Page 1

45

®

Dual Display Multimeter

Users Manual

PN 855981

January 1989, Rev. 4, 7/97

© 1999 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of thei r r espective c omp ani es.

Page 2

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is one year and begins on the date

of shipment. Parts, product repairs and services are warranted for 90 days. This

warranty extends only to the original buyer or end-user customer of a Fluke authorized

reseller, and does not apply to fuses, disposable batteries or to any product which, in

Fluke’s opinion, has been misused, altered, neglected or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to

end-user customers only but have no authority to extend a greater or different warranty

on behalf of Fluke. Warranty support is available if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke

reserves the right to invoice Buyer for importation costs of repair/replacement parts

when product purchased in one country is submitted for repair in another country.

Fluke’s warranty obligation is limited, at Fluke’s option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send

the product, with a description of the difficulty, postage and insurance prepaid (FOB

Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for

damage in transit. Following warranty repair, the product will be returned to Buyer,

transportation prepaid (FOB Destination). If Fluke determines that the failure was

caused by misuse, alteration, accident or abnormal condition of operation or handling,

Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer

transportation prepaid and the Buyer will be billed for the repair and return transportation

charges (FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMI TED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES O R LOSSES, I NCLUDING

LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED

ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and

exclusions of this warranty may not apply to every buyer. If any provision of this

Warranty is held invalid or unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Safety Class

This is an IEC safety class 1 (grounded enclosure) product. For safety, the ground wire

in the line cord must be connected when operating from AC power.

When operated from the optional battery pack, this product meets the safety

requirements for a safety class 2 (reinforced insulation) product and does not require

grounding for safety.

Interference Information

This equipment generates and uses radio frequency energy and if not installed and used

in strict accordance with the manufacturer’s instructions, may cause interference to radio

and television reception. It has been type tested and found to comply with the limits for a

Class B computing device in accordance with the specifications of Part 15 of FCC Rules,

which are designed to provide reasonable protection against such interference in a

residential installation.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may

cause undesired operation.

There is no guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one of more of the following measures:

• Reorient the receiving antenna

• Relocate the equipment with respect to the receiver

• Move the equipment away from the receiver

• Plug the equipment into a different outlet so that the computer and receiver are on

diffe rent branch circuits

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet prepared

by the Federal Communications Commission helpful: How to Identify and Resolve

Radio-TV Interference Problems. This booklet is available from the U.S. Government

Printing Office, Washington, D.C. 20402. Stock No. 004-000-00345-4.

Declaration of the Manufacturer or Importer

We hereby certify that the Fluke Model 45 Dual Display MultiMeter is in compliance with

BMPT Vfg 243/1991 and is RFI suppressed. The normal operation of some equipment (e.g.

signal generators) may be subject to specific restrictions. Please observe the notices in the

users manual. The marketing and sales of the equipment was reported to the Central Office

for Telecommunication Permits (BZT). The right to retest this equipment to verify compliance

with the regulation was given to the BZT.

Page 4

Page 5

Table of Contents

Chapter Title Page

1 Introduction ........................................................................................ 1-1

Introducing the Fluke 45 Dual Display Multimeter........................................... 1-1

Options and Accessories.................................................................................... 1-2

Where to go from Here...................................................................................... 1-2

2 Getting Started ................................................................................... 2-1

Introduction........................................................................................................ 2-1

Getting Started................................................................................................... 2-1

Unpacking and Inspecting the Meter............................................................. 2-1

Front Panel and Rear Panel ........................................................................... 2-1

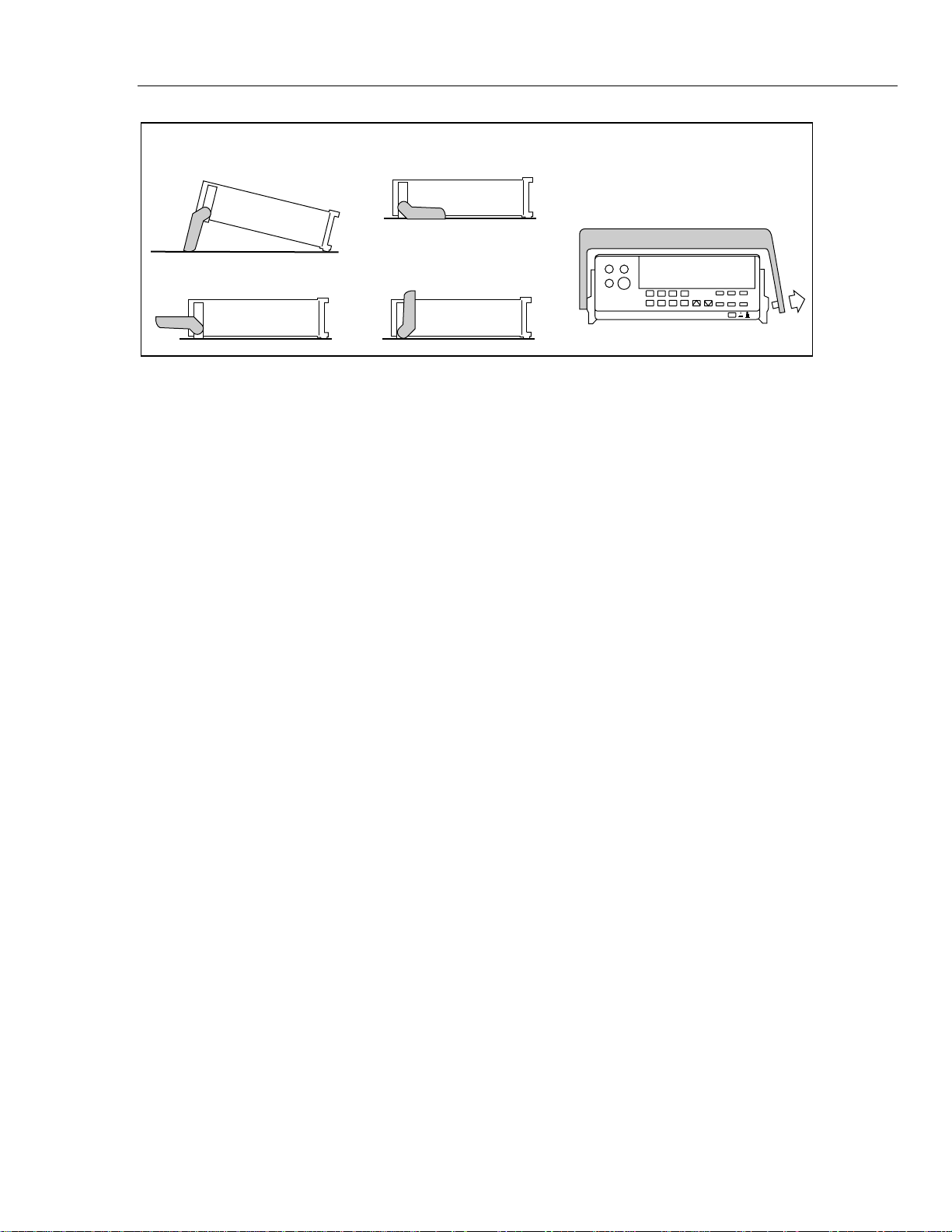

Adjusting the Handle..................................................................................... 2-1

Line Power..................................................................................................... 2-1

Turning the Meter on......................................................................................... 2-3

Using the Pushbuttons........................................................................................ 2-3

Selecting a Measurement Range........................................................................ 2-5

Automatic Input Terminal Selection.................................................................. 2-5

Taking Some Basic Measurements.................................................................... 2-5

Measuring Voltage, Resistance, or Frequency.............................................. 2-6

Measuring Current......................................................................................... 2-6

Diode/Continuity Testing.............................................................................. 2-6

Operating the Meter Under Battery Power (Optional)....................................... 2-9

Rack Mounting................................................................................................... 2-9

3 Operating the Meter From the Front Panel....................................... 3-1

Introduction........................................................................................................ 3-1

Front Panel Operations ...................................................................................... 3-1

Display............................................................................................................... 3-2

Primary Display............................................................................................. 3-2

Secondary Display......................................................................................... 3-2

Input Terminals.................................................................................................. 3-4

Selecting a Measurement Function.................................................................... 3-5

Ranging.............................................................................................................. 3-5

Autoranging................................................................................................... 3-5

Manual Ranging ............................................................................................ 3-8

i

Page 6

45

Users Manual

Measuring Frequency......................................................................................... 3-8

Frequency Ranging........................................................................................ 3-8

Frequency Measurement Rates...................................................................... 3-9

Measuring Frequency of Current (100 mA and 10A) Inputs......................... 3-9

Frequency Sensitivity Selection .................................................................... 3-9

Selecting A Function Modifier.......................................................................... 3-10

REL (Relative Readings) Modifier................................................................ 3-11

dB (Decibels and Audio Power) Modifier..................................................... 3-12

HOLD (Touch Hold) Modifier...................................................................... 3-13

MN MX (Minimum Maximum) Modifier..................................................... 3-13

Using Function Modifiers in Combination.................................................... 3-13

Selecting A Measurement Rate (Rate) .......................................................... 3-14

Using the S Button.................................................................................... 3-14

Using The Compare (Comp) Function............................................................... 3-16

The List and Number Editors........................................................................ 3-16

Using the List Editor ..................................................................................... 3-17

Using the Number Editor............................................................................... 3-18

