Page 1

Manual Supplement

Manual Title: 726 Users Supplement Issue: 7

Print Date: September 2005 Issue Date: 7/15

Revision/Date: Page Count: 8

This supplement contains information necessary to ensure the accuracy of the

above manual. This manual is distributed as an electronic manual on the

following CD-ROM:

CD Title: 725/726

CD Rev. & Date: 4, 9/2005

CD PN: 1549615

© 2007-2015 Fluke Corporation. All rights reserved.

Page 2

726 Users Manual Supplement

Change #1

On page 2, replace the Pulse row with the following:

Pulse

On page 12, Table 4, replace the Description for Number with the following:

Cycles through:

Slow repeating 0 % - 100 % - 0 % ramp

Configurable repeating 0 % - 100 % - 0% ramp

Configurable repeating 0 % - 100 % - 0 % ramp in 25 % steps

Used for the pulse train and totalizer functions.

1-100,000

Frequency Max 15 kHz

1-10,000

Frequency Range 2 CPM to 15 kHz

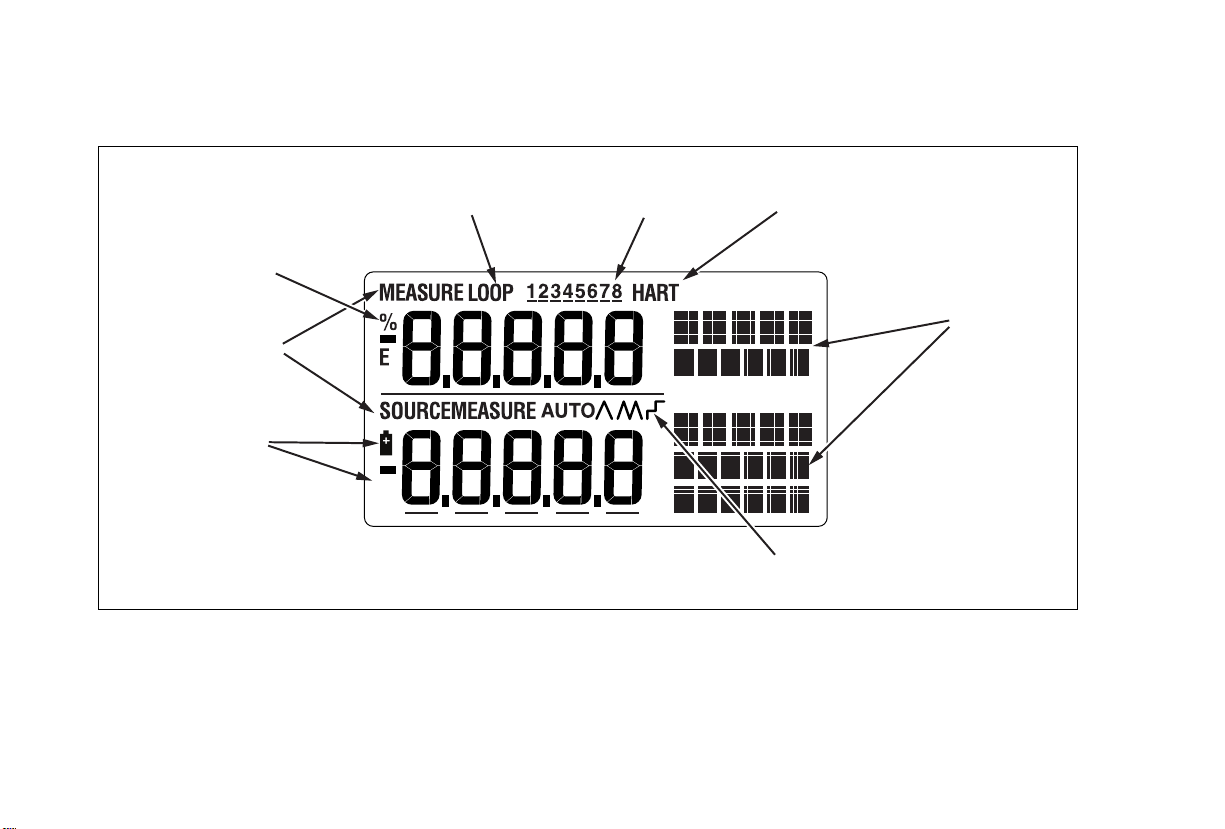

On page 13, replace Figure 4 with the following:

7/15 1

Page 3

Manual Supplement 726 Users

% Error

Indicators

Mode

Indicator

Low Battery

Symbol

Loop

Indicator

Figure 4. Elements of a Typical Disp lay

Memory Locations

for Calibrator Setups

HART Mode

Indicator

Units

Display

Auto

Ramp

2 7/15

Page 4

726 Users Manual Supplement

On page 14, under Configuration Menus, add the following under the last bullet:

• Step time

• Ramp time

On page 15, under Shut Down Mode, replace numbered steps with the following:

1. Press until SHUT DOWN appears on the display.

2.

