Page 1

Remote programming

and measuring

uncommon RTDs with

the Fluke 726

Using custom RTD temperature constants

The Fluke 726 Multifunction Process Calibrator can

measure temperature with most common resistance

temperature detectors (RTD’s). But what about the many

“legacy” non-standard RTD’s still in use, as well as standard

RTDs that have been specially calibrated? The 726 allows

you to enter custom RTD constants so you can measure

any RTD for which you have the constants. You can also

use custom constants to take advantage of the Fluke 726

ability to measure with 0.01° resolutions by coupling it with

a characterized RTD. This application note explains how

to use the 726 to measure non-standard or characterized

RTD’s. It covers the basic theory of RTD conversion formulas and shows how to load custom constants into the Fluke

726 using a Windows PC with an RS-232 serial port.

Application Note

RTD Temperature Curves

RTD’s take advantage of a natural property of

metals, namely that a metal’s resistance increases

with temperature. An RTD is a precisely manufactured metal wire or film, and by measuring its

resistance we can derive its temperature.

Resistance of an RTD is a function of the length

and cross sectional area of the wire or film used to

make it, and the resistivity of its metal. Resistivity

is a characteristic of a metal’s chemical makeup.

Most RTD’s are made of platinum, nickel, or copper.

The alloy of the platinum or copper must be tightly

controlled to produce precise resistivity. International standards like IEC 60751 and ASTM 1137

define the geometry and resistivity of standard

RTD’s. RTD manufacturers work to build their product to meet these standards.

In addition to defining the physical parameters of

standard RTD’s, international standards also define

equations and constants used to convert resistance

readings to temperature. Over a limited range the

relationship between temperature and resistance is

approximately linear, and you can convert temperature to resistance using Equation 1.

Equation 1: R

Where: t is the temperature of the sensor

R

a is a constant slope that describes

R

Using this simple linear equation delivers fairly

good results, especially at temperatures between 0

and 100 °C. To extend the range of the RTD and to

get more precision, IEC and ASTM standards specify

a more complex polynomial that fine-tunes the

resistance-temperature relationship. One form of

that equation is given here as Equation 2. The RTD

standards also specify values for the constants R

A, B, C. (The C constant is only used for temperatures less than 0 °C.)

= R0 (1 + at)

t

is the resistance at 0 °C.

0

resistance change per degree C.

is the resistance at temperature t,

t

in degrees C.

,

0

From the Fluke Digital Library @ www.fluke.com/library

Page 2

300.000

280.000

260.000

240.000

220.000

200.000

18 0.000

200 250 300 350 400 450 500

Temperature (C)

Resistance (Ohms)