Power-Up Configuration.................................................................................... 3-19

Factory Settings of Power-Up Configuration................................................ 3-19

Changing the Power-Up Configuration......................................................... 3-19

Calibration ......................................................................................................... 3-20

4 Applications........................................................................................ 4-1

Introduction........................................................................................................ 4-1

Using the Dual Display...................................................................................... 4-1

Using Measurement Functions in Combination............................................ 4-2

Taking Voltage and Current Measurements Using the Dual Display ........... 4-2

Response Times................................................................................................. 4-4

How the Meter Makes Dual Display Measurements......................................... 4-5

Updating the Primary and Secondary Displays with a Single Measurement 4-5

Updating the Primary and Secondary Displays with Separate Measurements4-5

Update Rate in the Dual Display Mode......................................................... 4-7

External Trigger................................................................................................. 4-7

Thermal Voltages............................................................................................... 4-8

When Measuring Resistance.............................................................................. 4-9

Two-Wire Configuration............................................................................... 4-9

Correcting for Test Lead Resistance ............................................................. 4-9

True RMS Measurements.................................................................................. 4-9

Effects of Internal Noise in AC Measurements............................................. 4-10

Calculated (AC + DC) RMS Measurements ................................................. 4-10

Waveform Comparison (True RMS vs. Average-Responding Meters) ........ 4-10

5 Operating the Meter Using the Computer Interface ......................... 5-1

Introduction........................................................................................................ 5-1

Local and Remote Operations....................................................................... 5-1

Preparing the Meter for Operations via the RS-232 Interface........................... 5-2

Setting Communication Parameters (RS-232)............................................... 5-2

RS-232 Print-Only Mode............................................................................... 5-3

Cabling the Meter to a Host or Printer (RS-232)........................................... 5-4

Character Echoing and Deletion.................................................................... 5-4

Device Clear Using ^C (CNTRL C).............................................................. 5-4

RS-232 Prompts............................................................................................. 5-4

Preparing the Meter to be Operated via IEEE-488 Interface............................. 5-5

IEEE-488 Operating Limitations................................................................... 5-5

ii

Page 7

Contents (continued)

Installing the IEEE-488 Interface.................................................................. 5-5

Enabling the IEEE-488 Interface................................................................... 5-5

Addressing the Meter..................................................................................... 5-5

Cabling the Meter to a Host........................................................................... 5-6

Getting Started With An Installation Test.......................................................... 5-6

Installation Test for RS-232 Operations........................................................ 5-6

Installation Test for IEEE-488 Operations.................................................... 5-6

If Test Fails.................................................................................................... 5-7

How the Meter Processes Input......................................................................... 5-7

Input Strings.................................................................................................. 5-7

Input Terminators.......................................................................................... 5-7

Typical IEEE-488 Input Strings .................................................................... 5-8

Sending Numeric Values to the Meter .......................................................... 5-8

Sending Command Strings to the Meter........................................................ 5-8

How the Meter Processes Output....................................................................... 5-11

Triggering Output.............................................................................................. 5-11

External Triggering from the Front Panel ..................................................... 5-11

Setting the Trigger Type Configuration........................................................ 5-12

External Triggering via the Computer Interface............................................ 5-12

Service Requests (IEEE-488 Only and Status Registers ................................... 5-13

Event Status and Event Status Enable Registers ........................................... 5-16

Status Byte Register ...................................................................................... 5-17

Reading the Status Byte Register .................................................................. 5-17

Service Request Enable Register................................................................... 5-18

Computer Interface Command Set..................................................................... 5-19

IEEE-488 Capabilities and Common Commands ......................................... 5-19

Function Commands and Queries.................................................................. 5-22

Function Modifier Commands and Queries .................................................. 5-22

Range and Measurement Rate Commands and Queries................................ 5-25

Measurement Queries.................................................................................... 5-26

Compare Commands and Queries................................................................. 5-27

Trigger Configuration Commands................................................................. 5-27

Miscellaneous Commands and Queries......................................................... 5-28

RS-232 Remote/Local Configurations .......................................................... 5-29

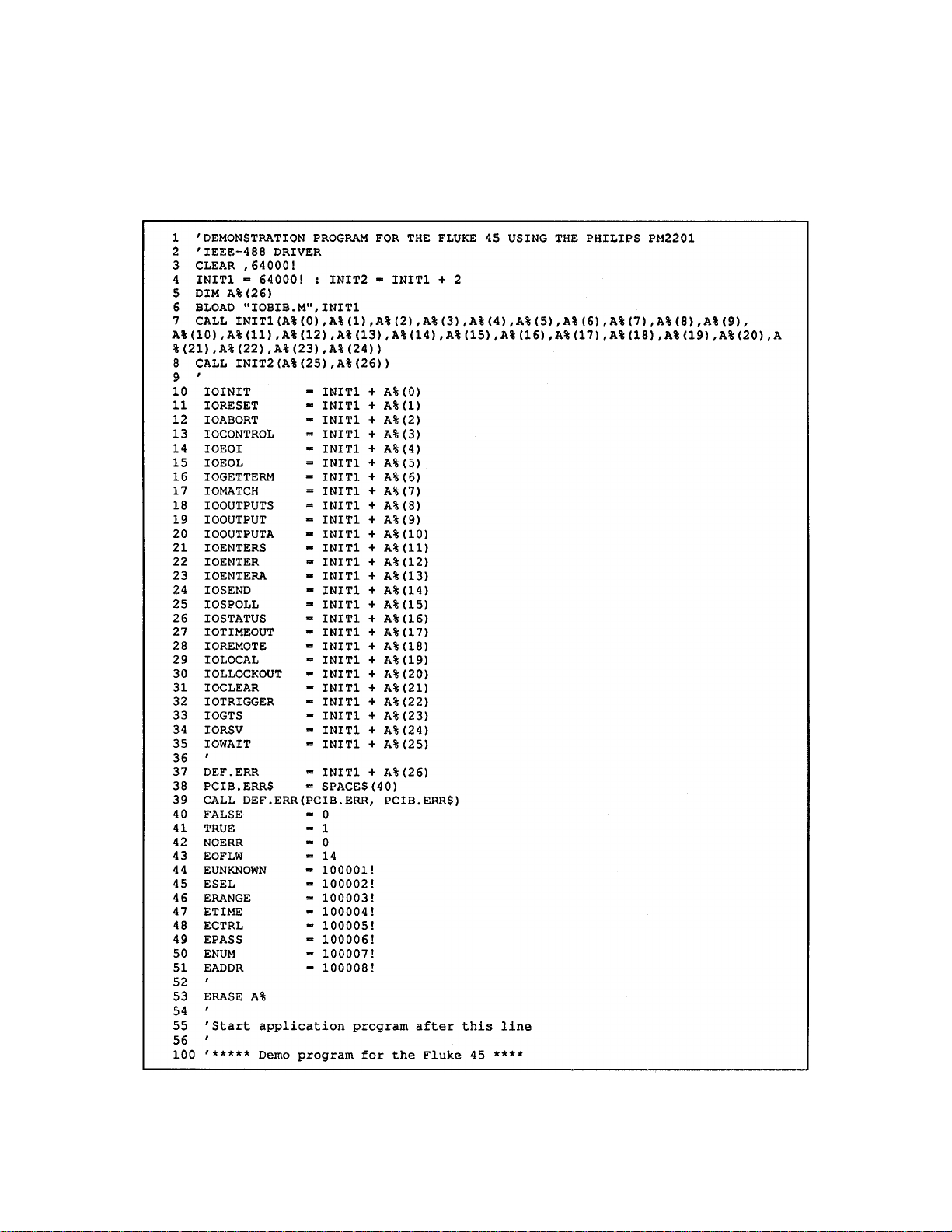

Sample Program Using the RS-232 Computer Interface................................... 5-30

Sample Programs Using the IEEE-488 Computer Interface.............................. 5-31

6 Maintenance........................................................................................ 6-1

Introduction........................................................................................................ 6-1

Cleaning............................................................................................................. 6-1

Line Fuse............................................................................................................ 6-1

Current Input Fuses............................................................................................ 6-2

Testing Current Input Fuses.......................................................................... 6-2

Replacing the 100 mA Input Fuse................................................................. 6-3

Replacing the 10 A Input Fuse...................................................................... 6-3

Self-Test Diagnostics and Error Codes.............................................................. 6-4

Performance Tests.............................................................................................. 6-4

Service ............................................................................................................... 6-5

Replacement Parts.............................................................................................. 6-7

Appendices

A Specifications .............................................................................................. A-1

B ASCII/IEEE-488 Bus Codes....................................................................... B-1

C IEEE-488.2 Device Documentation Requirements..................................... C-1

iii

Page 8

Page 9

List of Tables

Table Title Page

1-1. Accessories............................................................................................................. 1-2

3-2. Voltage Ranges and Full Scale Values................................................................... 3-6

3-3. Current Ranges and Full Scale Values................................................................... 3-7

3-4. Ohms Ranges and Full Scale Values...................................................................... 3-7

3-5. Frequency Ranges and Full Scale Values (Slow and Medium*) ........................... 3-7

3-6. Frequency Measurement Rates .............................................................................. 3-9

3-7. Maximum Sinewave Inputs for Frequency Measurements.................................... 3-10

3-8. Reference Impedances in Ohms............................................................................. 3-12