Use and to increase or decrease the time.

3. Use and to turn on and off.

4. Press to save the setting.

On page 16, under Hart

Resistor ON/OFF, replace step 2 with the following:

2. Use or and to toggle ON and OFF.

Add the following below the Note:

Step Time

Step Time sets the ramp step time from 1 sec to 99 sec.

1. Press until STEP TIME appears on the display.

2. Use and to set the step time.

3. Press to save the setting.

7/15 3

Page 5

Manual Supplement 726 Users

Ramp Time

Ramp Time sets the ramp time from 5 sec to 99 sec.

1. Press until RAMP TIME appears on the display.

2. Use and to set the ramp time.

3. Press to save the setting.

On page 25, Table 6, add the following:

Cu10 10 Ω Copper 0.0042 Ω/°C -100 to 250

On page 42, under Auto Ramping the Output, replace the 2

nd

and 3rd bullets with the following:

• 0 % - 100 % - 0 % configurable time smooth ramp. Set ramp time using configuration

menu.

• 0 % - 100 % - 0 % Stair-step ramp in 25 % steps, pausing at each step. Set ramp

time using configuration menu. Steps are listed in Table 7.

On page 60, under Frequency Measurement, add the following to the bottom of the table:

Sensitivity: 1 V peak to peak minimum

Waveform: Squarewave

4 7/15

Page 6

726 Users Manual Supplement

On page 62, change the Range entries for “Thermocouple in mV read” and “Thermocouple in

mV source”:

From:

To:

-10 °C to 75 °C

-10 mV to 75 mV

On page 63, under the RTD Accuacy (Read and Source) (ITRS-90) table, replace the CU10 row

with the following:

Cu10 -100.0 250.00 1.8

On page 64, under Pulse Read and Pulse Source, replace the Frequency entry with the

following:

2 CPM to 15 kHz

7/15 5

Page 7

Manual Supplement 726 Users

Change #2, 57003

On page 5, add the following under Caution:

Static Sensitive

The 726 MEASURE/SOURCE terminals are ESD (electro-static discharge) sensitive to

levels above ± 4 kV. The Calibrator can experience temporary loss of measurement or

source functionality, which may require operator intervention to restore product

function, or even cause permanent damage. In general, a disruptive ESD event will

only occur during connection of the test leads to the circuits being measured or if the

operator is carrying a large static charge and touches the Calibrator terminals. The

most common cause of ESD is the user carrying the Calibrator across a carpet, or

other similar triboelectric activity, before they connection to the circuit being

measured.

On page 59, in the notes under DC mA Measurement and Source, add:

When in a 3 V/m radiated EM field ≤ 300 MHz, floor counts are increased to 30 μA in mA Read.

On page 60, in the notes under Ohms Measurement add:

When in a 3 V/m radiated EM field ≤ 300 MHz, floor counts are increased to 2.5 Ω in 400 Ω range.

6 7/15

Page 8

726 Users Manual Supplement

On page 61, in the notes under Temperature, Thermocouples add:

When in a 3 V/m radiated EM field ≤ 300 MHz, add 2 % of range for all TC types.

Change #3

On page 54, Table 8:

Change:

To:

8

8 Fluke-7XX Test Lead Set 3397308 1

Test lead, red

Test lead, black

688051

688066

1

1

Change #4, 67391, 171, 512

On page 7, under Table 2, add:

Symbol

Consult user documentation.

Conforms to relevant Australian EMC standards.

Conforms to relevant South Korean EMC Standards.

7/15 7

Meaning

Page 9

Manual Supplement 726 Users

On page 65, under General Specifications, replace the Safety section and add:

Safety IEC 61010-1: Pollution Degree 2

Electromagnetic Compatibility

(EMC)

International IEC 61326-1: Portable Electromagnetic Environment

CISPR 11: Group 1, Class A

Group 1: Equipment has intentionally generated and/or uses conductively-coupled radio

frequency energy that is necessary for the internal function of the equipment itself.

Class A: Equipment is suitable for use in all establishments other than domestic and

those directly connected to a low-voltage power supply network that supplies buildings

used for domestic purposes. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted and radiated

disturbances.

Emissions that exceed the levels required by CISPR 11 can occur when the equipment

is connected to a test object.

Korea (KCC)

USA (FCC) 47 CFR 15 subpart B. This product is considered an exempt device per clause 15.103.

Class A Equipment (Industrial Broadcasting & Communication Equipment)

Class A: Equipment meets requirements for industrial electromagnetic wave equipment

and the seller or user should take notice of it. This equipment is intended for use in

business environments and not to be used in homes.

8 7/15

Loading...

Loading...