Rt polynomial

Rt linear

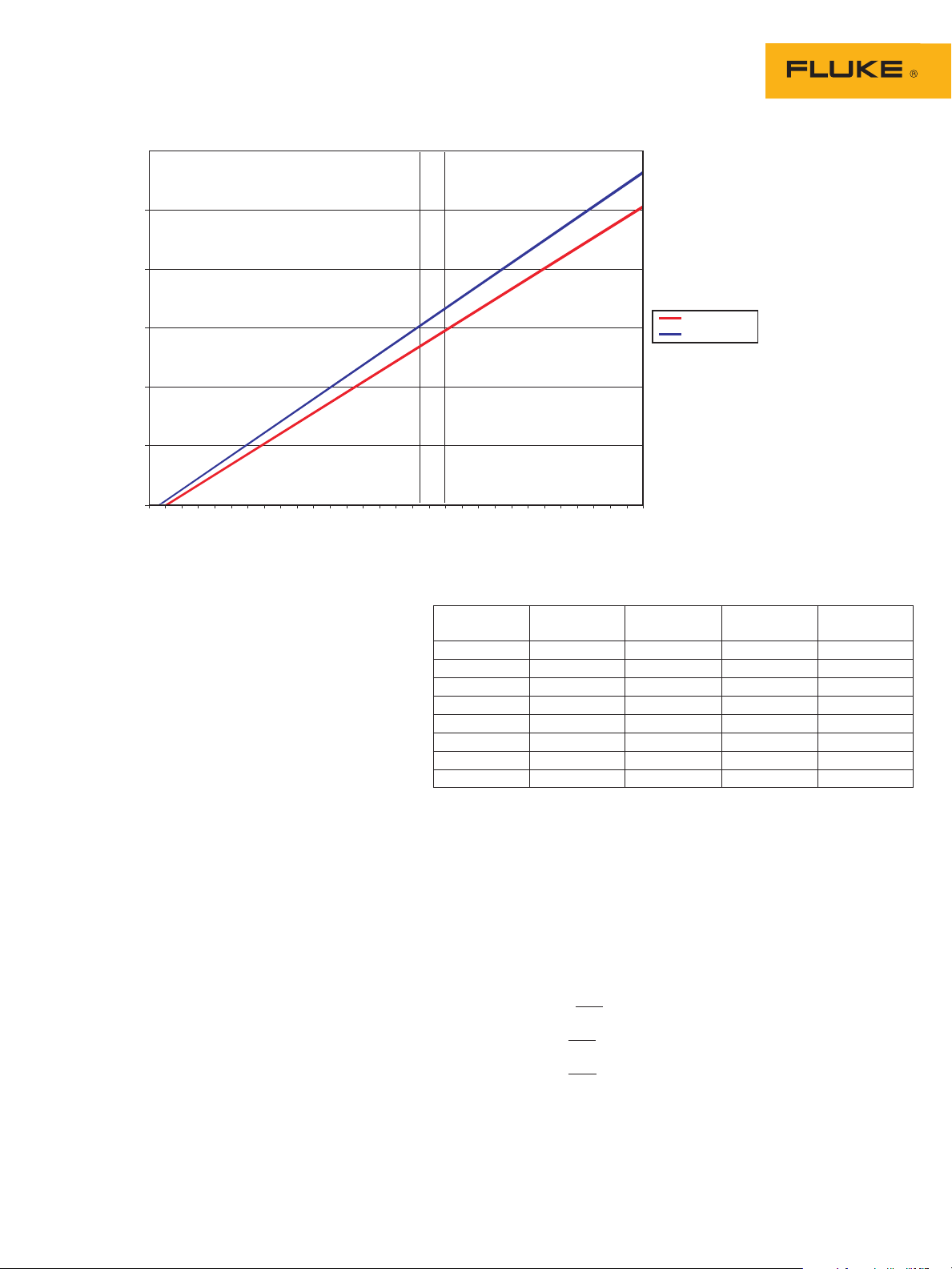

Figure 1. RTD Curves.

Equation 2: Rt = R0 [1 + At + Bt2 + C(t — 100)t3]

Figure 1 shows the difference between temperature values produced by the linear equation and

the polynomial between 200 and 500 °C. Note that

at 240 ohms, the polynomial curve of Equation 2

gives a more accurate temperature 16 °C higher

than the linear equation.

The Fluke 726 uses the polynomial in Equation

2 and it has built-in constants to support most

common RTD’s. Standard RTD’s supported by the

Fluke 726 are shown in Table 1.

Older or specialized equipment may use nonstandard RTDs. Well-equipped standards labs can

improve the accuracy of an RTD by adjusting the

constants to suit a particular sensor. The Fluke 726

allows you to check less common RTD’s or take

advantage of RTD’s that have been characterized,

by specifying your own values for R

For example, for the common Pt 385 RTD with

, A, B and C.

0

100 W resistance at 0 °C, the constants are:

R

= 100 W

0

A = 3.9083 x 10

B = -5.775 x 10

C = -4.183 x 10

Note: Instruments installed before and up to the early 1990s used a

slightly different temperature scale (IPTS-68) than newer instruments

(ITS-90). When a calibrator using ITS-90 RTD curves is used to

calibrate an instrument using IPTS-68 errors will result. The errors

are extremely small at room temperature and increase to a maximum

of 0.36 °C at 760 °C.

-3

-7

-12

RTD Type Reference R0, Metal a Range

Ohms W/W/°C °C

Pt 100 (3916) 100 Platinum 0.003916 -200 to 630

Pt 100 (385)* 100 Platinum 0.00385 -200 to 800

Pt 200 (385) 200 Platinum 0.00385 -200 to 630

Pt 500 (385) 500 Platinum 0.00385 -200 to 630

Pt 1000 (385) 1000 Platinum 0.00385 -200 to 630

Pt 100 (3926) 100 Platinum 0.003926 -200 to 630

Ni 120 (672) 120 Nickel 0.00672 -80 to 260

Cu 10 (42) 10 Copper 0.0042 -10 to 250

Table 1: Standard RTDs types included in the Fluke 726.

Pt 100 (385) is the IEC and ASTM standard.

Another common form of Equation 2, the Call-

endar Van Dusen or CVD, uses the constants a, d,

and b. This alternative form is directly derived from

Equation 1 and uses the same constant a. And even

though the two polynomials produce the same

results, the constants are different. The Fluke 726

uses the constants A, B, and C. If you know the a,

d, and b constants for an RTD you can convert them

to A, B, C constants by using Equations 3, 4 and 5.