3-9. Display Measurement Rates for Single Function Measurements........................... 3-14

3-10. S Button Operations........................................................................................... 3-15

3-11. Options Available Through List Editor.................................................................. 3-18

3-12. Number Editor Options.......................................................................................... 3-18

3-13. Power-Up Configuration Set at Factory................................................................. 3-20

4-1. Sample Dual Display Applications........................................................................ 4-3

4-2. Typical Single Measurement Response Times (in Seconds)................................. 4-6

4-3. Typical Settling Delays (in Seconds)..................................................................... 4-6

4-4. Typical Measurement Intervals (in Seconds) for Dual Display Measurements..... 4-8

4-5. Ohms Test Voltage................................................................................................. 4-9

5-1. Factory Settings of RS-232 Communication Parameters....................................... 5-2

5-2. Approximate Print Rates in RS-232 Print-Only Mode........................................... 5-3

5-5. Status Register Summary....................................................................................... 5-14

5-6. Description of Bits in ESR and ESE...................................................................... 5-17

5-7. Description of Bits in the Status Byte Register*.................................................... 5-18

5-8. IEEE-488 Interface Function Subsets .................................................................... 5-20

5-9. IEEE-488 Common Commands............................................................................. 5-20

5-11. Function Commands and Queries .......................................................................... 5-22

5-12. Function Modifier Commands and Queries........................................................... 5-23

5-13. Range and Measurement Rate Commands and Queries......................................... 5-25

5-14. Measurement Queries............................................................................................. 5-26

5-15. Compare Commands and Queries.......................................................................... 5-27

5-16. Trigger Configuration Commands......................................................................... 5-27

5-17. Miscellaneous Commands and Queries ................................................................. 5-28

5-18. Remote/Local Configuration Commands............................................................... 5-29

6-1. Self-Test Error Codes............................................................................................. 6-4

6-2. Performance Tests for Volts, Diode Test, Ohms, and Frequency, Functions........ 6-5

v

Page 10

45

Users Manual

6-3. Performance Tests for mA Current Functions ....................................................... 6-7

6-4. Performance Tests for A Current Functions........................................................... 6-7

6-5. Replacement Parts.................................................................................................. 6-7

vi

Page 11

List of Figures

Figure Title Page

2-1. Front Panel............................................................................................................. 2-2

2-2. Rear Panel .............................................................................................................. 2-2

2-3. Adjusting Handle.................................................................................................... 2-3

2-4. Summary of Basic Pushbutton Operations............................................................. 2-4

2-5. Measuring Voltage, Resistance, or Frequency....................................................... 2-7

2-6. Measuring Current or Frequency........................................................................... 2-7

2-7. Continuity Testing.................................................................................................. 2-8

2-8. Diode Testing......................................................................................................... 2-8

3-1. Primary Display...................................................................................................... 3-2

3-2. Display Annunciators............................................................................................. 3-3

3-3. Secondary Display.................................................................................................. 3-3

3-4. Input Terminals...................................................................................................... 3-4

3-5. Function Selection Buttons.................................................................................... 3-6

3-6. Range Selection Buttons........................................................................................ 3-8

3-7. Function Modifier Selection Buttons..................................................................... 3-11

4-1. Dual Display Showing Volts AC and Frequency................................................... 4-2

4-2. DC Voltage and DC Current Measurement on Input Signal.................................. 4-4

4-3. Waveform Comparison Chart................................................................................ 4-11

5-1. Typical IEEE-488 Input Strings............................................................................. 5-10

5-2. External Trigger Using Receive Pin (RX) of RS-232 Interface............................. 5-13

5-3. Overview of Status Data Structures ....................................................................... 5-15

5-4. Event Status and Event Status Enable Registers.................................................... 5-16

5-5. Sample Program for RS-232 Computer Interface.................................................. 5-31

5-6. Sample Programs for IEEE-488 Computer Interface............................................. 5-32

6-1. Replacing the Line Fuse......................................................................................... 6-2

6-2. Replacing the 100mA Input Fuse........................................................................... 6-3

vii

Page 12

Introduction

Introducing the Fluke 45 Dual Display Multimeter

Note

This manual contains information and warnings that must be followed to

ensure safe operation and retain the meter in safe condition.

W Warning

To avoid electric shock or injury, read the "multimeter safety"

sheet preceding Chapter 2 before using the meter.

The Fluke 45 Dual Display Multimeter (also referred to as "the meter") is a 4/2-digit

(30,000 count) meter with a 5-digit (100,000 count) high resolution mode. The meter is

designed for bench-top, field service, and system applications. Complete specifications

are provided in Appendix A.

With the (optional) IEEE-488 computer interface installed, the meter is fully

programmable for use on the IEEE Standard 488.1 interface bus(1987). The meter is also

designed in compliance with supplemental standard IEEE-488.2 (1987).

Chapter 1

Some features provided by the meter are:

• A dual, vacuum fluorescent, display that allows two properties of an input signal to

be displayed at the same time. (e.g., ac voltage in one display and frequency in the

other).

• Remote operation via the RS-232 interface (included) or the IEEE-488 interface

(optional).

• True rms ac

• (AC + DC) rms, calculated

• Frequency measurements to greater than 1 MHz

• I µV sensitivity in volts dc

• Decibels with variable reference impeda nce and audio power me asu re men t

capability.

• A compare mode to determine if a measurement is within, above, or below a

designated range.

1-1

Page 13

45

Users Manual

• 100,000, 30,000, and 3,000 selectable count resolution, with display reading speeds

of 2.5, 5, and 20 readings per second (rps), respectively.

• Built-in self-tests with closed-case calibration (no intern al cal ibrat ion adjustments).

Options and Accessories

Two options are available. These options can be installed in the meter at the factory or by

the customer on site:

• The IEEE-488 Interface (Option -O5K) provides full programmability, and

automated calibration. The IEEE-488 computer interface command set is identical to

the RS-232 interface commands wherever possible.

• The Battery Kit (Option -01 K) consists of a rechargeable, 8 V, lead-acid battery,

with battery bracket and charger assembly. The battery has a typical operating time

of eight hours and is fully operable at ambient temperatures between 0 and 50 °C. For

complete battery specifications, refer to Appendix A.

Available accessories are listed and described in Table 1-1.

Table 1-1. Accessories

Model Description

C40 Soft carrying case. Provides padded protection for the meter. Includes a pocket for the

manual and pouch for the test leads and line cord.

M00-200-634 Rackmount Kit. Allows meter to be mounted on either the right or left side of a standard

19-inch rack.

RS40 RS-232 terminal interface cable. Connects the Fluke 45 to any terminal or printer with

properly configured DTE connector (DB-25 socket), including an IBM PC

or IBM PS/2 (models 25, 30, 5O, P60, 70, and 80).

®

, IBM PC/XT

RS41 RS-232 modem cable. Connects the Fluke 45 to a modem with properly configured DB-25

male pin connector.

S45 QuickStart ™, a PC software package, simplifies operation of the Fluke 45 when using the

RS-232 computer interface. Readings are recorded in files that can be accessed by Lotus

®

1-2-3

, dBase lll® and other graphics packages.

Y8021 Shielded IEEE-488 one-meter (39.4 inches) cable, with plug and jack at each end.

Y8022 Shielded IEEE-488 two-meter (78.8 inches) cable, with plug and jack at each end.

Y8023 Shielded IEEE-488 four-meter (13 feet) cable, with plug and jack at each end.

Where to go from Here

This manual has been organized to assist you in getting started quickly. It is not necessary

for you to read the entire manual before using the meter effectively. However, we recommend that you do so in order to use your meter to its full advantage.

®

1-2

Begin by scanning the Table of Contents to familiarize yourself with the organization of

the manual. Then, read Chapter 2, "GETTING STARTED". Refer to the appropriate

chapter of the manual as needed. The contents of each chapter are summarized below.

Chapter 1: Introduction

Introduces the Fluke 45 Dual Display Multimeter, describing its features, options, acces-

sories, and users manual.

Page 14

Chapter 2: Getting started

Explains how to prepare the meter for operation and get started quickly taking basic

measurements from the front panel.

Chapter 3: Operating the meter from the front panel

Provides a complete description of each operation that can be performed using the push-

buttons on the front panel. Chapter 3 is organized so that related operations and functions

are grouped together.

Chapter 4: Applications

Describes how to use the meter in more advanced operations and sophisticated applica-

tions. Assumes a basic knowledge of the meter and front panel operations.

Chapter 5: Operating the Meter using the Computer Interface

Describes how to connect the meter to a terminal or host and operate it via the RS-232-C

or (optional) IEEE-488 interface. Assumes a basic knowledge of the meter and front

panel operations.

Introduction

Where to go from Here

1

Chapter 6: Maintenance

Describes how to perform basic maintenance and repairs (e.g., replacing fuses) and how

to order replacement parts. Complete serv ice and repa ir procedures are contained in the

"Fluke 45 Dual Display Multimeter Service Manual" (P/N 856042).

Appendices

A. Specifications

B. ASCII/ IEEE-488 Bus Codes

C. IEEE-488.2 Device Documentation Requirements

1-3

Page 15

45

Users Manual

1-4

Page 16

MULTIMETER SAFETY

The Fluke 45 Dual Display Multimeter has been designed and tested according to IEC

Publication 348, Safety Requirements for Electronic Measuring Apparatus. This manual

contains information and warnings which must be followed to ensure safe operation and

retain the meter in safe condition. Use of this equipment in a manner not specified herein

may impair the protection provided by the equipment.

