to the 5-pin LEMO connector at the top

of the UUT; then press U.

2. Verify that the display first shows -----psi, then changes to a pressure value.

3. Disconnect the pressure module from the UUT.

The performance tests for the 725 and 726 are now complete. Disconnect and secure all test

equipment.

Calibration Adjustment

Calibration Adjustment

The Calibrators have electronic calibration. There are no mechanical adjustments and the

calibration is done case closed. The calibration is done via serial communications port, by

sending and receiving commands and readings. For the 725 and 726 serial port

connection, you may use the 700SC Serial Interface Cable, PN 667425. This will permit

communication through the pressure port connection. The 724/725 Calibration Cable, PN

1556747 is required for the 724

the 10-pin header in the battery compartment.

Throughout these procedures, the Calibrators are referred to as “UUT” (Unit Under Test).

Two methods of calibration are available for the UUT: using a serial-based program via a

PC (see Table 6 for requirements), and using a Met/Cal calibration procedure. This

manual only describes the serial-based PC program. The automated Met/Cal procedures

are available from the Fluke Metrology Group. For more information on the automated

Met/Cal procedures contact Fluke or visit the Fluke Web site at www.fluke.com

, and can be used with the 725 and 726.. This connects to

.

Setup

As long as the calibrators have been within at a stable temperature within the range of

18

ºC to 28 ºC for an hour or more, they only need 5 minutes to warm up. If temperature

conditions were previously below 10

allowed to stabilize for a minimum of 3 hours prior to calibration.

The Calibrators should be calibrated at the required interval (defined by the factory as 1

year).

Setup the PC and UUT as follows:

1. Ensure that the terminal communications software is installed on the PC (such as

Hyper Terminal or PcPlus).

2. Connect the interface cable to the appropriate connector on the UUT. Remove the

jumper beside the ten-pin connector when using the 724/725 Calibration Cable on a

725. Replace the jumper after calibration is complete.

3. Connect the 9-pin 'D' connector to the PC serial port. An adapter may be needed for

PCs that use 25-pin 'D' serial connectors.

4. Verify the settings on the PC are as follows:

• Bits per second: 9600

• Data bits: 8

• Parity: None

ºC or higher then 40 ºC, then the Calibrator must be

• Stop bits: 1

• Flow control: None

• Local echo on

39

Page 48

724/725/726

Calibration Manual

To begin calibration, or to select a particular calibration step, type the cal step (letter or

number), then press Enter on the PC keyboard. It is not necessary to run all of the

calibration steps when in the calibration mode. However, for the 726, certain

dependencies exist in that certain functions must be calibrated before others can be

calibrated. These dependencies are related to calibration only.

You must first calibrate mV Input and mV Output before calibrating thermocouples for

the 724, 725, and 726. At the end of each step on the calibration menu, the new

calibration constants for that step are saved, but not actually used until power is recycled.

When calibrating a measurement function, you must enter an input signal. For the 724

and 725, when the signal is connected and stable, press the space bar to start the

adjustment. For the 726, press the Enter key. Usually, the UUT will display a calibration

constant, then prompt for a second input value. Apply the new input value, then press the

space bar or Enter key depending on the Calibrator. After the adjustment is complete,

press the proper key to return to the Calibration Menu.

When calibrating a source function, you must enter the value of a reading. Type in the

numerical value of the calibration desired. This will put the UUT into the desired

calibration mode. When entering the calibration data for any source mode calibration, be

sure to enter the value in the units listed, but don't enter the units (mV, mA, etc.). After

the adjustment is complete, press the proper key to return to Calibration Menu. The

calibration values will vary slightly, unit to unit. The constants used in this procedure

may not appear exactly the same as on your UUT, but they should be approximately the

same.

Initiating Communication (724 and 725)

Starting with the UUT off, push and hold Q while turning the UUT on. Continue to

hold Q until "Cal mode" is displayed. “Enter Password:" appears on the display of all

Calibrators that have firmware version V1.91 or higher. A password has been added to

prevent users from accidentally changing the calibration of the Calibrator. The password

for all 724 Calibrators is 427. The password for all 725 Calibrators is 527.

The calibration menus, as seen on the PC screen, are as follows:

725 Calibration Menu

Calibrate Menu

1 - Cal Volts Input

2 - Cal Volts Output

3 - Cal mA Input

4 - Cal mA Output

5 - Cal mV Input

6 - Cal mV Output

7 - Cal Thermocouples

8 - Cal Ohms Hi Source

9 - Cal Ohms Low Source

A - Cal RTD LOW Range

B - Cal RTD HI Range

C - Cal ISO Volts

D - Cal ISO mA

Enter Selection :

724 Calibration Menu

Calibrate Menu

1 - Cal Volts Input

2 - Cal Volts Output

3 - Cal mV Input

4 - Cal mV Output

5 - Cal Thermocouples

6 - Cal Ohms Hi Source

7 - Cal Ohms Low Source

8 - Cal RTD LOW Range

9 - Cal RTD HI Range

A - Cal ISO Volts

B - Cal ISO mA

Enter Selection :

40

Page 49

Calibrators

Calibration Adjustment

Calibration Adjustment Procedures (724 and 725)