Equation 3: A = a +

Equation 4: B = —

Equation 5: C = —

a.d

100

a.d

100

a.b

100

2

4

2 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Page 3

Loading custom RTD constants into the Fluke 726

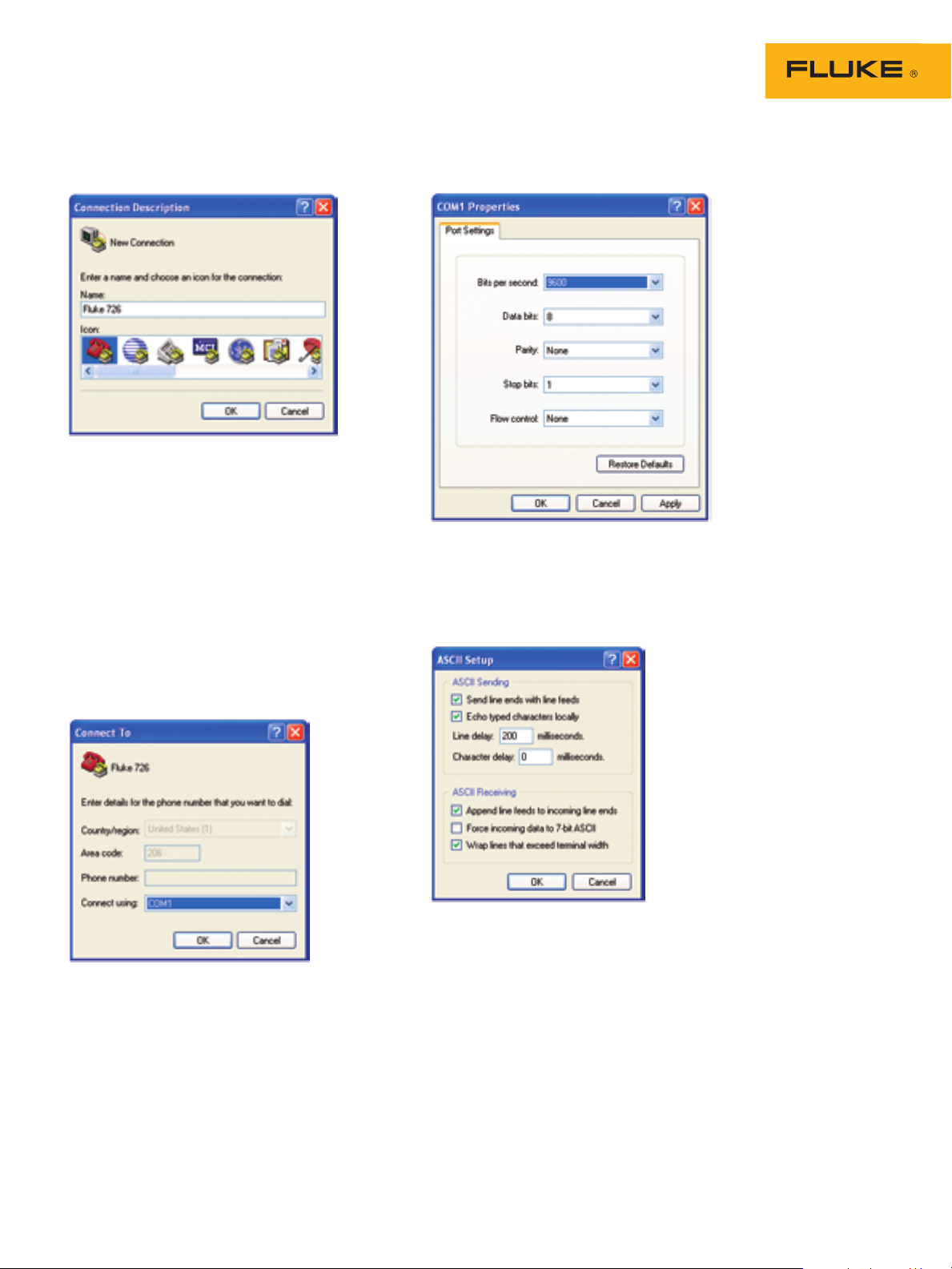

Setting up communications

Figure 2.

The Fluke 700SC Serial Interface Cable (PN

667425) is used to communicate with the Fluke

726. The serial cable connects to the round multipin connector at the top of the 726 and to a 9-pin

serial port on your PC. The serial cable can only

interface with one instrument or module at a time.

After connecting the cable, make sure the 726

is turned on. Call up the Windows HyperTerminal

Program. It is usually listed in the Windows Start

Programs menu under Accessories, Communications. The HyperTerminal program will ask you

to set up a file name to store your communication

settings. You can select any icon and click OK to

continue.

Figure 4.

Next, a COM Properties box will come up. Set

baud rate (9600 in Figure 4), data bits, parity,

stop bits and flow control as shown in the Figure

4. Once your settings match Figure 4, click OK to

continue.

Figure 3.

A second dialog box, “Connect To”, will pop up.

Skip down to the bottom, where it says “Connect

Using:” Select the COM port you connected to

the 726.

3 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Figure 5.

To make it easier to read the commands and

responses, you can make some adjustments to the

way the HyperTerminal program treats screen text.

Under the File menu select Properties and click on

the Settings tab. Click on the button labeled ASCII

Setup. You will see a dialog like the one shown in

Figure 5. Match the settings shown in the figure.