The meter is designed for IEC 664, Installation Category II use. It is designed for use in

circuits with a VA rating of <4800 VA.

Some common international electrical symbols used in this manual are shown below.

B

F

D

I

AC - ALTERNATING

CURRENT

DC - DIRECT

CURRENT

EITHER AC OR DC

CURRENT

FUSE

DANGEROUS

Y

VOLTAGE

EARTH GROUND

J

SEE EXPLANATION

W

IN MANUAL

DOUBLE INSULATION

T

FOR PROTECTION

AGAINST ELECTRIC

SHOCK

Before using the meter, read the following safety information carefully. In this manual,

"WARNING," is reserved for conditions and actions that pose hazard(s) to the user;

"CAUTION," is reserved for conditions and actions that may damage your meter.

W WARNING

TO AVOID ELECTRICAL SHOCK OR OTHER INJURY:

• Avoid working alone

• Follow all safety procedures for equipment being tested.

• Inspect the test leads for damaged insulation or exposed metal. Check test lead

continuity. Damaged leads should be replaced.

• Be sure the meter is in good operating condition.

• Select the proper function for your measurement.

• To avoid electrical shock, use caution when working above 60V dc or 30V ac RMS.

• Disconnect the live test lead before disconnecting the common test lead.

• Disconnect the power and discharge high-voltage capacitors before testing in Ω and

LR.

• When making a current measurement, turn the circuit power off before connecting

the meter in the circui t.

• Check meter fuses before measuring transformer secondary or motor winding

current. (See Section 6, MAINTENANCE.") An open fuse may allow high voltage

build-up, which is potentially hazardous.

• Use clamp-on probes when measuring circuits exceeding 10 amps.

• When servicing the meter, use only the replacement parts specified.

• Do not allow meter to be used if it is damaged or if its safety is impaired.

Page 17

Page 18

Introduction

Chapter 2 explains how to prepare the meter for operation, discusses general operating

features, and walks you through the basics of taking some common measurements.

Getting Started

Unpacking and Inspecting the Meter

Carefully remove the meter from its sh ipp ing conta ine r and inspec t it for poss ib le dama ge

or missing items. If the meter is damaged or something is missing, contact the place of

purchase immediately. Save the container and packing material in case you have to return

the meter.

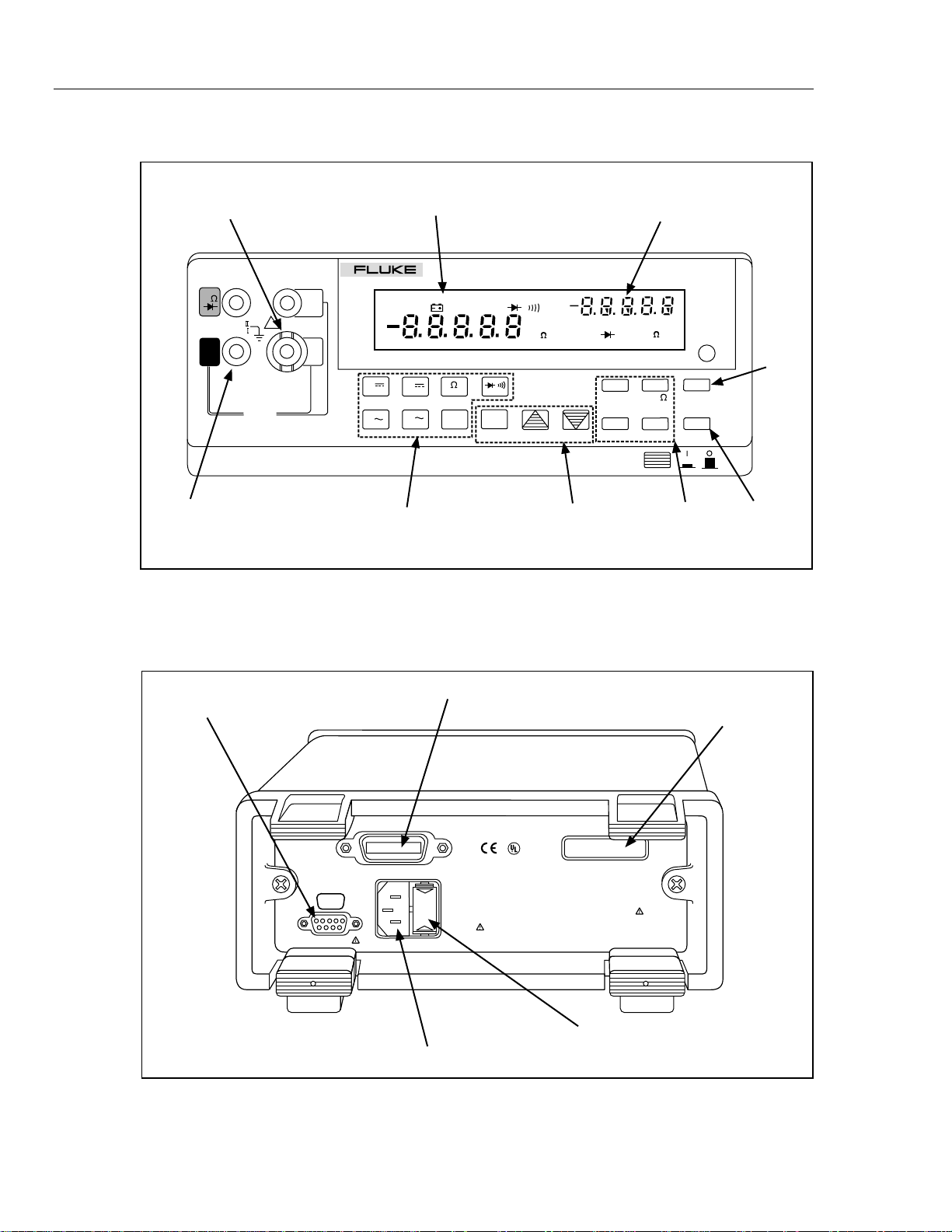

Front Panel and Rear Panel

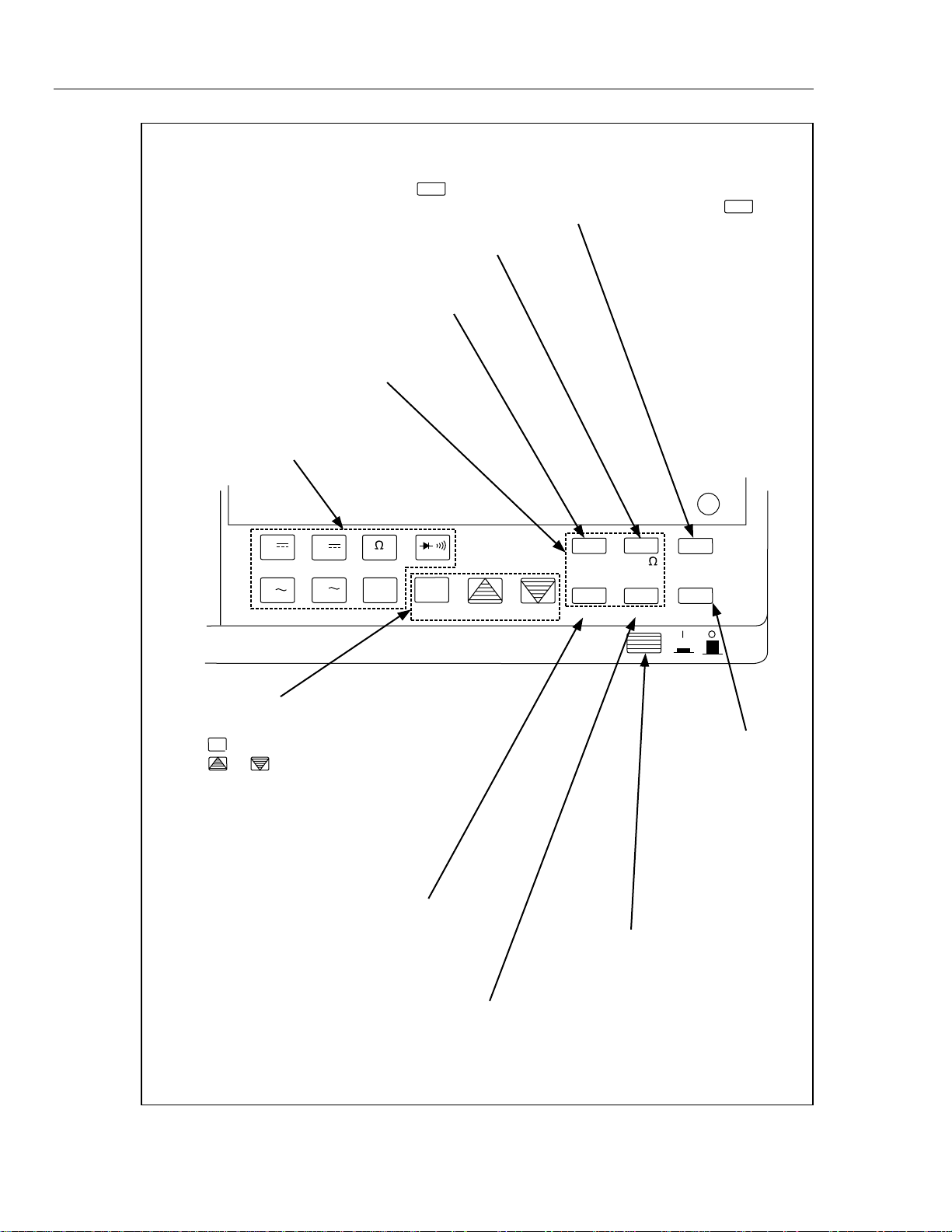

The front panel (shown in Figure 2-1.) has three main elements: the input terminals on

the left, the primary and secondary displays, and the pushbuttons. The pushbuttons are

used to select major functions, ranging oper ations , and function modi fi ers . These

elements are described in detail in Chapter 3.

Chapter 2

Getting Started

The rear panel (shown in Figure 2-2) contains the power-line cord connector, an RS-232

interface connector, a cutout for the (opti ona l) IEEE-4 88 int erfac e connec tor, a seri al

number label, and a line fuse. (For fuse testing and replace men t proce dur es, ref er to

Chapter 6.) Rotate the rear feet 180 degrees before using the meter.

Adjusting the Handle

For bench-top use, the handle can be positioned to provide two viewing angles. To adjust

its position, pull the ends out to a hard stop (about 1/4-inch on each side) and rotate it to

one of the four stop positions shown in Figure 2-3. To remove the handle, adjust it to the

vertical stop position and pull the ends all the way out.

Line Power

To avoid shock hazard, connect the instrument power cord to a

power receptacle with earth ground. A protective ground

connection by way of the grounding conductor in the power

cord is essential for safe operation.

WWarning

2-1

Page 19

45

Users Manual

Receptacle

Input

Terminals

mA Fuse

V

600V CAT I

1000V CAT I

COM

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

Primary

Display

DUAL DISPLAY MULTIMETER

45

SMF MAX

V

V

REMOTE

EXT TRG

A

A

MINdBHOLD

FREQ

Function

Buttons

Figure 2-1. Front Panel

AUTO

COMP

REL

AUTO

mA

mVDCAC

Hz

Mk

HI

mA

UNCAL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

Ranging

Buttons

mV

REL

Secondary

Display

DC AC

Hz

Mk

dB

REF

MN MX

Modifier

Buttons

CAL

ENABLE

2ND

RATE

Shift

Key

Reading

Rate

aam01f.eps

RS-232 Connector

*Available with IEEE-488

Interface Option only. Otherwise,

covered with insert

IEEE-488 Interface Connector*

IEEE STD 488 PORT

SH1, AH1, T5, L4, SR1, RL1,

DC1, DT1, PPO, CO ,E1

RX

DTR

GND

TX

IIII

1 2 3 4 5

6 7 8 9

RS-232C

Power-Line Cord Connector

Figure 2-2. Rear Panel

CAUTION:

FOR FIRE PROTECTION

REPLACE ONLY WITH

T 1/8A 250V (SLOW) FUSE

90-264V

50/60 Hz

20VA

R

CUS

LISTED

950 Z

WARNING:

TO AVOID ELECTRIC SHOCK DISCONNECT

MEASURING TERMINALS BEFORE OPENING

CASE

WARNING:

TO AVOID DAMAGE OR INJURY USE ONLY

IN CIRCUITS LESS THAN 4800VA

FLUKE CORPORATION

MADE IN USA

PAT. 4,217,543 4,556,867 4,532,470 4,825,392

4,857,878 5,332,963 5,418,464 DES 311,700

Line Power Fuse Housing

Serial Number Label

aam02f.eps

2-2

Page 20

Getting Started

Turning the Meter on

2

1. Viewing Position

3. Carrying Position

If you have not already done so, plug the line cord into the connector on the rear of the

meter. The meter will operate on any line voltage between 90 V ac and 264 V ac without

adjustment, and any frequency between 45 and 440 Hz. However, it is only warranted to

meet published specifications at 50/60 Hz.

Turning the Meter on

To turn the meter on, press in the green, POWER button located on the lower-right of the

front panel. If the meter is being operated under battery power and you turn the meter off,

you must wait five seconds before turning the meter back on. If you do not, the meter will

not power-up.

2. Alternate Viewing Position

Pull End Out and Towards You.

Then Slide to Left.

4. Removal Position

(to Remove, Pull Ends Out)

aam03f.eps

Figure 2-3. Adjusting Handle

When the meter is turned on, the primary and secondary displays light for about 4

seconds while the instrument per forms an inte rnal self-test of its digital ci rcu it ry. These

tests check RAM, ROM, A/ D, calibration, and the display. The meter has passed all tests

and is ready for normal operation if an error code is not displayed. However, if an error is

detected, the meter will still attempt to operate. (Refer to "Self-Test Diagnostics and

Error Codes" in Chapter 6.)

If any front panel button other than E is held down while the power-up sequence is in

progress, the entire display stays on until another button is pressed. Then, the powerup

sequence continues.

After the meter completes the power-up sequence, it assumes the power-up measurement

configuration stored in non-volatile memory. The power-up configuration set at the

factory is shown in Table 3-13. (To change the power-up configuration, refer to

"Changing the Power-Up Configuration" in Chapter 3.)

Using the Pushbuttons

The pushbuttons on the front panel select meter functions and operations. A summary of

basic pushbutton operations is shown in Figure 2-4.

Pushbuttons can be used in three ways. You can:

• Press a single button to select a function or operation.

EXAMPLE: Press Z to select volts ac for the prim ary display.

Press a combination of buttons, one after the other.

2-3

Page 21

45

Users Manual

2ND (SHIFT BUTTON):

-Press then a FUNCTION BUTTON to Select Function for

2ND

Secondary Display. (Refer to Section 3 for other uses of .)

-Press to Toggle In and Out of Decibels

-Press to Toggle In and Out of Relative Mode

FUNCTION MODIFIER BUTTONS

FUNCTION BUTTONS:

-Press to Select a Function

V

V

A

A

FREQ

AUTO

COMP

2ND

REL

REF# LOCAL

HOLD

HI

LO

THRESH ADDR

dB

REF

MN MX

2ND

RATE

BAUD

RANGE BUTTONS:

-Press to Toggle In and Out of Manual Ranging;

AUTO

-Press or to Up Range or Down Range

-Press to Select Touch Hold;

-Press to Force Update;

-Press and Hold Down for 2 Seconds to Exit.

-Press to Select the MN MX Modifier;

-Press to Toggle Between Minimum and Maximum Reading;

-Press and Hold Down for 2 Seconds to Exit MN MX Mode.

POWER

-Press to Step Through

Measurement Rate

(Slow, Medium, Fast)

-Press in to Power-Up

2-4

Figure 2-4. Summary of Basic Pushbutton Operations

aam04f.eps

Page 22

EXAMPLE: Press Z to select volts ac for the primary display, then press I to

select the decibels modifier.

• Press multiple buttons simultaneously.

EXAMPLE: Press Z and Ysimultaneously to sel ect true rms volts ac + volts dc

(calculated) in the primary display.

For more details on the uses of each button, refer to Chapter 3, "OPERATING THE

METER FROM THE FRONT PANEL."

Selecting a Measurem ent Range

Measurement ranges can be selected automatically by the meter in "autorange" or

manually by the user. In the autorange mode, the meter selects the appropriate range for

the measurement reading.

To manually select a range, press E to toggle in (and out) of the manual ranging mode,

or press U or T . In the manual range mode, press U or T to up range or down

range to the desired range. For more details on ranging, refer to "Ranging’’ in Chapter 3.

Automatic Input Terminal Se lection

If current (ac or dc) is being measured in the autorange mode and there is no input on the

100 mA terminal, the meter switches automatically between the 100 mA and 10 A input

terminals looking for a signal. A front panel annunciator indicates that the meter is in the

mA range while the meter attemp ts to select the correct input termin al.

Getting Started

Selecting a Measurement Range

2

When a signal is detected at either input terminal, the display updates with the

measurement results. If an input sign al is no t found on eith er inpu t ter min al, a

measurement is taken on the mA terminal.

Automatic input terminal selection is disabled when the meter is in the manual ranging

mode. Use the Uand T buttons to select the appropriate current input terminal and

range.

Taking Some Basic Measurements

W Warning

Read “Multimeter Safety” before operating this meter.

The following procedures describe the basics of taking common measurements from the

front panel. These procedures are provided for the user who needs to get started quickly,

but does not want to read the rest of the manual at this time. However, in order to take

full advantage of your meter, you should read the remainder of this manual carefully and

completely.

W Warning

To avoid electrical shock or damage to the meter, do not apply

more than the rated voltage between any terminal and earth

ground. The meter is protected against overloads up to the

limits shown in Table 3-1. Exceeding these limits poses a

hazard to the meter and operator.