Note that adding the 200 ms line delay makes it

possible to send short scripts to the 726. More on

this later.

To test the connection, type:

*idn?

After you hit Enter, the 726 should respond with

“FLUKE,726,0,X.X” where X.X is the version of the

firmware in the instrument.

Page 4

Sending custom RTD constants to the

Fluke 726

Once communication is established you can load

custom constants into the 726. You can also send

queries to the 726 to check the current settings and

to verify your changes. Here is an overview of the

steps to modify the constants:

1. Set the RTD type to the one of the custom types

(CUST1, CUST2 or CUST3)

2. Set the minimum and maximum temperatures for

the custom RTD

3. Set the constants R0, A, B, and C

4. Assign a six-character name that will appear

on the front panel of the instrument to help the

operator choose RTD types

The best way to show the detailed process is

through an example. Let’s say we need to measure

an RTD with the following attributes:

Range is from 0 to 630 °C

R

= 100 W

0

A = 3.9692 x 10

B = -5.8495 x 10

-3

-7

C = unknown and unnecessary since range is

0 °C or greater

Rather than having to type all of the commands

each time we want to change the constants, we

can define short text files and send them using

the HyperTerminal program. The Windows Notepad program may be used to create and edit the

command scripts.

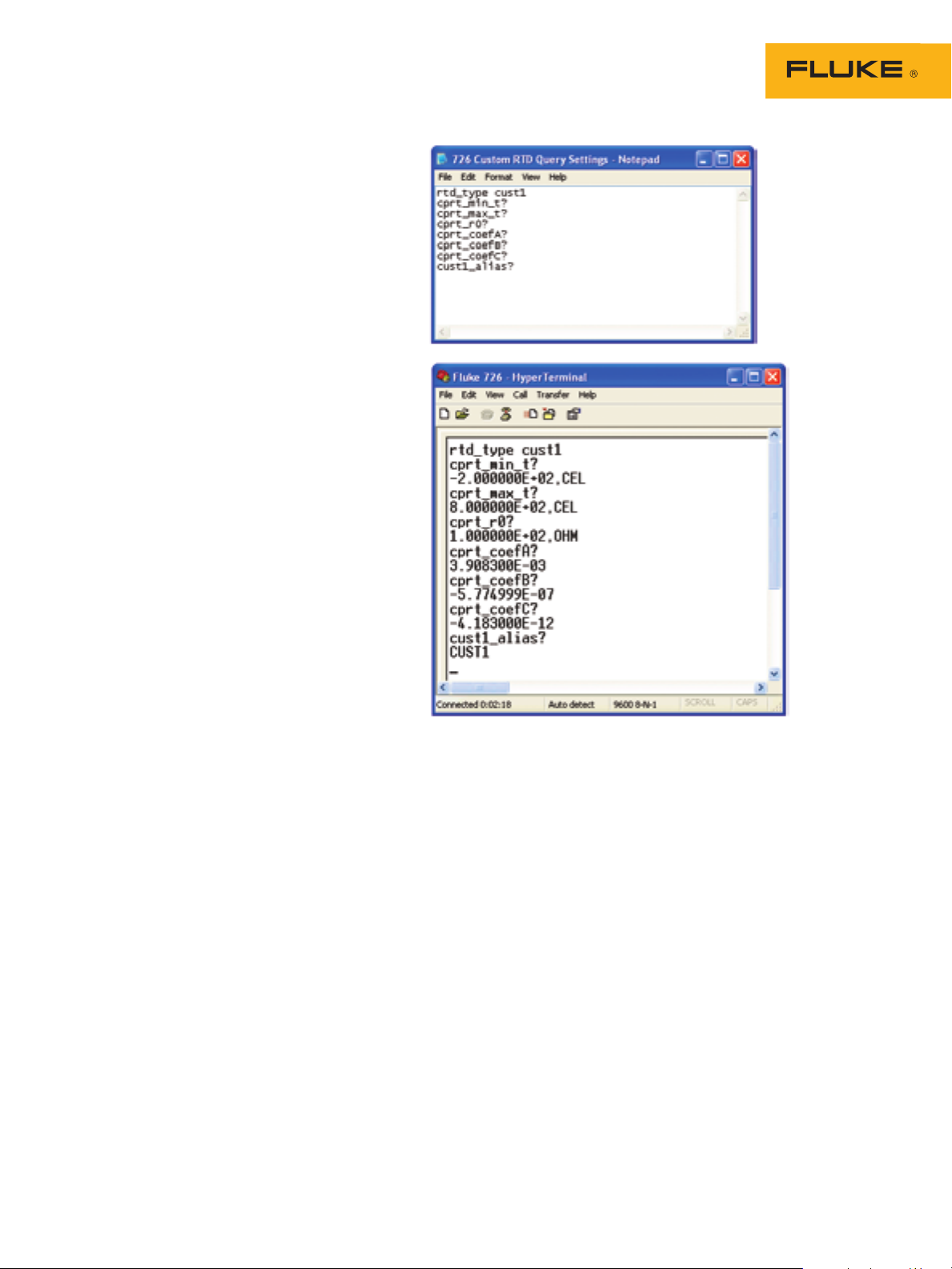

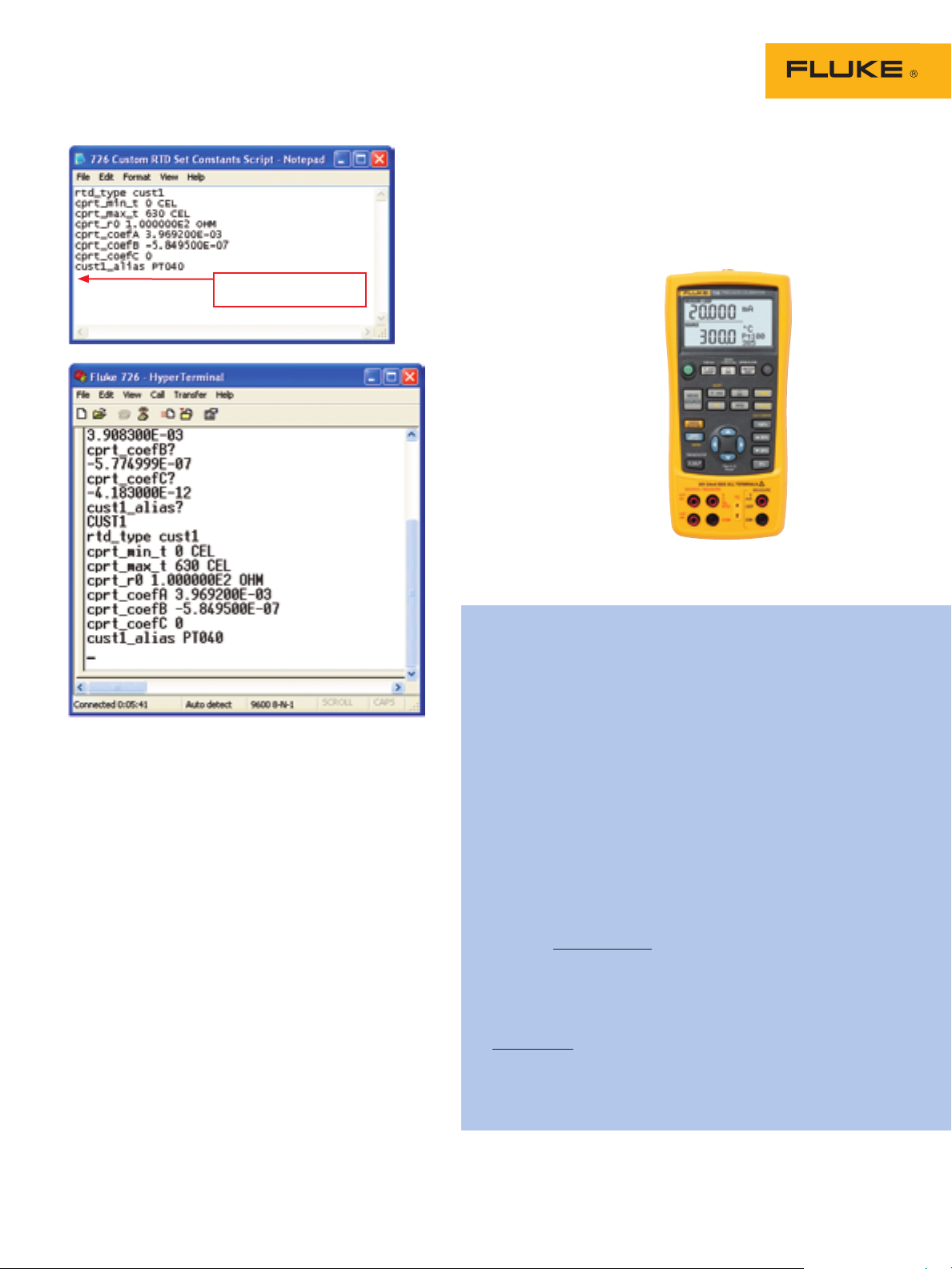

The text file in Figure 6 is designed to query all

of the parameters associated with the RTD type

CUST1. Try building and sending this query file first.

It is a good practice script and is useful for verifying

any changes you make to the constants later.

When you finish editing the script file, make sure

you hit Enter after the last command (in this example “cust1_alias?”). The cursor should be blinking

below the last command when you save the file.

This will ensure that the 726 sees the endline after

the last command and processes it.

To send a script file to the 726, click on Transfer,

Send Text File in HyperTerminal. The 726 will

respond to each of the queries with the current

values of each constant.

Figure 6. A script used to query custom RTD settings and the results

of sending it to the 726. Each query command is followed by a

response from the 726.