2-5

Page 23

45

Users Manual

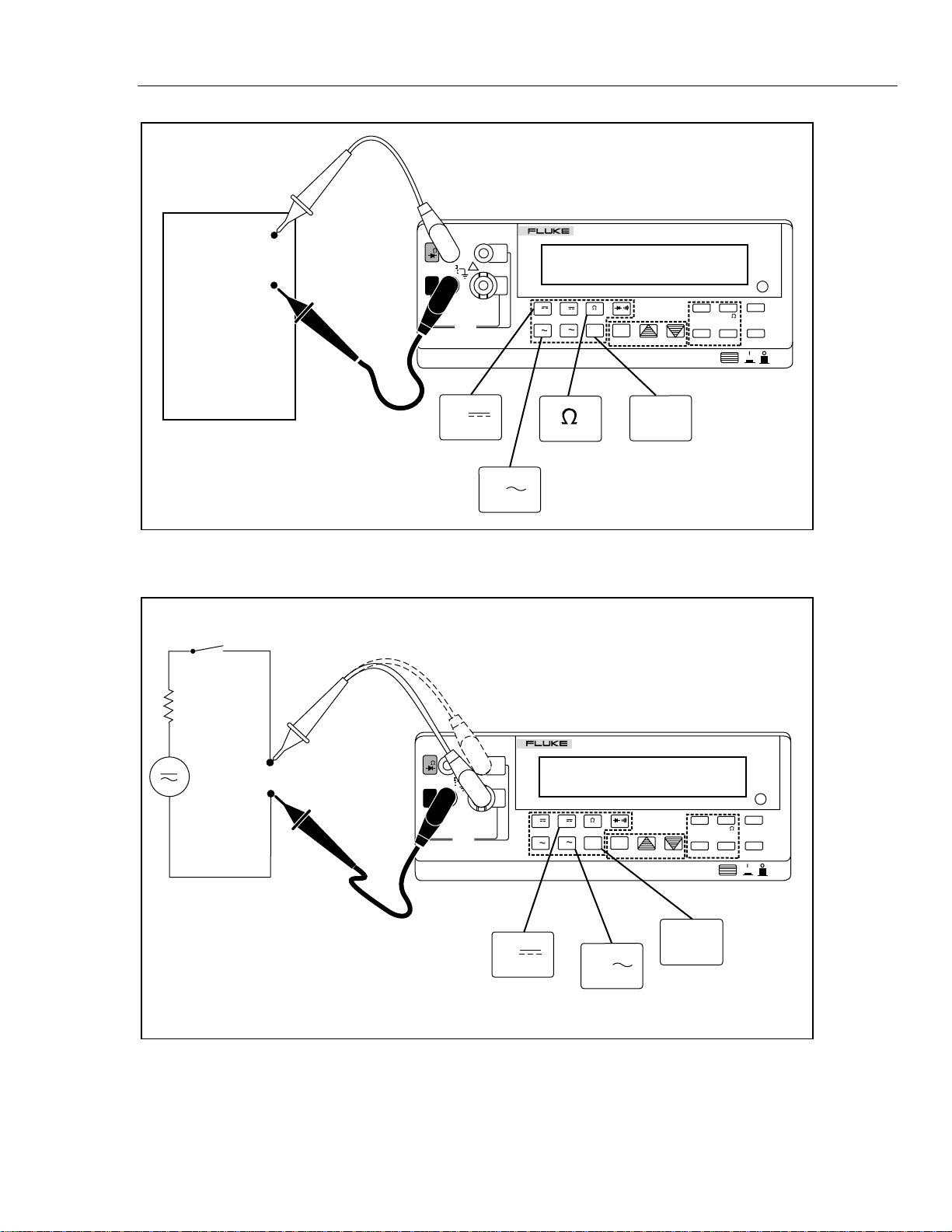

Measuring Voltage, Resistance, or Frequency

To measure voltage, resistance, or frequency, press the desired function button and

connect the test leads as shown in Figure 2-5. The meter will select the appropriate range

in the autorange mode, and an annunciator on the display will indicate measurement

units.

Note

After measuring high voltage to 1000 V dc, errors may occur when making

measurements with 1 to 10 µV resolution. Allow up to two minutes prior to

making low-level measurements.

Measuring Current

To measure current, insert the test leads in the 100 mA input terminal for currents up to

100 mA or in the 10 A input terminal for higher current. Press C or D and connect

the test leads as shown in Figure 2-6 and described in the following procedure:

1. Turn off power in the circuit to be measured.

2. Break the circuit (on the ground side to minimize the common mode voltage), and

place the meter in series at that point. (To measure current without breaking the

circuit, use a current clamp.)

3. Turn on power to the circuit, and read the display. The meter will select the

appropriate range automatically, and an annunciator on the display will indicate the

units of the measurement value shown.

4. Turn off power to the circuit and disconnect the meter from the tested circuit.

After measuring high current using the 10 A input, thermal voltages are

generated that may create errors when making low-level (high sensitivity)

dc measurements of volts, current, or ohms. To make the most accurate

measurements, allow up to ten minutes for the thermals to settle out.

Diode/Continuity Testing

Diode and continuity tests are performed by a diode test function with a continuity beeper

that can be turned on and off.

The continuity test determines whether a circuit is intact (i.e., has a resistance less than

about 30 Ω). The meter detects continuity for intervals as brief as 50 µs. The continuity

test function cannot be selected for the secondary display.

To perform a continuity test, press G , and connect the test leads as shown in Figure

2-7. The beeper emits a single beep when the input drops below +0.8 V (approximately

1 kΩ), and emits a continuous tone when the input goes below +25 mV (approximately

30 Ω).

The diode test measures the forward voltage of a semiconductor junction (or junctions) at

approximately 0.7 mA. Readings are displayed in the 3 V range at the medium and fast

measurement rates. "OL" is displayed for voltages above +2.5 V. If the diode test is

performed at the slow reading rate, readings are displayed in millivolts on the 1000 mV

(1 V) range.

Note

2-6

Page 24

VOLTAGE

SOURCE

Getting Started

Taking Some Basic Mea sur e ment s

DUALDISPLAY MULTIMETER

+

V

600V CATI

1000V CATI

-

COM

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

45

CAL

ENABLE

2ND

dB

V

A

FREQ

AUTO

COMP

HI

A

V

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

REF

MN MX

RATE

2

CURRENT

SOURCE

V

FREQ

V

Figure 2-5. Measuring Voltage, Resistance, or Frequency

DUAL DISPLAY MULTIMETER

45

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

V

A

FREQ

AUTO

COMP

HI

A

V

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

REF

MN MX

aam05f.eps

CAL

ENABLE

dB

2ND

RATE

Note:

Measurement can be also made using

current clamp without breaking circuit.

Figure 2-6. Measuring Current or Frequency

A

A

FREQ

aam06f.eps

2-7

Page 25

45

Users Manual

TEST

+

CIRCUIT

-

Note: This is a Diode Test Function

with a Continuity Beeper.

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

DUAL DISPLAY MULTIMETER

45

10A

CAL

REF

MN MX

ENABLE

2ND

dB

RATE

100

mA

V

A

FREQ

AUTO

COMP

HI

A

V

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

Figure 2-7. Continuity Testing

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

V

V

DUAL DISPLAY MULTIMETER

45

A

A

FREQ

AUTO

COMP

HI

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

REF

MN MX

aam07f.eps

CAL

ENABLE

2ND

dB

RATE

2-8

Figure 2-8. Diode Testing

aam08f.eps

Page 26

Operating the Meter Under Battery Power (Optional)

To perform a diode or transistor junction test, press G to select the diode/continuity

function. (Each press of G turns the continuity beeper on and off.) Then connect the

test leads across the diode as shown in Figure 2-8. Notice how the test leads are placed.

Reversing the polarity will reverse-bi as the dio de.

Operating the Meter Under Battery Power (Optional)

The meter can be powered by an 8 V, lead-acid battery. The battery module consists of a

battery, battery bracket, and battery charger circuit assembly. The battery is rechargeable,

requires no maintenance, and is fully operable at ambient temperatures between 0 and

50 °C. Refer to Appendix A for specifications.

The battery has a typical operating time of eight hours. When less than 1/2-hour of

battery life remains, N turns on. If you turn the meter off when it is being operated

under battery power, you must wait five seconds before turning the meter back on.

Otherwise the meter will not power-up.

To maintain a fully charged battery (and maximize battery life), always recharge the

battery after the meter has been operated on battery power. To recharge the battery, plug

the meter into line power and turn the meter off. It will take approximately 16 hours to

fully recharge a discharged battery with the meter turned off.

Getting Started

2

The battery remains fully charged as long as the meter is connected to line power. You

need not be concerned about over-charging the battery. Do not store the battery for

extended periods in a discharged state. Always fully charge the battery before storage and

at least once every six months during storage. If the meter has been stored for a long

period with the battery installed, fully recharge the battery before using the meter on

battery power.

Rack Mounting

You can mount the meter in a standard 19-inch rack using the M00-200-634 Rack Mount

Kit. The rear feet can be rotated to clear a narrow rack space.

To install the rack mount kit, refer to the instructions provided with it.

2-9

Page 27

45

Users Manual

2-10

Page 28

Operating the Meter From the Front

Introduction

Chapter 3 explains how to operate the meter from the front panel. Refer to Chapter 4 for

information concerning specific applications. Chapter 5 provides instructions on how to

operate the meter using the computer interface (RS-232 or IEEE-488).

Front Panel Operations

The following operations can be performed from the front panel:

• Select a measurement function (volts dc, volts ac, current dc, current ac, resistance,

frequency, and diode/continuity test) for the primary and secondary display.

• Take a measurement and display a reading.

• Select the manual or autorange mode (AUTO).

Chapter 3

Panel

• Manually select a measurement range for the primary display.

• Select function modifiers that cause the meter to display relative readings (REL),

minimum or maximum values (MN MX), or decibels (dB), or to enter the Touch

Hold mode (HOLD) to hold a reading on the primary display.