The HyperTerminal window shown in Figure

6 shows the response of the 726 to sending the

query commands. Each command that ends in a

question mark is followed by a response from the

726. These response are the factory default values

for the CUST1 RTD.

4 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Page 5

Note: The cursor should be

here before you save the file.

Using custom-defined RTD’s with the

Fluke 726

To use a custom RTD with the Fluke 726 you simply

select it by pressing the RTD button on the front

panel. This will cycle you through all of the available RTD types, including the three custom ones.

Figure 7. A script used to define custom RTD constants and the

results of sending it to the 726.

Figure 7 shows a script to change the constants

for the CUST1 type RTD. The script can be developed in Windows Notepad, just like the previous

example. Here’s how it works:

The script activates the RTD measurement and

•

sets the RTD type to CUST1.

It sends commands to establish new min and

•

max limits for the new RTD type.

The next three commands set the A, B, and C

•

constants. In this example we are limiting the

sensor to temperatures of 0 °C or greater, and

setting the C coefficient to 0.

The alias command will name the new RTD

•

PT040.

Note that numbers may be in integer, decimal or scientific notation.

Once the file is prepared, click on Transfer, Send

Text File in HyperTerminal to send the file to the

726. You can verify that the 726 has the correct

constants by using the query script from Figure 6.

Your 726 is now ready to make measurements

using your custom RTD curve.

Calculating the combined uncertainty of any

meter and transducer

The combination of the Fluke 726 and an RTD will have an

uncertainty that considers both the meter and the transducer.

Since the uncertainties of the meter and probe are independent of each other, rather than simply adding the uncertainties, we can take the square root of the sum of the squares.

The uncertainty of the Fluke 726 is expressed as a percentage of reading with a noise floor that is determined by the

range. The temperature specifications are 0.15 °C uncertainty

for the meter, 0.1 °C uncertainty for the probe. Here’s an

example of how to calculate the uncertainty for the Fluke 726

in °C at 100 °C.

Once you have the uncertainties of both the meter and the

probe at a particular point, you can combine these uncertainties to come up with the uncertainty of the system. The

formula for combining these independent uncertainties is:

= √U

2

probe

U

system

For example, the uncertainty of the Fluke 726 at 100 °C is

0.15 °C as calculated above. If we have an RTD whose uncertainty at 100 °C is 0.1 °C, then the combined accuracy will be

plus or minus

2

√0.1

+ 0.152 = 0.18 °C

*The above equation assumes that the U values follow a normal distribution. A

metrology standpoint would recommend dividing the ‘U’ values by √3 and then

doing the root sum square, when using the manufacture’s specification.

+ U

2

meter

*

5 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Page 6

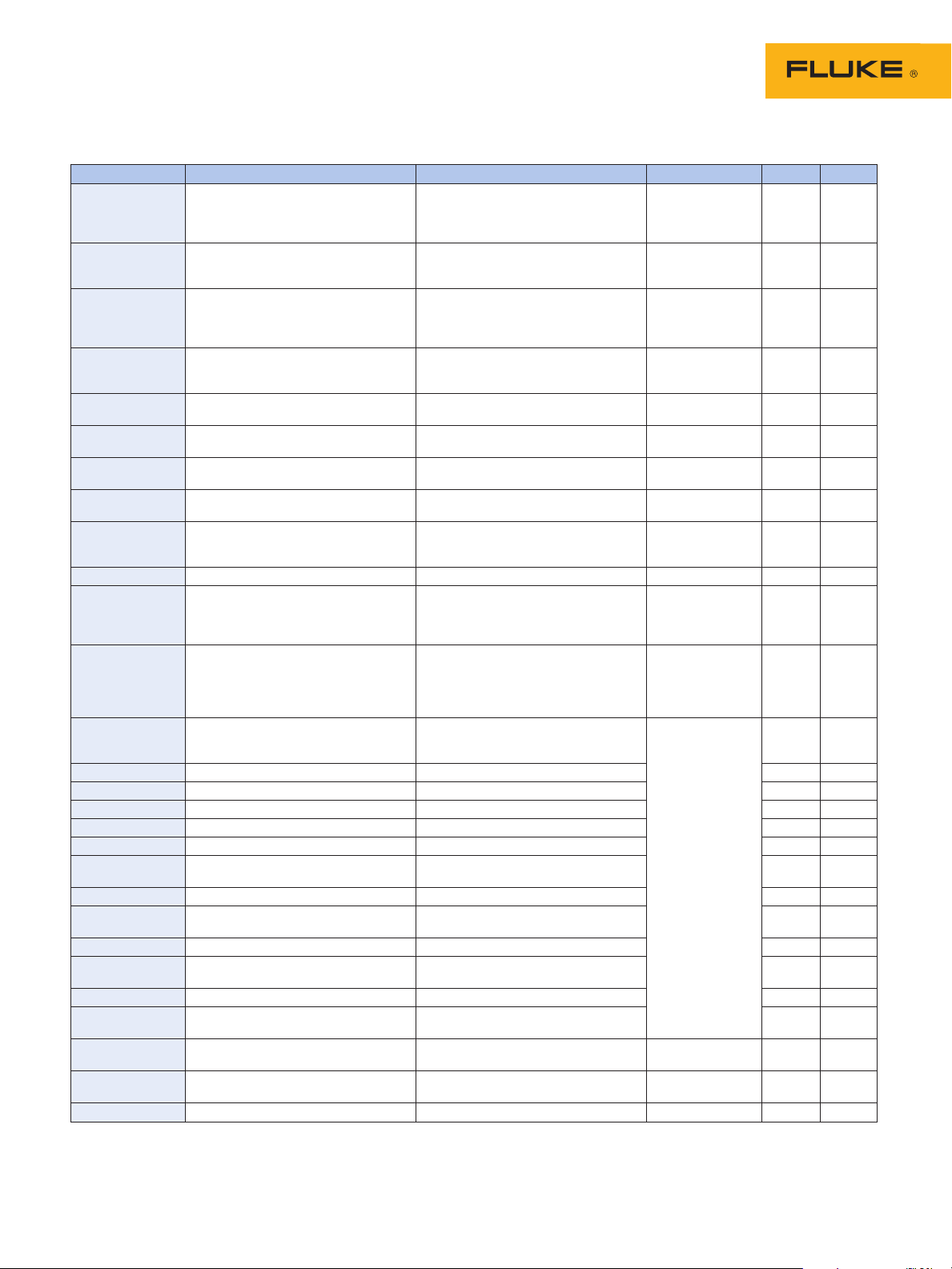

726 Serial Command List

Command Response/Actions Command Arguments Comment Ch 1 Ch 2

*IDN? Returns the ID string “FLUKE,726,0, Verify model

{sw_rev}” where sw_rev is the number, serial

firmware revision number and

firmware rev.

FUNC? Returns {Upper},{Lower} Answers with

{Upper} responses (Channel 1) the configured

DCI, DCI_LOOP, DCV, DCI_ERROR, function for the

DCI_ERROR_LOOP upper and lower

{Lower} responses display.

DCI, DCMV, DCV, DCI_SIM, TC, RTD,

FREQUENCY, PULSE_TRAIN

VAL? Returns the measured value with base

units for the upper and lower display

{upper_val},{upper_units},{lower_val},

{lower _units},

upper_units: V, A, PERCENT

lower _units: V, CEL, FAR, A, OHM,

CPM, HZ, COUNT

UPPER_MEAS 1 argument, valid settings: DCI, Set upper

DCI_LOOP, DCV, DCI_ERROR, channel

DCI_ERROR_LOOP measure mode.

OUT Arguments: {value} {units} Configures the

Multipliers u for micro, m for milli, and output source

k for kilo are accepted. function. If the

units: {value} and {units}

-V used for mV and Volts, the V_range are valid, this

command can be used to switch ranges command will

-CEL used for RTD, TC AND TC mV change modes if

-FAR used for RTD and TC necessary and set

-A used for mA (see SIM for mA SIM) the output value

-OHM used for RTD ohms, RTD_TYPE to {value} and

must be set to ohms {units} in that

-CPM used for frequency mode.

-HZ used for HZ and KHZ frequency

(unit will auto range)

-COUNT used for pulse

OUT? Returns the output (source) value Verify the output

with units or none. function and units.

FREQ_UNIT 1 argument: CPM, HZ or KHZ Set the output

frequency range.

FREQ_UNIT? Returns CPM, HZ, KHZ Verify the

frequency range.

LOWER_MEAS 1 argument, Valid Modes: Configures the

DCI, DCMV, DCV, TC, RTD, measurement

FREQUENCY, PULSE_TRAIN function. Sets the

specified measure

mode.

SIM 1 Argument {value} Multipliers u for If the value is

micro, m for milli, and k for kilo are valid, this

accepted,. A is for amps command will

change modes if

necessary and set

the output value

to {value} in that

mode.

SIM? Returns the simulate value in Amps Verify the SIM

with units or none output.

V_RANGE 1 Argument VOLTS or MVOLTS Sets the voltage

range.

V_RANGE? Returns the voltage range VOLTS or Verify the voltage

MVOLTS range.

PULSE_FREQ 2 arguments {number}{units}. Sets the pulse

(units CPM ,Hz ,Khz) output frequency

and range.

PULSE_FREQ? Returns the pulse output frequency Verify the pulse

with units. frequency.

• •

• •

• •

•

•

•

•

•

•

•

•

•

•

continued on next page

6 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Page 7

726 Serial Command List cont.

Command Response/Actions Command Arguments Comment Ch 1 Ch 2

FREQ_LEVEL 1 Argument, valid values: 1-20 V Sets the pulse

output and

frequency output

voltage.