• Change the measurement rate (slow, medium, fast).

• Set the dB reference resistance (REF Ω).

• Take a measurement and compare (COMP) it against a tolerance range (HI, LO, or

PASS).

• Use the "editor" to select from option lists, to enter a relative base, or to enter a HILO

range for the compare (COMP) mode.

• Configure the computer interface (RS-232 or IEEE-488).

• Take an audio power reading.

• Send measurements directly to a printer or terminal through the RS-232 interface

(RS-232 print-only mode).

These and other front panel operations are described in the remainder of Chapter 3.

3-1

Page 29

45

Users Manual

Display

The meter has a 5-digit, vacuum-fluorescent, dual display. This display shows measurement readings, annunciators, and messages. The annunciators indicate measurement units

and the meters operating configuration.

The dual display allows you to see two properties (e.g., volts ac and frequency) of the

input signal you are measuring. Readings are taken and displayed in an alternating

fashion. That is, a reading is taken of one property of the input and sent to a display; then

a reading of the other property is taken and sent to the other display. (For more detail, see

"How the Meter makes Dual Display Measurements" in Chapter 4.)

The display flashes when a measurement exceeds 1000 V dc or 750 V ac, the maximum

rated input level. If an input exceeds the full scale value of the selec ted rang e, the

overload annunciator (OL) is displayed.

Primary Display

The primary display (shown in Figure 3-1) consists of the larger digits and annunciators

(see Figure 3-2) and is located on the left side of the front panel. Readings using the relative (REL), minimum maximum (MN MX), Touch Hold (HOLD), or decibels (dB)

modifiers can be shown on the primary display only.

Secondary Display

The secondary display consists of a set of smaller digits on the right side of the dual display (see Figure 3-3).

Press S to turn the secondary display on and off. A series of five dashes is shown in

the secondary display when the secondary display has been turned on but a function has

not yet been selected.

DUAL DISPLAY MULTIMETER

45

SMF MAX

REMOTE

EXT TRG

Figure 3-1. Primary Display

MINdBHOLD

REL

AUTO

mA

mVDCAC

Hz

Mk

aam09f.eps

3-2

Page 30

Operating the Meter From the Front Panel

Display

3

Remote State

with or without

Front Panel Lockout

(REMS or RWLS))

REMOTE

EXT TRG

External

Trigger

Enabled

1/2 Hour Battery

Power Remains

Reading Rate:

Slow, Medium, Fast

SMF MAX

Less Than

Relative

Modifier

Decibels

Modifier

Touch Hold

Modifier

REL

AUTO

MIN MAX

Modifier

MINdBHOLD

mVDCAC

Mk

Diode T est

Overload, Out of Limits.

(Placement of Decimal

Point Varies According

to Range.)

Figure 3-2. Display Annunciators

Autorange

mA

Hz

Continuity

Test

UNCAL

Calibration

Corrupted

mA

Function and Unit

Annunciators

DC AC

mV

Mk

W

Diode T est

Hz

aam10f.eps

DUAL DISPLAY MULTIMETER

45

DC AC

mV

mA

UNCAL

Hz

Mk

aam11f.eps

Figure 3-3. Secondary Display

If the secondary display has been turned on, press a function button (white) to select a

measurement function for the secondary display. The reading in the primary display will

not be affected. When the secondary display is active, pressing any function button turns

off the secondary display and selects that function on the primary display. To turn the

secondary display off without affecting the primary display, press S twice.

Note

If you press G, only a diode test voltage reading will be shown in the

secondary display; continuity is restricted to the primary display.

3-3

Page 31

45

Users Manual

Neither function modifiers (REL, dB, HOLD, and MN MX) nor the manual range mode

can be selected in the secondary display. Measurement ranges in the secondary display

are always selected through autoranging.

Input Terminals

The input terminals, shown in Figure 3-4, are located on the left of the front panel.

The meter is protected against overloads up to the limits shown in Table 3-1. Exceeding

these limits poses a hazard to both the meter and operator.

Volts, Ohms, Diode Test Input Terminal

Amperes Input Terminal. For Current Measurements up to

10A continuous (or 20A for 30 sec).

Milliamperes Input Terminal. For Current Measurements

up to 100mA.

V

600V CAT I

1000V CAT I

COM

10A

!

FUSE F1

500 mA

F 250V

100

mA

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

FUSED

Note: Frequency Measurements are Normally taken

from the V Input, although the 10A and

100mA Inputs can be used.

Common Terminal. Return Terminal for all Measurements.

Figure 3-4. Input Terminals

DUAL DISPLAY MULTIMETER

45

CAL

ENABLE

2ND

dB

HI

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

REF

MN MX

RATE

V

A

AUTO

A

FREQ

V

COMP

Ω

aam12f.eps

3-4

Page 32

Operating the Meter From the Front Panel

Table 3-1. Input Limits

FUNCTION INPUT TERMINALS MAXIMUM INPUT

| VeG and COM 1000V dc

Selecting a Measurement Function

3

{ and FREQ VeG and COM 750V ac rms, 1000V peak, 2 x 107 V-Hz

normal mode, or 1 x 10

mode (whichever is less)

mAD and FREQ 100 mA and COM 300 mA dc or ac rms

\ and FREQ 10A and COM 10A dc or ac rms (or 20A dc or ac rms for

30 sec. Max)

e VeG and COM 500V dc or ac rms on all ranges

G VeG and COM 500V dc or ac rms

All Functions Any terminal to earth 1000V dc or peak ac

6

V-Hz common

Selecting a Measure m ent Function

Press a function button (white), shown in Figure 3-5, to select a measureme nt func tio n To

select ac + dc total rms readings, press Z and Y, or D and C, simultaneously.

When you select a function, annunciators turn on to indicate the function selected. If a

reading is shown on the secondary display when a function button is pressed, the

secondary display will be turned off.

Ranges and full scale values are summarized in Table 3-2 for voltage, Table 3-3 for

current, Table 3-4 for ohms, and Table 3-5 for frequency.

Ranging

(E, U, T)

Ranging operations are performed using the E, U, and T buttons (see Figure 3-6).

Autoranging

When you are in the autorange mode, the AUTO annunciator is lit.

In autorange, the meter automatically selects the next higher range when a reading is

greater than full scale. If no higher range is available, "OL" (overload) is displayed on the

primary or secondary display. The meter automatically selects a lower range when a reading is less than approximately 9 % of full scale.

3-5

Page 33

45

Users Manual

Volts DC

Volts AC

V

V

Amps AC

Frequency

Amps DC

A

A

Resistance

Diode Test/Continuity

FREQ

FUNCTION BUTTONS:

-Press to Select the Function Designated

DUAL DISPLAY MULTIMETER

45

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

V

A

A

V

FREQ

Figure 3-5. Function Selection Buttons

AUTO

COMP

HI

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

REF

MN MX

CAL

ENABLE

2ND

dB

RATE

aam13f.eps

Table 3-2. Voltage Ranges and Full Scale Values

Fast Reading Rate Medium Reading Rate Slow Reading Rate

Range Full Scale Range Full Scale Range Full Scale

300 mV 300.0 mV 300 mV 300.00 mV 100 mV 99.999 mV

3 V 3.000 V 3 V 3.0000 V 1000 mV 999.99 mV

30 V 30.00 V 30 V 30.000 V 10 V 9.9999 V

300 V 300.0 V 300 V 300.00 V 100 V 99.999 V

1000 V* 1000 V* 1000 V* 1000.0 V* 1000 V* 999.99 V*

* 750V for volts ac

3-6

Page 34

Operating the Meter From the Front Panel

Table 3-3. Current Ranges and Full Scale Values

Fast Reading Rate Medium Reading Rate Slow Reading Rate

Range Full Scale Range Full Scale Range Full Scale

30 mA 30.00 mA 30 mA

100 mA 100.0 mA 100 mA 100.00 mA 100 mA 99.999 mA

10 A 10.00 A* 10 A 10.000 A* 10 A 9.9999 A

* 20 A for maximum of 30 seconds

Table 3-4. Ohms Ranges and Full Scale Values

Fast Reading Rate Medium Reading Rate Slow Reading Rate

Range Full Scale Range Full Scale Range Full Scale*

300 Ω 300.0 Ω 300 Ω 300.00 Ω 100 Ω 98.000 Ω

3 kΩ 3.000 kΩ 3 kΩ 3.0000 kΩ 1000Ω 980.00 Ω

30 kΩ 30.00 kΩ 30 kΩ 30.000 kΩ 10 kΩ 9.8000 kΩ

30.000 mA

10 mA 9.9999 mA

Ranging

3

300 kΩ 300.0 kΩ 300 kΩ 300.00kΩ 100 kΩ 98.000 kΩ

3 MΩ 3.000 MΩ 3 MΩ 3.0000 MΩ 1000 kΩ 980.00 kΩ

30 MΩ 30.00 MΩ 30 MΩ 30.000 MΩ 10 MΩ 9.8000 MΩ

300 MΩ 300 MΩ 300 MΩ 300.0 MΩ 100 MΩ 98.0 MΩ**

*Typical

** Because of the method used to measure resistance, the 100 M (slow) and 300 M (medium and fast)

ranges cannot measure below 3.125 M and 20 M respectively. "UL" (Underload) is shown on the display

for resistances below these nominal points, and the computer interface outputs "+1 E-9".