FREQ_LEVEL? Returns the pulse output and Verify the

frequency output voltage 1-20 V frequency voltage

level.

TRIG Toggles the pulse mode and totalize Initialize totalized

trigger for read and source. pulse

measurement

or output.

TRIG? Returns the state of the pulse mode Verify TRIG state.

trigger, TRIGGERED, UNTRIGGERED

or NONE.

TC_TYPE One argument, valid settings: B, C, E, Set TC type.

J, K, L, N, R, S, T, U, BP, XK, MV

TC_TYPE? Returns TC type Verify TC type.

B, C, E, J, K, L, N, R, S, T, U, BP, XK, MV

TSENS_TYPE 1 argument TC or RTD Sets the sensor

type TC or RTD.

TSENS_TYPE? Returns the sensor type TC or RTD Verify is set for

RTD or TC.

CJC_STATE One argument ON or OFF Thermocouple

cold junction

compensation.

CJC_STATE? Returns ON or OFF Verify CJC state.

RTD_TYPE 1 argument: NI120, PT392_100, Sets RTD type

PT385_100, PTJIS_100, PT385_200,

PT385_500, PT385_1000, CU_10,

CUST1, CUST2, CUST3, OHMS

RTD_TYPE? Returns RTD type Verify the RTD

NI120, PT392_100, PT385_100, type setting.

PTJIS_100, PT385_200, PT385_500,

PT385_1000, CU_10, CUST1, CUST2,

CUST3, OHMS

CPRT_R0 2 arguments {number} OHM. RTD_TYPE must

Sets the custom CPRT R0. be either CUST1,

CUST2 or CUST3.

CPRT_R0? Returns CPRT R0 with units OHM.

CPRT_MIN_T 2 arguments {number} CEL.

CPRT_MIN_T? Returns {number} CEL.

CPRT_MAX_T 2 arguments {number} CEL.

CPRT_MAX_T? Returns {number} CEL.

CPRT_COEFA 1 argument. Sets the custom CPRT

Coefficient A.

CPRT_COEFA? Returns the custom CPRT Coefficient A.

CPRT_COEFB 1 argument. Sets the custom CPRT

Coefficient B.

CPRT_COEFB? Returns the custom CPRT Coefficient B.

CPRT_COEFC 1 argument. Sets the custom CPRT

Coefficient C.

CPRT_COEFC? Returns the custom CPRT Coefficient C.

RTD_WIRE 1 argument, 2W, 3W or 4W.

Sets RTD read wire.

RTD_WIRE? Returns RTD read wire. Verify connection

setting.

TEMP_UNIT 1 argument. Sets temperature units, CEL: Celsius

CEL or FAR FAR: Fahrenheit

TEMP_UNIT? Returns temperature units, CEL or FAR

continued on next page

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

7 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Page 8

726 Serial Command List

Command Response/Actions Command Arguments Comment Ch 1 Ch 2

CUST1_ALIAS 1 argument, sets screen name for

CUST1 RTD.

CUST1_ALIAS? Returns screen name for CUST1 RTD Verify RTD 1 alias.

CUST2_ALIAS 1 argument, sets screen name for

CUST2 RTD.

CUST2_ALIAS? Returns screen name for CUST2 RTD. Verify RTD 2 alias.

•

•

•

•

CUST3_ALIAS1 1 argument, sets screen name for

CUST3 RTD.

CUST3_ALIAS? Returns screen name for CUST3 RTD. Verify RTD 3 alias

HART_ON Turns HART mode on. Switches in 250

ohm resistor.

HART_OFF Turns HART mode off. Switches out 250

ohm resistor.

HART? Returns state of hart mode, ON or OFF

*CLS Clear the error queue

FA U LT Returns error code FILO

ERROR CODES: NONNUMERIC_ENRTY (100)

EBUFFER_OVERFLOW (101)

INVALID_UNITS_CODE (102)

ENTRY_OVER_RNG (103)

ENTRY_UNDER_RNG (104)

MISSING_PARM (105)

INVALID_UNIT_PARM (106)

INVALID_SENSOR_TYPE (108)

UNKNOWN_COMMAND (110)

BAD_PARM_VALUE (111)

INPUT_BUFF_OVERFLOW (112)

MSG_BUFF_OVERFLOW (113)

OUTPUT_BUFF_OVERFLOW (114)

OUTPUT_OVERLOAD (115)

CAL_START Initiates a password protected See Cal. Manual

calibration (password = 627) for details

•

•

• •

• •

• •

•

•

•

•

•

•

•

•

8 Fluke Corporation Measuring uncommon RTDs with the Fluke 726

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2007 Fluke Corporation. All rights reserved.

Specifications subject to change without notice.

Printed in U.S.A. 6/2007 2546483 A-EN-N Rev B

®

Loading...

Loading...