Table 3-5. Frequency Ranges and Full Scale Values (Slow and Medium*)

Range Full Scale

1000 Hz 999.99 Hz

10 kHz 9.9999 kHz

100 kHz 99 999 kHz

1000 kHz 999.99 kHz

1 MHz 9.9999 MHz

* Fast (F) reading rate has one digit of resolution less.

3-7

Page 35

45

Users Manual

Press to Toggle In and Out of Manual Ranging.

"AUTO" Annunciator Turns off when Manual Range Selected.

Press to Enter Manual Range and Up Range

Press to Enter Manual Range and Down Range

AUTO

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

V

A

A

V

DUAL DISPLAY MULTIMETER

45

AUTO

FREQ

COMP

HI

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

dB

REF

MN MX

CAL

ENABLE

2ND

RATE

Figure 3-6. Range Selection Buttons

Manual Ranging

Press E to toggle in and out of manual ranging. The range you are in when you enter

the manual range mode becomes the selected rang e.

In manual range, the meter remains in the selected range regardless of input. Press E to

toggle back to autoranging. Manual ranging can only be performed on readings shown on

the primary display; the secondary display always autoranges.

Press U to up range. If the U is pressed when the meter is still in autorange, manual

ranging is selected, the AUTO annunciator turns off, and the next higher range is selected

(if there is one).

Press T to down range. If the T is pre sse d when the me ter is still in autor ange,

manual ranging is selected, the AUTO annunciator turns off, and the next lower range is

selected (if there is one).

Measuring Frequency

(F)

Frequency Ranging

Frequency measurements from 5 Hz to > 1 MHz are automatically ranged so that a

frequency measurement is always displayed with maximum resolution.

aam14f.eps

3-8

If the frequency function (FREQ) is selected in the primary display, press the Uor T

to manually select a range. (Manual ranging is not allowed in the second ary dis pla y.) If

you select a frequency range manually, frequency measurements that exceed the full

scale value of that range cause "OL" (overload) to be displayed. Refer to Table 3-5 for

frequency ranges and full scale values.

Page 36

Frequency Measurement Rates

The rate at which frequency measurements are tak en is a factor of the frequen cy being

measured (see Table 3-6).

When the frequency function has been selected, pressing R has no effect on the

frequency update rate.

Table 3-6. Frequency Measurement Rates

Frequency Reading Rate

@ > 150 Hz 1.8/sec

@ 100 Hz 1.6/sec

@ 60 Hz 1.3/sec

@ 15 Hz 1/1.2sec

@10Hz 1/1.7sec

@5Hz 1/3.2 sec

Operating the Meter From the Front Panel

Measuring Frequency

3

Measuring Frequency of Current (100 mA and 10A) Inputs

Frequency measurements are always taken using the ac input circuitry of the meter.

Normally, measurements are taken on the Xinput terminal. However, frequency

measurements can also be taken on current inputs. If frequency is to be measured using a

current input, ac current must be selected in the primary display and frequency must be

selected in the secondary display.

When the ac current function in a mA range is selected in the primary display and

frequency is selected as the secondary display function, the frequency of the current at

the 100 mA terminal will be measured. Similarly, when the ac current function in the 10

A range is selected for the primary display and frequency is selecte d in the seco ndar y

display, the frequency of the current at the 10 A input terminal is measured.

Frequency Sensitivity Selection

Before a frequency measurement is started, the amplitude of the input signal is sampled

and the optimum ac range is selected automatically. For most applications, therefore, the

user need not be concerned with setting the measurement sens it iv ity fo r stabl e frequ ency

readings.

However, if necessary, measurement sensitivity can be selected manually. To do so, use

the dual display as described in the following procedure:

1. Power-up the meter and press Zor D to select an ac voltage or current function

in the primary display.

2. Press E ,U, or T to manually select an ac measurement range.

3. Press S then press F to select the frequency function in the secondary display.

All frequency measurements on the secondary display will be taken on the selected

ac range.

The maximum input voltage that may be applied on any ac measurement range for

reliable frequency measurements is listed in Table 3-7.

The minimum signal for a stable frequency measurement varies depending on the

frequency and waveform being measured.

3-9

Page 37

45

Users Manual

Table 3-7. Maximum Sinewave Inputs for Frequency Measurements

Range Maximim Input Voltage

300 mV 1 V rms

3 V 6 V rms

30 V 60 V rms

300 V 750 V rms

750 V 750 V rms

The input signal sensitivity is listed under the frequency specifications in Appendix A.

These values are based on sine waveforms. The signal level must be increased for lower

crest factor inputs (the crest factor is the ratio of the peak voltage to the ac rms voltage of

the waveform). If the input signal is below the required level, the frequency will be

displayed as zero. If the measurements are unstable, the input signal may be near the

threshold level.

Selecting A Function Modifier

(K, I, H, J)

Selecting a function modifier (see Figure 3-7) causes the meter to perform an action on

an input (e.g., convert to decibels or compare to another value) before a reading is

displayed. Function modifiers can be used in combination. (See “Using Function

Modifiers in Combination," later in Chapter 3.)

To use a function modifier, press a function button to select a primary function, then

press a function modifier button (or buttons). Modified readings are shown only on the

primary display.

After a function modifier has been selected, pressing any (white) function button turns off

all modifiers, causes the secondary display to go blank, and returns unmodified readings

to the primary display.

3-10

Page 38

-Press to Toggle In and Out of Relative Modifier

-Press to Toggle In and Out of Decibels Modifier

REL

dB

Operating the Meter From the Front Panel

Selecting A Function Modifier

-Press to Select MN MX Modifier;

-Press to Toggle Between Minimum

and Maximun Reading;

-Press and Hold Down for 2

Seconds to Exit MN MX Modifier.

3

HOLD

MN MX

-Press to Select Touch Hold Modifier;

-Press to Force New Reading;

-Press and Hold Down for

2 Seconds to Exit.

Figure 3-7. Function Modifier Selection Buttons

REL (Relative Readings) Modifier

When the relative modifier (REL) is selected, the reading on the primary display is

always the difference between the relative base and an input measurement. For example,

if the relative base is 15.000 V, and the present reading is 14.100 V, the display will show

-0.900.

To avoid electrical shock or damage to the meter, note that a

relative reading may not indicate the presence of dangerous

voltages at the input connectors or test leads.

V

COM

600V CAT I

1000V CAT I

FUSED

!

FUSE F1

500 mA

F 250V

10A

100

mA

WWarning

DUAL DISPLAY MULTIMETER

45

CAL

ENABLE

2ND

dB

V

A

FREQ

AUTO

COMP

HI

A

V

REL

REF# LOCAL

HOLD

LO

THRESH ADDR BAUD

POWER

REF

MN MX

RATE

aam15f.eps

Press K to toggle in and out of the relative modifier. When the rel at ive mod ifie r is

selected: the last valid reading is stored as the relative base, the primary display zeroes

out, and "K" is shown on the primary display. (The secondary display is unaffected.)

To edit the relative base, use the number editor as described in "Using the Number

Editor" later in Chapter 3).

Note

The relative modifier cannot be selected I the display shows "OL" or is

blank. (The display would be blank, for example, because of external

triggering or range changes.)

Selecting the relative modifier K turns off autoranging and locks in the present range.

Make sure you are in the correct range before selecting the relative modifier. If you press

U or T after the relative modifier has been selec ted, you will auto mat ica lly exit K.

When you are in REL, the relative base can be shown in the secondary display by

pressing S and, while holding it down, pressing K. Now, whene ver the rela tive

3-11

Page 39

45

Users Manual

modifier is selected, the relative base is shown in the secondary display. To turn off this

feature, press S and, while holding it down, press K .

dB (Decibels and Audio Power) Modifier

The decibels modifier takes a voltage measurement, converts it to dBm (measure of

decibels relative to one milliwatt), and displays the result on the primary display.

Press I to toggle in and out of the decibels modifier. When the decibe ls mod if ier is

selected, "dB" is shown on the primary display.

Decibels can be selected only when a voltage function is selected on the primary display

(volts ac, volts dc, or volts ac + dc). Decibels are always displayed in a single, fixed

range with 0.01 dB resolution. However, the basic measurement itself (e.g. volts ac)

autoranges.

A voltage measurement is converted to dBm using the following formula:

2

dBm = 10*log (1000*value

/reference impedance)

where "value" is the measurement value. The reference impedance can be set to any of 21

reference impedances listed in Table 3-8 by using the list editor as described in "Using

the List Editor" later in Chapter 3.

Table 3-8. Reference Impedances in Ohms

8000 300 93

1200 250 75

1000* 150 50

900 135 16†

800 125 8†

600 124 4†

500 110 2†

* Voltage annunciator lit

† Audio power readings possible

To access the reference impedance list, press S then press I (REF e). The reference

impedance currently selected is displayed, along with the db and e annunciators. Press

U or T to scroll to the desired value, then press E to select a reference impedance

and return the primary display to the measurement function. Press any function (white) or

modifier (light grey) button to exit the reference impedance list without selecting a new

value.

Setting the dB reference resistance to 16, 8, 4, or 2 ohms allows you to use the meter to

calculate audio power. After the reference resistance has been set to 16, 8, 4, or 2 ohms,

press I twice to select the audio power modifier. "POWER" will be shown on the

secondary display.

3-12